Page 1

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

8905

Data Sheet

26301.3

3-PHASE BRUSHLESS DC MOTOR

CONTROLLER/DRIVER WITH BACK-EMF SENSING

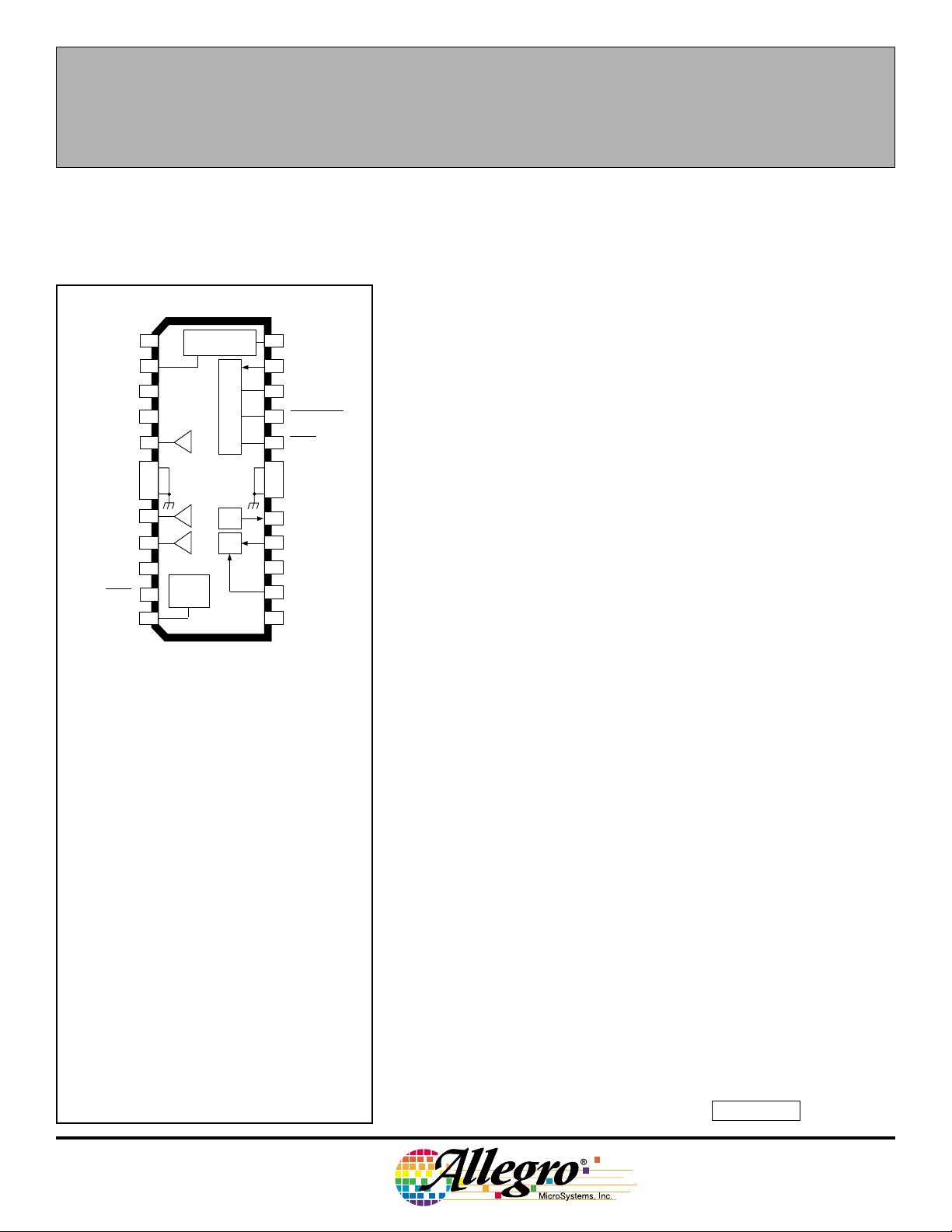

The A8905CLB isw a three-phase brushless dc motor controller/

driver for use with CD-ROM or DVD drives. The three half-bridge

LOAD

SUPPLY

C

D2

C

WD

C

ST

OUT

GROUND

GROUND

OUT

OUT

CENTERTAP

BRAKE

C

RES

A

B

C

1

2

3

4

5

6

7

8

9

9

10

11

V

BB

BOOST

CHARGE

PUMP

COMMUTATION

DELAY

SERIAL PORT

MUX

FLL

C

24

D1

23

DATA IN

22

CLOCK

21

CHIP SELECT

20

RESET

19

GROUND

18

GROUND

DATA OUT

17

OSCILLATOR

16

LOGIC

V

15

DD

SUPPLY

INDEX

14

1312

FILTER

Dwg. PP-040-1

ABSOLUTE MAXIMUM RATINGS

at T

= +25°C

A

Load Supply Voltage, VBB. . . . . . 14 V

Output Current, I

Logic Supply Voltage, V

. . . . . . . . ±1.25 A

OUT

. . . . 6.0 V

DD

Logic Input Voltage Range,

. . . . . . . -0.3 V to VDD + 0.3 V

V

IN

Package Power Dissipation,

. . . . . . . . . . . . . . . . See Graph

P

D

Operating Temperature Range,

. . . . . . . . . . . . . . 0°C to +70°C

T

A

Junction Temperature, T

. . . +150°C†

J

Storage Temperature Range,

. . . . . . . . . . . . -55°C to +150°C

T

S

† Fault conditions that produce excessive

junction temperature will activate device thermal

shutdown circuitry. These conditions can be

tolerated, but should be avoided.

