Page 1

DLL2020

User’s Manual

Page 2

DLL2020

USER'S MANUAL

Page 3

DATALOGIC S.p.A.

Via Candini 2

40012 - Lippo di Calderara di Reno

Bologna - Italy

DLL2020 User's Manual

Ed.: 11/2003

ALL RIGHTS RESERVED

Datalogic reserves the right to make modifications or improvements without prior

notification.

Datalogic shall not be liable for technical or editori al errors or omissions contained

herein, nor for incidental or consequential damages resulti ng from the use of this

material.

Product names mentioned herein are for identification purposes only and may be

trademarks and or registered trademarks of their respective companies.

© Datalogic S.p.A. 2001 - 2003

820000884 (Rev. D)

Page 4

CONTENTS

INTRODUCTION................................................................... v

COMPLIANCE..................................................................... vi

FCC ..................................................................................... vi

Warranty ............................................................................. vi

1

1.1

1.2

1.3

1.4

1.5

1.6

2

2.1

2.1.1 RS232 Direct Power.............................................................. 10

2.1.2 Keyboard Wedge Direct Power............................................. 10

2.2

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

GETTING S TARTED............................................................... 1

Unpacking the DLL2020 .......................................................... 1

Available Models..................................................................... 2

Scanning Bar Codes with the DLL2020................................... 3

Scanner Labelling ...................................................................5

Maintaining the Scanner.......................................................... 7

Controlling the Scanner from the POS System........................ 8

INSTALLING THE DLL2020................................................... 9

Connecting the Scanner.......................................................... 9

Interface Selection................................................................ 11

CONFIGURATION................................................................ 13

Change Scanner Settings ..................................................... 13

Factory Default Settings........................................................ 14

Default Message Format....................................................... 15

Editing Commands................................................................ 16

RS232................................................................................... 17

RS232 Presets...................................................................... 17

Keyboard Wedge .................................................................. 19

PC/Terminal Type................................................................. 19

Keyboard Nationality............................................................. 20

Operating Parameters........................................................... 22

Code Selection...................................................................... 24

Data Formatting.................................................................... 27

Pre-defined Terminators........................................................ 27

Code Identifiers..................................................................... 28

iii

Page 5

A CONNECTOR AND PIN DEFINITIONS ................................ 30

B TECHNICAL FEATURES...................................................... 31

C TROUBLESHOOTING.......................................................... 33

iv

Page 6

INTRODUCTION

The Datalogic DLL2020 is a high perform ance omni-directional scanner,

which provides optimal sc anni ng conditions.

Together with its compact and ergonomic design, operator fatigue and

other discomforts are less than any competi tive omni-directional scanner.

These characteristics make the DLL2020 especially suitable for

installation in small counters such as in drugstores, pharmacies,

department stores, tobacconists, kiosks, petrol stations, and

convenience stores.

The omni-directional sc an field of the DLL2020 generat es a scan pattern

of 16 lines, ensuring high performance scanning. Featuring an

unequalled scan rate of 800 scans per second, the DLL2020 is an

aggressive scanner.

Barcodes are read simply on presentation to the scanner window.

However, the ergonomic design of DLL2020 rubber sleeve, which fits

naturally in the hand, makes the unit easy to pick up when larger or

heavier products have to be scanned.

The scanner con be installed ‘f ree-standing’ on a counter surface using

its protective rubber sleeve or without the s leeve, fl ush or s urfac e fixed to

check-out furniture, making for a very neat instal l ation.

This manual contains three chapters and three appendices. The first

chapter describes the DLL2020 sc anner, its general features as well as

the way in which it can be used. The precise ins truc t ions f or ins tall ing the

scanner are listed in the second chapter. Default settings can be

changed using the bar code labels in chapter 3 "Configuration".

Appendix A shows the connector types of the scanner. Technical

specifications of the DLL2020 can be found in Appendix B. Refer to

Appendix C for troubleshooting if the s canner is not working properly.

v

Page 7

COMPLIANCE

FCC

This equipment has been tested and found to com ply with the limits for a Class B

digital device, pursuant to EN55022, and with the limi ts for a class A digital device,

pursuant part 15 of the FCC rules. These limi ts are designed to provide reasonable

protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the user's manual,

may cause harmful interference to radio communications. Operation of the

equipment in a residential area is li kely to cause harmful interference in which case

the user will be required to correct the interference at his own expense. Any

unauthorized changes or modifications to this equipment could void the user's

authority to operate this equipment.

For CE-countries:

-

The DLL2020 is in conformity with the CE standards.

For USA & Canada:

-

To be used with UL listed and CSA certified computers/POS systems.

-

À utiliser avec des ordinateurs/systèmes POS registrés UL/certifiés CSA.

Radio and Television Interference

Operation of this equipment in a residential area can cause interference to radio or

television reception. This can be determined by turning the equipment off and on.

The user is encouraged to try to correct the interference by one or more of the

following measures:

• Re-orientate the receiving antenna

• Relocate the device with respect to the receiver

• Move the device away from the receiver

• Plug the device into a different outlet in order to have the device and

WARRANTY

Datalogic warranties this product against defects in workmanship and materials, for a

period of 24 months from the date of shipment, provided that the product is operated

under normal and proper conditions.

Datalogic has the faculty to repair or replace the product, these provisions do not

prolong the original warranty term.

