Page 1

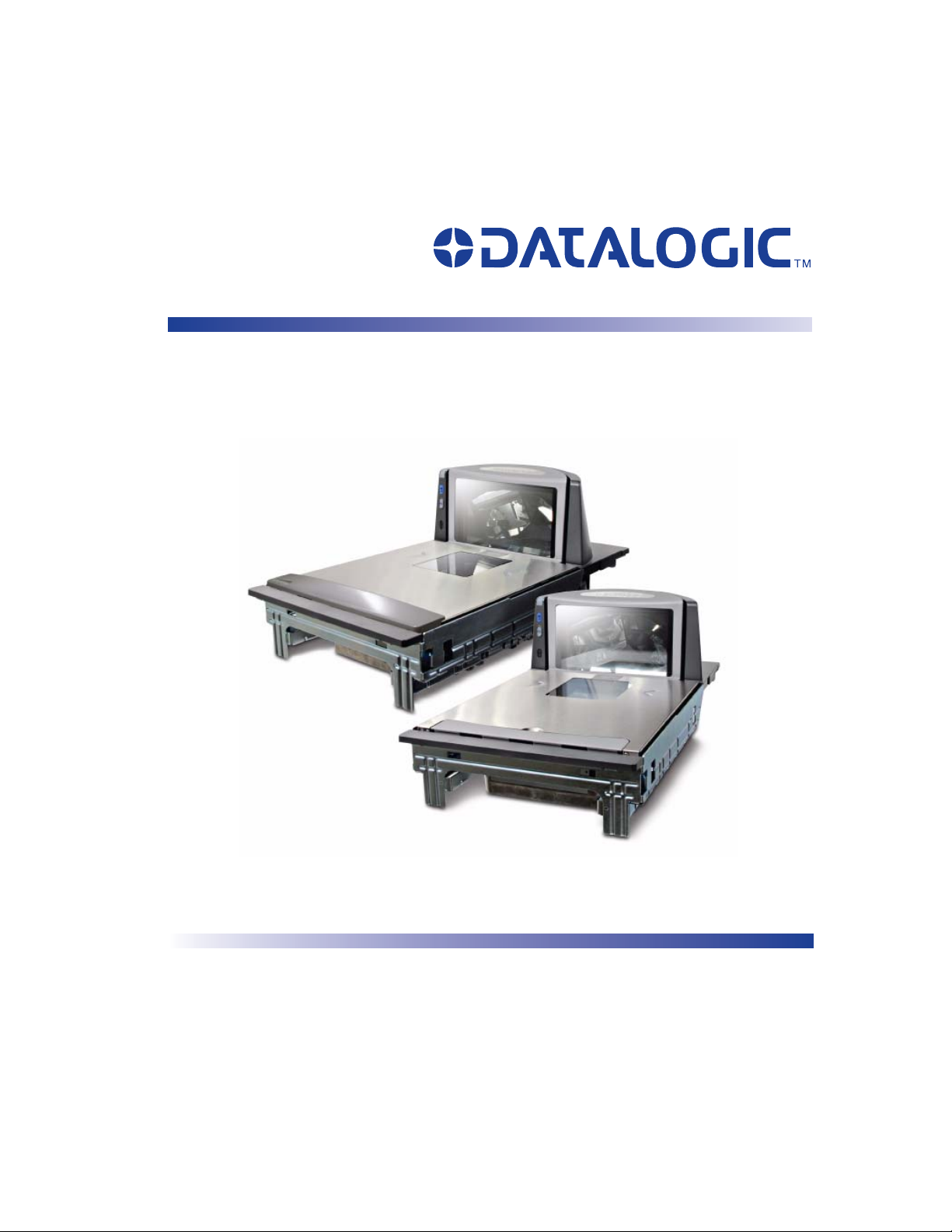

Magellan® 8300/8400

Product Reference Guide

Page 2

Datalogic Scanning, Inc.

959 Terry Street

Eugene, Oregon 97402

Telephone: (541) 683-5700

Fax: (541) 345-7140

An Unpublished Work - All rights reserved. No part of the contents of this documentation or the procedures

described therein may be reproduced or transmitted in any form or by any means without prior written permission of

Datalogic Scanning, Inc. or its subsidiaries or affiliates ("Datalogic" or “Datalogic Scanning”). Owners of Datalogic

products are hereby granted a non-exclusive, revocable license to reproduce and transmit this documentation for

the purchaser's own internal business purposes. Purchaser shall not remove or alter any proprietary notices,

including copyright notices, contained in this documentation and shall ensure that all notices appear on any reproductions of the documentation.

Should future revisions of this manual be published, you can acquire printed versions by contacting your Datalogic

representative. Electronic versions may either be downloadable from the Datalogic website (www.scanning.datalogic.com) or provided on appropriate media. If you visit our website and would like to make comments or suggestions about this or other Datalogic publications, please let us know via the "Contact Datalogic" page.

Disclaimer

Datalogic has taken reasonable measures to provide information in this manual that is complete and accurate,

however, Datalogic reserves the right to change any specification at any time without prior notice.

Datalogic is a registered trademark of Datalogic S.p.A. in many countries and the Datalogic logo is a trademark of

Datalogic S.p.A. All other brand and product names referred to herein may be trademarks of their respective owners.

This product may be covered by one or more of the following patents: 4603262 • 4639606 • 4652750 • 4672215 • 4699447 • 4709369 • 4749879

• 4786798 • 4792666 • 4794240 • 4798943 • 4799164 • 4820911 • 4845349 • 4861972 • 4861973 • 4866257 • 4868836 • 4879456 • 4939355 •

4939356 • 4943127 • 4963719 • 4971176 • 4971177 • 4991692 • 5001406 • 5015831 • 5019697 • 5019698 • 5086879 • 5115120 • 5144118 •

5146463 • 5179270 • 5198649 • 5200597 • 5202784 • 5208449 • 5210397 • 5212371 • 5212372 • 5214270 • 5229590 • 5231293 • 5232185 •

5233169 • 5235168 • 5237161 • 5237162 • 5239165 • 5247161 • 5256864 • 5258604 • 5258699 • 5260554 • 5274219 • 5296689 • 5298728 •

5311000 • 5327451 • 5329103 • 5330370 • 5347113 • 5347121 • 5371361 • 5382783 • 5386105 • 5389917 • 5410108 • 5420410 • 5422472 •

5426507 • 5438187 • 5440110 • 5440111 • 5446271 • 5446749 • 5448050 • 5463211 • 5475206 • 5475207 • 5479011 • 5481098 • 5491328 •

5493108 • 5504350 • 5508505 • 5512740 • 5541397 • 5552593 • 5557095 • 5563402 • 5565668 • 5576531 • 5581707 • 5594231 • 5594441 •

5598070 • 5602376 • 5608201 • 5608399 • 5612529 • 5629510 • 5635699 • 5641958 • 5646391 • 5661435 • 5664231 • 5666045 • 5671374 •

5675138 • 5682028 • 5686716 • 5696370 • 5703347 • 5705802 • 5714750 • 5717194 • 5723852 • 5750976 • 5767502 • 5770847 • 5786581 •

5786585 • 5787103 • 5789732 • 5796222 • 5804809 • 5814803 • 5814804 • 5821721 • 5822343 • 5825009 • 5834708 • 5834750 • 5837983 •

5837988 • 5852286 • 5864129 • 5869827 • 5874722 • 5883370 • 5905249 • 5907147 • 5923023 • 5925868 • 5929421 • 5945670 • 5959284 •

5962838 • 5979769 • 6000619 • 6006991 • 6012639 • 6016135 • 6024284 • 6041374 • 6042012 • 6045044 • 6047889 • 6047894 • 6056198 •

6065676 • 6069696 • 6073849 • 6073851 • 6094288 • 6112993 • 6129279 • 6129282 • 6134039 • 6142376 • 6152368 • 6152372 • 6155488 •

6166375 • 6169614 • 6173894 • 6176429 • 6188500 • 6189784 • 6213397 • 6223986 • 6230975 • 6230976 • 6244510 • 6259545 • 6260763 •

6266175 • 6273336 • 6276605 • 6279829 • 6290134 • 6290135 • 6293467 • 6303927 • 6311895 • 6318634 • 6328216 • 6332576 • 6332577 •

6343741 • 6454168 • 6478224 • 6568598 • 6578765 • 6705527 • 6857567 • 6974084 • 6991169 • 7051940 • 7170414 • 7172123 • 7201322 •

7204422 • 7215493 • 7224540 • 7234641 • 7243850 • 7374092 • 601 26 118.6 • AU703547 • D312631 • D313590 • D320011 • D320012 •

D323492 • D330707 • D330708 • D349109 • D350127 • D350735 • D351149 • D351150 • D352936 • D352937 • D352938 • D352939 • D358588

• D361565 • D372234 • D374630 • D374869 • D375493 • D376357 • D377345 • D377346 • D377347 • D377348 • D388075 • D446524 •

EP0256296 • EP0260155 • EP0260156 • EP0295936 • EP0325469 • EP0349770 • EP0368254 • EP0442215 • EP0498366 • EP0531645 •

EP0663643 • EP0698251 • EP01330772 • GB2252333 • GB2284086 • GB2301691 • GB2304954 • GB2307093 • GB2308267 • GB2308678 •

GB2319103 • GB2333163 • GB2343079 • GB2344486 • GB2345568 • GB2354340 • ISR107546 • ISR118507 • ISR118508 • JP1962823 •

JP1971216 • JP2513442 • JP2732459 • JP2829331 • JP2953593 • JP2964278 • MEX185552 • MEX187245 • RE37166 • RE40.071 • Other Patents Pending

Page 3

Table of Contents

Chapter 1. Introduction .................................................................................... 1-1

Manual Overview ..........................................................................................................1-1

How to Use This Manual ..........................................................................................1-2

Technical Support .........................................................................................................1-4

Datalogic Website Support .......................................................................................1-4

Datalogic Website TekForum ....................................................................................1-4

Reseller Technical Support .......................................................................................1-4

Telephone Technical Support ....................................................................................1-4

Scanner and Scanner/Scale Nomenclature .......................................................................1-5

Connections .................................................................................................................1-6

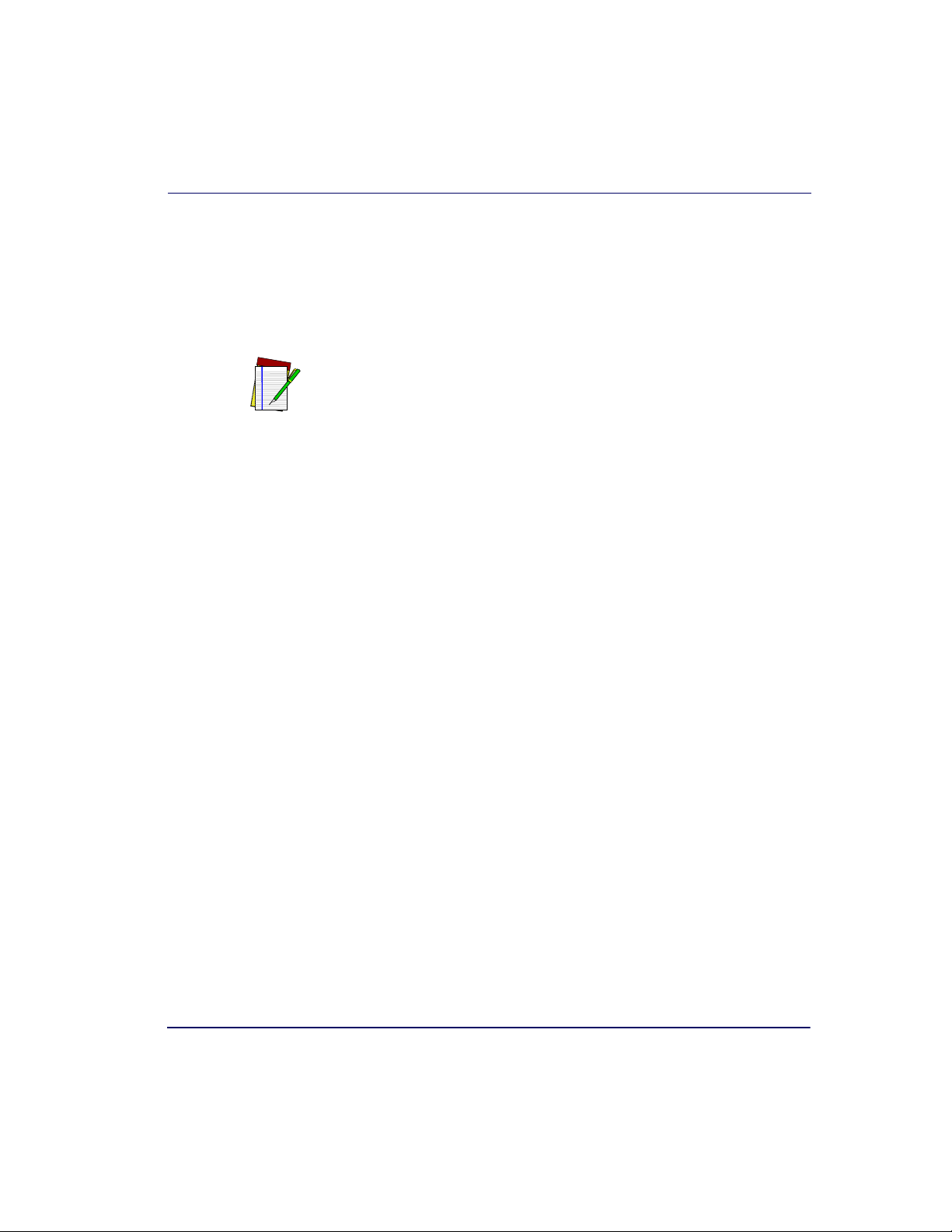

Physical Parameters ......................................................................................................1-7

Scanning ...............................................................................................................1-7

Deactivating EAS Labels ..........................................................................................1-7

Weighing ...............................................................................................................1-8

Warm-Up Time .......................................................................................................1-9

Electrical Specifications ................................................................................................ 1-10

Power Supply ....................................................................................................... 1-11

Laser and Product Safety .............................................................................................1-12

Canadian Notice ...................................................................................................1-13

Labeling ....................................................................................................................1-14

Agency Compliances ...................................................................................................1-15

Bar Codes Supported ..................................................................................................1-17

Retail Codes ........................................................................................................ 1-17

Industrial Codes ...................................................................................................1-17

Dual Bar Codes for Japan (2 label read) ................................................................... 1-18

