Page 1

Programmer’s Manual

Covers the following models:

E-Class Mark III Basic and Advanced (Serial# 4xxxxxxx or greater)

E-Class Mark III Pro/Pro+

I-Class Mark II

RL3 & RL4

Page 2

CG Times (based upon Times New Roman), CG Triumvirate, MicroType, and TrueType are

trademarks of the AGFA Monotype Corporation.

PCL, Intellifont, and HP Laser JetII are trademarks of the Hewlett Packard Corporation.

Macintosh is a trademark of the Apple Corporation.

Windows is a trademark of the Microsoft Corporation.

All other brand and product names are trademarks, service marks, registered trademarks,

or registered service marks of their respective companies.

Information in this manual is subject to change without notice and does not represent a

commitment on the part of Datamax-O’Neil Corporation. No part of this manual may be

reproduced or transmitted in any form or by any means, for any purpose other than the

purchaser’s personal use, without the expressed written permission of Datamax-O’Neil

Corporation.

All rights reserved

Copyright © 2013, Datamax-O’Neil

Part Number 88-2360-01

Revision B

Page 3

Contents

1 Overview ...................................................................................... 1

Who Should Use this Manual ...................................................................... 1

The Scope of this Manual ........................................................................... 1

General Conventions ................................................................................. 2

Computer Entry and Display Conventions .................................................... 2

Important Safety Instructions .................................................................... 2

Special Instructions .................................................................................. 2

Typical Data Flow Sequence ....................................................................... 3

2 Control Code Command Functions ................................................ 7

Introduction ............................................................................................ 7

Attention-Getters ..................................................................................... 7

Easy Control Codes .................................................................................. 7

Alternate Control Code Modes .................................................................... 8

3 Immediate Command Functions ................................................... 9

Introduction ............................................................................................ 9

SOH # Reset ...................................................................................... 9

SOH * Reset ...................................................................................... 9

SOH A Send ASCII Status String ......................................................... 10

SOH a Send ASCII Extended Status String ........................................... 10

SOH B Toggle Pause ......................................................................... 11

SOH C Stop/Cancel ........................................................................... 12

SOH D SOH Shutdown ....................................................................... 12

SOH E Send Batch Remaining Quantity ................................................ 12

SOH e Send Batch Printed Quantity .................................................... 13

SOH F Send Status Byte .................................................................... 13

4 System-Level Command Functions ............................................. 15

Introduction .......................................................................................... 15

STX A Set Time and Date .................................................................. 15

STX a Enable Feedback Characters ..................................................... 16

STX B Get Printer Time and Date Information ...................................... 16

STX c Set Continuous Paper Length ................................................... 17

i

Page 4

STX E Set Quantity for Stored Label ................................................... 17

STX e Select Edge Sensor ................................................................. 18

STX F Form Feed ............................................................................. 18

STX f Set Form Stop Position (Backfeed Command) ............................. 18

STX G Print Last Label Format ........................................................... 19

STX I Input Image Data ................................................................... 19

STX i Scalable Font Downloading ...................................................... 20

STX J Set Pause for Each Label ......................................................... 20

STX K Extended System-Level Commands ........................................... 20

STX k Test Communication Port ......................................................... 21

STX L Enter Label Formatting Command Mode ..................................... 21

STX M Set Maximum Label Length ...................................................... 21

STX m Set Printer to Metric Mode ....................................................... 21

STX n Set Printer to Imperial Mode .................................................... 22

STX O Set Start of Print (SOP) Position ............................................... 22

STX o Cycle Cutter ........................................................................... 22

STX P Set Hex Dump Mode ............................................................... 23

STX p Controlled Pause .................................................................... 23

STX Q Clear All Modules .................................................................... 23

STX q Clear Module .......................................................................... 24

STX R Ribbon Saver Control .............................................................. 24

STX r Select Reflective Sensor .......................................................... 24

STX S Set Feed Speed ...................................................................... 25

STX T Print Quality Label .................................................................. 25

STX t Test DRAM Memory Module ...................................................... 25

STX U Label Format String Replacement Field ...................................... 26

STX V Software Switch Settings ......................................................... 27

STX v Request Firmware Version ....................................................... 28

STX W Request Memory Module Information ........................................ 28

STX w Test Flash Memory Module ....................................................... 29

STX X Set Default Module ................................................................. 29

STX x Delete File from Module ........................................................... 30

STX Y Output Sensor Values.............................................................. 31

STX y Select Font Symbol Set ........................................................... 31

STX Z Print Configuration Label ......................................................... 32

STX z Pack Module .......................................................................... 32

ii

Page 5

5 Extended System-Level Command Functions .............................. 33

Introduction .......................................................................................... 33

STX K}E Empty Sensor Calibration ........................................................ 33

STX K}M Manual Media Calibration ......................................................... 34

STX K}Q Quick Media Calibration ........................................................... 34

STX KaR Read Data from RFID Tag ........................................................ 35

STX KaW Write Data to RFID Tag ........................................................... 36

STX Kb Backfeed Time Delay ............................................................... 36

STX KC Get Configuration ................................................................... 37

STX Kc Configuration Set ................................................................... 40

STX KD Database Configuration ........................................................... 92

STX Kd Set File as Factory Default ....................................................... 93

STX KE Character Encoding ................................................................. 93

STX KF Select Factory Defaults ............................................................ 95

STX Kf Set Present Distance ............................................................... 95

STX KH Dot Check ............................................................................. 96

STX KI GPIO Input ............................................................................ 98

STX Kn NIC Reset .............................................................................. 98

STX KO GPIO Output .......................................................................... 99

STX Kp Module Protection .................................................................. 100

STX Kr Resettable Counter Reset ....................................................... 101

STX KtA Write Application Family Identifier (AFI) to Tag .......................... 101

STX KtD Write Data Storage Format Identifier (DSFID) to Tag .................. 101

STX KtE Write Electronic Article Surveillance (EAS) Bit ............................ 102

STX KtH Read and Feedback Tag Information to Host .............................. 102

STX KtR Read Data from RFID Tag ....................................................... 103

STX KtU Read Unique Serial Number from RFID Tag ............................... 104

STX KtW Write Data to RFID Tag .......................................................... 104

STX KuB Read Data from Gen2 Tag Section ........................................... 106

STX KuF Send RFID Device Firmware Version ......................................... 106

STX KuJ Write Data to Gen 2 Tag Section .............................................. 106

STX KuR Read Data from RFID Tag ....................................................... 107

STX KuW Write Data to RFID Tag .......................................................... 108

STX KV Verifier Enable/Disable ........................................................... 108

STX Ky Download Plug-in File ............................................................. 109

STX KZ Immediately Set Parameter .................................................... 109

iii

Page 6

6 Label Formatting Command Functions ...................................... 111

Introduction ......................................................................................... 111

: Set Cut by Amount ................................................................ 111

A Set Format Attribute .............................................................. 112

B Bar Code Magnification ........................................................... 113

C Set Column Offset Amount ...................................................... 113

c Set Cut by Amount ................................................................ 114

D Set Dot Size Width and Height ................................................. 114

E Terminate Label Formatting Mode and Print Label ...................... 115

e Recall Printer Configuration ..................................................... 115

F Advanced Format Attributes .................................................... 115

G Place Data in Global Register ................................................... 116

H Enter Heat Setting ................................................................. 116

J Justification .......................................................................... 117

M Select Mirror Mode ................................................................. 117

m Set Metric Mode .................................................................... 118

n Set Inch (Imperial) Mode ........................................................ 118

P Set Print Speed ..................................................................... 118

p Set Backfeed Speed ............................................................... 119

Q Set Quantity of Labels to Print ................................................. 119

R Set Row Offset Amount .......................................................... 120

r Recall Stored Label Format ..................................................... 120

S Set Feed Speed ..................................................................... 122

s Store Label Format in Module .................................................. 122

T Set Field Data Line Terminator ................................................ 123

t

Add or subtract date time from the printer date ......................... 123

U

Mark Previous Field as a String Replacement Field ...................... 124

X Terminate Label Formatting Mode ............................................ 125

y Select Font Symbol Set .......................................................... 125

z Zero (Ø) Conversion to “0” ..................................................... 126

+ (>)(() Make Last Field Entered Increment .......................................... 126

– (<)()) Make Last Field Entered Decrement .......................................... 127

^ Set Count by Amount ............................................................. 128

Special Label Formatting Command Functions ........................................... 129

STX D Print adjusted date ................................................................ 129

STX S Recall Global Data and Place in Field ........................................ 130

STX T Print Time and Date ............................................................... 130

iv

Page 7

7 Font Loading Command Functions ............................................ 133

Introduction ......................................................................................... 133

*c###D Assign Font ID Number .......................................................... 133

)s###W Font Descriptor ..................................................................... 134

*c###E Character Code ..................................................................... 134

(s#W Character Download Data ....................................................... 134

8 Generating Label Formats ........................................................ 135

Introduction ......................................................................................... 135

Format Record Commands ...................................................................... 135

Generating Records ............................................................................... 136

The Structure of a Record ....................................................................... 136

Advanced Format Attributes .................................................................... 149

Appendix A .................................................................................... 153

ASCII Control Chart ............................................................................... 153

Appendix B .................................................................................... 155

Sample Programs .................................................................................. 155

VB Application to Send Raw Data via Printer Driver .................................... 159

Appendix C .................................................................................... 165

Available Fonts – Sizes, References, and Samples ...................................... 165

Appendix D .................................................................................... 171

Reset Codes ......................................................................................... 171

Appendix E .................................................................................... 173

Single Byte Symbol Sets ........................................................................ 173

Appendix F .................................................................................... 185

Bar Code Summary Data ........................................................................ 185

Bar Code Default Widths and Heights ....................................................... 188

Appendix G .................................................................................... 191

Bar Code Details ................................................................................... 191

Appendix H .................................................................................... 237

Single and Double Byte Character Font Mapping ........................................ 237

v

Page 8

Appendix I ..................................................................................... 239

Symbol Sets and Character Maps ............................................................ 239

Double-Byte Symbols, Chinese, Kanji, and Korean ..................................... 242

Appendix J ..................................................................................... 243

General Purpose Input Output (GPIO) Port Applications .............................. 243

Appendix K .................................................................................... 245

Maximum Field & Character Values .......................................................... 245

Print Resolutions and Maximum Width & Record Column Values ................... 245

Column, Present, & Row Adjust Fine Tune Range ....................................... 246

Memory Module Identifiers and Allocations ................................................ 246

Appendix L..................................................................................... 247

Speed Ranges ....................................................................................... 247

Appendix M .................................................................................... 249

Commands by Function .......................................................................... 249

Appendix N .................................................................................... 251

Image Loading ...................................................................................... 251

Appendix O .................................................................................... 253

UPC-A and EAN-13: Variable Price/Weight Bar Codes ................................. 253

Appendix P .................................................................................... 255

International Language Print Capability (ILPC) Programming Examples ......... 255

Appendix Q .................................................................................... 265

Plug and Play IDs .................................................................................. 265

Appendix R .................................................................................... 267

Line Mode 267

Appendix S .................................................................................... 271

RFID Overview ...................................................................................... 271

Appendix T .................................................................................... 277

WiFi Region Country Codes ..................................................................... 277

Appendix U .................................................................................... 283

Bar Code Symbology Information Resources ............................................. 283

Glossary ........................................................................................ 285

vi

Page 9

Overview

1 Overview

This manual is intended for programmers who wish to create their own label production

software.

