Page 1

QuickScan® QS6500

Handheld Bar Code Scanner

Quick Reference Guide

Page 2

Datalogic Scanning, Inc.

959 Terry Street

Eugene, Oregon 97402

Telephone: (541) 683-5700

Fax: (541) 345-7140

An Unpublished Work - All rights reserved. No part of the contents of

this documentation or the procedures described therein may be reproduced or transmitted in any form or by any means without prior written

permission of Datalogic Scanning, Inc. or its subsidiaries or affiliates

("Datalogic" or “Datalogic Scanning”). Owners of Datalogic products are

hereby granted a non-exclusive, revocable license to reproduce and

transmit this documentation for the purchaser's own internal business

purposes. Purchaser shall not remove or alter any proprietary notices,

including copyright notices, contained in this documentation and shall

ensure that all notices appear on any reproductions of the documentation.

Should future revisions of this manual be published, you can acquire

printed versions by contacting your Datalogic representative. Electronic

versions may either be downloadable from the Datalogic website

(www.scanning.datalogic.com) or provided on appropriate media. If

you visit our website and would like to make comments or suggestions

about this or other Datalogic publications, please let us know via the

"Contact Datalogic" page.

Disclaimer

Datalogic has taken reasonable measures to provide information in this

manual that is complete and accurate, however, Datalogic reserves the

right to change any specification at any time without prior notice.

Datalogic is a registered trademark of Datalogic S.p.A. and the Datalogic logo is a trademark of Datalogic S.p.A. all licensed to Datalogic

Scanning, Inc. All other trademarks and trade names referred to herein

are property of their respective owners.

This product may be covered by one or more of the following patents: 6,293,467 •

6,612,495 • 6,705,527 • Other Patents Pending

Page 3

Datalogic Scanning, Inc.

QUICKSCAN® END USER LICENSE

AGREEMENT

Notice to End User: The Datalogic Product you have acquired contains embedded Software, which is integral to the product’s operation. This Software is being provided to you

under license, subject to the terms and conditions of this Agreement. If you use the Datalogic Product, you will be deemed to have accepted the terms and conditions of this

Agreement. If you do not intend to be bound to the terms of this Agreement, Datalogic is

not willing to license the Software to you, you may not use the Datalogic Product or the

Software, and you must contact the party from whom you acquired the Datalogic Product

for instructions.

This End User Software License Agreement ("Agreement") is a legally binding agreement governing the licensing of the Software and Documentation by Datalogic,Scanning Holdings, Inc.

and its subsidiaries and affiliates ("Datalogic") to the entity or person who has purchased or otherwise acquired a Datalogic Product ("End User"). For purposes of this Agreement, any software that is associated with a separate end-user license agreement is licensed to you under the

terms of that license agreement. Datalogic and End User hereby agree as follows:

1. Definitions.

1.1 "Documentation" means materials such as user’s guides, program reference guides,

quick reference guides, manuals, or similar materials associated with or related to the

Datalogic Product, whether in printed, “online”, or other form.

1.2 "Proprietary Information" means: (a) source code, object code, software, documentation,

and any related internal design, system design, data base design, algorithms, technology, technical data or information, implementation techniques, and trade secrets related

to the Software, (b) any other trade secrets marked appropriately or identified as proprietary or confidential, and (c) any information that End User, under the circumstances,

should recognize as confidential. Proprietary Information does not include any information that the receiving party can establish was (1) in the public domain, (2) already in the

receiving party’s possession or rightfully known prior to receipt, (3) rightfully learned from

a third party not in violation of any other's proprietary rights, or (4) independently developed without access to Proprietary Information.

1.3 “Datalogic Product” means the Datalogic® Quickscan® series scanner product, including

all embedded Software in and all Documentation related to such product, which has

been purchased or otherwise acquired by End User, whether obtained directly or indirectly from Datalogic.

1.4 "Software" means any software or computer programs of Datalogic or its third party licensors in machine readable form which is embedded in the Datalogic Product, whether

obtained directly or indirectly from Datalogic, including any replacement, update,

upgrade, enhancement or modification.

2. Scope Of License Granted.

2.1 Datalogic grants to End User a non-exclusive, non-transferable, perpetual license to use

the Software, solely on the Datalogic Product in which it is embedded (“designated Datalogic Product”), in machine-readable form only, solely for End User's internal business

purposes. This Agreement does not convey ownership of the Software to End User.

Title to the Software shall be and remain with Datalogic or the third party from whom Datalogic has obtained a licensed right. As used in this Agreement, the term “purchase” or

its equivalents when applied to the Software shall mean “acquire under license.” End

User is not entitled to receipt or use of the source code to any Software.

2.2 End User shall not copy, modify, decompile, disassemble, reverse engineer, or otherwise

reproduce or remanufacture the Software, whether modified or unmodified, nor sell,

assign, sublicense, distribute, lend, rent, give, or otherwise transfer the Software to any

other person or organization, for purposes other than as expressly provided in this

Agreement, without Datalogic’s prior written consent.

Quick Reference Guide i

Page 4

3. Transfers, Support.

3.1 Any copying, installing, reproduction, remanufacture, reverse engineering, electronic

transfer, or other use of the Software on other than the designated Datalogic Product will

be a material breach of this Agreement. However, Datalogic may elect not to terminate

this Agreement or the granted licenses, but instead may elect to notify End User that End

User is deemed to have ordered and accepted a license for each breaching use. End

User shall pay Datalogic the applicable list price for such licenses as of the date of such

breach.

3.2 End User shall not sell, assign, sublicense, distribute, lend, rent, give, or otherwise transfer the Datalogic Product to any third party unless such third party agrees with Datalogic

in writing to be bound by the terms and conditions of this Agreement. Any such transfer

of the Datalogic Product absent such agreement shall be null and void.

3.3 End User may obtain support for Software from Datalogic at Datalogic’s standard support fees and under Datalogic’s standard support terms and conditions in effect at the

time the support is requested.

4. Intellectual Property.

End User acknowledges that the Software constitutes valuable trade secrets of Datalogic or

Datalogic’s third party licensors and that the Software is protected by intellectual property laws

and treaties. The license set forth in this Agreement does not transfer to End User any ownership of Datalogic’s or its third party licensors' copyrights, patents, trademarks, service marks,

trade secrets, or other intellectual property rights and End User shall have no right to commence any legal actions to obtain such rights. End User shall not remove, modify, or take any

other action that would obscure any copyright, trademark, patent marking, or other intellectual

property notices contained in or on the Datalogic Product.

5. Proprietary Information.

5.1 End User acknowledges that Proprietary Information is the confidential, proprietary, and

trade secret property of Datalogic and Datalogic’s third party licensors and End User

acquires no right or interest in any Proprietary Information.

5.2 End User shall not disclose, provide, or otherwise make available the Proprietary Information of Datalogic or its third party licensors to any person other than End User’s authorized employees or agents who are under confidentiality agreement, and End User shall

not use the Proprietary Information other than in conjunction with use of the Datalogic

Product exclusively for End User’s internal business purposes. End User shall take steps

to protect the Proprietary Information no less securely than if it were End User's own

intellectual property.

5.3 The provisions of this Proprietary Information Section shall survive and continue for five

(5) years after the termination of this Agreement.

6. Limited Warranty.

6.1 Datalogic warrants that, under normal use and operation, the Datalogic Product will conform substantially to the applicable Documentation for the period specified in the Documentation. During this period, for all reproducible nonconformities for which Datalogic

has been given written notice, Datalogic will use commercially reasonable efforts to remedy nonconformities verified by Datalogic. End User agrees to supply Datalogic with all

reasonably requested information and assistance necessary to help Datalogic in remedying such nonconformities. For all defects reported to Datalogic within the warranty

period, Datalogic’s liability is limited to providing End User with one copy of corrections or

responding to End User's problem reports according to Datalogic's standard assistance

practices. Datalogic does not warrant that the product will meet End User's requirements

or that use of the product will be uninterrupted or error free, or that Datalogic's remedial

efforts will correct any nonconformance. This limited warranty does not cover any product that have been subjected to damage or abuse, whether intentionally, accidentally, or

by neglect, or to unauthorized repair or unauthorized installation, and shall be void if End

User modifies the product, uses the product in any manner other than as established in

the Documentation, or if End User breaches any of the provisions of this Agreement.

