Datasheet AD637SQ-883B, AD637SD-883B, AD637SD, AD637SCHIPS, AD637KR Datasheet (Analog Devices)

...Page 1

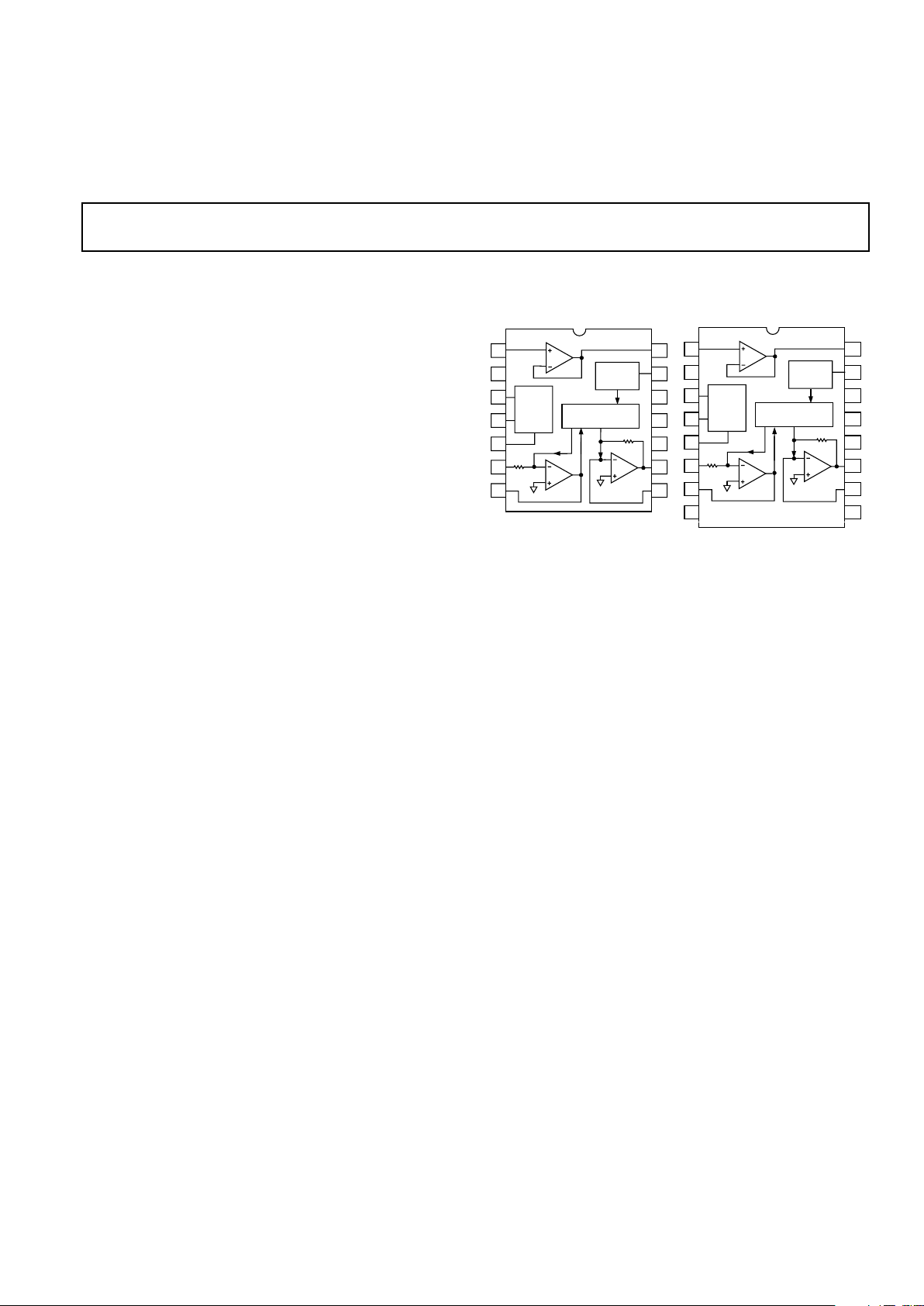

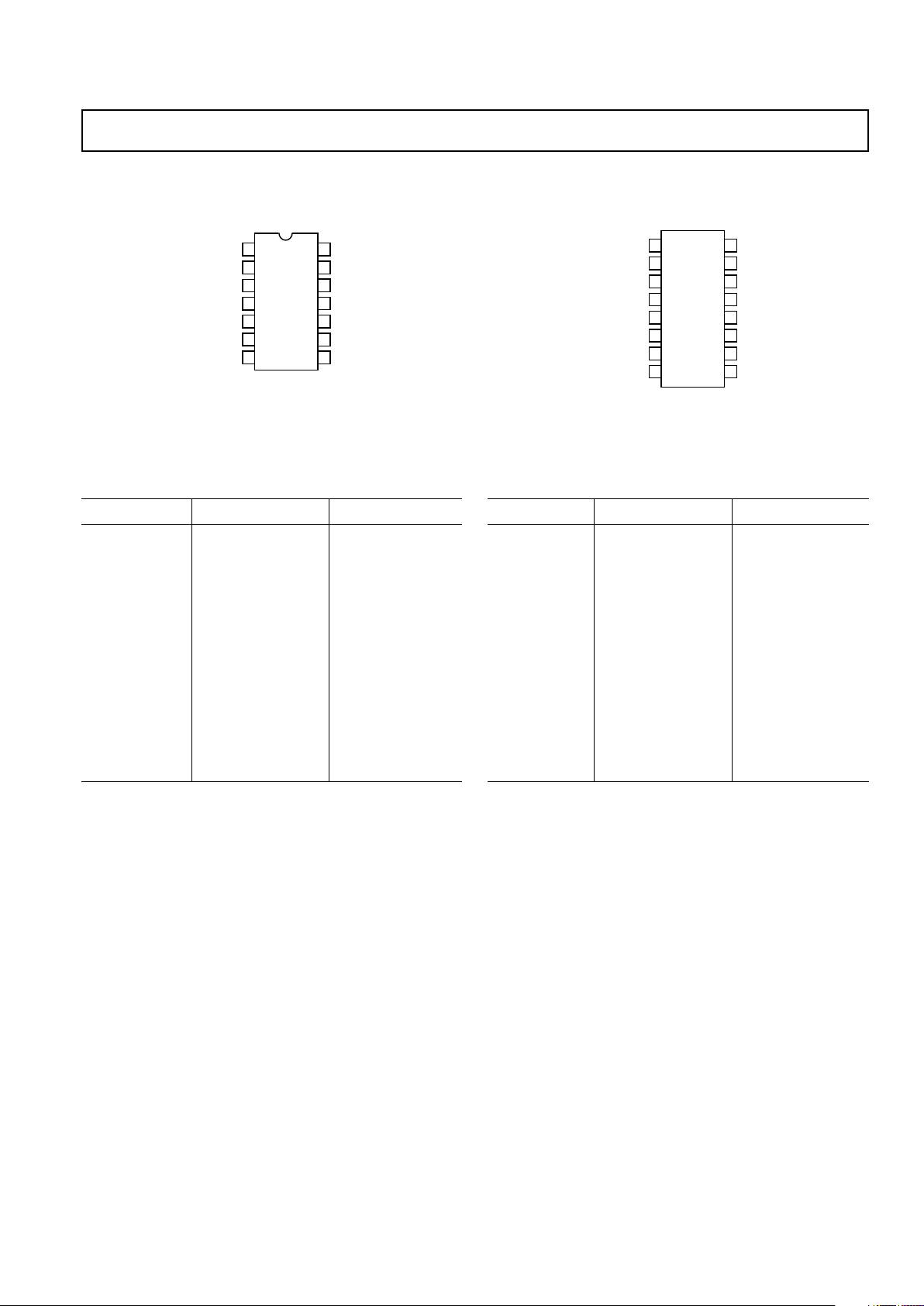

FUNCTIONAL BLOCK DIAGRAMS

REV. F

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

a

High Precision, Wideband

RMS-to-DC Converter

AD637

The AD637 is available in two accuracy grades (J and K) for

commercial (0°C to 70°C) temperature range applications;