This manual, arranged alphabetically by command, explains Datamax-O’Neil Programming

Language (DPL) and its related uses in the writing, loading and storing of programs for the

control and production of label formats (designs) for the following printers at, or above, the

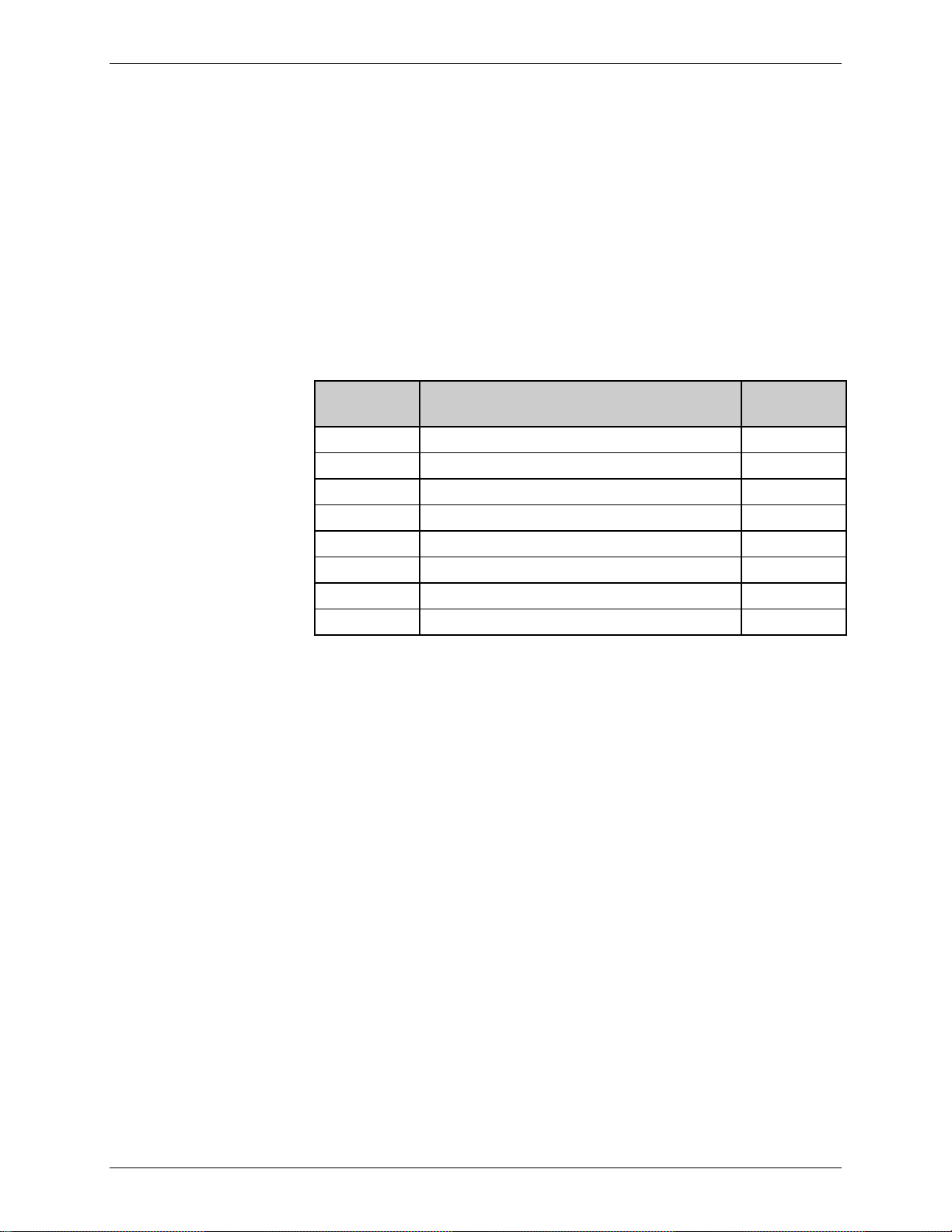

listed firmware version below:

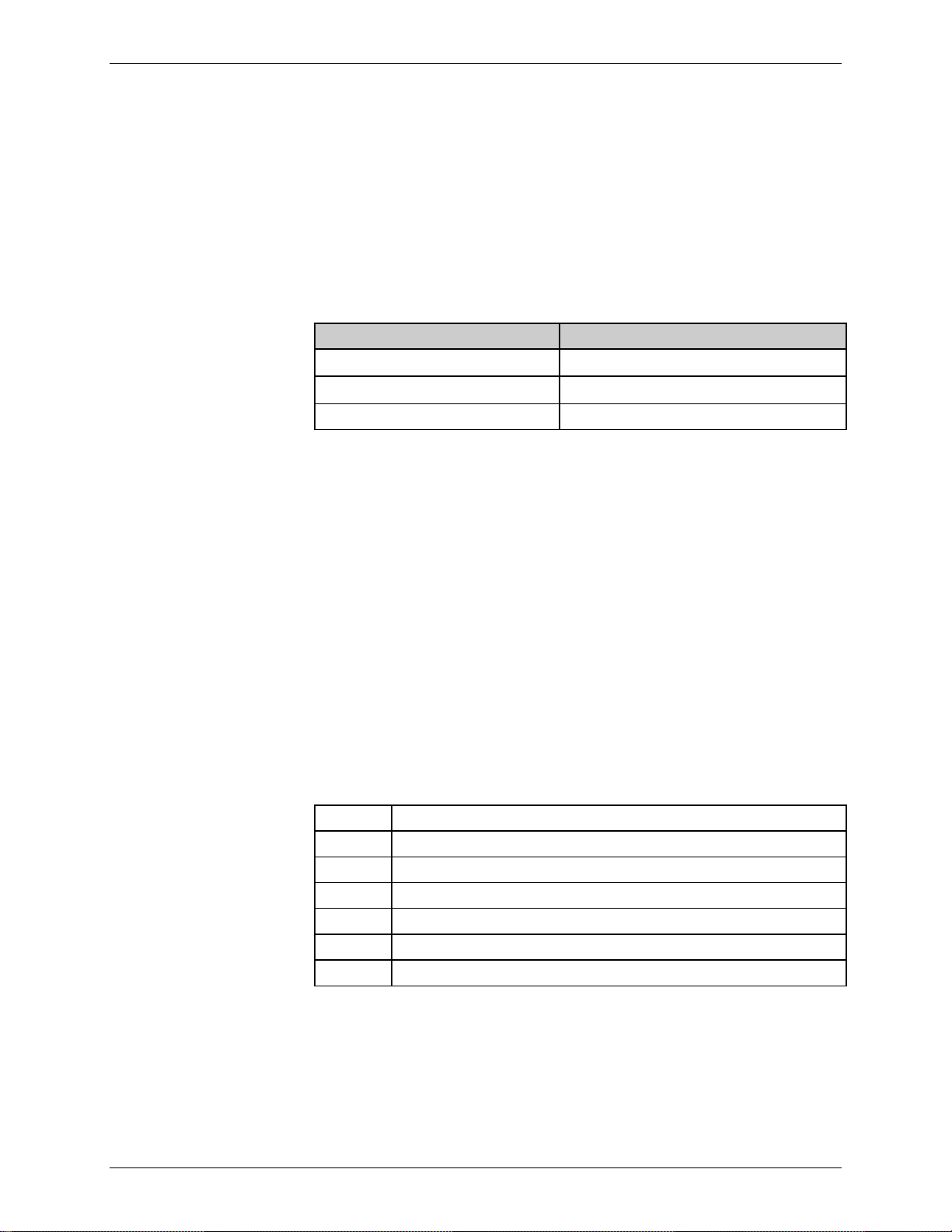

Model distinctions, including configurations and equipment types be indicated in this text to

differentiate command compatibility. The appendices of this manual also contain details that

cannot be ignored; the use of any command will require checking for possible exclusionary

conditions.

Who Should Use this Manual

The Scope of this Manual

Printer Firmware Version

E-Class Mark III Basic and Advanced Models

E-Class MARK III Pro/Pro+ All

I-Class Mark II All

RL3 & RL4 All

Serial# 4xxxxxxx or greater or Firmware

Version 9.04_0001 or greater

See the <STX>KC command for information regarding attainment of the printer’s firmware

•

version; and then, if necessary, upgrade that firmware. Upgrades are available at

http://www.datamax-oneil.com.

• Programming information for older Class Series printers Class Series II Programmer’s

Manual (part number 88-2341-01). All manuals can be downloaded from our web site at

http://www.datamax-oneil.com.

• References to “Menu Settings” refer either to the set-up menu or to the system menu of

the printer; consult to the appropriate Operator’s Manual for details.

• Where applicable, printer responses to a host device will depend upon the communication

port, port settings, and cabling.

1

Page 10

Overview

General Conventions

These are some of the conventions followed in this manual:

On the header of each page, the name of the section.

On the footer of each page, the page number and the title of the manual.

Names of other manuals referenced are in Italics.

Notes are added to bring your attention to important considerations, tips or helpful

suggestions.

Boldface is also used to bring your attention to important information.

This manual refers to IBM-PC based keyboard command characters for access to the

ASCII character set. Systems based on different formats (e.g., Apple’s Macintosh )

should use the appropriate keyboard command to access the desired ASCII

character. See Appendix A for the ASCII character set.

Computer Entry and Display Conventions

Command syntax and samples are formatted as follows:

The Courier font in boldface indicates the DPL command syntax, and Italics are

used to indicate the command syntax parameters.

Regular Courier font indicates sample commands, files and printer responses.

Square brackets ([ ]) indicate that the item is optional.

<CR> is used to identify the line termination character. Other strings placed

between < > in this manual represent the character of the same ASCII name, and

are single-byte hexadecimal values (e.g., <STX>, <CR>, and <0x0D> equal 02, 0D,

and 0D, respectively).

Hexadecimal values are often displayed in “C” programming language conventions

(e.g., 0x02 = 02 hex, 0x41 = 41 hex, etc.)

Important Safety Instructions

The exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance instructions.

Special Instructions

The green check box is intended to alert the user to conventions used within this

text or to notable operating details of the printer.

