Page 1

92-2435-01 Rev.C

Linear Scanner Option

Page 2

Page 3

Overview

With the H-Class Linear Scanner option and menu-selectable functions that include voiding and

replacement generation, labels can be interrogated at up to 700 times per second to ensure that correct,

readable symbologies have been printed.

Use the sections of this document to find needed information. As a starting point, if your Linear Scanner

arrived factory-installed, see “Controls and Features, Performance, and Configuration” to begin use;

otherwise, proceed to “Installation.”

Installation

If installing the kit, verify the experience level of the installer, the package contents, and the tools needed

before following the steps below.

Only qualified service personnel should perform this installation. For your safety and to

avoid printer damage, always turn OFF the power switch and unplug the AC power cord

CAUTION

before this installation and whenever performing service.

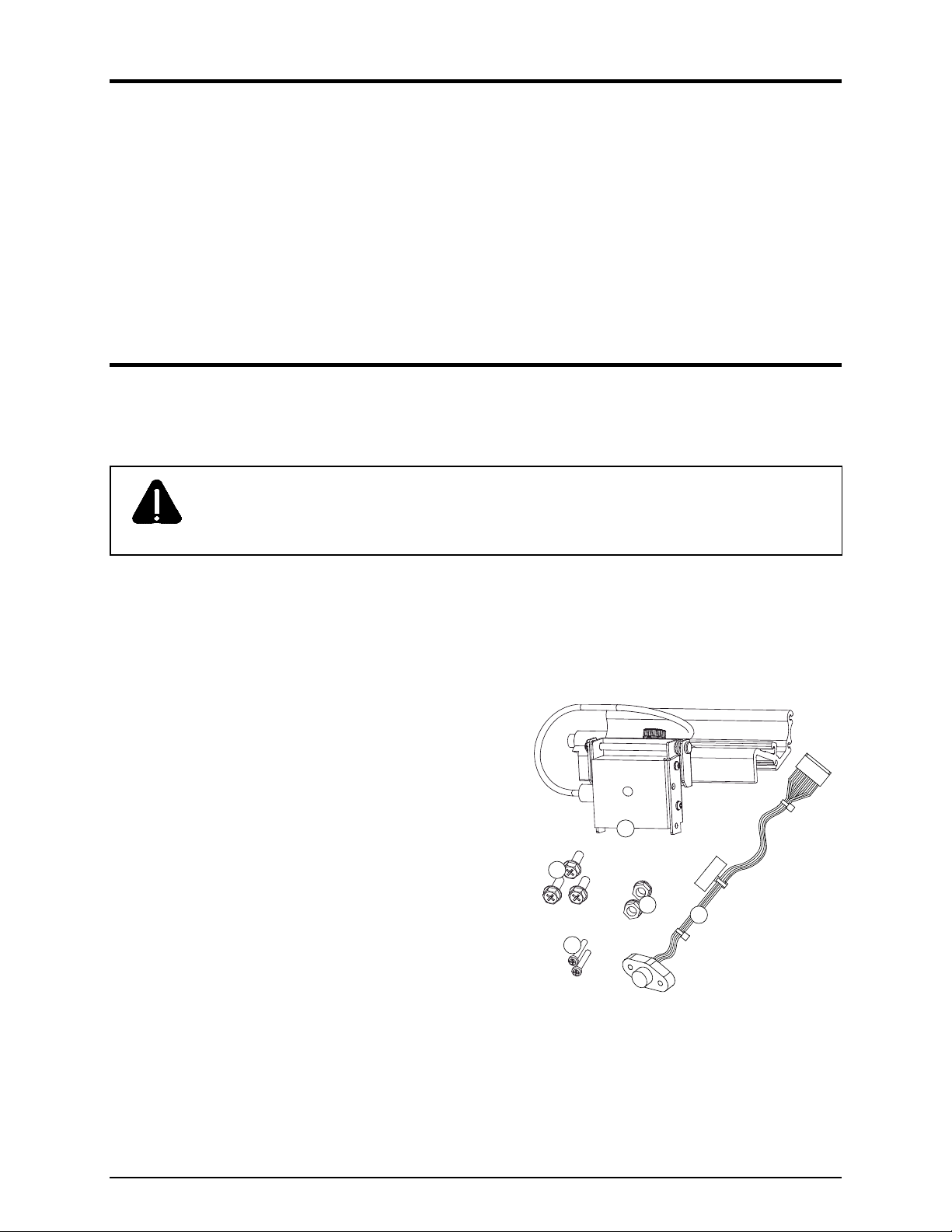

Contents of the Linear Scanner Kit

In addition to this document, this kit contains the following items:

Scanner and Mounting Assembly

Philips Screw (3), M4 x 12

Nut (2), M3 x .5

Philips Screw (2), M3 x 20

1

2

3

5

4

Cable Assembly

Tools Required

To install this option a small standard screwdriver and a Philips screwdriver are needed.

