Page 1

DX8200 Controller

Reference Manual

Page 2

Page 3

DX8200 Controller

INSTALLATION MANUAL

Page 4

DATALOGIC S.p.A.

Via Candini 2

40012 - Lippo di Calderara di Reno

Bologna - Italy

DX8200 Controller

Ed.: 10/2004

ALL RIGHTS RESERVED

Datalogic reserves the right to make modifications or improvements without prior notification.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

Product names mentioned herein are for identification purposes only and may be trademarks and or

registered trademarks of their respective companies.

© Datalogic S.p.A. 2000 - 2004

20/10/04

Page 5

CONTENTS

GUIDE TO INSTALLATION........................................................................................v

GENERAL VIEW.......................................................................................................vi

SAFETY PRECAUTIONS........................................................................................viii

Electrical Safety ........................................................................................................viii

Laser Safety..............................................................................................................viii

Power Supply............................................................................................................. ix

1 GENERAL FEATURES..............................................................................................1

1.1 Introduction.................................................................................................................1

1.1.1 Indicators ....................................................................................................................3

1.2 Model Description .......................................................................................................3

1.3 Accessories ................................................................................................................3

1.4 Applications ................................................................................................................4

2 INSTALLATION..........................................................................................................5

2.1 Package Contents.......................................................................................................5

2.2 Mechanical Installation................................................................................................6

2.3 Electrical Connections.................................................................................................7

2.3.1 Power Supply..............................................................................................................7

2.3.2 Ethernet......................................................................................................................8

2.3.3 Host Interface .............................................................................................................8

Main Interface .............................................................................................................9

Auxiliary Interface .....................................................................................................12

2.3.4 Lonworks ..................................................................................................................12

2.3.5 RS232 Debug ...........................................................................................................13

2.3.6 Inputs........................................................................................................................13

2.3.7 Outputs.....................................................................................................................14

2.4 Layouts.....................................................................................................................15

3 SOFTWARE CONFIGURATION...............................................................................16

3.1 Genius™ Installation.................................................................................................16

3.2 Guide to Configuration ..............................................................................................16

3.3 Advanced Genius™ Configuration ............................................................................17

3.4 Parameter Default Values .........................................................................................18

4 READING FEATURES.............................................................................................21

4.1 Advanced Code Reconstruction................................................................................21

4.2 PackTrack™ .............................................................................................................22

4.3 Performance .............................................................................................................23

4.3.1 Reading Conditions...................................................................................................23

4.4 Reading Diagrams ....................................................................................................25

5 MAINTENANCE .......................................................................................................37

5.1 Cleaning....................................................................................................................37

5.2 Automatic Scanner Replacement..............................................................................37

5.3 Replacing the Protection Fuses (for AC Models).......................................................38

6 TECHNICAL FEATURES.........................................................................................39

iii

Page 6

GLOSSARY..............................................................................................................41

INDEX....................................................................................................................... 44

iv

Page 7

GUIDE TO INSTALLATION

The following can be used as a checklist to verify all the necessary steps for complete

installation of the DX8200 Controller.

1. Read all information in the section Safety Precautions at the beginning of this manual.

2. Correctly position and mount the scanner for barcode reading according to the

information in par. 4.4.

3. Make electrical connections to your DX8200 Controller by:

a) correctly wiring the DX8200 Controller to the Host using one of the desired Host

interfaces: Ethernet, Main or Aux Serial port communication, see par. 2.3.2 and 2.3.3.

b) correctly wiring the Encoder and External Trigger (Presence Sensor) inputs as well

as any output devices to the DX8200 Controller signals, see par. 2.3.6 and 2.3.7.

c) completing the system wiring adding as many slave scanners as required by your

system layout (refer to par. 2.4).

d) correctly inserting either the BTK-8000 terminator or the CAB-8305 cable in the last

Slave reader of the network as shown in par. 2.4.

4. Configure the DX8200 Controller (Master) scanner by using the Genius™ program.

5. Configure the Slave scanners using the onboard program through HyperTerminal: The

main parameters are:

• defining each slave scanner address

• selecting the codes to be read

• selecting data formatting

The installation is now complete.