The warranty does not apply to any product that has been subject to misuse,

accidental damage, unauthorized repair or tampering.

receiver on different branch circuits.

vi

Page 8

GETTING STARTED

1

1 GETTING STARTED

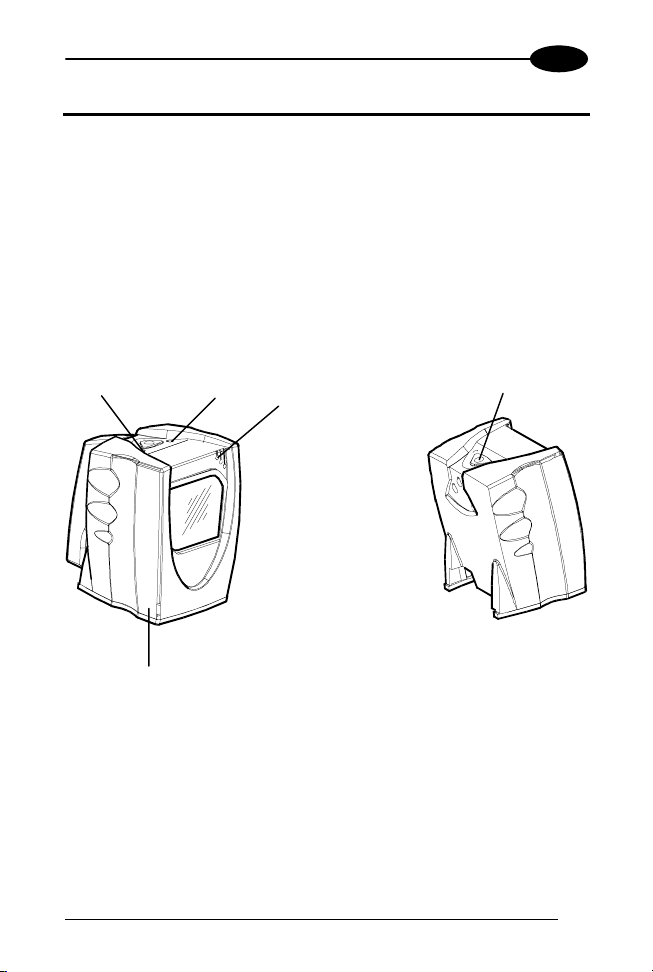

1.1 UNPACKING THE DLL2020

Take the scanner and its accessories out of the box and remove all

packing material s. Refer to the packing lis t in order to ensure that you

have received all the items ordered. Visually inspect the scanner and

accessories for any visible traces of damage. Refer to the figure in

paragraph 1.4 to locate the interface label and verify if the scanner

interface corresponds with the host system interface. Immediately

contact your supplier if anything appears to be damaged, or if the

supported interface does not correspond with the host system interface.

Green Led

Red Led

Good read beeper

Sleep mode switch

Rubber sleeve

1

Page 9

1

The various parts of the DLL2020 are:

Sleep mode switch: If a s leep mode time-out has been programmed,

the scanner can be reactivated by pres sing this switch. The sleep-mode

feature can be programmed us ing the Software Configurat ion Guide part

number 90ACC1620.

The default value for the sleep mode time-out is set to

30 minutes. When the sc anner is in sleep mode, the

LED is intermittently flashing red.

NOTE

Red LED: The red LED indicates that the scanner is ready to read a bar

code.

Green LED: The green LED indicates a good read.

Good read beeper: The beeper sounds whenever data have been

correctly read. The frequency can be adjusted using the Software

Configuration Guide part number 90ACC1620.

Rubber sleeve: A rubber sleeve encloses the scanner. The sleeve

protects the s canner, and t akes care that i t does not s lide when instal led

‘free-standing’ on a counter surf ace. Furthermore, its ergonomic design

makes the unit eas y t o pi ck up; it fits nat ural l y i n the hand.

DLL2020

1.2 AVAILABLE MODELS

The following two models are available:

− DLL2020, standard model

− DLL2021, with single line option (see par. 3.7 for detai l s).

2

Page 10

GETTING STARTED

1

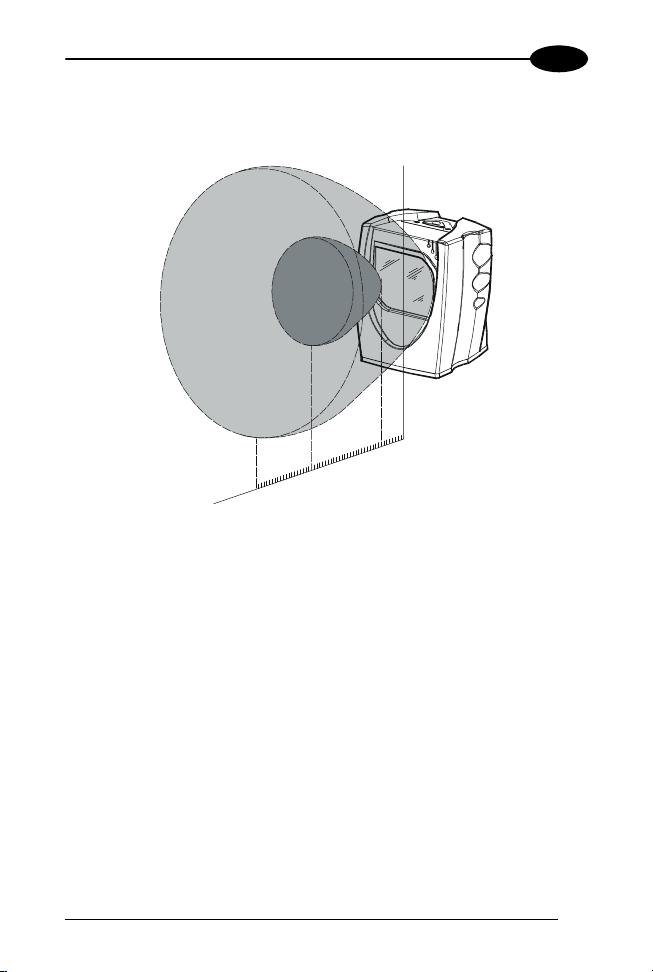

1.3 SCANNING BAR CODES WITH THE DLL2020

15 cm

15 cm

25 cm

X

The DLL2020 is an om ni di rectional scanner featuring a 4-directional scan

field with a 16-line scan pattern. Bar codes can easily be read by

presenting them to the scanner. The scan volume is illustrated in the

figure above. The optimal reading zone li es between 3 and 15 cm from

the scanner window. However, bar codes can s till be read up to 25 cm

(10 inches) from the scanner window.

