Page 1

CMOS-CCD 1H Delay Line for PAL

CXL5514M/P

Description

The CXL5514M/P are CMOS-CCD delay line ICs

designed for processing video signals. This ICs

provide a 1H delay time for PAL signals including

the external lowpass filter.

Features

• Single 5V power supply

• Low power consumption

• Built-in peripheral circuit

• Built-in tripling PLL circuit

• Sync tip clamp mode

Absolute Maximum Ratings (Ta = 25°C)

• Supply voltage VDD +6 V

• Operating temperature Topr –10 to +60 °C

• Storage temperature Tstg –55 to +150 °C

• Allowable power dissipation

PD

CXL5514M 350 mW

CXL5514P 480 mW

Recommended Operating Range (Ta = 25°C)

VDD 5V ± 5%

Recommended Clock Conditions (Ta = 25°C)

• Input clock amplitude

VCLK 0.2 to 1.0Vp-p (0.4Vp-p Typ.

• Clock frequency fCLK 4.433619MHz

• Input clock waveform Sine wave

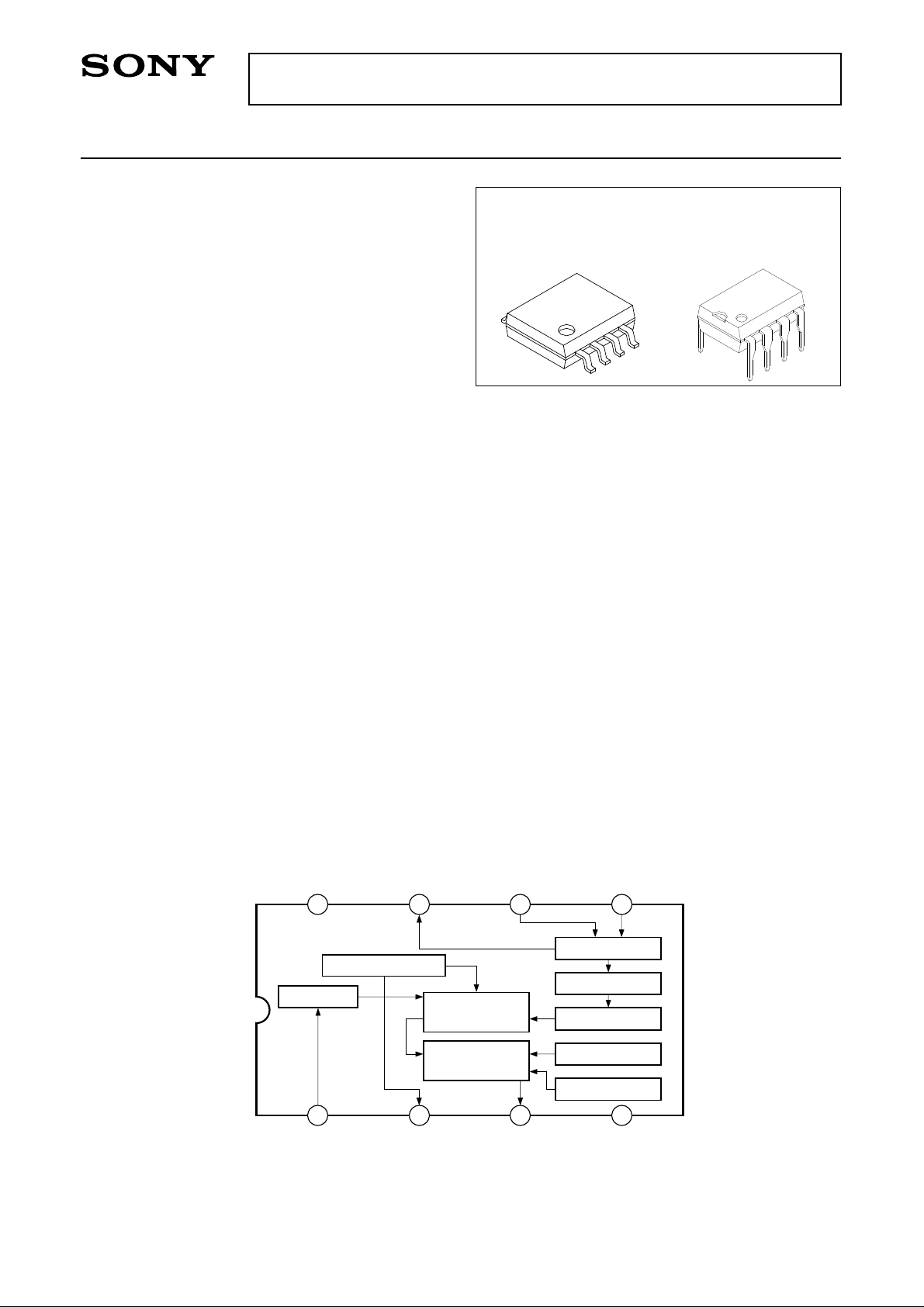

CXL5514M CXL5514P

8 pin SOP (Plastic) 8 pin DIP (Plastic)