v

Page 8

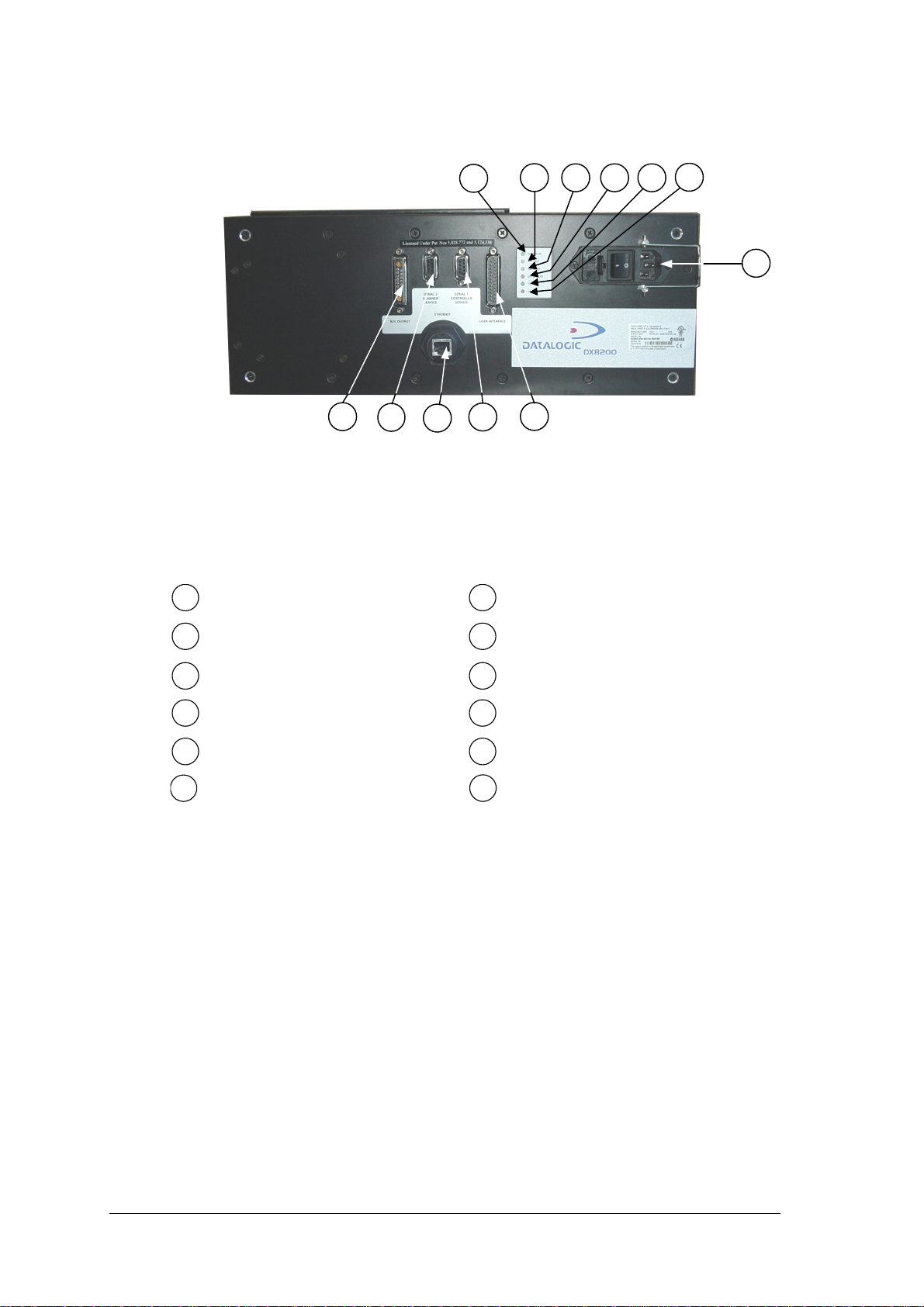

GENERAL VIEW

1

DX8200 Controller

2

5

4

3

Figure A - DX8200 Controller General View

Control Panel (see Figure B)

1

Product Label

2

Laser Warning Label

4

Mounting Rails

5

Laser Output Windows

3

vi

Page 9

6

7 8

9

10

11

12

5

4

3

2

1

Figure B – Control Panel

Host Interface Connector

1

Presence Sensor LED (N.A.)

7

Reserved Connector

2

Ethernet connector

3

RS232 Debug Connector

4

Lonworks Network Connector

5

Power ON LED

6

Encoder LED

8

Good Read LED

9

TX Data LED

10

Network LED

11

VAC Power Panel (for VAC models only)

12

Fuses, Power Switch, Power Connector,

vii

Page 10

SAFETY PRECAUTIONS

ELECTRICAL SAFETY

This product conforms to the applicable requirements contained in the European

Standard for electrical safety EN-60950-1 at the date of manufacture.

This symbol refers to operations that must be performed by qualified personnel

only. Example: opening the device.

This symbol refers to operations where there is danger of electrical shock. Before

opening the device make sure the power cable is disconnected to avoid electric

shock.

This device must be installed to a power source equipped with on/off switch or

breaker within range of the operator as protection against grounding failures.

This device is protected against overloading by correct value fuses. For

protection fuse replacement make sure correct value fuses are installed. See the

fuse selection table in par. 5.2.

For AC models

LASER SAFETY

The following information is provided to comply with the rules imposed by international

authorities and refers to the correct use of the DX8200 Controller scanner.

Standard Regulations

This scanner utilizes up to 3 low-power laser diodes. Although staring directly at the laser

beam momentarily causes no known biological damage, avoid staring at the beam as one

would with any very strong light source, such as the sun. Avoid that the laser beam hits the

eye of an observer, even through reflective surfaces such as mirrors, etc.

This product conforms to the applicable requirements of both EN 60825-1 and CDRH 21

CFR 1040 at the date of manufacture. The scanner is classified as a Class 2 laser product

according to EN 60825-1 regulations and as a Class II laser product according to CDRH

regulations.

There is a safety device which allows the laser to be switched on only if the motor is rotating

above the threshold for its correct scanning speed.

WARNING

viii

Use of controls or adjustments or performance of procedures other than

those specified herein may result in exposure to hazardous visible laser

light.

Page 11

The laser light is visible to the human eye and is emitted from the windows on the lower side

of the reader (Figure A, 3).

Warning labels indicating exposure to laser light and the device classification are applied

onto the body of the scanner (Figure A, 4 and 2):

DATALOGIC S.P.A. Via Candini, 2

LASER LIGHT

DO NOT STAR E INTO BEAM

CLASS 2 LASER PRODUCT

MAXIMUM OUTPUT RADIATION 1 mW

EMITTED WAVELENGTH 630~680 nm

TO EN 60825-1:2001

AVOID EXPOSURE TO BEAM

CAUTION-CLASS 3B LASER LIGHT WHEN OPEN

LASER LIGHT EMITTED FROM THIS APERTURE

40012 Calderara di Reno - Bologna - Italy

Manufactured Volt

Model No. Amp.

Serial No.

This product conforms to the applicable requirements

of 21CFR1040 at the date of manufacture.

Warning and device class labels

Disconnect the power supply when opening the device during maintenance or installation to

avoid exposure to hazardous laser light.

The laser diodes used in this device are classified as Class 3B laser products according to EN

60825-1 regulations and as Class IIIb laser products according to CDRH regulations. As it is

not possible to apply a classification label on the laser diodes used in this device, the

following label is reproduced here:

LASER LIGHT

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

MAXIMUM OUTP UT RADIATION 35 mW

EMITTED WAVELENGTH 630~68 0 nm

TO EN 60825-1 (2001)

Laser diode class label

Any violation of the optic parts in particular can cause radiation up to the maximum level of

the laser diode (35 mW at 630~680 nm).

POWER SUPPLY

The supply voltage for correct operation of the scanner depends on the models:

- between 20 and 30 VDC, supplied to the Lonworks Network connector, for

DX8200 Controller-X0X0 models

- between 85 and 264 VAC, supplied through the VAC power cable, for DX8200

Controller-X0X1 models.

A security system allows the laser to activate only once the motor has reached the correct

rotational speed; consequently, the laser beam is generated after a slight delay from the

power on of the scanner.

During power up of the scanner there is a current peak of about 3A caused by the motor

startup.

ix

Page 12

x

Page 13

GENERAL FEATURES

1

1 GENERAL FEATURES

1.1 INTRODUCTION

The DX8200 Controller scanner is a high performance omnidirectional barcode reader that

provides an innovative solution for omnidirectional system reading applications. In particular,

DX8200 Controller serves as both the Master of the cluster and Controller of the Lonworks

bus network where up to 13 scanners can be present to make up the reading station. The

major advantage is in eliminating the need for an external Lonworks Controller.

DX8200 Controller also interfaces directly to the Host to manage all interfacing activities:,

communications, inputs, outputs.

Another advantage of the DX8200 Controller is the built-in Ethernet connectivity which is

completely controlled by its own microprocessor and available as an alternative Host

connection to the Main and Aux port serial communication. With this connection there is no

loss in decoding performance because the TCP/IP protocol management is completely

separate from the decoding process.

The DX8200 Controller uses exclusively the PackTrack™ Operating Mode in which the

barcodes collected from the Slave scanners are assigned the correct parcel and the

message is transmitted to the Host.

However, the DX8200 Controller can also be used in Stand-Alone configurations.

The Genius™ configuration program is used to completely configure the DX8200 Controller

regarding enabled code symbologies, PackTrack™ parameters, Data formatting, etc.

Through the Controller, the relative Slave scanner configurations can also be managed.

The Controller maintains easy replacement and therefore down time reduction criteria in that

it stores the entire system configuration. If a slave scanner must be replaced, the

corresponding configuration is automatically downloaded by the Controller. If the DX8200

Controller fails, the system configuration can be restored through the Genius™ program.

