Page 1

DX8210

Reference Manual

Omnidirectional Barcode Scanner

Page 2

Datalogic S.r.l

Via S. Vitalino 13

40012 Calderara di Reno

Italy

DX8210 Barcode Scanner Reference Manual

Ed.: 04/2019

This manual refers to software version 3.6.1 and later.

© 2015 - 2019 Datalogic S.p.A. and/or its affiliates ALL RIGHTS RESERVED.

Without limiting the rights under copyright, no part of this documentation may be

reproduced, stored in or introduced into a retrieval system, or transmitted in any form

or by any means, or for any purpose, without the express written permission of Data

logic S.p.A. and/or its affiliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many

countries, including the U.S.A. and the E.U.

PackTrack, ACR, ASTRA and X-PRESS are trademarks of Datalogic S.p.A. and/or of its

affiliates. All other trademarks and brands are property of their respective owners.

Datalogic shall not be liable for technical or editorial errors or omissions contained

herein, nor for incidental or consequential damages resulting from the use of this

material.

-

Page 3

Contents

REFERENCES

Reference Documentation ............................................................................................................................................................ vii

Support Through the Website ...................................................................................................................................................... vii

Patents ............................................................................................................................................................................................ vii

CONVENTIONS ....................................................................................................................................................................VIII

COMPLIANCE

Electrical Safety ................................................................................................................................................................................ix

Laser Safety ..............................................................................................................................................................................ix

Standard Regulations ..............................................................................................................................................................ix

Bureau of Indian Standard (BIS) .....................................................................................................................................................ix

Warning and Serial labels ........................................................................................................................................................x

Power Supply ....................................................................................................................................................................................xi

CSA Certified .....................................................................................................................................................................................xi

CE Compliance ..................................................................................................................................................................................xi

EAC COMPLIANCE ............................................................................................................................................................................xii

FCC Compliance ...............................................................................................................................................................................xii

INTRODUCTION

Product Description ......................................................................................................................................................................... 1

General View ..................................................................................................................................................................................... 1

Applications ...................................................................................................................................................................................... 2

Model Description ............................................................................................................................................................................ 4

DX8210 versions .............................................................................................................................................................................. 4

X-PRESS (Human Machine Interface) ............................................................................................................................................ 4

Accessories ....................................................................................................................................................................................... 5

Photoelectric Sensor ........................................................................................................................................................................ 7

Encoder (Tachometer) ...................................................................................................................................................................... 8

Encoder/Tachometer Step Settings ...................................................................................................................................... 8

Photocraft Encoder/Tachometer Switch Setting ................................................................................................................. 9

CBX Industrial Connection Box ..................................................................................................................................................... 10

SC5000 System Controller ............................................................................................................................................................. 11

MECHANICAL INSTALLATION .............................................................................................................................................12

Preparing for Mechanical Installation ......................................................................................................................................... 12

Unpacking Instructions ................................................................................................................................................................. 13

Installation Sequence .................................................................................................................................................................... 13

What You Need to Know About Your Application ...................................................................................................................... 14

Installation ...................................................................................................................................................................................... 15

Dimensions and Clearances .................................................................................................................................................. 15

Physical Support Requirements ........................................................................................................................................... 15

Vibration Limitations ............................................................................................................................................................. 15

General Mounting Guidelines ............................................................................................................................................... 16

Mounting Structure Considerations .................................................................................................................................... 16

Mounting the Scanner ........................................................................................................................................................... 17

ELECTRICAL INSTALLATION

Preparing for Electrical Installation ............................................................................................................................................. 20

Connecting a DX8210 Scanner ...................................................................................................................................................... 21

Typical Connection Block Diagrams ............................................................................................................................................. 21

Single DX8210 Barcode Scanner to CBX .............................................................................................................................. 21

Master/Slave Array with CBX510 ........................................................................................................................................ 22

Reference Manual iii

Page 4

DX8210 Barcode Scanners in an Array with SC5000 Master .............................................................................................23

General Electrical Installation Guidelines and Precautions .......................................................................................................24

DX8210 Connector Panels ..............................................................................................................................................................25

Connecting a PC to the DX8210 .....................................................................................................................................................26

Power Connector Pin-Out Table ....................................................................................................................................................26

Power Connections .........................................................................................................................................................................26

CBX510 Connection Box .................................................................................................................................................................27

Wiring Into the CBX510 Connection Box ..............................................................................................................................27

Main Serial Interface ......................................................................................................................................................................28

RS232 Interface .......................................................................................................................................................................28

RS422 Full-Duplex Interface ..................................................................................................................................................29

Photoelectric Sensor Connections to CBX510 .............................................................................................................................30

Photoelectric Sensor (NPN) ...................................................................................................................................................30

Photoelectric Sensor (PNP) ....................................................................................................................................................31

Tachometer Wiring to CBX510 ......................................................................................................................................................31

Encoder/Tachometer Wiring for NPN Output (two models) ..............................................................................................32

Encoder/Tachometer Wiring for PNP Output (two models) ..............................................................................................34

Digital Output Configuration to CBX510 ......................................................................................................................................36

Unpowered Outputs ...............................................................................................................................................................37

Powered Outputs ....................................................................................................................................................................37

CBX100 Connection Box .................................................................................................................................................................38

Connecting to the SC5000 System Controller (Optional) ....................................................................................................39

Grounding ........................................................................................................................................................................................40

Check Scanner Installation ............................................................................................................................................................41

E-GENIUS

Getting Started ................................................................................................................................................................................42

Prerequisites ...........................................................................................................................................................................42

Starting e-Genius ....................................................................................................................................................................42

Monitor Mode ..................................................................................................................................................................44

e-Genius Basics ..............................................................................................................................................................................46

e-Genius Menu Tree ...............................................................................................................................................................46

Entering Text Using the Text Entry Tool ...............................................................................................................................46

Update and Reset Buttons ....................................................................................................................................................47

Disabled Check Boxes .............................................................................................................................................................47

Getting Help .............................................................................................................................................................................47

System Information ........................................................................................................................................................................48

Modify Settings ...............................................................................................................................................................................51

Operating Mode ..............................................................................................................................................................................52

Barcode Settings Table ...................................................................................................................................................................66

Barcode Configuration ...................................................................................................................................................................73

Single Label .....................................................................................................................................................................................74

Standard Multi Label ......................................................................................................................................................................78

Logical Combination .......................................................................................................................................................................82

Barcode Configuration | Code Collection .....................................................................................................................................92

Serial Ports ......................................................................................................................................................................................97

Main Serial Port ..............................................................................................................................................................................98

Aux Serial Port .............................................................................................................................................................................. 101

Ethernet ........................................................................................................................................................................................ 103

Ethernet | Line Settings ............................................................................................................................................................. 104

Ethernet | User Sockets .............................................................................................................................................................. 106

Ethernet | Ethernet_IP ............................................................................................................................................................... 110

Ethernet | WebSentinel .............................................................................................................................................................. 114

Fieldbus ........................................................................................................................................................................................ 116

Messaging ............................................................................................................................................................................ 121

Messaging | Message Format ................................................................................................................................................... 122

Messaging | Message Builder ................................................................................................................................................... 134

Messaging | Statistics ................................................................................................................................................................ 140

Messaging | Protocol Index ....................................................................................................................................................... 142

Messaging | Pass-Thru .............................................................................................................................................................. 146

Messaging | Diagnostics Messages ......................................................................................................................................... 148

Digital I/O ..................................................................................................................................................................................... 151

iv DX8210 Bar Code Scanner

Page 5

Diagnostics ................................................................................................................................................................................... 154

Energy Saving ............................................................................................................................................................................... 158

HMI Settings ................................................................................................................................................................................. 162

Device Settings ............................................................................................................................................................................. 163

Device Settings | Device Info ...................................................................................................................................................... 164

Device Settings | Mounting ........................................................................................................................................................ 166

PackTrack™ Calibration Wizard ................................................................................................................................... 168

Device Settings | Options ........................................................................................................................................................... 169

Diagnostics ................................................................................................................................................................................... 173

Diagnostics | Monitor ................................................................................................................................................................. 174

Diagnostics | Read Test .............................................................................................................................................................. 176

Diagnostics | Status Viewer ....................................................................................................................................................... 177

Utilities .......................................................................................................................................................................................... 180

Utilities | Backup or Restore ...................................................................................................................................................... 181

Utilities | Reboot .......................................................................................................................................................................... 183

Utilities | Update Firmware ........................................................................................................................................................ 184

Utilities | Launch Genius ............................................................................................................................................................ 186

Utilities | Help .............................................................................................................................................................................. 187

BARCODE SCANNING FEATURES

First-time Startup ........................................................................................................................................................................ 188

Default Parameters ............................................................................................................................................................. 188

Check Operations Using Test Mode ................................................................................................................................... 189

Basic Installation Procedures with the CBX510 ....................................................................................................................... 189

Basic Installation with SC5000 Controller ................................................................................................................................. 194

LED Indicators .............................................................................................................................................................................. 199

Control Panel Buttons ................................................................................................................................................................. 200

X-PRESS™ Human Machine Interface ................................................................................................................................ 200

