DS2400

Installation Manual

DS2400

Installation Manual

DS2400

INSTALLATION MANUAL

DATALOGIC S.p.A.

Via Candini 2

40012 - Lippo di Calderara di Reno

Bologna - Italy

DS2400

Ed.: 01/2002

Datalogic reserves the right to make modifications and improvements without prior notification.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for incidental or

consequential damages resulting from the use of this material.

Product names mentioned herein are for identification purposes only and may be trademarks and or

registered trademarks of their respective companies.

© Datalogic S.p.A. 1999 - 2002

821000423 (Rev. C)

CONTENTS

GUIDE TO INSTALLATION ......................................................................... v

GENERAL VIEW ..........................................................................................vi

SAFETY PRECAUTIONS............................................................................vii

Laser Safety.............................................................................................vii

Standard Regulations...............................................................................vii

Power Supply........................................................................................... ix

1 GENERAL FEATURES ................................................................................ 1

1.1 Introduction ................................................................................................... 1

1.2 Description.................................................................................................... 2

1.3 Available Models........................................................................................... 3

1.4 Accessories................................................................................................... 4

1.5 GFC-2100 Accessory Installation.................................................................. 4

2 INSTALLATION............................................................................................ 5

2.1 Package Contents......................................................................................... 5

2.2 Mechanical Installation.................................................................................. 6

2.3 Junction Box Installation ............................................................................... 7

2.3.1 Junction Box Mounting.................................................................................. 7

2.3.2 Junction Box Electrical Connections............................................................. 9

2.4 Electrical Connections ................................................................................ 12

2.4.1 Power Supply.............................................................................................. 13

2.4.2 Main Serial Interface................................................................................... 13

RS232 Interface ......................................................................................14

RS485 Full-Duplex Interface ...................................................................15

RS485 Half-Duplex Interface...................................................................16

20 mA Current Loop Interface (INT-22 Accessory Only)......................... 17

2.4.3 Auxiliary RS232 Interface............................................................................ 18

Code Verifier ........................................................................................... 19

2.4.4 Inputs .......................................................................................................... 19

2.4.5 Outputs ....................................................................................................... 21

2.5 Positioning .................................................................................................. 22

2.6 Typical Layouts........................................................................................... 23

2.6.1 Point-to-Point .............................................................................................. 24

2.6.2 Pass Through.............................................................................................. 25

2.6.3 RS232 Master/Slave................................................................................... 26

2.6.4 RS485 Master/Slave................................................................................... 27

2.6.5 Multiplexer................................................................................................... 28

iii

3 READING FEATURES ............................................................................... 29

3.1 Step-Ladder Mode ...................................................................................... 29

3.2 Picket-Fence Mode..................................................................................... 30

3.3 Performance ............................................................................................... 31

3.3.1 Raster ......................................................................................................... 31

3.4 Reading Diagrams ...................................................................................... 32

4 MAINTENANCE.......................................................................................... 34

4.1 Cleaning...................................................................................................... 34

5 TECHNICAL FEATURES ........................................................................... 35

iv

GUIDE TO INSTALLATION

The following can be used as a checklist to verify all of the steps necessary for

complete installation of the DS2400 scanner.

1) Read all information in the section "Safety Precautions” at the beginning of this

manual.

2) Correctly position and mount the scanner for barcode reading according to the

information in par. 2.2, 2.5 and 3.4.

3) Provide correct system cabling according to the signals necessary for your

application (see all sub-paragraphs under 2.3 and 2.4). See also sub-paragraphs

under 2.6 for reference.

4) Install the Configuration Disk.

Upon successful completion of the installation, the readme.hlp file is opened,

giving details about how to get started configuring your scanner.

See also the Guide To Rapid Configuration link.

Specific parameter details are available in the Help On Line.

Fine tuning of the scanner position for barcode reading can be

accomplished using the Test Mode as described in WinHost.

