Page 1

DS8100

Installation Manual

Page 2

DS8100

INSTALLATION MANUAL

Page 3

We

DATALOGIC S.p.A.

Via Candini, 2

40012 - Lippo di Calderara

Bologna - Italy

declare under our sole responsibility that the product

DS8100-XXXX, Laser Scanner and all its models

to which this declaration relates is in c onform ity with the f ollowing standards or other normat ive

documents

EN 55022, August 1994

:L

IMITS AND METHODS OF MEASUREMENTS OF RADIO DISTURBANCE

CHARACTERISTICS OF INFORMATION TECHNOLOGY EQUIPMENT

(ITE)

EN 50082-2, March 1995

:E

LECTROMAGNETIC COMPATIBILITY

. G

ENERIC IMMUNITY STANDARD

.

P

ART

2: I

NDUSTRIAL ENVIRONMENT

EN 60950, October 1996

:S

AFETY OF INFORMATION TECHNOLOGY EQUIPMENT, INCLUDING

ELECTRICAL BUSINESS EQUIPMENT

EN 60825, March 1993

:R

ADIATION SAFETY OF LASER PRODUCTS, EQUIPMENT

CLASSIFICATION

,

REQUIREMENTS AND USER’S GUIDE

Following the provision of the Directive(s):

89/336 CEE

AND SUCCESSIVE AMENDMENTS

, 92/31 CEE; 93/68 CEE; 73/23 CEE

Ruggero Cacioppo

Lippo di Calderara, 23.03.1998

Quality Assurance Supervi sor

Product names mentioned herein are for i dentification purposes only and m ay be trademarks

and or registered trademarks of t hei r respective companies.

Datalogic reserves the right t o make modificati ons and improvements without pri or not i fication.

© 1998 Datalogic S.p.A.

821000163 (Rev. C)

Page 4

iii

CONTENTS

General view .......................................................................................v

SAFETY PRECAUTIONS

................................................................ vii

Electrical Safety................................................................................ vii

Laser Safety...................................................................................... vii

Standard Regulations....................................................................... vii

Power Supply.....................................................................................ix

1. GENERAL FEATURES

...................................................................1.1

1.1 Introduction.......................................................................................1.1

1.2 Description .......................................................................................1.3

1.2.1 Indicators - DS8100 Serial Interface ................................................1.4

1.2.2 Indicators - DS8100 Bus Interface ...................................................1.4

1.3 Available Models..............................................................................1.5

1.4 Accessories......................................................................................1.5

1.5 Applications......................................................................................1.6

2. INSTALLATION - DS8100 SERIAL INTERFACE

...........................2.1

2.1 Package Contents ...........................................................................2.1

2.2 Guide To Installation........................................................................2.2

2.3 Opening The Scanner......................................................................2.3

2.3.1 Main Interface Selection..................................................................2.4

2.3.2 Multidrop Address Selection............................................................2.5

2.4 Mechanical Installation ....................................................................2.6

2.5 Electrical Connections.....................................................................2.7

2.5.1 DS8100 Connectors ........................................................................2.7

2.5.2 Power Supply.................................................................................2.10

2.5.3 Main Serial Interface......................................................................2.10

RS232 Interface.............................................................................2.11

RS485 Full-Duplex Interface..........................................................2.12

RS485 Half-Duplex Interface.........................................................2.13

20 mA Current Loop Interface .......................................................2.15

2.5.4 Auxiliary Interface..........................................................................2.16

RS232 Auxiliary Interface ..............................................................2.16

RS485 Half-Duplex Auxiliary Interface ..........................................2.17

2.5.5 Inputs.............................................................................................2.17

2.5.6 Outputs..........................................................................................2.21

2.6 Positioning.....................................................................................2.22

Page 5

iv

2.7 Typical Layouts..............................................................................2.24

2.7.1 Standard (Point-to-Point)...............................................................2.24

2.7.2 Pass Through ................................................................................2.25

2.7.3 RS485 Master/Slave......................................................................2.26

2.7.4 Multiplexer .....................................................................................2.27

2.7.5 Omnidirectional Reading ...............................................................2.28

3. INSTALLATION — DS8100 BUS INTERFACE

..............................3.1

3.1 Package Contents ...........................................................................3.1

3.2 Guide To Installation........................................................................3.2

3.3 Mechanical Installation ....................................................................3.3

3.4 Electrical Connections.....................................................................3.4

3.4.1 Power Supply...................................................................................3.5

3.4.2 Inputs...............................................................................................3.6

3.5 Positioning.......................................................................................3.7

3.6 Typical Layout..................................................................................3.8

4.

READING FEATURES

....................................................................4.1

4.1 Code Reconstruction.......................................................................4.1

4.1.1 The Tilt Angle For Code Reconstruction .........................................4.1

4.2 Performance....................................................................................4.2

4.3 Reading Diagrams...........................................................................4.3

5. MAINTENANCE

..............................................................................5.1