The following Datalogic advanced technologies are employed in the DX8200 Controller:

ACR™

Advanced Code Reconstruction technology allows the reading of low aspect ratio labels

placed anywhere on a parcel and enhances the readability of poorly printed or damaged

codes.

CD SQUARE™

CD SQUARE™ provides useful information on label position and object shape elaborated

during the barcode reading phase. This innovative technology identifies the area in which the

code is located and measures the code distance from the scanner.

1

Page 14

1

DX8200 CONTROLLER

PACKTRACK™

PackTrack™ is a Datalogic patented parcel tracking system which improves the reading

features in omnidirectional stations. In particular, PackTrack™ manages 6-sided reading

systems when it is impossible to detect the real position of the code on the parcel, thus

overcoming the need for external accessories essential in traditional tracking systems. See

par. 4.2 for more details.

ASTRA™

Automatically Switched Reading Area™ is a Datalogic technology based on a multi-laser

architecture and a fixed mounted optic system which concentrates the multiple laser

emissions in a single laser beam. As each laser emitter is focused on a specific range of the

reading area, a sophisticated electronic controller selects the best focused laser emitter with

respect to the code to read. This allows the reading of medium-high density codes in a large

reading area on very fast conveyors.

FLEXIBILITY

The high frequency laser diode modulation system guarantees complete immunity to ambient

light and allows installation of the DX8200 Controller in any working area.

The DX8200 Controller is easily configurable by means of the Windows-based user-friendly

Genius utility program provided on CD-ROM.

Some of the main features of DX8200 Controller are listed below:

• Lonworks high speed network

• scanning speed 500 scans/sec for each scan line (1000 scans/sec. total)

• reads all popular codes

• 85-264 VAC or 24 VDC operation

• light source: solid state laser diodes; the light emitted has a wavelength in the range

630~680 nm. For laser safety precautions refer to the “Safety precautions” section at the

beginning of this manual.

2

Page 15

GENERAL FEATURES

1.1.1 Indicators

The DX8200 Controller has six LEDs on the control panel.

The indicators have the following functions:

Power ON:

(green) Indicates the scanner is ON.

1

Ext Trig:

Encoder:

Good Read:

TX Data:

(yellow) Indicates the external presence sensor is active.

available for DX8200 Controllers.

(yellow) Indicates the external encoder signal is active.

(red) Indicates a probable code is present in the reading zone.

(green) Indicates data transmission both on the main and on the auxiliary

This LED is not

interface.

Network:

(red) Indicates data transmission on the Lonworks network.

1.2 MODEL DESCRIPTION

The DX8200 Controller scanner is available in versions that differ depending on:

• number of lasers

• optical resolution

• power supply

DX8200 Controller - X 0 X X

Laser Number:

2 = Double laser

3 = Triple laser

Power supply:

0 = VDC

1 = VAC

Optical Resolution:

0 = Standard resolution

1 = High resolution

1.3 ACCESSORIES

The following DX8200 Controller accessories are available on request:

Name

CAB-8101 Cable master/slave 1 m 93A051020

CAB-8102 Cable master/slave 2 m 93A051030

CAB-8105 Cable master/slave 5 m 93A051040

CAB-8305 Cable power + termination 5 m 93A051268

INT-60 20 mA C.L. interface board 93A151021

PWR-120 Power unit 110/230 V AC - 24 V DC 93ACC1530

BTK-8000 Terminator kit (5 pcs) 93ACC1090

Description Part Number

3

Page 16

1

DX8200 CONTROLLER

1.4 APPLICATIONS

The DX8200 Controller barcode reader is specifically designed for industrial applications and

for all cases requiring high reading performance such as:

• code reconstruction

• reading of codes covered by plastic film

• reading of codes with a wide depth of field

• reading of high resolution codes positioned at long distances from the reader

• code reading on fast moving objects.

4

Page 17

INSTALLATION

2

2 INSTALLATION

2.1 PACKAGE CONTENTS

Verify that the DX8200 Controller and all the parts supplied with the equipment are present

and intact when opening the packaging; the list of parts includes:

• DX8200 Controller

• Installation Manual + barcode test chart

• CD-ROM

Package Contents

5

Page 18

2

DX8200 CONTROLLER

2.2 MECHANICAL INSTALLATION

DX8200 Controller can be installed to operate in any position.

There are 2 mounting rails on the sides of the scanner for installation.

The diagram below gives all the information required for installation; refer to par. 4.4 for correct

positioning of the scanner with respect to the code passage zone.

40

10

1.6

0.4

0.4

576

22.7

470

18.5

170

6.7

9

170

6.7

118

4.6

53

2.1

385

64

15.16

2.5

513

20.2

mm

inch

150

5.9

94

3.7

POWER ON

EXT TRIG

ENCODER

GOOD READ

TX DATA

NETWORK

DX8200 Controller Overall Dimensions

6

Page 19

INSTALLATION

2

2.3 ELECTRICAL CONNECTIONS

The DX8200 Controller employs a Lonworks network used to build a multi-sided or extended

width omni-station system connecting several slave scanners. It interfaces with the Host

using either the serial port or Ethernet connection.

It is equipped with the following connectors:

6

5

4

Control panel

3

2

1

Host Interface connector 25-pin male

c

Reserved connector 9-pin female

d

Ethernet connector RJ45

e

RS232 debug connector – for Service only 9-pin female

f

Lonworks Network connector 17-pin female

g

VAC Power supply connector

h

2.3.1 Power Supply

The supply voltage for correct operation of the scanner depends on the models:

- between 20 and 30 VDC, supplied to the Lonworks OUTPUT connector, for DX8200

Controller-X0X0 models

- between 85 and 264 VAC, supplied through the VAC cable, for DX8200 Controller-

X0X1 models.

For VDC models, the PWR power supplies (optional), supply the power necessary for the

entire network of DX8200 Controller and relative Slaves and allows main power to be used.

For VAC models the main AC power connects directly to the DX8200 Controller to power the

entire network.

A security system allows the laser to activate only once the motor has reached the correct

rotational speed; consequently, the laser beam is generated after a slight delay from the

power on of the scanner.

During power up of the scanner there is a current peak of about 3A caused by the motor

startup.

7

Page 20

2

2.3.2 Ethernet

DX8200 Controller

1

TX+

2

TX-

3

RX+

n. c.

4

5

n. c.

6

RX-

n. c.

7

n. c.

8

n. c. = not connected

HUB / SWITCH

1

2

3

4

5

6

7

8

2.3.3 Host Interface

RJ45 Modular Connector

RJ45 Modular Connector

1

13

DX8200 CONTROLLER

14

25

25-pin male D-sub Connector

Host Interface Connector Pinout

Pin Name Function

1 Shield Internally connected by capacitor to chassis

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

18 EXT_TRIG A External trigger (polarity insensitive)

19 EXT_TRIG B External trigger (polarity insensitive)

6 ENC A Encoder input signal (polarity insensitive)

10 ENC B Encoder input signal (polarity insensitive)

14 IN3A Input signal 3

15 IN4A Input signal 4

24 IN_REF Common reference of IN3 and IN4

9, 13 VS VDC I/O supply voltage – positive pin

23, 25 GND VDC I/O supply voltage – negative pin

Pin RS232 RS485 Full-Duplex

RS485 Half-

Duplex

20 mA C.L.

