Page 1

92-2427-01 Rev.C

GPIO Option

Page 2

Page 3

Overview

This document describes the installation and use of the General Purpose Input Output

(GPIO) option for the H-Class printer. After verifying the kit contents and tools needed,

follow the steps to install and begin using the option.

For safety and to avoid equipment damage, turn OFF the power switch and

CAUTION

unplug the AC power cord from the printer before starting this installation.

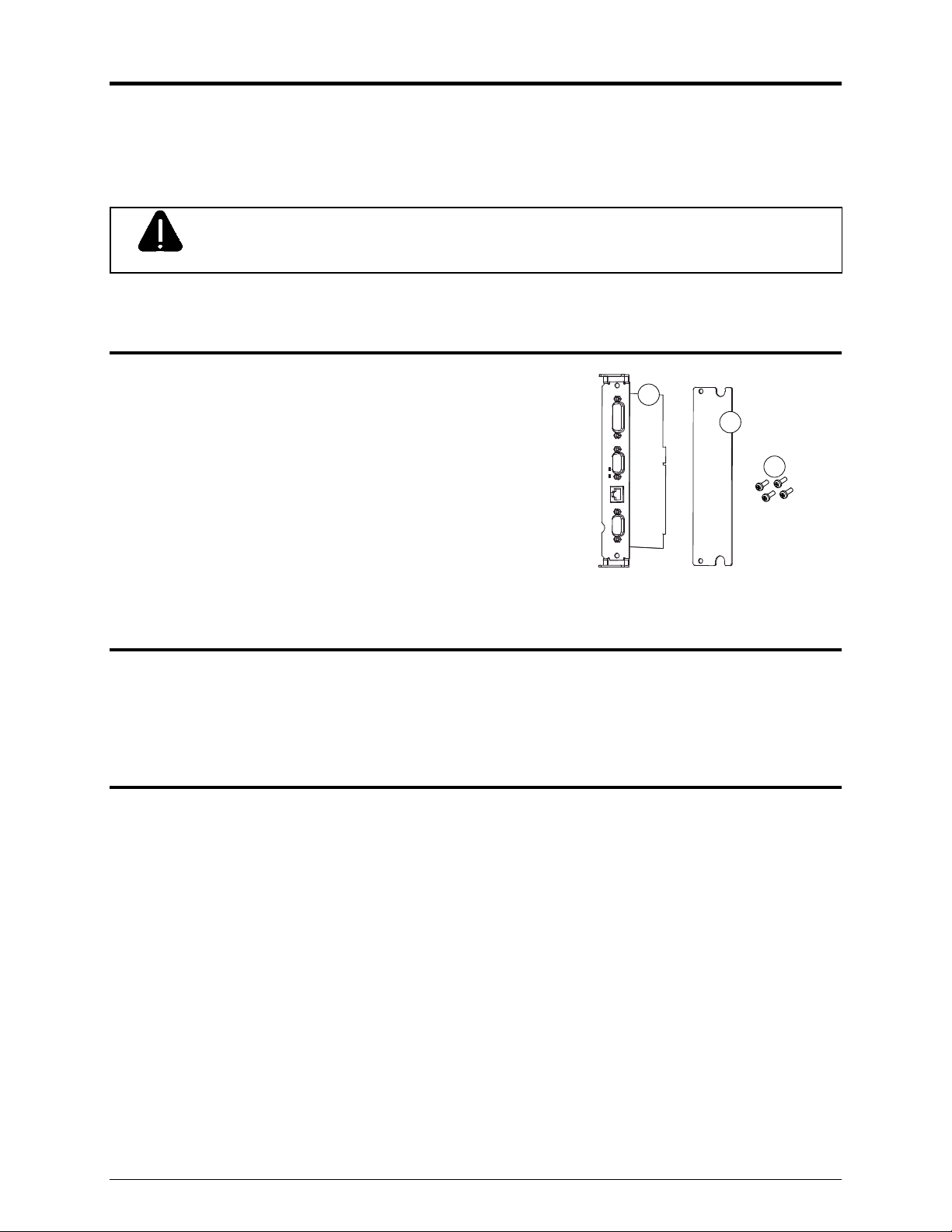

Contents

This kit contains the following items:

GPIO Circuit Card Assembly

Cover Plate

Screws

1

2

3

Tools Required

To install this option, you will need a Philips screwdriv er.