Z

3 cm

3

Page 11

1

DLL2020

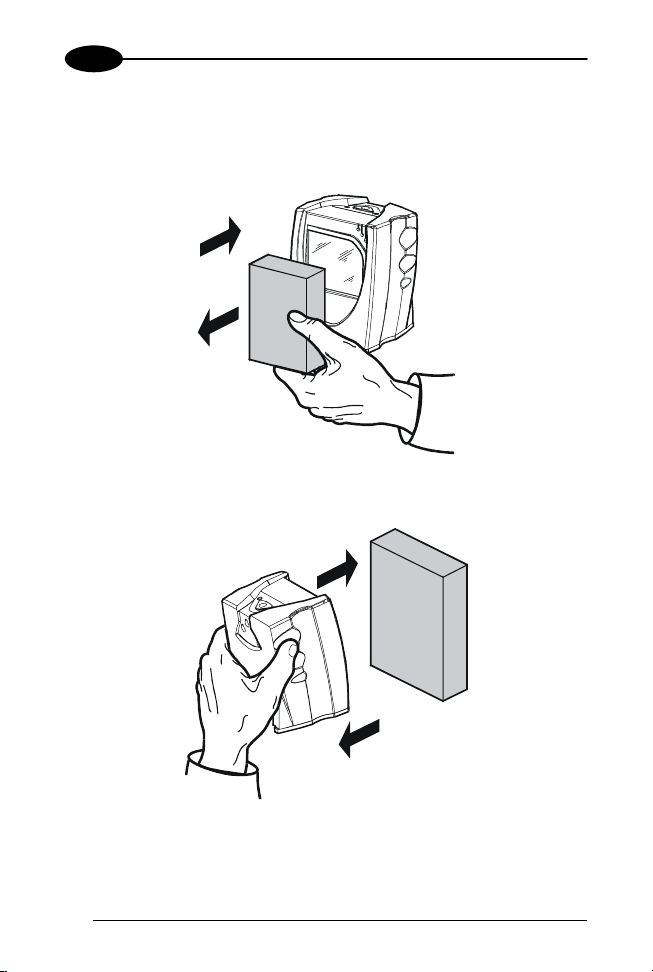

The DLL2020 scanner can be used handsfree as well as hand held,

e.g.:

a) Handsfree scanning by presenting t he i tem to the scanner.

1

1

2

2

b) You can also hold the scanner.

4

1

1

2

2

Page 12

GETTING STARTED

1

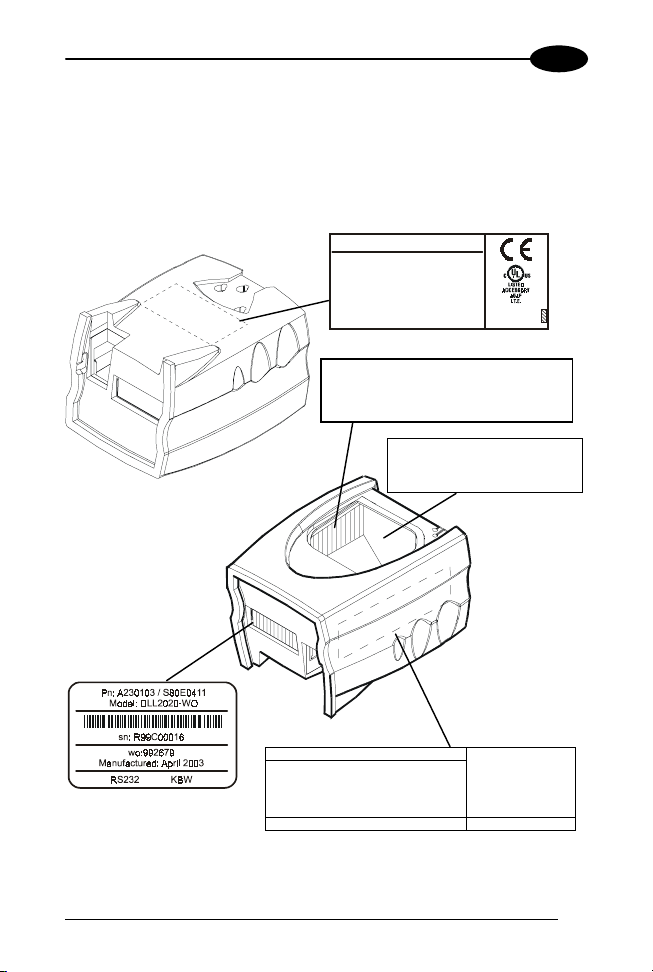

1.4 SCANNER LABELLING

There are four labels on the scanner. The f irst three labels can be found

on the housing of the DLL2020, as indic ated in the figures below. The

fourth label is visible through the scanner window.

All the labels have been attached by the manufac turer and should in no

case be removed.

DATALOGIC SPA - ITALY

CAUTION:

Laser light when open

Do not star e into beam

EN60825-1 (2001) CLASS 1 LASER PRODUCT

Complies with 21 CFR subchapter J as a

CLASS IIA LASER PRODUCT -

avoid long term viewing of direct laser light

+5V

250mA

CAUTION

Laser Radiation When Open

DO NOT STARE INTO BEAM

DO NOT BREAK SEAL

WARRANTY VOID IF SEAL IS BROKEN

NO SERVICEABLE PARTS INSIDE Model DLL2020-W O

DATALOGIC SPA

Via Candini 2

40012 LIPPO DI-

CALDERARA (BO)

ITALY

www.datalogic.it

5

Page 13

1

The scanner’s seri al num ber c an be found under t he bar code label . This

official regist ration number is strictly relat ed to the device. The supplier

may ask for this number when the scanner needs servicing.