Chapter 2. Site Preparation and Installation..................................................... 2-1

Models ........................................................................................................................2-2

Pre-Installation Considerations .......................................................................................2-3

Checkstand Design .......................................................................................................2-4

Scanner Installation ......................................................................................................2-5

Scanner Maintenance ....................................................................................................2-5

References ...................................................................................................................2-5

Scanner Usage .............................................................................................................2-5

Site Preparation Overview ..............................................................................................2-6

Ventilation and Spacing .................................................................................................2-8

Service Access ...........................................................................................................2-10

Power Installation .......................................................................................................2-11

Grounding ...........................................................................................................2-11

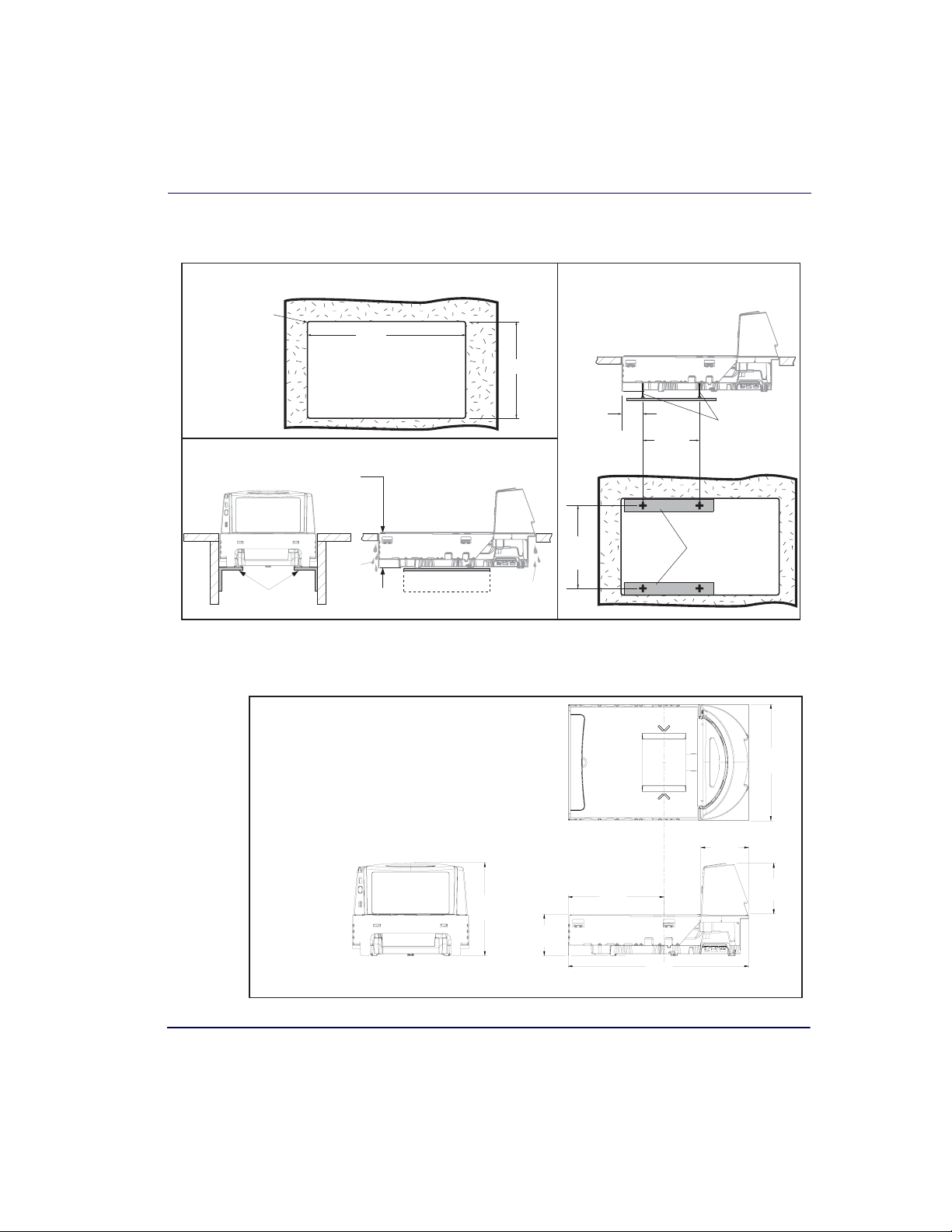

Checkstand Preparation ............................................................................................... 2-12

Liquid Spills and Moisture ......................................................................................2-13

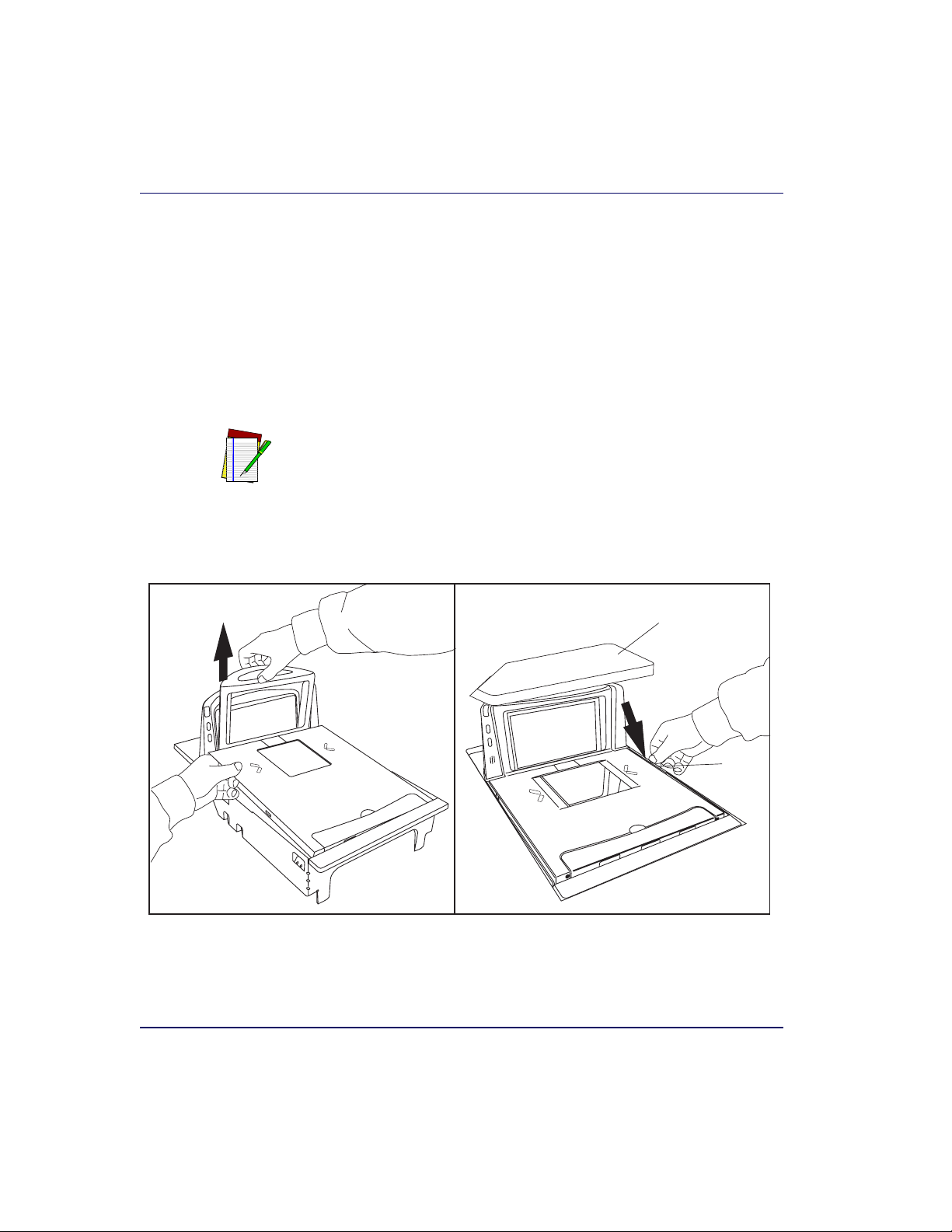

Counter Cutout ........................................................................................................... 2-13

Checkstand Mounting ............................................................................................ 2-21

Checkstand Vibration ............................................................................................2-21

Installation Overview ................................................................................................... 2-21

Unpacking ...........................................................................................................2-22

Product Reference Guide i

Page 4

Operational Verification .........................................................................................2-23

Diagnostic Modes .................................................................................................. 2-26

Cables & Connections ............................................................................................ 2-27

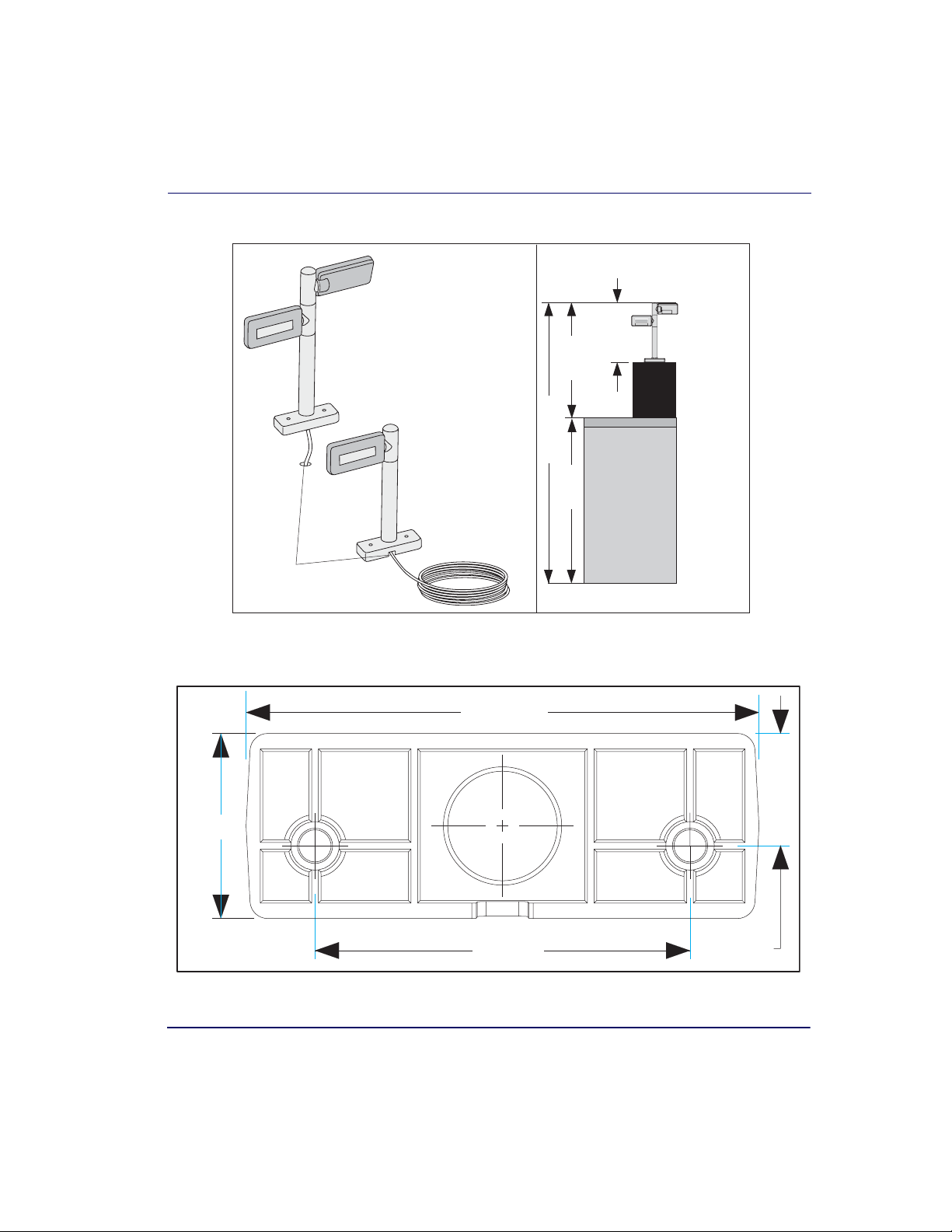

Remote Scale Display Placement/Installation ..................................................................2-29

Lighting Considerations .........................................................................................2-29

Viewing Angle ......................................................................................................2-30

Remote Display Cabling ......................................................................................... 2-31

Placing and Installing the Remote Scale Display ........................................................ 2-31

Changing Weighing Modes .....................................................................................2-34

Set-Up & Installation ...................................................................................................2-34

Set-up ................................................................................................................2-34

Installation ..........................................................................................................2-36

Adaptive Scale Platter Option .................................................................................2-38

System Power-Up Recap ..............................................................................................2-39

Chapter 3. Operation and Maintenance ............................................................ 3-1

Scanning Items ..................................................................................................... 3-1

Deactivating Security Labels .................................................................................... 3-3