DISCONTINUED PRODUCT

Output current rating may be restricted to a value

determined by system concerns and factors.

These include: system duty cycle and timing,

ambient temperature, and use of any heatsinking

and/or forced cooling. For reliable operation, the

specified maximum junction temperature should

not be exceeded.

— FOR REFERENCE ONLY

outputs are low on-resistance n-channel DMOS devices capable of

driving up to 1.25 A. The A8905CLB provides complete, reliable,

self-contained back-EMF sensing motor startup and running algorithms.

A programmable digital frequency-locked loop speed control circuit

together with the linear current control circuitry provides precise motor

speed regulation.

A serial port allows the user to program various features and modes

of operation, such as the speed control parameters, startup current limit,

sleep mode, diagnostic modes, and others.

APPLICATIONS

■ CD-ROMs

■ DVDs

FEATURES

■ DMOS Outputs

■ Low r

■ Startup Commutation Circuitry

■ Back-EMF Commutation Circuitry

■ Serial Port Interface

■ Frequency-Locked Loop Speed Control

■ Tachometer Signal Input

■ Programmable Start-Up Current

■ Diagnostics Mode

■ Sleep Mode

■ Linear Current Control

■ Internal Current Sensing

■ Dynamic Braking Through Serial Port

■ Power-Down Dynamic Braking

■ System Diagnostics Data Out

■ Data Out Ported in Real Time

■ Internal Thermal Shutdown Circuitry

Always order by complete part number, e.g., A8905CLB .

DS(on)