1

Page 4

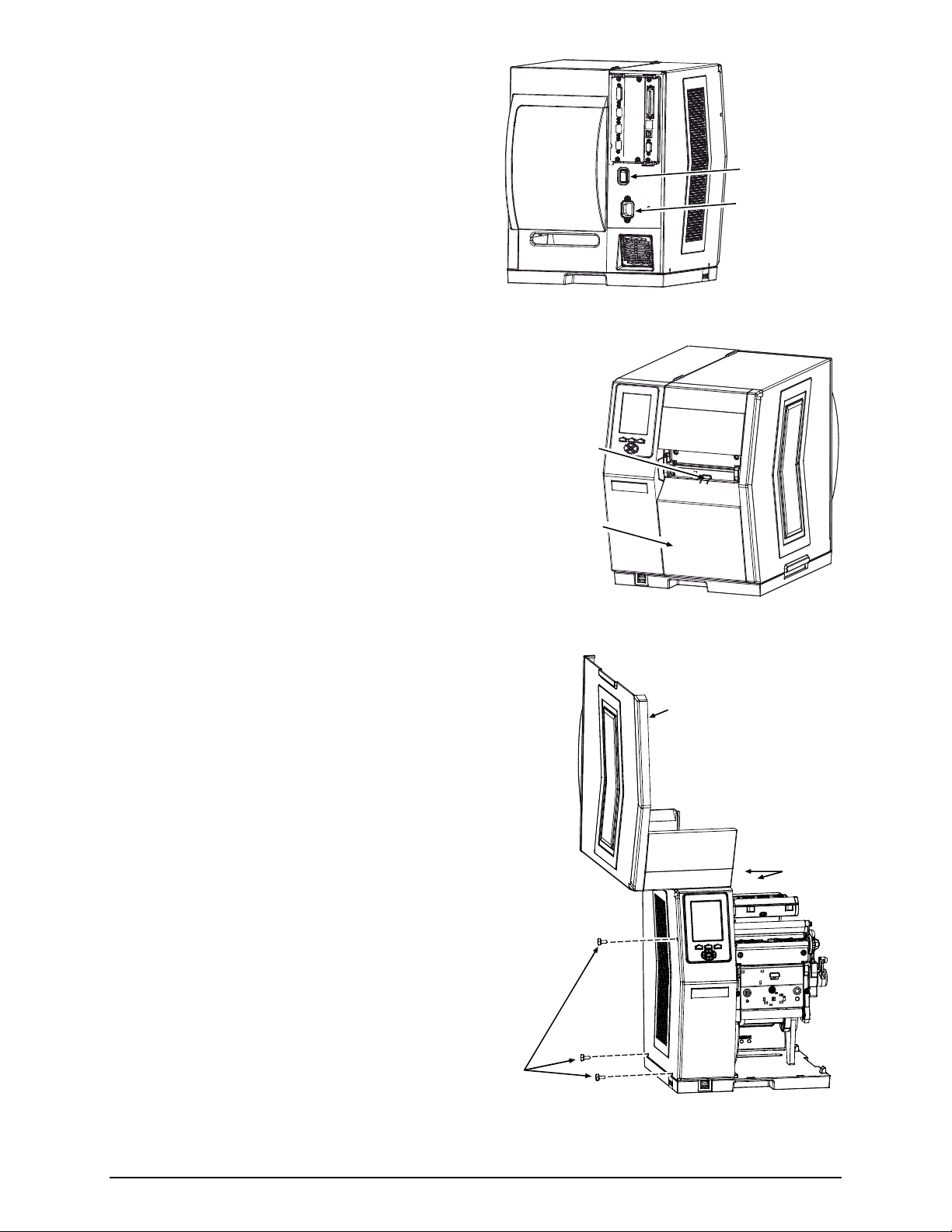

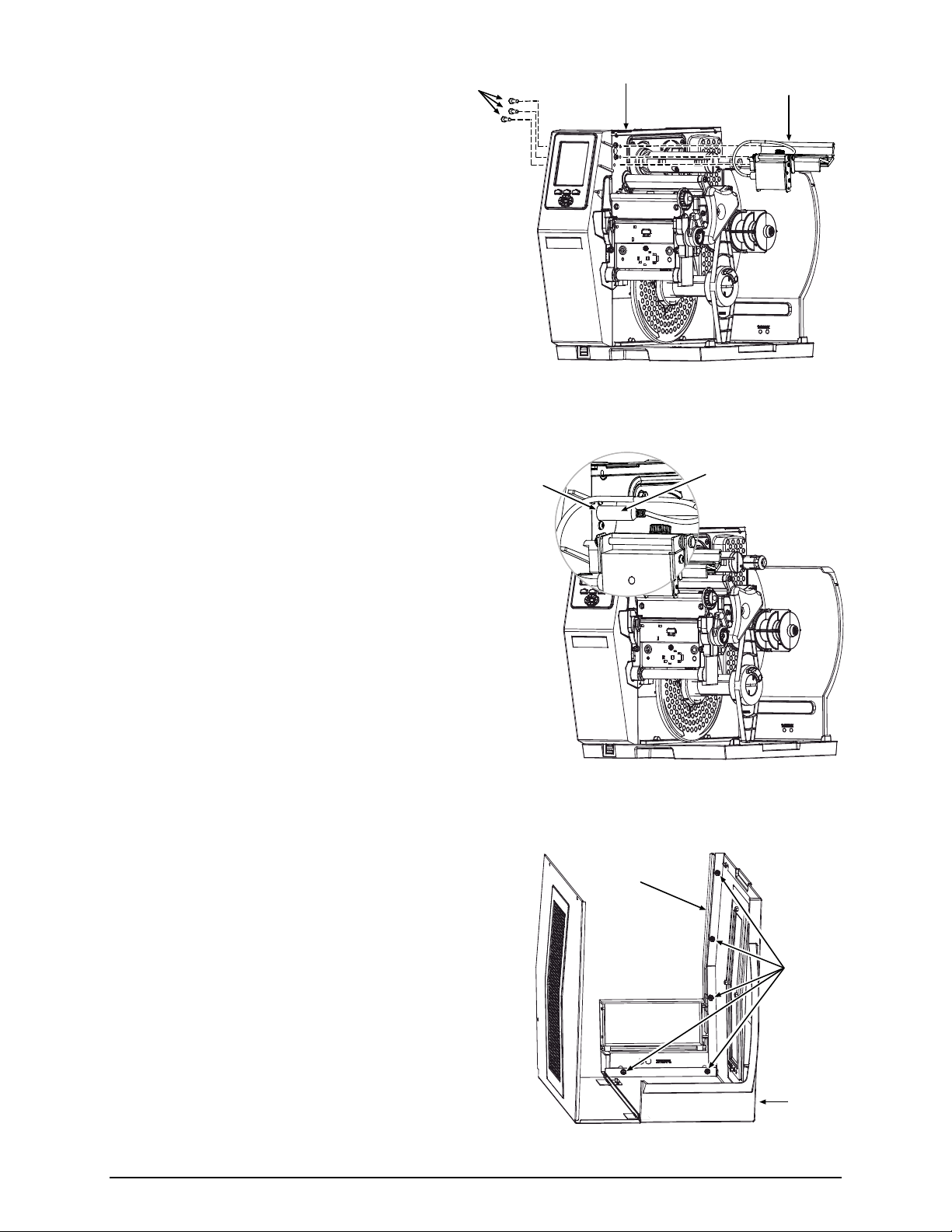

1) Turn OFF the Power Switch and unplug the

power cord from the AC Receptacle.

2) Press down on the Catch, then pull forward to remove

the Door.

Power Switch

AC Receptacle

Catch

Door

3) Raise the Cover. Loosen both Hinge

Screws. Remove the three Cover Screws,

and then lift the Cover off the printer.

Remove any media and ribbon from the

printer.