6.2 EXCEPT AS PROVIDED IN THIS AGREEMENT, THE DATALOGIC PRODUCT IS PROVIDED “AS IS” AND DATALOGIC MAKES NO WARRANTIES OF ANY KIND, EXPRESS

OR IMPLIED, WRITTEN OR ORAL, WITH RESPECT TO THE PRODUCT, AND SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

ii QuickScan® QS6500

Page 5

7. Infringement.

7.1 Datalogic will defend End User against any claim in a lawsuit that the Datalogic Product

furnished hereunder infringe a United States patent or copyright of a third party and Datalogic will pay any damages finally awarded against End User by a court of competent

jurisdiction that are attributable to such claim or will pay End User’s part of any settlement that is attributable to such claim, provided, that 1) End User notifies Datalogic

promptly in writing of the claim, 2) Datalogic controls the defense or settlement of the

claim, and 3) End User cooperates fully with Datalogic in such defense or settlement. All

notices of a claim should be sent to Datalogic Scanning, Inc., Legal Department, 111 SW

Fifth Ave. Suite 4100, Portland, OR 97204-3644.

7.2 In the defense or settlement of any such claim, Datalogic may, at its option, 1) procure for

End User the right to continue using the Datalogic Product, 2) modify the Datalogic Product so that it becomes non-infringing, 3) replace the Datalogic Product with an equivalent

product not subject to such claim, or 4) provide End User an opportunity to return the

Datalogic Product and receive a refund of the purchase price paid, less a reasonable

allowance for use.

7.3 Datalogic shall have no liability to End User for claims of infringement based upon 1) the

use of any Datalogic Product in combination with any product which Datalogic has not

either furnished or authorized for use with such Datalogic Product 2) the use of any Datalogic Product designed, manufactured, or modified to the specifications of End User, or

3) End User’s modification of the Datalogic Product without written authorization from

Datalogic.

7.4 THE FOREGOING STATES DATALOGIC’S COMPLETE AND ENTIRE OBLIGATION

CONCERNING CLAIMS OF PATENT, COPYRIGHT, OR OTHER INTELLECTUAL

PROPERTY INFRINGEMENT, CANCELS AND SUPERCEDES ANY PRIOR AGREEMENTS, WHETHER ORAL OR WRITTEN, BETWEEN THE PARTIES CONCERNING

SUCH CLAIMS, AND WILL NOT BE MODIFIED OR AMENDED BY ANY PAST, CONTEMPORANEOUS, OR FUTURE AGREEMENTS OR DEALINGS BETWEEN THE

PARTIES, WHETHER ORAL OR WRITTEN, EXCEPT AS SET FORTH IN A FUTURE

WRITING SIGNED BY BOTH PARTIES.

8. Limitation Of Liability.

EXCEPT AS PROVIDED IN SECTION 7, DATALOGIC SHALL NOT BE LIABLE FOR ANY

CLAIMS AGAINST END USER BY ANY OTHER PARTY. IN NO EVENT SHALL DATALOGIC'S

LIABILITY FOR DAMAGES, IF ANY, WHETHER BASED UPON CONTRACT, TORT (INCLUDING NEGLIGENCE), PRODUCT LIABILITY, STRICT LIABILITY, WARRANTY, OR ANY OTHER

BASIS, EXCEED THE PRICE OR FEE PAID BY END USER FOR THE DATALOGIC PRODUCT. UNDER NO CIRCUMSTANCES SHALL DATALOGIC BE LIABLE TO END USER OR

ANY THIRD PARTY FOR LOST PROFITS, LOST DATA, INTERRUPTION OF BUSINESS OR

SERVICE, OR FOR ANY OTHER SPECIAL, CONSEQUENTIAL, CONTINGENT, INDIRECT,

INCIDENTAL, PUNITIVE, EXEMPLARY, OR OTHER SIMILAR DAMAGES, EVEN IF DATALOGIC HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

9. Government Restricted Rights; International Use.

9.1 Use, duplication, or disclosure of the Software by the U.S. Government is subject to the

restrictions for computer software developed at private expense as set forth in the U.S.

Federal Acquisition Regulations at FAR 52.227-14(g), or 52.227-19 or in the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013(c)(1)(ii), whichever is applicable.

9.2 If End User is using the Datalogic Product outside of the United States, End User must

comply with the applicable local laws of the country in which the Datalogic Product is

used, with U.S. export control laws, and with the English language version of this Agreement. The provisions of the “United Nations Convention on International Sale of Goods”

shall not apply to this Agreement.

10. Termination.

10.1 Either party may terminate this Agreement or any license granted under this Agreement

at any time upon written notice if the other party breaches any provision of this Agreement.

10.2 Upon termination of this Agreement, End User immediately shall cease using any non-

embedded software and shall return to Datalogic or destroy all non-embedded software

covered by this Agreement, and shall furnish Datalogic with a certificate of compliance

with this provision signed by an officer or authorized representative of End User. For

Quick Reference Guide iii

Page 6

embedded software, End User agrees to sign a waiver prepared by Datalogic concerning

further use of the embedded Software. End User’s resumed or continued use of the

embedded Software after termination shall constitute End User’s agreement to be bound

by the terms and conditions of this Agreement for such use.

11. General Provisions.

11.1 Entire Agreement; Amendment. This document contains the entire agreement between

the parties relating to the licensing of the Software and supersedes all prior or contemporaneous agreements, written or oral, between the parties concerning the licensing of the

Software. This Agreement may not be changed, amended, or modified except by written

document signed by Datalogic.

11.2 Notice. All notices required or authorized under this Agreement shall be given in writing,

and shall be effective when received, with evidence of receipt. Notices to Datalogic shall

be sent to the attention of Contract Administration, Datalogic Scanning, Inc., 959 Terry

Street, Eugene, OR 97402, or such other address as may be specified by Datalogic in

writing.

11.3 Waiver. A party’s failure to enforce any of the terms and conditions of this Agreement

shall not prevent the party’s later enforcement of such terms and conditions.

11.4 Governing Law; Venue:This Agreement and the rights of the parties hereunder shall be

governed by and construed in accordance with the laws of the State of Oregon U.S.A,

without regard to the rules governing conflicts of law. The state or federal courts of the

State of Oregon located in either Multnomah or Lane counties shall have exclusive jurisdiction over all matters regarding this Agreement, except that Datalogic shall have the

right, at its absolute discretion, to initiate proceedings in the courts of any other state,

country, or territory in which End User resides, or in which any of End User's assets are

located.

11.5 Attorneys’ Fees. In the event an action is brought to enforce the terms and conditions of

this Agreement, the prevailing party shall be entitled to reasonable attorneys’ fees, both

at trial and on appeal.

- END -

iv QuickScan® QS6500

Page 7

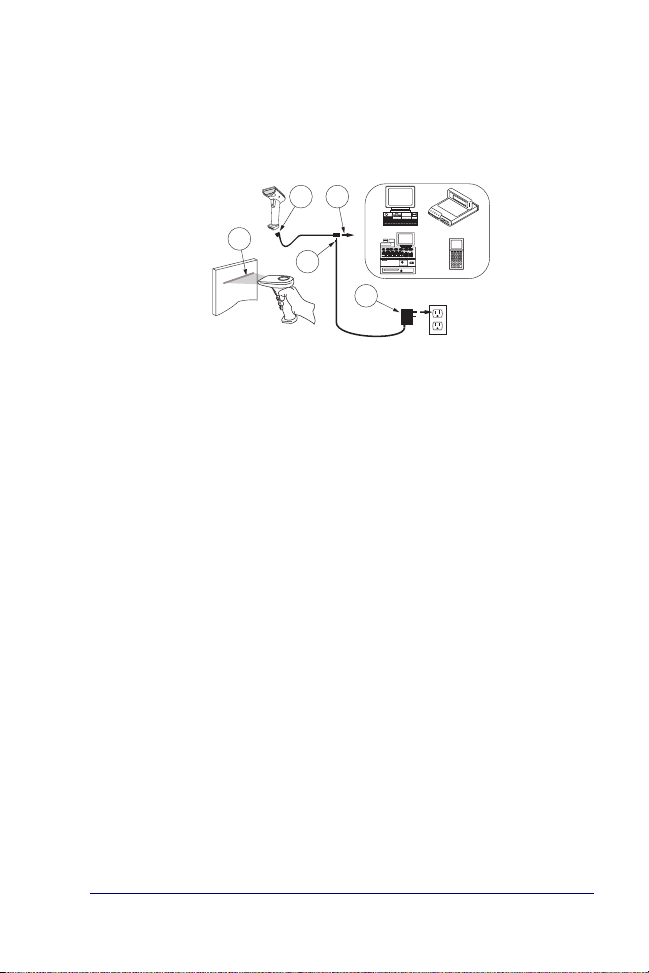

Installation

1 2

5

4

3

$4.50

$2.79

$3.99

The QuickScan® QS6500 linear imager is easy to install and use.

