Page 1

DS41

Installation Manual

Page 2

DS41

INSTALLATION MANUAL

Page 3

We

DATALOGIC S.p.A.

Via Candini, 2

40012 - Lippo di Calderara

Bologna - Italy

declare under our sole responsibility that the product

DS41-XX, Laser Scanner and all its m odels

to which this declarat ion relates is in conf ormi ty with the fol lowing standards or other norm ati ve

documents

EN 55022, August 1994

:L

IMITS AND METHODS OF MEASUREMENTS OF RADIO DISTURBANCE

CHARACTERISTICS OF INFORMATION TECHNOLOGY EQUIPMENT

(ITE)

EN 50082-2, March 1995

:E

LECTROMAGNETIC COMPATIBILITY

. G

ENERIC IMMUNITY STANDARD

.

P

ART

2: I

NDUSTRIAL ENVIRONMENT

Following the provision of the Directive(s):

89/336 CEE

AND SUCCESSIVE AMENDMENTS

, 92/31 CEE; 93/68 CEE

Ruggero Cacioppo

Lippo di Calderara, 23.03.1998

Quality Assurance Supervisor

Product names m entioned herein are for identificat ion purposes only and may be trademarks

and or registered trademarks of their respect i ve companies.

Datalogic S.p.A. reserves the right to make modifications and improvements without prior

notification.

- 1997 Datalogic S.p. A .

821000073 (Rev. C)

Page 4

iii

CONTENTS

General View.......................................................................................v

SAFETY PRECAUTIONS

..................................................................vii

Laser Safety.......................................................................................vii

Standard Regulations.........................................................................vii

Power Supply..................................................................................... ix

1 GENERAL FEATURES

...................................................................1.1

1.1 Introduction ......................................................................................1.1

1.2 Description.......................................................................................1.2

1.3 Available Models..............................................................................1.4

1.4 Accessories......................................................................................1.4

2 INSTALLATION

...............................................................................2.1

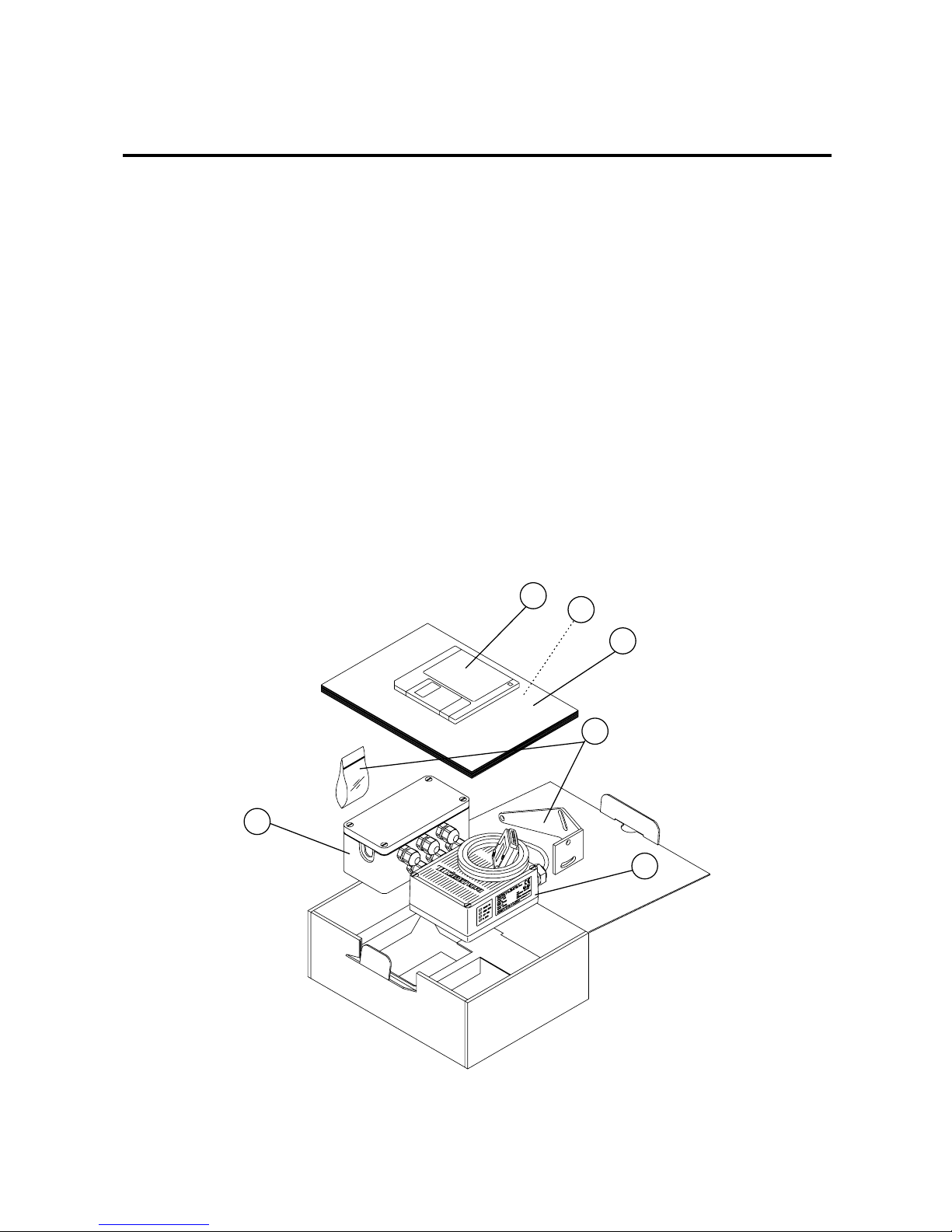

2.1 Package Contents............................................................................2.1

2.2 Guide To Installation........................................................................2.2

2.3 Opening The Device ........................................................................2.3

2.4 Main Interface Selection ..................................................................2.4

2.5 Mechanical Installation.....................................................................2.5

2.6 JBOX Installation .............................................................................2.6

2.6.1 Mounting JBOX................................................................................2.6

2.6.2 Electrical Connections For JBOX.....................................................2.8

2.7 Electrical Connections For 25-pin Models .....................................2.11

2.7.1 Power Supply.................................................................................2.12

2.7.2 Main Serial Interface......................................................................2.13

RS232 Interface.............................................................................2.14

RS485 Non Polled Interface ..........................................................2.15

RS485 Polled Interface..................................................................2.16

20 mA Current Loop Interface........................................................2.19

2.7.3 Auxiliary RS232 Interface...............................................................2.20

2.7.4 Inputs .............................................................................................2.21

2.7.5 Outputs ..........................................................................................2.23

2.8 Positioning......................................................................................2.24

2.9 Typical Layouts..............................................................................2.26

2.9.1 Master-Slave..................................................................................2.27

2.9.2 Local Echo .....................................................................................2.28

2.9.3 Pass Through.................................................................................2.28

Page 5

iv

3 READING FEATURES

....................................................................3.1

3.1 Step Ladder Mode............................................................................3.1

3.2 Picket Fence Mode ..........................................................................3.2

3.3 Performance ....................................................................................3.3

3.4 Reading Diagrams ...........................................................................3.4

4 MAINTENANCE

...............................................................................4.1

