Page 1

July 1997

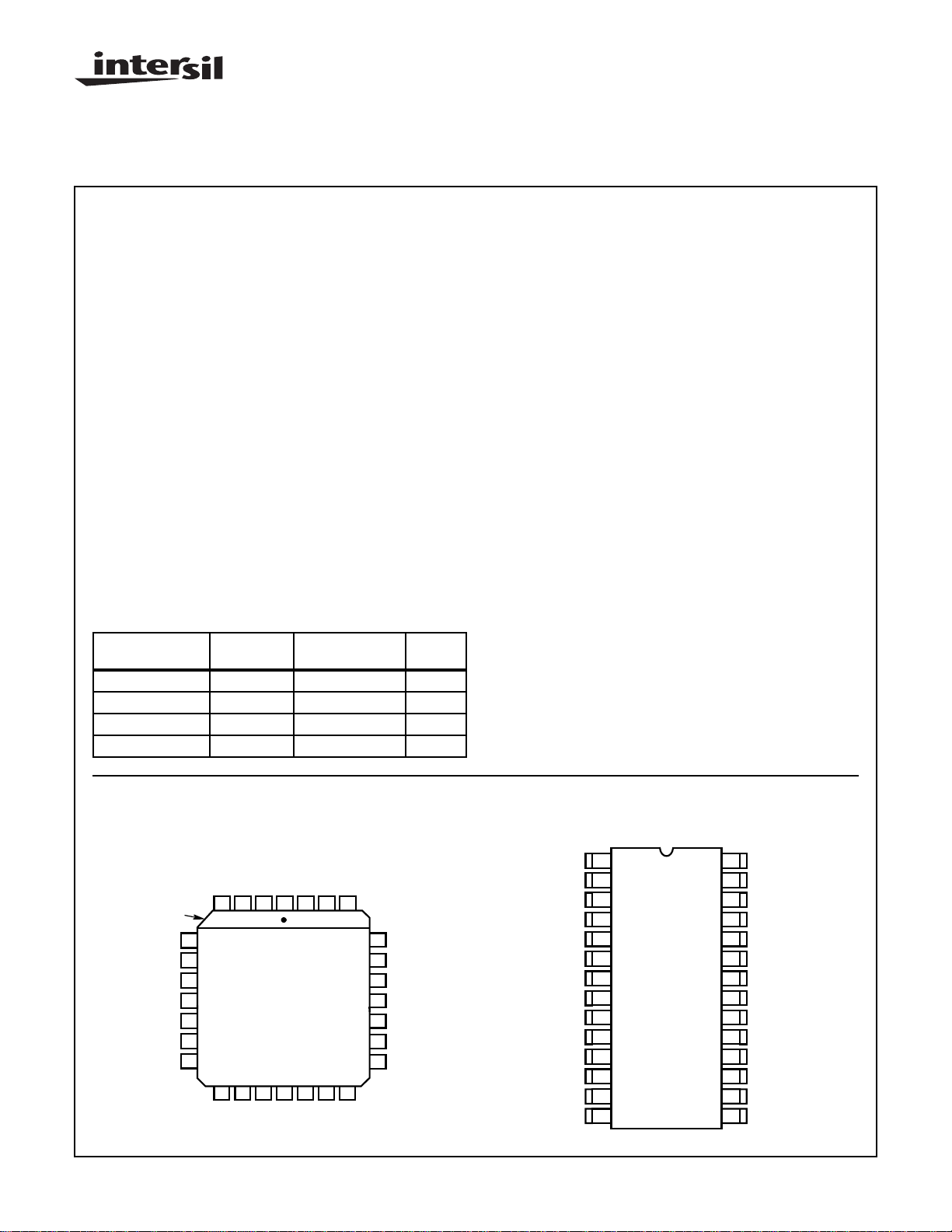

CA3272A, CA3292A

Quad-Gated Inverting Power Drivers with Fault

Mode Diagnostic Flag Output

Features

• Load Current Switching 600mA

• Suitable for Resistive or Inductive Loads

• Fault Mode Diagnostic Flag Output

• CA3292A Over-Voltage Zener Clamp

• Independent Over-Current Limiting

• Independent Over-Temperature Shutdown

• Temperature Shutdown Hysteresis

• 5V CMOS or TTL Input Logic

• High Dissipation Power-Frame Package

o

• Operating Temperature Range -40

C to 125oC

Applications System Applications

• Solenoids • Automotive

• Relays • Appliance

• Lamps • Industrial Control

• Steppers • Robotics

• Injectors

• Motors

Ordering Information

TEMP.

PART NUMBER

CA3272AQ -40 to 125 28 Ld PLCC N28.45

CA3292AQ -40 to 125 28 Ld PLCC N28.45

CA3272AM -40 to 125 28 Ld SOIC M28.3

CA3292AM -40 to 125 28 Ld SOIC M28.3

RANGE (oC) PACKAGE

PKG.

NO.

Description

The CA3272A and CA3292A are Quad-Gated Inverting Power

Drivers for interfacing low-level logic to inductive and resistive

loads such as: relays, solenoids, AC and DC motors and resistive loads such as incandescent lamps and other power drivers .

Each output is an open collector protected power transistor

driver. The CA3292A is similar to the CA3272A, except for an

added collector-to-base Zener diode that provides over-voltage

clamping protection on each power switching output. The

CA3292A block diagram is shown for one switching channel

with fault detection logic plus the output fault driver circuit for all

four switching channels. The FAULT output pin provides a flag

output when a fault condition occurs. All four Output Power

Driver stages are shown in the Block Diagrams .

