Page 1

Printer Protocol Interpreter (PPI) DGL™

Programmer’s Reference Manual for DGL,

a Datamax

®

DPL™ Printer Protocol Interpreter

Thermal Series Printers

Page 2

Page 3

Printer Protocol Interpreter (PPI) DGL

Programmer’s Reference Manual for DGL,

a Datamax DPL Printer Protocol Interpreter

Thermal Series Printers

Page 4

Trademark Acknowledgments

DPL is a trademark and Datamax is a registered trademark of Datamax

Technologies Corporation.

PPI is a trademark of Printronix, Inc.

Printronix and PSA are registered trademarks of Printronix, Inc.

COPYRIGHT © 2006 PRINTRONIX, INC.

All rights reserved.

Page 5

Table of Contents

1 Introduction ......................................................... 11

About This Manual............................................................................... 11

Coax/Twinax Interface Requirements ........................................... 11

PPI/DGL SETUP Menu........................................................................ 12

PPI/DGL SETUP Submenu........................................................... 13

Active ...................................................................................... 13

Character Set.......................................................................... 13

Euro Character ....................................................................... 14

Control Codes ......................................................................... 14

Feedback Chars ..................................................................... 14

Default Module........................................................................ 14

Units of Measure..................................................................... 14

Row Offset .............................................................................. 15

Column Offset ......................................................................... 15

Format Attrib. .......................................................................... 15

Error Handling......................................................................... 15

Vertical DPI Adjust .................................................................. 16

Command Ignore Menus ........................................................ 16

Length Cmd (STXc) ................................................................ 16

Heat Cmd (H).......................................................................... 16

Speed CMD (P,S) ................................................................... 16

Cut Cmd (o,:,c) ....................................................................... 16

Soft Switch (V) ........................................................................ 16

Sensor Cmd (e,r) .................................................................... 16

Format Attr.(A) ........................................................................ 16

2 Fully Supported Commands ............................... 17

System-Level Command Functions .............................................. 17

STX A - Set Time and Date .................................................... 17

STX a - Enable Feedback Characters .................................... 17

STX B - Get Printer Time and Date Information ..................... 17

STX c - Set Continuous Paper Length.................................... 17

STX E - Set Quantity For Stored Label................................... 17

STX e - Select Edge Sensor................................................... 17

STX F - Form Feed ................................................................. 18

STX G - Print Last Label Format ............................................ 18

Page 6

Table of Contents

STX I - Input Image Data ........................................................ 18

STX i - Downloading Scalable Fonts ...................................... 18

STX K - Extended-System Commands .................................. 18

STX KE - Character Encoding ................................................ 18

STX k - Test RS-232 Port ....................................................... 18

STX L - Enter Label-Formatting Command ............................ 18

STX m - Set Printer To Metric................................................. 19

STX n - Set Printer to Imperial (Inches) .................................. 19

STX o - Cycle Cutter ............................................................... 19

STX Q - Clear All Modules...................................................... 19

STX q - Clear Module ............................................................. 19

STX r - Select Reflective Sensor ............................................ 19

STX S - Set Feed Rate ........................................................... 19

STX U - Label Format Field Replacement.............................. 19

STX V - Software Settings ...................................................... 20

STX v - Print Firmware Version Information ........................... 20

STX W - Request Memory Module Information ...................... 20

STX X - Set Default Module.................................................... 20

STX x - Delete File from Module............................................. 20

STX y - Select Font Symbol Set ............................................. 20

Label Formatting Command Functions ......................................... 20

: - Set Cut By Amount ............................................................. 20

+ (>) Make Last Field Entered Increment Numeric

(Alphanumeric) ....................................................................... 21

- (<) Make Last Field Entered Decrement Numeric

(Alphanumeric) ....................................................................... 21

^ Set Count by Amount ........................................................... 21

A - Set Format Attribute .......................................................... 21

B - Barcode Magnification....................................................... 21

C - Set Column Offset Amount ............................................... 21

c - Set Cut By Amount ............................................................ 22

D - Set Dot Size Width and Height ......................................... 22

E - Terminate Label Formatting Mode and Print Label........... 22

F - Advanced Font Attributes .................................................. 22

FB +/- Turns Bolding on or off ............................................... 22

FI +/- Turns Italicizing on or off .............................................. 22

FU +/- Turns Underlining on or off ......................................... 22

FPn Points ............................................................................. 22

FSn Points ............................................................................. 22

G - Place Data in Global Register........................................... 22

H - Enter Heat Setting............................................................. 23

m Set Metric Mode.................................................................. 23

Page 7

Table of Contents

n Set Inch Mode (Imperial) ..................................................... 23

P Set Print Speed ................................................................... 23

Q Set Quantity Of Labels To Print .......................................... 23

R Set Row Offset Amount....................................................... 23

r Recall Stored Label Format .................................................. 23

S Set Slew Rate...................................................................... 24

s Store Label Format In Module ............................................. 24

T Set Field Data Line Terminator............................................ 24

U Make Previous Field A String Replace Field ....................... 24

X Terminate Label-Formatting Mode ...................................... 24

y Select Font Symbol Set ....................................................... 24

z Zero (Ø) Conversion to “0” ................................................... 24

STX S Recall Global Data And Place In Field ........................ 25

STX T Print Time and Date..................................................... 25

Font Loading Command Functions ............................................... 25

ESC *c###D - Assign Font ID Number ................................... 25

ESC )s###W - Font Descriptor ............................................... 25

ESC *c###E - Character Code ............................................... 25

ESC (s#W - Character Download Data .................................. 25

Barcode Symbologies ................................................................... 25

3 Command Enhancements And Differences........ 27

SOH # - Reset ........................................................................ 27

SOH *- Reset .......................................................................... 27

SOH A - Send ASCII Status String ......................................... 27

SOH B - Toggle Pause ........................................................... 27

SOH C - Stop/Cancel.............................................................. 27

SOH D - SOH Shutdown ........................................................ 27

SOH E - Send Batch Quantity ................................................ 28

SOH F - Send Status Byte ...................................................... 28

SOH U - Update System Database with Current Database ... 28

STX J - Set Pause for Each Label .......................................... 28

STX KC - Get Configuration ................................................... 28

STX Kc - Configuration Set..................................................... 28

STX Kd - Set File as Factory Default...................................... 28

STX KF - Select Factory Defaults........................................... 29

STX Kf - Set Present Distance ............................................... 29

STX Kp - Module Protection ................................................... 29

STX KQ - Query Memory Configuration ................................. 29

STX Kq - Query Memory Configuration (new format)............. 29

STX Kr - Resettable Counter Reset........................................ 29

STX KV - Verifier Enable/Disable ........................................... 29

Page 8

Table of Contents

STX Kx - Delete Configuration File......................................... 29

STX Kb - Backfeed Time Delay .............................................. 30

STX K- - Top of Form, Offset Distance................................... 30

STX KD Database Configuration ............................................ 30

STX KI - GPIO Input ............................................................... 30

STX KM - Configure Internal Memory Module Size ................ 30

STX KO - GPIO Output........................................................... 30

STX KR - Reset Memory Configuration.................................. 30

STX KS - Configure Scalable Font Cache Size ...................... 30

STX KW - Configure Print Width Size..................................... 30

STX M - Set Maximum Label Length...................................... 30

STX O - Set Start of Print (SOP) Position............................... 30

STX P - Character (HEX) Dump Mode ................................... 31

STX p - Controlled Pause ....................................................... 31

STX R - Ribbon Saver On/Off................................................. 31

STX T - Printhead Dot Pattern Test Label .............................. 31

STX t - Test RAM Memory Module......................................... 31

STX w - Test Flash Memory Module ...................................... 31

STX Y - Output Sensor Values ............................................... 31

STX Z - Print Internal Information ........................................... 32

STX z - Pack Module .............................................................. 32

STX b - Set Cutter signal time ................................................ 32

STX C - Copy Module ............................................................. 32

STX D - Memory Dump (Test Mode Only).............................. 32

STX d - Set Printer to double buffer mode.............................. 32

STX g - Internal Batch Software Mode ................................... 32

STX N - Enter Internal Batch .................................................. 32

STX s - Set Printer to single buffer mode ............................... 32

e - Recall Printer Configuration............................................... 32

f - Set Present Speed ............................................................. 33

M - Select Mirror Mode ........................................................... 33

p - Set Label Backup Speed ................................................... 33

W - Wait mode (Prodigy only)................................................. 33

Z - Zip Mode (Prodigy only) .................................................... 33

Print Area................................................................................ 33

Fonts....................................................................................... 34

Slash Zero .............................................................................. 36

Codepages ............................................................................. 37

Barcode Symbologies ............................................................. 38

Images .................................................................................... 40

Graphics - Supported graphics objects:.................................. 40

Flash / Ram Module compatibility........................................... 40

Page 9

Table of Contents

Bi-Directional Communications............................................... 41

Cutter Commands................................................................... 41

Emulations .............................................................................. 42

Printer Configuration ............................................................... 42

Command Reference.............................................................. 42

A Configuration Setting Compatibility..................... 45

B Contact Information............................................. 53

Printronix Customer Support Center.................................................... 53

Printronix Supplies Department ........................................................... 53

Corporate Offices................................................................................. 54

Page 10

Table of Contents

Page 11

1 Introduction

About This Manual

This manual explains the differences between the Printer Protocol Interpreter

Datamax Graphic Language (DGL) Utility and the Datamax

Use this manual with your

protocol operation.

