Page 1

1

Memory ICs

Non-volatile electronic potentiometer

BU9831 / BU9831F

The BU9831 / BU9831F is a non-volatile electronic potentiometer with an internal 2k bit EEPROM. The resistance

value can be set by means of serial communications, and because the product contains an internal memory, conditions can be retained.

In addition, the 2k bit memory capacity enables digital data to be stored in the memory.

•

Absolute maximum ratings (Ta = 25°C)

Applied voltage

Power

dissipation

BU9831

BU9831F

Pd

Storage temperature

Operating temperature

Input voltage

∗

1 Reduced by 5.0mW for each increase in Ta of 1°C over 25°C.

∗

2 Reduced by 3.5mW for each increase in Ta of 1°C over 25°C.

VCC

Parameter Symbol

Tstg

Topr

—

– 0.3 ~ + 7.0

Limits

– 65 ~ + 125

– 20 ~ + 85

– 0.3 ~ V

CC + 0.3

mW

V

Unit

°C

°C

V

Wiper current

I

W

± 1.0 mA

500

∗

1

350

∗

2

•

Applications

Portable LCD backlight adjustment devices for notebook computers, and other sound adjustment devices for sets

•

Features

1) Internal 2k bit EEPROM

2) 100kΩ (1kΩ×100 steps) electronic potentiometer

3) Data in memory is automatically read when power supply is turned on, and resistance value is set.

4) Resistance value can be set using serial communications.

5) Low current consumption

When operating: 3mA (max.)

In standby mode: 200µA (max.)

