Page 1

92-2431-01 Rev.C

Thermal Transfer Option

Page 2

Page 3

Overview

This document describes the contents, installation, and use of the Thermal Transfer option for the HClass printer. After verifying the kit contents and tools required, follow the steps below to install and begin

using the option. A ribbon selection guide and a parts listing are also included, so keep this

documentation for future reference.

For your safety and to avoid damaging the equipment, turn ‘Off’ power and unplug the AC

CAUTION

power cord from the printer before beginning this installation.

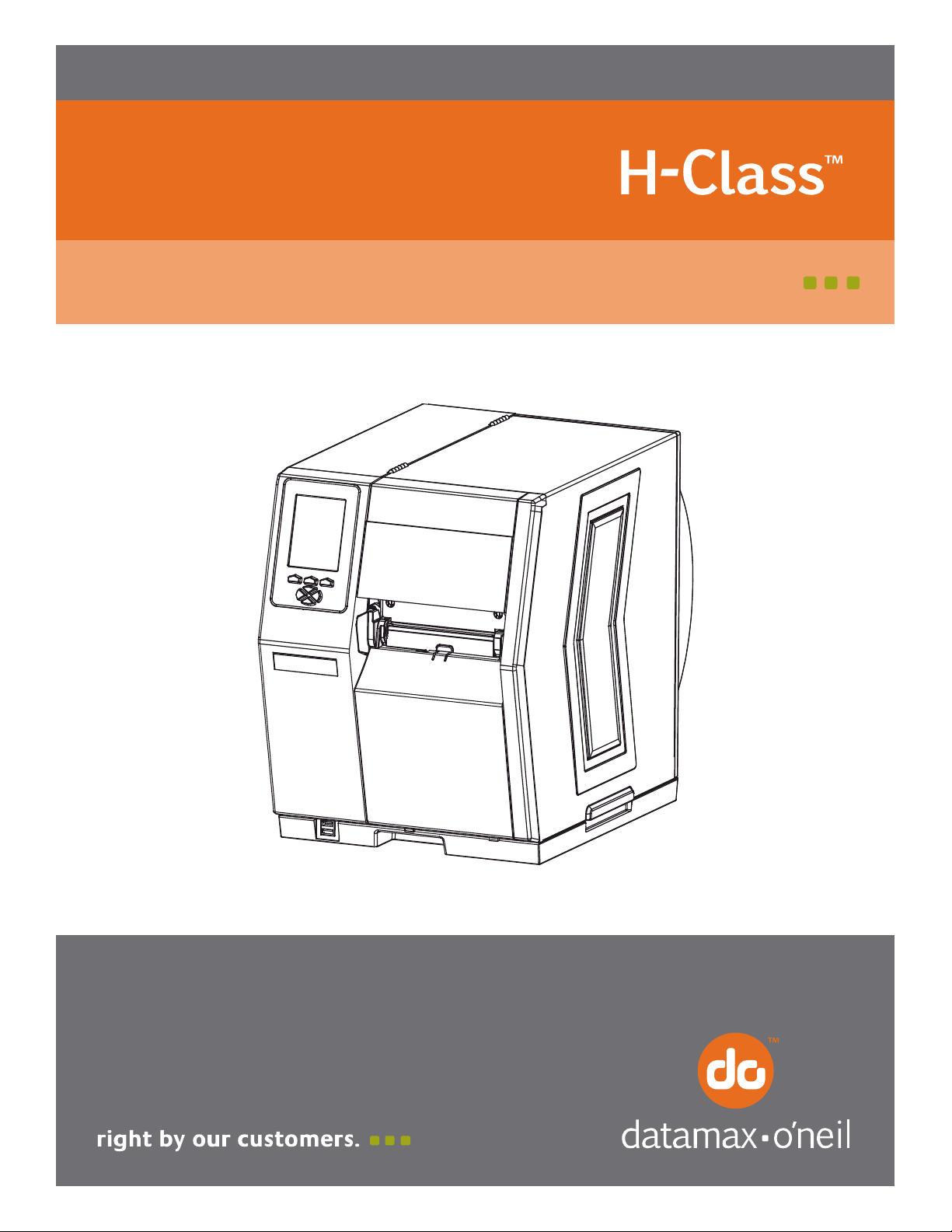

Contents of the Thermal Transfer Option

This kit contains the following items:

Thermal Transfer Assembly

Mounting Screws (3)

Static Brush (6” and 8” kits only)

1

2

Tools Required

To install this option, you will need a standard and a Phillips screwdriver.