The ENABLE input is common to each of the four power

switches and when low, disables the FAULT output. From the

Input to Output, each switch is inverting. When IN is high, OUT

is low and the transistor switch is “ON” (conducting). The block

diagram shows the functional logic associated with fault detection. The Fault Sense circuit detects the IN and OUT states and

switches Q

transistor Q

pin. A resistive load from the FAULT pin to the power supply is

used to detect a fault as a low state. Both shorted and open

load conditions are detected.

Note: The CA3272A replaces the CA3272 for new designs.

Refer to the Fault Sink Current specifications when making

design changes. The CA3272A and CA3292A have increased

pull-down current drive from the FAULT output pin.

“ON” if a fault is detected. When a fault is detected,

F

activates a current sink pull-down at the FAULT

F

Pinouts

CA3272A, CA3292A (PLCC)

TOP VIEW

OUT B

NC

OUT A

OUT B

INDEX

GND

5

GND

6

7

GND

8

GND

9

GND

10

GND

11

GND

12 13 14 15 16 17 18

OUT C

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

FAULT

1234

NC

NC

OUT D

| Copyright © Intersil Corporation 1999

IN A

IN D

IN B

IN C

ENABLE

262728

CC

V

GND

25

GND

24

GND

23

GND

22

21

GND

20

GND

19

GND

GND

GND

GND

GND

OUT C

1

CA3272A, CA3292A (SOIC)