4.1 Cleaning...........................................................................................4.1

5 TECHNICAL FEATURES

................................................................5.1

Page 6

v

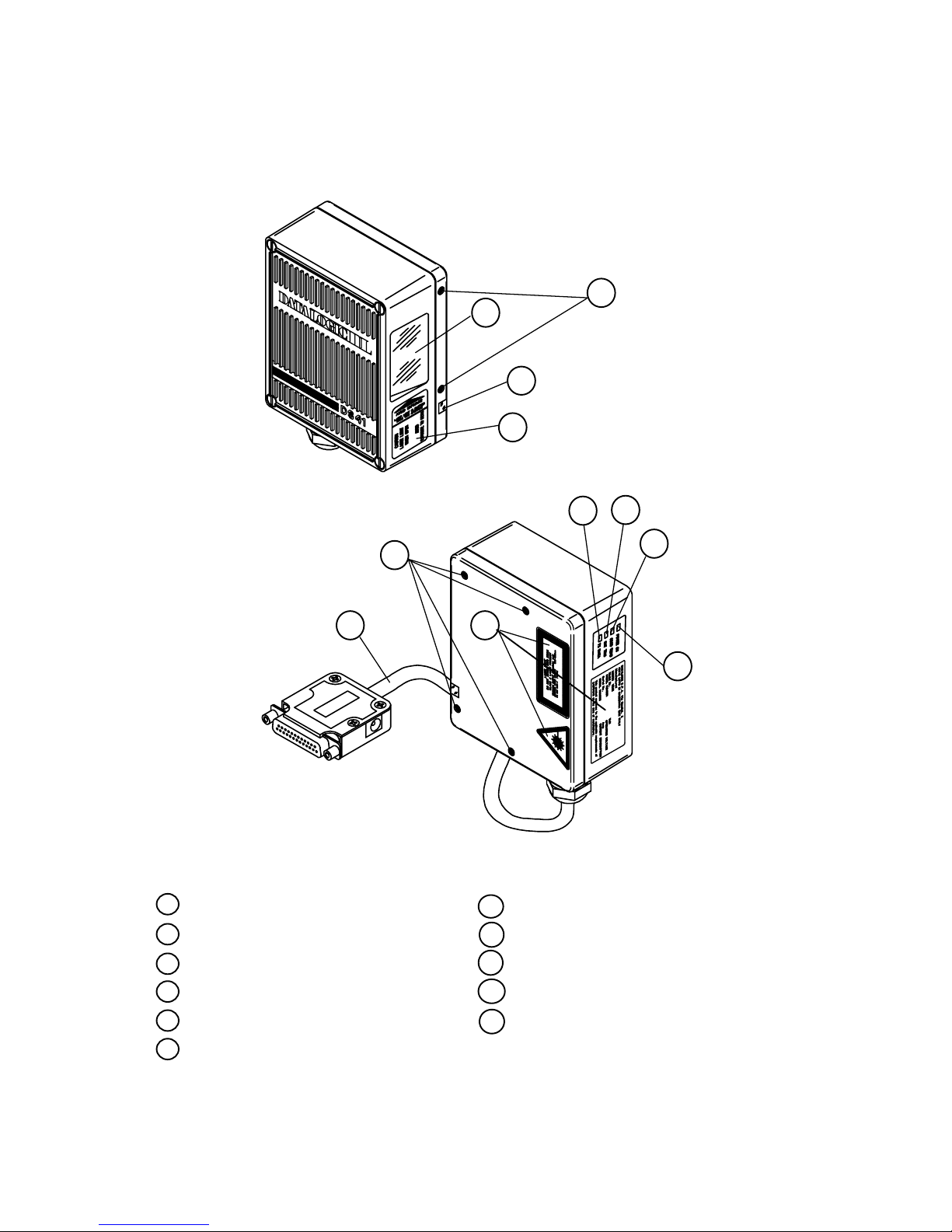

DS41

General View

1

11

10

9

8

2

7

6

5

4

3

Figure A

6 Data transmission LED

Cable with 25-pin connector

1

Mounting holes

2

Successful read LED

4

Presence sensor active LED5

Power on LED

3

Laser active LED

9

8

Warning label

Laser beam output window

10

7

Warning and Classification labels

11

Accessory mounting holes

Page 7

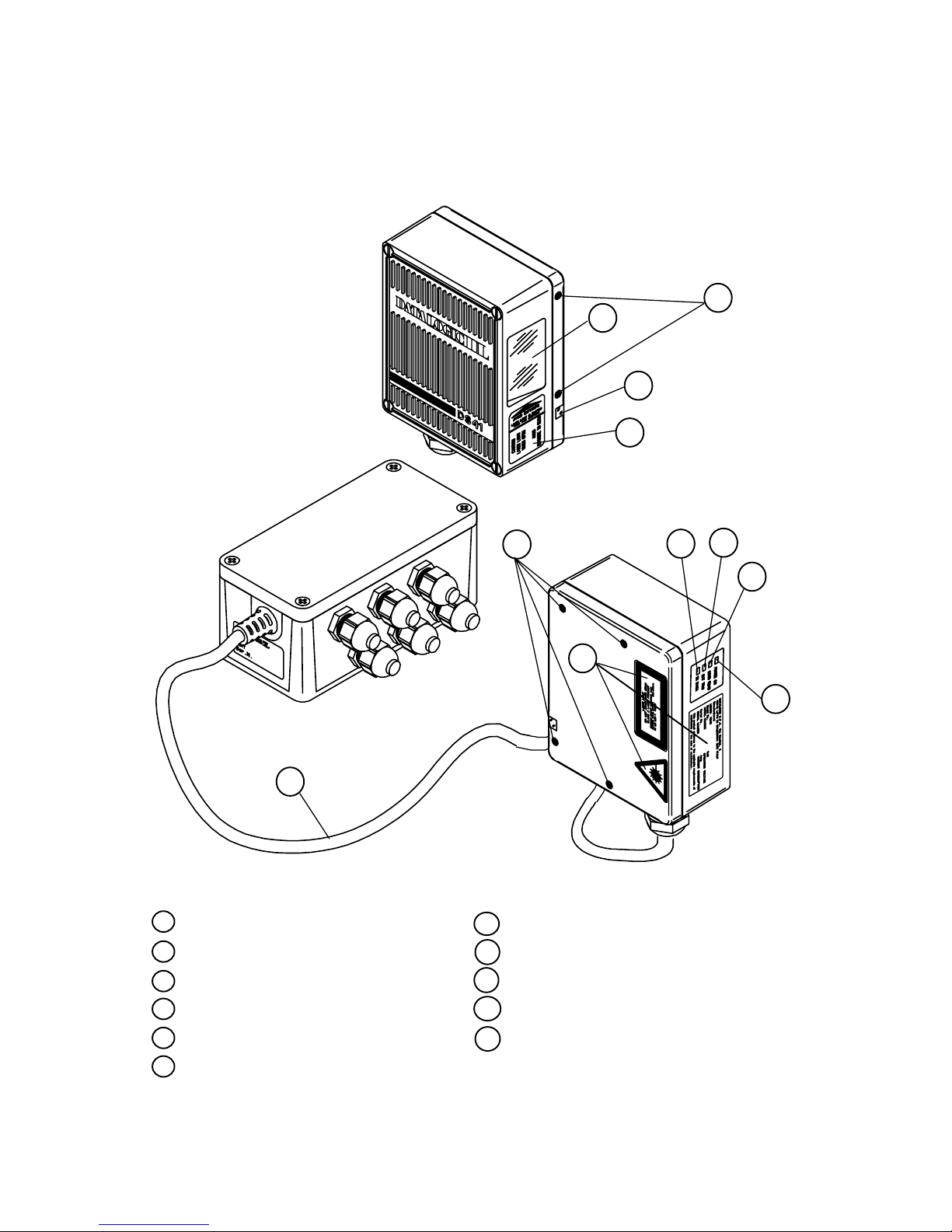

vi

DS41

General View

11

10

9

8

2

1

7

6

5

4

3

Figure B

6 Data transmission LED

Cable with junction box

1

Mounting holes

2

Successful read LED

4

Presence sensor active LED5

Power on LED

3

Laser active LED

9

8

Warning label

Laser beam output window

10

7

Warning and Classification labels

11

Accessory mounting holes

Page 8

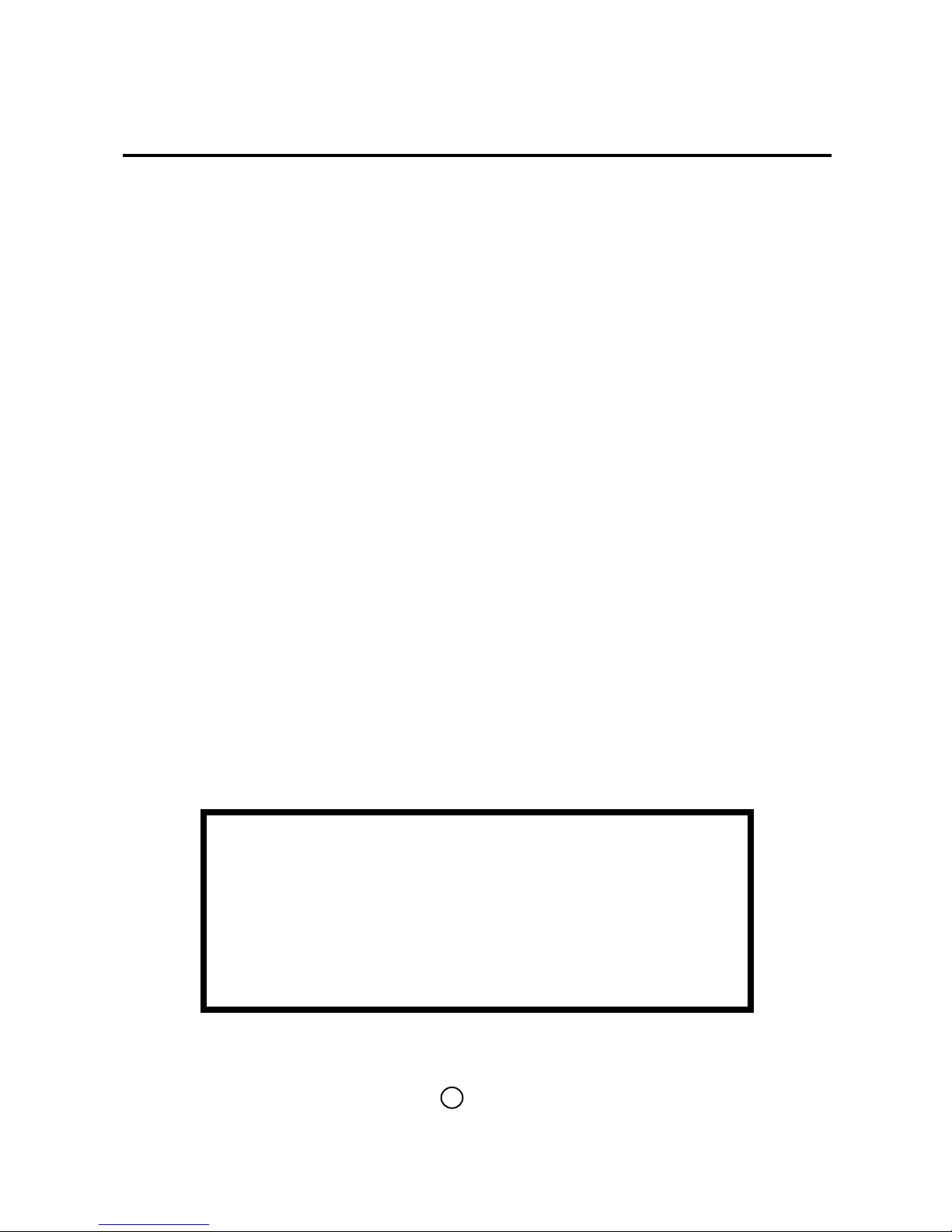

vii

SAFETY PRECAUTIONS

LASER SAFETY

The following information is provided to comply with the rules imposed by

international authorities and refers to the correct use of the DS41 scanner.

Standard Regulations

This scanner utilizes a low-power laser diode. Although staring direct ly at the

laser beam m omentarily causes no known biological dam age, avoid staring

at the beam as one would with any very strong light source, such as the s un.

Avoid that the laser beam hits the eye of an observer, even through ref lective

surfaces such as mirrors, etc.

This product conform s to the applicable requirements of both IEC 825-1 and

CDRH 21 CFR 1040 at the date of manufac ture. T he s c anner is c lass if ied as

a Class 2 laser product ac cording to IEC 825-1 regulations and as a Class II

laser product according to CDRH regulations.

There is a safety device which allows the laser to be s witched on only if the

motor is rotating above the threshold for its correct scanning speed.

The laser beam c an be switched off through a sof tware command ( see also

“Beam Shutter” in the WINHOST Help On Line).

WARNING

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in exposure to hazardous visible laser light.

The laser light is visible to the hum an eye and is em itted f rom the window on

the front of the scanner (Figure A,

10

).

Page 9

viii

W arning labels indicating expos ure to las er light and the devic e c lassif ication

are applied onto the body of the scanner (Figure A,

8

and

7

).

DATALOGIC S. p.A. Via Candini , 2

40012 LIPPO DI CALDERARA (BO) ITALY

Model No. Serial No.

Volt Amp.

Manufactured

This product conforms to the ap plicable requir em ents of

21CFR1040 at the date of manufacture.

LISTED

45AF

I.T.E.

R

R

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

MAXIMUM OUTPUT RADIATION 1 mW

EMITTED WAVE LENGTH 630~680 nm

TO IEC 825-1 (1993)

Warning and device class label s

Disconnect the power supply when opening the device during maintenance

or installation to avoid exposure to hazardous laser light.

The laser diode used in this device is classified as a class 3B las er product

according to IEC 825-1 regulations and as a Class IIIb laser product

according to CDRH regulations. As it is not poss ible to apply a classification