Input Signal Amplitude

VSIG 500mVp-p (Typ.), 575mVp-p (Max.)

(at internal clamp condition)

Functions

• 848-bit CCD register

• Clock driver

• Auto-bias circuit

• Sync tip clamp circuit

• Sample and hold circuit

• Tripling PLL circuit

• Inverted output

Structure

CMOS-CCD

)

Block Diagram and Pin Configuration (Top View)

V

DD VCO OUT VCO IN CLK

8

Auto-bias circuit

Clamp circuit

1

IN AB OUT V

Sony reserves the right to change products and specifications without prior notice. This information does not convey any license by

any implication or otherwise under any patents or other right. Application circuits shown, if any, are typical examples illustrating the

operation of the devices. Sony cannot assume responsibility for any problems arising out of the use of these circuits.

7

CCD

(848 bit)

Output circuit

(S/H 1 bit)

2

6

3

5

PLL

Timing circuit

Clock driver

Bias circuit A

Bias circuit B

4

SS

– 1 –

E94903-ST

Page 2

Pin Description

Pin No. Symbol I/O Description Impedance

CXL5514M/P

1

2

3

4

5

6

7

8

IN

AB

OUT

VSS

CLK

VCO IN

VCO OUT

VDD

Electrical Characteristics

Item

Symbol

Supply current

IDD

I

O

O

—

O

—

Signal input

Auto-bias DC output

Signal output

GND

I

Clock input (fsc)

I

VCO input

VCO output (3fsc)

5V power supply

>10KΩ

40 to 500Ω

>10KΩ

(Ta = 25°C, VDD = 5V, fCLK = 4.433619MHz, VCLK = 400mVp-p, sine wave)

See “Electrical Characteristics Test Circuit”.

SW conditions

Conditions

Min.

Typ.

Max. Unit

NOTE

12

—

a — 10 15 20 mA 1

Low frequency gain

Frequency response

Differential gain

Differential phase

S/H pulse coupling

S/N ratio

GL

fR

DG

DP

CP

SN

200kHz

500mVp-p

Sine wave

200kz ←→ 4.434MHz

150mVp-p Sine wave

5-staircase wave

(See Note 4.)

5-staircase wave

(See Note 4.)

No signal input

50% white video signal

(See Note 6.)

a b –2 0 2 dB 2

b ←→ c

b –2.7 –1.7 –0.7 dB 3

dc035%4

d c 0 3 5 degree 4

f a — — 350 mVp-p 5

e d 52 56 — dB 6

– 2 –

Page 3

NOTE

1. This is the IC supply current value during clock and signal input.

2. GL is the output gain of OUT pin when a 500mVp-p, 200kHz sine wave is fed to IN pin.

CXL5514M/P

GL = 20 log

OUT pin output voltage [mVp-p]

[dB]

500 [mVp-p]

3. Indicates the dissipation at 4.434MHz in relation to 200kHz. From the output voltage at OUT pin when a

150mVp-p, 200kHz sine wave is fed to IN pin, and from the output voltage at OUT pin when a 150mVp-p,

4.434MHz sine wave is fed to the same, calculation is made according to the following formula.

fR = 20 log

OUT pin output voltage (4.434MHz) [mVp-p]

[dB]

OUT pin output voltage (200kHz) [mVp-p]