5.1 Cleaning...........................................................................................5.1

6. TECHNICAL FEATURES

................................................................6.1

Page 6

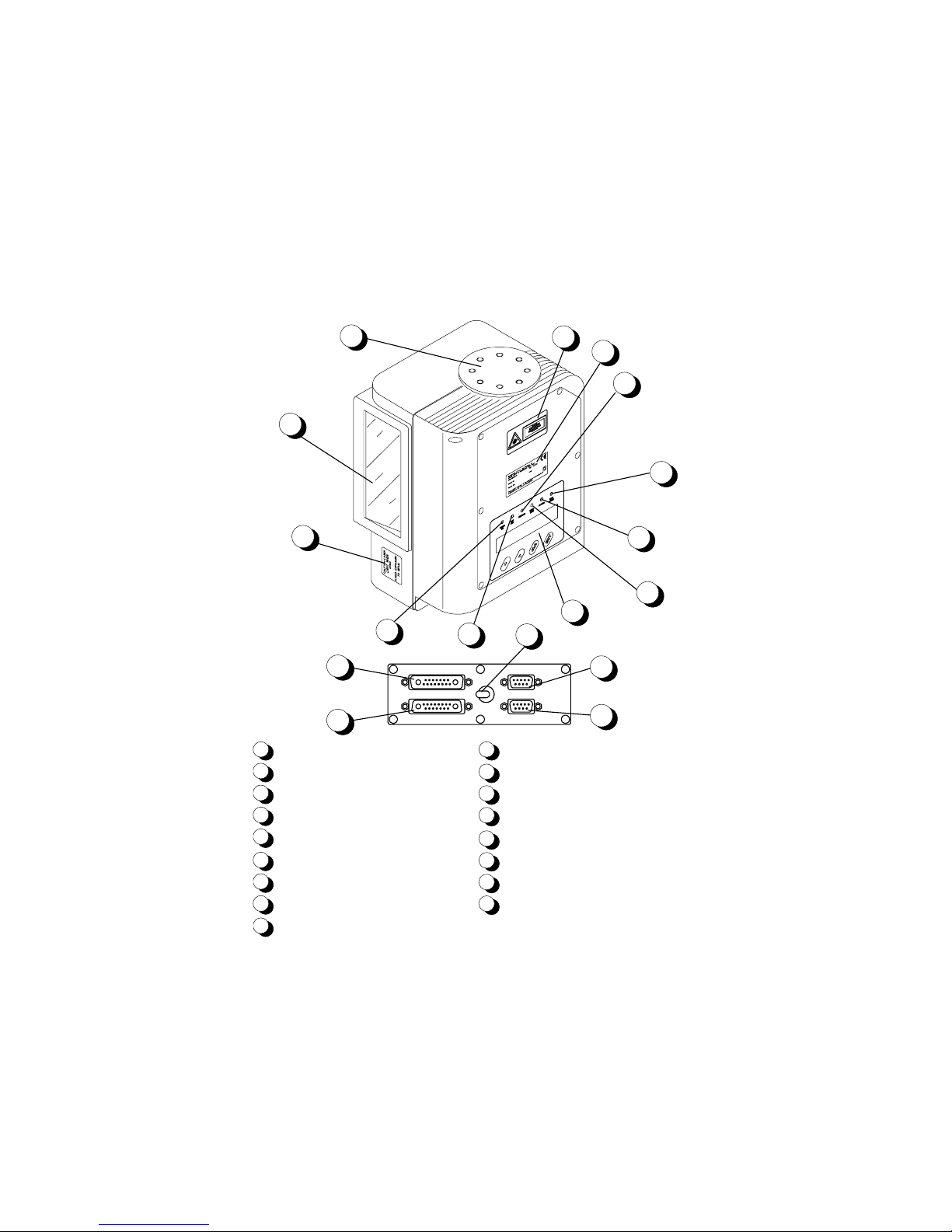

v

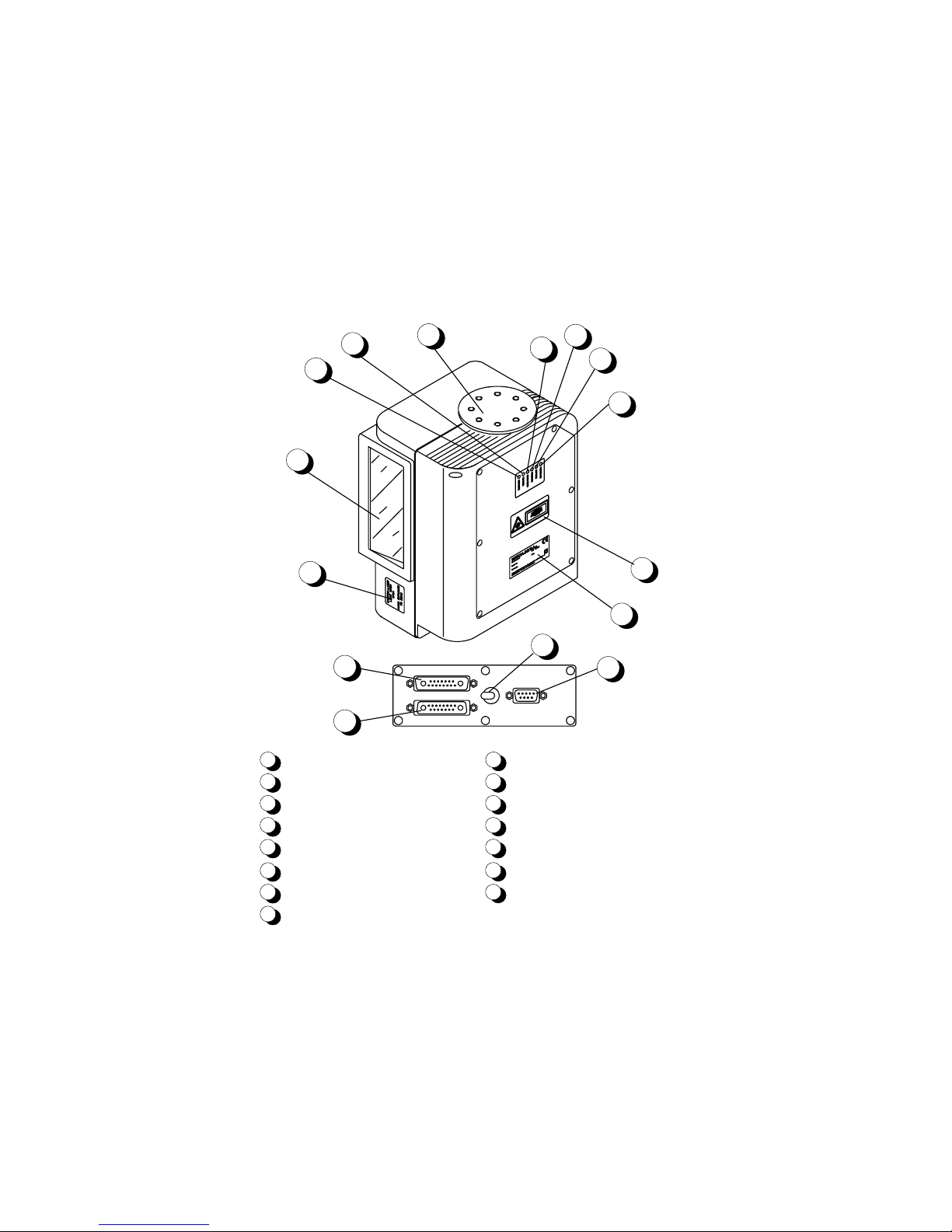

DS8100

General View

Laser Beam Output Window

Laser Safety Label

Power ON LED

Ext Trig LED

Keypad and Display

Good Read LED

TX Data LED

User Signal LED

1

2

3

4

5

6

7

8

9

Encoder LED

Warning and Device Class Label

Mounting Holes

15

11

12

13

14

16

17

10

Product Label

Main Interface Connector

Aux. Interface/Input Signal Connector A

Aux. Interface/Input Signal Connector B

Output Signal Connector

Laser Beam and Motor Power Switch

9

6

3

4

7

8

2

11

1

5

10

12

14

16

13

15

17

Figure A - DS8100 Serial Interface version

Page 7

vi

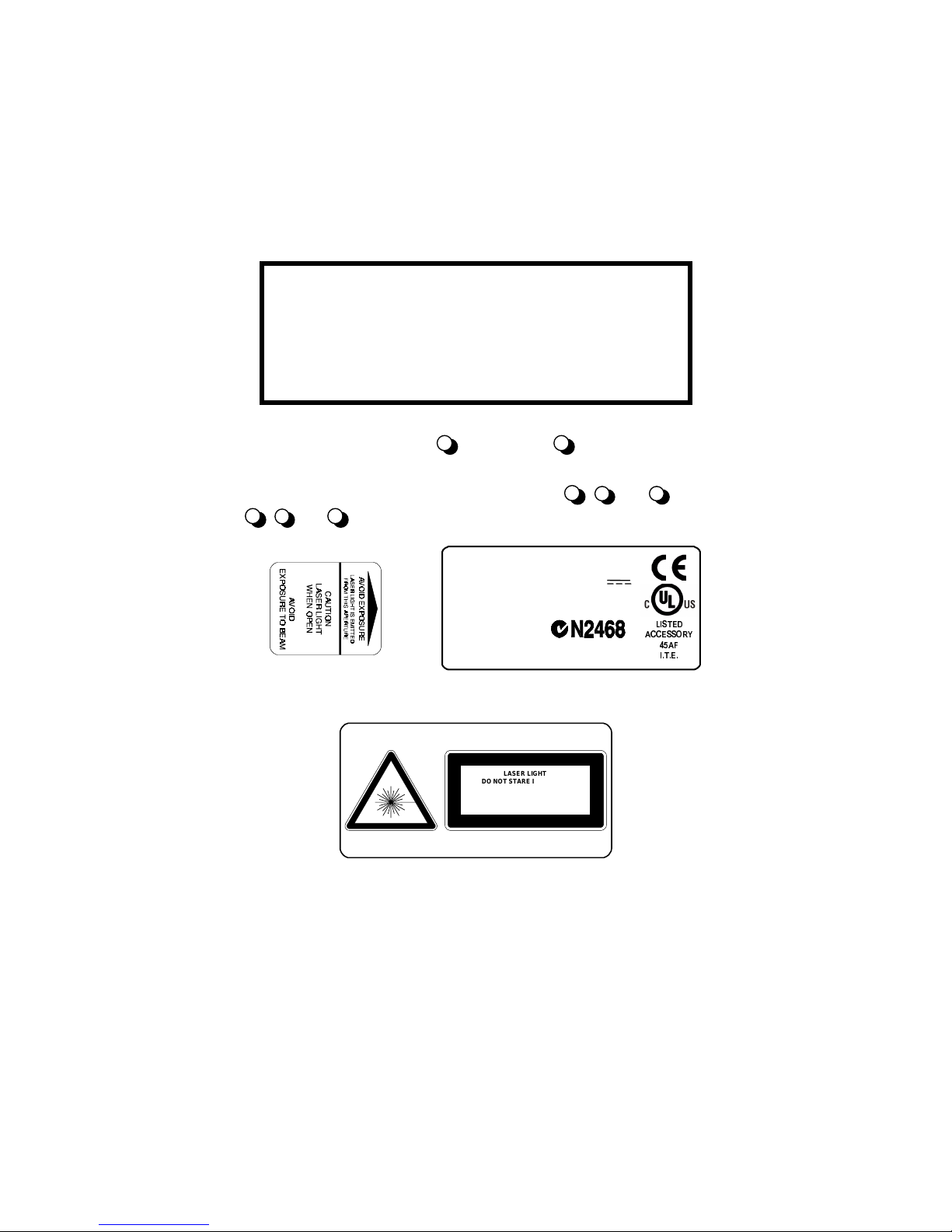

DS8100

General View

7

6

8

2

11

1

5

10

9

3

4

Laser Beam Output Window

Laser Safety Label

Product Label

Warning and Device Class Label

Power ON LED

Ext Trig LED

Encoder LED

Good Read LED

1

2

3

4

5

6

7

8

9

Mounting Holes

Network LED

11

Lonworks Input Connector

12

10

TX Data LED

15

13

Lonworks Output Connector

14

RS232 Debug Connector

13

14

12

15

Laser Beam and Motor Power Switch

Figure B - DS8100 Bus Interface version

Page 8

vii

SAFETY PRECAUTIONS

ELECTRICAL SAFETY

This product conforms to the applicable requirements contained in

the European Standard for electrical safety EN-60950 at the date of

manufacture.

!

This symbol refers to operations that must be performed by

qualified personnel only.

Example: opening the device.

This symbol refers to operations where there is danger of

electrical shock.

Before opening the device make s ure the power

cable is disconnected to avoid electric shock.

LASER SAFETY

The following information is provided to comply with the rules imposed by

international authorities and refers to the correct use of the DS8100 scanner.

Standard Regulations

This scanner utilizes up to 4 low-power laser diodes. Although s tar ing dir ec tly

at the laser beam mom entarily causes no known biological dam age, avoid

staring at the beam as one would with any very strong light source, suc h as

the sun. Avoid that the laser beam hits the eye of an observer, even through

reflective surfaces such as mirrors, etc.

This product conforms to the applicable requirements of both IEC 825-1 and

CDRH 21 CFR 1040 at the date of manufacture. The s c anner is classified as

a Class 2 laser product according to IEC 825-1 regulations and as a Clas s II

laser product according to CDRH regulations.

There is a safety device wich allows the laser to be switched on only if the

motor is rotating above the threshold for its correct scanning speed.

