OBSOLETE PRODUCT

CA3165

May 1999

Call Central Applications 1-800-442-7747

or email: centapp@harris.com

Features

NO RECOMMENDED REPLACEMENT

• Switching Initiated by Damping of Internal Oscillator

• Proximity Sensing of Rotational Motion

[ /Title (CA3165)

• Repeatable Timing of Switching States

/Subject (Electronic Switching Circuit)

• Five Outputs - Two Complementary Pairs and One

/Author ()

Non-Inverting Output CA3165E1

/Keywords ()

• Two Outputs - One Complementary Pair CA3165E

/Creator ()

/DOCINFO pdfmark

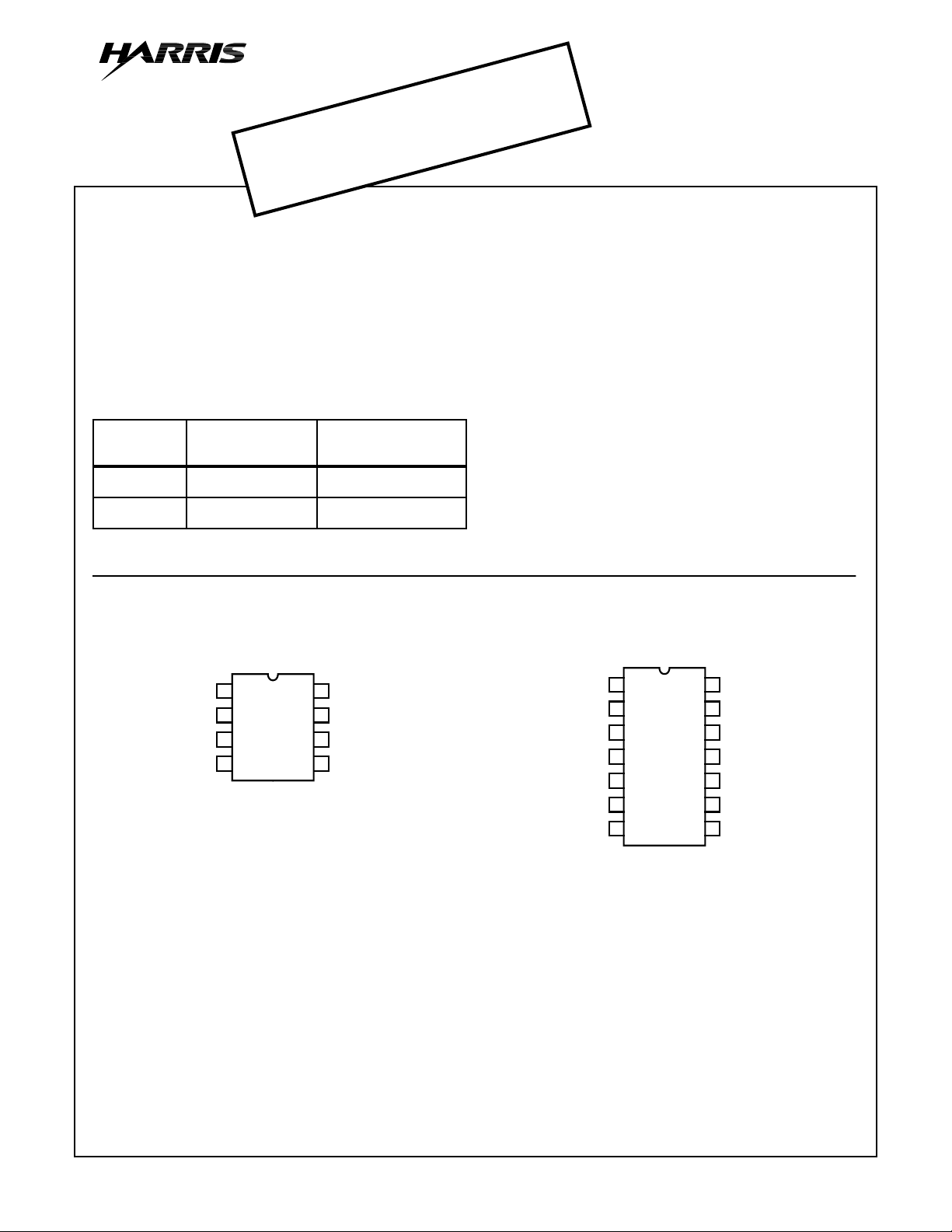

Part Number Information

PART

[ /PageMode /UseOutlines

NUMBER TEMPERATURE PACKAGE

/DOCVIEW pdfmark

CA3165E -40oC to +85oC 8 Lead Plastic DIP

CA3165E1 -40oC to +85oC 14 Lead Plastic DIP

Pinouts

Electronic Switching Circuit

Description

The CA3165 is a single chip electronic switching circuit

intended primarily for ignition applications. It includes an

oscillator that is amplitude-modulated by the rotor teeth of a

distributor, a detector that develops the positive going modulation envelope, a Schmitt trigger that eliminates switching

