Page 1

11111 Bren Road West

Minnetonka, MN 55343-9015

952.933.1223

952.933.7971 FAX

Datacard is a registered trademark of DataCard Corporation.

July 2005 558871-201 Rev. A

Dealer information:

CP60 Printer Guide

558871-201 Rev. E

July 2005

Page 2

Information resources for the CP60 Card Printer

CP60 Quick

Install Guide

The Quick Install Guide, packe d at the t op of the p rinter

carton, shows you the steps to install the printer.

For detailed installation information, see e-Guide/

InfoCent.chm on the driver CD-ROM.

CP60 Printer

Guide

Info Central For in-depth information about using the printer, install

Data

Formatting

Guide

Dealer

Customer Care

The Printer Guide (this document) contains operating

information for the printer. It also tells you how install

the printer.

Info Central on a Windows PC, then click the icon on

the desktop. (Insert the Card Printer CD-ROM and

choose User Information to install Info Central.)

Describes how to set up the printer and your data

stream to use the Open Card data format.

Find the Guide on the Open Card CD-ROM, shipped

only with the Open Card option.

For help with questions not addressed by other CP Series printer information, contact your dealer.

Contact the Datacard Customer Care Center at 1.800.328.3996 (U.S. & Canada) or 1.952.988.2316

(worldwide).

Page 3

About the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The outside of the printer . . . . . . . . . . . . . . . . 1

The inside of the printer. . . . . . . . . . . . . . . . . . 3

Features and options. . . . . . . . . . . . . . . . . . . . 3

Loading cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Loading print ribbon . . . . . . . . . . . . . . . . . . . . . . . . 7

Power on the printer. . . . . . . . . . . . . . . . . . . . . . . . 9

The LCD panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Make a printer test card . . . . . . . . . . . . . . . . . . . . 13

Data formats for the CP60 Card Printer . . . . . . . . 15

CP Driver data. . . . . . . . . . . . . . . . . . . . . . . . 16

Open Card data format . . . . . . . . . . . . . . . . . 17

Data formats summary . . . . . . . . . . . . . . . . . 19

Printer Installation. . . . . . . . . . . . . . . . . . . . . . . . . 21

Site requirements . . . . . . . . . . . . . . . . . . . . . 22

Useful tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Network installation . . . . . . . . . . . . . . . . . . . . . . . 25

