Page 1

Page 2

Datalogic S.r.l.

Via S. Vitalino 13

40012 Calderara di Reno

Italy

DS5100 Reference Manual

Ed.: 08/2017

© 2017 Datalogic S.p.A. and/or its affiliates ALL RIGHTS RESERVED. Without limiting the rights

under copyright, no part of this documentation may be reproduced, stored in or introduced into a

retrieval system, or transmitted in any form or by any means, or for any purpose, without the express

written permission of Datalogic S.p.A. and/or its affiliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries,

including the U.S.A. and the E.U.

Genius, e-Genius, ACR, DST, EBC, ID-NET, PackTrack, Subzero, and X-PRESS are trademarks of

Datalogic S.p.A. and/or its affiliates. All other trademarks and brands are property of their respective

owners.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

04/08/17

Page 3

iii

CONTENTS

REFERENCES ............................................................................................................ vi

Conventions ................................................................................................................. vi

Reference Documentation ........................................................................................... vi

Support Through the Website ...................................................................................... vi

Patents ......................................................................................................................... vi

SAFETY AND COMPLIANCE NOTICES ................................................................... vii

Laser Safety ................................................................................................................. vii

Power Supply .............................................................................................................. viii

FCC Compliance ......................................................................................................... ix

CE Compliance ............................................................................................................ ix

EAC Compliance ......................................................................................................... ix

Bureau of Indian Standard (BIS) .................................................................................. ix

Handling ........................................................................................................................ x

GENERAL VIEW ........................................................................................................ xii

1 RAPID CONFIGURATION ........................................................................................... 1

Step 1 – Connect the System ....................................................................................... 1

Step 2 – Mount and Position the Scanner .................................................................... 3

Step 3 – Focus the Scanner ......................................................................................... 5

Step 4 – X-PRESS Configuration ................................................................................. 6

Step 5 – Install Genius Configuration Program .......................................................... 11

Step 6 – Test Mode .................................................................................................... 17

Advanced Scanner Configuration ............................................................................... 18

2 INTRODUCTION ........................................................................................................ 19

2.1 Product Description .................................................................................................... 19

2.1.1 Indicators .................................................................................................................... 20

2.2 ID-NET ........................................................................................................................ 20

2.2.1 How To Setup/Configure the Scanner Network .......................................................... 22

2.3 X-PRESS Human Machine Interface .......................................................................... 23

2.3.1 Diagnostic Indication ................................................................................................... 23

2.3.2 X-PRESS Functions ................................................................................................... 24

2.4 External Memory Backup & Restore ........................................................................... 26

2.5 Automatic Scanner Replacement ............................................................................... 29

2.6 Display ........................................................................................................................ 30

2.6.1 Display Messages ....................................................................................................... 30

2.7 Model Description ....................................................................................................... 34

2.8 Oscillating Mirror Models ............................................................................................ 35

2.9 Subzero Temperature Models .................................................................................... 36

2.10 IP Address Alignment using Genius Discovery .......................................................... 37

2.11 Accessories ................................................................................................................ 39

3 MECHANICAL INSTALLATION ................................................................................ 42

3.1 Package Contents ...................................................................................................... 42

3.2 Mechanical Installation ............................................................................................... 43

3.2.1 Mounting DS5100 ....................................................................................................... 50

3.3 Mounting Scanner Accessories .................................................................................. 53

3.3.1 Mounting a GFC-40 Accessory Deflection Mirror ....................................................... 53

3.4 Positioning .................................................................................................................. 54

Page 4

iv

4 ELECTRICAL INSTALLATION .................................................................................. 56

4.1 Power Supply .............................................................................................................. 57

4.2 Main Serial Interface ................................................................................................... 57

4.2.1 RS232 Interface .......................................................................................................... 58

4.2.2 RS485 Full-Duplex Interface ....................................................................................... 59

4.3 ID-NET Interface ......................................................................................................... 60

4.3.1 ID-NET Cables ............................................................................................................ 60

4.3.2 ID-NET Response Time .............................................................................................. 61

4.3.3 ID-NET Network Termination ...................................................................................... 65

4.4 Auxiliary RS232 Interface ........................................................................................... 65

4.5 Inputs .......................................................................................................................... 66

4.5.1 Code Verifier ............................................................................................................... 69

4.6 Outputs ....................................................................................................................... 69

4.7 User Interface - Host ................................................................................................... 71

5 TYPICAL LAYOUTS .................................................................................................. 72

5.1 Point-to-Point .............................................................................................................. 72

5.2 External Fieldbus Using Host Mode Interface Modules .............................................. 73

5.3 Built-In Ethernet Networks .......................................................................................... 74

5.3.1 External Trigger Ethernet Host ................................................................................... 74

5.4 Built-in Profinet-IO Networks ...................................................................................... 75

5.4.1 Multi Station Layout with Single Port Scanners ................................ .......................... 75

5.4.2 Single Station Layout with Dual Port Scanners .......................................................... 76

5.4.3 Multi Station Layout with Dual Port Scanners ............................................................. 77

5.5 EBC™ Networks ......................................................................................................... 78

5.6 ID-NET Synchronized Networks ................................................................................. 83

5.7 ID-NET Multidata Networks ........................................................................................ 88

5.8 Pass-Through ............................................................................................................. 89

5.9 Other Layouts ............................................................................................................. 89

6 READING FEATURES ............................................................................................... 90

6.1 Advanced Code Reconstruction (ACR 4) ................................................................... 90

6.1.1 Tilt Angle for Advanced Code Reconstruction ............................................................ 91

6.1.2 ACR Reading Conditions for Medium Range Models ................................................. 92

6.1.3 ACR Reading Conditions for Long Range Models ..................................................... 94

6.2 Linear Code Reading .................................................................................................. 96

6.2.1 Step-Ladder Mode ...................................................................................................... 96

6.2.2 Picket-Fence Mode ..................................................................................................... 97

6.3 Performance ............................................................................................................... 98

6.4 Reading Diagrams .................................................................................................... 100

6.4.1 Linear Medium Range Models .................................................................................. 100

6.4.2 Linear Medium Range Subzero Models ................................................................... 105

6.4.3 Linear Long Range Models ....................................................................................... 110

6.4.4 Oscillating Mirror Medium Range Models ................................................................. 114

6.4.5 Oscillating Mirror Medium Range Subzero Models .................................................. 119

6.4.6 Oscillating Mirror Long Range Models ...................................................................... 124

7 MAINTENANCE ....................................................................................................... 128

7.1 Cleaning .................................................................................................................... 128

8 TROUBLESHOOTING ............................................................................................. 129

8.1 General Guidelines ................................................................................................... 129

9 TECHNICAL FEATURES ......................................................................................... 132

Page 5

v

A ALTERNATIVE CONNECTIONS FOR SERIAL MODELS ...................................... 134

Power, COM and I/O Connector ............................................................................... 134

ID-NET Network Termination .................................................................................... 135

Inputs ........................................................................................................................ 135

Outputs ..................................................................................................................... 136

User Interface - Serial Host ...................................................................................... 137

B ALTERNATIVE CONNECTIONS FOR ETHERNET MODELS ................................ 138

Power, COM and I/O Connector ............................................................................... 138

On-Board Ethernet Connector .................................................................................. 139

ID-NET Network Termination .................................................................................... 139

Inputs ........................................................................................................................ 139

Outputs ..................................................................................................................... 140

C CONNECTIONS FOR PROFINET-IO MODELS ...................................................... 142

On-Board Profinet-IO Connectors (2) ....................................................................... 142

Power + Input (Trigger) ............................................................................................. 142

GLOSSARY .............................................................................................................. 143

INDEX ....................................................................................................................... 146

Page 6

vi

REFERENCES

CONVENTIONS

This manual uses the following conventions:

“User” or “Operator” refers to anyone using the scanner.

“Device” refers to the scanner.

“You” refers to the System Administrator or Technical Support person using this manual to

install, mount, operate, maintain or troubleshoot the scanner.

REFERENCE DOCUMENTATION

The documentation related to the scanner management is listed below:

CBX100 Installation Manual

CBX500 Installation Manual

CBX Accessory Manuals

Genius Help On Line

SUPPORT THROUGH THE WEBSITE

Datalogic provides several services as well as technical support through its website. Log on

to www.datalogic.com and click on the SUPPORT > Unattended Scanning Systems

category link. From this page you can select your product model from the dropdown list

which gives you access to:

Downloads including Data Sheets, Manuals, Software & Utilities, and Drawings;

Repair Program for On-Line Return Material Authorizations (RMAs) plus Repair

Center contact information;

Service Program containing details about Maintenance Agreements;

Technical Support through email or phone.

PATENTS

See www.patents.datalogic.com for patent list.

This product is covered by one or more of the following patents:

Design patents: USD743397

Utility patents: EP0789315B1, EP0959426B9, EP1217571B1, EP2215583B1, EP2519856,

IT0282308, JP4033958B2, JP4376353B2, US5992740, US6347740, US6394352,

US6443360, US6629639, US6742710, US7161685, US8740079, US9104928, US9355292

Page 7

vii

SAFETY AND COMPLIANCE NOTICES

CAUTION: Subzero model scanners must not be opened in an uncontrolled

environment.

LASER SAFETY

The following information is provided to comply with the rules imposed by international

authorities and refers to the correct use of the DS5100 scanner.

Standard Regulations

This scanner utilizes a low-power laser diode. Although staring directly at the laser beam

momentarily causes no known biological damage, avoid staring at the beam as one would

with any very strong light source, such as the sun. Avoid that the laser beam hits the eye of

an observer, even through reflective surfaces such as mirrors, etc.

This product conforms to the applicable requirements of IEC 60825-1 and complies with 21

CFR 1040.10 except for deviations pursuant to Laser Notice N° 50, date June 24, 2007. The

scanner is classified as a Class 2 laser product according to IEC 60825-1 regulations.

There is a safety device, which allows the laser to be switched on only if the motor is rotating

above the threshold for its correct scanning speed.

The laser beam can be switched off through a software command (see also the Genius Help

On Line).

WARNING: Use of controls or adjustments or performance of procedures

other than those specified herein may result in exposure to hazardous visible

laser light.

The laser light is visible to the human eye and is emitted from the window on the front of the

scanner (Figure A, 4).

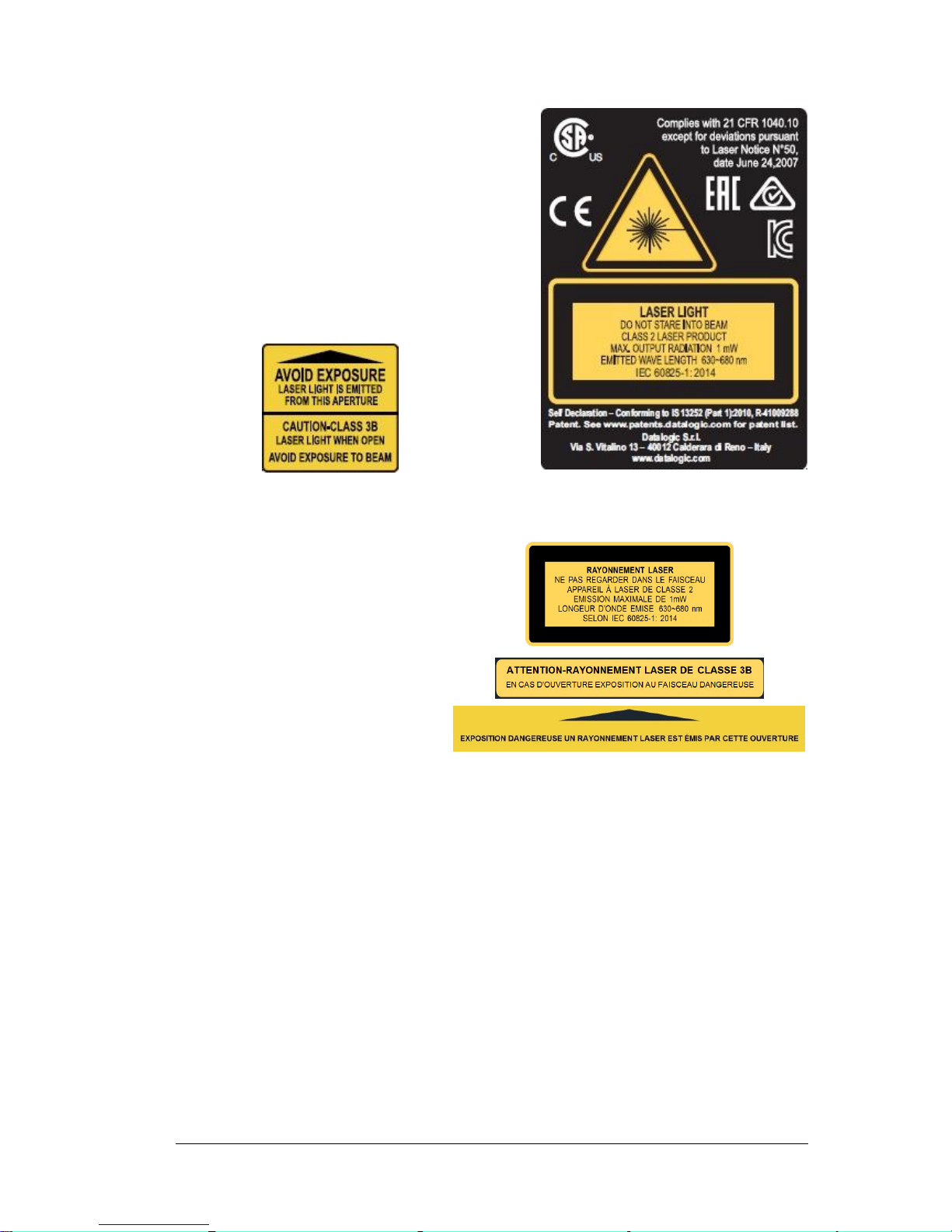

Warning labels indicating exposure to laser light and the device classification are applied

onto the body of the scanner.

