Page 1

DX6400/DX6500

Reference Manual

Page 2

Page 3

DX6400/DX6500

REFERENCE MANUAL

Page 4

DATALOGIC S.p.A.

Via Candini 2

40012 - Lippo di Calderara di Reno

Bologna - Italy

DX6400/DX6500 Reference Manual

Ed.: 04/2005

ALL RIGHTS RESERVED

Datalogic reserves the right to make modifications or improvements without prior notification.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

Product names mentioned herein are for identification purposes only and may be trademarks and or

registered trademarks of their respective companies.

© Datalogic S.p.A. 2003 - 2005

06/04/2005

Page 5

CONTENTS

REFERENCES .............................................................................................................v

Reference Documentation............................................................................................ v

Services and Support ...................................................................................................v

SAFETY REGULATIONS ...........................................................................................vi

Electrical Safety........................................................................................................... vi

Laser Safety................................................................................................................. vi

Power Supply...............................................................................................................vii

GENERAL VIEW.......................................................................................................viii

GUIDE TO INSTALLATION ......................................................................................... x

Point-to-Point Installation..............................................................................................x

Master/Slave Lonworks Installation ............................................................................. xi

1 INTRODUCTION ..........................................................................................................1

1.1 Product Description ......................................................................................................1

1.2 Model Description.........................................................................................................2

1.3 Indicators ......................................................................................................................3

1.4 Accessories ..................................................................................................................3

2 INSTALLATION ...........................................................................................................5

2.1 Package Contents ........................................................................................................5

2.2 Mechanical Mounting....................................................................................................6

2.2.1 Mounting the Scanner...................................................................................................6

2.2.2 Mounting the Scanner with Accessories.......................................................................8

2.3 Electrical Connections ..................................................................................................9

2.3.1 Main/Aux. Serial Interface and I/O Connector ............................................................11

Main Interface.............................................................................................................12

Auxiliary Interface .......................................................................................................14

Inputs..........................................................................................................................14

Outputs .......................................................................................................................17

2.3.2 Lonworks Connectors.................................................................................................19

Network Termination...................................................................................................20

Lonworks Interface .....................................................................................................20

2.3.3 Ethernet Connector.....................................................................................................22

Ethernet Interface .......................................................................................................23

2.3.4 Power Supply..............................................................................................................24

2.4 User Interface .............................................................................................................25

2.5 Mounting Position .......................................................................................................26

2.6 Typical Layouts...........................................................................................................27

2.6.1 Point-to-Point..............................................................................................................27

2.6.2 Pass Through .............................................................................................................29

2.6.3 RS232 Master/Slave...................................................................................................30

2.6.4 Multiplexer ..................................................................................................................32

2.6.5 Local Lonworks Network.............................................................................................33

2.6.6 Fieldbus Network........................................................................................................37

2.7 DX6400 FLASH™ Dynamic Focus.............................................................................38

2.7.1 Fixed Mode.................................................................................................................38

2.7.2 Continuous Mode........................................................................................................ 38

2.7.3 Triggered Mode ..........................................................................................................39

iii

Page 6

2.7.4 D-FLASHTM Mode ....................................................................................................... 39

2.8 Keypad and Display....................................................................................................40

2.8.1 Internal Net .................................................................................................................40

2.8.2 Test Mode...................................................................................................................40

3 SOFTWARE CONFIGURATION................................................................................41

3.1 Genius™ Installation...................................................................................................41

3.2 Guide to Rapid Configuration .....................................................................................41

3.2.1 Wizard for Quick Reader Setup..................................................................................41

Test Operating Mode..................................................................................................42

On Line Operating Mode ............................................................................................43

Automatic Operating Mode.........................................................................................43

3.2.2 Network Wizard ..........................................................................................................44

3.3 Advanced Genius™ Configuration .............................................................................46

3.4 Parameter Default Values...........................................................................................47

4 READING FEATURES...............................................................................................50

4.1 Advanced Code Reconstruction (ACR™ 3)................................................................ 50

4.2 PackTrack™ ...............................................................................................................50

4.2.1 Parameter Setting and Calibration..............................................................................51

4.3 Reading Conditions ....................................................................................................53

4.4 Reading Diagrams......................................................................................................55

4.4.1 DX6400-100-0XX Resolution: 0.38 mm/15 mils ........................................................55

4.4.2 DX6500-200-0XX Resolution: 0.38 mm/15 mils ........................................................57

5 MAINTENANCE .........................................................................................................59

5.1 Cleaning......................................................................................................................59

5.2 Automatic Scanner Replacement ...............................................................................59

6 TROUBLESHOOTING ...............................................................................................61

7 TECHNICAL FEATURES........................................................................................... 64

GLOSSARY................................................................................................................ 66

INDEX.........................................................................................................................69

iv

Page 7

REFERENCES

REFERENCE DOCUMENTATION

The documentation related to the DX6400/DX6500 management is listed below:

• C-BOX 100 Installation Manual

• INT-30 20 mA Current Loop Interface Board for C-BOX 100

• PWR-120 power supply unit

• Document about the Ethernet connectivity

• Help On-Line in PDF format

SERVICES AND SUPPORT

Datalogic provides several services as well as technical support through its website. Log on

to www.datalogic.com and click on the

links indicated for further information including:

•

PRODUCTS

Search through the links to arrive at your product page where you can download specific

Manuals and Software & Utilities

•

SERVICES & SUPPORT

Datalogic Services - Warranty Extensions and Maintenance Agreements

Authorised Repair Centres

-

•

CONTACT US

E-mail form and listing of Datalogic Subsidiaries

v

Page 8

SAFETY REGULATIONS

ELECTRICAL SAFETY

This product conforms to the applicable requirements contained in the European Standard for

electrical safety EN-60950 at the date of manufacture.

LASER SAFETY

The following information is provided to comply with the rules imposed by international

authorities and refers to the correct use of the DX6400/DX6500 readers.

Standard Regulations

This scanner utilizes a low-power laser diode. Although staring directly at the laser beam

momentarily causes no known biological damage, avoid staring at the beam as one would

with any very strong light source, such as the sun.

Avoid that the laser beam hits the eye of an observer, even through reflective surfaces such

as mirrors, etc.

This product conforms to the applicable requirements of both EN60825-1 and

CDRH 21 CFR1040 at the date of manufacture. The reader is classified as a Class 2 laser

product according to EN60825-1 regulations and as a Class II laser product according to

CDRH regulations.

Disconnect the power supply when opening the device during maintenance or installation to

avoid exposure to hazardous laser light.

There is a safety device which allows the laser to be switched on only if the motor is rotating

above the threshold for its correct scanning speed.

Use of controls or adjustments or performance of procedures other than those

specified herein may result in exposure to hazardous visible laser light.

WARNING

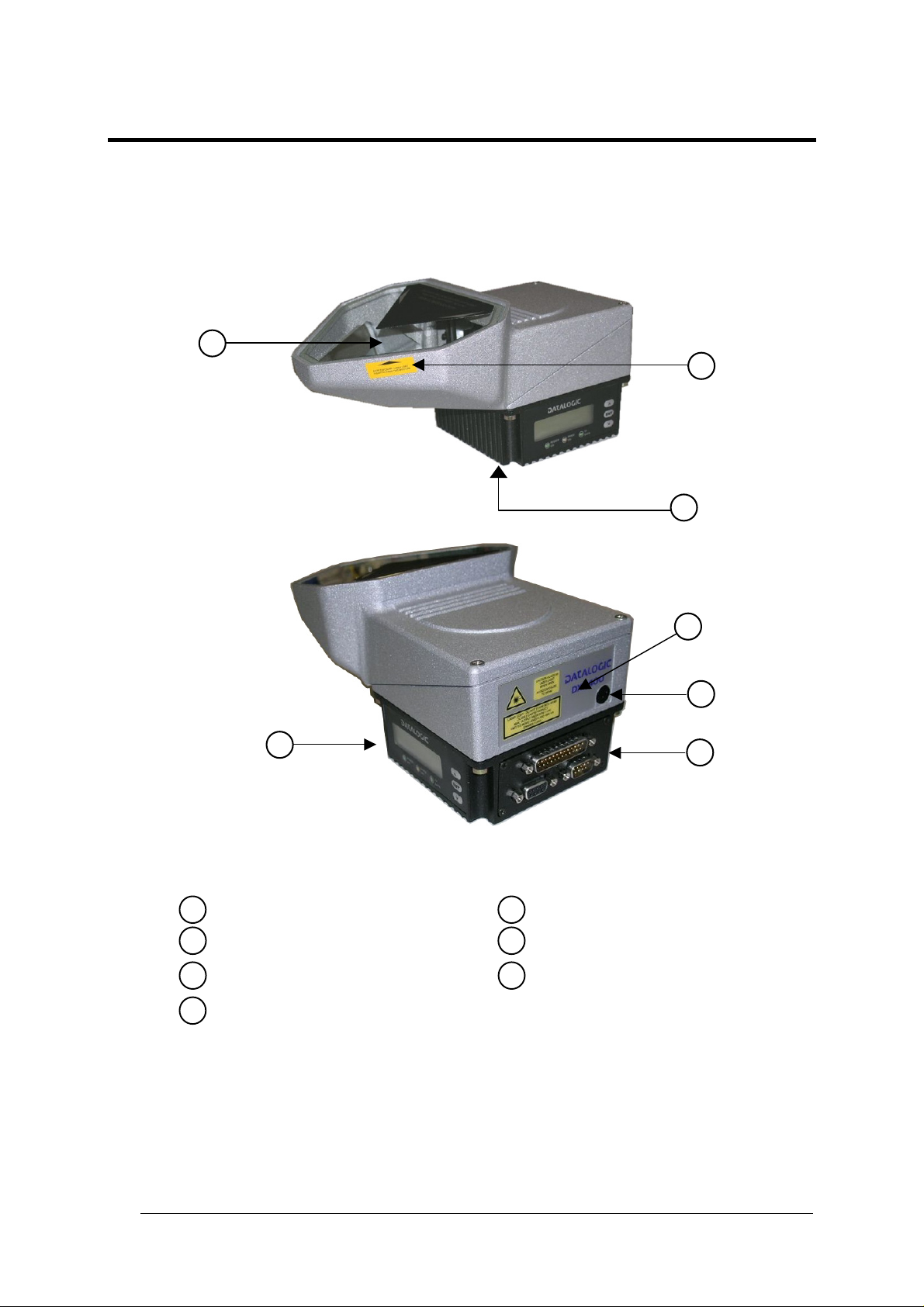

The laser light is visible to the human eye and is emitted from the window on the head of the

reader (Figure 1, 7).

Warning labels indicating exposure to laser light and the device classification are applied

onto the head of the reader (Figure 1,1 & 3):

vi

LASER RADIATION IS EMITTED FROM THIS APERTURE

AVOID EXPOSURE

Laser Safety Label for Oscillating Mirror and Standard Models

AVOID EXPOSURE – LASER LIGHT

IS EMITTED FROM THIS APERTURE

Page 9

CAUTION-CLASS 3B

LASER LIGHT

WHEN OPEN

AVOID EXPOSURE

TO BEAM

LASER LIGHT – DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

MAX. OUTPUT RADIATION 1 mW

EMITTED WAVE LENGTH 630 ~ 680 nm

EN60825-1:2001

Warning and Device Class Label

The identification label is applied onto the bottom part of the scanner (Figure 1, 2):

DATALOGIC S.p.A. Via Candini, 2

40012 LIPPO DI CALDERARA DI RENO (BO) ITALY

MANUFACTURED VOLT Amp.

JANUARY 2002 15-30 DC 1.2-0.6

MODEL No.

SERIAL No.

This product conforms to the applicable requirements

of 21CFR 1040 at the date of manufacture.

N2468

Device Identification Label

The laser diode used in this device is classified as a Class 3B laser product according to

EN60825-1 regulations and as a Class IIIb laser product according to CDRH regulations. As it

is not possible to apply a classification label on the laser diode used in this device, the

following label is reproduced here:

MAXIMUM OUTPUT RADIATION 35 mW

EMITTED WAVE LENGTH 630~680 nm

TO EN60825-1 (2001)

LASER LIGHT

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

Laser Diode Class Label

Any violation of the optic parts in particular can cause radiation up to the maximum level of

the laser diode (35 mW at 630~680 nm).

POWER SUPPLY

- This product is intended to be installed by Qualified Personnel only.

