Page 1

QuickScan

®

6000/6000 Plus

Handheld Laser Scanner

Programming Guide

Page 2

Datalogic Scanning, Inc.

959 Terry Street

Eugene, Oregon 97402

Telephone: (541) 683-5700

Fax: (541) 345-7140

An Unpublished Work - All rights reserved. No part of the contents of this

documentation or the procedures described therein may be reproduced or

transmitted in any form or by any means without prior written permission

of Datalogic Scanning, Inc. or its subsidiaries or affiliates (“Datalogic” or

“Datalogic Scanning”). Owners of Datalogic products are hereby granted a

non-exclusive, revocable license to reproduce and transmit this documentation for the purchaser’s own internal business purposes. Purchaser shall

not remove or alter any proprietary notices, including copyright notices,

contained in this documentation and shall ensure that all notices appear

on any reproductions of the documentation.

Should future revisions of this manual be published, you can acquire

printed versions by contacting your Datalogic representative. Electronic

versions may either be downloadable from the Datalogic website

(www.scanning.datalogic.com) or provided on appropriate media. If you

visit our website and would like to make comments or suggestions about

this or other Datalogic publications, please let us know via the “Contact

Datalogic” page.

Disclaimer

Datalogic has taken reasonable measures to provide information in this

manual that is complete and accurate, however, Datalogic reserves the

right to change any specification at any time without prior notice.

Datalogic is a registered trademark of Datalogic S.p.A. and the Datalogic

logo is a trademark of Datalogic S.p.A. all licensed to Datalogic Scanning,

Inc. All other trademarks and trade names referred to herein are property

of their respective owners.

Page 3

Contents

Introduction ------------------------------------------------------------------------ 1

Understanding the Basics ......................................................................... 1

Integrating Peripherals With Host Systems ............................................... 1

Changing Interfaces .................................................................................. 2

Customizing Your Scanner Operation ....................................................... 4

Programming Overview .................................................................................... 4

What Is Programming Mode? ................................................................... 5

How To Program Using Bar Codes ........................................................... 5

The Programming Session ....................................................................... 6

Scanner Response When In Programming Mode..................................... 6

If You Make a Mistake... ............................................................................ 7

Return to Factory Settings ........................................................................ 7

Where To Go From Here ........................................................................... 8

IBM 4683/84 • 4693/94 Port 5B Interface Selection .................................. 9

IBM 4683/84 • 4693/94 Port 9A, 9B, 9C, 9E I/F Selection ...................... 10

IBM 4682/92 Port E Interface Selection .................................................. 11

Datalogic OCIA1 Interface Selection ...................................................... 12

NCR OCIA Eight Bit (short format) Interface Selection ........................... 12

NCR OCIA Nine Bit (long format) Interface Selection ............................. 12

SNI OCIA Interface Selection ................................................................. 12

OCIA Options ......................................................................................... 13

Wand Emulation Interface Selection ....................................................... 14

RS-232 Interface Selection ..................................................................... 16

SNI RS-232 Interface Selection .............................................................. 16

Hardware Control ................................................................................... 19

Software Control ..................................................................................... 20

RS-232 ACK/NAK Options (QuickScan 6000 Plus ONLY) ...................... 21

PC Keyboard Wedge Interface Selection ................................................ 24

PC Keyboard Wedge Interface Selection—continued ............................. 25

PC Keyboard Wedge –

Connect to a Laptop/No Keyboard Attached........................................... 26

Caps Lock (QuickScan 6000 Plus ONLY) ............................................... 27

Country Mode (QuickScan 6000 Plus ONLY) ......................................... 28

Intercharacter Delay ............................................................................... 30

Label Transmit Format Configuration Items .................................................... 32

(RS-232 and Keyboard Wedge Interfaces Only) ..................................... 32

Prefix & Suffix ......................................................................................... 32

Non-Symbology Specific Items ............................................................... 34

Programming Guide

Page 4

ASCII Character Set ............................................................................... 38

Symbology-Specific Label I.D. ................................................................ 39

Symbologies ---------------------------------------------------------------------- 46

Symbology Options Overview......................................................................... 47

Symbology Selection ...................................................................................... 48

UPC/EAN Options .......................................................................................... 51

UPC/EAN Expansion .............................................................................. 52

UPC/EAN Add-Ons ................................................................................ 53

C128 and Custom Add-Ons .................................................................... 54

Price/Weight Check Digit ........................................................................ 54

Code 39 Options ............................................................................................ 58

Code 39 (continued) ....................................................................................... 59

Code 39 (continued) ....................................................................................... 60

Code 128 Options .......................................................................................... 62

Interleaved 2 of 5 ............................................................................................ 63

Check Digit and Variable Length Label Selections .................................. 64

Standard 2 of 5 ............................................................................................... 67

Check Digit and Variable Length Label Selections .................................. 68

Setting Standard 2 of 5 Fixed and Minimum Label Lengths.................... 69

Codabar Options ............................................................................................ 72

Codabar Check Digit & Variable Length .................................................. 73

Codabar Start/Stop Character ................................................................ 74

Codabar Fixed Length ............................................................................ 75

MSI/Plessey Check Digit ........................................................................ 77

MSI/Plessey Fixed Length ...................................................................... 78

General Features............................................................................................ 80

Good Read Beeper Settings ................................................................... 80

Read Verification ..................................................................................... 82

Low Power Mode .................................................................................... 85

Debug Mode ........................................................................................... 86

AutoSense® Stand Mode ....................................................................... 86

Appendix A

Additional Information -------------------------------------------------------- 87

Host Programming.......................................................................................... 87

Creating MultiFunction Labels ........................................................................ 87

Need More Information? ................................................................................. 87

Appendix B

Sample Bar Codes --------------------------------------------------------------88

ii

QuickScan 6000/6000 Plus

Page 5

Introduction

This manual contains instructions for changing interfaces and bar codes

for customizing the scanner's operation. Since the

scanner contains software enhancements and characteristics that set it

apart from other scanners, it is recommended that this guide be used as

the sole source of programming labels and information (except for other

QuickScan 6000/6000 Plus

The organization of this manual is intended to support a variety of users

while making it quick and easy to find the information you need. Look at

the descriptions that follow to find where to go from here.

product-specific publications).

Understanding the Basics

If you do not regularly use bar code labels to configure (program)

scanners, it will be very helpful to read the introductory portions of this

manual prior to beginning your programming session. In addition to the

information that follows, information of specific interest to you is titled:

— Integrating Peripherals with Host Systems

— Changing Interfaces

— Customizing Your Scanner Operation

— Programming Overview

— What is Programming Mode?

— How to Program Using Bar codes

— The Programming Session

— Scanner Response When in Programming Mode

— If You Make A Mistake

— Where to Go From Here

Integrating Peripherals With Host Systems

It's important to understand that the scanner must contain software and

hardware that supports a specific interface in order to use that interface.

The following pages describe interface hardware and list software interface groups available on current models.

QuickScan 6000/6000 Plus

Optimally, you'll want details about how your scanner was configured at

the factory before attempting to customize any settings. If you don't have

that information, contact your dealer for factory configuration information.

After determining the changes and/or additions you desire, locate the

programming labels and follow the related instructions in this manual to

adjust the scanner. Once you've completed these steps, you can begin

scanning.