Cover

Screws

Cover

Hinge

Screws

2

Page 5

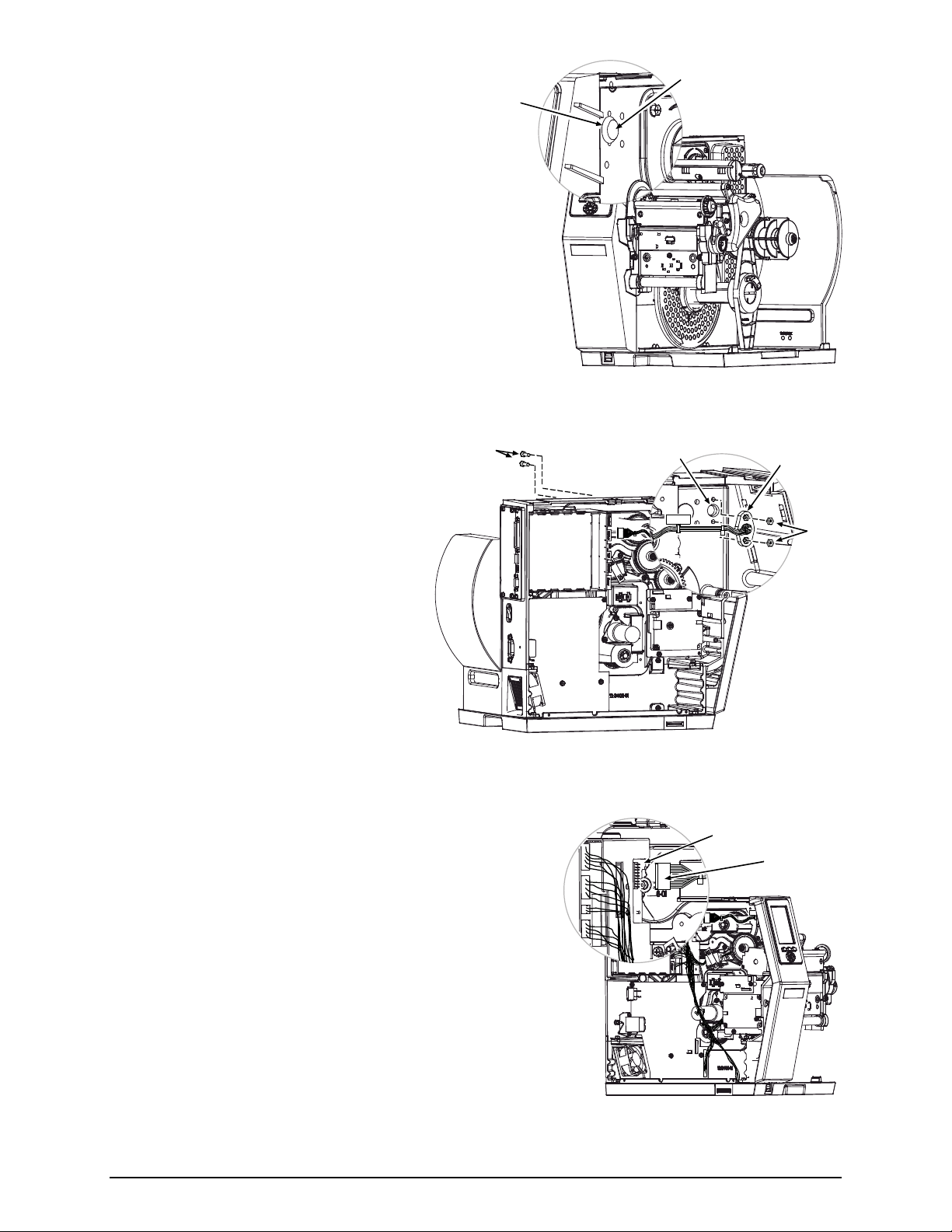

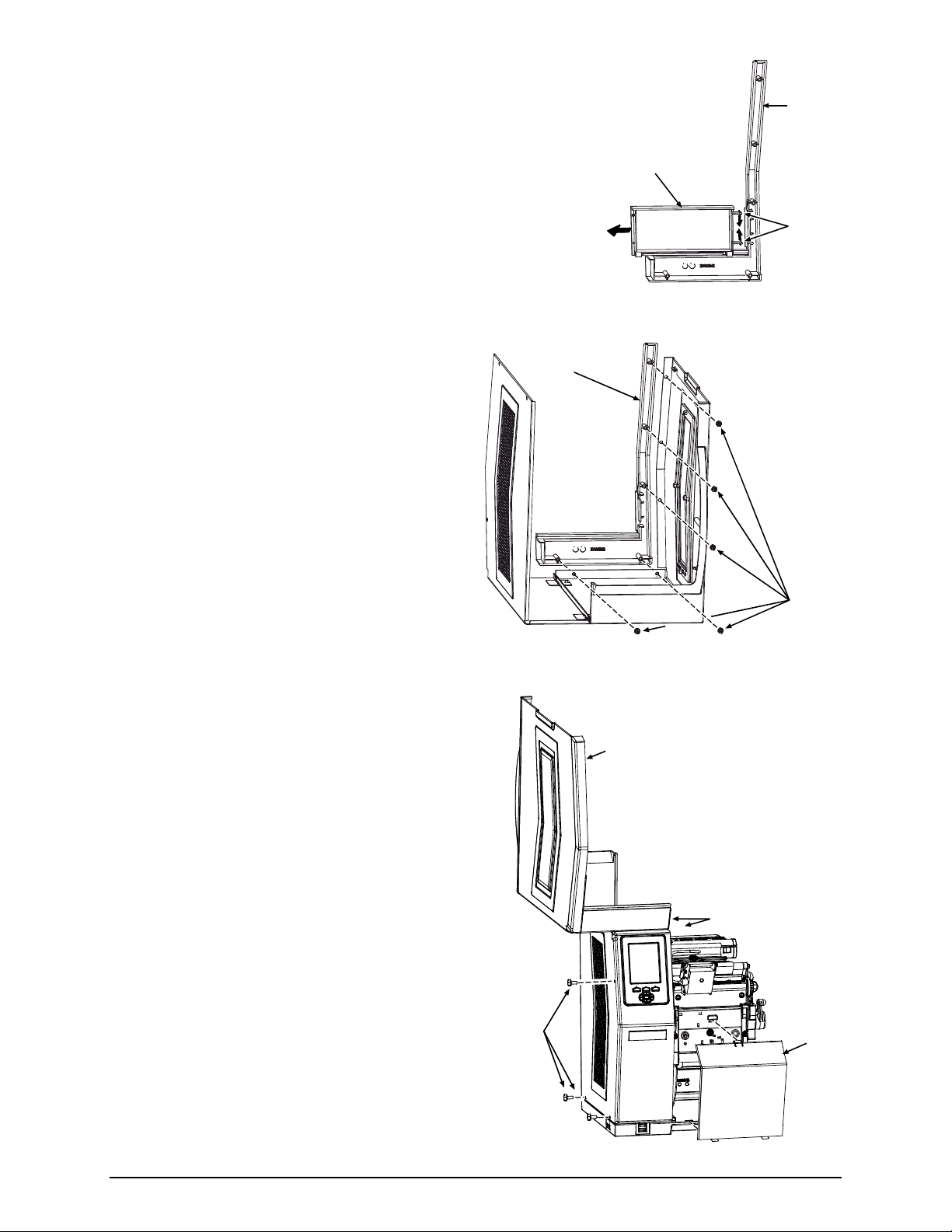

4) Remove the Plug from the Center Plate

Center Plate

Aperture

Plug

Aperture.

5) Secure the mini-din connector of the

Cable Assembly (Item 5) to the Center

Plate Aperture using two Screws (Item

4) and two Nuts (Item 3).

Screws

Center Plate

Aperture

Cable

Assembly

Nuts

6) After routing the Cable Assembly away from movable

parts, attach its 8-pin connector to J13 of the Backplane

CCA.

J13

Backplane

CCA

Cable

Assembly

3

Page 6

7) Secure the Scanner and Mounting

Assembly (Item 1) to the Center Plate

Screws

Center Plate

Scanner and

Mounting Assembly

using three Screws (Item 2).

8) Connect the Scanner Cable to the Center

Plate Connector.

Center Plate

Connector

Scanner

Cable

9) Remove the five Screws that secure the Fascia to the

Cover.

4

Fascia

Screws

Cover

Page 7

Fascia

10) Press the Tabs of the Lens together. Then slide the Lens off

the Fascia. (Store the Lens in a safe place, for future use.)

Fascia

11) Secure the Fascia to the Cover using the five

previously removed Screws.

Lens

Tabs

Screws

12) Lower the Cover onto the printer. Reinstall and

tighten the three Cover Screws. Tighten both

Hinge Screws. Reinstall the Door and lower

the Cover.

Plug the power cord into the AC

Receptacle. Align the scanner; see “Alignment”

section, below.