NOTE

The installation is now complete.

v

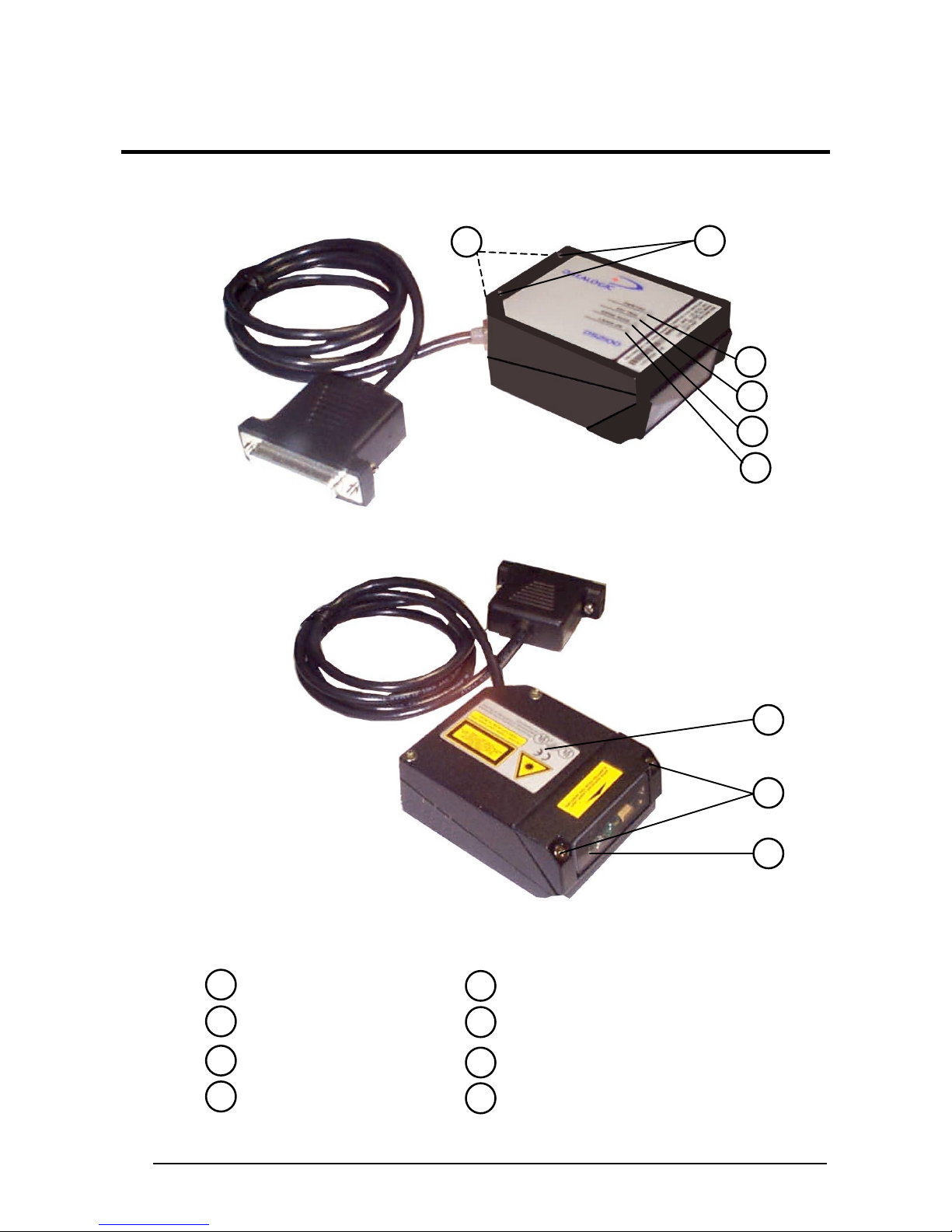

GENERAL VIEW

DS2400

8

8

1

2

3

4

Power ON \ Data Tx LED

1

2

External Trigger LED

Good Read LED

3

Laser ON LED

4

Figure A

5

6

7

8

5

7

6

Warning and Device Class Labels

Laser Beam Output Window

Accessory Mounting Holes

Mounting Holes

vi

SAFETY PRECAUTIONS

LASER SAFETY

The following information is provided to comply with the rules imposed by

international authorities and refers to the correct use of the DS2400 scanner.

Standard Regulations

This scanner utilizes a low-power laser diode. Although staring directly at the laser

beam momentarily causes no known biological damage, avoid staring at the beam as

one would with any very strong light source, such as the sun. Avoid that the laser

beam hits the eye of an observer, even through reflective surfaces such as mirrors,

etc.

This product conforms to the applicable requirements of both IEC 825-1 and CDRH

21 CFR 1040 at the date of manufacture. The scanner is classified as a Class 2 laser

product according to IEC 825-1 regulations and as a Class II laser product according

to CDRH regulations.

There is a safety device which allows the laser to be switched on only if the motor is

rotating above the threshold for its correct scanning speed.

The laser beam can be switched off through a software command (see also «Beam

Shutter» in the WinHost Help On Line).