label on the laser diode used in this device, the following label is reproduced

here:

LASER LIGHT

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

MAX. OUTPUT RADIATION 7 mW

EMITTED WAVE LENGTH 630~680 nm

TO IEC 825-1 (1993)

Laser diode class label

Any violation of the optic parts in particular can cause radiation up to the

maximum level of the laser diode (7 mW at 630 to 680 nm).

Page 10

ix

POWER SUPPLY

ATTENTION:

READ THIS INFORMATION BEFORE INSTALLING THE PRODUCT

- This product is intended to be installed by Qualified Personnel only.

-

Model DS41-X0:

This device is intended to be supplied by a UL Listed Direct Plug-in

Power Unit marked "Class 2", rated 10-30 V, minimum 0.46 A.

This device may also be supplied by a UL Listed Power Unit with a

"Class 2" or LPS power source which supplies power directly to the

scanner via the 25-pin connector.

-

Model DS41-X1:

This device is intended to be supplied via the Junction Box by an NEC

Class 2 power source, rated 10-30 V, minimum 0.46 A.

See par. 2.6.2 or 2.7.1 for correct power supply connections.

Page 11

x

This page is intenti onal l y l ef t blank.

Page 12

DATALOGIC DS41

General features - 1.1

1 GENERAL FEATURES

1.1 INTRODUCTION

The DS41 scanner is a bar code reader complete with decoder , available in

16 standard models. These were designed to satisfy the most demanding

requirements associated with high performance scanning.

Standard Application Program

A Standard Application Program is factory-loaded onto the DS41. This

program controls bar c ode reading, s er ial port inter f ac ing, data f or matting and

many other operating and control parameters.

It is completely user configur able from a host com puter using the WINHOST

interface utility program provided on diskette with the scanner or using the

Host Mode programming procedure, by ESC sequences via the serial

interface.

There are four different programmable operating modes to suit various

barcode reading system requirements. Included in these is a test mode to

verify the reading features and exact positioning of the sc anner without using

external tools.

C Programmability

The DS41 belongs to the generation of Datalogic scanners that operate

under the 'C' programming environment which is a recognized industry

standard.

If your requirements are not met by the Standard Application Program,

Custom Application Programs can be developed by your local Datalogic

distributor.

Page 13

DS41 DATALOGIC

1.2 - General features

1.2 DESCRIPTION

Some of the main features of this scanner are given below:

•

very high scanning speed (800 scans/sec).

•

raster versions available.

•

completely configurable from host computer.

•

2 serial communic ation interfaces; one can be set as RS232, RS485, or

20 mA C.L., and the other is an RS232 auxiliary interface.

•

reads all popular codes.

•

supply voltage from 10 to 30 Vdc.

•

test mode to verify the reading features and exact positioning of the

scanner without the need for external tools.

•

configurable in different oper ating modes to suit the mos t var ious bar c ode

reading system requirements.

•

code verifier

•

possibility to detect the absolute position of the label in the scan line (for

DSP models only, see paragraph 1.3).