•

Recommended operating conditions

Power supply voltage

Power supply voltage for writing Vccwr

VCC

Parameter Symbol

V

V

Unit

2.7 ~ 5.5

Limits

2.8 ~ 5.5

Input voltage V

IN V 0 ~ VCC

Voltage at resistor ends VRHL V 0 ~ VCC

Wiper pin voltage VW V 0 ~ VCC

Page 2

2

Memory ICs BU9831 / BU9831F

•

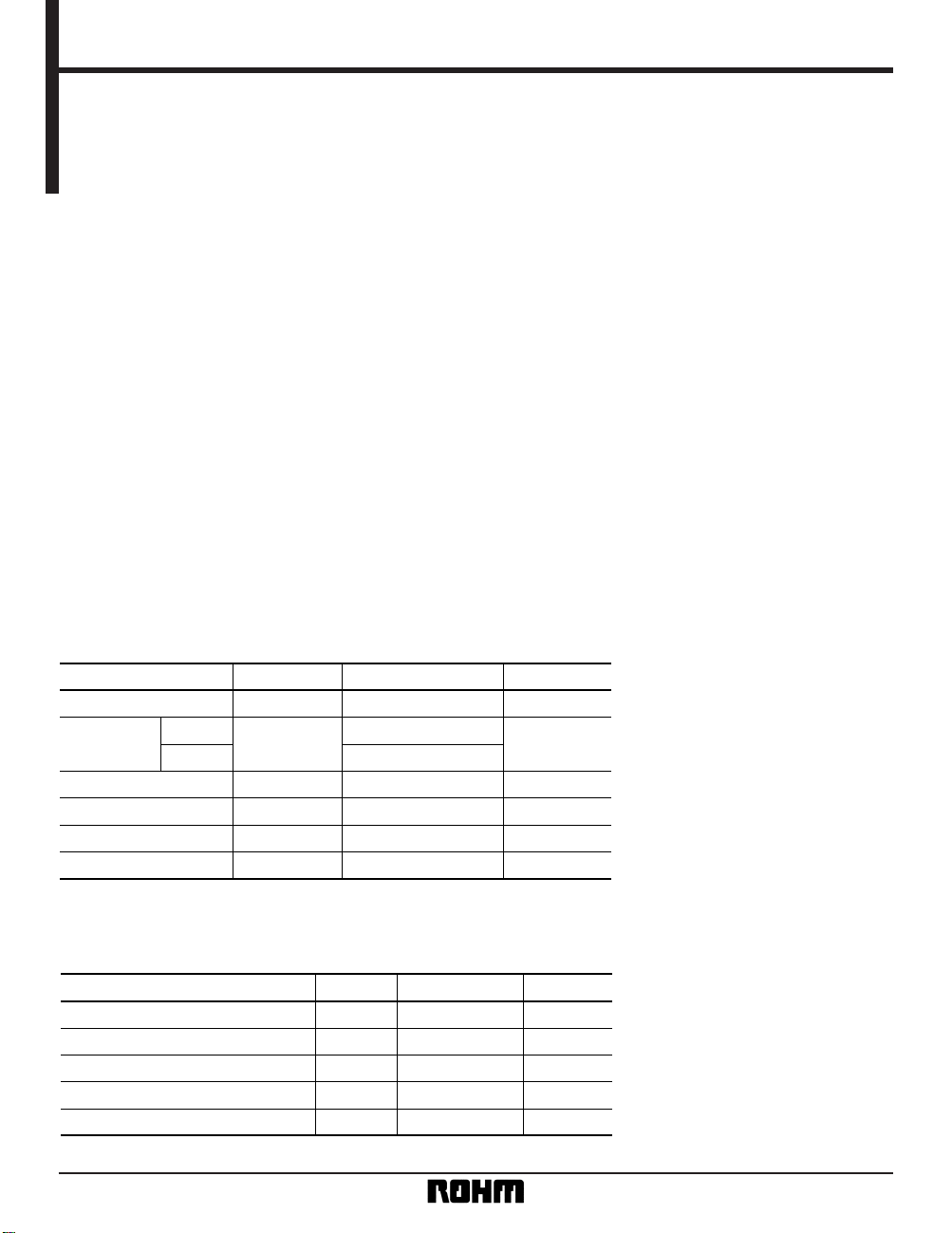

Block diagram

Command decode

Control

Timing Counter

EEPROM

Array

Wiper

decoder

Transistor

switch

Register

array

VW

VL

VH

High

voltage

generator

Write

Disable

Power supply

voltage detector

7bit

16bit

SK

DIO

CS

•

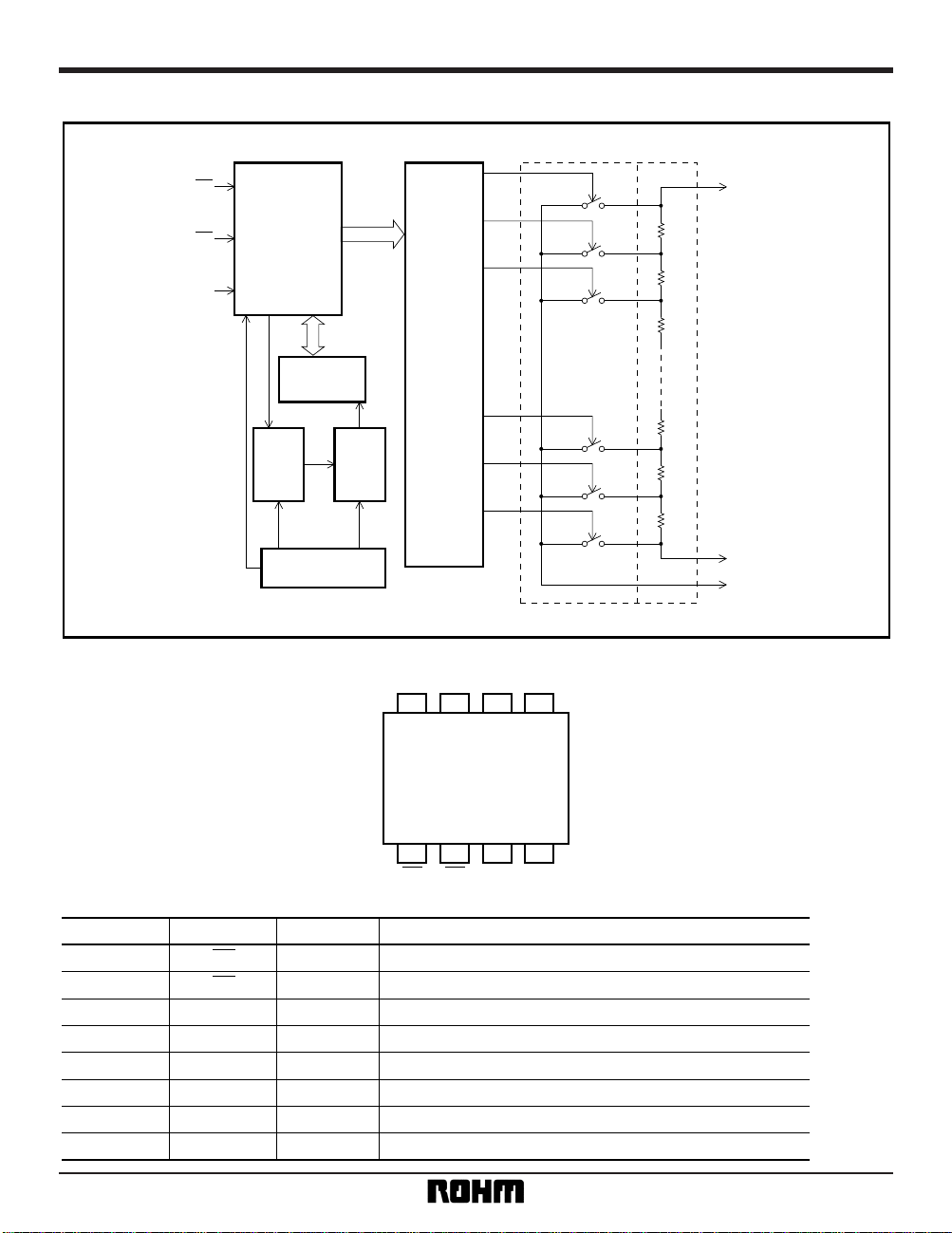

Pin assignments

CS SK DIO GND

VCC VH VW VL

BU9831

1234

8765

•

Pin desoriptions

DIO Input / output of operating codes, addresses, and serial data