(INT-60 Only)

2 TX TX485+ RTX485+ CLOUT+

3 RX RX485+ CLIN+

4 RTS TX485- RTX485- CLOUT5 CTS RX485- CLIN7 GND_ISO GND_ISO GND_ISO GND*

* For 20 mA C.L. connections, GND is the same of the scanner power supply.

8

Page 21

INSTALLATION

2

Main Interface

The main serial interface is compatible with the following electrical standards:

RS232

RS485 full-duplex

RS485 half-duplex

20 mA current loop

The 20 mA Current Loop interface is available if the optional INT-60 accessory is installed.

This accessory interface replaces the RS232/RS485 selections.

The main serial interface type and its relative parameters (baud rate, data bits, etc.) are

selected via software using the Genius™ utility program. For more details refer to the

section "Main Serial Port" in the Genius™ Help On Line.

Details regarding the connections and use of the main interface selection are given in the

next paragraphs.

RS232 Interface

The main serial interface is used for communication with the Host computer and allows both

transmission of code data and configuring the reader.

The following pins of the 25-pin connector are used for RS232 interface connection

depending on the reader model:

Pin Name Function

2 TX Transmit

3 RX Receive

4 RTS Request to send

5 CTS Clear to send

7 GND-ISO Main signal ground

The RTS and CTS signals control data transmission and synchronize the connected devices.

If the RTS/CTS hardware protocol is enabled, the DX8200 Controller activates the RTS

output to indicate a message can be transmitted. The receiving unit must activate the CTS

input to enable the transmission.

DX8200 Controller

Shield

RS232 Connections

2

TX

3

RX

RTS4

CTS

5

7

GND-ISO

1

USER INTERFACE

RXD

TXD

GND

Earth

Ground

9

Page 22

2

DX8200 CONTROLLER

RS485 Full-Duplex Interface

The RS485 full-duplex interface is used for non-polled communication protocols in

point-to-point connections over longer distances than those acceptable for RS232

communications or in electrically noisy environments.

The following pins of the 25-pin connector are used for RS485 full-duplex interface

connection:

Pin Name Function

2 TX485 + RS485 output (+)

3 RX485 + RS485 input (+)

4 TX485 - RS485 output (-)

5 RX485 - RS485 input (-)

7 GND-ISO Main signal ground

DX8200 Controller

USER INTERFACE

2

TX485+

3

RX485+

4

TX485-

RX485-

5

RX485+

TX485+

RX485-

TX485-

7

GND_ISO

1

Shield

GND

Earth

Ground

RS485 Full-Duplex Interface Connections

RS485 Half-Duplex Interface

The RS485 half-duplex interface can be used for multidrop connections with a Datalogic

multiplexer or it can also be used for a master/slave layout.

The following pins of the 25-pin connector are used for RS485 half-duplex interface

connection:

Pin Name Function

2 RTX485 + RS485 input/output (+)

4 RTX485 - RS485 input/output (-)

7 GND-ISO Main signal ground

DX8200 Controller

MULTIPLEXER

10

2

Shield

RTX485+

4

RTX485-

7

GND_ISO

1

RTX485+

RTX485-

RS485REF

Earth

Ground

RS485 Half-Duplex Interface Connections

Page 23

INSTALLATION

r

2

20 mA Current Loop (INT-60 Accessory Only)

When the INT-60 accessory board is installed, the DX8200 Controller is equipped with a 20

mA current loop interface. The INT-60 board supports both active and passive type

connections.

Active Connections

The following pins of the 25-pin output connector are used for the active connections:

Pin Name Function

4 CLOUT - Current Loop Output (-)

5 CLIN - Current Loop Input (-)

7 GND Earth Ground*

* For 20 mA C.L. connections, GND is the same as the scanner power supply GND.

DX8200 Controller

20 mA

5

C.L. IN-

USER INTERFACE

GND

7

20 mA

C.L. OUT-

4

20 mA C.L. Active Connections

Passive Connections

The following pins of the 25-pin output connector are used for the passive connections:

Pin Name Function

2 CLOUT + Current Loop Output (+)

4 CLOUT - Current Loop Output (-)

3 CLIN + Current Loop Input (+)

5 CLIN - Current Loop Input (-)

DX8200 Controlle

3

5

C.L. IN+

C.L. IN-

USER INTERFACE

+

2

C.L. OUT+

4

C.L. OUT-

MAX. 300 METERS

+

20 mA C.L. Passive Connections

11

Page 24

2

X

X

5

DX8200 CONTROLLER

Auxiliary Interface

The auxiliary serial interface is equipped with RS232 full-duplex interface connections. The

interface type is exclusive and is selectable through the Genius™ configuration program.

The following pins of the 25-pin connector are used for RS232 full-duplex interface

connection:

Pin Name Function

20 RXAUX Receive data

21 TXAUX Transmit data

23 SGND AUX Auxiliary signal ground

DX8200 Controller

Shield

USER INTERFACE

20

RXAUX

21

TXAU

23

GNDAU

1

TXD

RXD

GND

Earth

Ground

2.3.4 Lonworks

Pin Name Function

A1 GND supply voltage (negative pin)

A2 VS supply voltage 20 to 30 Vdc (positive pin)

1 Shield A

3 Shield B

8 Lon A+ lonworks A line (positive pin)

9 Lon A- lonworks A line (negative pin)

10 Lon B+ lonworks B line (positive pin)

11 Lon B- lonworks B line (negative pin)

13 SYS_ENC Rigenerated encoder output

15 Refer Reference voltage of I/O circuit

RS232 Auxiliary Interface Connections

1

scanner side

external vi ew

1

A1

OUTPUT

Lonworks OUTPUT pinout

A2

12

Page 25

INSTALLATION

A

A

V

2

2.3.5 RS232 Debug

The use of this connector is reserved for Service:

5

RS232 debug connector

1

69

RS232 Debug connector pinout

Pin Name Function

2 TXD Transmitted data

3 RXD Received data

5 GND Ground

2.3.6 Inputs

ENC is the encoder input and detects the conveyor speed.

EXT_TRIG is the presence sensor that, when active, tells the scanner that a pack is entering

the reading area.

All inputs are optocoupled and driven by a constant current generator; the command signal is

filtered through an anti-disturbance circuit which generates a configurable delay of about 5

ms or 500 µs.