Page 8

viii

Disconnect the power supply when opening the

device during maintenance or installation to avoid

exposure to hazardous laser light.

The laser diode used in this device is classified as a

class 3B laser product according to EN 60825-1

regulations and as a Class IIIb laser product

according to CDRH regulations.

Any violation of the optic parts in particular can

cause radiation up to the maximum level of the laser

diode (60 mW at 630 to 680 nm).

Warning and Device Class Labels

Produit(s) conforme selon 21CFR

1040.10 sauf des dérogations relatives

à la Laser Notice N° 50, date Juin 24,

2007.

Dans le paquet il y a l’étiquette(s) pour

les pays où le texte d'avertissement en

français sont obligatoires. Le(s) mettre

sur le produit à la place de la version

anglaise.

Exemple d'étiquettes d'avertissement laser

POWER SUPPLY

This product is intended to be installed by Qualified Personnel only.

This product is intended to be connected to a UL Listed or CSA Certified Power Unit marked

LPS or “Class 2”.

Page 9

ix

FCC COMPLIANCE

Modifications or changes to this equipment without the expressed written approval of

Datalogic could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference which may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

CE COMPLIANCE

CE marking states the compliance of the product with essential requirements listed in the

applicable European directive. Since the directives and applicable standards are subject to

continuous updates, and since Datalogic promptly adopts these updates, therefore the EU

declaration of conformity is a living document. The EU declaration of conformity is available

for competent authorities and customers through Datalogic commercial reference contacts.

Since April 20th, 2016 the main European directives applicable to Datalogic products require

inclusion of an adequate analysis and assessment of the risk(s). This evaluation was carried

out in relation to the applicable points of the standards listed in the Declaration of Conformity.

Datalogic products are mainly designed for integration purposes into more complex systems.

For this reason it is under the responsibility of the system integrator to do a new risk

assessment regarding the final installation.

Warning

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

EAC COMPLIANCE

Customs Union:

The CU Conformity certification has been achieved; this allows the Product to bear the

Eurasian mark of conformity.

BUREAU OF INDIAN STANDARD (BIS)

Self Declaration – Conforming to IS 13252 (Part 1):2010, R-41009288.

Page 10

x

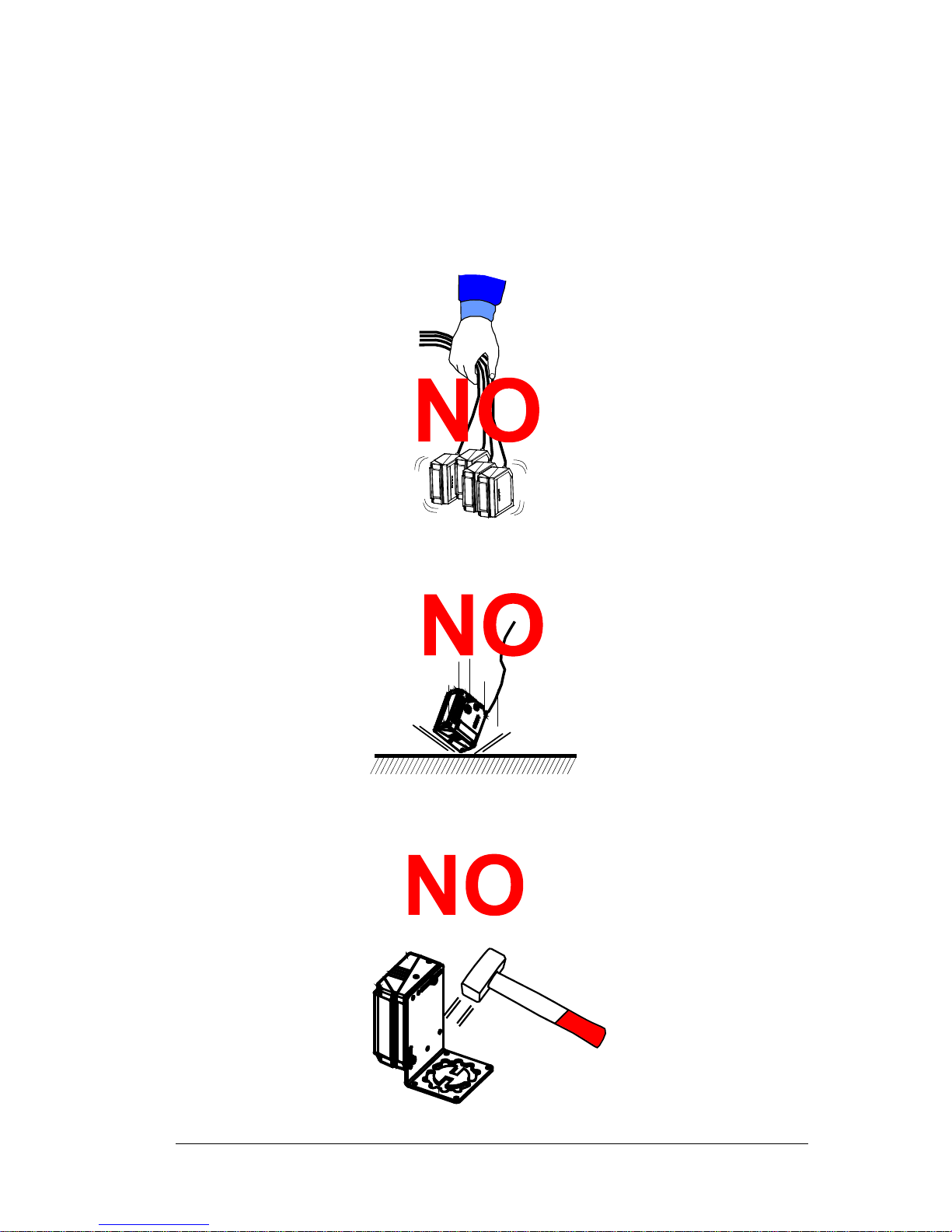

HANDLING

The DS5100 is designed to be used in an industrial environment and is built to withstand

vibration and shock when correctly installed, however it is also a precision product and

therefore before and during installation it must be handled correctly to avoid damage.

avoid that the scanners hit one another causing damage. They should be handled

separately.

avoid that the scanners are dropped (exceeding shock limits).

do not fine tune the positioning by striking the scanner or bracket.

Page 11

xi

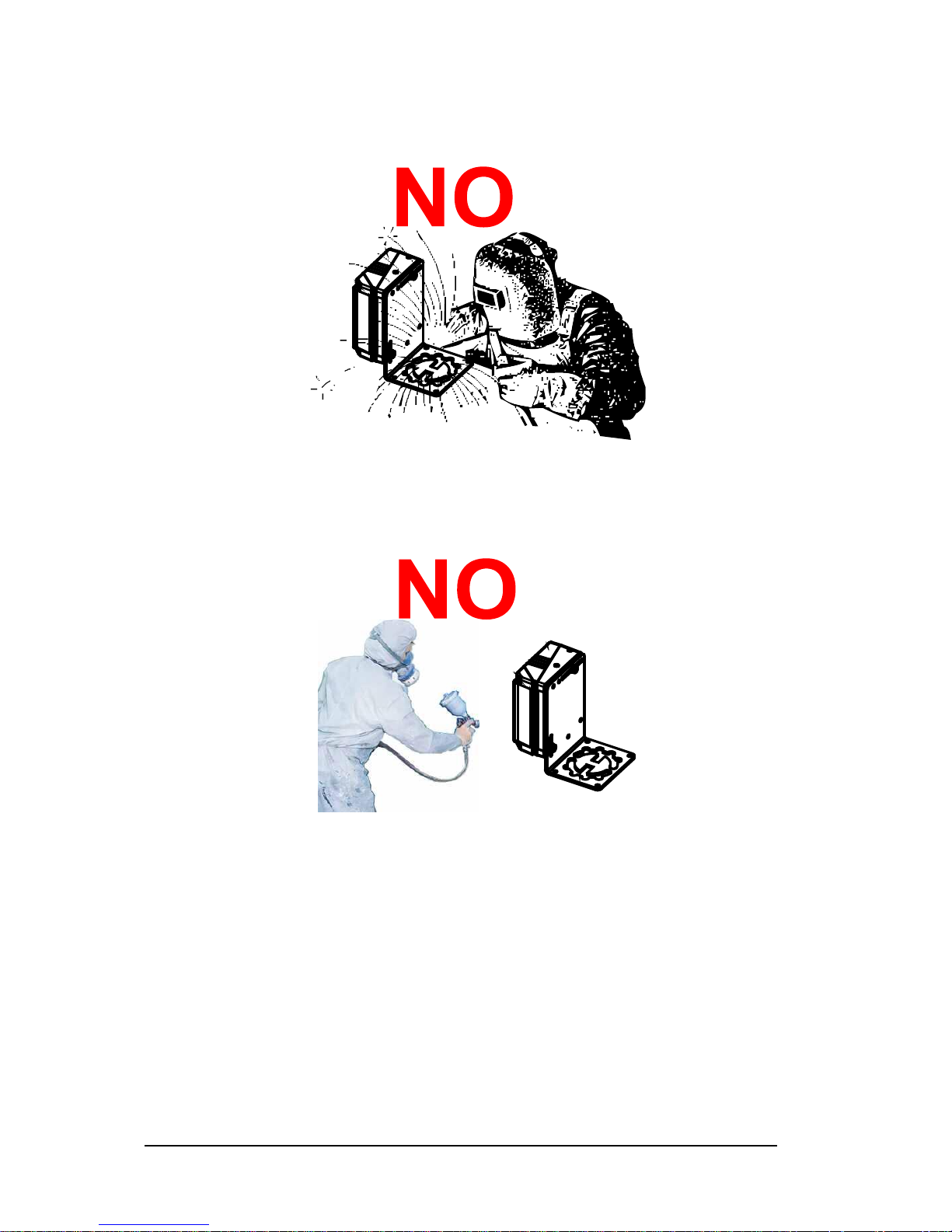

do not weld the scanner into position which can cause electrostatic, heat or output

window damage.

do not spray paint near the scanner which can cause output window damage.

Page 12

xii

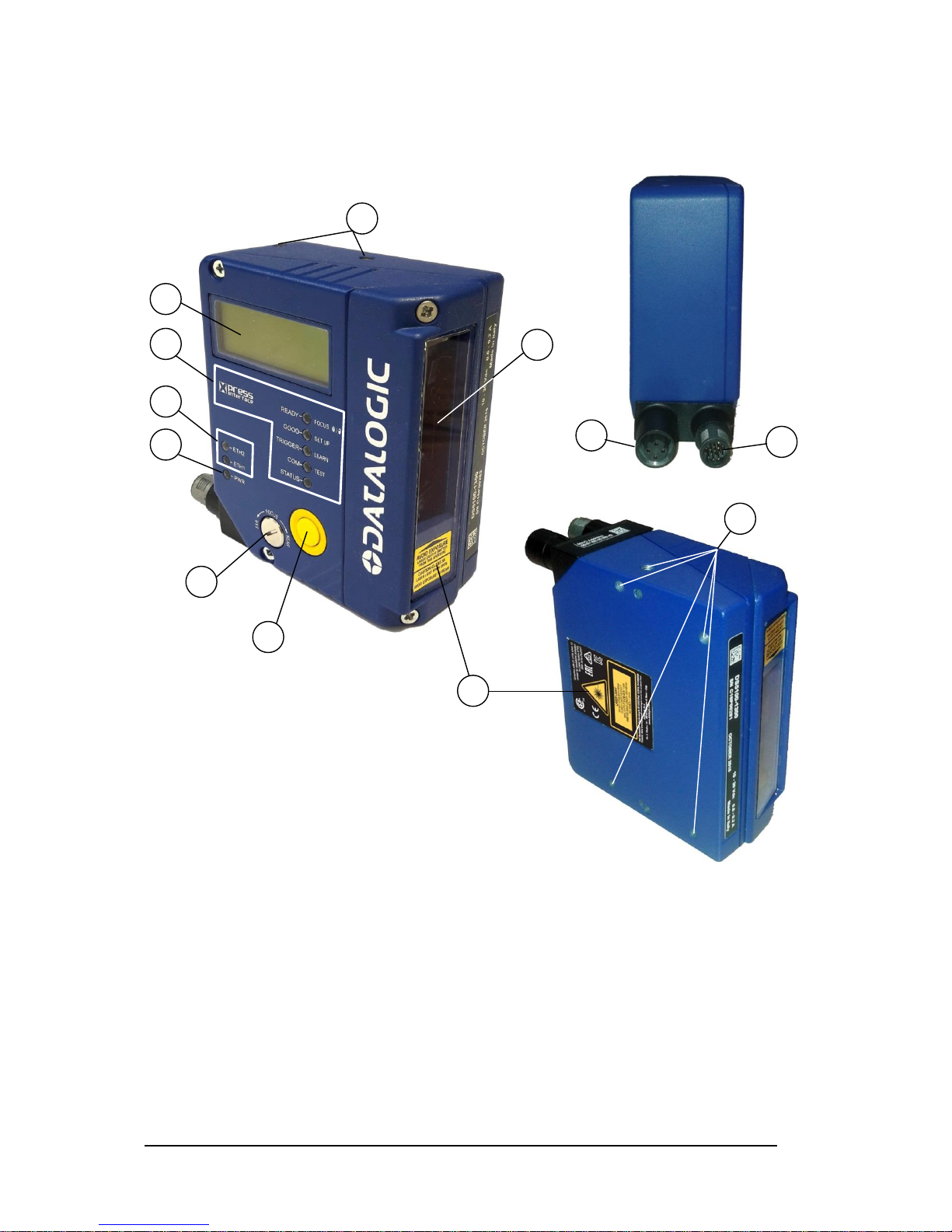

GENERAL VIEW

DS5100-X200

Serial Models

Figure A

1

Warning and Device Class Labels

7

Indicator LEDs

2

Power – Serial Interfaces – I/O Cable

8

Network LEDs

with 25-pin D-sub connector

9

Power On LED

4

Laser Beam Output Window

10

Focus Adjustment Screw

5

Mounting Holes (7)