GND Reference voltage of 0V for all input / output

VH Resistance high-potential

VCC Connection for power supply

I / O

—

Resistance pin

—

Pin name

3

4

7

SK Serial data clock input

VW Wiper

I

Resistance pin

2

6

CS Chip select input

VL Resistance low-potential

I

Resistance pin

1

5

8

Pin No. FunctionI / O

Page 3

3

Memory ICs BU9831 / BU9831F

•

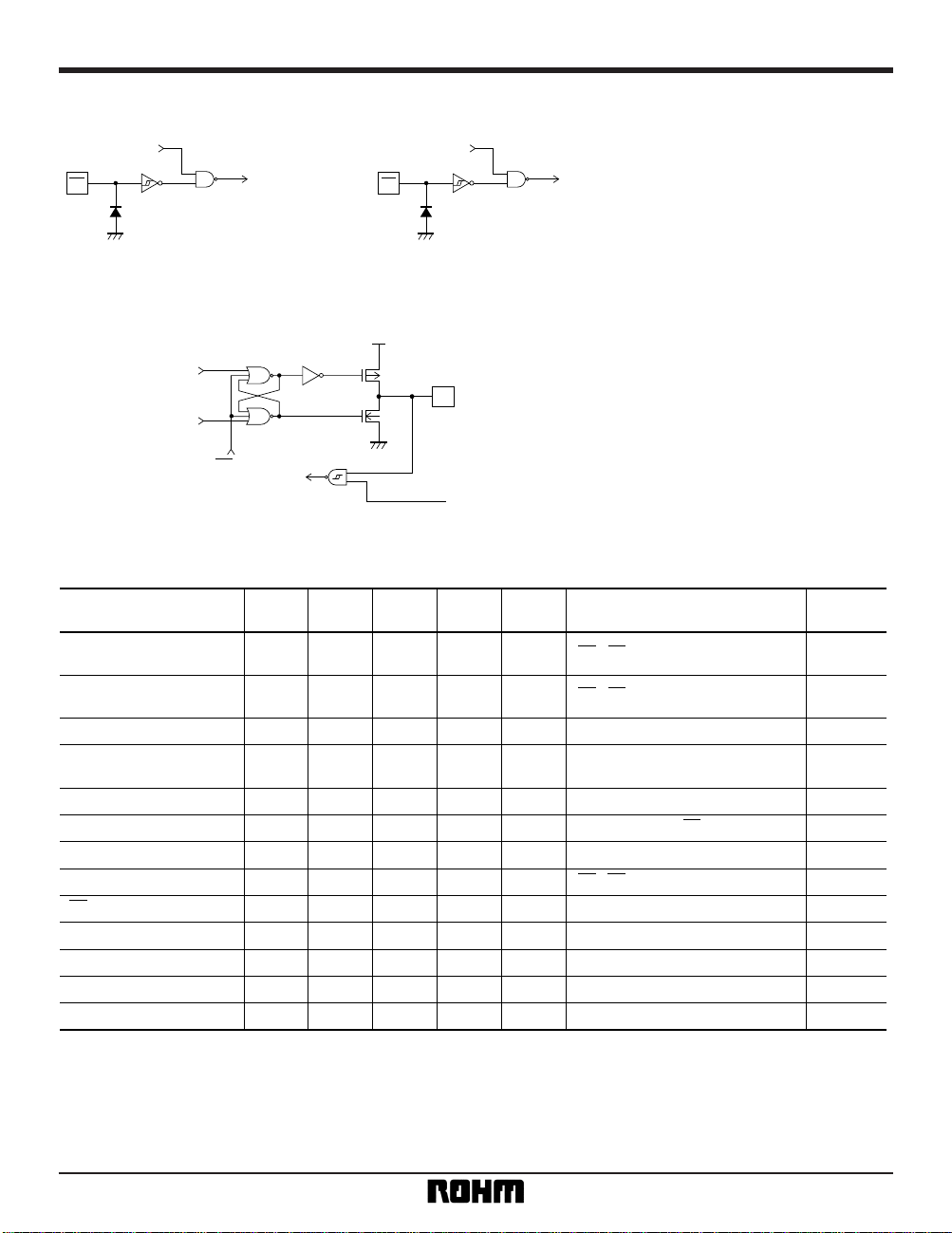

Input circuits

RESET int.

CS

SK

CS int.

•

Output circuits

CS int.

DIO

OE int.

•

Electrical characteristics (unless otherwise noted, Ta = – 20 to + 85°C, VCC = 5V ± 10%)

Input low level voltage

V

IL

Parameter Symbol Min. Typ. Max. Unit

——

0.2 ×

V

CC

V

0.8

×

V

CC

——V

0—0.4 V

VCC –

0.4

—V

CC V

– 1 — 1 µA

–1 — 1 µA

—— 3mA

——200 µA

—— 1 MHz

— 100 — kΩ

— 0.5 1 kΩ

0—VCC V

0—VCC V

Measurement

Circuit

CS, SK, DIO pin

Input high level voltage

V

IH

CS, SK, DIO pin

Output low level voltage

V

OL

IOL = 2.1mA

I

OH = – 0.4mAOutput high level voltage

V

OH

Input leakage current

I

LI

VIN = 0 ~ VCC

Output leakage current

I

LO

VOUT = 0 ~ VCC, CS = VCC

Operating current consumption

ICC

f = 1MHz, tE / W = 10ms (WRITE) Fig.5

Fig.4

Fig.3

Fig.6

Fig.1

—

—

Standby current

I

SB

CS, SK, DIO, VH, VL, VW = VCC Fig.6

SK frequency

f

SK

Total resistance

R

T

If = 10µA

Wiper resistance

R

W

IW = – 1mA Fig.8

Fig.7

—

—

Resistance potential on High side

VVH

—

Resistance potential on Low side

VVL

Conditions

Page 4

4

Memory ICs BU9831 / BU9831F

(unless otherwise noted, Ta = – 20 to + 85°C, VCC = 3V ± 10%)