- All DX6400/DX6500 Models:

This device is intended to be supplied by a UL Listed Power Unit marked “Class 2” or LPS

power source which supplies power directly to the scanner via the 25/26-pin connector.

vii

Page 10

GENERAL VIEW

7

DX6400/DX6500

1

2

3

4

6

Figure 1 - DX6400/DX6500

1

Laser Safety Label

Identification Label

2

Warning and Device Class Label

3

Service Cap

4

5

Connector Panel

Display and Keypad Panel

6

Laser Beam Output Window

7

5

viii

Page 11

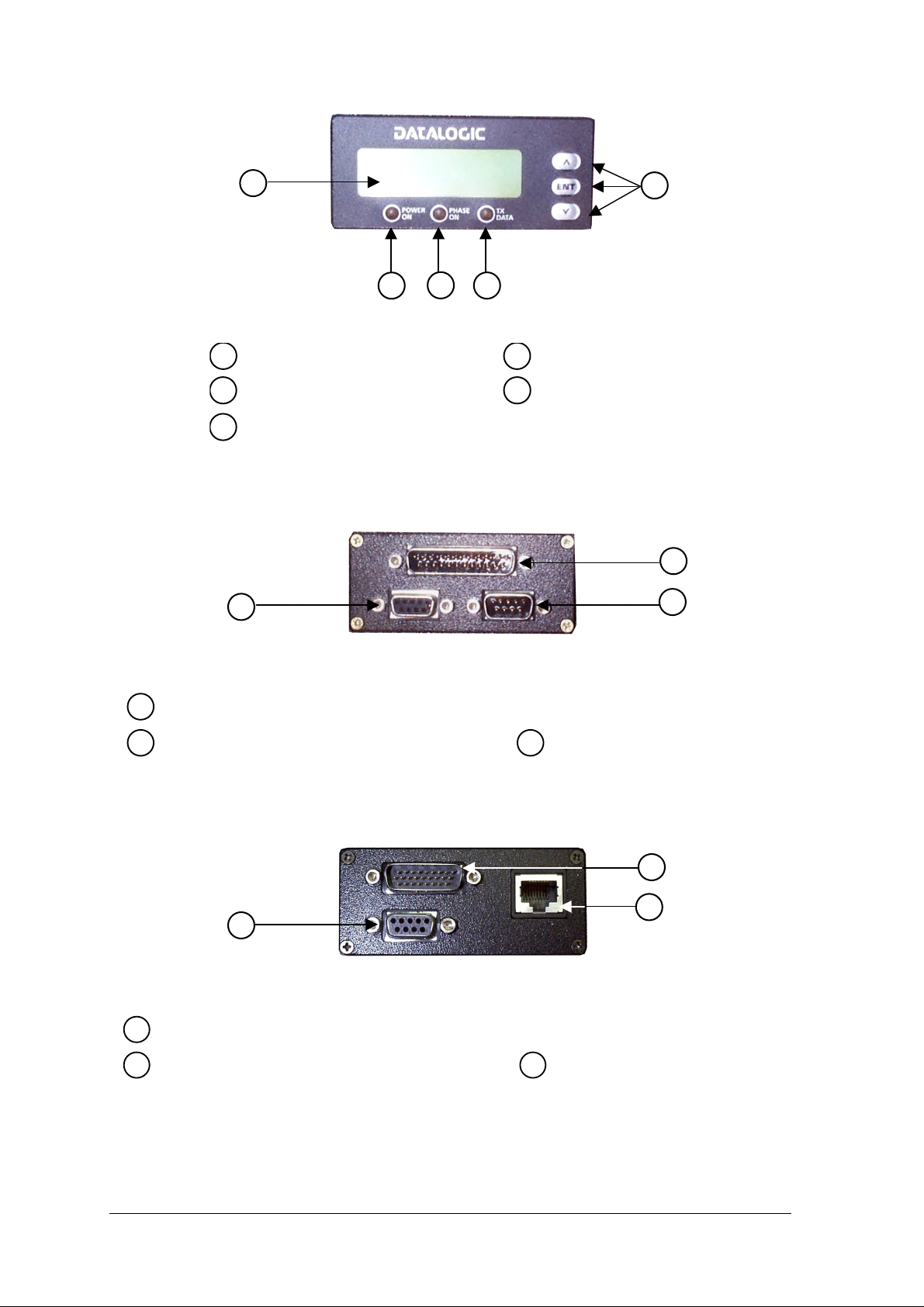

5

1

3

4

Figure 2 - Display and Keypad Panel

2

Programming Keypad

1

2

TX Data LED

3

Phase On LED

Power On LED

4

LCD Display

5

1

3

2

Figure 3 - Connector Panel for Master/Slave Models

Main/Aux. Interface 25-pin D-Sub male connector

1

Lonworks 9-pin male connector

2

3

Lonworks 9-pin female connector

1

2

3

Figure 4 – Connector Panel for Ethernet Models

Main/Aux. Interface 26-pin D-Sub male connector

1

RJ45 modular connector for Ethernet Interface

2

3

Lonworks 9-pin female connector

ix

Page 12

GUIDE TO INSTALLATION

POINT-TO-POINT INSTALLATION

The following can be used as a checklist to verify all the steps necessary to complete

installation of the DX6400/DX6500 scanner.

1) Read all information in the section “Safety Precautions” at the beginning of this manual.

2) Correctly mount the scanner using the bracket provided according to the information in

par. 2.2.2 and par. 2.5 and position the reader at the correct reading distance according

to the reading diagrams in par. 4.3.

3) Make electrical connections to your DX6400/DX6500 scanner by:

a) Connecting the DX6400/DX6500 scanner to the C-BOX 100 by means of one of the

cables provided as accessory (see par. 1.4).

b) Providing correct and complete system cabling through the C-BOX 100 according to

the signals (trigger, inputs, outputs) necessary for the layout of your application.

• Layout: Point-to-Point, RS232 Master/Slave, Lonworks, Fieldbus. See sub-

paragraphs under 2.6 for reference.

• Cabling: Power, Main Serial Interface – RS232, RS485 Half Duplex, RS485 Full

Duplex, 20 mA Current Loop, Auxiliary Interface, Inputs, Outputs, etc -. For further

details, see all sub-paragraphs under par. 2.3.

4) Configure the DX6400/DX6500 scanner by installing and running the Genius™

configuration program from the CD-ROM provided. The main steps are:

• Select the codes to be read

• Set-up the communication parameters

• Define data formatting parameters

• Fine tune your DX6400/DX6500 scanner using the Test Mode as described in

Genius™.

5) Exit the configuration program and run your application.

The installation is now complete.

x

Page 13

MASTER/SLAVE LONWORKS INSTALLATION

The following can be used as a checklist to verify all the steps necessary to complete

installation of the DX6400/DX6500 scanner in a Master/Slave Lonworks network.

1) Repeat the previous procedure from step 1 to step 3.

2) Make electrical connections to your DX6400/DX6500 scanner by:

a) Connecting the DX6400/DX6500

Master scanner to the C-BOX 100 by means of one

of the cables provided as accessory (see par. 1.4).

b) Correctly inserting the BTK-6000 terminator in the DX6400/DX6500 Master reader

according to the information given under “Local Lonworks Network” in par. 2.3.2.

c) Completing the system wiring adding as much slave scanners as required by your

system layout (refer to par. 2.6).

d) Correctly inserting the BTK-6000 terminator in the last DX6400/DX6500 Slave reader

of the network according to the information given under “Local Lonworks Network” in

par. 2.3.2.

3) Configure the DX6400/DX6500 Slave scanners using one of the procedures given below:

a) Defining each DX6400/DX6500 slave scanner address by using the scanner keypad

according to the information given in par. 2.8.1.

b) Installing and running the Genius™ configuration program from the CD-ROM

provided and defining each DX6400/DX6500 slave scanner address as described in

par. 3.2.2.

4) Configure the DX6400/DX6500 Master scanner using one of the procedures given below:

c) Configure the DX6400/DX6500 scanner as Master by using the scanner keypad

according to the information given in par. 2.8.1.

d) Configure the DX6400/DX6500 scanner as Master by using the Genius™ program as

described in par. 3.2.2.

5) Connect the DX6400/DX6500 Master scanner to configure the network layout by using

the Genius™ program.

6) Configure all the DX6400/DX6500 slave scanners through the Genius™ program. The

main steps are:

• Select the codes to be read

• Set-up the communication parameters

• Define data formatting parameters

All slave scanners may also be configured remotely via Genius™

NOTE

through the Master scanner.

7) Fine tune your DX6400/DX6500 scanner using the Test Mode as described in Genius™.

The installation is now complete.

xi

Page 14

xii

Page 15

INTRODUCTION

1

1 INTRODUCTION

1.1 PRODUCT DESCRIPTION

The DX6400/DX6500 is a high performance laser scanner in a complete range of industrial

bar code readers offering an innovative and modular solution in terms of reading

performance, connectivity and maintenance, in addition to a completely new hardware and

software platform.

The DX6400/DX6500 has been specifically designed for simple installation, easy use and

flexibility. An innovative mechanical design together with the Datalogic patent pending Stepa-Head

independently from each other. Step-a-Head

installed in the ideal position, by modifying the orientation of the connector panel while

leaving the laser window in the desired position. The need for space is minimized and

installation is easier.

The DX6400 has an innovative linear motor designed to control the focus position of the

scanner via software. This dynamic system, called FLASH

position rail to rail, from the minimum position to the maximum position, in less than 10 msec.

In typical applications, where a DOF <1 meter is required, the focus position is adjusted in 4

msec.

The DX6500 is based on the ASTRA™ technology which allows to switch electronically the

two laser diodes depending on the distance from the barcode. The real time depth of field

(DOF) provided by the DS6500 covers a wide set of applications, from the stand alone one to

the multisided tunnels conveyors.

The DX6400/DX6500 can read all most popular barcodes even in the most difficult

conditions, thanks to a new generation decoder with StrongARM CPU and code

reconstruction technology (ACR™ 3).

Great attention has been given to built-in connectivity for market standards. Lonworks, and

Ethernet bus have been integrated in dedicated versions of the decoder base.

Some of the main features of DX6400/DX6500 are listed below:

• omni-directional reading;

• scanning speed up to 750 scans/sec per scan line (total 1500 scans/sec);

• 2 serial communication interfaces

• reading all popular codes;

• supply voltage from 15 to 30 Vdc;

• electrical connection through connectors;

• high speed Lonworks connectivity for Master/Slave layout;

• built-in connectivity for Ethernet;

• programmable in 5 different operating modes to suit the most various barcode reading

• light source: solid state laser diode; the light emitted has a wavelength between

• IP64 protection class of the enclosure (for Master/Slave models).

TM

feature make it possible to rotate the reader head and the decoder base

TM

enables the DX6400/DX6500 to always be

TM,

is able to move the focus

system requirements;

630~680nm.

1

Page 16

1

Feature

Modular solution with separated

head and base and Step-A-

TM

Head

feature

Benefit

• Possibility to select the combination of head and

base that best fits the needs of the application;

• Great scalability of the offer;

• Down time cost reduction, since the decoder base

DX6400/DX6500

works even if the head has been removed;

• Easy maintenance. In case of replacement of the

head, all the configuration parameters are stored

in the base, and the scanner is automatically

configured;

Reading on pallets or big objects

• Easy installation with the minimum room needed.

• DX6400 with FLASH

TM

dynamic focusing system.

where a large reading distance /

wide reading field are needed

Reading parcels on conveyors • As a result of the ASTRA™ double laser

technology, DX6500 gives a great real time DOF

even on high speed conveyors.

• DX6400/DX6500 implements the Packtrack

TM

functionality which leads to an increase of the

plant production as a result of the augmented

system throughput.

Master working as a multiplexer

on a high speed Lonworks bus

• Great competitiveness of the offer, since the cost

of an external multiplexer is saved;

• High data transfer on a industrial, reliable bus

running at 1,2 Mbit/sec.

GENIUSTM Configurator SW • Reduced learning time, with an easy wizard

approach;

• Multilanguage platform;

• All the configuration parameters stored into the

scanner;

• Not dependent on the Physical interface.

1.2 MODEL DESCRIPTION

The DX6400/DX6500 scanner is available in versions that differ in regard to the Decoder

Model (Base):

DX6400 - 100 - 0YY

2

Decoder Model (Base)

10 = Master/Slave

12 = Ethernet

DX6500 - 200 - 0YY

Decoder Model (Base)

10 = Master/Slave

12 = Ethernet

Page 17

INTRODUCTION

1

1.3 INDICATORS

The DX6400/DX6500 decoder base provides an LCD display for system messages and

configuration menus. The three keys present on the side of the display allow configuration

menu navigation (Figure 2, 1). The three LED indicators have the following functions:

POWER ON

PHASE ON

TX DATA

(red) Indicates the reader is turned on (Figure 2, 4)

(yellow) Indicates the presence sensor is turned on (Figure 2, 3).

(green) Indicates the main serial interface is operating correctly during

data transmission (Figure 2, 2).