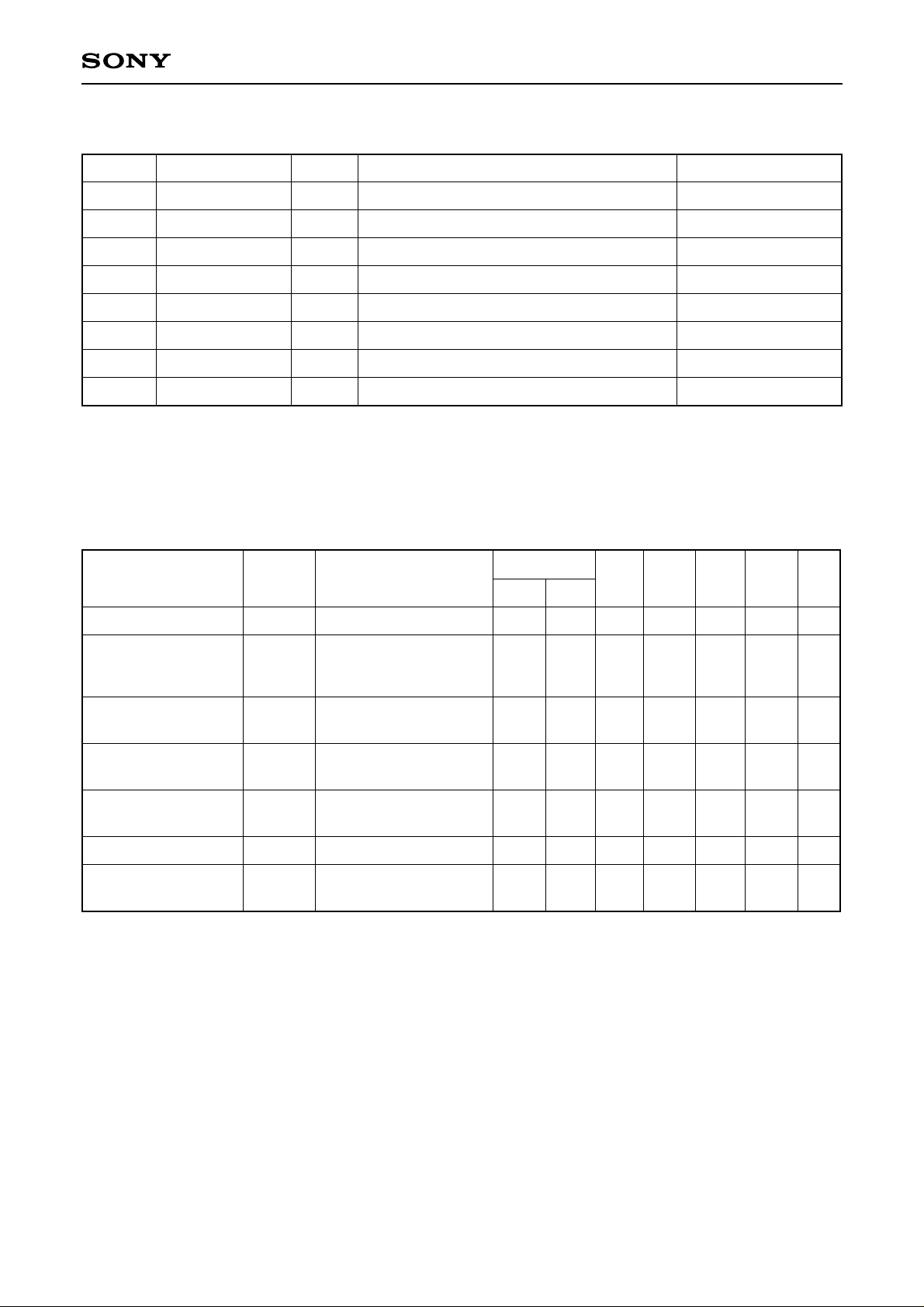

4. In Fig. below, the differential gain (DG) and the differential phase (DP) are tested with a vector scope when

the 5-staircase wave is fed.

150mV

350mV

500mV

150mV

1H 64µs

5. Leakage of internal clock components and related high frequency component to the output signal, during

no signal input, is tested.

Test value

[mVp-p]

– 3 –

Page 4

CXL5514M/P

6. S/N ratio during a 50% white video signal input shown in Fig. below is tested at the video noise meter, in

BPF 100kHz to 5MHz, Sub Carrier Trap mode.

175mV

325mV

150mV

1H 64µs

CLOCK

fSC (4.433619MHz) Sine wave

400mVp-p (Typ.)