The following figure shows the steps to perform an installation.

Turn off the host computer before connection. Consult the host

terminal’s manual if necessary.

1. Connect the interface (I/F) cable to the linear imager.

2. Connect the I/F cable to the terminal’s communication port.

3. Connect the power cord to the I/F cable connector if

required. Linear imagers that use power off the terminal

(P.O.T.) do not require a power supply.

4. If required, connect the AC adapter to the wall outlet.

5. To verify operation, point the linear imager at a bar code and

pull the trigger. The linear imager should emit a single beep

indicating that the label has been scanned successfully.

The linear imager installation is complete.

Power Supply

Models require either a Listed class II or class III with a Limited

Power Source (LPS). For the safety certification to be valid, class

III input power sources must be IEC/EN60950-1 (EN 60335series, EN 60065 or relevant) approved.

Input: 100 - 240 VAC Output: 9 - 10 VDC

Max. Current: 2.0 A Max. Power: 20 W

Quick Reference Guide 1

Page 8

How to Scan

1

1

2

2

PDF

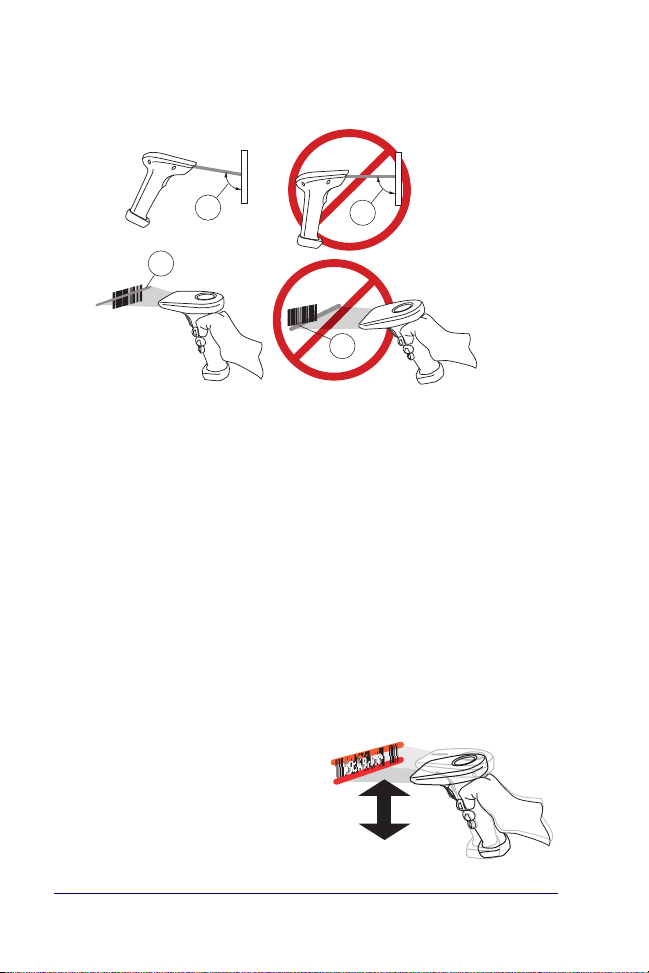

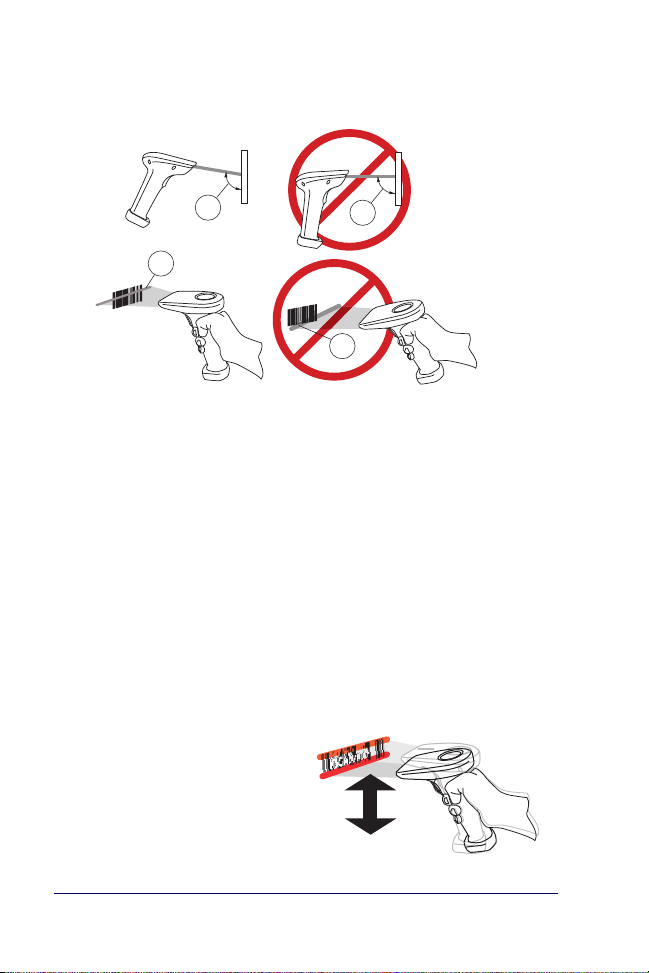

The figure below shows the right and wrong ways to scan a bar

code.

1. The linear imager must be pointed at a slight angle to the bar

code so that the light reflected off the bar code can be “seen”

by the linear imager. Do not hold the linear imager perpen

dicular to the bar code.

2. The targeting beam must cross the entire label. The linear

imager cannot read the bar code data without seeing the

entire label.

Scanning PDF417 Bar Codes (PDF models ONLY)

To read a PDF417 bar code, aim the targeting beam at the top of

the bar code, and in a smooth motion, scan down through the bar

code. You will hear a series of

ticks, followed by a final beep

when the bar code’s content has

been completely decoded. You

may need to repeat this process if

the PDF code is hard to read.

-

2QuickScan

®

QS6500

Page 9

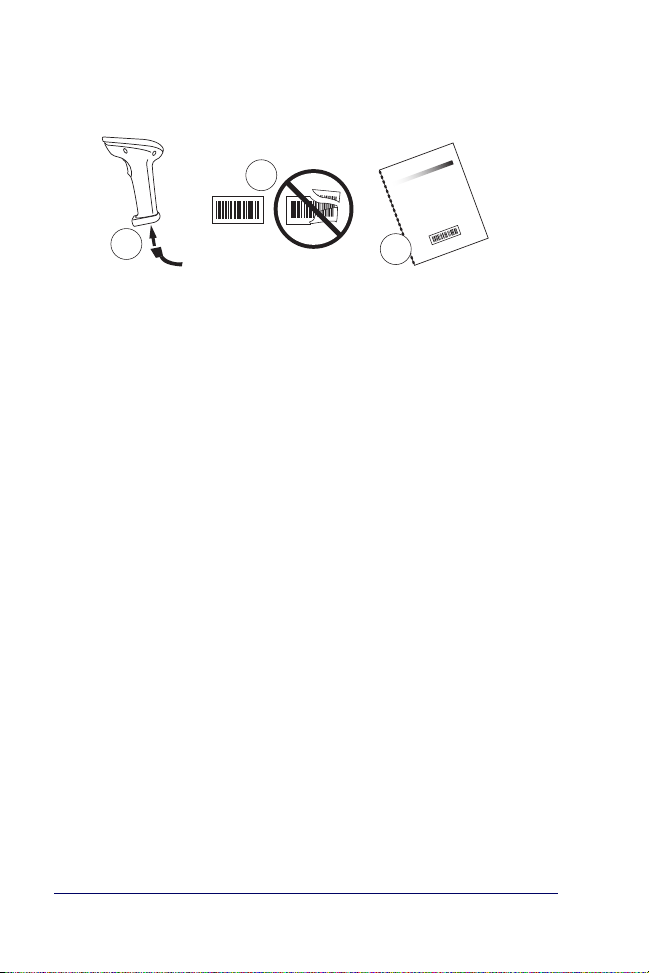

Troubleshooting

OFF

ON

1

2

3

If the linear imager is not operating properly, the following checks

should be performed:

1. Since the linear imager can receive its power from the host

computer (Power Off the Terminal—P.O.T.), it will not

operate without the system power on. If the linear imager

uses an external power supply and the external power supply

has failed, the linear imager will not operate.