X-PRESS Functions ...................................................................................................................................................... 200

Restore Button and Other Functions ................................................................................................................................ 204

Built-In Calibration for Top-Mount ............................................................................................................................................ 204

Built-In Calibration Static Test ........................................................................................................................................... 208

Built-In Calibration Dynamic Test ...................................................................................................................................... 209

PackTrack™ .................................................................................................................................................................................... 211

Using the PackTrack Wizard ............................................................................................................................................... 212

Top-Mounted Barcode Scanner Calibration Using PackTrack ......................................................................................... 216

Side-Mounted Barcode Scanner Calibration Using PackTrack ....................................................................................... 230

Verifying PackTrack Calibration .......................................................................................................................................... 241

Replacing an Installed DX8210 ................................................................................................................................................... 243

Replacing a Standalone Scanner Using Restore ............................................................................................................... 243

Replacing a Slave Scanner in an Array/Tunnel Automatically ........................................................................................ 244

Replacing a Slave Scanner in an Array/Tunnel Using Restore ....................................................................................... 244

Replacing a Master Scanner in an Array/Tunnel Using Restore .................................................................................... 245

Checking the Operation of the Replacement .................................................................................................................... 246

Typical Layouts ............................................................................................................................................................................. 246

Large Synchronized Network Layout ................................................................................................................................. 247

Advanced Code Reconstruction (ACR™) ...................................................................................................................................... 250

Tilt Angle for Advanced Code Reconstruction ................................................................................................................... 250

Minimum Code Height for Advanced Code Reconstruction ............................................................................................ 252

Reading Diagrams ........................................................................................................................................................................ 254

MAINTENANCE

Overview ........................................................................................................................................................................................ 264

Maintenance Tasks ...................................................................................................................................................................... 265

Cleaning the Exit Window ................................................................................................................................................... 265

Cleaning the Photoelectric Sensor ..................................................................................................................................... 266

Cleaning the Tachometer .................................................................................................................................................... 267

Tighten Mounting Hardware ............................................................................................................................................... 267

Checking Barcode Scanning System Connections ............................................................................................................ 267

Verify Barcode Scanner Operation ..................................................................................................................................... 268

Verify Photoelectric Sensor Operation ............................................................................................................................... 268

Verify Tachometer Operation .............................................................................................................................................. 268

Reference Manual v

Page 6

TROUBLESHOOTING

LED Diagnostic Indication ........................................................................................................................................................... 270

Error Codes and Resolutions ...................................................................................................................................................... 271

TECHNICAL FEATURES

Technical Specifications .............................................................................................................................................................. 279

INDEX ................................................................................................................................................................................. 282

vi DX8210 Bar Code Scanner

Page 7

Reference Documentation

The documentation related to the DX8210 management is listed below:

• CBX510 Connection Box Installation Manuals

• SC5000 Controller Manuals

Support Through the Website

Datalogic provides several services as well as technical support through its website. Log on to www.datalogic.com.

For quick access, from the home page click on the search icon , and type in the

name of the product you’re looking for. This allows you access to download Data

Sheets, Manuals, Software & Utilities, and Drawings.

Hover over the Support & Service menu for access to Services and Technical Support.

References

Patents

See www.patents.datalogic.com for patent list.

This product is covered by one or more of the following patents:

Utility patents: EP0959426B9, EP1217571B1, EP2519856, JP4376353B2,

US6394352, US6443360, US6742710, US9104928, US9230146, US9530037,

US9625715

Reference Manual vii

Page 8

Conventions

This symbol draws attention to details or procedures that may be useful in improving, maintaining, or enhancing the performance of the hardware or software being

discussed.

This symbol identifies a hazard or procedure that,

cause personal injury or result in equipment damage. It is also used to bring the

user’s attention to details that are considered IMPORTANT.

This symbol alerts the user they are about

dangerous level of voltage, or to warn against an action that could result in damage

to devices or electrical shock.

This symbol alerts the user they are about to perform an action involving

exposure to laser light radiation.

This symbol identifies a procedure that require

trostatic Discharge (ESD) e.g., use an ESD wrist strap. Circuit boards are most at

risk. Please follow ESD procedures.

to perform an action involving, either a

if incorrectly performed, could

possible

s you take measures to prevent Elec-

viii

DS8110 Barcode Scanner

Page 9

Electrical Safety

This product conforms to the applicable requirements contained in the European

Standard for electrical safety EN 60950 at the date of manufacture.

Laser Safety

The following information is provided to comply with the rules imposed by international authorities and refers to the correct use of the DX8210 barcode scanners.

Standard Regulations

These barcode scanners use low-power laser diodes. Avoid staring at the beam

as one would with any very strong light source, such as the sun.

Take care when installing the laser device to avoid inadvertent laser beam contact with the eye of an observer, including through reflective surfaces.

This product conforms to th

plies with 21 CFR 1040.10 except for deviations pu

date June 24, 2007. The scanner is classified as a Class 2 laser product according to IEC 60825-1 regulations.

There is a safety device which allows the laser to be switched on only if the

tor is rotating above the threshold for its correct scanning speed.

mo

Compliance

e applicable requirements of IEC 60825-1 and com-

rsuant to Laser Notice N° 50,

Use of controls or adjustments or performance of procedures other than those

specified herein may result in exposure to hazardous visible laser light

Bureau of Indian Standard (BIS)

Self Declaration – Conforming to IS 13252 (Part 1):2010, R-41009288.

Reference Manual ix

Page 10

Warning and Serial labels

The Warning Label on the front of the barcode scanner indicates exposure to

laser light and the device classification.

Produit(s) conforme selon 21CFR

1040.10 sauf des dérogations relatives

à la Laser Notice N° 50, date Juin 24,

2007.

Dans le paquet il y a l’étiquette(s) pour

les pays où le texte d'avertissement en

français sont obligatoires. Le(s) mettre

sur le produit à la place de la version

anglaise.

Exemple d'étiquettes d'avertissement la

ser

x

DS8110 Barcode Scanner

Page 11

Disconnect the power supply when installing the device or during maintenance to

avoid unintentional exposure to laser light.

There are no user serviceable parts inside the barco

be performed by Datalogic trained and certified technicians.

Any violation of the optical parts in particular could result in exposure to Class 3B

laser light.

Power Supply

This product is intended to be installed by Qualified Personnel only.

This product is intended to be supplied by a

with “Class 2” or LPS power source.

CSA Certified

de scanner. Service should only

UL listed or CSA Certified Power unit

CE Compliance

CE marking states the compliance of the product with essential requirements

listed in the applicable European directive. Since the directives and applicable

standards are subject to continuous updates, and since Datalogic promptly

adopts these updates, therefore the EU declaration of conformity is a living document. The EU declaration of conformity is available for competent authorities

nd customers through Datalogic commercial reference contacts. Since April

a

20th, 2016 the main European directives applicable to Datalogic products

require inclusion of an adequate analysis and assessment of the risk(s). This

evaluation was carried out in relation to the applicable points of the standards

listed in the Declaration of Conformity. Datalogic products are mainly designed

for integration purposes into more complex systems. For this reason it is under

the responsibility of the system integrator to do a new risk assessment regarding

the final installation.

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Reference Manual xi

Page 12

EAC COMPLIANCE

Customs Union:

The CU Conformity certification has been achieved; this allows the Product to

bear the Eurasian Mark of conformity.

FCC Compliance

Modifications or changes to this equipment without the expressed written

approval of Datalogic could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

which may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equip

ment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accor

dance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his/her own expense.

-

-

xii

DS8110 Barcode Scanner

Page 13

Product Description

The DX8210 omnidirectional barcode scanner is designed to provide an innovative and high performance solution in omnidirectional reading applications by

c

ombining the following advanced technologies with Datalogic solid experience

in the material handling sector.

Some of the main features of the DX8210 are listed below:

• Scanning speed 1000 scans/sec

• Reads all popular codes

• Supply voltage from 20 to 30 vdc

• Test mode to verify the reading featur

ner without the need for external tools

• Programmable in several different operating modes to suit the most various

barcode

• Light source: solid state laser diodes; the light emitted has a wave length

be

section at the beginning of this manual

reading system requirements

tween 630~680 nm. For laser safety precautions refer to the “compliance”

Chapter 1

Introduction

es and exact positioning of the scan-

General View

Reference Manual 1

Page 14

Introduction

Applications

The DX8210 barcode scanners are specifically designed for industrial applications and for all cases requiring high reading performance such as:

• Code reconstruction (ACR™)

• Reading of codes covered by plastic film

• Reading of codes with a wide depth of field

• Reading codes within a wide field of view

• Reading of high resolution codes positioned at long distances from the

• Code reading on fast moving objects

These barcode scanners are designed for both single-reader layouts and multireader layouts. For typical layouts, see

reader

section

.

2

DX8210 Barcode Scanner

Page 15

FEATURE BENEFIT

Digital Signal Technology converts analog signals to digital before processing

DST

f

or much improved decoding capability especially on poorly printed or dam-

aged codes.

Applications

ACR™

PACKTRACK™

ASTRA™

Flexibility

Reading parcels on conveyors

Fifth generation Advanced Code Reconstr

ing of low aspect ratio labels placed anywhe

readability of poorly printed or damaged codes.