TOP VIEW

1

2

NC

NC

3

4

NC

5

NC

6

7

8

9

NC

10

NC

11

NC

12

13

NC

14

28

OUT A

FAULT

27

IN A

26

IN B

25

ENABLE

24

GND

23

GND

22

GND

21

GND

20

NC

19

18

V

CC

17

IN C

1615IN D

OUT D

File Number 2223.7

Page 2

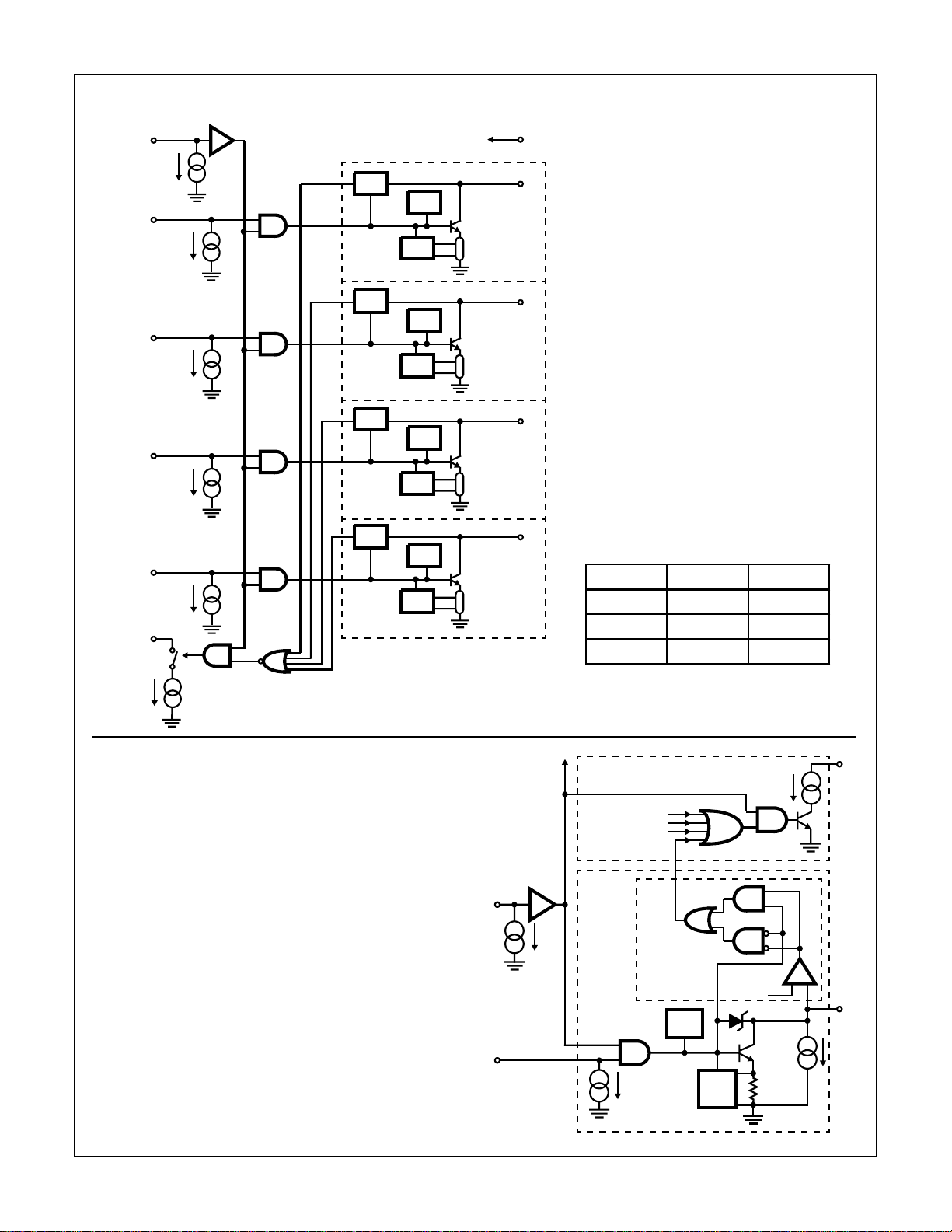

Block Diagram of the CA3272A

A

ENABLE

CA3272A, CA3292A

V

CC

IN D

IN C

IN B

IN A

FAULT

F

T

LIM

I

LIM

F

T

LIM

I

LIM

F

T

LIM

I

LIM

F

T

LIM

I

LIM

Q

D

0.02Ω

Q

C

0.02Ω

Q

B

0.02Ω

Q

A

0.02Ω

OUT D

OUT C

OUT B

OUT A

TRUTH TABLE

ENABLE IN OUT

HHL

HLH

LXH

H = High, L = Low, X = Don’t Care

Block Diagram of the CA3292A

(1 of 4 Outputs Shown with Expanded Fault Logic)

NOTE: The CA3292A is identical to the CA3272A except for the

collector-to-base Zener diode on each low side power output driver

(shown here as ZA). The Zener diode clamp is used as an overvoltage clamp to protect the output when switching inductive loads.

When the output voltage exceeds the Zener threshold, QA conducts

to suppress further increase in output voltage. The fault sense and

fault flag logic circuits are the same in the CA3272A and CA3292A.

ENABLE LINE

TO B, C AND D

INPUTS AND

FAULT OUTPUT

ENABLE

IN A

2

FAULT INPUT

FROM B, C, D

CHANNELS

CHANNEL A

1 OF 4

OUTPUTS

FAULT

FLAG LOGIC

FAULT SENSE

CHANNEL A

T

LIM

I

LIM

FAULT

Q

F

4V

Z

A

Q

A

0.02Ω

OUT

Page 3

CA3272A, CA3292A

Absolute Maximum Ratings Thermal Information

Output Voltage, VO (CA3272A) . . . . . . . . . . . . . . . . . . . . . . . . +60V

Output Sustaining Voltage, V

Output Voltage, VO (CA3292A) . . . . . . . . . . . . . . . . . . . . . V

(CA3272A) . . . . . . . . . . . 40V

CE(SUS)

CLAMP

Maximum Output Clamp Energy (CA3292A) . . . . . . . . . . . (Note 8)

Output Transient Current, (Note 1) . . . . . . . . . . . . . . . . . . 1.6A Max.

Output Load Current, (Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . .0.7A

Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +7V

Logic Input Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15V

FAULT Output Voltage, VF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16V

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 125oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance (Typical, Note 3) θJA (oC/W)

For surface mount without added copper ground area:

CA3272AQ, CA3292AQ (PLCC) . . . . . . . . . . . . . . 45oC/W

CA3272AM, CA3292AM (SOIC). . . . . . . . . . . . . . . 56oC/W

For surface mount with 2 sq. in. of added copper ground area:

CA3272AQ, CA3292AQ (PLCC) . . . . . . . . . . . . . . 36oC/W

CA3272AM, CA3292AM (SOIC). . . . . . . . . . . . . . . 35oC/W

See Maximum Power Dissipation vs Temperature Curves,

Figures 6 and 7.

Maximum Junction Temperature (Plastic Packages) . . . . . . . 150oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300oC

(SOIC, PLCC - Lead Tips Only)