2

Page 11

Overview

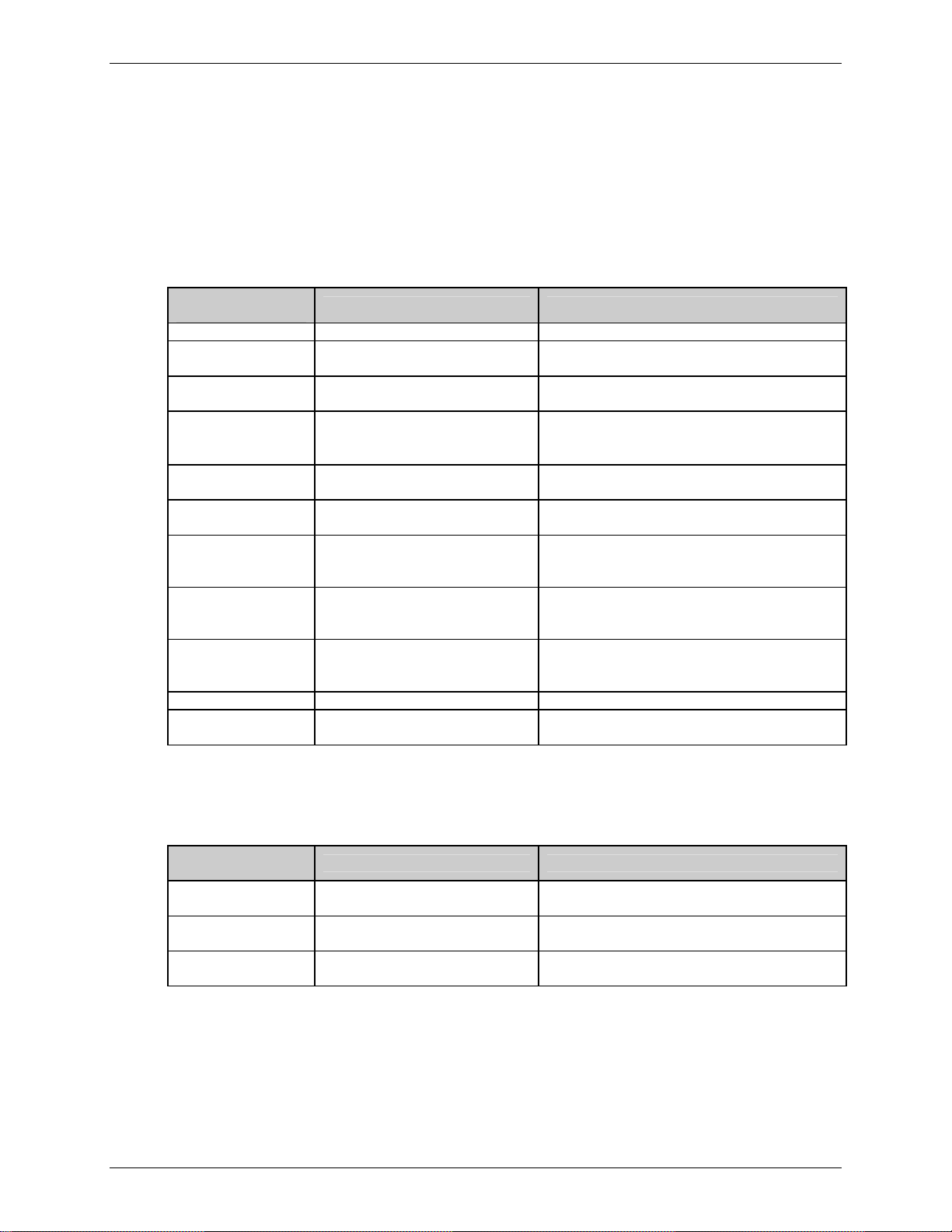

Typical Data Flow Sequence

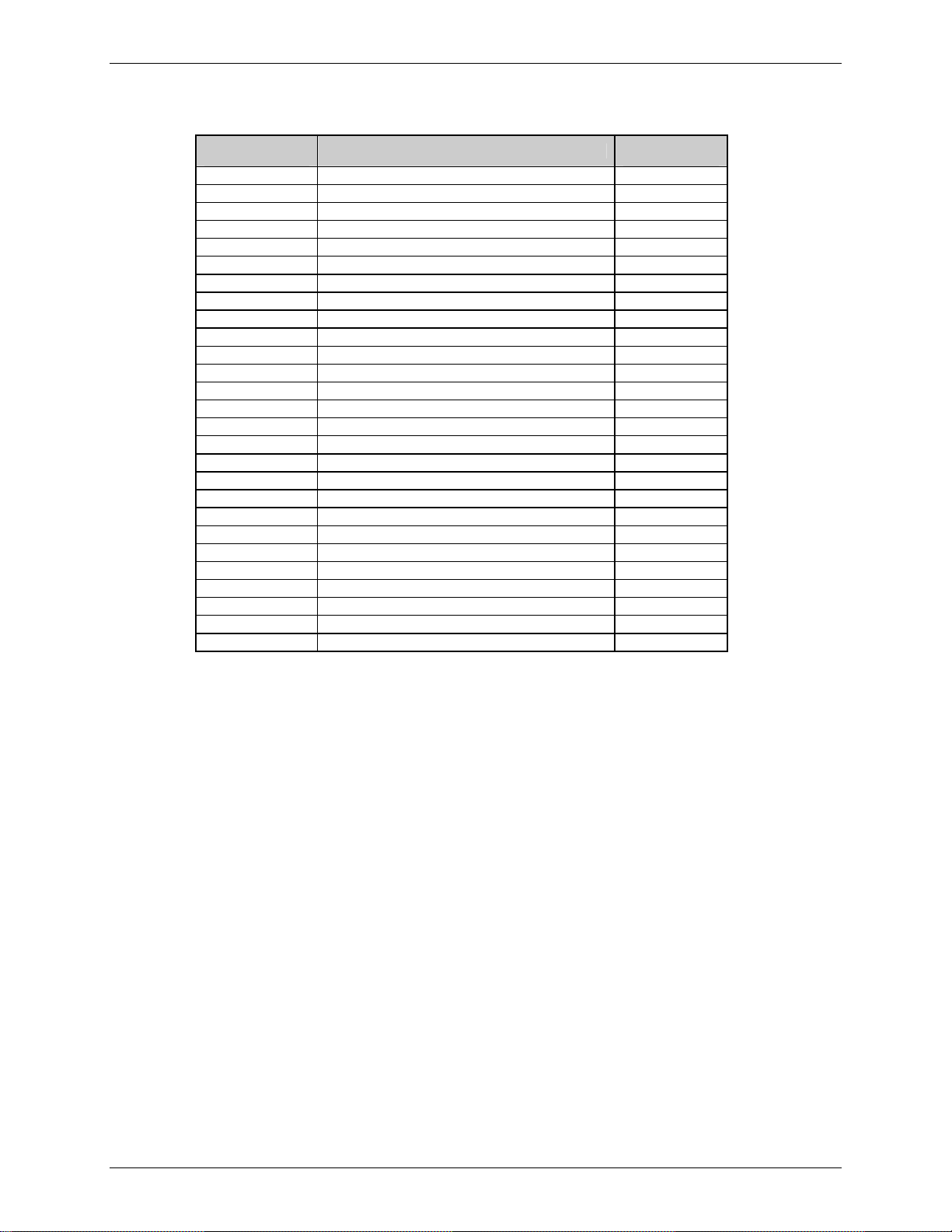

The typical data flow sequence is summarized in the following bullets and detailed in the

table below. Printer Commands data is transmitted to the printer as shown in the table from

left to right, top to bottom.

Status commands

Configuration commands

Download commands

Label format

Status commands

Label reprint commands

Memory cleanup

Typical commands used in the various stages shown above are listed in the tables that

follow.

Status Commands

Commands are available for retrieving stored label formats, updating data, and adding

new data. These techniques are used for increasing throughput; see <STX>G, Label Recall

Command “r”, and Label Save Command “s”.

Printer Commands Description Notes

<SOH>A

<STX>WG

<STX>O220

<STX>n

<STX>V0

<SOH>D

<STX>IApImagename<CR>image data...data

<CR>

<STX>L

D11

131100000500050Typical text field 01

Q0001

E

<SOH>A

<STX>U01new data for field 01

<STX>E0005

<STX>G

<STX>xImagename<CR>

<STX>zA

“Status” commands: Get

Status, Request Memory

Module Storage

Information…

“Configuration”

commands, download

image…

“Download” commands,

image, fonts…

Begin label

Label Header record

Label Formatting Data

record –

Object type, orientation,

position, data

Label Quantity

Label Terminate record

Status command

Reprint with New Data

Records

Memory cleanup

Optional,

bidirectional

communication

required for these

commands.

See <STX>Kc to

reduce configuration

commands

transferred

RAM (temporary) or

Flash (semipermanent)

memory.

Existing label

formats may be

recalled. Label

header records are

not required.

Optional,

bidirectional

communication

required for these

commands.

Used for fast

reprints.

Typically used for

temporary storage.