Second generation Datalogic patented pa

improves the reading features in omnidirectional stations. In particular,

PackTrack manages 6-sided reading systems when it is impossible to detect

the real position of the code on the parcel, thus overcoming the need for

external accessories essential in traditional tracking systems.

Third generation Automatically SwiTched

nology based on a multi-laser architecture

tem which concentrates the multiple laser emissi

As each laser emitter is focused on a specific range of the reading area, a

sophisticated electronic controller selects the best focused laser emitter

with respect to the code to read. This allows the reading of medium-high

density codes in a large reading area on very fast conveyors.

The high frequency laser diode modulat

immunity to ambient light and allows installation of the DX8210 in any

working area.

As a result of the ASTRA multiple lase

a great real time DOF even on high speed conveyors. Furthermore, DX8210

and DX8210 implement the PackTrack functionality which leads to an

increase of the plant production as a result of the augmented system

throughput.

uction technology allows the read-

re on a parcel and enhances the

rcel tracking system which

Reading Area is the Datalogic tech-

and a fixed mounted optic sys-

ons in a single laser beam.

ion system guarantees complete

r technology, DX8210 and DX8210 give

EBC

e-Genius

Energy Saving

Ethernet Based Connectivity is a reliable real-time n

between scanners in a reading station tunnel or array.

e-Genius

tics:

No software to install;

Multilanguage platform;

All the configuration parameters stored i

Not dependent on the Physical interface; R

work.

A software parameter group which allows manage

feature. In particular, it allows turning on/off the motor and laser of all network scanners according to the selected digital input, encoder, or communication channel.

The time required to restart the system is less than 1 mi

from the number of scanners connected.

It is suggested to use this parameter f

stopped for a lengthy period.

is a browser-based User Interface with the following characteris-

n the scanner;

emote access through local net-

or example when the conveyor is

etwork communication

ment of the energy saving

nute independently

Reference Manual 3

Page 16

Introduction

Model Description

The DX8210 barcode scanner is available in versions that differ depending on

the interface connection, the optical resolution and the optic version:

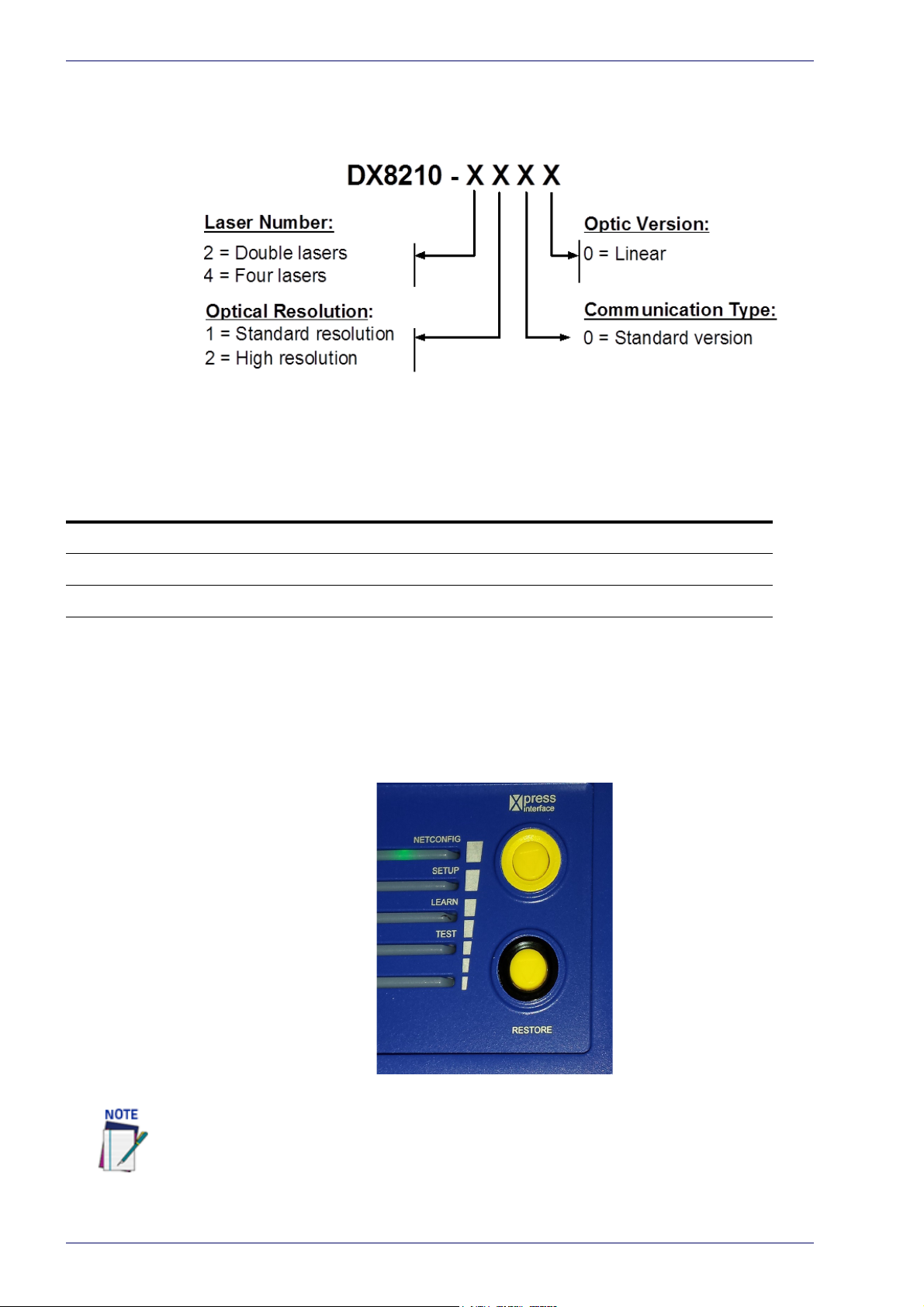

DX8210 versions

Model Description Part Number

DX8210-2100 2 Laser, Standard Resolution 936300001

DX8210-4100 (focus 1) 4 Laser, Standard Resolution 936300003

DX8210-4200 (focus 2) 4 Laser, High Resolution 936300004

X-PRESS (Human Machine Interface)

The DX8210 barcode scanner includes two external buttons that make up the XPRESS HMI interface and perform specific tasks without the need of connecting

See

to e-Genius.

for functional description:

Some of these functions may be performed using e-Genius. See Chapter .

4

DX8210 Barcode Scanner

Page 17

Accessories

The following accessories are available on request for the DX8210 barcode scanner.

Category Description Part Number

Cables and Terminators

Accessories

Ethernet Cables

ETH CABLE M12-M12 1M (straight-straight)

Scanner to Scanner EBC (ETH1 or ETH2)

ETH CABLE M12-M12 3M (straight-straight)

Scanner to Scanner EBC (ETH1 or ETH2)

ETH CABLE M12-M12 5M (straight-straight)

Scanner to Scanner EBC (ETH1 or ETH2)

ETH CABLE M12-M12 1M (straight- 90°)

SC5000 to Scanner EBC (ETH1 or ETH2)

ETH CABLE M12-M12 3M (straight- 90°)

SC5000 to Scanner EBC (ETH1 or ETH2)

ETH CABLE M12-M12 5M (straight- 90°)

SC5000 to Scanner EBC (ETH1 or ETH2)

ETH CABLE M12-RJ45 5M (90°-RJ45)

SC5000 to the Host or Configuration PC (HOST or CFG)

CAB-ETH-M01 M12-IP67 1M (straight- RJ45)

Scanner to the Host or Configuration PC

CAB-ETH-M03 M12-IP67 3M (straight- RJ45)

Scanner to the Host or Configuration PC

93A050065

93A050066

93A050067

93A050068

93A050069

93A050070

93A050088

93A051346

93A051347

CAB-ETH-M05 M12-IP67 5M (straight- RJ45)

Scanner to the Host or Configuration PC

REDs Cables

EBC Patch Cable

Interface Cable SC5000 to CBX510 for Serial or I/O connections 93A050071

CBX Cables

AS-I Terminal AS-I CABLE TERMINAL for AS-I branch topology wiring 93ACC0083

ETH CABLE M12-M12 1M (90°- 90°)

SC5000 to SC5000 EBC (ETH1 or ETH2)

REDS POWER ALARM CABLE 5M

PWR-480B to CBX510 power alarm connections

ETH CABLE M12-M12 0.5M (straight-straight)

