Page 1

ATAN0046

User Guide for the Evaluation Kit ATA8510-EK1

APPLICATION NOTE

Features

• User guide for the ATA8510-EK1 evaluation kit

• Demonstrates an application with the

– RF transceiver Atmel® ATA8515 in a base station with an

Xplained PRO SAMD20 kit

– Atmel ATA8510 RF transceiver remote sensor with an

AT30TS75A temperature sensor and an optional CMM-1923

real-time clock

– Two-way RF communication

• New software version of the SAMD20 base station V2.0 is without

FreeRTOS

Description

This user guide describes an evaluation kit for industrial RF applications

having the following components:

• A base station using an

– Xplained PRO SAMD20 evaluation kit

– Xplained PRO OLED1 extension board

– Xplained PRO ATA8510/15 extension board

• Remote temperature sensor with Atmel® ATA8510 running a Flash

application

The Atmel ATA8515 is used as an RF transceiver in the base station and

runs in polling mode to detect data telegrams and displays the received

message on the OLED. The received message is also streamed to a PC

terminal program using a virtual COM port connection.

The remote sensor includes an AT30TS75A temperature sensor device and

a CMM-1923 real-time-clock device for waking up the Atmel ATA8515 RF

transceiver. The Flash application reads the temperature data from the

sensor device using a TWI bus protocol implemented in software and

broadcasts the temperature data via the RF link.

The RF application uses a 2-way communication, i.e., the transmitted RF

telegrams are acknowledged from the receiver.

Atmel-9343D-ATAN0046_Application Note-09/2016

Page 2

The RF link operates on channel 433.92MHz at an 8kBit/s data rate using FSK modulation with

Manchester encoding.

References

[1] Atmel® ATA8510/ATA8515 datasheet

[2] Atmel AT30TS75A datasheet

[3] C-MAX CMM-1923-V1.0 datasheet

[4] http://www.atmel.com

[5] http://www.iar.com

[6] Atmel ATAN0096 - ATA8510 Programmers Guide

[7] Atmel ATAN0035 - ATA583x and ATA578x Configuration Tool Guide and software

[8] Atmel ATAN0036 - ATA583x and ATA578x Flash Application Development

[9] Atmel ATA8510/ATA8515 User Manual

[10] ATA8510-EK1_Tool_Pack_V2.0.zip

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

2

Page 3

Table of Contents

Features.......................................................................................................................... 1

Description.......................................................................................................................1

References...................................................................................................................... 2

1. Getting Started...........................................................................................................4

1.1. Kit Setup.......................................................................................................................................4

1.2. Upgrade Kit V1.x to V2.0 .............................................................................................................6

2. Data Protocol and Signal Timing............................................................................... 7

2.1. Data Protocol for Remote Sensor Telegram.................................................................................7

2.2. Data Protocol for Base Station Acknowledge...............................................................................8

2.3. Signal Timing................................................................................................................................8

3. Hardware Description................................................................................................ 9

3.1. Base Station Transceiver............................................................................................................. 9

3.2. Remote Sensor Transceiver.......................................................................................................10

4. Software Description................................................................................................13

4.1. Flash Application for the ATA8510 Remote Sensor................................................................... 13

4.2. Base Station Application for SAMD20 MCU...............................................................................14

4.3. Software Development...............................................................................................................16

4.4. EEPROM Data Settings............................................................................................................. 20

5. Revision History.......................................................................................................21