two accuracy grades (A and B) for industrial (–40°C to +85°C)

applications; and one (S) rated over the –55°C to +125°C temperature range. All versions are available in hermetically sealed,

14-lead side brazed ceramic DIPs as well as low cost cerdip

packages. A 16-lead SOIC package is also available.

PRODUCT HIGHLIGHTS

1. The AD637 computes the true root-mean-square, meansquare, or absolute value of any complex ac (or ac plus dc)

input waveform and gives an equivalent dc output voltage.

The true rms value of a waveform is more useful than an

average rectified signal since it relates directly to the power of

the signal. The rms value of a statistical signal is also related

to the standard deviation of the signal.

2. The AD637 is laser wafer trimmed to achieve rated

performance without external trimming. The only external

component required is a capacitor that sets the averaging

time period. The value of this capacitor also determines

low-frequency accuracy, ripple level, and settling time.

3. The chip select feature of the AD637 permits the user to

power down the device during periods of nonuse, thereby

decreasing battery drain in remote or hand-held applications.

4. The on-chip buffer amplifier can be used either as an input

buffer or in an active filter configuration. The filter can be

used to reduce the amount of ac ripple, thereby increasing

the accuracy of the measurement.

PRODUCT DESCRIPTION

The AD637 is a complete high accuracy monolithic rms-to-dc

converter that computes the true rms value of any complex waveform. It offers performance that is unprecedented in integrated

circuit rms-to-dc converters and comparable to discrete and

modular techniques in accuracy, bandwidth, and dynamic range.

A crest factor compensation scheme in the AD637 permits measurements of signals with crest factors of up to 10 with less than

1% additional error. The circuit’s wide bandwidth permits the

measurement of signals up to 600 kHz with inputs of 200 mV

rms and up to 8 MHz when the input levels are above 1 V rms.

As with previous monolithic rms converters from Analog Devices,

the AD637 has an auxiliary dB output available to the user. The

logarithm of the rms output signal is brought out to a separate

pin, allowing direct dB measurement with a useful range of

60 dB. An externally programmed reference current allows the

user to select the 0 dB reference voltage to correspond to any

level between 0.1 V and 2.0 V rms.

A chip select connection on the AD637 permits the user to decrease the supply current from 2.2 mA to 350 µA during periods

when the rms function is not in use. This feature facilitates the

addition of precision rms measurement to remote or hand-held

applications where minimum power consumption is critical. In

addition when the AD637 is powered down the output goes to a

high impedance state. This allows several AD637s to be tied

together to form a wideband true rms multiplexer.

The input circuitry of the AD637 is protected from overload

voltages that are in excess of the supply levels. The inputs will

not be damaged by input signals if the supply voltages are lost.

FEATURES

High Accuracy

0.02% Max Nonlinearity, 0 V to 2 V RMS Input

0.10% Additional Error to Crest Factor of 3

Wide Bandwidth

8 MHz at 2 V RMS Input

600 kHz at 100 mV RMS

Computes:

True RMS

Square

Mean Square

Absolute Value

dB Output (60 dB Range)

Chip Select/Power-Down Feature Allows:

Analog “Three-State” Operation

Quiescent Current Reduction from 2.2 mA to 350 A

Side Brazed DIP, Low Cost Cerdip and SOIC

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

BUFFER

AD637

ABSOLUTE

VALUE

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

98

16

15

SOIC (R) Package

BUFFER

AD637

ABSOLUTE

VALUE

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

Ceramic DIP (D) and

Cerdip (Q) Packages

Page 2

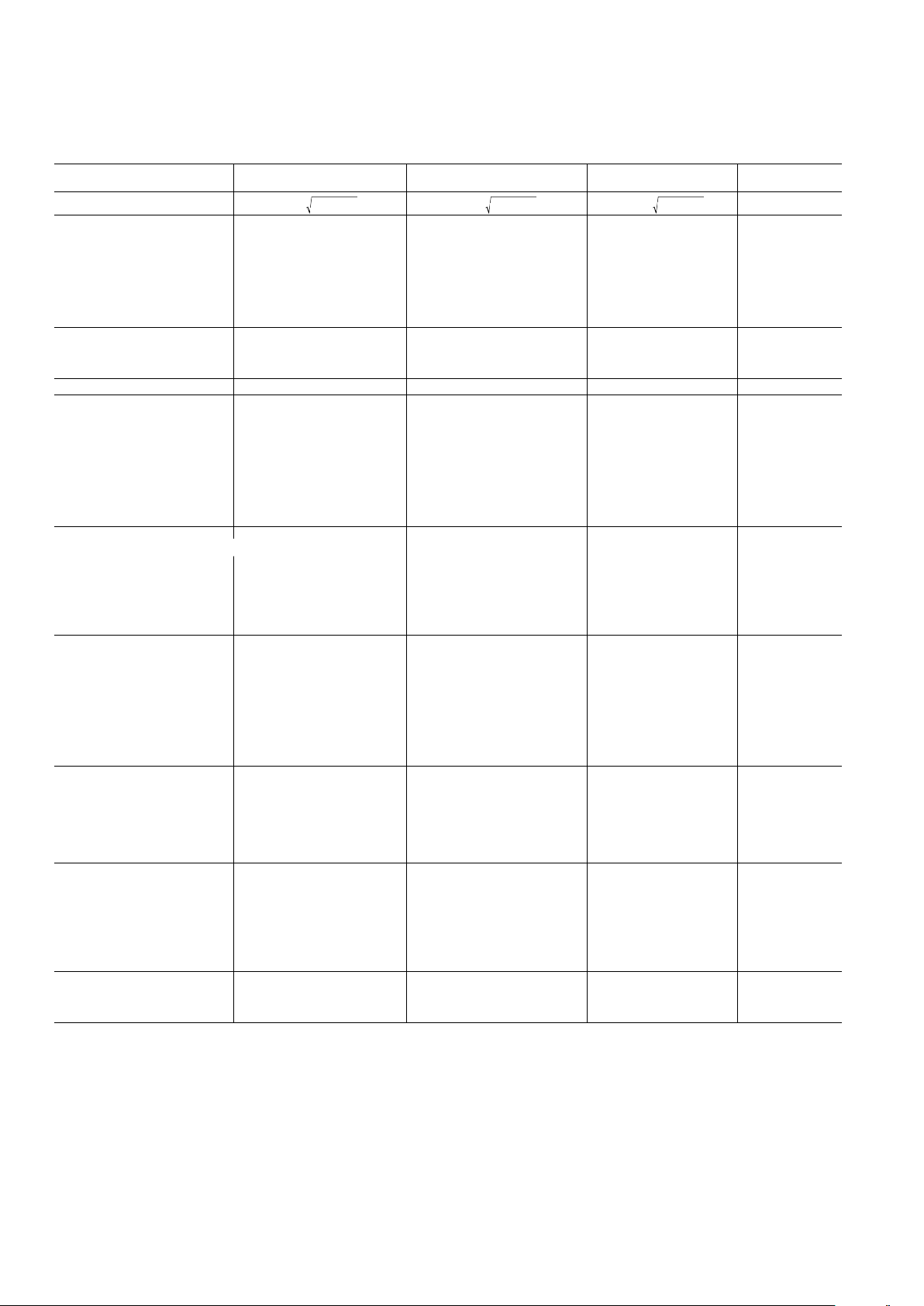

AD637J/A AD637K/B AD637S

Model Min Typ Max Min Typ Max Min Typ Max Unit

TRANSFER FUNCTION

V avg V

OUT IN

=×

()

2

V avg V

OUT IN

=×

()

2

V avg V

OUT IN

=×

()

2

CONVERSION ACCURACY

Total Error, Internal Trim

1

(Fig. 2)

1

0.5

0.5 0.2

1

0.5 mV ± % of Reading

T

MIN

to T

MAX

3.0 0.6

2.0 0.3

6

0.7 mV ± % of Reading

vs. Supply, + V

IN

= +300 mV 30 150 30 150 30 150 µV/V

vs. Supply, – V

IN

= –300 mV 100 300 100 300 100 300 µV/V

DC Reversal Error at 2 V 0.25 0.1 0.25 % of Reading

Nonlinearity 2 V Full Scale

2

0.04 0.02 0.04 % of FSR

Nonlinearity 7 V Full Scale 0.05 0.05 0.05 % of FSR

Total Error, External Trim ±0.5 ± 0.1 ±0.25 ± 0.05 ±0.5 ± 0.1 mV ± % of Reading

ERROR VS. CREST FACTOR

3

Crest Factor 1 to 2 Specified Accuracy Specified Accuracy Specified Accuracy

Crest Factor = 3 ±0.1 ±0.1 ±0.1 % of Reading

Crest Factor = 10 ± 1.0 ±1.0 ± 1.0 % of Reading

AVERAGING TIME CONSTANT 25 25 25 ms/µF C

AV

INPUT CHARACTERISTICS

Signal Range, ±15 V Supply

Continuous RMS Level 0 to 7 0 to 7 0 to 7 V rms

Peak Transient Input ±15 ±15 ±15 V p-p

Signal Range, ±5 V Supply

Continuous rms Level 0 to 4 0 to 4 0 to 4 V rms

Peak Transient Input ±6 ±6 ±6 V p-p

Maximum Continuous Nondestructive

Input Level (All Supply Voltages) ±15 ±15 ±15 V p-p

Input Resistance 6.4 8 9.6 6.4 8 9.6 6.4 8 9.6 kΩ

Input Offset Voltage ±0.5 ± 0.2 ±0.5 mV

FREQUENCY RESPONSE

4

Bandwidth for 1% Additional Error (0.09 dB)

V

IN

= 20 mV 11 11 11 kHz

V

IN

= 200 mV 66 66 66 kHz

V

IN

= 2 V 200 200 200 kHz

±3 dB Bandwidth

V

IN

= 20 mV 150 150 150 kHz

V

IN

= 200 mV 1 1 1 MHz

VIN = 2 V 8 8 8 MHz

OUTPUT CHARACTERISTICS

Offset Voltage

1

0.5

1 mV

vs. Temperature ±0.05

0.089 ±0.04

0.056 ±0.040.07 mV/°C

Voltage Swing, ±15 V Supply,

2 kΩ Load 0 to 12.0 13.5 0 to 12.0 13.5 0 to 12.0 13.5 V

Voltage Swing, ±3 V Supply,

2 kΩ Load 0 to 2 2.2 0 to 2 2.2 0 to 2 2.2 V

Output Current 66 6mA

Short Circuit Current 20 20 20 mA

Resistance, Chip Select “High” 0.5 0.5 0.5 Ω

Resistance, Chip Select “Low” 100 100 100 kΩ

dB OUTPUT

Error, V

IN

7 mV to 7 V rms, ±0.5 ± 0.3 ±0.5 dB

0 dB = 1 V rms

Scale Factor –3 –3 –3 mV/dB

Scale Factor Temperature Coefficient +0.33 +0.33 +0.33 % of Reading/°C

–0.033 –0.033 –0.033 dB/°C

I

REF

for 0 dB = 1 V rms 5 20 80 52080 52080 µA

I

REF

Range 1 100 1 100 1 100 µA

BUFFER AMPLIFIER

Input Output Voltage Range –V

S

to (+VS – 2.5 V) –VS to (+VS – 2.5 V) –VS to (+VS – 2.5 V) V

Input Offset Voltage ±0.8

2 ± 0.5

1 ± 0.82 mV

Input Current ± 2

10 ± 2

5 ± 2

10 nA

Input Resistance 10

8

10

8

10

8

Ω

Output Current (+5 mA, –130 µA) (+5 mA, –130 µA) (+5 mA, –130 µA)

Short Circuit Current 20 20 20 mA

Small Signal Bandwidth 1 1 1 MHz

Slew Rate

5

55 5V/µs

DENOMINATOR INPUT

Input Range 0 to 10 0 to 10 0 to 10 V

Input Resistance 20 25 30 20 25 30 20 25 30 kΩ

Offset Voltage ±0.2 ±0.5 ±0.2 ± 0.5 ±0.2 ±0.5 mV

AD637–SPECIFICATIONS

(@ 25C, and 15 V dc unless otherwise noted.)