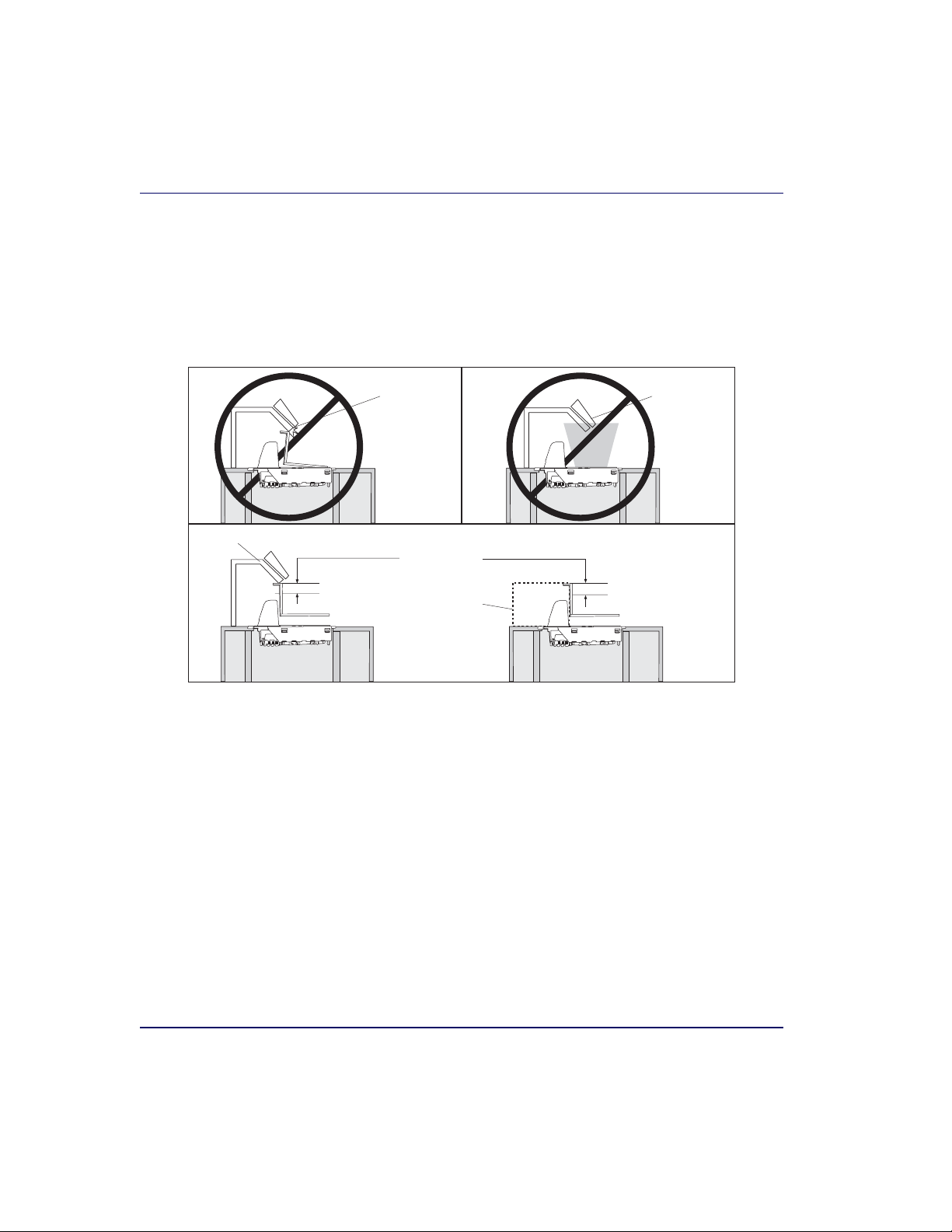

Proper Weighing Technique ..................................................................................... 3-4

Operational Controls ..................................................................................................... 3-5

Operational Modes ....................................................................................................... 3-5

Power-Up/Selftest & Pre-Operation ........................................................................... 3-5

Operating Mode ..................................................................................................... 3-7

Additional Functions ..................................................................................................... 3-8

Programming ........................................................................................................ 3-8

Diagnostic Mode .................................................................................................... 3-8

Scanner and Scale Reset ........................................................................................ 3-9

Scale Adjustments ................................................................................................. 3-9

Operational Maintenance ..............................................................................................3-11