Page 4

1. Getting Started

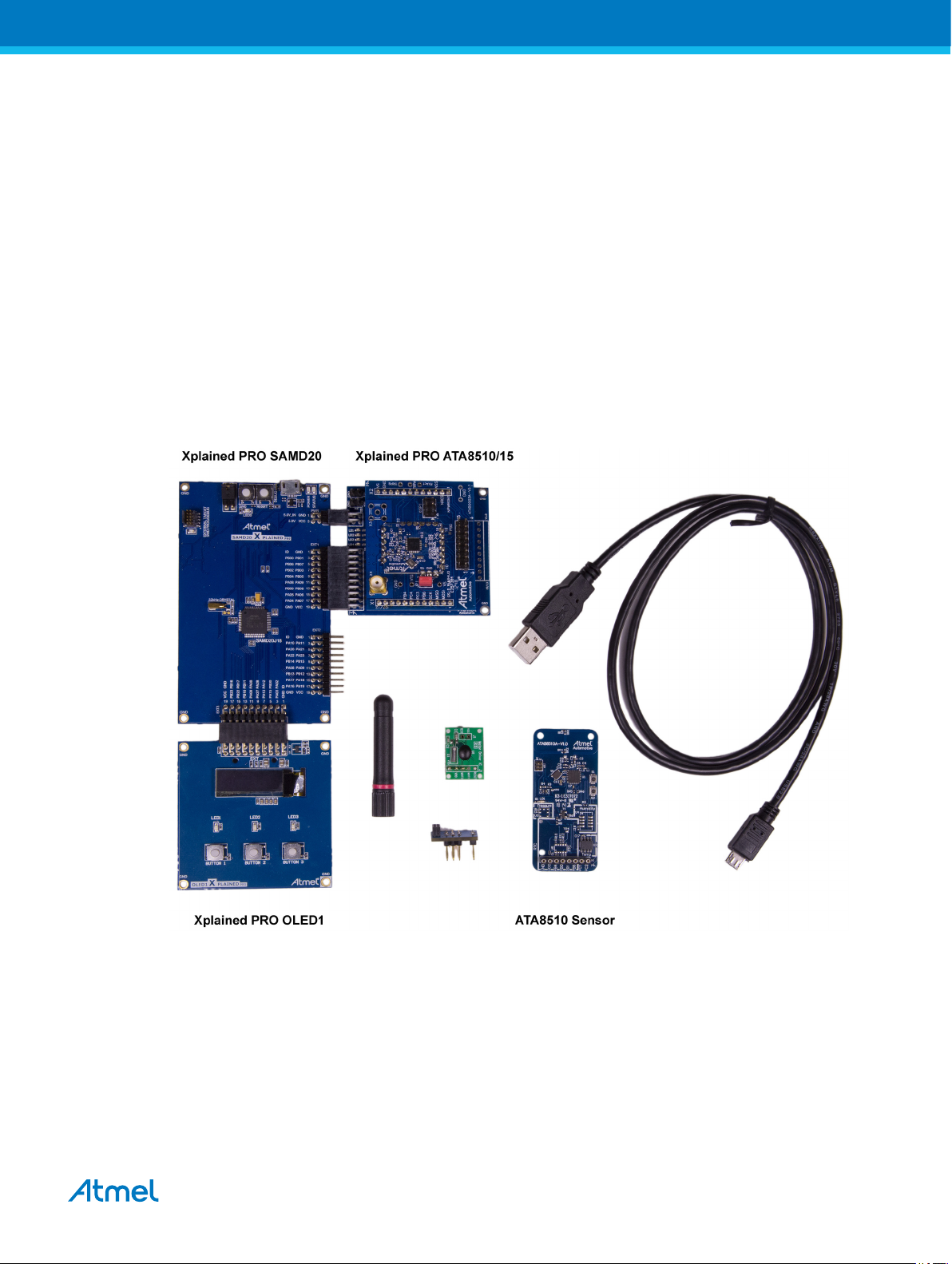

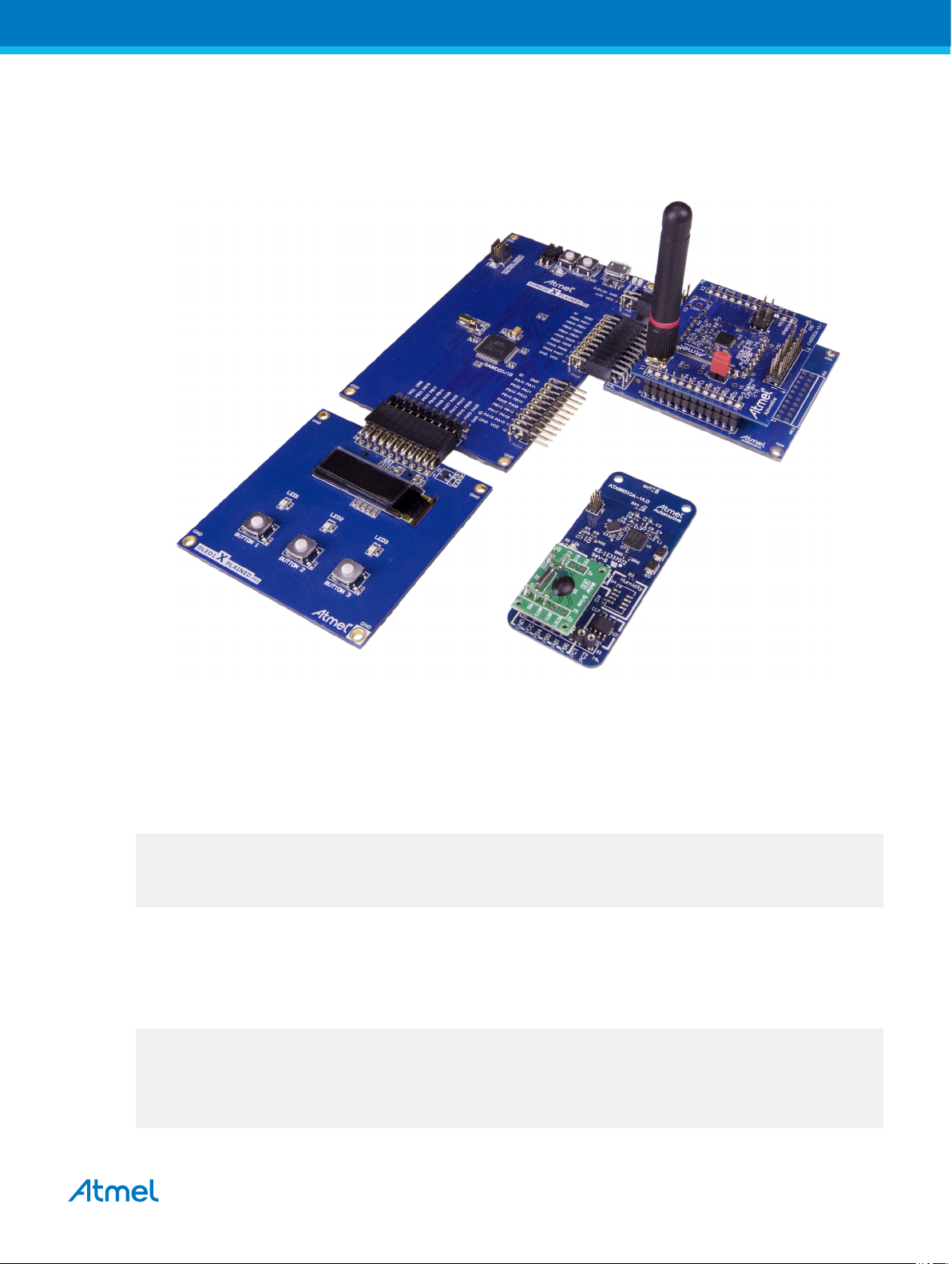

Figure 1-1 shows the components which are included in the evaluation kit. The kit includes