Programming Guide 1

Page 6

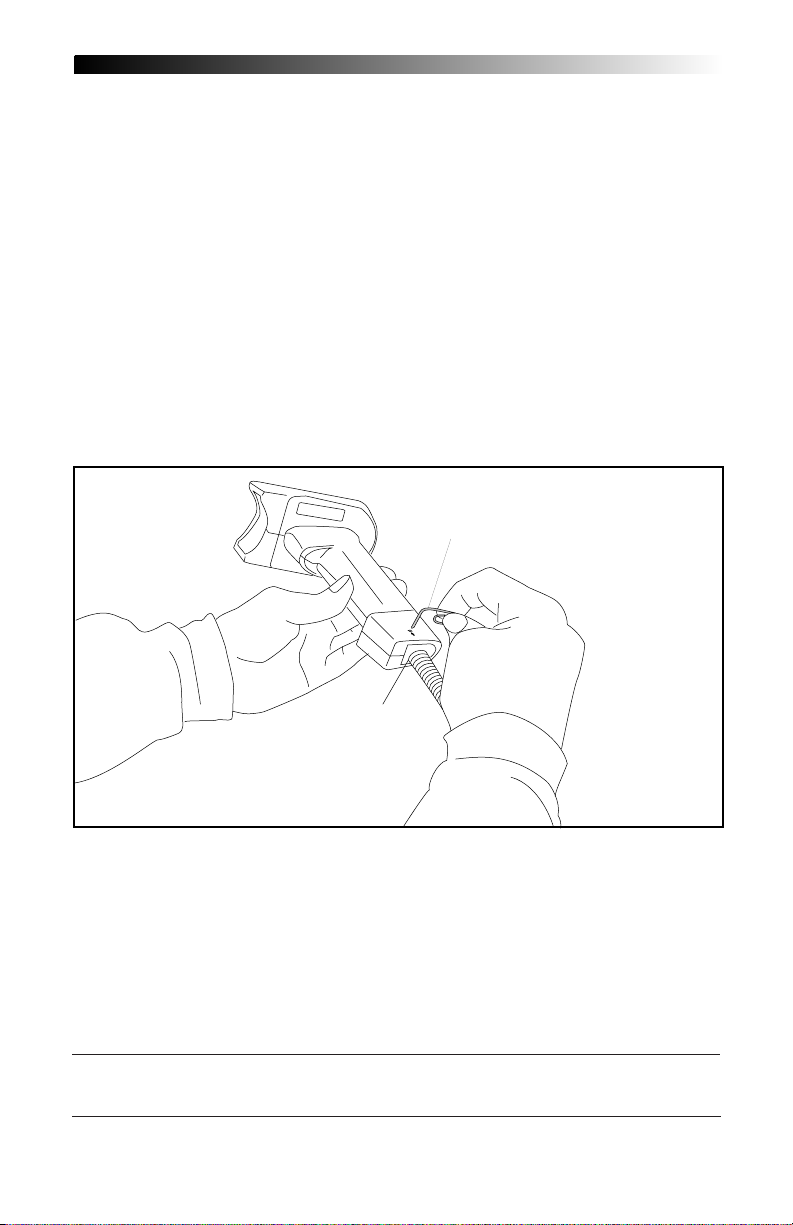

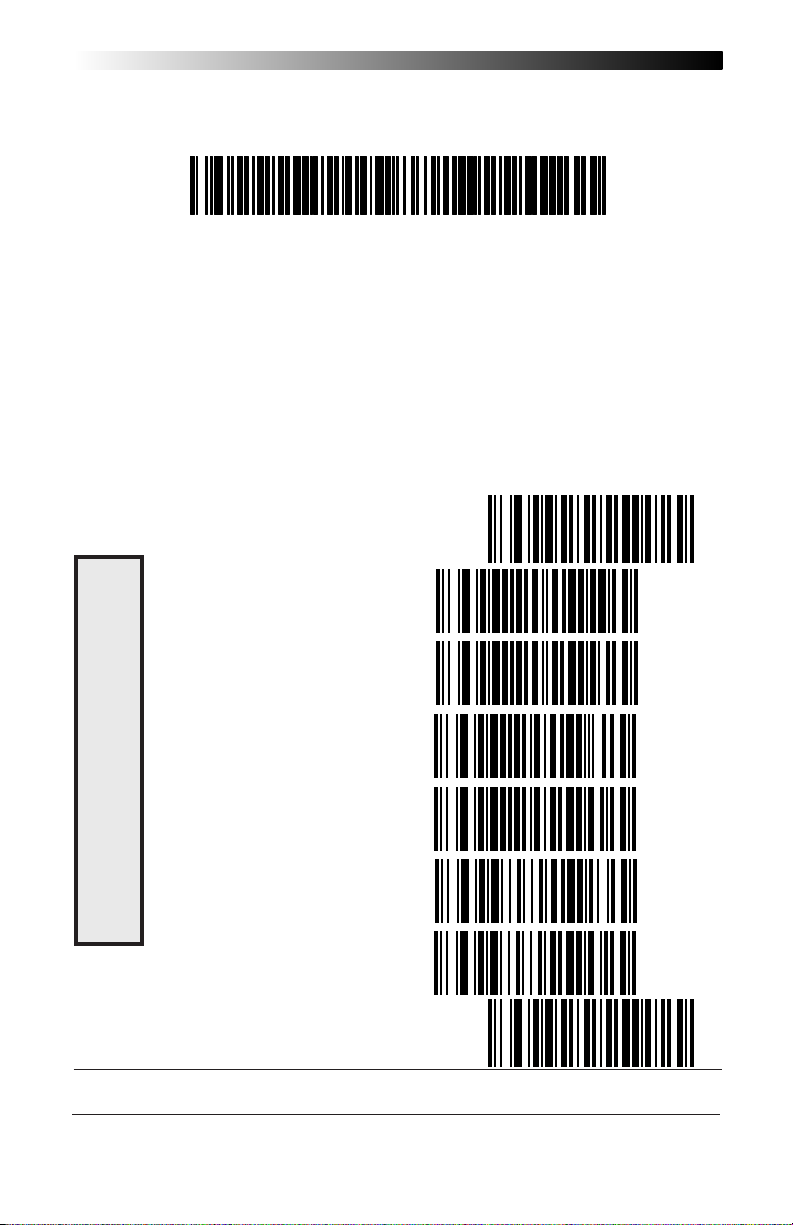

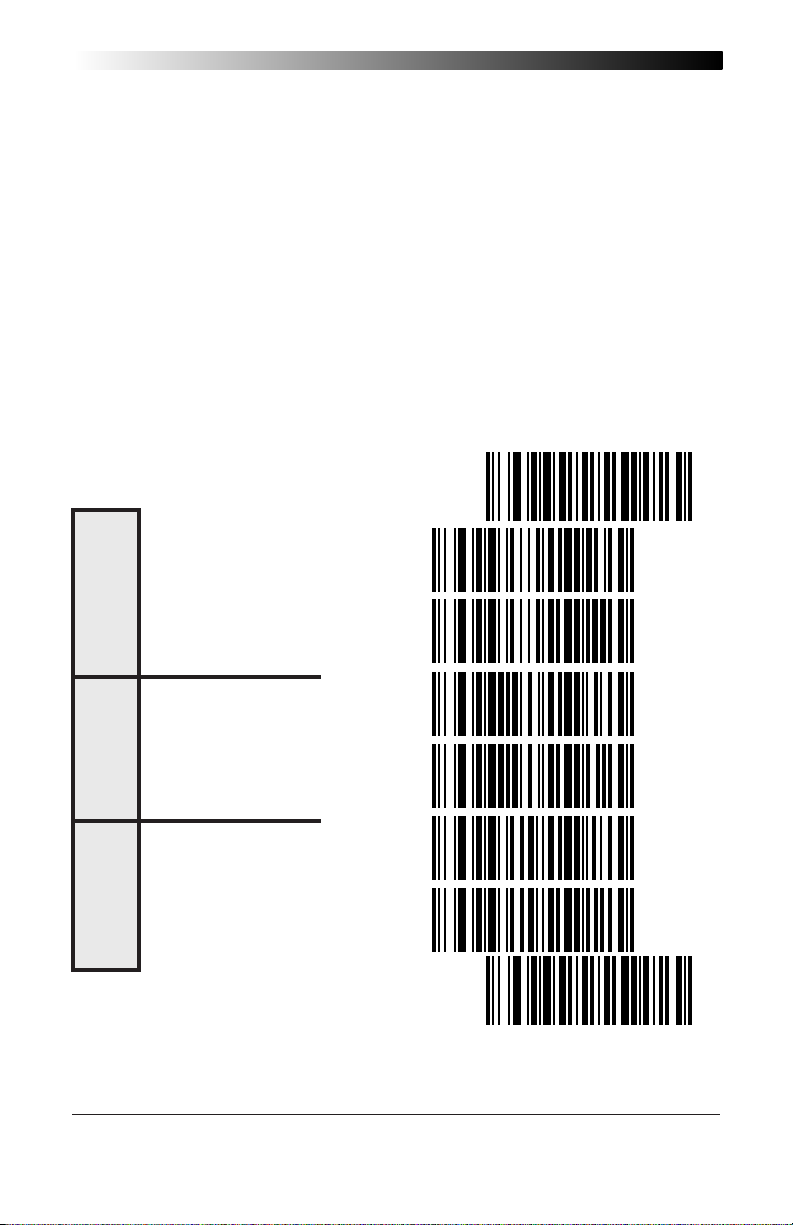

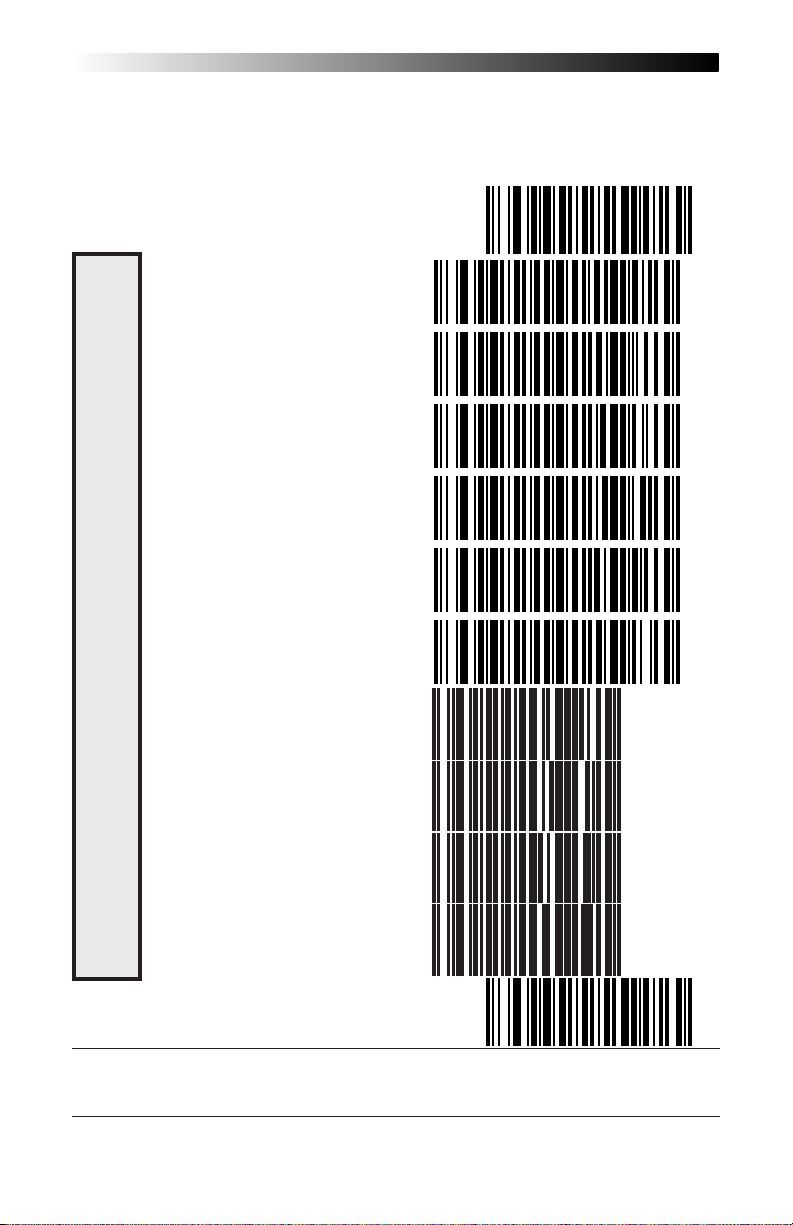

Changing Interfaces

To change a scanner's interface…

Hardware

If necessary, replace the scanner's interface cable to match the new host

terminal's connection requirements. To disconnect the cable from the

scanner, insert a .050” hex driver or bent paper clip into the CABLE RELEASE hole, and press down to unlock the cable connector. Reference

Figure 1.

NOTE

We recommend that you disconnect power before plugging/

unplugging cables to avoid any possibility of equipment damage.

Figure 1. Disconnecting the Interface Cable`

Paper Clip

Cable Release

Interface

Connector

Software

1. Verify that your scanner supports the desired interface1. The list

on the following page indicates interfaces available at the time of

this writing. Your scanner comes equipped from the factory with

the ability to connect and communicate with at least two major

interface types. For example, OCIA/RS-232 and Keyboard Wedge/

Wand Emulation are two common pairings. Contact your nearest service

depot if you don't know your scanner's interface group, or need to have the

scanner altered to change to another I/F group.

1 Contact your dealer if your desired interface is not listed. Interface group definitions

are subject to change without notice.

2

QuickScan 6000/6000 Plus

Page 7

OCIA

• Datalogic OCIA

• NCR 8-Bit OCIA

• SNI OCIA

• NCR 9-Bit OCIA

RS-232

• Datalogic RS-232

• SNI RS-232

IBM

• IBM 4683/84, 4693/94 Port 5B

• 4682/92 Port E

• IBM 4683/84, 4693/94 Port 9A, 9B, 9C, 9E

Wand Emulation

Keyboard Wedge

• I/F Type A — PC/XT w/foreign keyboard

• I/F Type B — AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80, 90 &

95 w/foreign keyboard

• I/F Type C — PS/2 25 and 30 w/foreign keyboard

• I/F Type D — PC/XT w/US keyboard

• I/F Type E — AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80, 90 &

95 w/US keyboard

• I/F Type F — PS/2 25 and 30 w/US keyboard

• I/F Type G — IBM 3xxx w/122 keyboard

• I/F Type H — IBM 3xxx w/102 keyboard

• I/F Type I — PS/55 5530T w/104 keyboard

• I/F Type J NEC 9801

(QuickScan 6000 Plus ONLY)

(QuickScan 6000 Plus ONLY)

(QuickScan 6000 Plus ONLY)

(QuickScan 6000 Plus ONLY)

2. Turn to the appropriate page in this manual and enable the

desired interface or interface sub-type by scanning its programming bar code. These interface/interface sub-type

selection bar codes are located at the beginning of each of

these sections of the manual: IBM, OCIA, Wand Emulation,

RS-232, and Keyboard Wedge. This will enable the software

for the new interface and disable the 'old' interface software.

Once enabled, the new interface becomes the default interface that is active whenever power is applied to the scanner.

3. Scan a bar code to verify that the scanner communicates

correctly with the host system. Some sample bar codes are

provided on the last pages of this manual. If any changes to

the scanner's factory settings are needed, use the instructions

titled, Customizing Your Scanner Operation.

Programming Guide 3

Page 8

Customizing Your Scanner Operation

When enabling a new interface, it may be necessary to modify the original factory

settings to match your specific host system's communication and symbology

requirements. Check with your system administrator to identify your host system's

specific interface requirements to ensure that they match the new interface you've

selected. Also, the scanner's operational features, such as speaker volume, can be

customized to match your unique requirements.

1. Use the labels in this manual to modify the standard configuration to

match your specific interface requirements or user preference.

NOTE

Ensure that your planned modifications are compatible with the

current interface. For example, baud rate selections are only valid

in the RS-232 interface. The scanner will sound an error tone (six

rapid beeps) when scanning programming labels for features

invalid to the current interface.

2. Enable any additional symbologies as required and exit

Programming Mode.

3. Scan a regular bar code label and verify that the scanner and

host communicate correctly.

4. You have completed the factory settings change procedure.

If you experience difficulties, have questions or require additional information, contact your local distributor using the listings located on the

back cover of this guide.

4

QuickScan 6000/6000 Plus

Page 9

Programming Overview

This section describes how to set the scanner's programmable features. These

features can be configured using the bar code labels contained in this manual or by

using commands sent from the host. Refer to Appendix A, Additional Information,

for host programming details. If you program the scanner using these bar codes, the

scanner stores the changes until reprogrammed.

What Is Programming Mode?

To change the scanner's programmed settings, it is necessary to place the

scanner in Programming Mode using the special SET label. This ensures

that the scanner only recognizes the special programming labels contained in this programming guide.

How To Program Using Bar Codes

The following pages contain special bar code labels that are used to

change or enable the scanner's programmable options. All programming

sessions follow this order, unless otherwise instructed:

1. Scan the SET label at the top of the page. The scanner will

emit a 'good read' beep, indicating it has read the label.

2. Scan the feature label(s) for the programmable options

you wish to enable. With few exceptions1, the scanner will

emit a triple beep each time you scan a valid programming

label. (Note that not all features are available for all interfaces and that the scanner will sound an error tone when

scanning programming labels for features invalid to the

current interface.)

3. Scan the END label at the bottom of the page to complete

the programming session and exit Programming Mode. The

scanner will sound one 'good read' beep upon exiting

Programming Mode.

4. Maintain a good record of all changes made to ensure that

you know if the original factory settings have been changed.

1 Some features, such as Minimum Label Length or Label ID, require you to select the length

by scanning a series of single-digit bar codes. A single 'good read' beep is sounded

when scanning these single digits in Programming Mode. Only the final required digit

in the sequence will produce a triple beep when scanned, indicating a successfully

programmed feature.

Programming Guide 5

Page 10

The Programming Session

It is possible to program multiple features during a single programming

session (a programming session is defined as the period of time between

scanning the “set” label and scanning the “end” label). However, it is recommended

that sessions be limited to one feature, as it can be difficult to discover where an error

has been made, should you make a mistake in the programming sequence. Additionally, it can be confusing to determine which features may or may not have been

successfully set following such a session.

The scanner will not exit Programming Mode unless the END label is scanned.

Disconnecting power during Programming Mode, before scanning the END label,

will cause the scanner to forget any programming labels scanned during the current

programming session and will cause the scanner to return to its previous settings.

Scanner Response When In Programming Mode

As discussed earlier, Programming Mode is entered by scanning a SET

label. The green LED will flash continuously at 1Hz duty cycle while the

scanner is in Programming Mode. As long as it is in Programming Mode,

the scanner will not decode regular bar code labels and will only enable

features supported by the currently active interface.

Scanning regular (non-programming) bar code labels — the

scanner will reject the label, sounding an error tone (six rapid

beeps).

Scanning a valid programming label —

a. If the feature is supported by the active interface, the

scanner will sound three beeps.

b. If incorrect programming has been entered, the error tone

will be sounded (six rapid beeps). Additionally, when

programming a feature requiring you to scan single digits

to set a multi-digit number, such as Minimum Label

Length or Label ID, scanning the END label before

completing all input will result in an error tone and cause

the scanner to exit Programming Mode. Under these

circumstances, the current feature you were trying to set

is thrown out; any previous labels scanned during the

session will take effect.

6

QuickScan 6000/6000 Plus

Page 11

If You Make a Mistake...

If, during a programming session, you find that you are unsure of the scanner's

settings or wish to reset the scanner's configuration, use the Return to Factory

Settings label on this page to return the scanner's configuration to the factory settings.

Scanning this label will also reset any changes made during previous programming

sessions.

Return to Factory Settings

Scan this label to return the scanner to the default settings configured at the factory for

your scanner’s original interface specifications. This label is typically used to return the

scanner to a “known” operating state when the present programming status is not

known, faulty, or suspect.

WARNING

Use this label with caution, since it will disable ALL features that

may have been programmed since the scanner’s installation.

If you don't have a record of your site/system's original configuration, you may need

to call your nearest service depot for assistance to return the scanner to normal

function. Please be prepared to provide information about the store/chain, location,

POS system and other pertinent information about the scanner being repaired.

Programming Guide 7

Page 12

Where To Go From Here

Programming is easy and straightforward if you follow these steps:

1. If you are changing interfaces, first connect the scanner to the new host

using the new interface cable. Scan the interface enable bar code label1 .

2. Scan any feature labels that are unique to the interface you are currently

programming. These interface specific programming labels immediately follow each interface selection label.

3. Turn to the Symbology section if you are going to change any bar code

symbologies or modify any symbology related features.

4. Turn to the General Features section of this guide if you wish to

change or modify any of the scanner's other features.

Once the necessary changes have been made, and you have scanned the END label,

you are ready to scan.

1 This step is not necessary for QuickScan 6000 Plus scanners, unless you require a

specific interface sub-type such as SNI OCIA or IBM sub-type 4682/92 Port E.

Interface software is automatically selected when the QuickScan 6000 Plus hardware

connection (via a new interface cable) is made.