Input low level voltage

VIL

Parameter Symbol Min. Typ. Max. Unit

——

0.2 ×

V

CC

V

0.8

×

V

CC

——V

0—0.4 V

VCC –

0.4

—V

CC V

– 1 — 1 µA

– 1 — 1 µA

—— 2mA

——100 µA

——500 kHz

— 100 — kΩ

— 12kΩ

0—VCC V

0—VCC V

Measurement

Circuit

CS, SK, DIO pin

Input high level voltage

VIH

CS, SK, DIO pin

Output low level voltage

VOL

IOL = 100µA

I

OH = – 100µA

Output high level voltage

VOH

Input leakage current

ILI

VIN = 0 ~ VCC

Output leakage current

ILO

VOUT = 0 ~ VCC, CS = VCC

Operating current consumption

ICC

f = 1MHz, tE / W = 10ms (WRITE) Fig.5

Fig.4

Fig.3

Fig.6

Fig.1

—

—

Standby current

I

SB

CS, SK, DIO, VH, VL, VW = VCC Fig.6

SK frequency

f

SK

Fig.7Total resistance

R

T

If = 10µA

Wiper resistance

R

W

IW = – 500µA Fig.8

Resistance potential on High side

VVH

—

Resistance potential on Low side

VVL

—

Conditions

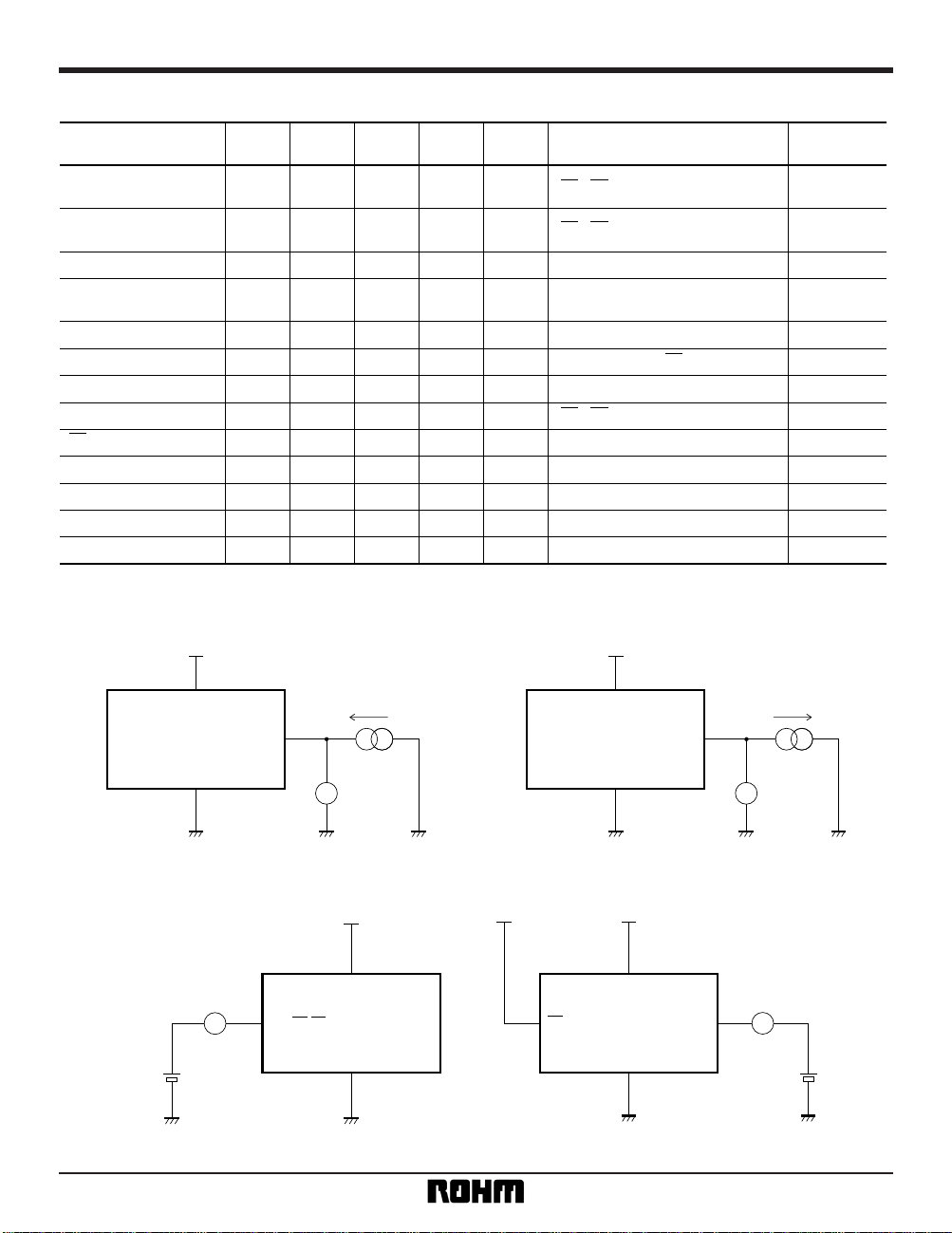

•

Measurement circuits

VCC

VOL

IOL

VCC

DIO

GND

Data set when output is LOW

V

Fig. 1 LOW output voltage measurement circuit

VCC

VOH

IOH

VCC

DIO

GND

Data set when output is HIGH

V

Fig. 2 HIGH output voltage measurement circuit

VCC

ILI

VCC

DIO, SK, CS

GND

A

VIN = 0 ~ VCC

Fig. 3 Input leakage current measurement circuit

VCCVCC

ILO

VO = 0 ~ VCC

VCC

CS

DIO

GND

A

Fig. 4 Output leakage current measurement circuit

Page 5

5

Memory ICs BU9831 / BU9831F

VCC

ICC

VCC

DIO

GND

A

SK

CS

Input

1MHz Clock

V

IL

Fig. 5 Current consumption measurement circuit

VCC

VCC VCC

ISB

V

CC

DIO

VH, VL, VW

GND

A

SK

CS

Fig. 6 Standby current measurement circuit

VCC

GND

V

DIO

V

W

VH

VL

I force

R

T =

V

I force

I force = 10µA

CS

SK

Fig. 7 Total resistance measurement circuit

IW

VCC

GND

V

DIO

V

W

VH

VL

V force

Measured after wiper

position is set to 64h

RWL = V / IW

V force = 1 / 2 · VCC

SK

CS

Fig. 9 Wiper resistance measurement circuit on High side

VCC

GND

V

DIO

V

W

VH

VL

IW

V force

Measured after wiper

position is set to 00h

RWL = V / IW

V force = 1 / 2 · VCC

CS

SK

Fig. 8 Wiper resistance measurement circuit on Low side

Page 6

6

Memory ICs BU9831 / BU9831F

•

Command modes

Command

Write enabled