Page 2

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

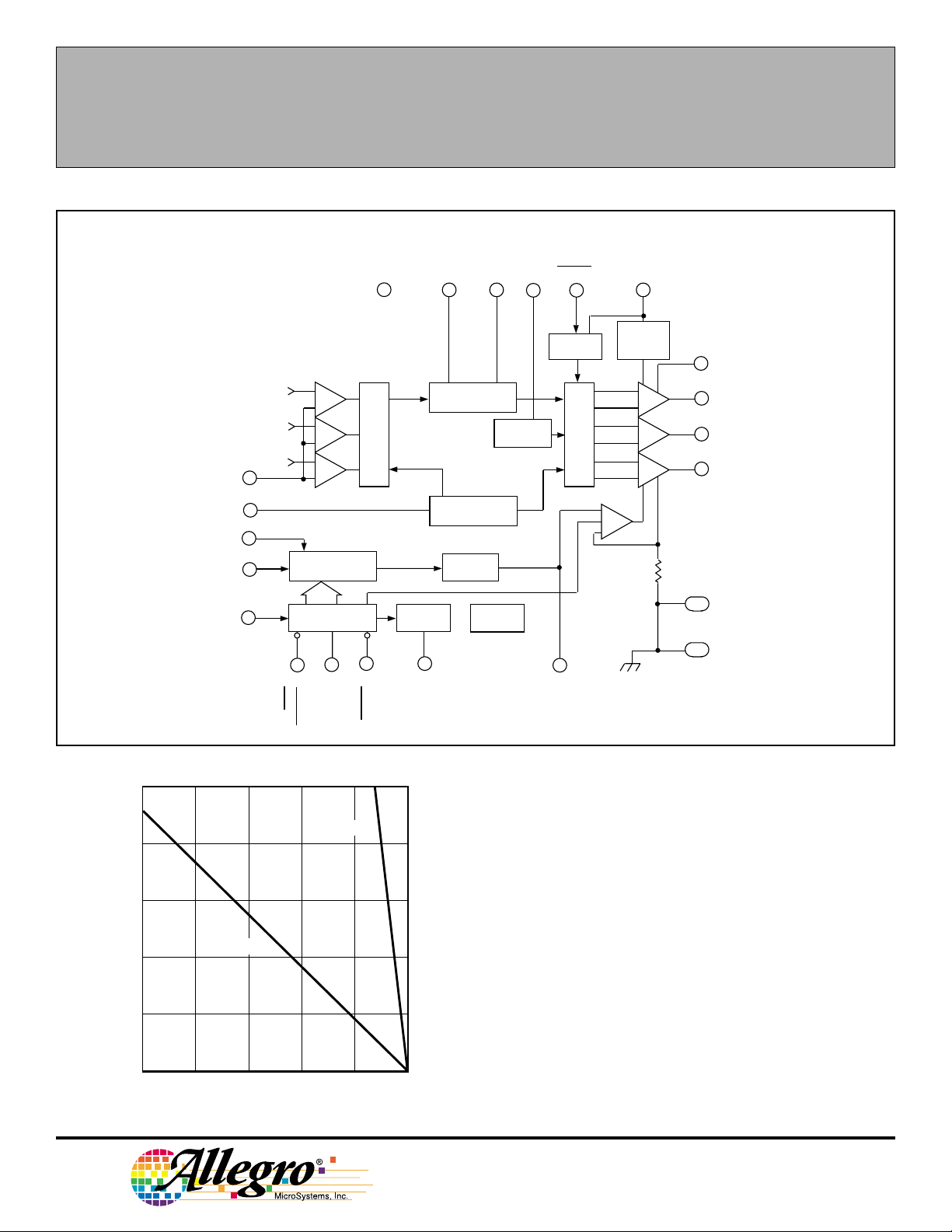

FUNCTIONAL BLOCK DIAGRAM

CENTERTAP

C

WD

INDEX

OSC

DATA IN

14

23

10

16

OUT

OUT

OUT

3

LOGIC

SUPPLY

A

B

C

FREQUENCY-

LOCKED LOOP

SERIAL PORT MUX

CHIP

SELECT

2221

CLOCK

COMMUTATION

RESET

15

V

DD

LOGIC

FCOM

BLANK

1720

C

D1

24 2

COMMUTATION

DELAY

WATCHDOG

TIMER

CHARGE

PUMP

OUT

DATA

C

D2

START-UP

OSC.

TSD

C

ST

4

BRAKE

BRAKE

13

FILTER

11

LOGIC

SEQUENCE

CURRENT

CONTROL

C

RES

12

BOOST

CHARGE

PUMP

V

BB

R

LOAD

1

SUPPLY

5

OUT

A

8

OUT

B

9

OUT

C

S

6-7

GROUND

18-19

GROUND

Dwg. FP-034-1

2.5

R = 6°C/W

θJT

2.0

1.5

R = 55°C/W

1.0

θJA

0.5

0

25

ALLOWABLE PACKAGE POWER DISSIPATION in WATTS

50 75 100 125 150

TEMPERATURE in °C

Dwg. GP-019B

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1998 Allegro MicroSystems, Inc.