1.4 ACCESSORIES

The following accessories are available on request for DX6400/DX6500:

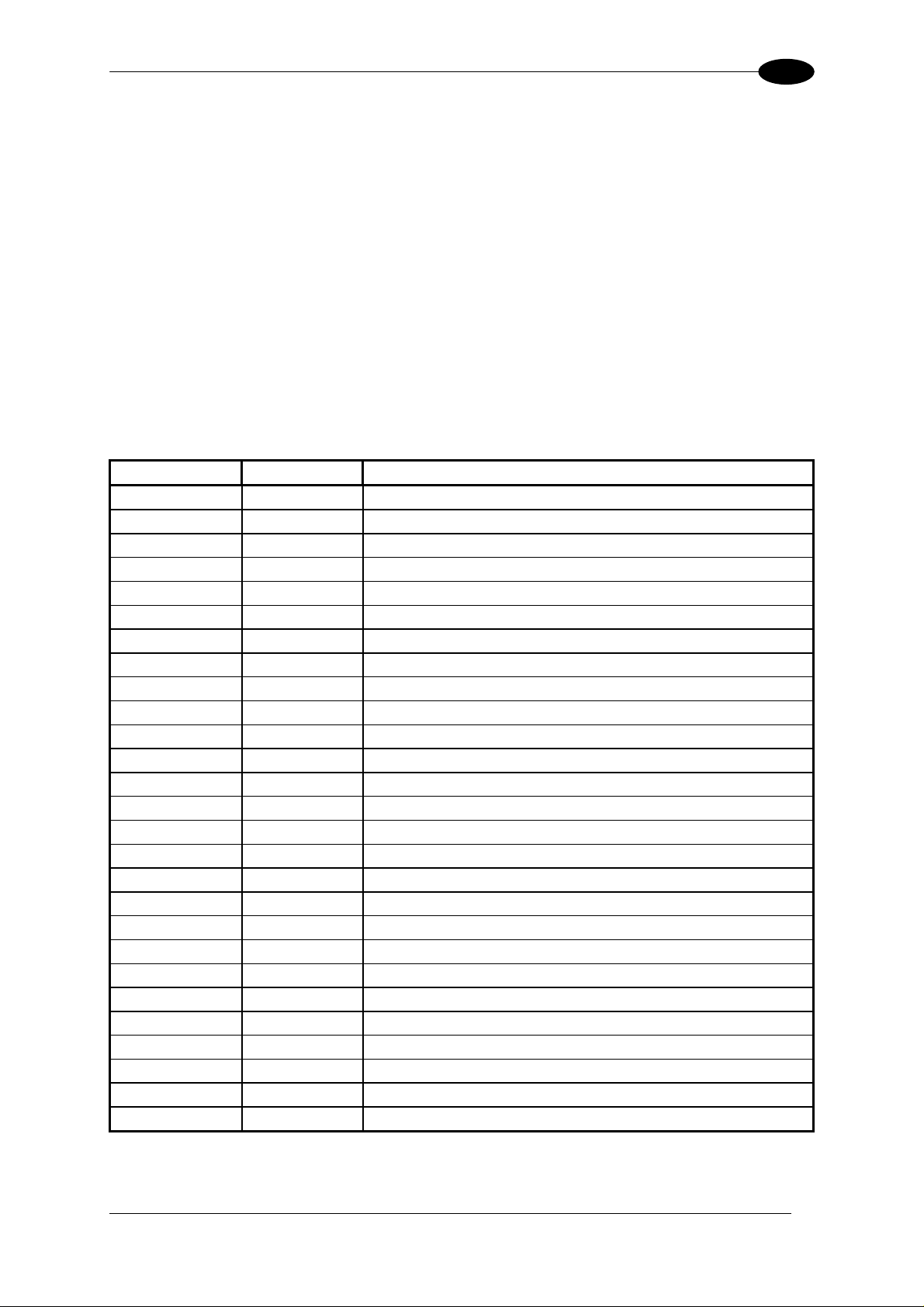

Order no. Accessory Description

93A051190 CAB-6001 cable to C-BOX100 1 m

93A051200 CAB-6002 cable to C-BOX100 2 m

93A051210 CAB-6005 cable to C-BOX100 5 m

93A051271 CAB-6010 cable to C-BOX100 10 m

93A051221 CAB-6011 cable to C-BOX100 1 m (DX6400/DX6500 Ethernet version)

93A051222 CAB-6012 cable to C-BOX100 2 m (DX6400/DX6500 Ethernet version)

93A051223 CAB-6015 cable to C-BOX100 5 m (DX6400/DX6500 Ethernet version)

93A051220 CAB-6101 cable master/slave 1 m

93A051230

93A051240 CAB-6105 cable master/slave 5 m

93A051224 CAB-6112 cable master/slave no power 2 m

93A051225 CAB-6115 cable master/slave no power 5 m

93ACC1752 CAB-6310 Power cable Fam 6k 10 m

93ACC1510

93A15022 INT-30 20 m.A. C.L. interface board for C-BOX 100

93A301000

93A301030

93A301010

93A301040

93ACC1530 PWR-120 power unit 110/230 V AC 24 V

93ACC1710

93ACC1718

93ACC1719

93ACC1720 PG6000 single unit power supply (EU)

93ACC1721 FBK-6000 fast bracket kit (2 pcs)

93ACC1727 MEP-542 Photocell kit – PNP

93ACC1728 MEP-543 Photocell kit - NPN

CAB-6102 cable master/slave 2 m

C-BOX 100

C-BOX 300

C-BOX 310

C-BOX 400

C-BOX 410

BTK-6000 terminator kit (5 pcs)

PG6002

PG6001

passive connection box

Profibus-DP connection box

Profibus-DP connection box with display

Devicenet connection box

Devicenet connection box with display

single unit power supply (US)

single unit power supply (UK)

3

Page 18

2

DX6400/DX6500

2 INSTALLATION

To install the system follow the given procedure:

• Select the mounting location for DX6400/DX6500;

• Mount the DX6400/DX6500 scanner;

• Proceed with system electrical connection;

• Position the scanner with respect of the barcode;

• Install the GENIUS™ program on the PC;

• Set the Flash™ dynamic focus by means of the GENIUS™ software tool

.

only)

If your system requires the DX6400/DX6500 reader to be connected to C-

NOTE

BOX refer to the Reference Documentation section for details.

2.1 PACKAGE CONTENTS

Verify that the DX6400/DX6500 reader and all the parts supplied with the equipment are

present and intact when opening the packaging; the list of parts includes:

(for DX6400

• DX6400/DX6500 reader

• Installation Quick Reference + barcode test chart

• DX6400/DX6500 configuration CD-ROM

• Mounting bracket and screws

4

Page 19

INSTALLATION

w

2

2.2 MECHANICAL MOUNTING

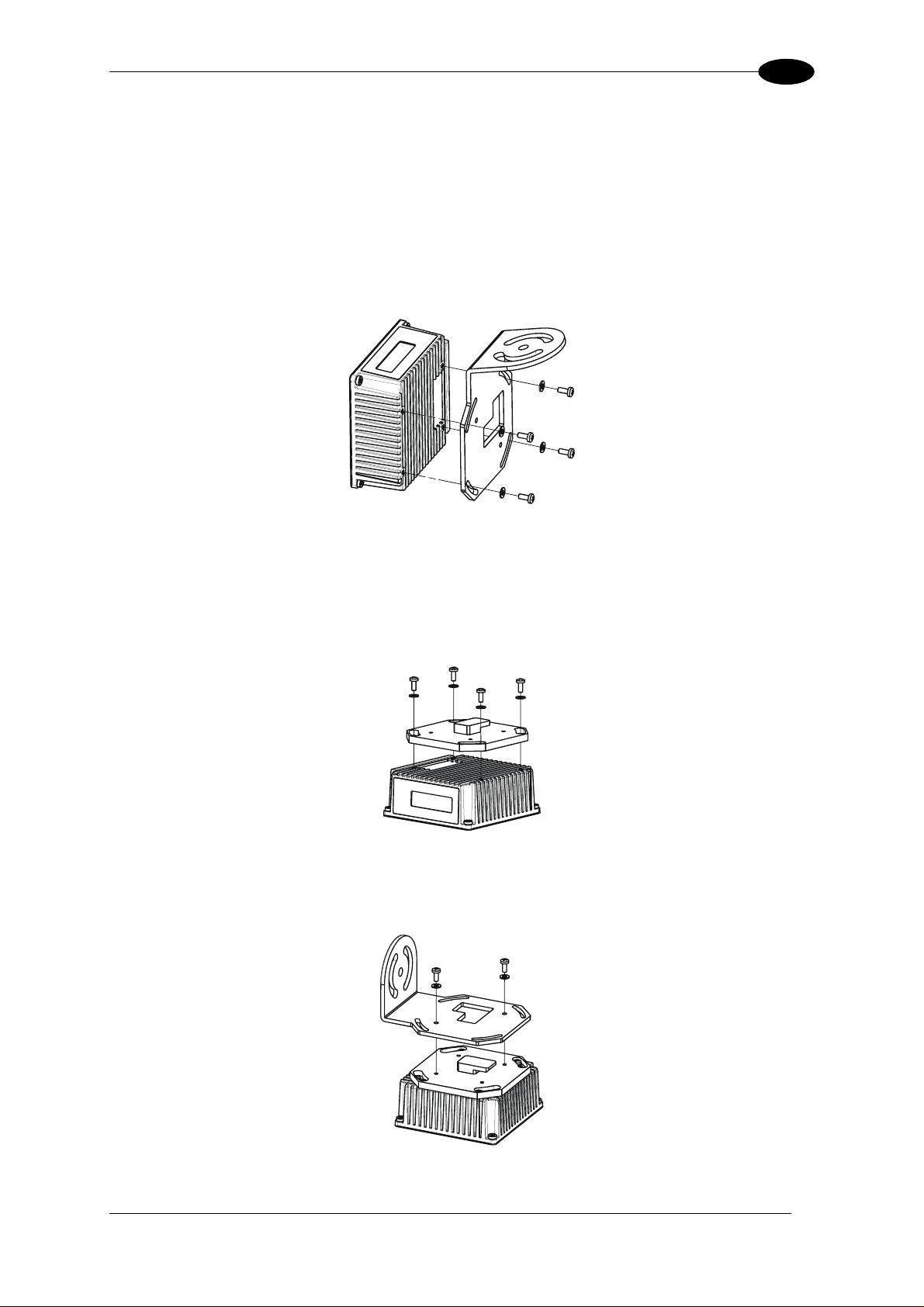

2.2.1 Mounting the Scanner

The DX6400/DX6500 reader can be positioned and installed in the best way possible as a

result of the Step-a-Head™ feature. Thanks to the separation between Head and Base, you

can modify the orientation of the decoder base, and therefore display-keypad and connector

panels, while keeping the optic head in the correct reading position. The reading head and

the decoder base can be rotated independently from each other allowing the installation even

in the most critical locations.

Head Screws

Fixing S

cre

(4)

Figure 5 - Step-A-Head™ Feature

To rotate the head follow the given procedure:

1. detach the head from the base by unscrewing the four fixing screws;

2. rotate the head in the desired position;

3. loosen but don't remove the two screws on top of the head;

4. affix the head onto the base carefully aligning the four fixing screws and progressively

tightening them about half-way;

5. completely tighten the two screws on top of the head;

6. completely tighten the four fixing screws.