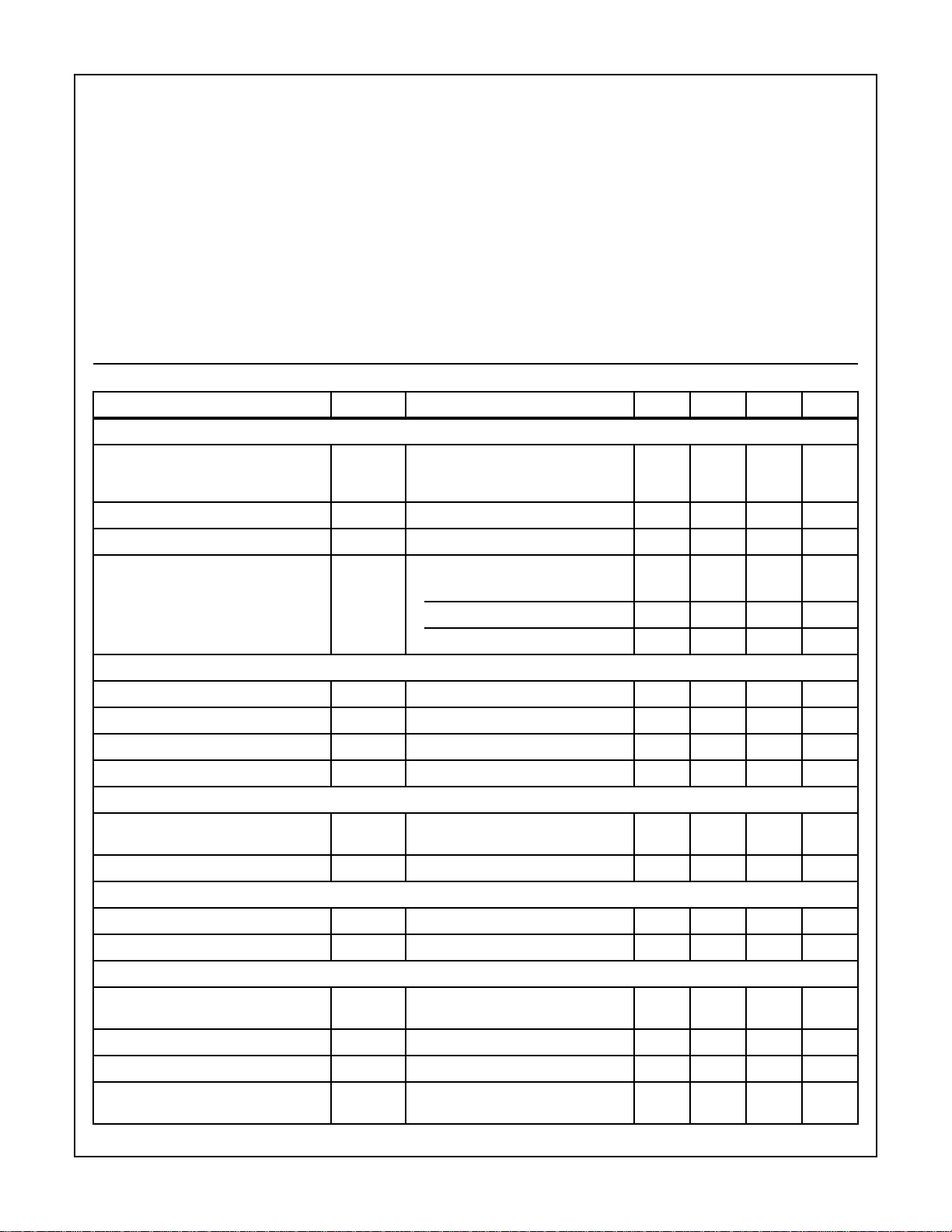

Electrical Specifications T

= -40oC to 125oC, VCC = 5.5V, Unless Otherwise Specified

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

OUTPUT PARAMETERS

Output (OFF) Current I

Output Sustaining Voltage: CA3272A V

Output Clamp Voltage: CA3292A V

Collector-to-Emitter Saturation Voltage V

LOGIC INPUT THRESHOLDS

Input Low Voltage V

Input High Voltage V

Input Low Current I

Input High Current I

SUPPLY CURRENT

All Outputs ON I

All Outputs OFF I

PROPAGATION DELAY

Turn-ON Delay t

Turn-OFF Delay t

FAULT PARAMETERS

Output Low Current, I

F(SINK)

(with Fault)

Output High Current, I

F(LK)

Output Low Voltage V

Output Driver Fault Sense, High

Threshold (Open)

CEX

VIN = 0.8V; VEN = 5.5V; (Note 4)

VCE = 60V for CA3272A

VCE = 24V for CA3292A

CE(SUS)

CLAMPIC

CE(SAT)VIN

CC(ON)VIN

CC(OFF)VIN

PHL

PLH

I

OL

Note 7 40 - - V

VCC = 3.5V - - 0.8 V

IL

IH

VIN = VEN = 0.8V; VCC = 4.75V 10 45 70 µA

IL

VIN = VEN = 5.5V 10 45 70 µA

IH

I

OUTC

I

LOAD

I

LOAD

VIN = 0.8V; VEN = 2.0V; VF = 4V

V

I

OH

V

HTHDVIN

No Fault (Note 5) - - 20 µA

External Load Equal Min. I

OL

- 30 100 µA

= 300µA; VEN = 0.8V 28 32 36 V

= 2V, VCC = 4.75V,

IC = 400mA, TA = 125oC - - 0.3 V

IC = 500mA, TA = 25oC - - 0.4 V

IC = 600mA, TA = -40oC - - 0.5 V

2--V

= VEN = 5.5V; I

= I

OUTD

= 400mA

OUTA

= I

OUTB

=

- - 65 mA

= 0V - - 10 mA

= 500mA - 3 10 µs

= 500mA - 3 10 µs

124mA

= Low = 1V; (Note 5)

OUT

OL

- 0.2 0.4 V

= 0.8V; VEN = 2V (Note 6) 3 4 5.5 V

3

Page 4

CA3272A, CA3292A

Electrical Specifications T

= -40oC to 125oC, VCC = 5.5V, Unless Otherwise Specified (Continued)

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Output Driver Fault Sense, Low Threshold

V

LTHD

VIN = VEN = 2V (Note 6) 3 4 5.5 V

(Short)

PROTECTION PARAMETERS

Over-Current Limiting I

Over-Temperature Limiting

T

LIM

LIM

VIN = VEN = 2V, V

= 4Ω to 16V 0.7 - Note 1 A

OUT

- 165 -

(Junction Temperature)

Over-Temperature Limiting, Hysteresis T

HYS

-15-∆oC

DESIGN PARAMETERS

Input Capacitance C

Enable Capacitance C

IN

EN

-3-pF

- 4.6 - pF

NOTES:

1. Output Transient Currents are controlled by on-chip limiting for each output. Under short-circuit conditions with voltage applied to the

collector of the output transistor and with the output transistor turned ON, the current will increase to 1.2A, typical. Over-Current Limiting

protects a short circuit condition for a normal operating range of output supply voltage. During a short circuit condition, the output driver

will shortly thereafter (approximately 5ms) go into Over-Temperature Shutdown. While Over-Current Limiting may range to peak currents as high as 1.6A, each output will typically withstand a direct short circuit at normal single battery supply levels. Excessive dissipation before thermal shutdown occurs may cause damage to the chip for supply voltages greater than 16V. When sequentially

switched, the outputs are rated to withstand peak current, cold turn-on conditions of lamp loads such as #168 or #194 lamps.