DLL2020

Laser safety

English:

The DLL2020 scanner complies with s afety standard EN60825-1 (2001)

for a Class 1 laser product. It also complies with U.S. 21CFR1040 as

applicable to a Class II a laser product. Avoid long term viewing of direct

laser light.

German:

Der Strichcode-Scanner DLL2020 ents pricht den Sicherheitsvorschrif ten

nach EN60825-1 (2001) für ein Laserprodukt der K lasse 1. Er ent spricht

auch U.S. 21CFR1040, anwendbar auf ein Laserprodukt der Klasse II a.

Vermeiden Sie langzeitiges Hineinblicken in direktes Laserlicht.

French:

Le scanner DLL2020 est conforme aux normes de sécurité

EN60825-1 (2001) s’appliquant à un produit laser de la class e 1. Il est

également conform e à la U.S. 21CFR1040 telle qu’ell e s’applique à un

produit laser de la classe IIa. Eviter de rester exposé longtemps à la

lumière directe du laser.

Italian:

Lo scanner DLL2020 è conforme alle norme di sicurezza EN60825-1

(2001) relative ad un prodot to laser di Classe 1. È inoltre conforme alla

norma U.S. 21CFR1040 relativa ad un prodotto laser di Classe IIa.

Evitare l’esposizione prolungata all’emissione diretta di luce laser.

Spanish:

El scanner DLL2020 reune las normas de seguridad EN60825-1 (2001)

para un producto laser de Clase 1. Y también reune las normas U.S.

21CFR1040 que se aplican a un producto laser de Clase IIa.

Se debe evitar mirar muy fijo en luz lasérica direct a.

Optical The use of optical instrum ents with this product will increase eye

hazard. Optical instruments include binoculars, microscopes and

magnifying glasses but do not include eye glasses worn by the user.

6

Page 14

GETTING STARTED

Radiant Energy The DLL2020 uses a low-power laser diode operating

at 650 nm in an opto-mechani cal scanner resulting i n less than 0.7 mW

peak output power.

Laser light observed at 15. 0 cm (5. 9 inch) above the window through a 7

mm (0.28 in.) aperture and averaged over 1000 s econds is less than 3.9

µW per CDRH Class IIa specification. Do not attempt to remove the

protective housing of the scanner, as unsc anned laser light with a peak

output up to 0.90 mW could be accessibl e i nside.

Laser Light Viewer The sc anner window is the only aperture through

which laser light may be observed on t his product.

A failure of the scanner m otor, while the laser diode conti nues to emit a

laser beam, may cause emission levels to exceed those for safe

operation.

The scanner has safeguards to prevent this occurrence. If, however, a

stationary laser beam is emitted, the failing scanner should be

disconnected from i ts power source immediat el y.

Adjustments Do not att empt t o mak e any adjustm ents to or alterat ion of

this product. Do not remove the s canner’s protect ive housing. There are

no user-serviceable parts ins i de.

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous laser light exposure.

CAUTION

1

1.5 MAINTAINING THE SCANNER

The DLL2020 scanner requires little maintenance. Only occasional

cleaning of the scanner window is necess ary in order to remove dirt and

fingerprints. The scanner c an be cleaned during operation. To this end

use a non-abrasive glass spray cl eaner and a soft lint-free cloth onl y.

7

Page 15

1

DLL2020

1.6 CONTROLLING THE SCANNER FROM THE POS SYSTEM

The DLL2020 can be controlled from the POS system via the RS232

interface. Controlling is accomplished by transmitting the following si nglebyte commands to the scanner. In the Datalogic default setting the

following commands are avai l abl e (more details upon request):

Command Description Hex.

Ctrl - E Power-up re-initialization 05 Hex

Ctrl - N Enable decoding 0E Hex

Ctrl - O Disable decoding 0F Hex

Ctrl - R Sleep 12 Hex

Ctrl - T Wake 14 Hex

When the scanner dec oding is disabled, the scanner motor will remain

switched-on until the scanner goes i nto sleep mode.

POS system

DLL2020

Scanner control

8

Page 16

INSTALLING THE DLL2020

2

2 INSTALLING THE DLL2020

2.1 CONNECTING THE SCANNER

This chapter describes the instructions necessary for installing the

DLL2020 scanner.

Due to many POS systems on the market, a large number of

communication cables is available. Make sure that you have the right

cable to connect the scanner to your POS or computer.

The scanner and the host system must be switched off

before starting the installation of the scanner. By

following this precaution you prevent any electrical

damage.

NOTE

Follow these steps carefully in order to install the scanner:

1. Locate the optimal scanner position in relation to the counter

surface.

Pay attention to the product flow, the distance to the counter edge

and convenience for the operator.

2. You have two options to connect the scanner to your POS or

computer.

You are advised to install the scanner in an air

circulated place out of di rect sunlight.

9

Page 17

2

DLL2020

2.1.1 RS232 Direct Power

For those systems which supply electrical power on the serial port

(minimal requirements: +5 V dc, 250 mA), the following setup is

applicable.

Plug the cab 376 into the sc anner port until a firm ‘click’ is heard.

Connect the serial cable to the cab 376 and the other end to the

appropriate serial port of your POS or computer.

DLL2020

Cable 376

To host

2.1.2 Keyboard Wedge Direct Power

For those systems which supply electrical power on the keyboard port

(minimal requirements: +5 V dc, 250 mA), the following setup is

applicable.