Cover

Screws

Cover

Hinge

Screws

Door

5

Page 8

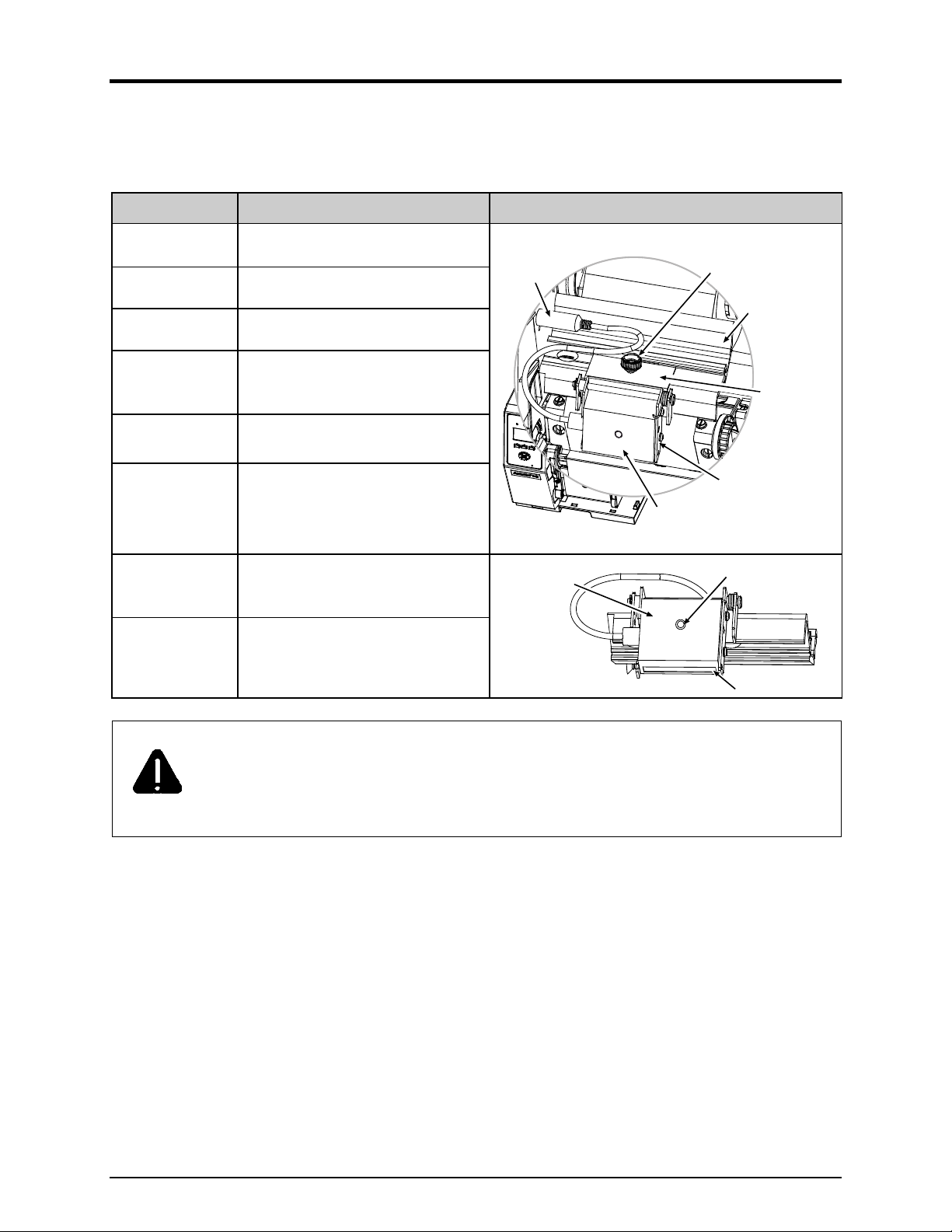

Controls and Features, Performance, and Configuration

This section includes topics on operations.

Controls and Features

Item Function Location

Connector Cable Scanner to printer interface.

Horizontal Mount Lateral position adjustment.

Mounting Bracket Horizontal support.

Spring-loaded holder, also for vertical

Pivoting Mount

Scanner

Thumbscrew

LED

Window

Scanner positioning (scan resolution).

CCD scanning device.

Secures the Scanner to the

Horizontal Mount, for lateral

positioning.

Goes green to signify a “good” read.

Portal for image illumination and

capture; glows red.

The Pivot Mount should never be over-extended. The use of controls, adjustments, or

procedures other than those specified herein may result in hazardous LED light exposure.

CAUTION

Class 1 LED power up to 15 mW in a 0.1 ms pulse at 635-670 nm could be accessible in

the interior of the Linear Scanner.

Connector

Cable

Scanner

Scanner

Thumbscrew

Mounting

Bracket

Horizontal

Mount

Pivoting

Mount

LED

Window

Performance Considerations

Printing with the scanner is a seamless operation; however, consider some important factors that can

affect performance:

6

Page 9

Integrity and Speed

If the primary objective is to ensure that correct data is read over a significant region of the

symbology, maximize integrity by (1) increasing the REDUNDANCY LEVEL or the MIN

READABLE HEIGHT setting, (2) slowing the print speed, and (3) increasing the bar code height.

When emphasizing data accuracy, the allowable maximum throughput rate may be affected.

If the primary objective is to achieve the highest label throughput rate, maximize speed by (1)

decreasing the REDUNDANCY LEVEL or the MIN READABLE HEIGHT setting, and (2)

increasing the print speed. When emphasizing throughput, data reliability may be affected.

Media and Ribbon Selection

For best results use carbon-based inks on matte-finished label stocks to achieve a high print contrast.

Label Layout

For proper recognition, the Linear Scanner must be positioned over the bar codes, and the codes

used and the label layout must meet certain requirements:

The bar codes must be placed in the picket fence orientation, with proper quiet zones, and a

narrow bar resolution that is no less than the scan resolution position.

If encoding the same information in multiple-up bar codes arranged in ordered columns (see

below), allow at least ¼ inch of white space between the rows.

Column

Print

Row

104 104 104

104

104 104

1/4 inch (6.5 mm)

Direction

When printing bar codes on small labels, avoid the possible need for backup repositioning by

placing the code(s) near the leading edge of the label.

Although a reduction of print speed may actually improve throughput, to maintain proper

detection when printing small bar codes at high speeds the following parameters should not be

exceeded:

Minimum Bar Code Height Maximum Print Speed (IPS)*

1/16 inch (1.5 mm) 8

1/8 inch (3 mm) 10

* Inches per Second

7

Page 10

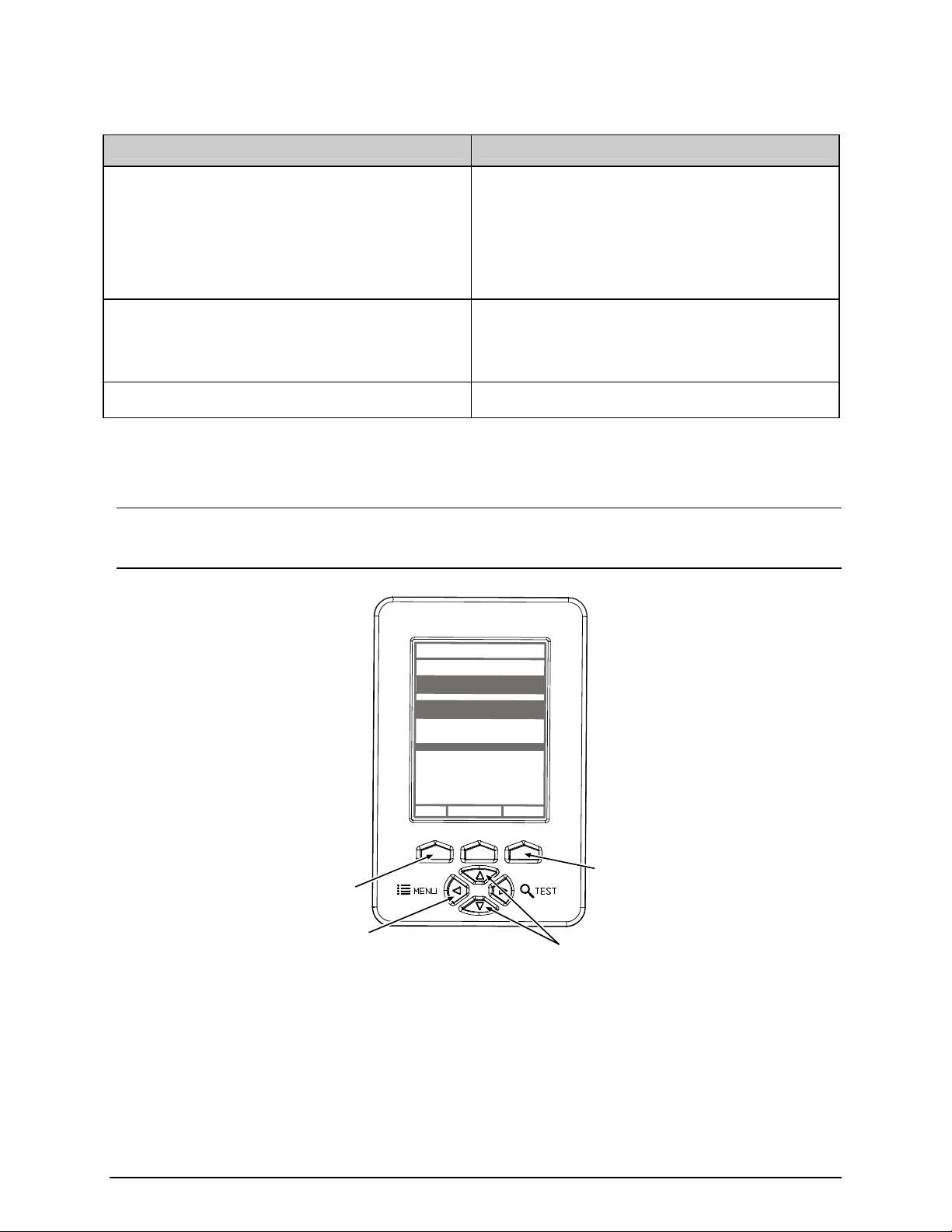

Configuration

A printer equipped with the Linear Scanner arrives with these default settings:

Menu Location Function and Default Setting

MODE = Auto

BARCODES = All, except IATA and codes with

certain addendums

PRINTER OPTIONS SCANNER

SYSTEM SETTINGS FAULT HANDLING

COMMUNICATIONS HOST SETTINGS OPTION FEEDBACK = Disabled

Most settings can be changed via the User Interface, as described below:

BAR CODE COUNT = 00 (Auto Mode)

MIN READABLE HEIGHT = Disabled

REDUNDANCY LEVEL = 2X

IGNORE NO DATA = Disabled

FAULT HANDLING = Standard

VOID DISTANCE = 0.5 Inches

RETRY COUNT = 1

BACKFEED ON CLEAR = Disabled

Note: Before proceeding, ensure that the ADVANCED MENU is selected: Press MENU then go to

SYSTEM SETTINGS MENU MODE ADVANCED MENU and press ENTER.