8

QuickScan 6000/6000 Plus

Page 13

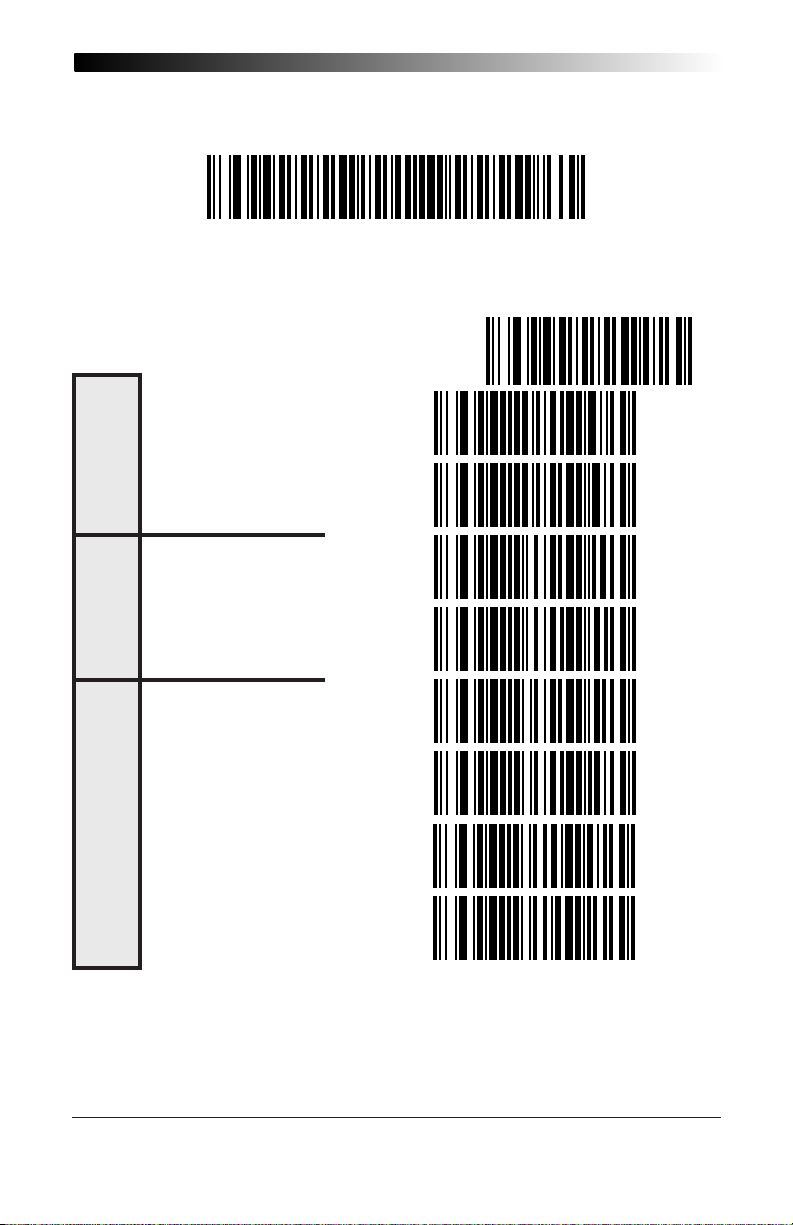

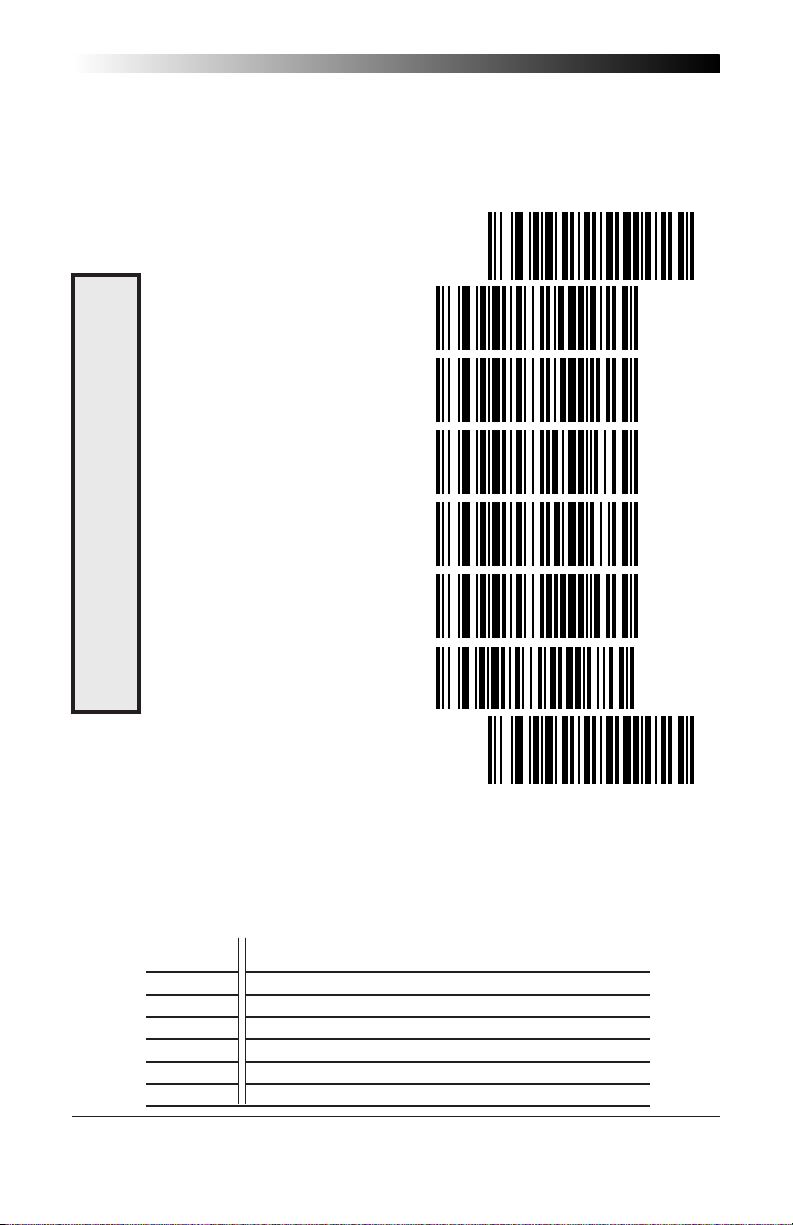

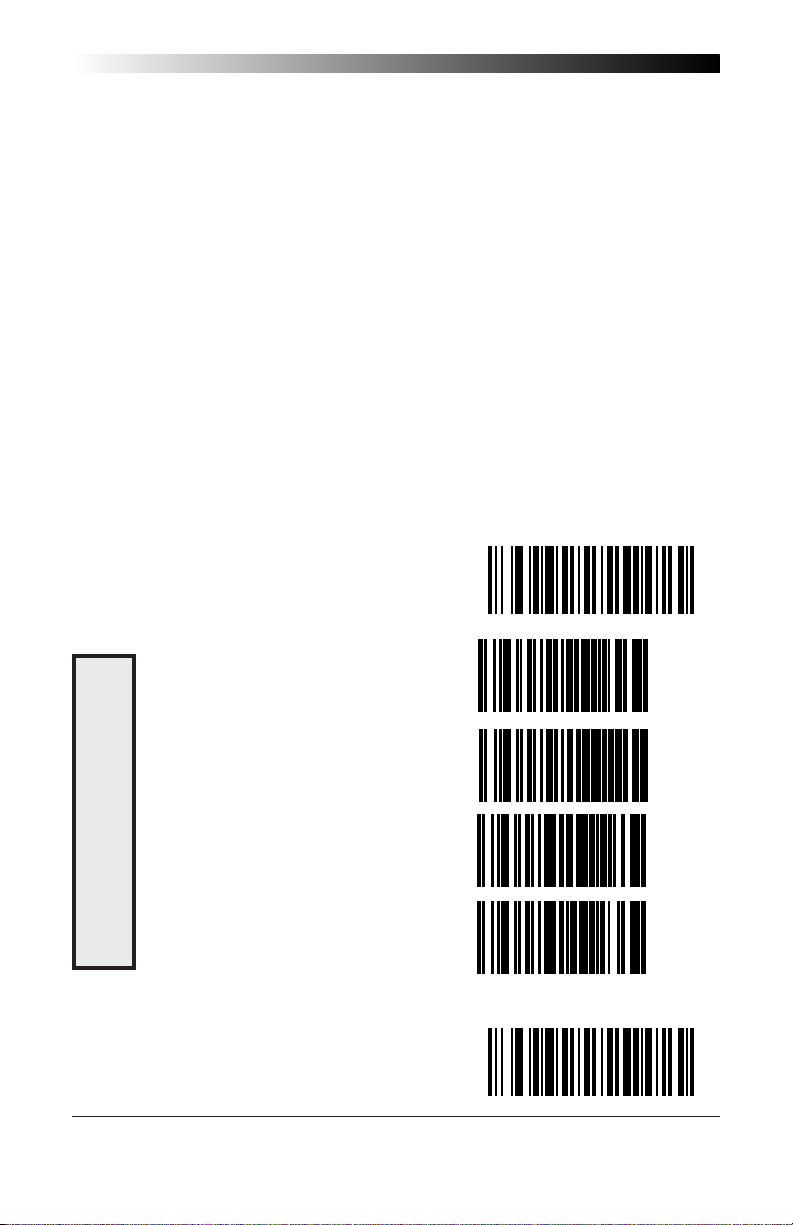

IBM 4683/84 • 4693/94 Port 5B Interface Selection

Scan this label to enable the IBM 468x Port 5B interface.

IBM 4683/84 • 4693/94 Port 5B Settings

Data Format: Send As Code 39 — converts bar code data (UPC/EAN,

add-ons, Code 93, Codabar, MSI/Plessey and Code 128) into Code 39

format before sending the data to the host.

These settings are for IBM 4683/84 • 4693/94 Port 5B interface ONLY.

Limit Command Set — is an option that causes the scanner to ignore

'enable scanner' and 'disable scanner' commands sent from the host.

Transmit Unsolicited Status1 — when enabled, this option causes the

scanner to transmit a status message to the host upon receipt of an "SNRM".