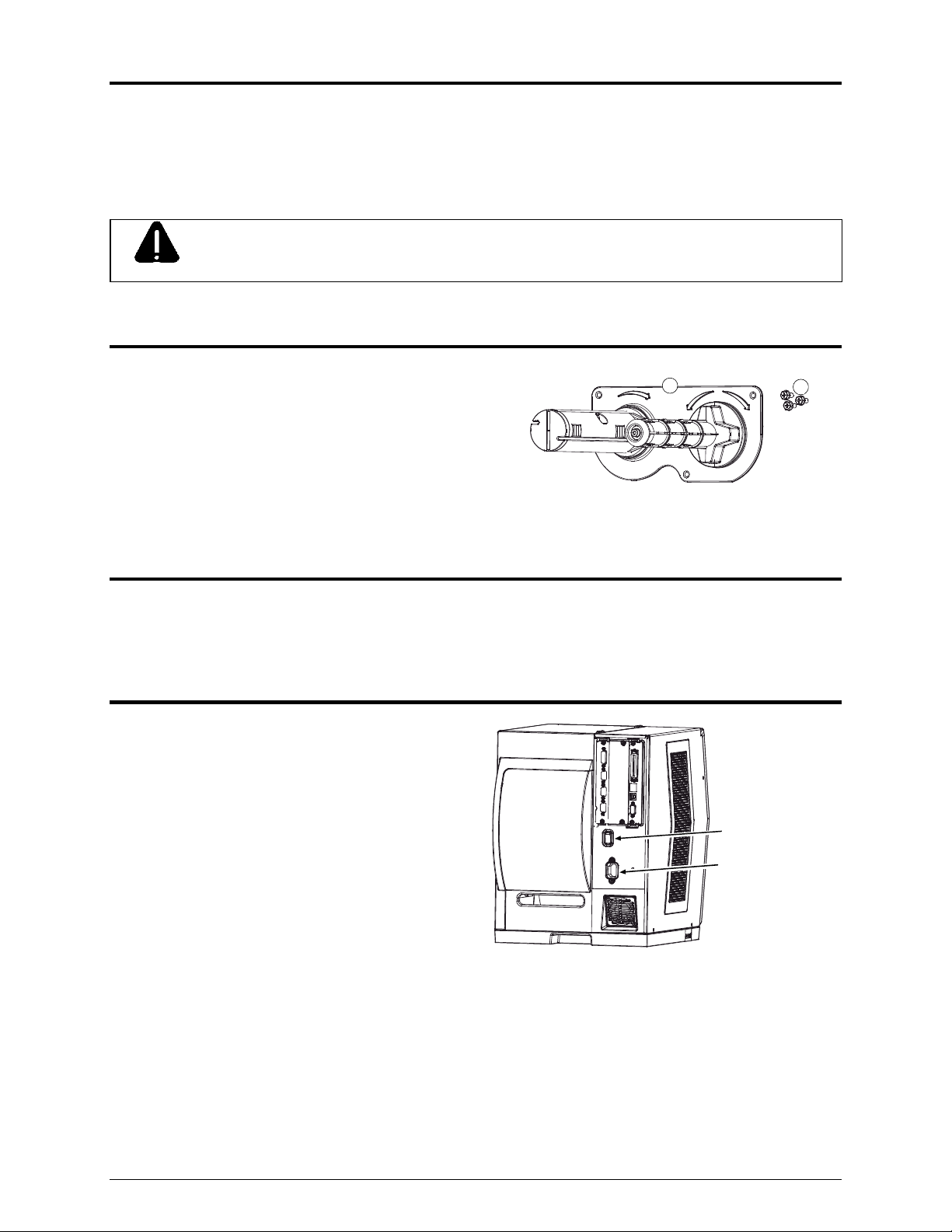

Step 1: Preparing the Printer

A) Turn ‘Off’ the Power Switch and unplug the

power cord from the AC Receptacle.