WED 09:32A 06NOV2006

OFFLINE

PRINTER OPTIONS

MODULES

PRESENT SENSOR

CUTTER

SCANNER

RFID

GPIO PORT

REWINDER

RFID

EXIT

ENTERSYSTEM

ENTER Key

EXIT Key

MENU Button

UP & DOWN

Buttons

To change SCANNER settings –

1) Press MENU. Use DOWN or UP to scroll to PRINTER OPTIONS, and then press ENTER.

2) Scroll to SCANNER and then press ENTER. (See table below for listing.)

3) When finished, press EXIT and then YES at the SAVE CHANGES prompt to complete setup.

8

Page 11

Scanner Menu Item Description

MODE

ENABLED

Sets device power-up detection:

Detection is performed: If found, normal printing and scanning occurs; or, if

not found, a fault will be declared.

DISABLED No detection is performed and no scanning functions will occur.

AUTO

BARCODES

Detection is attempted: If found, normal printing and scanning occurs; or, if

not found, no fault will be declared and no scanning will occur.

Specifies the bar code type(s) for scanning, where:

CODE 39

IATA

CODABAR

INTERLEAVED 2 OF 5

INDUSTRIAL 2 OF 5

CODE 93

CODE 128

MSI/PLESSEY

EAN(13/8)

EAN(13/8)+2

Is / are the type(s) to be checked; see the Class Series 2 Programmer’s

Manual for symbology details.

Note: Enabling only the symbologies to be examined maximizes

throughput.

EAN(13/8)+5

UPC(A/E)

UPC(A/E)+2

UPC(A/E)+5

BARCODE COUNT

(0 – 99)

00

MIN READABLE HEIGHT

1/16 – ½ in (1.5 – 12.5

mm)

DISABLED Operation switches to REDUNDANCY LEVEL.

Sets the number of codes per label to be read.

The scanner will count the specified number (1 to 99) of bar codes per label;

if all are not present a fault is declared.

The default setting (00) enables Auto Mode; this mode, appropriate for most

applications, calculates the number of bar codes present and permits a

variable number of codes to be read per label. See the note below (and

Label Layout) for possible exceptions.

Note: If sent as bitmaps (i.e., imaged) to the printer, enter the

minimum count to be read on each label. Check with your

software application if questioning bar code generation.

Ensures bar code integrity by establishing a minimum vertical read

distance. (The optimum scan rate and consecutive read count for this

distance will be automatically calculated.)

This distance must have identical decodes for the bar code to pass (e.g., a

setting of ¼ requires that .25 inches of the code be 100% readable).

Note: Setting should not exceed 50% of the measured bar code

height.

(continued)

9

Page 12

Scanner Menu Item Description

REDUNDANCY LEVEL

(1X – 6X)

READ BARCODE 2X

AUTO Operation switches to MIN READABLE HEIGHT.

IGNORE NO DATA

DISABLED Checks for correct bar code data in the bar code(s).

ENABLED Ignores the data present in the bar code(s).

SET DEFAULTS

YES / NO

Ensures bar code integrity by specifying a redundant read count.

This count (1 – 6) sets the number of consecutive and identical decodes

that must occur for a bar code to pass.

Allows an override of the verification function, where:

Restores the Linear Scanner settings to the factory default values.

Selecting YES will return these settings:

MODE = Auto

BARCODES = All, except IATA and codes with certain addendums

BAR CODE COUNT = 00 (Auto Mode)

MIN READABLE HEIGHT = Disabled

REDUNDANCY LEVEL = 2X

IGNORE NO DATA = Disabled

To change FAULT HANDLING settings –

1) Press MENU. Press DOWN or UP to scroll to SYSTEM SETTINGS, and then press ENTER.

2) Scroll to FAULT HANDLING and then press ENTER. (See table below for listing.)

3) When finished, press EXIT and then YES at the SAVE CHANGES prompt to complete setup.

Fault Handling Menu Item Description

LEVEL

NO REPRINT

Determines the amount of interaction required to proceed after a fault.

Printing stops and a fault message is displayed. Following correction of the

problem, FEED must be pressed to clear the fault, but the label in process is

not reprinted.

STANDARD

Printing stops and a fault message is displayed. Following correction of the

problem, FEED must be pressed to clear the fault then the label in process is

reprinted.

VOID AND RETRY

Depending upon the RETRY COUNT (see below), one of the following:

• If the count has not been exceeded, VOID is printed (see VOID

DISTANCE) on the failed label and reprinting automatically occurs;

• If the count has been exceeded, printing stops and a fault message is

displayed. Following correction of the problem, FEED must be pressed to

clear the fault before the label in process is reprinted; or,

• If CANCEL is pressed, reprinting is optional: to reprint, press NO; or, to

cancel the reprint, press YES (and press YES again to cancel the batch.)

(continued)

10

Page 13

Fault Handling Menu Item Description

Increases throughput when bar codes reside near the trailing edge (in the

print direction) of the label.

DELAYED SCAN FAULT

VOID RETRY & CONT.

Note: If unreadable, the fault will occur after the next label prints; the

label immediately following a faulted label will not be scanned;

and, since VOID AND RETRY and REPRINT are automatically

disabled, the job can only be cancelled.

VOID is printed if faulted, with reprint attempts occurring automatically, until

the RETRY COUNT has been exceeded and then that label will be skipped

(discarded) and printing will continue to the next label in queue.

VOID DISTANCE

Sets the distance to backup and print VOID on a faulted label.

This distance, measured from the trailing edge (in the print direction) of the

(0.10 to 2.00 in.)

RETRY COUNT

label, indirectly establishes the font size of the message.

Note: VOID will not be printed if insufficient text space exists, or if the

fault occurred after the label was printed.

Sets the number of reprint attempts.

(0 - 3) If the last label printed in this count has been voided, a fault will be declared.

BACKFEED ON CLEAR

Determines the printer's response after a fault is cleared.

ENABLED After fault clearing, backup label positioning will occur.

After fault clearing, no backup label positioning will occur. The printer will

assume that the current position is correct.

DISABLED

Note: If reloading media, the label must be placed in its presented

position.

To change HOST SETTINGS (for data capturing applications) –

Note: Bi-directional cabling and communications must be used.

1) Press MENU. Use DOWN or UP to scroll to COMMUNICATIONS, and then press ENTER.

2) Scroll to HOST SETTINGS and then press ENTER.

3) Scroll to OPTION FEEDBACK and then press ENTER.

4) Select SCANNER and then press ENTER.

5) Press EXIT and then YES at the SAVE CHANGES prompt to complete setup.

Once enabled, the printer will output data to the active port in the form <A;B;C;D;E;F>[CR]; where:

11

Page 14

A -

Is the device type: S = Linear Scanner

B C D E -

F -

Is the resulting status: C = entire label complete; F = faulted (failed) label; and, U = unknown.