3

Page 12

Overview

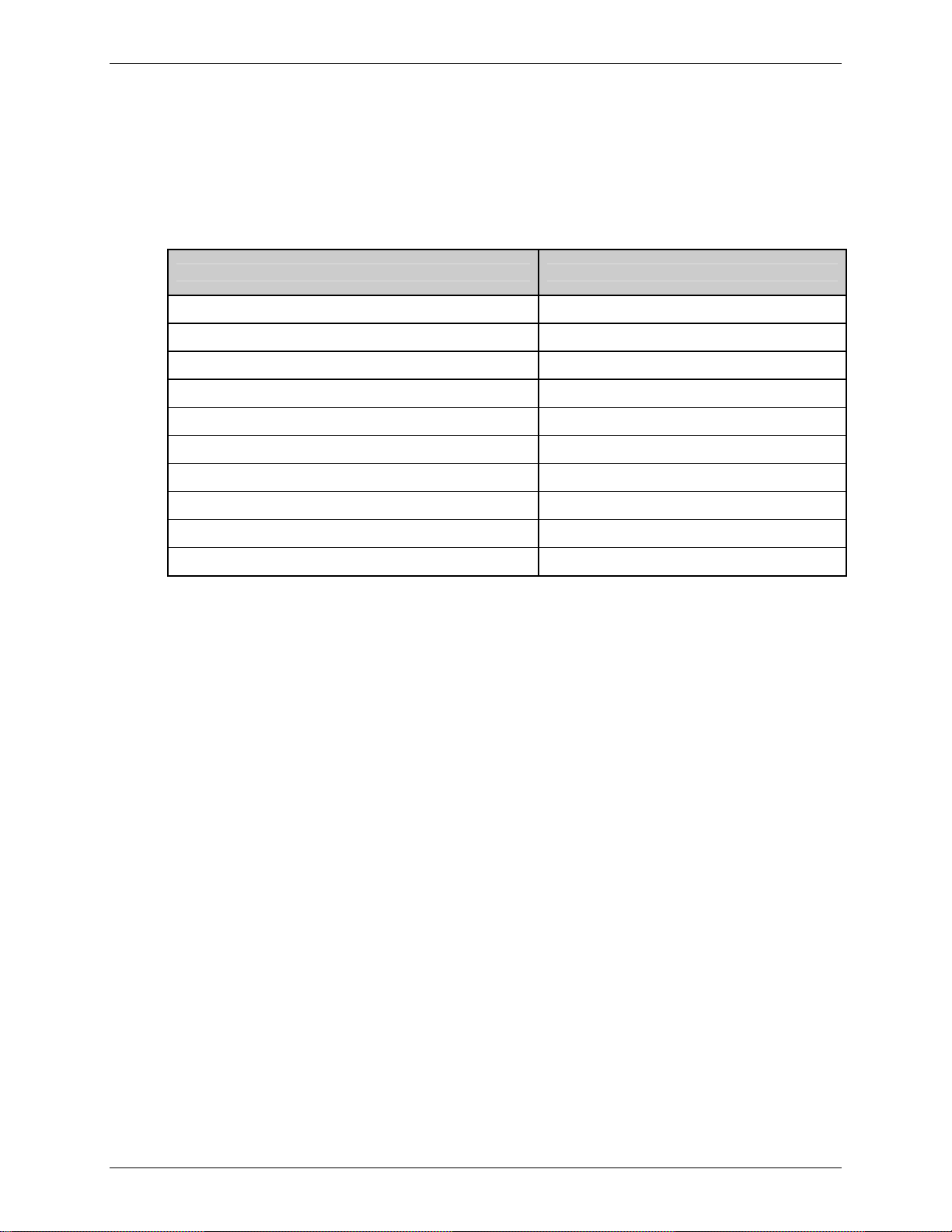

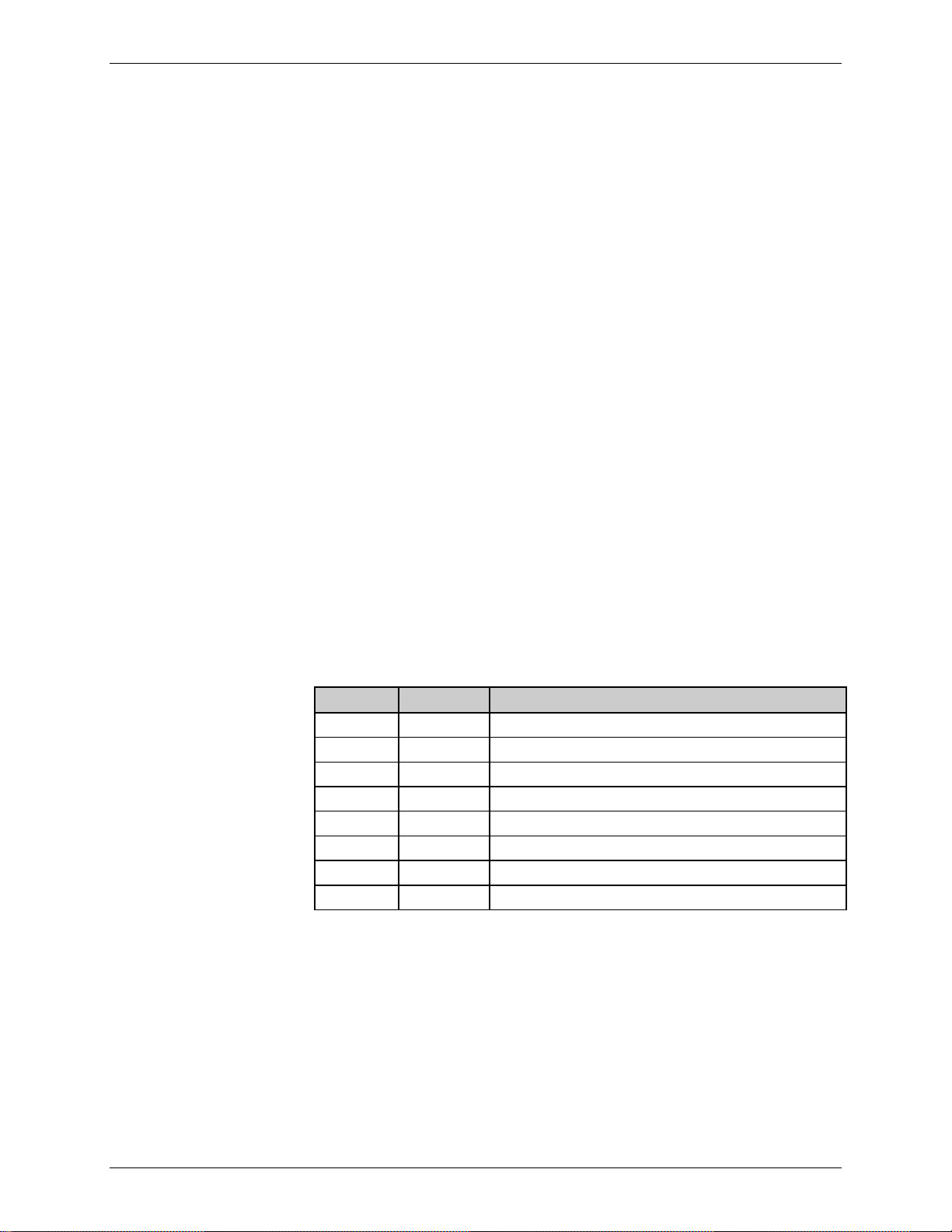

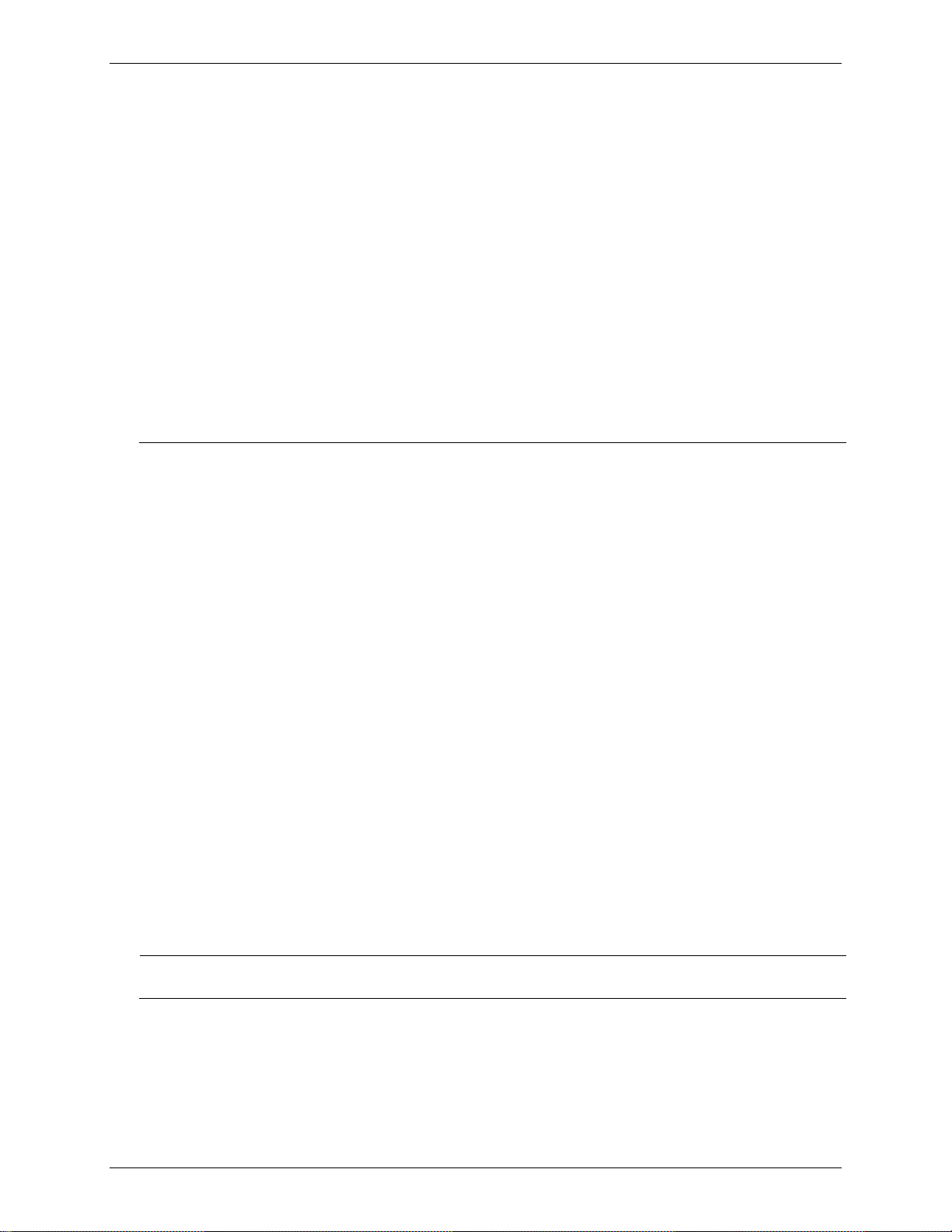

Configuration Commands

The following table lists some commands useful in controlling printer configuration.

These commands are generally effective only for the current power-up session; toggling

power restores the default configuration. See <STX>Kc for changes to the default powerup configuration. Changing the default power-up configuration and saving objects in

printer Flash memory can reduce the data transmitted for each label and therefore

improve throughput.

Configuration

Command

<STX>A

<STX>c

<STX>e

<STX>Kf

<STX>Kc

<STX>F

<STX>M

<STX>m

<STX>n

<STX>S

<STX>V

Download Commands

Download

Command

<STX>I

<STX>i

<ESC>

Set Date and Time Sets Date and Time.

Set Continuous Paper Length

Set Edge Sensor

Set Present Distance

Configuration Set

Send Form Feed

Set Maximum Label Length

Set to Metric Mode

Set to Inch Mode

Set Feed Rate Sets blank label movement speed.

Software Switch

Download Image

Download Scalable Font

Download Bitmapped Font

Name Function

Must be 0000 for gap media; not used

for reflective media.

Sets sensing for gap or registration hole

type stock.

Determines label stop position, head

relative. <STX>f edge sensor relative

equivalent command, older models.

Determines default power-up

configuration.

Sets the stop position of the printed

label.

Length to search for next gap or

reflective mark; not used with

continuous media.

Subsequent measurements interpreted

in metric (most units, mm/10). Label

equivalent command can be used.

Subsequent measurements interpreted

in inches (most units in/100) label

equivalent command can be used.

Enables optional hardware, cutter, and

present sensor.

Name Function

Downloads Image to selected memory

module.

Downloads Scalable Font to selected

memory module.

Downloads Bitmapped Font to selected

memory module.