Additional Requirements

Depending on your application, you may need the following hardware to interface the card:

GPI/O A – DB15 Male connector (e.g., StarTech C15PCM) and shielded cabling.

GPI/O B – High Density DB15 Male VGA connector (e.g., StarTech C15HPSM) and

shielded cabling.

COM C – DB9 Male connector (e.g., StarTech C9PSM) and shielded cabling, or a

prefabricated cable (see part numbers and pin out requirements below).

COM D – RJ45 Plug (e.g., Belkin R6G088) and shielded cabling, or a prefabricated

cable (see part number and pin out requirements below).

1

Page 4

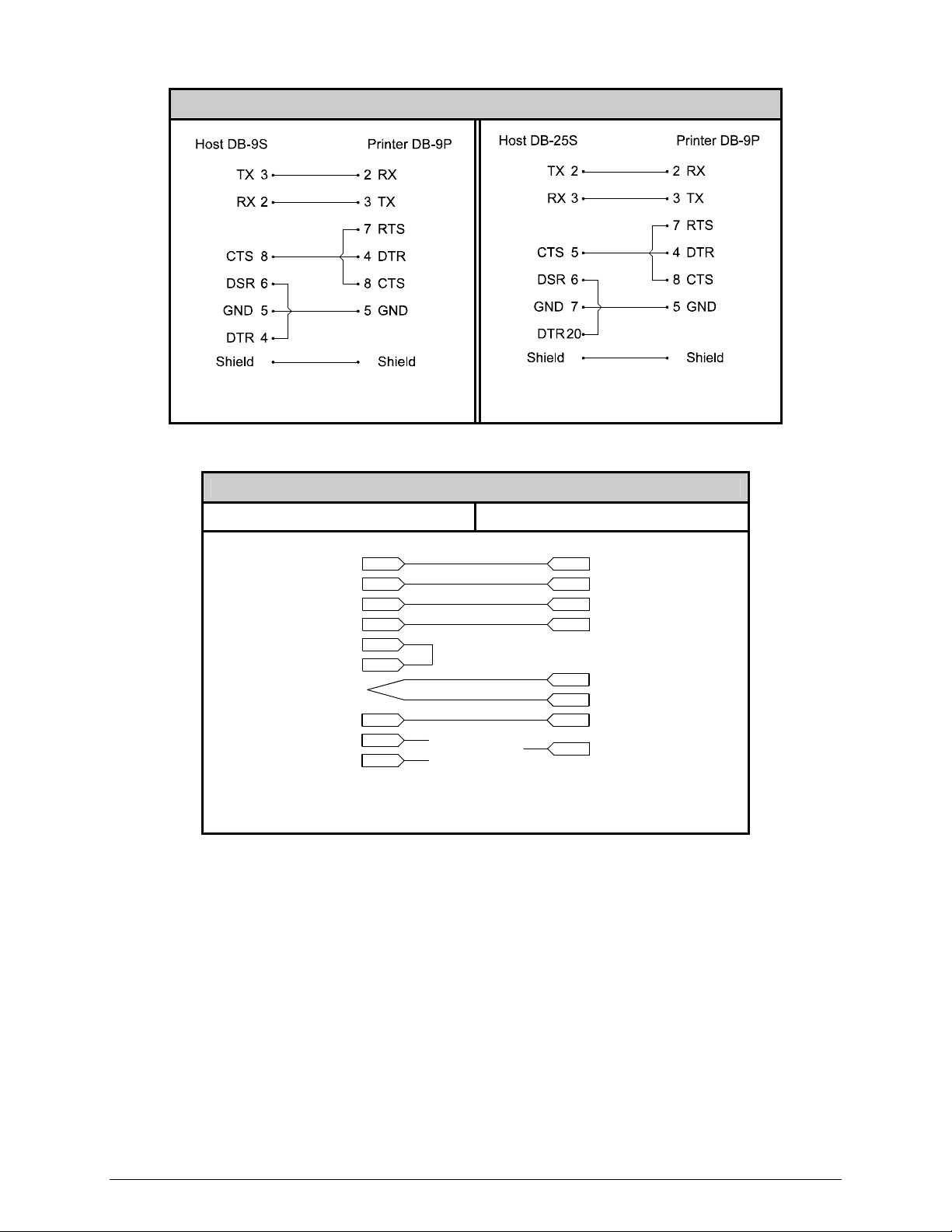

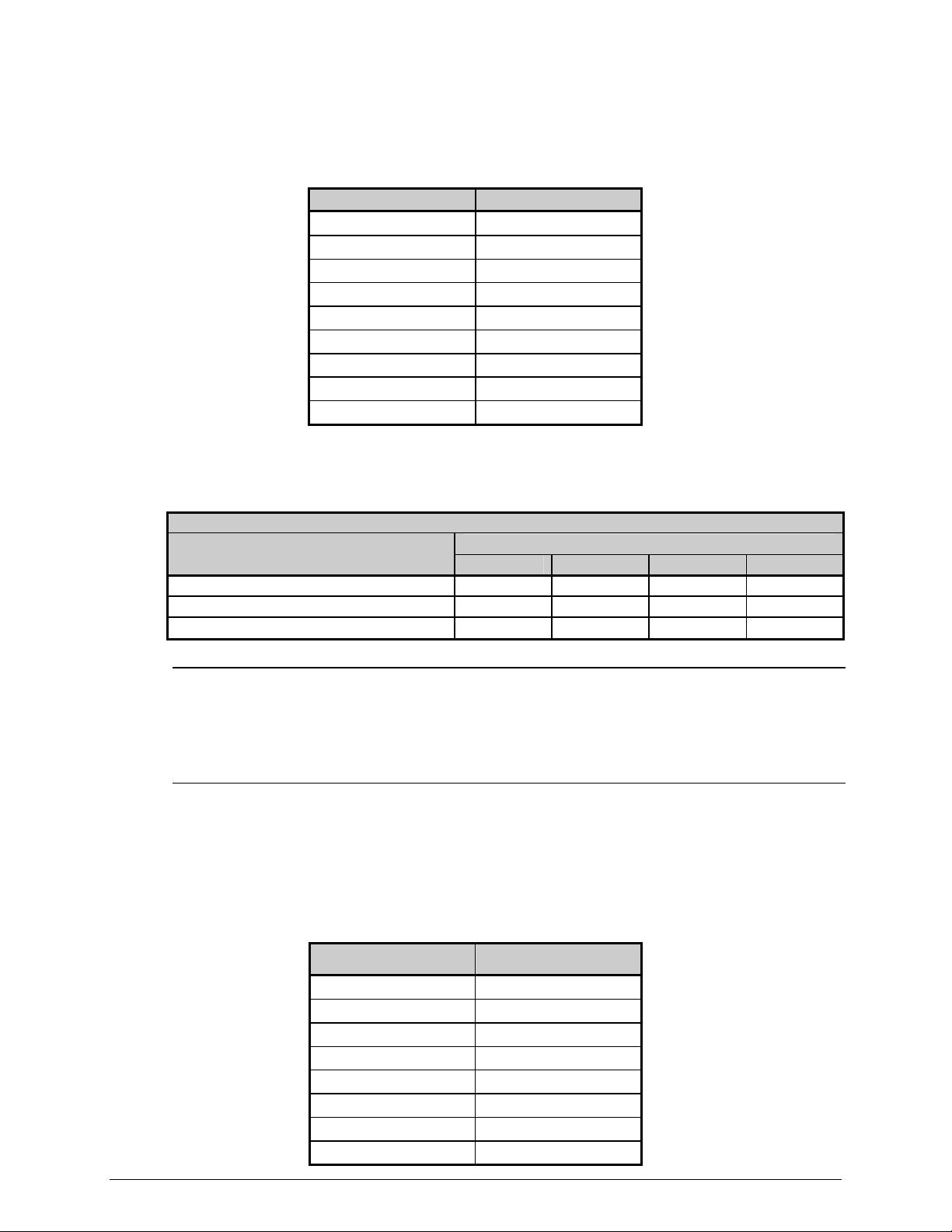

COM C RS-232 Cables

Part # 32-2300-01

Part # 32-2301-01

COM D RS-232 Cable

Host DB-9S Printer RJ45P