Is the number of expected reads, given in two characters.

Is the number of good reads, given in two characters.

Is the printer’s internal Job and Sub Job Identifier, given in four characters each.

Is the data that was read, delimited with semicolons (;) on multiple reads.

Maintenance, Alignment, and Scan Resolutions

Maintenance

CAUTION

While there is no scheduled maintenance requirement, as debris accumulates and performance declines,

For your safety and to avoid printer damage, always turn OFF the power switch and

unplug the AC power cord before performing service.

clean the Scanner as follows:

1) Turn OFF and unplug the printer.

2) Using a Cotton Swab, lens tissue, or lint free cloth dampened with water, carefully wipe the

Window clean (see illustration). Use care

. Avoid excessive moisture, which can penetrate the

housing then obscure the Window. (While the use of another cleaning fluid is not recommended, if

necessary, a neutral detergent or ethanol is preferable; never use bleach at any strength because

damage may result.)

Scanner

Cotton Swab

Window

12

Page 15

Alignment

Although normally not required if factory-installed, scanner alignment may be necessary under certain

circumstances:

If the scanner option was just field-installed;

If the original alignment has been changed (e.g., if the scanner was lowered to the 5-Mil Position); or,

If the exit angle of the labels has changed (e.g., if an output device such as an external rewinder has

been added).

CAUTION

The use of controls, adjustments, or procedures other than those specified herein may

result in hazardous LED light exposure. Class 1 LED power up to 15 mW in a 0.1 ms

pulse at 635-670 nm could be accessible in the interior of the Linear Scanner.

Follow the steps below to align the Linear Scanner:

Note: If scanning 5-Mil bar codes, change the scanner’s position before proceeding; see “Scan

Resolutions.”

1) Load the printer with four-inch (101 mm) wide media and ribbon. Ensure that the Tear Bar, Peel

Mechanism, or Rewind Plate has been mounted onto the printer. (If using an external rewinder,

attach the labels to that device; see the Operator’s Manual or the manufacturer’s documentation for

details.)

2) Turn ON the printer.

3) Press TEST, and then press it again to produce a Print Quality Label.

Print Quality Label

4) Raise the Printhead Assembly. Position a Print Quality Label squarely under the Printhead Assembly,

so that only 1/8-inch (3 mm) of the Picket Fence Bar Code is evenly visible (as shown below). Lower

and lock the Printhead Assembly.

13

Page 16

Scanner

LED

Printhead

Assembly

Picket Fence

Bar Code

Note: Ensure that the Scanner is enabled in the following steps.

5) Press MENU. Press DOWN or UP to scroll to DIAGNOSTICS and then press Enter. Scroll to

OPTIONS TESTING and press ENTER. Scroll to TEST SCANNER and press ENTER. Select

ALIGNMENT TEST and press ENTER.

6) Observe the LED (or the displayed SCAN COUNT) then proceed accordingly:

If the green LED is illuminated (or if the count increments rapidly), press EXIT to end the test (see

“Troubleshooting” if problems persist); or

If the green LED is not illuminated (or if the numbers do not increment, or increment slowly),

proceed according the Scan Position:

• 10-Mil Scan Position, go to Step 7; or,

• 5-Mil Scan Position, go to Step 9.

Note: When making adjustments, avoid contact with the Scanner Window; otherwise, see

Maintenance for cleaning details.

7) Loosen the Thumbscrew and then slide the Scanner to the rightmost position on the Mounting

Bracket.

14

Page 17

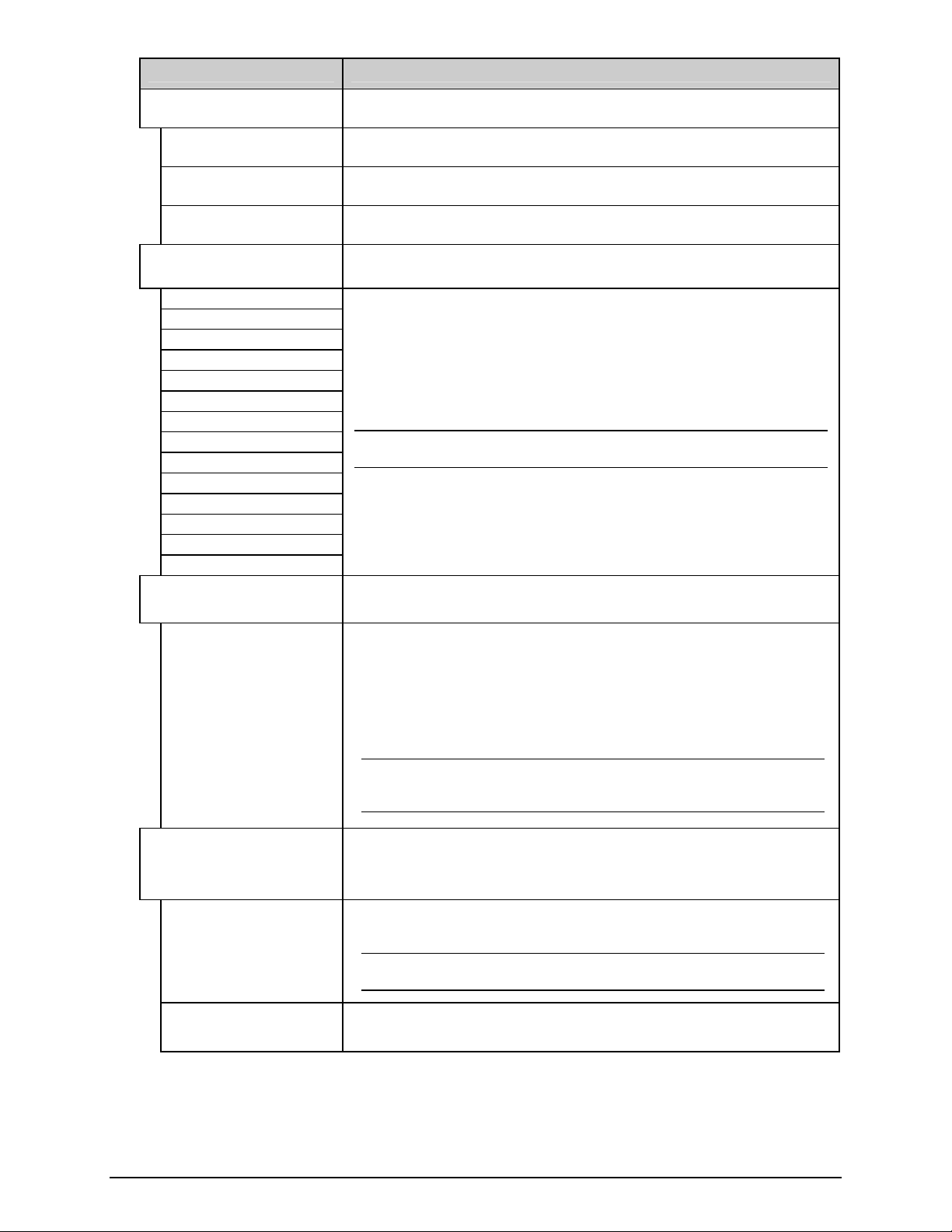

8) Slightly raise the Pivoting Mount. Loosen the Locking Screws and the Mounting Adjustment Screw

enough to allow the Scanner to be positioned. Carefully lower the Pivoting Mount. Re-center the

Scanner over the label and tighten the Thumbscrew.

Locking Screws

Mounting

Adjustment Screw

Pivoting Mount

9) Proceed according to the Scan Position:

10-Mil Position: Without moving the Pivoting Mount,

pull the bottom of the Scanner outward and then,

while observing the LED (or the SCAN COUNT),

Scanner

Pivoting

Mount

slowly pivot the bottom of the Scanner inward until the

green LED illuminates continuously (or the count

increments rapidly).