2. If an external power supply is used, exchange the power supply with a known good power supply and retest the linear

imager.

3. If the linear imager receives power from the host (P.O.T.),

connect the linear imager to a known good host and retest.

4. Verify that the interface cable is securely attached to the host.

Consult your technical support personnel or refer to your

host system manual to verify the proper connection for the

linear imager.

5. Verify that the interface cable is securely attached to the linear imager.

6. Check that the labels are of sufficient quality to be recognized by the linear imager. Wrinkled, smudged, or torn

labels can cause the linear imager to not read at all. Scan a

known good label to check the linear imager's read opera

tion.

Quick Reference Guide 3

-

Page 10

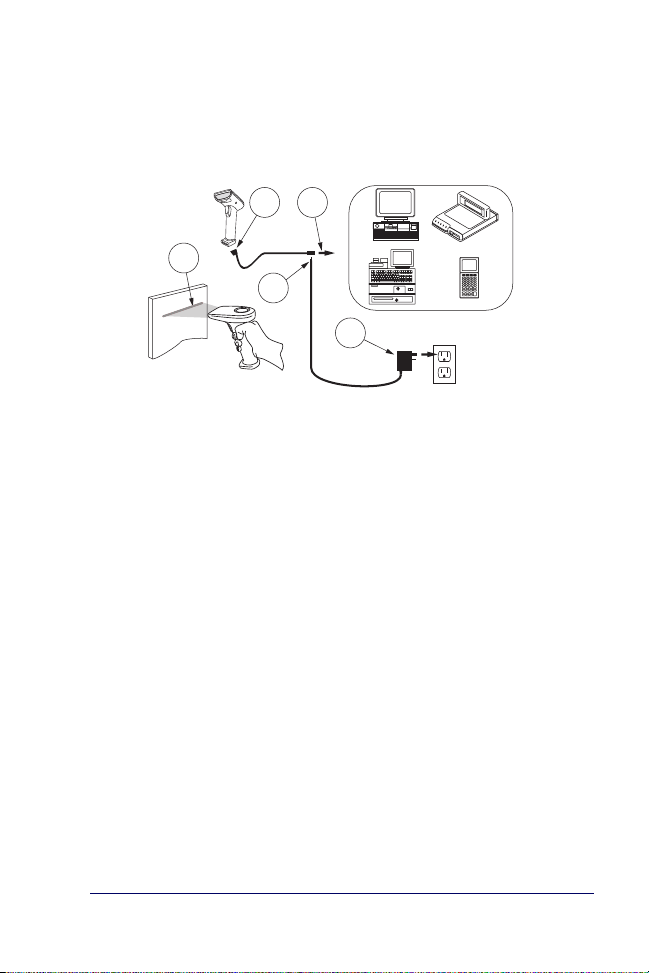

7. Ensure that the linear imager's interface type is compatible

with the host terminal by consulting your POS system man

ual and/or the linear imager’s Product Reference Guide

found on the CD included with your linear imager.

-

6

5

7

Product

Reference

Guide

If the linear imager still does not function properly, contact your

local supplier or Datalogic Customer Support Services.

Compliance Statement

This device complies with Part 15 rules. Operation is subject to

the following conditions:

1. This device may not cause harmful interference; and

2. This device must accept any interference received, including

interference that may cause undesired operation.

This Class A digital apparatus complies with Canadian ICES -003.

Cet appareil numérique de la classe A est confrome à la norme NMB-003 du

Canada.

LED Class

CLASS 1 LED PRODUCT APPARECCHIO LED CLASSE 1

LED KLASSE 1 APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

4QuickScan

®

QS6500

Page 11

Installation

Le lecteur de code à barres Linear Imager QS6500 est un linear imager de

poche facile à utiliser. Le schéma suivant illustre la procédure d’installa

tion du imager. Eteignez l’ordinateur avant de connecter le imager. Consultez le manuel de l’ordinateur si nécessaire.

1 2

$4.50

$2.79

5

3

$3.99

4

1. Connectez le câble d’interface (I/F) au imager.

2. Connectez le câble I/F au port de communication de l’ordinateur.

3. Connectez le cordon d’alimentation au câble I/F si requis. Les

imagers qui sont alimentés par l’ordinateur n’ont pas besoin d’une

autre source d’alimentation.

4. Si nécessaire, branchez l’adaptateur CA sur la prise murale.

5. Pour vérifier le fonctionnement, pointez le linear imager sur le code

à barres et appuyez sur la gâchette. Le linear imager doit émettre un

seul bip indiquant que l’étiquette a été déchiffrée correctement.

-

L’installation du linear imager est terminée.

Alimentation

Modèles référencés Classe II et Classe III nécessitant une alimentation externe (Limited Power Source). Afin de valider le certificat

de sécurité, l’alimentation classe III doit être certifiée IEC/

EN60950-1 (Séries EN 60335, EN 60065 ou équivalent).

Input: 100 - 240 VAC Output: 9 - 10 VDC

Max. Current: 2.0 A Max. Power: 20 W

Quick Reference Guide 5

Page 12

Procédure de lecture

1

1

2

2

PDF

Le dessin ci-dessous montre la bonne et la mauvaise façon de

scanner un code à barres.

1. Le linear imager doit être légèrement incliné par rapport au code à

barres afin que la lumière réfléchie sur le code peut être vue par le

linear imager. Ne pointez pas le linear imager perpendiculairement

au code.

2. Le faisceau lumineux doit balayer l'étiquette entièrement. Le linear

imager ne peut pas déchiffrer le code à barres sans avoir entièrement

parcouru l’étiquette.

Lecture des codes à barres PDF417 (Modèles PDF seulement)

Afin de lire les codes à barres PDF417, le faisceau lumineux doit balayer

le code à barres du haut vers le bas. Vous allez entendre une série de sig

naux sonores, suivie d’un bip final lorsque le code à barres aura été complètement déchiffré. Vous devez

répéter ce processus si le PDF est

difficilement lisible.

6QuickScan

®

QS6500

Page 13

Dépannage

OFF

ON

1

2

3

Si le linear imager ne fonctionne pas correctement, effectuez les vérifications suivantes :

1. Si le lecteur est alimenté par l’ordinateur, ce dernier doit être sous

tension. Si le linear imager utilise une source d’alimentation

externe, et que cette source d’alimentation est défaillante, le linear

imager ne peut pas fonctionner.

2. Si le linear imager utilise une source d’alimentation externe, remplacez celle-ci par une autre source dont vous êtes certain du bon

fonctionnement et testez à nouveau le linear imager.

3. Si le linear imager est alimenté par l’ordinateur, connectez-le à un

autre ordinateur dont vous êtes certain du bon fonctionnement et

testez à nouveau le linear imager.

4. Vérifiez que le câble d’interface est solidement relié à l’ordinateur.

Contactez un technicien d’assistance ou consultez le manuel de

l’ordinateur pour vérifier que la connexion au linear imager est cor

recte.

5. Vérifiez que le câble d’interface est solidement relié au linear

imager.

6. Vérifiez que les étiquettes sont de qualité suffisante pour être reconnues par le linear imager. Des étiquettes ridées, maculées ou

déchirées peuvent ne pas être déchiffrées par le linear imager. Procédez à la linear imager d’une étiquette en bon état pour vérifier le

fonctionnement du linear imager.

-

Quick Reference Guide 7

Page 14

7. Assurez-vous que le type d’interface du linear imager est compatible

avec l’ordinateur, en consultant le manuel de ce dernier et/ou le

Guide de référence du linear imager inclus dans le CD fourni avec

le lecteur.

6

5

7

Product

Reference

Guide

Si le linear imager ne fonctionne toujours pas correctement, contactez

votre revendeur ou le Service après-vente Datalogic.