+5 VDC

RXD

TXD

GROUND

DTR

DSR

CTS

1

2

3

5

4

6

8

9

7

NC

NC

NC

1

4

5

3

2

7

8

6

+5 VDC

TXD

RXD

GROUND

RTS

CTS

DTR

Part # 32-2603-00

2

Page 5

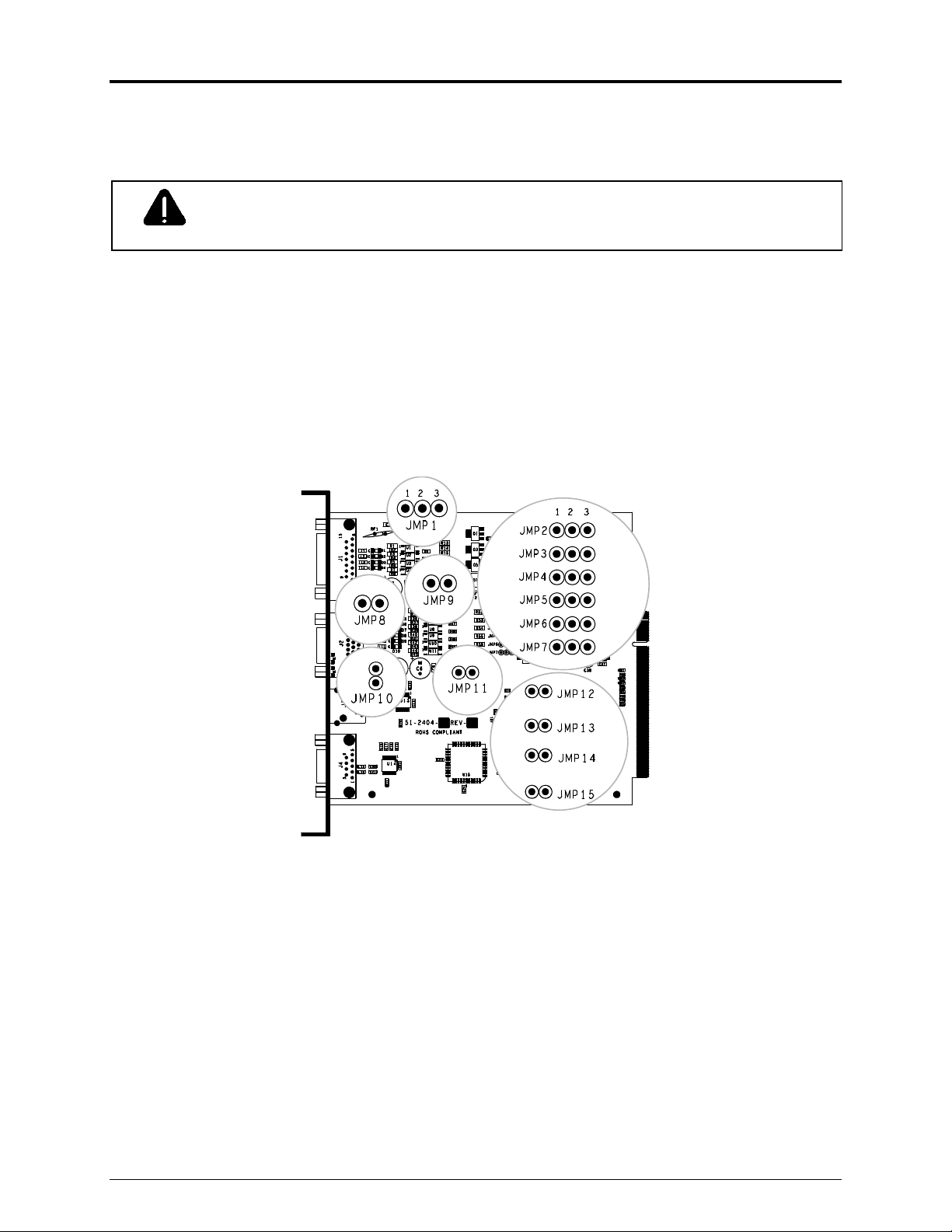

Step 1: Configuring the Hardware

Configure the card to meet your interfacing requirements by arranging hardware jumpers,

as described in the following procedure:

Always wear a wrist strap and follow standard ESD prevention measures

CAUTION

when handling the card.

A) Remove the card from the packaging and then place the card onto a static-free work

area.

B) Set the jumpers on the card (detailed below) to meet the requirements of your

application:

► GPI/O A (J1)

Four dedicated inputs control printer functions. Designed to interface to opencollector outputs, these inputs require no external pu ll-ups, while blocking diodes

allow the use of totem pole outputs from +4.5 VDC to + 26 VDC. Optical isolators

provide galvanic isolation. Two print control interface circuit examples are given

below.

3

Page 6

For direct inputs –

Use the printer’s +5VDC and Ground to supply

the devices interfacing to the GPI/O A inputs

(as shown in the sample circuit, right).

For isolated inputs –

To provide galvanic isolation for the GPI/O A

inputs, remove Jumper JMP 9 then supply an

external +5VDC source voltage to Pin 2, and

remove Jumper JMP 8 then supply an external

Ground to Pin 1 (as shown this sample circuit,

right).

+5 VDC External Source

GPI/O A - J1

Start of Print

3

Slew Label

4

Toggle/Pause

5

Reprint

6

Ground

1

GPI/O A - J1

2

Vcc

3

Start of Print

4

Slew Label

5

Toggle/Pause

6

Reprint

Ground

1

Seven dedicated outputs are available for control, warning, and error functions.

These open-collector outputs have slew-limited signal-edge rise and fall times to

prevent cross talk in the cabling. Optional 10K ohm pull-up resistors, tied to a

common point for use at either +5 or +24 VDC, are available via Jumper JMP 1.

Note: If external pull-ups are used (that is, without Jumper JMP1 installed),

ensure that the applied external voltage does not exceed +30VDC.

The table below details the GPI/O A pin assignments, settings and functions.

4

Page 7

Failure to properly configure the GPIO Port can result in damage to the printer and / or connected devices.

WARNING

Pin

1

2 +5 VDC

3 Start Of Print

4 Slew Label

5 Toggle / Pause The printer pauses when the signal is taken LOW.

6 Reprint

7 +24 VDC Printer +24 VDC (1.5 amp maximum).

8 Ground

9 Ribbon Low Programmable

10 Service Required Evoked by occurrences listed under ‘Fault Messages.’

11 End Of Print Programmable

12 Media Out Evoked during an Out of Stock condition. Active LOW.

13 Ribbon Out Evoked during an Out of Ribbon condition. Active LOW.

14 Data Ready

15 Option Fault

[1]

Signal directions given relative to the printer.

[2]

If active with no current print job, “WAITING FOR DATA” will be displayed. Specifying a quantity of 9999 while keeping this signal ON will cause non-stop label printing, except

in single label “Imaging Mode”, which will cause the printer to stop between labels. See the Operator’s Manual for details.

[3]

For details see PRINTER OPTIONS / GPIO PORT in the Operator’s Manual.

Signal

Name

Ground

GPI/O Port A Jumper Overview

Direction

JMP 8

[1]

Jumper

Position Function / Description

Installed Printer chassis is used.

Removed Ground must be supplied.

N/A

JMP 9

Installed

Printer +5VDC is used (.5 amp maximum)

Note: Drawing more than .5 amps can cause unreliable printer operation.

Removed +5VDC must be supplied.

[2]

Programmable

Media is advanced until the signal goes HIGH and, if not in continuous mode, the label

is positioned at the next available TOF.