Page 3

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

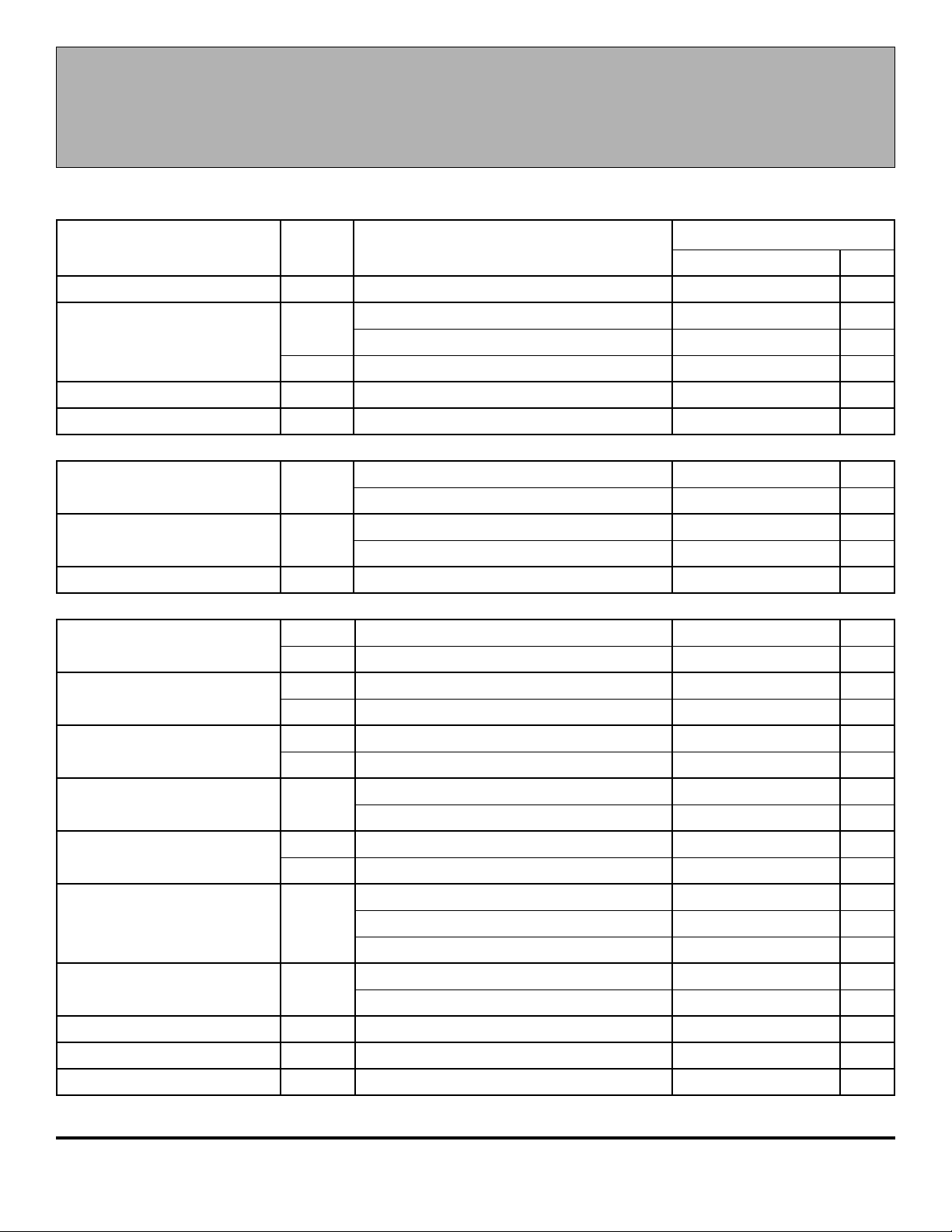

ELECTRICAL CHARACTERISTICS at T

= +25°C, V

A

= 5.0 V

DD

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Logic Supply Voltage V

Logic Supply Current I

DD

DD

Operating 4.5 5.0 5.5 V

Operating — 7.5 10 mA

Sleep Mode — — 1.5 mA

Load Supply Voltage V

Thermal Shutdown T

Thermal Shutdown Hys. ∆T

BB

J

J

Operating 4.5 — 14 V

— 165 — °C

—20—°C

Output Drivers

Output Leakage Current I

Total Output ON Resistance r

Output Sustaining Voltage V

DS(on)

DS(sus)

Clamp Diode Forward Voltage V

DSX

F

VBB = 14 V, V

VBB = 14 V, V

I

= 600 MA — 1.1 1.4 Ω

OUT

V

= 14 V, I

BB

= 14 V — 1.0 300 µA

OUT

= 0 V — -1.0 -300 µA

OUT

= I

OUT

(MAX), L = 3 mH 14 — — V

OUT

IF = 1.0 A — 1.25 1.5 V

Control Logic

Logic Input Voltage V

Logic Input Current I

DATA Output Voltage V

V

CST Current I

IN(0)

V

IN(1)

IN(0)

I

IN(1)

OUT(0)

OUT(1)

CST

INDEX, RESET, CLK, -0.3 — 1.5 V

CHIP SELECT, OSC, BRAKE 3.5 — 5.3 V

V

= 0 V — — -0.5 µA

IN

V

= 5.0 V — — 1.0 µA

IN

I

= 500 µA — — 1.5 V

OUT

I

= -500 µA 3.5 — — V

OUT

Charging 14 20 28 µA

Discharging -14 -20 -28 µA

CST Threshold V

Filter Current I

CSTH

V

CSTL

FILTER

Charging 7.0 10 15 µA

2.1 2.5 2.9 V

— 500 — mV

Discharging -7.0 -10 -15 µA

CD Current I

CD

Leakage, V

Charging 14 22 28 µA

= 2.5 V — 5.0 — nA

FILTER

Discharging -26 -35 -66 µA

CD Current Matching — I

CD Threshold V

CWD Current I

CD

CWD

CD(DISCHRG)/ICD(CHRG)