Page 9

viii

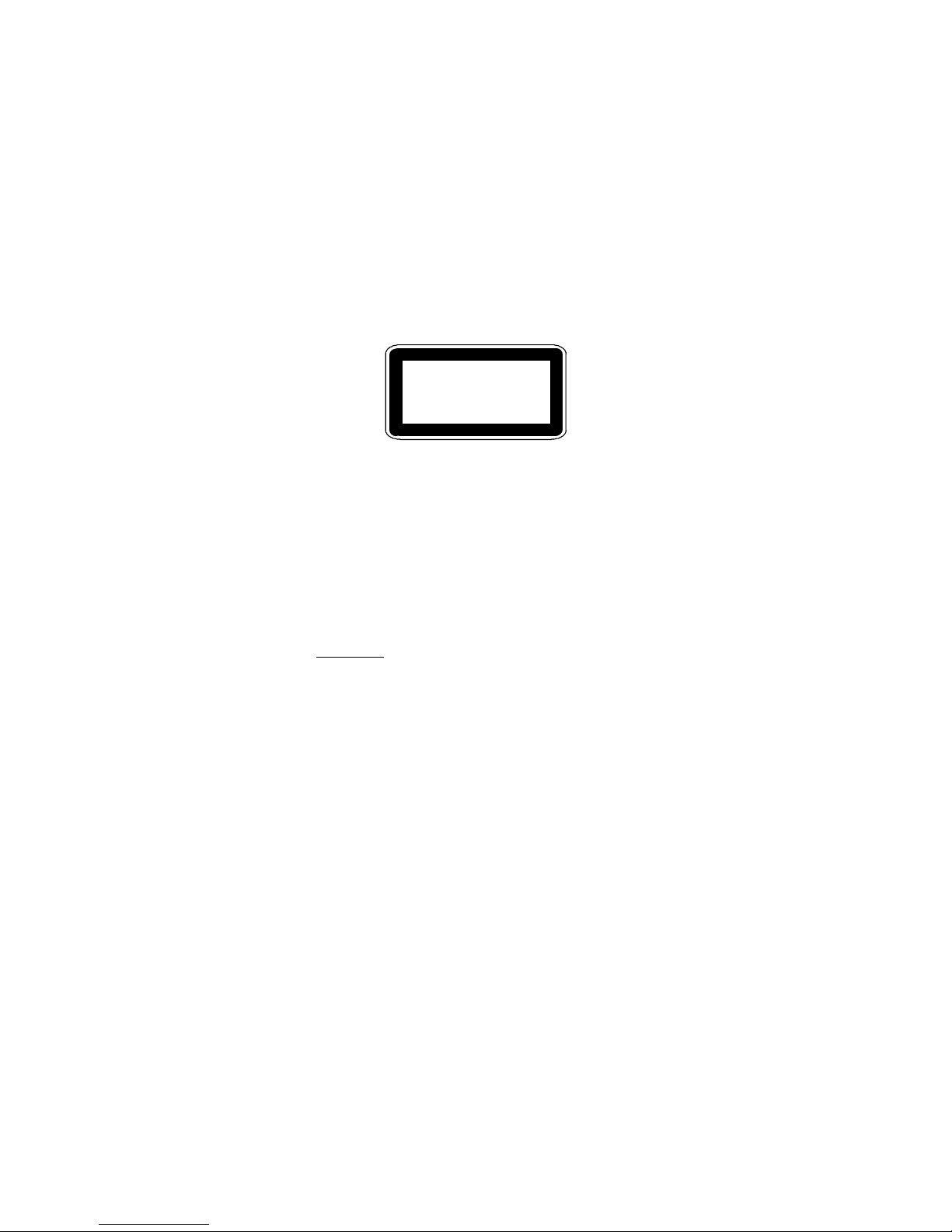

WARNING

Use of controls or adjustments or performance of

procedures other than those specified her ein may result

in exposure to dangerous laser radiation.

The laser light is visible to the human eye and is em itted from the window on

the side of the reader (Figure A,

1

and Figure B, 1).

Warning labels indicating ex posure to las er light and the device c lass ification

are applied onto the body of the scanner (Figure A,

2

, 10

and

11

, Figure

B,

2

,

3

and

4

):

Model No. Amp.

Serial No.

DATALOGIC S.P.A. Via Candini, 2

40012 Calderara di Reno - Bologna - Italy

Manufa c t ured Volt

This product conforms to the applicable requirements

of 21CFR1040 at the date of manufacture.

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

MAXIMUM OUTPUT RADIATION 1 mW

EMITTED WAVELENGTH 630~680 mW

TO IEC 825-1 (1993)

Warning and device class labels

Disconnect the power supply when opening the device during m aintenance or

installation to avoid exposure to hazardous laser light.

Page 10

ix

The laser diodes used in this device are classified as Class 3B laser products

according to IEC 825-1 regulations and as Clas s IIIb laser produc ts according

to CDRH regulations. As it is not p o ssible t o apply a classification label on the

laser diodes used in this device, the following label is reproduced here:

LASER LIGHT

AVOID EXPOSURE TO BE AM

CLASS 3B LASER PRODUCT

MAXIMUM OUTPUT RADIATION 30 mW

EMITTED WAVELENGTH 630~680 nm

TO IEC 825-1 (1993)

Laser diode class label

Any violation of the optic parts in particular can cause radiation up to the

maximum level of the laser diode (30 mW at 630~680 nm).

POWER SUPPLY

This scanner is intended to be supplied by either a UL Listed power supply

marked 'Class 2' or 'LPS', output rated 20 - 30 V dc , m inimum 1.0 A or by a

UL Listed computer with LPS outputs.

In any case, all models of DS8100 must be supplied by a Class II Power

Supply Unit conforming to the EN 60950 safety regulation.

Page 11

x

This page is intentionally lef t blank.

Page 12

DATALOGIC DS8100

General features -

2.1

1 GENERAL FEATURES

1.1 INTRODUCTION

The DS8100 scanner is a barcode reader complete with decoder des igned to

provide an innovative and high performance solution in omnidirectional

reading applications by combining the following advanc ed technologies with

Datalogic’s solid experience in the material handling sector.

ACR™

Advanced Code Reconstruction technology allows the reading of low aspect

ratio labels placed anywhere on a parcel and enhances the readability of

poorly printed or damaged codes.

CD SQUARE™

CD SQUARE™ provides useful information on label position and object

shape elaborated during the barcode reading phase. This innovative

technology identifies the area in which the code is located and measures the

code distance from the scanner.

PACKTRACK™

PackTrack ™ is a Datalogic patented parcel trac king system which im proves

the reading features in omnidirectional stations. In particular, PackTrack™

manages 6-sided reading systems when it is im possible to detect the real

position of the code on the parcel, thus overcoming the need for external

accessories essential in traditional tracking systems.

ASTRA™

Automatically SwiTched Reading Area™ is the new Datalogic technology

based on a multi-laser architec ture and a fixed mounted optic system which

concentrates the multiple laser emissions in a single laser beam. As each

laser emitter is focused on a specific range of the reading area, a

sophisticated electronic controller select s the best focused laser emitter with

Page 13

DS8100 DATALOGIC

2.2

- General features

respect to the code to read. This allows the reading of medium- high density

codes in a large reading area on very fast conveyors.

TBS™

Twin Beam System™ improves the reading of c odes covered by plastic film

or wrapping material. The optic architec ture is able to c hange the laser diode

path and to adapt the beam’s skew angle on the code to read. This makes

the scanner insensitive to direct reflections and to the bars’ distortion caused

by the plastic film.

Single-scanner and Multi-scanner Applications

DS8100 Serial Interface version is provided with two standard interfaces

allowing easy use and connection and is therefore suitable f or single-reader

applications.

DS8100 Bus Interface version is particularly suited for multi-scanner

applications. It is provided with a Lonworks network for connections with

other DS8100s and with an SC8000 unit which performs real time data

collection and control of the reading station.

Flexibility

The high frequency laser diode modulation system guarantees complete

immunity to ambient light and allows installation of the DS8100 in any

working area.

The DS8100 Serial Interface is easy configurable by means of the W indowsbased user-friendly Winhost utility program provided on diskette.

It can also be configured from a Host PC through the Hos t Mode procedure

or using the built-in keypad through the Keyboard Mode procedure.

Page 14

DATALOGIC DS8100

General features -

2.3

1.2 DESCRIPTION

Some of the main features of DS8100 are listed below:

•

scanning speed 1000 scans/sec. for standard models; higher speeds

available on request.

•

reads all popular codes.

•

supply voltage from 20 to 30 Vdc.

•

test modes to verify the reading features and exact positioning of the

scanner without the need for external tools.

•

programmable in 5 different operating modes to suit the most various

barcode reading system requirements.

•

light source: solid state laser diodes; the light emitted has a wave length

of 630~680 nm. For laser safety precautions refer to the “Safety

precautions” section at the beginning of this manual.

•

2 serial communication interfaces for Serial Interface models.

Page 15

DS8100 DATALOGIC

2.4

- General features

1.2.1 Indicators - DS8100 Serial Interface

The DS8100 Serial Interface has six LEDs and an LCD display on the front panel.

The indicators have the following functions:

Power ON:

LED (green). Indicates the scanner is ON. (Figure A,

3

).

Ext Trig:

LED (yellow). Indicates the external presence sensor is active.

(Figure A,

4

).

Encoder:

LED (yellow). Indicates the external encoder si

g

nal is active

(when provided). (Figure A,

9

).

Good Read:

LED (red). Indicates a code is present in the readin

g

zone.

(Figure A,

6

).

TX Data:

LED (

g

reen). Indicates data transmission both on the m ain

and on the auxiliary interface. (Figure A,

7

).

User Defined:

LED (red). The use of this indicator depends on the

application. (Figure A,

8

).

LCD display:

The LCD displays messa

g

es relative to the DS8100

confi

g

uration and to the code read after decoding. It is a 2 x

20 character display. (Figure A,

5

).

1.2.2 Indicators - DS8100 Bus Interface

The DS8100 Bus Interface has six LEDs on the rear panel.

The indicators have the following functions:

Power ON:

LED (red). Indicates the scanner is ON. (Figure B,

5

).

Ext Trig:

LED (yellow). Indicates the external presence sensor is active.

(Figure B,

6

).

Encoder:

LED (

g

reen). Indicates the external encoder signal is active

(when provided). (Figure B,

7

).

Good

Read:

LED (red). Indicates a probable code is present in the readin

g

zone. (Figure B, 8).

TX Data:

LED (

g

reen). Indicates data transmission both on the main and

on the auxiliary interface. (Figure B,

10

).