Plug the cab 376 into the sc anner port until a firm ‘click’ is heard.

Connect the wedge cable to the cab 376 and the other end to the

keyboard.

10

DLL2020

Cable 376

To computer

To keyboard

Computer

Page 18

INSTALLING THE DLL2020

2

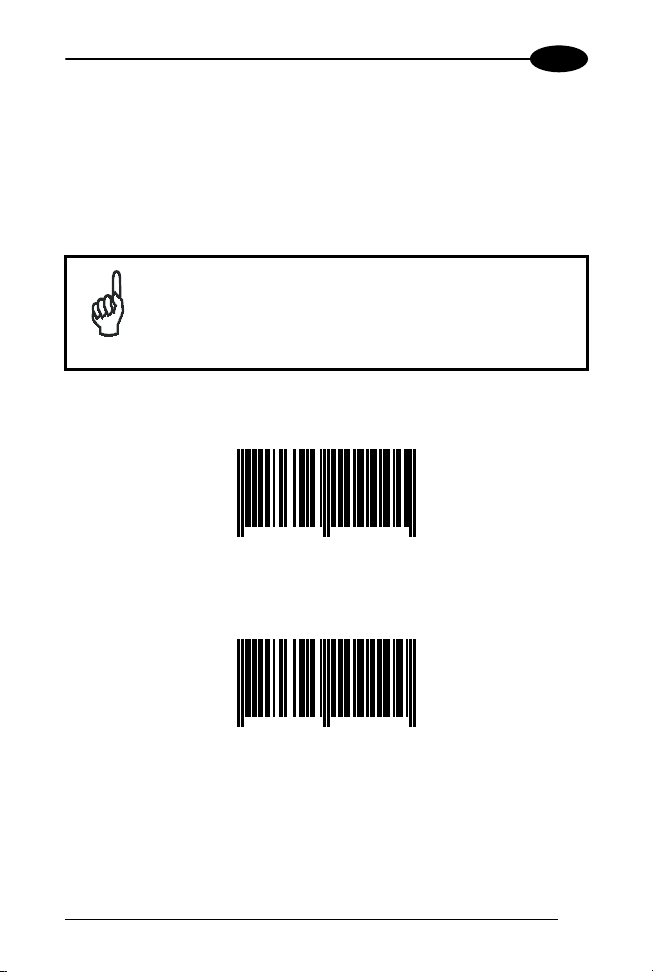

2.2 INTERFACE SELECTION

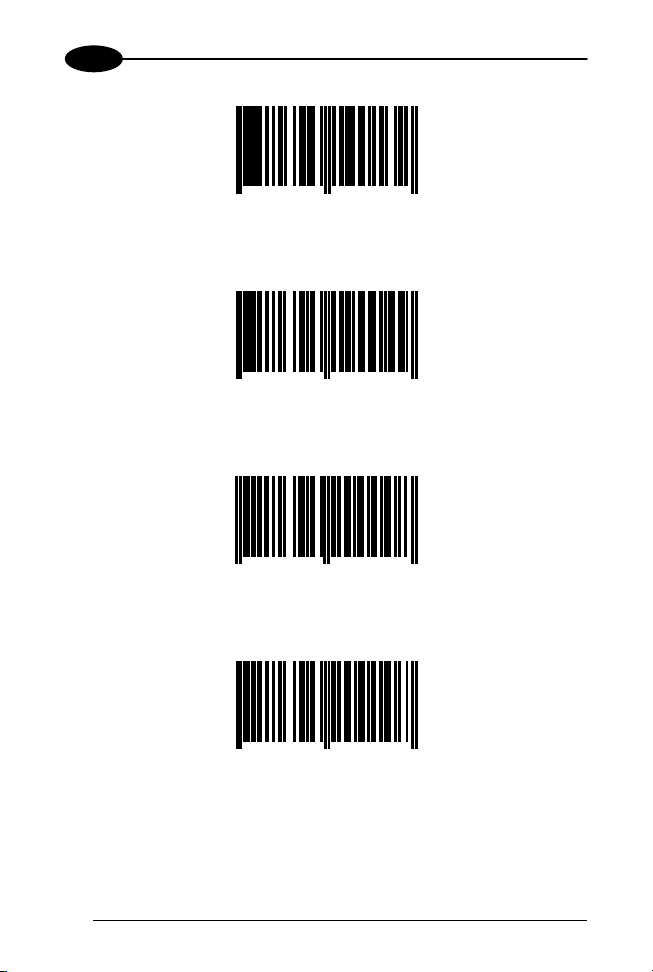

To select the scanner int erf ace scan the following codes:

1. read the "Enter/Exit and Save Programming Mode" code;

2. scan either "RS232 default" code or "Keyboard Wedge default"

code.

RS232 is the factory default interface.

NOTE

Enter/Exit and Save Programming Mode

8 712345 100001

RS232 Default

8 712345 100100

Programming Mode is cl osed after scanning this c ode.

11

Page 19

2

Keyboard Wedge Default

DLL2020

8 712345 100131

Programming Mode is cl osed after scanning this c ode.

12

Page 20

CONFIGURATION

3

3 CONFIGURATION

The present manual provides information on how to set the

DLL2020 reader in operation, as wel l as to set up its basic

configuration parameters.

Additional customized configurations are also available

NOTE

3.1 CHANGE SCANNER SETTINGS

In order to change the scanner settings please follow the sequence

below:

1. Enter the scanner P rogramming Mode by scanning the Enter/Exit

2. Change Scanner Settings by scanning the desired codes from

3. Exit the scanner Programming Mode by scanning the Enter/Exit

Reading the Enter/Exit code in par. 3.4 gives a double tone beep (Low

High).