• A base station with

• Xplained PRO SAMD20 evaluation board

• Xplained PRO OLED1 extension board

• Xplained PRO ATA8510/15 extension board

• A remote temperature sensor with Atmel® ATA8510 [1], AT30TS75A [2], and an optional CMM-1923

[3] devices

• A mini USB cable

• A mini ISP adapter

• A 433MHz whip antenna

The remote sensor requires a CR2032 coin cell battery not included in the kit.

Figure 1-1. ATA8510-EK1 Kit Components

1.1. Kit Setup

The Xplained PRO OLED1 board is connected to the EXT3 extension header and the Xplained PRO

ATA8510/15 board is connected to the EXT1 extension header of the Xplained PRO SAMD20 board as

shown in Figure 1-2. The 433MHz whip antenna is mounted on the X4 connector of the Xplained PRO

ATA8510/15 board. These boards are powered using the USB cable connected to the debug USB

connector of the Xplained PRO SAMD20 board. The USB cable can be connected to a 5V/500mA USB

power supply for stand-alone operation. When using the virtual COM port, the USB cable is connected to

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

4

Page 5

a PC's USB port, which requires previous installation of Atmel Studio 6 or 7 IDE [4]. This installation

includes all required USB drivers for operation of the Xplained PRO SAMD20 board.

Figure 1-2. ATA8510-EK1 Kit

Atmel Studio 6 or 7 can be downloaded from [4] with additional user instructions and tools.

Documentation for the Xplained PRO SAMD20 and Xplained PRO OLED1 are also available from [4].

Documentation for other components in the kit and the software is included in the tool pack zip folder [10]

available on the Atmel web site [4].

The OLED displays a welcome screen after power-up

ATA8510-EK1 Demo Kit

(c)2016 Atmel V2.0

ATA8515 V1.2

wait for RF signal ...

and waits for an RF telegram from the remote sensor. After installing the CR2032 coin cell into the remote

sensor (be sure to observe correct polarity), the sensor immediately starts sending RF telegrams at 2s

intervals when the optional RTC module is installed. The OLED shows the temperature value from the

sensor with a resolution of 1°C. The time interval between the RF signal reception in seconds and the

signal strength rssi on the base station and RSSI on the sensor is also shown:

___________________

| dt=2s rssi=221 |

| |

| T=22°C |

| RSSI=128 |

|___________________|

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

5

Page 6

When removing the CMM-1923 real-time clock, the transmission of an RF telegram can be initiated by

pressing the S2 button (for more information, see Figure 3-2). The display can be switched to different

modes via the buttons 1-3 on the Xplained PRO OLED1 extension board (for more information, see

section Base Station Application for SAMD20 MCU).

The tool pack zip folder [10] contains the documentation and software for the kit. Extract the folder into a

directory on the PC to get the following structure:

..\Application_Notes Documentation for the kit and the application notes

for the devices

..\Documentation Device datasheets

..\Hardware Hardware documentation of the boards

..\Software Kit software and tool support extensions

..\Software\Programming_Files Device programming files in *.hex format

..\Software\IDE_Support_Files Tool support files for IAR Workbench and Atmel

Studio 6

..\Software\base Software project and sources for the Xplained PRO

kit

..\Software\base\EEPROM Configuration file for the Atmel ATA8515 device of

the base station

..\Software\base\SAMD20_XplainedPRO_SW Atmel Studio 6 or 7 project directory

..\Software\sensor Software project and sources for the remote sensor

..\Software\sensor\EEPROM Configuration file for the Atmel ATA8510 device of

..\Software\sensor\ATA5831_FLASH_IAR_2.32.0 IAR Embedded Workbench project directory

1.2. Upgrade Kit V1.x to V2.0

Any Atmel® ATA8510-EK1 kit can operate with V2.0 tool pack by programming the SAMD20 base station

with the application software from tool pack V2.0 [10]. The remote sensor need no update and will

operate with V1.x and V2.0 base station applications (see section Xplained PRO SAMD20 Base Station

for more details).

the remote

sensor

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

6

Page 7

2. Data Protocol and Signal Timing

The remote sensor is sending a RF data telegram every 2s or when the button S2 is pressed with the

temperature data. The base station receiver is polling for this data telegram on RF channel 433.92MHz in

regular intervals of 5ms. The RF transmission and data protocol of the remote sensor and the base

station is using the following settings:

• Transmission order is MSB first for preamble and data section

• RF channel: 433.92MHz

• Data rate: 8kBit/s with FSK modulation and Manchester encoding

• Deviation: ±8kHz

Each data packet uses 2 bits before and after the data telegram to force a Manchester code violation,

which is detected by the receiver to separate the data packets and to restart the synchronization

procedure of the receiver.

2.1. Data Protocol for Remote Sensor Telegram

The remote sensor data protocol parameters are shown in Table 2-1. The Manchester encoding is using a

low-to-high transition for a '0' bit and a high-to-low transition for a '1' bit.