4

Page 13

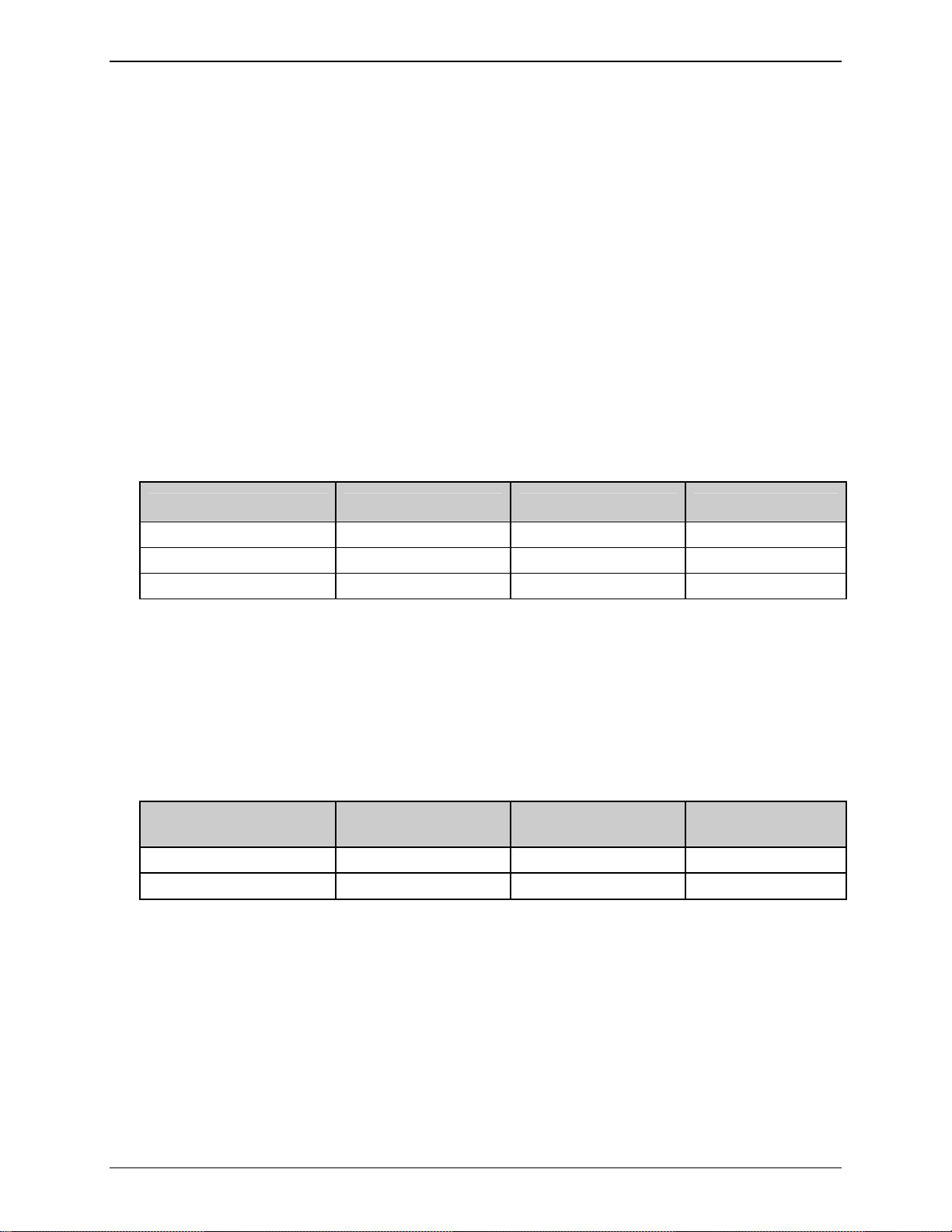

Overview

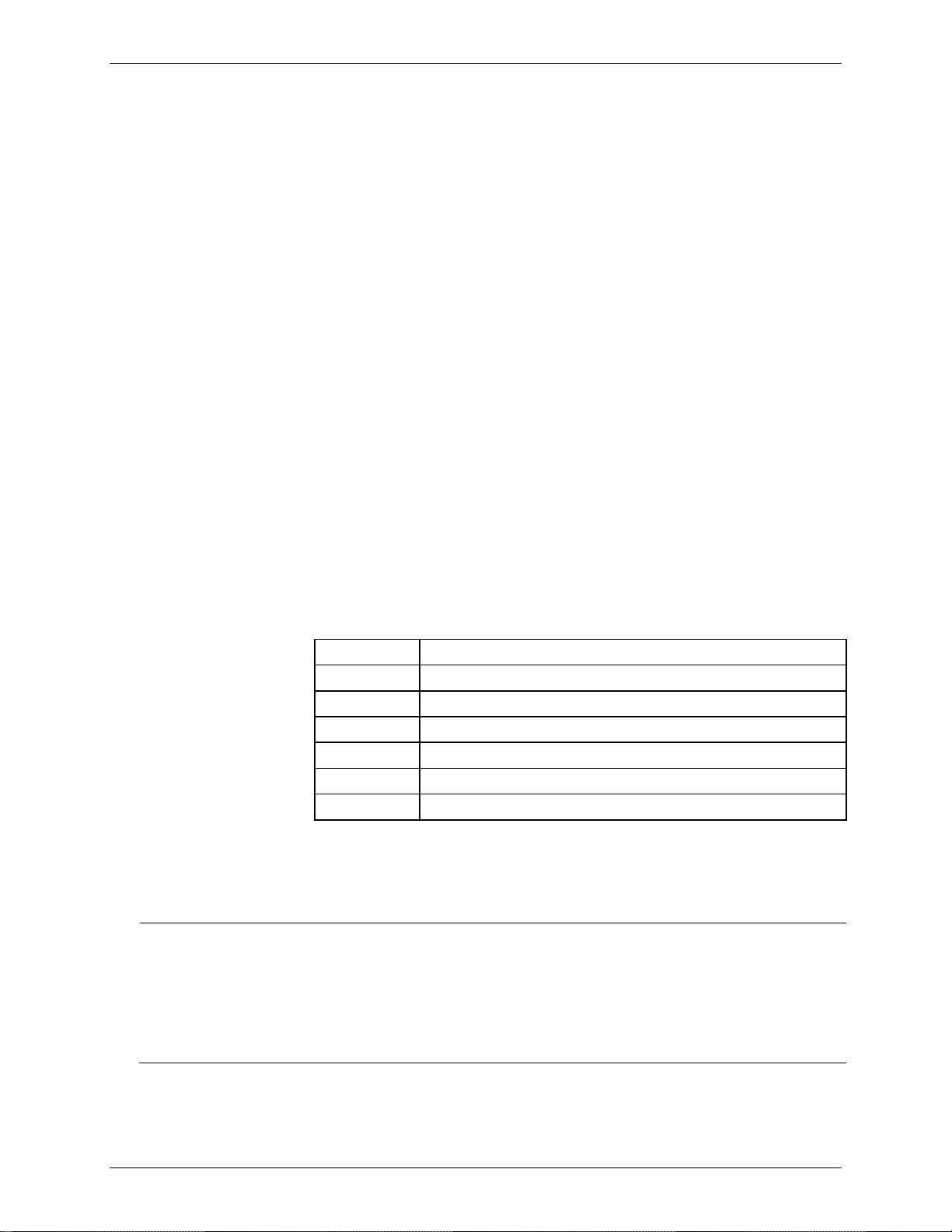

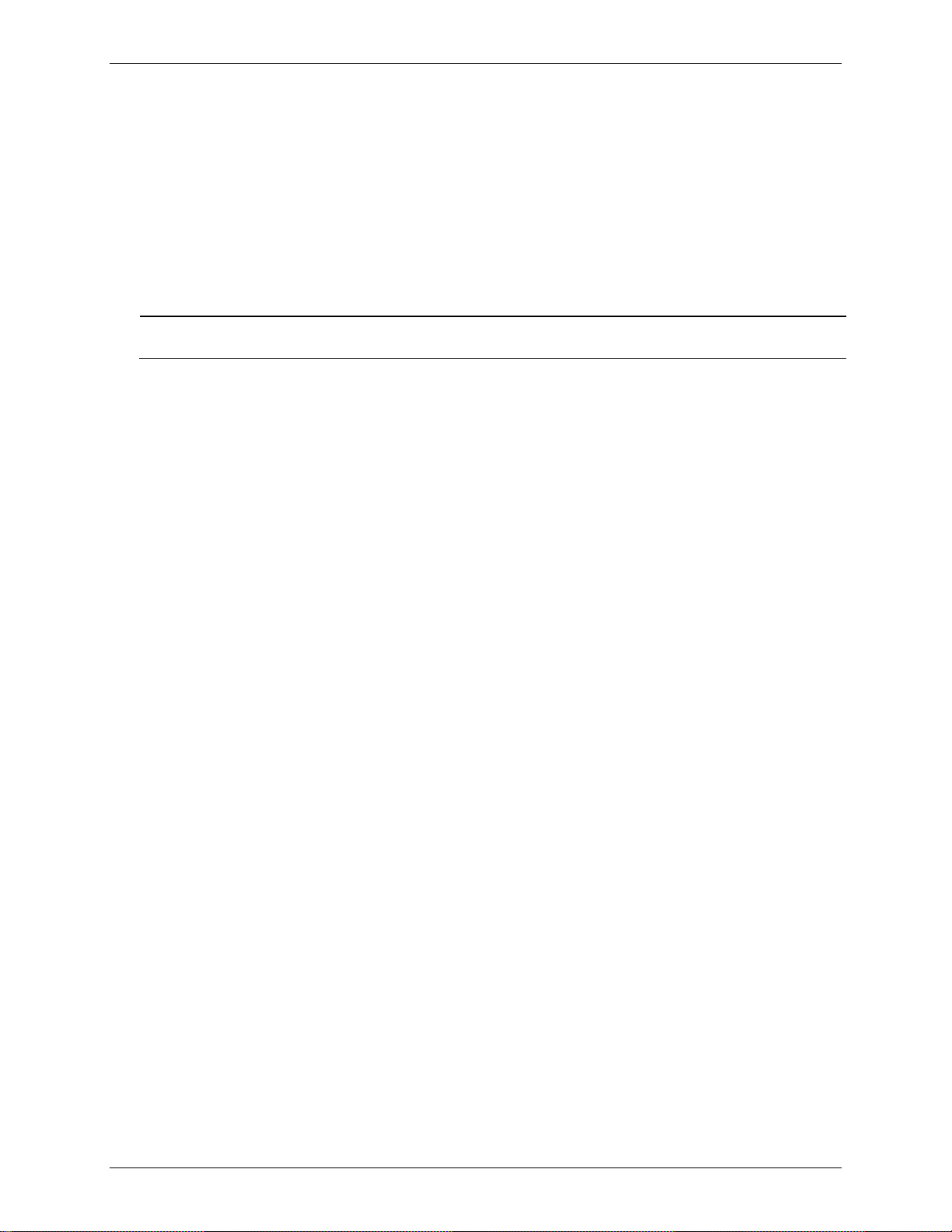

Label Header Commands

These commands determine how the label formatting occurs, the print quality and

quantity. They are typically issued immediately following the <STX>L start of the label

format. The Format Attribute (A) and the Offset (C, R) commands can be changed at

any point between format records to achieve desired effects.

Label Header Command Name

A

C

D

H

M

P

P

Q

R

S

Set Format Attribute

Column Offset

Set Width and Dot Size

Set Heat Setting

Set Mirror Mode

Set Print Speed

Set Backup Speed

Set Quantity

Set Row Offset

Set Feed Speed

5

Page 14

Overview

6

Page 15

Control Code Command Functions

2 Control Code Command Functions

Introduction

The printer requires a special “attention-getter” character in order to receive a command

sequence, informing the printer that it is about to receive a command and the type of

command it will be. Control Commands, System-Level Commands, and Font Loading

Commands have their own unique attention-getter, followed by a command character that

directs printer action.

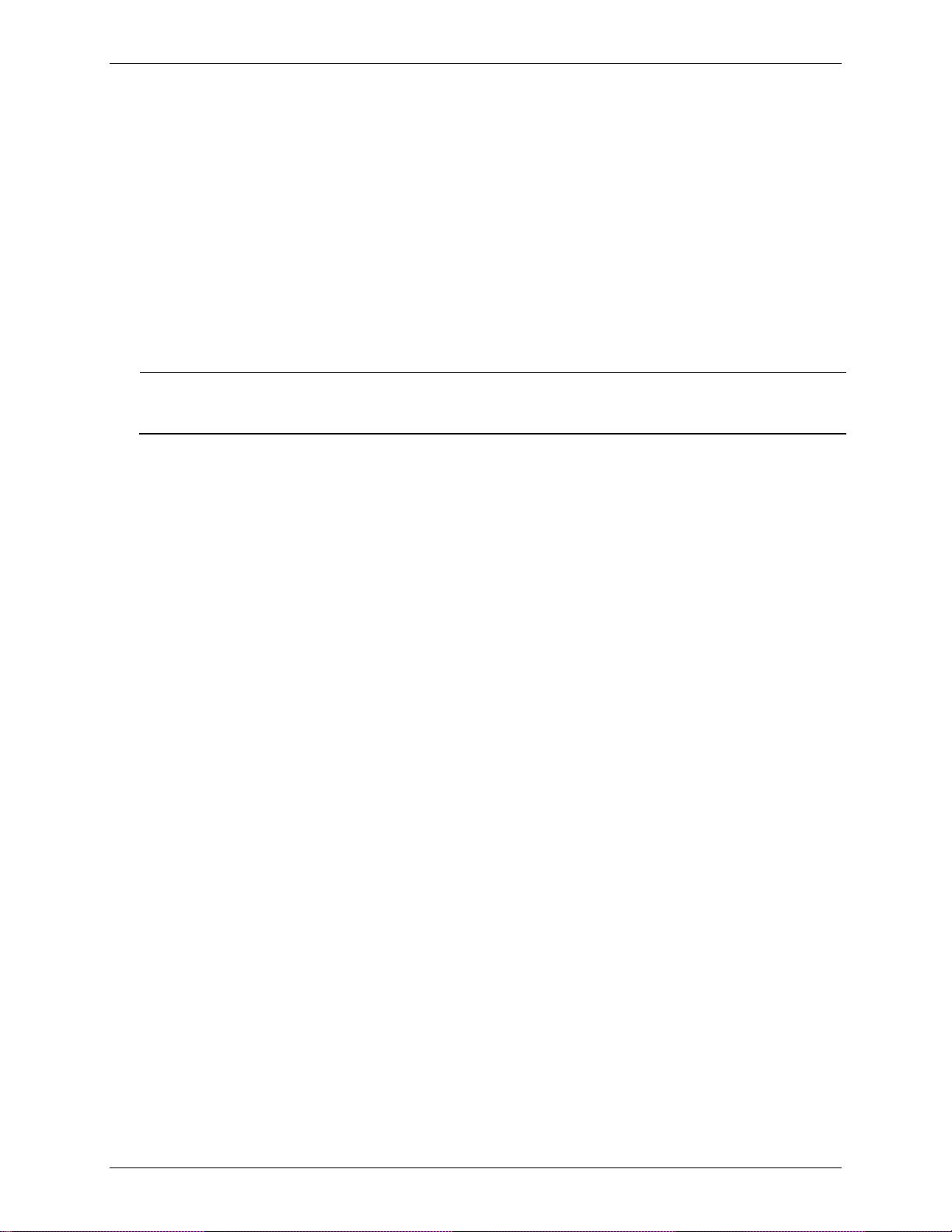

Attention-Getters

The attention-getters (e.g., “SOH”) are standard ASCII control labels that represent a one

character control code (i.e., ^A or Ctrl A). Appendix A contains the entire ASCII Control

Code Chart.

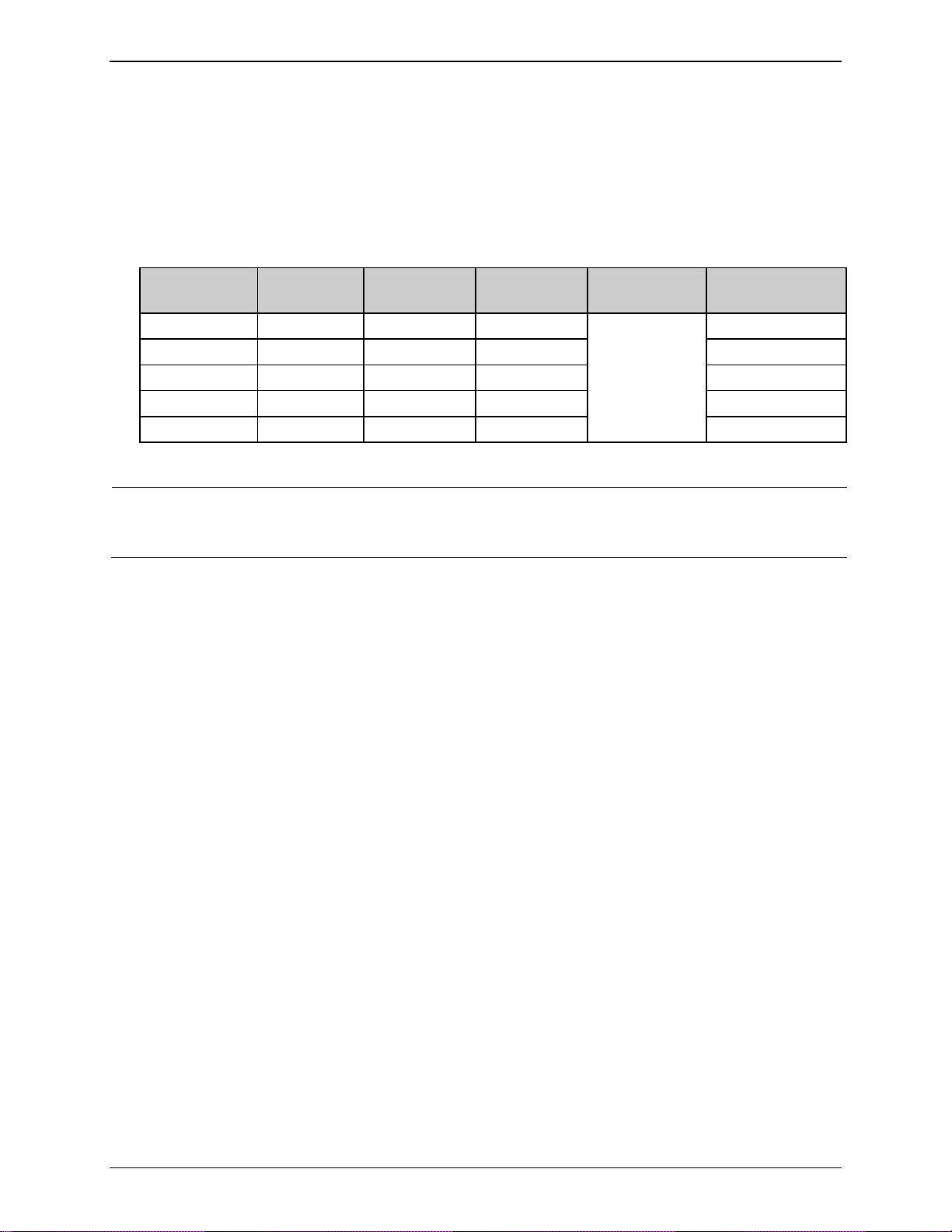

Attention-Getter ASCII Character Decimal Value HEX Value

Immediate Commands

System-Level Commands

Font Loading Commands

SOH 1 01

STX 2 02

ESC 27 1B

Easy Control Codes

DPL has been enhanced to accept a 3-character SOH and STX sequence. Easy Control Codes

are always enabled, whether in Standard, Alternate, Alternate 2, or Custom Control Code

Mode. Two types of sequences have been created to meet any application’s requirements.

Use these sequences where you normally would use a single SOH or STX character.

These sequences will not function when the printer input mode is selected to “auto”.

Control Character

SOH %01 ^01

STX %02 ^02

3 “%” Character

Sequence

3 “^”Character

Sequence

Command Type

Control

System

7

Page 16

Control Code Command Functions

Alternate Control Code Modes

For systems unable to transmit certain control codes, Alternate Control Code Modes are

available. Configuring the printer to operate in an Alternate Control Code Mode (selected via

the Setup Menu, the <STX>Kc command or, where applicable, the <STX>KD command)

requires the substitution of Standard Control Characters with Alternate Control Characters in

what is otherwise a normal data stream.

Control

Character

Standard Alternate Alternate 2 Custom

SOH 0x01 0x5E 0x5E

STX 0x02 0x7E 0x7E

CR 0x0D 0x0D 0x7C

ESC 0x1B 0x1B 0x1B

“Count By”

[1]

See Label Formatting Commands, ^ set count by amount.

