Page 1

92-2469-01 Rev.B

Cutter Option

Page 2

Page 3

Overview

This document describes the installation, use and care of the Cutter option for wide model H-Class

printers. After taking a moment to verify the contents of the kit and the tools required, follow the steps

below to install, use and maintain the Cutter option.

Contents

In addition to this procedure, the kit contains the following items:

Item Description

Cutter Assembly

Screw (2)

1

2

Tools Required

To install this option, you will need a Phillips screwdriver.

Installing the Cutter

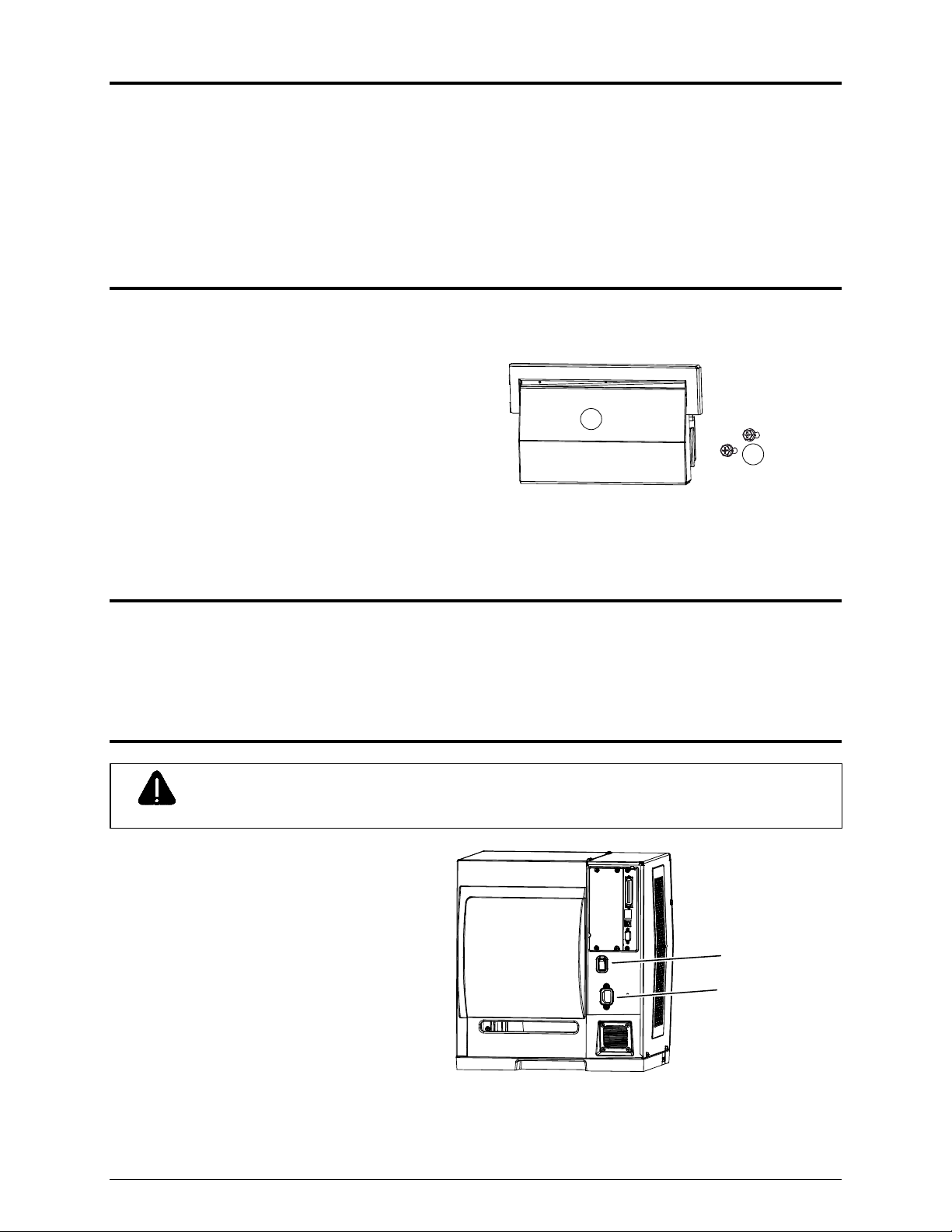

Always remove power before performing installation or maintenance.

