Page 1

92-2423-01 Rev.B

HD Peel & Present Option

Page 2

Page 3

Overview

This document describes the contents, installation, and use of the Heavy Duty Peel and Present option

for the H-Class printer. After verifying the contents of the kit and the tools needed, follow the steps below

to install and begin using the option. A maintenance procedure is also included, so keep this

documentation for future reference.

For your safety and to avoid equipment damage, always turn ‘Off’ power and unplug the

CAUTION

printer’s power cord before beginning this installation and when performing service.

Contents of the Heavy Duty Peel and Present Option

This kit contains the following item:

Heavy Duty Peel and Present Assembly

Tools Required

To install this option, you will need a standard screwdriver.

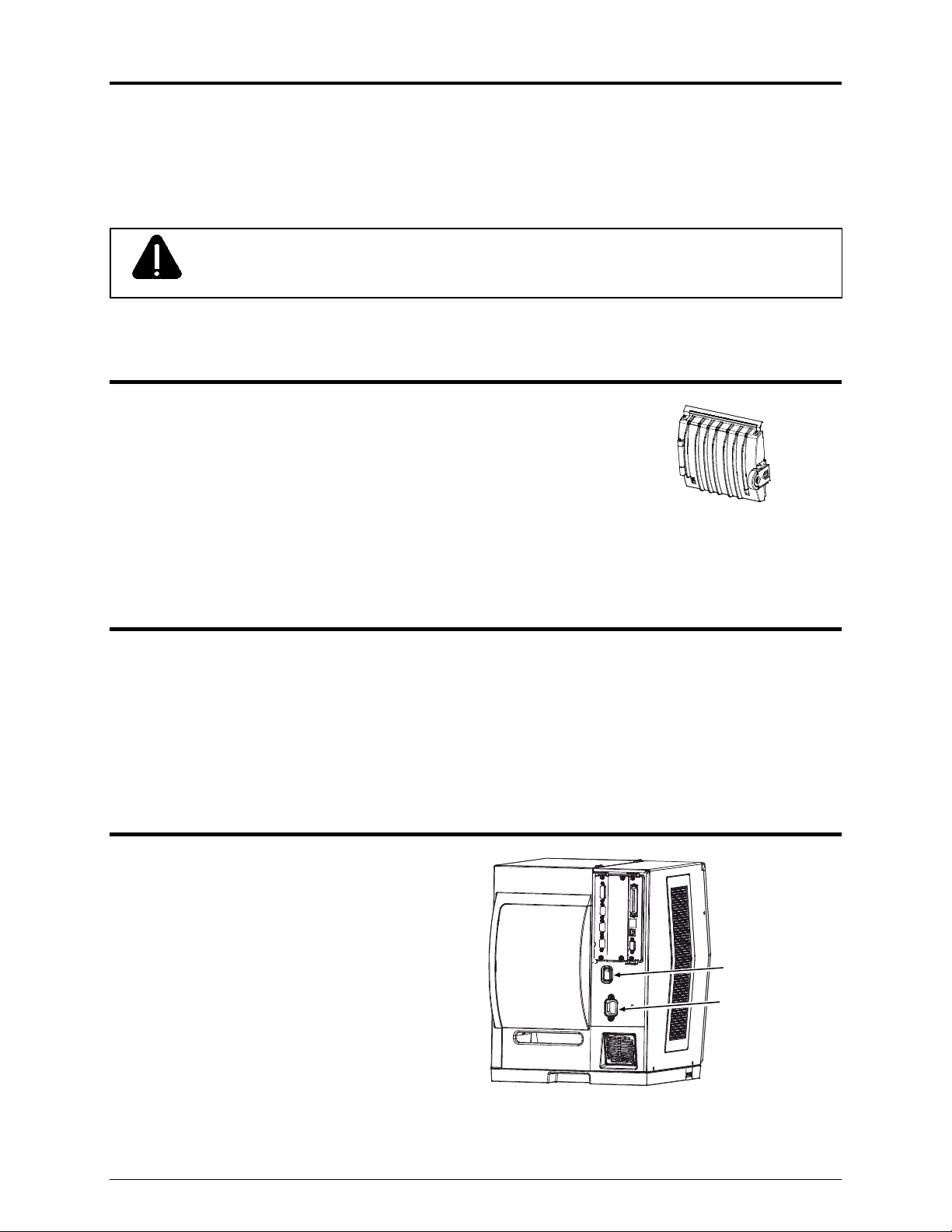

Step 1: Preparing the Printer

A) Turn ‘Off’ the Power Switch and unplug the

power cord from the AC Receptacle.

Power Switch

AC Receptacle

1

Page 4

B) Press down on the Catch, then pull forward to

remove the Door.

C) Raise the Access Cover and remove your

media from the printer.

D) Remove the Thumbscrew and Tear Plate.

Catch

Door

Tear Plate

Thumbscrew

Access

Cover

(Alternately, if equipped with an Arc Plate,

Present Sensor, or Cutter, remove that

device.)

Step 2: Installing the Heavy Duty Peel and Present Assembly

A) Press the Latch and open the Peel and

Present Assembly.

Peel and Present

Assembly

Latch

2

Page 5

B) Carefully press the Peel and Present

Assembly into the Front Plate Connector.

C) Tighten the Mounting Screw to secure the

Mounting

Screw

Peel and Present Assembly to the printer.

Peel and Present

Assembly

Front Plate

Connector

Step 3: Using the Option

During operation, labels will be peeled from the backing material and dispensed “on-demand” – that is,

subsequent printing will occur only after a previously printed label has been removed from the printer. As a

reminder, “REMOVE LABEL” will be displayed to prompt you when a label awaits removal.