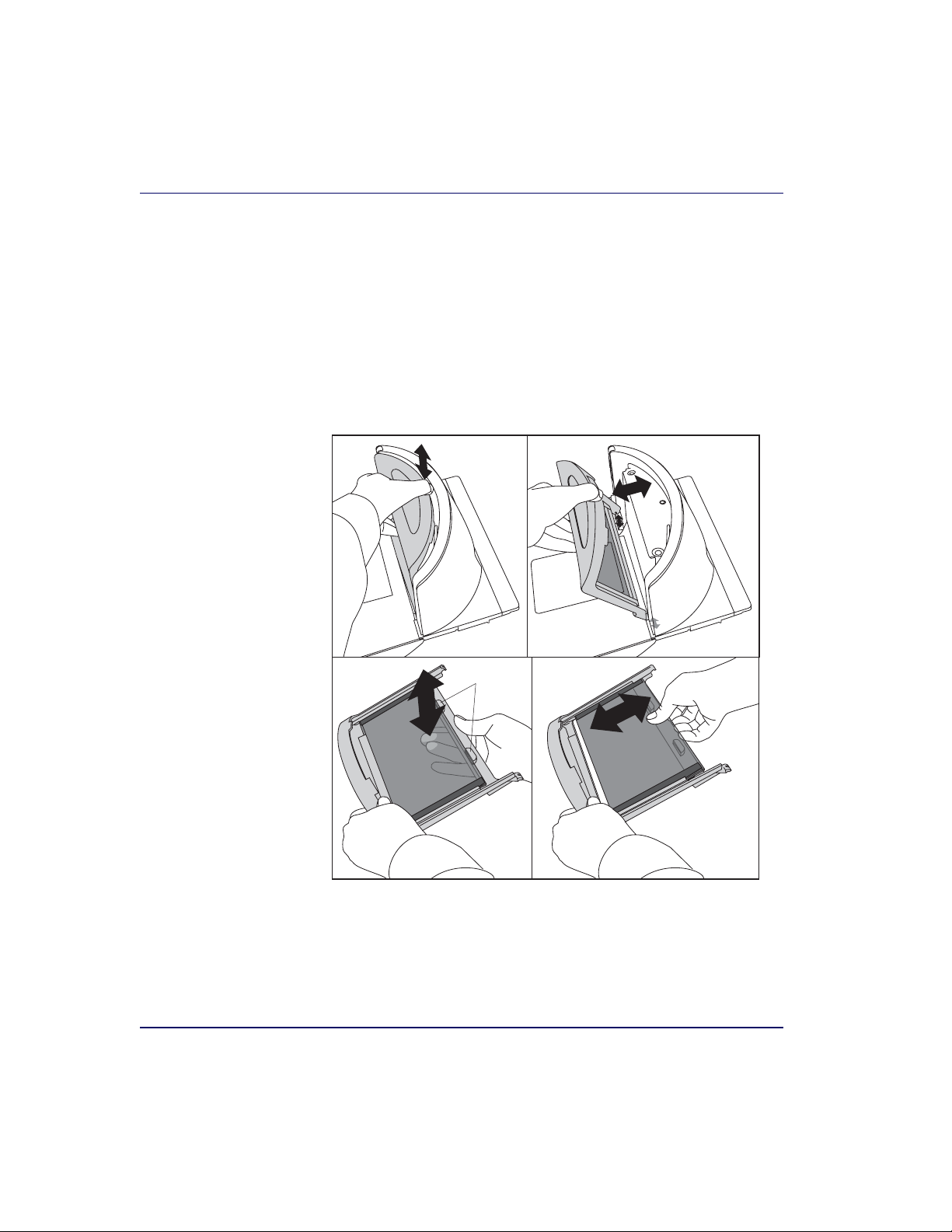

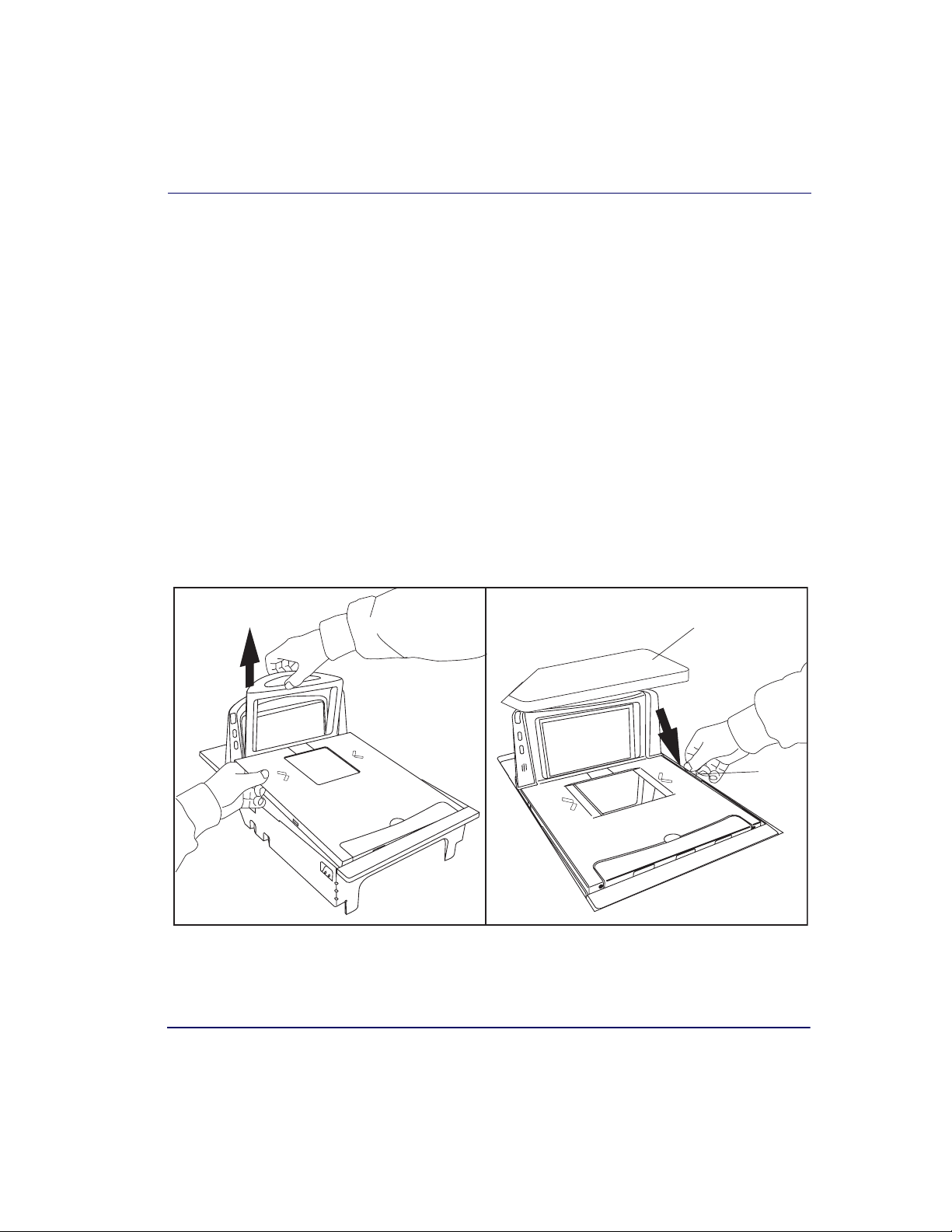

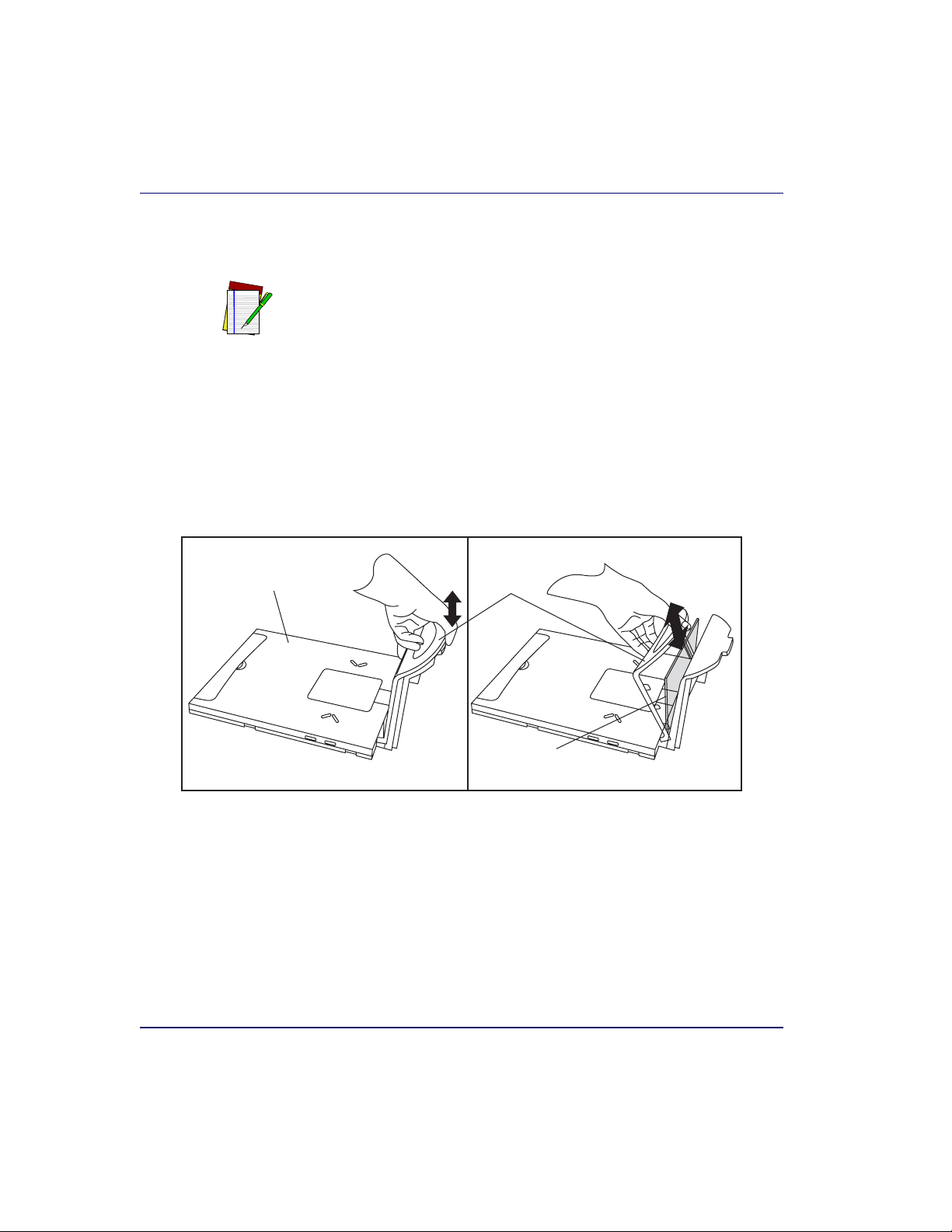

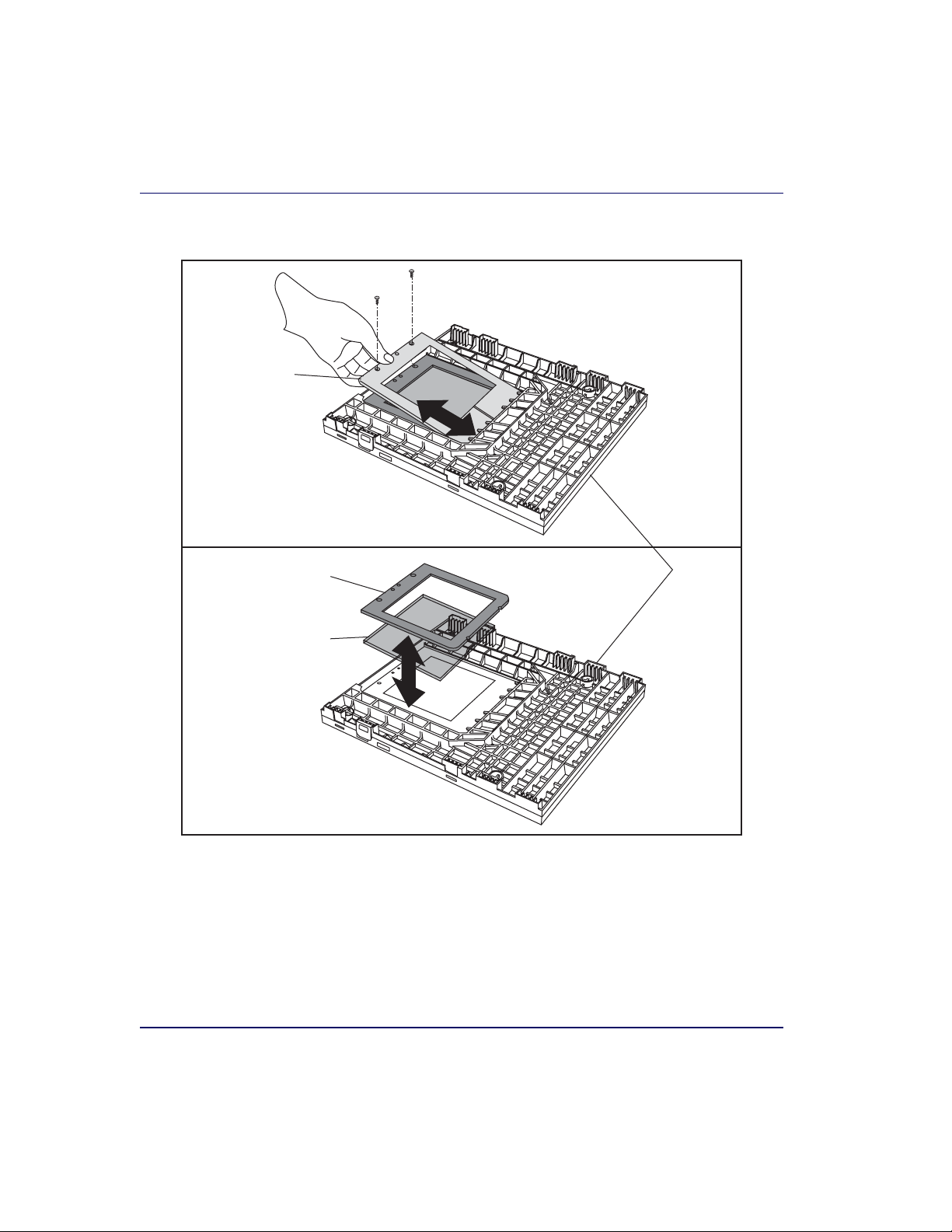

Vertical Scan Window Replacement .........................................................................3-12

Horizontal Scan Window Replacement (WRG) ...........................................................3-15

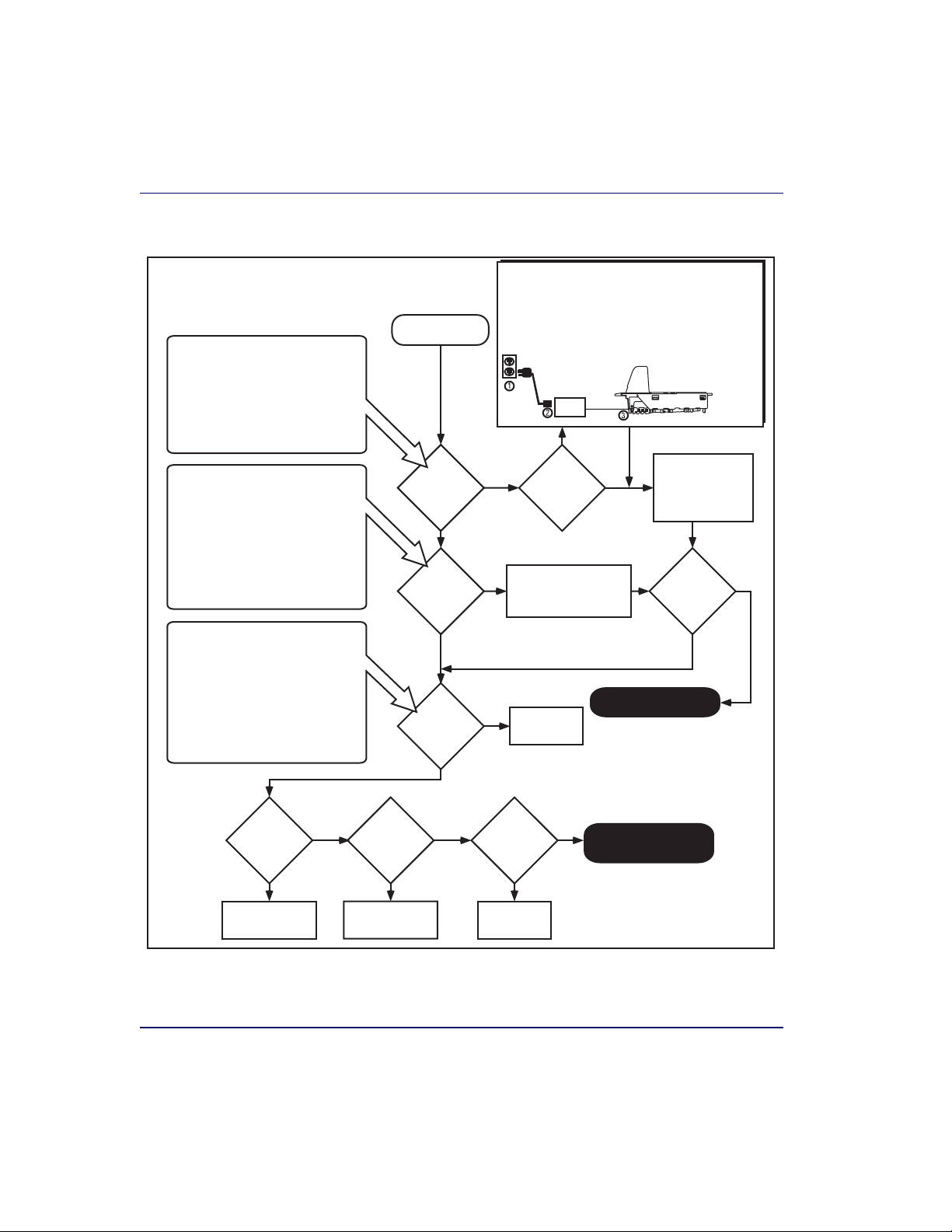

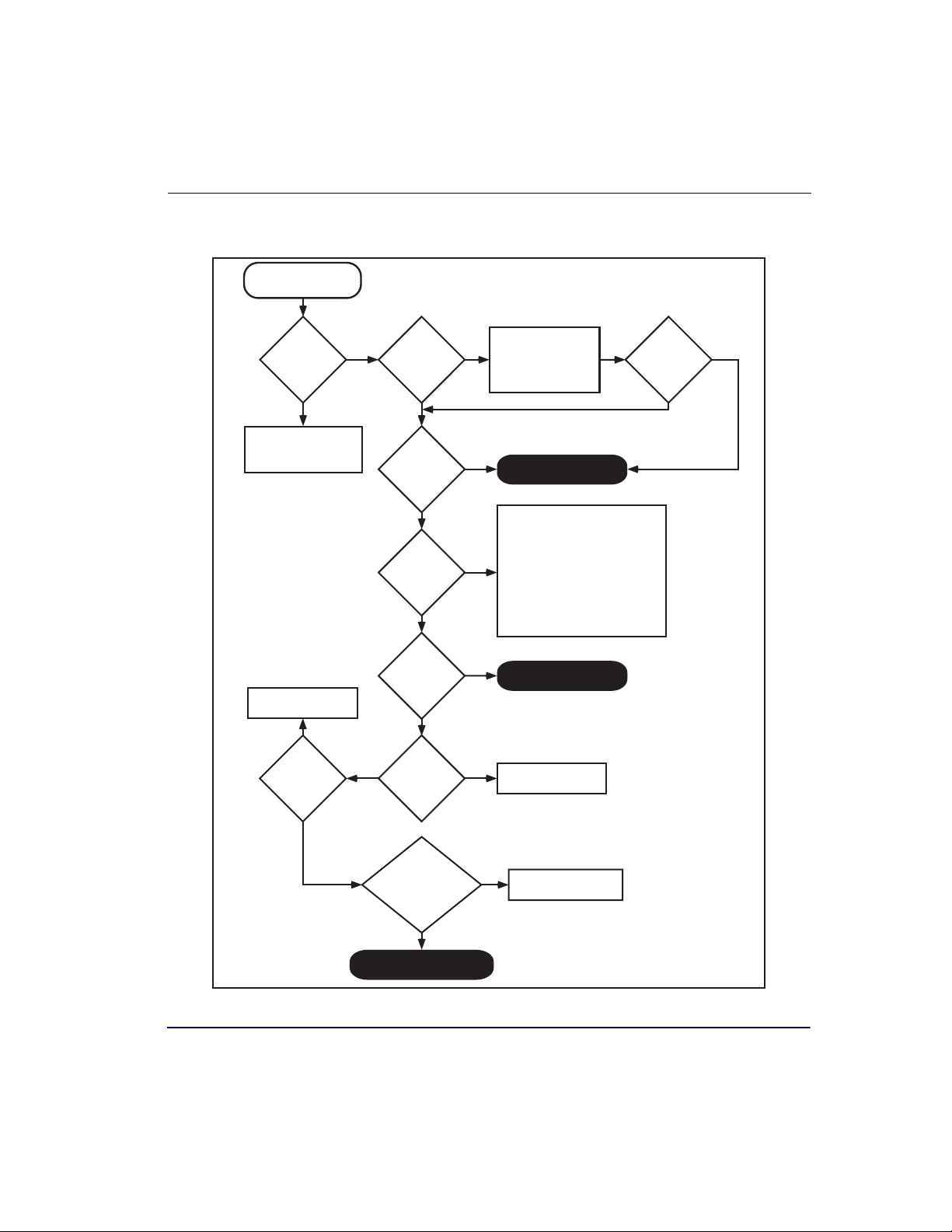

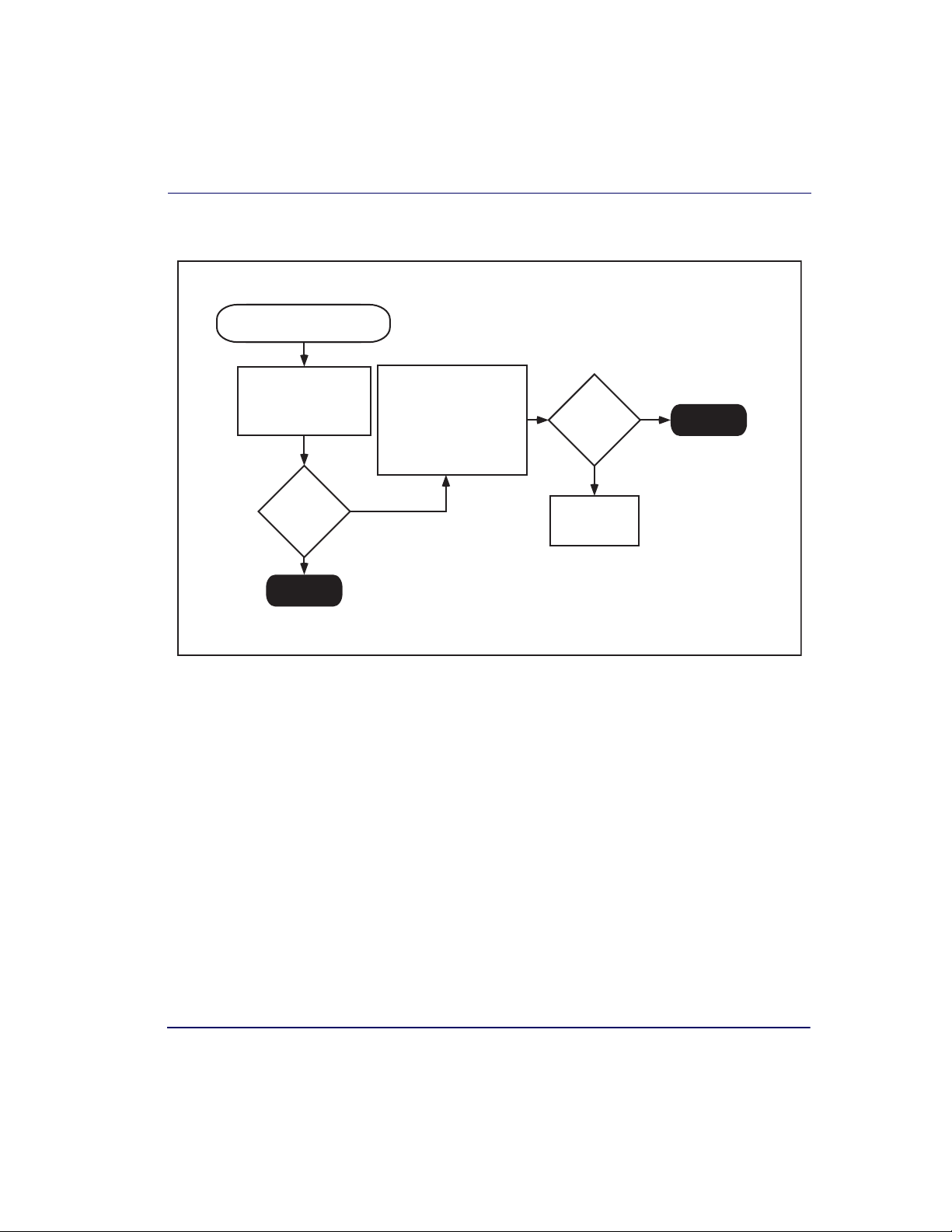

Chapter 4. Problem Isolation ........................................................................... 4-1

Diagnostic Procedures .................................................................................................. 4-2

Error Codes ................................................................................................................. 4-3

Scale Error Reporting ................................................................................................... 4-6

Flowcharts .................................................................................................................. 4-7

Chapter 5. Calibration ...................................................................................... 5-1

Description of Calibration Sequence ................................................................................ 5-2