NOTE: When substituting a Datamax printer with an SL5000r/T5000r printer,

refer to DGL Menu Conversions on page 45.

SL500r/T5000r User’s Manual

®

DPL™ language.

for complete printer-

Coax/Twinax Interface Requirements

If you are using a coax or twinax interface, you must select the correct control

code in the DGL configuration menu. Refer to the

Reference Manual

select the appropriate control code.

and your printer

User’s Manual

Coax/Twinax Programmer’s

for instructions on how to

11

Page 12

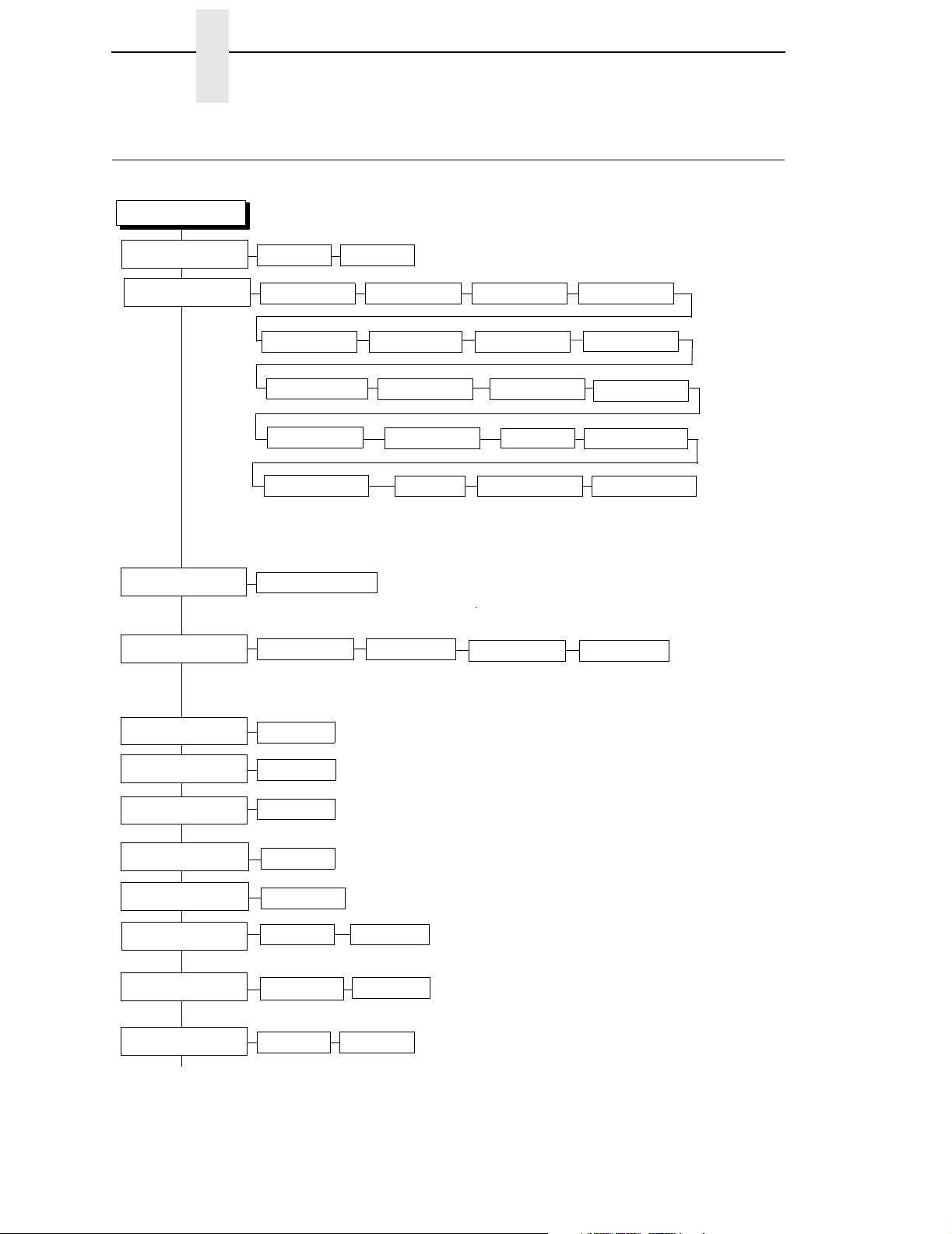

Chapter 1 PPI/DGL SETUP Menu

PPI/DGL SETUP Menu

PPI/DGL SETUP

Active

Character Set

Euro Character

Control Codes

Yes* No

PC-8 CP437*

English Ascii Win3.0 Latin 1

Win3.1 Latin 2

8859-2 Latin 2

Italian

128* (0..255)

Standard* Alternate

Roman 8 Spanish Swedish

Win3.1 Latin 5

8859-5 Latin 5

Legal Code Page 852 Code page 850

Danish/Norweg.

Alternate2 User-Defined

French

Win3.1 Latin 1

8859-1 Latin 1

German

CC: <SOH>

CC: <STX>

CC: <CR>

CC: <ESC>

CC: <CNT>

Feedback Chars

Default Module

Units of Measure

(Continued on next

page)

12

1

1

1

1

1

1* (0..255)

2* (0..255)

13* (0..255)

27* (0..255)

94* (0..255)

Enabled Disabled*

RAM*

Imperial* Metric

Flash

Notes:

* = Factory Default.

1

These menus are only present when ‘User Defined’ is

selected in the ‘Control Codes’ menu.

2

These menus are only present when ‘Admin User’ is set to

‘Enable’ in the ‘PRINTER CONTROL’ menu.