Use of controls or adjustments or performance of procedures other

than those specified herein may result in exposure to hazardous

WARNING

The laser light is visible to the human eye and is emitted from the window on the front

of the scanner (Figure A, 6).

visible laser light.

vii

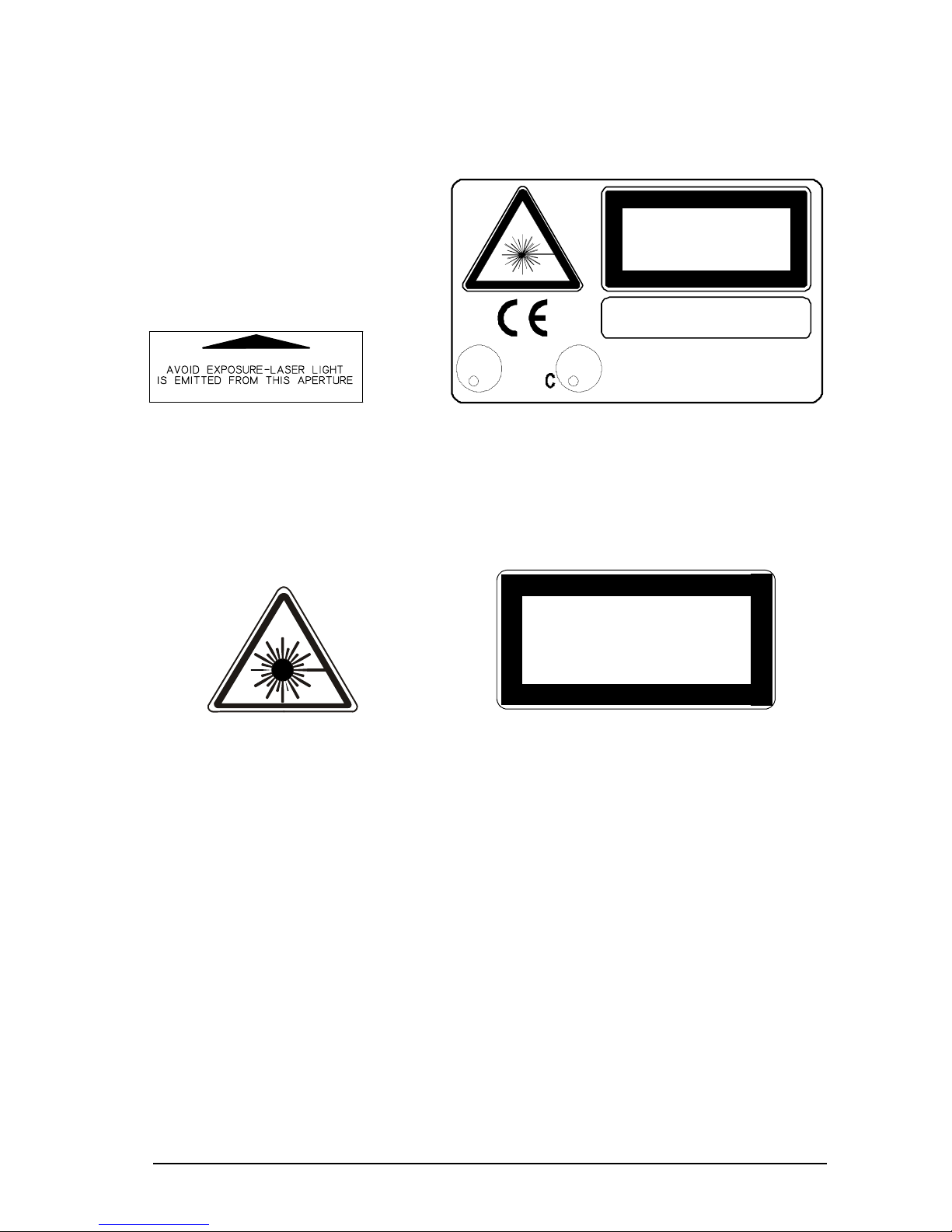

Warning labels indicating exposure to laser light and the device classification are

applied onto the body of the scanner (Figure A, 5).

LASER LIGHT

DO NOT S TARE INT O BEAM

CLASS 2 LASER PRODUCT

MAX. OUTPUT RADIATION 1 mW

EMITTED WAVE LENGTH 630~680 nm

TO IEC 825-1 (1993)

CAUTION - LASER LIGHT WHEN OPEN

AVOID E XPOSURE T O BEAM

U

R

L

LISTED

ACCES SORY

45AF

I.T.E.

This product conforms to the applicable

U

requirements of 21CFR1040 at the date

L

R

of manufacture.