5-Mil Position: Without moving the Pivoting Mount,

push the top of the Scanner inward and then, while

observing the LED (or the SCAN COUNT), slowly

pivot the top of the Scanner outward until the green

LED illuminates continuously (or the count increments

rapidly).

Scanner

Pivoting

Mount

Scanner

15

Page 18

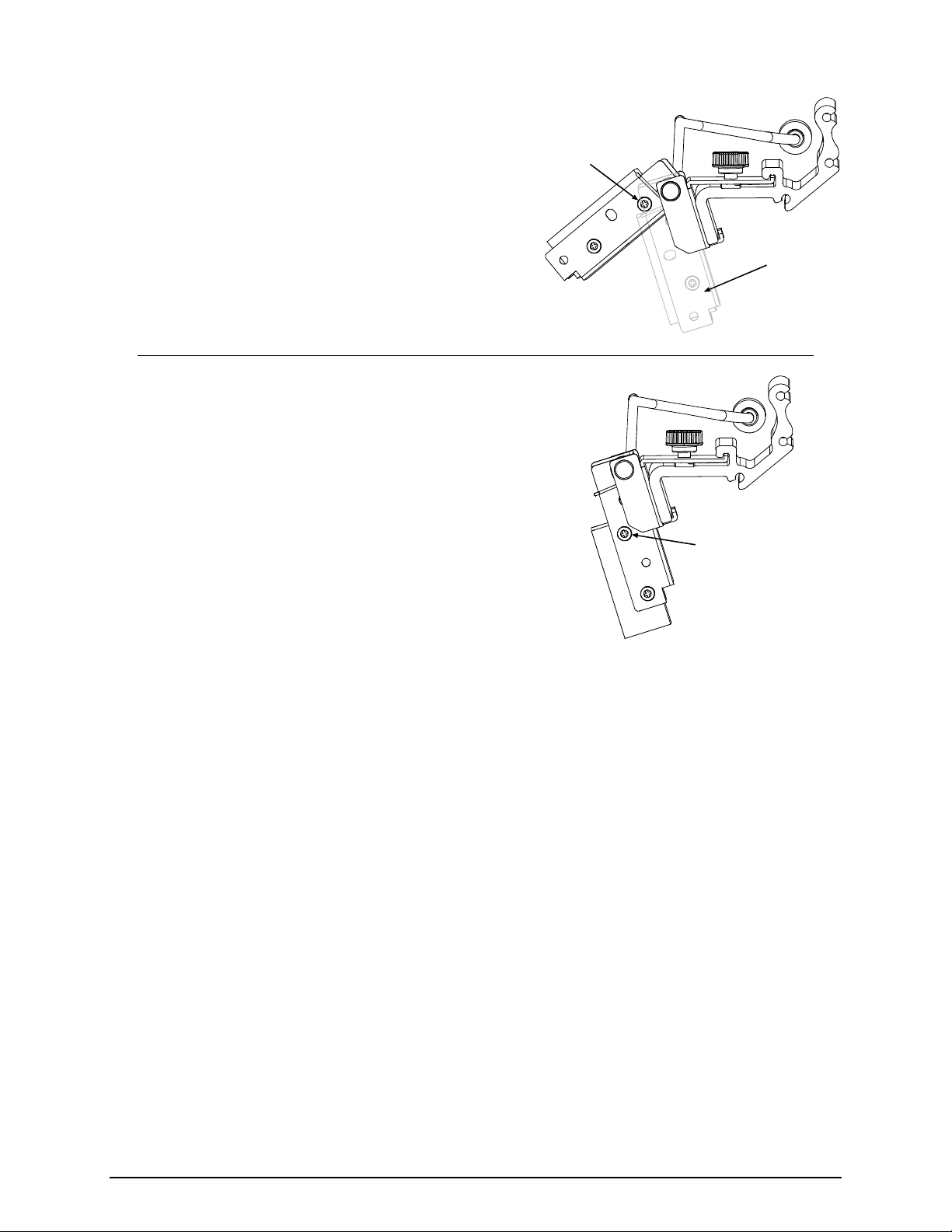

10) Proceed according to the Scan Position:

10-Mil Position: Carefully tighten the Mounting Adjustment

Screw.

Mounting

Adjustment Screw

5-Mil Position: Carefully tighten the Locking Screw on the right

side of the Scanner.

Locking Screw

16

Page 19

11) Proceed according to the Scan Position:

10-Mil Position: Carefully raise the Pivoting Mount

and then tighten the Locking Screw. Carefully lower

the Pivoting Mount.

5-Mil Position: Carefully tighten the Mounting Adjustment

Locking

Screw

Pivoting

Mount

Screw.

Mounting Adjustment

Screw

17

Page 20

12) Proceed according to the Scan Position:

10-Mil Position: Loosen the

Thumbscrew and slide the Scanner to

the rightmost position on the Mounting

Bracket. Carefully raise the Pivoting

Mount and then tighten the left Locking

Mounting

Bracket

Thumbscrew

Pivoting Mount

Screw. Lower the Pivoting Mount.

Locking Screw

Thumbscrew

Mounting

5-Mil Position: Loosen the Thumbscrew

Bracket

Pivoting Mount

and slide the Scanner to the rightmost

position on the Mounting Bracket.

Tighten the left Locking Screw.

Locking Screw

13) Center the Scanner over the label and tighten the Thumbscrew. Observe the LED (or the SCAN

COUNT) then proceed accordingly:

If the green LED is illuminated (or if the count rapidly increments), go to Step 14.

If the green LED is not illuminated (or if the count does not rapidly increment), restart the

alignment beginning at Step 6.

Note: If using the 5-Mil Scan Position, loosen the Mounting Adjustment Screw and the

Locking Screws before returning to Step 6.

14) Press EXIT. Remove the Print Quality Label and load operating media. Clear faults and position the

labels by pressing FEED. With the printer at READY, print a batch of live labels. If Scanner Faults

occur, re-center and secure the Scanner above the bar code(s); and, if problems persist see

“Troubleshooting.” This completes alignment.

18

Page 21

Scan Resolutions

Capable of scanning 5- or 10-mil symbologies, the scan resolution is determined by the Linear Scanner’s

height above the label surface. Most typically set for a 10-mil resolution, in order to scan 5-mil bar codes,

the scanner must be repositioned then aligned as follows:

Note: In the 5-Mil position, the available scan width is reduced to approximately 3.5 inches (89 mm).

1) Turn OFF and unplug the printer.

2) Loosen the Thumbscrew then slide the Scanner to the rightmost position on the Mounting Bracket.

3) Slightly raise the Pivoting Mount. Remove the Locking Screws, and then lower the Scanner. While

supporting the Scanner in the Pivoting Mount, remove the Mounting Adjustment Screw.

Locking Screws

Mounting

Adjustment Screw

Scanner

Pivoting Mount

4) Align the Scanner to the 5-Mil Position Holes in the Pivoting Mount. Install, but do not tighten, the two

Locking Screws. Install the Mounting Adjustment Screw and tighten it only enough to allow the

Scanner to be positioned for alignment.

Pivoting

Mount

Mounting

Adjustment

Screw

Locking

Screws

5-Mil

Position

Holes

Scanner

5) Center the Scanner over the label and tighten the Thumbscrew. Plug in the Power Cord, and then

proceed to “Alignment.”

19

Page 22

Troubleshooting

Use the table below to locate a description of the symptom that best fits the problem and then find a

corresponding solution.

CAUTION

Note: Press FEED to clear a fault.

No faults are generated when

scanning.

The Linear Scanner contains no user serviceable parts. All product service must be

performed by Datamax-O’Neil. Opening the device will void the warranty and could expose

the hazardous LED light.

Problem Possible solution…

If the barcodes are faulty, the scanner may not be enabled: Ensure that the

MODE is set to Auto, or Enabled; see Operation.

The scanner may be disconnected: Turn OFF the printer. Ensure that the

Connector Cable is attached (look for the red glow at power-up); see Operation.

A Scanner Fault is generated

as soon as printer power is

applied to the printer.