Page 13

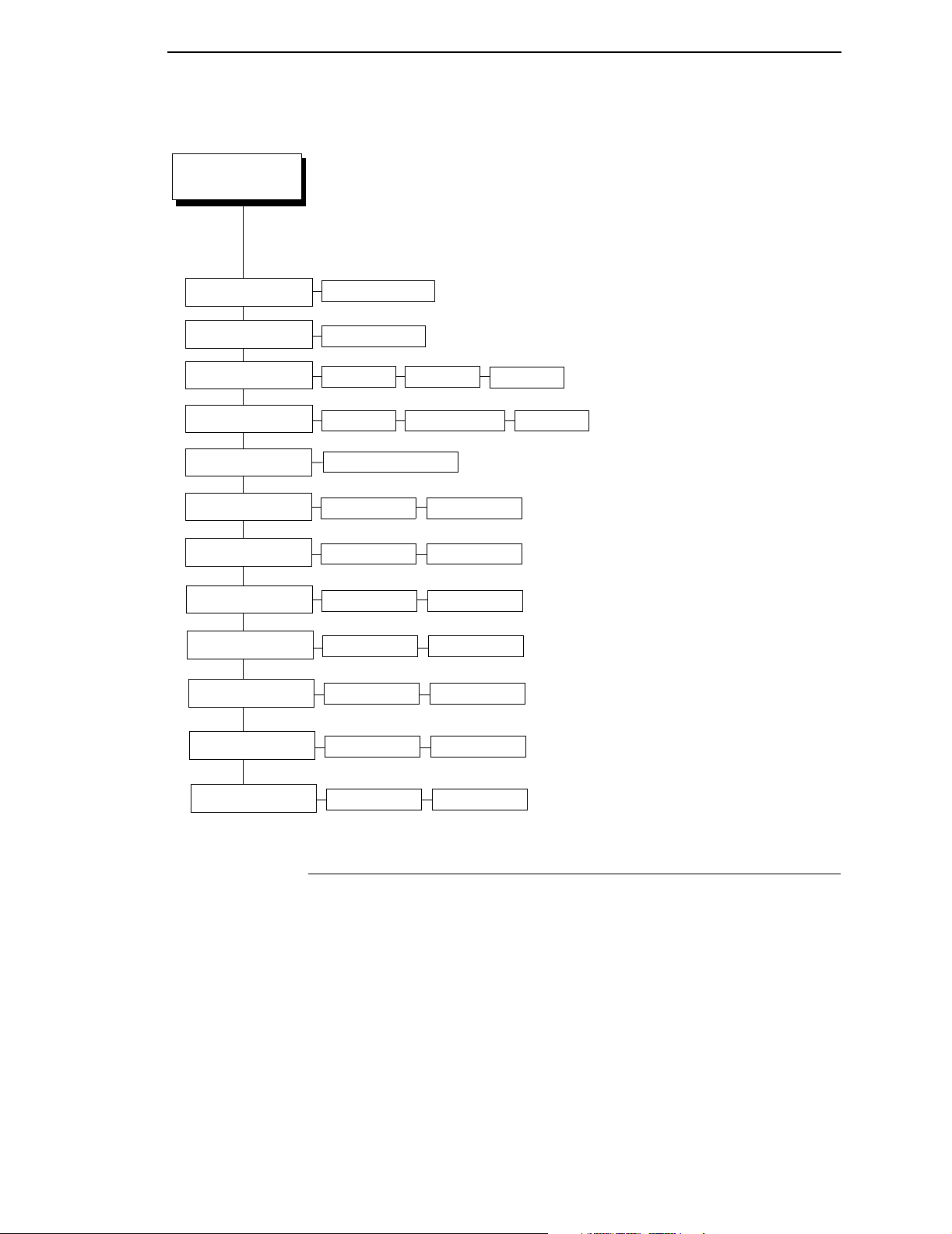

PPI/DGL SETUP Submenu

PPI/DGL SETUP

Con’t

Row Offset 0* (0-99.99 Inch

Column Offset

Format Attrib.

Error Handling

Vert. DPI Adjust

Length CMD (STXc)

Heat CMD (H)

Speed CMD (P,S)

2

2

2

2

0* (0-99.99 inch

XOR

0* (-100 to 100 dots)

*

Transparent

Off* Report

Process*

Process*

Process*

Ignore

Ignore

Ignore

Notes:

* = Factory Default.

1

These menus are only present when ‘User Defined’ is

selected in the ‘Control Codes’ menu.

2

These menus are only present when ‘Admin User’ is set to

‘Enable’ in the ‘PRINTER CONTROL’ menu.

Opaque

Beep

Cut CMD (o,:,c)

Soft. Switch (V)

Sensor Cmd (e,r)

Format Attr. (A)

2

2

2

2

Process*

Process*

Process*

Process*

Ignore

Ignore

Ignore

Ignore

PPI/DGL SETUP Submenu

Active

This setting determines if the DGL parser should process all incoming data or

pass all the data to the underlying emulation.

• Yes. DGL is active; processes all DPL commands.

• No. DGL is inactive; data is processed by underlying emulation.

The default is Yes.

Character Set

Allows the operator to select the character set.

13

Page 14

Chapter 1 PPI/DGL SETUP Menu

Euro Character

Allows the operator to select the position of the Euro character in the code

page.

Control Codes

Allows the operator to change the prefix of the software commands

interpreted by the printer.

Standard

Alternate

Alternate 2

User-Defined

When ‘User-Defined’ is selected, 5 additional sub-menus are inserted in the

menu tree. These sub-menus allow the user to set a value for each of the

control codes. The default ‘User-Defined’ values are shown in the table

above.

SOH STX CR ESC ‘Count By’

0x01 0x02 0x0D 0x1B 0x5E

0x5E 0x7E 0x0D 0x1B 0x40

0x5E 0x7E 0x7C 0x1B 0x40

0x01 0x02 0x0D 0x1B 0x5E

Feedback Chars

When enabled, the printer returns a Hex 1E [RS] after each label successfully

prints, and Hex 1F [US] after each batch of labels is printed.

For invalid characters, the printer responds with Hex 07 [BEL].

• Enabled. Feedback characters are sent to the host.

• Disabled. No feedback characters are sent.

The default is Disabled.

Default Module

Sets the default module used to store files when no module or default module

is specified in the command. (See Chapter 3 for further details.)

.

• RAM.

14

• Flash.

The default is RAM.

Units of Measure

Sets the printer to interpret measurements as Imperial or Metric values.

• Imperial.

• Metric.

The default is Imperial.

NOTE: <STX>n and <STX>m commands override this setting, and stay in

effect until the printer is take Offline and back Online.

Page 15

PPI/DGL SETUP Submenu

Row Offset

Shifts the vertical start of the print position. This is the user setting for row

adjustment.

• 0 (0 to 99.99 Inch or 999.9 mm)

The default is 0.

NOTE: The Label Formatting command [R] only temporarily overrides this

setting; it reverts back to this setting after the current label format is

finished.

Column Offset

Shifts the horizontal, left-justified start of the print position to the right without

shifting the Label Width termination point to the right. This is the user setting

for row adjustment.

• 0 (0 to 99.99 Inch or 999.9 mm)

The default is 0.

NOTE: The Label Formatting command [C] only temporarily overrides this

setting; it reverts back to this setting after the current label format is

finished.

Format Attrib.

Affects the manner in which overlapping text and graphics are treated as the

label is printed.

• XOR. Intersecting text strings, images, and barcodes print on top of one

another.

• Transparent. Intersecting text strings, images, and bar codes will not be

printed. (An odd number of overlapping objects will print.)

• Opaque. Intersecting text strings, images, and barcodes are obliterated

by those formatted last. Each character cell is treated as opaque.

The default is XOR.

Error Handling

This setting defines how the emulation handles errors detected in the data

stream. For all selections, data processing will not be aborted when errors are

detected: labels will be printed as good as possible. Commands containing

errors will be ignored.

• Off. No signal to the user when errors are detected.

• Report. The printer will beep when one or more errors are detected, and

the first command that contains an error is shown on the printer’s LCD in

mnemonic form.

• Beep. The printer will beep once if one or more errors are detected.

The default is Off.

15

Page 16

Chapter 1 PPI/DGL SETUP Menu

Vertical DPI Adjust

This option fine adjusts the resolution used to scale the page elements/

coordinates. In cases where the printed label length is incorrect, the vertical

resolution value DGL uses for calculations can be fine adjusted by this menu

between -100 and +100. Negative values result in a lower DPI value and thus

a longer label. Positive values result in a higher DPI value, and thus a shorter

label. Note that this adjustment does not affect the size of images and

downloaded bitmap fonts.

• 0 (-100 to +100).

The default is 0.

Command Ignore Menus

The Admin User menus allow ignoring of several configuration commands in

the host data. This allows using their corresponding front-panel settings,

without being overridden by host commands.

The default is to process all commands.

Length Cmd (STXc)

Allows the user to disable the Length Command.

Heat Cmd (H)

Allows the user to disable the Heat Command.

Speed CMD (P,S)

.Allows the user to disable the speed commands (Print, Feed, and Reverse).

Cut Cmd (o,:,c)

Allows the user to disable the commands affecting the cutter.

Soft Switch (V)

Allows the user to disable the ‘Software Switch Settings’ Command (this

command enables Cut or Tear-Off mode, or disables both by selecting

Continuous mode).

Sensor Cmd (e,r)

Allows the user to disable the commands that select the Gap / Mark sensor

(<STX>e and <STX>r).

16

Format Attr.(A)

Allow the user to disable the commands that select the Format Attribute.

Page 17

2 Fully Supported

Commands

System-Level Command Functions

STX A - Set Time and Date

This command sets the time and date. The initial setting of the date will be

stored in the printer’s internal memory. This date can be verified by printing a

configuration label.

STX a - Enable Feedback Characters

This command enables the feedback ASCII HEX characters 07, 1E, and 1F to

be returned from the printer following specific events.

STX B - Get Printer Time and Date Information

This command retrieves the time and date information from the printer and

transmits the response to a host device. See <STX>A for details and

restrictions.

STX c - Set Continuous Paper Length

This command is used to define the page (label) size when printing on

continuous media. It disables the media sensor top-of-form function but

continues to monitor paper-out conditions.

STX E - Set Quantity For Stored Label

This command sets the number of labels to print for the label format currently

stored in the print buffer. (The printer automatically stores the most recent

label format in the buffer until the printer is reset or turned ‘Off’.) To print, this

command is used in conjunction with the <STX>G command.