The electrical features of the inputs are:

Maximum voltage 30 V

Maximum current 10 mA

DX8200 Controller

+ 5V

DX8200 Controller

+ 5V

Input NPN

Polarity Insensitive Common Reference

EXTERNAL TRIGGER/

9

VS

~

-

+

~

B

GND

Vext

ENCODER

V

Ground

DX8200 Controller

+ 5V

~

+

~

9

INREF

-

IN3A

EXTERNAL TRIGGER/

9

VS

B

~

-

+

~

GND

Vext

ENCODER

V

Ground

+ 5V

~

-

+

~

IN4A

EXTERNAL DEVICE

ext

VS

V

GND

Vext

EXTERNAL DEVICE

V

GND

13

Page 26

2

A

A

r

Input PNP Connections

Polarity Insensitive Common Reference

DX8200 Controller

+ 5V

~

-

+

~

B

GND

EXTERNAL TRIGGER/

Vext

ENCODER

V

DX8200 Controller

+ 5V

DX8200 Controller

+ 5V

~

-

+

~

B

GND

EXTERNAL TRIGGER/

Vext

ENCODER

V

+ 5V

2.3.7 Outputs

The electrical features of the outputs are given below:

Output Open Collector Connections

Polarity Insensitive Polarity Sensitive

DX8200 Controller

USER INTERFACE

100 Vdc max

Vext

DX8200 Controlle

DX8200 CONTROLLER

Vext

EXTERNAL DEVICE

V

IN3A

~

-

+

~

IN4A

~

-

+

~

INREF

GND

Vext

V

GND

USER INTERFACE

Vext 30 Vdc max

A

B

The OUT3 electrical features are given below:

Collector-Emitter voltage ± 100 V max.

Collector current.: 240 mA pulse max

160 mA continuous max

R on 6 – 15 Ω

R off > 500 Ω

Off-state leakage current < 1 µA

Maximum power dissipation 550 mW at 50°C

(Ambient temperature).

+

-

The OUT1 / OUT2 electrical features are given

below:

Collector-Emitter voltage 30 V max.

Collector current.: 130 mA pulse max.

40 mA continuous max.

Saturation voltage (VCE) 1 V at 10 mA max.

Maximum power dissipation 90 mW at 50°C

(Ambient temperature).

14

Page 27

INSTALLATION

2

2.4 LAYOUTS

DX8200 Controller Master interprets data from each scanner and performs the correct

barcode assignment to the parcel using the PackTrack™

External devices such as a presence sensor and an encoder are all connected to the

DX8200 Controller, which is also connected to a Host PC.

A single DX8200 Controller provides a Lonworks communication line having up to 5

scanners. The last scanner requires the termination connector BTK-8000. The maximum

allowable length for the entire bus cabling is 65 m.

The following figures show 2 possible layouts for the DX8200 Controller.

Bus Interface SLAVE Scanners

1 ...

DX8200 Controller MASTER Scanner

(VAC model)

operating mode.

*

85-260 VAC

HOST

85-260 VAC85-260 VAC

PRESENCE

SENSOR**

BTK-8000

DATALOGIC CAB-810X CABLES

ENCODER

PWR-120/240/480

Bus Interface SLAVE Scanners

1

2

DX8200 Controller MASTER Scanner

(VDC model)

3

…

HOST

PRESENCE

SENSOR**

CAB-8305

DATALOGIC CAB-810X CABLES

ENCODER

** Presence Sensor connected to External Trigger Input

*

The maximum number of scanners on the Lonworks cluster is 6 (1 DX8200 controller + 5 slaves). Positive environmental

conditions (i.e reduced number of barcodes, conveyor speed, reading area dimensions…) to be evaluated case by case, may

further increase the number of slaves up to the theoretical limit of 13.

15

Page 28

3

DX8200 CONTROLLER

3 SOFTWARE CONFIGURATION

3.1 GENIUS™ INSTALLATION

Genius

advantages:

• Multi-language version;

• Defined configuration directly stored in the reader;

• Communication protocol independent from the physical interface allowing to consider the

To install Genius™, proceed as follows:

1) Turn on the PC that will be used for configuration and launch Windows 95/98 or NT;

2) Insert the Genius™ CD-ROM;

3) Wait for the CD autorunning and follow the installation procedure.

3.2 GUIDE TO CONFIGURATION

After installing the Genius™ software program (see par. 3.1) the following window appears

asking the user to choose the desired configuration level:

™

is a new Datalogic scanner configuration tool providing several important

reader as a remote object to be configured and monitored.

Genius™ Wizard Opening Window

For the DX8200 Controller the Wizard is not available and if selected a warning message

appears indicating that Advanced Mode will be used.

16

Page 29

SOFTWARE CONFIGURATION

3

3.3 ADVANCED GENIUS™ CONFIGURATION

The ADVANCED selection available when starting the Genius™ program is addressed to

expert users being able to complete a detailed scanner configuration. By choosing this option

it is possible either to start a new scanner configuration or to open and modify an old one.

The desired parameters can be defined in the following window, similar to the MS Explorer:

Genius™ Parameter Explorer Window

The procedure for setting the scanner parameters is supported by a help on-line, which is

displayed in an HTML browser.

It can be selected from the Configuration Help option available in the Help menu. In addition,

a context-sensitive help can be enabled by pressing the <F1> key after selecting the desired

parameter.

17

Page 30

3

DX8200 CONTROLLER

3.4 PARAMETER DEFAULT VALUES

The following table contains the list of the factory default settings for the DX8200 Controller.

Genius™ also allows checking the parameter default values by selecting the "Compare

parameters" option available in the Tools menu and comparing the current scanner

configuration to the default one.

Parameter Default Setting

Code Definition

Code Combination Single Label

No read Message

No Read String <CAN>

Code Label Settings #1

Code Symbology Interleaved 2 of 5

Label Length 8

Min Code Position 0

Max Code Position 255

Check Digit Disabled (unchecked)

Pattern Match String Empty

Code Label Settings #2

Code Symbology Code 39

Label Length Variable

Minimum Label Length 1

Maximum Label Length 48

Min Code Position 0

Max Code Position 255

Check Digit Disabled (unchecked)

Pattern Match String Empty

Operating Modes

Operating Mode Selection PackTrack

Physical Encoder Enabled (checked)

Encoder Step (hundredths of mm) 100

PS Line (mm) 0

Presence Sensor Input 1

Presence Sensor Input Level Active Closed

Distance from PS Line to Tx Line (mm) 1500

Transmission Edge Trailing

Max Number of Packs 10

Minimum Distance Error Behaviour Compose

Minimum Distance Between Packs (mm) 30

Minimum Pack Length Error Behaviour Discard Item

Minimum Pack Length (mm) 50

Window Dimension (mm) 15

Statistics Disabled (unchecked)

Reading System Layout

Number of Scanners 1

Modify Scanner Configuration Disabled (unchecked)

Global No Read Message

18

Page 31

SOFTWARE CONFIGURATION

3

Parameter

Data Communication Settings

Default Setting

Host Application Protocol Type Standard

Data Format

Termination After No Read Message Enabled

Parameters

Header String <STX>

Code Identifier Disabled

Termination String <CR><LF>

Data Packet Separators <CR><LF>

Code Field Length Setting Variable Length

Main Serial Port

Data Tx Enabled (checked)

