Page 1

92-2432-01 Rev.C

Powered Internal Rewind Option

Page 2

Page 3

Overview

This document describes the contents, installation, and use of the Powered Internal Rewind option for the

H-Class printer. After verifying the kit contents and tools required, follow the steps below to install and

begin using the option. A parts listing is also included, so keep this documentation for future reference.

For your safety and to avoid damaging the equipment, turn ‘Off’ power and unplug the

CAUTION

printer’s power cord before performing this installation.

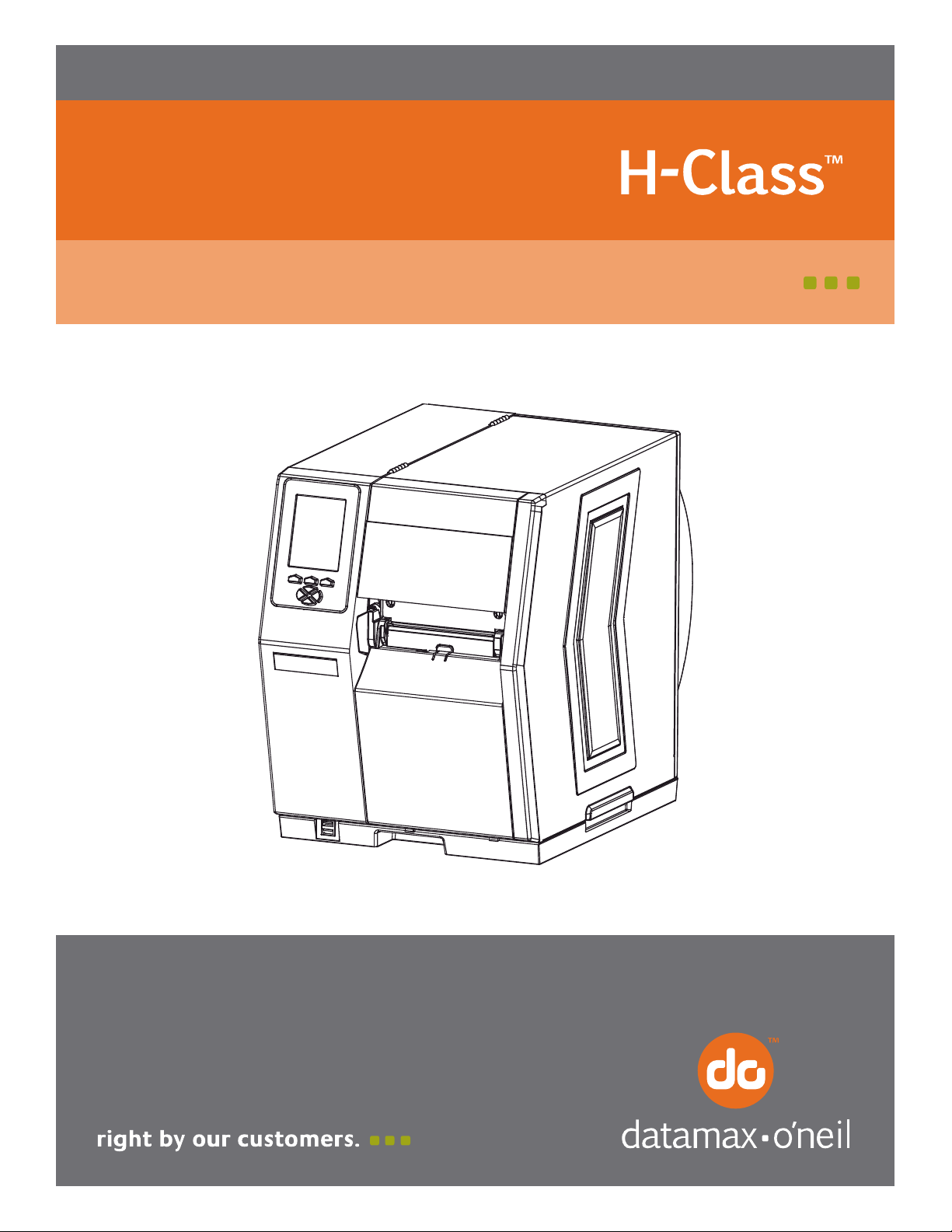

Contents of the Kit

This kit contains the following items:

Rewinder Assembly

Media Retainer

Core Adapter

Mounting Screws (3)

Arc Plate

Media Clasp

4

1

2

3

5

6

Tools Required

To install this option, you will need a Phillips screwdriver.