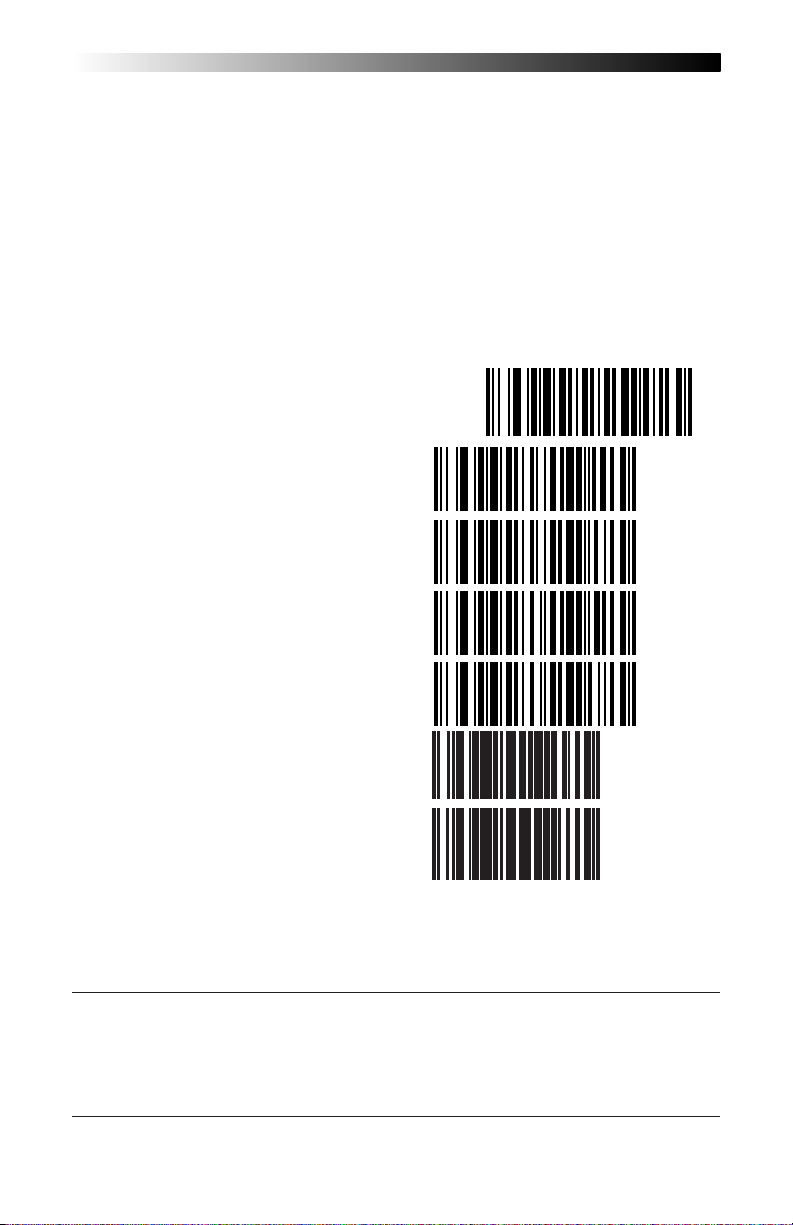

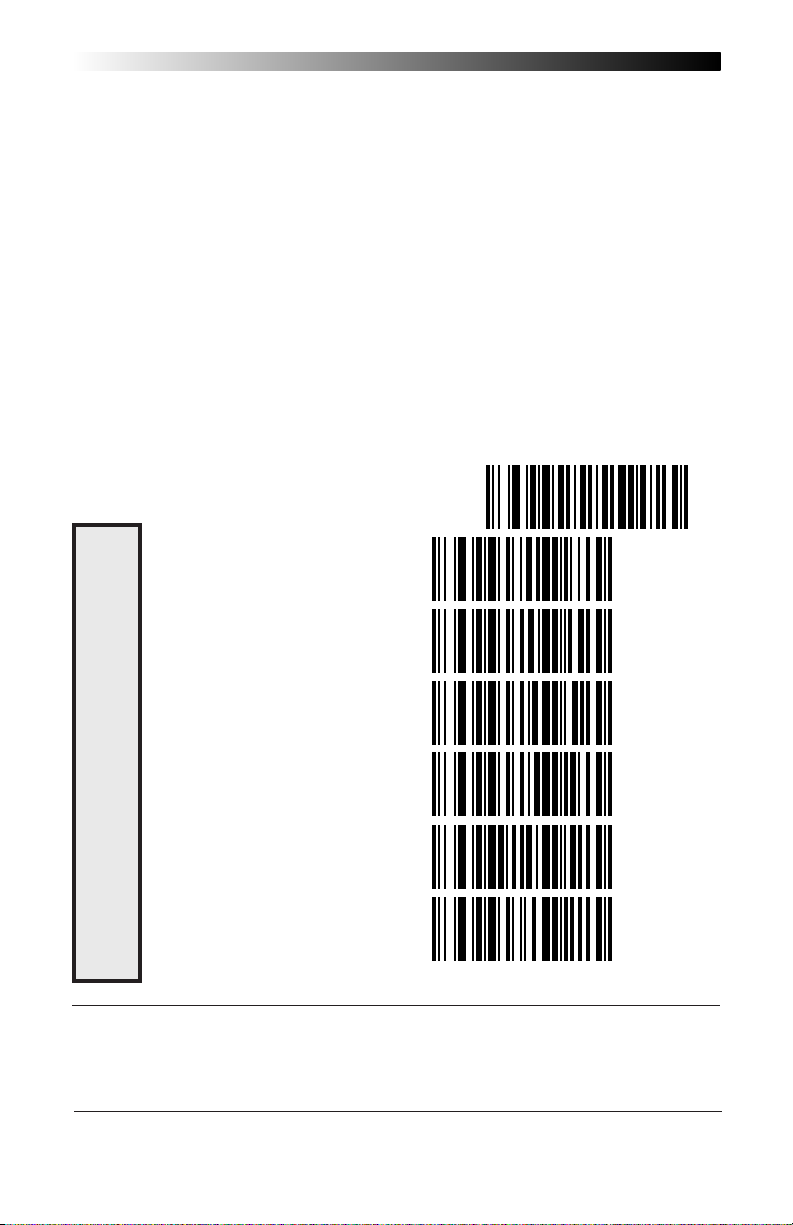

SET ----------------------------------------------

SEND AS CODE 39 ----------------

DON'T SEND AS CODE 39 --------

ORMAT

F

ATA

D

ENABLE LIMIT COMMAND SET -----

DISABLE LIMIT COMMAND SET -----

TRANSMIT UNSOLICITED STATUS ---

DON'T TRANSMIT UNSOLICITED STATUS ---

END ----------------------------------------------

1 For this IBM interface, the setting for Unsolicited Status is normally Enabled.

Programming Guide 9

Page 14

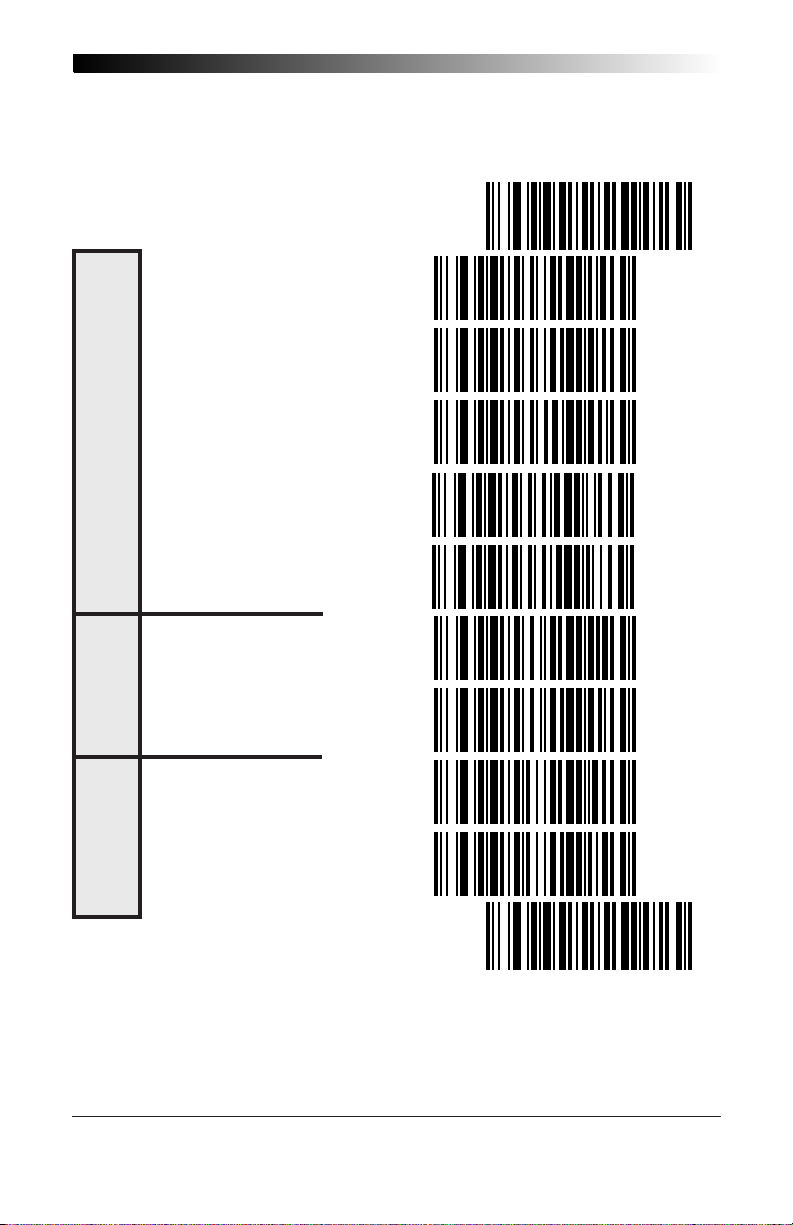

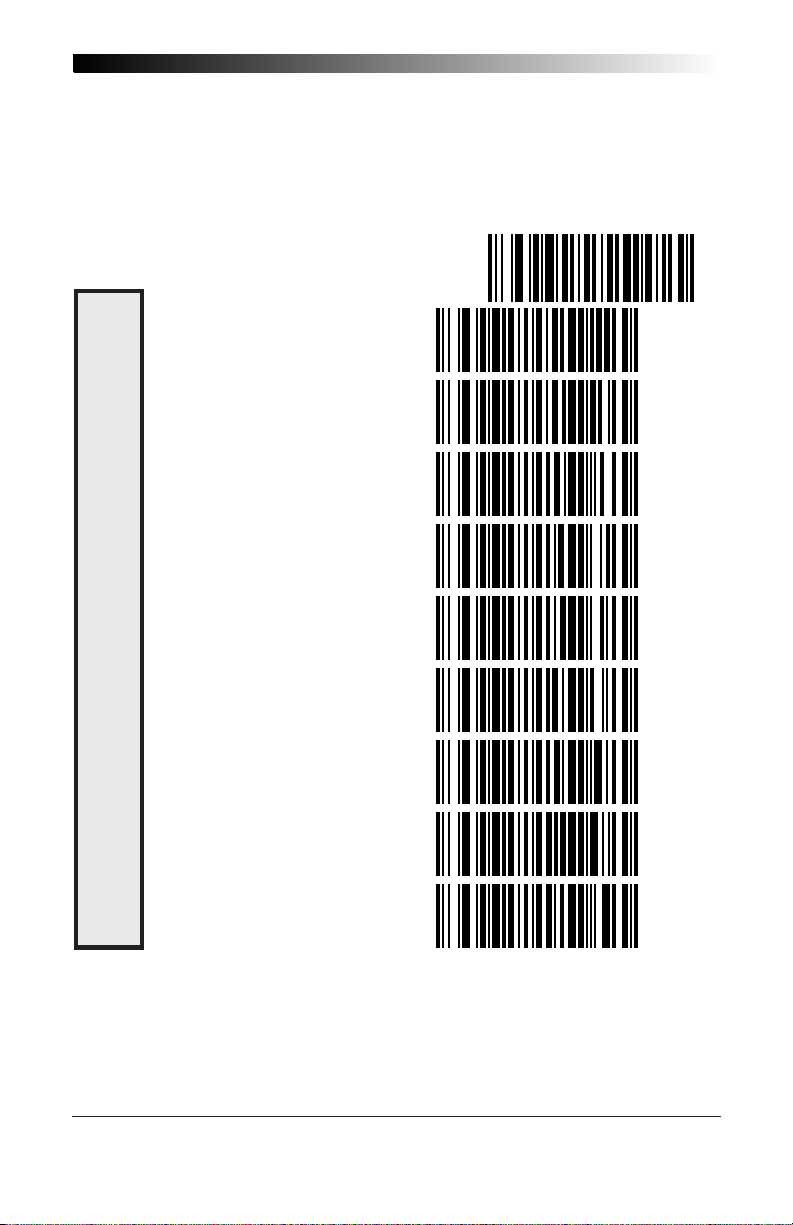

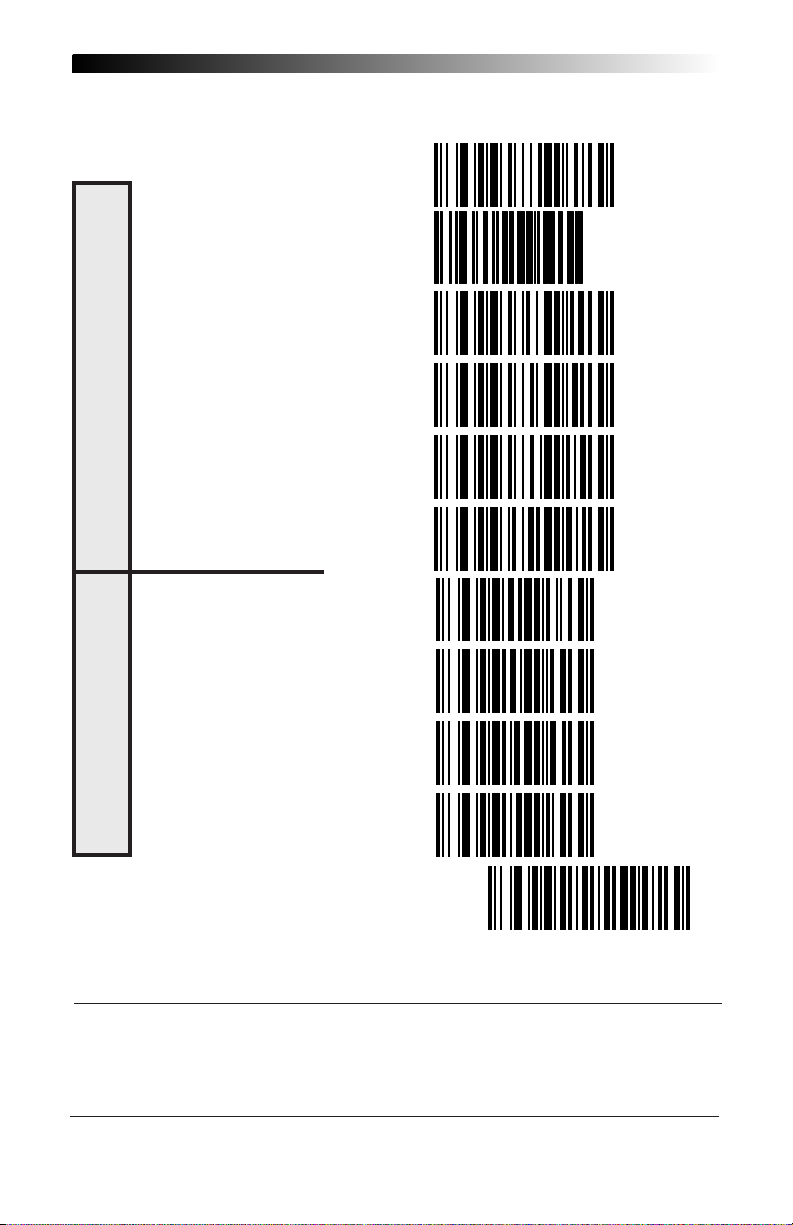

IBM 4683/84 • 4693/94 Port 9A, 9B, 9C, 9E I/F Selection

Scan this label to enable the IBM 468x/9x Port 9x interface.

IBM 4683/84 • 4693/94 Port 9A, 9B, 9C, 9E Settings

Data Format: Send As Code 39 — converts bar code data (UPC/EAN,

add-ons, Code 93, Codabar, MSI/Plessey and Code 128) into Code 39

format before sending the data to the host.

These settings are for IBM 4683/84 • 4693/94 Port 9A, 9B, 9C, 9E interface ONLY.

Limit Command Set — is an option that causes the scanner to ignore

'enable scanner' and 'disable scanner' commands sent from the host.

Transmit Unsolicited Status1 — when enabled, this option causes the

scanner to transmit a status message to the host upon receipt of an

"SNRM".

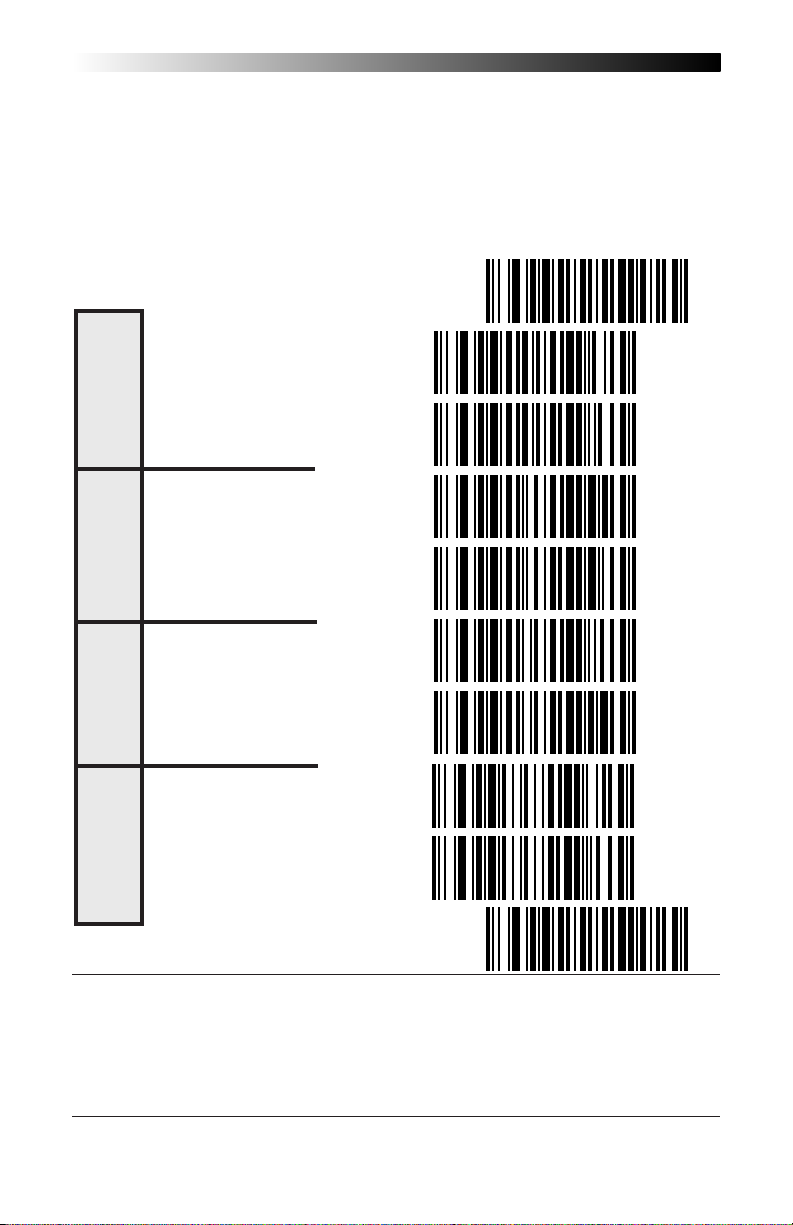

SET ----------------------------------------------

SEND AS CODE 39 ----------------

DON'T SEND AS CODE 39 --------

ORMAT

F

ATA

D

ENABLE LIMIT COMMAND SET -----

DISABLE LIMIT COMMAND SET -----

TRANSMIT UNSOLICITED STATUS ---

DON'T TRANSMIT UNSOLICITED STATUS ---

END ----------------------------------------------

1 For this IBM interface, the setting for Unsolicited Status is normally Disabled.

10

QuickScan 6000/6000 Plus

Page 15

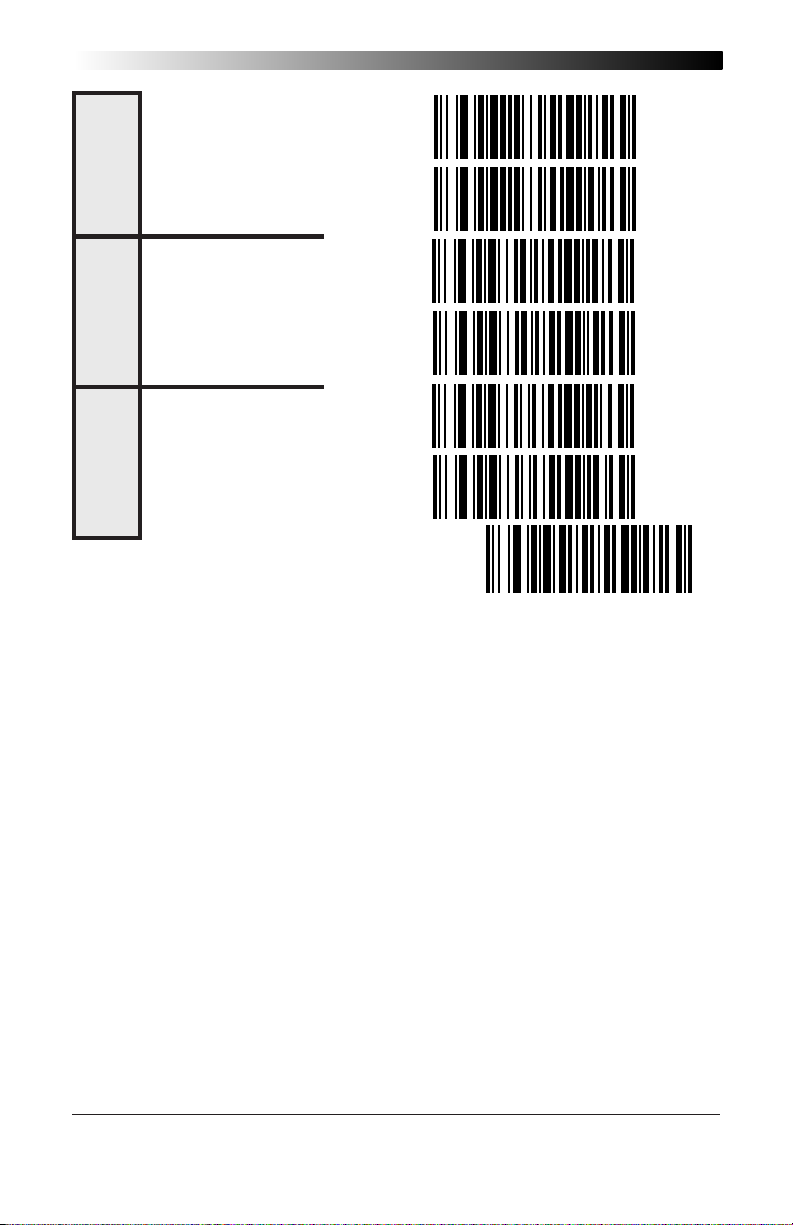

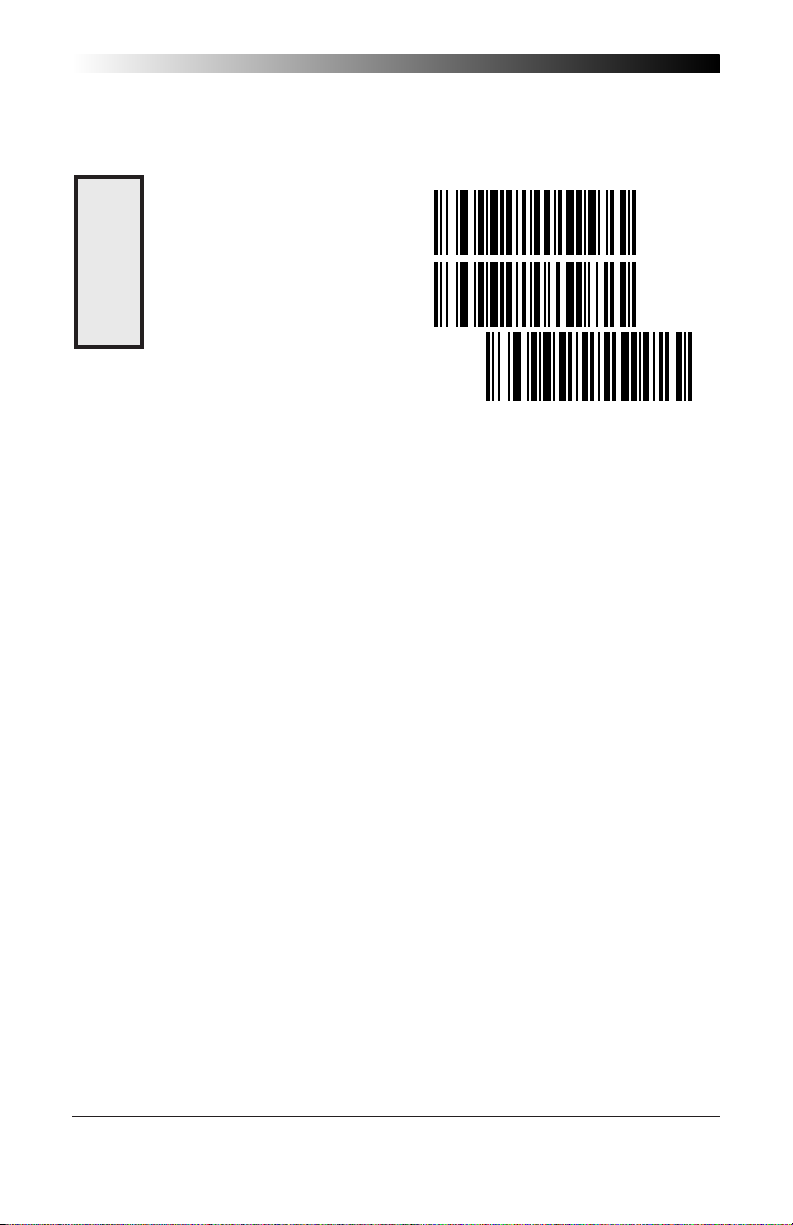

IBM 4682/92 Port E Interface Selection

Scan this label to enable the IBM 468x/9x Port E interface.