•

PCS verification (for DSP models only, see paragraph 1.3).

The DS41 scanner uses a solid state laser diode as a light s ource; the light

emitted has a wavelength between 630 and 680 nm. Refer to the section

"Safety Precautions" at the beginning of this m anual for inform ation on laser

safety.

The use of a semiconductor laser has made it possible to develop an

extremely compact scanner with low power consumption. The reader is

contained in a rugged aluminum housing; the mechanical dimensions are

101 x 83.5 x 42 mm and it weighs about 800 g.

The protection class of the enclosure is IP65, therefore the reader is

particularly suitable for industrial environm ents where high pr otection against

harsh external conditions is required.

Page 14

DATALOGIC DS41

General features - 1.3

Electrical connection is provided through a cable on the side of the reader;

this cable is terminated with a 25-pin connector (25-pin connector models,

see paragraph 1.3, Figure A,

1

) or by a junction box (junction box m odels,

see paragraph 1.3, Figure B,

1

).

The laser beam output window is on the right hand side of the scanner

(Figure A,

10

). A green LED on the same side indicates the laser is active

(Figure A,

9

).

A security system allows the laser to activate only once the motor has

reached the correct rotational speed; consequently the laser beam is

generated after a slight delay from the power on of the scanner.

The four LEDs on the left hand side of the scanner indicate the following:

POWER ON

LED (red) (Figure A, 3) indicates the reader is connected to

the power supply.

GOOD READ

LED (red) (Figure A, 4) is used to signal successful barcode

decoding. It is also used in Tes t m ode to signal the decoding

percentage (for details refer to the s ec tion "T es t Mode" in the

WINHOST Help On Line).

EXT TRIG

LED (yellow) (Figure A, 5) indicates the code presence

sensor is active (for details refer to the section "On Line

Mode" in the WINHOST Help On Line).

TX DATA

LED (green) (Figure A, 6) indicates data transmission on

the main serial output line.

The screw holes on the body of the reader are f or mec hanical fixtur e (Figure

A,

2

); the screw holes shown in Figure A, 11 are to attach accessories such

as the optional 90° mirror.

Page 15

DS41 DATALOGIC

1.4 - General features

1.3 AVAILABLE MODELS

The DS41 scanner is available in versions that differ in regard to the

following parameters:

•

Resolution

•

Termination of the cable

•

Distance between the scan beams (raster models only)

•

DSP or NPP

The following models are therefore available:

DS41 - X X

1 = Standard Resolution = 6

2 = Very High Resolution = 7

3 = Raster Version R2 = 8

4 = Raster Version R1 = 9

Termination of the cable

0 = 25-pin connector

1 = junction box

Optical Resolution

NPP models

Optical Resolution

DSP models

All models perform 800 scans/sec.

1.4 ACCESSORIES

The following accessories are available on request for the DS41:

•

90° deflection mirror GFC-41

Page 16

DATALOGIC DS41

Installation - 2.1

2 INSTALLATION

2.1 PACKAGE CONTENTS

Verify that the DS41 reader and all the parts supplied with the equipm ent ar e

present and intact when opening the packaging; the list of parts includes:

1) DS41 reader with cable

2) Installation manual

3) Barcode test chart(s)

4) DS41 communication and utility program disk

5) Mounting kit

•

Mounting screws and washers (4 ea.)

•

Mounting bracket (1)

* Junction box (for junction box models only, see paragraph 1.3)

1

4

3

2

5

*

Figure 2.1 - DS41 package contents

Page 17

DS41 DATALOGIC

2.2 - Installation

2.2 GUIDE TO INSTALLATION

The following can be used as a checklist to verif y all of the steps necessary

for complete installation of the DS41 scanner.

1) Read all information in the section "Safety Precautions" at the

beginning of this manual.

2) Open the scanner to select the main serial interface type as required

(see paragraphs 2.3 and 2.4).

3) Correctly position and mount the scanner for barcode reading

according to the information in paragraphs 2.5, 2.8 and 3.4.

4) Provide correct system cabling according to the signals necessary

(see the applicable sub-paragraphs under 2.6 or 2.7).

5) Configure the software parameters from a host computer using

either the WINHOST interface utility program provided on disk ette, or

using the Host Mode programming procedure, by ESC sequences

via the serial interface.

For more details about these configuration methods refer to the

section "DS41 Configuration" in the WINHOST Help On Line.

NOTE

Fine tuning of the scanner position for

barcode reading can be accom plished using

the Test Mode. For further details refer to the

section "Test Mode" in the WINHOST Help

On Line.

The installation is now complete.

Page 18

DATALOGIC DS41

Installation - 2.3

2.3 OPENING THE DEVICE

Before installing the DS41 it m ay be necessary to open the scanner to select

the interface required.

WARNING

The scanner m ust be dis connected f rom the power

supply during this operation.

Refer to the following instructions and diagram below when opening the

reader:

•

Unscrew the four screws as shown below to open the scanner for

access to the output interface jumper.

•

Carefully remove the cover of the scanner. Avoid any contact with the

mirrored rotor, the lenses, or other optical components.

Figure 2.2 - Opening the DS41

Page 19

DS41 DATALOGIC

2.4 - Installation

2.4 MAIN INTERFACE SELECTION

One of the following interface types can be selected to connect the main

interface of the DS41 to the host computer.

EIA RS232 20 mA CURRENT LOOP

EIA RS485 POLLED EIA RS485 NON POLLED

To select the interface type, position the jumper block as indicated in the

diagram below:

RS232

RS485

POLLED

20 mA C.L.

RS485 NON

POLLED

SW2SW3

SW4

SW2SW3

SW4

SW2SW3

SW4

SW2SW3

SW4

Figure 2.3 - Interface type selection

The RS232 interface type is factory set.

Page 20

DATALOGIC DS41

Installation - 2.5

2.5 MECHANICAL INSTALLATION

DS41 can be installed to operate in different positions. The four s crew holes

(M4 x 5) on the body of the reader are for mechanical fixture (Figure A,

2

).