11

X-PRESS™ Push Button

6

Display

10

11

2

4

7

9 8 6

5

1

5

Page 13

xiii

DS5100-X300

Built-in Ethernet Models

Figure B

1

Warning and Device Class Labels

7

Indicator LEDs

2

Power – Serial Interfaces – I/O Connector

8

Network LEDs

3

Ethernet Connector

9

Power On LED

4

Laser Beam Output Window

10

Focus Adjustment Screw

5

Mounting Holes (7)

11

X-PRESS™ Push Button

6

Display

Connector block rotates to 90° position.

9

6

10

11

8

2 4 5

7

1

3

5

Page 14

xiv

DS5100-X400

Profinet-IO Models

Figure C

1

Warning and Device Class Labels

7

Indicator LEDs

2

Power – Trigger Input Connector

8

Network LEDs

3

Profinet-IO – EBC Network Connectors

9

Power On LED

4

Laser Beam Output Window

10

Focus Adjustment Screw

5

Mounting Holes (7)

11

X-PRESS™ Push Button

6

Display

Connector block rotates to 90° position.

2

4

11

1

3

6

7 8 9

10

5

Page 15

xv

DS5100-XX20

OM Models

Figure D

1

Warning and Device Class Labels

7

Indicator LEDs

2

Power – Serial Interfaces – I/O Cable

8

Network LEDs

with 25-pin D-sub connector

9

Power On LED

4

Laser Beam Output Window

10

Focus Adjustment Screw

5

Mounting Holes (7)

11

X-PRESS™ Push Button

6

Display

4

1

6

7

8

9

11

10

2

5

Page 16

xvi

DS5100-XX05

Subzero™ Models

Figure E

1

Warning and Device Class Labels

7

Indicator LEDs

2

Power – Serial Interfaces – I/O Connector

8

Network LEDs

3

Ethernet Connector

9

Power On LED

4

Laser Beam Output Window w/ heater

10

Focus Adjustment Screw

5

Mounting Holes (7)

11

X-PRESS™ Push Button

6

Display

12

Subzero™ Logo

Connector block rotates to 90° position.

9

10

11

12

2

4

5

7

3

5

6

1

8

Page 17

RAPID CONFIGURATION

1

1

1 RAPID CONFIGURATION

NOTE: This chapter illustrates a Stand Alone application. For other types of

installations, such as ID-NET, Fieldbus, Pass-Through layouts, etc., refer to

chapters 4, and 5. For complete scanner configuration using the Genius

configuration program, refer to the Context-Sensitive Help On-Line.

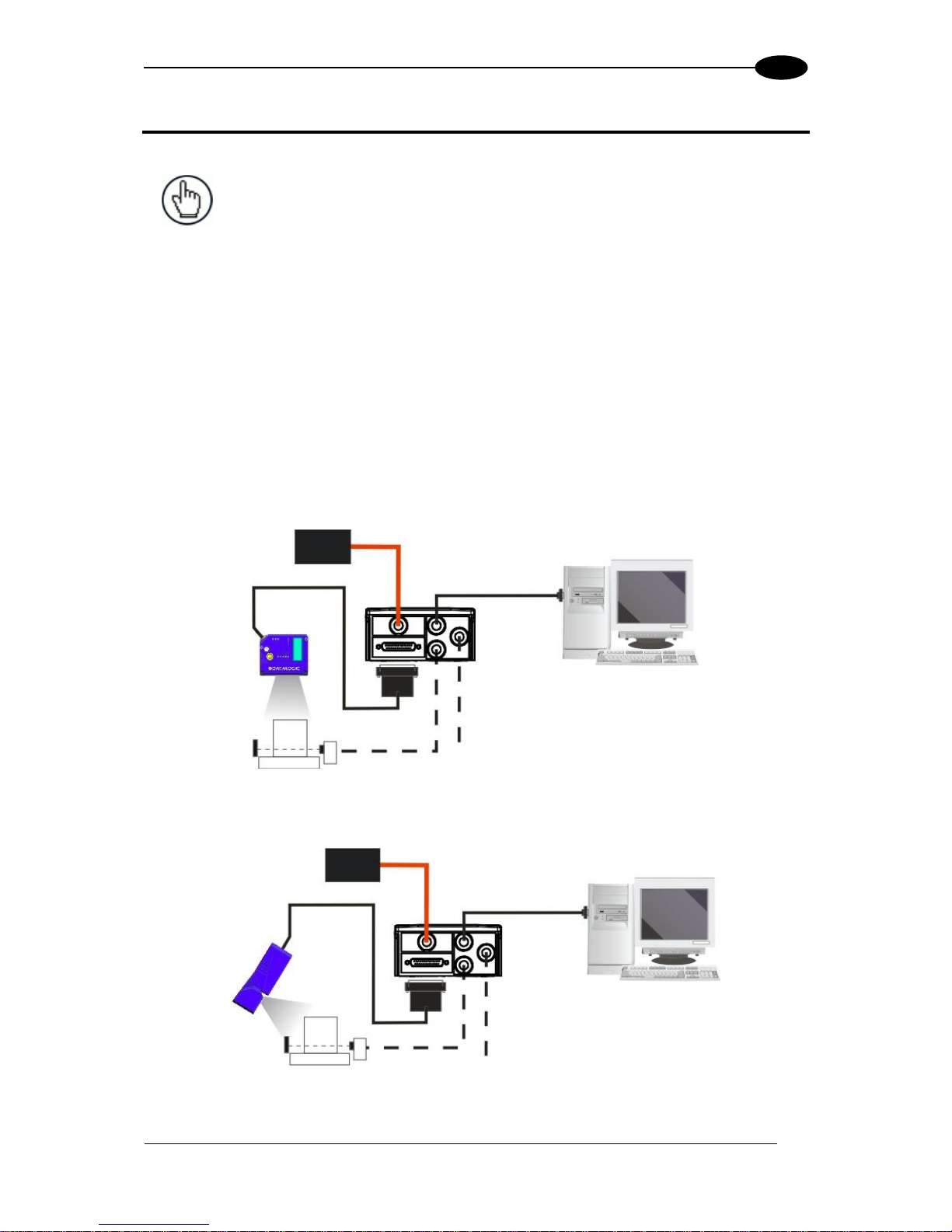

STEP 1 – CONNECT THE SYSTEM

To connect the system in a Stand Alone configuration, you need the hardware indicated in

Figure 1.

In this layout the data is transmitted to the Host on the main serial interface.

In Local Echo communication mode, the RS232 auxiliary interface can be used to transmit

data independently from the main interface selection.

When On-Line Operating mode is used, the scanner is activated by an External Trigger

(photoelectric sensor) when the object enters its reading zone.

Figure 1 – Scanner Connected to a Serial Host in a Stand Alone Layout

Figure 2 – OM Model Scanner Connected to a Serial Host in a Stand Alone Layout

DS5100

Host

PG 6000

P.S.*

* Presence Sensor

(for On-Line mode)

CBX100/500

I/O, AUX

MAIN

DS5100 OM

Host

PG 6000

P.S.*

* Presence Sensor

(for On-Line mode)

CBX100/500

I/O, AUX

MAIN

Page 18

DS5100 REFERENCE MANUAL

2

1

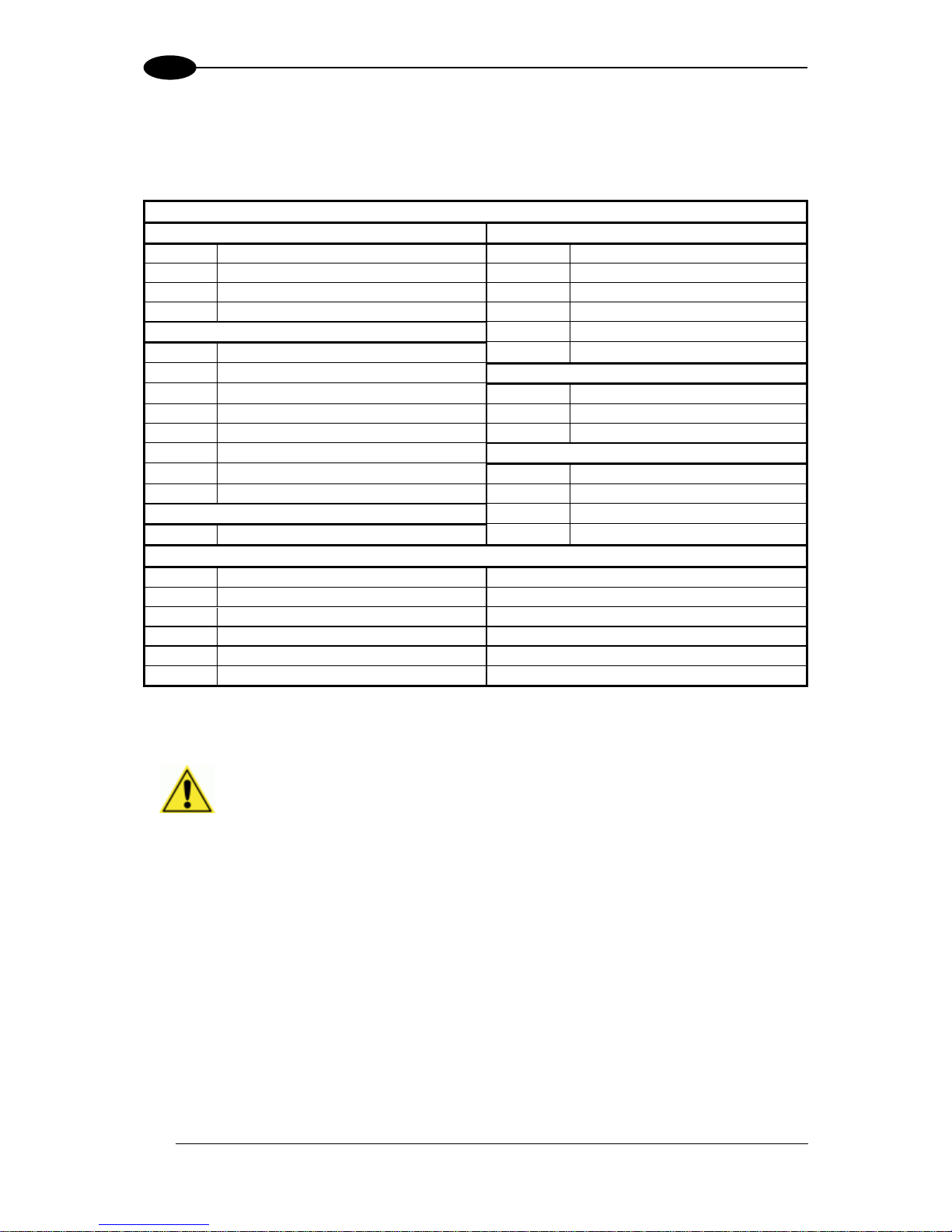

CBX100/500 Pinout for DS5100

The table below gives the pinout of the CBX100/500 terminal block connectors. Use this

pinout when the DS5100 reader is connected by means of the CBX100/500:

CBX100/500 Terminal Block Connectors

Input Power

Outputs

Vdc

Power Supply Input Voltage +

+V

Power Source - Outputs

GND

Power Supply Input Voltage -

-V

Power Reference - Outputs

Earth

Protection Earth Ground

O1+

Output 1 +

O1-

Output 1 -

Inputs

O2+

Output 2 +

+V

Power Source – External Trigger

O2-

Output 2 -

I1A

External Trigger A (polarity insensitive)

Auxiliary Interface

I1B

External Trigger B (polarity insensitive)

TX

Auxiliary Interface TX

-V

Power Reference – External Trigger

RX

Auxiliary Interface RX

+V

Power Source – Inputs

SGND

Auxiliary Interface Reference

I2A

Input 2 A (polarity insensitive)

ID-NET

I2B

Input 2 B (polarity insensitive)

REF

Network Reference

-V

Power Reference – Inputs

ID+

ID-NET network +

Shield

ID-

ID-NET network -

Shield

Network Cable Shield

Main Interface

RS232

RS485 Full-Duplex

TX

TX+

RTS

TX-

RX

*RX+

CTS

*RX-

SGND

SGND

* Do not leave floating, see par. 4.2.2 for connection details.