IBM 4682/92 Port E Settings

Data Format: Send As Code 39 — converts bar code data (UPC/EAN,

add-ons, Code 93, Codabar, MSI/Plessey and Code 128) into Code 39

format before sending the data to the host.

These settings are for IBM 4682/92 Port E interface ONLY.

Limit Command Set — is an option that causes the scanner to ignore

'enable scanner' and 'disable scanner' commands sent from the host.

Transmit Unsolicited Status1 — when enabled, this option causes the scanner

to transmit a status message to the host upon receipt of an "SNRM"

SET ----------------------------------------------

SEND AS CODE 39 ----------------

DON'T SEND AS CODE 39 --------

.

ORMAT

F

ATA

D

ENABLE LIMIT COMMAND SET -----

DISABLE LIMIT COMMAND SET -----

TRANSMIT UNSOLICITED STATUS ---

DON'T TRANSMIT UNSOLICITED STATUS ---

END ----------------------------------------------

1 For this IBM interface, the setting for Unsolicited Status is normally Disabled.

Programming Guide 11

Page 16

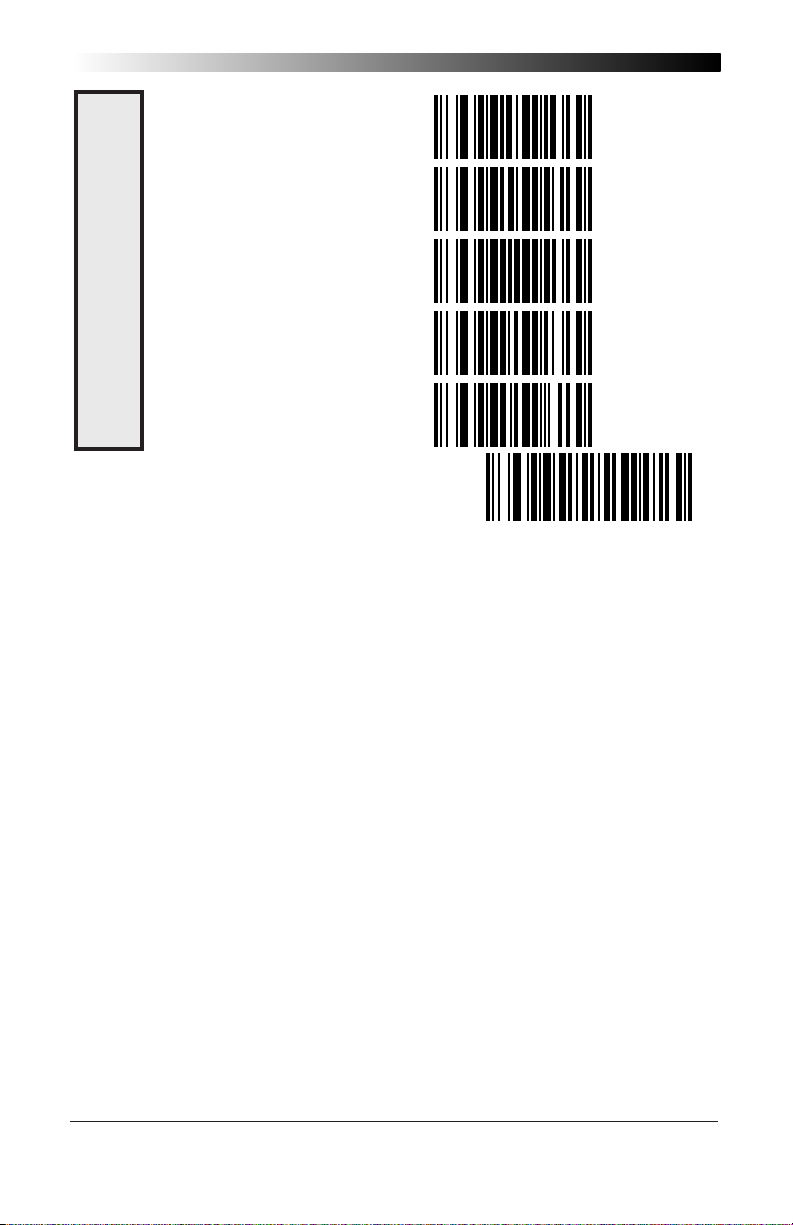

Datalogic OCIA1 Interface Selection

Scan this label to enable the Datalogic OCIA interface.

NCR OCIA Eight Bit (short format) Interface Selection

Scan this label to enable the NCR OCIA (short format) interface.

NCR OCIA Nine Bit (long format) Interface Selection

Scan this label to enable the NCR OCIA Nine Bit (long format) interface.

SNI OCIA Interface Selection

Scan this label to enable the SNI OCIA interface.

1 NOTE: In previous publications, this interface was termed, "SP OCIA".

12

QuickScan 6000/6000 Plus

Page 17

OCIA Options

Use these labels to change the settings as desired. The following brief

descriptions explain each selection.

Beep if Not on File — when enabled requires the scanner to

beep when a label is scanned that is not on file.

Host Commands — when enabled allows the scanner to

accept commands directly from the host.

Intercharacter Delay — refers to a pause, if any, between

each character before being sent to the host. This time delay is

used to control the flow of data from the scanner, but it should

not be required for most applications. When enabled, OCIA

intercharacter delay is set at 70µs.

SET ----------------------------------------------

ILE

IF

EEP

B

ENABLE -----------------------------

F

ON

OT

N

DISABLE -----------------------------

ENABLE -----------------------------

OST

H

OMMANDS

DISABLE -----------------------------

C

ENABLE -----------------------------

ELAY

D

NTERCHARACTER

I

DISABLE -----------------------------

END ----------------------------------------------

Programming Guide 13

Page 18

Wand Emulation Interface Selection

Scan this label to enable the Wand Emulation interface.

Wand Emulation Settings

SET ----------------------------------------------

SPACE LOW, BAR HIGH -----------

OLARITY

P

SPACE HIGH, BAR LOW -----------

14

PEED

S

IGNAL

S

ORMAT

F

ATA

D

LOW (660 µS) --------------------

HIGH (330 µS) --------------------

TRANSMIT IN NORMAL FORMAT-----

TRANSMIT IN C39 FORMAT --------

TRANSMIT IN C128 FORMAT ------

TRANSMIT IN C39 ----------------FULL ASCII

QuickScan 6000/6000 Plus

Page 19

TATE

S

DLE

I

LOW ---------------------------------

HIGH --------------------------------

TRANSMIT PRE-NOISE -------------

PATTERN BEFORE

TRANSMIT A NOISE

C128

RANSMIT

T

DON'T TRANSMIT PRE-NOISE ------

LABEL TRANSMISSION

S

'

ENABLE -----------------------------

HAR

C

DISABLE -----------------------------

UNCTION

F

END ----------------------------------------------

Go to the sections titled Symbology Selection and General Features in the

back of this programming guide if you want to change any other settings

for this interface.

Programming Guide 15

Page 20

RS-232 Interface Selection

Scan this label to enable the standard RS-232 interface (Datalogic RS-232).

SNI RS-232 Interface Selection

Scan this label to enable the SNI RS-232 interface.

RS-232 Communication Parameters

This section contains the following RS-232 communication parameters in

the order listed:

• Baud Rate

• Data Bits

• Parity

• Stop Bit(s)

• Hardware Handshaking (CTS/RTS)

• Software Handshaking (Xon/Xoff)

• ACK/NAK Options

• Intercharacter Delay

Go to the sections titled Symbology Selection and General Features in the

back of this programming guide if you want to change any other settings

for this interface.

16

QuickScan 6000/6000 Plus

Page 21

Baud Rate

Use the bar codes on this page to select the communications Baud Rate.

Only one Baud Rate selection may be active at any one time. The last

Baud Rate label you scan during a programming session will be the

setting that is stored when you scan the END label.

SET ----------------------------------------------

= 1200 ----------------------------

= 2400 ----------------------------

ATE

= 4800 ----------------------------

R

AUD

B

= 9600 ----------------------------

= 19200 --------------------------

= 38400 --------------------------

END ----------------------------------------------

Data Format Table

There are many possible data format configurations for an RS-232 interface.

Check your host system manual to find out your system's communications

requirements. This table shows the acceptable format options.

Data Bits Start Bit Parity Bit(s) Stop Bit(s)

Seven 1 0 2

Seven 1 1 1

Seven 1 1 2

Eight 1 0 1

Eight 1 0 2

Eight 1 1 1

Programming Guide 17

Page 22

Data Format Settings

The bar codes on this page can be used to select the data format configuration needed to communicate with your system.

SET ----------------------------------------------

NONE -------------------------------

EVEN --------------------------------

ARITY

P

ODD --------------------------------

MARK -------------------------------

SPACE ------------------------------

ITS

ONE ---------------------------------

B

TOP

S

TWO --------------------------------

SEVEN BITS ------------------------

ITS

B

ATA

D

EIGHT BITS -------------------------

END ----------------------------------------------

18

QuickScan 6000/6000 Plus

Page 23

Handshaking

Review your system documentation to identify handshaking requirements,

and use these labels to change the settings if required. The following brief

descriptions explain each selection.

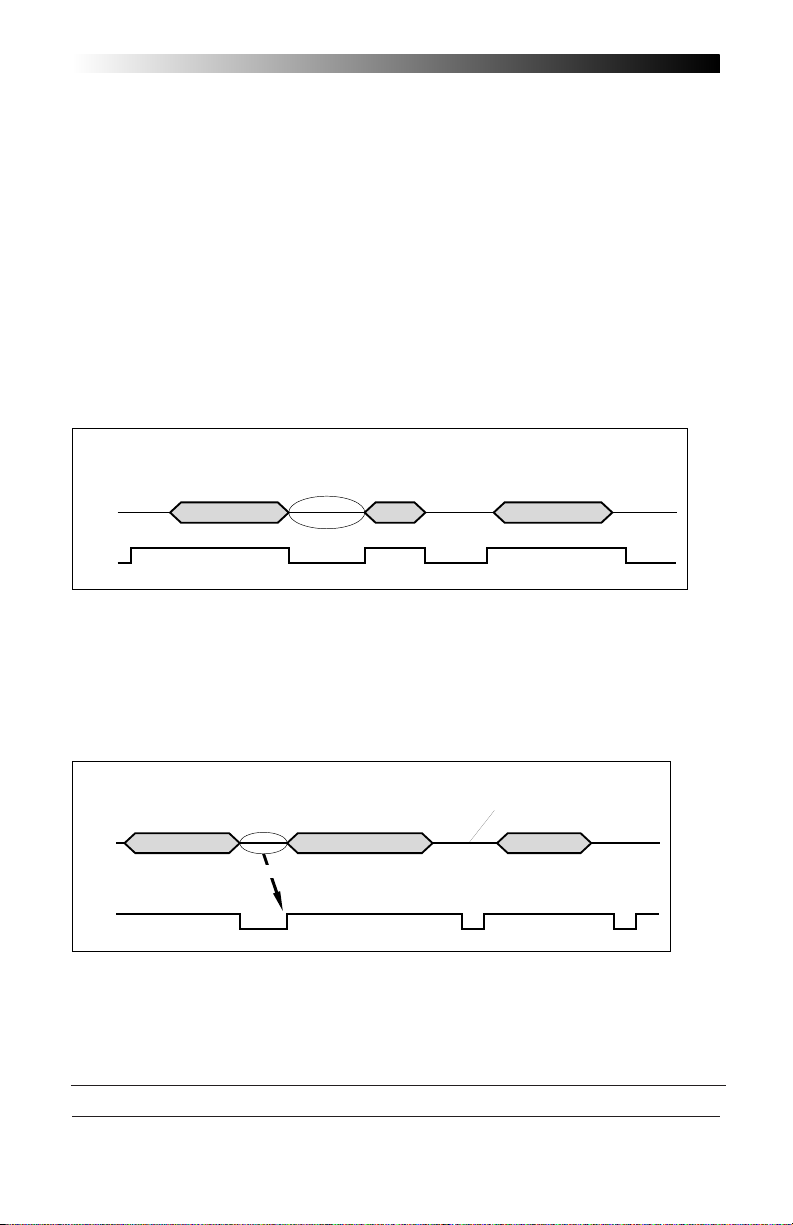

Hardware Control

CTS/RTS Flow Control — is hardware handshaking. The

scanner activates the RTS (Ready to Send) line when it is ready to

send data to the host. The scanner waits for an active Clear to

Send (CTS) signal from the host before transmitting data. If

hardware control is disabled, CTS/RTS communication will not

take place. If the host deactivates the CTS line during data transmission, the host will receive additional characters for no more

than 2msec1.

CTS/RTS Flow Control

Data

CTS

Label Transmission Label TransmissionXmission

Active

Disabled

Inactive

CTS Scan Control — is also a hardware control. When scan

control is enabled, label transmission is disabled until CTS is

asserted and de-asserted.

Data

CTS

CTS Scan Control

Label 1 Label 2Label 1

Disabled until

Assert

De-assert

Will not scan again

until toggle

1 Varies slightly depending upon baud rate selected.

Programming Guide 19

Page 24

Software Control

XON/XOFF — this is software handshaking that allows the host to

control data transmission. If the host sends an XOFF command to

the scanner, the scanner will not send the bar code data until it

receives an XON command from the host. If the host sends the

XOFF command during data transmission, the host will receive

additional characters for no more than 2msec1.

NOTE

Hardware/software controls are mutually exclusive. Enable only one

of these features at a time, as enabling multiple controls can produce

unpredictable results.

SET ----------------------------------------------

DISABLE HARDWARE CONTROL -----

ONTROL

C

ENABLE CTS/RTS FLOW CONTROL --

ARDWARE

H

ONTROL

ENABLE CTS SCAN CONTROL ----

ENABLE XON/ XOFF ----------------

C

DISABLE XON/XOFF ----------------

OFTWRE

S

END ----------------------------------------------

1 Varies slightly depending upon baud rate selected.

20

QuickScan 6000/6000 Plus

Page 25

RS-232 ACK/NAK Options (QuickScan 6000 Plus ONLY)

Several ACK/NAK parameters can be set for your QuickScan 6000 Plus

scanner. Contact your Datalogic dealer if the specific ACK/NAK option you wish to

set is not included in this section.

Options for RS-232 ACK/NAK are:

• Disable ACK/NAK

• Enable ACK/NAK for bar code transmission

• Enable ACK/NAK for host command acknowledge

• Enable ACK/NAK for bar code transmission and host command

acknowledge.