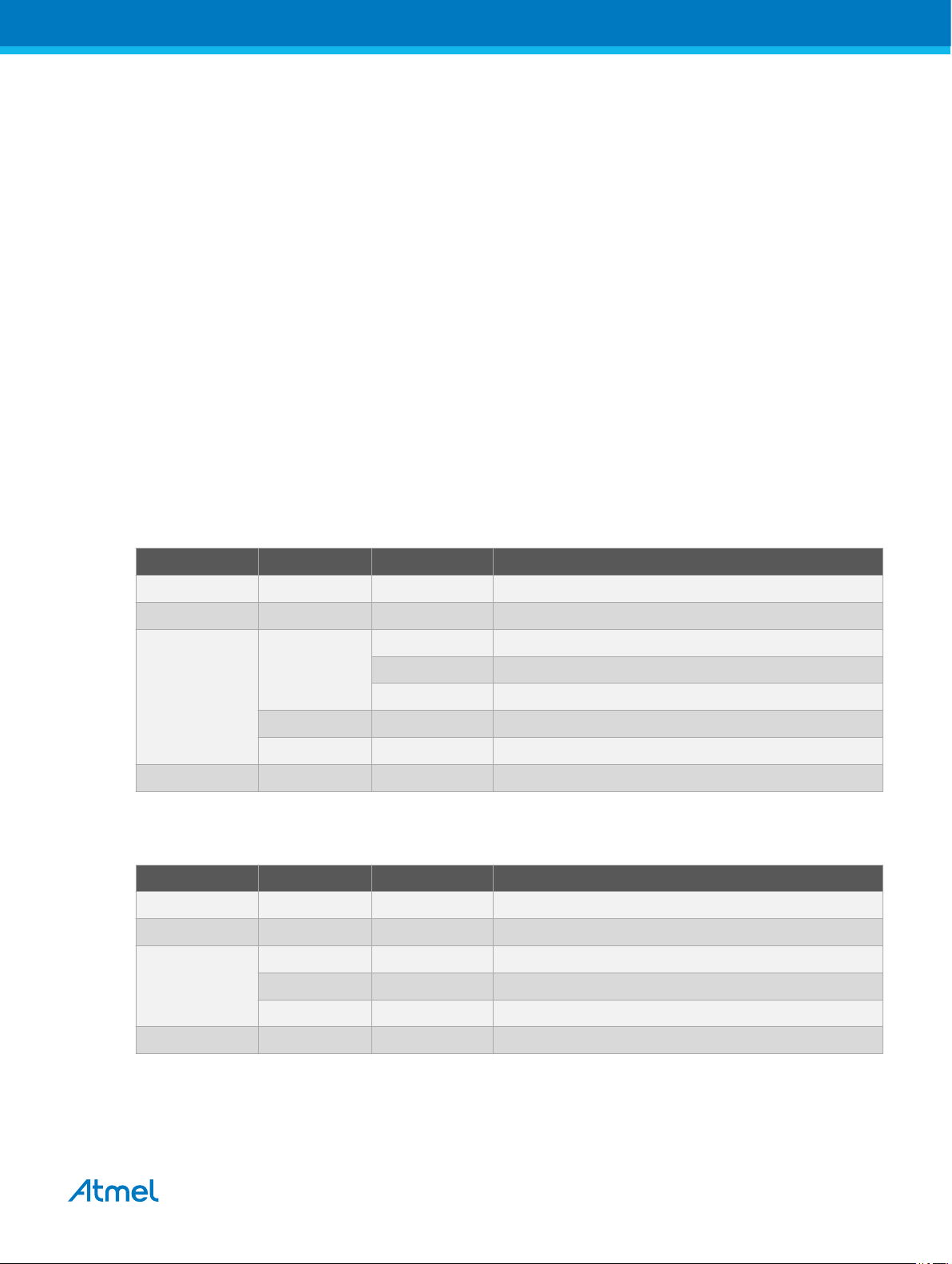

Table 2-1. Data Protocol

Protocol Item

Preamble 55 ‘1’ Pre-burst for wake-up and synchronization

Start bit 1 ‘0’ Start bit to indicate data payload

Data payload

Total 88 Data telegram with Ttx = 11ms at 8kBit/s

# of Data Bits Value Description

0x14 ID for no valid sensor data

8

16 Signed integer Temperature value (0.1°C resolution)

8 Checksum Checksum of ID and data payload as 2th complement

0x19 ID for low battery voltage (VCC < 2.2V)

0x64 ID for temperature data (–55 to +125°C)

The acknowledge protocol send by the remote sensor has the following data:

Table 2-2. Acknowledge Protocol

Protocol Item

Preamble 55 ‘1’ Pre-burst for wake-up and synchronization

Start bit 1 ‘0’ Start bit to indicate data payload

Data payload

Total 88 Data telegram with Ttx = 11ms at 8kBit/s

# of Data Bits Value Description

8 0x60 ID for RSSI data

16 Integer RSSI value [0-255]

8 Checksum Checksum of ID and data payload as 2th complement

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

7

Page 8

2.2. Data Protocol for Base Station Acknowledge

TX1

Remote

sensor

11ms

1.5ms

9ms

5.5ms

5ms

polling

2s

TX1TX2RX

RX2

RX1Base TX RX1 TX

RX

The base station acknowledge protocol parameters are shown in Table 2-3. The Manchester encoding is

using a low-to-high transition for a '0' bit and a high-to-low transition for a '1' bit.