CAUTION: Do not connect GND, SGND and REF to different (external)

ground references. GND, SGND and REF are internally connected through

filtering circuitry which can be permanently damaged if subjected to voltage

drops over 0.8 Vdc.

Page 19

RAPID CONFIGURATION

3

1

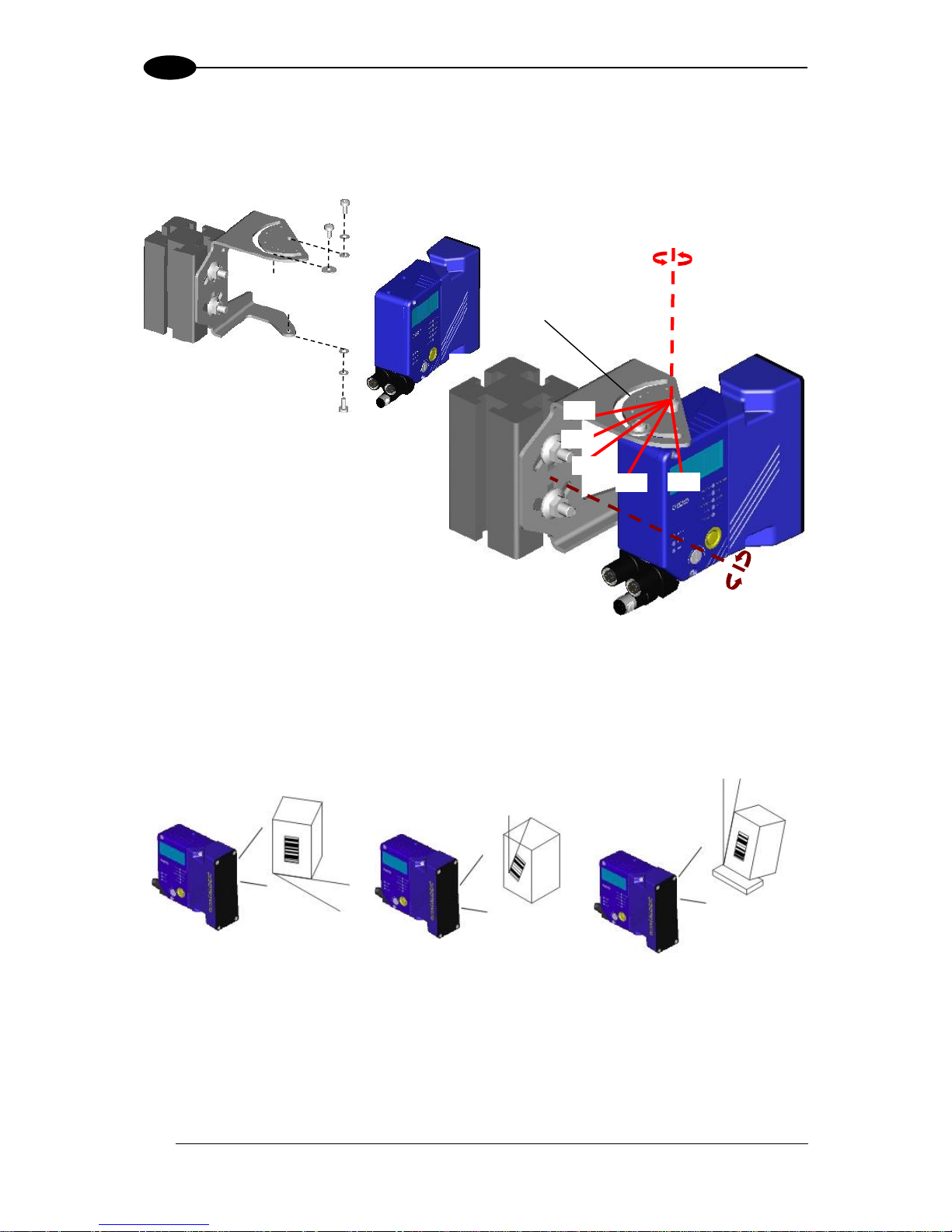

STEP 2 – MOUNT AND POSITION THE SCANNER

DS5100 Standard and Subzero Models

1. To mount the scanner, use the mounting bracket to obtain the most suitable position for

the reader as shown in the figures below.

Figure 3 - Positioning with Mounting Bracket

2. When mounting the scanner take into consideration these three ideal label position angles:

Skew 15° to 30°, Tilt 0° and Pitch 0°.

Assure at least 15° Minimize Minimize

Figure 4 –Skew, Tilt and Pitch Angles

3. Refer to the Reading Diagrams in par. 6.4 to decide the distance your scanner should be

positioned at.

Skew

-45° -15° 0° 15° 45°

Pitch

S

T

P

Page 20

DS5100 REFERENCE MANUAL

4

1

DS5100 OM Models

1. To mount the DS5100 OM, use the mounting bracket to obtain the most suitable position

for the reader as shown in the figures below.

Figure 5 - Positioning with Mounting Bracket

2. When mounting the DS5100 OM take into consideration these three ideal label position

angles: Skew 15° to 30°, Tilt 0° and Pitch 0°. The Skew angle refers to the most inclined

or external raster line, so that all other raster lines assure more than 15° Skew.

Assure at least 15° Minimize Minimize

Figure 6 –Skew, Tilt and Pitch Angles

3. Refer to the Reading Diagrams in par. 6.4 to decide the distance your scanner should be

positioned at.

S

T

P

Tilt

alignment marks

Skew

0°

45°

-45°

-15°

15°

Page 21

RAPID CONFIGURATION

5

1

STEP 3 – FOCUS THE SCANNER

The reading distance depends on the focus distance of the scanner and should be set

according to the application requirements. The Focus Position is set directly through the

focus adjustment screw on the front panel of the scanner. This screw moves the internal lens

of the scanner to change the focal point of the scanner. The setting is continuous but should

not be set beyond the limits "Too Far" or "Too Near" which appear on the display at the

extremes of the focus range. Although the scanner reads across the entire focus range, there

are three guaranteed positions which correspond to the reading diagrams in par. 6.4.

1. Power up the scanner. For Subzero models, At -35 °C, a 20-

minute warm-up period is required before the scanner is

ready to read barcodes, the Ready LED blinks. Wait for the

power up sequence to finish. By default the scanner focus is in

the Unlocked position. The alternating message on the display

shows the mechanical Focus Position as well as the message

“Please Lock Focus!” on the scanner display.

2. Using a screwdriver turn the focus adjustment screw in the

desired direction, clockwise (focus nearer to the scanner) or

counterclockwise (focus farther from the scanner). The focus

position in centimeters and inches is shown on the scanner

display.

NOTE: After correctly focusing the scanner, it is strongly recommended to store

the value of the Focus Position in memory (Locked Position parameter). When

Locked, if the mechanical position changes by more than the allowed tolerance

of the value in memory, a diagnostic alarm will be sent to the display. See the

Focus Lock function in step 4, X-PRESS Configuration.

As an additional visual aid during focusing, the indicator LEDs show the relative focus

position as follows:

Model

1xxx less than 30 cm

30 cm NEAR

32-38 cm

40 cm MEDIUM

2xxx

less than 45 cm

45 cm NEAR

47-63 cm

65 cm MEDIUM

Model

1xxx

42-58 cm

60 cm FAR

more than 60 cm

2xxx

67-73 cm

75 cm FAR

more than 75 cm

Page 22

DS5100 REFERENCE MANUAL

6

1

STEP 4 – X-PRESS CONFIGURATION

X-PRESS is the intuitive Human Machine Interface designed to improve ease of installation

and maintenance.

Status and diagnostic information are clearly presented by means of the colored LEDs,

whereas the single push button gives immediate access to the following relevant functions:

AutoSetup to self-optimize and auto-configure reading

performance in demanding applications

AutoLearn to self-detect and auto-configure for

reading unknown barcodes (by type and length)

Focus Lock to memorize the mechanical focus

position

Test Mode with bar graph visualization to check static

reading performance

EBC/Profinet-IO network selection to set the scanner

as a Slave in an EBC network. (only for on-board

Profinet 2 port models).

NOTE: When entering the X-PRESS interface on the DS5100-xx2x the

Oscillating Mirror remains in the default fixed position (0°) in order to make

barcode reading easier while performing the X-PRESS functions.

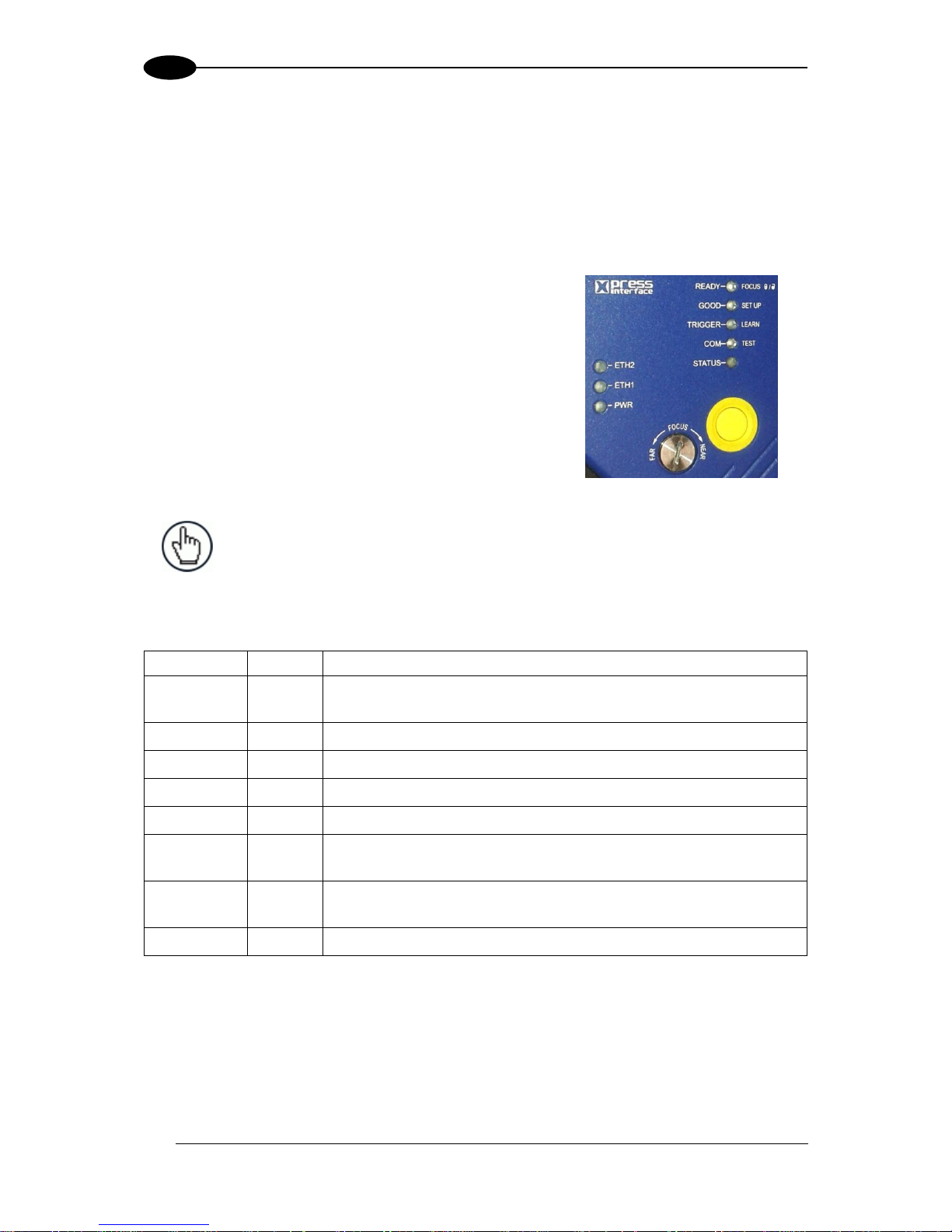

The colors and meaning of the indicator LEDs are illustrated in the following table:

LED

Color

Description

READY

Green

Indicates the device is ready to operate. For Subzero models this

LED blinks during the warm-up phase.

GOOD

Green

Confirms successful reading.

TRIGGER

Yellow

Indicates the status of the reading phase. *

COM

Yellow

Indicates active communication on main serial port. **

STATUS

Red

Indicates a NO READ result.

ETH2

Yellow

Indicates connection to the on-board Profinet-IO network port 2.

Not used on other models.

ETH1

Yellow

Indicates connection to the on-board Ethernet or on-board

Profinet-IO network port 1. Not used on Serial models.

PWR

Blue

Indicates that the reader is connected to the power supply.

* In On-Line mode the TRIGGER LED corresponds to the active reading phase signaled by the Presence Sensor.

In Automatic and Continuous modes the TRIGGER LED is always on indicating that the reader is ready to read a

code.

** When connected to a Fieldbus network through a Host Interface Module inside the CBX500 or through a QLM,

the COM LED is always active, even in the absence of data transmission, because of polling activity on the

Fieldbus network.