STX e - Select Edge Sensor

This command enables “see-through” sensing for top-of-form detection of diecut and notched media. The printer’s transmissive media sensor will detect a

minimum gap of 0.05 inches (1.27mm) between labels. Label stock must be

at least 0.1 inches (2.5mm) between each top-of-form (start of print point on

the next label).

17

Page 18

Chapter 2

STX F - Form Feed

This commands the printer to form feed one label.

STX G - Print Last Label Format

This command prints a previously formatted label and restarts a canceled

batch job after the last processed label. This is used when there is a label

format in the print buffer. The <STX>E command is used to enter the quantity.

STX I - Input Image Data

This command must precede image data downloading from a host computer

to the printer. The data that immediately follows the command string will be

image data.

STX i - Downloading Scalable Fonts

The command structure for downloading TrueType (.TTF) scalable fonts

follows, (font files must be single character systems).

STX K - Extended-System Commands

This expands the System-Level Commands. See the Extended-System

Commands for more information.

STX KE - Character Encoding

This command specifies a character in the DPL datastream to be substituted

with a delimited two-character ASCII hexadecimal numeric equivalent.

Any character in the DPL datastream may be substituted with a delimited twocharacter ASCII hexadecimal numeric equivalent. The command allows the

delimiting character to be selected, and the encoding to be enabled or

disabled. When character encoding is enabled, the printer will decode any

ASCII hexadecimal numeric pairs following the delimiter as single byte

values. This command is used where control characters cannot be

transmitted or where control characters within data may prematurely

terminate a label format record. Although the delimiter may be changed at any

time (except within a label format definition) there cannot be more than one

defined delimiter, and character encoding must be disabled with <STX>KN

prior to re-enabling, regardless of any change in the delimiter.

STX k - Test RS-232 Port

This command instructs the printer to transmit the character Y from the

printer’s RS-232 port. (Failure to receive Y could indicate an interfacing

problem.)

18

STX L - Enter Label-Formatting Command

This command switches the printer to the Label-Formatting command input

mode. Once in this mode, the printer expects to receive Record Structures

and Label-Formatting commands. Status and Control, System-Level, and

Font-Loading commands will be ignored until the label formatting mode is

Page 19

System-Level Command Functions

terminated with E, s, or X, (see Label-Formatting Commands for additional

information.)

STX m - Set Printer To Metric

This command sets the printer to interpret measurements as metric values

(e.g., <STX>c0100 will equal 10.0mm). See <STX>n.

STX n - Set Printer to Imperial (Inches)

This command sets the printer to interpret measurements as Imperial values

(e.g., <STX>c0100 will equal 1.00 inch). See <STX>m.

STX o - Cycle Cutter

This command will immediately cycle the cutter blade on the option Cutter

Mechanism. The Cutter must be installed, enabled and the interlocks closed

for operation. The Commands to activate the Cutter (System Level Command

<STX>o, and Label Formatting Commands ‘c’ and ‘:’) are only processed

when the Media Handling menu is set to ‘Cut’, and the DGL Advanced-User

Menu ‘Cut Cmds’ is set to ‘Process’.

STX Q - Clear All Modules

This command instructs the printer to clear all of the Flash, RAM, and Internal

Modules.

STX q - Clear Module

This command clears the selected memory module (Flash or RAM).

STX r - Select Reflective Sensor

This command selects the reflective media sensor for top-of-form detection of

reflective stock (e.g., fan-folded tags with carbon-based black marks printed

along the underside of the media). The end of the black mark determines

label TOF. Labels must be at least 0.5” (13mm) between each TOF mark.

(The <STX>e command switches from reflective back to edge sensing).

STX S - Set Feed Rate

This command determines the feed rate of the media when the printer’s

FEED button is pressed.

STX U - Label Format Field Replacement

This command places new label data into format fields. Format fields are

used to build a label. The new data string must equal the original string length

and contain valid data. To easily keep track of fields, place all of the fields to

be updated with the command at the beginning of the label format. A

maximum of 99 format fields can be updated. Fields are numbered

consecutively 01 to 99, in the order received.

19

Page 20

Chapter 2

STX V - Software Settings

Printer options are set by entering selections through the menu. The software

setting command allows two of these option settings to be modified without

returning to the menu. Choosing the appropriate values allow the option(s) to

be turned ‘On’ or ‘Off’. Each has a corresponding bit whose value is 1 when

enabled. Enabling the Cutter bit selects ‘Cut’ Media Handling, and the Present

bit selects ‘Tear-Off’. Disabling the Cutter or Present bit selects the FactoryDefault media handling setting: ‘Continuous’ Media Handling.

The <STX>V command can be ignored by setting the DGL Advanced-User

menu ‘Soft. Switch (V)’ to Ignore.

STX v - Print Firmware Version Information

This command causes the printer to respond by sending a version string. The

version may be different from printer to printer (this data is the same as that

printed on the configuration label).

STX W - Request Memory Module Information

This command requests a directory listing for memory module(s). Although a

module can store font, graphics and format data together, it can display only

one type of information at a time. If the module contains all three types of

data, it will be necessary to check the directory three times, using each of the

control parameters, F, G, and L, to determine the contents.

STX X - Set Default Module

This command is used when downloading information to a module memory. It

is designed to allow the user to select between modules. If ‘C’ is entered to

select a memory bank, the data will go to the bank set by this command (Set

Default Module). See Chapter 3, Flash/Ram Module Compatibility.

STX x - Delete File from Module

This command removes a specific file from the specified module. The file

name is removed from the module directory and thus the file cannot be

accessed. The actual storage space occupied by the file is not released (this

only applies to the flash memory). The menu option ‘Optimize and Reboot’

can be used to reclaim all deleted file storage space.

STX y - Select Font Symbol Set

This command selects the scalable font symbol set. The selected symbol set

remains active until another symbol set is selected. Not all symbol sets can be

used with all fonts.

20

Label Formatting Command Functions

: - Set Cut By Amount

This command allows a predetermined number of labels to be printed before

a cut is initiated. This feature is useful when it is necessary to print an uncut

Page 21

Label Formatting Command Functions

strip of labels. Between 1 and 9999 labels may be printed before a cut is

made. The amount must be smaller than the quantity of labels printed.

+ (>) Make Last Field Entered Increment Numeric

(Alphanumeric)

The printer is capable of automatically incrementing fields on each label of a

batch. This command is useful to print labels numbered in sequence. The

data in the field will increment by the value after the + sign, each time a label

is printed. The + character may be replaced by a > character to make the field

increment alphabetically rather than numerically. This command is effective

only on the label format record it follows. It is intended for use with the label

batch quantity Q or the System-Level Commands for quantities and reprint,

<STX>E and <STX>G.

- (<) Make Last Field Entered Decrement Numeric

(Alphanumeric)

The printer is capable of counting down fields on labels in a batch. This

command is useful when printing labels need to be numbered in reverse

sequence. The data in the field will decrement by the value after the minus

sign with every label printed. The minus character may be replaced by a <

character in order to make the field decrement alphabetically rather than

numerically. This command has effect on only the label format record that it

follows. It is intended for use in conjunction with the label batch quantity Q, or

the System-Level Commands for quantity and reprint, <STX>E and <STX>G.

^ Set Count by Amount

An application using incrementing or decrementing fields (+, -, >, <) will

occasionally require that more than one label be printed with the same values

before the field data is updated. This situation is handled with the ^nn

command. All printers default to 1.

A - Set Format Attribute

This command specifies the type of format operation and remains in effect

until another format command is specified or another label format has begun

(<STX>L). Each label format defaults to the menu value.

B - Barcode Magnification

This command provides a mechanism to specify barcodes greater than 36

dots (0-9,A-Z in the field record). The value is reset to 1 at the start of every

label and stays active for the entire label or set to a new value.

C - Set Column Offset Amount

This command allows horizontal adjustment of the point where printing

begins. This feature is useful when a single format must be printed on several

different types of labels that contain pre-printed information. (If the pre-print

does not appear in the same place on every label, the new data may overlap

21

Page 22

Chapter 2

the pre-printed data.) The ‘C’ command instructs the printer to print label

formats nnnn units to the right of the position that the format specifies.

c - Set Cut By Amount

This command is the same as the ‘:’ command except only a two-digit value

can be entered. This command allows a predetermined number of labels to

be printed before a cut is made. 1 to 99 labels may be printed before a cut is

made.

D - Set Dot Size Width and Height

This command is used to change the size of a printed dot, hence the print

resolution – dots per inch (DPI) of the printhead. By changing the height of a

dot, the maximum length of a label can be increased or decreased.