Power Switch

AC Receptacle

1

Page 4

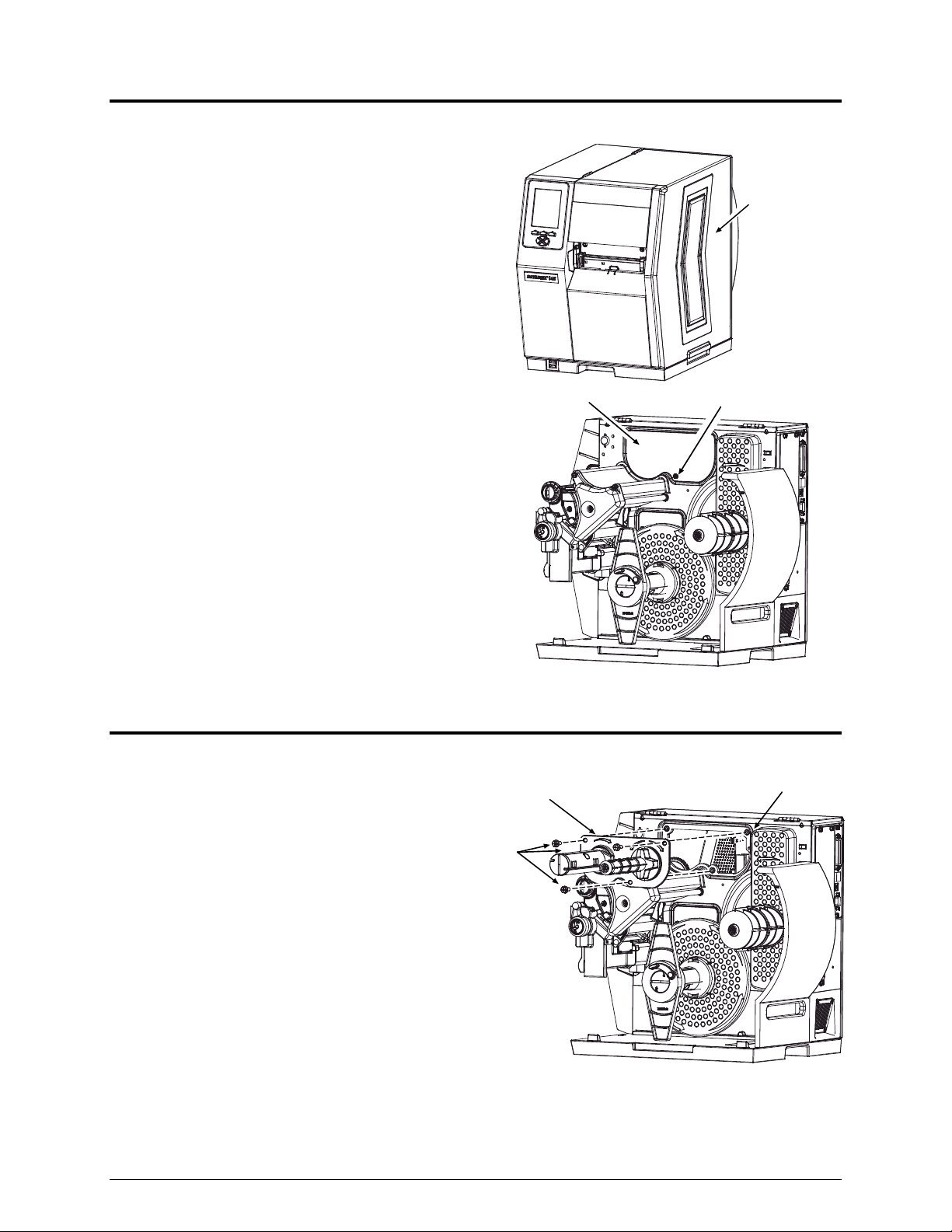

Step 1: Preparing the Printer (continued…)

B) Raise the Access Cover. If installed, remove

your media from the printer.

Access

Cover

C) Remove the Cover Screw then the Cover

Plate.

Step 2: Installing the Option

A) Carefully position the Thermal Transfer

Assembly (Item ) onto the Center Plate

of the printer and secure it using the three

Cover Plate

Thermal Transfer

Assembly

Mounting

Screws

Cover Screw

Center

Plate

Mounting Screws (Item ).

2

Page 5

6” and 8” printers only

B) Using a Cotton Swab or cloth, moistened with isopropyl alcohol, gently clean the surface where the

Static Brush will be installed.

Isopropyl alcohol is a flammable solvent; always take the proper precautions when using this substance.