REV. F

–2–

Page 3

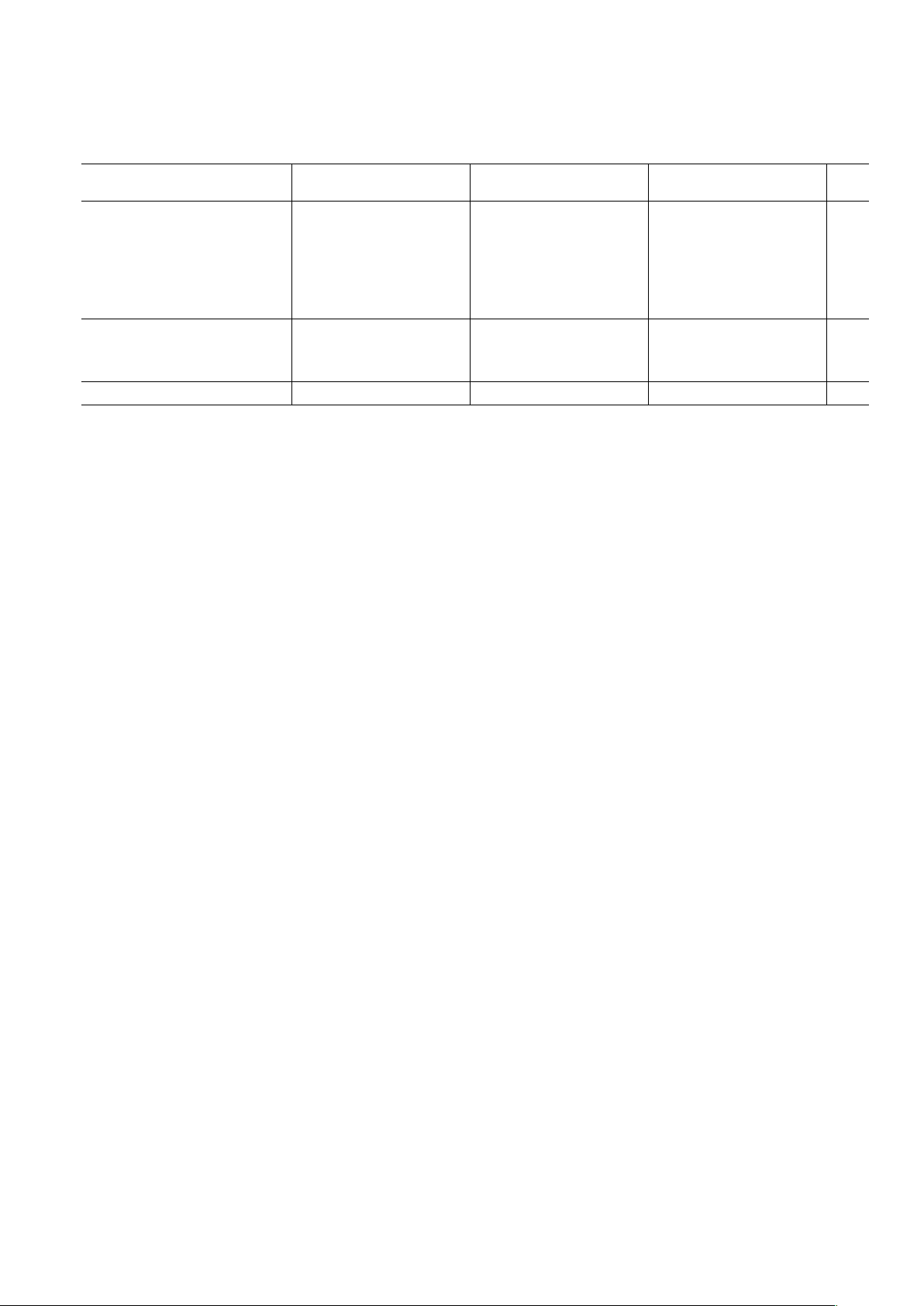

AD637

REV. F

–3–

AD637J/A AD637K/B AD637S

Model Min Typ Max Min Typ Max Min Typ Max Unit

CHIP SELECT PROVISION (CS)

RMS “ON” Level Open or 2.4 V < V

C

< +V

S

Open or 2.4 V < VC < +V

S

Open or 2.4 V < VC < +V

S

RMS “OFF” Level VC < 0.2 V VC < 0.2 V VC < 0.2 V

I

OUT

of Chip Select

CS “Low” 10 10 10 µA

CS “High” Zero Zero Zero

On Time Constant 10 µs + ((25 kΩ) ⫻ C

AV

) 10 µs + ((25 kΩ) ⫻ CAV) 10 µs + ((25 kΩ) ⫻ CAV)

Off Time Constant 10 µs + ((25 kΩ) ⫻ CAV) 10 µs + ((25 kΩ) ⫻ CAV) 10 µs + ((25 kΩ) ⫻ CAV)

POWER SUPPLY

Operating Voltage Range ±3.0

18

3.0

18

3.0

18 V

Quiescent Current 2.2 3 2.2 3 2.2 3 mA

Standby Current 350 450 350 450 350 450 µA

TRANSISTOR COUNT 107 107 107

NOTES

1

Accuracy specified 0–7 V rms dc with AD637 connected as shown in Figure 2.

2

Nonlinearity is defined as the maximum deviation from the straight line connecting the readings at 10 mV and 2 V.

3

Error vs. crest factor is specified as additional error for 1 V rms.

4

Input voltages are expressed in volts rms. % are in % of reading.

5

With external 2 kΩ pull-down resistor tied to –VS.

Specifications shown in bold are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min and max specifications

are guaranteed, although only those shown in boldface are tested on all production units.

Specifications subject to change without notice.

Page 4

ABSOLUTE MAXIMUM RATINGS

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 V

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V dc

Internal Quiescent Power Dissipation . . . . . . . . . . . . 108 mW

Output Short Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering 10 secs) . . . . . . . . 300°C

Rated Operating Temperature Range

AD637J, K . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

AD637A, B . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

AD637S, 5962-8963701CA . . . . . . . . . . . –55°C to +125°C

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD637AR –40°C to +85°C SOIC R-16

AD637BR –40°C to +85°C SOIC R-16

AD637AQ – 40°C to +85°C Cerdip Q-14

AD637BQ – 40°C to +85°C Cerdip Q-14

AD637JD 0°C to 70°C Side Brazed Ceramic DIP D-14

AD637JD/+ 0°C to 70°C Side Brazed Ceramic DIP D-14

AD637KD 0°C to 70°C Side Brazed Ceramic DIP D-14

AD637KD/+ 0°C to 70°C Side Brazed Ceramic DIP D-14

AD637JQ 0°C to 70°C Cerdip Q-14

AD637KQ 0°C to 70°C Cerdip Q-14

AD637JR 0°C to 70°C SOIC R-16

AD637JR-REEL 0°C to 70°C SOIC R-16

AD637JR-REEL7 0°C to 70°C SOIC R-16

AD637KR 0°C to 70°C SOIC R-16

AD637SD –55°C to +125°C Side Brazed Ceramic DIP D-14

AD637SD/883B –55°C to +125°C Side Brazed Ceramic DIP D-14

AD637SQ/883B –55°C to +125°C Cerdip Q-14

AD637SCHIPS –55°C to +125°CDie

5962-8963701CA* –55°C to +125°C Cerdip Q-14

*A standard microcircuit drawing is available.