Interference de la Radio Frequence

Cet appareil est conforme au paragraphe 15 du règlement FCC. Les

opération sont soumises aux deux conditions suivantes :

1. Cet appareil ne doit pas causer d'interférences nuisibles, et

2. Il doit accepter n'importe quelle interférence reçue, y compris les

interférences pouvant provoquer un dysfonctionnement.

Cet appareil numérique de classe 13 est conforme aux normes Canadiennes

de réglementation des équipements provoquant des interférences.

Cet appareil numérique de la classe A est confrome à la norme NMB-003 du Can-

ada.

LED Class

CLASS 1 LED PRODUCTAPPARECCHIO LED CLASSE 1

LED KLASSE 1APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

8QuickScan

®

QS6500

Page 15

Installation

Der QS6500 Linear Imager ist ein Handheld Scanner mit benutzerfreundlichem Design. Anhand folgender Abbildung wird in Schritten

gezeigt, wie der Scanner installiert werden soll. Schalten Sie den Hos

trechner aus, bevor Sie den linear imager anschließen. Falls notwendig,

schlagen Sie im Host-Terminal Handbuch nach.

1 2

$4.50

$2.79

5

3

$3.99

4

1. Verbinden Sie die Schnittstelle (I/F) mit dem linear imager.

2. Verbinden Sie das I/F Kabel mit dem Datenübertragungsport im

Te r m i n al .

3. Falls notwendig, verbinden Sie das Spannungsversorgungskabel mit

dem I/F Kabelanschluß. Imager, die das P.O.T Feature (Spannung

vom Terminal) verwenden, benötigen keine Spannungsversorgung.

4. Wenn notwendig, stecken Sie den Wechselstromadapter in die

Steckdose.

5. Um diese Anwendung zu überprüfen, zielen Sie mit den linear

imager auf einen Barcode und drücken Sie zum Scannen den

Abzug. Der linear imager sollte ein einzelnes Signal von sich geben,

um zu zeigen, dass der Barcode erfolgreich gescannt wurde.

Der linear imager wurde erfolgreich installiert.

-

Netzteil

Die Modelle erfordern eine Stromquelle der Klasse II oder III mit

einer Leistungsbegrenzung (LPS).

Quick Reference Guide 9

Page 16

Für eine gültige Sicherheitszertifizierung müssen Klasse III

Stromquellen am Eingang nach den Bestimmungen IEC/

EN60950-1 (EN 60335-Serien, EN 60065 oder entsprechenden)

zugelassen sein.

Eingang: 100 - 240 VAC Ausgang: 9 - 10 VDC

Max. Strom: 2.0 A Max. Leistung: 20 W

Der Vorgang des Scannens selbst

Die untenstehende Zeichnung zeigt, wie man Barcodes richtig

und falsch scannt.

1

2

1

2

1. Der linear imager muß dem Barcode in einem leichten Winkel

zuwandt sein, damit das reflektierte Licht des Barcodes vom Linear

Imager erfaßt werden kann. Der linear imager darf nicht

rechtwinkelig zum Barcode ausgerichtet sein.

2. Der Scanstrahl muß über den gesamten Barcode gehen.. Der linear

imager kann keine Barcodedaten lesen, wenn er nicht den gesamten

Barcode erfassen kann.

Das Scannen von PDF417 Barcodes (nur PDF-Modelle)

Um einen PDF417-Barocde zu lesen, richten Sie den Scanstrahl an das

obere Ende des Barcodes und scannen Sie den Barcode mit einer flüs

sigen Bewegung nach unten. Sie werden ein Ticken und anschließend

einen Piepton zur Bestätigung hören, wenn der

Inhalt des Barcodes vollständig dekodiert

wurde.

Sie müssen möglicherweise den

PDF

Prozess wiederholen, wenn der PDF-Code

schwer zu lesen ist.

10 QuickScan® QS6500

Page 17

Problembehandlung

OFF

ON

1

2

3

Die folgenden Tests sollten durchgeführt werden, wenn der linear imager

nicht einwandfrei funktioniert.

1. Nachdem der linear imager durch den Hostrechner mit Strom versorgt wird (P.O.T), kann das Gerät nicht ohne eine eingeschaltete

Spannungsversorgung durch das System funktionieren. Der linear

imager kann nicht in Betrieb gesetzt werden, wenn das Gerät auf

Fremdstrom läuft und dieser ausgefallen ist.

2. Wenn das Gerät mit Fremdstrom läuft, wechseln Sie die Stromversorgung und überprüfen Sie den linear imager nochmals.

3. Sollte der linear imager die Spannung vom Hostrechner erhalten

(P.O.T.), schließen Sie den linear imager an einen anderen Host an

und überprüfen Sie den linear imager nochmals.

4. Überprüfen Sie, ob das Schnittstellenkabel sicher mit dem linear

imager verbunden ist. Setzen Sie sich mit Ihrem technischen Sup

portteam in Verbindung oder schlagen Sie im Handbuch für Ihr

Hostsystem nach, um die einwandfreie Verbindung zum linear

imager zu erörtern.

5. Überprüfen Sie, ob das Schnittstellenkabel sicher mit dem linear

imager verbunden ist.

-

6. Überprüfen Sie, ob die Barcodes genügend Qualität aufweisen,

damit Sie vom linear imager erfaßt werden können. Zerknitterte,

schmutzige oder angerissene Barcodes können dazu führen, dass

vom linear imager gar nichts erfaßt werden kann. Scannen Sie einen

intakten Barcode, um die Lesefähigkeit des linear imagers zu über

prüfen.

Quick Reference Guide 11

-

Page 18

7. Stellen Sie sicher, dass der Schnittstellentyp des linear imagers mit

Ihrem Host-Terminal kompatibel ist, indem Sie in Ihrem POS-Systemhandbuch und/oder in der linear imager Product Reference

Guide nachschlagen, die sich auf der CD befinden, die mit dem lin

ear imager geliefert wurde.

-

6

5

7

Product

Reference

Guide

Bitte kontaktieren Sie entweder Ihren örtlichen Anbieter oder den Datalogic Kunden-Support-Dienst, wenn der linear imager noch immer nicht

einwandfrei funktioniert.

Hochfrequente Störungen

Dieses Gerät erfüllt Teil 15 der FCC-Bestimmungen. Der Betrieb unterliegt den folgenden zwei Bedingungen:

1. Dieses Gerät verursacht keine schädlichen Störungen.

2. Dieses Gerät akzeptiert alle empfangenen Störungen, einschließlich

Störungen, die einen nicht gewünschten Betrieb verursachen.

Dieser digitale Apparat der Klasse A erfüllt Canadian ICES-003.

Cet appareil numérique de la classe A est confrome à la norme NMB-003 du

Canada.

LED Class

CLASS 1 LED PRODUCTAPPARECCHIO LED CLASSE 1

LED KLASSE 1APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

12 QuickScan® QS6500

Page 19

Installazione

Il QS6500 linear imager è un lettore portatile di facile utilizzo. La

seguente figura illustra le fasi di installazione del linear imager.

Spegnere il computer prima di collegare il linear imager. Se neces

sario, consultare il manuale fornito unitamente al computer.

1 2

$4.50

$2.79

5

3

1. Collegare il cavo di interfaccia (I/F) al linear imager.

2. Collegare il cavo di interfaccia (I/F) alla porta di comunicazione del terminale.

3. Se necessario, collegare il cavo di alimentazione al connettore

del cavo I/F. I lettori di tipo P.O.T. (Power Off the Terminal)

non devono essere alimentati in quanto utilizzano l'alimen

tazione del terminale.

4. Se necessario, collegare il trasformatore di CA alla presa a

muro.

5. Per verificare il funzionamento, puntare il linear imager in

direzione di un codice a barre e premere il grilletto. Il linear

imager dovrebbe emettere un unico tono per indicare che

l'etichetta è stata letta con successo.

$3.99

4

-

-

L'installazione del linear imager è terminata.

Alimentazione

Questi modelli devono essere alimentati con alimentatori

omologati di classe II o classe III LPS (Limited Power Source, sor

gente di corrente limitata).

Quick Reference Guide 13

-

Page 20

Affinché il certificato di sicurezza sia valido, le sorgenti di alimen-

1

1

2

2

PDF

tazione di classe III devono essere conformi a IEC/EN60950-1

(serie EN 60335, EN60065 o relativi).