WARNING

C) Peel the backing from the adhesive strip on

the back of the Static Brush and affix the

brush to the printer in the location shown.

Static

Brush

Be sure to locate the Static Brush as

close to the printer’s Centerplate as

possible.

Note: The Static brush should be installed so the bristles are as close to the ribbon without actually touching. It

may be necessary to install a roll of ribbon in order to properly align the brush to the ribbon.

Step 3: Configuring the Printer

Note: During this procedure, consult the Operator’s Manual for detailed front panel instructions.

Configure the printer for the thermal transfer use as follows:

A) Plug the power cord into the AC Receptacle and turn ‘On’ the Power Switch.

B) Press the MENU Button on the printer’s front panel.

C) Press the ENTER Key to select MEDIA SETTINGS, and press the key again to select MEDIA TYPE.

D) Using the DOWN Button, scroll to THERMAL TRANSFER then press the ENTER Key.

E) Press the EXIT Key and then, at the SAVE CHANGES? prompt, press YES.

3

Page 6

Step 4: Aligning the Ribbon Path

Thermal transfer printing relies on a smooth, taut flow of ribbon for consistent print quality; to accomplish

this, some components in the printer may need to be adjusted. Align the ribbon path as follows:

A) Install full width thermal transfer Media into the printer. Install a slightly wider Ribbon onto the

Supply Hub and route it through the printer (see the Operator’s Manual for details). Allow the Ribbon

to feed from the printer along with the Media, as shown below:

Supply Hub

Ribbon

Media

B) Adjust the Media Guide to fit the label width, set the Leveling Cam to the lowest (disengaged)

position, and ensure that the Printhead Pressure is balanced (see the Operator’s Manual for

details).

Printhead

Pressure

Adjustment

Leveling

Cam

Media

Guide

4

Page 7

C) Press the FEED Key several times, until media tracking is normalized through the printer. Then, while

feeding several more labels, observe the flow of the Ribbon from the Supply Hub. Proceed

according to your observations:

If the ribbon flow is rippling, or if bagging is present, proceed to D; or,

If the ribbon flow is evenly tensioned and smooth, proceed to E.

Ribbon

Supply

Hub

FEED

Key

observe

for flow

D) Slightly loosen the Support Cover Screw and, while repeatedly pressing the FEED Key, slowly

adjust the Idler Adjustment Screw to smooth the ribbon flow from the Supply Hub. Afterward,

carefully tighten the Support Cover Screw, and then feed several more labels to verify your

adjustment.

Supply Hub

smooth the ribbon flow

Idler Alignment

Screw

Support Cover

Screw

5

Page 8

E) Wrap the Ribbon in a clockwise direction around the Take-Up Hub. Press the TEST Button on the

Front Panel then use the UP / DOWN Buttons to select the RIBBON TEST LABEL. Select a small

quantity of labels and press the ENTER Key. As the labels are output, observe the flow of the

Ribbon from the Printhead Assembly to the Take-Up Hub. Proceed according to your

observations:

Ribbon

Take-Up

Hub

Printhead

llllllllllllllllllllllllll

Assembly

llllllllllllllllllllllllll

llllllllllllllllllllllllll

llllllllllllllllllllllllll

Front

Panel

observe for flow

If the ribbon flow is smooth, press the CANCEL Key, and then proceed to F; or,

If the ribbon flow is rippling or if bagging is present, slightly loosen both Ribbon Shield Screws

and then move the Ribbon Shield ‘in’ or ‘out’ to smooth the flow of the ribbon. Afterward,

carefully tighten the Ribbon Shield Screws. Print several more labels to verify your adjustment.

When finished, press the CANCEL Key to stop printing.

llllllllllllllllllllllllll

llllllllllllllllllllllllll

llllllllllllllllllllllllll

llllllllllllllllllllllllll

Ribbon Shield

Screws

lllllll llll lll llllllllll lllll

lllllll llll lll llllllllll lllll

6

Ribbon

Shield

Page 9

F) Press the TEST Button then use the UP / DOWN Buttons to select the PRINT QUALITY LABEL or

the TEST LABEL. Set a quantity of labels to print and then press the ENTER Key. After printing

stops, carefully examine the labels for evidence of ribbon wrinkling (i.e., irregular diagonal voids that

extend through printed areas). Proceed according to your examinations:

If no evidence of wrinkling is present on the labels, press the CANCEL Key to stop printing and

complete the procedure; or,

If evidence of wrinkling is present, enter the Test Menu again and reselect the PRINT QUALITY

LABEL or the TEST LABEL. Set a quantity of labels to print and press the ENTER Key. Slightly

loosen the Ribbon Shield Screws then slightly readjust the Ribbon Shield to eliminate the latent

wrinkling. When finished, press the CANCEL Key to stop printing and complete the procedure.