5

Page 20

2

5

DX6400/DX6500

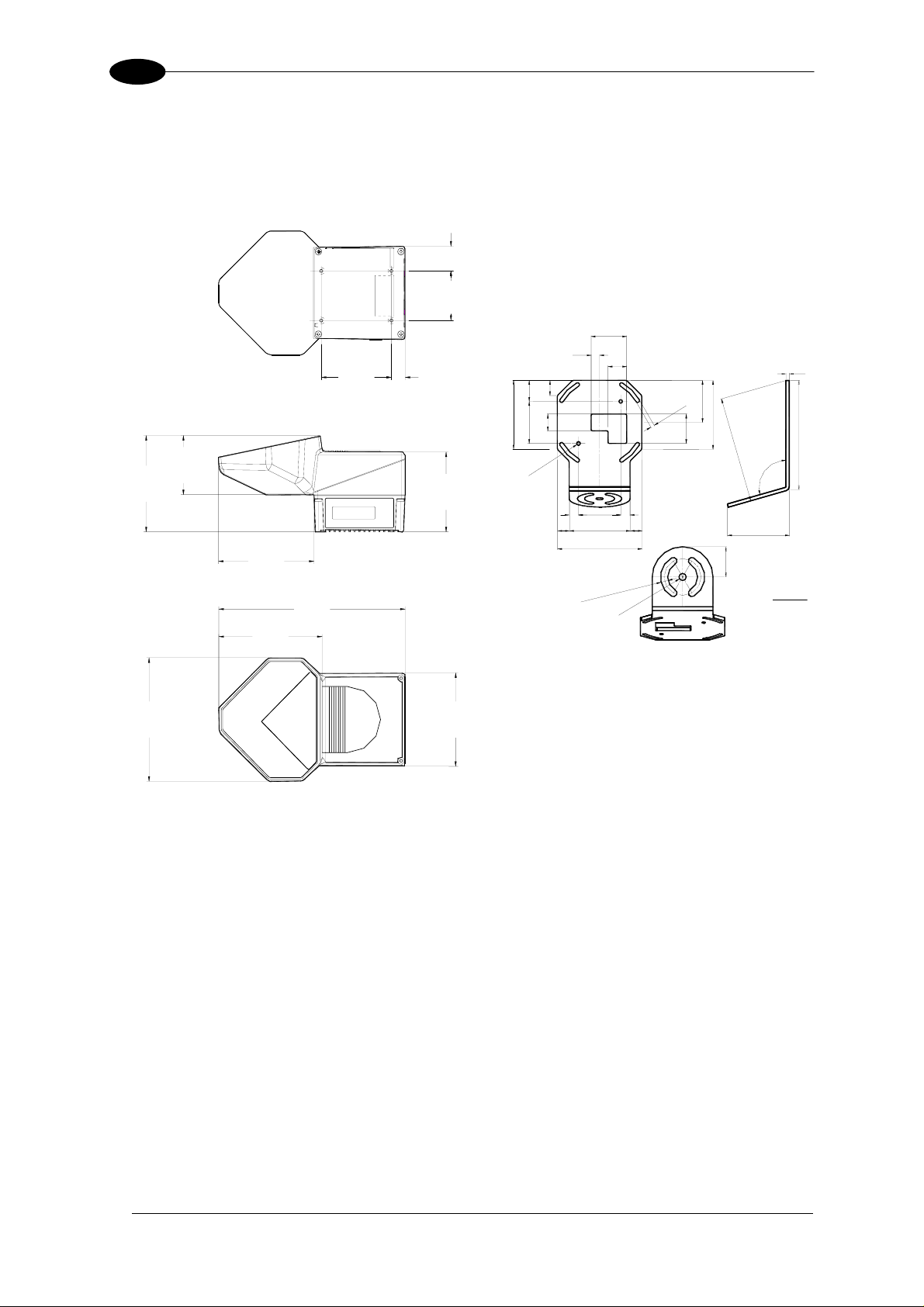

The following diagrams give the overall dimensions of the reader and mounting brackets.

They may be used for their installation. Refer to par. 2.5 for correct positioning of the

scanner.

29.9

[1.18]

60

[2.36]

42

1.65

10

0.4

8

1.96

2.83

100

3.93

.

0

22

0.86

S

50

T

O

1.96

L

S

T

S

O

4

L

°

S

N

4

5

°

.

4

N

82

8

1

.

0

==

50

==

72

S

T

O

L

S

2

S

T

N°

O

5

L

S

2

°

N

3

3

5

.

.

8

3

Ø

3

.

0

Ø

3.22

35

1.37

1

4

2

.

6

9

6

106°

73.2

2.88

36

1.41

85

[3.35]

71.8

[2.83]

116.8

[4.60]

16.5

[0.65]

96.9

[3.82]

18

0.71 N°2

25

0.98

82

3.22

50

20

0.78

1.96

2

°

2

°

N

N

1

.

6

4

1

.

Ø

0

Ø

115.9

[4.56]

225.9

[8.89]

125.3

[4.93]

mm

inch

4

0.1

5.12

130

149.8

[5.90]

113.1

[4.45]

Figure 6 - DX6400/DX6500 Overall Dimensions Figure 7 – ST-237 Mounting Bracket Overall

Dimensions

6

Page 21

INSTALLATION

2

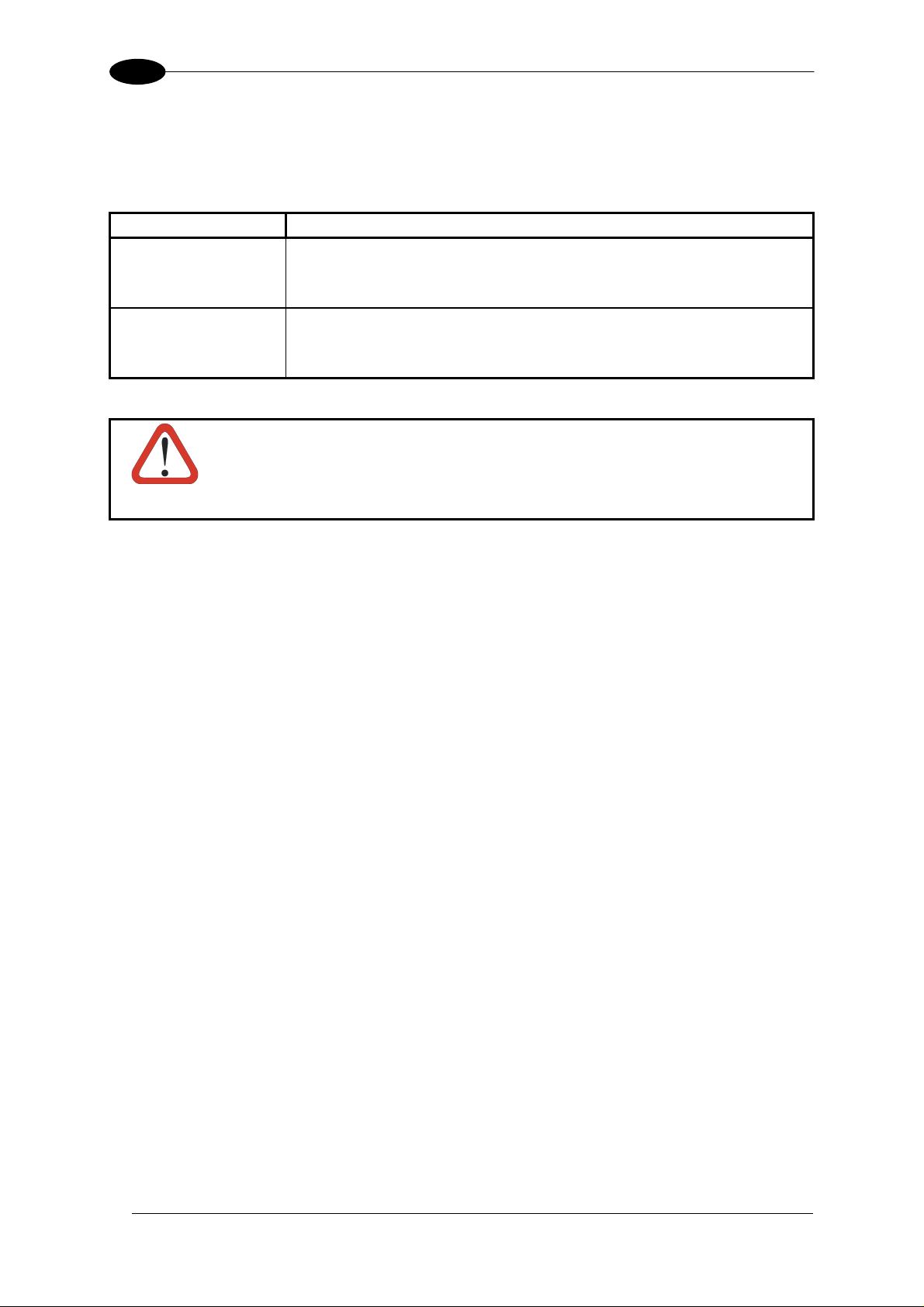

2.2.2 Mounting the Scanner with Accessories

The following accessories allow installing the DX6400/DX6500 reader in the most suitable

position for your network layout:

- ST-237 mounting bracket;

- FBK-6000 fast bracket.

The ST-237 is a 106° mounting bracket to be mounted on the reader as displayed in the

image below:

Figure 8 – Mounting the ST-237 Mounting Bracket

The FBK-6000 is a fast bracket kit allowing a quick and easy mounting of the scanner on the

ST-237 bracket.

First, it is necessary to fix the FBK-6000 to the DX6400/DX6500 scanner by means of the

mounting screws:

Figure 9 – Mounting the FBK-6000 on the Scanner

Then, attach the assembly to the mounting bracket by slipping the hook into the bracket hole.

Finally, fix it by means of the 2 fixing screws:

Figure 10 – Mounting the Assembly on the Bracket

7

Page 22

2

2.3 ELECTRICAL CONNECTIONS

All the connectors available for each scanner model are the following:

Scanner Model Connector

Master/Slave 25-pin male serial interface and I/O connector

9-pin male Lonworks connector*

9-pin female Lonworks connector

Ethernet 26-pin male serial interface and I/O connector

9-pin female Lonworks connector

RJ45 modular connector

* Do not connect an RS232 port to the 9-pin Lonworks Connector. This may

damage your Laptop PC.

CAUTION

DX6400/DX6500

8

Page 23

INSTALLATION

2

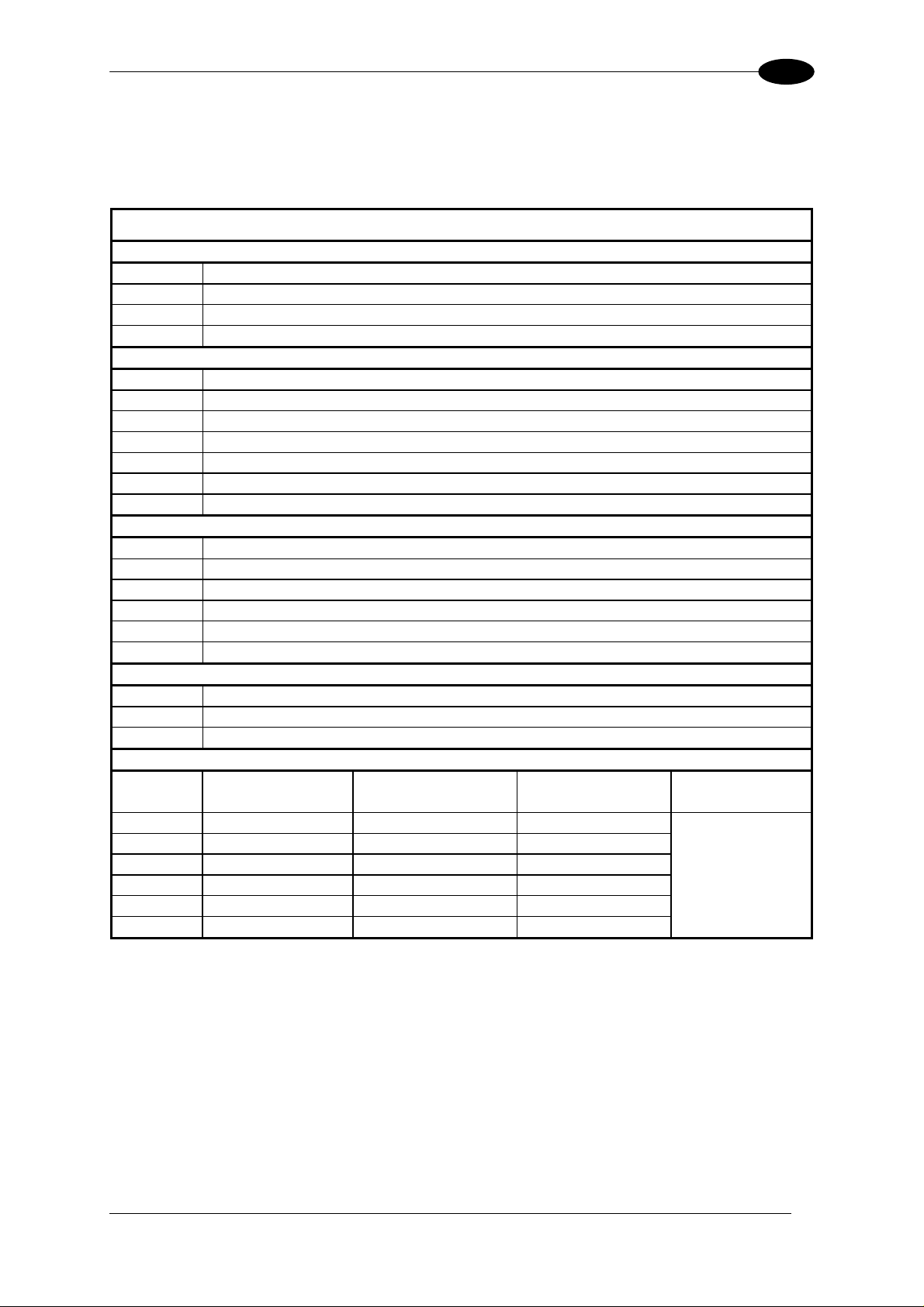

The table below gives the pinout of the C-BOX 100 terminal block connectors. Use this

pinout when the DX6400/DX6500 reader is connected in a network by means of the

C-BOX 100:

C-BOX 100 Terminal Block Connectors

Power

1, 3, 5 VS

2, 4, 6 GND

7, 8 EARTH GROUND

20, 40 Reserved

Inputs

27 EXT TRIG A (polarity insensitive)

28 EXT TRIG B (polarity insensitive)

29 IN 2A (polarity insensitive)

30 IN 2B (polarity insensitive)

31, 33 IN 3A (polarity insensitive)

32, 34 IN 4A (polarity insensitive)

36 IN 3B/IN 4B Reference (polarity insensitive)

Outputs

21 OUT 1+

22 OUT 1-

23 OUT 2+

24 OUT 2-

25 OUT 3A (polarity insensitive)

26 OUT 3B (polarity insensitive)

Auxiliary Interface

35 TX AUX

37 RX AUX

38, 39 GND

Main Interface

RS232

RS485

Full-Duplex

RS485

Half-Duplex

20 mA C.L.