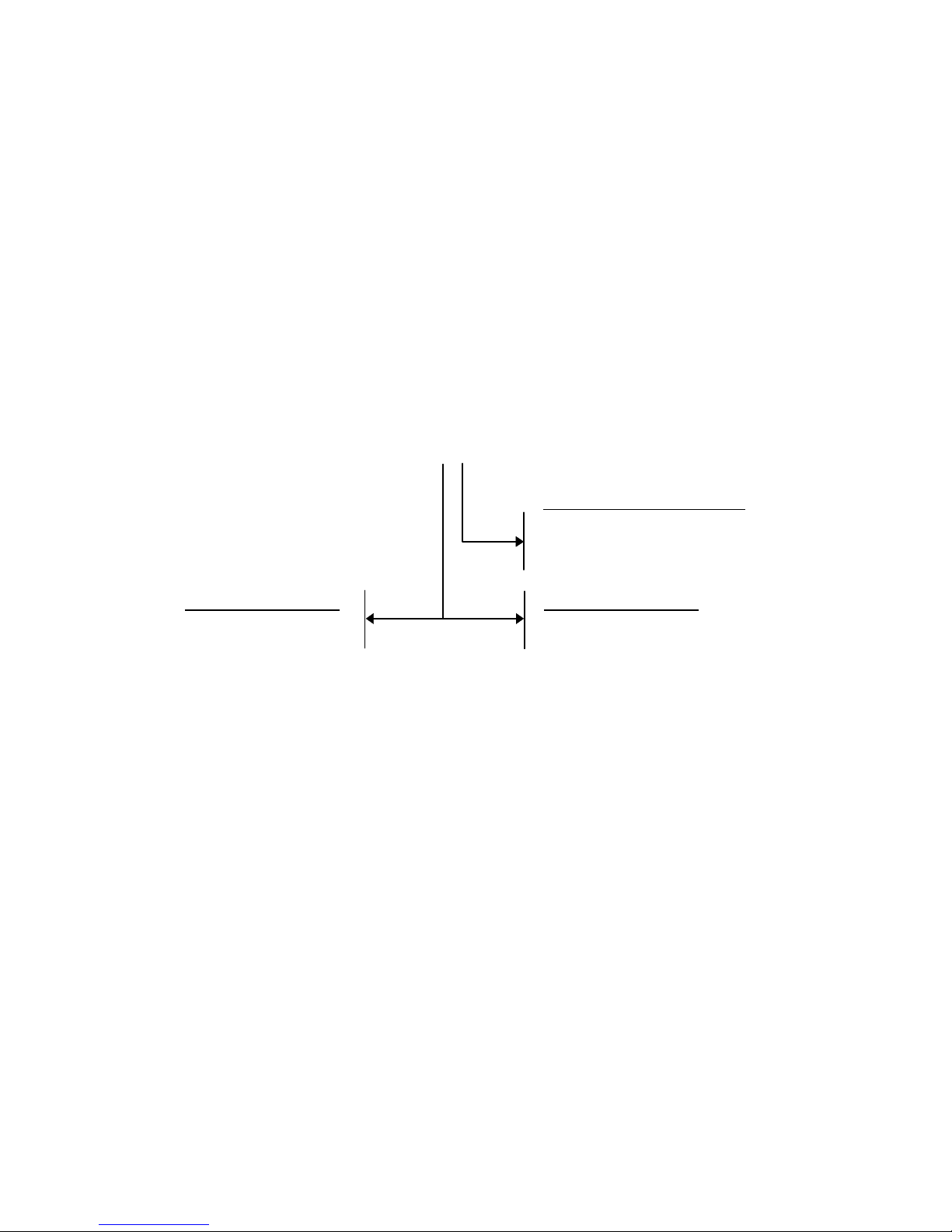

The diagram below gives the overall dimensions of the scanner and may be

used for its installation.

Refer to paragraph 2.8 for correct positioning.

ST - 37

Mounting

bracket

mm

in

Figure 2.4 - Overall dimensions

Page 21

DS41 DATALOGIC

2.6 - Installation

2.6 JBOX INSTALLATION

JBOX provides a passive connec tion between your scanner and the outside

world in a fast and practical way. It represents an alternative to the 25-pin

connector models. Figure 2.5 shows the basic layout of DS41 using the

junction box.

DS41

Scanner

cable

Junction Box

S

y

stem cables

Figure 2.5 - Scanner using JBOX

For JBOX connections, the scanner has a cable that terminates in a 24-pin

connector that plugs into the junction box . T he system cables pas s through 6

glands in the side of the JBOX and the individual wires connect to spring

clamp terminal blocks inside which provide access to all scanner signals.

2.6.1 Mounting JBOX

The diagram below shows the dim ensions of the junction box and its relative

mounting holes.

mm

in

Figure 2.6 - JBOX dimensions

Page 22

DATALOGIC DS41

Installation - 2.7

JBOX is designed to be mounted to a panel of metal, plastic or other

appropriate material using the m ounting screws pr ovided in the pack age. To

do this:

1) Open the junction box by unscrewing the 4 cover screws.

If necessary, using the two mounting holes inside the junction box as a

pattern, mark the panel with an appropriate object and then dr ill two s m all

pilot holes in the panel.

2) Align the junction box and insert the two self -threading screws with their

washers and screw them into the panel until tight (see Figure 2.7).

Figure 2.7 - Mounting JBOX

Page 23

DS41 DATALOGIC

2.8 - Installation

2.6.2 Electrical Connections for JBOX

The connection and wiring procedure for JBOX is described as follows:

1) Open the junction box by unscrewing the 4 cover screws.

2) Pass all System cables through the glands in the junction box housing.

3) To connect the power and input/output signals:

•

Prepare the individual wires of the system cables by stripping the

insulation back approximately 11 mm.

•

Us ing a device such as a sc rewdriver, push down on the orange lever

directly above the clamp (see Figure 2.8).

•

Insert the wire into the clamp and release the lever.

The wire will now be held in the spring clamp.

Figure 2.8 - System cable connections to the junction box

The wiring used can be solid or stranded but must meet the following

specifications.

Positions 1-4: 24 - 16 AWG 0.2 - 1.5 mm²

Positions 5-39: 26 - 20 AWG 0.14 - 0.5 mm²

The junction box pinouts are indicated in the following table:

Page 24

DATALOGIC DS41

Installation - 2.9

Figure 2.9 - JBOX connector and pinout

To allow connection of an NEC Class 2

Power Unit, use a correct female plug

adapter.

Figure 2.10 - NEC Class 2 Pow er uni t connecti ons

* The signals on pins 24, 25, and 26 are repeated on pins 29, 30, and 31 to fac ilitate network

connections (i. e. Multiplexer connec tions us ing the RS485 P olled Int erface). I n this way the

network bus can enter and exit the junction box from different spring clamps but be

physically connected together.

117

18 39

J1

5

JBOX pinout for DS41

Pin Name

01 VS

02 SGND

03 VS

04 SGND

05 CHASSIS

06 VS

07 VS

08 PS+

09 PS10 SGND

11 SGND

12 VS

13 VS

14 n.c.

15 n.c.

16 SGND

17 SGND

18 NOREAD+

19 NOREAD20 RIGHT+

21 RIGHT22 WRONG+

23 WRONG*24 TX232/TX485+/CLOUT +

*25 RTS232/TX485-/CLOUT*26 SGND

27 n.c.

28 SGND

29 TX232/TX485+/CLOUT+

30 RTS232/TX485-/CLOUT31 SGND

32 RX232/RX485+/CLIN+

33 CTS232/RX485-/CLIN34 SGND

35 TXAUX

36 RTSAUX

37 SGND

38 RXAUX

39 CTSAUX

Junction Box

NEC Class 2

Power supply

Female Plug

System cables

Page 25

DS41 DATALOGIC

2.10 - Installation

4) After wiring the junction box and while the scanner is unplugged from the

power supply, place the Scanner cable so that the rubber seal fits into the

cutout in the housing of the junction box and plug the 24-pin connector

into connector J1 on the PCB inside the junc tion box as shown in figure

2.11.

Scanner cable

J1

Rubber seal

Figure 2.11 - Scanner cable connections to the junction box

5) Close the junction box using the 4 cover screws making sure the rubber

seal is fitted correctly between the parts of the housing.

The junction box is now installed which completes the elec trical connections

for your scanning system.

If it ever becomes necessary to disconnect the scanner from the JBOX,

simply reverse the procedure in step 4.

Page 26

DATALOGIC DS41

Installation - 2.11

2.7 ELECTRICAL CONNECTIONS FOR 25-PIN MODELS

25-pin connector models (see paragraph 1.3) are equipped with a cable

terminated by a 25-pin D-sub connector for connection to the power supply

and input/output signals. The details of the connector pins are indicated in

the following table:

Figure 2.12 - 25-pin D-sub connector

25-pin D-sub connector pinout

Pin Name Function

13 VS Power supply input voltage (+)

25 SGND Power supply input voltage (-)

1 CHASSIS Chassis Ground

9 VS Presence sensor supply voltage (+)

18 PS+ Presence sensor (+)

19 PS- Presence sensor (-)

8 NO READ + No read output (+)

22 NO READ - No read output (-)

11 RIGHT + Right read output (+)

12 RIGHT - Right read output (-)

14 WRONG + Wrong read output (+)

15 WRONG - Wrong read output (-)

2* TX232/TX485+/CLOUT+

3* RX232/RX485+/CLIN+ * Main interface signals

4* RTS232/TX485-/CLOUT- (see par. 2.7.2)

5* CTS232/RX485-/CLIN-

7 SGND Signal Ground

20 RXAUX Auxiliary input

21 TXAUX Auxiliary output

23 CTSAUX Auxiliary handshake

24 RTSAUX Auxiliary handshake

6, 10, 16, 17 NC No Connect

* Pins 2, 3, 4, and 5 of the 25-pin connector have different meanings depending on which

interface type is s elect ed. To selec t the int erface t ype, follow the ins truct ions i n paragraphs

2.3 and 2.4.