Input

N/A N/A

The last label is reprinted exactly, with no increment or time stamp changes;

recommended for use during error conditions. Keeping this signal LOW produces nonstop printing.

N/A

Printer chassis.

When inactive, outputs will be

pulled up to a voltage

determined by this jumper

setting, where:

Output JMP 1

Pins 1 – 2 = +5VDC;

Pins 2 – 3 = +24VDC; or,

None = an external voltage

(not to exceed +30VDC) via

external pull-ups providing a

20K ohm feedback path

through any two outputs.

Evoked when a label is waiting to print. After Start of Print is received, printing will begin.

For synchronization with the print cycle, End Of Print indicates the completion of the

process. Active LOW.

Evoked during a Linear Scanner or RFID fault condition. Active LOW.

[3]

[1]

. Signifies a RIBBON LOW DIAMETER warning condition.

[1]

Active LOW.

[1]

. Signifies the End of Print (EOP) process.

5

Page 8

► GPI/O B (J2)

Six unassigned inputs are designed to interface to open-collector outputs. These

inputs require no external pull-ups, while blockin g diodes allow the use of totem pole

outputs from +4.5 VDC to + 26 VDC. Optical isolators provide galvanic isolation. Two

print control interface circuit examples are given below.

For direct inputs:

Use the printer’s +5VDC to supply the devices

interfacing to the GPI/O B inputs (as shown in

the sample circuit, right).

+5 VDC External Source

For isolated inputs:

To provide galvanic isolation for the GPI/O B

inputs, remove Jumper JMP 11 then supply an

external +5VDC source voltage to Pin 1, and

remove Jumper JMP 10 then supply an

external Ground to Pin 6 (as shown in the

sample circuit, right).

13

8

3

12

7

2

6

1

13

8

3

12

7

2

6

GPI/O B - J2

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Ground

GPI/O B - J2

Vcc

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Ground

Six unassigned outputs have slew-limited signal-edge rise and fall times to

prevent cross talk in the cabling. Optional 10K ohm pull-up resistors, one for each of

the output lines, can be used at either +5 or +24 VDC via Jumpers JMP 2 – 7.

Note: If external pull-ups are employed (that is, when Jumpers JMP 2 - 7 are

not installed), ensure that the applied external voltage does not exceed

+30VDC.

The table below details the GPI/O B pin assignments, settings and functions.

6

Page 9

Failure to properly configure the GPIO Port can result in damage to the printer and / or connected devices.

WARNING

Pin Signal Name / Direction

1

2 Input 6 N/A N/A Programmed input function.

3 Input 3 N/A N/A Programmed input function.

4 Output 6 JMP 7

5 Output 3 JMP 4

6 Ground JMP 10

7 Input 5 N/A N/A Programmed input function.

8 Input 2 N/A N/A Programmed input function.

9 Output 5 JMP 6

10 Output 2 JMP 3

11 +24 VDC N/A N/A Printer +24 VDC (1.5 amp maximum).

12 Input 4 N/A N/A Programmed input function.

13 Input 1 N/A N/A Programmed input function.

14 Output 4 JMP 5

15 Output 1 JMP 2

[1]

Signal directions given relative to the printer.

GPI/O Port B Overview

[1]

Jumper Position Function / Description

Printer +5VDC is used (.5 amp maximum).

+5 VDC JMP 11

Installed

Note: Drawing more than .5 amps can cause unreliable printer operation.

Removed +5VDC must be supplied.

Installed: Pins 1 – 2 Programmed output function pulled-up to +5VDC.

Installed: Pins 2 – 3 Programmed output function pulled-up to +24VDC.

Removed An external voltage via external pull-ups will determine this level, not exceed +30VDC.

Installed: Pins 1 – 2 Programmed output function pulled-up to +5VDC.

Installed: Pins 2 – 3 Programmed output function pulled-up to +24VDC.

Removed An external voltage via external pull-ups will determine this level, not exceed +30VDC.

Installed Printer chassis is used.

Removed Ground must be supplied.

Installed: Pins 1 – 2 Programmed output function pulled-up to +5VDC.