Motion Test ................................................................................................................. 5-3

Automatic Zero Tracking Test ........................................................................................ 5-3

Preparing the Scanner/Scale for Calibration ..................................................................... 5-4

Calibrating the Scale (Pounds & Kilograms) ..................................................................... 5-4

Calibration Verification (U.S. Pounds) ............................................................................. 5-7

Increasing-Load Test (Phase 1) ............................................................................... 5-7

Shift Test .............................................................................................................. 5-8

Increasing- Load Test (Phase 2) .............................................................................. 5-9

Blanking Test ........................................................................................................ 5-9

Decreasing-Load Test ............................................................................................5-10

Return to Zero Test ...............................................................................................5-10

ii Magellan

®

8300/8400

Page 5

Calibration Verification (Kilograms) ...............................................................................5-11

Increasing-Load Test (Phase 1) ..............................................................................5-11

Shift Test (Metric) ................................................................................................. 5-12

Increasing- Load Test (Phase 2) .............................................................................5-13

Blanking Test ....................................................................................................... 5-14

Decreasing-Load Test ............................................................................................ 5-15

Return to Zero Test .............................................................................................. 5-15

Chapter 6. Programming................................................................................... 6-1

Introduction to Label Programming .................................................................................6-1

Understanding the Basics ...............................................................................................6-1

Integrating the Scanner With Your Host System ................................................................6-2

Customizing Your Scanner’s Operation .......................................................................6-2

Programming Overview .................................................................................................6-4

Programming via Handheld Device ............................................................................6-4

What Is Programming Mode? ....................................................................................6-5

Entering and Exiting Programming Mode. ...................................................................6-5

Programming Session ..............................................................................................6-6

LED and Beeper Indicators ........................................................................................... 6-10

If You Make a Mistake... ..............................................................................................6-10

Return to Factory Settings ..................................................................................... 6-10

Test Mode ...........................................................................................................6-11

General Scanner Features ............................................................................................ 6-12

Scanner Button Options ......................................................................................... 6-12

Double Read Timeout ............................................................................................ 6-14

Laser Timeout ...................................................................................................... 6-16

Motor Timeout ..................................................................................................... 6-18

Label Gone Timeout .............................................................................................. 6-21

Auxiliary Port Mode ............................................................................................... 6-24

Auxiliary Port Baud Rate ........................................................................................ 6-26

Laser Failure Mode ................................................................................................ 6-30

Productivity Index Reporting (PIR)/Cashier Training (CT) ........................................... 6-31

Indication Features ..................................................................................................... 6-32

Green LED Idle State ............................................................................................6-32

Power-up Beep Control .......................................................................................... 6-33

Good Read Beep Control ........................................................................................6-34

Good Read Beep Frequency ................................................................................... 6-35

Good Read Beep Length ........................................................................................6-37

Good Read Beep Volume .......................................................................................6-38

Good Read When to Indicate .................................................................................. 6-41

Scale Features ............................................................................................................ 6-43

Scale Enable ........................................................................................................ 6-43

Scale Country Mode .............................................................................................. 6-44

Scale Enforced Zero Return .................................................................................... 6-46

Scale Interface Type ............................................................................................. 6-49

Scale Motion Level Filter ........................................................................................ 6-51

Scale Warm-up Time ............................................................................................. 6-53

Scale LED Enable .................................................................................................. 6-55

Scale Diagnostics Mode Enable ............................................................................... 6-56

Scale Calibration Notification .................................................................................. 6-57

Scale Intercharacter Delay ..................................................................................... 6-58

Remote Display — Enable/Disable ........................................................................... 6-59

Product Reference Guide iii

Page 6

EAS Features ..............................................................................................................6-60

EAS Active State ...................................................................................................6-60

EAS Timeout ........................................................................................................6-61

Interface Related Features ...........................................................................................6-62

Interface Type ......................................................................................................6-62

Number of Host Transmission Buffers ......................................................................6-84

AIM ID ................................................................................................................ 6-85

Label ID Control ...................................................................................................6-87

Global Prefix ........................................................................................................6-90

Global Suffix ........................................................................................................6-92

Case Conversion ...................................................................................................6-94

IBM Features .............................................................................................................. 6-96

IBM Interface Options ...........................................................................................6-96

IBM Number of Host Resets ....................................................................................6-97

IBM Scale Address ................................................................................................ 6-98

IBM Transmit Labels in Code 39 Format ................................................................. 6-100

IBM Label Slicing Control ..................................................................................... 6-101

IBM Maximum Label Slice Length .......................................................................... 6-102

IBM USB Scanner Device Type .............................................................................. 6-103

RS-232 Features ....................................................................................................... 6-104

RS-232 Baud Rate ..............................................................................................6-104

RS-232 Number of Data Bits ................................................................................6-108

RS-232 Number of Stop Bits ................................................................................. 6-109

RS-232 Parity ..................................................................................................... 6-110

RS-232 Hardware Control ....................................................................................6-112

RS-232 Intercharacter Delay ................................................................................ 6-115

RS-232 Software Flow Control .............................................................................. 6-116

RS-232 Host Echo ............................................................................................... 6-117

RS-232 Host Echo Quiet Interval ........................................................................... 6-118

RS-232 Ignore Host Commands ............................................................................ 6-119

RS-232 TTL ........................................................................................................ 6-120

RS-232 TTL Invert ..............................................................................................6-121

RS-232 ICL DC1 Character Delay Enable ................................................................ 6-122

RS-232 Team POS ICL Scale ................................................................................6-123

RS-232 Beep on ASCII BEL ..................................................................................6-124

RS-232 Beep After Weigh .................................................................................... 6-125

RS-232 Beep on Not on File ................................................................................. 6-126

RS-232 ACK NAK Enable ...................................................................................... 6-127

RS-232 ACK Character ........................................................................................ 6-129

RS-232 NAK Character ........................................................................................6-130

RS-232 Retry on ACK NAK Timeout ....................................................................... 6-131

RS-232 ACK NAK Timeout Value ........................................................................... 6-132

RS-232 ACK NAK Retry Count ............................................................................... 6-133

RS-232 ACK NAK Error Handling ........................................................................... 6-134

RS-232 Indicate Transmission Failure .................................................................... 6-136

Single Cable RS-232 Options ...................................................................................... 6-137

Single Cable RS-232 Scanner Only Protocol ............................................................ 6-138

Single Cable RS-232 Stale Weight Timeout ............................................................. 6-139

Single Cable RS-232 Scale — Transmit Weight Digits ............................................... 6-141

Single Cable Manufacturer Extensions .................................................................... 6-142

Single Cable Pacesetter Plus Enable ....................................................................... 6-143

Single Cable RS-232 RTS CTS Selection ................................................................. 6-144

iv Magellan

®

8300/8400

Page 7

Single Cable RS-232 Use BCC ............................................................................... 6-147

Single Cable RS-232 Use ACK/NAK ....................................................................... 6-148

Single Cable RS-232 Use STX ............................................................................... 6-149

Set Single Cable RS-232 STX Character ................................................................. 6-150

Set Single Cable RS-232 ETX Character ................................................................. 6-151

Keyboard Wedge/USB Keyboard Features .................................................................... 6-152

Keyboard Interface — Keyboard Layout ................................................................. 6-152

Keyboard Interface Quiet Interval ......................................................................... 6-161

Keyboard Interface Caps Lock State ...................................................................... 6-162

Keyboard Interface — Keyboard Simulation ............................................................ 6-164

Keyboard Interface — Control Characters ............................................................... 6-165

Keyboard Interface — Intercharacter Delay ............................................................ 6-167

Symbology Programming ........................................................................................... 6-168

Coupon Control .................................................................................................. 6-168

UPC-A Enable ........................................................................................................... 6-170

UPC-A Number System Character Transmission ...................................................... 6-171

UPC-A Check Character Transmission .................................................................... 6-172

Expand UPC-A to EAN-13 ..................................................................................... 6-173

UPC-A Label ID .................................................................................................. 6-174

UPC-A 2-Digit Supplemental Label ID .................................................................... 6-175

UPC-A 5-Digit Supplemental Label ID .................................................................... 6-176

UPC-A 128 Supplemental Label ID ........................................................................ 6-177

UPC-A Minimum Reads ........................................................................................ 6-178

UPC-E Enable ........................................................................................................... 6-180

UPC-E Number System Character Transmission ...................................................... 6-181

UPC-E Check Character Transmission .................................................................... 6-182

Expand UPC-E to UPC-A ....................................................................................... 6-183

Expand UPC-E to EAN-13 ..................................................................................... 6-184

UPC-E Label ID ................................................................................................... 6-185

UPC-E 2-Digit Supplemental Label ID .................................................................... 6-186

UPC-E 5-Digit Supplemental Label ID .................................................................... 6-187

UPC-E 128 Supplemental Label ID ........................................................................ 6-188

UPC-E Minimum Reads ........................................................................................ 6-189

EAN-13 Enable ......................................................................................................... 6-191

EAN-13 First Character Transmission ..................................................................... 6-192

EAN-13 Check Character Transmission .................................................................. 6-193

EAN-13 ISBN Conversion Enable ........................................................................... 6-194

EAN 13 Label ID ................................................................................................. 6-195

EAN-13 2-Digit Supplemental Label ID .................................................................. 6-196

EAN-13 5-Digit Supplemental Label ID .................................................................. 6-197

EAN-13 128 Supplemental Label ID ....................................................................... 6-198

EAN-13 Minimum Reads ...................................................................................... 6-199

Bookland Label ID .............................................................................................. 6-201

EAN-8 Enable ........................................................................................................... 6-202

EAN-8 Check Character Transmission .................................................................... 6-203

Expand EAN-8 to EAN-13 ..................................................................................... 6-204

EAN-8/JAN-8 Guard Insertion ............................................................................... 6-205

EAN-8/JAN-8 Guard Substitution ........................................................................... 6-206

EAN-8/JAN-8 Both Guards Substitution .................................................................. 6-207

EAN-8 Stitch Exact Label Halves ........................................................................... 6-208

EAN-8 Stitch Unlike Label Halves .......................................................................... 6-209

EAN 8 Label ID ................................................................................................... 6-210

Product Reference Guide v

Page 8

EAN-8 2-Digit Supplemental Label ID ....................................................................6-211

EAN-8 5-Digit Supplemental Label ID ....................................................................6-212

EAN-8 128 Supplemental Label ID ........................................................................ 6-213

EAN-8 Decoding Levels ........................................................................................ 6-214

EAN-8 Minimum Reads ........................................................................................ 6-217

EAN-8 Minimum Segment Length .......................................................................... 6-219

Other UPC/EAN Options ............................................................................................. 6-225

Price Weight Check ............................................................................................. 6-226

In-Store Label Minimum Reads ............................................................................. 6-229

Enable EAN Two Label ......................................................................................... 6-231

EAN Two Label Combined Transmission .................................................................6-232

UPC/EAN Guard Insertion ..................................................................................... 6-233

UPC/EAN Stitch Exact Label Halves ....................................................................... 6-234

UPC/EAN Stitch Unlike Label Halves ...................................................................... 6-235

UPC/EAN Character Reconstruction .......................................................................6-236

EAN Two Label Minimum Reads ............................................................................6-237

UPC/EAN Correlation ........................................................................................... 6-239

UPC/EAN Minimum Segment Length ...................................................................... 6-240

Addons .............................................................................................................. 6-246

Addon Timer ...................................................................................................... 6-250

2-Digit Add-ons Minimum Reads ........................................................................... 6-251

5-Digit Add-ons Minimum Reads ........................................................................... 6-253

Code 128 Add-ons Minimum Reads .......................................................................6-255

GTIN Enable ............................................................................................................. 6-257

GTIN Label ID ....................................................................................................6-258

GTIN 2-Digit Supplemental Label ID ...................................................................... 6-259

GTIN 5-Digit Supplemental Label ID ...................................................................... 6-260

GTIN Code 128 Supplemental Label ID .................................................................. 6-261

DataBar Omnidirectional Enable .................................................................................. 6-262

DataBar Omnidirectional/EAN-128 Emulation .......................................................... 6-263

DataBar Omnidirectional Label ID ......................................................................... 6-264

DataBar Omnidirectional Minimum Reads ............................................................... 6-265

DataBar Expanded Enable .......................................................................................... 6-267

DataBar Expanded EAN-128 Emulation .................................................................. 6-268

DataBar Expanded Label ID .................................................................................. 6-269

DataBar Expanded Length Control ......................................................................... 6-270

DataBar Expanded Length 1 ................................................................................. 6-271

DataBar Expanded Length 2 ................................................................................. 6-272

DataBar Expanded Minimum Reads ....................................................................... 6-273

Code 39 Enable ........................................................................................................6-275

Code 39 Start Stop Character Transmission ............................................................ 6-276

Code 39 Check Character Calculation ..................................................................... 6-277

Code 39 Check Character Transmission .................................................................. 6-278

Code 39 Full ASCII .............................................................................................. 6-279

Code 39 Label ID ................................................................................................ 6-280

Code 39 Require Quiet Zones ............................................................................... 6-281

Code 39 Length Control ....................................................................................... 6-282

Code 39 Length 1 ...............................................................................................6-283

Code 39 Length 2 ...............................................................................................6-284

Code 39 Correlation ............................................................................................ 6-285

Code 39 Stitching ...............................................................................................6-286

Code 39 Minimum Reads ..................................................................................... 6-287

vi Magellan

®

8300/8400

Page 9

Pharmacode 39 Enable .............................................................................................. 6-289

Pharmacode 39 Start Stop Character Transmission ................................................. 6-290

Pharmacode 39 Check Character Transmission ....................................................... 6-291

Pharmacode 39 Label ID ...................................................................................... 6-292

Code 128 Enable ...................................................................................................... 6-293

Code 128 Transmit Function Characters ................................................................. 6-294

Convert Code 128 to Code 39 ............................................................................... 6-295

Code 128 Label ID .............................................................................................. 6-296

Code 128 Length Control ..................................................................................... 6-297

Code 128 Length 1 ............................................................................................. 6-298

Code 128 Length 2 ............................................................................................. 6-299

Code 128 Correlation .......................................................................................... 6-300

Code 128 Stitching ............................................................................................. 6-302

Code 128 Minimum Reads .................................................................................... 6-303

EAN-128 Enable ....................................................................................................... 6-305

EAN-128 Label ID ............................................................................................... 6-306

Interleaved 2 of 5 (I 2 of 5) Enable ............................................................................. 6-307

I 2 of 5 Check Character Calculation ...................................................................... 6-308