(These features available for QuickScan 6000 Plus ONLY)

SET ----------------------------------------------

DISABLE ACK/NAK -------------------

NABLE

FOR BAR CODE TRANSMISSION --------

FOR HOST COMMAND ACKNOWLEDGE --

ACK/NAK E

FOR BAR CODE TRANSMISSION --------

AND HOST COMMAND ACKNOWLEDGE

END ----------------------------------------------

Programming Guide 21

Page 26

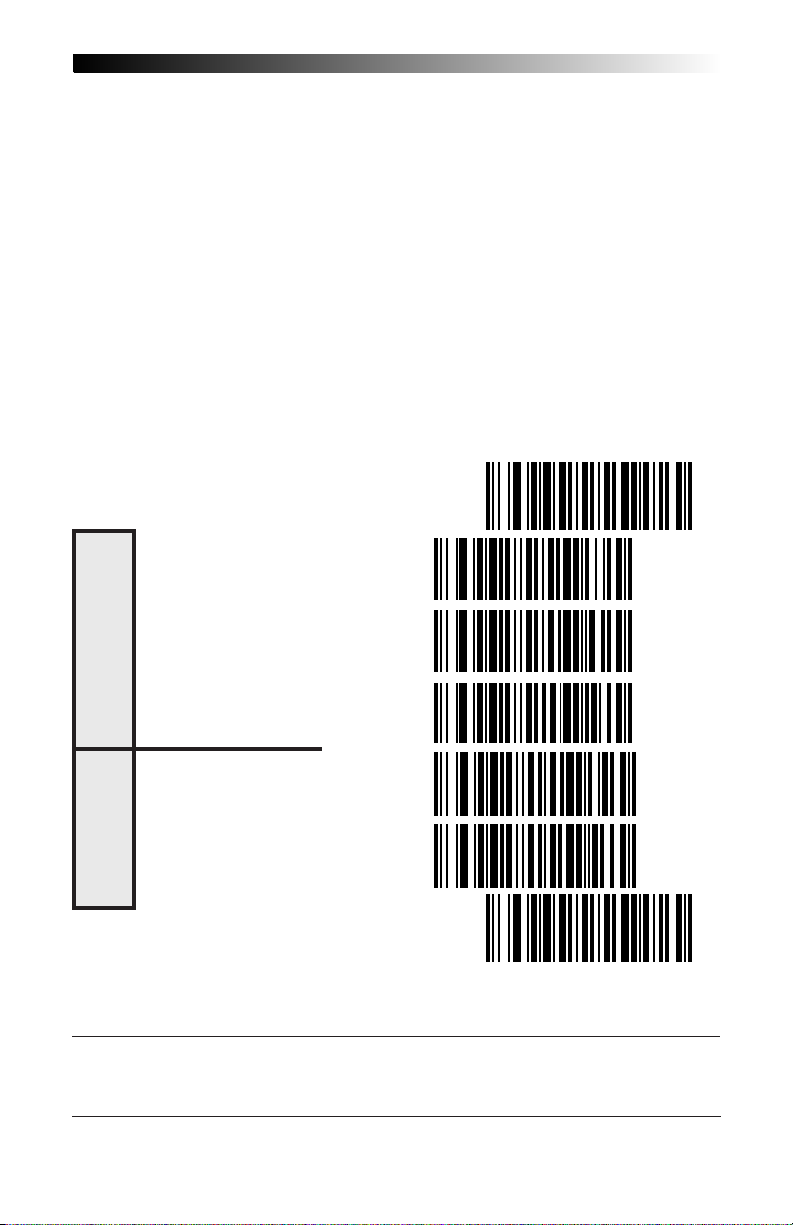

Intercharacter Delay

Intercharacter Delay refers to the pause, if any, between each character

before it is sent to the host. This time delay is used to control the flow of

data from the scanner, but it should not be required for most applications.

Use these labels to select the desired Intercharacter Delay.

SET ----------------------------------------------

= NONE ----------------------------

= 10 MILLISECONDS ----------------

= 20 MILLISECONDS ----------------

ELAY

= 30 MILLISECONDS ----------------

D

= 40 MILLISECONDS ----------------

NTERCHARACTER

I

= 50 MILLISECONDS ----------------

= 60 MILLISECONDS ----------------

= 70 MILLISECONDS ----------------

= 80 MILLISECONDS ----------------

22

QuickScan 6000/6000 Plus

Page 27

Intercharacter Delay

(continued)

= 90 MILLISECONDS ----------------

ELAY

D

NTERCHARACTER

I

= 100 MILLISECONDS --------------

END ----------------------------------------------

Programming Guide 23

Page 28

This section contains the following PC Keyboard Wedge communication

parameters in the order listed:

Keyboard Wedge Communication Parameters

• Interface Selection

• Connect to Laptop

• Caps lock Settings

• Country modes

• Intercharacter Delay

Go to the sections titled Symbology Selection and General Features in the

back of this programming guide if you want to change any other settings.

NOTE

If the transmission parameters are configured such that a label

results in no actual data to send, the label will be accepted, beeped,

and no data transmitted.

PC Keyboard Wedge Interface Selection

The scanner supports ten1 PC Keyboard Wedge interfaces. The table

below defines the different interface selections.

I/F Type PCs Supported

A PC/XT w/Alternate Key Encoding

B AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80, 90 & 95 w/Alternate Key Encoding

C PS/2 25 and 30 w/Alternate Key Encoding

D PC/XT w/Standard Key Encoding

E AT, PS/2 25-286, 30-286, 50, 50Z, 60, 70, 80, 90 & 95 w/Standard Key Encoding

F PS/2 25 and 30 w/Standard Key Encoding

G IBM 3xxx w/122 keyboard

H IBM 3xxx w/102 keyboard

I PS/55 5530T w/104 keyboard

J NEC 9801

NOTE

We recommend that you disconnect power before plugging/

unplugging cables to avoid any possibility of equipment damage.

24

(QuickScan 6000 Plus ONLY)

(QuickScan 6000 Plus ONLY)

(QuickScan 6000 Plus ONLY)

(QuickScan 6000 Plus ONLY)

QuickScan 6000/6000 Plus

Page 29

PC Keyboard Wedge Interface Selection—continued

The scanner supports ten1 PC Keyboard Wedge interfaces. The table

below defines the different interface selections.

SET ----------------------------------------------

A------------------------------------

B------------------------------------

C -----------------------------------

)

D -----------------------------------

PAGE

YPE

E------------------------------------

PREVIOUS

(I/F) T

ON

F ------------------------------------

TABLE

NTERFACE

I

SEE

(

G -----------------------------------

H -----------------------------------

I -------------------------------------

J ------------------------------------

END ----------------------------------------------

1 Keyboard Wedge interfaces G through J are only supported by the

scanner.

Programming Guide 25

QuickScan 6000 Plus

Page 30

PC Keyboard Wedge –

Connect to a Laptop/No Keyboard Attached

If no keyboard is attached, the scanner must provide the acknowledge

signal to the PC. In this case, enable the "Laptop/No External Keyboard"

mode. If a keyboard is attached, enable "Keyboard Attached".

Laptop (integrated keyboard) — scan the "Laptop/No External Keyboard" label below when the scanner is connected to a laptop computer

or when the scanner is operated with no external keyboard attached.

PC (external keyboard) — if you move the scanner to a standard PC,

change the setting to "Keyboard Attached".

Send Control Characters — when this feature is disabled, all ASCII

characters except NUL (00h) are transmitted. Enabling this feature limits

transmission of ASCII characters to the following:

• Only ASCII characters between 20h..127h, plus…

- Carriage Return (CR=0Dh)

- BackSpace (BS=08h)

- Right Tab (HT=09h)

- Left Tab (0Bh)

- Esc (1Bh)

SET ----------------------------------------------

TO

PC

ONNECT

C

LAPTOP/NO EXTERNAL KEYBOARD-

OR

APTOP

KEYBOARD ATTACHED --------------

L

ENABLE -----------------------------

ONTROL

C

HARACTERS

END

S

DISABLE -----------------------------

C

END ----------------------------------------------

26

QuickScan 6000/6000 Plus

Page 31

Caps Lock (QuickScan 6000 Plus ONLY)

Three caps lock settings are available for the QuickScan 6000 Plus

scanner. These are:

• Caps Lock Off — to send character data (to the host)in normal

format.

• Caps Lock On — to send character data (to the host) in reverse

case:

(a…z) = (A…Z)

(A…Z) = (a…z)

Use this feature if your caps lock is on.

• Caps Lock = Shift-Lock — to send character data (to the host) in

shifted case. Use this feature if your shift lock is on. For use with

interface type G (122-keyboard) ONLY.

SET ----------------------------------------------

CAPS LOCK OFF ------------------

PTIONS

O

OCK

L

APS

C

CAPS LOCK ON -------------------

CAPS LOCK = SHIFT-LOCK --------

END ----------------------------------------------

Programming Guide 27

Page 32

Country Mode (QuickScan 6000 Plus ONLY)

The following country/languages can be selected for the QuickScan 6000

Plus scanner when configured for I/F Type E only:

• USA • France • Portugal • Japanese 106-Key

• Belgium • Germany • Spain

• Britain • Italy • Sweden

• Denmark • Norway • Switzerland

SET ----------------------------------------------

USA -------------------------------

BELGIUM ----------------------------

BRITAIN -----------------------------

28

ODE

M

OUNTRY

C

DENMARK ---------------------------

FRANCE -----------------------------

GERMANY ---------------------------

ITALY --------------------------------

NORWAY ----------------------------

PORTUGAL --------------------------

QuickScan 6000/6000 Plus

Page 33

Country Mode (QuickScan 6000 Plus ONLY)—continued

SPAIN -------------------------------

ODE

M

OUNTRY

C

SWEDEN ----------------------------

SWITZERLAND -----------------------

JAPANESE 106-KEY ---------------

END ----------------------------------------------

Programming Guide 29

Page 34

Intercharacter Delay

Intercharacter Delay refers to the pause, if any, between each character

before it is sent to the host. This time delay is used to control the flow of

data from the scanner, but it should not be required for most applications.

Use these labels to select the desired Intercharacter Delay.

SET ----------------------------------------------

= NONE ----------------------------

= 5 MILLISECONDS ------------------

= 10 MILLISECONDS ----------------

= 15 MILLISECONDS ----------------

ELAY

D

NTERCHARACTER

I

30

= 20 MILLISECONDS ----------------

= 25 MILLISECONDS ----------------

= 30 MILLISECONDS ----------------

= 35 MILLISECONDS ----------------

= 40 MILLISECONDS ----------------

= 45 MILLISECONDS ----------------

= 50 MILLISECONDS ----------------

QuickScan 6000/6000 Plus

Page 35

Intercharacter Delay—continued

= 55 MILLISECONDS ----------------

= 60 MILLISECONDS ----------------

= 65 MILLISECONDS ----------------

= 70 MILLISECONDS ----------------

ELAY

D

= 75 MILLISECONDS ----------------

= 80 MILLISECONDS ----------------

NTERCHARACTER

I

= 85 MILLISECONDS ----------------

= 90 MILLISECONDS ----------------

= 95 MILLISECONDS ----------------

= 99 MILLISECONDS ----------------

END ----------------------------------------------

Programming Guide 31

Page 36

Label Transmit Format Configuration Items

(RS-232 and Keyboard Wedge Interfaces Only)

If you need to send information in addition to label data, the scanner can

be configured to transmit prefixes and/or suffixes as well as symbology

specific identifier characters (Label I.D.).

Prefix & Suffix

As the examples below show, none, one or two symbology specific ASCII

characters can be added to the beginning of label in addition to multiple

prefix and suffix characters.

NOTE

Using this feature requires a thorough understanding

of your specific system requirements.

The options available using this feature are:

• Symbology specific (0 - 2) characters + label data

PP + label data

• Non-symbology specific characters (1-2) as a prefix + label

data

CpCp + label data

• Label data + non-symbology specific characters (0-2) as a

suffix

label data + CsC

• Non-symbology specific characters (1-2) as a prefix + symbology specific characters (0-2) + label data

CpCp + PP + label data

• Symbology specific characters (0-2) + label data + nonsymbology specific characters (1-2) as a suffix

PP + label data + CsC

32

s

s

QuickScan 6000/6000 Plus

Page 37

• Non-symbology specific characters (1-2) as a prefix + label

data + non-symbology specific characters (1-2) as a suffix

CpCp + label data + CsC

s

• Non-symbology specific characters (1-2) as a prefix + symbology specific characters (0-2) + label data + non-symbology

specific characters (1-2) as a suffix

CpCp + PP + label data + CsC

s

• Non-symbology specific characters (1-2) as a prefix + label

data + symbology specific characters + non-symbology

specific characters used as suffixes.

CpCp + label data + PP + CsC

s

PP = symbology specific characters (Label I.D.)

CpCp = non-symbology specific ASCII characters used as prefixes

CsCs = non-symbology specific ASCII characters used as suffixes

Programming Guide 33

Page 38

Non-Symbology Specific Items

Setting Non-Symbology Specific Prefix(es)

These characters will be added to the standard label format when your

host system has specific and unique requirements for information added

to the barcode label data before it is sent to the host. Identify your

specific system requirements before adding or modifying these settings,

then...

1. Look at the ASCII chart shown on page 38 and identify the

ASCII character(s) and the corresponding Hex Code(s) for the

ASCII characters you will use as prefixes.

For example, if you are going to send two prefix characters as

'STX' (start transmit) and 'SP' (Space). The ASCII chart shows

that 'STX' equals 02

and 'SP' equals 20

hex

2. Scan the SET label.

3. Scan the SET PREFIX label on this page.

4. Scan the digits that correspond to the Hex Values.

For the example in step four, scan 0, 2, 2, 0.

NOTE

If you make a mistake, or lose your place while setting this option,

scan the END label to exit Programming Mode. The scanner will

sound an error tone (six rapid beeps) to indicate that programming

was incomplete, and the setting will remain as it was before

entering Programming Mode.

hex

.

5. Scan END.

You have added a two character prefix to all label data, regardless of label symbology, that will be added to the label data

before it is sent to the host.

SET ----------------------------------------------

SET PREFIX ------------------------

Go to the second page following this and scan the appropriate characters

before scanning the END label to exit programming session.

34

QuickScan 6000/6000 Plus

Page 39

Setting Non-Symbology Specific Suffix(es)

These characters will be added to the standard label format when your

system has specific and unique requirements for information added to the

barcode label data before it is sent to the host. Suffix characters follow

the label data.

Identify your specific system requirements before adding or modifying

these settings, then...

1. Look at the ASCII chart shown on page 38 and identify the

ASCII character(s) and the corresponding Hex Code(s) for the

ASCII characters you will use as suffixes.

For example, if you are going to send two suffix characters as

'BEL' (sound host tone) and 'ETX' (end transmission). The

ASCII chart shows that 'BEL' equals 07

03

.

hex

2. Scan the SET label.

3. Scan the SET SUFFIX label on this page.

4. Scan the digits that correspond to the Hex Values.

For the example in step five, scan 0, 7, 0, 3.

NOTE

If you make a mistake, or lose your place while setting this option,

scan the END label to exit Programming Mode. The scanner will

sound an error tone (six rapid beeps) to indicate that programming

was incomplete, and the setting will remain as it was before

entering Programming Mode.

and 'ETX' equals

hex

5. Scan END.

You have added a two character suffix to all label data, regardless of label symbology, that will be added to the label data

before it is sent to the host.

SET ----------------------------------------------

SET SUFFIX ------------------------

Go to the next two pages and scan the appropriate characters before

scanning the END label to exit programming session.

Programming Guide 35

Page 40

Setting A Single Character Prefix or Suffix

To set one ASCII character as a prefix or suffix, follow steps one through

four on the previous two pages (select prefix or suffix), then...

1. Scan the two digit Hex Code for that character.

(e.g. 03, 8F, ...FF)

NOTE

If you make a mistake, or lose your place while setting this option,

scan the END label to exit Programming Mode. The scanner will

sound an error tone (six rapid beeps) to indicate that programming

was incomplete, and the setting will remain as it was before

entering Programming Mode.

2. Scan the ONE CHARACTER ONLY label on the following

page.

3. Scan the END label.

You have set a single character prefix or suffix.

Setting Prefix and/or Suffix Characters

NOTE

You must scan the SET label and either the SET PREFIX or SET

SUFFIX label before using the labels on this page.