2. The total DC current with all 4 outputs ON should not exceed the total of (4 x 0.7A + Max. ICC) ~ 2.85A. This level of current will significantly increase the chip temperature due to increased dissipation and may cause thermal shutdown in high ambient temperature conditions (See Absolute Maximum Ratings for Dissipation). Any one output may be allowed to exceed 0.7A but may be subject to OverCurrent Limiting above the I

the I

minimum limit of 0.7A. As a practical limit, no single output should be loaded to more than 1A maximum.

LIM

minimum limit of 0.7A. No single output should be loaded to more than Over-Current Limiting above

LIM

3. The PLCC and SOIC packages have power lead frame construction through the ground pins to conduct heat from the frame to the PC

Board ground area. Thermal resistance, θJA is given for a surface mount of the 28 lead PLCC and the 28 lead SOIC pac kages on a 1 oz.

copper PC board with minimal ground area and with a 2 square inches of ground area.

4. I

is the static leakage current at each output when that output is OFF (ENABLE Low). Refer to the Figure 3 illustration of an output

CEX

stage. The value of I

is both the leakage into the output driver and a pull-down current sink, I

CEX

. The purpose of the current

O(SINK)

sink is to detect open load conditions.

5. The IOL value of “Output Low Current, I

I

. The current sink is active only when a fault exists. When no fault exists, the IOH current at the FAULT pin is the maximum

F(SINK)

leakage current, I

. Refer to Figure 2 for an illustration of the FAULT output and associated external components. Refer to FAULT

F(LK)

” at the FAULT pin is both the static leakage of the output driver QF and the current sink,

F(SINK)

LOGIC TABLE for Fault Modes.

6. The Voltages, V

transitions for voltage forced at the outputs. V

V

indicates a shorted load when the output is increased greater than the threshold. The output voltage is changed until the FAULT

LTHD

HTHD

, V

are the comparator threshold reference values (Min. and Max. Range) sensed as a high and low state

LTHD

indicates an open load fault when the output is decreased to less than the threshold.

HTHD

pin indicates a Low (Fault). Refer to Figure 2 for test value of external resistor. Refer to IOL and IOH FAULT PARAMETERS Test Limits

to determine VOL and VOH at the FAULT pin.

7. Tested with 120mA switched off in a Load of 70mH and 32Ω series resistance;

CA3272A: Outputs clamped with an external Zener diode, limiting V

CA3292A: Outputs limited to the V

voltage by the internal collector-to-base Zener diode and output transistor clamp.

CLAMP

OUT

to the V

maximum rating of +40V.

CE(SUS)

8. The single pulse clamp energy rating for the CA3292A is defined over a range of operating conditions. The Clamp Energy is a function

of the Load Inductance, Load Resistance, Clamp Voltage, Supply Voltage, the Saturated ON Resistance (V

) and the Steady State

SAT

Load Current at the instant of Turn-OFF. Refer to Figure 5 for the Safe Operating Area when driving inductive loads. Rating limits for

Energy vs Single Pulse Width Time are plotted for different coil values. Refer to Application Note - AN9416 for pulse energy calculation

methods.

o

C

4

Page 5

Applications

CA3272A, CA3292A

The CA3272A and CA3292A are quad-gated inverting lowside power drivers with a fault diagnostic flag output. Both

circuits are rated for 125

o

C ambient temperature applications and have current limiting and thermal shutdown. While

functionally similar to the CA3262AQ, they differ in the mode

of over-voltage protection and have the added feature of a

FAULT flag output. Also, as shown in Figure 1, the inputs to

channels A, B, C, D and ENABLE have internal pulldowns to

turn “OFF” the outputs when the inputs are floating.

V

CC

CONSTANT

CURRENT SOURCE

INPUT

ENABLE

FIGURE 1. SCHEMATIC OF ONE INPUT STAGE

REFERENCE

1.2 VOLTS

TO PREDRIVER

AND

OUTPUT STAGES

As noted in the Block Diagrams, the CA3292A is equivalent

to the CA3272A except that it has internal clamp diodes on

the outputs to handle inductive switching pulses from the

output load. The structure of each CA3292A output includes

a Zener diode from collector-to-base of the output transistor.

This is a different form of protection from other quad drivers

with current steering clamp diodes on each output, paired to

one of two “CLAMP” output pins. The CA3292A output transistor will turn-on at the Zener diode clamp voltage threshold

which is typically 32V and the output transistor will dump the

pulse energy through the output driver to ground.

Each output driver is capable of switching 600mA load currents

and operate at 125

o

C ambient temperature without interaction

between the outputs. The CA3272A and CA3292A can drive

four incandescent lamp loads without modulating their brilliance

when the “cold” lamps are energized. The outputs can be connected in parallel to drive larger loads. Over-current or short circuit output load conditions are fault protected by current limiting

with a typical limit value of 1.2A. The current limiting range is

set for 0.6A to 1.6A. The output stage does not change state

(oscillate) when in the current limit mode.

FAULT LOGIC TABLE

IN OUT FAULT MODE

H L H Normal

H H L Over Current, Over T emper ature Open

LL L

L H H Normal

Load or Short to Power Supply

Any one output that faults (see F ault Logic Table) will switch the

F AULT output at pin 1 to a constant current pull-down.