uncertainties. Both types include two complementary high

current switched outputs for driving power transistors requiring up to 120mA. The CA3165E also includes two complementary low current outputs that incorporate internal current

limiting and a non-inverting output amplifier with uncommitted input capable of switching 27mA.

The CA3165 is supplied in the 8 lead dual-in-line plastic

package (E suffix) and in the 14 lead dual-in-line plastic

package (E1 suffix).

OSC FB

SENSE

GND

OUTPUT

CA3165 (PDIP)

TOP VIEW

1

2

3

4

8

FB_RF

7

V+

6

DET_OUT

5

INV_OUT

OSC FB

SENSE

GND

OUTPUT

+SIGNAL

INV_OUT

–SIGNAL

CA3165 (PDIP)

TOP VIEW

1

2

3

4

5

6

7

14

NC

13

FB_R

V+

12

11

NC

10

DET_OUT

AMPL_IN

9

AMPL_OUT

8

F

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper I.C. Handling Procedures.

Copyright

© Harris Corporation 1999

10-25

File Number 1278.3

Functional Block Diagrams

CA3165

DC SUPPLY 5V - 24V

NC

54

200Ω

100K

TO POWER

TRANSISTORS

AMP

976

847Ω

OUTPUT

8

6.8KΩ

0.0047µF

FEEDBACK

RESISTOR

(6kΩ ± 0.5%)

L = 100µH

≈ 53

Q

0.01µF

13

OSCILLATOR DET

1

2

220Ω

R

1500

pF

10

0.01

REPRESENTS

ROTOR LOADING

220Ω

3.5V - 18V

12

SCHMITT

TRIGGER

OUTPUT OUTPUT

SWITCHING

3

0.01µF

OSCILLATOR

CONDITION TERMINAL 10 TERMINAL 4 TERMINAL 5 TERMINAL 6 TERMINAL 7 TERMINAL 8

Unloaded Low High High Low Low Low

Loaded High Low Low High High High

FIGURE 1. FUNCTIONAL BLOCK DIAGRAM FOR CA3165E1

FEEDBACK

RESISTOR

(6.49kΩ)

L = 100µH

≈ 53

Q

0.1µF

8

OSCILLATOR DET

1

2

220Ω

R

†

R

A

B

1500

pF

OSCILLATOR

CONDITION TERMINAL 4 TERMINAL 5 TERMINAL 6

Unloaded High High Low

Loaded Low Low High

†

REPRESENTS

ROTOR LOADING

DC SUPPLY 5V - 24V

220Ω

7

SCHMITT

TRIGGER

6

0.01

†VALUES OF R

BY CORRELATION.

A

3.5V - 18V

OUTPUT

SWITCHING

3

AND RB DETERMINED

4

200Ω

5

TO POWER

TRANSISTORS

300Ω

INVERTED

OUTPUT

FIGURE 2. FUNCTIONAL BLOCK DIAGRAM FOR CA3165E

10-26

Specifications CA3165

Absolute Maximum Ratings Thermal Information

DC Voltage (With Reference to Terminal 3)

CA3165E1

Terminals 4, 6, 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24V

Terminals 5, 7, 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18V

Terminal 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5V

CA3165E

Terminals 4, 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24V

Terminal 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18V

Current (At Terminals Indicated)

CA3165E1

Terminals 4, 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120mA

Terminals 5, 7 . . . . . . . . . . . . . . . . . . . . . . . . . -0.1mA to 0.1mA

Terminal 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30mA

CA3165E

Terminals 4, 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120mA

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Thermal Resistance θ

JA

Plastic DIP Package 8 Lead . . . . . . . . . . . . . . . . . . . . . 150oC/W

Plastic DIP Package 14 Lead . . . . . . . . . . . . . . . . . . . . 100oC/W

Operating Temperature Range . . . . . . . . . . . . . . . . .-40oC to +85oC

Storage Temperature Range. . . . . . . . . . . . . . . . . .-65oC to +150oC

Lead Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +265oC

At Distance 1/16” ±1/32” (1.59 ±0.79mm) from Case

for 10s Maximum

Device Dissipation Plastic DIP Package 8 Lead

Up to TA = +55oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600mW

Above TA = +55oC. . . . . . . . . . . . . Derate Linearly at 6.67mW/oC

Device Dissipation Plastic DIP Package 14 Lead

Up to TA = +55oC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 950mW

Above TA = +55oC. . . . . . . . . . . . . . .Derate Linearly at 10mW/oC

Electrical Specifications At T

= +25oC, V+ = 13V, Measured in the circuit of Figure 5 (CA3165E1) or Figure 6 (CA3165E)