Female to Female EBC patch cable; close the EBC when a

scanner is sent to repair, only for Master/Slave

CAB-DS01-S M12-IP67 1M

Scanner to CBX for Serial or I/O connections

CAB-DS03-S M12-IP67 3M

Scanner to CBX for Serial or I/O connections

CAB-DS05-S M12-IP67 5M

Scanner to CBX for Serial or I/O connections

93A051348

93A050087

93A050086

93A050085

93A050058

93A050059

93A050060

Reference Manual 5

Page 18

Introduction

Category Description Part Number

Power Cables PWR CABLE, AS-I, 2 Wires, 10M (Backbone with caps) 93ACC0081

PWR CABLE, AS-I, 2 Wires, 25M (Backbone with caps) 93ACC0082

PWR CABLE M12- ASI standard 1M (Node) 93ACC0067

PWR CABLE M12- ASI standard 2M (Node) 93ACC0068

PWR CABLE ext. M12 Male-M12 Fem 3M for PG-240 93ACC0149

PWR CABLE ext. M12 Male-M12 Fem 5M for PG-240 93ACC0150

PWR CABLE, CAB-LP-05 M12 Female-Free Wires 5M

for alternative power connections

Connection Boxes

CBX100 Compact 93A301067

CBX100 Compact All in One (includes BM100) 93A301076

CBX510 Modular 93A301087

CBX510 Modular All in One (includes BM100) + BA200 93A301091

Backup Module BM100 Backup Module 93ACC1808

Mounting Hardware

Fieldbus Modules BM300/310 Profibus Module STD/IP65

Fieldbus Modules BM700/710 Profinet Module STD/IP65

Controllers

BA200 Mounting Adapters (to Bosch or 80/20 Frames) 93ACC1822

SC5000-1000 Standard System Controller 935750001

93A050037

93ACC1810,

93ACC1811

93ACC1816,

93ACC1886

SC5000-1100 Profibus System Controller 935750002

SC5000-1200 Profinet System Controller 935750003

Mounting Hardware

Power Supplies

Sensors

BA200 Mounting Adapters (to Bosch or 80/20 Frames) 93ACC1822

PG-100-K03 POWER SUPPLY 60W KIT (US) w/ M12 cable 93ACC0058

PG-100-K01 POWER SUPPLY 60W KIT (EU) w/ M12 cable 93ACC0059

PG-100-K02 POWER SUPPLY 60W KIT (UK) w/ M12 cable 93ACC0060

PG-240-K03 POWER SUPPLY 240W 8 Port M12 (US)

w/o M12 Cable

PG-240-K01 POWER SUPPLY 240W 8 Port M12 (EU)

w/o M12 Cable

PWR-480B POWER UNIT 110/230VAC 24V 93ACC0076

MEP-593 PHOTOCELL KIT PNP (PH-1) with Free Wires 93ACC1791

93ACC0144

93ACC0145

6

DX8210 Barcode Scanner

Page 19

Photoelectric Sensor

Category Description Part Number

MEP-604 PHOTOCELL KIT PNP M12-M12

Photocell with M12 connector for SC500

Encoders

OEK-2 OPTICAL ENCODER KIT (CAB 10M +SPRING) 93ACC1770

OEK-4 ENC KIT PNP 250PPR + M12-M12 CABLE 95B082040

OEK-4 ENC KIT PNP 250PPR + M12-FREE CABLE 95B082050

Field Mount Connectors

Mounting Brackets

L-Bracket DX8210 L-SHAPE Mtg Bracket-Standard 93ACC0151

L-Bracket

FMC-5000 2xM12 TRIG+ENC INPUT KIT

Connectors for PLC signal to SC5000

(Tilt-Tray or Cross-Belt applications)

DX8210 L-SHAPE SIDE MOUNTING BRACKET (for side Airport mounting)

0

93ACC0140

93ACC0181

93ACC0079

Photoelectric Sensor

The optional Datalogic Photoelectric Sensor is used in DX8210 barcode scanner

systems to detect the presence of an item in the scanning area.

The photoelectric sensor is used in singulated systems where the packages are

se

parated by an open space between the trailing edge of one package and the

leading edge of the next. The photoelectric sensor, along with the encoder,

enables a programmable transmit point at a defined distance from the sensor.

Without the photoelectric sensor, the barcode scanner can be run in continuous

mode.

Depending on the application, these device

ently. While the photoelectric sensor and tachometer work well with belt conveyors, a special configuration is needed

applications.

See Modify Settings | Global Settings | Operating Mode.

s may need to be configured differ-

for tilt-tray and cross-belt sorter

See section for wiring options.

Photoelectric Sensor and Cable (recommended)

MEP-593 PHOTOCELL KIT PNP (PH-1) with Stripped Wires 93ACC1791

MEP-604 PHOTOCELL KIT

PNP M12-M12 Photocell with

M12 connector for SC500

0

93ACC0140

Reference Manual 7

Page 20

Introduction

Encoder (Tachometer)

The tachometer provides a continuous pulse to the system, which provides feedback on conveyor speed and transmit point,

package position along the length of the conveyor.

Encoder (Tachometer)

OEK-2 ENCOD KIT OEK-2 ENC KIT (CAB 10m +SPRING) 93ACC1770

and can be used to help track the

OEK-4 ENCOD KIT

OEK-4 ENCOD KIT

OEK-4 ENC KIT PNP 250PPR + M12-

2 CABLE

M1

OEK-4 ENC KIT PNP 250PPR + M12FREE

Encoder/Tachometer Step Settings

The following table shows the Encoder Step setting used based on pulses per

revolution. The Encoder Step setting is entered in e-Genius

Settings | Global Settings | Operating Mo

meter)).

PPR

Encoder Model

OEK-4 (Datalogic) 250 20 63

OEK-2 (Photocraft) 24 2 635

OEK-2 48 4 317

(Pulses Per

Revolution)

CABLE

95B082040

95B082050

(see section Modify

de – Encoder Step (hundredths of milli-

PPI

(Pulses Per

Inch)

Encoder Step

tting

Se

OEK-2 192 16 79

OEK-2 240 20 63

This symbol draws attention to details or procedures that may be useful in improving,

maintaining, or enhancing the performance of the hardware or software being discussed.

8

DX8210 Barcode Scanner

Page 21

Photocraft Encoder/Tachometer Switch Setting

Encoder (Tachometer)

Only switches 1-5 are used to set the PPR (Pulses Per Revolution). Switches 6-8 are

used for PNP/NPN settings as shown in the label on the arm of the encoder.

Reference Manual 9

Page 22

Introduction

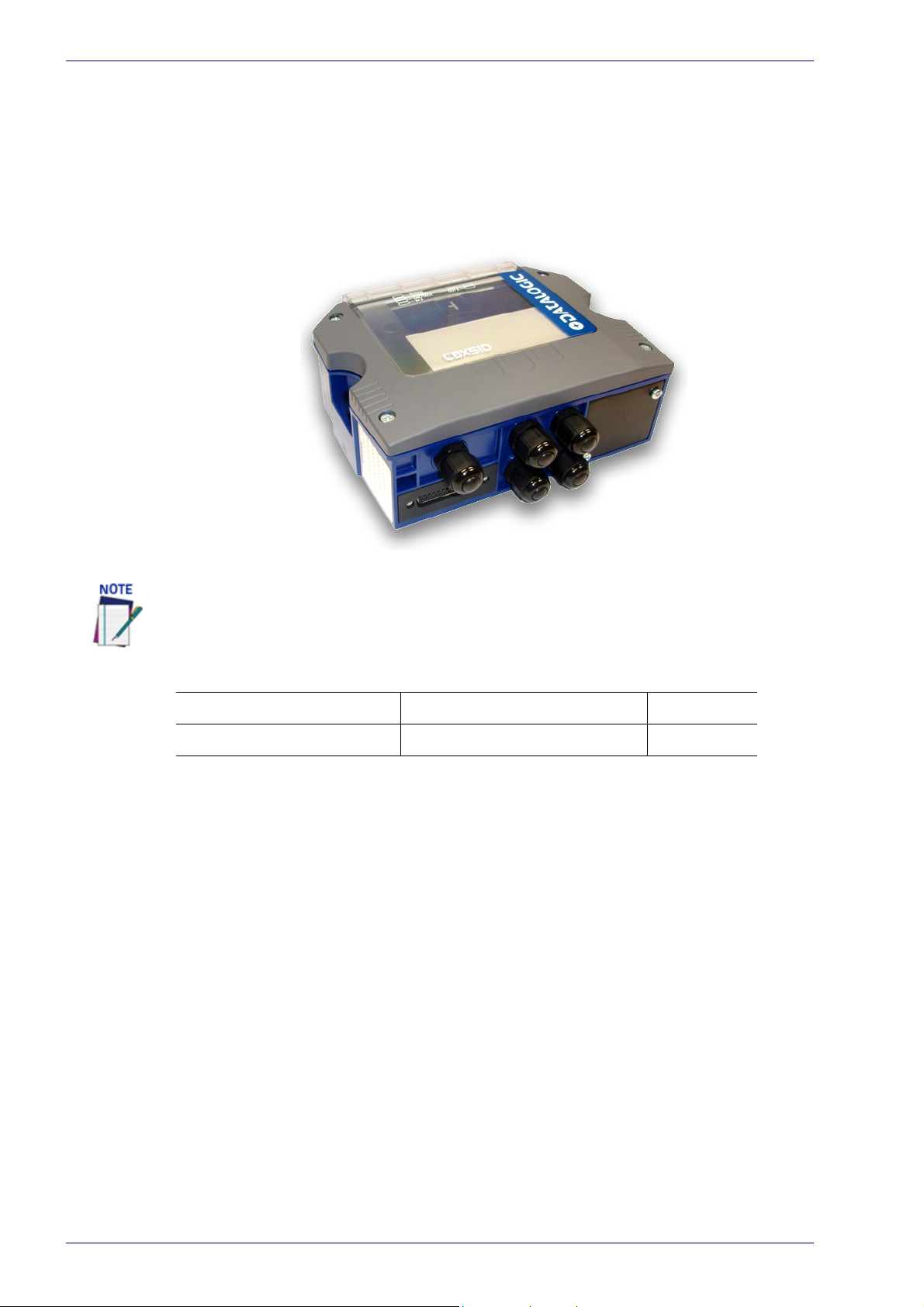

CBX Industrial Connection Box

CBX Series are industrial connection boxes that can be used to connect the barcode scanners to an encoder/tachometer, photoelectric sensor, serial devices,

lays, or other peripherals. The CBX510 includes a BM100 backup module,

re

which allows easy parameter restore and backup operations. The backup module

also provides an easy way to upload existing parameters to a replacement barcode scanner when necessary. See section for wiring options.