E - Terminate Label Formatting Mode and Print Label

When the printer is processing Label-Formatting Commands and receives an

‘E’ command, it will immediately print a label based upon the data received at

that point. Even if no printable data has been received, the printer will

generate and feed a label (other termination commands are ‘X’ and ‘s’).

Commands sent to the printer after a “terminate label” command must be

Status and Control, System-Level or Font Download type.

F - Advanced Font Attributes

These commends extend the text presentation capabilities for Scalable Fonts.

The format attribute allows a set of label format records to select Bolding,

Italicizing and Underlining. Additional commands allow the specification of line

rotation and font changes within a label field.

FB +/- Turns Bolding on or off

FI +/- Turns Italicizing on or off

FU +/- Turns Underlining on or off

FPn Points

Specify the vertical point size of the following text relative to the base line.

FSn Points

Specify the horizontal point size of the following text relative to the base line.

G - Place Data in Global Register

The ‘G’ command saves the print data of a print format record in a global

register (temporary storage). This data may be retrieved and copied to

another record in the same label format using the special Label-Formatting

Command, <STX>S. Global registers are named in the order received,

22

Page 23

Label Formatting Command Functions

beginning with register A, ending at register P, and incrementing with each

instance of the G command use.

H - Enter Heat Setting

This command changes the “on time” of elements of the printhead. (The

default setting can be changed through the keypad). An increase or decrease

in this value results in a change of heat applied by the printhead to the media,

lightening or darkening the print contrast accordingly. This is helpful when

using different media types, each requiring a different amount of heat to

properly image the media. The host device can send this command value to

correct the heat setting per the application.

m Set Metric Mode

This command sets the printer to measure in metric. When this command is

sent, all measurements will be interpreted as metric values, (e.g., a column

offset of 0010 will be interpreted as 1.0mm). All printers default to Imperial

(inch) mode. Menu selectable.

n Set Inch Mode (Imperial)

This command sets the printer to measure in inches. When this command is

sent, all measurements will change to inches. All printers default to Imperial

units. Menu selectable.

P Set Print Speed

This command sets a print speed for a label or batch of labels.

Q Set Quantity Of Labels To Print

This command sets the number of the label copies to be printed. All printers

default to 1.

R Set Row Offset Amount

This command allows vertical adjustment of the point where printing begins.

This is useful when a single format is printed on several different types of

labels that contain pre-printed information. However, if the pre-printing does

not appear in the same place on every label, data may overprint the preprinted areas. The ‘R’ command instructs the printer to print label formats

nnnn increments above the position the format specifies. Valid input values

are numbers between 0000 and 9999, (refer to the C, Set Column Offset

Amount Command.)

r Recall Stored Label Format

This command is used to retrieve entire label formats that have been stored

on a memory module.

23

Page 24

Chapter 2

S Set Slew Rate

This command sets the rate for the printer to feed non-printed areas of the

label through the printer. The slew rate remains unchanged unless another

slew rate command is sent, the printer is reset or a new rate is set via the

menu.

s Store Label Format In Module

This command stores a label format in a specified module. Supplying memory

module name A, B, or D will store the label to that module. (Using C will cause

the label format to be stored in whichever module has been set as the default

module, refer to the Set Default Module Command, <STX>X.) The store labelformat command will terminate the Label-Formatting Command.

T Set Field Data Line Terminator

This command is valid only for the next format record, after which the

terminator defaults to a carriage return. This allows the user to embed special

binary control codes (e.g., carriage returns) into the data to be printed. It is

intended to be used with record types (e.g., PDF417), that will accept binary

data.

U Make Previous Field A String Replace Field

This command does not require the use of an updated field (register loading);

the command only controls the way the bit-mapped data is formatted. The

data used when it is created must be valid for the font type being used. If the

command is used, only the changing data will be reformatted; if this command

is not used the entire label will be formatted. The U command is used in

conjunction with the <STX>U command to reformat only portions of a label,

resulting in faster label generation.

X Terminate Label-Formatting Mode

When the printer is in Label-Formatting mode and receives this command, it

will immediately switch to the System-Level Command mode and generate a

label format based on whatever data it has already received. However, unlike

the ‘E’ command, it will not print a label. (Other termination commands are the

‘E’ and ‘s’ Label-Formatting Commands.)

y Select Font Symbol Set

Same as a System-Level Command <STX>y. Symbol sets are used only with

scalable fonts (see Generating Label Formats; also see <STX>y).

z Zero (Ø) Conversion to “0”

This command removes the slashes from zeros in fonts 0 to 8, and barcodes.

The command is effective only for the label format in which it appears, and

applies to all format records containing fonts 0 through 8 or barcodes A

through Z. (None of the smooth fonts [font 9] have a slash zero.) The

command has no effect on scalable fonts.

24

Page 25

Font Loading Command Functions

STX S Recall Global Data And Place In Field

Once a global register has been defined, its contents can be used as data in

other fields. When the printer receives the command <STX>Sn in a format

record data field, it will place data from the specified global register into the

data field, (see Label-Formatting Command G). Global registers contain the

data in the first A through P format record data fields.

STX T Print Time and Date

Time and date string data is selected by choosing the string character A

through Z and a through h to retrieve data from the printer’s internal clock.

The date string characters are not printed, instead the printed label will show

the corresponding print values.

The <STX>T may now be preceded by data to be printed/encoded and/or the

string may now be terminated by a <STX> command followed by data

terminated by a <CR>.

Font Loading Command Functions

ESC *c###D - Assign Font ID Number

This command is the first command required for downloading a font to either

RAM or Flash Memory modules. ESC represents the ASCII control character

27.

ESC )s###W - Font Descriptor

This command (typically first data in a font file) contains all of the information

about the font contained in the file. Different font generation software will

create different length header information, but the initial 64 bytes will remain

consistent with the PCL-4 (HP LaserJet II) format.

ESC *c###E - Character Code

This code is the ASCII decimal value corresponding to the next downloaded

character.

ESC (s#W - Character Download Data

This command contains all of the information for one downloaded character.

Barcode Symbologies

(1)

A

: Code 3 of 9

(1)

B

: UPC-A

(1)

C

: UPC-E (See Partially Supported Commands)

(1)

: Interleaved 2 of 5 (I 2 of 5)

D

(1)

E

: Code 128

25

Page 26

Chapter 2

(1)

F

: EAN-13

(1)

G

: EAN-8

(1)

H

: Health Industry Barcode (HBIC) (Code 39 barcode with a modulo 43

checksum)

(1)

I

: Codabar

(1)

J

: Interleaved 2 of 5 with a modulo 10 checksum

(1)

K

: Plessey (See Partially Supported Commands)

(1)

: Interleaved 2 of 5 with a modulo 10 checksum and shipping bearer bars

L

(1)

M

: 2-digit UPC addendum

(1)

N

: 5-digit UPC addendum

(1)

O

: Code 93

P: Postnet

(1)

Q

: UCC/EAN Code 128 (See Partially Supported Commands)

(1)

R

: UCC/EAN Code128 K-MART NON EDI barcode. (See Partially

Supported Commands)

(1)

S

: UCC/EAN Code 128 Random Weight (See Partially Supported

Commands)

(1)

T

: Telepen

u: UPS MaxiCode (Modes 2&3) (See Partially Supported Commands)

U: UPS MaxiCode (Modes 2&3) with Byte Count Specifier (See Partially

Supported Commands)

v: FIM

Z: PDF-417

Z: PDF-417 with Byte Count Specifier

W1c: DataMatrix

W1C: DataMatrix with Byte Count Specifier

W1f: Aztec

W1f: Aztec with Byte Count

W1g and W1G: USD-8 (Code 11)

W1k: RSS (six types) (See Partially Supported Commands)

(1)

W1R

: UCC/EAN Code 128 K-Mart NON EDI barcode (alternate type) (See

Partially Supported Commands)

(1)

These barcodes print human readable interpretation when uppercase ID is

specified. Lowercase prints barcode without HR.

26

Page 27

3 Command Enhancements

And Differences

For more information on SOH command functionality, refer to the BiDirectional Communications section on page 41.

SOH # - Reset

This command resets the printer. Resetting the printer returns all settings to

default and clears both the communications and printing buffers. The

command also clears the internal RAM memory.

SOH *- Reset

This command resets the printer. Resetting the printer returns all settings to

default and clears both the communications and printing buffers. The

command also clears the internal RAM memory.

(Not supported.)

(Not supported.)

SOH A - Send ASCII Status String

This command allows the host computer to check the current printer status.