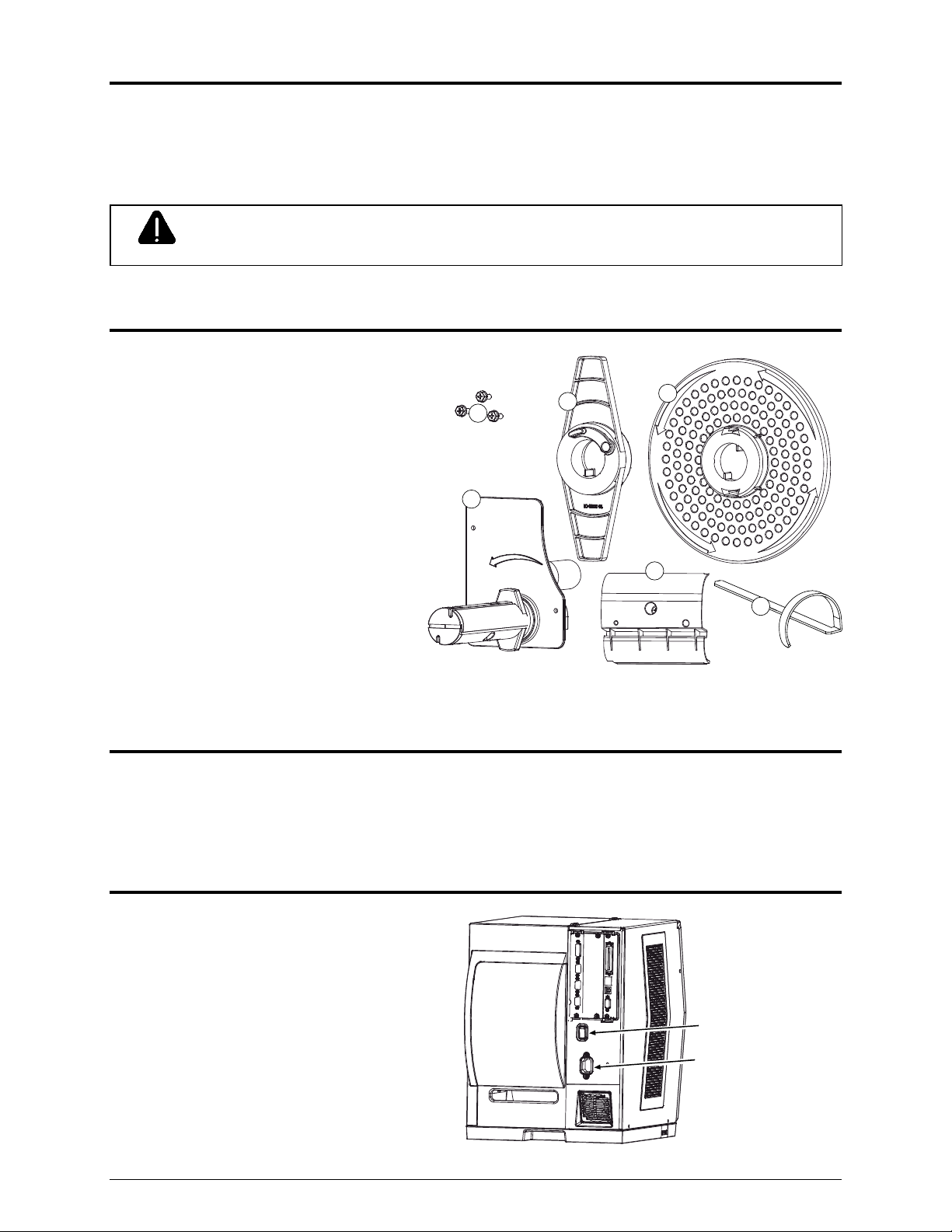

Step 1: Preparing the Printer

A) Turn ‘Off’ the Power Switch and

unplug the power cord from the AC

Receptacle.

Power Switch

AC Receptacle

1

Page 4

B) Press down on the Catch, then pull

forward to remove the Door.

C) Raise the Access Cover and remove

your media from the printer. Then,

remove the Thumbscrew and Tear

Plate. (Alternately, if equipped with a

Cutter or Present Sensor, remove that

Catch

Door

Tear Plate

Access

Cover

device.)

D) Remove the Cover Screw and the

Cover Plate.

Thumbscrew

Cover Screw

Cover Plate

2

Page 5

Step 2: Installing the Option

A) Align the Rewinder Assembly (Item

) to the Center Plate opening then,

while carefully seating it into the

Center

Plate

Power

Receptacle

Power Receptacle, insert the

Rewinder Assembly.

Rewinder

Assembly

Mounting

Screws

B) Using the three Mounting Screws

(Item ), secure the Rewinder

Assembly to the Center Plate.