Network:

LED (red). In a normal situation, this LED is OFF. If the LED blinks,

check the connections between the DS8100 and the SC8000.

When this LED is ON, the network card needs to be

reprogrammed. Contact your Datalogic distributor. (Figure B,

11

).

Page 16

DATALOGIC DS8100

General features -

2.5

1.3 AVAILABLE MODELS

The DS8100 scanner is available in four versions that differ depending on the

system of connection and on the laser number:

DS8100 - X X 0 0

Communication Type:

0 = Bus Interface version

1 = Serial Interface version

Laser number:

2 = Double laser

4 = Quad. laser

1.4 ACCESSORIES

The following DS8100 accessories are available on request:

•

Power supply unit

•

90° deflection mirror

•

Oscillating mirror

•

XMF-10 Single cross metal frame

•

XMF-20 Double cross metal frame

•

FBK-8100 Fast bracket kit

•

US-8100 Bracket kit

•

CAB-8101 1.2 m. DS8100-DS8100 Connection cable

•

CAB-8102 2.5 m. DS8100-DS8100 Connection cable

•

CAB-8105 5 m. DS8100-DS8100 Connection cable

•

CAB-8005 5 m. DS8100-SC8000/Host Connection cable

•

CAB-8010 10 m. DS8100-SC8000/Host Connection cable

•

BTK-8100 Bus terminator kit for DS8100 Lonworks version

Page 17

DS8100 DATALOGIC

2.6

- General features

1.5 APPLICATIONS

The DS8100 barcode reader is specifically designed for industrial

applications and for all cases requiring high reading performance such as:

•

code reconstruction

•

reading of codes covered by plastic film

•

reading of codes with a wide depth of field

•

reading of high resolution codes positioned at long distances from the

reader

•

barcode reading combined with parcel dimensioning

•

code reading on fast moving objects.

DS8100 is designed for both single-reader layouts and m ulti-reader layouts.

For typical layouts see par. 2.7 and 3.6.

Page 18

DATALOGIC DS8100

Installation — DS8100 Serial I nterface -

2.1

2 INSTALLATION — DS8100 SERIAL INTERFACE

2.1 PACKAGE CONTENTS

Verify that the DS8100 reader and all the parts supplied with the equipment

are present and intact when opening the packaging; the list of parts includes:

1. DS8100 reader

2. Installation Manual + barcode test chart

3. DS8100 configuration disk

4. Mounting bracket and screws

1

2

3

4

Figure 2.1 - DS8100 package contents

Page 19

DS8100 DATALOGIC

2.2

- Installation — DS8100 Serial I nterface

2.2 GUIDE TO INSTALLATION

The following can be used as a checklist to verify all the necessary steps for

complete installation of the DS8100 scanner.

1. Read all information in the s ection Safety Precautions at the beginning of

this manual.

2. Correct ly position and mount the scanner f or barcode reading according

to the information in paragraphs 2.3, 2.4 and 2.6.

3. Provide correct system cabling according to the signals necessary (see all

applicable sub-paragraphs under 2.5).

4. Install the Configuration Disk and configure the s oftware param eters f rom

a host computer using one of the following methods:

•

WINHOST interface utility program. For more details refer to the

section “DS8100 Configuration” in the WINHOST Help On Line.

•

Host Mode programming pr ocedure by ESC sequences via the serial

interface. For more details refer to the Word docum ent hds 8100.doc in

the DS8100 directory.

•

Keyboard Mode through the keypad and the display. For more details

refer to the Word document kds8100.doc in the DS8100 directory.

NOTE

Fine tuning of the scanner position for barcode

reading can be accomplished using the T est Mode

as described in WINHOST.

The installation is now complete.

Page 20

DATALOGIC DS8100

Installation — DS8100 Serial I nterface -

2.3

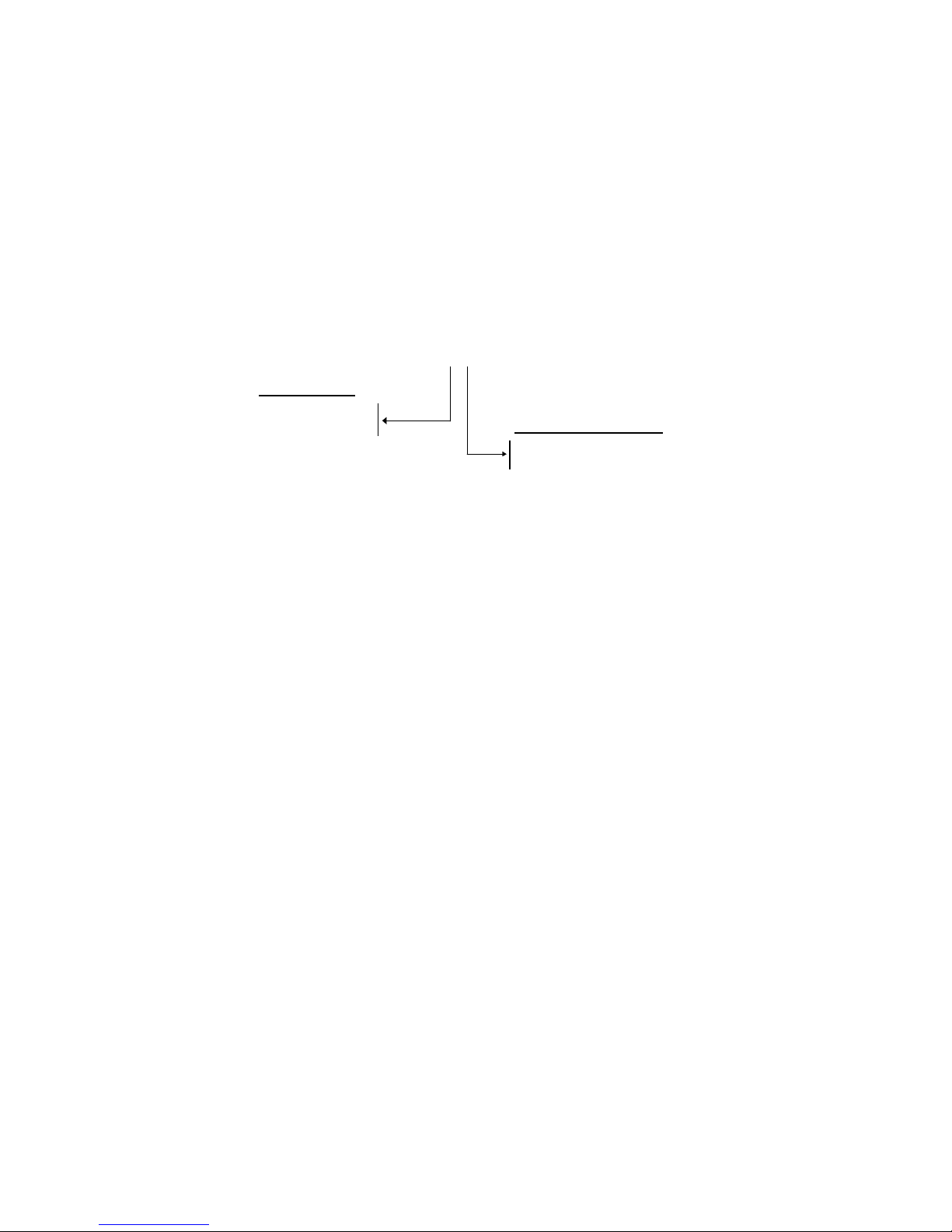

2.3 OPENING THE SCANNER

Before installing the DS8100 Serial Interface m odel, it may be necessar y to

open the scanner to select the Main interface type and the Multidrop Address

(see par. 2.3.1 and 2.3.2)

WARNING

Before unscrewing the display panel of the DS8100,

make sure the power supply cable is disconnected

to avoid shock or harm to the operator

.

The following operation should be performed by

qualified personnel only.

Refer to the following instructions and Figure 2.2 when opening the reader:

1. The part of the device to be opened is the display panel.

2. Unscrew the six screws to open the scanner.

3. Carefully remove the panel as shown in Figure 2.2.

Figure 2.2 - Opening the DS8100

!

Page 21

DS8100 DATALOGIC

2.4

- Installation — DS8100 Serial I nterface

2.3.1 Main Interface Selection

The main serial interfac e of the DS8100 offers the f ollowing communication

types:

RS232

RS485 full-duplex

RS485 half-duplex

20 mA current loop

The RS232 interface is factory set.

To select the interface type:

1. Remove the panel as described in par. 2.3.

2. Position the jumper onto the correct connector as indicated in Figure 2.3.

RS232

20 mA C.L.

RS485 half-duplex

RS485 full-duplex

DISPLAY

JUMPER

Can be aligned

at either edge

J3

J2

J1

J1

J2

J3

J3

Figure 2.3 - DS8100 main interface selecti o n

!

Page 22

DATALOGIC DS8100

Installation — DS8100 Serial I nterface -

2.5

2.3.2 Multidrop Address Selection

When using the RS485 half-duplex interfac e, the Multidrop Address m ust be

selected. Proceed as follows:

1. Open the panel as described in par. 2.3.

2. Position the switches as desired, referring to Figure 2.4.

DISPLAY

DIP SWITCH

ON

1

2

3

4

5

DIP

Figure 2.4 - DS8100 Multidrop Address selection

The following table shows the Multidrop Address settings where:

1 = ON 0 = OFF

Position Address Position Address

54321 54321

11111

31

01111

15

11110

30

01110

14

11101

29

01101

13

11100

28

01100

12

11011

27

01011

11

11010

26

01010

10

11001

25

01001

9

11000

24

01000

8

10111

23

00111

7

10110

22

00110

6

10101

21

00101

5

10100

20

00100

4

10011

19

00011

3

10010

18

00010

2

10001

17

00001

1

10000

16

00000

0

!