A

CA3165E1 CA3165E

PARAMETERS SYMBOL TEST CONDITIONS

UNITSMIN TYP MAX MIN TYP MAX

Input Current at Term. (Note 1) ∆ Dwell - 18.4 - - 18.4 - mA

Spark - 17.5 - - 17.5 - mA

Output Voltage at Term. 4 V

Dwell 12.8 - - 12.8 - - V

4

Spark - - 0.5 - - 0.5 V

Output Volatge at Term. 7 V

Output Voltage at Term. 8 V

Dwell - - 1 - - - V

7

Dwell - - 0.9 - - - V

8

Portion of Spark 1.2 -----V

Oscillator Voltage at Term. 2 V

Dwell - 4.4 - - 4.4 - Vp-p

2

Spark - 0.6 - - 0.6 - Vp-p

NOTE:

1. CA3165E at Term. 7

CA3165E1 at Term. 12

∆

I7

I12

10-27

Schematic Diagrams

ALL RESISTANCES ARE IN KILOHMS

R1

0.18

Q1

1

R2

0.18R30.18R40.18

Q7

R10

0.35

Q11

R11

R12

2.9

1.8

Q14

Q16

Q2 Q3 Q4 Q5

R7

6.2

R6

0.6

Q9

Q8

R13

R8

3.3

Q12

R14

0.1

2

Q10

Q13

Q15

R9

3.3

0.18

Q6

R16

R15

1

Q17

R5

2.5

Q18

12

R17

R24

0.1

R29

0.05

CA3165

9

R18

R19

10

10

Q27

R20

6.2

4.3

Q21

Q20

Q19

R22

2.4

R25

Q24

2.1

R30

0.1

Q28 Q29

Q22 Q23

R27

1.8

R26 2.1

R

R32

31

5

2

R33

Q30

0.1

Q25

R21

2.4

R23

5.1

R28

2

Q26

R34

2

Q31

R35

5

Q38

R36

4.6

Q32

Q33

Q34

Q36

Q39 Q40

Q37

Q36

R37

4.5

8

13

3

ALL RESISTANCES ARE IN KILOHMS

Q1

1

R1

0.18R20.18

Q2

Q6

R11

0.35

Q9

R12

1.8

R10

Q38

2.9

Q21

R3

0.18

Q3 Q4 Q5

R6

R7

6.2

0.6

Q8

Q7

Q11

R13

2

R8

3.3

R13A

0.1

FIGURE 3. SCHEMATIC DIAGRAM FOR CA3165E1

7

Q10

Q13

Q12

R4

0.18

R9

3.3

R15

1

Q39

R5

0.18

Q33

R14

2.5

Q15

R1810R1910R20

R17

10

Q16

R16

0.1

Q14

R15A

0.05

Q25

Q17

R25

2.1

R31

R21

2.4

0.1

Q23

4.3

Q18

R24A

1.8

R32

2

R27

7654102

R22

2.4

Q19

Q20

R23

5.1

Q22

R24B

2

Q24

R26

2.1

R33

R34

0.1

5

Q26

2

Q28

R28

5

Q27

Q35

Q40

Q36

R29

4.6

Q29

Q41

Q30

Q32

Q37

Q31

R30

4.5

2 8 3 6 4 5

FIGURE 4. SCHEMATIC DIAGRAM FOR CA3165E

10-28

CA3165

Application Information Figure 5 and Figure 6 show the application of the CA3165 in a typical ignition system.