Scanner operation requires a CBX510 connection box or SC5000 controller.

Industrial Connection Box

CBX510 Connection Box CBX510 for DX8210 and DX8210 93A301087

CBX510 Connection Box CBX510 ALL IN ONE + BA200 93A301091

10

DX8210 Barcode Scanner

Page 23

SC5000 System Controller

The SC5000 Controller offers all the necessary functions to make the phases of

installation, setup, testing, and maintenance of the omni-directional reading

array or tunnel easy and quick.

The SC5000 Controller is fully compatible with DX8210 and DX8210 scanners

an

d its sturdy mechanical structure makes the SC5000 Controller the ideal solu-

tion for industrial environments. The Controller allows connection to the Trigger

nd Encoder/Tachometer. PNP inputs are available via M12 circular connectors,

a

placed on the lower front panel

SC5000 System Controller

.

System Controller

SC5000-1000 System Controller Standard 935750001

SC5000-1100 System Controller Profibus 935750002

SC5000-1200 System Controller Profinet 935750003

Reference Manual 11

Page 24

Mechanical Installation

Electrical Installation by Qualified Service Technicians Only! Procedures may involve

exposure to high-voltage. A trained and authorized technician must perform these

procedures. Do not attempt to perform any electrical installation procedures unless

you are a trained technician.

DX8210 barcode scanners contain electronics that may be affected by electrostatic discharge (ESD). To prevent personal injury or damage to the unit, please follow the safety

precautions and warnings found in the References section at the beginning of this

manual. Failure to follow these precautions may void your warranty.

Preparing for Mechanical Installation

Chapter 2

Application-specific drawings and documents provided by Datalogic supersede any

contradictory content in this manual.

Before mounting any components, please do the following:

• Read all instructions before beginning your installation.

• Define and confirm the accuracy of your application’s requirements and

cture position, especially the height of the conveyor from the floor.

stru

• Review all installation-specific drawings provided with your equipment.

• Review and plan the mechanical installation of all devices used in your

pplication. Be sure to allow adequate clearance for maintenance.

a

• Review and plan the power requi

• Check the contents of the shipping ca

• Record all product serial numbers.

Refer to the Chapter Electrical Installation and Reference Documentation for details on

connecting your barcode scanners to other devices in the system.

rements for your application.

rtons against the packing list.

12

DX8210 Barcode Scanner

Page 25

When installing several scanners, take care to position them so that no laser beam

enters the reading window of other scanners. This condition could occur more frequently for side mounted applications. If these precautions are not followed, read rate

could be negatively affected. To resolve this problem, it is sufficient to slightly change

the inclination and position of one of the two scanners involved if possible.

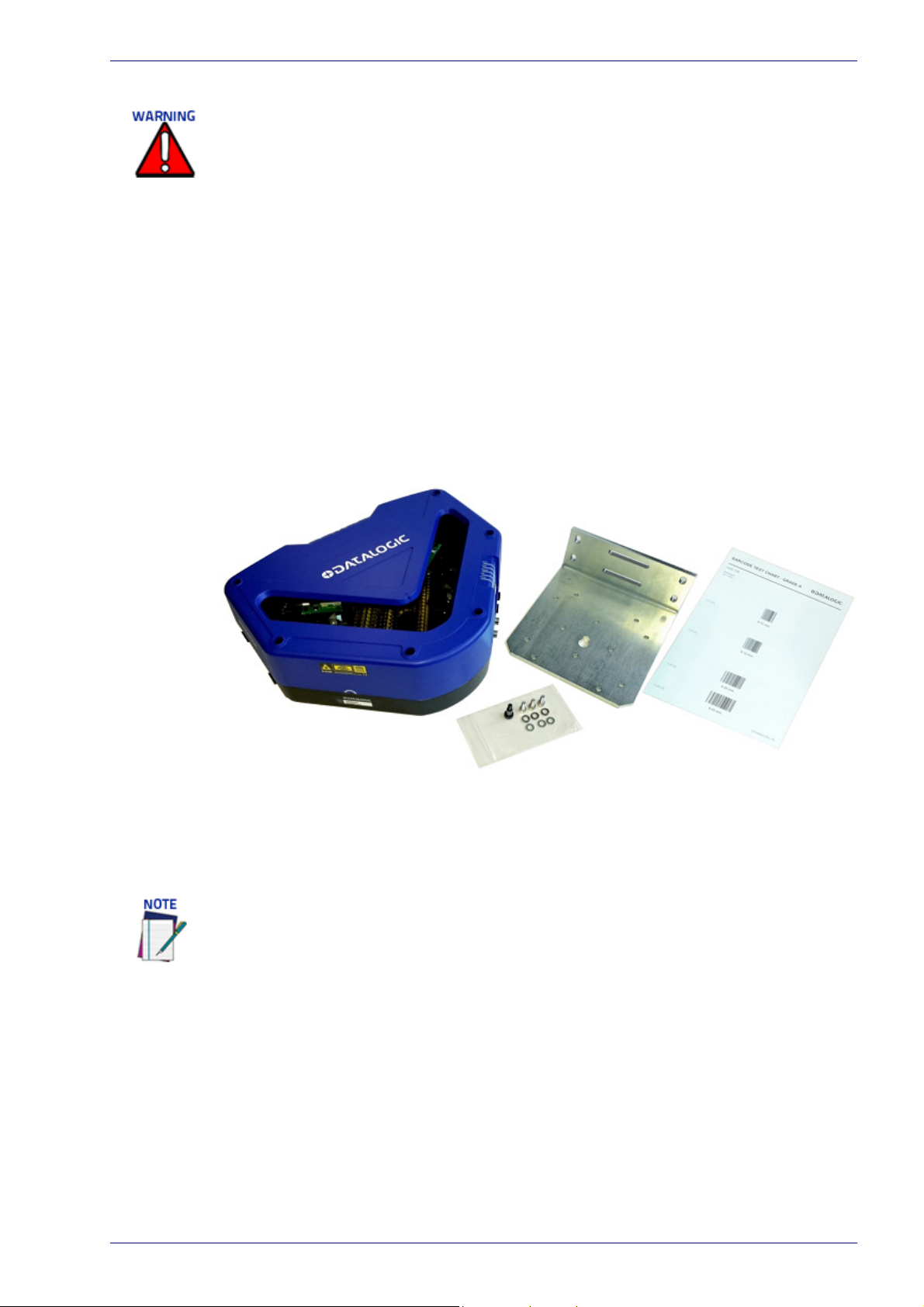

Unpacking Instructions

Verify that the DX8210 barcode scanners and all the parts supplied with the

equipment are present and intact when opening the packaging; the list of parts

includes:

• DX8210 reader

•L-bracket

•Mounting screws and washers

• Shoulder screw

•Barcode Test Chart

Unpacking Instructions

Installation Sequence

Everything should be MECHANICALLY INSTALLED before performing any ELECTRICAL

INSTALLATION.

See Chapter 3 Electrical Installation for electrical installation details.

To complete mechanical installation and setup, you must:

• Review the details of your application’s requirements

• Erect mounting structure or other supporting structures

• Determine and mark the Mounting Bracket location(s)

• Mount the bracket to the mounting structure

• Mount the DX8210 to its mounting bracket

• Mount the photoelectric sensor to the mounting structure (optional)

• Mount the tachometer to the mounting structure (optional)

• Mount the CBX connection box to the mounting structure

Reference Manual 13

Page 26

Mechanical Installation

• Mount the SC5000 to the mounting structure

• Complete electrical installation

• Align the DX8210 for proper operation

• Configure the DX8210

• Check DX8210 operations

(See Chapter

(See Chapter 3

4)

(See Chapter 5

)

)

What You Need to Know About Your Application

To assure you get optimal performance out of your DX8210, it must be installed

to meet the complete needs of your application. Therefore, take the time to learn

the details of your application. The better you know your application, the easier

it is to apply the DX8210’s capabilities to meet your application’s requirements.

Below is what you will need to know before you can begin installation:

• Conveyor Specifications

- Conveyor type: Belt, tilt-tray, cross belt, other?

- What is the conveyor width?

- What is the conveyor speed?