Table 2-3. Acknowledge Protocol

Protocol Item # of Data Bits Value Description

Preamble 55 ‘1’ Pre-burst for wake-up and synchronization

Start bit 1 ‘0’ Start bit to indicate data payload

Data payload

Total 72 Data telegram with Ttx = 9ms at 8kBit/s

2.3. Signal Timing

The signal timing of the data transfer is shown in Figure 2-1.

1. The remote sensor transmits a data telegram with duration of 11ms every 2s or when button S2 is

pressed (TX1). The pre-amble duration is 7ms while the data payload duration is 4ms. The remote

sensor switches then into receive mode with a timeout period of 20ms (RX).

2. The base station is polling for a valid RF signal which matches the RF channel, the data rate, the

modulation scheme and the correct data encoding every 5ms. This polling interval is chosen to

match with the length of the pre-amble. When a valid telegram is received (RX1) the base station

acknowledges this telegram (TX) and waits for an acknowledgement frame from the remote sensor

with the remote sensor signal strength data and a timeout of 90ms (RX2).

3. The remote sensor transmits the acknowledgement frame with the RSSI signal strength (TX2) and

switches then into OFF mode.

4. The base station reads the acknowledgement frame with the RSSI data (RX2), displays the result

and switches into polling mode again.

Figure 2-1. Signal Timing

8 0x60 ID for RSSI data

8 0x60 Repeated

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

8

Atmel-9343D-ATAN0046_Application Note-09/2016

Page 9

3. Hardware Description

The description and documentation of the Xplained PRO SAMD20 board and the Xplained PRO OLED1

board are available within Atmel® Studio 6 or 7 on the Atmel website [4]. The hardware description of the

Xplained PRO ATA8510/15 extension board and the remote sensor are included in the tool pack zip folder

[10]. The base station is powered by the USB cable whereas the remote sensor uses a CR2032 coin cell

battery.

3.1. Base Station Transceiver

The Atmel® ATA8515 base station transceiver is mounted on an adapter board as shown in Figure 3-1.

This adapter board is plugged onto the Xplained PRO ATA8510/15 extension board which includes the

LEDs 1-4. The adapter board has a programming adapter XISP1 which is used for programming the

EEPROM configuration data into the device. This extension board is connected to the EXT1 and PWR

header of the Xplained PRO SAMD20 board. The extension board has two additional connectors, X6 for

supplying the kit with 5V and X7 to access the kit’s internal 3V supply voltage.

Figure 3-1. Base Station Transceiver Board

The connector pins of the Xplained Pro ATA8510/15 extension board are summarized in the following

tables Table 3-1, Table 3-2, Table 3-3 and Table 3-4.

Table 3-1. Connector X3

Function Pin Pin Function

ID_data 1 2 GND

-- 3 4 --

NPWRON1 (PB06) 5 6 NRESET (PB07)

LED3 (PB02) 7 8 LED4 (PB03)

EVENT (PB04) 9 10 --

-- 11 12 --

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

9

Page 10

Function Pin Pin Function

LED1 (PB09) 13 14 LED2 (PB08)

NSS 15 16 MOSI (PA06)

MISO (PA04) 17 18 SCK (PA07)

GND 19 20 VCC

Table 3-2. Connector X5

Function Pin Pin Function

5V in 1 2 GND

-- 3 4 --

Table 3-3. Connector X6

Function Pin Pin Function

5V in 1 2 GND

Table 3-4. Connector X7

Function Pin Pin Function

VCC 1 2 GND

3.2. Remote Sensor Transceiver

The Atmel® ATA8510 remote sensor transceiver is placed on a key fob board as shown in Figure 3-2.

This remote sensor is powered by a CR2032 coin cell battery (not included) mounted on the bottom of the

board. The board contains the real-time clock CMM-1923 [3] attached to the connector X1 and the

AT30TS75A [2] temperature sensor. The S1 and S2 buttons are placed on the board with the S1 button

not used in this application and the S2 button used for initiating data telegram transmission. The LED

flashes during a temperature measurement before transmitting the RF data telegram. The mini ISP

header is used for Flash and EEPROM programming and for Flash application debugging of the Atmel

ATA8510 (see [8] for more details about Flash application development).

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

10

Page 11

Figure 3-2. Remote Sensor Transceiver Board

0 10

9.40000

tx mode

Off mode

measure mode and LED

measure mode only

i [mA]

t [ms]

0.53500

0.06500

20

30 40 50 60 70 80

0.00035

The current consumption profile over time is shown in Figure 3-3. During the temperature measurement

period of 40ms, the LED is switched on in parallel, increasing current consumption. Figure 3-3 shows

current consumption for the measurement period with and without LED. The RF telegram transmission

takes about 11ms at a power level of 6dBm, resulting in current consumption of about 9.4mA. In OFF

mode the temperature sensor is switched off and the resulting current is indicated by the Atmel ATA8510

transceiver and the CMM-1923 RTC current consumption. This OFF mode current is highly dependent on

ambient temperature shown in the datasheets [1] and [3]. Figure 3-3 indicates current consumption

measured at a room temperature of 24°C.

Figure 3-3. Remote Sensor Current Consumption at 24°C

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

11

Page 12

Table 3-5 summarizes battery life for a CR2032 and CR2450 coin cell without using the LED during

temperature measurement at 20°C. It is assumed that the battery voltage drops from the initial value of

3V down to 2V by the end of battery service. The self discharge is defined by the manufacturer with

typically 1% per year at an ambient temperature of 20°C. The battery life for this application primarily

depends on the measurement interval Ts, which defines the duration of the OFF mode whereas

measurement and transmit mode have fixed durations.