Prepare the printer for installation . . . . . . . . . 26

Connect the printer to the network . . . . . . . . 27

Set up the network printer . . . . . . . . . . . . . . .30

Set the Data Format. . . . . . . . . . . . . . . . . . . .34

Set up for your card design . . . . . . . . . . . . . .35

SNMP Support . . . . . . . . . . . . . . . . . . . . . . . .36

Print a card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

From the CP Driver . . . . . . . . . . . . . . . . . . . .37

Using the Open Card data format . . . . . . . . .38

Cleaning the printer. . . . . . . . . . . . . . . . . . . . . . . .39

Cleaning the printer rollers. . . . . . . . . . . . . . .41

Getting the most out of your printer. . . . . . . . . . . .43

Printer LCD settings . . . . . . . . . . . . . . . . . . . . . . .45

LCD menu system . . . . . . . . . . . . . . . . . . . . .46

View status settings . . . . . . . . . . . . . . . . . . . .47

View the Serial Number . . . . . . . . . . . . .47

View the Firmware Revision . . . . . . . . . .48

View Card Counts. . . . . . . . . . . . . . . . . .49

View the Data Format . . . . . . . . . . . . . . .50

View the Network Address Mode,

IP Addresses, and MAC Address . .51

Change settings . . . . . . . . . . . . . . . . . . . . . . .53

539398-201 Page iii

Page 4

Page iv

Set LCD Backlighting. . . . . . . . . . . . . . . 53

Set the Data Format. . . . . . . . . . . . . . . . 54

Set the Address Mode . . . . . . . . . . . . . . 55

Set the IP Address, Subnet Mask,

and Gateway Address. . . . . . . . . . . 57

Set the K Power. . . . . . . . . . . . . . . . . . . 59

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . 61

Printer supplies . . . . . . . . . . . . . . . . . . . . . . . 63

Color print ribbon . . . . . . . . . . . . . . . . . . 63

Monochrome and Topcoat ribbon . . . . . 63

Monochrome print ribbon . . . . . . . . . . . . 63

Cleaning supplies. . . . . . . . . . . . . . . . . . 64

Printer messages . . . . . . . . . . . . . . . . . . . . . . . . . 65

DM-00760 Duplex Error . . . . . . . . . . . . . 66

DM-00762 Duplex Jam . . . . . . . . . . . . . 67

DM-00765 No Duplex. . . . . . . . . . . . . . . 68

DM-00767 Duplex Jam . . . . . . . . . . . . . 69

IS-01206 No Card Picked . . . . . . . . . . . 70

SY-01305 Data Error . . . . . . . . . . . . . . . 71

SY-01306 Data Error . . . . . . . . . . . . . . . 72

SY-01310 Flash Error . . . . . . . . . . . . . . 73

SY-01312 Flash error . . . . . . . . . . . . . . 74

SY-01314 Flash Error . . . . . . . . . . . . . . 75

SY-01317 Memory Error . . . . . . . . . . . . 76

SY-01325 Data Error. . . . . . . . . . . . . . . 77

SY-01327 Data Error. . . . . . . . . . . . . . . 79

SY-01331 Comm Error . . . . . . . . . . . . . 80

SY-01332 Hardware Error. . . . . . . . . . . 81

MS-01401, MS-01402, MS-01403

Mag Stripe Data . . . . . . . . . . . . . . . 82

MS-01404, MS-01405, MS-01406

Mag Stripe Error. . . . . . . . . . . . . . . 83

MS-01407, MS-01408, or MS-01409

Mag Stripe Error. . . . . . . . . . . . . . . 84

MS-01410, MS-01411, or MS-01412

Mag Stripe Error. . . . . . . . . . . . . . . 85

MS-01413, MS-01414, or MS-01415

Mag Stripe Error. . . . . . . . . . . . . . . 86

MS-01417, MS-01418, MS-01419,

MS-01420, MS-01421 Card Jam . . 87

MS-01424 Mag Stripe Error. . . . . . . . . . 89

Page 5

MS-01425 Mag Stripe Error. . . . . . . . . . 91

MS-01426 EEPROM Error. . . . . . . . . . . 92

MS-01427 or MS-01428 Mag

Stripe Error . . . . . . . . . . . . . . . . . . . 93

MS-01429 Mag Stripe Data . . . . . . . . . . 94

MS-01430 Mag Stripe Error. . . . . . . . . . 95

MS-01435 No Mag Stripe. . . . . . . . . . . . 96

PR-01703 Printhead Error . . . . . . . . . . . 97

PR-01705, PR-01706 Card Jam . . . . . . 99

PR-01710 EEPROM Error . . . . . . . . . . 101

PR-01715, PR-01716 Cover Open . . . 102

PR-01718 Printhead Temp . . . . . . . . . 103

PR-01719 Printhead Error . . . . . . . . . . 104

PR-01720 Ribbon Error . . . . . . . . . . . . 10 5

PR-01721 EEPROM Error. . . . . . . . . . 106

PR-01723 Hardware Error. . . . . . . . . . 107

PR-01724 Ribbon Break . . . . . . . . . . . 109

PR-01726 Ribbon Out . . . . . . . . . . . . . 111

PR-01730 Printhead Error. . . . . . . . . . 112

PR-01737 Ribbon Low. . . . . . . . . . . . . 113

PR-01738 Ribbon Error. . . . . . . . . . . . 114

SC-01804 No Smart Card . . . . . . . . . . 115

Safety and compliance (FCC). . . . . . . . . . . 124

Regulatory compliance . . . . . . . . . . . . 124

Liability statement . . . . . . . . . . . . . . . . 126

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . 127

Acknowledgments . . . . . . . . . . . . . . . . 128

Page v

Page 6

About the printer

This guide applies to CP60 Card Printer. The informatio n also applies to the SP60 Card Printer. The printers

include the Built-in Ethernet feature and can include the Open Card option.