I 2 of 5 Check Character Transmission ................................................................... 6-309

I 2 of 5 Label ID ................................................................................................. 6-310

I 2 of 5 Length Control ........................................................................................ 6-311

I 2 of 5 Length 1 ................................................................................................ 6-312

I 2 of 5 Length 2 ................................................................................................ 6-313

I 2 of 5 Correlation ............................................................................................. 6-314

I 2 of 5 Stitching ................................................................................................ 6-315

I 2 of 5 Minimum Reads ....................................................................................... 6-316

Standard 2 of 5 (Std 2 of 5) Enable ............................................................................. 6-318

Standard 2 of 5 Check Character Calculation .......................................................... 6-319

Standard 2 of 5 Check Character Transmission ....................................................... 6-320

Standard 2 of 5 Label ID ..................................................................................... 6-321

Standard 2 of 5 Length Control ............................................................................. 6-322

Standard 2 of 5 Length 1 ..................................................................................... 6-323

Standard 2 of 5 Length 2 ..................................................................................... 6-324

Standard 2 of 5 Correlation .................................................................................. 6-325

Standard 2 of 5 Stitching ..................................................................................... 6-326

Standard 2 of 5 Minimum Reads ........................................................................... 6-327

Codabar Enable ........................................................................................................ 6-329

Codabar Start Stop Character Transmission ........................................................... 6-330

Codabar Start Stop Character Set ......................................................................... 6-331

Codabar Start Stop Character Match ..................................................................... 6-333

Codabar Check Character Calculation .................................................................... 6-334

Codabar Check Character Transmission ................................................................. 6-335

Codabar Label ID ................................................................................................ 6-337

Codabar Require Quiet Zones ............................................................................... 6-338

Codabar Length Control ....................................................................................... 6-339

Codabar Length 1 ............................................................................................... 6-340

Codabar Length 2 ............................................................................................... 6-341

Codabar Correlation ............................................................................................ 6-342

Codabar Stitching ............................................................................................... 6-343

Codabar Minimum Reads ..................................................................................... 6-344

Code 93 Enable ........................................................................................................ 6-346

Code 93 Label ID ................................................................................................ 6-347

Product Reference Guide vii

Page 10

Code 93 Length Control ....................................................................................... 6-348

Code 93 Length 1 ...............................................................................................6-349

Code 93 Length 2 ...............................................................................................6-350

Code 93 Correlation ............................................................................................ 6-351

Code 93 Stitching ...............................................................................................6-352

Code 93 Minimum Reads ..................................................................................... 6-353

MSI/Plessey Enable ................................................................................................... 6-355

MSI/Plessey Check Character Calculation ............................................................... 6-356

MSI/Plessey Number of Check Characters ..............................................................6-357

MSI/Plessey Check Character Transmission ............................................................ 6-358

MSI/Plessey Label ID ........................................................................................... 6-359

MSI/Plessey Length Control .................................................................................. 6-360

MSI/Plessey Length 1 .......................................................................................... 6-361

MSI/Plessey Length 2 .......................................................................................... 6-362

MSI/Plessey Correlation ....................................................................................... 6-363

MSI/Plessey Stitching .......................................................................................... 6-364

MSI/Plessey Minimum Reads ................................................................................ 6-365

Appendix A. LED/Beeper Indications & Controls ................................. A-1

Controls and Indicators ................................................................................................. A-2

LED and Beeper Indications ..................................................................................... A-2

Volume/Tone Push Button ....................................................................................... A-3

Scale Zero Push Button .......................................................................................... A-5

Calibration Switch .................................................................................................. A-6

Appendix B. Cable Information............................................................ B-1

Introduction ................................................................................................................ B-1

General Specifications ............................................................................................ B-1

Scanner ................................................................................................................ B-2

Scale ................................................................................................................... B-3

IBM Cable Pinout ......................................................................................................... B-4

Scanner and Scale ................................................................................................. B-4

IBM USB Cable Pinout ................................................................................................... B-5

Scanner and Scale ................................................................................................. B-5

Auxilliary Port .............................................................................................................. B-6

External Handheld Input ......................................................................................... B-6

Power Cable ................................................................................................................ B-7

Connector Hardware .............................................................................................. B-7

Remote Display ........................................................................................................... B-8

Connector Hardware .............................................................................................. B-8

EAS Comm Port (Sensormatic® systems ONLY) ................................................................ B-9

EAS Deactivator Control Box Connection ................................................................... B-9

Appendix C. Keypad............................................................................. C-1

Appendix D. Host Commands............................................................... D-1

Accepting Commands from an RS-232 Scanner Host ......................................................... D-1

Appendix E. Keyboard Function Key Mappings .................................... E-1

Keyboard Model Cross Reference .................................................................................... E-1

viii Magellan

®

8300/8400

Page 11

Appendix F. Factory Defaults............................................................... F-1

Appendix G. Handheld Data Format Requirements .............................. G-1

Handheld Data Format Requirements General ............................................................ G-1

Datalogic Handheld Data Format Requirements ......................................................... G-2

AIM Formats ....................................................................................................... G-10

Product Reference Guide ix

Page 12

NOTES

x Magellan

®

8300/8400

Page 13

DATALOGIC SCANNING, INC. MAGELLAN® END USER LICENSE

AGREEMENT

Notice to End User: The Datalogic Product you have acquired contains embedded Software, which is integral to the product's operation. This

Software is being provided to you under license, subject to the terms and conditions of this Agreement. If you use the Datalogic Product, you will

be deemed to have accepted the terms and conditions of this Agreement. If you do not intend to be bound to the terms of this Agreement, Datalogic is not willing to license the Software to you, you may not use the Datalogic Product or the Software, and you must contact the party from

whom you acquired the Datalogic Product for instructions.

This End User Software License Agreement ("Agreement") is a legally binding agreement governing the licensing of the Software and Documentation by Datalogic,Scanning Holdings, Inc. and its subsidiaries and affiliates ("Datalogic") to the entity or person who has purchased or otherwise acquired a Datalogic

Product ("End User"). For purposes of this Agreement, any software that is associated with a separate end-user license agreement is licensed to you under

the terms of that license agreement. Datalogic and End User hereby agree as follows:

1. Definitions.

1.1 "Documentation" means materials such as user's guides, program reference guides, quick reference guides, manuals, or similar materials associated

with or related to the Datalogic Product, whether in printed, "online", or other form.

1.2 "Proprietary Information" means: (a) source code, object code, software, documentation, and any related internal design, system design, data base

design, algorithms, technology, technical data or information, implementation techniques, and trade secrets related to the Software, (b) any other trade

secrets marked appropriately or identified as proprietary or confidential, and (c) any information that End User, under the circumstances, should recognize as confidential. Proprietary Information does not include any information that the receiving party can establish was (1) in the public domain, (2)

already in the receiving party's possession or rightfully known prior to receipt, (3) rightfully learned from a third party not in violation of any other's proprietary rights, or (4) independently developed without access to Proprietary Information.

1.3 "Datalogic Product" means the Datalogic Magellan® 1000i series, Magellan® 1400i series, Magellan® 8100 series, Magellan® 8200 series, Magellan® 8300 series, Magellan® 8400 series, Magellan® 8500 series, Magellan® 9500 series, and/or Magellan SL® series scanner and/or scanner/scale

product, including all embedded Software in and all Documentation related to such product, which has been purchased or otherwise acquired by End

User, whether obtained directly or indirectly from Datalogic.

1.4 "Software" means any software or computer programs of Datalogic or its third party licensors in machine readable form which is embedded in the Datalogic Product, whether obtained directly or indirectly from Datalogic, including any replacement, update, upgrade, enhancement or modification.

2. Scope Of License Granted.

2.1 Datalogic grants to End User a non-exclusive, non-transferable, perpetual license to use the Software, solely on the Datalogic Product in which it is

embedded ("designated Datalogic Product"), in machine-readable form only, solely for End User's internal business purposes. This Agreement does

not convey ownership of the Software to End User. Title to the Software shall be and remain with Datalogic or the third party from whom Datalogic has

obtained a licensed right. As used in this Agreement, the term "purchase" or its equivalents when applied to the Software shall mean "acquire under

license." End User is not entitled to receipt or use of the source code to any Software.

2.2 End User shall not copy, modify, decompile, disassemble, reverse engineer, or otherwise reproduce or remanufacture the Software, whether modified

or unmodified, nor sell, assign, sublicense, distribute, lend, rent, give, or otherwise transfer the Software to any other person or organization, for purposes other than as expressly provided in this Agreement, without Datalogic's prior written consent.

3. Transfers, Support.

3.1 Any copying, installing, reproduction, remanufacture, reverse engineering, electronic transfer, or other use of the Software on other than the designated Datalogic Product will be a material breach of this Agreement. However, Datalogic may elect not to terminate this Agreement or the granted

licenses, but instead may elect to notify End User that End User is deemed to have ordered and accepted a license for each breaching use. End User

shall pay Datalogic the applicable list price for such licenses as of the date of such breach.

3.2 End User shall not sell, assign, sublicense, distribute, lend, rent, give, or otherwise transfer the Datalogic Product to any third party unless such third

party agrees with Datalogic in writing to be bound by the terms and conditions of this Agreement. Any such transfer of the Datalogic Product absent

such agreement shall be null and void.

3.3 End User may obtain support for Software from Datalogic at Datalogic's standard support fees and under Datalogic's standard support terms and conditions in effect at the time the support is requested.

4. Intellectual Property.

End User acknowledges that the Software constitutes valuable trade secrets of Datalogic or Datalogic's third party licensors and that the Software is protected by intellectual property laws and treaties. The license set forth in this Agreement does not transfer to End User any ownership of Datalogic's or its third

party licensors' copyrights, patents, trademarks, service marks, trade secrets, or other intellectual property rights and End User shall have no right to commence any legal actions to obtain such rights. End User shall not remove, modify, or take any other action that would obscure any copyright, trademark,

patent marking, or other intellectual property notices contained in or on the Datalogic Product.

5. Proprietary Information.

5.1 End User acknowledges that Proprietary Information is the confidential, proprietary, and trade secret property of Datalogic and Datalogic's third party

licensors and End User acquires no right or interest in any Proprietary Information.

5.2 End User shall not disclose, provide, or otherwise make available the Proprietary Information of Datalogic or its third party licensors to any person

other than End User's authorized employees or agents who are under confidentiality agreement, and End User shall not use the Proprietary Information other than in conjunction with use of the Datalogic Product exclusively for End User's internal business purposes. End User shall take steps to

protect the Proprietary Information no less securely than if it were End User's own intellectual property.

5.3 The provisions of this Proprietary Information Section shall survive and continue for five (5) years after the termination of this Agreement.

6. Limited Warranty.

6.1 Datalogic warrants that, under normal use and operation, the Datalogic Product will conform substantially to the applicable Documentation for the

period specified in the Documentation. During this period, for all reproducible nonconformities for which Datalogic has been given written notice, Datalogic will use commercially reasonable efforts to remedy nonconformities verified by Datalogic. End User agrees to supply Datalogic with all reasonably

requested information and assistance necessary to help Datalogic in remedying such nonconformities. For all defects reported to Datalogic within the

warranty period, Datalogic's liability is limited to providing End User with one copy of corrections or responding to End User's problem reports accord-

Product Reference Guide xi

Page 14

ing to Datalogic's standard assistance practices. Datalogic does not warrant that the product will meet End User's requirements or that use of the product will be uninterrupted or error free, or that Datalogic's remedial efforts will correct any nonconformance. This limited warranty does not cover any

product that has been subjected to damage or abuse, whether intentionally, accidentally, or by neglect, or to unauthorized repair or unauthorized installation, and shall be void if End User modifies the product, uses the product in any manner other than as established in the Documentation, or if End

User breaches any of the provisions of this Agreement.

6.2 EXCEPT AS PROVIDED IN THIS AGREEMENT, THE DATALOGIC PRODUCT IS PROVIDED "AS IS" AND DATALOGIC MAKES NO WARRANTIES

OF ANY KIND, EXPRESS OR IMPLIED, WRITTEN OR ORAL, WITH RESPECT TO THE PRODUCT, AND SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

7. Infringement.

7.1 Datalogic will defend End User against any claim in a lawsuit that the Datalogic Product furnished hereunder infringe a United States patent or copyright of a third party and Datalogic will pay any damages finally awarded against End User by a court of competent jurisdiction that are attributable to

such claim or will pay End User's part of any settlement that is attributable to such claim, provided, that 1) End User notifies Datalogic promptly in writing of the claim, 2) Datalogic controls the defense or settlement of the claim, and 3) End User cooperates fully with Datalogic in such defense or settlement. All notices of a claim should be sent to Datalogic Scanning Holdings, Inc., Legal Department, 959 Terry Street, Eugene, OR 97402.

7.2 In the defense or settlement of any such claim, Datalogic may, at its option, 1) procure for End User the right to continue using the Datalogic Product,

2) modify the Datalogic Product so that it becomes non-infringing, 3) replace the Datalogic Product with an equivalent product not subject to such

claim, or 4) provide End User an opportunity to return the Datalogic Product and receive a refund of the purchase price paid, less a reasonable allowance for use.

7.3 Datalogic shall have no liability to End User for claims of infringement based upon 1) the use of any Datalogic Product in combination with any product

which Datalogic has not either furnished or authorized for use with such Datalogic Product 2) the use of any Datalogic Product designed, manufactured, or modified to the specifications of End User, or 3) End User's modification of the Datalogic Product without written authorization from Datalogic.

7.4 THE FOREGOING STATES DATALOGIC'S COMPLETE AND ENTIRE OBLIGATION CONCERNING CLAIMS OF PATENT, COPYRIGHT, OR OTHER

INTELLECTUAL PROPERTY INFRINGEMENT, CANCELS AND SUPERSEDES ANY PRIOR AGREEMENTS, WHETHER ORAL OR WRITTEN,

BETWEEN THE PARTIES CONCERNING SUCH CLAIMS, AND WILL NOT BE MODIFIED OR AMENDED BY ANY PAST, CONTEMPORANEOUS,

OR FUTURE AGREEMENTS OR DEALINGS BETWEEN THE PARTIES, WHETHER ORAL OR WRITTEN, EXCEPT AS SET FORTH IN A FUTURE

WRITING SIGNED BY BOTH PARTIES.