Page 23

DS8100 DATALOGIC

2.6

- Installation — DS8100 Serial I nterface

2.4 MECHANICAL INSTALLATION

DS8100 can be installed to operate in any position.

There are 16 screw holes (M6 X 8) on the sides of the scanner for mounting.

The diagram below gives all the infor mation required f or ins tallation; ref er to par.

2.6 for correct positioning of the scanner with respect to the code passage zone.

Figure 2.5 - DS8100 overall dimensions

MOUNTING BRACKET

Page 24

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.7

2.5 ELECTRICAL CONNECTIONS

2.5.1 DS8100 Connectors

The DS8100 Serial Interface version is equipped with 4 connectors for the

following signals:

Aux. Interface/Input Signal connector A(male, 17 pins) (Figure A,

13

).

Aux. Interface/Input Signal connector B(female, 17 pins) (Figure A,

14

).

Output Signal connector (female, 9 pins) (Figure A,

16

).

Main Interface connector (female, 9 pins) (Figure A,

15

).

Aux. Interface/Input Signal Connector A

A1

A2

1

15

scanner side

external view

Figure 2.6 - Aux. Interface/Input Signal connector A (male)

Aux. Interface/Input Signal Connector A pinout

Pin Name Function

A1 GND Ground

A2 VS Power Supply

1 GND485 RS485 Ground Reference

2 NC Not connected

3 NC Not connected

4 NC Not connected

5 NC Not connected

6 NC Not connected

7 NC Not connected

8 RXTX485+ Positive Transmit/Receive

9 RXTX485- Negative Transmit/Receive

10 ENC+ Encoder signal (Positive pin)

11 ENC- Encoder signal (Negative pin)

12 PS2+ Presence Sensor 2 signal (Positive pin)

13 PS2- Presence Sensor 2 signal (Negative pin)

14 PS1+ Presence Sensor 1 signal (Positive pin)

15 PS1- Presence Sensor 1 signal (Negative pin)

Page 25

DS8100 DATALOGIC

2.8

- Installation — DS8100 Serial I nterface

Aux. Interface/Input Signal Connector B

A1

A2

1

15

scanner side

external view

Figure 2.7 - Aux. Interface/Input Signal connector B (female)

Aux. Interface/Input Signal Connector B pinout

Pin Name Function

A1 GND ground

A2 VS power supply

1 GND485 RS485 ground reference

2 I.U. (

TXDEBUG

) only for service use

3 I.U. (

GNDDEBUG

) only for service use

4 I.U. (

RXDEBUG

) only for service use

5 GNDAUX232 auxiliary RS232 ground

6 RXAUX232 auxiliary RS232 input

7 TXAUX232 auxiliary RS232 output

8 RXTX485+ positive RS485 transmit/receive

9 RXTX485- negative RS485 transmit/receive

10 ENC+ encoder signal (positive pin)

11 ENC- encoder signal (negative pin)

12 PS2+ presence sensor 2 signal (positive pin)

13 PS2- presence sensor 2 signal (negative pin)

14 PS1+ presence sensor 1 signal (positive pin)

15 PS1- presence sensor 1 signal (negative pin)

Page 26

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.9

Output Signal Connector

5

1

69

Figure 2.8 - Output Signal connector

Output Signal Connector pinout

Pin Name Function

1 VS supply voltage (positive pin)

2 GND supply voltage (negative pin)

3 NO READ+ no read output (positive pin)

4 NO READ- no read output (negative pin)

5 RIGHT+ right code output (positive pin)

6 RIGHT- right code output (negative pin)

7 I.U. internal use

8 I.U. internal use

9

Main Interface Connector

5

1

69

Figure 2.9 - Main Interface connector

Main Interface Connector pinout

Pin RS232 RS485

full-duplex

RS485

half-duplex

20 mA C.L.

1 DRVREF

2 TXD TX485+ RTX485+ CLOUT+

3 RXD TX485- RTX485- CLOUT4 DRVIN

5 GND GNDRS485 GNDRS485

6 RS485CNTR

7 CTS RX485+ CLIN+

8 RTS RX485- CLIN9 DRVOUT

* The function of these pins depends on the interface type select ed.

Page 27

DS8100 DATALOGIC

2.10

- Installation — DS8100 Serial I nterface

2.5.2 Power Supply

The supply voltage for correct operation of the scanner must be between 20

and 30 VDC.

The max. power consumption is 30 W.

The power supply unit (optional) supplies the power necessary for the

DS8100 and allows mains power to be used.

A security system allows the laser to activate only once the motor has

reached the correct rotational speed; consequently, the laser beam is

generated after a slight delay from the power on of the scanner.

The switch (Figure A,

17

) on the connector panel turns off power to both the

motor and the laser beams.

During power up of the scanner there is a cur rent peak of about 3A caused

by the motor startup.

2.5.3 Main Serial Interface

The main serial interface of the DS8100 Serial Interface version is

compatible with the following electrical standards:

RS232

RS485 full-duplex

RS485 half-duplex

20 mA current loop

The configuration param eters of the selected inter face can be defined using

one of the programming methods available. For this procedure refer to the

WINHOST Help On Line shipped on the diskette.

The connections regarding the interface selected are described in the

following sections.

NOTE

The signals relative to the selected interface are only available

on the Main Interface connector if the jumper ins ide the sc anner

is correctly positioned. Refer to par. 2.3.1 for further details.

Page 28

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.11

RS232 Interface

The main serial interf ace is used in this c ase f or point to point connec tions; it

handles communication with the Host computer and allows both transmission

of code data and configuring the scanner.

The following pins of the Main Interface c onnector (Figure A,

15

) are used

for RS232 interface connection:

Pin Name Function

2 TXD transmitted data

3 RXD received data

5 GND ground

7 CTS clear to send

8 RTS request to send

DS8100 USER INTERFACE

TXD

RXD

CTS

RTS

GND

RXD

TXD

GND

2

3

7

8

5

Figure 2.10 - RS232 connections

The RTS and CTS signals control data transmission and synchronize the

connected devices.

If the RTS/CTS hardware protocol is enabled, the DS8100 activates the RTS

output to indicate a message can be transmitted. The receiving unit must

activate the CTS input to enable the transmission.

Page 29

DS8100 DATALOGIC

2.12

- Installation — DS8100 Serial I nterface

RS485 Full-Duplex Interface

The RS485 full-duplex interface is used for non-polled communication

protocols in point to point connections over longer distances than those

acceptable for RS232 communications or in electrically noisy environments.

The following pins of the Main Interface c onnector (Figure A,

15

) are used

for RS485 full-duplex communications:

Pin Name Function

2 TX485+ RS485 transmitted data +

3 TX485- RS485 transmitted data 5 GNDRS485 RS485 ground reference

7 RX485+ RS485 received data +

8 RX485- RS485 received data -

DS8100

5

GNDRS485

TX485+

2

TX485-

3

RX485+

7

RX485-

8

RX485

TX485

GND

USER INTERFACE

Figure 2.11 - RS485 full-duplex interface connections

Page 30

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.13

RS485 Half-Duplex Interface

The RS485 half-duplex (3 wires + shield) interface is used for polled

communication protocols. It can be used for Multidrop connections in a

master/slave layout or with a Datalogic Multiplexer, (see par. 2.7.3, 2.7.4 and

2.7.5).

Device connection to the Multidrop line can be controlled externally through

the RS485CNTR line. For example, it may be necessary to disconnect a

scanner from the line if the device is dam aged or the line is overloaded. To

do this, apply a voltage from 20 to 30 Vdc to the RS485CNTR signal using

the same GND of the power supply as a reference.

The following pins of the Main Interface c onnector (Figure A,

15

) are used

for RS485 half-duplex interface connection:

Pin Name Function

6 RS485CNTR multidrop device disconnect

2 RTX485+ transmit/receive data +

3 RTX485- transmit/receive data 5 GNDRS485 RS485 ground reference

GND

DS8100

USER INTERFACE

RXTX+

RTX485-

3

RXTX-

RTX485+

2

GND

5

GNDRS485

RS485GND

Vext

20 to 30 Vdc

RS485CNTR

6

VS

20 to 30 Vdc

±

Figure 2.12 - RS485 half-duplex interface connections

Page 31

DS8100 DATALOGIC

2.14

- Installation — DS8100 Serial I nterface

The figure below shows an example of a multidrop conf iguration between a

Multiplexer and DS8100 scanners.

120 Ohm

max. 1200 m.

DS8100

# x

(up to 31)

Multiplexer

RTX485+

RTX485-

shield

# 1

DS8100

120 Ohm

max. 2 m.

5

3

2

RTX485+

RTX485-

GNDRS485

# 0

DS8100

RS485REF

5

3

2

5

3

2

Figure 2.13 - DS8100 Multidrop connection to a M ultiplexer

Page 32

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.15

20 mA Current Loop Interface

The DS8100 has two current generators (one for transmission and one f or

reception), allowing for both active and passive type connections.

The following pins of the Main Interface c onnector ( F ig ur e A,

15

) are used for

20 mA C.L. connections:

Pin Name Function

1 DRVREF current generator reference

2 CLOUT+ current loop output +

3 CLOUT- current loop output 4 DRVIN input current generator

7 CLIN+ current loop input +

8 CLIN- current loop input 9 DRVOUT output current generator

DS8100

USER INTERFACE

MAX. 300 METERS

C.L. IN-

C.L. IN+

C.L. OUT-

C.L. OUT+

DRVREF

DRVIN

8

7

3

2

1

4

9

DRVOUT

I = 20 mA

I = 20 mA

Figure 2.14 - 20 mA C.L. active connections

Page 33

DS8100 DATALOGIC

2.16

- Installation — DS8100 Serial I nterface

DS8100

MAX. 300 METERS

8

C.L. IN-

7

C.L. IN+

3

C.L. OUT-

2

C.L. OUT+

USER INTERFACE

+

+

Figure 2.15 - 20 mA C.L. passive connections

2.5.4 Auxiliary Interface

The auxiliary serial interface of the DS8100 Serial Interface version is

equipped with both RS232 and RS485 half-duplex interface connections.