The printer returns a string of eight characters to the host, followed by a

carriage return. Each character is either a ‘Y’ or ‘N’ indicating that the

associated condition is true (Y) or false (N). Byte 1 is the first character

transmitted by the printer. See <SOH>F.

(Not supported.)

SOH B - Toggle Pause

This command toggles the printer’s paused state on and off. (This is the same

function achieved when pressing the PAUSE button on the printer. (

supported)

Not

SOH C - Stop/Cancel

This command performs the same function as pressing the STOP/CANCEL

button on the printer’s front panel. This function clears the current label format

from the print buffer, pauses the printer, and illuminates the pause/stop

indicator.

(Not supported.)

SOH D - SOH Shutdown

The internal firmware architecture no longer requires the execution of an

“SOH” shutdown for binary downloading.

(Obsolete command.)

27

Page 28

Chapter 3

SOH E - Send Batch Quantity

This command causes the printer to send back a 4-digit number indicating the

quantity of labels left to print in the current batch, followed by a carriage

return. Communications latency may cause this value to be higher than actual

on some printers.

(Not supported.)

SOH F - Send Status Byte

This command instructs the printer to send a single status byte where each bit

(1 or 0) represents one of the printer’s status flags, followed by a carriage

return, see table below. If an option is unavailable for the printer, the single bit

will always be 0. A satisfied condition equals 1.

(Not supported.)

SOH U - Update System Database with Current Database

This command will copy the current User database into the system database.

There are various DPL commands that modify the configuration of the printer.

See the <STX>K…command for specifics on how these commands function.

The user should send the <SOH>U command after these configuration

commands so that these commands can take affect. This command will

cause the printer to reset. See the <SOH># command above for details on

what events occur during a reset.

(Not supported.)

STX J - Set Pause for Each Label

This command causes the printer to pause after printing each label and is

intended for use with the optional Peel and Present Mechanism or with a Tear

Bar when no Present Sensor is installed. After removing the printed label, the

PAUSE button must be pushed in order to print the next label. (The printer

must be reset to clear the <STX >J command.)

(Not supported.)

STX KC - Get Configuration

This command returns the configuration of the printer. The form of the

returned data is similar to that of a printed Configuration Label. This command

should be Parsed by KEYWORDS, not by Character POSITIONS. Each line

is terminated by a CR (0x0d) & LF (0x0a).

(Not supported.)

STX Kc - Configuration Set

This command specifies the Power-up Configuration parameter values for the

printer. It is equivalent to using other system commands followed by the

<SOH>U. The printer will reset upon completion of a command stream

containing parameter value changes; no commands should be sent to the

printer until this reset is complete. This command is intended for easily

configuring a custom setup, not for dynamic configuration changes.

supported.)

(Not

28

STX Kd - Set File as Factory Default

This command selects the specified file name as the “factory default” for the

printer’s configuration. After execution, subsequent “Select Factory Default”

commands will configure the printer to the file’s configuration. Currently there

are three ways to “Select Factory Defaults”: 1) by the <STX>KF command; 2)

Page 29

power-up the printer while pressing the PAUSE and CANCEL keys; or, 3) via

the printer’s menu system entry System Settings / Set Factory Defaults.

supported.)

(Not

STX KF - Select Factory Defaults

This command restores the printer’s configuration to the “factory default”

settings. These factory default values may be either the Datamax default

settings or the configuration file previously specified in the <STX>Kd

command.

(Not supported.)

STX Kf - Set Present Distance

This command specifies an additional amount to advance the label after

printing.

(Not supported.)

STX Kp - Module Protection

This command controls memory module protection. When “protected”, a

module will ignore format, downloads and delete commands. This command

can be useful to add data to Datamax reserved modules, Z (ILPC) and Y

(EFIGS).

(Not supported.)

STX KQ - Query Memory Configuration

This command causes the printer to transmit its internal DRAM memory

configuration to the host device. The transmitted data provides information

regarding the total amount of installed internal DRAM, the amount available

for configuration and the amount currently assigned to specific functions or

entities.

(Reported values are not all actual values.)

STX Kq - Query Memory Configuration (new format)

This command causes the printer to transmit its internal DRAM memory

configuration to the host device. The transmitted data provides information

regarding the total amount of internal DRAM installed, the amount available

for configuration, and the amount currently assigned to specific functions or

entities.

(Not supported.)

STX Kr - Resettable Counter Reset

This command resets the internal counters. Follow this command with an

<SOH>U command to retain the reset or the counters will revert to the

previous values after cycling power.

(Not supported.)

STX KV - Verifier Enable/Disable

This command allows the verifier (option, if installed), to be enabled and

disabled.

(Not supported.)

STX Kx - Delete Configuration File

This command deletes the specified configuration file.

(Not supported.)

29

Page 30

Chapter 3

STX Kb - Backfeed Time Delay

(Obsolete Extended System Command)

.

STX K- - Top of Form, Offset Distance

(Obsolete Extended System Command

).

STX KD Database Configuration

(Obsolete Extended System Command

).

STX KI - GPIO Input

(Obsolete Extended System Command).

STX KM - Configure Internal Memory Module Size

(Obsolete Extended System Command

).

STX KO - GPIO Output

(Obsolete Extended System Command

).

STX KR - Reset Memory Configuration

(Obsolete Extended System Command

).

STX KS - Configure Scalable Font Cache Size

(Obsolete Extended System Command.)

STX KW - Configure Print Width Size

(Obsolete Extended System Command.)

STX M - Set Maximum Label Length

This command instructs the printer to travel this distance in search of top-ofform (label edge, notch, black mark, etc.) before declaring a paper out fault.

The fault condition can occur if this value is set too close to the physical length

of the label (within 0.1inch/2.54mm). Therefore, it is good practice to set this

value at 2.5 to 3 times the actual label length used. The minimum value

should be at least 5” (127mm).

(Not supported.)

STX O - Set Start of Print (SOP) Position

This command sets the point where printing starts relative to the selected

SOP Emulation (SOP Emulation may be enabled and selected using the

printer’s Menu System). The position specified by this command emulates a

selected legacy printer’s distance, as measured between the Media Sensor

and the Printhead burn line. This value is independent of the <STX>f

command. If the SOP Emulation is set to ‘Disabled’, this command is ignored.

(Not supported.)

30

Page 31

STX P - Character (HEX) Dump Mode

This command instructs the printer to enter the Character Hex Dump Mode

(ASCII Dump / “monitor mode”). All data sent to the printer following this

command will be printed in the raw ASCII format. Labels must be at least four

inches (102mm) long and as wide as the maximum print width. This command

has the same effect as turning the printer ‘On’ while pressing the FEED

button; in this case however, a Configuration and Test label will be printed. To

return to normal operation, the printer must be manually reset.

supported.)

(Not

STX p - Controlled Pause

The controlled pause command will cause the printer to pause only after all

previously received commands are executed. This is often useful between

label batches. (This command will not clear the pause condition, see

<SOH>B).

(Not supported.)

STX R - Ribbon Saver On/Off

This is the only command used for the optional Ribbon Saver. This does not

instruct the Ribbon Saver when to engage, rather it turns the operation ‘On’ or

‘Off’. The option will operate automatically, lifting when the minimum amount

of label white space is exceeded. The operation is continuous when enabled.

The printer must be set to thermal transfer (ribbon) printing mode.

supported.)

(Not

STX T - Printhead Dot Pattern Test Label

This command instructs the printer to print a dot pattern test label. To view all

dots, the labels must be at least four inches (102mm) long and as wide as the

maximum print width.

(Not supported.)

STX t - Test RAM Memory Module

This command tests all RAM modules; however, the printer must be in

feedback mode for the command to function. The printer returns a one-line

message stating whether the module is good or bad, (no message is returned

if a module is unavailable). Feedback mode can be enabled via the menu

(see the corresponding Operator’s Manual for additional information).

returns OK status.)

(Always

STX w - Test Flash Memory Module

This command performs a test sequence on flash memory modules; however,

the time for each test will vary (from 20 seconds up to two minutes),

depending on the size of the module. The module must have the write protect

switch ‘Off’ for testing; all stored data will be destroyed. The printer responds

with ‘good’ or ‘bad’ message results for each module tested. (No modules

present will result in no printer response.)

(Always returns OK status.)

STX Y - Output Sensor Values

This command causes the printer to respond with the sensor value status.

The printer must be in feedback mode (menu setting). When <STX>Y is

31

Page 32

Chapter 3

received, the printer will respond with the internal A-D sensor values, see

table below. To repeat the display of values, send the printer a ‘SPACE’ (20

hexadecimal). Send <ESC> to terminate the function.