[1]

0x5E 0x40 0x40

Throughout this manual <SOH>, <STX>, <CR>, <ESC>, and ^ will be used to indicate control

codes. The actual values will depend on whether standard or alternate control codes are

enabled for the particular application.

User Defined

Command

Type

Control

System

Line Termination

Font Loading

Label Formatting

Alternate Line Terminator Example: Alternate Control Codes provide for substitution of

the line terminator, as well as the control characters listed above. For example using

Alternate 2, the line terminator <CR> (0x0D) is replaced by | (0x7C). The following is a

sample label format data stream for a printer configured for Alternate-2 Control Codes:

~L|1911A10001000101234560|X|~UT01ABCDE|~G|

8

Page 17

Immediate Command Functions

<

<

3 Immediate Command Functions

Introduction

When the printer receives an Immediate Command, its current operation will be

momentarily interrupted to respond to the command. Immediate Commands may be issued

before or after System-Level commands; however, they may not be issued among Label

Formatting Commands or during font or image downloading. Immediate Commands consist

of:

1. Attention-Getter, 0x01 or 0x5E; see Control Code Command Functions.

2. Command Character

SOH # Reset

This command resets the printer. Resetting the printer returns all settings to default and

clears both the communications and printing buffers. The command also clears DRAM

memory.

Syntax:

Printer Response: The printer will reset.

SOH * Reset

This command forces a soft reset of the microprocessor. The printer is initialized to the

same state as a power cycle.

Syntax:

Printer Response: The printer will reset.

SOH>#

<XON> T

SOH>*

<XON> R

(The T may come before the <XON>)

(The R may come before the <XON>)

9

Page 18

Immediate Command Functions

<

<

SOH A Send ASCII Status String

This command allows the host computer to check the current printer status. The printer

returns a string of eight characters, followed by a carriage return. Each character (see

below) indicates an associated condition, either true (Y) or false (N). Byte 1 is

transmitted first. See <SOH>F.

Syntax:

Sample:

Printer Response:

Where:

SOH a Send ASCII Extended Status String

This command allows the host computer to check an extended current printer status.

The printer returns a string of seventeen characters, followed by a carriage return. Most

characters (see below) indicate an associated condition, either true (Y) or false (N). Byte

1 is transmitted first. See <SOH>F.

Syntax:

Sample:

Printer Response:

The printer response size may grow as new requirements are defined. The response will

always be backward compatible and terminated with a <CR>. The user should not

assume a fixed length response.

SOH>A

<SOH>A

abcdefgh<CR>

Possible

Values

-

a

b

c

d

e

f

g

h

Y/N Y = Interpreter busy (imaging) 1

-

Y/N Y = Paper out or fault 2

-

Y/N Y = Ribbon out or fault 3

-

Y/N Y = Printing batch 4

-

Y/N Y = Busy printing 5

-

Y/N Y = Printer paused 6

-

Y/N Y = Label presented 7

-

Y/N Y = (Internal) Rewinder out or fault 8

Interpretation

SOH>a

<SOH>a

abcdefgh:ijklmnop:qrstuvwx<CR>

Transmit

Sequence

10

Page 19

Immediate Command Functions

<

Where:

SOH B Toggle Pause

This command toggles the printer’s paused state between “On” and “Off.” (This is the

same function achieved by pressing the PAUSE Key.)

Syntax:

Sample:

Printer Response: This command will illuminate the Paused/Stop Indicator and/or

Possible

Values

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

u

v

w

x

Interpretation

-

Y/N Y = Interpreter busy (imaging) 1

-

Y/N Y = Paper out or fault 2

-

Y/N Y = Ribbon out or fault 3

-

Y/N Y = Printing batch 4

-

Y/N Y = Busy printing 5

-

Y/N Y = Printer paused 6

-

Y/N Y = Label presented 7

-

Y/N Y = Rewinder out or fault 8

-

: : = Always : 9

-

Y/N Y = Cutter Fault 10

-

Y/N Y = Paper Out 11

-

Y/N Y = Ribbon Saver Fault 12

-

Y/N Y = Print Head Up 13

-

Y/N Y = Top of Form Fault 14

-

Y/N Y = Ribbon Low 15

-

Y/N Y = N (reserved for future) 16

-

Y/N Y = N (reserved for future) 17

-

: : = Always : 18

-

Y/N Y = Ready (no data or signal) 19

-

Y/N Y = Waitng for Signal 20

-

Y/N Y = Waitng for Data 21

-

Y/N Y = Com1 has data not parsed 22

-

Y/N Y = N (reserved for future) 23

-

Y/N Y = N (reserved for future) 24

-

Y/N Y = N (reserved for future) 25

-

Y/N Y = N (reserved for future) 26

<CR> 27

SOH>B

<SOH>B

indicate PAUSED on the LCD or graphics display panel, suspend

printing, and wait until one of the following occurs:

• The <SOH>B command is sent to the printer.

• The PAUSE Key is pressed.

Upon which the printer will turn the Paused/Stop Indicator “Off”

and/or remove PAUSED from the LCD or graphics display, then

resume operation from the point of interruption. (If the Receive

Buffer is not full, an <XON> character will be transmitted from

the printer.)

Transmit

Sequence

11

Page 20

Immediate Command Functions

<

<

SOH C Stop/Cancel

This command performs the same function as pressing the STOP/CANCEL Key (i.e., it

clears the current format from the print buffer, pauses the printer, and illuminates the

Paused/Stop Indicator). (The pause condition is terminated as described under <SOH>B.)

Syntax:

Sample:

Printer Response: The print buffer is cleared and the Paused/Stop Indicator is

SOH D SOH Shutdown

This command is ignored by the printer.

SOH E Send Batch Remaining Quantity

This command causes the printer to return a four-digit number indicating the quantity of

labels that remain to be printed in the current batch, followed by a carriage return.

Communications latency may cause this value to be higher than actual on some printers.

Syntax:

Printer response:

Where:

SOH>C

<SOH>C

illuminated (and/or PAUSED is displayed on the LCD or graphics

display) as operations are suspended, until one of the following

occurs:

• The <SOH>B command is sent to the printer; or

• The PAUSE Key is pressed.

Upon which the printer will turn the Paused/Stop Indicator

“Off” and/or remove PAUSED from the LCD or graphics

display. (If the Receive Buffer is not full, an <XON> character

will be transmitted from the printer.)

SOH>E

nnnn<CR>

nnnn -

Are four decimal digits, 0-9999.

12

Page 21

Immediate Command Functions

<

<

“

SOH e Send Batch Printed Quantity

This command causes the printer to return a four-digit number indicating the quantity of

labels that have been printed in the current batch, followed by a carriage return.

Communications latency may cause this value to be lower than actual on some printers.

Syntax:

Printer response:

Where:

SOH F Send Status Byte

This command instructs the printer to send a single status byte where each bit (1 or 0)

represents one of the printer’s status flags, followed by a carriage return (see below). If

an option is unavailable for the printer, the single bit will always be zero. See <SOH>A.

Syntax:

Response format:

Where:

SOH>e

nnnn<CR>

nnnn -

Are four decimal digits, 0-9999.

SOH>F

X<CR>

X” is 0 through 0xef with bits as indicated in the “Condition”

column below:

Bit* Value Condition

8 1 or 0 (Internal) Rewinder out or fault

7 1 or 0 Label presented

6 1 or 0 Printer paused

5 1 or 0 Busy printing

4 1 or 0 Printing batch

3 1 or 0 Ribbon out or Fault

2 1 or 0 Paper out or Fault

1 1 or 0 Command interpreter busy (imaging)

*

One is the least significant bit.

13

Page 22

Immediate Command Functions

14

Page 23

System-Level Command Functions

<

j

4 System-Level Command Functions

Introduction

The most commonly used commands are the System-Level Commands. These are used to

load and store graphics information, in addition to printer control. System-Level Commands

are used to override default parameter values (fixed and selectable) and may be used

before or after Immediate Commands but cannot be issued among Label Formatting

Commands. System-Level Commands consist of:

1. Attention-Getter, 0x02 or 0x7E; see Control Code Command Functions.

2. Command Character

3. Parameters (if any).

STX A Set Time and Date

This command sets the time and date. The initial setting of the date will be stored in the

printer’s internal inch counter. This date can be verified by printing a Configuration

Label.

Syntax:

Where:

Sample:

Printed response:

•

• Printers without the Real Time Clock option lose the set time/date when power is

• Response format is variable; see the Special Label Formatting Command <STX>T.

When set to 000, the Julian date is automatically calculated; otherwise, the Julian

date will print as entered, without daily increments. If factory defaults are restored

the actual Julian date will also be restored.

removed.

STX>AwmmddyyyyhhMMjj

w

mm

dd

yyyy

hh

MM

jjj

1 digit for day of week; 1 = Monday; 7 = Sunday

2 digits for month

2 digits for day

4 digits for year

2 digits for hour in 24 hour format

2 digits for minutes

3 digits for Julian date / constant; see notes below.

<STX>A1020319960855034

Mon. Feb 3, 1996, 8:55AM, 034

15

Page 24

System-Level Command Functions

<

<

STX a Enable Feedback Characters

This command enables the feedback ASCII hex characters to be returned from the

printer following specific events after each completed batch of labels when using serial

communications. The default value is ”OFF”.

Syntax:

Printer response: Event dependent. (Also see Appendix D for error codes.)

Where:

STX B Get Printer Time and Date Information

This command instructs the printer to retrieve its internal time and date information.

Syntax:

Sample:

Response format:

Where:

Response sample:

STX>a

Event Return Characters

Invalid character

Label printed

End of batch

STX>B

<STX>B

wmmddyyyyhhMMjjj<CR>

w

mm

dd

yyyy

hh

MM

jjj

* See <STX>A for details and restrictions.

1 digit for day of week; 1 = Monday

2 digits for month

2 digits for day

4 digits for year

2 digits for hour in 24 hour format

2 digits for minutes

3 digits for Julian date / constant*

1020319960855034<CR>

0x07 ( BEL )

0x1E ( RS )

0x1F ( US )

16

Page 25

System-Level Command Functions

<

<

>

STX c Set Continuous Paper Length

This command sets the label size for applications using continuous media. It disables the

top-of-form function performed by the Media Sensor. The sensor, however, continues to

monitor paper-out conditions. See <STX>M.

Syntax:

Where:

Sample:

This command must be reset to zero for edge or reflective sensing operation.

STX E Set Quantity for Stored Label

This command sets the number of labels for printing using the format currently in the

print buffer. (The printer automatically stores the most recent format received in the

buffer until the printer is reset or power is removed.) When used in conjunction with the

<STX>G command, this will print the format.

Syntax:

Where:

Sample:

Printer response: 25 labels of the current format in memory will be printed.

If no <CR> terminates the command, a four-digit quantity (nnnn) can be entered; and,

specifying 9999 will cause continuous printing.

STX>cnnnn

nnnn -

<STX>c0100

Specifies the length of the media feed for each label

format, in inches/100 or millimeters/10 (see <STX>m).

The sample above sets a label length of 100, which equals 1.00

inch (assuming Imperial Mode is selected).

STX>Ennnnn<CR

nnnnn -

<CR> -

<STX>E00025<CR>

<STX>G

A five-digit quantity, including leading zeros.

0x0d terminates the name.

17

Page 26

System-Level Command Functions

<

<

<

STX e Select Edge Sensor

This command enables transmissive (see-through) sensing for top-of-form detection of

die-cut and holed (notched) media. This sensor will detect a minimum gap of 0.1 inches

(2.5 mm) between labels (see the Operator’s Manual for media requirements). This is

the default setting.

Syntax:

This command is ignored when <STX>cnnnn is issued with a non-zero value for nnnn.

STX F Form Feed

This commands the printer to form feed to the next start of print.

Syntax:

Printer response: The printer will form feed.

STX f Set Form Stop Position (Backfeed Command)

This sets the stop position of the printed label, allowing the label to stop at a point past

the start-of-print position. When the next label format is sent, the printer motor

reverses direction to retract the media to the start-of-print position. If quantities of more

than one label are requested, the printer will operate without backfeeding. Backfeed will

then only occur when printing has stopped for a few seconds.

D-O recommend not using the <stx>Kf command instead of this command. This is a

legacy command.

Syntax:

Where:

Sample:

STX>e

STX>F

STX>fnnn

nnn -

Is a three-digit distance from the Media Sensor, in

inches/100 or mm/10. This distance is independent of

the start-of-print position (<STX>O), yet it must be

greater than the start-of-print position to take effect.

<STX>f230

The sample above sets a stop position distance of 230 (2.3 inches

from the Media Sensor’s eye).

18

Page 27

System-Level Command Functions

<

<

>

d

STX G Print Last Label Format

This command prints a previously formatted label and restarts a canceled batch job

following the last processed label. This is used when there is a label format in the buffer.