– 4 –

Page 5

CXL5514M/P

400mVp-p

Sine wave

fsc (4.433619MHz)

6.8µ2200p

0.1µ 0.1µ

× 3

Note 2)

d

Noise meter

BPF

Note1) Note 2)

BPF frequency response

0

[dB]

LPF frequency response

[dB]

–3

0

–3

–50

–50

6M 13.3M

Frequency [Hz]

50 200

6M 13.3M

Frequency [Hz]

Oscilloscope

Spectrum analyzer

+15V

SS

IN AB OUT V

b

2.2k

4

3

0.1µ

2

1

a

5

6

7

8

CXL5514M/P

VDD VCO OUT VCO IN CLK

× 3

Note1)

SW2

Vector scope

LPF

c

5V

200kHz

500mVp-p

Sine wavea200kHz

150mVp-p

Sine waveb4.434MHz

Electrical Characteristics Test Circuit

1µ

SW1

c

150mVp-p

– 5 –

1M

Sine wave

d

5-staircase wave

e

50% white

video signal

f

Page 6

CXL5514M/P

400mVp-p

Sine wave

fsc (4.433619MHz)

0.1µ 0.1µ

LPF

Output

56k 1k

2.2k

Transistor used

NPN: 2SC403

Transistor used

NPN: 2SA403

5V

470

33k

5

6

SS

4

1µ

3

6.8µ2200p

5V

0.1µ

7

8

CXL5514M/P

VDD VCO OUT VCO IN CLK

2

1

IN AB OUT V

1M

1µ

Input

5V

1.8k

When VCO OUT (7Pin) in use

3fsc OUT

2SC403

7

2.2k

Application circuits shown are typical examples illustrating the operation of the devices. Sony cannot assume responsibility for

any problems arising out of the use of these circuits or for any infringement of third party patent and other right due to same.

Application Circuit

– 6 –

Page 7

Example of Representative Characteristics

CXL5514M/P

Supply current vs. Supply voltage

20

15

Supply current [mA]

10

4.75

5 5.25

Supply voltage [V]

Frequency response vs. Supply voltage

0

Low frequency Gain vs. Supply voltage

1

0

–1

Low frequency Gain [dB]

–2

4.75

Supply voltage [V]

5 5.25

Differential gain vs. Supply voltage

10

8

–1

–2

Frequency response [dB]

–3

4.75

5 5.25

Supply voltage [V]

Supply current vs. Ambient temperature

20

18

16

14

Supply current [mA]

12

6

4

Differential gain [%]

2

0

4.75

Supply voltage [V]

5 5.25

Low frequency Gain vs. Ambient temperature

1

0

–1

Low frequency Gain [dB]

10

–20

06020

Ambient temperature [°C]

40 80

– 7 –

–2

–20

40 8006020

Ambient temperature [°C]

Page 8

CXL5514M/P

Frequency response vs. Ambient temperature

0

–1

–2

Frequency response [dB]

–3

–20

Ambient temperature [°C]

2

40 8006020

Differential gain vs. Ambient temperature

10

8

6

4

Differential gain [%]

2

0

–20

Frequency response

40 8006020

Ambient temperature [°C]

0

–2

–4

Gain [dB]

–6

–8

–10

10k

10M100k 1M

Frequency [Hz]

– 8 –

Page 9

Package Outline Unit : mm

CXL5514M

CXL5514M/P

8PIN SOP (PLASTIC)

CXL5514P

+ 0.1

0.4 – 0.05

SONY CODE

EIAJ CODE

JEDEC CODE

+ 0.4

5.0 – 0.1

85

1

4

1.27

± 0.12

SOP-8P-L03

∗SOP008-P-0225-A

+ 0.3

4.4 – 0.1

M

PACKAGE STRUCTURE

A

+ 0.1

0.15 – 0.05

0° to 10°

A

DETAIL

MOLDING COMPOUND

LEAD TREATMENT

LEAD MATERIAL

PACKAGE WEIGHT

1.25 – 0.15

+ 0.15

0.1 – 0.1

0.5 ± 0.2

EPOXY / PHENOL RESIN

SOLDER PLATING

42 ALLOY

0.1g

+ 0.4

0.10

6.4 ± 0.4

SONY CODE

EIAJ CODE

JEDEC CODE

8

1

2.54

0.5 ± 0.1

1.2 ± 0.15

+ 0.4

9.4 – 0.1

DIP-8P-01

∗DIP008-P-0300-A

8PIN DIP (PLASTIC) 300mil

5

7.62

4

+ 0.4

3.7 – 0.1

0.5 MIN

3.0 MIN

PACKAGE STRUCTURE

+ 0.3

6.4 – 0.1

PACKAGE MATERIAL

LEAD TREATMENT

LEAD MATERIAL

PACKAGE WEIGHT

+ 0.1

0.25 – 0.05

0° to 15°

EPOXY RESIN

SOLDER PLATING

COPPER ALLOY

0.5g

– 9 –

Loading...

Loading...