Installed: Pins 2 – 3 Programmed output function pulled-up to +24VDC.

Removed An external voltage via external pull-ups will determine this level, not exceed +30VDC.

Installed: Pins 1 – 2 Programmed output function pulled-up to +5VDC.

Installed: Pins 2 – 3 Programmed output function pulled-up to +24VDC.

Removed An external voltage via external pull-ups will determine this level, not exceed +30VDC.

Installed: Pins 1 – 2 Programmed output function pulled-up to +5VDC.

Installed: Pins 2 – 3 Programmed output function pulled-up to +24VDC.

Removed An external voltage via external pull-ups will determine this level, not exceed +30VDC.

Installed: Pins 1 – 2 Programmed output function pulled-up to +5VDC.

Installed: Pins 2 – 3 Programmed output function pulled-up to +24VDC.

Removed An external voltage via external pull-ups will determine this level, not exceed +30VDC.

7

Page 10

► COM C (J4)

Recognized by the printer as Serial Port C, COM C functions as an auxiliary RS-232

interface or dedicated device port for the RFID and Linear Scanner options. Pin

assignments for the port are as follows:

Pin Number COM C (J4)

1 +5V (@ .5 amps)

2 RX

3 TX

4 DTR

5 Ground

6 Ground

7 RTS

8 CTS

9 N/C

At default settings, the COM C port automatically selects its function. To force a

selection, however, change the jumper settings as denoted in the table below:

COM C Jumper Setting Functions

Selected Function

RS-232 Communications (default)

RFID Off On On On

Linear Scanner On Off On On

JMP 12 JMP 13 JMP 14 JMP 15

On On On On

Jumper and Setting

Note: Jumper settings override menu settings: If set for RS-232 (default) with

the RFID and Linear Scanner menu-enabled, the printer will assign RFID to

Serial Port B (back plane port J13) and the Linear Scanner to the COM C

port.

► COM D (J3)

Recognized by the printer as Serial Port D, COM D is an auxiliary RS-232 interface.

Pin assignments for the port are as follows:

Pin Number COM D (J3)

1 +5V (@ .5 amps)

2 RTS

3 Ground

4 TX

5 RX

6 Ground

7 CTS

8 DTR

8

Page 11

Step 2: Installing the Option

Install the GPIO Card as described below:

A) Turn OFF the Power Switch and

unplug the power cord from the AC

Receptacle.

B) Remove the two Screws that secure

the Back Panel to the Card Cage,

and then remove the Back Panel.

C) Slide the GPIO Card (Item 1),

Screws

Card Cage

Slot

Power Switch

AC Receptacle

Card Cage

Back Panel

GPIO Card

Notch down, into the leftmost Card

Cage Slot. Firmly push the GPIO

Card to seat it and then secure the

card using the two Screws (Item 3).

Screws

Notch

9

Page 12

D) Place the Cover Plate (Item 2) onto

the Card Cage, as shown, then

install and tighten the two Screws

(Item 3) to secure the plate.

Card Cage

Cover Plate

Screws

Step 3: Interfacing

Interface the card according to your application requirements (see the drawing below for

connector pin-outs, refer to Step 1 for signal details) as follows:

8

15

7

14

6

13

5

12

11

10

9

J2

15

14

13

12

11

10

5

4

9

3

8

2

7

1

6

5

9

4

8

J4

3

7

2

6

1

A) For GPIO functions connect a GPI/O interface cable to the GPI/O A (J1) and / or GPI/O

J1

4

3

2

1

1

J3

8

B (J2) ports.

B) For RS232 communications connect a serial interface cable to COM C (J4) and / or COM

D (J3); for dedicated devices, connect the cabling from that device to COM C (J4).

Note: If using both the RFID and Linear Scanner, see Configuring Hardware

Settings, above.

C) Connect the AC power cord to the printer and then turn the power switch ON.