Parameters

Main Port Communication Mode Standard

Main Port Electrical Interface RS232

Handshake None

Baud Rate 9600

Parity None

Data Bits 8

Stop Bits 1

Auxiliary Serial Port

Data Tx Enabled (checked)

Pass Through Disabled (unchecked)

Parameters

Baud Rate 115200

Parity None

Data Bits 8

Stop Bits 1

Digital I/O Setting

Digital Input Lines Setting

Debouncing For Input 1, 3 and 4 5ms

Debouncing For Input 2 500 µs

Input 1 Active Level Overridden by Op. Mode Active Closed

Input 2 Active Level Overridden by Op. Mode Active Closed

Input 3 Active Level Overridden by Op. Mode Active Closed

Input 4 Active Level Overridden by Op. Mode Active Closed

19

Page 32

3

DX8200 CONTROLLER

Parameter

Default Setting

Output 1

Line State Normally Open

Activation Event Complete Read

Alternative Activation Event Multiple Read

Deactivation Event Timeout

Alternative Deactivation Event None

Deactivation Timeout (ms) 50

Output 2

Line State Normally Open

Activation Event No Read

Alternative Activation Event Partial Read

Deactivation Event Timeout

Alternative Deactivation Event None

Deactivation Timeout (ms) 50

Output 3

Line State Normally Open

Activation Event None

Alternative Activation Event None

Deactivation Event None

Alternative Deactivation Event None

20

Page 33

READING FEATURES

4

4 READING FEATURES

4.1 ADVANCED CODE RECONSTRUCTION

The traditional way of barcode reading could be called "Linear Reading". In this case, the

laser beam crosses the barcode symbol from its beginning to its end as shown in the figure

below.

Laser Beam

Linear reading

In "Advanced Code Reconstruction" mode it is no longer necessary for the laser beam to

cross the label from the start to the end. With just a set of partial scans on the label (obtained

using the motion of the label itself), the DX8200 Controller is able to "reconstruct" the

barcode. A typical set of partial scans is shown below.

Code Direction

Partial scans

None of the partial scans contains the whole label. The decoder aligns each partial scan

correctly and combines them in order to obtain the entire code.

The alignment is performed by calculating the time difference from one partial scan to

another using a reference code element.

21

Page 34

4

DX8200 CONTROLLER

4.2 PACKTRACK™

PackTrack™ is a patented operating mode for DATALOGIC Omnidirectional Reading

Stations used to read and correctly assign codes read on parcels when placed in the scanner

Reading Area at the same time.

In fact, in the example below, the codes of two or more consecutive parcels are found at the

same time in the scanner reading area. Therefore the condition occurs where, in the

sequence of the two parcels, the code of the second parcel is read first, just before the code

of the previous parcel. A system without PackTrack™ would assign the code of the second

parcel to the first parcel and viceversa, thus causing a gross error in the sortation.

Conveyor

direction

End of the

PS Photocell or

equivalent signal

Conveyor

direction

Reading Area

PS

line

PackTrack™ Conditions

Tracking Area

Tracking Area

TX

line

22

Page 35

READING FEATURES

4

4.3 PERFORMANCE

The scan rate is 500 scans/sec for each scan line (1000 total).

Refer to the diagrams in par. 4.4 for further details on the reading features.

These diagrams are taken on various resolution sample codes at a 25 °C ambient

temperature depending on the conditions listed under each diagram.

4.3.1 Reading Conditions

• ANSI Grade B minimum

The following tables describe the requirements for standard applications. Please contact

Datalogic for specific advice on maximizing the reading performance possibilities to obtain

the best possible performance for your application.

Minimum Code Height for Omnidirectional Reading (mm)

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3

2/5 Interleaved

Code Resolution

(mm)

0.25

0.30

0.33

0.38

0.50

0.60

1.00

10 12 14 17 19 21

12 14 16 18 20 22

13 14 17 19 21 23

14 16 18 20 22 24

18 19 21 23 25 27

21 22 24 26 28 30

34 35 36 37 39 41

Table 1

Minimum Code Height for Omnidirectional Reading (mm)

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3

Code 39

Code Resolution

(mm)

0.25

0.30

0.33

0.38

0.50

0.60

1.00

9 10 12 15 17 19

10 11 13 16 18 20

11 12 14 16 18 20

12 13 15 17 19 21

15 16 17 19 21 24

18 19 20 21 23 26

28 29 30 31 32 34

Table 2

Minimum Code Height for Omnidirectional Reading (mm)

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3

Code 128 – Ean 128

Code Resolution

(mm)

0.25

0.30

0.33

0.38

0.50

0.60

1.00

7 9 12 14 16 18

8 10 12 15 17 19

9 11 13 15 17 19

10 12 14 16 18 20

12 13 16 18 20 22

14 15 17 19 21 24

22 23 24 26 28 30

Table 3

23

Page 36

4

DX8200 CONTROLLER

Minimum Code Height for Omnidirectional Reading (mm)

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3

Codabar

Code Resolution

(mm)

0.25

0.30

0.33

0.38

0.50

0.60

1.00

12 14 16 18 20 22

13 15 17 20 22 24

14 16 18 20 23 25

16 18 20 22 24 26

20 22 24 26 28 30

23 25 27 29 31 34

36 38 40 42 44 47

Table 4

Minimum Code Height for Omnidirectional Reading (mm)

Conveyor Speed (m/s) 0.5 1 1.5 2 2.5 3

EAN 8-13, UPC-A

Code Resolution

(mm)

0.25

0.30

0.33

0.38

0.50

0.60

1.00

8 9 11 13 15 17

9 10 11 14 16 18

9 10 12 14 16 18

11 12 13 15 17 19

13 14 15 16 18 20

15 16 17 18 19 22

24 25 26 27 28 29

Table 5

24

Page 37

READING FEATURES

4.4 READING DIAGRAMS

Single Configuration DX8200 Controller 201X

4

0.25 mm codes

DOF

400

FW

500

Reading Area

120

Ref.

1100

Dimensions given in mm

CONVEYOR PLANE

Reading diagram for double-diode high resolution model

25

Page 38

4

DX8200 CONTROLLER

Single Configuration DX8200 Controller 200X

0.30 mm codes

Ref.

DOF

Dimensions given in mm

1300

20

CONVEYOR PLANE

600

500

FW

700

600

Reading Area

Reading diagram for double-diode standard resolution model

26

Page 39

READING FEATURES

Single Configuration DX8200 Controller 200X

4

0.50 mm codes

Ref.

Dimensions given in mm

1500

FW

800

600

DOF

900

700

Reading Area

20

CONVEYOR PLANE

Reading diagram for double-diode standard resolution model

27

Page 40

4

DX8200 CONTROLLER

Single Configuration DX8200 Controller 301X

0.25 mm codes

Ref.