CAUTION

1) Turn OFF the Power Switch and unplug

the power cord from the AC Receptacle.

Power Switch

AC Receptacle

1

Page 4

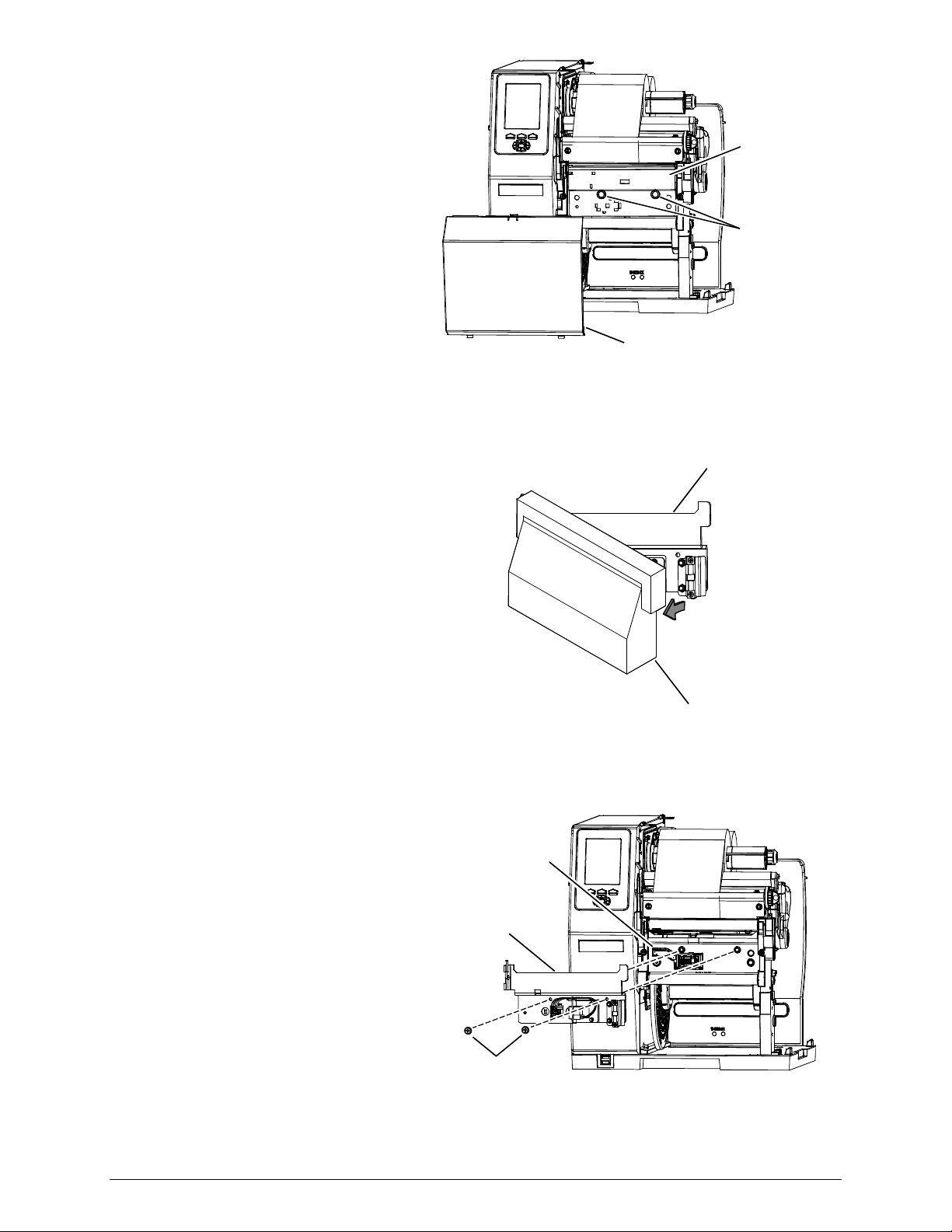

2) Raise the cover and remove media.