Page 27

DS41 DATALOGIC

2.12 - Installation

2.7.1 Power supply

Power can be supplied to the scanner through the pins provided on the 25pin connector used for communication with the host (Figure 2.13):

DS41

13

25

VS

SGND

1

CHASSIS

Earth Grou nd

USER INTERFACE

CHASSIS

GND

V+ (10 - 30 Vdc)

Figure 2.13 - Power supply connections

or through the jack connector on the side of the 25-pin connector for

connections to a UL Listed Direct Plug-in Power Unit (Figure 2.14). If the jack

input is used to supply power to the DS41, pin 13 is automatically

disconnected; the supply voltage for the presence s ensor remains on pin 9.

The plug connector is not supplied with the DS41.

V+ (10 - 30 Vdc)

Jack

Plug

GND

Figure 2.14 - Power supplied using the jack connector

The power must be between 10 and 30 Vdc only. There is a current peak of

about 1A at 10 V during power on caused by the motor starting.

It is recommended to connect pin 1 (CHASSIS) to a common earth ground.

Page 28

DATALOGIC DS41

Installation - 2.13

2.7.2 Main serial interface

The signals relative to the following serial interfac e types are available on the

input/output connector:

EIA RS232

EIA RS485 NON POLLED

EIA RS485 POLLED

(for connection with a Datalogic multiplexer)

20 mA PASSIVE CURRENT LOOP

DS41 automatically recognizes the type of interface s elected at each power

on of the scanner.

If the recognized interface type is not compatible with the current

communication handshaking, then the system forces the XON/XOFF

protocol.

The parameters relative to the interfac e selected (baud rate, data bits, etc.)

can be configured using the WINHOST utility program or Host Mode

programm ing. For more details refer to the section "Main Interface Menu" in

the WINHOST Help On Line.

Details regarding the connections and use of the main interfac e selection ar e

given in the next paragraphs.

Page 29

DS41 DATALOGIC

2.14 - Installation

RS232 interface

The serial interface is used in this case for point to point connections; it

handles comm unication with the host computer and allows both tr ansm iss ion

of code data and the configuration of the scanner. This is the default

interface.

The following pins of the 25-pin connector are used for RS232 interface

connection:

Pin Name Function

2 TX232 Transmitted Data

3 RX232 Received Data

4 RTS232 Request To Send

5 CTS232 Clear To Send

7 SGND Signal Ground

RTS/CTS HARDWARE HAND SHAKING ENABLED

DS41

USER INTERFACE

7

SGND

SGND

RTS232

4

DCD

CTS232

5

DTR

RX232

3

TXD

TX232

2

RXD

Figure 2.15 - RS232 main interface connections

Page 30

DATALOGIC DS41

Installation - 2.15

Figure 2.16 - RS232 control signals

The RTS232 and CTS232 signals control data transm ission and s ynchronize

the connected devices.

If the RTS/CTS handshaking protocol is enabled, the DS41 activates the

RTS232 output to indicate a message is to be trans m itted. The r eceiving unit

activates the CTS232 input to enable the transmission.

RS485 non polled interface

The RS485 NON POLLED interface is a Full Duplex interface.

The NON POLLED conf iguration is used for point to point connections over

longer distances than those acceptable for RS232 communications or in

electrically noisy environments.

The following pins of the 25-pin connector are used for RS485 NON

POLLED communications:

Pin Name Function

2 TX485+ RS485 output (+)

4 TX485- RS485 output (-)

3 RX485+ RS485 input (+)

5 RX485- RS485 input (-)

7 SGND Signal Ground

Page 31

DS41 DATALOGIC

2.16 - Installation

DS41

USER INTERFACE

7

SGND

TX485+

2

TX485-

4

RX485+

3

RX485-

5

RX485

TX485

SGND

Figure 2.17 - RS485 NON POLLED connections

To select this interface type, follow the instructions in paragraphs 2.3 and 2.4.

RS485 polled interface

The RS485 POLLED interface is a Half Duplex (3 wires + shield) interface.

The POLLED configuration can be used for multidrop connections with a

Datalogic multiplexer or it can also be used for a master-slave layout (see

paragraph 2.9.1).

The following pins of the 25-pin connector are used for RS485 POLLED

communications:

Pin Name Function

2 TX485+ RS485 input/output (+)

4 TX485- RS485 input/output (-)

7 SGND Signal Ground

DS41

MULTIPLEXER

TX485+

2

TX485-

4

+ RTX485

- RTX485

7

SGND

RS485REF

Figure 2.18 - RS485 POLLED connections

To select this interface type, follow the instructions in paragraphs 2.3 and 2.4.

Page 32

DATALOGIC DS41

Installation - 2.17

For this interface type, the multidrop address must also be set on the DIP

switch as shown in the figure below. Record this inf orm ation f or f urther setup

of the multidrop line.

SW1

SW2

SW3

SW4

SW1

Figure 2.19 - DIP switch for m u ltidrop address selection

The following table shows the address settings where:

Position Address Position Address

12345 12345

11111 31 01111 15

11110 30 01110 14

11101 29 01101 13

11100 28 01100 12

11011 27 01011 11

11010 26 01010 10

11001 25 01001 9

11000 24 01000 8

10111 23 00111 7

10110 22 00110 6

10101 21 00101 5

10100 20 00100 4

10011 19 00011 3

10010 18 00010 2

10001 17 00001 1

10000 16 00000 0

1 = ON 0 = OFF

Page 33

DS41 DATALOGIC

2.18 - Installation

The figure below shows a multidrop configuration with DS41 scanners

connected to a Multiplexer.

1

1

CHASSIS

DS41

# 1

TX485+

TX485-

SGND

DS41

# 0

max. 1200 m.

three wires

+ shield

7

4

2

7

4

2

120 Ohm

MULTIPLEXER

+RTX485

-RTX485

RS485REF

SHIELD

1

120 Ohm

DS41

(up to 31)

# x

max. 2 m.

7

4

2

Figure 2.20 - DS41 multidrop connection to a Multiplexer

Page 34

DATALOGIC DS41

Installation - 2.19

20 mA current loop interface

The DS41 only supports passive type current loop connections. The following

pins of the 25-pin connector are used:

Pin Name Function

5 CLIN- Current Loop Input (-)

3 CLIN+ Current Loop Input (+)

4 CLOUT- Current Loop Output (-)

2 CLOUT+ Current Loop Output (+)

DS41

USER INTERFACE

5

3

4

C.L. IN-

C.L. IN+

C.L. OUT-

2

C.L. OUT+

MAX. 300 METERS

I = 20 mA

I = 20 mA

Figure 2.21 - 20 mA C.L. connections

To select this interface type, follow the instructions in paragraphs 2.3 and 2.4.

Page 35

DS41 DATALOGIC

2.20 - Installation

2.7.3 Auxiliary RS232 interface

The auxiliary serial interface is used exclusively for RS232 point to point

connections.

The parameter s relative to the auxiliary interface (baud rate, data bits , etc.)

as well as particular operating modes such as local echo can be defined

using the WINHOST utility program or Host Mode programming. For more

details refer to paragr aph 2.9 and to the section "Auxiliar y Interface Menu" in

the WINHOST Help On Line.

The following pins of the 25-pin connector are used to connect the RS232

auxiliary interface:

Pin Name Function

20 RXAUX Auxiliary input

21 TXAUX Auxiliary output

23 CTSAUX Auxiliary handshake

24 RTSAUX Auxiliary handshake

7 SGND Signal Ground

7

SGND

SGND

DS41

USER INTERFACE

TXD

RXAUX

20

RXD

TXAUX

21

RTS/CTS HARDWARE HANDSHAKING ENABLED

DCD

RTSAUX

24

DTR

CTSAUX

23

Figure 2.22 - RS232 auxiliary interface connections

The RTSAUX and CTSAUX signals control data transmission and

synchronize the connected devices. If the RTS/CTS handshaking pr otocol is

enabled, the DS41 activates the RTSAUX output to indicate a m essage is to

be transmitted. T he receiving unit activates the CTSAUX input to enable the

transmiss ion.