10

Page 13

Step 4: Configuring the Software Settings

Configure the printer’s m

A) Using the Control Panel, enter the ADVANCED MENU (see the Operator’s Manual for

menu navigation details):

• If using the GPIO A (J1) port, configure the settings to meet the requirements of

your system using the PRINTER OPTIONS GPIO PORT APPLICATOR

menu selection;

• If using the GPIO B (J2) port, refer to your MCL documentation;

• If using the COM C (J4) port for serial communications, configure the it to meet the

requirements of your host system’s serial port settings using the

COMMUNICATIONS SERIAL PORT C menu selection; or,

If using the COM C (J4) port for a dedicated device, enable that device using the

enu settings for the option’s operation.

PRINTER OPTIONS menu selection; and,

• If using the COM D (J3) port for serial communications, configure the port to meet

the requirements of your host system’s serial port settings using the

COMMUNICATIONS SERIAL PORT D menu selection.

B) After entering the desired settings exit the menu system and save your changes. The

printer is now ready to operate using the GPIO option.

Verifying Setup and Operation

Verification of the settings and active monitoring is provided:

Indicators – View incoming (IN) and outgoing (OUT)

signal activity via the card bracket. Sampled every

millisecond, these LED indicators change color as incoming

or outgoing GPIO signals change state.

11

Signal In

Signal Out

Page 14

Input Monitor – Display incoming GPIO binary signal states using the ADVANCED

MENU DIAGNOSTICS OPTIONS TESTING TEST GPIO MONITOR GPIO

INPUT selection.

GPIO A

Signals

SOP FEED PAUSE REPRT

1 1 0 0

i1 i2 i3 i4 i5 i6

0 1 0 1 1 1

GPIO B

Signals

Note: Unused, non-connected inputs will have an indeterminate state, and may

assume a value of 1 or 0.

Output Monitor – Display outgoing GPIO binary signal states using the ADVANCED

MENU DIAGNOSTICS OPTIONS TESTING TEST GPIO MONITOR GPIO

OUTPUT selection.

GPIO A

Signals

EP RL SR MO RO DR OF

0 0 0 0 0 0 0

o1 o2 o3 o4 o5 o6

0 0 0 0 0 0

GPIO B

Signals

Note: Unused, non-connected outputs will have an indeterminate state, and may

assume a value of 1 or 0.

GPIO Report – Print the configuration and current signal state information using the

ADVANCED MENU / DIAGNOSTICS / OPTIONS TESTING / TEST GPIO / PRINT

SIGNAL INFO selection:

GPIO SIGNAL INFO

WED 11:04AM 4JUL2005

CARD ID#3

OUTPUT SIGNALS

END OF PRINT

PIN# 11 GPIO A

LOW PULSE

CURRENT LEVEL 1

RIBBON LOW

PIN# 9 GPIO A

ACTIVE LOW

CURRENT LEVEL 0

SERVICE REQUIRED

PIN# 10 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

MEDIA OUT

PIN# 12 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

RIBBON OUT

PIN# 13 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

DATA READY

PIN# 14 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

OPTION FAULT

PIN# 15 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

o1

PIN# 15 GPIO B

CURRENT LEVEL 1

o2

PIN# 10 GPIO B

CURRENT LEVEL 0

o3

PIN# 5 GPIO B

CURRENT LEVEL 1

o4

PIN# 14 GPIO B

CURRENT LEVEL 1

o5

PIN# 9 GPIO B

CURRENT LEVEL 1

o6

PIN# 4 GPIO B

CURRENT LEVEL 1

INPUT SIGNALS

START OF PRINT

PIN# 3 GPIO A

ACTIVE HIGH

CURRENT LEVEL 1

FEED

PIN# 4 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

TOGGLE PAUSE

PIN# 5 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

REPRINT

PIN# 6 GPIO A

ACTIVE LOW

CURRENT LEVEL 1

i1

PIN# 13 GPIO B

CURRENT LEVEL 1

i2

PIN# 8 GPIO B

CURRENT LEVEL 0

i3

PIN# 3 GPIO B

CURRENT LEVEL 1

i4

PIN# 12 GPIO B

CURRENT LEVEL 1

i5

PIN# 7 GPIO B

CURRENT LEVEL 1

i6

PIN# 2 GPIO B

CURRENT LEVEL 1

12

Loading...

Loading...