- Does conveyor speed vary or is it constant?

• Product Specifications

- Are the packages being transported always singulated (not touching) or

non-singulated (possibly touching)?

- How many different product sizes may be involved?

- Are products justified: toward/away from reader, centered, or variable?

• Application Specifications

- How will the barcode information be used in your application?

- What are your communication requirements?

While it is nearly impossible to cover all application configurations, the next several pages provide the basics on determining how to mechanically install your

DX8210. If you need additional assistance, feel free to contact your sales repre

sentative or customer service (www.datalogic.com).

-

14

DX8210 Barcode Scanner

Page 27

Installation

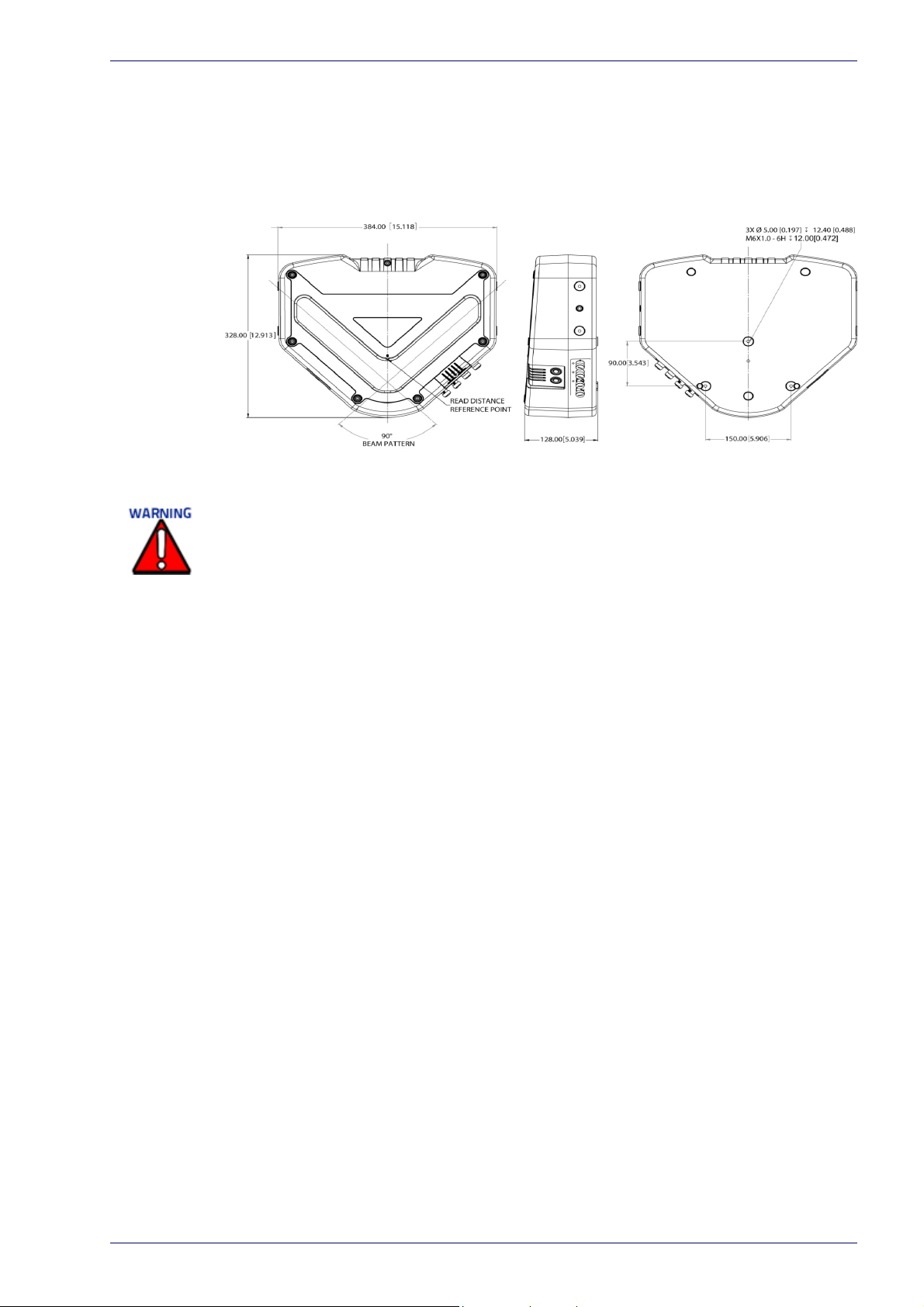

Dimensions and Clearances

The overall dimensions of the DX8210 are 384 x 128 x 328 mm [15.1 x 5 x 12.9 in].

Installation

The DX8210 is a sealed, unventilated unit. Mounting the unit with 300mm [12 inches] of

clearance (front, top, and sides) is recommended for cooling and ease of maintenance.

Physical Support Requirements

For details on the weight of the barcode scanners,

Multiple-head systems may include further details on the physical support

tures.

requirements with any application-specific documentation provided.

Vibration Limitations

See “Technical Features” on page 278.

see Chapter 8, Technical Fea-

Reference Manual 15

Page 28

Mechanical Installation

General Mounting Guidelines

It is important that you follow these general precautions when installing, setting

up, operating, maintaining, troubleshooting, or replacing any Datalogic prod

ucts, parts or related equipment.

As you plan and install your DX8210 barcode scanning system application, be

sure to keep the following guidelines in mind:

• All mounting structure assembly and equipment installation can be performed by one installer.

• Determine the proper orientation and position of the barcode scanner.

• Leave adequate clearances (approximately 300 mm [12 inches]) for wiring.

• Route wires carefully to reduce or minimize electrical noise. When power

and communication wiring must cross, make their intersection perpendicu

lar.

• Proper grounding limits the effects of noise due to Electromagnetic Interference (EMI).

-

-

Mounting Structure Considerations

Your first task is to mount your DX8210 barcode scanner. You can provide your

own mounting structure or Datalogic can design one for you. We recommend

using a Datalogic mounting structure for standard applications.

Your mounting structure must provide the following capabilities:

• It is adjustable enough for you to move your unit to the optimum position

for proper scanning.

• It allows a technician access to the barcode scanner while it is mounted.

• It must be as vibration free as possible so as not to affect the scanning

accuracy.

• It is constructed of steel or aluminum.

• It provides approximately 300 mm [12 inches] minimum clearance on all

sides. This clearance is necessary to provide proper ventilation, allow

access to all panels of the barcode scanner, and allow room for proper ser

vicing.