During the reader startup (reset or restart phase), the first five LEDs blink for one second.

Page 23

RAPID CONFIGURATION

7

1

Auto Learn

If you are configuring your scanner using X-PRESS, you must start with the Auto Learn

procedure.

1. Enter the Auto Learn function by holding the X-PRESS push button pressed until the

LEARN LED is on.

2. Release the button to enter the Auto Learn function.

Once entered, the reader starts a procedure to automatically detect and recognize

barcodes (by type and length), which are presented to it (*). The laser turns on and the

LEARN LED blinks to indicate the ongoing process.

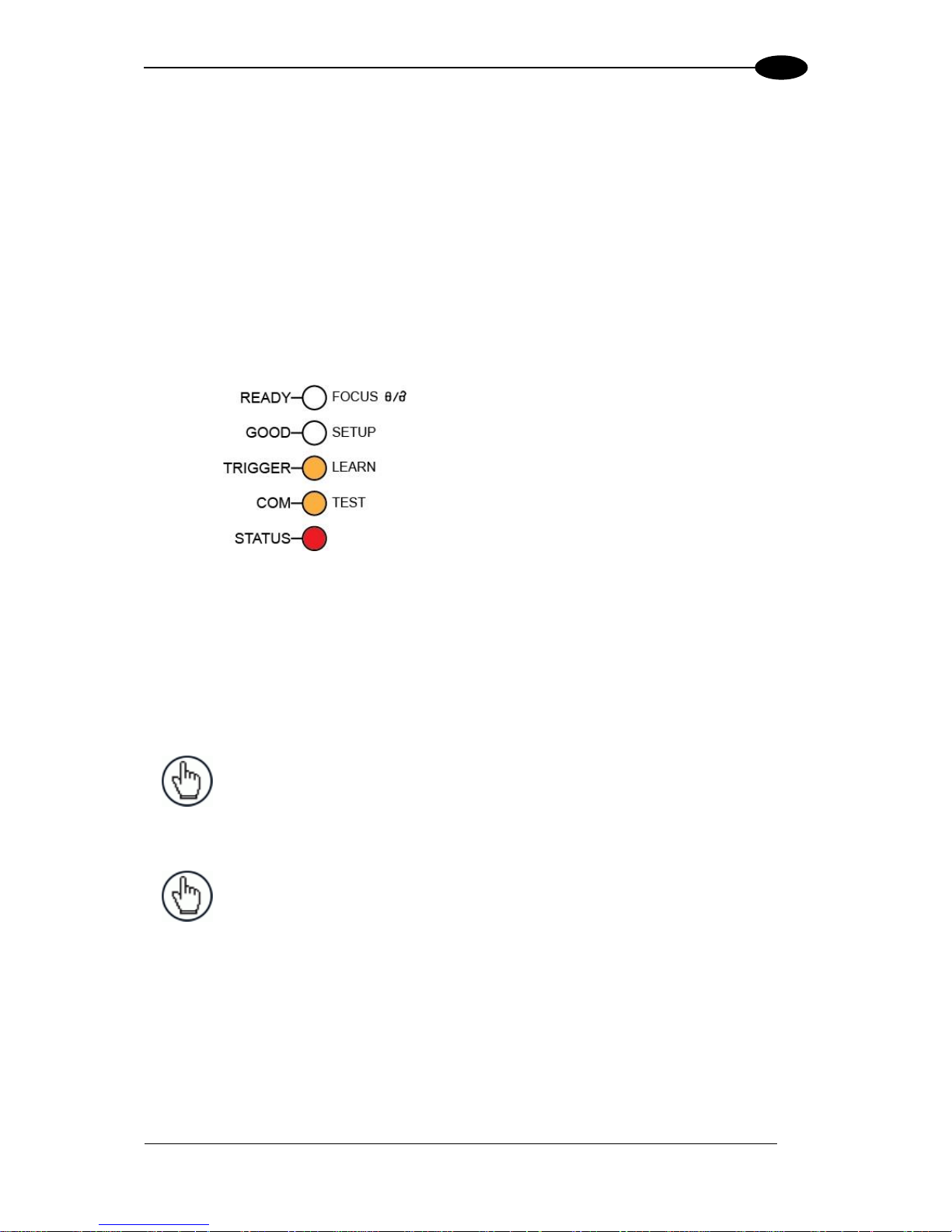

Figure 7 – X-PRESS Interface: Auto Learn Function

The procedure is as follows:

A) place the desired barcode on the

scanline.

B) wait until the LEARN LED stays

steady on (indicating the reader

has detected the barcode).

C) repeat, if needed, the above two

steps to program up to 10 different

barcodes (the LEARN LED returns

to the blinking state for the next

code). If more than one barcode is

detected in the scan line, the Multi

Label mode is enabled (refer to the

“5K Family Software Configuration

Parameter Guide” Help file).

3. Exit the process by pressing the X-PRESS push button once. The scanner will restart at

the end of the process, and then the detected barcodes are automatically configured in

scanner memory.

NOTE: If the barcode cannot be read because of low contrast or excessive

ambient light, you can perform the AutoSetup function to optimize the optical

parameters. Then you can perform AutoLearn to recognize the barcode

symbology.

NOTE: On exit from Autolearn, the following parameters are forced: Code

Combination = Single Label, Reading Mode = Linear. If necessary, these

parameters can be changed through Genius.

* In case of Programming Barcodes, refer to the “Setup Procedure Using Programming Barcodes” document in

the downloadable Genius mini-DVD zip file.

Page 24

DS5100 REFERENCE MANUAL

8

1

Auto Setup (Optional)

At the end of the Auto Learn procedure, you have the possibility to follow the Auto Setup

procedure to set up the reading parameters.

1. Enter the Auto Setup function by holding the X-PRESS push button pressed until the

SETUP LED is on.

2. Release the button to enter the Auto Setup function.

3. Once entered, if a barcode label is positioned in front of the scanline, the scanner

automatically performs the optimal setup of the reading parameters for that specific

barcode.

Figure 8 – X-PRESS Interface: Auto Setup Function

The procedure is as follows:

A) place the desired barcode on

the scanline.

B) enter the AutoSetup function

(the laser turns on and the

SETUP LED blinks to indicate

the ongoing process)

C) wait until the SETUP LED

stays steady on (indicating the

reader has detected the

barcode)

This procedure ends either when the barcode is successfully decoded or after a timeout of

about 7 (seven) seconds.

The scanner will restart at the end of the process, and then the optimized reading

parameters for that barcode are automatically configured in scanner memory.

Page 25

RAPID CONFIGURATION

9

1

Focus Lock/Unlock

You must perform the Focus Lock procedure to save the mechanical focus position to

memory. When Locked, if the mechanical focus position is changed by more than the

allowed tolerance of the value in memory, a diagnostic alarm will be sent to the display. See

par. 2.3.1 for details.

NOTE: For Stand Alone or Master devices, the diagnostic alarm can also be

sent to any of the desired communication channels by selecting it in the

Diagnostic>Actions branch of the Genius configuration tool.

1. Enter the Focus Lock function by holding the X-PRESS push button pressed until the

FOCUS LOCK LED is on.

2. Release the button to enter the Focus Lock function.

Once entered, the scanner automatically performs the Lock (saving) or Unlock procedure

depending on the previous state of the Locked Position parameter.

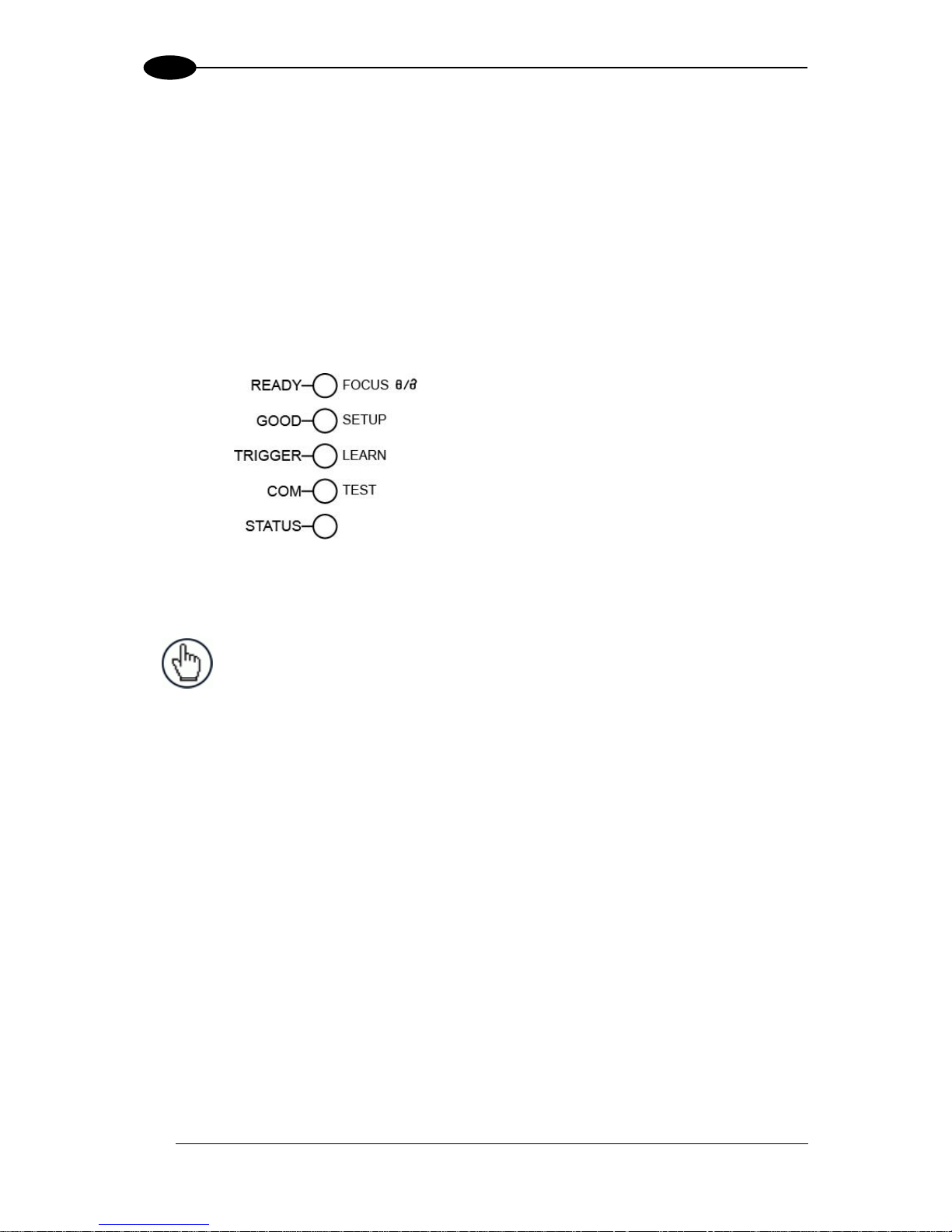

Figure 9 – X-PRESS Interface: Focus Lock/Unlock

Function

The procedure is as follows:

A) enter the Focus Lock function

B) wait until the "Focus locked at..."

message appears on the display

(indicating the focus position has

been saved to memory). The

following parameters are set:

Locked Position = your mechanical

setting

Focus Displacement (Alarm) = set

(default to display only)

The scanner will be reset at the end of the process. The LEDs turn off, the Display goes

blank and then the Ready LED will turn on indicating the scanner is ready.

NOTE: If your application has been configured using X-PRESS, go to

STEP 6.

Page 26

DS5100 REFERENCE MANUAL

10

1

EBC/Profinet-IO Network Selection (only on Profinet-IO dual port models)

For on-board Profinet 2 port models, the DS5100 scanner can be configured to work as a

Slave in an EBC network. The only way to make this selection is through the X-PRESS

button.

1. Enter the EBC/Profinet-IO Network Selection function by holding the X-PRESS push button

pressed until the all X-PRESS LEDs are off.

2. Release the button to enter the Network Selection function.

Once entered, the scanner automatically performs the procedure to set itself as either an

EBC slave or a Profinet-IO slave depending on the previous state of the network

selection.

Figure 10 – X-PRESS Interface: EBC/Profinet-IO Network

Selection Function

The procedure is as follows:

A) enter the Network selection function.

B) wait until the "EBC Slave" o

“Profinet-IO” message appears on

the display (indicating the scanner

has been set and saved.

The scanner will restart at the end of the process.

NOTE: To reset the scanner to its default Profinet interface settings, you can

also perform the Reset Scanner to Factory Default procedure as described in

the paragraph below.

Reset Scanner to Factory Default (Optional)

If it ever becomes necessary to reset the scanner to the factory default values, you can

perform this procedure by holding the X-PRESS push button pressed while powering up the

scanner and waiting for all the X-PRESS LEDs to blink simultaneously three times before

releasing the push button.

This procedure takes ≈ 5-6 seconds for Serial Models, ≈ 10 seconds for Ethernet Models, ≈

20 seconds for 2 port Profinet-IO models. At the end of the procedure the Configuration and

Environmental parameters are reset and the message "Default Set" is shown on the scanner

display. If connected through a CBX500 with BM150 display module, the "Default Set"

message is also shown on the CBX500 display.