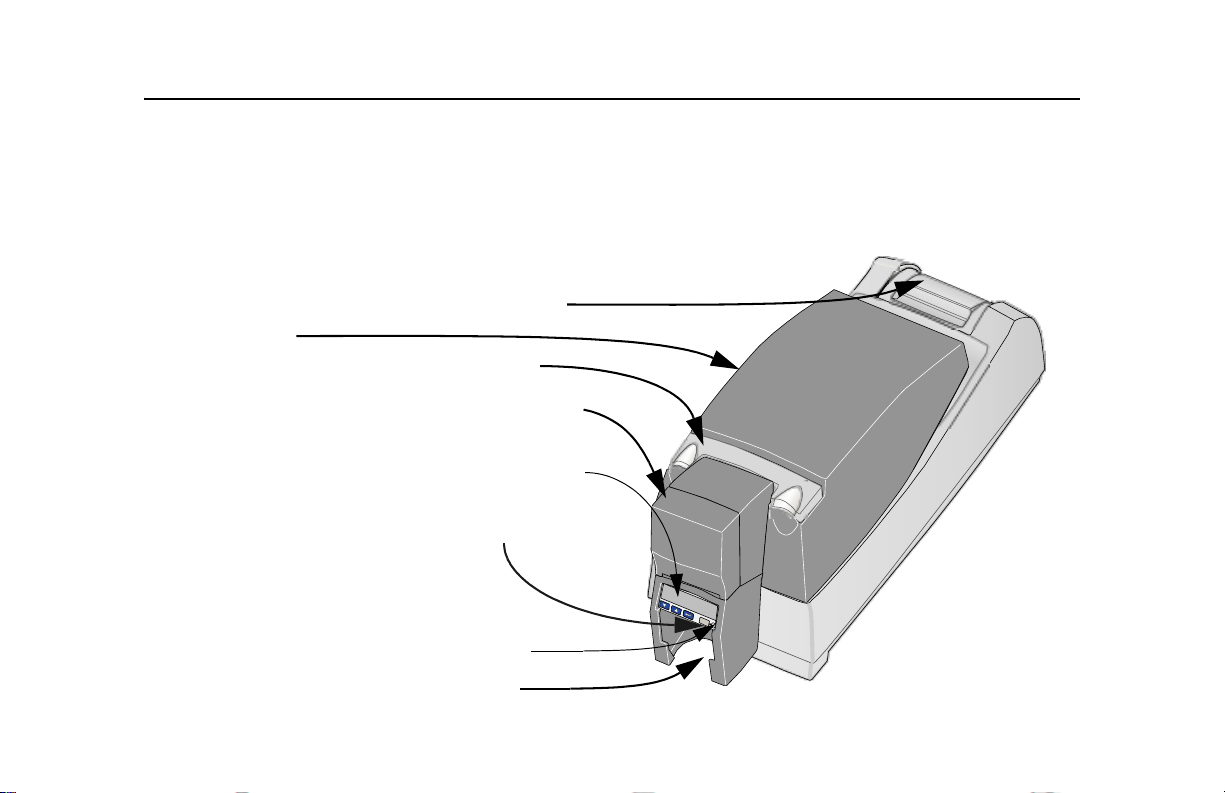

The outside of the printer

Duplex Module: Optional module at the back of the

printer that turns the card to print the other side.

Printer Cover.

Latch: Lift the latch to open the printer cover.

Input Hopper: Open the cover to load blank cards.

LCD Panel: Shows the printer status and any

messages. Use the LCD panel to change network

settings.