-

16

DX8210 Barcode Scanner

Page 29

Mounting the Scanner

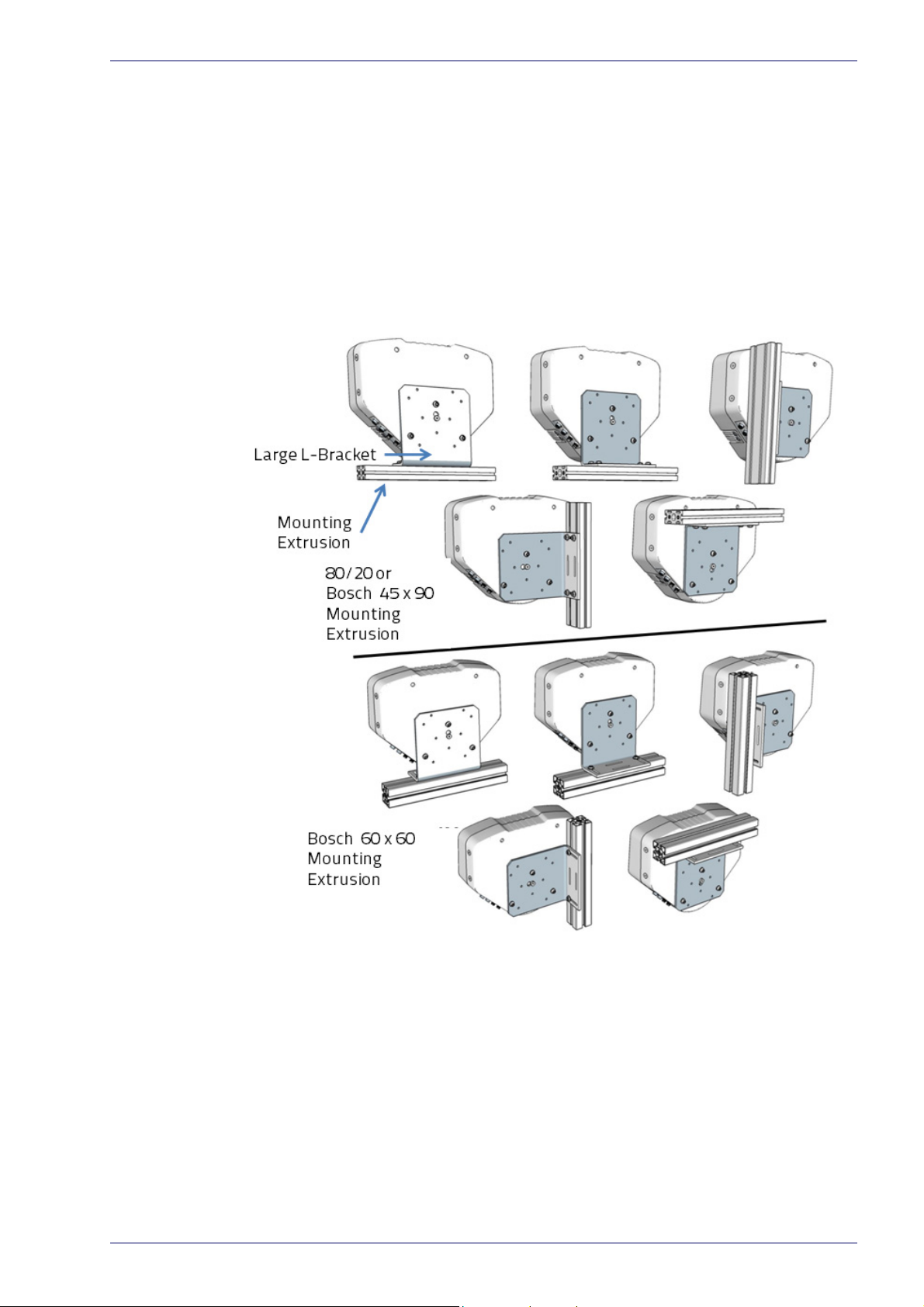

The DX8210 can be installed to operate in any position. There are screw holes

(M6 X 8) on the sides and back of the scanner for mounting. The diagram below

can be used for installation; refer to your application drawing for correct positioning of the scanner with respect to the reading zone and scanner orientation.

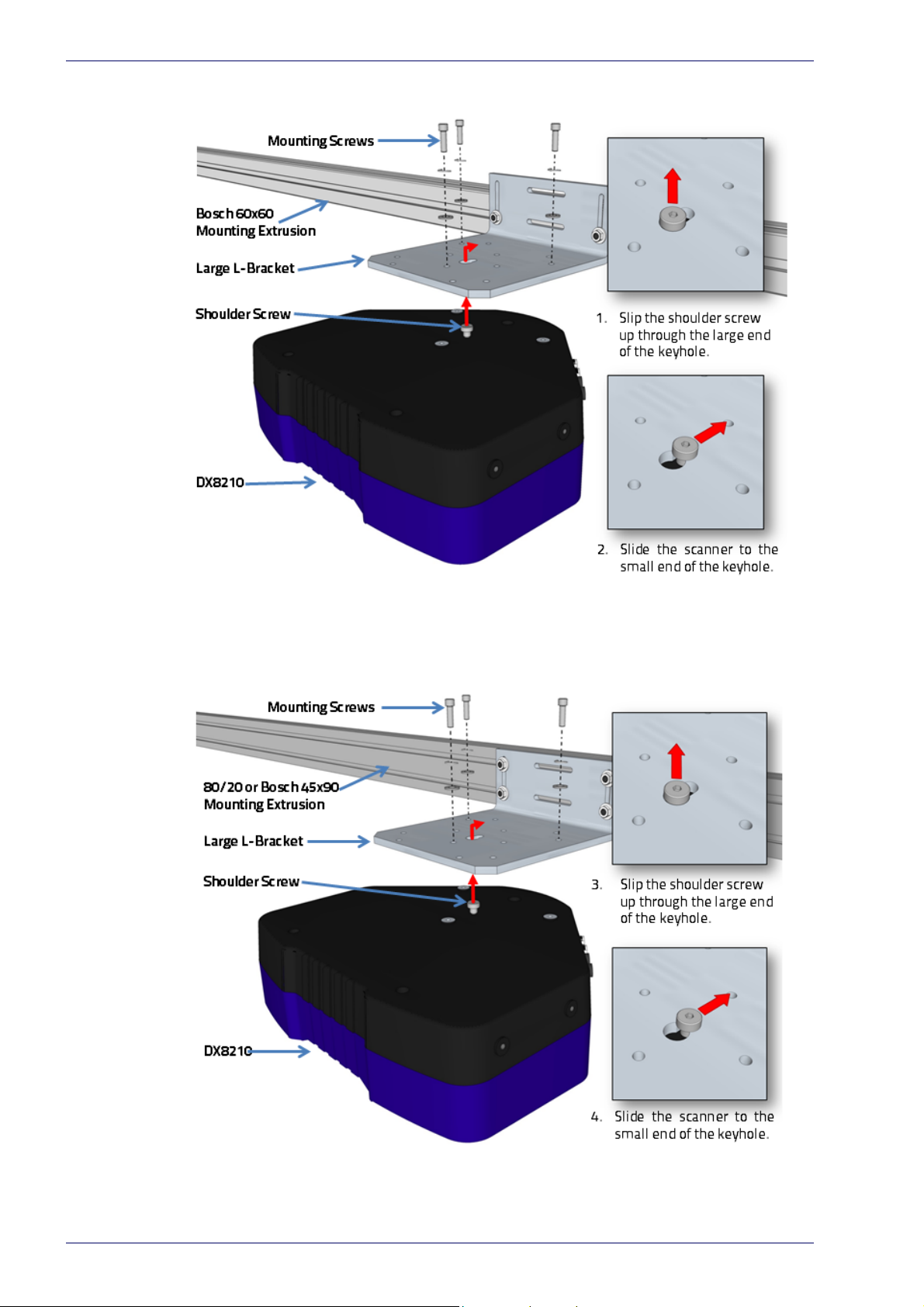

There are two bracket options for mounting the DX8210, the large rear-mounted

Bracket (93ACC0151, included in the box with the reader), and two smaller

Lside-mounted L-Brackets (93ACC0079, optional accessories).

Large Rear-Mounted L-Bracket

Installation

To aid in mounting the DX8210 with the large L-Bracket, mount the bracket to

the mounting structure as shown. Next, insert the shoulder screw (provided) into

the central mounting hole in the back of the unit, and then hang the scanner

using the brackets keyhole, as shown in figure 14 below. Finally, secure the

scanner to the bracket with mounting screws.

Reference Manual 17

Page 30

Mechanical Installation

Keyhole Mounting with Large L-Bracket (Bosch 60x60 Extrusion)

Keyhole Mounting with Large L-Bracket (80/20 or Bosch 45x90 Extrusion)

18

DX8210 Barcode Scanner

Page 31

Small Side-Mounted L-Bracket Options

Installation

Reference Manual 19

Page 32

Electrical Installation

Electrical Installation by Qualified Service Technicians Only! Procedures may involve

exposure to high-voltage. A trained and authorized technician must perform these

procedures. Do not attempt to perform any electrical installation procedures unless

you are a trained technician.

The DX8210 barcode scanners contain electronics that may be affected by electrostatic

discharge (ESD). To prevent personal injury or damage to the unit, please follow the

safety precautions and warnings found in the References section at the beginning of

this manual. Failure to follow these precautions may void your warranty.

Preparing for Electrical Installation

Before mounting any components, please do the following:

• Read all instructions before beginning your installation.

• Observe all electrical safety requirements discussed in the Introduction to

this manual.

• Define and confirm the accuracy of your application’s requirements.

• Review all installation-specific drawings.

• Review and plan the power requi

• Review and plan the communications requirements for your application.

rements for your application.

Chapter 3

20

The content of this manual may be superseded by any customer-specific documentation provided by Datalogic. Before proceeding with any installation procedures, be sure

to review ALL documentation, especially content that contains details specific to your

installation.

Everything should be MECHANICALLY INSTALLED before performing any ELECTRICAL

INSTALLATION. See Chapter for mechanical installation details.

Most DX8210

sary cabling required to electrically install the system. If your system requires customlength cables or other special wiring, documentation specific to these requirements has

been provided in your shipment. This special documentation supersedes any contradictory content in this manual.

To reduce the possibility of damage to the unit, check all cabling between the scanner

and other devices for accuracy.

applications are shipped with the CBX connection box and all the neces-

DX8210 Barcode Scanner

Page 33

Connecting a DX8210 Scanner

To install a DX8210 barcode scanner, follow this sequence:

• Complete mechanical installation

• Complete electrical installation.

• Observe all electrical safety requirements.

• Ground the mounting structure to pr

• If used, wire the photoelectric sensor (or other trigger) to the CBX510 connection box/SC5000.

• Wire the tachometer to the CBX510 connection box/SC5000 (if used).

• Wire serial ports to the CBX510 con

• Connect the M12 end of the Ethernet cable to the scanner’s HOST port and

etwork switch as required by your application.

n

• Connect the scanner to

• Connect the power supply to the power source.

• Setup / check scanner operations

its power supply.

Connecting a DX8210 Scanner

(See Chapter

otective earth (PE) ground.

nection box/SC5000 if needed.

(See Chapter 5

2.)

.)

Typical Connection Block Diagrams

Single DX8210 Barcode Scanner to CBX

Reference Manual 21

Page 34

Electrical Installation

The BM100 switches indicated below must be set to 0 (zero), and the connector indicated is not supported.

Master/Slave Array with CBX510

22

The BM100 switches indicated below must be set to 0 (zero), and the connector indicated is not supported.