8. Limitation Of Liability.

EXCEPT AS PROVIDED IN SECTION 7, DATALOGIC SHALL NOT BE LIABLE FOR ANY CLAIMS AGAINST END USER BY ANY OTHER PARTY. IN NO

EVENT SHALL DATALOGIC'S LIABILITY FOR DAMAGES, IF ANY, WHETHER BASED UPON CONTRACT, TORT (INCLUDING NEGLIGENCE), PRODUCT LIABILITY, STRICT LIABILITY, WARRANTY, OR ANY OTHER BASIS, EXCEED THE PRICE OR FEE PAID BY END USER FOR THE DATALOGIC

PRODUCT. UNDER NO CIRCUMSTANCES SHALL DATALOGIC BE LIABLE TO END USER OR ANY THIRD PARTY FOR LOST PROFITS, LOST DATA,

INTERRUPTION OF BUSINESS OR SERVICE, OR FOR ANY OTHER SPECIAL, CONSEQUENTIAL, CONTINGENT, INDIRECT, INCIDENTAL, PUNITIVE,

EXEMPLARY, OR OTHER SIMILAR DAMAGES, EVEN IF DATALOGIC HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

9. Government Restricted Rights; International Use.

9.1 Use, duplication, or disclosure of the Software by the U.S. Government is subject to the restrictions for computer software developed at private

expense as set forth in the U.S. Federal Acquisition Regulations at FAR 52.227-14(g), or 52.227-19 or in the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013(c)(1)(ii), whichever is applicable.

9.2 If End User is using the Datalogic Product outside of the United States, End User must comply with the applicable local laws of the country in which the

Datalogic Product is used, with U.S. export control laws, and with the English language version of this Agreement. The provisions of the "United

Nations Convention on International Sale of Goods" shall not apply to this Agreement.

10. Termination.

10.1 Either party may terminate this Agreement or any license granted under this Agreement at any time upon written notice if the other party breaches any

provision of this Agreement.

10.2 Upon termination of this Agreement, End User immediately shall cease using any non-embedded software and shall return to Datalogic or destroy all

non-embedded software covered by this Agreement, and shall furnish Datalogic with a certificate of compliance with this provision signed by an officer

or authorized representative of End User. For embedded software, End User agrees to sign a waiver prepared by Datalogic concerning further use of

the embedded Software. End User's resumed or continued use of the embedded Software after termination shall constitute End User's agreement to

be bound by the terms and conditions of this Agreement for such use.

11. General Provisions.

11.1 Entire Agreement; Amendment. This document contains the entire agreement between the parties relating to the licensing of the Software and supersedes all prior or contemporaneous agreements, written or oral, between the parties concerning the licensing of the Software. This Agreement may not

be changed, amended, or modified except by written document signed by Datalogic.

11.2 Notice. All notices required or authorized under this Agreement shall be given in writing, and shall be effective when received, with evidence of receipt.

Notices to Datalogic shall be sent to the attention of Contract Administration, Datalogic Scanning Holdings, Inc., 959 Terry Street, Eugene, OR 97402,

or such other address as may be specified by Datalogic in writing.

11.3 Waiver. A party's failure to enforce any of the terms and conditions of this Agreement shall not prevent the party's later enforcement of such terms and

conditions.

11.4 Governing Law; Venue: This Agreement and the rights of the parties hereunder shall be governed by and construed in accordance with the laws of the

State of Oregon U.S.A, without regard to the rules governing conflicts of law. The state or federal courts of the State of Oregon located in either Multnomah or Lane counties shall have exclusive jurisdiction over all matters regarding this Agreement, except that Datalogic shall have the right, at its

absolute discretion, to initiate proceedings in the courts of any other state, country, or territory in which End User resides, or in which any of End User's

assets are located.

11.5 Attorneys’ Fees. In the event an action is brought to enforce the terms and conditions of this Agreement, the prevailing party shall be entitled to reasonable attorneys' fees, both at trial and on appeal.

- END -

xii Magellan

®

8300/8400

Page 15

This Product Reference Guide contains comprehensive instructions on

scanner or scanner/scale installation. Either model may be termed “scanner” for the purpose of simplicity in this manual. Also included are feature

configuration using special programming feature bar code labels and

advanced user information as described in the following chapter descriptions.

Manual Overview

Chapter 1, Introduction, outlines the manual’s contents, details features

and specifications, provides regulatory and safety information, and lists

the symbologies (bar code types) the scanner will read.

Chapter 2, Site Preparation and Installation, presents physical dimen-

sions for the scanner or scanner/scale and popular accessories, and provides counter preparation and installation procedures. Cable routing,

connection and testing are additionally detailed in this chapter.

Chapter 1

Introduction

Chapter 3, Operation and Maintenance, contains use and maintenance

instructions; providing details about operator controls, programming and

diagnostic modes, scale “zeroing” and calibration. Scanner and scale routine maintenance is also outlined in this chapter.

Chapter 4, Problem Isolation, outlines the three scanner/scale test modes:

Selftest, Operational Tests and Diagnostic Tests. Procedures for system

problem and troubleshooting flowcharts to aid in problem resolution are

also presented in this chapter.

Chapter 5, Calibration, explains scale calibration and verification proce-

dures, including procedures for calibrating the scale in pounds as well as

kilograms.

Product Reference Guide 1-1

Page 16

Chapter 6, Programming, highlights the function(s) of each programma-

ble feature and provides a dedicated set of bar codes for configuring scanner and scanner/scale features. This chapter is organized by the categories:

General Features, Interface Related Features and Symbology Related Features.

Appendix A, LED/Beeper Indications & Controls, contains tables describ-

ing the various functions and indications of the scanner/scale control

panel features.

Appendix B, Cable Information, references wire requirements, connector

specifications and pinout details for product cabling.

Appendix C, Keypad, is a set of bar codes representing the digits and char-

acters required to enter extended programming data needed during certain

programming sessions.

Appendix D, Host Commands, furnishes a partial listing of available host

commands that can be used with a compatible host interface.

Appendix E, Keyboard Function Key Mappings, summarizes the key-

board models, their defined protocol, scancode set, and some unique features. Other tables in this chapter provide the function key maps

associated with each of the scancode sets.

Appendix F, Factory Defaults, lists factory default programmable settings

for common interfaces.

Appendix G, Handheld Data Format Requirements, contains application

notes describing the general format of data accepted by the scanner

through the auxilliary port as transmitted from a handheld scanner.

How to Use This Manual

Reference the first chapter of this manual for a general description of the

product’s features and an outline of the manual’s contents and organization. View the remaining chapters for procedures regarding scanner or

scanner/scale installation, operation, maintenance, calibration and bar

code programming.

1-2 Magellan

®

8300/8400

Page 17

Manual Conventions

‘NOTE’ blocks contain information that is helpful and recommended. They provide information that is critical to

operations and/or procedures described in this manual.

Manual Overview

LEGAL NOTE

‘LEGAL NOTE’ blocks indicate procedures or activities

which may be regulated under law by governmental

agencies. It is your responsibility to ensure compliance

with the regulations that govern installation of weighing

devices.

‘CAUTION’ blocks inform you that proper handling

(adherence to the procedures described) is required to

avoid damage to equipment and/or property.

‘WARNING’ blocks alert you to potential physical harm or

injury. These statements do not include potentially fatal

hazards, which would be designated as ‘DANGER’

blocks. Use of this product does not warrant the need for

a DANGER block.

Product Reference Guide 1-3

Page 18

Technical Support

Datalogic Website Support

The Datalogic website (www.scanning.datalogic.com) is the complete

source for technical support and information for Datalogic products. The

site offers the Datalogic TekForum, product support, product registration,

warranty information, product manuals, product tech notes, software

updates, demos, and instructions for returning products for repair.

Datalogic Website TekForum

Search for information on the TekForum by clicking on the Support link

on the Datalogic home page. Browse the TekForum to find answers to

your questions about common technical issues.

Reseller Technical Support

An excellent source for technical assistance and information is an authorized Datalogic reseller. A reseller is acquainted with specific types of businesses, application software, and computer systems and can provide

individualized assistance.

Telephone Technical Support

If you do not have internet or email access, you may contact Datalogic

technical support at (541) 349-8281.

1-4 Magellan

®

8300/8400

Page 19

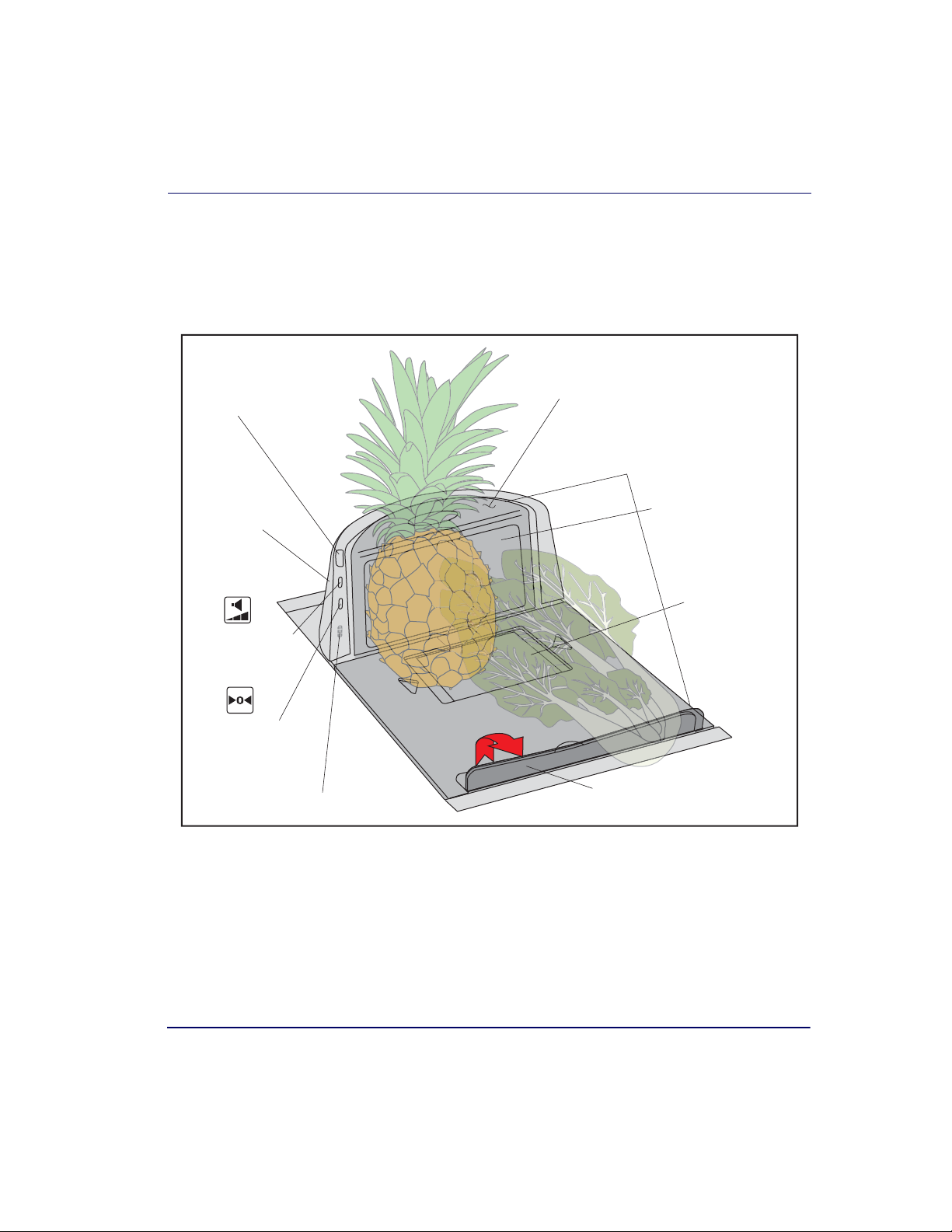

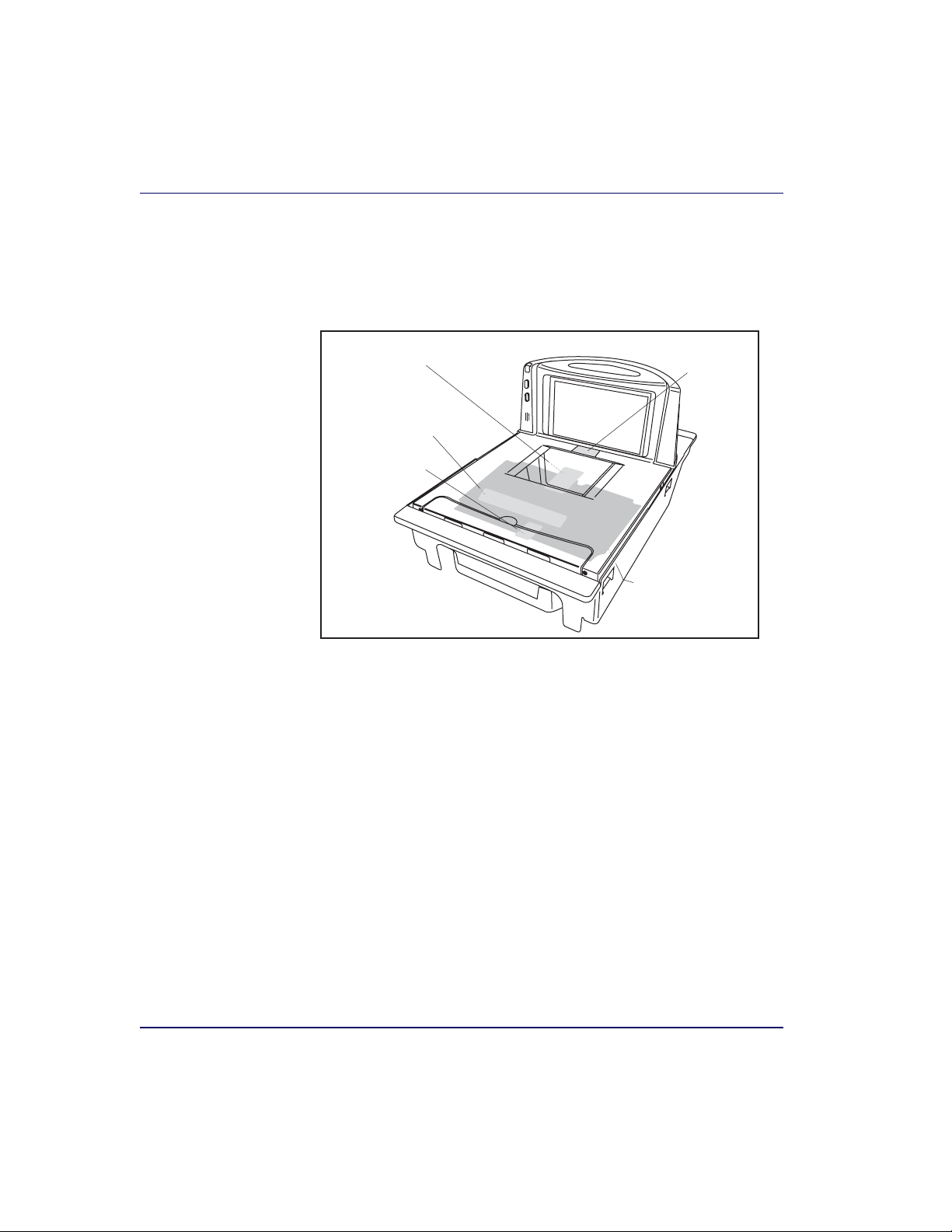

Scanner and Scanner/Scale Nomenclature

Scanner and Scanner/Scale Nomenclature

Controls, indicators and other nomenclature are shown in Figure 1-1.