Ready Key: Push to pause or resume the

printer.

The Status Light helps you understand printer operation.

"The LCD panel" on page 10 for details.

See

Page 1

Output Hopper: Remove completed cards.

Page 7

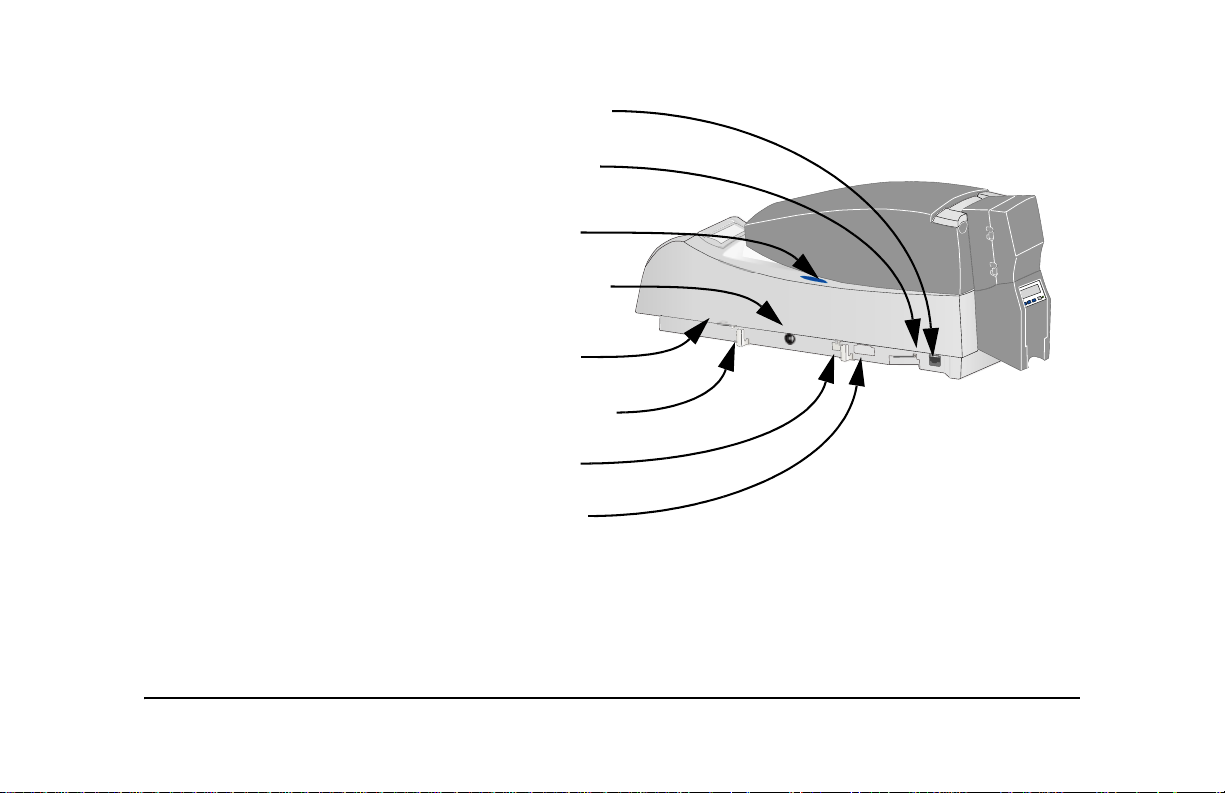

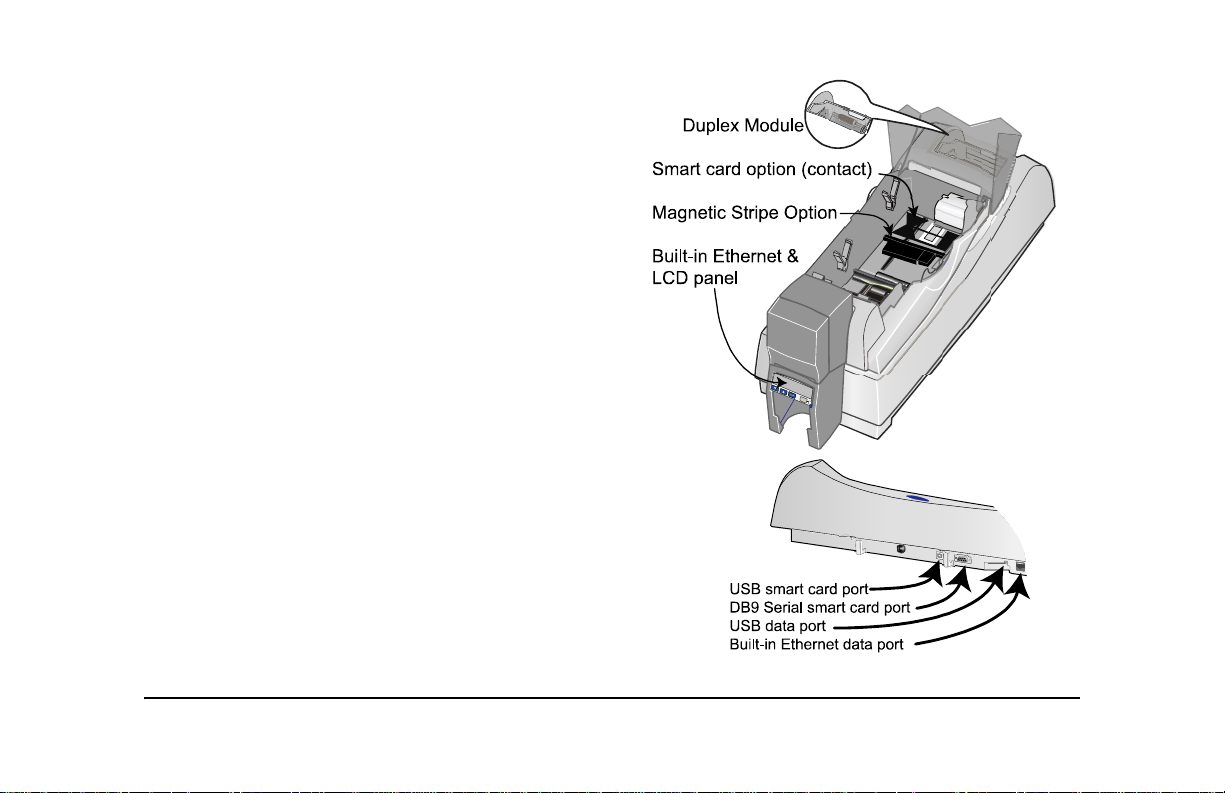

Ports are located on the left side of the printer.

Network Port: Use the Ethernet port to connect a printer

with the Built-in Ethernet feature.

USB Data Port: Connect the data cable to the printer.

ALL printers have this port.

Manual Advance Knob: Use to move a card in the

printer or to turn rollers.

Power Receptacle: Plug in the power supply to power

on the printer.

Security Lock Receptacle: Connect the optional

security lock to the opening under the ledge of the

printer (not visible in this drawing).

Cable Guides: Place the data cable in the guides. (You

can also place the power cable in the guide.)

Optional Smart Card USB Port: See "Features and

options" on page 3.

Optional Smart Card Serial Port: See "Features and

options" on page 3.