The signals for the auxiliary interface are available on the

Aux. Interface A

and B connectors to simplify the master/slave connections (Figure A,

13

and 14).

RS232 Auxiliary Interface

The following pins of the

Aux. Interface B connector

connector are used:

Pin Name Function

5 GNDAUX232 ground

6 RXAUX232 receive data

7 TXAUX232 transmit data

Page 34

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.17

TXD

RXAUX232

RXD

TXAUX232

7

5

GNDAUX232

GND

DS8100

USER INTERFACE

6

Figure 2.16 - RS232 Auxiliary interface connections

RS485 Half-Duplex Auxiliary Interface

The following pins of the

Aux. Interface A and B connectors

(Figure A,

13

and

14

) are used:

Pin Name Function

1 GND485 ground

8 RTX485+ transmit/receive data +

9 RTX485- transmit/receive data -

DS8100

USER INTERFACE

RTX485+

RTX485-

9

RTX485-

RTX485+

8

1

GND485

GND485

Figure 2.17 - RS485 Auxiliary interface connections

2.5.5 Inputs

The inputs of the scanner are on the

Input Signal A and B connectors

on

the body of the DS8100 (Figure A,

13

and

14

).

These inputs are called ENC, PS1 and PS2.

ENC is the Encoder input. In PackTrack™ operating mode, it detects the

conveyor speed.

Page 35

DS8100 DATALOGIC

2.18

- Installation — DS8100 Serial I nterface

PS1 is the main presence sensor (external trigger). When ac tive, this input

tells the scanner to scan for a c ode and that decoding can take plac e. The

yellow LED (Figure A,

4

) indicates that PS1 is active.

PS2 can be used as the stop signal for the reading phase.

All inputs are optocoupled and driven by a constant current generator; the

command signal is filtered through an anti-disturbance circuit which

generates a delay of about 5 ms for PS1 and PS2 and 500 µs for ENC.

PS2+/PS1+

PSIN

+

VS

12/14

13/15

A2

A1

GND

DS8100

PRESENCE SENSOR

PS2-/PS1-

Figure 2.18 - Presence sensor input PNP command

Signal

PSIN

+

12/14

13/15

A2

A1

PS2+/PS1+

PS2-/PS1-

VS

GND

Ground

PRESENCE SENSOR

DS8100

V

Figure 2.19 - Presence sensor input NPN command

Page 36

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.19

Signal

ENC+

ENC-

10

11

+ 5V

VS

A2

A1

GND

Ground

ENCODER

DS8100

V

Figure 2.20 - Encoder NPN input command using DS8100 power

Signal

ENCODER

ENC+

ENC-

10

11

+ 5V

DS8100

V

Vext

Figure 2.21 - Encoder NPN input command using external power

+

10

11

A2

A1

ENC+

ENC-

VS

GND

ENCODER

DS8100

Figure 2.22 - Encoder PNP input command using DS8100 pow er

Page 37

DS8100 DATALOGIC

2.20

- Installation — DS8100 Serial I nterface

ENCODER

Signal

DS8100

ENC+

ENC-

10

11

+ 5V

V

Vext

Figure 2.23 - Encoder PNP input command using external power

Isolation between the command logic and the scanner is maintained by

powering the inputs with a different supply voltage (Vext) from that supplied

on the

Aux. Interface/Input Signal A

and

B

connectors (VS).

The driving logic of the input signals m ay be powered, for convenience, with

the voltage supply between pins A2 (VS) and A1 (GND) of the connector. In

this case, however, the device is no longer electrically isolated.

The electrical features of these inputs are:

Maximum voltage 30 V

Maximum current 25 mA

Page 38

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.21

2.5.6 Outputs

The relative signals are available on the Output Signal connec tor (Figure A,

16

).

Pin Name Function

1 VS power for external devices (Positive pin)

2 GND power for external devices (Negative pin)

3 NO READ+ no read output +

4 NO READ- no read output 5 RIGHT+ right code output +

6 RIGHT- right code output 7

8

I.U.

I.U.

internal use

internal use

9 N.C. not connected

A D.C. output voltage, the same as that powering the DS8100, is present

between pins 1 and 2. This may be used to power external devices: electrical

isolation between the scanner and external devices is lost in this case.

The

No Read

output activates when a code signalled by the presence sensor

is not decoded.

The

Right

output is used to signal the presence of a right code, thus a good

decode condition.

All outputs are level or pulse program mable: a 50 ms pulse is generated in

the second case. Further programming information is supplied in the

WINHOST Help File.

These outputs are created using optoisolated Dar lington drivers and supply

both the collector and emitter in output, allowing both loads referenced to

ground and to the power supply to be driven.

The electrical features are given below:

Collector-emitter voltage 30 V Max.

Collector current 130 mA Max (pulsed).

Saturation voltage (VCE) 1 V at 10 mA Max.

Maximum power dissipation 90 mW at 50 °C (Ambient temperature).

Page 39

DS8100 DATALOGIC

2.22

- Installation — DS8100 Serial I nterface

DS8100

USER INTERFACE

NO READ+

RIGHT+

Vext

30 Vdc max

NO READ-

RIGHT-

3/5

4/6

Figure 2.24 - Output interface

When the load is powered by an external power supply, the voltage m ust be

less than 30 V. The limit requested by the maximum power dissipation is

more important than that of the maxim um collector current: if one of these

outputs is continuously driven, the maximum cur rent must not be mor e than

40 mA although 130 mA may be reached in pulse conditions.

2.6 POSITIONING

The DS8100 scanner is able to decode barcode labels at a variety of angles,

however significant angular distortion may degrade reading performance.

When mounting the DS8100 take into consideration these three ideal label

position angles:

Pitch 0°, Skew 0° to 45° and Tilt 0°

.

Follow the suggestions for the best orientation:

The

Pitch

angle is represented by the

value P in Figure 2.25. Position the

reader in order to minimize the Pitch

angle.

Figure 2.25 - "Pitch" angle

P

Page 40

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.23

The

Skew

angle is represented by the value S in Figure 2.26.

S

Figure 2.26 - "Skew" angle

The

Tilt

angle is represented by the value T in Figure 2.27. For code

reconstruction, see par. 4.1.1.

T

Figure 2.27 - "Tilt" angle

Page 41

DS8100 DATALOGIC

2.24

- Installation — DS8100 Serial I nterface

2.7 TYPICAL LAYOUTS

2.7.1 Standard (Point-to-Point)

In this layout, data is transmitted to the Host on the main serial interface. The

selectable interface types are RS232, RS485 full-duplex or 20 mA C.L.

communications.

1

Host

3

Presence sensor (for On-Line mode)

3

Main serial interface

1

DS8100

Auxiliary serial interface

2

2

Terminal

Figure 2.28 - Standard (point to point) layout

When On-Line Operating mode is used, the scanner is activated by an

External Trigger (presence sensor) when the object enters its reading zone.

The data is also transmitted on the Auxiliary interface (if configured for

Standard communication mode), as well as on the Main interface.

The

auxiliary interface uses RS232 for this layout.

Host Mode programming can be accomplished either thr ough the Main or the

Auxiliary interface.

Page 42

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.25

2.7.2 Pass Through

Pass Through Mode allows two or more devic es to be connected to a single

external serial interface. The DS8100 tr ans mits the messages rec eived by its

auxiliary interface (RS232 only) onto its main interface.

In this configuration a series of s canners can be connected together using

RS232 on the main interface and all messages will be passed through this

chain to the host.

The reading phase of each scanner is independent from the others in a Pas s

Through chain.

When On-Line Operating mode is used, the scanner is

activated by an External Trigger (presence sensor) when the object enter s its

reading zone.

Applications can be implem ented to connect a device such as a hand-held

reader to the Auxiliary port for manual code reading capability.

3 3

1

Main serial interface

2

Auxiliary serial interface

3

Presence sensor (for On-Line mode)

Host

DS8100 DS8100

Hand-Held reader

1

2

1

Figure 2.29 - Pass through layout

Page 43

DS8100 DATALOGIC

2.26

- Installation — DS8100 Serial I nterface

2.7.3 RS485 Master/Slave

The RS485 Master/Slave connection is used to collect data from several

scanners to build either an omni-directional or multi-sided reading system;

there can be one Master and up to 8 Slaves connected together.

The Master and Slave scanners are connected together using RS485 halfduplex on the auxiliary serial interface.

The Master scanner is also connected to either a Host or a Multiplexer on the

main serial interface. T he possible main inter face type selections are RS232

or RS485 full-duplex for Host connections or RS485 half-duplex for

Multiplexer connections (see “Main Interface Selection” in par. 2.3.1).

For the Slave scanners the Multidrop Address Selection can be m ade using

the DIP switch. The addresses m ust be consec utive and not inc lude zero for

hardware configuration, or be selected in software (in this case the DIP

switch address must be zero for each Slave). See par. 2.3.2.

NOTE

The main serial port of the Slave scanners can be used

for configuration. The termination r esistors of the RS485

bus must not be installed.

Single P.S.

The P.S. signal is unique to the system; there is a single reading phase and

a single message from the master scanner to the Host.

Presence sensor

3

Auxiliary serial interface: RS485 half-duplex

2

Main serial interface

1

HOST

PC or PLC

RS232

RS485 full-duplex

MULTIPLEXER

MX4000

RS485 half-duplex

Slave

Master

2

Slave

DS8100

DS8100

DS8100

1

3

Figure 2.30 - Master-slave Single P.S . l ayout

Page 44

DATALOGIC DS8100

Installation — DS8100 Serial I nterface –

2.27

Multi P.S.