Begin using the option as follows:

A) Load Media (see the Operator’s Manual for

details). Extend 20 inches (50 cm) of Media

from the printer.

B) Remove the labels from this extended portion

of media, leaving only the Backing Material.

Crease the leading edge of this Backing

Material.

3

Backing

Material

Media

Supply

Hub

Page 6

C) Route the Backing Material under the Assist

Roller and the Internal Rewinder.

D) Wrap the Backing Material in a

counterclockwise direction around the

Rewinder Hub and insert the creased

leading edge into one of its Slots. Insert the

Backing

Material

creased

leading edge

Rewinder

Hub

Internal

Rewinder

Assist

Roller

Slots

Media Clasp (Item ) into the Slot over the

creased leading edge of the Backing

Material and around the Rewinder Hub.

E) Close the Peel and Present Assembly.

Close the Access Cover, plug the power cord

into the AC Receptacle, and turn ‘On’ the

Power Switch.

Backing

Material

Media

Clasp

Peel and Present

Assembly

4

Page 7

F) Ensure that READY is displayed on the Front Panel then press

Front Panel

the FEED Key and proceed according to your observations:

If REMOVE LABEL is displayed on the Front Panel, this

completes the installation; or,

If REMOVE LABEL is not displayed on the Front Panel,

proceed to Step 4: “Configuring the Printer.”

FEED

Key

Notes: (1) The operation of the Present Sensor on this option can also be controlled by host

software commands, so ensure that your labeling program is properly configured for use

when sending label formats to the printer.

(2) If this option is removed with power applied, the printer will behave as if a label awaits

removal; to restore normal operation, cycle power to the printer.

Step 4: Configuring the Printer

While the Heavy Duty Peel and Present option is a plug and play device, this step may be necessary if the

printer’s default configuration has been changed. Follow the steps below to configure the printer:

Note: In the following procedure, consult the Operator’s Manual for detailed front panel instructions.

A) Press the MENU Button on the printer’s front panel.

B) Using the DOWN Button, scroll to PRINTER OPTIONS then press the RIGHT Button.

C) Using the DOWN Button, scroll to PRESENT SENSOR then press the ENTER Key.

D) Using the DOWN Button, scroll to MODE then press the ENTER Key.

E) Using the DOWN Button, scroll to AUTO then press the ENTER Key.

F) Press the EXIT Key then, at the SAVE CHANGES? prompt, select YES to complete the installation.

G) Turn the Power Switch ‘Off’ and ‘On’ to reset the printer and complete the configuration.

Note: If the printer fails to separate the labels from the backing material, and the Internal Rewinder

is not turning, it may need to be enabled. Using the procedure above as a guide, press the

MENU Button, scroll to PRINTER OPTIONS, then to REWINDER, and select AUTO.

Afterward, press the EXIT Key and save your changes when prompted.

5

Page 8

Maintaining the Heavy Duty Peel & Present Assembly

To ensure trouble free operation, the Heavy Duty Peel and Present Assembly should be cleaned after

every 100,000 inches (254,000 cm) of media use. This interval depends on the label adhesive, where

“gummy” adhesives may require more frequent cleaning. (To easily track label usage, go to SYSTEM

SETTINGS MEDIA COUNTERS in the printer’s menu system.)

Clean the assembly as follows:

1. Turn ‘Off’ the Power Switch and unplug the power cord from the AC Receptacle. Raise the Access

Cover and remove the media from the printer.

2. Remove the Peel & Present Assembly from the printer.

3. Using compressed air or a soft brush, clean the Sensors on the assembly.

Sensors

Note: For cleaning heavy deposits, isopropyl alcohol can be used – provided it is carefully

applied using a cotton swab, and then allowed to dry before reconnecting the option to

the printer.

6

Page 9

4. Press the Latch to open the Peel and Present Assembly. Then remove the C-Clip that secures the

Upper Roller Shaft to the Front Cover.

C-Clip

Latch

Front Cover

5. Remove the Upper Roller Shaft and the associated Rollers.

Upper Roller

Shaft

Rollers

Upper Roller

Shaft

6. Using a Cotton Swab dampened with alcohol, wipe all Roller and Upper Roller Shaft surfaces

clean. Pay special attention to the ridges on the Rollers to ensure that they are clean.

Note: For cleaning heavy deposits from the Rollers and Shafts in the following steps, WD-40

or another non-damaging adhesive remover can be substituted for isopropyl alcohol –

provided this adhesive remover is carefully applied using a cotton swab.

7. Slide the Rollers back onto the Upper Roller Shaft, place the components into the Front Cover,

and reinstall the C-Clip.

7

Page 10

8. Push and Lift both Tabs that secure the Lower Roller Assembly to the Front Cover (as shown)

and then, while keeping it intact, carefully

Tab

Front Cover

remove the entire Lower Roller Assembly.

Lift

Push

Lower Roller

Assembly

Tabs

9. Take note of the individual Roller positions – they must be

carefully

remove the Rollers from the Lower Roller Shaft.

reinstalled in the same order – then,

Lower Roller

Shaft

10. Using a Cotton Swab dampened with alcohol, wipe all Roller and Lower Roller Shaft surfaces

clean. Pay special attention to the ridges on the Rollers to ensure that they are clean.

11. Slide the Rollers, in their original order, onto the Lower Roller Shaft and reinstall it in the Front

Cover, ensuring that the Tabs are properly seated. Reinstall the Peel and Present Assembly onto the

printer to complete the cleaning procedure.

8

Loading...

Loading...