Charging 14 22 28 µA

1.7 2.2 2.3 —

— 2.5 — V

Continued next page …

Page 4

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

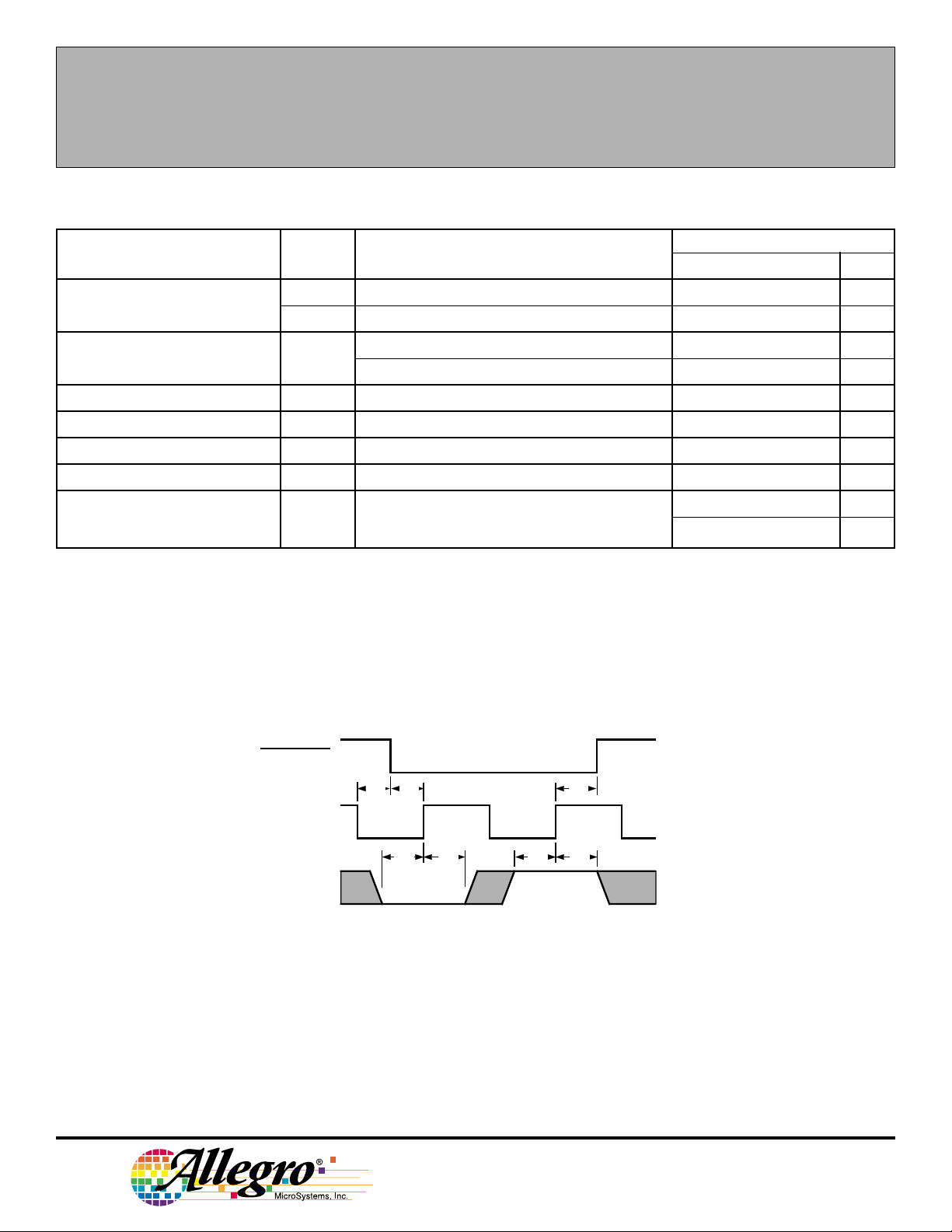

ELECTRICAL CHARACTERISTICS continued

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

CWD Threshold Voltage V

Max. FLL Oscillator Frequency f

I

(MAX) Accuracy — I

OUT

BRAKE Threshold V

Transconductance Gain g

Centertap Resistors R

V

OSC

TL

TH

BRK

m

CT

Back-EMF Hysteresis — V

VDD = 5.1 V, T

VDD = 4.5 V, T

= 1 A — ±20 — %

OUT

- V

BEMF

= 25°C20——MHz

A

= 70°C—10—MHz

A

at 152540mV

CTAP

FCOM Transition -15 -25 -40 mV

0.80 0.85 0.95 V

2.4 2.75 3.0 V

1.4 1.7 2.0 V

0.26 0.35 0.50 A/V

5.0 10 13 kΩ

SERIAL PORT TIMING CONDITIONS

CHIP SELECT

A

E

CLOCK

C

D C D

DATA

A. Minimum CHIP SELECT setup time before CLOCK rising edge ...... 100 ns

B. Minimum CHIP SELECT hold time after CLOCK rising edge ........... 150 ns

C. Minimum DATA setup time before CLOCK rising edge .................... 150 ns

D. Minimum DATA hold time after CLOCK rising edge ........................ 150 ns

E. Minimum CLOCK low time before CHIP SELECT .............................. 50 ns

F. Maximum CLOCK frequency........................................................... 3.3 MHz

B

Dwg. WP-019

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

TERMINAL FUNCTIONS

Term. Terminal Name Function

1 LOAD SUPPLY VBB; the 5 V or 12 V motor supply.

2C

3C

4CSTStartup oscillator timing capacitor.

5 OUT

6-7 GROUND Power and logic ground and thermal heat sink.

8 OUT

9 OUT

10 CENTERTAP Motor centertap connection for back-EMF detection circuitry.

11 BRAKE Active low turns ON all three sink drivers shorting the motor windings to ground. External

12 C

13 FILTER Analog voltage input to control motor current. Also, compensation node for internal speed

14 INDEX External tachometer input.

15 LOGIC SUPPLY VDD; the 5 V logic supply.

16 OSCILLATOR Clock input for the speed reference counter. Typical max. frequency is 10 MHz.

17 DATA OUT Thermal shutdown indicator, FCOM, TACH, or SYNC signals available in real time,

18-19 GROUND Power and logic ground and thermal heat sink.

20 RESET When pulled low forces the chip into sleep mode; clears all serial port bits.

21 CHIP SELECT Strobe input (active low) for data word.

22 CLOCK Clock input for serial port.

23 DATA IN Sequential data input for the serial port.

24 C

D2

WD

A

B

C

RES

D1

One of two capacitors used to generate the ideal commutation points from the back-EMF

zero-crossing points.

Timing capacitor used by the watchdog circuit to disable the back-EMF comparators

during commutation transients, and to detect incorrect motor position.