Table 3-5. Battery Life at 20°C

Interval Ts Mean Current Battery Lifetime (Days/Years)

(s) (mA) CR2032 (230mAh) CR2450 (560mAh)

Days Years Days Years

2 0.053 180 0.5 437 1.2

5 0.022 445 1.2 1083 3.0

10 0.011 875 2.4 2131 5.8

20 0.006 1696 4.6 4130 11.3

50 0.002 3880 10.6 9448 25.9

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

12

Page 13

4. Software Description

check wake-up source

switch sensor power and LED on

Initialisation

Off mode

Off mode

perform temperature

measurement [40ms]

Measurement

switch off LED and

transmit data telegram [11ms]

Low battery

voltage?

Perform 2-way RF communication

[200ms]

Wait

transmit error telegram [11ms]

Transmission

Wake-up

source?

yes

applied

released

no

The demo application uses the following programs:

1. A Flash application with EEPROM settings for the Atmel® ATA8510 remote sensor

2. A SAMD20 application with EEPROM settings for the Atmel ATA8515 receiver

The following section describes each program flow. The IAR embedded workbench for AVR® [5] is used

together with the JTAGICE3 debug tool for Flash application development of the remote sensor. Atmel

Studio 6 or 7 [4] is used together with the debug tool included on the Xplained PRO SAMD20 board for

SAMD20 application development.

The source code for all applications is available within the tool pack distribution [10].

4.1. Flash Application for the ATA8510 Remote Sensor

The program flow for the remote sensor application is illustrated in Figure 4-1. The initial state of the

device is the OFF mode. The real-time clock of the remote sensor wakes up the transceiver every 2s and

switches the device to active mode. The temperature sensor is powered up and read out followed by the

transmission of the data telegram. During transmission of this data telegram the supply voltage level is

checked and if this is below 2.2V, an error message is transmitted after a delay of 200ms. The device

then enters the OFF mode again until the next wake-up by the RTC (or by pressing the S2 button).

Figure 4-1. Flash Application for the Atmel ATA8510 Remote Sensor

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

13

Atmel-9343D-ATAN0046_Application Note-09/2016

Page 14

4.2. Base Station Application for SAMD20 MCU

Initialisation

IO, USART, SPI, ATA8515,

OLED, LED

Reset

Display temperature and

RSSI data

yes

yes

yes

no

no

RF event?

Set ATA8515 in Polling mode

Enable timer

Show COM port settings

Show RF statistics

Read RX and RSSI buffer

Send Acknowledge

Wait for Sensor answer

no

no

no

Button 1

pressed?

Button 2

pressed?

Button 3

pressed?

Data correct?

Show RF settings

yes

yes

The program flow for the SAMD20 application is illustrated in Figure 4-2. This application performs at the

start an initialization of the peripherals, the LEDs and the OLED display. The ATA8515 RF transceiver is

switched into RF polling mode to check for the reception of a valid remote sensor signal. In addition a

timer is initialized for time measurements between RF signal transmissions. The software is then entering

an infinite loop to check for an RF event signal from the RF transceiver or for a button press of one of the

buttons on the OLED1 extension board. A button press will show the corresponding information on the

OLED display as shown in Figure 4-2. When a RF event is detected the RX and RSSI buffer are read and

the RX data are checked with their checksum to be a valid data stream. If the data is not valid the polling

mode is enabled again to check for another RF signal. If the data is valid an acknowledge signal is send

followed by waiting for an RF answer telegram. Finally the received temperature and RSSI data are

shown on the OLED display. All text shown on the OLED display is also streamed via the USART

peripheral and can be shown on a PC Terminal program connected to the virtual COM port of the

SAMD20 kit.

Figure 4-2. Flash Application for SAMD20 MCU

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

14

Page 15

The OLED display will show the following text information:

Start page:

shows the welcome message with software and transceiver firmware version information and awaits a

remote sensor signal.

ATA8510-EK1 Demo Kit

(c) Atmel 2016 V2.0

ATA8515 V1.2

wait for RF signal ...

Button 1 menu:

shows parameters used in the RF telegram.

RF-Channel 433.92MHz

Data rate 8kBit/s

FSK deviation +/-8kHz

Manchester coding

Button 2 menu:

shows parameters used for the virtual COM port. These parameters have to be set in the PC terminal

application to receive the text strings.

COM port settings

baudrate 38.4kBaud

8 data + 1 stop bit

no parity, no handshake

Button 3 menu:

shows parameters used for the virtual COM port. These parameters have to be set in the PC

terminal application. To receive the text strings.

Receiver statistics:

valid# 3062

error# 15

total# 3099

Measurement results:

The measurement display shows the time interval dt between two consecutive RF telegram receptions

together with the RSSI value for the RF signal strength at the base station and at the Remote sensor. The

temperature at the sensor is shown with a resolution of 1°C.

___________________

| dt=2s rssi=221 |

| |

| T=22°C |

| RSSI=128 |

|___________________|

In case of an error the following error messages are displayed:

This message is shown when the received data telegram is corrupted or when the temperature sensor is

broken or not present.

!!!!!!!!!!!!!!!!!!!!!!

Sensor error:

Invalid sensor data!

!!!!!!!!!!!!!!!!!!!!!!