Scanner Faults are

generated, but VOID is not

printed on faulted labels.

Note: Normal if the fault

occurs after a label printed.

Unable to capture feedback

data.

The scanner may be disconnected while Enabled: Turn OFF the printer. Ensure

that the Connector Cable is attached (look for the red glow on power-up); otherwise,

to continue printing without scanning, change the MODE setting to Auto, or

Disabled; see Operation.

Ensure the FAULT HANDLING – LEVEL is set to VOID AND RETRY; see

Operation.

Ensure that sufficient text space exists by adjusting the VOID DISTANCE; see

Operation.

Ensure that OPTION FEEDBACK (Host Settings) is enabled; see Operation.

Depending upon your communication interface, ensure that a bi-directional

cable is being used; see the Operator’s Manual.

If using parallel communications, ensure that BI-DIRECTIONAL

(Communications) is enabled; see the Operator’s Manual.

Depending upon your communication interface, ensure that your host device

settings match those of the printer, and that your software program is set to

parse the received data.

(continued)

20

Page 23

Problem Possible solution…

Scanner Faults are generated

when scanning.

Note:

• Faults are normal when

a bar code has defects,

including insufficient

quiet zones that can

make it unreadable.

• Adjust the HEAT and/or

PRINT SPEED settings

to achieve print quality.

Consult your software

application (or make

changes via the User

Interface; see the

Operator’s Manual for

details).

Try the following –

Examine the print quality of the failed label: If the bar code(s) appear(s) to be

free of voids with sufficient quiet zone space, ensure that the scanner is down,

centered over the labels, and secured with the Thumbscrew.

Dirt or debris could be covering the scanner window: Turn OFF the printer.

Examine the window for obstructions and clean if necessary; see

Maintenance.

The bar codes may be too close together: For multiple-up identical bar codes,

ensure sufficient white space between rows; see Operation.

Ambient lighting could adversely be affecting readability: Reduce / redirect

bright light sources, or increase light in dim areas.

Reflected light off the media may be blinding the optics: Ensure that the label

stock has a matte finish, and not a reflective or glossy surface; see Operation.

The label exit angle may have changed: Ensure that the Tear Bar, Peel

Mechanism, or Rewind Plate has been mounted to the printer and that the

label pathway is unobstructed; see the Operator’s Manual for details.

Current scanner settings may be too restrictive: Try decreasing the MIN

READABLE HEIGHT or REDUNDANCY LEVEL setting, lowering the print

speed, or increasing the height of the bar code; see Operation.

The bar code may not be recognized: Ensure that the symbology is

supported; see Specifications.

The symbology may not be generated by as a font: Bitmapped bar codes or

those containing certain addendums must be specified by number (BAR

CODE COUNT in the menu); see Operation.

The focal length may be incorrect for the bar code resolution: Consult your

software application for the bar code X dimension, and then ensure the scan

position matches and if not change it; see Maintenance.

If problems persist, yet the bar codes are readable on other devices, scanner

misalignment is possible; see Alignment. If you have questions, please contact

Datamax-O’Neil Technical Support.

21

Page 24

Specifications

Physical

Case Material Steel (Black)

Dimensions (L x H x W) 47 x 20 x 55 mm (1.95 x 0.78 x 2.2 in)

Cable Length 7.0 inches with 8 pin Mini DIN connection

Mini DIN Connector

Optical

Scan Rate 700 scans per second ±10%

Wavelength of LED Illumination 660 nanometers

Read Sensor CCD linear array

Narrow Bar Resolution Mounting position dependent: 10-mil or 5-mil

Maximum Character Input 51 digits

Maximum Scanning Width 4.0 inches (101 mm) @ the10-Mil position; and,

Pin Number: Signal:

1 +5 VDC

2 TXD

3 Trigger

4 RTS

5 Signal Ground

6 Chassis Ground

7 RXD

8 CTS

3.5 inches (89 mm) @ the 5-Mil position.

8-pin Mini DIN Connector

MD-80

Minimum Print Contrast Signal 0.45 (min. background reflectance of 70%)

Symbology Orientation Picket fence

Electrical

Operating Voltage +5 VDC + 5%

Current:

Operating 158 mA typical, 220 mA maximum

Static 150 mA maximum

Surge 3 A maximum

Environmental

Temperature:

Operating

Storage

0 to +40 C (+32 to +104 F)

-10 to +60 C (+14 to +140 F)

Humidity (non-condensing):

Operating 20 to 80%

Storage 20 to 90%

Ambient light restrictions: Fluorescent or incandescent: below 5 kilolux

Supported Symbologies*

Codabar (NW-7) Code 39 Code 93

Code 128 Industrial 2 of 5 Interleaved 2 of 5

MSI / Plessey WPC (UPC / EAN / JAN)* IATA

* Bitmapped images and UPC 2 & 5 digit addendums only readable when specified by number in BARCODE COUNT.

22

Page 25

Warranty Information

Warranty Service Procedures

Datamax-O’Neil warrants to Purchaser that under normal use and service, the Scanner purchased

hereunder shall be free from defects in material and workmanship for a period of one year (365 days)

from the date of shipment by Datamax-O’Neil. Expendable and/or consumable items or parts such as

lamps and fuses, are not covered under this warranty. This warranty does not cover equipment or parts

that have been misused, altered, neglected, handled carelessly, or used for purposes other than those for

which they were manufactured. This warranty also does not cover loss, damages resulting from accident,

or damages resulting from unauthorized service.

If a defect should occur during the warranty period, the defective unit shall be returned, freight and

insurance prepaid, in the original shipping container to:

Datamax-O’Neil Corporate Headquarters

4501 Parkway Commerce Boulevard

Orlando, Florida USA 32808

A Return Material Authorization (RMA) number must be issued before the product can be returned. To

open an RMA, please call the Datamax-O’Neil Technical Support Department at (407) 523-5540. Include

your RMA number on the outside of the box and on the shipping document. Include a contact name,

action desired, a detailed description of the problem(s), and media examples when possible with the

defective unit. Datamax-O’Neil shall not be responsible for any loss or damages incurred in shipping. Any

warranty work to be performed by Datamax-O’Neil shall be subject to Datamax-O’Neil’s confirmation that

such product meets Datamax-O’Neil warranty. In the event of a defect covered by its warranty, DatamaxO’Neil will return the repaired or replaced product to the Purchaser at Datamax-O’Neil’s cost.

With respect to a defect in hardware covered by the warranty, the warranty shall continue in effect until

the end of the original warranty period, or for ninety (90) days after the repair or replacement, whichever

is later.

General Warranty Provisions

Datamax-O’Neil makes no warranty as to the design, capability, capacity or suitability of any of its

hardware, supplies, or software.

Software is licensed on an “as is” basis without warranty. Except and to the extent expressly provided in

this warranty and in lieu of all other warranties, there are no warranties, expressed or implied, including,

but not limited to, any warranties of merchantability or fitness for a particular purpose.

Purchaser shall be solely responsible for the selection, use, efficiency and suitability of Datamax-O’Neil’s

products.

Limitation of Liability

In no event shall Datamax-O’Neil be liable to the purchaser for any indirect, special or consequential

damages or lost profits arising out of or relating to Datamax-O’Neil’s products, or the performance or a

breach thereof, even if Datamax-O’Neil has been advised of the possibility thereof. Datamax-O’Neil’s

liability, if any, to the purchaser or to the customer of the purchaser hereunder shall in no event exceed

the total amounts paid to Datamax-O’Neil hereunder by the purchaser for a defective product.

In no event shall Datamax-O’Neil be liable to the purchaser for any damages resulting from or related to

any failure or delay of Datamax-O’Neil in the delivery or installation of the computer hardware, supplies or

software or in the performance of any services.

Some states do not permit the exclusion of incidental or consequential damages, and in those states the

foregoing limitations may not apply. The warranties here give you specific legal rights, and you may have

other legal rights which vary from state to state.

23

Page 26

Loading...

Loading...