(Not supported.)

STX Z - Print Internal Information

This command prints the configuration. To capture all printed information, use

labels as wide as the print width and at least 4 inches (102mm) long.

supported.)

(Not

STX z - Pack Module

This command causes the printer to reclaim all storage space associated with

all deleted files on the specified module. A Flash Module cannot be packed.

(Not supported.)

STX b - Set Cutter signal time

(Obsolete System Command.)

STX C - Copy Module

(Obsolete System Command.)

STX D - Memory Dump (Test Mode Only)

(Obsolete System Command.)

STX d - Set Printer to double buffer mode

(Obsolete System Command.)

STX g - Internal Batch Software Mode

(Obsolete System Command.)

STX N - Enter Internal Batch

(Obsolete System Command.)

STX s - Set Printer to single buffer mode

(Obsolete System Command.)

e - Recall Printer Configuration

This command recalls a previously stored printer configuration. It is highly

recommended that only one Recall Printer Configuration command be used

per label, and that it be used at the beginning of the label; otherwise,

unpredictable results will occur. (Printer Configurations may be stored using

the Extended System Commands or the printer’s menu system.)

supported.)

(Not

32

Page 33

f - Set Present Speed

(Not supported.)

M - Select Mirror Mode

This command instructs the printer to “mirror” all subsequent print field

records. This command toggles the mirroring mode. Mirrored fields are

transposed visually, as if the object is viewed in a Printed Result.

supported.)

(Not

p - Set Label Backup Speed

This command is used for the “Peel and Present” and “Cut Label Operations”.

It allows the user to specify the rate at which the printer will reverse the label

direction to align the next start of print position. The rate set by this command

remains in effect until another backup speed command is received, see

Appendix L for valid ranges. The speed is modified via the menu or when the

printer is reset.

(Not supported.)

W - Wait mode (Prodigy only)

(Obsolete System Command.)

Z - Zip Mode (Prodigy only)

(Obsolete System Command.)

Print Area

When looking at the front of the printer, the origin of the label is positioned at

the bottom left of the label, and extends up and to the right. The label length

for continuous labels can be set in the Menu and through the

command.

On Datamax printers, the print width is adjusted through the menu ‘LABEL

WIDTH’. According to the manual, objects extending beyond the page width

will not print. However, this does not seem to have any effect on the I-42xx:

the full width can always be used. On DGL, objects draw beyond the adjusted

page width will not print.

Physical page-rotation is not available on Datamax. When rotation is needed,

each object should be rotated individually.

See figure below for a graphical representation of the print area, and the

coordinate system used by DGL.

<STX>cnnnn

33

Page 34

Chapter 3

Fonts

See the tables below for the different types of fonts that will be available.

All Single-Byte fonts will be supported, and will be available in DGL by default.

Double-Byte support has not been planned.

34

Page 35

Internal Bitmapped Non-Proportional fonts:

Description

Type

DPI Hei ght Width Spacing Point Size Agfa Typeface

(b)

0

96-character alphanumeric font, uppercase and lowercase.

203 7 5 1 2.5

300 10 7 1 2.4

1

145-character uppercase and lowercase alphanumeric font

that includes desenders and ascenders.

203 13 7 2 4.6

300 19 10 3 4.6

2

138-character alphanumeric upper and lowercase font.

203 18 10 2 6.4

300 27 15 3 6.5

3

62-character alphanumeric uppercase font.

203 27 14 2 9.6

300 40 21 3 9.6

4

62-character alphanumeric uppercase font.

203 36 18 3 12.8

300 53 27 4 12.7

5

62-character alphanumeric uppercase font.

203 52 18 3 18.4

300 77 27 4 18.5

6

62-character alphanumeric uppercase font.

203 64 32 4 22.7

300 95 47 6 22.8

7

OCR-A, si ze I.

203 32 15 5 11.3

300 47 22 7 11.3

8

OCR-B, size III.

203 28 15 5 9.9

300 41 22 7 9.8

35

Page 36

Chapter 3

ISmooth, Scalable and Downloaded fonts:

Size field

(eee)

Bit-Mapped Resident Fonts

(1)

A04 – A72

000 - 010

CG Triumvirate, Bit-Mapped Smooth Font

(1)

(Point sizes 4, 5, 6, 8, 10, 12, 14, 18, 24, 30,

Description Agfa

TypeFace

36, 48 and 72)

Scalable Resident Fonts (standard)

S00 CG Triumvirate Bold Condensed

S01 CG Triumvirate

Scalable Resident Fonts (optional)

SA0 CG Times

SA1 CG Times Italic

SA2 CG Times Bold

SA3 CG Times Bold Italic

U40 Gothic B Kanji, Double Byte (Binary)

u40 Gothic B Kanji, Double Byte (Hex ASCII)

UC0 GB Simplified Chinese, Double Byte (Binary)

uC0 GB Simplified Chinese, Double Byte (Hex

ASCII)

UH0 Korean Hangul, Double Byte (Binary)

uH0 Korean Hangul, Double Byte (Hex ASCII)

Bit-Mapped Downloaded Fonts

100 - 999 Bit-Mapped Downloaded Fonts N/A

Scalable Downloaded Fonts

S50 - S5z...

Single Byte (Binary) N/A

S90 - S9z

U50 -U5z...

Double Byte (Binary) N/A

U90 -U9z

u50 -u5z...

Double Byte (Hex ASCII) N/A

u90 -u9z

36

eee

Font ID 9 uses the Size field (

) in the Record Format to select the Smooth,

Scalable, or Downloaded fonts.

NOTE: For I42xx: The Smooth Internal CG Triumvirate Bitmap Fonts are

automatically converted to the CG Triumvirate Scalable Font, which

therefore also affects the code pages.

Slash Zero

All resident bitmap fonts use the slashed zero by default. This can be disabled

through Label Formatting command ‘

None of the scalable fonts have the slashed zero available.

z

’.

Page 37

Codepages

Resident Bitmap Fonts

The Resident Bitmap fonts don’t use different codepages; the characters are

mapped at predefined positions, defined in the table below.

See the print samples in Appendix C in the ‘Class Series Programmers

Manual’ for the reference characters.

Valid ASCII Characters for bitmap fonts:

Font Valid ASCII Characters (decimal) Euro

Char

0 32-127 255

1, 2 32-168, 171, 172, 225 255

3, 4, 5, 6 32, 35-38, 40-58, 65-90, 128, 142-144, 146, 153, 154, 156, 157,

165, 168, 225

7 32-126 N/A

8 32, 48-57, 60, 62, 67, 69, 78, 83, 84, 88, 90 N/A

Scalable Fonts

The scalable fonts allow codepage selection through the System Command

<STX>ySxx

letter CP Identifier.

, and the Label Formatting Command

ySxx

, where xx is a two

255

Note that on Datamax, not all fonts have an entire compliment of character

codes for a given code page.

The default codepage is (PT) PC-8 TK, Code Page 437T.

See table below for an overview of the available codepages. Additional info

and print samples can be found in the ‘Class Series Programmers Manual’,

Appendix E and I.

Codepages used by Scalable Fonts:

CPG ID Description CPG ID Description

DN ISO 60 Danish / Norwegian PT PC-8 TK, Code Page 437T

E1 ISO 8859/1 Latin 1 R8 Roman-8

E2 ISO 8859/2 Latin 2 SP ISO 17: Spanish

E5 ISO 8859/9 Latin 5 SW ISO 11: Swedish

FR ISO 69: French UK ISO 4: United Kingdom

GR ISO 21: German US ISO 6: ASCII

IT ISO 15: Italian W1 Windows 3.1 Latin 1

LG Legal WE Windows 3.1 Latin 2

PE PC-852 Latin 2 WO Windows 3.0 Latin 1

PM PC-850 Multilingual WT Windows 3.1 Latin 5

37

Page 38

Chapter 3

Downloading Bitmap Fonts

The Font-loading <ESC> commands are used to download bitmap-fonts in

the PCL-4 (HP LaserJet II) format.

Downloading Scalable Fonts

Two types of Scalable fonts can be downloaded to the printer with

command:

<STX>i

·IntelliFont (.CDI)

·TrueType (.TTF)

Advanced Format Attributes

Advanced Format Attributes can be used to manipulate the font / string

attributes. They can even affect partial strings by embedding them in the text

data stream.

NOTE: DGL will not support these commands when embedded in a text-

string (only when they appear as separate commands).

Dot Size

Label formatting command ‘Dwh’ can be used to change the size of a printed

dot, hence the print resolution – dots per inch (DPI).