The printer should now be ready for use in thermal transfer mode; however, if you are still experiencing

problems with the installation or application of this option, refer to the troubleshooting guide below.

Troubleshooting

The following table covers common installation and use problems.

If experiencing this problem… Try this solution…

‘RIBBON FAULT’ is indicated on the

printer’s display panel:

Ensure that ribbon is correctly installed and that the

printhead is latched; see the Loading Diagrams on the

printer’s cover or in the Operator’s Manual.

Check the ribbon hubs for obstructions that may be

inhibiting movement.

Ensure that the ribbon core fits snugly on the Supply Hub.

Ensure that the media is not slipping under the ribbon

(usually caused by an incorrect ribbon and media

combination); see Selecting Media and Ribbon, below.

Used ribbon is not being wound by

the Take-Up Hub:

Ensure that the leader has been correctly wound and

secured to the Take-Up Hub.

7

Page 10

If experiencing this problem… Try this solution…

Labels and ribbon advance normally,

but no image is printed:

Examine the used ribbon for an image and proceed

accordingly:

If there is an image on the used ribbon:

Verify that the ribbon was properly loaded. The inked side

of the ribbon must face the media. (To verify the inked side,

press the adhesive backing of a label against the ribbon

surface. Ink will only lift from the coated side of the ribbon.)

Clean the printhead (see the Operator’s Manual). Then flip

the roll of ribbon on the Supply Hub; see the Loading

Diagrams on the printer’s cover or in the Operator’s

Manual.

If there is no image on the used ribbon:

The Heat setting may be too low. Make an adjustment in

your software program or through the printer’s menu

system. (Note that the same functional commands from the

host computer may override the menu settings; see the

Operator’s Manual for details.)

The media and ribbon combination may be incorrect; see

Selecting Media and Ribbon, below.

If you have questions, or if problems persist, contact Datamax-O’Neil Technical Support.

8

Page 11

Selecting Media and Ribbon

Because the media and ribbon used will determine the printer’s heat and speed settings, consider these

factors when selecting your thermal transfer stock and ribbon combination:

The combination of label facestocks / topcoatings and ribbon formulation may affect image quality.

The ribbon backcoating can provide printhead protection and, depending upon the formulation, help

reduce static build-up.

The use of a ribbon that is slightly wider than the media backing material (if any) can protect the

printhead against wear.

The following table is for reference only; for detailed advice, consult a Datamax-O’Neil Media

Representative.

Ribbon

Type

GPR Plus Great Label TTL

GPR Plus

PGR+

Coated and Uncoated Paper,

Tag Stock, some Films, some

Synthetics

Coated and Glossy Paper, Tag

Stock, some Synthetics, Films

Thermal Transfer

Media Type

Inches per

Second

Millimeters per

Second

Print

Energy

Image

Durability

10 – 12 * 254 – 305 * Medium Medium

2 - 10 51 - 254 Medium Medium

2 - 8 51 - 203 Medium Medium

SDR Synthetics, Films 4 - 6 102 - 152 High High

Print Speed

*Highly recommended for optimum print quality at speeds above 10 IPS.

Ribbon Requirements

Ribbon Core:

1.010” .006” (25.6 mm .2 mm) inner diameter; where the core is not

to protrude beyond ribbon’s edge.

Maximum Ribbon Length: 1968 feet (600 meters)

[1]

The ribbon width should exceed the web width of the label (label + liner).

Approved Media

Specially formulated for optimum print quality and maximum printhead life, Datamax-O’Neil media and

ribbons are strongly suggested for use in your printer. The use of non-Datamax-O’Neil materials may

affect the print quality, performance, and life of the printer components (see the Operator’s Manual

Warranty Statement for details). For a current list of approved media and ribbons, contact a Media

Representative at (407) 523-5650.

9

Page 12

Loading...

Loading...