FILTER/AMPLIFIER

24k

24k

ONE QUADRANT

SQUARER/DIVIDER

BUFFER

AMPLIFIER

Q1

Q2

Q3

Q4

125

6k

6k

12k

24k

A5

A1

A2

ABSOLUTE VALUE VOLTAGE –

CURRENT CONVERTER

I

1

I

3

I

4

A4

A3

BIAS

Q5

CAV

+V

S

RMS

OUT

COM

CS

DEN

INPUT

OUTPUT

OFFSET

dB

OUT

AD637

V

IN

BUFF OUT

BUFF IN

–V

S

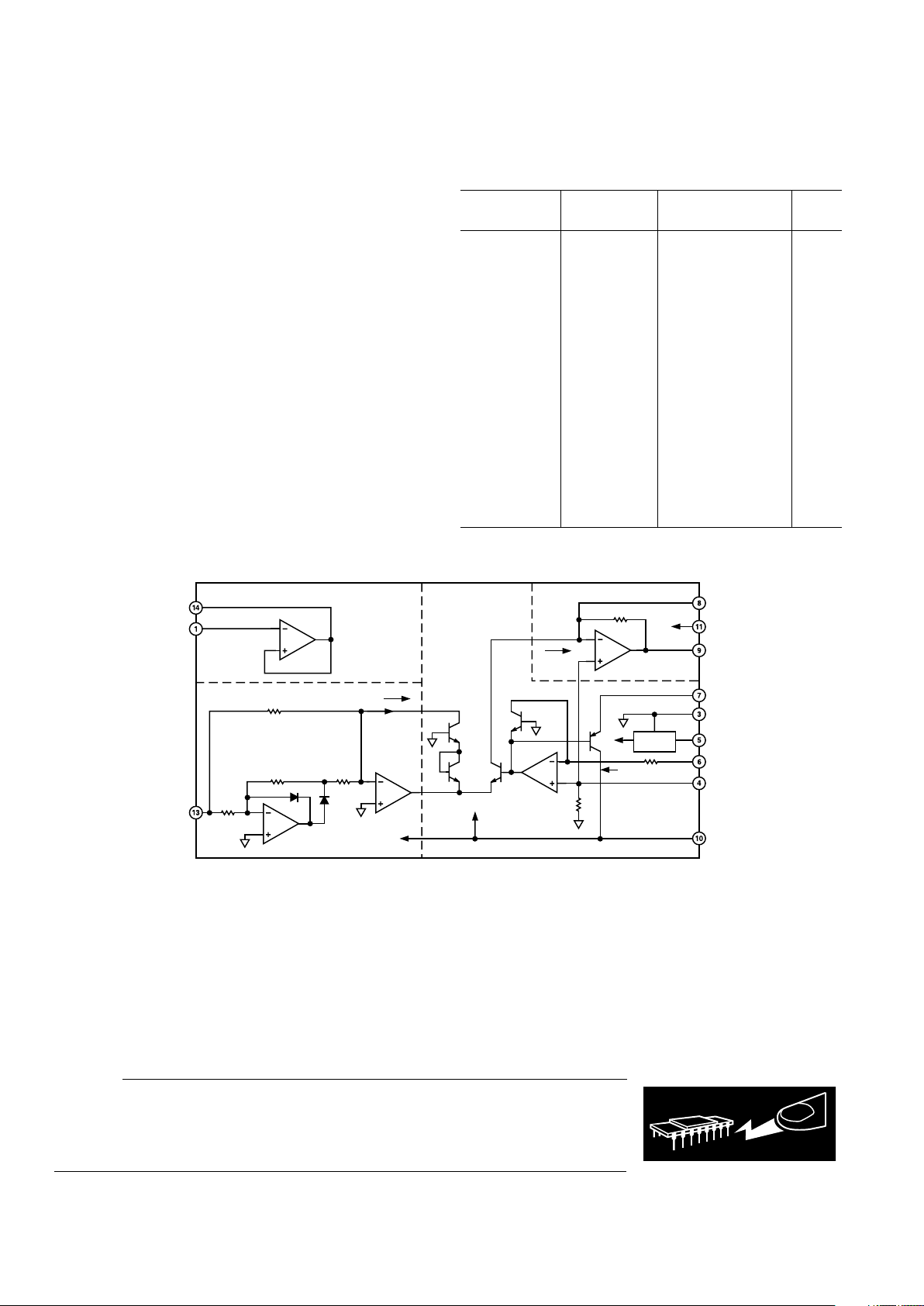

Figure 1. Simplified Schematic

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD637 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

AD637

REV. F

–4–

WARNING!

ESD SENSITIVE DEVICE

Page 5

REV. F

–5–

AD637

PIN CONFIGURATIONS

14-Lead DIP

TOP VIEW

(Not to Scale)

14

13

12

11

10

9

8

1

2

3

4

5

6

7

NC = NO CONNECT

BUFF IN

NC

COMMON

OUTPUT OFFSET

CS

DEN INPUT

dB OUTPUT

BUFF OUT

V

IN

NC

+V

S

–V

S

RMS OUT

C

AV

AD637

16-Lead SOIC

TOP VIEW

(Not to Scale)

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

NC = NO CONNECT

BUFF IN

NC

COMMON

OUTPUT OFFSET

CS

DEN INPUT

dB OUTPUT

NC

BUFF OUT

V

IN

NC

+V

S

–V

S

RMS OUT

C

AV

NC

AD637

14-Lead DIP

Pin No. Mnemonic Description

1 BUFF IN Buffer Input

2, 12 NC No Connection

3 COMMON Analog Common

4 OUTPUT OFFSET Output Offset

5 CS Chip Select

6 DEN INPUT Denominator Input

7 dB OUTPUT dB Output

8C

AV

Averaging Capacitor

Connection

9 RMS OUT rms Output

10 –V

S

Negative Supply

Rail

11 +V

S

Positive Supply Rail

13 V

IN

Signal Input

14 BUFF OUT Buffer Output

PIN FUNCTION DESCRIPTIONS

16-Lead SOIC

Pin No. Mnemonic Description

1 BUFF IN Buffer Input

2, 8, 9, 14 NC No Connection

3 COMMON Analog Common

4 OUTPUT OFFSET Output Offset

5 CS Chip Select

6 DEN INPUT Denominator Input

7 dB OUTPUT dB Output

10 C

AV

Averaging Capacitor

Connection

11 RMS OUT rms Output

12 –V

S

Negative Supply

Rail

13 +V

S

Positive Supply Rail

15 V

IN

Signal Input

16 BUFF OUT Buffer Output

Page 6

AD637

REV. F

–6–

STANDARD CONNECTION

The AD637 is simple to connect for a majority of rms measurements. In the standard rms connection shown in Figure 2, only a

single external capacitor is required to set the averaging time

constant. In this configuration, the AD637 will compute the true

rms of any input signal. An averaging error, the magnitude of

which will be dependent on the value of the averaging capacitor,

will be present at low frequencies. For example, if the filter

capacitor, C

AV

, is 4 µF, this error will be 0.1% at 10 Hz and

increases to 1% at 3 Hz. If it is desired to measure only ac

signals, the AD637 can be ac coupled through the addition of a

nonpolar capacitor in series with the input as shown in Figure 2.

BUFFER

AD637

ABSOLUTE

VALUE

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

AV

–V

S

+V

S

NC

V

IN

NC

OPTIONAL

AC COUPLING

CAPACITOR

V

O

=

VIN2

NC = NO CONNECT

Figure 2. Standard RMS Connection

The performance of the AD637 is tolerant of minor variations in

the power supply voltages; however, if the supplies being used

exhibit a considerable amount of high frequency ripple it is

advisable to bypass both supplies to ground through a 0.1 µF

ceramic disc capacitor placed as close to the device as possible.

The output signal range of the AD637 is a function of the supply voltages, as shown in Figure 3. The output signal can be

used buffered or nonbuffered depending on the characteristics

of the load. If no buffer is needed, tie the buffer input (Pin 1) to

common. The output of the AD637 is capable of driving 5 mA

into a 2 kΩ load without degrading the accuracy of the device.