Page 27

RAPID CONFIGURATION

11

1

STEP 5 – INSTALL GENIUS CONFIGURATION PROGRAM

Genius is a Datalogic scanner configuration tool providing several important advantages:

Wizard approach for new users;

Multi-language version;

Defined configuration directly stored in the reader;

Communication protocol independent from the physical interface allowing to consider

the reader as a remote object to be configured and monitored.

To install Genius, on the PC that will be used for configuration, (running Windows XP,

or 7), download the Genius mini-DVD .zip file. Extract the files to a local folder and

launch the Setup.exe file. Select Install Genius and follow the installation procedure.

This configuration procedure assumes scanner connection to a CBX100/500. Genius,

running on a laptop computer, is connected to the scanner auxiliary port through the

CBX100/500 9-pin connector. To communicate with the scanner, Genius performs an auto

baudrate detection starting from its default parameters which are 115200, 8, N, 1. These

parameters can also be set in the Genius Tools>Options>Communications window.

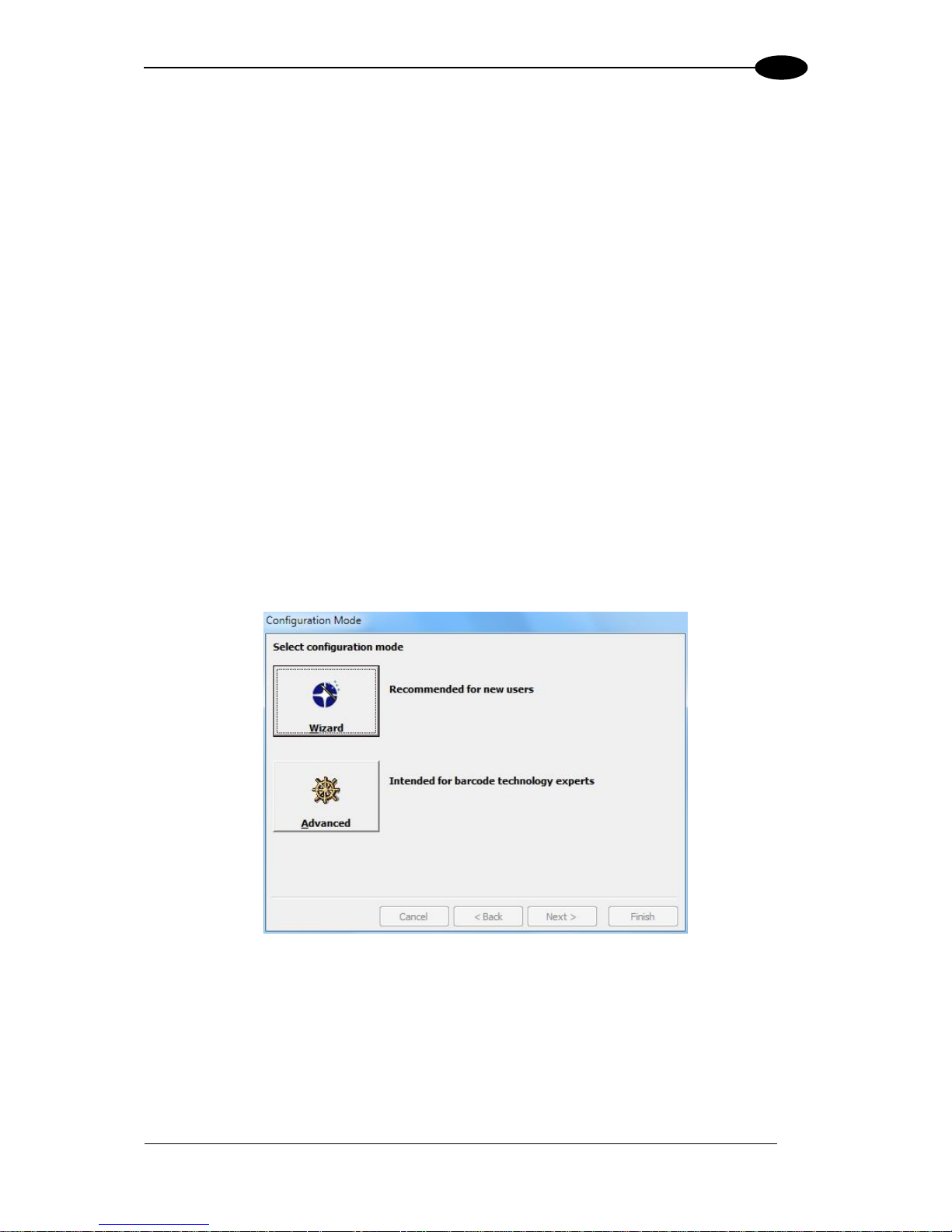

Wizard for Quick Reader Setup

After installing the Genius software program the following window appears asking the user to

choose the desired configuration level.

Figure 11 - Genius Wizard Opening Window

The Wizard option is advised for rapid configuration or for new users, since it shows a stepby-step scanner configuration.

Page 28

DS5100 REFERENCE MANUAL

12

1

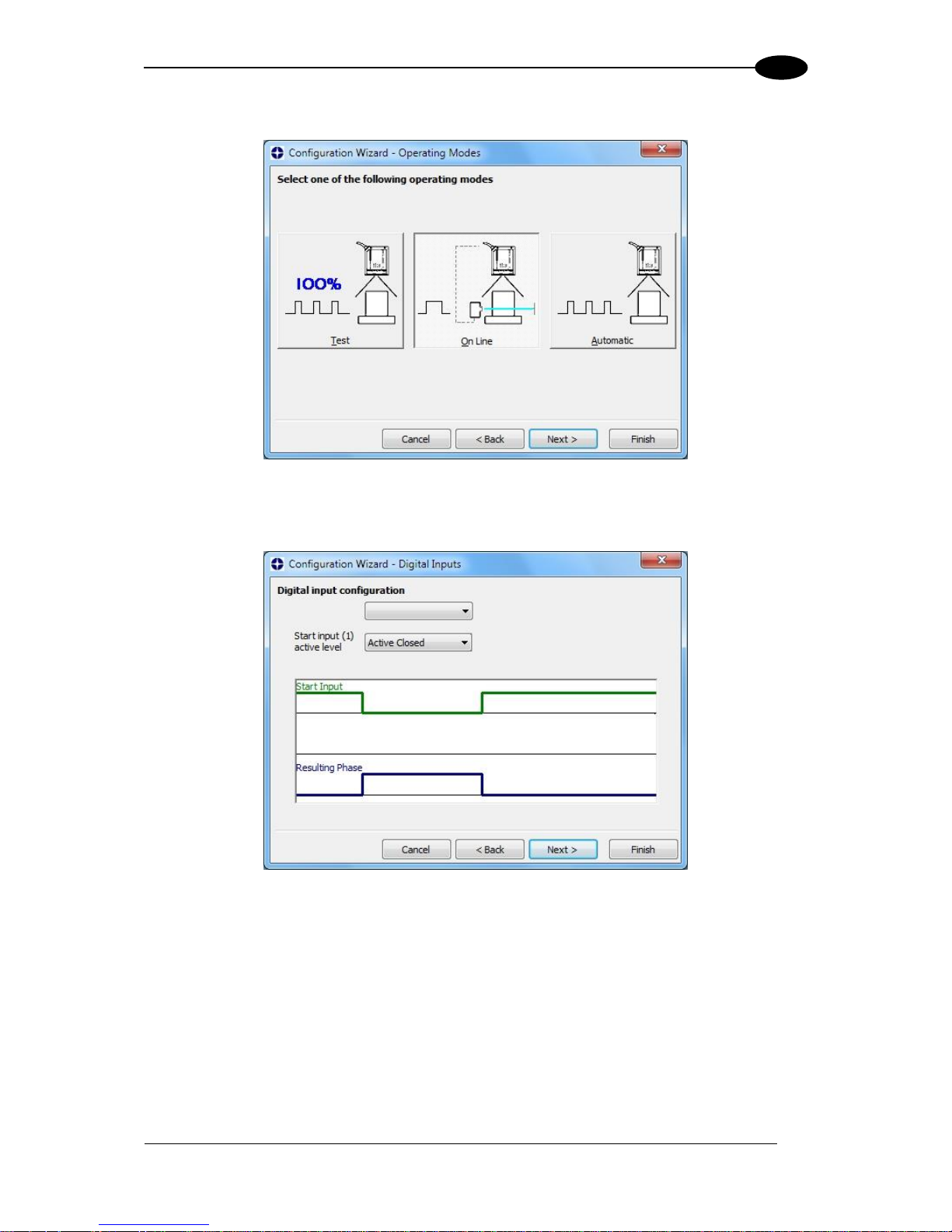

1. Select the Create a new configuration button.

You will be guided through the configuration being asked to define the following

parameters:

a. Barcode selection and definition

Page 29

RAPID CONFIGURATION

13

1

b. Operating mode selection and definition

a. Digital Inputs configuration

Page 30

DS5100 REFERENCE MANUAL

14

1

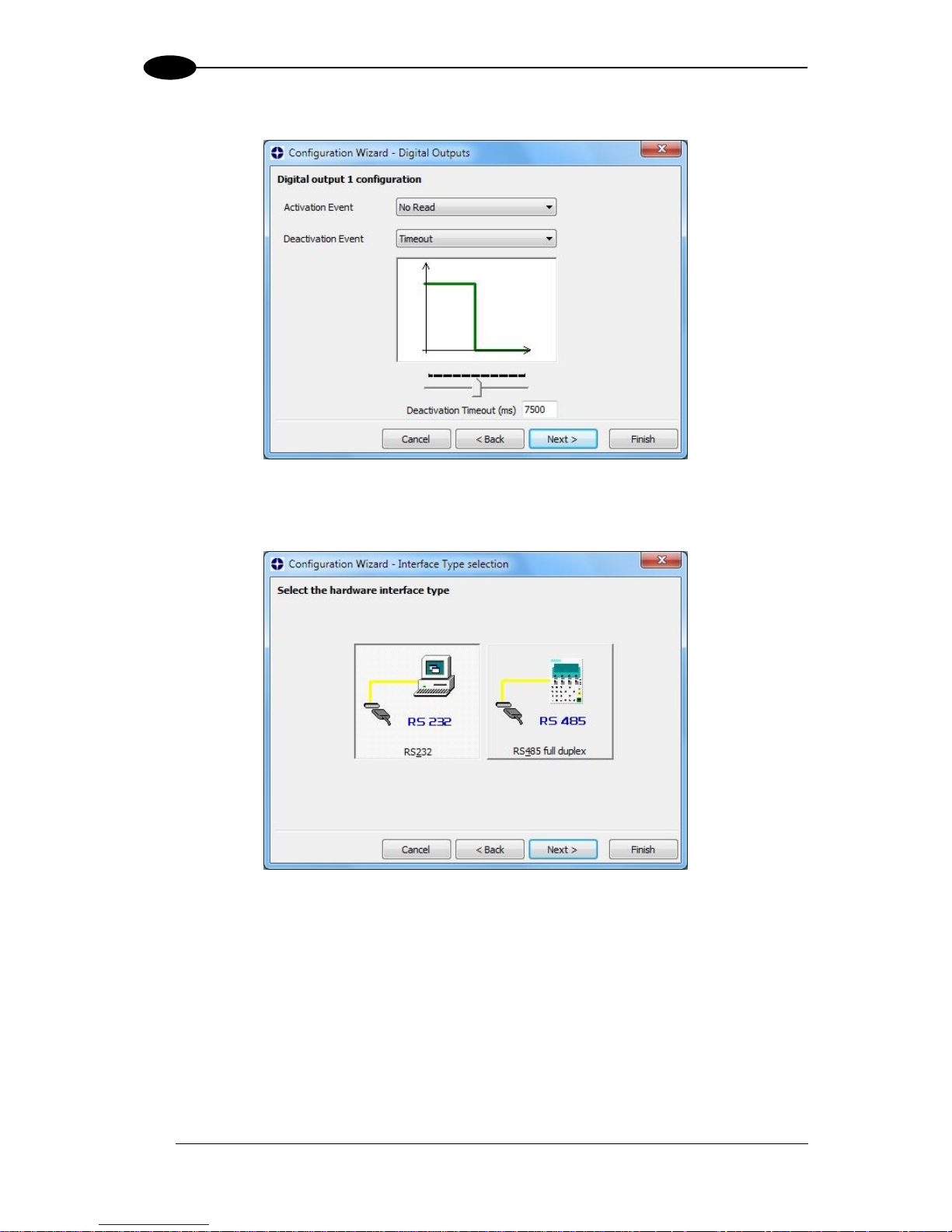

b. Digital Outputs configuration

c. Hardware interface selection

Page 31

RAPID CONFIGURATION

15

1

d. Output data format configuration

The On Line operating Mode requires the reader to be connected to an External

Trigger/Presence Sensor using I1A and I1B inputs.

The Automatic operating mode does not require connection to an external Presence

Sensor. When working in this mode the reader is continuously scanning, while the

reading phase is activated each time a barcode enters the reader reading zone. The

reader stops reading after an N number of scans without a code. Barcode characters

are transmitted on the serial interface. In case of a failed reading phase no message is

sent to the host computer.