36

0 ------------------------------------

1 ------------------------------------

2 ------------------------------------

3 ------------------------------------

4 ------------------------------------

5 ------------------------------------

QuickScan 6000/6000 Plus

Page 41

6 ------------------------------------

7 ------------------------------------

8 ------------------------------------

9 ------------------------------------

A------------------------------------

B------------------------------------

C -----------------------------------

D -----------------------------------

E------------------------------------

F ------------------------------------

ONE CHARACTER ONLY ------------

END ----------------------------------------------

Programming Guide 37

Page 42

ASCII Character Set

The table on this page shows a set of ASCII characters and their corresponding Hex Values. The Hex Values in this table are needed for setting symbology specific label identifiers, as well as enabling custom prefix and suffix

characters.

ASCII Hex ASCII Hex ASCII Hex ASCII Hex

Char Value Char Value Char Value Char Value

nul 00 SP 20 @ 40 ‘ 60

soh 01 ! 21 A 41 a 61

stx 02 “ 22 B 42 b 62

et x 03 # 23 C 43 c 63

eot 04 $ 24 D 44 d 64

enq 05 % 25 E 45 e 65

ack 06 & 26 F 46 f 66

bel 07 ‘ 27 G 47 g 67

bs 08 ( 28 H 48 h 68

ht 09 ) 29 I 49 i 69

lf 0A * 2A J 4A j 6A

vt 0B + 2B K 4B k 6B

ff 0C ‘ 2C L 4C l 6C

cr 0D - 2D M 4D m 6D

so 0E . 2E N 4E n 6E

si 0F / 2F O 4F o 6F

dle 10 0 30 P 50 p 70

dc1 11 1 31 Q 51 q 71

dc2 12 2 32 R 52 r 72

dc3 13 3 33 S 53 s 73

dc4 14 4 34 T 54 t 74

nak 15 5 35 U 55 u 75

sy n 16 6 36 V 56 v 76

etb 17 7 37 W 57 w 77

ca n 18 8 38 X 58 x 78

em 19 9 39 Y 59 y 79

sub 1A : 3A Z 5A z 7A

esc 1B ; 3B [ 5B { 7B

38

QuickScan 6000/6000 Plus

Page 43

Symbology-Specific Label I.D.

Setting Symbology-Specific Label Identifiers (Label I.D.)

Symbology-specific label identifiers comprise one or two ASCII characters

that can precede or follow barcode label data as it is transmitted to the

host. The host uses these characters as a means of distinguishing between symbologies.

Industry standards have been established for symbology-specific label

identifiers, and are listed in the table below. Most scanners will have

factory default identifiers preset to these standards.

Table 1. Industry Standard Label Identifiers (all are prefixes)

UPC-A ------------------------------ 'A' EAN-8 (5 Add-on) ------------ 'FF'

UPC-E ------------------------------ 'E' EAN-8 (8 Add-on) ------------- 'FF'

EAN-8 ---------------------------- 'FF' EAN-13 (2 add-on) ------------- 'F'

EAN-13 ----------------------------- 'F' EAN-13 (5 Add-on) ------------- 'F'

UPC-A (2 add-on) -------------- 'A' EAN-13 (8 Add-on)-------------- 'F'

UPC-A (5 Add-on) -------------- 'A' Code 39 ----------------------------- '*'

UPC-A (8 Add-on) --------------- 'A' Codabar --------------------------- '%'

UPC-E (2 add-on) -------------- 'E' Interleaved.2 of 5 ---------------- 'i'

UPC-E (5 Add-on) -------------- 'E' Code 93 ---------------------------- '&'

UPC-E (8 Add-on) --------------- 'E' Code 128 -------------------------- '#'

EAN-8 (2 add-on) ------------- 'FF' MSI/Plessey --------------------- '@'

To set symbology-specific label identifiers:

1. Look at the ASCII chart shown on the previous page and

identify the ASCII character(s) and the corresponding Hex

Code(s) for the ASCII characters you will use as identifiers.

You will also need to determine whether the character(s) will

need to be sent as a prefix or a suffix.

For example: You need to change the label identifier prefix for

UPC-A to 'A1'.

2. Scan the SET label below.

3. Scan either the TRANSMIT LABEL I.D. AS PREFIX or TRANSMIT LABEL I.D. AS SUFFIX, depending on your requirements.

For our example, the 'transmit as prefix' label would be scanned.

Programming Guide 39

Page 44

Setting Symbology Specific Label Identifiers (Label I.D.)

(Continued)

4. Scan the label representing the symbology whose label

identifier you wish to modify.

In our example, we would scan the 'UPC-A' symbology label.

5. Identify and scan the digits that correspond to the Hex

Values.

The hex values from the ASCII chart that correspond to 'A1'

from our example are as follows: 41

31

= '1'. Thus, we would scan digit programming labels in this

hex

order: 4, 1, 3, 1.

6. Scan the END label.

In our example, you have changed the default label identifier

prefix for UPC-A from 'A' to 'A1'.

= 'A', and

hex

SET ----------------------------------------------

DISABLE LABEL I.D. CONTROL -------

40

TRANSMIT LABEL I.D. AS PREFIX -----

TRANSMIT LABEL I.D. AS SUFFIX -----

QuickScan 6000/6000 Plus

Page 45

Label I.D. Symbology Selection

UPC-A ----------------------------

UPC-A W/2 DIGIT ADD-ON--------

UPC-A W/5 DIGIT ADD-ON--------

UPC-A W/C128 ADD-ON --------

:

FOR

DENTIFIER

I

ABEL

L

PECIFIC

S

YMBOLOGY

UPC-E ----------------------------

UPC-E W/2 DIGIT ADD-ON--------

UPC-E W/5 DIGIT ADD-ON--------

UPC-E W/C128 ADD-ON --------

EAN-8 ----------------------------

S

ET

S

EAN-8 W/2 DIGIT ADD-ON --------

EAN-8 W/5 DIGIT ADD-ON --------

EAN-8 W/C128 ADD-ON --------

EAN-13---------------------------

Programming Guide 41

Page 46

Label I.D. Symbology Selection

(Continued)

EAN-13 W/2 DIGIT ADD-ON ------

EAN-13 W/5 DIGIT ADD-ON ------

:

FOR

EAN-13 W/C128 ADD-ON -------

CODE 39 ---------------------------

DENTIFIER

I

ABEL

CODABAR ---------------------------

L

PECIFIC

INTERLEAVED 2 OF 5 ---------------

S

STANDARD 2 OF 5 -----------------

YMBOLOGY

S

ET

S

CODE 93 ---------------------------

CODE 128 -------------------------

MSI/PLESSEY ----------------------

END ----------------------------------------------

42

QuickScan 6000/6000 Plus

Page 47

How to Set Single Character Label I.D.

If you only want a single character identifier, follow this modified procedure for setting label identifier.

1. Look at the ASCII chart shown on page 38 and identify the

ASCII character and the corresponding Hex Code for the

ASCII character you will use as the symbology specific

identifier.

2. Scan the SET label.

3. Scan the label identifier label for the symbology identifier that

you are going to change.

As an example, assume that you want to change the label

identifier for EAN-8 from the default setting FF to the ASCII

value 8. Scan the Set Symbology Specific Label Identifier

barcode for EAN-8.

5. Identify the hex value that correspond to the ASCII character.

In this example '8' equals 38

Simply follow the hex value for '8' (38

Only label. This tells the scanner that '8' is a single digit label

identifier.

hex

.

) with the One Character

hex

6. Scan the barcodes values.

For the example in step five, scan 3, 8, One Character Only on

the following two pages.

NOTE

If you make a mistake, or lose your place while setting this option,

scan the END label to exit Programming Mode. The scanner will

sound an error tone (six rapid beeps) to indicate that programming

was incomplete, and the setting will remain as it was before

entering Programming Mode.

7. Scan the END label.

You have changed the default label identifier for EAN-8 from

'FF' to '8'.

Programming Guide 43

Page 48

Disabling Label I.D. for a Specific Symbology

This procedure is the same as setting a single character symbology

identifier, except you should scan two zeros and the One Character Only

labels before scanning the END label.

Symbology Specific Label Identifiers Characters

Use the labels on this page to change or modify symbology identifiers.

0 ------------------------------------

1 ------------------------------------

2 ------------------------------------

3 ------------------------------------

4 ------------------------------------

44

5 ------------------------------------

6 ------------------------------------

7 ------------------------------------

8 ------------------------------------

9 ------------------------------------

QuickScan 6000/6000 Plus

Page 49

A------------------------------------

B------------------------------------

C -----------------------------------

D -----------------------------------

E------------------------------------

F ------------------------------------

ONE CHARACTER ONLY ------------

END ----------------------------------------------

Programming Guide 45

Page 50

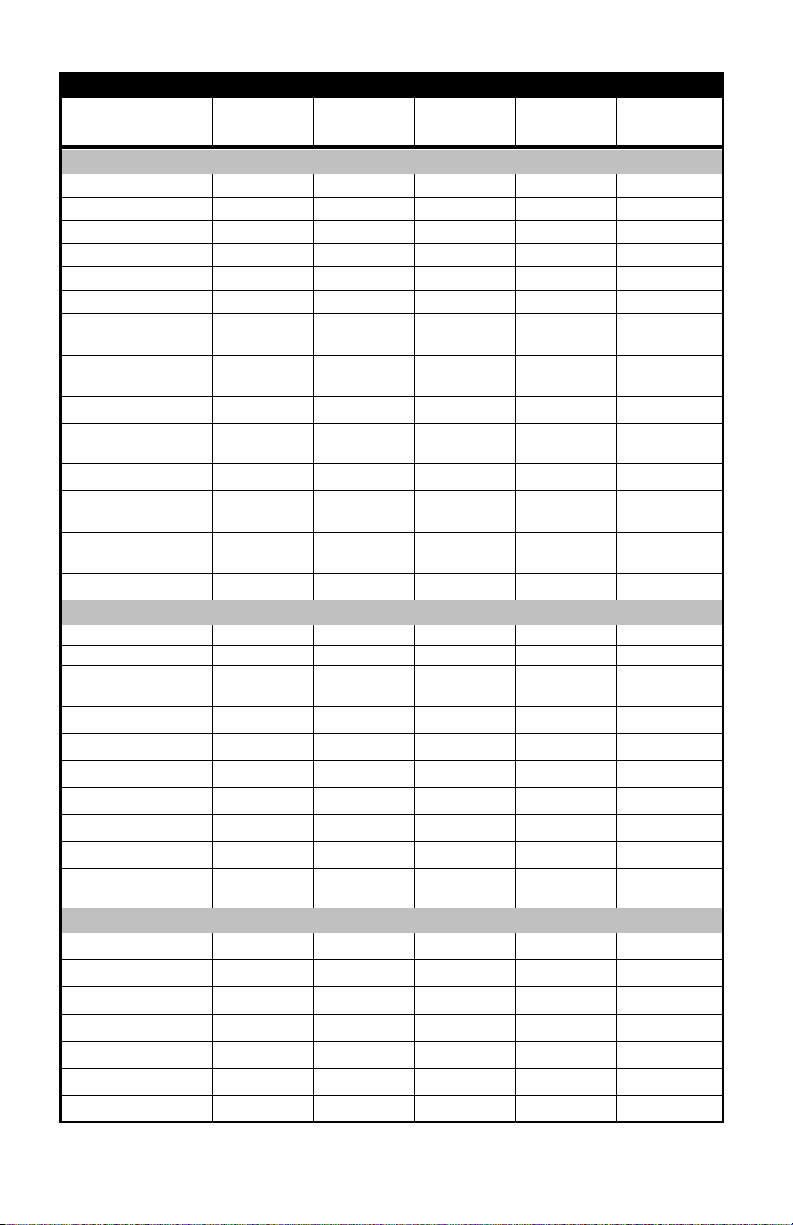

Symbologies

Symbology selection (bar code type) determines which symbologies the scanner will

decode. The chart below shows the symbologies that are supported by each interface.

Once you have identified the symbologies you wish to enable, turn to the following

pages, enable those symbologies and set the data format options (e.g. check digit,

start/stop characters) required by your host system for each symbology type. You

must enable the symbology format options settings that are compatible with your

host system.

The factory settings for each interface were chosen to meet the standard industry

requirements and in most cases you will not need to change the symbology format

settings. If you are unsure of your system requirements, test the scanner using the

factory settings before making any changes.

UPC-A & E, EAN-8 & 13

UPC/EAN w/P2 Add-ons

UPC/EAN w/P5 Add-ons

UPC/EAN w/C128 Add-ons

Code 39

Code 39 Pharmacodes

Interleaved 2 of 5

Interleaved 2 of 5/IATA

Standard 2 of 5

Codabar

Code 93

Code 128

INTERFACE TYPE

IBM Port 5B

IBM Port 9B

IBM Port E

NCA OCIA (8 bit)

NCA OCIA (9 bit)

Datalogic OCIA

SNI OCIA

Wand Emulation

RS-232

Keyboard Wedge

MSI/Plessey

46

KEY

QuickScan 6000 and QuickScan 6000 Plus

QuickScan 6000 Plus

The symbology can be enabled through configuration item; however,

labels will not be decoded or transmitted by the interface.

{

QuickScan 6000/6000 Plus

Page 51

Symbology Options Overview

Enable All Symbologies — allows the scanner to auto-discriminate between

all the symbologies in this list. Use this selection only if you must constantly

read a wide variety of symbologies. Turn to the following pages for

enabling additional symbology specific options.

Disable All Symbologies — disables all symbologies1. The scanner will only

recognize the programming labels contained in this manual while you are

in Programming Mode.

Enable UPC/EAN — tells the scanner to recognize UPC-A, UPC-E, EAN-

8, and EAN-13. If you enable this symbology, additional options for

symbology expansion and reading add-ons are available. Allows selection

of expansion and add-on options.

Enable Code 39 — selects Code 39 as an active symbology. Allows selection

of Check Digit, Start/Stop and Single Digit options.

PharmaCode 39 — is a symbology subset of Code 39. Enabling PharmaCode

39 selects this special Italian code as the active Code 39 symbology

(superceding standard Code 39 features).

NOTE

Standard Code 39 must be enabled before PharmaCode can be

enabled.

Enable Interleaved 2 of 5 — selects Interleaved 2 of 5 as an active

symbology. Allows change of Check Digit or label format (fixed

or variable length) options.

Enable Standard 2 of 5 — selects Standard 2 of 5 as an active

symbology. Options for this symbology are similar to Interleaved 2 of 5 features.

1 Code 128 is always active for the purpose of reading programming bar code labels; however,

the scanner does not transmit data to the host when in Programming Mode. Scanning the

DISABLE ALL SYMBOLOGIES label will disable Code 128 transmission to the host.

Programming Guide 47

Page 52

IATA — is a special symbology subset of Standard 2 of 5. Enabling IATA

selects this custom code as the active Standard 2 of 5 symbology (superceding any other Standard 2 of 5 features).

NOTE

Standard 2 of 5 must be enabled before IATA can be enabled.

Enable Codabar — selects Codabar as an active symbology. Allows selection

of Check Digit, Start/Stop character and format, or label format (fixed or

variable length) options.

Enable Code 93 — selects Code 93 as an active symbology. The scanner is preset

to recognize all Code 93 bar codes that have between 2 and 50 characters.

Code 93 has no user-selectable options.

Enable Code 1281 — selects Code 128 as an active symbology. The scanner

is preset to recognize all Code 128 bar codes that have between 2 and 50

characters. Code 128 has no user selectable options.

Enable MSI/Plessey — selects MSI/Plessey as an active symbology. Allows

selection of Check Digit or label format (fixed or variable length) options.