In this layout, each DS8100 has its own P.S. and therefore multiple reading

phases. The master sends the individual messages collected from the

multidrop line as well as its own to the Host.

DS8100

3

Main serial interface

Auxiliary serial interface: RS485 half-duplex

Presence sensor (for On-Line mode)

3

2

1

Slave

DS8100

Master

3

2

2

1

HOST

PC or PLC

RS232

RS485 full-duplex

MULTIPLEXER

MX4000

RS485 half-duplex

Figure 2.31 - Multi P.S. layout connections

2.7.4 Multiplexer

Each scanner is connected to an MX4000 us ing RS485 half-duplex on either

the main or the auxiliary interface. The other interface can be used for

configuration.

Host

MX4000

01 31

P.S.

P.S.

P.S.

Figure 2.32 - Multiplexer layout

Page 45

DS8100 DATALOGIC

2.28

- Installation — DS8100 Serial I nterface

2.7.5 Omnidirectional Reading

Two or more scanner s are cor rectly positioned in a Master/Slave Single P.S.

type layout to compose an omnidirectional reading station.

The XMF series metal frames provide easy mounting for this type of layout.

P.S.

PHOTOCELL

code motion

READING

AREA

Figure 2.33 - Omnidirectional reading

Page 46

DATALOGIC DS8100

Installation — DS8100 Bus Interface -

3.1

3 INSTALLATION — DS8100 BUS INTERFACE

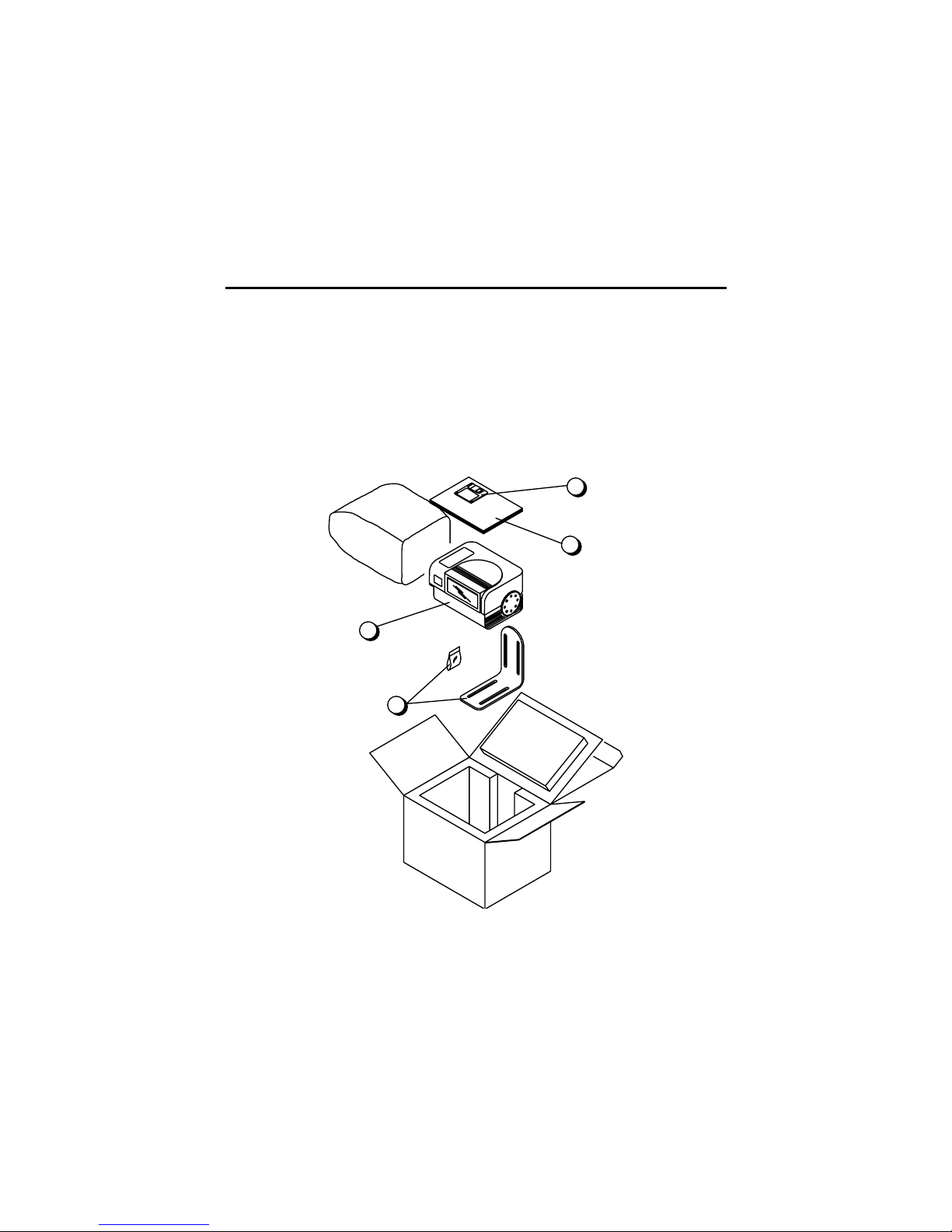

3.1 PACKAGE CONTENTS

Verify that the DS8100 reader and all the parts supplied with the equipment

are present and intact when opening the packaging; the list of parts includes:

1. DS8100 reader

2. Installation Manual + barcode test chart

3. Mounting bracket and screws

1

3

2

Figure 3.1 - DS8100 package contents

Page 47

DS8100 DATALOGIC

3.2

- Installation — DS8100 Bus Interface

3.2 GUIDE TO INSTALLATION

The following can be used as a checklist to verify all the necessary steps for

complete installation of the DS8100 scanner.

1. Read all information in the s ection Safety Precautions at the beginning of

this manual.

2. Correct ly position and mount the scanner f or barcode reading according

to the information in paragraphs 3.3 and 3.5.

3. Provide correct s ystem cabling according to the s ignals necessary (see

paragraph 3.4 and 3.6).

4. Configure your DS8100 by means of the SC8000 unit.

NOTE

Fine tuning of the scanner position for barcode

reading can be accomplished by performing a test

through the SC8000 unit.

The installation is now complete.

Page 48

DATALOGIC DS8100

Installation — DS8100 Bus Interface -

3.3

3.3 MECHANICAL INSTALLATION

DS8100 can be installed to operate in any position.

There are 16 screw holes (M6 X 8) on the sides of the scanner for mounting.

The diagram below gives all the infor mation required f or ins tallation; ref er to par.

3.5 for correct positioning of the scanner with respect to the code passage zone.

Figure 3.2 - DS8100 Bus Interface overall dimensions

MOUNTING BRACKET

Page 49

DS8100 DATALOGIC

3.4

- Installation — DS8100 Bus Interface

3.4 ELECTRICAL CONNECTIONS

The DS8100 Bus Interface version employs a Lonworks network used for

both input and output connections to build a multi-sided or omni-station

system connecting several DS8100 scanners and one or more SC8000

units.

This version is equipped with the following 3 connectors:

•

Lonworks INPUT male connector (17 pins) (Figure B,

12

).

•

Lonworks OUTPUT female connector (17 pins) (Figure B,

13

).

•

RS232 debug connector – for Service only, (9 pins) (Figure B,

14

).

Lonworks INPUT/OUTPUT Connector

A1

A2

1

15

scanner side

external view

A1

A2

1

15

OUTPUT

INPUT

Figure 3.3 - Lonworks INPUT/OUTPUT connectors

The following pinout is valid for the INPUT connector as well as for the

OUTPUT connector.

Lonworks INPUT/OUTPUT Connector pinout

Pin Name Function

A1 GND supply voltage (negative pin)

A2 VS supply voltage 20 to 30 vdc (positive pin)

1 Shield A

3 Shield B

8 Lon A+ lonworks a line (positive pin)

9 Lon A- lonworks a line (negative pin)

10 Lon B+ lonworks b line (positive pin)

11 Lon B- lonworks b line (negative pin)

12 PS+ presence sensor

13 ENC+ encoder input

14 PSAux+ auxiliary presence sensor

15 Refer- input reference

Page 50

DATALOGIC DS8100

Installation — DS8100 Bus Interface –

3.5

RS232 Debug Connector

The use of this connector is reserved for Service:

5

1

69

Figure 3.4 - RS232 debug connector

RS232 Debug Connector pinout

Pin Name Function

2 TXD transmit data

3 RXD receive data

5 GND ground

3.4.1 Power Supply

The supply voltage for correct operation of the scanner must be between 20

and 30 VDC.

The max. power consumption is 30 W.

The power block (optional), supplies the power necessary for the DS8100

and allows mains power to be used.

A security system allows the laser to activate only once the motor has

reached the correct rotational speed; consequently, the laser beam is

generated after a slight delay from the power on of the scanner.

The switch (Figure B,

15

) on the connector panel turns off power to both the

motor and the laser beams.

During power up of the scanner there is a cur rent peak of about 3A caused

by the motor startup.

Page 51

DS8100 DATALOGIC

3.6

- Installation — DS8100 Bus Interface

3.4.2 Inputs

The inputs for the DS8100 Bus Interface version are provided by SC8000

and are called ENC, PS and PSAux.

ENC is the Encoder input. In PackTrack™ operating mode, it detects the

conveyor speed.

PS is the main presence sensor (external trigger). W hen active, this input

tells the scanner to scan for a c ode and that decoding can take plac e. The

yellow LED (Figure B,

6

) indicates that PS is active.

PSAux can be used in special applications.