Page 32

DS5100 REFERENCE MANUAL

16

1

2. After defining the parameter values the following window appears allowing to complete

the reader configuration as follows:

Saving the configuration to disk;

Switching to Advanced mode;

Sending the configuration to the scanner.

3. After sending the configuration to the

scanner you have completed the

configuration process.

4. By clicking Finish, the System

Information window will be displayed

with specific information concerning the

scanner.

Page 33

RAPID CONFIGURATION

17

1

STEP 6 – TEST MODE

NOTE: When entering the X-PRESS interface on the DS5100-XX2X the

Oscillating Mirror remains in the default fixed position (0°) in order to make

barcode reading easier while performing the X-PRESS functions.

Use a code suitable to your application to test the system. Alternatively, you can use the

Datalogic Test Chart (Code 128).

1. Enter the Test mode function by holding the X-PRESS push button pressed until the

TEST LED is on.

2. Release the button to enter the Test mode function.

Once entered, the Bar-Graph on the five LEDs is activated and if the scanner starts

reading barcodes the Bar-Graph shows the Good Read Rate. In case of no read

condition, only the STATUS LED is on and blinks.

Figure 12 – X-PRESS Interface: Test Mode Function

3. To exit the Test Mode, press the X-PRESS push button once.

NOTE: By default, the Test Mode exits automatically after two minutes.

Page 34

DS5100 REFERENCE MANUAL

18

1

ADVANCED SCANNER CONFIGURATION

The ADVANCED configuration mode (instead of the Wizard) is available when starting the

Genius program and is addressed to expert users being able to complete a detailed scanner

configuration. By choosing this option it is possible either to start a new scanner configuration

or to open and modify an old one. The desired parameters can be defined in the following

window, similar to the MS Explorer:

Figure 13 - Genius Parameter Explorer Window

Host Mode Programming

The scanner can also be configured from a host computer using the Host Mode

programming procedure, by commands via the serial interface. See the Host Mode

Programming manual on the downloadable Genius mini-DVD zip file.

Alternative Layouts

The ID-NET network is a built-in high-speed interface dedicated for high-speed scanner

interconnection. ID-NET is in addition to the Main and Auxiliary serial interfaces. If you

need to install an ID-NET network refer to chapters 4 and 5 of this Reference Manual.

The scanner can also be configured by reading programming barcodes. See the "Setup

Procedure Using Programming Barcodes" printable from the downloadable Genius miniDVD zip file.

If you need to install an Ethernet network, Fieldbus network or Pass-Through network,

refer to chapters 4 and 5 of this Reference Manual.

Page 35

INTRODUCTION

19

2

2 INTRODUCTION

2.1 PRODUCT DESCRIPTION

The DS5100 laser scanner satisfies the most advanced needs of a wide range of users. It

has been developed focusing on the realistic requirements of its target market. The

outstanding result is an extremely compact, cost-effective and easy to use industrial scanner.

Standard Application

Program

A standard application program is factory-loaded onto the

scanner. This program controls barcode reading, serial port

interfacing, data formatting and many other operating and control

parameters.

It is completely configurable from a host computer through the

Genius utility program provided on the downloadable Genius

mini-DVD zip file, or via the serial interface (Genius based Host

Mode Programming).

Custom Application

Programs

If the Standard Application Program does not meet your

requirements, please contact your local Datalogic distributor.

Some of the main features are listed below:

Medium, Long Range, Linear and Oscillating Mirror models, user selectable focus for

high application flexibility

ID-NET™ and EBC™ (Ethernet Bus Connections)

Embedded PROFINET-IO and EtherNet/IP for connectivity to main industrial Fieldbus

X-PRESS™ interface, Genius™ software tool, embedded multi-language display for easy

scanner setup and maintenance

Rotating connector block for flexible form factor and easy installation

DST™ (Digital Signal Technology)

ACR4™ reconstruction technology

PackTrack™ (only for Long Range models working in EBC)

Superior ambient light immunity from high frequency laser modulation

Top industrial grade, IP65 and Subzero™ version for low temperature environments

The scanner uses a solid-state laser diode as a light source; the light emitted has a

wavelength between 630 and 680 nm. Refer to the section “Safety Precautions” at the

beginning of this manual for information on laser safety.

The protection class of the enclosure is IP65, the reader is therefore suitable for industrial

environments where high protection against harsh external conditions is required.

Page 36

DS5100 REFERENCE MANUAL

20

2

2.1.1 Indicators

The five LEDs on the side of the scanner (Figure A, B, C, D, E, 7) indicate the following:

LED

Color

Description

READY

Green

This LED indicates the device is ready to operate. For Subzero

models this LED blinks during the warm-up phase.

GOOD

Green

This LED confirms successful reading.

TRIGGER

Yellow

This LED indicates the status of the reading phase. *

COM

Yellow

This LED indicates active communication on main serial port. **

STATUS

Red

This LED indicates a NO READ result.

* In On-Line mode the TRIGGER LED corresponds to the active reading phase signaled by the Presence Sensor.

In Automatic and Continuous modes the TRIGGER LED is always on indicating that the reader is ready to read a

code.

** When connected to a Fieldbus network through the CBX500, the COM LED is always active, even in the

absence of data transmission, because of polling activity on the Fieldbus network.

During the reader startup (reset or restart phase), all the LEDs blink for one second.

PWR (blue)

This LED indicates that the reader is connected to the power

supply.

ETH (yellow)

This LED indicates connection to the on-board Ethernet or

Profinet-IO network.

2.2 ID-NET

The ID-NET network is a built-in high-speed interface dedicated for

high-speed scanner interconnection. ID-NET is in addition to the

Main and Auxiliary serial interfaces.

The following network configurations are available:

ID-NET Synchronized: Single station – multiple scanners

ID-NET interface allows local connection of

multiple scanners reading different sides of

the same target. All scanners share a

single presence sensor and

activate/deactivate simultaneously.

At the end of each reading phase a single

data message is transmitted to the host.

Thanks to ID-NET, data communication

among scanners is highly efficient so that

an immediate result will be available.

Page 37

INTRODUCTION

21

2

ID-NET Multidata: Multiple stations – single scanner

ID-NET interface allows connection of scanners reading objects placed on independent

conveyors. All scanners are typically located far away from each other and they use a

dedicated presence sensor.

At the end of each reading phase, each scanner transmits its own data message to the host.

Thanks to ID-NET, data collection among readers is accomplished at a high speed without

the need of an external multiplexing device. This leads to an overall cost reduction and to a

simple system wiring.

Page 38

DS5100 REFERENCE MANUAL

22

2

2.2.1 How To Setup/Configure the Scanner Network

A complete ID-NET scanner network can be rapidly setup, as follows:

Mounting & Connection

1. Mechanically mount/install all the readers (refer to par. 3.2 and 3.3).

2. Wire ID-NET (refer to par. 4.3).

3. Connect the planned Master scanner to a PC by means of the Genius configuration

software.

4. Power up the entire system.

Configuration

1. Launch Genius.

2. From the Genius Device Menu select “Local Device Network Settings” and program the

Role of the Master scanner (Synchronized or Multidata).

This procedure requires the Network Baud Rate be the same for all Slaves and Master,

(500 kbs is the default value). It can be changed after network setup using Genius

through the Master scanner. See also the alternative procedure in the note below.

3. At the prompt to "Send updated Network configuration to the Local Device" (Master)

choose "Yes".

4. Then run the NET-AUTOSET procedure from the Icon in the Devices Area. Genius sets

all slave scanners according to the Master Role (Synchronized or Multidata), and assigns

each a random address. If necessary, this address can be changed through the Network

Wizard.

5. Configure the System parameters via Genius.

6. If using the CBX connection box equipped with a BM100 Backup module, perform

System Backup at the Master. See par. 2.4 of this manual or the BM100 or BM150

manuals for details.

The scanner network is ready.

NOTE: If necessary, the ID-NET baudrate can be set individually on each

Slave scanner to match the Master. Connect each Slave to Genius and set the

Reading System Layout > Network Baudrate parameter. Then follow the

procedure above.

NOTE: An alternative method of programming scanner address and role

assignment can be accomplished by using the "Connectivity Programming

Barcodes" (refer to the "Setup Procedure Using Programming Barcodes"

document on the downloadable Genius mini-DVD zip file.).

Page 39

INTRODUCTION

23

2

2.3 X-PRESS HUMAN MACHINE INTERFACE

X-PRESS is the intuitive Human Machine Interface

designed with the precise goal of improving ease of

installation and maintenance.

Status and diagnostic information are clearly presented

by means of five-colored LEDs, whereas the single

multi-function key gives immediate access to relevant

functions:

Autosetup to self-optimize reading performance in

demanding applications

Autolearn to self-detect unknown barcodes

Focus Lock to memorize the mechanical focus

position

Test Mode with bar-graph visualization to check

static reading performance

X-PRESS is the common interface adopted in all new products: “You learn one, you can use

them all”.

The colors and meaning of the five LEDs when in the one of the operating modes (On-Line,

Automatic or Continuous) are illustrated in par 2.1.1.

NOTE: Except for the Focus Lock/Unlock function, the X-PRESS functions do

not work if the motor or laser are turned off, see chp. 8 for details.

2.3.1 Diagnostic Indication

The “STATUS” and “READY” LEDs blink simultaneously to signal the presence of an alarm

or failure.

Diagnostic messages can be enabled to provide details about specific failure conditions.

These messages will be shown on the display and if enabled for transmission, also on the

selected interfaces. See par. 2.6 for details.

At the same time one or more LEDs light up according to the following scheme:

LED

STATUS

READY

BLINK

GOOD

ON to indicate any Failure different than

Motor or Laser failures.

TRIGGER

ON to indicate a Motor Failure.

COM

ON to indicate a Laser Failure.

STATUS

BLINK

Page 40

DS5100 REFERENCE MANUAL

24

2

2.3.2 X-PRESS Functions

Quick access to the following functions is provided by

an easy procedure using the push button:

1 – Press the button (the STATUS LED will give a

visual feedback).

2 – Hold the button until the specific function LED is

on (TEST, LEARN or SETUP).

3 – Release the button to enter the specific function.

Once button is pressed, the cycle of LEDs activation is as follows:

Release button to

Exit

Release button to

enter Test Mode

Release button to

enter AutoLearn

Release button to

enter AutoSetup

Release button to

enter Focus Lock/Unlock

(cycle)

Release button to

Exit

Test Mode Function

Once entered, the Bar-Graph on the five LEDs is activated and if the scanner starts reading

barcodes the Bar-Graph shows the Good Read Rate. In case of no read condition, only the

STATUS LED is on and blinks.

To exit the Test Mode, press the X-PRESS push button once.

Page 41

INTRODUCTION

25

2

AutoLearn Function

Once entered, the reader starts a procedure to automatically detect and recognize barcodes

(by type and length), which are presented to it1. The laser turns on and the LEARN LED

blinks to indicate the ongoing process.

The procedure is as follows:

- place the desired barcode on the scanline.

- wait until the LEARN LED stays steady on (indicating the reader has detected the

barcode).

- repeat, if needed, the above two steps to program up to 10 different barcodes (the LEARN

LED returns to the blinking state for the next code). If more than one barcode is detected

in the scan line, the Multi Label mode is enabled (refer to the “5K Family Software

Configuration Parameter Guide” Help file).

- exit the process by pressing the X-PRESS push button once.

The scanner will restart at the end of the process, and then the detected barcodes are

automatically configured in scanner memory.

AutoSetup Function

Once entered, if a barcode label is positioned in front of the scanline, the scanner

automatically performs the optimal setup of the reading parameters for that specific barcode.

The procedure is as follows:

- place the desired barcode on the scanline.

- enter the AutoSetup function (the laser turns on and the SETUP LED blinks to indicate

the ongoing process).

- wait until the SETUP LED stays steady on (indicating the reader has detected the

barcode).

This procedure ends either when the barcode is successfully decoded or after a timeout of

about 7 (seven) seconds.

The scanner will restart at the end of the process, and then the optimized reading

parameters for that barcode are automatically configured in scanner memory.

NOTE: The AutoSetup function does not modify the programmed barcode

symbologies. If needed, the AutoLearn function can be performed after

Autosetup.

1

In case of Programming Barcodes, refer to the “Setup Procedure Using Programming Barcodes” document on

the downloadable Genius mini-DVD zip file.

Page 42

DS5100 REFERENCE MANUAL

26

2

Focus Lock/Unlock

Once entered, the scanner automatically performs the Focus Lock procedure to save the

mechanical focus position to memory. If the mechanical focus position is changed by more

than the allowed tolerance of the value in memory, a diagnostic alarm will be sent to the

display.

The procedure is as follows:

- enter the Focus Lock function.

- wait until the "Focus locked at..." message appears on the display (indicating the focus

position has been saved to memory). The following parameters are set:

Locked Position = your mechanical setting

Focus Displacement (Alarm) = set (default to display only)

If the Focus lock has already been set, this procedure can be used to Unlock the focus value.

In this case control of the focus position is disabled.

The scanner will restart at the end of the process.

Reset Scanner to Factory Default

If it ever becomes necessary to reset the scanner to the factory default values, you can

perform this procedure by holding the X-PRESS push button pressed while powering up the

scanner and waiting for all LEDs to blink simultaneously three times before releasing the

push button.