Figure 1-1. Scanner/Scale Nomenclature

Weighing Surface — Lean

Oversize Produce Here

Scanner LED

All Weighs™ Platter

Vertical Window

Bonnet

Horizontal

Window

Volume/Tone

Push Button

Scale Zero

Push Button

Speaker (Beeper) Port

Product Reference Guide 1-5

Produce Bar

in raised position

Page 20

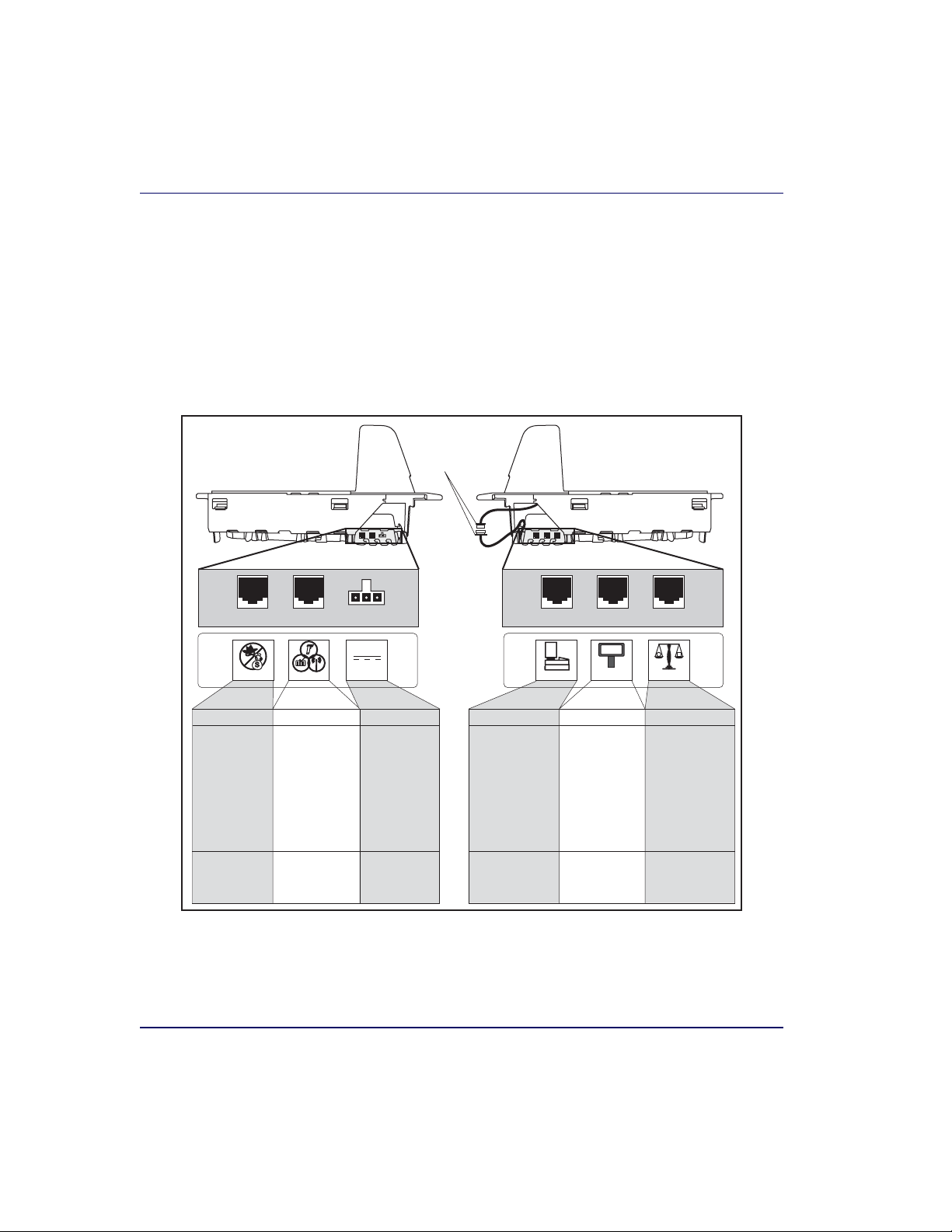

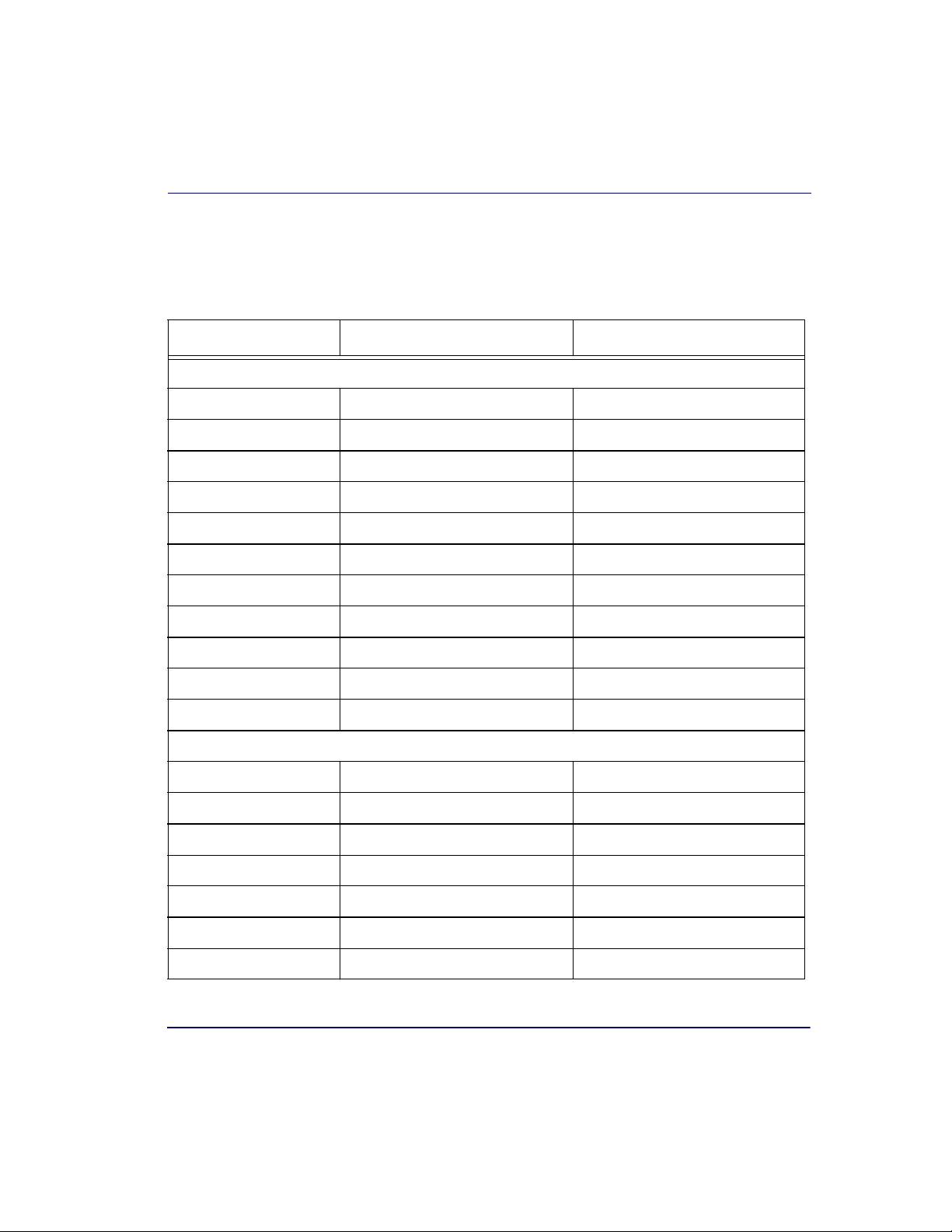

Connections

Two connector panels are located on either side of the scanner as shown in

Figure 1-2. The appearance of these panels will vary depending upon the

factory options purchased with your model. Additionally, a service “pigtail” extends from the scanner’s base to connect the control panel cable

from the Bonnet area.

Figure 1-2. Connectors

Scanner Right Profile Scanner Left Profile

Power

Control Panel

Service Loop

0.00

POS Terminal Remote DisplayAux. PortEAS Port Scale Host

POS TERMINAL REMOTE DISPLAYAUXILIARY PORT SCALE HOSTEAS PORT

· Scale Data (for

single cable interfaces)

· Application Download

(where appropriate)

Drives Remote Display· Label Data

Models with scale

only

Scale Data (dual

cable scanner/scale)

Dual cable units only.

(Scale connection may

be handled through

POS Terminal port)

Connection to

external EAS device.

Controls EAS

deactivation system.

· Test Po rt

· On Screen

Programming (OSP)

· Application Download

· RS-232 Handheld

Scanner Input

· Auxiliary RS-232

Label Data Output

Connection to

this port is

Optional

POWER

AC Brick Input

OR

Power off Terminal

(POT) Brick Input

1-6 Magellan

®

8300/8400

Page 21

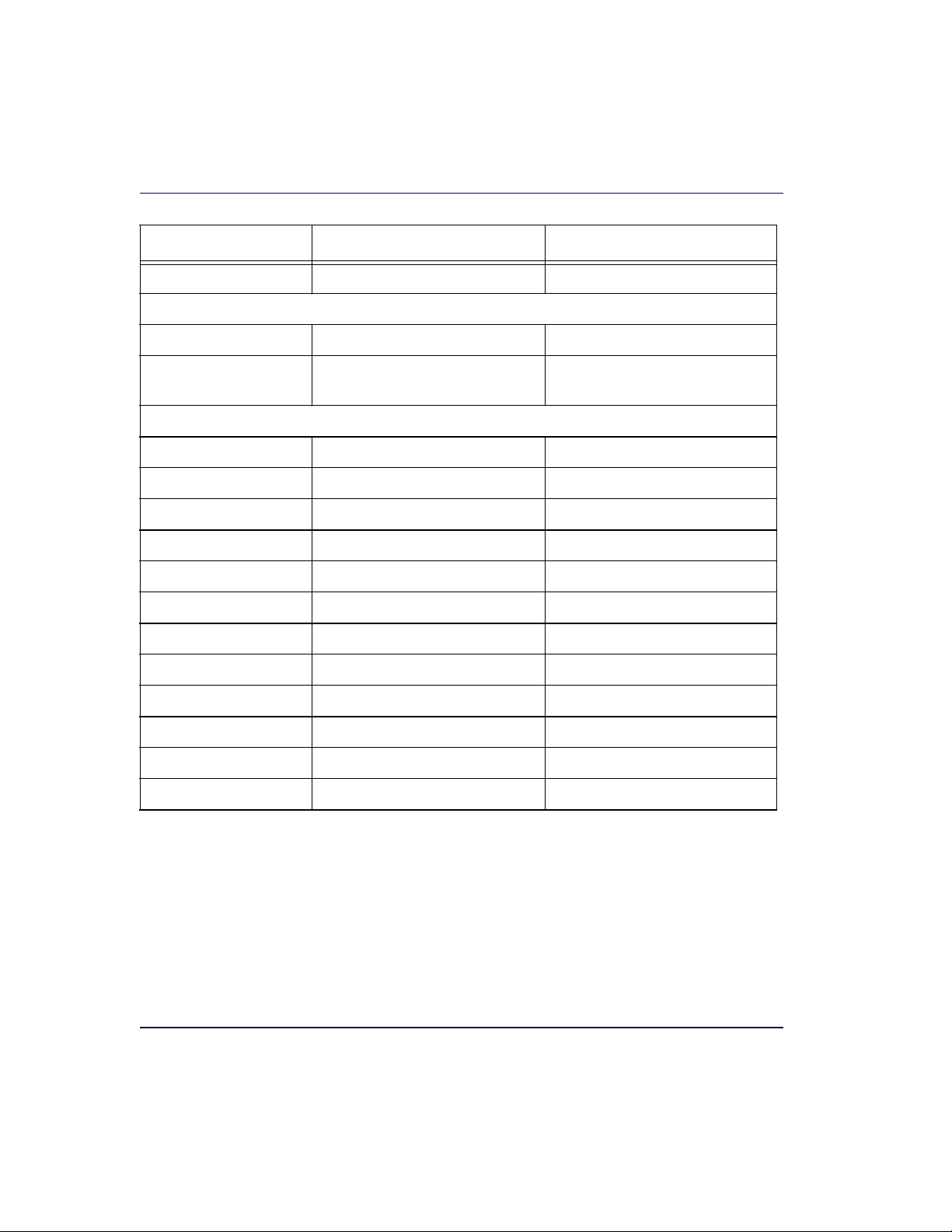

Physical Parameters

This chapter provides specifications for performance, environmental and

electrical parameters. Reference

tion, for physical measurements of all models and some accessories.

Scanning

The scanner has a scan zone between the two windows where the scanner

projects laser light in order to scan items. Two separate projections, one

from the horizontal window and one from the vertical window, combine

to form a zone where bar code labels are read. Refer to

ning Items, for more information.

Deactivating EAS Labels

Deactivation of EAS (Electronic Article Surveillance) anti-theft labels is an

additional function that can be performed by the scanner. More information about this feature can be referenced under the following topics:

Chapter 3, Deactivating Security Labels

•

Physical Parameters

Chapter 2, Site Preparation and Installa-

Chapter 3, Scan-

• Chapter 6, EAS Features

Product Reference Guide 1-7

Page 22

Weighing

Specifications for scale capacity, settling time, minimum and maximum