NOTE: The dot size does not affect all printed objects;

- Barcodes are only affected in horizontal direction (Barcode PDF

affected in both directions!)

- Graphics are not affected at all

Not Supported.

Barcode Symbologies

The sections below list the limitations for the barcodes that are partially

supported.

Positioning

The barcode origin lies at the lower left coordinate, and indicates the origin of

the PDF interpretation.

38

Origin

UPC / EAN

If the user provides the checksum, the printer will check that it matches the

expected checksum. If it does not match, the printer will print all zeros and the

expected checksum.

(Not supported for UPC-E.)

Page 39

UCC/EAN Code 128

DGL follows the UCC standards, and requires the amount of data that is

defined for the provided AI (Application Identifier). For example, with barcode

‘Q’ the required amount of data is 19 according to the Datamax manual. An AI

of ‘00’ requires 19 databytes, however, Datamax also prints the barcode when

19 databytes are provided with another AI. DGL does not; the amount of data

required is based only on the provided AI.

Barcodes Q, R, S and W1R all print the same UCC barcode on DGL (except

for differences in PDF placement); required lengths only depend on the

provided AI.

Plessey

DGL does not accept more than 14 bytes as barcode data, while Datamax

does. However, according to the Datamax manual the maximum length is 14,

so problems are not expected.

PostNet

Datamax has a slightly larger width for the first space in the start character, all

other sizes match exactly.

MaxiCode

The postal code can have a length of up to 9 digits, and up to 6 for

alphanumeric on Datamax. DGL, however, always encodes using exactly 6 or

9. When less than 6 alphanumeric bytes are provided, trailing spaces will be

added, and trailing zeros will be added when the given data is numeric and

less than 9.

RSS14

The maximum accepted item number for RSS Limited barcodes is

1999999999999; DGL will not print the barcode when a larger number is

provided. Datamax does accept larger numbers.

DGL does not support X and Y Pixel-Undercut.

Not Implemented Barcodes:

W1d: QR Code - Auto format

W1D: QR Code - Manual Format

W1I: EAN 128 w/auto subset switching

W1J: Code 128 w/auto subset switching

W1t: TCIF Linked Barcode 3 of 9 (TLC39)

W1z: MicroPDF417

W1Z: MicroPDF417 with Byte Count

39

Page 40

Chapter 3

Images

Images can be downloaded to the printer to be stored in Flash or DRAM in the

following formats using the

Image Formats:

ID Format Comp

F 7-bit Datamax image load file

B .BMP 8-bit format (image will be flipped) black & white

b .BMP 8-bit format (save image as received) black & white

I .IMG 8-bit format (image will be flipped) black & white

I .IMG 8-bit format (save image as received) black & white

P .PCX 8-bit format (image will be flipped) black & white

P .PCX 8-bit format (save image as received) black & white

<STX>I

Command.

F

F

F

F

F

F

F

NOTE: The first image-row received will be printed at given coordinates. All

following rows are appended on top of each other. So when using the

‘save image as received’ version, the image will be printed upsidedown

Graphics - Supported graphics objects:

• Lines / Boxes

• Filled / non-filled) Polygons

• Filled / non-filled) Circles

NOTE: Only Lines and boxes will be supported by DGL.

Flash / Ram Module compatibility

DPL can store / read several different types of objects to separate modules,

and perform operations on these modules.

Objects that can be stored to modules can be Labels, Images, Scalable or

Bitmap fonts.

40

Page 41

Module Operations:

Cmd Description Comment

<STX>x File delete from module Supported

<STX>q Module clear Supported

<STX>Q Modules, clear all Supported

<STX>z Module, compress Not Supported

<STX>W Module, directory request Partially Supported

<STX>X Module, set default Supported

<STX>w Module, FLASH memory Test Do the stutus report, always oke

<STX>t Module, RAM memory Test Do the stutus report, always oke

<STX>Kp Module Protection Not Supported

DGL will emulate 2 different Modules: Ram and Flash. Datamax has several

Flash and Ram modules, but DGL will map all Flash modules to the same

PTX Flash File System, and all Ram Modules to the global Memory Pool.

When recalling something from a module, the Module Identifier is not

specified in the command, so this should not cause a problem when DGL

maps them to a single Flash / Ram module.

The only problem that might occur is when there is bi-directional

communication needed for a Windows driver, which might verify an object got

stored correctly by requesting a module directory.

When specifying a module that is not available, the printer will automatically

select the default module.

Bi-Directional Communications

Bi-Directional communications can be divided in two groups: time-critical

(immediate), and non-time-critical responses.

Datamax describes the time critical responses as follows:

When the printer receives a Status and Control Command, its current

operation will be momentarily interrupted to respond to the command. Status

and Control Commands may be issued before or after System-Level

Commands; however, they cannot be issued among (a) Label-Formatting

Commands, (b) during font downloading, or (c) during image downloading.

Commands that require immediate action (including commands that request

immediate response) will not be supported.

Non time-critical responses are supported by DGL. For example the feedback

or memory module information request commands.

Cutter Commands

The Commands to activate the Cutter (System Level Command

Label Formatting Commands ‘

Handling menu is set to ‘Cut’, and the DGL Advanced-User Menu ‘Cut Cmds’

is set to ‘Process’.

c

’ and ‘:’) are only processed when the Media

<STX>o

, and

41

Page 42

Chapter 3

The Media Handling menu setting can be set up through the Software Switch

Setting command <STX>V. Enabling the Cutter bit selects ‘Cut’ Media

Handling, and the Present bit selects ‘Tear-Off’. Disabling cutter or present bit

selects media handling setting ‘Continuous’.

The <STX>V command can be ignored by setting the DGL Advanced-User

menu ‘Soft. Switch (V)’ to Ignore.

Emulations

Datamax allows emulation of legacy and other resolution printers through

menu settings (Plus, Allegro, Column and SOP emulations).

emulations are supported on DGL.

None of these

Printer Configuration

All DPL commands affecting the printer configuration will be ignored.

DGL has its own configuration management to save / load configuration

settings that can be used instead. See table below for the affected commands

(all ignored):

Cmd Desc

<SOH>U Update System Database with Current Database

<STX>KC Get Configuration

<STX>Kc Set Configuration

<STX>Kd Set File as Factory Defaults

<STX>KF Select Factory Defaults

<STX>Kx Delete Configuration File

e Recall Printer Configuration

Command Reference

The following sections explain why certain commands are partially supported

or ignored.

Ignored Commands

<STX>Kb Backfeed Time Delay

<STX>K- Top-of-Form. Offset Distance

<STX>KF Set Present Distance

42

<STX>M Set Maximum Label Length (Distance to search for Gap before

error)

<STX>R Ribbon Saver

<STX>b Set Cutter signal time

Page 43

<STX>Y Output Sensor Values

DataMax Values do not correspond with PTX values.

<STX>D Memory Dump (Test Mode Only)

<STX>d Set Printer to double buffer mode

<STX>s Set Printer to single buffer mode

This only affects the internal processing of dynamic fields, cannot

be changed in DGL, which always prints using display list.

<STX>g Internal Batch Software Mode

<STX>N Enter Internal Batch

f Set Present Speed

p Set Backfeed Speed

FR[+/-]n Degrees

Label Length:

When Datamax receives a label that exceeds the configured

physical page-length, it will still print the whole job by spanning it

across multiple physical pages. DGL will clip the job at the

configured physical page-length.

Workaround

·<SOH>U Update System Database with Current Database

<STX>KC Get Configuration

<STX>Kc Set Configuration

<STX>Kd Set File as Factory Defaults

<STX>KF Select Factory Defaults

<STX>KQ Query Memory Configuration

<STX>Kq Query Memory Configuration (new format)

<STX>Kx Delete Configuration File

<STX>KD Database Configuration

<STX>KR Reset Memory Configuration

e Recall Printer Configuration

PTX has its own Configuration Management.

<STX>Kr Reset Internal Counters

Use DIAGNOSTICS/Reset Head Data

Distance

<STX>KV Verifier Enable/Disable

to reset the Head Print

Use

Validator Menu

<STX>KI GPIO Input

options

43

Page 44

Chapter 3

<STX>KO GPIO Output

PTX has its own GPIO configuration methods

<STX>KS Configure Scalable Font Cache Size

PTX Font cache is configured in

<STX>P Enter Character Dump Mode

HexDump Mode is available in

<STX>T Printhead Dot Pattern Test Label

<STX>Z Print Configuration and Dot Pattern Labels

PRINTER CONTROL