Power amplifier output A to motor.

Power amplifier output B to motor.

Power amplifier output C to motor.

capacitor and resistor at BRAKE provide brake delay. The brake function can also be

controlled via the serial port.

External reservoir capacitor used to hold charge to drive the source drivers’ gates. Also

provides power for brake circuit.

control loop.

controlled by 2-bit multiplexer in serial port.

One of two capacitors used to generate the ideal commutation points from the back-EMF

zero-crossing points.

Page 6

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

FUNCTIONAL DESCRIPTION

Power Outputs. The power outputs of the

A8905CLB are n-channel DMOS transistors with

a total source plus sink r

of typically 1.1 Ω.

DS(on)

Internal charge pump boost circuitry provides

voltage above supply for driving the high-side

DMOS gates. Intrinsic ground clamp and flyback

diodes provide protection when switching inductive loads and may be used to rectify motor backEMF in power-down conditions. An external

Schottky power diode or pass FET is required in

series with the load supply to allow motor backEMF rectification in power-down conditions.

Back-EMF Sensing Motor Startup and

Running Algorithm. The A8905CLB provides a

complete self-contained back-EMF sensing startup

and running commutation scheme. The three halfbridge outputs are controlled by a state machine.

There are six possible combinations. In each state,

one output is high (sourcing current), one low

(sinking current), and one is OFF (high impedance

or ‘Z’). Motor back EMF is sensed at the OFF

output. The truth table for the output drivers

sequencing is:

Sequencer

State OUT

A

OUT

B

OUT

C

1 High Low Z

2 Z Low High

3 Low Z High

4 Low High Z

5 Z High Low

6 High Z Low

At startup, the outputs are enabled in one of

the sequencer states shown. The back EMF is

examined at the OFF output by comparing the

output voltage to the motor centertap voltage at

CENTERTAP. The motor will then either step

forward, step backward, or remain stationary (if in

a null-torque position). If the motor moves, the

back-EMF detection circuit waits for the correct

polarity back-EMF zero crossing (output crossing

through centertap). True back-EMF zero crossings are used by the adaptive commutation delay

circuit to advance the state sequencer (commutate)

at the proper time to synchronously run the motor.

Back-EMF zero crossings are indicated by FCOM, an internal signal that

toggles at every zero crossing. FCOM is available at the DATA OUT terminal

via the programmable data out multiplexer.

V

OUTA

V

OUTB

V

OUTC

FCOM

V

SOURCE ON

CTAP

BACK-EMF VOLTAGE

SINK ON

FCOM TOGGLES AT

BACK-EMF ZERO CROSSING

Dwg. WP-016-1

Startup Oscillator. If the motor does not move at the initial startup state,

then it is in a null-torque position. In this case, the outputs are commutated

automatically by the startup oscillator after a period set by the external

capacitor at CST.

V

CSTH

V

CST

V

CSTL

t

CST

V

CWD

Dwg. WP-020

where t

CST

=

4(V

I

ST(charge)

CSTH

- V

+ I

CSTL

) x C

ST(discharge)

ST

In the next state, the motor will move, back EMF will be detected, and the

motor will accelerate synchronously. Once normal synchronous back-EMF

commutation occurs, the startup oscillator is defeated by pulses of pulldown

current at CST at each commutation, which prevents CST from reaching its

upper threshold and thus completing a cycle and commutating.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 7

8905

Dwg. WP-022

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

Adaptive Commutation Delay. The

adaptive commutation delay circuit uses the

back-EMF zero-crossing indicator signal

(FCOM) to determine an optimal commutation

time for efficient synchronous operation. This

circuit commutates the outputs, delayed from the

last zero crossing, using two external timing

capacitors, CD1 and CD2, to measure the time

between crossings.

t

FCOM

FCOM

V

CWD

t

CD1

V

CD1

t

CD2

V

CD2

capacitors, the voltage excursion should be 1.5 V to 2.5 V at rated speed.

Solving for C in the equation I = Cdv/dt, where dv = 2.5 V, I = 22 µA, and

dt = t

FCOM

20/RPM

=

#motor poles

Use of a capacitor slightly greater than this value will ensure that the commutation delay capacitors never charge to the high rail.

Blanking and Watchdog Timing Functions. The blanking and watchdog

timing functions are derived from one timing capacitor, CWD.

where t

BLANK

and tWD =

=

VTL x C

VTH x C

I

CWD

I

WD

WD

CWD

The CWD capacitor begins charging at each commutation, initiating the

BLANK signal. BLANK is an internal signal that inhibits the back-EMF

comparators during the commutation transients, preventing errors due to

inductive recovery and voltage settling transients.

V

TL

V

CWD

t

BLANK

BLANK

Dwg. WP-016-2

I

where tCD = t

FCOM

x

CD(charge),

[I

CD(discharge)

]

CD1 charges up with a fixed current from its

2.5 V reference while FCOM is high. When

FCOM goes low at the next zero crossing, CD1 is

discharged at approximately twice the charging

current. When CD1 reaches the CD threshold, a

commutation occurs. CD2 operates similarly

except on the opposite phase of FCOM . Thus

the commutations occur approximately halfway

between zero crossings. The actual delay is

slightly less than halfway to compensate for

electrical delays in the motor, which improves

efficiency.