Page 2

Page 8

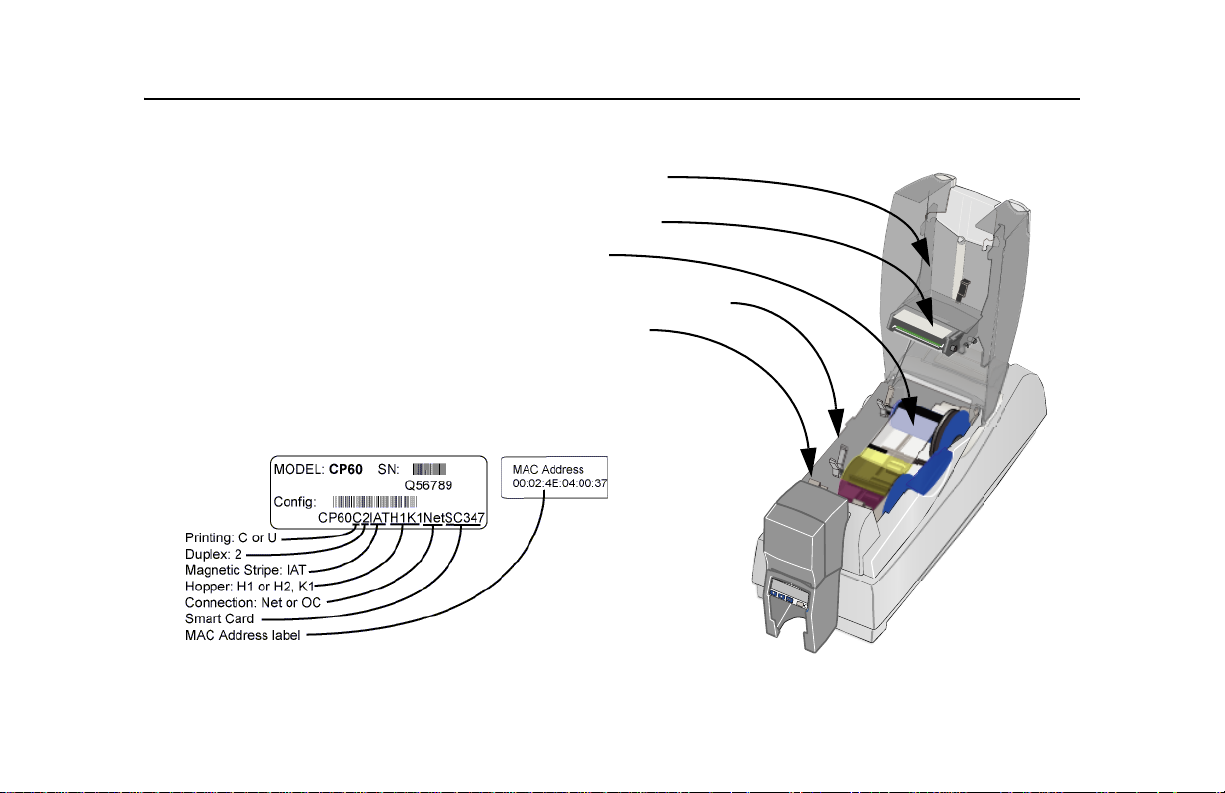

The inside of the printer

Cover Arm: Holds the cover and printhead cartridge in place.

Printhead Cartridge: Applies the image to the card. The label

includes”YMC” for color or “K” for monochrome printheads.

Print Ribbon Cartridge (shown with color print ribbon).

Printer Label: Includes the serial number and model information

(located on the left side of the printer and not visible in this drawing).

Cleaning Roller (not visible in this drawing): Removes dust

and debris from cards.

Features and options

Features and options are identified on the printer label:.

Page 3

• Printers have a MAC address label.

Page 9

• Printers with “U” printing can print one color

(monochrome) only. “C” printing is full-color or

monochrome (with specific ribbons).

• All CP60 printers have a USB data connection. They

also have one of the following:

— Built-in Ethernet (Net) connection

— Open Card (OC) data format and Built-in Ethernet

• Printers can include a duplex (2) module.

•A magnetic stripe module can be a three-track (IAT)

module.

• Printers can have a 100-card (H1) or 200-card (H2)

input hopper. The input hopper can have a lock (K1).

• An optional smart card module can have:

— Combination smart card reader (SC347) with

contact and contactless reader. Visible inside the printer;

includes a USB port on the printer.