Remove the Panel, Thumbscrews and

Tear Bar

Tear Bar.

3) Separate the Hinge Plate from the

Cutter Assembly (Item ).

Panel

Thumbscrews

Hinge Plate

4) Carefully press the Hinge Plate onto the

Front Plate and then secure it using the

two Screws (Item ).

Hinge

Plate

Screws

Front

Plate

Cutter Assembly

2

Page 5

Mounting

Pins

5) Mount the Cutter Assembly onto the

Mounting Pins of the Hinge Plate.

6) Plug the Cutter Cable into the Hinge

Plate Jack, and then close the Cutter

Assembly. This completes the

installation.

Cutter

Assembly

Cutter

Cable

Hinge

Plate

Hinge Plate

Jack

Using the Cutter

1) Ensure the Media has a clean, straight

edge then load and route it through the

Cutter Opening. (See the Operator’s

Manual for detailed loading information.)

Cutter

Assembly

Media

Cutter

Opening

3

Page 6

2) Close the cover then plug the power cord

into the AC Receptacle and turn ON the

Power Switch

Power Switch.

3) Press the FEED Key on the Front

Panel, and then proceed accordingly:

If cutting standard size labels and a

cut was performed, this completes

installation; or,

If a cut was not performed, see

“Configuring the Printer,” below.

Note: If cutting small labels,

performance may be increased; see

“Increasing Small Label Throughput,”

Front Panel

FEED

Key

AC Receptacle

below.

Configuring the Printer

The Cutter, a plug and play option, may require configuration if the default setup has changed:

Note: The Cutter can also be controlled by host software commands. Ensure that your labeling

program is properly set to cut, including the desired label size. To test the Cutter, see

“Testing the Cutter”; or, if problems occur, see “Troubleshooting” (below).

a) Press the MENU Key on the printer’s front panel. (See the Operator’s Manual for menu details.)

b) Using the DOWN ARROW Key, scroll to PRINTER OPTIONS then press the ENTER Key.

c) Using the DOWN ARROW Key, scroll to CUTTER then press the ENTER Key.

d) Using the DOWN ARROW Key, scroll to AUTO then press the ENTER Key.

e) Press the ESCAPE Key and then, at the SAVE CHANGES? prompt, select YES.

f) Turn the Power Switch OFF and ON to complete configuration.

4

Page 7

Increasing Small Label Throughput

CUT BEHIND is a menu setting that allows the printer to queue then cut a specified number (0 – 2) of

small labels, where the elimination of repeated positioning operations can result in a throughput

increase. To achieve faster throughputs when cutting batches of small labels, follow the procedure

below to establish the queue amount and setup the printer:

a) Measure the length (L) of your media, label edge to label edge including gap, if any.

b) Calculate the Cut Behind number (N): Divide the distance** of 1.24 inches (31.50 mm) by the

length (L) of the media. N = 1.24 ÷ L

**This distance may vary between printers and require slight modification.

c) Calculate the Present Distance (PD): Subtract the product of the length (L) and the Cut Behind

number (N) from the distance** of 1.24 inches (31.50 mm). PD = 1.24 – (N x L)

d) Enter the calculated Present Distance (PD) in the PRINT CONTROL / PRESENT DISTANCE

menu.

e) Enter the calculated Cut Behind number (N) in the PRINTER OPTIONS / CUTTER / CUT

BEHIND menu, and then exit the menu and save your settings.

f) Test the setup: With the media installed, repeatedly press the FEED Key to verify the cut location

– if the location is incorrect adjust the PRESENT DISTANCE accordingly, adding distance to

move the cut farther out or subtracting to move it closer. When satisfactory, the printer is ready

for use.

Notes:

PRINT CONTROL / PRESENT DISTANCE cannot be set to AUTO.

SYSTEM SETTINGS / FAULT HANDLING / VOID AND RETRY should not be used with this

function.

During the setup process some queued blank labels may be lost.