(with INT-30 only)

11, 15 TX232 TX485+ RTX485+

12, 16 RTS232 TX485- RTX485-

17 RX232 RX485+

18 CTS232 RX485-

10, 14, 19

9, 13

SGND Main Isolated SGND Main Isolated SGND Main Isolated

RS485 Cable Shield RS485 Cable Shield

see INT-30

instructions

9

Page 24

2

DX6400/DX6500

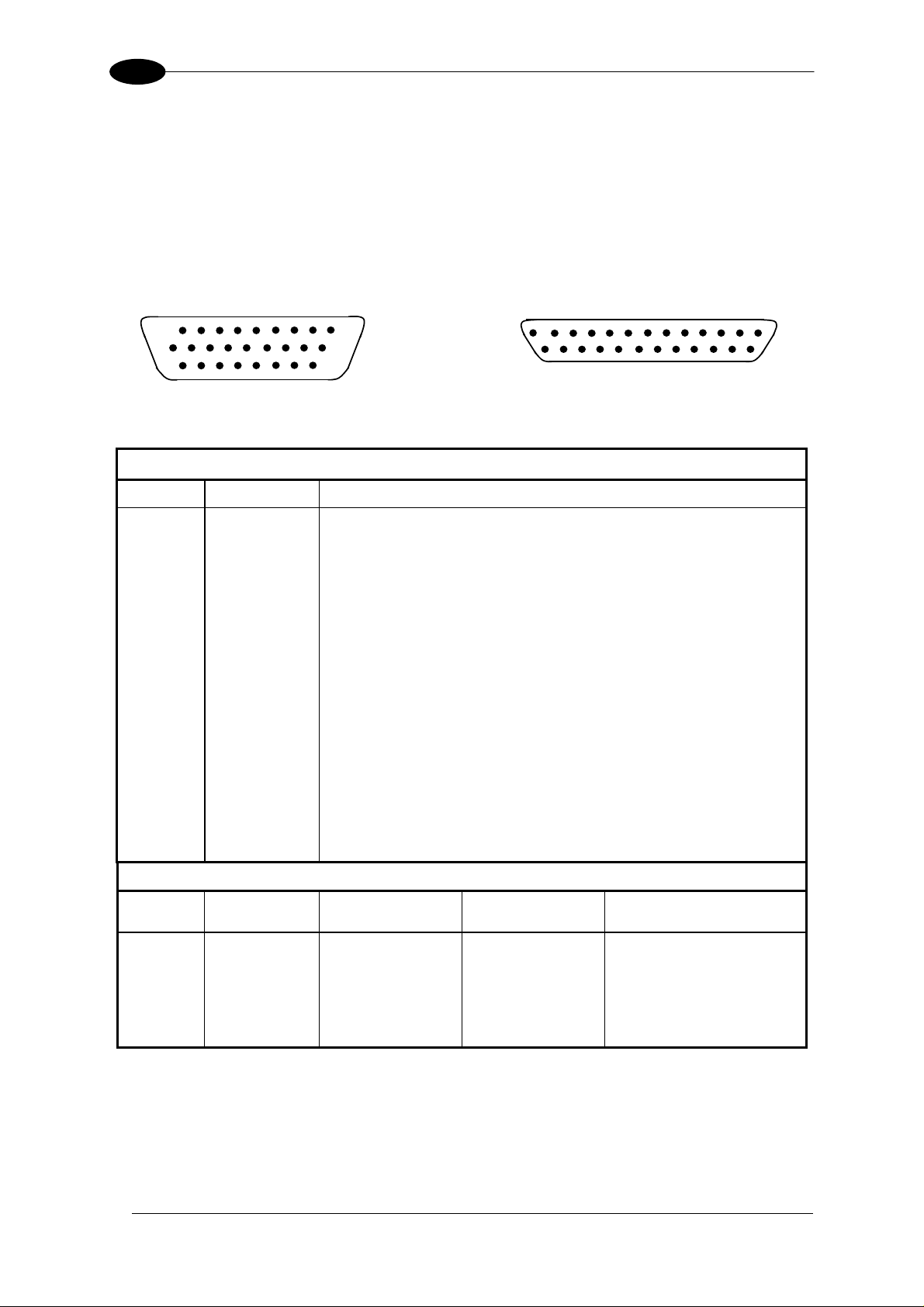

2.3.1 Main/Aux. Serial Interface and I/O Connector

The DX6400/DX6500 master/slave model is equipped with a 25-pin male D-sub connector

for connection to the host computer, power supply and input/output signals.

The DX6400/DX6500 Ethernet models adopt a 26-pin male connector instead of the 25-pin

one.

The details of the connector pins are indicated in the following table:

1

1

10

19

Figure 11 - 26-pin Connector Figure 12 - 25-pin Connector

26

9

18

14

DX6400/DX6500 25-pin/26-pin D-sub connector pinout

Pin Name Function

1 Shield Cable shield - internally connected by capacitor to the chassis

20 RXAUX Receive data of auxiliary RS232 (referred to GND)

21 TXAUX Transmit data of auxiliary RS232 (referred to GND)

8 OUT 1+ Configurable digital output 1 - positive pin

22 OUT 1- Configurable digital output 1 - negative pin

11 OUT 2+ Configurable digital output 2 - positive pin

12 OUT 2- Configurable digital output 2 - negative pin

16 OUT 3A Configurable digital output 3 - polarity insensitive

17 OUT 3B Configurable digital output 3 - polarity insensitive

18 EXT_TRIG A External trigger (polarity insensitive)

19 EXT_TRIG B External trigger (polarity insensitive)

6 IN 2A Input signal 2 (polarity insensitive)

10 IN 2B Input signal 2 (polarity insensitive)

14 IN 3A Input signal 3 (polarity insensitive)

15 IN 4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

9,13 VS Supply voltage - positive pin

23,25,26* GND Supply voltage - negative pin

Main Interface Connector Pinout

Pin

RS232

RS485

Full Duplex

RS485

Half Duplex

20 mA C.L.

(INT-30 with C-BOX 100 only)

2 TX TX485 + RTX485 +

3 RX RX485 +

4 RTS TX485 - RTX485 -

see INT-30 instructions

5 CTS RX485 -

7 GND_ISO GND_ISO GND_ISO

* Pin 26 is only available for Ethernet models.

25

13

10

Page 25

INSTALLATION

2

Main Interface

The main serial interface is compatible with the following electrical standards:

RS232

RS485 full-duplex

RS485 half-duplex

(20 mA current loop)

The 20 mA Current Loop interface is available by using the C-BOX 100 with the optional

INT-30 accessory installed in it. The scanner communicates to the C-BOX 100 through the

RS232 interface and the INT-30 converts the signals.

The main serial interface type and its relative parameters (baud rate, data bits, etc.) are

selected via software using the Genius™ utility program. For more details refer to the

section "Main Serial Port" in the Genius™ Help On Line.

Details regarding the connections and use of the main interface selection are given in the

next paragraphs.

RS232 Interface

The main serial interface is used for communication with the Host computer and allows both

transmission of code data and configuring the reader.

The following pins of the 25-pin and 26-pin connector are used for RS232 interface

connection depending on the reader model:

Pin Name Function

2 TX Transmit

3 RX Receive

4 RTS Request to send

5 CTS Clear to send

7 GND-ISO Main signal ground

The RTS and CTS signals control data transmission and synchronize the connected devices.

If the RTS/CTS hardware protocol is enabled, the DX6400/DX6500 activates the RTS output

to indicate a message can be transmitted. The receiving unit must activate the CTS input to

enable the transmission.

DX6X00

TX

2

3

RX

RTS

4

CTS

5

7

GND-ISO

Shield

1

Figure 13 - RS232 Connections

USER INTERFACE

RXD

TXD

GND

Earth

Ground

11

Page 26

2

DX6400/DX6500

RS485 Full-Duplex Interface

The RS485 full-duplex interface is used for non-polled communication protocols in

point-to-point connections over longer distances than those acceptable for RS232

communications or in electrically noisy environments.

The following pins of the 25-pin and 26-pin connector are used for RS485 full-duplex

interface connection:

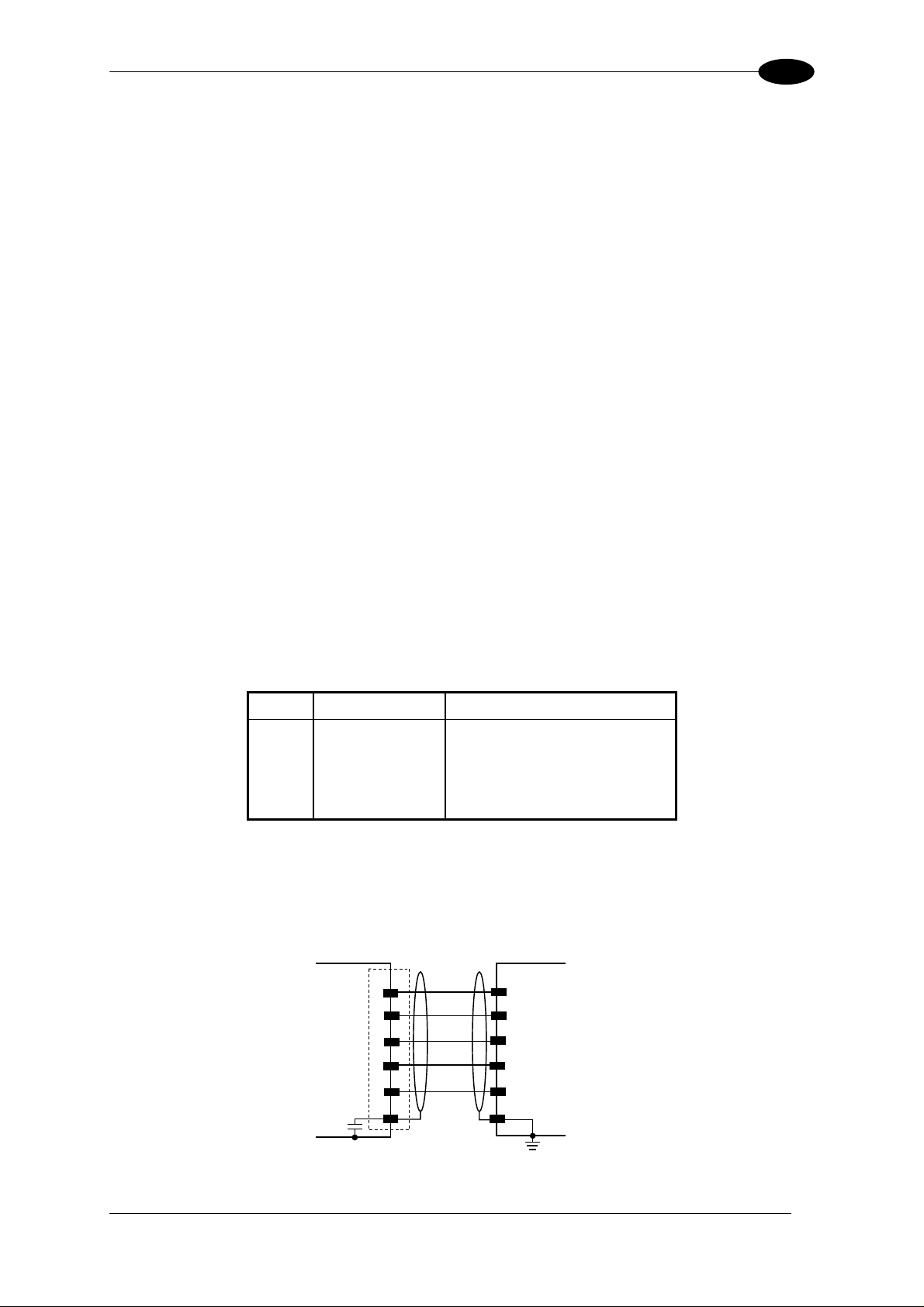

Pin Name Function

2 TX485 + RS485 output (+)

3 RX485 + RS485 input (+)

4 TX485 - RS485 output (-)

5 RX485 - RS485 input (-)

7 GND-ISO Main signal ground

DX6X00

2

TX485+

3

RX485+

4

TX485-

RX485-

5

USER INTERFACE

RX485+

TX485+

RX485-

TX485-

7

GND_ISO

1

Shield

GND

Earth

Ground

Figure 14 - RS485 Full-Duplex Interface Connections

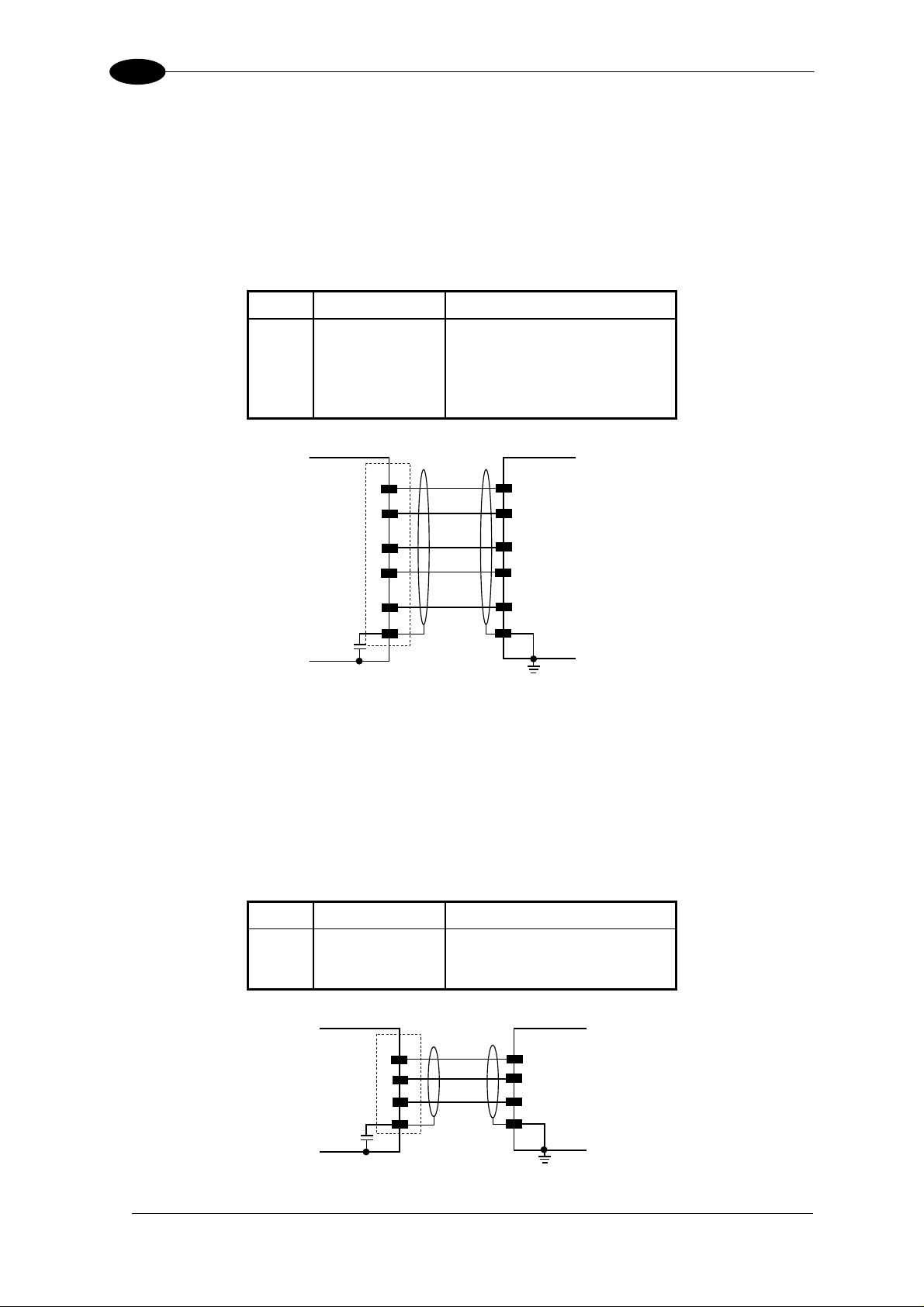

RS485 Half-Duplex Interface

The RS485 half-duplex interface can be used for multidrop connections with a Datalogic

multiplexer or it can also be used for a master/slave layout.

The following pins of the 25-pin and 26-pin connector are used for RS485 half-duplex

interface connection:

Pin Name Function

2 RTX485 + RS485 input/output (+)

4 RTX485 - RS485 input/output (-)

7 GND-ISO Main signal ground

DX6X00

MULTIPLEXER

12

2

Shield

4

7

1

RTX485+

RTX485-

GND_ISO

RTX485+

RTX485-

RS485REF

Earth

Ground

Figure 15 – RS485 Half-Duplex Interface Connections

Page 27

INSTALLATION

2

Auxiliary Interface

The auxiliary serial interface is equipped with RS232 full-duplex interface connections. The

interface type is exclusive and is selectable through the Genius™ configuration program.

The following pins of the 25-pin and 26-pin connector are used for RS232 full-duplex

interface connection:

Pin Name Function

20 RXAUX Receive data

21 TXAUX Transmit data

23 SGND AUX Auxiliary signal ground

Shield

DX6X00

USER INTERFACE

20

RXAUX

21

TXAUX

23

GNDAUX

1

TXD

RXD

GND

Earth

Ground

Figure 16 - RS232 Auxiliary Interface Connections

Inputs

The inputs of the reader are on the 25-pin and 26-pin connector (Figure 4, 1 and Figure 5, 1)

of the DX6400/DX6500.

These inputs are called EXT_TRIG, IN2, IN3 and IN4.

Pin Name Function

18 EXT_TRIG A External trigger (polarity insensitive)

19 EXT_TRIG B External trigger (polarity insensitive)

6 IN2A Input signal 2 (polarity insensitive)

10 IN2B Input signal 2 (polarity insensitive)

14 IN3A Input signal 3 (polarity insensitive)

15 IN4A Input signal 4 (polarity insensitive)

24 IN_REF Common reference of IN3 and IN4 (polarity insensitive)

IN2 is normally used for the Encoder input. In PackTrack™ mode, it detects the conveyor

speed.

EXT_TRIG is the main presence sensor. When active, this input tells the scanner to scan for

a code and that decoding can take place. The yellow LED (Figure 3,3) indicates the

EXT_TRIG is active.

IN3 and IN4 can be used as the stop signal for the reading phase.

All inputs are optocoupled, polarity insensitive, and driven by a constant current generator;

the command signal is filtered through an anti-disturbance circuit which generates a delay

13

Page 28

2

DX6400/DX6500

which can be set to 5 ms or 500 µs. In particular, EXT_TRIG, IN3 and IN4 share the same

value which usually corresponds to 5 ms when using a photoelectric sensor, while IN2 has a

different value which is set to 500 µs when this input is used for the Encoder.

GND

Vext

EXTERNAL TRIGGER/ENCODER

V

PSIN

+ 5V

DX6X00

+

A

~

-

~

B

Figure 17 – PNP Command Input Connection

GND

Vext

EXTERNAL TRIGGER/ENCODER

V

PSIN

+ 5V

DX6X00

+

B

~

-

~

A

Figure 18 - PNP Command Input Connection

PSIN

DX6X00

+ 5V

EXTERNAL TRIGGER/ENCODER

9

A

~

-

+

~

B

VS

GND

Vext

V

Ground

Figure 19 - NPN Command Input Connection

PSIN

+ 5V

DX6X00

+

EXTERNAL TRIGGER/ENCODER

VS

GND

Vext

V

Ground

9

B

~

-

~

A

14

Figure 20 - NPN Command Input Connection

Page 29

INSTALLATION

V

2

PSIN

PSIN

+ 5V

+ 5V

DX6X00

+

+

IN3A

~

-

~

IN4A

~

-

~

INREF

Vext

EXTERNAL DEVICE

V

GND

Vext

V

GND

Figure 21 - PNP Input Command

PSIN

+ 5V

DX6X00

~

+

~

9

VS

INREF

-

IN3A

EXTERNAL DEVICE

ext

V

GND

Vext

EXTERNAL DEVICE

PSIN

+ 5V

~

-

+

~

IN4A

V

GND

Figure 22 - NPN Input Command

The inputs can be powered using the VS signal on the scanner (pin 9).

However, isolation between the command logic and the scanner is maintained by powering

the inputs with a different supply voltage (Vext) from that supplied on pin 9 of the

25-pin/26-pin I/O connector.

The driving logic of the input signals may be powered, for convenience, with the voltage

supply between pins A (VS) and B (GND) of the connector. In this case, however, the device

is no longer electrically isolated.

The voltage available on the input connector, between pins A and B, is physically the same

as used to power the scanner.

The electrical features of these inputs are:

Maximum voltage 30 V

Maximum current 10 mA

15

Page 30

2

DX6400/DX6500

Outputs

Three general purpose outputs are available.

Pin Name Function

8 OUT 1+ Configurable digital output 1 – positive pin

22 OUT 1- Configurable digital output 1 – negative pin

11 OUT 2+ Configurable digital output 2 – positive pin

12 OUT 2- Configurable digital output 2 – negative pin

16 OUT 3A Configurable digital output 3 – polarity insensitive

17 OUT 3B Configurable digital output 3 – polarity insensitive

The function of the three outputs OUT1, OUT2 and OUT3 can be defined by the user.

Refer to Genius™ Help On-Line for further details.

By default, OUT1 is associated with COMPLETE READ event, which activates when the code

has been read correctly. In case the reader has been programmed to read several codes

within the same reading phase, the event activates when all codes have been read.

OUT2 is associated with NO READ event, which activates when no code has been read.

OUT3 is associated with NONE, which means that the output is always in line state.

The OUT1 and OUT2 electrical features are given below:

Collector-emitter voltage 30 V Max.

Collector current 130 mA Max.

Saturation voltage (VCE) 1 V at 10 mA Max.

Maximum power dissipation 90 mW at 50°C (Ambient temperature).

The limit requested by the maximum power dissipation is more important than that of the

maximum collector current: if one of these outputs is continuously driven, the maximum

current must not be more than 40 mA although 130 mA may be reached in pulse conditions.

DX6X00

USER INTERFACE

30 Vdc max

Vext

+

-

Figure 23 – Output 1 and Output 2 Interface

OUT3 has different electrical features, since it is a bi-directional solid state relay with a

built-in current limit protection. If this output is continuously driven, the maximum current

must be not more than 200 mA although more than 300 mA may be reached in pulse

conditions for an ambient temperature of 25°C. At the maximum ambient temperature of

50°C the maximum respective current is 160 mA continuous and 240 mA pulse.

16

Page 31

INSTALLATION

2

The OUT3 electrical features are given below:

Maximum voltage ± 100 V

Collector current (pulse) 240 mA Max.

R on 6 – 15 Ω

R off > 500 Ω

Off-state leakage current < 1 µA

Maximum power dissipation 550 mW at 50°C (Ambient temperature).

DX6X00

A

B

USER INTERFACE

30 Vdc max

Vext

Figure 24 – Output 3 Interface

The command signal is filtered and generates a delay of about 50 µs for OUT1 and OUT2

and 1 ms for OUT3.

When the load is powered by an external power supply, the voltage must be less than 30 V.

17

Page 32

2

DX6400/DX6500

2.3.2 Lonworks Connectors

Do not connect an RS232 port to the 9-pin Lonworks Connector. This may

damage your Laptop PC.

CAUTION

The local network used by DX6400/DX6500 exploits a Lonworks standard communication

system requiring only two wires (polarity insensitive) to enable a connection. The connector

also provides a positive and a negative supplying wire. In this way, all the slave readers can

be powered by the master through the Datalogic standard cables.

When working in applications requiring enhanced synchronization capabilities, the

DX6400/DX6500 master reader (output) transmits two system signals named Sys_I/O and

Sys_Enc_I/O to the slave readers (input). For example, when working with applications

requiring an encoder the signal is received by the master and directly transmitted to the

slaves through the cable.

The internal circuits generating the system signals are externally supplied by means of the

VS_I/O and REF_I/O pins and are isolated from the reader supply voltage.