— Contactless iCLASS® (SC205) or HID® (SC202) reader;

includes a USB port.

— Contact station (SC400): Visible inside the printer; includes

a serial port.

Page 4

Page 10

Loading cards

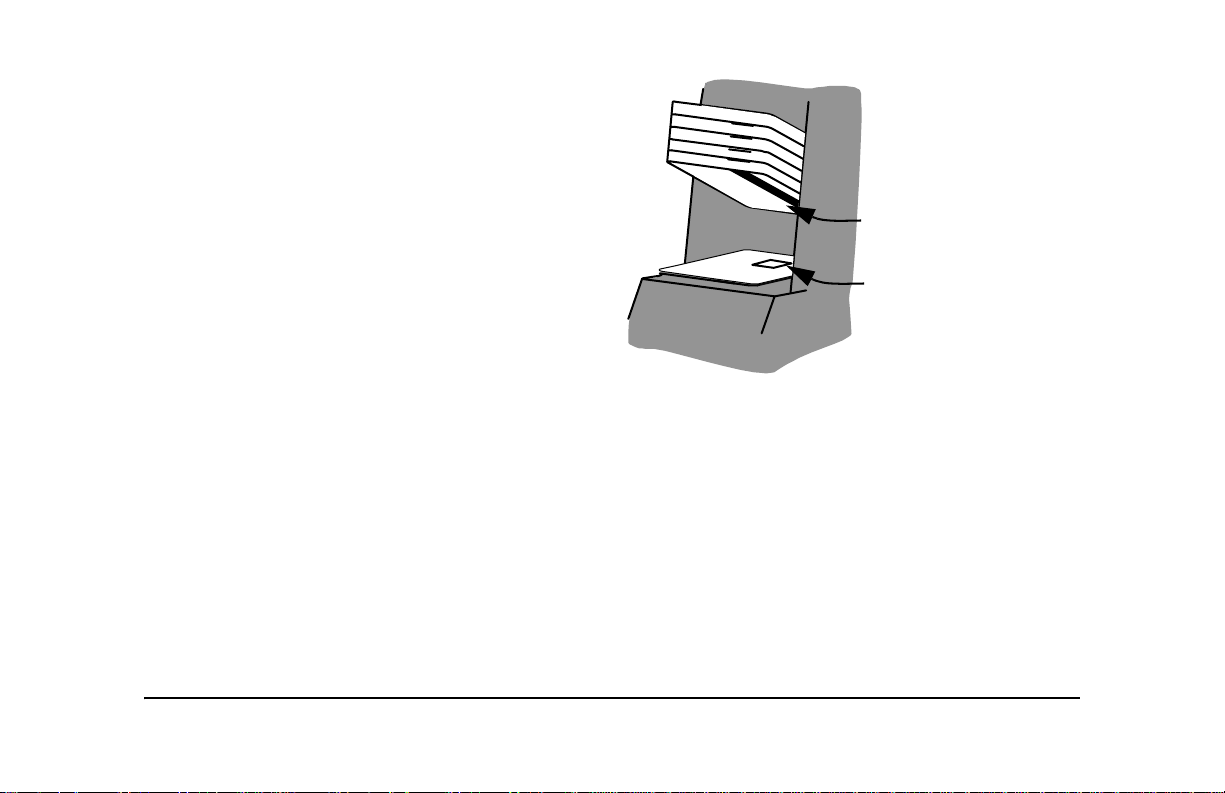

1 Open the input hopper cover.

2 Remove cards from the original package.

Tips: Handling cards

• Cards can stick together: Slide or fan cards to separate the

edges.

• Do not touch the surface of cards before printing them. (Oils

on hands will reduce printing quality.)

• Handle cards by the edges or wear gloves.

• Orient all cards the same way.

Page 5

Page 11

3 Place the cards in the input hopper.

The diagram shows the typical locations for the

magnetic stripe and smart card chip.