DX8210 Barcode Scanner

Page 35

Typical Connection Block Diagrams

DX8210 Barcode Scanners in an Array with SC5000 Master

In an array (tunnel) using the SC5000 Controller, the chain of scanners completes a circle from and to the SC5000 Controller via ETH1 and ETH2. In this scenario, if one scanner fails, communication from the other scanners to the

SC500

0 Controller is not interrupted.

When using the SC5000, a Fieldbus Host only connects to the SC5000 Fieldbus model

(Profinet or Profibus) at the connectors shown. It cannot connect to the CBX.

An Ethernet Host connects to the HOST connector on the SC5000 top cover. A Serial

Host must connect through the CBX (see )

Reference Manual 23

Page 36

Electrical Installation

DX8210 Barcode Scanners in an Array with CBX

General Electrical Installation Guidelines and Precautions

It is important that you follow these general precautions when installing, setting

up, operating, maintaining, troubleshooting or replacing any Datalogic products,

parts or related equipment. As you plan and install your scanner(s), be sure to

keep the following guidelines in mind:

• Determine the scanner is in the proper location as outlined in Chapter 2.

• Leave adequate clearances (approximatel

• Route wires carefully to reduce or minimize electrical noise.

• When extraneous power and communication wiring must cross, make their

tersection perpendicular. Avoid running power and data wiring parallel to

in

each other. If possible, maintain one of the following separations between

the power and data wiring:

- 300 mm [12 inch] gap

- use steel conduit and 25 mm [1 inch] gap

- 6.5 mm [0.25 inch] of aluminum.

When planning your installation wiring, remember all power connections must be

quick-disconnect. For PERMANENTLY CONNECTED EQUIPMENT a readily accessible

disconnect device must be incorporated in the building installation wiring. For PLUGGABLE EQUIPMENT the socket-outlet must be installed near the equipment and must

be easily accessible.

y 300mm [12 inches]) for wiring.

24

To assure no ESD damage will occur, be sure to observe the precautions outlined in the

Introduction to this manual.

Ground the mounting structure to safety ground (protective earth ground (PE)). See wiring recommendations for safety ground.

DX8210 Barcode Scanner

Page 37

DX8210 Connector Panels

After completing mechanical installation, use this section to properly wire your

scanners for optimal performance in your application. DX8210 wiring connections are made to the connector panel and through the CBX connection box

nected to the I/O port of the scanner). In most applications, the cable con-

(con

nections to the scanner will include:

1. ETH 2 (Setup or EBC scanner network, default IP Address: 192.168.3.100)

DX8210 Connector Panels

2. ETH 1 (Host or EBC scanner network,

3. POWER

4. I/O (Connects directly to the 25-pin D type connector on the CBX connection

box)

The M12 I/O connector Vcc pin is allowed a max sink current of 0.6A.

default IP Address: 172.27.101.220)

Route wiring from the scanner’s connector panel through the wiring channels (if

available) on the Datalogic mounting structure when interconnecting cables to

other devices.

Reference Manual 25

Page 38

Electrical Installation

Connecting a PC to the DX8210

During initial setup, a PC (laptop) may be connected to the DX8210 with a M12

to RJ45 cable. Screw the M12 connector to the ETH 2 port of the scanner and

plug the RJ45 into the Ethernet port of your PC. If the ETH 2 port is in use, ETH 1

port can be used. For information on connecting to e-Genius,

ETH2 is the Setup port, ETH1 is the HOST port.

A laptop can only communicate to a scanner that is connected to a CBX Connection Box

or SC5000 Controller.

Parameters for tunnel are set up in MASTER scanner (or SC5000 Controller) only.

Power Connector Pin-Out Table

A recommended power supply and cabling is available with the DX8210 and

DX8210 (and SC5000 Controller). However, if your installation requires custom

power supply wiring, the pin-outs of the unit power connector are provided

below for your convenience.

see Chapter .

When using a DX8210 barcode scanner, no power supply is required for the CBX510

connection box. All power and some communication options are fed to the CBX510

through the scanner’s 17-pin I/O connector to the CBX510 25-pin connector using the

cable provided.

In cases where the AS-I cabling is not used, the alternative CAB-LP-05 cable can be

used to connect the power supply to the scanner. Connect the Brown/White pair to +24

Vdc and the Blue/Black pair to 0 V- (GND).

Power Connections

When planning your installation wiring, remember all power connections must be

quick-disconnect.

The socket-outlet must be installed near the scanner. The outlet must be a readily

accessible disconnect device.

While performing the following wiring connection procedures, be sure to follow all

safety procedures regarding high-voltage as outlined in the Introduction to this manual. No power should be applied to any device until all wiring is completed and checked

for accuracy.

26

DX8210 Barcode Scanner

Page 39

Ground the scanner to safety ground (protective earth ground (PE)). See wiring recommendations for safety ground.

The CBX connection boxes provide flexible connectivity to a range of I/O devices

as well as serial hosting. The DX8210 connects to the CBX via its I/O port using a

single 17-pin M12 to 25-pin D cable. The CBX connection box also provides

space for an optional BM100 backup module (recommended) for parameter storage, allowing quick replacement and configuration of the scanners.

In a system with multiple scanners and other devices

array (tunnel), an SC5000 Controller serves as the system Master and provides

communications between devices and to the Host. Complete installation information for the SC5000 Controller is available in the

Reference Manual

available at www.datalogic.com.

CBX510 Connection Box

Complete installation information for the connection box is available in the

CBX510 Installation Manual available at www.datalogic.com. A simple drawing of

the interior of the box is shown below.

CBX510 Connection Box

required in a scanning

SC5000 System Controller

Wiring Into the CBX510 Connection Box

DO NOT connect a separate power source to the CBX510 connection box. The CBX510

receives its power through its connection to the DX8210/DX8210 Barcode Scanner.

Connecting a separate power source will be detrimental to the system operation.

DISCONNECT POWER from the scanning system and CBX510 before wiring any components.

Loose-lead cables must pass through the water-tight seals in the base of the

CBX510 connection box. Insert the cables allowing enough slack for the individual wires to reach the appropriate pin block connectors. Securely tighten the

er-tight seals after the cables have been inserted.

wat

Insulation on individual wires

bare metal before inserting into the pin block.

Reference Manual 27

should be removed to expose 13 mm [0.5 inch] of

Page 40

Electrical Installation

Main Serial Interface

The optocoupled main serial interface is compatible with the following electrical

standards:

• RS232

• RS422 full-duplex

RS232 Interface

The main serial interface is used for communication with the Host computer and

allows transmission of code data.

It is always advisable to use shielded cable

must be less than 15 m (49.2 ft).

The following positions of the CBX510 spring clamp connector (row 4) are used

for RS23

2 interface connection:

s. The overall maximum cable length

Name Function

SGND Signal ground (isolated)

TX Transmit

RTS Request to send

RX Receive

CTS Clear to send

As suggested above, the cable shield should be connected in the ‘Shield’ position.

The RTS and CTS signals control data t

nected devices. If the RTS/CTS hardware prot

vates the RTS output to indicate a message

activate the CTS input to enable the transmission.

RTS/CTS lines should only be connected if the Main serial port handshaking is configure

for Hardware (RTS/CTS) (see section ).

ransmission and synchronize the con-

ocol is enabled, the scanner acti-

can be transmitted. The Host must

28

DX8210 Barcode Scanner

Page 41

RS422 Full-Duplex Interface

The RS422 full-duplex interface is used for non-polled communication protocols in point-to-point connections over longer distances (max 1200 m / 3940 ft)

those acceptable for RS232 communications or in electrically noisy envi-

than

ronments.

The following positions of the CBX510 spring clamp connector (row 4) are used

fo

r RS422 full-duplex interface connection:

Name Function

SGND Signal ground (isolated)

TX+ RS422 output (+)

TX- RS422 output (-)

Main Serial Interface

RX+ RS422 input (+)

RX- RS422 input (-)

For applications that do not use RS422 RX signals, do not leave these lines floating but

connect them to SGND as shown below

.

Reference Manual 29

Page 42

Electrical Installation

Photoelectric Sensor Connections to CBX510

Barcode scanning applications may use a Datalogic photoelectric sensor as a

trigger device. The photoelectric sensor is wired directly into the CBX510 terminal.

If your application uses a trigger other than the one specified by Datalogic, follow the appropriate wiring diagram to assure proper wiring.

To confirm the photoelectric sensor is functioning properly, watch the TRIG LED while

the photoelectric sensor’s beam is blocked. The Datalogic photoelectric sensor also

includes a status LED.

The following diagrams illustrate standard recommended wiring of the Photoelectric Sensor to the CBX510 terminal block.

Photoelectric Sensor (NPN)

30

DX8210 Barcode Scanner

Page 43

Photoelectric Sensor (PNP)

Tachometer Wiring to CBX510

Tachometer Wiring to CBX510

DX8210 applications over a conveyor belt use an accessory tachometer and

mounting kit. The following diagrams illustrate standard recommended wiring of

an encoder to the CBX510 terminal block.

Reference Manual 31

Page 44

Electrical Installation

Encoder/Tachometer Wiring for NPN Output (two models)

Some tachometers may have a different color coding:

(+V) Red or White/Orange

(Signal) White or White/Blue