Write disabled

Wiper counter data output

Wiper counter data input

Data read

Data write

Transmission memory data read

Transmission memory data write

Increment / decrement wiper

WEN

WDS

WCR

WCW

DRD

DWR

D8 - D14 X

XXXXXXXX D8 - D14 X

D0 - D15

D0 - D15

Wiper counter → output

Input → wiper counter

Memory → output

Input → memory

Memory → wiper counter

Wiper counter → memory

Wiper counter → INC / DEC

TDWR

TWDW

INC/DEC

Start bit

Operation code

Address

1010 0011

XXXXXXXX

1010 0000

XXXXXXXX

1010 1011

XXXXXXXX

1010 0110

XXXXXXXX

1010 1000 A0 - A6 X

1010 0100 A0 - A6 X

1010 1001 A0 - A6 X

1010 0101 A0 - A6 X

1010 1111

Data Operation

X: Don't Care (data may be either 0 or 1)

—

—

—

—

—

—

—

䊊

Auto recall function (ARF)

• After the power supply is turned on, the data for address 00h is automatically loaded and the wiper position set. At

this point, if the data for address 00h is larger than 64h, the wiper position is set to 32h. Since the wiper position is

set using seven bits, the eighth bit may be set to any value. This function is carried out 10ms after the power supply

is turned on, and subsequently the IC enters the standby state.

•

Operation timing characteristics (unless otherwise noted, Ta = – 20 to + 85°C, VCC = 5V ± 10%)

Parameter

Symbol

Min. Typ. Max. Unit

t

CSS 200 — — ns

CS setup time

t

CSH 0——ns

CS hold time

t

DIS 150 — — ns

Data setup time

t

DIH 150 — — ns

Data hold time

t

PD1 — — 350 ns

DO rise delay time

t

PD0 — — 350 ns

DO fall delay time

tE / W — — 10 ms

Self-timed programming cycle

t

CS 1——µs

CS minimum HIGH time

t

SV —— 1 µs

Time during which READY / BUSY display is effective

tOH 0 — 400 ns

Time that DO is HIGH-Z from (CS)

t

WH 450 — — ns

Data clock HIGH time

t

WL 450 — — ns

Data clock LOW time

t

AW — — 500 µs

Resistance value stabilization time

Page 7

䊊

Reading of input data is done at the rising edge of SK.

䊊

Output of data is synchronized to the falling edge of SK.

䊊

Between commands, CS should be set to HIGH for longer than tCS.

If CS remains LOW, the next command cannot be received.

7

Memory ICs BU9831 / BU9831F

(unless otherwise noted, Ta = – 20 to + 85°C, VCC = 5V ± 10%)