Tensione ingresso: 100 - 240 VAC Tensione uscita: 9 - 10 VDC

Consumo massimo: 2.0 A Potenza massima: 20 W

Come eseguire una lettura

La figura sottostante illustra il modo corretto e quello non corretto di come effettuare la scansione di un codice a barre

1. Il linear imager deve essere puntato con un leggero angolo

rispetto al codice a barre in modo che la luce riflessa dal bar

code possa essere "vista" dal linear imager. Non puntare il

codice tenendo il linear imager perpendicolare ad esso.

2. Si deve puntare il raggio in modo che esso copra l'intera supperficie del codice a barre. Il linear imager non può leggere i

dati del codice a barre senza vedere tutta l'etichetta.

-

Lettura di codici a barre PDF417 (Solo per i

modelli PDF)

Per leggere una simbologia PDF,puntare il raggio in cima al codice

a barre, e con movimento lento, attraversare il codice a barre

dall'alto verso il basso. Sarà possibile udire

una serie di scatti seguiti dal tono finale che

viene emesso una volta letto tutto il conte

nuto del codice. Il processo e' da ripetere se

il codice PDF risulta difficile da leggere.

14 QuickScan® QS6500

Page 21

Risoluzione dei problemi

OFF

ON

1

2

3

Eseguire i seguenti controlli in caso di cattivo funzionamento del

linear imager:

1. Poiché il linear imager è alimentato solo dal terminale

(P.O.T. Power Off the Terminal, alimentazione da termi

nale), esso non funziona quando il sistema è spento. Se il linear imager utilizza un'alimentazione esterna e questa è

assente, il linear imager non funziona.

2. In caso di utilizzo di una fonte di alimentazione esterna, sostituirla con una fonte funzionante e controllare nuovamente

il linear imager.

3. Se il linear imager viene alimentato dal terminale (P.O.T.),

collegarlo ad un terminale funzionante e ripetere il controllo.

4. Verificare che il cavo di interfaccia sia saldamente collegato al

terminale. Consultare il personale di supporto tecnico o il

manuale del sistema utilizzato come terminale per verificare

il corretto collegamento dello scanner.

5. Verificare che il cavo di interfaccia sia saldamente collegato al

linear imager.

-

6. Verificare che la qualità delle etichette sia adatta al linear

imager. Un'etichetta accartocciata, macchiata o strappata

può impedire del tutto la lettura. Eseguire una scansione su

un'etichetta in buono stato per verificare il corretto funzion

-

amento del linear imager.

Quick Reference Guide 15

Page 22

7. Assicurarsi che il tipo di interfaccia del linear imager sia compatibile con il terminale consultando il manuale del sistema

POS utilizzato e/o la Guida di riferimento prodotto del lin

ear imager presente sul CD fornito con il linear imager.

-

6

5

7

Product

Reference

Guide

Se il linear imager continua a non funzionare correttamente, contattare il fornitore locale o il servizio di assistenza clienti di Datalogic.

Disturbi in radiofrequenza

Questo dispositivo è conforme alla sez. 15 delle norme FCC.

L'utilizzo è subordinato alle due condizioni seguenti:

1. Il dispositivo non deve causare interferenze dannose, e

2. Il dispositivo deve sopportare le interferenze captate, incluse

quelle che possono determinare un funzionamento anomalo.

Questo dispositivo digitale di Classe A è conforme alle normative canadesi

ICES-003.

Cet appareil numérique de la classe A est confrome à la norme NMB-003 du

Canada.

LED Class

CLASS 1 LED PRODUCT APPARECCHIO LED CLASSE 1

LED KLASSE 1 APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

16 QuickScan® QS6500

Page 23

Instalación

El QS6500 linear imager para códigos de barras es un escáner manual

muy fácil de utilizar. La siguiente figura muestra los pasos que se deben

seguir para instalar el escáner. Apague la computadora host antes de

conectar el linear imager. De ser necesario, consulte el manual del termi

nal host.

1 2

$4.50

$2.79

5

3

1. Conecte el cable de interfaz (I/F) al linear imager.

2. Conecte el cable I/F al puerto de comunicaciones del terminal.

3. Si corresponde, conecte el cable de alimentación al conector del

cable I/F. Los linear imagers que se alimentan con la energía del ter

minal (P.O.T.) no necesitan a conectar con una fuente de alimentación.

4. Si es necesario, conecte el adaptador CA al tomacorriente de la

pared.

5. Para verificar el funcionamiento, apunte el linear imager hacia un

código de barras y apriete el gatillo. El linear imager debe emitir un

solo bip, lo que indica que ha leído la etiqueta correctamente.

$3.99

4

-

-

Con esto, queda completa la instalación del linear imager.

Conección al Corriente

Se require fuente limitada de alimentación (LPS) alistada en la

clase II o la clase III para estos modelos.

Quick Reference Guide 17

Page 24

La certificación de seguridad solamente es válida si las enchufadas

PDF

para fuente de alimentación clase III están aprobadas por IECEN60950-1 (serie EN 60335, EN 60065 o comparable).

Enchufada 100-240 VAC Despacho 9 - 10 VDC

Corriente máximo 2.0 A Poder máximo 20 W

Cómo leer

El diseño que aparece en seguida demuestra la manera correcta e

incorrecta de rastrear un código de barras.

1

2

1

2

1. Se debe apuntar el "linear imager" con el menor ángulo posible para

que la luz que se refleja del código de barras sea captada por el "lin

ear imager." No coloque el linear imager en manera perpendicular al

código de barras.

2. La luz directiva tiene que cruzar al totalidad del código de barras. El

linear imager no puede leer los datos del código de barras si no ve la

etiqueta completo.

Cómo escanear códigos de barras PDF417 (Unicamente para los modelos PDF)

Para la lectura de un código de barras PDF417, apunta la luz directiva

por el código de barra con movimiento constante, desde arriba hacia

abajo. Deber

un bip final cuando el linear imager haya desci

frado completamente el contenido del código.

Puede que usted necesite repetir este proceso, si

el código PDF es difícil de leer.

18 QuickScan® QS6500

oír una serie de tics, seguidos con

-

-

Page 25

Solución de problemas

OFF

ON

1

2

3

Si el linear imager no funcíona adecuadamente, se deben realizar estas

pruebras:

1. Dado que el linear imager puede alimentarse de la computadora

host (Alimentación a través de la energía del terminal, “P.O.T.”), no

funcionará si el sistema no está encendido. Si el linear imager

emplea una fuente de alimentación externa y esta fuente ha sufrido

una falla operativa, el linear imager no funcionará.

2. Si se utiliza una fuente de alimentación externa, reemplácela por

una fuente de alimentación que esté funcionando bien y vuelva a

probar el linear imager.

3. Si el linear imager se alimenta con el terminal host (P.O.T.), conecte

el linear imager a un host que esté funcionando bien y vuelva a

probarlo.

4. Verifique si el cable de interfaz está bien conectado al host. Consulte

a su personal de soporte técnico o consulte el manual del sistema

host para verificar si el linear imager está bien conectado.

5. Verifique si el cable de interfaz está bien conectado al linear imager.

6. Controle si la calidad de las etiquetas es suficiente para que el linear

imager pueda reconocerlas. Es posible que el linear imager no lea

las etiquetas que están arrugadas, manchadas o rotas. Para verificar

si el linear imager lee correctamente, páselo por una etiqueta que

esté en buenas condiciones.

7. Verifique que el tipo de interfaz que emplea el linear imager sea

compatible con el terminal host. Para esto, consulte el manual de su

Quick Reference Guide 19

Page 26

sistema de punto de venta (POS) o la guía de referencia de producto

que viene en el CD provisto con el escaner.

6

5

7

Product

Reference

Guide

Si el linear imager no funciona de manera adecuado, comuníquese con su

proveedor local o con el Servicio de Atención al Cliente de Datalogic.

Interferencia de radio frecuencia

Este unidad cumple con la Parte 15 de las Normas FCC (Comisión Federal de Comunicaciones de EE.UU.). Su funcionamiento está sujeto a las

dos condiciones siguientes:

1. Esta unidad no podrá causar interferencia peligrosa, y

2. Esta unidad deberá aceptar cualquier interferencia recibida, incluyendo aquella interferencia que pudiese provocar una operación no

deseada.