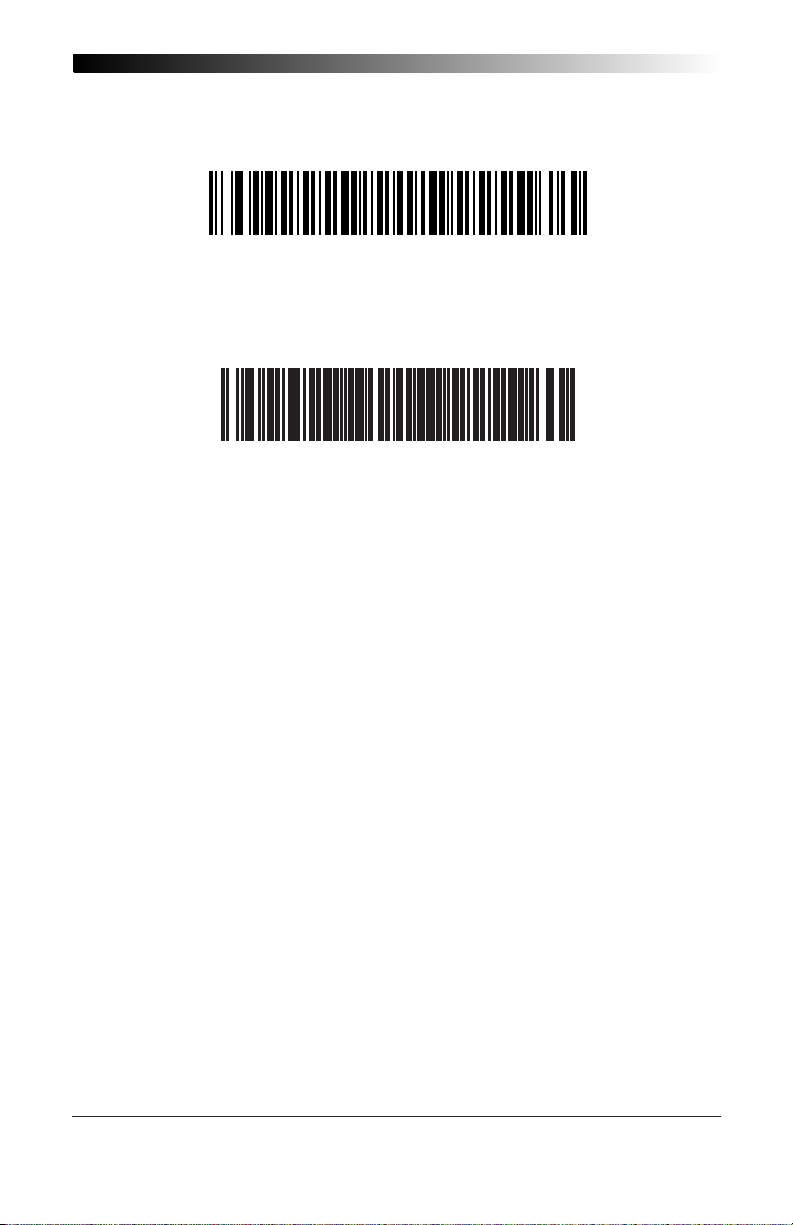

Universal Symbology Selection

To set the scanner to read all symbologies, scan the ENABLE ALL SYMBOLOGIES bar code below.

NOTE

DO NOT scan SET or END bar codes when programming universal

symbology features. Programming mode is automatically entered

and exited when one of the two special bar codes below are

scanned.

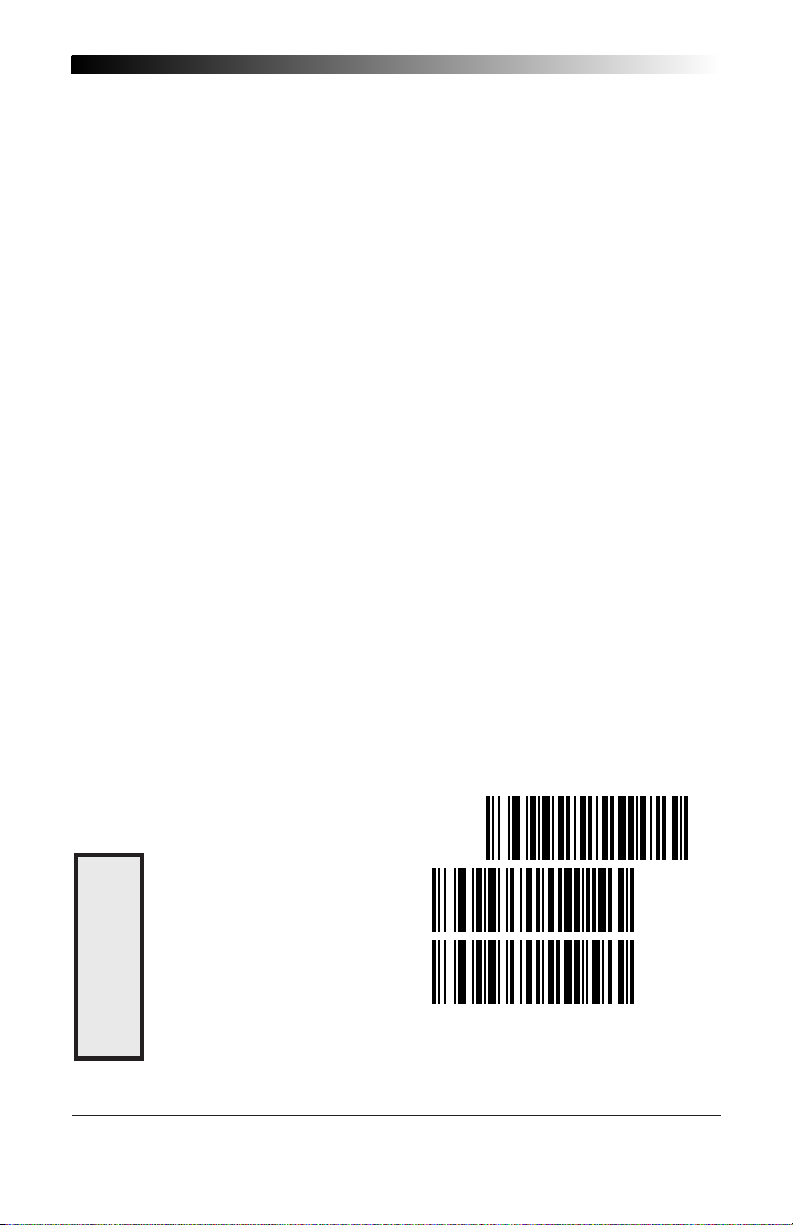

Enable All Symbologies

Disable All Symbologies

1 Code 128 is always active for the purpose of reading programming bar code labels;

however, the scanner does not transmit data to the host when in Programming Mode.

48

1

QuickScan 6000/6000 Plus

Page 53

Symbology Selection

The bar code programming labels on the following pages allow you to enable or

disable individual symbologies.

NOTE

If you enable a symbology that has additional features that should

be set, turn to the pages that support that symbology and its

programmable features.

SET ----------------------------------------------

ENABLE UPC/EAN --------------

DISABLE UPC/EAN --------------

ENABLE CODE 39 ------------------

DISABLE CODE 39 -----------------

ENABLE PHARMACODE2 39 -------

DISABLE PHARMACODE 39 --------

2 Code 39 must first be enabled for the scanner to read PharmaCode 39 labels. Enabling PharmaCode

39 will convert Code 39 data to PharmaCode format whenever possible.

Programming Guide 49

Page 54

ENABLE INTERLEAVED 2 OF 5 -----

DISABLE INTERLEAVED 2 OF 5 -----

ENABLE STANDARD 2 OF 5--------

DISABLE STANDARD 2 OF 5 -------

ENABLE IATA3--------------------

DISABLE IATA ---------------------

3 Standard 2 of 5 must first be enabled before IATA can be enabled; however, the scanner will not read

Standard 2 of 5 labels when IATA is enabled.

50

QuickScan 6000/6000 Plus

Page 55

ENABLE CODABAR ------------------

DISABLE CODABAR------------------

ENABLE CODE 93 ------------------

DISABLE CODE 93 -----------------

ENABLE CODE 128 ----------------

DISABLE CODE 1284--------------

ENABLE MSI/PLESSEY ------------

DISABLE MSI/PLESSEY ------------

END ----------------------------------------------

4 Code 128 is always active for the purpose of reading programming bar code labels. Scanning the

DISABLE ALL SYMBOLOGIES or the DISABLE CODE 128 labels disables Code 128 transmission to

the host (disables decoding of all C128 non-programming labels).

Programming Guide 51

Page 56

UPC/EAN Options

The information below provides a brief description of the programmable UPC/EAN

features included on the following pages.

Expand UPC-A to EAN-13 — adds a leading zero to a UPC-A label

which 'expands' the label to the EAN-13 data format. Selecting this

feature also changes the symbology ID to match those required for

EAN-13.

Expand UPC-E to UPC-A — expands UPC-E labels to UPC-A data

format. Selecting this feature also changes the symbology ID to match

those required for UPC-A.

If this feature and Expand UPC-A to EAN-13 are both enabled, label

data will be sent to the host in EAN-13 label format.

Expand EAN-8 to EAN-13 — adds five zeros in front of an EAN-8

label. Data is sent in EAN-13 data format. Selecting this feature also

changes the symbology ID to match those required for EAN-13.

Expand UPC-E to EAN-13 — expands UPC-E labels to EAN-13 data

format. Selecting this feature also changes the symbology ID to match

those required for EAN-13.

UPC-A or UPC-E and EAN-8 or EAN-13 Two and Five Digit Add-

Ons

Optional — scanner will read UPC/EAN bar codes with or without

add-ons.

Required — UPC/EAN bar codes must have add-on or label will not

be read.

Disable — scanner will not recognize/read add-on portion of UPC/

EAN labels, but will read the main body of the label.

Price/Weight Check Digit — provides options for enabling price/

weight check digits. The feature includes selections for domestic four

or five digit, and European four or five digit, as well as the option to

disable the price/weight check.

52

QuickScan 6000/6000 Plus

Page 57

UPC/EAN Expansion

Use these labels to enable or disable:

• Expand UPC-A to EAN-13 • Expand EAN-8 to EAN-13

• Expand UPC-E to UPC-A • Expand UPC-E to EAN-13

SET ----------------------------------------------

1

EXPAND

XPANSION

E

UPC-A TO EAN-13

DON'T EXPAND ---------------------

EXPAND1----------------------------

XPANSION

E

UPC-E TO UPC-A

DON'T EXPAND ---------------------

EXPAND1----------------------------

-------------------------------------------------

XPANSION

DON'T EXPAND ---------------------

E

EAN-8 TO EAN-13

1

EXPAND

XPANSION

DON'T EXPAND ---------------------

E

UPC-E TO EAN-13

-------------------------------------------------

END ----------------------------------------------

1 When any expansion feature is enabled, the transmission of the Prefix, Suffix, Check Digit

and Number System Digit (NSD) are controlled by your selections for the symbology

'expanded to' rather than the symbology 'expanded from'. For example, if you expand UPC-E

to UPC-A, settings for UPC-A determine how the scanner sends a bar code's contents.

Programming Guide 53

Page 58

UPC/EAN Add-Ons

If you need to scan UPC or EAN labels that include add-on codes, the selections on

this page set the scanner's Add-on feature. Three add-on read modes are available:

optional, required and disabled.

Optional — the scanner will recognize UPC bar codes with or without

add-ons.

NOTE

Due to the structure of add-on codes, selecting the Optional

setting makes it impossible to ensure that the scanner will always

read the add-on portion of the label. Datalogic makes no guarantee, either written or implied, that scanners with optional add-on

decoding enabled will perform with the speed and accuracy required for any given application.

Required — the scanner will not recognize or decode any UPC/

EAN labels that do not contain an add-on segment.

Disabled — the scanner will not recognize or decode any add-

on segment of UPC/EAN labels. The scanner will read and

decode the standard UPC/EAN portion of the label.

SET ----------------------------------------------

IGIT

D

IVE

& F

IGIT

OPTIONAL ---------------------------

NS

-O

REQUIRED ---------------------------

DD

A

D

WO

T

DISABLED ---------------------------

END ----------------------------------------------

C128 and Custom Add-Ons

A wide array of add-on options are available to streamline your installation to best advantage. Call your salesman or service provider for assistance in customizing your scanner's add-on capabilities to your own

unique specifications.

54

QuickScan 6000/6000 Plus

Page 59

Price/Weight Check Digit

The price/weight check digit selections allow you to specify whether the scanner

should calculate an extra check digit based on a four or five-digit price/weight block

and compare it with the price/weight check digit contained in the bar code. If the

calculated check digit does not match the value of the check digit contained in the bar

code, the label will be rejected as invalid. Select domestic four or five digit, European

four or five digit, or disable the price/weight check.

SET ----------------------------------------------

DISABLE PRICE/WEIGHT CHECK ---

ENABLE 4 DIGIT CHECK -----------

IGIT

D

HECK

ENABLE 5 DIGIT CHECK -----------

C

EIGHT

/W

ENABLE EURO 4 DIGIT CHECK ----

RICE

P

ENABLE EURO 5 DIGIT CHECK ----

END ----------------------------------------------

UPC Data Format Settings

Programming Guide 55

Page 60

These settings affect UPC data format when RS-232 or OCIA is the active interface.

Number System Digit (NSD) settings operate with RS-232 and Keyboard Wedge

interfaces ONLY.

SET ----------------------------------------------

SEND CHECK DIGIT ----------------

DON'T SEND CHECK DIGIT --------

UPC-A

SEND NSD1-----------------------

DON'T SEND NSD1---------------

SEND CHECK DIGIT2---------------

DON'T SEND CHECK DIGIT2-------

SEND NSD2-----------------------

UPC-E

DON'T SEND NSD2---------------

END ----------------------------------------------

1

NSD = Number System Digit. The NSD character is the character that precedes the UPC bar

code. The NSD for regular UPC-A bar codes is a zero. Other commonly used Number

System Digits used with UPC-A are:

2

If UPC-E is expanded to UPC-A, the transmission of Check Digit (CD) and NSD will be

determined by the UPC-A settings on this page, not by these settings.

2 - used for random weight items such as meat and produce

3 - used for the drug and health items

4 - used for in-store non-food items

5 - used for coupons

56

QuickScan 6000/6000 Plus

Page 61

EAN Data Format Settings

These settings affect EAN data format when RS-232, Keyboard Wedge or OCIA is

the active interface.

SET ----------------------------------------------

SEND CHECK DIGIT ----------------

EAN-8

DON'T SEND CHECK DIGIT --------

SEND CHECK DIGIT ----------------

EAN-13

DON'T SEND CHECK DIGIT --------

END ----------------------------------------------

Programming Guide 57

Page 62

Code 39 Options

The Code 39 symbology has the following programmable features:

Check Digit — calculates the Check Digit to verify that the

Check Digit contained in the bar code label is correct. If you

enable this feature, your bar codes must contain a Check

Digit.

You may also choose to transmit or not transmit the Check

Digit independent of whether the Check Digit is calculated by

the scanner. If you choose to Transmit Check Digit, but not

calculate, the scanner sends the Check Digit encoded in the

bar code without verifying its accuracy. If you choose Don't

Transmit Check Digit, the scanner will remove the Check

Digit's contents before sending the bar code data to the host.

Start/Stop Characters — you can choose either Send or Don't

Send depending on your host's interface requirement.

Code 39 Full ASCII — enables or disable the ability to decode

Code 39 Full ASCII labels.

Code 39 Minimum Label Length — sets the minimum label

length required for Code 39 labels (not including the check

character). This feature is provided to ignore small label

segments, reducing the possibility that a portion of a good

label is incorrectly seen as an entire label.

58

QuickScan 6000/6000 Plus

Page 63

Code 39 (continued)

Use these labels to change the Code 39 programmable features.

SET ----------------------------------------------

DON'T COMPUTE -------------------

IGIT

D

HECK

C

COMPUTE ---------------------------

DON'T TRANSMIT -------------------

TRANSMIT ---------------------------

TOP

/S

TART

S

ULL

39 F

ODE

C

DON'T TRANSMIT --------------------

TRANSMIT ---------------------------

ENABLE -----------------------------

ASCII

DISABLE -----------------------------

END ----------------------------------------------

Programming Guide 59

Page 64

Code 39 (continued)

Follow these steps to set Code 39 Minimum Label Length:

1. Identify the minimum length setting you want to make. The