The use of these system circuits is not required in all the operating modes (see par. 2.6 for

details). Anyway, for a correct system functioning it is suggested to use Datalogic cables and

accessories and follow the description of the typical layout (see par. 2.6 for details).

5

1

1

5

9

Female (all models)

6

Figure 25 – 9-pin Local Lonworks Connectors

Male (Master/Slave model)

6

9

DX6400/DX6500 9-pin Lonworks connector pinout

Pin Name Function

1 Shield Cable shield

9 VS Supply voltage - positive pin

2 GND Supply voltage - negative pin

6 VS_I/O Supply voltage of I/O circuit

3 Ref_I/O Reference voltage of I/O circuit

4 SYS_ENC_I/O System signal

5 SYS_I/O System signal

7 LON A Lonworks line (polarity insensitive)

8 LON B Lonworks line (polarity insensitive)

18

Page 33

INSTALLATION

2

Network Termination

When building a Lonworks system the network must be properly terminated by positioning

BTK-6000 terminator in the DX6400/DX6500 master reader and in the last DX6400/DX6500

slave reader.

Each side of the terminator provides a different connector; thus, it can be inserted either into

the Lonworks 9-pin male connector of the master reader or in the Lonworks 9-pin female

connector of the last slave reader:

Slave

Master

Female

Male

Male

Female

Figure 26 - BTK-6000 Network Terminator

For Fieldbus models no terminator must be inserted in the reader, since it

NOTE

is internally integrated.

Lonworks Interface

The Lonworks network is used for both input and output connection to build a multi-sided or

omni-station system connecting several readers.

The DX6400/DX6500 master usually employs the 9-pin female connector for output

connection to the first slave, while the 9-pin male one is terminated by inserting the BTK6000

terminator (see par. 2.6.2 for details). If creating a T network configuration, it is necessary to

use both connectors to create the double branch line of slave readers.

Both connectors are always employed when connecting together the slave readers. In

particular, the 9-pin female connector is used for output connection and the male one for

input connection. The female connector is always terminated in the last slave reader to close

the system network.

The following diagram represents the connection between a DX6400/DX6500-XXX-010

working as master and a DX6400/DX6500-XXX-010 working as a slave reader.

19

Page 34

2

DX6400/DX6500

Master

VS_I/O

REF_I/O

LON A

LON B

VS

GND

4

5

3

7

8

1

AWG 16

9

AWG 16

2

Slave

4

5

3

7

8

1

9

2

= male connector

= female connector

Figure 27 – DX6400/DX6500-XXX-010 Master/Slave Lonworks Connection

The maximum current to be propagated to the slave readers through the

master is 2 A.

For this reason, it is suggested the use of a 24 V power supply allowing to

CAUTION

supply up to three readers (master + 2 slaves).

The following diagrams represent different network terminations using the BTK-6000

terminator. In each diagram the terminator is indicated by the

element, while the figure

below shows its electrical circuit in details:

Figure 28 – BTK-6000 Electrical Circuit

The diagram below represents the termination of a DX6400/DX6500-XXX-010 working as

master by means of the BTK-6000 terminator.

BTK-6000 Female Side

9

6

7

8

2

3

T

20

Master

VS

VS_I/O

LON A

LON B

GND

REF_I/O

9

6

7

8

2

3

= male connector

= female connector

Figure 29 – DX6400/DX6500-XXX-010 Master Termination

Page 35

INSTALLATION

2

The diagram below represents the termination of a DX6400/DX6500-XXX-010 working as

slave by means of the BTK-6000 terminator.

Slave

LON A

LON B

7

8

= male connector

= female connector

Figure 30 – DX6400/DX6500-XXX-010 Slave Termination

BTK-6000 Male Side

7

8

T

The diagram below represents the connection between a DX6400/DX6500 Fieldbus model,

which always works as master, and a DX6400/DX6500-XXX-010 working as a slave reader.

Fieldbus Master

VS_I/O

Slave

REF_I/O

4

5

3

LON A

T

LON B

GND

7

8

1

VS

9

2

= male connector

= female connector

AWG 16

AWG 16

4

5

3

7

8

1

9

2

Figure 31 – DX6400/DX6500-XXX-010 Master/Slave Lonworks Connection

2.3.3 Ethernet Connector

This connector is only available for DX6400/DX6500 Ethernet models and allows the

Ethernet connection between the host and the reader.

8

1

Figure 32 – Cable RJ45 Male Modular Connector

21

Page 36

2

DX6400/DX6500

1

8

Figure 33 – DX6400/DX6500 RJ45 Female Modular Connector

This interface and the connector pinout (see the following table) are IEEE 802.3 10 BaseT

and IEEE 802.3u 100 Base Tx compliant.

RJ45 Modular Jack Pinout

Pin Name Function

1 TX + Transmitted data (+)

2 TX - Transmitted data (-)

3 RX + Received data (+)

6 RX - Received data (-)

4, 5, 7, 8 N.C. Not connected

Ethernet Interface

The Ethernet interface (NIC) can be used for TCP/IP communication with remote or local

host computer by connecting the scanner to a LAN as well as with a host PC directly

connected to the scanner.

The following is an example of a connection to a LAN through a Hub using a straight through

cable:

DS6400

1

TX+

2

TX-

3

RX+

n. c.

4

n. c.

5

HUB / SWITCH

1

2

3

4

5

22

6

RX-

n. c.

7

n. c.

8

n. c. = not connected

6

7

8

Figure 34 – Straight Through Cable

Page 37

INSTALLATION

The following is an example of direct connection to a PC using an inverted cable:

DS6400

1

TX+

2

TX-

3

RX+

n. c.

4

n. c.

5

HOST PC

3

6

1

4

5

2

6

RX-

n. c.

7

n. c.

8

n. c. = not connected

2

7

8

Figure 35 – Inverted Cable

For further details refer to the “Ethernet.pdf” document provided as reference documentation.

2.3.4 Power Supply

The supply voltage of a single scanner must be between 15 and 30 VDC.

Datalogic strongly recommends a minimum 24 VDC supply voltage when using a

master/slave configuration.

The power consumption of the different DX6400/DX6500 models is slightly different.

In particular, when connecting several DX6400/DX6500 readers in a master/slave

connection, the maximum power consumption for each scanner is 15 W. There is a power

peak of about 20 W lasting 5..10 seconds caused by the motor starting.

Shield

DX6X00

9/13

23/25

1

VS

GND

USER INTERFACE

V+ (10 – 30 Vdc)

V- (Ground)

Chassis

Figure 36 – Power Supply Using the 25/26-pin Connector

23

Page 38

2

2.4 USER INTERFACE

1

RS232 PC-side connections

1

5

DX6400/DX6500

13

9 6

9-pin male connector

25-pin male connector

25 14

Pin Name Pin Name

2 RX 3 RX

3 TX 2 TX

5 GND 7 GND

7 RTS 4 RTS

8 CTS 5 CTS

How To Build A Simple Interface Test Cable:

The following wiring diagram shows a simple test cable including power, external

(push-button) trigger and PC RS232 COM port connections.

DX6X00

25-pin D-sub female

TXAUX

21

20

RXAUX

GND

23

13

VS

25

GND

9-pin D-sub female

2

RX

3

TX

5

GND

PC

9

VS

18

EXT TRIG A

19

EXT TRIG B

Trigger

Power Supply

VS (15 – 30 VDC)

Power GND

Test Cable for DX6400/DX6500

24

Page 39

INSTALLATION

2

2.5 MOUNTING POSITION

Mount the scanner using the ST-237 mounting bracket which assures an angle of 16°, as

indicated in the figure below, in order to obtain an angle of 90° between the two scan lines.

This guarantees an omni directional reading of the barcode, if the code label satisfies the

ACR3™ conditions (see par. 4.3 for details).

Figure 37 – Mounting Position

25

Page 40

2

DX6400/DX6500

2.6 TYPICAL LAYOUTS

The following typical layout refers to the system hardware configurations, but it also requires

the correct setup of the software configuration parameters (see par. 3.2 for details).

Other layouts require the use of DX6400/DX6500 scanner having a specific decoder base.

The accessories and cables indicated in the following figures are Datalogic products. We

suggest their use to guarantee the correct system functioning.

2.6.1 Point-to-Point

Using a Point-to-Point layout, the data is transmitted on the Main interface as well as on the

Auxiliary interface. The Main interface can be selected for RS232 or RS485 full-duplex

communications.

Two different layouts are available according to the DX6400/DX6500 reader model used for

the connection.

26

Page 41

INSTALLATION

2

Master/Slave Models

When On-Line operating mode is used, the reader is activated by an External Trigger

(photoelectric sensor) when the object enters its reading zone. In the following case, the

signal is passed to the DX6400/DX6500 by the C-BOX 100, which also supplies the system.

DX6X00

CAB600X

**P.S.

* C-BOX 100

Local Host

PG6000

* Presence Sensor connected to External Trigger input.

Figure 38 – Point-to-Point for Master/Slave Models

Fieldbus Models

In this case no External Trigger is used and the C-BOX 100 only supplies the reader. The

DX6400/DX6500 Ethernet model is connected to a fieldbus remote Host. It can be activated

by a signal generated by the remote Host or be always active if working in Automatic

operating mode.

Remote Host

Fieldbus

Network

CAB601X

* C-BOX 100

PG6000

**P.S.

DX6X00

* P.S. (Presence Sensor) connected to External Trigger input.

Figure 39 – Point-to-Point for Fieldbus Models

27

Page 42

2

A

DX6400/DX6500

2.6.2 Pass Through

When Pass Through is activated on the Auxiliary interface, the DX6400/DX6500 reader (all

models) can be integrated in a network consisting of different scanners not provided with a

Lonworks interface.

This connection mode allows two or more devices to be connected to a single external serial

interface. The DX6400/DX6500 transmits the messages received by its auxiliary interface

(RS232 only) onto its main interface.

In this configuration a series of scanners can be connected together using RS232 on the

main interface and all messages will be passed through this chain to the host. The reading

phase of each scanner is independent from the others. In Pass Through connections each

scanner is provided with its relative External Trigger (multi P.S.).

Applications can be implemented to connect a device such as a hand-held reader to the

Auxiliary port for manual code reading capability.

For the RS232 connections the maximum cable length is 15 m (49.21 ft).

The DS4600A scanners represented in the following figures are configured in Pass Through

mode.

*P.S.

*P.S.

DX6X00

CAB600X

C-BOX 100

1

*P.S.

PWR120

C-BOX 100

AUX

MAIN

1

2

Local Host

* P.S. (Presence Sensor) connected to External Trigger input.

1

Main Serial Interface

DS4600A

2

Gryphon

DS4600A

C-BOX 100

1

uxiliary Serial Interface

2

Figure 40 – Pass Through Connection for DX6400/DX6500 Master/Slave Models

28

Page 43

INSTALLATION

A

Remote Host

Fieldbus

Network

**P.S.

DX6X00

**P.S.

DS4600A

2

**P.S.

Gryphon

DS4600A

CAB601X

PWR-120

* C-BOX 100

AUX

2

* C-BOX 100

1

* C-BOX 100

2

1

uxiliary Serial Interface

1

Main Serial Interface

* P.S. (Presence Sensor) connected to External Trigger input.

2

Figure 41 – Pass Through Connection for Fieldbus Models

2.6.3 RS232 Master/Slave

The RS232 master/slave connection is used to integrate a DX6400/DX6500 reader (all

models) in a network consisting of different scanners not provided with a Lonworks interface.

The Slave scanners use RS232 only on the main and auxiliary interfaces. Each slave

scanner transmits the messages received by the auxiliary interface onto the main interface.

All messages will be transferred towards the master.

The master scanner is connected to the Host PC on the main RS232 serial interface through

the C-BOX 100 (20 mA C.L. can also be used if the INT-30 accessory is installed).

In RS232 Master/Slave connections the External Trigger signal is unique to the system

(single P.S.).

The DX6400/DX6500 master/slave scanner model (DX6400/DX6500-

NOTE

10X-010 only), working as Master in an

simultaneously connected to a Lonworks network consisting of

DX6400/DX6500 slave scanners. Be careful when assigning the slave

address, since the number of the first Lonworks slave must be a

progressive number with respect to the address number defined for the

last slave scanner of the RS232 network. For example, if the RS232

network consists of Slave 1 and Slave 2, the address to be assigned to

the first Lonworks slave scanner will be Slave 3 (not Slave 1).