The Fault Logic circuit, as shown in the Block Diagram for

the CA3292A, applies to both the CA3272A and CA3292A.

The Fault Sense circuits do not override or control the power

switching circuits of the IC. Their primary function is to provide an external diagnostic fault flag output. Each Power

Switching Channel has diagnostic fault sensing input to the

Fault Logic. The Fault Logic block of the functional Block Diagram illustrates the logic functions associated with Fault

detection. The diagnostic output for each of the four channels

of switching is processed through the fault logic circuit associated with each channel. It is then passed to an OR gate

which controls the FAULT flag output transistor, Q

thru A 2

F

input AND gate.

ENABLE IN

B, C AND D

FAULT MODE

INPUTS

FAULT MODE

INPUT

CHANNEL “A”

FIGURE 2. EXTERNAL FAULT OUTPUT CIRCUIT AND I

AS FAULT SINK PULLDOWN CURRENT, WHICH IS

ACTIVATED BY TRANSISTOR, QF, WHEN A FAULT

EXISTS

I

F(SINK)

Q

F

1

FAULT

LOGIC

OUTPUT

TX = RXC

VCC = +5V

R

X

FAULT FLAG

DIAGNOSTIC

OUTPUT, V

C

X

≈ 0.5 TO 1ms

X

F

F(SINK)

The ENABLE input is common to each of the 4 power

switches and also disables the FAULT flag output at the

2 input AND gate when it is low. The Fault Logic circuit

senses the IN and OUT states and switches Q

fault is detected. Transistor Q

activates a sink current

F

“ON” if a

F

source to pull-down the FAULT pin to a 0 (low) state when

the fault is detected. Both shorted and open load conditions

are detected.

It is normal for thermal shutdown and current limiting to

occur sequentially during a short circuit fault condition. A

precaution applies for potential damage from high transient

dissipation during thermal shutdown. (See Note 1 following

the Electrical Specifications Table).

Each of the outputs are independently protected with overcurrent limiting and over-temperature shutdown with thermal

hysteresis. If an output is shorted, the remaining outputs

function normally unless the temperature rise of the other

output devices can be made to exceed their shutdown temperature of 165

a driver exceeds the 165

o

C typical. When the junction temperature of

o

C thermal shutdown value, that

output is turned off. When an output is shutdown, the resulting decrease in power dissipation allows the junction temperature to decrease. When the junction temperature

decreases by approximately 15

o

C, the output is turned on.

5

Page 6

CA3272A, CA3292A

The output will continue to turn on and off for as long as the

shorted condition exists or until shutdown by the input logic.

The resulting frequency and duty cycle of the output current

flow is determined by the ambient temperature, the thermal

resistance of the package in the application and the total

power dissipation in the package. Since each output is independently protected, the frequency and duty cycle of the current flow into multiple shorted outputs will not be related in

time. Long lead lengths in the load circuit may lead to oscillatory behavior if more than two output loads are shorted.

V

FAULT SENSE

THRESHOLD, V

4V

ZENER

CLAMP

Z

T

LIM

FIGURE 3. OUTPUT OPEN LOAD DETECTION WHERE I

IS AN ACTIVE CURRENT SINK PULLDO WN FOR

OPEN-LOAD FAULT DETECTION. THE CURRENT

I

IS I

CEX

O(SINK)

THE OUTPUT DRIVER

A

Q

A

I

LIM

PLUS LEAKAGE CURRENTS OF

0.02Ω

THD

BATT

2

OUT A

I

O(SINK)

R

LOAD

O(SINK)

Since a diagnostic flag indicates when an output is shorted,

this information can be used as input to a microprocessor or

dedicated logic circuit to provide a fast switch-off when a

short occurs and, by sequence action, can be used to determine which output is shorted. A fault condition in any output

load will cause the FAULT output to switch to a logic “low”.

Since a fault condition may be detected during switching,

use of an appropriate size capacitor to filter the FAULT output is recommended. The recommended FAULT output circuit is shown in Figure 2. This will prevent the FAULT output

voltage from reaching a logic level “0” within the maximum

switching time.

The FAULT detection circuitry compares the state of the

input and the state of the output for each A, B, C and D

channel. The output is considered to be in a high state if the

voltage exceeds the typical FAULT threshold reference voltage, V

of 4V. If the output voltage is less than V

THD

THD

, the

output is considered to be in a low state. For example, if the

input is high and the output is less than V

, a normal

THD

“ON” condition exists and the FAULT output is high. If the

input is high and the output is greater than V

, a shorted

THD

load condition is indicated and the FAULT output is low.

When the input is low and the output is greater than V

THD

, a

normal “OFF” condition is indicated and the FAULT output is

high. If the input is low and the output is less than V

THD

, an

open load condition exists and the FAULT output is low. The

Output Driver Fault Sense state is determined by high and

low comparator threshold limits which are defined in the

Fault Parameters section of the Electrical Specifications.

The FAULT output diagram of Figure 2 shows the circuit

component interface for sensing a diagnostic fault condition.

As noted, the time constant of T

= RXCX should be greater

X

than the ON-OFF output switching times to avoid false fault

readings during switching. For applications requiring fast

period repetition rates, the maximum time constant should

be significantly less than the period of switching. The shortest practical time constant is preferred to limit the duration of

a fault condition.