DOF

Dimensions given in mm

1100

FW

500

600

Reading diagram for triple-diode high resolution model

Reading Area

120

CONVEYOR PLANE

28

Page 41

READING FEATURES

Single Configuration DX8200 Controller 300X

4

0.30 mm codes

Ref.

DOF

800

600

FW

700

500

Reading Area

Dimensions given in mm

1400

20

100

CONVEYOR PLANE

Reading diagram for triple-diode standard resolution model

29

Page 42

4

DX8200 CONTROLLER

Single Configuration DX8200 Controller 300X

0.50 mm codes

Ref.

DOF

1000

700

300

Dimensions given in mm

1500

100

FW

900

500

Reading Area

CONVEYOR PLAN E

Reading diagram for triple-diode standard resolution model

30

Page 43

READING FEATURES

Side-by-Side Configuration DX8200 Controller 201X

4

0.25 mm codes

1140

Ref.

Dimensions given in mm

1100

FW

DOF

400

900

Reading Ar ea

Reading diagram for side-by-side double-diode high resolution model

120

CONVEYOR PLANE

Side-by-side configurations ar e shown with the minimum overlap. You should adapt

the distance between the scanners and therefore the field width according to your

application.

31

Page 44

4

DX8200 CONTROLLER

Side-by-Side Configuration DX8200 Controller 200X

0.30 mm codes

1240

Ref.

DOF

600

FW

1200

Reading Area

Dimensions given in mm

1300

20

CONVEYOR PLANE

Reading diagram for side-by-side double-diode standard resolution model

Side-by-side configurations ar e shown with the minimum overlap. You should adapt

the distance between the scanners and therefore the field width according to your

application.

32

Page 45

READING FEATURES

Side-by-Side Configuration DX8200 Controller 200X

0.50 mm codes

1240

Ref.

4

DOF

900

700

FW

1200

1000

Reading Area

Dimensions given in mm

1500

20

100

CONVEYOR PLANE

Reading diagram for side-by-side double-diode standard resolution model

Side-by-side configurations ar e shown with the minimum overlap. You should adapt

the distance between the scanners and therefore the field width according to your

application.

33

Page 46

4

DX8200 CONTROLLER

Side-by-Side Configuration DX8200 Controller 301X

0.25 mm codes

1140

Ref.

DOF

600

FW

900

Reading Area

Dimensions given in mm

1100

120

CONVEYOR PLANE

Reading diagram for side-by-side triple-diode high resolution model

Side-by-side configurations ar e shown with the minimum overlap. You should adapt

the distance between the scanners and therefore the field width according to your

application.

34

Page 47

READING FEATURES

Side-by-Side Configuration DX8200 Controller 300X

0.30 mm codes

1240

Ref.

4

DOF

800

600

FW

1200

1000

Reading Area

Dimensions given in mm

1400

20

100

CONVEYOR PLANE

Reading diagram for side-by-side triple-diode standard resolution model

Side-by-side configurations ar e shown with the minimum overlap. You should adapt

the distance between the scanners and therefore the field width according to your

application.

35

Page 48

4

DX8200 CONTROLLER

Side-by-Side Configuration DX8200 Controller 300X

0.50 mm codes

1040

Ref.

DOF

1000

700

FW

1200

1000

Reading Area

Dimensions given in mm

100

1500

CONVEYOR PLANE

Reading diagram for side-by-side triple-diode standard resolution model

Side-by-side configurations ar e shown with the minimum overlap. You should adapt

the distance between the scanners and therefore the field width according to your

application.

36

Page 49

MAINTENANCE

5

5 MAINTENANCE

5.1 CLEANING

Clean the laser beam output windows periodically for correct operation of the reader.

Dust, dirt, etc. on the window may alter the reading performance.

Repeat the operation frequently in particularly dirty environments.

Use soft material and alcohol to clean the windows and avoid any abrasive substances.

Clean the windows of the DX8200 Controller when the scanner is t urned

off or at least when the laser beam is not active.

WARNING

5.2 AUTOMATIC SCANNER REPLACEMENT

Principally used for PackTrack configurations, the

functioning automatically after one or more Slave scanners are replaced in a Master/Slave

Lonworks network.

1.

When the Modify Scanner Configuration parameter in Genius™ i s checked, you

can configure the Lonworks Slave Scanner Common Parameters (Code and

Reconstruction Parameters), through the Master. By configuring the Slave scanners

through the Master, the Automatic Scanner Replacement procedure (ASR) is

implemented.

2. After system configuration through the Master,

Environmental parameters to the Master EEPROM. The Master will force the

Slaves Operating Mode and Code Reading Symbologies and store all the Slave

PackTrack calibration tables.

ASR procedure allows restoring system

Send the configuration with

By Saving thi s configuration to file (.ddc), the Master scanner can be

replaced if necessary. To replace the Master, first load the saved

NOTE

configuration from file to the new Master. Then replace the Master.

Slave Scanner Replacement

A. Power down the entire system.

B. Replace the Slave scanner with a new one (default settings).

C. Power up the system and wait for initialization.

37

Page 50

5

DX8200 CONTROLLER

ASR works only if the Slave devices have software 1.30 and later for 6000

NOTE

Family scanners.

5.3 REPLACING THE PROTECTION FUSES (FOR AC MODELS)

The device must be opened by qualified personnel only.

WARNING

Before removing the fuses from DX8200 Contr oller, make sure t he power

supply cable is disconnected to avoid shock or harm to the operator.

WARNING

Two protection fuses are located next to the on/off switch (Figure B, 12).

To replace them, turn the device off and disconnect the power supply cable; then, with a

screwdriver remove the fuses and replace them with new ones of the correct value (see the

following fuse selection table).

Connect the power supply cable and turn the device on again to verify the success of the

operation.

Version Fuse Type

85 - 264 Vac 3.15 A F

38

Page 51

TECHNICAL FEATURES

6

6 TECHNICAL FEATURES

DX8200 Controller

ELECTRICAL FEATURES (see note 1)

Models X0X1 Models X0X0

Input voltage 85-264 VAC 20 to 30 VDC

Current consumption (max.) 0.4 ~ 0.2 A 1.5 ~ 1.0 A

Communication interf aces

Lonworks network 1,25 Mb/s

Main RS232, RS485 full-duplex,

20 mA C.L. (INT-60) 19200

Auxiliary RS232 1200-115200

Inputs

(optocoupled, NPN or PNP)

Outputs

(optocoupled, open emitter

collector)

RS485 half-duplex,

1 external trigger, 3 auxiliary digital inputs.

3 software programmable digital ouputs.