Este aparato digital de la clase A se conforma con ICES-003 canadiense.

Cet appareil numérique de la classe A est confrome à la norme NMB-003 du

Canada.

LED Class

CLASS 1 LED PRODUCTAPPARECCHIO LED CLASSE 1

LED KLASSE 1APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

20 QuickScan® QS6500

Page 27

Instalação

O QS6500 linear imager é um leitor portátil de fácil utilização. A figura

seguinte mostra os passos para instalação do linear imager. Desligue o

computador antes de conectar o linear imager. Consulte o manual do ter

minal caso necessário.

1 2

$4.50

$2.79

5

3

4

1. Conecte o cabo de interface (I/F) ao linear imager.

2. Conecte o cabo I/F à porta de comunicação do terminal.

3. Conecte o fio de energia ao conector do cabo I/F, caso necessário.

Os linear imagers que usam o fornecimento de energia do terminal

(power off the terminal - P.O.T.) não exigem um suprimento de

energia.

4. Se necessário, conecte o adaptador CA/CC a tomada.

5. Para verificar a operação, aponte o linear imager para um código de

barras e aperte o gatilho. O linear imager deve emitir um sinal de

bip único, indicando que a etiqueta foi lida corretamente.

$3.99

-

A instalação do linear imager está completa.

Adaptador CA/CC

Modelos podem ser classificados como Classe II ou Classe III,

com Fonte de Energia Limitada (LPS).

Quick Reference Guide 21

Page 28

Para o certificado de segurança eletrica ser válido, uma fonte de

1

1

2

2

PDF

entrada de energia Classe III precisa ser approvada como IEC/

EN60950-1 (EN 60335-serie, EN 60065 ou relevante).

Entrada: 100 - 240 V c.a. Saída: 9 - 10 Vc.c.

Corrente Max.: 2.0 A Potencia Max.: 20 W

Como operar o linear imager

A figura baixo indica as formas correta e incorreta de ler um

código de barras.

1. O Linear Imager necessita ser direcionado ao código de barras com

um pequeno angulo, de forma que a luz que reflete na superfície do

código de barras possa ser "vista" pelo Linear Imager. Não segure o

linear imager perpendicularmente ao código de barras.

2. O feixe de posicionamento necessita cruzar toda a extensão do

código de barras. O linear imager não pode ler o código de barras

sem visualizar a etiqueta inteira.

Fazendo de leitura de Códigos de Barras PDF417

(Sómente modelos PDF)

Para ler um codigo do tipo PDF417, aponte o feixe de posicionamento

no topo do código e em um movimento devagar siga lendo o código da

parte superior até a parte inferior. Você irá ouvir uma série de tiques,

seguidos por um bip final, quando o conteúdo

do código de barras tiver sido completa

decodificado. Pode ser que seja necessario

repetir este processo caso tenha dificuldade

de ler este codigo em PDF

22 QuickScan® QS6500

mente

Page 29

Diagnóstico de Problemas

OFF

ON

1

2

3

Se o linear imager não estiver operando adequadamente, as seguintes verificações devem ser feitas:

1. Visto que o linear imager pode receber sua energia do terminal que

o hospeda (Power Off the Terminal—P.O.T.), este não irá operar

sem que o sistema esteja ligado. Se o linear imager usa um supri

mento de energia externo e este tiver falho, o linear imager não irá

funcionar.

2. Se um suprimento de energia externo for usado, troque o suprimento de energia por um reconhecidamente bom e teste novamente

o linear imager.

3. Se o linear imager recebe a energia do terminal (P.O.T.), conecte o

linear imager a um terminal reconhecidamente bom e teste novamente.

4. Verifique se o cabo de interface está ligado de forma segura ao terminal. Consulte seu suporte técnico ou o manual do sistema do terminal para verificar a conexão apropriada para o linear imager.

5. Verifique se o cabo de interface está ligado de forma segura ao linear

imager.

6. Cheque se as etiquetas são de qualidade suficiente para serem reconhecidas pelo linear imager. Etiquetas rasgadas, sujas ou molhadas

podem impedir que o linear imager faça a leitura completa. Faça a

leitura com uma etiqueta reconhecidamente em bom estado para

checar a operação de leitura do linear imager.

-

7. Certifique-se de que o tipo de interface do linear imager é com-

patível com o terminal, consultando o manual de sistema POS e/ou

Quick Reference Guide 23

Page 30

o Guia de Referência do Produto do linear imager, encontrado no

CD incluso em seu linear imager.

6

5

7

Product

Reference

Guide

Caso o linear imager ainda não funcione corretamente, contate seu

fornecedor local ou os Serviços de Suporte ao Cliente Datalogic.

Interferência de Radio — Frequência

Este dispositivo concorda com a Parte 15 das Regras FCC. A operação é

sujeita às seguintes duas condições:

1. Este dispositivo não deve causar interferências que tragam risco, e

2. Este dispositivo deve aceitar quaisquer interferências recebidas,

incluindo interferências que possam causar operações não desejadas.

Este aparelho digital de Classe A é conforme a norma Canadense ICES-003.

Cet appareil numérique de la classe A est confrome à la norme NMB-003 du

Canada.

Classe Do LED

PRODUTO LED - CLASSE 1

CLASS 1 LED PRODUCTAPPARECCHIO LED CLASSE 1

LED KLASSE 1APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

24 QuickScan® QS6500

Page 31

安装

电源块要求class II或class III有限电源。为保证安全证书有效,class

III输入源必须满足IEC/EN60950-1(EN 60335-series, EN 60065 or relevant)标准。

输入:100-240 VAC 输出:9 - 10 VDC

最大电流:2.0A 最大功率:20W

QuickScan QS6500 线性扫描器安装和使用都十分容易。

下面的图演示的是安装步骤。在接线前首先关闭主计算

机。如果需要,请查阅主机终端手册。

1 2

$4.50

$2.79

5

3

1.将连接电缆与线性扫描器相连。

2.将连接电缆与终端的通讯口相连。

3.如果需要,将电源线与连接电缆的连接器相连。使用

使用终端供给电源 (P.O.T.) 的线性扫描器不需要电

源。

4.如果需要,将交流电适配器与墙面插头相连。

5.要检查操作情况,将线性扫描器对准条形码,然后扣

动按钮。线性扫描器应当发出一声 “滴”音,表明条

码扫描成功。

$3.99

4

至此,线性扫描器安装完毕。

关于电源

快速参考指南 25

Page 32

如何扫描

1

1

2

2

PDF

下图演示的是正确的和错误的扫描条码的方法。

1.必须将线性扫描器以稍小的斜角对着条码扫描,这样

条码上反射的光才可以被线性扫描器 “看到”。不要

将扫描器垂直对着条码。

2.扫描光线应当对准整个条码标签,否则扫描器不能读

取条码数据。

扫描 PDF417 条码 ( 仅适用于 PDF 机型 )

要扫描 PDF417 条码,将扫描光线对准条码的顶部,然后

平滑地向下扫描条码。在一系列的滴答声后,有一声

“滴”,确认条码内容被完全解码。为了成功扫描,您可

能需要扫描条码标签几次。

故障排除

如果线性扫描器出现故障,

应当作如下的检查:

26 QuickScan® QS6500

1.由于线性扫描器从主计

算机 ( 终端供给电源

P.O.T.) 上获得电力,

Page 33

如果系统电源没有接通,则扫描器就不能工作。 如果

OFF

ON

1

2

3

线性扫描器使用外部电源,而外部电源出现故障,则

扫描器也不会工作。如果使用的是外部电源,换上完

好的电源,然后测试线性扫描器。

2.如果线性扫描器是从主机 (P.O.T.) 获得电力,将线

性扫描器与完好的主机相连,然后测试扫描器是否工

作。

3.检查连接电缆与主机连接的是否牢固。请教技术支持

人员或查阅主机系统手册,以检查线性扫描器的接线

是否正确。

4.检查连接电缆与线性扫描器的连接是否牢固。

5.检查条码是否足够清晰、易于扫描器识别。皱的、脏

的或破损的条码标签扫描器是不能识别的。扫描一个

好的条码,然后检查扫描器是否能正确读取。

6.通过查阅您的 POS 系统手册或随机携带的 CD 中包含

的线性扫描器 《产品参考手册》,确认线性扫描器的

连接线型号与主机终端兼容。

6

5

快速参考指南 27

7

Product

Reference

Guide

Page 34

如果线性扫描器仍然不能工作,与您当地的供应商或

Datalogic 的客户服务部联系。

符合法规之声明

该设备符合第 15 章的有关规定。其操作符合下列条件:

1.该设备不会引发有害的干扰;并且

2.该设备必须接受任何接收到的干扰,包括可能引发错

误的干扰。

该 A 级数字设备符合加拿大 ICES -003。

Cet appareil num 巖 ique de la classe A est confrome ? la

norme NMB-003 du Canada.