All inputs are optocoupled and driven by a constant current generator; the

command signal is filtered through an anti-disturbance circuit which

generates a delay of about 5 ms for PS and PSAux and 500 µs for ENC.

REFER-

DS8100 SC8000

Vext

20-30 Vdc

PS

12

Vext

20-30 Vdc

PSAux

13

Vext

20-30 Vdc

ENC

14

15

Figure 3.5 - DS8100 Bus Interface inputs

Page 52

DATALOGIC DS8100

Installation — DS8100 Bus Interface –

3.7

3.5 POSITIONING

The DS8100 scanner is able to decode barcode labels at a variety of angles,

however significant angular distortion may degrade reading performance.

When mounting the DS8100 take into consideration these three ideal label

position angles:

Pitch 0°, Skew 0° to 45° and Tilt 0°

.

Follow the suggestions for the best orientation:

The

Pitch

angle is represented by the value P in Figure 3.6. Position the

reader in order to

minimize

the

Pitch

angle.

P

Figure 3.6 - "Pitch" angle

The

Skew

angle is represented by the value S in Figure 3.7.

S

Figure 3.7 - "Skew" angle

Page 53

DS8100 DATALOGIC

3.8

- Installation — DS8100 Bus Interface

The

Tilt

angle is represented by the value T in Figure 3.8. For code

reconstruction, see par. 4.1.1.

T

Figure 3.8 - "Tilt" angle

3.6 Typical Layout

The scanner is generally activated by a photoelectric sensor used as a code

presence sensor when the object enters its reading zone.

The following figures show a typical layout for DS8100 Bus Interface.

A Lonworks cable provides a communic ation line (branch) between up to 4

scanners and an SC8000 unit. The last scanner on the line requires a

Termination connector. Up to 4 br anches of this type can be connected to a

single SC8000. The allowed maximum length of the cable is 65 m.

External devices such as a presence sensor , an encoder and the supply unit

are all connected to the SC8000, which collects all signals driving them to all

scanners.

The SC8000 is also connected to a Host.

Page 54

DATALOGIC DS8100

Installation — DS8100 Bus Interface –

3.9

ENCODER

PRESENCE

SENSOR

1

2

34

9

10

11 12

13

14

15 16

SC8000

DATALOGIC

POWER SUPPLY

UNIT

HOST

CAB-8101

CAB-8102

CAB-8105

5

6

78

BKT-8100

CAB-8005

CAB-8010

Figure 3.9 - DS8100 Bus Interface Typical Layout

Page 55

DS8100 DATALOGIC

3.10

- Installation — DS8100 Bus Interface

CONVEYOR

SC8000

Figure 3.10 - DS8100 Bus Interface typical application

Page 56

DATALOGIC DS8100

Reading features -

4.1

4 READING FEATURES

4.1 ADVANCED CODE RECONSTRUCTION

The traditional way of barcode reading could be called "Linear Reading". In

this case, the laser beam cros ses the barcode symbol from its beginning to

its end as shown in Figure 4.1.

Laser Beam

Figure 4.1 - Linear reading

In "Advanced Code Reconstruction" mode, it is no longer necessary for the

laser beam to cross the label from the start to the end. W ith just a set of

partial scans on the label (obtained using the motion of the label itself), the

DS8100 is able to "reconstruct" the barcode. A typical set of partial scans is

shown in Figure 4.2.

Code Direction

Figure 4.2 - Partial scans

None of the partial scans contains the whole label. The decoder aligns each

partial scan correctly and combines them in order to obtain the entire code.

The alignment is performed by calculating the time difference from one

partial scan to another using a reference code element.

4.1.1 Tilt Angle For Advanced Code Reconstruction

The most important parameter in Advanced Code Reconstruction is the

value of the maximum tilt angle (α maximum) under which the code

reconstruction process is still possible.

Page 57

DS8100 DATALOGIC

4.2

- Reading features

We define the T ilt angle as the angle (α) between the laser beam and a line

parallel to the barcode label, as shown in Figure 4.3.

α

Laser Beam

= tilt an

g

le

α

0° toαmax

Figure 4.3 - Tilt angle

The formulas to calculate α maximum depend on various parameters such

as: label height, number of scans per second, code motion speed, etc. To

obtain α maximum for your application, please contact your Datalogic

representative.

You must remember that the decoder will be able to read the label with a tilt

angle between + α max and - α max as shown in Figure 4.4 (the shaded

zones are the NO READ zones).

Laser Beam

α

-

+

α

0°

Figure 4.4 - Reading zones with α max

4.2 PERFORMANCE

The scan rate is 1000 scans/sec.

Refer to the diagrams in par. 4.3 for further details on the reading features.

These diagrams are taken on various resolution sam ple codes at a 25 °C

ambient temperature depending on the conditions listed under each diagram.

If standard models do not satis fy specific requirem ents, contac t your nearest

Datalogic distributor, supplying code samples, to obtain complete inf orm ation

on the reading possibilities.

Page 58

DATALOGIC DS8100

Reading features -

4.3

4.3 READING DIAGRAMS

The following diagram shows the reading distance for barc odes with diff erent

densities for DS8100-2x00 (double laser models).

Note: (0,0) is the center of the laser beam output window

-600

-400

-200

0

200

400

600

0

200 400 600 800

1000 1200 1400 1600

1800

2000 2200

0.50 mm

(mm)

Figure 4.5

-

Reading diagram for DS8100

Code = Interleaved 2/5 or Code 39

PCS = 0.90

"Pitch" angle = 0°

"Skew" angle = 10°

"Tilt" angle = 0°

Reading mode = Linear

Page 59

DS8100 DATALOGIC

4.4

- Reading features

The following diagram shows the reading distance for barc odes with diff erent

densities for DS8100-4x00 (quad laser models).

Note: (0,0) is the center of the laser beam output window

-600

-400

-200

0

200

400

600

0

200 400 600 800

1000 1200 1400 1600

1800

2000 2200

0.50 mm

(mm)

0.30 mm

Figure 4.6

-

Reading diagram for DS8100

Code = Interleaved 2/5 or Code 39

PCS = 0.90

"Pitch" angle = 0°

"Skew" angle = 10°

"Tilt" angle = 0°

Reading mode = Linear

Page 60

DATALOGIC DS8100

Maintenance -

5.1

5 MAINTENANCE

5.1 CLEANING

Clean the laser beam output window (Figure A and Figure B, 1) periodically

for correct operation of the reader.

Dust, dirt, etc. on the window may alter the reading performance.

Repeat the operation frequently in particularly dirty environments.

Use soft material and alcohol to c lean the window and avoid any abrasive

substances.

WARNING

Clean the window of the DS8100

when the scanner is turned off or at

least when the laser beam is not

active.

Page 61

DS8100 DATALOGIC

5.2

- Maintenance

This page is intentionally lef t blank.

Page 62

DATALOGIC DS8100

Technical Features -

6.1

6 TECHNICAL FEATURES

DS8100 model

Serial Interface Bus Interface

ELECTRICAL FEATURES

(see note 1)

Maximum input voltage 35 Vdc

Supply voltage 20 to 30 Vdc

Operating current 1.3 - 0.9 A

Power consumption 30 W

INPUTS/OUTPUTS

Serial interfaces

Main RS232

RS485 Lonworks network

20 mA C.L.

Auxiliary RS232, RS485

Baud Rates 1200 to 1.25 Mb/s

Command inputs (NPN or PNP ) Presence sensor (optocoupled)

Encoder input (optocoupled)

Auxiliary input (optocoupled)

Outputs NO READ (optocoupled)

(open emitter or collect or) RIGHT CODE (optocoupled)

OPTICAL FEATURES

(see note 1)

Light source up to 4 semiconductor laser diodes

Wave length 630 to 680 nm

Safety class Class 2 - IEC 825-1; Class II - CDRH

Light receiver Avalanche photodiode

READING FEATURES

Scan rate 1000 scans/s

Maximum resolution

Max. reading distance (see reading diagram in par. 4.3)

Max. reading width

Max. depth of field

Aperture angle

USER INTERFACE

LCD Display:

2 lines, 20 characters

4 key keypad

LED indicators Power ON, Ext Trig,

Encoder, Good Read, TX

Data, User Defined

Power ON, Ext Trig,

Encoder, Good Read, TX

Data, Network.

Page 63

DS8100 DATALOGIC

6.2

- Technical Features

DS8100 model

Serial Interface Bus Interface

SOFTWARE FEATURES

Readable code symbologies

• Interleaved 2/5 • Code 128

• Code 39 Standard • EAN128

• EAN/UPC

Code selection

Up to 5 code symbologies during one reading phase

Decoding safety

Several good reads of the same code can be enabled

separately for each code

Headers and Terminators

Transmitted messages can be personalized using up to 4

headers and 4 terminators

Operating modes

ON LINE

SERIAL ON LINE Depending on SC8000

AUTOMATIC

TEST

PACK TRACK™

Configuration modes

WINHOST utility program

SC8000

KEYBOARD MODE:

using the built-in keypad

HOST MODE:

receiving commands from the

serial port

Parameter storage

Non-volatile internal

EEPROM

ENVIRONMENTAL FEATURES

Operating temperature 0 to 40 °C

Storage temperature -20 to 70 °C

Humidity 90% non condensing

Vibration resistance IEC 68-2-6 test FC

1.5 mm; 10 to 55 Hz;

2 hours on each axis

Shock resistance IEC 68-2-27 test EA

30 G; 11 ms;

3 shocks on each axis

Protection Class IP64

PHYSICAL FEATURES

Mechanical dimensions 215.5 x 170.5 x 126.5 mm

Weight 5 Kg

Note 1

: The features given are typical at 25 °C ambient temperature (if not otherwise

indicated).

Loading...

Loading...