Example:

For changing the keyboard to German the following codes must be

scanned success i vel y:

"Enter/Exit and Save Programming Code", "German", "Enter/Exit and

Save Programming Code".

After reading a valid configuration barcode in Programming Mode the

scanner will give a High beep.

The scanner will generate a Low beep after receiving an unexpected

code.

At any moment (in Programming Mode) you can scan the "Return to

Factory Default Settings" code to return to default s ettings.

by changing basic parameters: please refer to the

Software Configuration Manual (Part No. 90ACC1620)

for a complete list of codes and procedures.

code (see par. 3.4);

par. 3.5 to par. 3.9.

code in par. 3.4.

13

Page 21

3

3.2 FACTORY DEFAULT SETTINGS

DLL2020

Configuration Field Default Setting

Sleep Mode

Sleep mode After 30 minutes

Scanner Timing

Same code delay 600 msec

RS232

Baudrate 9600

Parity None

Data bits 8

Stop bits 2

RTS/CTS Off

Terminator <CR>

Keyboard Wedge

PC Terminal type PC/AT

Keyboard International (Alt method)

Caps Lock OFF

Intercharacter delay 2 msec

Terminator Enter (Alphanumeric)

Operating Parameters

Freeze Frame disabled

Single Line(DLL2021 models only) disabled

Code Selection

EAN/UPC On (ADD ON not sent)

Code 128/EAN 128 Off

Code 39 Off

Code 32 Off

Codabar Off

Interleaved 2/5 Off

Code Length

Min. length Interleaved 2/5 8

Data Formatting

Code Identifiers Off

14

Page 22

CONFIGURATION

3.3 DEFAULT MESSAGE FORMAT

Code Message Format

EAN13 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13

EAN8 D1 D2 D3 D4 D5 D6 D7 D8

UPCA D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12

UPCE D1 D2 D3 D4 D5 D6 D7

Code 128 D1 - Dx

EAN 128 ]C1 D1 - Dx

Code 39 D1 - Dx

Code 32 D1 - Dx

Codabar D1 - Dx

Interleaved 2/5 D1 - Dx

EAN/UPC codes wit h ADD ON are transmitted without

a separator.

NOTE

3

15

Page 23

3

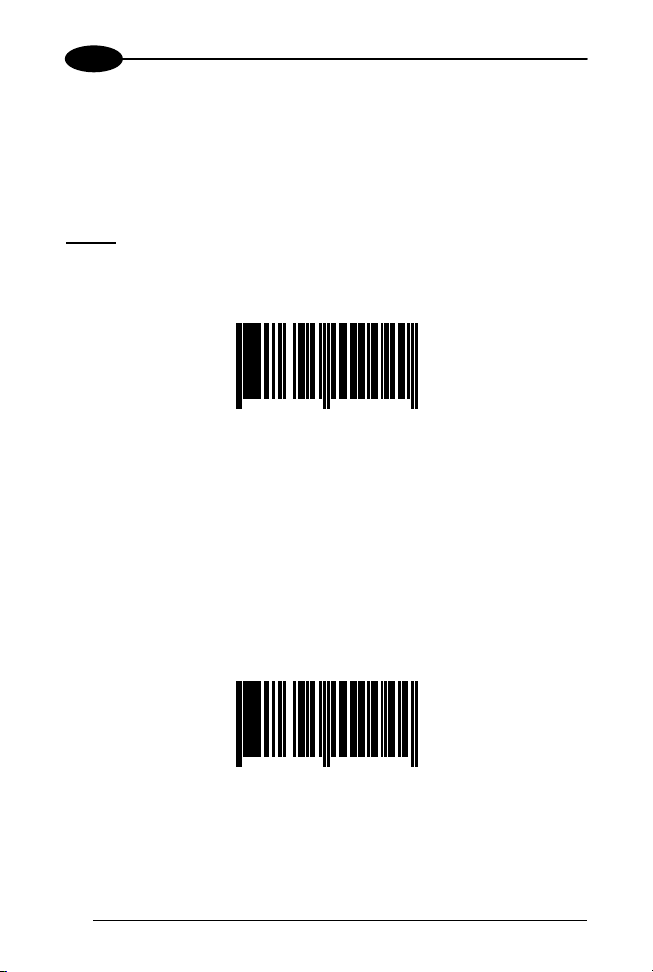

3.4 EDITING COMMANDS

Enter/Exit and Save Programming Mode

DLL2020

8 712345 100001

Restore Factory Default

8 712345 100087

Return to Custom Default Setting s

8 712345 100070

16

Page 24

CONFIGURATION

3

3.5 RS232

RS232 Presets

Each of the following barcode selections enable a complete preset

parameter configuration for correct use with the respective POS

Terminal.

The scanner must first be set with the RS232 interface selec tion (see

par.2.2).

Wincor Nixdorf Beetle Mode A1

8 712345 190101

Wincor Nixdorf Beetle Mode A2

8 712345 190118

Wincor Nixdorf Beetle Mode B1

8 712345 190125

17

Page 25

3

Wincor Nixdorf Beetle Mode B2

DLL2020

8 712345 190132

Wincor Nixdorf Beetle Mode B3

8 712345 190149

ICL Mode

8 712345 200008

Fortronic (UK) Mode

8 712345 200107

18

Page 26

CONFIGURATION

3.6 KEYBOARD WEDGE

PC/Terminal Type

PC/XT

3

8 712345 400002

PC/AT (Default)

8 712345 400019

PC PS2

8 712345 400026

IBM 347 x terminals

8 712345 400033

19

Page 27

3

IBM 3179 x terminal

DLL2020

8 712345 400040

Keyboard Nationality

International Keyboard (ALT Method)(Default)

8 712345 400200

8 712345 400217

US

UK

20

8 712345 400224

Page 28

CONFIGURATION

3

French

8 712345 400231

German

8 712345 400248

Spanish

8 712345 400255

21

Page 29

3

3.7 OPERATING PARAMETERS

Scanning Mode

Two different options are available to defi ne t he scanning mode:

− Freeze Frame mode;

− Single Line mode;

reading the code enabling the desired mode it is necessary to

Before

read the following code starting the procedure:

Scanning Mode

DLL2020

8 712345 150020

Freeze Frame Mode

The Freeze Frame m ode is a special trigger mode allowing to aim t he

laser pattern on the code before reading.