Parameter

Symbol

Min. Typ. Max. Unit

t

CSS 400 — — ns

CS setup time

t

CSH 0——ns

CS hold time

t

DIS 300 — — ns

Data setup time

t

DIH 300 — — ns

Data hold time

t

PD1 — — 700 ns

DO rise delay time

t

PD0 — — 700 ns

DO fall delay time

tE / W — — 15 ms

Self-timed programming cycle

t

CS 2——µs

CS minimum HIGH time

t

SV —— 2 µs

Time during which READY / BUSY display is effective

tOH 0 — 800 ns

Time that DO is HIGH-Z from (CS)

t

WH 900 — — ns

Data clock HIGH time

t

WL 900 — — ns

Data clock LOW time

t

AW — — 1000 µs

Resistance value stabilization time

•

Synchronous data I / O timing

t CSS

t CSH

t PD

t DIS

t PD

t OH

t DIH

t WH

t CS

t WL

CS

SK

Input DIO

Output DIO

Fig. 10 Synchronous data I / O timing

Page 8

8

Memory ICs BU9831 / BU9831F

•

Timing charts

(1) Writing enabled / disabled

SK

CS

DIO

H

L

H

L

H

L

ENABLE = 1 1

DISABLE = 0 0

14 8 12 16

110000

Fig. 11 Writing enabled and disabled

1) When the power supply is turned on, the writing recognition latch is reset in the same way as when the write dis-

able command is executed. The write enable command must be input before the write command is input.

2) Once the write enable command has been set, it remains effective until either the write disable command is input,

or the power supply is turned off.

3) No clocks longer than 16 clocks are required. These will be ignored by the IC if input. The command is received

following the clock input for the eight bits of the address subsequent to input of the operation code. The contents of

the address are not related to either of these commands, however, and will be ignored.

(2) Wiper counter data output (WCR)

SK

CS

DIO

1

1

1

11

000

H

L

H

L

H

L

(DO)

D8 D14

HIGH-ZHIGH-Z

14 8 16

24

t CS

Fig. 12 Wiper counter data output

1) When the Wiper Counter Data Output (WCR) command is received, seven bits of the data at the current wiper

position are output to D8, D9, D10, ..., D14, in sequential order. If a clock of longer than 24 clocks is input, indefinite

data may be output. (For the DIO output, the data may change at the tPD0 and tPD1 time delays, in response to the

internal circuit delay starting from the falling edge of the SK signal. During the tPD0 and tPD1 time internals, data

should be loaded after the tPD time has been assured, in case the previous data is indefinite. Refer to Fig. 10,

Synchronous data I / O timing.)

Page 9

9

Memory ICs BU9831 / BU9831F

(3) Wiper counter data input (WCW)

SK

CS

DIO

1

1

0

10

001

H

L

H

L

H

L

VW

14 8

24 32

t AW

D8 D14

Fig. 13 Wiper counter data input

1) This command is used for direct input of wiper position data. Since the data is 7-bit data sequentially input in the

order of D8, D9, D10, ..., D14, it determines one wiper position among 100 taps. Since no address exists at this

point, the address is ignored. The resistance stabilizes after an interval of tAW from the rise of the 32nd clock.

(4) Data read (DRD)

SK

CS

DIO

1

1

1

0A0 A60

00 0

H

L

H

L

H

L

(DO)

D0 D15

HIGH-ZHIGH-Z

14 8 16

32

t CS

Fig. 14 Data read

1) When the data read (DRD) command is received, data is output from the addresses specified by A1 and A0.

2) Output is synchronized to the fall of SK, in order of D0, D1, D2, ..., D15, at the fall of the 16th clock. After 32

clocks have elapsed, the D15 data is retained even if other clocks are input.

Page 10

10

Memory ICs BU9831 / BU9831F

(5) Data write (DWR)

SK

CS

DIO

110 00001

H

L

H

L

H

L

14 8

16 32

t E / W

A0 A6 D0 D15

Fig. 15 Data write

1) This command stores the input data in the address specified by A0 to A6.

2) CS must be LOW during the write mode input, but once writing begins, CS may be either HIGH or LOW.

3) The internal timer circuit in the IC begins to function after the rising edge of the SK at which the last data D0 was

read, and data is written to memory cells during the time period tE / W. The process is terminated automatically.

At this point, the SK input during the tE / W time period may be either HIGH or LOW.

4) The time period between input of this command and the automatic termination of the writing of data is the time

during which data is written to the internal non-volatile memory, so commands input during this interval will not be

accepted. The maximum time interval must be within tE / W.

5) After the write command has been input, if CS is set to LOW after having been set to HIGH, command reception

is enabled following termination of the automatic data writing. Data can then be received from SK and DIO. If CS is

left at LOW following input of the command, however, without being set to HIGH, input of the command is canceled.