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

15

Page 16

This message is shown when the sensor battery has a voltage below 2.2V and needs to be replaced.

!!!!!!!!!!!!!!!!!!!!!!

Sensor error:

Low battery voltage!

!!!!!!!!!!!!!!!!!!!!!!

This message is shown when a wrong acknowledge telegram was received.

::::::::::::::::::::::

RF telegram error:

Wrong ACK telegram!

::::::::::::::::::::::

This message is shown when no RF acknowledge telegram was received.

::::::::::::::::::::::

RF channel error:

No RF ACK telegram!

::::::::::::::::::::::

This message is shown when the RF acknowledgement from the base station could not be send.

::::::::::::::::::::::

RF channel error:

RF TX telegram err!

::::::::::::::::::::::

This message is shown when the RF receiver is detecting a signal on another RF channel (this must be

enabled in the EEPROM configuration of the receiver).

::::::::::::::::::::::

RF channel error:

Wrong RF telegram!

::::::::::::::::::::::

4.3. Software Development

Atmel® Studio 6 or 7 is required for base station software development and can be downloaded from the

Atmel website [4]. In addition, the tool pack [10] with software and documentation is required. IAR

Embedded Workbench for AVR [5] and the JTAGICE3 AVR® debug tool [4] are required for remote sensor

software development.

4.3.1. Xplained PRO SAMD20 Base Station

For the software development of the base station the project file is located in the extracted folder in the

subdirectory

..\Software\base\SAMD20_XplainedPRO_SW Atmel Studio 6 or 7 project directory

After the installation of Atmel® Studio 6 or 7 the USB driver will be installed automatically when

connecting the Xplained Pro SAMD20 board for the first time. When opening Atmel Studio you will see

the landing page of this kit were you can obtain the documentation and sample projects. The OLED

display will show the welcome screen and wait for a RF telegram from the remote sensor. After attaching

the battery to the remote sensor the RF telegram will be immediately transmitted and is repeated every

2 seconds with an update on the temperature, RF telegram interval and RSSI signal strength parameter

(if the optional real time clock is installed on the sensor otherwise the button S2 on the remote sensor can

be pressed to transmit a RF telegram). You can also view the received information when opening a PC

terminal application and selecting the COM port of the XplainedPRO board with a baudrate of 38.4kBaud,

8 data bit, 1 stop bit no parity and no handshake selected.

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

16

Page 17

To start evaluating the software, you can select the main.c file from the solution window inside Atmel

Studio 6 or 7 (see Figure 4-3):

The implementation can be analyzed and debugged together with the program flow shown in Figure 4-2.

Additional documentation regarding the other ASF functions can be obtained within Atmel Studio 6 or 7

Help.

Figure 4-3. Base Software

The debugging of the application is performed within Atmel Studio 6 or 7 together with the Xplained PRO

SAMD20 board. This board includes an embedded debugger which is controlled by Atmel Studio.

4.3.2. Remote Sensor

IAR Embedded Workbench for AVR® is required for remote sensor software development [5]. The project

file is located in the extracted subfolder:

..\Software\sensor\ATA5831_FLASH_IAR_2.32.0 IAR Embedded Workbench project directory

After opening the IAR project Remote_sensor.eww file, the following workspace window is available (see

Figure 4-4).

Figure 4-4. Remote Sensor Software

Select the following files from the workspace window to start evaluating the software:

FlashRomAppl.c Main() program start with initialization and activation of the application loop

KeyFobSensor_flash_temp.c Application functions called within the main() function

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

17

Page 18

The implementation can be analyzed, compiled, and linked together with the program flow shown in

Figure 4-1.

Debugging of the application is currently not supported within IAR Embedded Workbench using the AVR

debug tool JTAGICE3. Atmel Studio 6 or 7 has to be used instead. Once the program is compiled and

linked within IAR Workbench, the file fwFLASH.d90 has to be opened within Atmel Studio 6 or 7 as

shown in Figure 4-5. To select the right directory paths use the <...> buttons to locate the *.d90 file and for

the ‘Location’.

Figure 4-5. Debugging the Remote Sensor Software

After selecting Next>, the device has to be selected. The Atmel ATA8510 device is not currently listed and

the ATA5831 device (the similar automotive device) has to be selected instead as shown in Figure 4-6.

Selecting “Finish” shows the project window and after selecting the debug tool, the debugging can be

performed much the way you would when using the base software.

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

18

Page 19

Figure 4-6. Device Selection for Debugging

The Atmel ATA8510 device uses the debugWire interface for the debug connection (described in the user

manual [9]). This connection uses the reset line on pin PC0 of the device and must be enabled within ISP

programming mode. If debugWire mode is enabled, the ISP mode is not available and vice versa. Select

“Disable debugWire connection” within the “Debug” menu to return to ISP mode. The 6-pin ISP connector

is used as a connection to the debugger and it is recommended to connect only the VCC, GND and reset

signal when debugging, leaving the SPI signals open for the application. This is important because the

TWI driver software uses the PB1 pin as an SCL line shared with the ISP and SPI peripheral. Additional

information on how to perform development and debugging with the Atmel ATA8510 device is provided in

[6] and [8]. This application note describes development for the Atmel ATA5831 device which, in terms of

Flash development, is similar to the Atmel ATA8510 device.

4.3.3. Re-programming of the Devices

The tool pack [10] includes the original programming files to re-program all devices in the kit.