To match a standard CMOS or TTL interface, the switched

current at the FAULT pin must be converted to V

and V

IH

voltage levels using the RX external pullup resistor. The minimum specified I

(Fault) state which is used to test for a V

0.4V. This makes the calculation for the V

tively simple. Where V

the power supply voltage, R

limit at the F AULT output defines the Low

OL

is the FAULT output voltage, VCC is

F

is the pullup resistor to V

X

maximum limit of

OL

input level rela-

IL

CC

from the FAULT pin and IOL is the fault condition sink current, I

O(SINK)

VF = VCC - RXIOL≤ V

, the low state equation is:

IL

(EQ. 1)

As an example: Since TTL is the worst case for a low state,

V

= 0.8V. Using VCC = 5V, maximum VF = VOL = 0.4V and

IL

minimum I

worst case limit, the minimum value of R

RX = (VCC - VIL)/IOL = (5 - 0.4)V/0.001mA = 4.6kΩ

= 1mA for the CA3272A and CA3292A. At the

OL

is:

X

The preferred value for RX would be greater than the values

calculated.

For the logic V

VF = VCC - RXIOH≥ V

High (normal state),

IH

IH

(EQ. 2)

Where the IOH current is the specified leakage current,

I

at the FAULT pin, it remains to check the calculated

F(LK)

value for R

resistance. To determine that the minimum V

FAULT pin is greater than V

as a leakage current times the chosen pullup

X

to an external logic match, V

IH

from the

OH

is calculated using Equation 2. For example, using the minimum R

VF = [5 - (4.6kΩ x 20µA)] = 4.9V

resistor value calculated for the CA3272A,

X

which is more than suitable for CMOS or TTL Input s witching

levels; suggesting that a larger value of R

(such as 10kΩ)

X

could be used for a better noise margin in the Low f ault state.

To detect an open load, each output has an inter nal low-level

current sink, shown in Figure 3, which acts as a pull-down

under open load fault conditions and is alwa ys active . The magnitude of this current plus any leakage associated with the output transistor will always be less than 100µA. (The data sheet

specification for I

includes this internal low-level sink cur-

CEX

rent). The output load resistance must be chosen such that the

voltage at the output will not be less than V

when the I

THD

CEX

sink current flows through it under worse case conditions with

minimum supply voltage. For example, assume a 6.5V minimum driver output supply voltage, a FAULT threshold reference

voltage of V

I

= 100µA. Calculate the maximum load resistance that will

CEX

= 5.5V and an output current sink of

THD

not result in a F AULT output low state when the output is OFF.

IL

F

6

Page 7

CA3272A, CA3292A

R

(max) = [V

LOAD

R

(max) = (6.5V - 5.5V) / 100µA = 10kΩ (EQ. 4)

LOAD

Since the CA3272A do not have on-chip diodes to clamp

voltage spikes which may be generated during inductive

switching of the load circuit, an external Zener diode (30V or

less is recommended) should be connected between the

output terminal and ground. Only those outputs used to

switch inductive loads require this protection. Note that since

the rate of change of output current is very high, even small

values of inductance can generate voltage spikes of considerable amplitude on the output terminals which may require

clamping. External free-wheeling diodes returned to the supply voltage are generally not acceptable as inductive clamps

if the supply voltage exceeds 30V during transients. Typical

loads for either the CA3272A or CA3292A are shown in the

application circuit of Figure 4A. Where inductive loads are

driven from outputs A and B, no external Zener diode clamp

is needed for the CA3292A but is required for the CA3272A

as shown in Figure 4B.

SUPPLY

(min) - V

THD

(max)] / I

(max) (EQ. 3)

CEX

The CA3272A and CA3292A are supplied in specially configured power packages to conduct heat from the junction

through the mounting structure and device leads to the PC

Board. The ground leads are directly connected to the

mounting pad of the chip. The junction-to-air thermal resistance, θ

may be significantly improved by suitable layout

JA

design of the PC board to which the package is soldered.

Two or more square inches of PC Board ground area next to

the device ground pins is recommended. The PC Board

ground layer should be on the device side of the board with

open space for heat radiation.

Refer to Application Note AN9416 for additional thermal

information. Further information is provided on pulse energy

calculation methods for inductive load applications with

detail explaining the Safe Operating Area shown in Figure 5.

The SOA area for single energy transients is below the dotted lines for the given ambient temperature conditions. The

energy locus plots of the three inductive coils were made for

arbitrarily chosen values of inductance and are shown here

for reference information. The RL time constant, ambient

temperature, clamp voltage and the stored energy in the coil

determine the SOA limits.

FAULT

FAULT

FAULT

FAULT

CA3292A

OUT A

Z

I

I

I

I

LIM

LIM

LIM

LIM

A

Q

A

OUT B

Z

B

Q

B

OUT C

Z

C

Q

C

OUT D

Z

D

Q

D

T

LIM

T

LIM

T

LIM

T

LIM

RELAY

LAMP

+V

BATT

SOLENOID

+V

BATT

HIGH CURRENT

HIGH SIDE DR

MOTOR

+V

BATT

INDUCTIVE

FAULT

T

LIM

I

LIM

CA3272A

(1 OF 4 CHANNELS)

EXTERNAL ZENER DIODE CLAMP

PROTECTION FROM POSITIVE VOLTAGE

SPIKE (INDUCTIVE KICK PULSE) AT TURN-OFF

OUT A

Q

A

LOAD

+V

BATT

V

Z(EXT)

NOTE: The internal drive circuit with self protection and fault output

is the CA3292A with the over voltage Zener diode clamp.