Warning and device class labels

Disconnect the power supply when opening the device during maintenance or

installation to avoid exposure to hazardous laser light.

LASER LIGHT

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

MAX. OUTPUT RADIATION 7 mW

EMITTED WAVE LENGTH 630~680 nm

TO IEC 825- 1 (1993)

Laser diode class label

The laser diode used in this device is classified as a class 3B laser product according

to IEC 825-1 regulations and as a Class IIIb laser product according to CDRH

regulations. As it is not possible to apply a classification label on the laser diode used

in this device, the following label is reproduced on the right.

Any violation of the optic parts in particular can cause radiation up to the maximum

level of the laser diode (7 mW at 630 to 680 nm).

viii

POWER SUPPLY

- This product is intended to be installed by Qualified Personnel only.

- Models DS2400-XXX0:

This accessory device is intended to be supplied by a UL Listed Power Unit with

«Class 2» or LPS power source which supplies power directly to the scanner via the

25-pin connector.

- Model DS2400-XXX1:

This accessory device is intended to be supplied via the Junction Box by an NEC

Class 2 Power Source rated 10-30 V, minimum 0.55 A.

ix

x

GENERAL FEATURES

1

1 GENERAL FEATURES

1.1 INTRODUCTION

The DS2400 laser scanner satisfies the most advanced needs of a wide range of

users. It has been developed focusing on the realistic requirements of its target

market. The outstanding result is an extremely compact, cost-effective and easy to

use industrial scanner.

C-Programmability The DS2400 belongs to the generation of Datalogic scanners

that operate under the 'C' programming environment, which

is a recognized industry standard.

Standard Application

Program

Custom Application

Programs

A standard application program is factory-loaded onto the

DS2400. This program controls barcode reading, serial port

interfacing, data formatting and many other operating and

control parameters.

It is completely configurable from a host computer through

the WinHost utility program provided on diskette with the

scanner, or through ESC sequences via the serial interface.

If the Standard Application Program does not meet your

requirements, please contact your local Datalogic distributor.

1

1

DS2400

1.2 DESCRIPTION

Some of the main features of DS2400 are listed below:

• small dimensions and light weight.

• software programmable scanning speed (400 to 1000 scans/sec) on all models.

• linear and raster versions.

• connector and junction box versions.

• completely configurable via serial interface (WinHost).

• 2 serial communication interfaces.

• supply voltage from 10 to 30 Vdc.

• reads all popular codes.

• test mode to verify the reading features and exact positioning of the scanner

without the need for external tools.

• programmable in 4 different operating modes to suit the most various barcode

reading system requirements.

• code verifier.

The DS2400 uses a solid state laser diode as a light source; the light emitted has a

wavelength between 630 and 680 nm. Refer to the section “Safety precautions” at

the beginning of this manual for information on laser safety.

The protection class of the enclosure is IP65, the reader is therefore suitable for

industrial environments where high protection against harsh external conditions is

required.

The four LEDs on the side of the scanner indicate the following:

PWR/TXD

LED (red) (Figure A, 1) indicates the reader is connected to the

power supply or, when blinking (green), data transmission.

GOOD READ

LED (red) (Figure A, 3) is used to signal the possibility of a

successful barcode reading.

EXT TRIG

LED (yellow) (Figure A, 2) indicates external trigger activity. Refer

to par. 2.4.4.

LASER ON LED (green) (Figure A, 4) indicates laser ON state.

The screw holes on the body of the reader are for mechanical fixture (Figure A, 8).

2

GENERAL FEATURES

1

1.3 AVAILABLE MODELS

The DS2400 scanner is available in versions that differ in regard to the following

parameters:

• Reading range

• Serial interfaces

• Linear or raster reading

• Connections

The following models are therefore available:

DS2400 - X X X X

Reading Range

1 = Medium range

2 = Long range

Serial Communication Interface

0 = RS232 main + RS232 aux

1 = RS485 main + RS232 aux

Connections

0 = Connector

1 = Junction Box

Linear/Raster

0 = Linear

1 = Raster

The following tables display each version’s reading performance.

Version Max Code Resolution Speed

mm (mils) scans/s

1XXX 0.25 (10) 400 to 1000

2XXX 0.35 (14) 400 to 1000

Version Reading Distance

1XXX 100 mm (4 in) - 440 mm (17 in) on 0.50 mm (20 mils) codes

2XXX 200 mm (8 in) - 600 mm (23.5 in) on 0.50 mm (20 mils) codes

See reading diagrams in par. 3.4 for further details.

3

Loading...

Loading...