To work in this mode:

1. Press the DLL2020 trigger. The laser pattern starts blinking but the

scanner does not read the code;

2. Move the scanner towards the barcode (zoom-in);

3. Release the scanner trigger to read the barcode.

Freeze Frame ON

8 712345 150044

22

Page 30

CONFIGURATION

Single Line Mode (DLL2021 only)

The single line option allows tem porarily switching from full scan pattern

to a single scan line preventing the wrong barcode to be read. This

feature is especially helpful on sheets or products where multiple

barcodes are printed.

To use this option proceed as f ol l ows:

1. Press the button on top of the scanner t o switch from the full scan

pattern to a single scan li ne;

2. Aim t he singl e sc an line on t he barcode t o be scanned while holding

the button;

3. Make the line to completely cross the barcode, then release the

button. A beep indicates the barcode has been accepted by the

scanner;

4. After successful reading the s ingle line blinks. During the scan line

blinking, the scanner will not read a barcode. Af ter one second, the

scanner will return to normal m ode. I f pres sing t he trigger during t he

scan line blinking, the single line procedure will start again.

Single Line ON

3

8 712345 150051

23

Page 31

3

3.8 CODE SELECTION

All EAN/UPC ON (ADD ON not sent) (Default)

DLL2020

8 712345 141011

All EAN/UPC OFF

8 712345 141004

Code 128/EAN 128 ON

8 712345 143107

Code 128/EAN 128 OFF

8 712345 143114

24

Page 32

CONFIGURATION

3

Code 39 ON

8 712345 143015

Code 39 OFF

8 712345 143053

CODABAR ON

8 712345 143022

CODABAR OFF

8 712345 143060

25

Page 33

3

Interleaved 2/5 ON

DLL2020

8 712345 142025

Interleaved 2/5 OFF

8 712345 142001

26

Page 34

CONFIGURATION

3

3.9 DATA FORMATTING

Pre-defined Terminators

To program the terminator string follow the given procedure:

1) If not working in Programming Mode, s can the "Enter/Exit and Save

Programming Mode" code;

2) Choose the desired pre-defined term i nator from the list below

3) Scan the "Enter/Exit and Save Programming Mode" code OR

configure other parameters.

Terminator = CR

8 712345 110505

Terminator = LF

8 712345 110611

Terminator = CR + LF

8 712345 110512

27

Page 35

3

DLL2020

Code Identifiers

A code identifier is a dat a string, giving information to the host system

concerning the barcode type that has been read After scanning the

"Enable Default Code Identifiers" code, the scanner is configured to

transmit data according to the following format:

CODE CODE IDENTIFIER MESSAGE FORMAT

EAN13 F D1 D2 D3 D4 D5 D6 D7 D8 D9

EAN8 FF D1 D2 D3 D4 D5 D6 D7 D8

UPCA A D1 D2 D3 D4 D5 D6 D7 D8 D9

UPCE E 0 D1 D2 D3 D4 D5 D6

Code 128 # D1 Dx

EAN 128 P ]C1 D1 Dx

Code 39 * D1 Dx

Code 32 * D1 Dx

Codabar % D1 Dx

Interleaved 2/5 i D1 Dx

The UPCE format will be changed. The scanner will

transmit UPCE codes wi th leading 0 and w ithout c heck

digit.

NOTE

To return to the default form at without code identifi ers read the "Disable

Code Identifiers" code.

D10 D11 D12 D13

D10 D11 D12

28

Page 36

CONFIGURATION

3

Enable Default Code Identifiers

8 712345 110475

Disable Code Identifiers

8 712345 110468

29

Page 37

A

CONNECTOR AND PIN DEFINITIONS

A

The DLL2020 has a dual interface: RS232/Keyboard Wedge. The pin

definition for the scanner port and the connector to be used for the port

are shown in the connection diagram below.

PIN DESCRIPTION

Pin 1

RJ-48 PCB

(front view)

Scanner port

NOTE

Pin 10

Use approved Datalogic cables onl y.

1 PC - CLOCK

2 CTS

3 RXD

4 TXD

5 RTS

6 GND

7 +5V

8 KB - DATA

9 KB - CLOCK

10 PC - DATA

Pin 1

RJ-48 Cable-connect o r

(front view)

10 pin connector

DLL2020

Pin 10

Slot for screwdriver

30

1

2

Locking pin

Page 38

TECHNICAL FEATURES

TECHNICAL FEATURES

B

Electrical Features

Input power to scanner +5 Vdc t o +5. 25 Vdc, 250 mA

Dual interface RS232/Keyboard W edge

Adapter Cable Cab 376

Optical Features

Light source Visibl e l aser diode (650 nm)

Depth of field 250 mm

Scan pattern 4 directions, 16 lines

Scan rate 800 scans/seconds

Decoding Features

Barcode types EAN/UPC/JAN + Add ON

Code 128, EAN 128, Code 39, Code 32,

Codabar, ITF

B

31

Page 39

B

S

Physical Features

Weight 0.3 kg

Dimensions

(L x W x D)