Because the commutation-delay capacitors

are adaptive in nature, the absolute value and

tolerance is not critical. In choosing these

V

CWD

BLANK

NORMAL COMMUTATION

V

V

TL

t

BLANK

t

WD

Dwg. WP-021

WATCHDOG-TRIGGERED COMMUTATION

TH

Page 8

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

The watchdog timing function allows time to detect correct motor position

by checking the back-EMF polarity after each commutation. If the correct

polarity is not observed between t

and tWD, then the watchdog timer

BLANK

commutates the outputs to the next state to synchronize the motor. This

function is useful in preventing excessive reverse rotation, and helps in

resynchronizing (or starting) with a moving spindle.

Current Control. The A8905CLB provides linear current control via the

FILTER terminal, an analog voltage input. Maximum current limit is also

provided, and is controlled in four steps via the serial port. Output current is

sensed via an internal sense resistor (RS). The voltage across the sense resistor

is compared to one-tenth the voltage at the FILTER terminal less two diode

drops, or to the maximum current limit reference, whichever is lower. This

transconductance function is I

OUT

= (V

-2VD) / 10RS, where RS is

FILTER

nominally 0.3 Ω and VD is approximately 0.7 V.

YANK

S Q

R

SPEED-CONTROL

INITIALIZATION

+

x1

–

1.85 V

ERROR FAST

SEQUENTIAL

LOGIC

V

C

RES

BOOST

CHARGE

V

DD

MUX

–

+

I

V max

FROM

SERIAL PORT

REGISTER

D3 AND D4

PUMP

÷10

LINEAR

CURRENT CONTROL

+

–

BB

OUT

R

S

Dwg. EP-046

ERROR SLOW

FROM FLL

C

F1

R

F1

POWER UP

ERROR FAST

FROM FLL

FILTER

C

F2

CHARGE

V

DD

I

c

I

d

Speed Control. The A8905CLB includes a frequency-locked loop speed

control system. This system monitors motor speed via internal or external

digital tachometer signals, generates a precision speed reference, determines

the digital speed error, and corrects the motor current via an internal charge

pump and external filtering components on the FILTER terminal.

A once-per-revolution TACH signal can be

generated by counting cycles of FCOM (the

number of motor poles must be selected via the

serial port). TACH is then a jitter-free signal that

toggles once per motor revolution. The rising

edge of TACH triggers REF, a precision speed

reference derived by a programmable counter.

The duration of REF is set by programming the

counter to count the desired number of OSC

cycles

desired

total count

=

desired motor speed (rpm)

60 x f

OSC

where the total count (number of oscillator cycles)

is equal to the sum of the selected (programmed

low) count numbers corresponding to bits D5

through D18.

The speed error is detected as the difference

in falling edges of TACH and REF. The speed

error signals control the error-correcting charge

pump on the FILTER terminal, which drive the

external loop compensation components to correct

the motor current.

Index. An external tachometer signal may be

used to create the TACH signal, rather than the

internally derived once around. To use this mode,

the signal is input to the INDEX terminal, and the

index mode must be enabled via the serial port.

When Switching from the once-around mode to

index mode, it is important to monitor the SYNC

signal on DATA OUT, and switch modes only

when SYNC is low. This ensures making the

transition without disturbing the speed control

loop. The speed reference counter should be

reprogrammed at the same time.

FCOM

OSC

SECTOR

COUNT

(3 x MOTOR POLES)

D20 &

D21

4-BIT

FIXED

COUNTER

ONCE-AROUND

PULSE

SERIAL PORT

REGISTER

D5–D18

14-BIT

PROGRAMMABLE

COUNTER

D19

MUX

REF

Speed Loop Initialization (YANK). To

improve the acquire time of the speed control

÷2

TACH

loop, there is an automatic feature controlled by an

internal YANK signal. The motor is started at the

maximized programmed current by bypassing the

REF

TACH

ERROR

SLOW

REF

TACH

ERROR

FAST

Dwg. EP-045

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

FILTER terminal. The FILTER terminal is

clamped to two diodes above ground, initializing it

near the closed loop operating point. YANK is

enabled at startup and stays high until the desired

speed is reached. Once the first error-fast occurs,

indicating the motor crossed through the desired

speed, YANK goes low. This releases the clamp

on the FILTER terminal and current control is

returned to FILTER. This feature optimizes speed

Page 9

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

acquire and minimizes settling. The Current Control Block Diagram illustrates

the YANK signal and its effects.

Braking. A dynamic braking feature of the A8905CLB shorts the three

motor windings to ground. This is accomplished by turning the three source

drivers OFF and the three sink drivers ON. Activation of the brake can be

implemented through the BRAKE input or through the D2 bit in the serial port.