OPTICAL FEATURES (see note 1)

Light source up to 3 semiconductor laser diodes

Wavelength 630 to 680 nm

Safety class Class 2 - EN 60825-1; Class II - CDRH

Light receiver Avalanche photodiode

Baud rate

1200-115200

READING FEATURES

Scan rate 500 scans/s for each scan line (1000 total)

USER INTERFACE

LED indicators Power ON, Ext Trig, Encoder, Good Read, TX Data,

Network

39

Page 52

6

DX8200 Controller

SOFTWARE FEATURES

READABLE CODE SYMBOLOGIES

Interleaved 2/5 Code 128/EAN 128

Code 39 standard EAN/UPC

Codabar Code 93 (standard & Full ASCII)

Code Selection

Headers and Terminators

Up to 10 code symbologies during one reading phase

Transmitted messages can be personalized using up to 128

headers and 128 terminators

Operating Modes

Configuration Modes

PackTrack™

Genius™ utility program

DX8200 CONTROLLER

Parameter Storage

Non-volatile internal FLASH

ENVIRONMENTAL FEATURES

Operating temperature 0° to +50 °C (+32° to +122 °F)

Storage temperature -20° to +70 °C (-4° to +158 °F)

Humidity 90% non condensing

Vibration resistance EN 60068-2-6 test FC

1.5 mm @ 5 to 9.1 Hz; 0.5 G @ 9.1 to 150 Hz;

2 hours on each axis

Shock resistance EN 60068-2-27 test EA

15 G; 11 ms;

3 shocks on each axis in each direction

Protection class IP54

PHYSICAL FEATURES

Mechanical dimensions 576 x 513 x 150 mm (22.7 x 20.2 x 5.9 in)

Weight about 22 Kg (48.5 lbs.)

Note 1: The features given are typical at 25 °C ambient temperature (if not otherwise

indicated).

40

Page 53

GLOSSARY

ACR™

Advanced Code Reconstruction technology allows the reading of low aspect ratio labels

placed anywhere on a parcel and enhances the readability of poorly printed or damaged

codes.

Aperture

Term used on the required CDRH warning labels to describe the laser exit window.

ASTRA™

Automatically Switched Reading Area™ is a Datalogic technology based on a multi-laser

architecture and a fixed mounted optic system which concentrates the multiple laser

emissions in a single laser beam. As each laser emitter is focused on a specific range of the

reading area, a sophisticated electronic controller selects the best focused laser emitter with

respect to the code to read. This allows the reading of medium-high density codes in a large

reading area on very fast conveyors.

Barcode

A pattern of variable-width bars and spaces which represents numeric or alphanumeric data

in machine-readable form. The general format of a barcode symbol consists of a leading

margin, start character, data or message character, check character (if any), stop character,

and trailing margin. Within this framework, each recognizable symbology uses its own unique

format.

Barcode Label

A label that carries a barcode and can be affixed to an article.

Baud Rate

A unit used to measure communications speed or data transfer rate.

CD SQUARE™

CD SQUARE™ provides useful information on label position and object shape elaborated

during the barcode reading phase. This innovative technology identifies the area in which the

code is located and measures the code distance from the scanner.

CDRH (Center for Devices and Radiol ogical Health)

This organization (a service of the Food and Drug Administration) is responsible for the

safety regulations governing acceptable limitations on electronic radiation from laser devices.

Datalogic devices are in compliance with the CDRH regulations.

EEPROM

Electrically Erasable Programmable Read-Only Memory. An on-board non-volatile memory

chip.

Full Duplex

Simultaneous, two-way, independent transmission in both directions.

Half Duplex

Transmission in either direction, but not simultaneously.

41

Page 54

Host

A computer that serves other terminals in a network, providing services such as network

control, database access, special programs, supervisory programs, or programming

languages.

Interface

A shared boundary defined by common physical interconnection characteristics, signal

characteristics and meanings of interchanged signals.

LED (Light Emitt ing Diode)

A low power electronic device that can serve as a visible or near infrared light source when

voltage is applied continuously or in pulses. It is commonly used as an indicator light and

uses less power than an incandescent light bulb but more than a Liquid Crystal Display

(LCD). LEDs have extremely long lifetimes when properly operated.

Multidrop Line

A single communications circuit that interconnects many stations, each of which contains

terminal devices. See RS485.

PackTrack™

PackTrack™ is a Datalogic patented parcel tracking system which improves the reading

features in omnidirectional stations. In particular, PackTrack™ manages 6-sided reading

systems when it is impossible to detect the real position of the code on the parcel, thus

overcoming the need for external accessories essential in traditional tracking systems. See

par. 4.2 for more details.

Parameter

A value that you specify to a program. Typically parameters are set to configure a device to

have particular operating characteristics.

Position

The position of a scanner or light source in relation to the target of a receiving element.

Protocol

A formal set of conventions governing the formatting and relative timing of message

exchange between two communicating systems.

Resolution

The narrowest element dimension which can be distinguished by a particular reading device

or printed with a particular device or method.

RS232

Interface between data terminal equipment and data communication equipment employing

serial binary data interchange.

RS485

Interface that specifies the electrical characteristics of generators and receivers for use in

balanced digital multipoint systems such as on a Multidrop line.

Scanner

A device that examines a printed pattern (barcode) and either passes the uninterpreted data

to a decoder or decodes the data and passes it onto the Host system.

42

Page 55

Serial Port

An I/O port used to connect a scanner to your computer, identifiable by a 9-pin or 25-pin

connector.

Signal

An impulse or fluctuating electrical quantity (i.e.: a voltage or current) the variations of which

represent changes in information.

Symbol

A combination of characters including start/stop and checksum characters, as required, that

form a complete scannable barcode.

Trigger Signal

A signal, typically provided by a photoelectric sensor or proximity switch, which informs the

scanner of the presence of an object within its reading zone.

UPC

Acronym for Universal Product Code. The standard barcode type for retail food packaging in

the United States.

Visible Laser Diode

A light source used in scanners to illuminate the barcode symbol. Generates visible red light

at wavelengths between 630 and 680 nm.

43

Page 56

INDEX

A

Accessories; 3

Advanced Code Reconstruction; 21

E

Electrical Connections; 7

Host Interface; 8

Power Supply; 7

F

Fuse Replacement; 38

G

General View; vi

Genius™

Advanced Configuration; 17

Guide to Configuration; 16

Installation; 16

Glossary; 41

Guide to Installation; v

I

M

Maintenance; 37

Mechanical Dimensions; 6

Model Description; 3

O

Outputs; 14

P

Package Contents; 5

PackTrack™; 22

Parameter Explorer Window; 17

Parameter Groups

Default Values; 18

Performance; 23

R

Reading Conditions; 23

Reading Diagrams; 25

Reading Features; 21

S

Indicators; 3

Inputs; 13

Installation; 5

Interfaces

Auxiliary; 12

Ethernet; 8

Lonworks; 12

Main 20 mA Current Loop; 11

Main RS232; 9

Main RS485 Full Duplex; 10

Main RS485 Half Duplex; 10

RS232 Debug; 13

L

Layouts; 15

Safety Precautions; viii

Electrical Safety; viii

Laser Safety; viii

Power Supply; ix

Software Configuration; 16

T

Technical Features; 39

Electrical; 39

Environmental; 40

Indicators; 39

Optical; 39

Physical; 40

Reading; 39

Software; 40

44

Loading...

Loading...