Front view

100 x 80 x 60 mm

3.9 x 3.1 x 2.4 in

ide view

98.8 mm

DLL2020

8.00°

78.2 mm

Environmental Features

Operating Temperature 0° to + 40 °C

Humidity 0% to 95% RH (non-condensing)

Safety Features

Laser safety EN60825-1 (2001) class 1, U.S. 21CFR1040

Class Ila

Electrical safety EN 60950 second edition UL1950 (third

edition), c-UL (according CSA22.2.950-95)

EM Compatibility

Radio and TV interference EN 55022 Class B (1994), FCC

part 15 Class A (1992)

Harmonic current emi ssions EN 61000-3-2 (1995)

EM-immunity EN 50082-1 (1992) based on:

ElectroStatic Discharge (ESD) IEC 801-2 (1991)

Radio frequency immunity IEC 801-3 (1984) / ENV 50140

(1993)

Electrical fast transient IEC 801-4 (1998)

32

Page 40

TROUBLESHOOTING

TROUBLESHOOTING

C

Problem Diagnostic Tips

The scanner is on but a

barcode cannot be read. The

LED is red.

The scanner is on, but the

motor is not rotating. A

barcode cannot be read. The

LED is intermittently flashing

red.

The red LED and green LED

are alternating.

The red LED and green LED

are alternating and beeps are

heard.

The scanner does not accept

more than two or three

barcodes.

Both the red LED and green

LED are on.

C

• The scanner window is dirty. Clean

the scanner window as described

in the Maintenance section.

• The presented barcode type is not

enabled. Select the barcode type

with the Configuration Guide.

• The scanner is disabled by the

host. Refer to par. 1.6.

• The barcode type you presented to

the scanner is not supported by

DLL2020.

• The scanner is in sleep mode.

Press the switch on top of the

scanner to reactivate the scanner

(or use the wake protocol. Refer to

par. 1.6).

• Mirror motor is defective and m ust

be replaced (Authorized personnel

only).

• Possible failure of the scanning

safeguard circuit. Immediately

disconnect the scanner from its

power source. Contact your

supplier.

• There is no proper handshaking

with the host system. Switch the

host system on and check

connection and communication

settings.

• The laser is not functioning. The

laser is defective. Contact your

supplier.

33

Page 41

C

Problem Diagnostic Tips

Both the red LED and green

LED are blinking.

The green LED stays on.

A barcode is read by the

scanner but not accept ed by

the host system.

DLL2020

• The ambient temperature is too

high. Make sure the scanner has

enough air ventilation and is not

placed in direct sunlight.

• The scanner is continuously seeing

a barcode. Remove all barcode

labels from the sc an volume of the

scanner and try again.

• The scanner cannot send the data

to the host system. There is no

proper handshaking between the

scanner and the host. Scanner

buffer is full. Make sure that all

cables are connected and your

host system is ready to receive

data.

• The scanner is in test mode.

Power off and on the scanner.

• The communication cable is not

connected to the seri al port of your

host system. Refer to the manual

of your host system to locate the

serial port.

• The communication sett ings of the

host and scanner do not match.

Ensure that the setting value for

both devices are the same. For

proper adjustment values see the

Software Configuration Guide.

• The communication cabl e does not

suit your host system. Contact your

supplier for the correct

communicati on cable.

• The data format is not supported

by the software running on the host

system.

34

Page 42

DATALOGIC S.p.A.,

Via Candini, 2

40012 - Lippo di Calderara

dichiara che

declares that the

déclare que le

bescheinigt, daß das Gerät

declare que el

DLL202X-XX Presentation Scanner

e tutti i suoi modelli

and all its models

et tous ses modèles

und seine modelle

y todos sus modelos

sono conformi alle Direttive del Consiglio Europeo sottoelencate:

are in conformity with the requirements of the European Council Directives listed below:

sont conformes aux spécifications des Directives de l'Union Européenne ci-dessous:

den nachstehenden angeführten Direktiven des Europäischen Rats:

cumple con los requisitos de las Directivas del Consejo Europeo, según la lista siguiente:

89/336/EEC EMC Directive e 92/31/EEC, 93/68/EEC emendamenti successivi

and further amendments

et ses successifs amendements

und späteren Abänderungen

y succesivas enmiendas

Basate sulle legislazioni degli Stati membri in relazione alla compatibilità elettromagnetica ed alla

sicurezza dei prodotti.

On the approximation of the laws of Member States relating to electromagnetic compatibility and

product safety.

Basées sur la législation des Etates membres relative à la compatibilité électromagnétique et à la

sécurité des produits.

Über die Annäherung der Gesetze der Mitgliedsstaaten in bezug auf elektromagnetische

Verträglichkeit und Produktsicherheit entsprechen.

Basado en la aproximación de las leyes de los Países Miembros respecto a la compatibilidad

electromagnética y las Medidas de seguridad relativas al producto.

Questa dichiarazione è basata sulla conformità dei prodotti all e norme seguenti:

This declaration is based upon compliance of the products to the following standards:

Cette déclaration repose sur la conformité des produits aux normes suivantes:

Diese Erklärung basiert darauf, daß das Produkt den folgenden Normen entspricht:

Esta declaración se basa en el cumplimiento de los productos con las siguientes normas:

EN 55022, August 1994: L

EN 55024, September 1998: I

Lippo di Calderara, 25/06/2001

Ruggero Cacioppo

Quality Assurance Supervisor

Bologna - Italy

IMITS AND METHODS OF MEASUREMENTS OF RADIO

DISTURBANCE CHARACTERISTICS OF INFORMATION

TECHNOLOGY EQUIPM E NT

NFORMATION TECHNOLOGY EQUIPMENT, IMMUNITY

CHARACTERISTICS

MEASUREMENTS

(ITE)

IMITS AND METHODS OF

. L

Loading...

Loading...