Page 36

DATALOGIC DS41

Installation - 2.21

2.7.4 Inputs

The inputs available on the DS41 scanner are the pins relative to the code

presence sensor, as indicated below:

Pin Name Function

18 PS+ Presence sensor (input+)

19 PS- Presence sensor (input-)

The inputs indicated are always used to connect the code pres ence sensor

which tells the scanner to sc an for a code. The yellow led (Figur e A,

5

) is

on during the active phase of the PS signal indicating that decoding can tak e

place.

This input is optocoupled and can be driven by both an NPN or PNP type

command. The connections are indicated in the following diagrams:

PRESENCE SENSORDS41

30 Vdc max.

Vext

PS+

PS-

18

19

+ 5V

Signal

V

Figure 2.23 - Input NPN command using external power

PRESENCE SENSORDS41

Signal

PS+

PS-

18

19

+ 5V

VS

9

25

GND

Ground

V

Figure 2.24 - Input NPN command using DS41 power

Page 37

DS41 DATALOGIC

2.22 - Installation

PS+

PS-

18

19

+ 5V

DS41

PRESENCE SENSOR

V

Signal

Ground

30 Vdc max.

Vext

Figure 2.25 - Input PNP command using external power

PRESENCE SENSOR

DS41

PS+

PS-

18

19

VS

9

25

GND

V

Signal

+ 5V

Figure 2.26 - Input PNP command using DS41 power

The electrical features are given below:

Maximum voltage 30 Vdc

Maximum current 25 mA

An anti-disturbance filter is im plem ented on the pr esence sens or input with a

nominal delay of about 5 milliseconds.

Page 38

DATALOGIC DS41

Installation - 2.23

2.7.5 Outputs

In addition to the pins relative to the comm unication interfaces as described

in the previous paragraphs, the following pins are present on the 25-pin

connector of the scanner:

Pin Name Function

8 NO READ+ No read output (+)

22 NO READ- No read output (-)

11 RIGHT+ Right read output (+)

12 RIGHT- Right read output (-)

14 WRONG+ Wrong read output (+)

15 WRONG- Wrong read output (-)

The NO READ output activates when the code signalled by the presence

sensor is not decoded.

DS41

USER INTERFACE

22

8

NO READ-

NO READ+

40 Vdc max

Vext

Figure 2.27 - NO READ output connection

The RIGHT output activates when the code is decoded correctly.

DS41

USER INTERFACE

Vext

40 Vdc max

RIGHT+

RIGHT-

11

12

Figure 2.28 - RIGHT code output connection

Page 39

DS41 DATALOGIC

2.24 - Installation

The WRONG output is used either for "Verifier" mode or for PCS control

(PCS control is available for DSP models only, see paragraph 1.3). For

Verifier this output activates when the decoded code does not c orrespond to

the one set in the configuration. For PCS this output activates when the PCS

level is below the threshold value.

DS41

USER INTERFACE

Vext

40 Vdc max

WRONG+

WRONG-

14

15

Figure 2.29 - WRONG code output connection

These outputs are all level or pulse programmable: a 50 ms pulse is

generated in the second case. Further program ming information is supplied

in the section "Output Lines" in the WINHOST Help On Line.

2.8 POSITIONING

The DS41 scanner is able to decode moving barcode labels at a variety of

angles, however significant angular distortion may degrade reading

performance.

When mounting the DS41 take into consideration these three ideal label

position angles:

Pitch 0° , Skew 10° to 30° and Tilt 0°

.

Follow the suggestions below for the best orientation:

The

Pitch

angle is represented by the value P in figure 2.30. Position the

reader in order to

minimize

the

Pitch

angle.

Page 40

DATALOGIC DS41

Installation - 2.25

P

Figure 2.30 - Pitch angle

The

Skew

angle is represented by the value S in Figure 2.31. Position the

reader to

assure at least 10°

for the

Skew

angle. This avoids the direct

reflection of the laser light emitted by the DS41.

For raster models, this angle refers to the most inclined or external raster

line, so that all other raster lines assure

more

than 10° Skew.

S

Figure 2.31 - Skew Angle

The

Tilt

angle is represented by the value T in figure 2.32. Position the

reader in order to

minimize

the

Tilt

angle.

T

Figure 2.32 - Tilt angle

Page 41

DS41 DATALOGIC

2.26 - Installation

2.9 TYPICAL LAYOUTS

The DS41 barcode reader was specifically designed for industrial

applications. A typical use is real time identification of moving objects on

conveyor belts.

A photoelectric sensor used as a code presence sensor signals when an

object enters the scanner reading zone (see Figure 2.33).

1

2

Host

DS41

2

Main serial interface

Presence sensor

1

Figure 2.33 - DS41 typical layout

DS41 can be mounted vertically or horizontally to read labels in the two

standard 'picket fence' or 'step ladder' pos itions. A system c an be configured

to read labels in any orientation using several scanners positioned at different

angles.

For each application it is advised that the length of the scan line, the scan

speed, the height of the bars and the code motion speed with respect to the

scanner, allow at least five scans on the code.

The possibility of using raster models allows a greater surface area of the

code to be scanned, increasing the probability of correct reads even if the

code printing quality is poor or the code is positioned incorrectly.

Page 42

DATALOGIC DS41

Installation - 2.27

2.9.1 Master-slave

The master-slave layout is used to collect data from several scanners to

build a multi-sided reading system; there can be one master and up to 5

slaves connected with the RS485 polled mode on the main serial interface.

The master scanner is also connected to a host computer with the RS232

auxiliary interface.

The P.S. signal is unique to the system; there is a single reading phas e and

a single message from the master scanner to the host computer.

In every scanner the jumper block for the selection of the main serial

interface type must be set for RS485 polled (see paragraph 2.4).

In every slave scanner the multidrop address s elec tion must be set within the

range from 0 to 4 max (see paragraph 2.7.2 under "RS485 polled interface").

The DIP switch selections in the master scanner are ignored.

Host

DS41 Master

1

3

2

Main serial interface

1

Auxiliary serial interface

3 Presence sensor

2

DS41 Slave

2

DS41 Slave

2

Figure 2.34 - Master-slave layout

NOTE

The auxiliary serial port of the slave scanners is

only used for configuration.

The termination resistors of the RS485 bus must

not be installed.

Page 43

DS41 DATALOGIC

2.28 - Installation

2.9.2 Local echo

In local echo mode data is tr ans mitted on the auxiliary interface as well as on

the main interface.

Host Mode programming can be accomplished either through the main

interface or the auxiliary interface in local echo mode.

DS41

2

3

Terminal

1

Host

2

3

Main serial interface

Auxiliary serial interface

Presence sensor

1

Figure 2.35 - Local echo layout

2.9.3 Pass through

Pass through mode allows two or m ore devices to be connec ted to a single

external serial interface.

Each DS41 transmits the messages received by the auxiliary interface onto

the main interface.

All messages will be passed through this chain to the host. The main and

auxiliary ports are connected as shown in the figure below:

2

3

3

1

1

Main serial interface

2 Auxiliary serial interface

3 Presence sensor

Host

1

DS41 DS41

Figure 2.36 - Pass through layout

Page 44

DATALOGIC DS41

Reading features - 3.1

3 READING FEATURES

The number of reads performed by the DS41 and therefore the decoding

capacity, is influenced by the following parameters:

•

number of scans per second

•

code motion speed

•

label dimensions

•

scan direction in respect to code motion

At least 5 scans during the code passage should be allowed to ensure a

successful read.

3.1 STEP LADDER MODE

Code motion

moving at LS speed

LH

Laser Beam

DS41

Figure 3.1 - "Step Ladder" scanning mode

If scanning is perpendic ular to the code motion direction (Figure 3.1 - "step

ladder" mode), the number of effective scans performed by the reader is

given by the following formula:

SN = [(LH/LS) * SS] - 2

These symbols signify:

SN = number of effective scans

LH = label height (in mm)

LS = label movement speed (in mm/s)

SS = number of scans per second

Page 45

DS41 DATALOGIC

3.2 - Reading features

For example, the DS41 (800 scans/s ec.), for a 25 mm high c ode moving at

1250 mm/s performs:

[(25/1250) * 800] - 2 = 14 effective scans.