The <STX>E command is used to enter the quantity. (Without the <STX>E command, one

label will print.)

Syntax:

STX>G

STX I Input Image Data

This command must precede image downloading from the host to the printer. The data

that immediately follows the command string will be image data.

The native format for storing downloaded PCX and BMP images is RLE-2, which results

in a better compression ratio for less module space usage when downloading gray-scale

Syntax:

Where:

Sample:

images and images with large black or white areas.

STX>Iabfnn…n<CR

ata

a -

b -

f -

nn…n -

<CR> -

data -

<SOH>D

<STX>IDpTest <CR>

data...data <CR>

The sample above instructs the printer to (1) receive an 8-bit PCX

image sent by the host in an 8-bit data format, (2) name the

image “Test”, and (3) store it in Module D (with a .dim file

extension).

Memory Module Bank Select (see Appendix K).

Data Type (optional), A or omit:

b Value: Image Data Value Range:

A ASCII Characters 0-9, A-F, (7 bit)

omit 00-FF, (8 bit)

Format Designator:

f Designator: Format Type:

F

B

b

I

i

P

p

Up to 16 characters used as an image name.

0x0d terminates the name.

Image data

7-bit D-O image load file

.BMP 8-bit format, flipped, black

and white (B&W)

.BMP 8-bit format, B&W

.IMG 8-bit format, flipped, B&W

.IMG 8-bit format, B&W

.PCX 8-bit format, flipped, B&W

.PCX 8-bit format, B&W

19

Page 28

System-Level Command Functions

<

e

<CR>

x

…

<

STX i Scalable Font Downloading

The command structure for downloading TrueType (.TTF) scalable fonts (files may be

single-byte or double-byte character systems) is as follows:

Syntax:

STX>imtnnNam

Where:

Sample:

m -

The designator of the module where the font is to be

saved; see Appendix K.

t -

Type of scalable font being downloaded:

T = TrueType

nn -

Two-digit font reference ID. Valid range is 03-99,

9A-9Z, 9a-9z (base 62 numbers).

Name -

The title, up to 15 characters, for this font.

<CR> -

0x0d terminates the Name.

xx…x -

Eight-digit size of the font data, number of bytes,

hexadecimal, padded with leading zeros.

data -

The scalable font data.

<STX>iDT52Tree Frog<CR>000087C2data...

The sample above downloads a TrueType font to Module D, and

assigns it the Font ID of 52 with the name “Tree Frog” and file

extension .dtt. The size of the font data is 0x87C2 bytes long.

STX J Set Pause for Each Label

This command causes the printer to pause after printing each label. It is intended for

use with the peel mechanism or tear bar when the Present Sensor option is not installed.

After removing the printed label, the PAUSE Key must be pushed in order to print the

next label. (The printer must be reset to clear the <STX>J command.)

Syntax:

STX>J

STX K Extended System-Level Commands

This is an expansion of the System-Level Command structure; see Extended SystemLevel Commands for more information.

x…xdata

20

Page 29

System-Level Command Functions

<

<

<

<

STX k Test Communication Port

This command instructs the printer to transmit the Y character from the printer’s port

that received this command. (Failure to receive Y could indicate an interfacing problem.)

Syntax:

Printer response:

STX L Enter Label Formatting Command Mode

This command switches the printer to the Label Formatting Command Mode, where the

printer expects to receive only Record Structures and Label Formatting Commands.

Immediate, System-Level, and Font Loading commands will be ignored until the label

formatting mode is terminated with E, s, or X, (see Label Formatting Commands for

additional information).

Syntax:

STX M Set Maximum Label Length

This command instructs the printer move media this distance in search of the top-ofform (label edge, notch, black mark, etc.) before declaring a paper fault. A paper fault

condition can occur if this setting is too close (within 0.1 inch [2.54 mm]) to the physical

length of the label. Therefore, it is a good practice to set this command to 2.5 to 3 times

the actual label length used. The minimum value should be at least 5” (127 mm).

Syntax:

Where:

Sample:

STX m Set Printer to Metric Mode

This command sets the printer to interpret measurements as metric values (e.g.,

<STX>c0100 will equal 10.0 mm). The default is Imperial (see <STX>n).

Syntax:

STX>k

Y

STX>L

STX>Mnnnn

nnnn -

Is a four-digit length, 0000-9999, in/100 or mm/10.

Maximum setting is 9999 (99.99 inches or 2540

mm). The default setting is 16 inches/ 406.4 mm.

<STX>M0500

The sample above sets a maximum travel distance of 5 inches

(unless the printer is in metric mode; see <STX>m).

STX>m

21

Page 30

System-Level Command Functions

<

<

<

STX n Set Printer to Imperial Mode

This command sets the printer to interpret measurements as inch values (e.g.,

<STX>c0100 will equal 1.00 inch), and is the default mode.

Syntax:

STX O Set Start of Print (SOP) Position

This command sets the point to begin printing relative to the top-of-form (the label’s

edge as detected by the Media Sensor). The printer will feed from the top-of-form to the

value specified in this command to begin printing.

This value operates independently of the <STX>f command.

D-O recommend not using the row adjust feature instead of this command. This is a

legacy command.

Syntax:

Where:

Sample:

STX o Cycle Cutter

This command will cause the optional cutter mechanism to immediately perform a cut

after all previously received commands are executed. The cutter must be installed,

enabled and the interlock(s) closed for operation.

Syntax:

STX>n

STX>Onnnn

nnnn -

Is a four-digit offset value in inches/100 or mm/10.

The “zero” setting is the default value, and settings

below 50 are adjusted back to the default value.

The default setting is “Off” and the printer assumes

the natural SOP position.

<STX>O0210

The sample above will begin printing 0.1 inch closer to the leading

edge of the label if the 220 (Allegro) SOP Emulation was selected,

or 1.0 inch farther away from the leading edge if 110 (ProdPlus)

SOP Emulation was selected.

STX>o

22

Page 31

System-Level Command Functions

<

<

<

STX P Set Hex Dump Mode

This command instructs the printer to assume Hex Dump Mode. Instead of a formatted

product, data sent following this command will be printed in its raw ASCII format. To

capture all data, labels should be at least four inches (102 mm) long and as wide as the

maximum print width. This command has the same effect as turning “On” the printer

while depressing the FEED Key (return normal operation by manual reset).

Syntax:

Printer response is

data dependent

(layout may vary):

STX>P

STX p Controlled Pause

This command will cause the printer to pause only after all previously received

commands are executed, often useful between label batches. (This command will not

clear the pause condition; see <SOH>B).

Syntax:

STX>p

STX Q Clear All Modules

This command instructs the printer to clear all Flash and DRAM modules (except as

noted); see the corresponding Operator’s Manual for applicable module options. All

stored data will be destroyed.

Syntax:

Will not affect Module Y or the ILPC Font module.

STX>Q

23

Page 32

System-Level Command Functions

<

<

<

STX q Clear Module

This command clears the selected Flash or DRAM module. During normal operations if a

module becomes corrupted (identifiable when the printer responds with a “No Modules

Available” message to a <STX>W command) it must be cleared. All stored data will be

destroyed.

Syntax:

Where:

Sample:

Will not affect Module Y or the ILPC Font module.

STX R Ribbon Saver Control

This command enables the operation of the optional Ribbon Saver. It is the only

command used to control the Ribbon Saver. Its operation is continuous when enabled.

The printer must be set to thermal transfer (ribbon) printing mode then, during

operation, the Ribbon Saver engages automatically, lifting when the minimum amount of

label white space is exceeded.

Syntax:

Where:

Sample:

STX>qa

a -

<STX>qA

Memory module designator; see Appendix K.

STX>Rx

x -

Y - Enabled (Default = Menu selection.)

N - Disabled

<STX>RY

The sample above will turn the ribbon saver on.

This command is ignored on non-equipped printers.

STX r Select Reflective Sensor

This command enables reflective (black mark) sensing for top-of-form detection of rolled

butt-cut, and fan-fold or tag stocks with reflective marks on the underside. This Media

Sensor will detect a minimum mark of 0.1 inches (2.54 mm) between labels (see the

Operator’s Manual for media requirements). The end of the black mark determines the

top of form. Use the <STX>O command to adjust the print position.

Syntax:

Default setting: Edge sensing

STX>r

24

Page 33

System-Level Command Functions

<

<

<

STX S Set Feed Speed

This command controls the output rate of the media when the FEED Key is pressed.

Syntax:

Where:

STX T Print Quality Label

This command instructs the printer to produce a Print Quality label, a format comprised

of different patterns and bar codes useful in printer setup. To capture all printed

information, use the labels as wide as the maximum print width (see Appendix K) and at

least four inches (102 mm) long.

Syntax:

Printer response

(dot patterns may

vary):

STX>Sn

n -

STX>T

Is a letter value (see Appendix L).

STX t Test DRAM Memory Module

This command tests the DRAM module. The printer returns a one-line message stating

the module condition (no message is returned if a module is unavailable). The printer

must have Feedback Characters enabled for this command to function. Feedback

Characters can be enabled via the menu (see the Operator’s Manual for additional

information).

Syntax:

3

Response format:

Where:

STX>t

Module D: xxxxK RAM Tested results <CR>

xxxx

Module size in Kbytes.

-

results

Test results given as “Good” or “Bad”.

-

25

Page 34

System-Level Command Functions

<

>

<

>

STX U Label Format String Replacement Field

This command places new label data into format fields to build a label. Two options are

available: Exact Length and Truncated Length.

To easily keep track of fields, place all of the fields to be updated with the command at

the beginning of the label format. A maximum of 99 format fields can be updated. Fields

are numbered consecutively 01 to 99 in the order received.

Exact Length Replacement Field Functions – The new data string must equal the

original string length and contain valid data. When the dynamic data is shorter than the

length of the originally defined data field, then field will be padded with blanks (or zero

when the Format Record header specifies a numeric bar code).

Syntax:

Where:

Exact Length

Sample:

Truncated Length Replacement Field Functions – A variant of the <STX>U command

includes the truncate option “T”, where dynamic data shorter than the originally defined

field length will not be padded and the original maximum field length is maintained for

subsequent replacements.

Syntax:

Where:

STX>Unnss…s<CR

nn

ss…s

- Is the format field number, 2 digits.

Is the new string data, followed by a <CR>

-

<STX>L

1A1100001000100data field 1<CR>

161100001100110data field 2<CR>

161100001200120data field 3<CR>

Q0001

E

<STX>U01123<CR>

<STX>U02New data F2<CR>

<STX>E0002

<STX>G

The sample above produces three labels. The first is formatted

with the commands between <STX>L and E. The next two labels

print with the replacement data contained in the <STX>U

commands (see <STX>E and <STX>G). The bar code is the same

length: 3 digits and nine spaces.

STX>UTnnss…s<CR

nn

T

ss…s

- Is the format field number, 2 digits.

-

Truncate option

-

Is the new string data, followed by a <CR>.

26

Page 35

System-Level Command Functions

<

Truncated Sample:

STX V Software Switch Settings

This command controls the printer options, where the appropriate value allows the

option(s) to be “On” or “Off.” Each option has a corresponding bit whose value is “1”

when enabled. The tables below indicate the bit assignments and corresponding

command value needed to enable the desired option(s). Printer options are set by

entering selections through the menu. The software setting command allows two of

these option settings to be modified without returning to the menu.

Syntax:

Where:

Sample:

Bit Assignment Printer Option

0 Cutter

1 N/A

2 Present Sensor

3 N/A

Use the bit assignment table above to determine the command value n in the binary

table below (e.g., the command value 5 sets the bits 0 and 2 to “1”).

n Value

0 0 0 0 0

1 0 0 0 1

4 0 1 0 0

5 0 1 0 1

<STX>L

1A1100001000100data field 1<CR>

161100001100110data field 2<CR>

161100001200120data field 3<CR>

Q0001

E

<STX>UT01123<CR>

<STX>U02New data F2<CR>

<STX>E0002

<STX>G

The sample above produces three labels. The first is formatted

with the commands between <STX>L and E. The next two labels

print with the replacement data contained in the <STX>U

commands (see <STX>E and <STX>G). The bar code is shortened;

it only has three digits (and no spaces).

STX>Vn

n

<STX>V5

The sample above corresponds to setting Bits 0 and 2, creating a

command value of 5. When applied, this enables the Present

Sensor and Cutter options.

- Is a single digit ASCII numeric value from 0-F. The

value of n is used to override the power-up option

settings. Reset or power-up returns the printer to the

original settings.

Command Values for Bits Assigned

Bit

3 2 1 0

27

Page 36

System-Level Command Functions

<

<

STX v Request Firmware Version

This command causes the printer to send its version string (same as printed on the

configuration label). The version may be different from printer to printer.