C) Given the available uses of this option, proceed with the installation according to the needs of your

application:

To rewind onto empty media cores, proceed to D; or,

To rewind directly onto the Rewinder Hub, go to Step 3: “Using the Option.”

D) Insert the Tabs of the Core Adapter

(Item ) into the Rewinder Hub

Slots then slide the Core Adapter

onto the Rewinder Hub.

E) Grasp, pull and squeeze to collapse

the Rewinder Hub then slide the

Core Adapter forward until it snaps

into position over the Backstops.

Rewinder Hub

Core

Adapter

Tabs

Rewinder

Hub Slots

Backstops

3

Page 6

F) Slide a three-inch diameter Media

Core onto the Core Adapter Collar.

(Note that the width of the Media Core

should be at least as wide as the

media you will be winding.)

Core

Adapter Collar

G) Open the Latch. Slide the Retainer

(Item ) onto the Rewinder Hub so

that it securely captivates the Media

Core, and then close the Latch.

Step 3: Using the Option

A) To use this option, proceed according

Media

Core

Rewinder

Latch

Retainer

Hub

Media Core

to your application:

To wind printed labels onto a

media core, attach the Arc Plate

(Item ) to the Front Housing

with the built-in Screw; or,

To wind liner material only, attach

your Peel and Present device to

the printer.

Front Housing

Arc Plate

Screw

4

Page 7

B) Load Media as you normally would, but extend

about 20 inches (50 cm) of it from the printer –

then proceed according to your application:

Media

To wind onto a Media Core –

Follow the directional arrows on the Core

Adapter and wrap the Media in a

counterclockwise direction around the

Media Core then secure the leading edge

using Tape. Rotate the Hub by hand to

take up any slack in the media. There

should be at least 2 or 3 full wraps of the

media on the empty core before starting

printing to ensure tight rewinded rolls.

To wind onto the Rewinder Hub –

Remove the labels from the extended

portion of media and crease the leading

edge of this Liner Material.

Core

Adapter

creased

leading edge

Media

(Labels & Liner)

Rewinder

Hub

Tape

Media

Core

Slots

Wrap the Liner Material in a

counterclockwise direction around the

Rewinder Hub and insert the creased

leading edge into one of its Slots. Insert

the Media Clasp (Item ) into the Slot

over the creased leading edge of the

Liner Material and around the Rewinder

Hub.

Liner

Material

Media

Clasp

5

Page 8

C) Plug the power cord into the AC Receptacle

and turn ‘On’ the Power Switch.

(Depending upon its database configuration

and other attached devices, the printer may

sense and enable the option. In this case, the

Rewinder will slowly turn for about thirty

Power Switch

AC Receptacle

seconds.)

D) Press the FEED Key on the Front Panel while

watching the Rewinder Hub, and then proceed

according to your observations:

If the Rewinder Hub turns, this completes

the installation; or,

If the Rewinder Hub does not turn, proceed

to Step 4: “Configuring the Printer.”

Step 4: Configuring the Printer

Front Panel

FEED

Key

Note: In the following procedure, consult the Operator’s Manual for detailed front panel instructions.

Configure the printer for the option, as follows:

A) Press the MENU Button on the printer’s front panel.

B) Using the DOWN Button, scroll to PRINTER OPTIONS then press the RIGHT Button.

C) Using the UP Button, scroll to REWINDER then press the ENTER Key.

D) Using the DOWN Button, scroll to ENABLE then press the ENTER Key.

E) Press the EXIT Key then, at the SAVE CHANGES? prompt, select YES to complete the installation.

F) Turn the Power Switch ‘Off’ and ‘On’ to reset the printer and complete the configuration.

6

Page 9

Removing Stock from the Internal Rewinder

The Internal Rewinder allows you to wind an 8-inch (203 mm) outer diameter roll of media or liner.

Proceed according to your application to remove material from the rewinder:

To remove rolled media, open the Latch on the Media Retainer, remove the Media Retainer, and then

slip the rolled media and core off the Core Adapter; or,

To remove rolled liner material, grasp the roll, squeeze, pull, and slip the liner off the Rewinder Hub.

Changing Applications

If your application for the Internal Rewinder changes, proceed according to the printer’s current

configuration to add or remove components as necessary:

If you are currently winding labels onto a media core but want to begin winding liner material directly

onto the hub, open the Latch and remove the Label Retainer. Carefully slide the Core Adapter off the

Rewinder Hub (use a slight rocking motion, if necessary). Afterward, reference Step 3 (above) to

wind onto the hub; or,

If you are currently winding liner material onto the hub but want to begin winding labels onto a media

core, install the necessary components, starting with Step 2, part d (above).

7

Page 10

Loading...

Loading...