1. For re-programming of the SAMD20 device select the device ATSAMD20J18 in the device

programming tool of Atmel® Studio 6 and the file SAMD20_Flash.hex for the flash memory.

2. For re-programming of the Atmel ATA8515 device on the XplainedPRO ATA8510/15 extension

board disconnect the board and apply an external 3V power supply to the connector X7. Connect

pin 5 of connector X3 to GND (to prevent the device from entering the OFF mode) and select the

device ATA5833 in the device programming tool and ensure that the ISP clock is set < 64kHz.

Select the file Base_Station_EEPROM.hex for the EEPROM memory. For the fuse settings the

fuses SPIEN and EESAVE should be set.

3. For re-programming of the Atmel ATA8510 device of the remote sensor attach the mini-ISP

connector to the connector ISP and the debug tool and insert the CR2032 battery or apply an

external 3V power supply to the mini ISP connector. Remove the CMM1923 rtc module and

connect pin VCC to PB4 on connector X1 (to prevent the device from entering the OFF mode).

Select the device ATA5831 in the device programming tool and ensure that the ISP clock is set <

64kHz. Select the file Remote_Sensor_Flash.hex for the flash memory and the file

Remote_Sensor_EEPROM.hex for the EEPROM memory. For the fuse settings the fuses SPIEN

and EESAVE should be set.

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

19

Atmel-9343D-ATAN0046_Application Note-09/2016

Page 20

4.4. EEPROM Data Settings

The EEPROM of the Atmel® ATA8510 and ATA8515 device includes the configuration of the device and

the settings for the RF protocol. This EEPROM must be programmed before running application software

either as an embedded Flash application or as a host application using the SPI communication link. The

Atmel ATA5831 device has to be selected instead of the Atmel ATA8510 or ATA8515 within the

programming dialog of Atmel Studio 6. Make sure that the ISP signals are available for the programmer

only and that the device is not in OFF mode by pulling an NPWRONx pin to GND level, i.e., connect the

PC1 pin to GND.

A Java GUI tool is used for generating the EEPROM programming file in HEX format (see [7] for the tool

software and user guide, which is not included in the tool pack [10]). This tool can save all settings in an

xml file and handling is described in the user guide [7] and the settings in the user manual [9].

The tool pack includes two subdirectories which contains the xml and HEX files for the base and the

remote sensor:

..\Software\base\EEPROM Configuration file for the Atmel ATA8515 base station device

..\Software\sensor\EEPROM Configuration file for the Atmel ATA8510 remote sensor device

Only service 0 with channel 0 is used for the RF telegram. All other service settings can be ignored. For

the base station the polling is defined in the polling tab of the GUI.

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

20

Page 21

5. Revision History

Please note that the following page numbers referred to in this section refer to the specific revision

mentioned, not to this document.

Revision No. History

• Features: new bullet point added

• Reference no. [10] on page 2 changed

• Chapter 1: "Getting Started" changed and new heading "Kit Setup" added

after figure 1-1 and the following text

• in new Chapter 1.1 "Kit Setup" text changed

• new Chapter 1.2: "Upgrade Kit V1.x to V2.0" added

• Chapter 2.3: text in point 2 changed and figure 2-1 changed

9343D-09/16

• Chapter 3: "Hardware Description" text changed

• Chapter 3.1: new text and tables added after figure 3-1

• Chapter 4: text changed

• Chapter 4.2: completely changed

• Chapter 4.3: text changed

• Chapter 4.3.1: completely changed

• Chapter 4.3.2: text changed

• Chapter 4.3.3: text changed

Atmel User Guide for the Evaluation Kit ATA8510-EK1 [APPLICATION NOTE]

Atmel-9343D-ATAN0046_Application Note-09/2016

21

Page 22

Atmel Corporation 1600 Technology Drive, San Jose, CA 95110 USA T: (+1)(408) 441.0311 F: (+1)(408) 436.4200 | www.atmel.com

©

2016 Atmel Corporation. / Rev.: Atmel-9343D-ATAN0046_Application Note-09/2016

Atmel®, Atmel logo and combinations thereof, Enabling Unlimited Possibilities®, and others are registered trademarks or trademarks of Atmel Corporation in U.S. and

other countries. Other terms and product names may be trademarks of others.

DISCLAIMER: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN THE ATMEL TERMS AND

CONDITIONS OF SALES LOCATED ON THE ATMEL WEBSITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED

OR STATUTORY WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT,

CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS AND PROFITS, BUSINESS

INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no representations or warranties with respect to the accuracy or completeness of the contents of this

document and reserves the right to make changes to specifications and products descriptions at any time without notice. Atmel does not make any commitment to

update the information contained herein. Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive

applications. Atmel products are not intended, authorized, or warranted for use as components in applications intended to support or sustain life.

SAFETY-CRITICAL, MILITARY, AND AUTOMOTIVE APPLICATIONS DISCLAIMER: Atmel products are not designed for and will not be used in connection with any

applications where the failure of such products would reasonably be expected to result in significant personal injury or death (“Safety-Critical Applications”) without

an Atmel officer's specific written consent. Safety-Critical Applications include, without limitation, life support devices and systems, equipment or systems for the

operation of nuclear facilities and weapons systems. Atmel products are not designed nor intended for use in military or aerospace applications or environments

unless specifically designated by Atmel as military-grade. Atmel products are not designed nor intended for use in automotive applications unless specifically

designated by Atmel as automotive-grade.

Loading...

Loading...