SUPPLY VOLTAGE – DUAL SUPPLY – V

20

15

0

0 185

MAX V

OUT

– Volts 2k Load

10

10

5

153

Figure 3. AD637 Max V

OUT

vs. Supply Voltage

FUNCTIONAL DESCRIPTION

The AD637 embodies an implicit solution of the rms equation

that overcomes the inherent limitations of straightforward rms

computation. The actual computation performed by the AD637

follows the equation

V rms Avg

V

V rms

IN

=

2

Figure 1 is a simplified schematic of the AD637, subdivided

into four major sections: absolute value circuit (active rectifier), square/divider, filter circuit, and buffer amplifier. The

input voltage V

IN

, which can be ac or dc, is converted to a

unipolar current I1 by the active rectifier A1, A2. I1 drives one

input of the squarer/divider, which has the transfer function

I

I

I

4

1

2

3

=

The output current of the squarer/divider I4 drives A4, which

forms a low-pass filter with the external averaging capacitor. If the

RC time constant of the filter is much greater than the longest

period of the input signal, then A4’s output will be proportional

to the average of I4. The output of this filter amplifier is used by

A3 to provide the denominator current I3, which equals Avg. I4

and is returned to the squarer/divider to complete the implicit

rms computation

I Avg

I

I

I rms

4

1

2

4

1

=

=

and

V

OUT

= VIN rms

If the averaging capacitor is omitted, the AD637 will compute the

absolute value of the input signal. A nominal 5 pF capacitor should

be used to ensure stability. The circuit operates identically to that

of the rms configuration except that I3 is now equal to I4, giving

I

I

I

II

4

1

2

4

41

=

=

The denominator current can also be supplied externally by providing a reference voltage, V

REF

, to Pin 6. The circuit operates

identically to the rms case except that I3 is now proportional to

V

REF

. Thus:

I Avg

I

I

4

1

2

3

=

and

V

V

V

O

IN

DEN

=

2

This is the mean square of the input signal.

Page 7

REV. F

–7–

AD637

CHIP SELECT

The AD637 includes a chip select feature that allows the user to

decrease the quiescent current of the device from 2.2 mA to

350 µA. This is done by driving the CS, Pin 5, to below 0.2 V dc.

Under these conditions, the output will go into a high impedance

state. In addition to lowering power consumption, this feature

permits bussing the outputs of a number of AD637s to form a

wide bandwidth rms multiplexer. If the chip select is not being

used, Pin 5 should be tied high.

OPTIONAL TRIMS FOR HIGH ACCURACY

The AD637 includes provisions to allow the user to trim out

both output offset and scale factor errors. These trims will result

in significant reduction in the maximum total error as shown in

Figure 4. This remaining error is due to a nontrimmable input

offset in the absolute value circuit and the irreducible

nonlinearity of the device.

The trimming procedure on the AD637 is as follows:

l. Ground the input signal, V

IN

, and adjust R1 to give 0 V

output from Pin 9. Alternatively R1 can be adjusted to give

the correct output with the lowest expected value of V

IN

.

2. Connect the desired full-scale input to V

IN

, using either a dc

or a calibrated ac signal, and trim R3 to give the correct output at Pin 9, i.e., 1 V dc should give l.000 V dc output. Of

course, a 2 V peak-to-peak sine wave should give 0.707 V dc

output. Remaining errors are due to the nonlinearity.

INPUT LEVEL – V

5.0

2.5

5.0

0 2.00.5

ERROR – mV

1.0

0

2.5

1.5

AD637K MAX

INTERNAL TRIM

AD637K

EXTERNAL TRIM

AD637K: 0.5mV 0.2%

0.25mV 0.05%

EXTERNAL

Figure 4. Max Total Error vs. Input Level AD637K

Internal and External Trims

BUFFER

AD637

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

AV

–V

S

+V

S

V rms

OUT

R4

147

+

R3

1k

SCALE FACTOR ADJUST, 2%

R2

1M

R1

50k

–V

S

+V

S

V

IN

OUTPUT

OFFSET

ADJUST

ABSOLUTE

VALUE

Figure 5. Optional External Gain and Offset Trims

CHOOSING THE AVERAGING TIME CONSTANT

The AD637 will compute the true rms value of both dc and ac

input signals. At dc the output will track the absolute value of the

input exactly; with ac signals the AD637’s output will approach the

true rms value of the input. The deviation from the ideal rms value

is due to an averaging error. The averaging error is comprised of an

ac and dc component. Both components are functions of input signal frequency f and the averaging time constant τ (τ: 25 ms/µF of

averaging capacitance). As shown in Figure 6, the averaging error is

defined as the peak value of the ac component, ripple, plus the

value of the dc error.

The peak value of the ac ripple component of the averaging

error is defined approximately by the relationship:

50

6.3 τf

in % of reading where (t > 1/f)

DC ERROR = AVERAGE OF OUTPUT – IDEAL

DOUBLE-FREQUENCY

RIPPLE

E

O

TIME

AVERAGE ERROR

IDEAL

E

O

Figure 6. Typical Output Waveform for a Sinusoidal Input

This ripple can add a significant amount of uncertainty to the

accuracy of the measurement being made. The uncertainty can

be significantly reduced through the use of a post filtering network or by increasing the value of the averaging capacitor.

The dc error appears as a frequency dependent offset at the

output of the AD637 and follows the equation:

1

0.16 + 6. 4 τ

2f2

in % of reading

Since the averaging time constant, set by C

AV

, directly sets the

time that the rms converter “holds” the input signal during

computation, the magnitude of the dc error is determined only

by C

AV

and will not be affected by post filtering.

Page 8

AD637

REV. F

–8–

SINEWAVE INPUT FREQUENCY – Hz

100

0.1

1.0

10 10k

DC ERROR OR RIPPLE % OF READING

1k100

10

DC ERROR

PEAK RIPPLE

Figure 7. Comparison of Percent DC Error to the Percent

Peak Ripple over Frequency Using the AD637 in the Standard RMS Connection with a 1

× µ

F C

AV

The ac ripple component of averaging error can be greatly

reduced by increasing the value of the averaging capacitor.

There are two major disadvantages to this: first, the value of the

averaging capacitor will become extremely large, and second,

the settling time of the AD637 increases in direct proportion to

the value of the averaging capacitor (Ts = 115 ms/µF of averag-

ing capacitance). A preferable method of reducing the ripple is

through the use of the post filter network, shown in Figure 8.

This network can be used in either a one or two pole configuration. For most applications the single pole filter will give the

best overall compromise between ripple and settling time.

BUFFER

AD637

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

AV

–V

S

+V

S

+

ABSOLUTE

VALUE

RMS

OUTPUT

BUFFER

OUTPUT

ANALOG COM

OUTPUT

OFFSET

+

C2

Rx

24k

BUFFER INPUT

NC

CHIP

SELECT

DENOMINATOR

INPUT

dB

24k

FOR 1 POLE

FILTER, SHORT

Rx AND

REMOVE C3

SIGNAL

INPUT

+

C3

NC

NC = NO CONNECT

Figure 8. Two Pole Sallen-Key Filter

Figure 9a shows values of CAV and the corresponding averaging

error as a function of sine-wave frequency for the standard rms

connection. The 1% settling time is shown on the right side of

the graph.