LED 等级

1 级 LED 产品 1级APPARECCHIO LED

LED KLASSE 1APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

28 QuickScan® QS6500

Page 35

インストール

QuickScan® QS6500リニアイメージャーは、

簡単にインストール、ご使用いただけます。以下の図はインス

トール手順の説明です。接続する前にホストコンピュータをオ

フにしてください。必要に応じてターミナルのマニュアルを参

照してください。

1. インターフェイス(I/F)ケーブルをリニアイメージャーに接

続します。

2. インターフェイス(I/F)ケーブルをターミナルの通信ポート

に接続します。

3. 必要に応じて電源コードをI/Fケーブルコネクタに接続して

ください。ターミナル(P.O.T.)からの電源を使用するリニ

アイメージャーは、外部電源を必要としません。

4. 必要に応じてACアダプタを壁コンセントに差し込んでくだ

さい。

5. バーコードに向けてリニアイメージャーのトリガーを引い

て、正しく作動するか確認してください。リニアイメージ

ャーはビープ音を一回発して、ラベルがスキャンされたこ

とを知らせます。

6. これでリニアイメージャーのインストールが完了しまし。

電源装置

このモデルはリステッドクラスIIかクラスIIIのどちらかの限

られた電源(LPS)を必要とします。

安全証明が有効であるためには、クラスIIIの入力電源がIEC/E

N60950-1(EN 60335

クイック・リファレンス・ガイド 29

Page 36

シリーズ、EN60065、もしくは同等)に承認されなければならな

りません。

入力: 100 - 240 VAC 出力: 9 -10 VDC

最大. 電流: 2.0A 最大. 電力: 20W

スキャンの仕方

以下の図は、バーコードの正しいスキャンの仕方と間違ったス

キャンの仕方を説明しています。

1. バーコードに反射した光がリニアイメージャーによって認

識されるように、リニアイメージャーは、バーコードに対

してわずかな角度で当ててください。リニアイメージャー

をバーコードに対して垂直に持たないでください。

2. 照準光は、ラベル全体を当てなければなりません。ラベル

全体がを当てないとリニアイメージャーはバーコードを読

み取ることができません。

PDF417 バーコードのスキャン (PDF モデル限定)

PDF417バーコードを読み取るには、照準光をバーコードの最上

部に当てて、バーコードの上から下までをなめらかな動きでス

キャンします。一連の作動音の

後、バーコードの解読が完了し

たことを告げる最後のビープ

音が鳴ります。コードの読み取

りが難しい場合は、この手順を繰

り返さなければならない場合があ

ります。

30 QuickScan® QS6500

Page 37

トラブルシューティング

リニアイメージャーが正しく作動しない場合は、以下の確認作

業を行ってください。

1. リニアイメージャーはホストコンピュータ(パワーオフタ

ーミナルP.O.T.)から電力を引いて作動させることができ、その場

合はシステム電源がオンになっていないとリニアイメージ

ャーは作動しません。外部電源に接続してリニアイメージ

ャーを作動させる場合、その電源装置が停電になっている

とリニアイメージャーは作動しません。

2. 外部電源をお使いの場合は、信頼できる電源装置に替えて

からリニアイメージャーを再テストしてください。

3. リニアイメージャーがホスト(P.O.T.)から電力を引いてい

る場合は、リニアイメージャーを信頼できるホストに接続

してから再テストしてください。

4. インターフェース・ケーブルがホストにしっかりと接続さ

れていることを確認します。リニアイメージャーの正しい

接続方法については、テクニカルサポートの担当者にお問

い合わせいただくか、ホストのシステムマニュアルを参照

してください。

5. インターフェース・ケーブルがリニアイメージャーにしっ

かりと接続されているか確認してください。

6. ラベルの状態がリニアイメージャーが認識するのに十分な

状態であることを確認してください。ラベルのシワや汚れ

、破れなどは、リニアイメージャーが全く読み取りをしな

原因になります。状態のよいラベルをスキャンして、リニ

アイメージャーの読み取り機能をテストしてください。

クイック・リファレンス・ガイド 31

Page 38

7. リニアイメージャーのインターフェイスのタイプがホスト

ターミナルと互換性があるか確認します。確認方法は、PO

Sシステムマニュアルを参照するか、ならびに/

または付属のCDに入っているリニアイメージャー製品ガイ

ドをご覧ください。

上記の方法を実行してもリニアイメージャーが正しく作動しな

い場合は、お近くのサプライヤーまたはDatalogic

カスタマーサポートサービスにご連絡ください。

適合性について

本製品は、パート15

の規制に適合しています。操作は以下の条件に従います。

1. この装置は有害な干渉をおこさない。

2. この装置は、誤作動を起こす可能性がある干渉を含む、受

信したあらゆる干渉を受け入れなければならない。

本製品は、カナダICES - 003に準拠したクラスAデジタル装置です。

Cet appareil numérique de la classe A est confrome à la norme

NMB-003 du Canada.

LED Class

CLASS 1 LED PRODUCTAPPARECCHIO LED CLASSE 1

LED KLASSE 1APPAREIL A LED DE CLASSE 1

EN60825-1/All:1996

32 QuickScan® QS6500

Page 39

DECLARATION OF CONFORMITY

Datalogic hereby declares that the Equipment specified below has been tested

and found compliant to the following Directives and Standards:

Directives:

Standards:

Equipment

Products:

Placed into EU

Service:

Responsible

Manufacturer:

89/336/EEC EMC

73/23/EEC Low Voltage

EN55022-B:1998 - Generic Emissions

EN55024:1998/2001 - Generic Immunity - ITE

EN60950:2000 - ITE Safety

EN60825-1/A2:2001 - LED Safety

EN61000-3-2:2000 - Harmonic Current

EN61000-3-3:1994 - Voltage Fluctuation/Flicker

Handheld Barcode Scanning Equipment

Type:

QuickScan 6500 Plus (QS6500)

April 2007 under the Datalogic trademark.

Nov. 2004 under the PSC trademark.

Datalogic Scanning, Inc. 959 Terry St. Eugene, OR USA

Page 40

Austr alia

Datalogic Scanning Pty Ltd

North Ryde, Australia

Telephone: [61] (2) 9870 3200

Fax: [61] (2) 9878 8688

France and Benelux

Datalogic Scanning Sarl

LES ULIS Cedex, France

Telephone: [33].01.64.86.71.00

Fax: [33].01.64 46.72.44

Germany

Datalogic Scanning GmbH

Darmstadt, Germany

Telephone: 49 (0) 61 51/93 58-0

Fax: 49 (0) 61 51/93 58 58

Italy

Datalogic Scanning SpA

Vimercate (MI), Italy

Telephone: [39] (0) 39/62903.1

Fax: [39] (0) 39/6859496

Japan

Datalogic Scanning KK

Shinagawa, Tokyo, Japan

Telephone: 81 (0)3 3491 6761

Fax: 81 (0)3 3491 6656

Latin America

Datalogic Scanning, Inc

Miami, Florida, USA

Telephone: (305) 591-3222

Fax: (305) 591-3007

Spain and Portugal

Datalogic Scanning Sarl Sucursal

en España

Madrid, Spain

Telephone: 34 91 746 28 60

Fax: 34 91 742 35 33

United Kingdom

Datalogic Scanning LTD

Watford, England

Telephone: 44 (0) 1923 809500

Fax: 44 (0) 1923 809 505

©2004-2007 Datalogic Scanning, Inc. 6/07

www.scanning.datalogic.com

Datalogic Scanning, Inc.

959 Terry Street

Eugene, OR 97402

Telephone: (541) 683-5700

Fax: (541) 345-7140

R44-2815 (Rev. A)

Loading...

Loading...