This procedure takes ≈ 5-6 seconds for Serial Models, ≈ 10 seconds for Ethernet Models, ≈

20 seconds for Profinet-IO models. At the end of the procedure the Configuration and

Environmental parameters are reset and the message "Default Set" is shown on the scanner

display. If connected through a CBX500 with display module, the "Default Set" message is

also shown on the CBX500 display.

2.4 EXTERNAL MEMORY BACKUP & RESTORE

By selecting "External Memory Backup & Restore" from the Device menu, the following

dialog box appears allowing Complete Configuration and Environmental parameter storage

for network and reading devices.

Backup & Restore can be applied to any connected device through which backup memory is

available, regardless of the devices' network configuration.

Backup & Restore automatically checks whether a previous backup or configuration is

already stored in backup memory for each device, speeding up the procedure and making it

more secure.

Page 43

INTRODUCTION

27

2

The Backup & Restore function is supported by the scanner when connected to or through:

CBX + BM100 and/or BM2x0

QL500 (Ethernet TCP/IP)

SC4000 ID-NET Controller

QLM-Series Gateways

NOTE:

Before executing a Backup on a BM100 backup module make sure the

Write Protection switch is set to Unlocked.

If BM100 and BM2x0 are both installed B&R is automatically performed

only on the BM100 module.

BM2x0 can execute B&R only with Network up and running (network cable

connected).

QL500 can backup up to 10 nodes (Master + 9 slaves).

Page 44

DS5100 REFERENCE MANUAL

28

2

In the pictures above, the Backup/Restore Dialog is shown:

the Devices window lists all of the available devices in the current configuration,

the Backup Contents window lists any previous device backups.

To perform a Backup:

1. Press the Backup button (you will be warned that all previous backups will be

overwritten)

2. The Status window shows information as the backup procedure is being executed

To perform a Restore:

1. Press the Restore button (you will be warned that all scanner configurations will be

overwritten)

2. The Status window shows information as the restore procedure is being executed

The Restore function also provides easy and secure Single Device Replacement:

1. Remove the scanner to be replaced

2. Connect the new scanner (make sure the new scanner has been previously

set to default)

3. Run the Restore procedure by pressing the Restore Button (see: Restore

procedure)

NOTE: If the Automatic Scanner Replacement parameter is enabled the

Restore procedure starts automatically when the new scanner is recognized.

To Erase any previous Backup:

1. Press the Erase button

2. All backups are deleted

The Status window shows the status of the backup procedure as it is being executed.

The following is a list of possible error messages:

Module not present: backup module not mounted (BM100) or not ready (QL500 , BM2x0,

SC4000, QLMxxx), or Search for Backup Memory at Device Startup parameter disabled

Unable to Read Backup State: Genius is unable to get connected to the device

Backup function not allowed: when device is in X-PRESS Menu mode (BM100) or is out of

memory (QL500)

Failed! (Device not found): Master is unable to reach the addressed device

Failed! (Module is write protected): BM100 Write Protection switch is set to Locked

Page 45

INTRODUCTION

29

2

2.5 AUTOMATIC SCANNER REPLACEMENT

This parameter allows single scanner replacement to take place automatically (at power on

time only) whenever a scanner substitution is made. Data for the Automatic Scanner

Replacement are stored in the backup memory [BM100 Backup Module or QLMxxx

Gateway]. To correctly activate the Automatic Scanner Replacement feature follow these

steps:

Master/Slave Configuration:

1. Connect to the Master and properly configure all of the scanners in your system

according to your application needs.

2. Enable the Automatic Scanner Replacement parameter on the Master, then Send the

configuration to the Master.

3. Backup the complete network configuration by selecting Backup & Restore in the

Device drop-down list from the Genius menu.

4. Get the Masters' configuration and verify that the Automatic Scanner Replacement

parameter is enabled.

The Automatic Scanner Replacement is now enabled. If any network scanner (Master

or Slave) is ever replaced by a new one (which must be set to the Default

Configuration or have the proper node address) the Automatic Scanner Replacement

feature will be performed.

Other Configuration:

1. Connect to the scanner and properly configure it according to your application needs.

2. Enable the Automatic Scanner Replacement parameter, then Send the configuration

to the scanner.

3. Backup the configuration by selecting Backup & Restore in the Device drop-down list

from the Genius menu.

4. Get the configuration and verify that the Automatic Scanner Replacement parameter

is enabled.

The Automatic Scanner Replacement is now enabled. If the scanner is ever replaced

by a new one (which must be set to the Default Configuration), the Automatic Scanner

Replacement feature will be performed.

NOTE 1: The Automatic Scanner Replacement feature can only be performed at power up (either

Master or Other: Stand Alone) and only one scanner at a time can be replaced.

NOTE 2: Once the Automatic Scanner Replacement has been activated, the Restore feature is also

available.

NOTE 3: Once the Automatic Scanner Replacement has been activated, it will be forced if a "Reset

Scanner to Factory Default" procedure is performed (by pressing and holding the X-PRESS

button at power-up).

NOTE 4: Once the Automatic Scanner Replacement has been activated, it can be disabled only by

Erasing the Backup content from the backup memory or by backing up a configuration once

the Automatic Scanner Replacement parameter has been disabled.

Page 46

DS5100 REFERENCE MANUAL

30

2

2.6 DISPLAY

The DS5100 is equipped with a 2 line by 16 character LCD display which shows various

diagnostic, menu and operating mode messages according to a defined priority (0 = top

priority):

Priority

Message Type

0:

File Transfer, Backup & Restore, Restore Default Parameters

1:

X-PRESS Menu Selection

2:

Focus Setup Procedure

3:

Diagnostic Alarms *

4:

Reading Results

5:

Welcome Message 2

* Diagnostic Alarm Messages can be enabled/disabled in Genius.

The display language for messages can be selected in Genius. The currently supported

languages are:

English (default)

French

German

Italian

Japanese

2.6.1 Display Messages

The following examples of DS5100 Local Display messages are given to help interpret the

information reported.

Test Mode Results:

A A A % Z Z Z Z Z Z Z Z Z Z Z F = X X X c m - Y Y . Y i

n

A = reading percentage from 000 to 100%.

Z = code content.

F = focus distance in given in centimetres and inches.

2

For Master devices only, Network Diagnostics can be enabled through the Network Status Monitor parameter in Genius

instead of the Welcome Message.

Page 47

INTRODUCTION

31

2

Autolearn Results:

X X X X X X X X X

Y Y D G T A u t o l e a r n O k # Z Z

X = recognized code symbology.

Y = number of digits in the read code

Z = number of configured slot (at the end of the procedure this number represents the total

slots configured).

Diagnostic Alarms:

A l e r t : F o c u s E x p = X X X c m - X X . X i

n

X = expected focus distance in cm and inches

A l e r t : M o t o r S p e e d = X X X X / Y Y Y

Y

X = expected speed

Y = actual speed

Generic Alarms:

A l e r t : F a i l u r e # X X X

X = numeric error value (even if User Defined Messages are selected for data transmission

the numeric error value is sent to the display)

Slave Node Alarms:

A l e r t : I D - N E T N o d e # X X F a i l # Y Y

Y

X = slave node number (1-31)

Y = numeric error value

Page 48

DS5100 REFERENCE MANUAL

32

2

Reading Results:

A A A A X X X X X X X X X X X Y Y C o d e s

A = reading result – Good (Good Read), Part (Partial Read), Mult (Multiple Read)

X = code content

Y = number of codes read

G o o d X X X X X X X X X X X Y Y D G T D W W W S S

S

X = code content

Y = number of digits in the code

DGT = "digits"

D = code direction – F=forward, R=reverse, U=unknown

Linear Reading (only if the Quality Counters parameter is enabled)

W = number of scans on the code

S = Quality Counters value (max 100)

Code Reconstruction

W = number of scans on the code (max 255)

S = number of decodes (max 255), on the digit in the code which was decoded the least

number of times

Network Diagnostic Messages (Master only):

The display alternates between message 1 and 2.

0 N e t w o r k 1 5 M S S S S S S S S S S S S S S

S

1 6 N e t w o r k 3 1 S S S S S S S S S S S S S S S

S

M = Master diagnostic condition; S = Slave diagnostic condition:

* = scanner OK

- =scanner not detected at startup

? =scanner detected at startup but not responding to diagnostic polling

! = scanner diagnostic error

Message 1

Message 2

Page 49

INTRODUCTION

33

2

Welcome Message:

The display alternates between message 1, 2 and 3.

X X X X X X X X X X X X R R R K K K Y Y Y Y Y Y Y Y Y N N

N

X = scanner model

K = software – STD=Standard, SS=Special

Y = software version

R = Device Network Type – MUL=Multidata, SYN=Synchronized, ALN=Alone

NOTE: For dual port Profinet-IO/EBC models, R = Operating Mode –

ONL=On Line, AUT=Automatic, CON=Continuous, TST=Test,

PKT=PackTrack (EBC only).

N = Device Network Setting – M00=ID-NET Network Master, Sxx= ID-NET Network Slave

address or EBC Slave address, Null string= Alone (no network)

Focus Locked:

F o c u s L o c k e d a t F = Z Z Z c m - Y Y . Y i

n

X = device serial number

Z = focus position in cm

Y = focus position in inches

Focus Unlocked:

If focus is not locked an additional message “Please Lock Focus!” appears as well as the

following:

S N X X X X X X X X X F = Z Z Z c m - Y Y . Y i

n

X = device serial number

Z = focus position in cm

Y = focus position in inches

X X X X X X X X X X X X X X X Y Y Y Y Y Y Y Y Y Y Y Y Y Y Y

X = connection type – Ethernet TCP/IP, Profinet-IO, EBC

Y = IP address

Message 1

Message 2

Message 3

Message 2

Page 50

DS5100 REFERENCE MANUAL

34

2

2.7 MODEL DESCRIPTION

DS5100 scanners are described by their model number which indicates the characteristics

listed in the diagram below. Not all combinations are available. For a complete list of

combinations see the Models tab on the Product page of the website.

Communication Interface

2 = SER: RS232/RS485main + RS232aux

3 = ETH: Built-in Ethernet; PNET 1 port: Profinet I/O; SER RS232/RS485main + RS232aux

4 = PNET 2 ports: Profinet IO; EBC Network

Reading Range

1 = Medium

2 = Long

Special Features

0 = Standard

5 = Subzero

Optic Version

0 = Linear

2 = Oscillating Mirror

DS5100 – X X X X

Page 51

INTRODUCTION

35

2

2.8 OSCILLATING MIRROR MODELS

The DS5100 OM is completely software controlled and software programmable through

Genius which allows adjusting the oscillating frequency and the minimum and maximum

oscillation angles of two separate reading zones.

When the oscillating mirror is programmed to read barcode labels at small angles, position

the reader to assure at least 15° for the Skew angle. This angle refers to the most inclined

or external laser line, so that all other laser lines assure more than 15° Skew. This avoids the

direct reflection of the laser light emitted by the reader.

0°

15°

35°

code

surface

-5°

Figure 5 – Oscillating Mirror Skew Angle

Otherwise, the scanner can be mounted at an angle of inclination of 15° in order to attain

symmetrical deflection ranges.

0°

-20°

20°

code

surface

15°

Figure 6 - Oscillating Mirror Reading Position

In the above case, the zone where the scan line is perpendicular to the reflecting surface

corresponds to a neutral zone at the center of the reading field.

NOTE: By limiting the raster width to the minimum necessary, the number of

scans on the reading surface is increased.

The oscillating

angles have a

tolerance of ± 2°.

The oscillating

angles have a

tolerance of ± 2°.

Page 52

DS5100 REFERENCE MANUAL

36

2

2.9 SUBZERO TEMPERATURE MODELS

The DS5100 Subzero scanner is an industrial scanner designed to operate in industrial

refrigerator/freezer cells or other stable subzero degree environments, which are below the

operating range of standard industrial scanners. It is not designed to move between subzero

and normal environments (rapid temperature changes).

The DS5100 Subzero has an intelligent microprocessor-driven and efficient internal heating

system which constantly monitors and automatically controls internal temperature. Only the

necessary temperature-sensitive components are heated, resulting in an efficient heating

system which has very low power consumption. Part of this system also heats the Laser

Beam Output window to eliminate ice and/or condensation build-up from negatively affecting

the reading results.

Upon power-up in a subzero environment, the scanner waits until these internal components

are heated to within their operating temperature range. Power-up at -35 °C can take about 20

minutes before the scanner is ready to read barcodes. During this time the laser, motor, and

display remain off and the Ready LED blinks, indicating the warm-up phase. While in the

warm-up phase, scanner communication is operative and the device can be configured

through Genius or through Host Mode Programming.

Internal Temperature (°C)

20

Scanner Normal Operation

Starting Point

Stabilized Temperature Phase

Warm-Up

Phase

Cold Start

0

Time (min)

-35

0

The DS5100 Subzero can be connected to the CBX100 LT Subzero connection box which

can withstand the same low temperature environment as the scanner. A CBX100 LT all-inone model includes a BM100 backup and restore module having an extended temperature

range also for use in subzero environments.

Page 53

INTRODUCTION

37

2

2.10 IP ADDRESS ALIGNMENT USING GENIUS DISCOVERY

For Bulit-in Ethernet and Profinet-IO models, the scanner IP address can automatically be

found on the Ethernet network by using the Genius Discovery utility available in the

Options>Communications tab.