Figure 9b shows the relationship between averaging error, signal frequency settling time, and averaging capacitor value. This

graph is drawn for filter capacitor values of 3.3 times the averaging capacitor value. This ratio sets the magnitude of the ac

and dc errors equal at 50 Hz. As an example, by using a 1 µF

averaging capacitor and a 3.3 µF filter capacitor, the ripple for a

60 Hz input signal will be reduced from 5.3% of reading using the

averaging capacitor alone to 0.15% using the single pole filter.

This gives a factor of thirty reduction in ripple and yet the settling

time would only increase by a factor of three. The values of C

AV

and C2, the filter capacitor, can be calculated for the desired value

of averaging error and settling time by using Figure 9b.

The symmetry of the input signal also has an effect on the magnitude of the averaging error. Table I gives practical component

values for various types of 60 Hz input signals. These capacitor

values can be directly scaled for frequencies other than 60 Hz;

i.e., for 30 Hz double these values, for 120 Hz they are halved.

For applications that are extremely sensitive to ripple, the

two pole configuration is suggested. This configuration will

minimize capacitor values and settling time while maximizing

performance.

Figure 9c can be used to determine the required value of C

AV

,

C2, and C3 for the desired level of ripple and settling time.

INPUT FREQUENCY – Hz

100

0.01

1 100k10

REQUIRED C

AV

– F

100 1k 10k

10

1.0

0.1

VALUES FOR CAV AND

1% SETTLING TIME

FOR STATED % OF READING

AVERAGING ERROR*

ACCURACY 2% DUE TO

COMPONENT TOLERANCE

*%dc ERROR + %RIPPLE (Peak)

10% ERROR

1% ERROR

0.1% ERROR

0.01% ERROR

FOR 1% SETTLING TIME IN SECONDS

MULTIPLY READING BY 0.115

100

0.01

10

1.0

0.1

Figure 9a.

INPUT FREQUENCY – Hz

100

0.01

1 100k10

REQUIRED C

AV

(AND C2)

C2 = 3.3 C

AV

100 1k 10k

10

1.0

0.1

5% ERROR

1% ERROR

0.1% ERROR

0.01% ERROR

VALUES OF CAV, C2 AND

1% SETTLING TIME FOR

STATED % OF READING

AVERAGING ERROR*

FOR 1 POLE POST FILTER

*%dc ERROR + % PEAK RIPPLE

ACCURACY 20% DUE TO

COMPONENT TOLERANCE

FOR 1% SETTLING TIME IN SECONDS

MULTIPLY READING BY 0.400

100

0.01

10

1.0

0.1

Figure 9b.

Page 9

REV. F

–9–

AD637

INPUT FREQUENCY – Hz

100

0.01

1 100k10

REQUIRED C

AV

(AND C2 + C3)

C2 = C3 = 2.2 C

AV

100 1k 10k

10

1.0

0.1

5% ERROR

1% ERROR

0.1% ERROR

0.01% ERROR

VALUES OF CAV, C2 AND C3

AND 1% SETTLING TIME FOR

STATED % OF READING

AVERAGING ERROR*

2 POLL SALLEN-KEY FILTER

*%dc ERROR + % PEAK RIPPLE

ACCURACY 20% DUE TO

COMPONENT TOLERANCE

FOR 1% SETTLING TIME IN SECONDS

MULTIPLY READING BY 0.365

100

0.01

10

1.0

0.1

Figure 9c.

Table I. Practical Values of CAV and C2 for Various Input

Waveforms

Input Waveform

and Period

Absolute Value

Circuit Waveform

and Period

Minimum

R C

AV

Time

Constant

Recommended C

AV

and C2

Values for 1% Averaging

Error@60Hz with T = 16.6ms

Recommended

Standard

Value C

AV

Recommended

Standard

Value C2

1%

Settling

Time

Symmetrical Sine Wave

Sine Wave with dc Offset

Pulse Train Waveform

1/2T

T

A

B

C

D

181ms

325ms

2.67sec

2.17sec

1.5F

2.7F

22F

18F

6.8F

0.82F

0.47F

5.6F

10(T – T2)

10(T – 2T

2

)

1/2T

T

2

T

2

T

2

T

2

0V

0V

0V

0V

T

T

T T

T

T

T

FREQUENCY RESPONSE

The frequency response of the AD637 at various signal levels is

shown in Figure 10. The dashed lines show the upper frequency

limits for 1%, 10%, and ±3 dB of additional error. For example,

note that for 1% additional error with a 2 V rms input the highest frequency allowable is 200 kHz. A 200 mV signal can be

measured with 1% error at signal frequencies up to 100 kHz.

To take full advantage of the wide bandwidth of the AD637,

care must be taken in the selection of the input buffer amplifier.

To ensure that the input signal is accurately presented to the

converter, the input buffer must have a –3 dB bandwidth that is

wider than that of the AD637. A point that should not be overlooked is the importance of slew rate in this application. For

example, the minimum slew rate required for a 1 V rms 5 MHz

sine-wave input signal is 44 V/µs. The user is cautioned that this

is the minimum rising or falling slew rate and that care must be

exercised in the selection of the buffer amplifier, as some amplifiers exhibit a two-to-one difference between rising and falling slew

rates. The AD845 is recommended as a precision input buffer.

INPUT FREQUENCY – Hz

10

1k 10M10k

V

OUT

– V

100k 1M

1

0.1

0.01

1%

3dB

10%

7V RMS INPUT

2V RMS INPUT

1V RMS INPUT

100mV RMS INPUT

100mV RMS INPUT

Figure 10. Frequency Response

AC MEASUREMENT ACCURACY AND CREST FACTOR

Crest factor is often overlooked in determining the accuracy of

an ac measurement. Crest factor is defined as the ratio of the

peak signal amplitude to the rms value of the signal (CF =

Vp/V rms). Most common waveforms, such as sine and triangle

waves, have relatively low crest factors (≤2). Waveforms that

resemble low duty cycle pulse trains, such as those occurring in

switching power supplies and SCR circuits, have high crest

factors. For example, a rectangular pulse train with a 1% duty

cycle has a crest factor of 10 (CF = 1

η

).

PULSEWIDTH – s

10

1.0

0.01

1 100010

INCREASE IN ERROR – %

100

0.1

CAV = 22F

CF = 10

CF = 3

0

100F

Vp

T

e

0

= DUTY CYCLE =

100s

T

CF = 1/

e

IN

(RMS) = 1 V RMS

Figure 11. AD637 Error vs. Pulsewidth Rectangular Pulse

Page 10

AD637

REV. F

–10–

Figure 12 is a curve of additional reading error for the AD637

for a 1 volt rms input signal with crest factors from 1 to 11. A

rectangular pulse train (pulsewidth 100 µs) was used for this test

since it is the worst-case waveform for rms measurement (all the

energy is contained in the peaks). The duty cycle and peak

amplitude were varied to produce crest factors from l to 10

while maintaining a constant 1 V rms input amplitude.