See the Operator’s Manual for menu and other details.

5

Page 8

Maintaining the Cutter

To ensure trouble free operation, the Cutter should be cleaned (using the items listed below) after printing

each roll of labels, and more often if the cutting action becomes sluggish.

Recommended Cleaning Items

Isopropyl alcohol

Cotton swabs

Compressed air or soft-bristle brush

CAUTION

Follow these steps to clean the Cutter:

Remove power before performing maintenance.

Cutter Blades are SHARP. Keep body parts away from the cutting surfaces.

Never use metal objects on the cutting surfaces.

Take proper precautions when using isopropyl alcohol, a flammable liquid.

1) Turn OFF the Power Switch and unplug

the power cord from the AC Receptacle.

2) Remove media from the printer. Open

the Cutter Assembly, disconnect the

Cutter Cable from the Hinge Plate

Jack, and then remove the Cutter

Assembly from the Hinge Plate.

Cutter

Cable

Cutter

Assembly

Power Switch

AC Receptacle

Hinge Plate

Jack

6

Page 9

3) Remove the four Cover Screws and two

Rear Shields from the Cutter

Assembly.

Cutter Assembly

Cover Screws

4) Remove the Cover from the Mechanism

and then, using compressed air (or a

brush), remove all debris.

5) Pressing on the Lever to gain access

Cover

Fixed

Blade

Rear Shields

(Cabling not shown for clarity.)

Mechanism

Cotton Swab

and using a Cotton Swab dampened

with alcohol (see note below), wipe clean

Movable

Blade

the Fixed Blade, the Movable Blade,

and the other areas where adhesive has

accumulated.

Note: Heavy deposits can be removed using WD-40 (or another non-damaging adhesive

remover) if carefully and sparingly applied using a cotton swab. Never spray directly onto

the assembly; severe damage can result.

7

Lever

Page 10

6) Place the Cover and the two Rear Shields onto the Mechanism, and then secure all with the four

Cover Screws.

Cover

Cover

Screws

Mechanism

Rear

Shields

7) Place the Cutter Assembly onto the

Hinge Plate then connect the Cutter

Cable to the Hinge Plate Jack. Close

the Cutter Assembly.

Cutter

Cable

Cutter

Assembly

Hinge Plate

Jack

8) Load media. Close the cover. Plug the

power cord into the AC Receptacle and

turn ON the Power Switch.

Power Switch

AC Receptacle

8

Page 11

Testing the Cutter

Diagnostics allow the function of the option to be tested by executing and displaying a count of cutting

attempts. Follow the steps below to perform a functional test of the Cutter:

1) Press the MENU Key on the printer’s front panel.

2) Using the DOWN ARROW Key, scroll to DIAGNOSTICS then press the ENTER Key.

3) Using the DOWN ARROW Key, scroll to OPTIONS TESTING then press the ENTER Key.

4) Using the DOWN ARROW Key, scroll to TEST CUTTER then press the ENTER Key.

5) Using the DOWN ARROW Key or the UP ARROW Key, select the number of test cycles (1, 10, or

100 times) to perform.

6) Press the ENTER Key to begin the test.

Note: Press the CANCEL Key to terminate testing and return to operating mode.

Troubleshooting

Follow the guide below if a problem arises:

If experiencing this problem… Try this possible solution:

Cannot load media through the cutter: The mechanism may be in an intermediate position – with

the cutter closed, turn the Power Switch ON and OFF; and

then, try to load media.

Cut labels are not the correct size: The label size may not be correctly set in your software

program (or in the printer’s menu system) – change your

software settings (and / or the printer’s label size settings,

see the “Operator’s Manual for details).

Cutter Fault is displayed: The Cutter Cable may not be connected – connect the

Cutter Cable to the Hinge Plate Jack.

No cuts are made:

The Cutter Cable may not be connected – connect the

Cutter Cable to the Hinge Plate Jack.

The Cutter may not be enabled in your software

program (or in the printer’s menu system) – change

your software settings (and / or enable the cutter in

the menu, see the “Configuring the Printer,” above).

9

Page 12

Loading...

Loading...