TERMINAL DESCRIPTIONS

TERMINAL

FUNCTIONCA3165E1 CA3165E

1 1 Oscillator Feedback Resistor, R

F

2 2 220Ω Protective Resistor To Tank Circuit

3 3 Ground

4 4 Direct Output - R7 load resistor 200Ω± 5%, and R8 to power Darlington 15Ω± 10%

5 - Direct Output - Low Current - Not Connected

6 5 Inverted High Current Output

7 - Inverted Low Current Output Through C1 (0.01µF) to D3 and R3 (100kΩ)

8 - Output Amplifier Output - Through R6 and R5 (27Ω and 820Ω to Supply)

9 - Output Amplifier Input - through R4 (6800Ω) to D3 and C5 (0.0047µF)

10 6 Detector Output - C2 to Ground (0.01µF)

11 - No Connection

12 7 Circuit Supply Voltage Through R1 (220Ω Protective Resistor) to Automotive Supply

13 8 Oscillator Feedback Resistor RF to Terminal 1

14 - No Connection

AUTOMOTIVE SUPPLY 5V - 24V

R1

C1

0.01µF

R

F

220

NC

14 13 12 11 10 9 8

H.V.

CA3165E1 TOP VIEW

NC

C2

0.01µF

R4

6.8k

R6

R7

200

R5

820

27

D2

C6

H.V.

0.0047µF

METALLIC

TRIGGER WHEEL

ONE TOOTH PER

CYLINDER

1 2 3 4 5 6 7

NC NC

C4

R2

220

L1

L1 SENSOR COIL INDUCTANCE

0.01µF

R3

100k

C3

1500pF

D3

C5

0.0047

µF

CURRENT

LIMITER

≈ 100µH UNLOADED Q ≈ 53

EXCEPT AS NOTED, RESISTOR VALUES IN OHMS

R8

15

R10

220

R11

≈ 1100

SET FOR 4 AMPERES IN R13

FIGURE 5. TYPICAL IGNITION SYSTEMS USING THE CA3165E1

10-29

R12

100

R9

6.8k

D4

D1

R13

0.18

R1

220

CA3165

820

1W

5%

200

1W

±5%

+13V

6

CA3165E

TOP

7

VIEW

8

R6

0.01µF

C6

L1 SENSOR COIL,

INDUCTANCE ≈ 100µH,

UNLOADED Q

≈ 53

C3

0.01µF

6490 ± 0.15%

METALLIC TRIGGER WHEEL,

ONE TOOTH PER CYLINDER

FIGURE 6. TYPICAL IGNITION SYSTEM USING THE CA3165E

Application Information

Figure 5 and Figure 6 show the application of the CA3165 in

a typical ignition system. The oscillator on the chip operates

at about 400kHz as determined by the tuned circuit L1, C2.

The amplitude of the oscillation is detected on the chip and

applied to a Schmitt trigger which sets the terminal voltage

as shown in the chart in Figure 1 and Figure 2 for the

unloaded condition of the oscillator. As a metallic tooth in the

rotor passes the coil L1, eddy-current losses occur which

reduce the Q of the resonant circuit and decrease the amplitude of the oscillations to a level below that of a reference in

the detector circuit. The output terminals are then switched

to states as shown in the chart in Figure 1 and Figure 2 for

the loaded condition of the oscillator. The oscillation is maintained at this lower amplitude by switching in additional feedback in the oscillator circuit. The fact that the oscillator

continues to operate at some minimum level during this

dwell period eliminates timing variations which would occur if

the oscillator had to be restarted by random noise.

Spark occurs as terminal 4 is switched from high to low. The

output amplifier clamps terminal 4 low through the regulator

during the duration of the spark.

The Dwell period represents the time that terminal 10

(CA3165E1) or terminal 6 (CA3165E) is high, terminal 4 is

low, and the coil is charged.

The value of the oscillator feedback, resistor, R

to set the dwell period. With a sintered-iron 8 f-tooth rotor, a

typical value of R

is 6500Ω for 28.5 degrees of dwell out of

F

a 45 degree cycle. For a star-type rotor and a particular coil

in a typical distributor, the feedback resistor would be larger

(typically 8800Ω) depending on clearances, coil geometry

and tooth shape.

, is selected

F

5

4

3

2

1

220

V

OUT

C2

L1

1500pF

SILVER

MICA

ALL RESISTORS 1/2 W ±5%

UNLESS OTHERWISE SPECIFIED

RESISTOR VALUES IN OHMS

For typical F-Tooth Rotor with Rod Sensor and 113µH of coil

inductance, the Q and frequency with respect to rotor position was measured for the following positions

CENTER 46 at 377kHz

SLOT 6 at 390kHz

FIRE 15 at 381kHz

(Free air Q = 55.7 at 375kHz.)

HIGH

DETECTOR

TERM 10

LOW

HIGH

TERM 4

LOW

SPARK

OSCILLATOR

OSC

LOADED

DWELL

COIL

CHARGE

FIGURE 7. TIMING SEQUENCE

DWELL

PERIOD

DWELL

OSC

UNLOADED

10-30

Loading...

Loading...