CREST FACTOR

1.5

0

–1.5

1112

INCREASE IN ERROR – %

345678910

1.0

0.5

–0.5

–1.0

POSITIVE INPUT PULSE

CAV = 22F

Figure 12. Additional Error vs. Crest Factor

VIN – V rms

2.0

1.8

0.0

2.00.5 1.0 1.5

1.2

0.6

0.4

0.2

1.6

1.4

0.8

1.0

MAGNITUDE OF ERROR – % of rms Level

CF = 10

CF = 7

CF = 3

0

Figure 13. Error vs. RMS Input Level for Three Common

Crest Factors

CONNECTION FOR dB OUTPUT

Another feature of the AD637 is the logarithmic, or decibel,

output. The internal circuit that computes dB works well over a

60 dB range. The connection for dB measurement is shown in

Figure 14. The user selects the 0 dB level by setting R1 for the

proper 0 dB reference current (which is set to exactly cancel the

log output current from the squarer/divider circuit at the desired

0 dB point). The external op amp is used to provide a more

convenient scale and to allow compensation of the +0.33%/°C

temperature drift of the dB circuit. The special T.C. resistor R3

is available from Tel Labs in Londonderry, NH (model Q-81)

and from Precision Resistor Inc., Hillside, NJ (model PT146).

AD707JN

–V

S

+V

S

dB SCALE

FACTOR

ADJUST

R2

COMPENSATED

dB OUTPUT

+ 100mV/dB

5k

33.2k

R3

60.4

1k

*

BUFFER

AD637

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

AV

–V

S

+V

S

+

ABSOLUTE

VALUE

BUFFER

OUTPUT

ANALOG COM

OUTPUT

OFFSET

BUFFER INPUT

NC

CHIP

SELECT

DENOMINATOR

INPUT

dB

SIGNAL

INPUT

NC

1F

SIGNAL

INPUT

RMS OUTPUT

+V

S

AD508J

+2.5 VOLTS

R1

500k

0dB ADJUST

10k

* 1k + 3500ppm

TC RESISTOR TEL LAB Q81

PRECISION RESISTOR PT146

OR EQUIVALENT

NC = NO CONNECT

Figure 14. dB Connection

Page 11

REV. F

–11–

AD637

dB CALIBRATION

1. Set VIN = 1.00 V dc or 1.00 V rms

2. Adjust R1 for 0 dB out = 0.00 V

3. Set V

IN

= 0.1 V dc or 0.10 V rms

4. Adjust R2 for dB out = – 2.00 V

Any other dB reference can be used by setting V

IN

and R1

accordingly.

LOW-FREQUENCY MEASUREMENTS

If the frequencies of the signals to be measured are below 10 Hz,

the value of the averaging capacitor required to deliver even 1%

averaging error in the standard rms connection becomes extremely

large. The circuit shown in Figure 15 shows an alternative method

of obtaining low-frequency rms measurements. The averaging time

constant is determined by the product of R and C

AV1

, in this circuit

0.5 s/µF of C

AV

. This circuit permits a 20:1 reduction in the value

of the averaging capacitor, permitting the use of high quality tantalum capacitors. It is suggested that the two pole Sallen-Key filter

shown in the diagram be used to obtain a low ripple level and

minimize the value of the averaging capacitor.

If the frequency of interest is below 1 Hz, or if the value of the

averaging capacitor is still too large, the 20:1 ratio can be increased.

This is accomplished by increasing the value of R. If this is done, it

is suggested that a low input current, low offset voltage amplifier

such as the AD548 be used instead of the internal buffer amplifier.

This is necessary to minimize the offset error introduced by the

combination of amplifier input currents and the larger resistance.

BUFFER

AD637

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

AV

–V

S

+V

S

+

ABSOLUTE

VALUE

NC

SIGNAL

INPUT

NC

100F

AD548JN

–V

S

+V

S

FILTERED

V RMS OUTPUT

1F

1F

1000pF

6.8M

NOTE: VALUES CHOSEN TO GIVE 0.1%

AVERAGING ERROR @ 1Hz

1M

50k

–V

S

+V

S

OUTPUT

OFFSET

ADJUST

C

AV1

3.3F

499k

1%

R

3.3M 3.3M

V

IN

2

V rms

NC = NO CONNECT

Figure 15. AD637 as a Low Frequency RMS Converter

VECTOR SUMMATION

Vector summation can be accomplished through the use of two

AD637s as shown in Figure 16. Here the averaging capacitors

are omitted (nominal 100 pF capacitors are used to ensure stability of the filter amplifier), and the outputs are summed as

shown. The output of the circuit is

VVV

OXY

=+

22

This concept can be expanded to include additional terms by

feeding the signal from Pin 9 of each additional AD637 through a

10 kΩ resistor to the summing junction of the AD711 and tying

all of the denominator inputs (Pin 6) together.

If C

AV

is added to IC1 in this configuration, the output is

VV

XY

22

+

. If the averaging capacitor is included on both

IC1 and IC2, the output will be

VV

XY

22

+

.

This circuit has a dynamic range of 10 V to 10 mV and is limited only by the 0.5 mV offset voltage of the AD637. The useful

bandwidth is 100 kHz.

Page 12

AD637

REV. F

–12–

BUFFER

AD637

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

–V

S

+V

S

ABSOLUTE

VALUE

100pF

VX IN

BUFFER

AD637

SQUARER/DIVIDER

BIAS

SECTION

FILTER

25k

25k

1

2

3

4

5

6

7

14

13

12

11

10

9

8

–V

S

+V

S

ABSOLUTE

VALUE

100pF

VYIN

V

OUT

= V

X

2

+ V

Y

2

5pF

10k

AD711K

EXPANDABLE

10k

10k

20k

IC1

IC2

Figure 16. Vector Sum Configuration

Page 13

REV. F

–13–

AD637

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

TO-116 Package

(D-14)

14

1

7

8

0.098 (2.49) MAX

0.310 (7.87)

0.220 (5.59)

0.005 (0.13) MIN

PIN 1

0.100

(2.54)

BSC

SEATING

PLANE

0.023 (0.58)

0.014 (0.36)

0.060 (1.52)

0.015 (0.38)

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.070 (1.78)

0.030 (0.76)

0.150

(3.81)

MAX

0.785 (19.94) MAX

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

Cerdip Package

(Q-14)

14

1

7

8

0.310 (7.87)

0.220 (5.59)

PIN 1

0.005 (0.13) MIN 0.098 (2.49) MAX

SEATING

PLANE

0.023 (0.58)

0.014 (0.36)

0.200 (5.08)

MAX

0.785 (19.94) MAX

0.150

(3.81)

MIN

0.070 (1.78)

0.030 (0.76)

0.200 (5.08)

0.125 (3.18)

0.100

(2.54)

BSC

0.060 (1.52)

0.015 (0.38)

15°

0°

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

SOIC Package

(R-16)

SEATING

PLANE

0.0118 (0.30)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

0.1043 (2.65)

0.0926 (2.35)

0.050 (1.27)

BSC

16 9

81

0.4193 (10.65)

0.3937 (10.00)

0.2992 (7.60)

0.2914 (7.40)

PIN 1

0.4133 (10.50)

0.3977 (10.00)

0.0125 (0.32)

0.0091 (0.23)

8

0

0.0291 (0.74)

0.0098 (0.25)

45

0.0500 (1.27)

0.0157 (0.40)

Page 14

AD637

REV. F

–14–

Revision History

Location Page

Data Sheet changed from REV. E to REV. F.

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Page 15

–15–

Page 16

–16–

C00788–0–3/02(F)

PRINTED IN U.S.A.

Loading...

Loading...