The supply voltage for the brake circuitry is the C

voltage, allowing the brake

RES

function to remain active after power failure. Power-down braking with delay can

be implemented by using an external RC and other components to control the

brake terminal, as shown. Brake delay can be set using the equation below to

ensure that voice-coil head retract occurs before the spindle motor brake is

activated. Once the brake is activated, due to the inherent capacitive input, the

three sink drivers will remain active until the device is reset.

V

BRK

V

FAULT - VD

FAULT D

24

23

22

21

SERIAL PORT

20

19

BRAKE

ACTIVATED

t

BRK

DATA IN

CLOCK

CHIP SELECT

RESET

V

Dwg. OP-004

C

D1

BRK

TYPICAL

FAULT

V

RET

BYPASS

t

= RBCB 1 – l

BRK

C

B

R

B

V

BB

1

V

2

C

D2

3

C

WD

4

C

ST

5

6

BRAKE

COMMUTATION

BB

n

V – V

DELAY

APPLICATION

18

BYPASS

17

16

V

15

DD

14

1312

INDEX

+5 V

DATA OUT

OSC (REF)

R

F1

C

F2

Dwg. EP-036-1

C

F1

FAULT

7

8

9

9

10

BOOST

CHARGE

B

C

RES

0.22 µF

11

PUMP

C

R

B

MUX

FLL

Centertap. The A8905CLB internally

simulates the centertap voltage of the motor.

To obtain reliable start-up performance from

motor to motor, the motor centertap should be

connected to this terminal.

Serial Port. The serial port functions to

write various operational and diagnostic modes

to the A8905CLB. The serial port DATA IN is

enabled/disabled by the CHIP SELECT

terminal. When CHIP SELECT is high the

serial port is disabled and the chip is not

affected by changes in data at the DATA IN or

CLOCK terminals.

To write data to the serial port, the

CLOCK terminal should be low prior to the

CHIP SELECT terminal going low. Once

CHIP SELECT goes low, information on the

DATA IN terminal is read into the shift register

on the positive-going transition of the CLOCK.

There are 24 bits in the serial input port.

Data written into the serial port is latched

and becomes active upon the low-to-high

transition of the CHIP SELECT terminal at the

end of the write cycle. D0 will be the last bit

written to the serial port.

Reset. The RESET terminal (when pulled

low) clears all serial port bits, including the D0

latch, which puts the A8905CLB in the sleep

mode.

Page 10

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

SERIAL PORT BIT DEFINITIONS

D0- Sleep/Run Mode; LOW = Sleep, HIGH = Run

This bit allows the device to be powered down when not in

use.

D1- Step Mode; LOW = Normal Operation, HIGH = Step Only

When in the step-only mode the back-EMF commutation

circuitry is disabled and the power outputs are commutated

by the start-up oscillator. This mode is intended for device

and system testing.

D2- Brake; LOW = Run, HIGH = Brake.

D3 and D4-These two bits set the output current limit:

D3 D4 Current Limit

0 0 Saturated

01 1 A

1 0 800 mA

1 1 600 mA

D5 thru D18-This 14-bit word (active low) programs the REF time

to set desired motor speed.

Bit Number Count Number

D19-Speed-control mode switch;

LOW = internal once-around speed signal,

HIGH = external index data.

D20 and D21-These bits program the number of motor poles

for the once-around FCOM counter:

D20 D21 Motor Poles

00 8

01 –

10 16

11 12

D22 and D23-Control the multiplexer for DATA OUT:

D22 D23 Data Out

0 0 TACH (once around or index)

0 1 Thermal Shutdown

1 0 SYNC

1 1 FCOM

D5 16

D6 32

D7 64

D8 128

D9 256

D10 512

D11 1 024

D12 2 048

D13 4 096

D14 8 192

D15 16 384

D16 32 768

D17 65 536

D18 131 072

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 11

8905

°

°

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

Dimensions in Inches

(for reference only)

0.2992

0.2914

0.020

0.013

0.0926

0.1043

24 13

1 2

3

0.6141

0.050

0.5985

0.0040 MIN.

Dimensions in Millimeters

(controlling dimensions)

24 13

BSC

NOTE 1

NOTE 3

0.0125

0.0091

0.491

0.394

0.050

0.016

0° TO 8

Dwg. MA-008-25 in

0.32

0.23

7.60

7.40

1 2

0.51

0.33

3

15.60

15.20

2.65

2.35

0.10

MIN

.

NOTES: 1. Webbed lead frame. Leads 6, 7, 18, and 19 are internally one piece.

2. Lead spacing tolerance is non-cumulative.

3. Exact body and lead configuration at vendor’s option within limits shown.

1.27

BSC

NOTE 1

NOTE 3

10.65

10.00

1.27

0.40

0° TO 8

Dwg. MA-008-25A mm

Page 12

8905

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

Allegro MicroSystems, Inc. reserves the right to make, from time

to time, such departures from the detail specifications as may be

required to permit improvements in the design of its products.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no

responsibility for its use; nor for any infringements of patents or

other rights of third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...