RS232 network, may be

29

Page 44

2

A

r

A

DX6400/DX6500

DX6X00

Master

CAB601X

DS4600A

1

Slave 1

**P.S.

* C-BOX 100

AUX

MAIN

2

Local Host

* C-BOX 100

2

DS4600A

Slave 2

* C-BOX 100

1

* P.S. (Presence Sensor) connected to External Trigger input.

uxiliary Serial Interface

1

Main Serial Interface

2

Figure 42 – RS232 Master/Slave for DX6400/DX6500 Master/Slave Models

CAB601X

PWR-120

* C-BOX 100

AUX

DX6X00

Maste

2

PWR-120

Fieldbus

Network

1

Remote Host

DS4600A

1

2

* C-BOX 100

* P.S. (Presence Sensor) connected to

External Trigger input.

1

Main Serial Interface

uxiliary Serial Interface

2

Figure 43 – RS232 Master/Slave for DX6400/DX6500 Fieldbus Models

30

Slave 1

**P.S.

DS4600A

Slave 2

* C-BOX 100

1

Page 45

INSTALLATION

2

2.6.4 Multiplexer

The Multiplexer connection is used to integrate a DX6400/DX6500

Multidrop network consisting of different scanners not provided with a Lonworks interface.

Each scanner is connected to a Multiplexer (MX4000) with the RS485

half-duplex main interface.

*P.S.

*P.S.

*P.S.

slave reader in a

#0

DS4600A

PWR-120

MX4000

1

Local Host

DX6X00

C-BOX 100

#31

* P.S. (Presence Sensor) connected to External Trigger input.

C-BOX 100

DS4600A

#1

C-BOX 100

1

RS485 HD Main Interface

Figure 44 – Multiplexer for DX6400/DX6500 Master/Slave Models

The auxiliary serial interface of the slave scanners can be used to visualize collected data or

to configure it using the Genius™ utility.

When On-Line operating mode is used, the scanner is activated by an External Trigger when

the object enters its reading zone.

31

Page 46

2

DX6400/DX6500

2.6.5 Local Lonworks Network

A local Lonworks network allows electrically connecting a DX6400/DX6500 master reader up

to 31 DX6400/DX6500 slaves. Actually, the maximum number of readers to be employed in

the network depends on the system operating conditions, that is adopted operating mode

and amount of data stream. For example, the On Line operating mode, (see Genius™ Help

On-Line for further details), typically supports a maximum number of 8 slave readers.

Whenever creating your network, always keep in mind the following guidelines:

• the network electrically supports a maximum number of 31 DX6400/DX6500 readers and

may extend up to 130 m (426.5 ft);

• the maximum number of DX6400/DX6500 readers supported depends on the type of

power propagation adopted by the system (see par. 2.3.4 for details).

Contact Datalogic S.p.A., if your network requires a higher number of readers or in case the

application throughput is very high.

When building the network, the DX6400/DX6500 master reader must be connected to a local

host computer or a C-BOX 100 by means of a cable connected to the 25 D-sub male

connector.

The local Lonworks 9-pin female connector connects the master reader to the first slave

reader of the system, while the local Lonworks 9-pin male connector must be properly

terminated by inserting the BTK-6000 terminator.

The slave readers are connected together through the local Lonworks connectors. Only the

9-pin female connector of the last slave reader must be terminated by the BTK-6000

terminator.

Single P.S.

The presence sensor is connected to the C-BOX 100 and is unique to the system. There is

only a single reading phase and a single message from the master reader to the Local Host.

The On-Line operating mode is used for this layout.

CAB610X

Master

Slave 1

BTK6000

* Presence Sensor connected to External Trigger input.

BTK6000

*P.S.

CAB600X

C-BOX 100

Local Host

PG6000

Figure 45 - Single P.S. with 2 Readers

32

Page 47

INSTALLATION

2

The following image shows a system consisting of four readers supplied by two different

power units. The Master reader receives external signals (trigger, serial to host, etc.) and

together with Slave 1 is powered by the first PG6000 through a C-BOX 100, while Slave 2

and Slave 3 are connected to another PG6000 through a C-BOX 100 and the 610X cable.

Each PG6000 supplies up to 2 readers. CAB611X cable connects two different groups:

Master, Slave 1 AND Slave 2, Slave 3. It does not propagate power but only network and

synchronization signals.

CAB610X

CAB611X

CAB600X

PG6000

BTK6000

Master

Slave 1

Slave 2

CAB610X

C-BOX 100

CAB600X

*P.S.

Slave 3

BTK6000

* P.S. (Presence Sensor) connected to External Trigger input.

C-BOX 100

Local Host

PG6000

** PG6000 can be connected directly to Slave 2 by means of a custom cable with 2 AWG 20 wires (VS + GND).

Figure 46 - Single P.S. with more than 2 Readers and Multiple Power Units

33

Page 48

2

DX6400/DX6500

The following image shows a system consisting of five readers where the Master reader

receives external signals (trigger, serial to host, etc.) and together with Slave 1 and Slave 2

is powered by the C-BOX 100, while Slave 3 and Slave 4 are connected to the power supply

through the PWR-120 and the 610X cable. This is due to the fact the C-BOX 100 can supply

a maximum of 3 readers. This means that the CAB611X cable connects two different groups:

Master, Slave 1, Slave 2 AND Slave 3, Slave 4. It does not propagate power but only

network and synchronization signals.

The CAB-6310 power cable has two AWG 20 wires (VS + GND) and connects PWR-120 to

Slave 3.

CAB610X

BTK6000

Master

Slave 1

CAB610X

Slave 2

Slave 3

CAB611X

CAB600X

*P.S.

Slave 4

CAB610X

CAB-6310

* P.S. (Presence Sensor) connected to External Trigger input.

Figure 47 – Single P.S. with more than 2 Readers and Single Power Unit

C-BOX 100

Local Host

BTK6000

PWR-120

34

Page 49

INSTALLATION

X

2

Multi P.S.

In this layout, up to 7 DX6400/DX6500 slave readers have their own P.S. and therefore

multiple reading phases, while the P.S. activating the master reader is managed by the CBOX 100.

The master sends all the individual messages collected from the Lonworks interface as well

as its own to the Local Host through the C-BOX 100.

The following image shows a system consisting of four readers, where the fourth one must

be connected to a dedicated power supply by means of a C-BOX 100, since a single

C-BOX 100 can supply groups consisting of a maximum of 3 readers. This means that the

cable (CAB611X) connecting two different groups, in this case the cable connecting Slave 2

and Slave 3, does not propagate power.

P.S.* P.S.*

P.S.*

P.S.*

CAB611

Slave 3 Slave 2 Slave 1 Master

* P.S. (Presence Sensor) connected to External Trigger input.

C-BOX 100

CAB610X

CAB610X

PWR-120

Figure 48 – Multi P.S. with more than 3 Readers

CAB600X

C-BOX 100

Local Host

35

Page 50

2

r

DX6400/DX6500

2.6.6 Fieldbus Network

The Fieldbus Ethernet model offers connectivity without any converter or adapter needed.

The DX6400/DX6500 master Fieldbus communicates with a remote host (for ex. remote PC

connected via Internet) by means of a cable connected to the Fieldbus (Ethernet) connector

provided.

The local Lonworks 9-pin female connector connects the Fieldbus master reader to the first

slave reader of the system, while the 26 D-sub male connector may be connected to the

C-BOX 100 to supply the reader.

The slave readers (DX6400/DX6500 master/slave models) are connected together through

the local Lonworks connectors.

be terminated by the BTK-6000 terminator. No terminator must be inserted in the Fieldbus

master reader, since it is internally integrated.

Single P.S.

The DX6400/DX6500 Ethernet model master is connected to a fieldbus remote Host. It can

be activated by a signal generated by the remote Host or be always active if working in

Automatic operating mode.

Only the 9-pin female connector of the last slave reader must

PWR-120

**P.S.

* C-BOX 100

Remote Host

CAB601X

Fieldbus Network

* P.S. (Presence Sensor) connected to External Trigger input.

BTK6000

Fieldbus

Maste

CAB610X

Slave 2

Slave 1

CAB610X

** The Slave scanners are Master/Slave models wich allow Lonworks network propagation.

Figure 49 – Fieldbus Single P.S.

As described before, C-BOX 100 can supply a maximum number of 3 readers. Therefore, if

using more than 3 readers, connect the different groups by means of a cable (CAB6111X)

not bringing power to, and power each group individually.

36

Page 51

INSTALLATION

2

2.7 DX6400 FLASH™ DYNAMIC FOCUS

The DX6400 has an innovative linear motor designed to control the focus position of the

scanner via software. This dynamic system, called FLASH

TM,

is able to move the focus

position rail to rail, from the minimum position to the maximum position.

The FLASHTM functionalities are programmed via the GENIUS™ tool (refer to the GENIUS™

Help On-Line for details) and can operate in the following modes:

• Fixed Mode

• Continuous Mode

• Triggered Mode

• D-Flash™ Mode

2.7.1 Fixed Mode

In Fixed mode, the focus is set in the wished position via software (expressed in cm/inches).

This mode represents the basic Flash™ function, in which the focus is software adjusted

before the reading application and its position are stored in the scanner decoder. This

function is similar to the focus adjustment available for the DS6300 scanner with the great

difference that the adjustment is performed via software through the GENIUS™ tool and not

through a manual adjustment of an external screw.

Figure 50 – Flash™ Fixed Mode

2.7.2 Continuous Mode

In Continuous mode, the focus position is continuously moving from a minimum position to a

maximum position with a defined frequency (f1 in the figure below). This Flash™ function

allows exploiting the whole reading range of the current DX6400 when the object to be

detected is big and slowly moving. Typical examples of applications for the Continuous mode

are front side reading of big pallets, or reading on a fork lift truck.

Figure 51 – Flash™ Continuous Mode

37

Page 52

2

DX6400/DX6500

2.7.3 Triggered Mode

In Triggered mode, the focus position can be set depending on the received external input

(photocell, barrier, serial message…). This mode represents the most traditional Flash™

function, since it requires photocells, barriers or a dedicated interface to the Host (PC or

PLC).

Figure 52 – Flash™ Triggered Mode

2.7.4 D-FLASHTM Mode

IN D-Flash™ mode, the focus position can be set depending on the measured distance (Dn

in the figure below) between the scanner and the scanned object. This is the most innovative

and flexible function, that makes possible different software implementations. The

D-FLASH

solve the

according to the specific application needs.

TM

development has been based on the minimum distance detected. Thus, it can

main part of the applications. Further developments of D-FLASH

TM

will be provided

38

Figure 53 – Flash™ D-Flash™ Mode

Page 53

INSTALLATION

2

2.8 KEYPAD AND DISPLAY

The DX6400/DX6500 keypad allows entering a menu where selecting one of the following

functions:

• Internal Net

• Test Mode

The same settings may be performed by using the Genius™ program (see chapter 3 for

details).

2.8.1 Internal Net

The Internal Net submenu has to be used when configuring the DX6400/DX6500 scanner

within a master/slave network.

It allows defining the scanner function (slave/master) within the network and, if configured as

Slave, its address.

To enter the Internal Net submenu and configure the scanner follow the given procedure:

1) Press and hold both the ▲ (up arrow) and ▼ (down arrow) keys for about 2 seconds to

enter the Main menu;

2) Use the ▲ (up arrow) or ▼ (down arrow) key to select the “Internal Net” item, then press

the ENT (enter) key to confirm;

3) Use the ▲ (up arrow) or ▼ (down arrow) key to select the “LonWAddrSel”” item, then

press the ENT (enter) key to confirm;

4) Use the ▲ (up arrow) or ▼ (down arrow) key to select your scanner function among

“Master”, “Slave n”, “Disabled”; then, press the ENT (enter) key to confirm;

5) Use the ▲ (up arrow) or ▼ (down arrow) key to select the “Exit” item, then press the ENT

(enter) key to confirm. Repeat this step again to exit the Main Menu and return to the

scanner current operating mode.

2.8.2 Test Mode

Test Mode is particularly advised during the installation phase, since it causes the reader to

be continuously activated allowing to verify its reading features and its reading position with

respect to the barcode.

To enter the Test Mode submenu and configure the scanner follow the given procedure:

1) Press and hold both the ▲ (up arrow) and ▼ (down arrow) keys for about 2 seconds to

enter the Main menu.

2) Use the ▲ (up arrow) or ▼ (down arrow) key to select the “Test Mode” item, then press

the ENT (enter) key to confirm. The reader enters Test Mode.

3) Press the ▲ (up arrow) key to exit the Test Mode.

4) Use the ▲ (up arrow) and ▼ (down arrow) key to select the “Exit” item, then press the

ENT (enter) key to confirm. The scanner exits the Main Menu and returns to its current

operating mode.

39

Page 54

3

DX6400/DX6500

3 SOFTWARE CONFIGURATION

3.1 GENIUS™ INSTALLATION

Genius

advantages:

• Wizard approach for low skilled users;

• Multi-language version;

• Defined configuration directly stored in the reader;