Syntax:

Printer Response:

STX W Request Memory Module Information

This command requests a memory module directory listing. Results may vary depending

on printer class, model, or firmware version.

Syntax:

Where:

Sample:

Printer response:

STX>v

VER: 9.02_0004 01/01/2008<CR>

STX>W[b][c]a

b s

c e

a -

<STX>WF

MODULE: D<CR>

S50 92244ttf50<CR>

AVAILABLE BYTES: 945152<CR>

MODULE: G<CR>

AVAILABLE BYTES: 852480<CR>

MODULE: X<CR>

AVAILABLE BYTES: 852480<CR>

MODULE: Y<CR>

AVAILABLE BYTES: 852480<CR>

optional – list file size also

optional – list file extension also

Data type:

F

=

G

L

C

X

N

M

f

p

*

Downloaded fonts

=

Graphics (Image)

=

Label formats

=

Configuration files

=

Menu language files

=

Plug-ins

=

Miscellaneous type files

=

Resident fonts

=

Entire module contents

=

All types

28

Page 37

System-Level Command Functions

<

<

STX w Test Flash Memory Module

This command tests the Flash module. The time for each test will vary from 20 to 120

seconds, depending upon the size of the module. All stored data will be destroyed. If

no module is present, there will be no printer response.

Syntax:

Where:

Response format:

Where:

STX X Set Default Module

This command, typically used prior to the loading of PCL-4 bitmapped fonts (see Font

Loading Commands), is designed to allow the user to select between modules when

downloading information. The default module is one of the following:

1. The first alpha designator of the existing modules if item 2 has not occurred.

2. The module selected by this command.

Syntax:

Where:

Sample:

The sample above sets “B” as the default module.

STX>wa

a

Module A: xxxxK results

A

xxxx

results - Test results given as “Good” or “Bad”.

STX>Xa

-

Module designator; see Appendix K.

Module tested.

-

-

Module size in Kbytes.

a

<STX>XB

- Module designator; See Appendix K.

29

Page 38

System-Level Command Functions

<

>

G

L F

S C X N M u

STX x Delete File from Module

This command removes a specific file from the specified module. The file name is

removed from the module directory and thus the file cannot be accessed. The actual

storage space occupied by the file is not released. To reclaim deleted file storage space

use <STX>z to pack the module.

Syntax:

Where:

Sample:

STX>xmtnn…n<CR

m

t

nn…n -

- Module designator; see Appendix K.

The file type identification code:

-

=

Image file

=

Label format file

=

Downloaded bitmapped font file

=

Downloaded scalable font file

=

Configuration file

=

Language file

=

Plug-in file

=

Miscellaneous file type

=

Unknown type – must use extension if

applicable

The file to delete, where:

• Font (bitmapped), three character font identifier;

• Font (scalable), two character font identifier;

• Graphic name, up to sixteen alphanumeric

characters; or,

• Label format name, up to sixteen alphanumeric

characters.

<STX>xDS50<CR>

The sample above deletes a downloaded scalable font with ID 50

from Module D.

30

Page 39

System-Level Command Functions

<

<

STX Y Output Sensor Values

This command causes a sensor value response. When <STX>Y is received, the printer will

respond with the digitally converted values of the internal analog sensors (see below).

To repeat the display of values, send the printer a “SPACE” character (20 hexadecimal);

or, send <ESC> to terminate this function.

The printer must have Feedback Characters enabled for this command to function.

(Feedback Mode [Characters] can be enabled via command or menu setting; see the

<STX>KcFM command or the Operator’s Manual for additional information).

Syntax:

Printer response:

Where:

•

• Some readings require printer-controlled paper movement to produce a meaningful

• Media Sensor readings require the appropriate sensor selection, transmissive

Equipped sensors vary with printer, model, and options;

value; and,

(<STX>e) or reflective (<STX>r), and label stock placed in the sensor.

STX>Y

Thermistor ADC: 0048 Reflective ADC: 0000

Transmissive ADC: 0000 24 Volt ADC: 0217 Contrast ADC:

0093 TOF Adjust ADC: 0170 Ribbon ADC: 0125 Battery

Level: Good <CR>

Battery level: Good indicates a sufficient battery charge;

Low indicates an insufficient charge.

STX y Select Font Symbol Set

This command selects the scalable font symbol set. The selected symbol set remains

active until another symbol set is selected. See the <STX>KS command and Appendices

E, I, and H for more information. Option dependent and not all symbol sets can be used

with all fonts.

Syntax:

Where:

Sample:

STX>ySxx

S

Byte-size designation; see Appendix H:

-

S = Single byte symbol sets.

U = Double byte symbol sets.

xx

-

Symbol set selection.

<STX>ySPM

The sample above selects the PC-850 multilingual set.

31

Page 40

System-Level Command Functions

<

<

STX Z Print Configuration Label

This command causes the printer to produce a Database Configuration Label. To capture

all printed information, use the labels as wide as the maximum print width (see

Appendix K) and at least four inches (102 mm) long.

Syntax:

Printer response:

STX>Z

CONFIGURATION

TUE 09:09 AM 10 FEB2009

PRINTER KEY:

4212-HE25-060224-090

APPLICATION VERSION:

83-2541-11H3 11.083 12/22/2008

MCL Version: 1.00.06-072

BOOT LOADER:

83-2539-11A 11.01 10/02/2007

UNLOCKED:

CG TIMES

FPGA:

HP10

iPH:

5x-00289 #163

MACM:

00-0d-70-03-8b-b9

MACO:

NOT SET

MACR:

00-90-c9-01-D0-64

SYSTEM INFORMATION

PRINT BUFFER SIZE:

100 in.

FLASH SIZE:

8 MB

RAM TEST:

PASS

MODE:

DISABLED

BACKUP DELAY (1/50s):

0

FONT EMULATION:

STANDARD FONTS

LABEL STORE:

STATE & FIELDS

MENU LANGUAGE:

ENGLISH

FAULT HANDLING:

LEVEL:

STANDARD

VOID DISTANCE:

0.50 in.

RETRY COUNT:

1

BACKFEED ON CLEAR:

DISABLED

COMMUNICATIONS

SERIAL PORT A:

BAUD RATE:

9600 BPS

PROTOCOL:

BOTH

PAR ITY:

NONE

DATA BITS:

8

Printed information will vary according to printer, model, firmware version, and options.

STX z Pack Module

Ignored.

This command causes the printer to reclaim all storage space associated with all deleted

files on the specified module (see <STX>X and <STX>x).

STX>zm

m

- The module identification character; see Appendix K.

Syntax:

Where:

ignored

32

Page 41

Extended System-Level Command Functions

Extended System-Level

5

Command Functions

Introduction

Issued in the same context as System-Level Commands, the Extended System-Level

Commands expand certain System-Level Commands to provide an extra degree of printer

control.

STX K}E Empty Sensor Calibration

This command causes the printer to determine and save the calibration value for an

empty media sensor condition. This calibration function should be performed when no

material is installed in the media sensor. Depending upon the printer model, different

front panel LED flash sequences and printer responses (below) will indicate calibration

progress and outcome; see the corresponding printer operator manual for LED flash

sequences details.

Printer Response Alternate

REMOVE STOCK[CR] N/A

ENTER TO CONTINUE[CR] N/A

PASSED CALIBRATION[CR] FAILED CALIBRATION[CR]

33

Page 42

Extended System-Level Command Functions

STX K}M Manual Media Calibration

This command causes the printer to save the sampled calibration values as an operator

places different portions of label stock within the media sensor. Depending upon the

printer model, different front panel LED flash sequences and printer responses (below)

will indicate calibration progress and outcome; see the corresponding printer operator

manual for LED flash sequences details. Sending <ESC> to the printer instead of <CR>

will terminate the process and leave the TOF Sensor values unchanged.

Printer Response Alternate

LOAD STOCK[CR]

ENTER TO CONTINUE[CR]

LOAD MARK[CR]

ENTER TO CONTINUE[CR]

REMOVE STOCK[CR]

ENTER TO CONTINUE[CR]

N/A

LOAD GAP[CR]

N/A

PASSED CALIBRATION[CR] FAILED CALIBRATION[CR]

STX K}Q Quick Media Calibration

This command causes the printer to move media, sample, and then save sensor samples

as calibration values. This calibration function should be performed with media installed

over the TOF sensor in the printer. Depending upon the printer model, different front

panel LED flash sequences and printer responses (below) will indicate calibration

progress and outcome; see the corresponding printer operator manual for LED flash

sequences details.

Printer Response Alternate

FAILED CALIBRATION[CR]

ADJUST GAIN SETTING[CR]

N/A

PASSED CALIBRATION[CR] FAILED CALIBRATION[CR]

34

Page 43

Extended System-Level Command Functions

<

e

<CR>

STX KaR Read Data from RFID Tag

(Direct Mode – Generic Read/Write Interface)

This command instructs the RFID device to read data from the tag and then place that

data into a replaceable field. It is expected that the tag transponder will be within the

read / write distance of the RFID programming device; otherwise, “Void” will be printed

in the text or bar code label field.

Syntax:

Where:

Sample:

STX>KaRAaaabbbcde

A

aaa

bbb

c

d

ee

<STX>L

1911A1802000010TEXT

U

X

<STX>KaR0000010001

<STX>G

- Optional – for data in the ASCII format.

The number of bytes to read.

-

HF - Starting block number (000 maximum block

number, which is dependent upon the

transponder manufacturer).

UHF – Should be 000.

Command 1. Reserved. Should be 0.

-

Command 2. Reserved. Should be 0.

-

-

Field number in which to place the data (must be 01,

02, 03, etc.) matching the order of Label Formatting

command U.

The 00 value will send read data to the host with no

printing.

The sample above creates a replaceable text field (01), recalls data

from the RFID tag block zero (reading only one block), and prints

the data in the location specified by the replaceable field. Since

there are two digits per each hex value, replaceable fields should be

twice as long than if using ASCII data (e.g., the character “A” would

be returned as “41”).

35

Page 44

Extended System-Level Command Functions

<

e

<CR>

<

>

STX KaW Write Data to RFID Tag

(Direct Mode – Generic Read/Write Interface)

This command instructs the RFID device to write data to the tag. It is expected that the

tag transponder will be within the read / write distance of the RFID programming device;

otherwise, a warning will occur and a warning message (Read / Write Fail) will be

displayed.

Syntax:

STX>KaWAaaabbbcdee…

Where:

Aaaa

-

Optional – for data in the ASCII format, followed by

the byte count (000-999).

bbb

HF – Starting block number (000 maximum block

-

number, which is dependent upon the

transponder manufacturer).

UHF – Should be 000.

c

Command 1. Reserved for Future (should be 0)

-

d

Command 2. Reserved for Future (should be 0)

-

ee…e

Data to be encoded on RFID tag (HF – the last used

-

block will be null-padded, if necessary).

UHF ASCII formats must be 8 or 12 characters; and,

UHF Hexadecimal formats must be 16 or 24

character pairs.

Sample:

<STX>KaW0000054455354[CR]

The sample above writes the data “TEST” at block zero.

STX Kb Backfeed Time Delay

This command controls the time a printed label is allowed to remain “presented” before

being retracted to the start of print position.

Syntax:

Where:

STX>Kbnnn<CR

nnn

-

Seconds/10 (0 to 255)

36

Page 45

Extended System-Level Command Functions

<

>

STX KC Get Configuration

This command returns the configuration of the printer. The form of the returned data is

similar to that of a printed Configuration Label. This command should be parsed by

KEYWORDS, not character positions. Each line is terminated by a CR (0x0d) & LF

(0x0a).

Syntax:

Printer response:

PRINTER INFORMATION[CR ]

[LF ] TUE 10:07AM

18JUN2013[CR ]

[LF ] PRINTER KEY:[CR ]

[LF ] 4310-VN10-900067846[CR ]

[LF ] APPLICATION

VERSION:[CR ]

[LF ] I4310e 10.03_0035 0002

May 25 2013[CR ]

[LF ] BOOT1 VERSION:[CR ]

[LF ] ver: 1.10 0002[CR ]

[LF ] BOOT1 PN:[CR ]

[LF ] 83-2848-01A[CR ]

[LF ] BOOT2 VERSION:[CR ]

[LF ] ver: 2.06 0002[CR ]

[LF ] BOOT2 PN:[CR ]

[LF ] 83-2856-01B[CR ]

[LF ] PLUGIN MODULES:[CR ]

[LF ] Y: ??-2860-01B[CR ]

[LF ] UNLOCKED:[CR ]

[LF ] CG Times[CR ]

[LF ] CG TRIUM[CR ]

[LF ] FPGA:[CR ]

[LF ] IB04[CR ]

[LF ] Printer DPI:[CR ]

[LF ] 300[CR ]

[LF ] iPH:[CR ]

[LF ] 11-00036 #164[CR ]

[LF ]SYSTEM