FIGURE 4A. TYPICAL APPLICATION CIRCUIT SHOWING OUT-

PUT LOAD CONTROL CAPABILITY OF THE

CA3272A OR CA3292A

NOTE: The V

voltage rating is the maximum voltage for full

CE(SUS)

load switching.

FIGURE 4B. CA3272A OVER-VOLTAGE PROTECTION IS AN

EXTERNAL ZENER DIODE CLAMP WHERE

V

≤ V

Z(EXT)

CE(SUS)

7

Page 8

CA3272A, CA3292A

200

550mH COIL - LINE 1

265mH COIL - LINE 2

136mH COIL - LINE 3

100

DO NOT

OPERATE ABOVE

THE DOTTED

LINES

50

SINGLE PULSE ENERGY (mJ)

10

110100

2

3

SINGLE PULSE TIME (ms)

FIGURE 5. CA3292A SINGLE PULSE INDUCTIVE FLYBACK CLAMP ENERGY SOA RATING CHART FOR EACH OUTPUT DRIVER

25oC MAX LIMIT

V

CLAMP

1

V

SAFE OPERATING

AREA - BELOW

DOTTED LINES

= VZ+V

Z

OUT x

Q

X

BE

L

125oC MAX

LIMIT

V

BATT

R

2.0

1.5

1

0.5

PACKAGE DISSIPATION (W)

0

-50oC0

o

C50

AMBIENT TEMPERATURE (

SOIC

PLCC

o

C 100oC 150oC

ο

C)

FIGURE 6. MAXIMUM POWER DISSIP ATION RATING vs

TEMPERATURE FOR THE CA3272AQ, CA3292AQ

PLCC P A CKA GE AND THE CA3272AM, CA3292AM

SOIC PACKAGE WITH NO ADDITIONAL PC

BOARD AREA FOR HEAT SINKINGS

2.0

1.5

1

0.5

PACKAGE DISSIPATION (W)

0

-50oC0

o

C50

AMBIENT TEMPERATURE (οC)

o

C 100oC

SOIC/PLCC

FIGURE 7. MAXIMUM POWER DISSIP ATION RATING vs

TEMPERATURE FOR THE CA3272AQ, CA3292AQ

PLCC P A CKA GE AND THE CA3272AM, CA3292AM

SOIC PACKA GE WITH 2 SQ. IN. OF 1 OZ. COPPER

PC BOARD AREA FOR HEAT SINKING

150oC

8

Page 9

CA3272A, CA3292A

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

0.25(0.010) B

E

SEATING PLANE

D

-C-

H

-B-

A

M

L

h x 45

M

o

α

e

B

0.25(0.010) C AMB

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010

inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual

index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch)

10. Controlling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

A1

0.10(0.004)

S

M28.3 (JEDEC MS-013-AE ISSUE C)

28 LEAD WIDE BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0926 0.1043 2.35 2.65 -

A1 0.0040 0.0118 0.10 0.30 -

B 0.013 0.0200 0.33 0.51 9

C 0.0091 0.0125 0.23 0.32 D 0.6969 0.7125 17.70 18.10 3

E 0.2914 0.2992 7.40 7.60 4

e 0.05 BSC 1.27 BSC H 0.394 0.419 10.00 10.65 -

C

h 0.01 0.029 0.25 0.75 5

L 0.016 0.050 0.40 1.27 6

N28 287

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

9

Page 10

CA3272A, CA3292A

Plastic Leaded Chip Carrier Packages (PLCC)

0.042 (1.07)

0.048 (1.22)

PIN (1) IDENTIFIER

0.020 (0.51) MAX

3 PLCS

C

L

D1

D

0.026 (0.66)

0.032 (0.81)

0.050 (1.27) TP

0.042 (1.07)

0.056 (1.42)

C

L

E1

E

0.013 (0.33)

0.021 (0.53)

0.004 (0.10) C

0.025 (0.64)

0.045 (1.14)

D2/E2

D2/E2

A1

A

-C-

VIEW “A”

0.020 (0.51)

MIN

SEATING

PLANE

R

N28.45 (JEDEC MS-018AB ISSUE A)

28 LEAD PLASTIC LEADED CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.165 0.180 4.20 4.57 -

A1 0.090 0.120 2.29 3.04 -

D 0.485 0.495 12.32 12.57 D1 0.450 0.456 11.43 11.58 3

D2 0.191 0.219 4.86 5.56 4, 5

E 0.485 0.495 12.32 12.57 E1 0.450 0.456 11.43 11.58 3

E2 0.191 0.219 4.86 5.56 4, 5

N28 286

NOTESMIN MAX MIN MAX

Rev. 1 3/95

0.045 (1.14)

MIN

VIEW “A” TYP.

0.025 (0.64)

MIN

NOTES:

1. Controlling dimension: INCH. Converted millimeter dimensions

are not necessarily exact.

2. Dimensions and tolerancing per ANSI Y14.5M-1982.

3. Dimensions D1 and E1 do not include mold protrusions. Allowable mold protrusion is 0.010 inch (0.25mm) per side.

4. To be measured at seating plane contact point.

-C-

5. Centerline to be determined where center leads exit plastic body.

6. “N” is the number of terminal positions.

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

10

Loading...

Loading...