3.2 PICKET FENCE MODE

FW

LW

Code motion

moving at LS speed

Laser Beam

DS41

Figure 3.2 - "Picket Fence" scanning mode

If scanning is parallel to the code motion, (Figur e 3.2 - "picket f ence" mode) ,

the number of effective scans is given by:

SN = [((FW-LW)/LS) * SS] - 2

These symbols signify:

SN = number of effective scans

FW = reading field width (in mm)

LW = label width (in mm)

LS = label movement speed (in mm/s)

SS = scans per second

For example, for a 50 mm wide code moving in a point where the reading

field is 250 mm wide at a 1500 mm /s speed, the DS41 (800 s cans per sec .),

performs :

[((250-50)/1500) * 800] - 2 = 104 scans

Page 46

DATALOGIC DS41

Reading features - 3.3

3.3 PERFORMANCE

The DS41 scanner is available in four standard versions according to the

optical resolution characteristics (see paragraph 1.3).

The Standard resolution version is a general purpose model whose optical

resolution allows code reading from 0.20 mm to 1.00 mm narrow bars in the

zone between 50 and 400 mm from the emission window. This version can

distinguish between high density codes (between 0.20 mm and 0.30 mm)

and low density codes (above 0.33 mm) by programming the software

resolution parameter (see the section "Scanner Res olution" in the WINHOST

Help On Line).

The Very High resolution version has an optical resolution that allows reading

very high density codes (typical values from 0.10 mm to 0.20 mm narrow

bars) in the zone from 55 to 125 mm from the emission window. The

software resolution param eter for this vers ion should be set to high (see the

section "Scanner Resolution" in the WINHOST Help On Line).

The Raster version R1 is a raster model used to read codes from 0.20 mm to

1.00 mm narrow bars with a raster aperture of about 12 mm at a 200 mm

distance.

The Raster version R2 is a raster model used to read codes from 0.20 mm to

1.00 mm narrow bars with a raster aperture of about 40 mm at a 200 mm

distance.

Refer to the diagrams given in paragraph 3.4 for further details on the

reading features. Thes e diagrams refer to the two standard optical versions

and are taken on various resolution sample codes at a 25 °C ambient

temperature, depending on the conditions in the notes under each diagram.

If standard devices do not s atisfy specif ic requirem ents , contac t your nearest

Datalogic distributor, supplying code samples, to obtain com plete infor m ation

on the reading possibilities.

Page 47

DS41 DATALOGIC

3.4 - Reading features

3.4 READING DIAGRAMS

DS41-1x and DS41-6x

(Standard Resolution, 800 scans/s)

NOTE: (0,0) IS THE CENTER OF THE LASER BEAM OUTPUT WINDOW

0.30 mm

0.20 mm

CONDITIONS:

Code = Interleaved 2/5 or Code 39

PCS = 0.90

"Pitch" angle = 0

°

"Skew" angle = 10

°

"Tilt" angle = 0

°

SW Resolution = High

Page 48

DATALOGIC DS41

Reading features - 3.5

DS41-1x and DS41-6x

(Standard Resolution, 800 scans/s)

NOTE: (0,0) IS THE CENTER OF THE LASER BEAM OUTPUT WINDOW

0.50 mm

0.60 mm

0.80 mm

1.00 mm

CONDITIONS:

Code = Interleaved 2/5 or Code 39

PCS = 0.90

"Pitch" angle = 0

°

"Skew" angle = 10

°

"Tilt" angle = 0

°

SW Resolution = Low

Page 49

DS41 DATALOGIC

3.6 - Reading features

DS41-2x and DS41-7x

(Very High resolution, 800 scans/s)

NOTE: (0,0) IS THE CENTER OF THE LASER BEAM OUTPUT WINDOW

0.20 mm

0.15 mm

0.10 mm

CONDITIONS:

Code = Interleaved 2/5 or Code 39

PCS = 0.90

"Pitch" angle = 0

°

"Skew" angle = 10

°

"Tilt" angle = 0

°

SW Resolution = High

Page 50

DATALOGIC DS41

Maintenance - 4.1

4 MAINTENANCE

4.1 CLEANING

Clean the laser beam output window periodically for continued correct

operation of the reader.

Dust, dirt, etc. on the window may alter the reading performance.

Repeat the operation frequently in particularly dirty environments.

Use soft material and alcohol to clean the window and avoid any abrasive

substances.

WARNING

Clean the window of the DS41 when the scanner is

turned off or, at least when the laser beam is deactivated.

Page 51

DS41 DATALOGIC

4.2 - Maintenance

This page is intenti onal l y l ef t blank.

Page 52

DATALOGIC DS41

Technical features - 5. 1

5 TECHNICAL FEATURES

DSP MODELS

(Note 1)

NPP MODELS

(Note 1)

ELECTRICAL FEATURES

INPUT POWER

Supply voltage 10 to 30 Vdc

Power consumption max. 5 W 4 W

SERIAL INTERFACES

MAIN RS232, RS485 Non Polled, RS485 Polled,

20 mA Pass ive C. L.

AUXILIARY RS232

BAUD RATES

All Interfaces 150 to 19200

CONTROL INPUTS

PRESENCE SENSOR (optocoupled NPN or PNP)

Voltage max. 30 Vdc

Input current m ax. 25 mA

CONTROL OUTPUTS

NO READ, RIGHT READ, WRONG READ (optocoupled)

V

CE

max. 40 Vdc

Collector current max. 40 mA continuous; 130 mA pulsed

VCE saturation 1V at 10 mA max.

Power dissipation m ax.

90 mW at 40 °C (Ambient temp.)

OPTICAL FEATURES

Light source Semiconductor laser diode

Wave length (Note 2) 630 ~ 680 nm

Safety class Class 2

READING FEATURES

(Note 3)

Scan rate 800 scans/second

Reading distance 50 to 400 mm

Maximum resolution 0.1 mm

Aperture angle 60 degrees

USER INTERFACE

LED indicators power, laser beam active, barcode decoded,

presence sensor act i ve, data transmis sion

Page 53

DS41 DATALOGIC

5.2 - Technical feat ures

DSP MODELS

(Note 1)

NPP MODELS

(Note 1)

SOFTWARE FEATURES

READABLE CODE SYMBOLOGIE S

Up to 22 readable symbologies including:

Code 93 (Standard and Full ASCII )

• •

EAN/UPC (including Add-on 2 and Add-on 5)

• •

Code 39 (Standard and Full ASCII )

• •

2/5 Interleaved

• •

Codabar

• •

Code 128

• •

EAN 128

• •

Plessey

•

CODE SELECTION

up to six codes during one reading phase

CODE POSITON

can be verified and

displayed

cannot be verified

and displayed

DECODING SAFETY

can enable multiple good reads of same

code

HEADERS AND TERMI NATORS

up to four headers and four terminators

OPERATING MODES

ON LINE, AUTOMATIC, SERIAL ON LINE, TEST

CONFIGURATION MODES

• through menus using WINHOST ut ility

• receiving commands from one of the

serial ports (HOST MODE)

PARAMETER STORAGE

Non-volatile internal EEPROM

ENVIRONMENTAL FEATURES

Operating temperature (Not e 4)

0 to 40 °C

Storage temperature

-20 to 70 °C

Humidity m ax. 90% non condensing

Vibration resistance IEC 68-2-6 test FC 1.5 mm;

10 to 55 Hz; 2 hours on each axis

Shock resistance IEC 68-2-27 test EA 30G;

11 ms; 3 shocks on each axis

Protection class IP65

PHYSICAL FEATURES

Mechanical dimens i ons 101 x 83.5 x 42 mm

Weight 800 g.

Note 1: Refer to paragraph 1.3 for model descript i ons.

Note 2: The features given are typical at a 25 °C ambient temperature (if not otherwise

indicated).

Note 3: Further details given in paragraphs 3.3 and 3.4.

Note 4: If the reader is used in high tem perature environm ent s (over 35 °C), us e of the B eam

shutter is advis ed (for details ref er to the sect ion "Beam shut ter" in the Help On Line

of the WINHOST utility program provided with the DS41 dis k.

Loading...

Loading...