(6) Transmission memory data read (TDWR)

SK

CS

DIO

0

1 1 1 1 A0 A60000

H

L

H

L

H

L

VW

14 8 16

t AW

Fig. 16 Transmission memory data read

1) This command transmits the data from the addresses specified by A0 to A6 to the wiper counter. The wiper

moves to the position indicated by the seven bits D8 to D14 of the specified address, and the resistance value stabilizes after the tAW time period starting with the fall of the 15th clock. Data subsequent to the 16th clock is ignored.

Page 11

11

Memory ICs BU9831 / BU9831F

(7) Transmission memory data write (TWDW)

SK

CS

DIO

1

1

1

1A0 A60

000

H

L

H

L

H

L

14 8 16

t E / W

Fig. 17 Transmission memory data write

1) This command transmits the wiper position data to the addresses specified by A0 to A6. The data from the seven

bits D8 to D14 of the specified address are stored in the memory during the time tE / W, starting from the rise of the

16th clock.

2) Writing is done to the internal non-volatile memory during the time when this command is input and automatic

writing of the data is completed. Commands input during this time will not be accepted. The maximum time for this

period must be within tE / W.

3) After the write command has been input, if CS is set to LOW after having been set to HIGH, command reception

is enabled following termination of the automatic data writing. Data can then be received from SK and DIO. If CS is

left at LOW following input of the command, however, without being set to HIGH, input of the command is canceled.

(8) INC / DEC

SK

CS

DIO

1 1 1 1 DEC INC1001

H

L

H

L

H

L

VW

1 4 8 9 10 11

t AW

t AW t AW

Fig. 18 Increment / decrement wiper

1) The wiper position is incremented or decremented starting from the next clock following input of the INC / DEC

command, based on the status of the INC pin.

DIO = H: Incremented. The wiper position moves from the VL to the VH side by 1 tap per clock.

DIO = L: Decremented. The wiper position moves from the VH to the VL side by 1 tap per clock.

2) The tap is moved at each rise of the clock, until CS is set to HIGH.

When the tap is farthest to the VH side, incrementing is ignored.

In the same way, when the tap is farthest to the VL side, decrementing is ignored.

Page 12

12

Memory ICs BU9831 / BU9831F

•

Application examples

BU9831

VH

VW

VL

Fig. 19 Operation amplifier gain adjustment

BU9831

Fine adjustment of the input offset voltage can be done in order to

suppress the error voltage of the output based on the input voltage.

Fig. 20 Adjustment of the operation amplifier offset voltage

Reg

Output current can be adjusted by adjusting the output load.

BU9831

Fig. 21 Variable output adjustment of regulator

•

Operation notes

(1) When turning the power supply on and off

1) When turning the power supply on and off, CS should be set to HIGH ( = V

CC).

2) When CS is LOW, the BU9831 is active, meaning that input can be received. If the power supply is turned on in

this state, noise and other factors can cause malfunctioning and erroneous writing. To prevent this, when turning the

power supply on, make sure that CS is HIGH ( = V

CC).

(Example of proper operation) The CS pin is pulled up to V

CC.

After turning the power supply off, wait at least 10ms before turning it on again.

If the power supply is turned on without observing this condition, please be aware that there may be times

when the circuits in the IC are not reset.

(Example of incorrect operation) The CS pin is LOW when the power supply is turned on or off.

In this case, CS is normally LOW, and the EEPROM may cause malfunctioning or erroneous writing

because of noise.

∗ Be aware that the case shown in this example may occur even if the CS input is HIGH-Z.

Page 13

13

Memory ICs BU9831 / BU9831F

VCC

VCC

GND

VCC

CS

GND

Correct example

Incorrect example

(2) Noise countermeasures

1) SK noise

If there is noise in the rise of the SK clock input, the system may recognize more clocks than were actually input,

and malfunctioning may occur because of offset bits.

2) V

CC noise

Noise and surges in the power supply line can cause malfunctioning. To eliminate these factors, we recommend

installing a bypass capacitor between the power supply and the ground.

•

External dimension (Units: mm)

DIP8 SOP8

BU9831 BU9831F

0.5 ± 0.1

3.2 ± 0.2 3.4 ± 0.3

85

14

9.3

± 0.3

6.5 ± 0.3

0.3

±

0.1

0.51Min.

2.54

0° ~ 15°

7.62

0.4 ± 0.11.27

0.15

0.3Min.

0.15 ± 0.1

0.11

6.2 ± 0.3

4.4 ± 0.2

5.0 ± 0.2

85

41

1.5 ± 0.1

Loading...

Loading...