4 Push the input hopper cover closed until it

latches.

See Info Central for current information about cards to use in the printer.

Magnetic stripe

Smart card chip

Page 6

Page 12

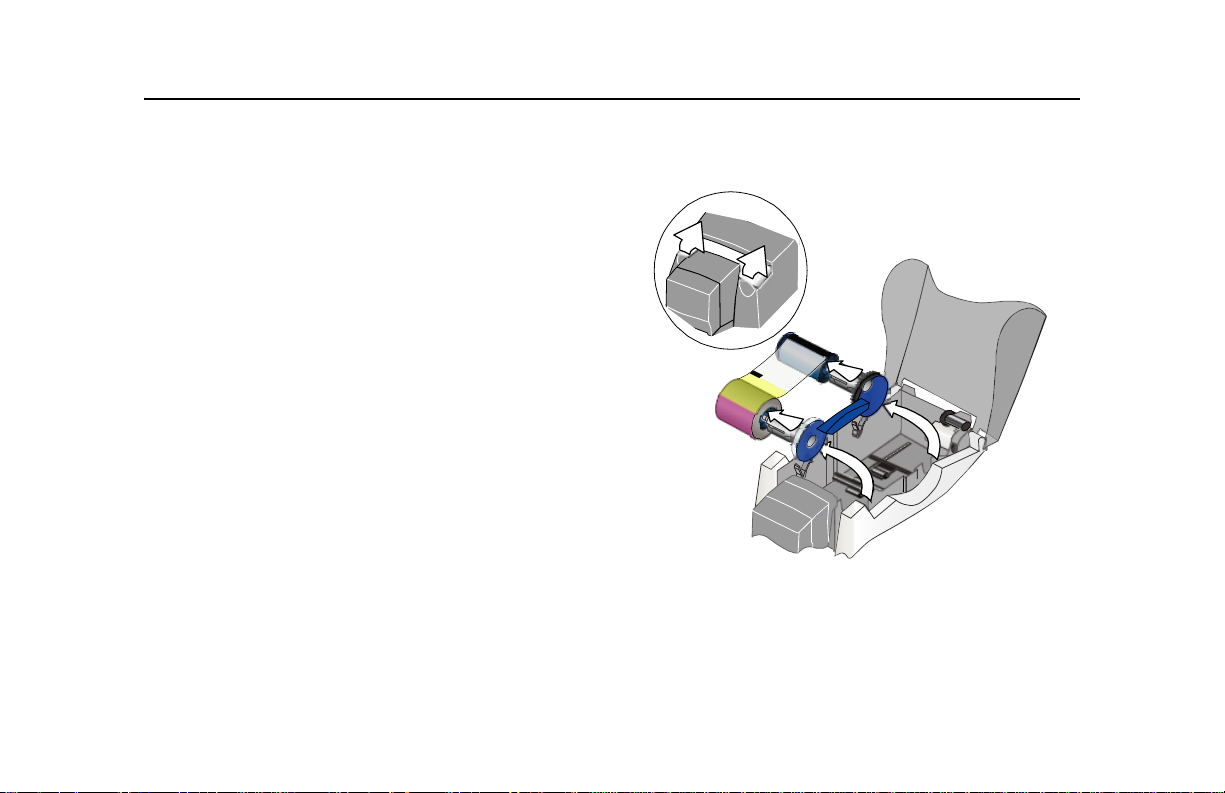

Loading print ribbon

1 Open the printer cover.

2 Remove the ribbon cartridge.

3 Remove both used ribbon spools from the cartridge (if

present).

Tips: Handling print ribbon

• Keep unused ribbon in the original package.

• Don’t place ribbon on a dusty or dirty surface–dirt

could damage the printhead.

4 Run a cleaning card and replace the cleaning sleeve

at the same time that you load a new print ribbon. See

"Cleaning the printer" on page 39 for the steps to

follow.

Page 7

Page 13

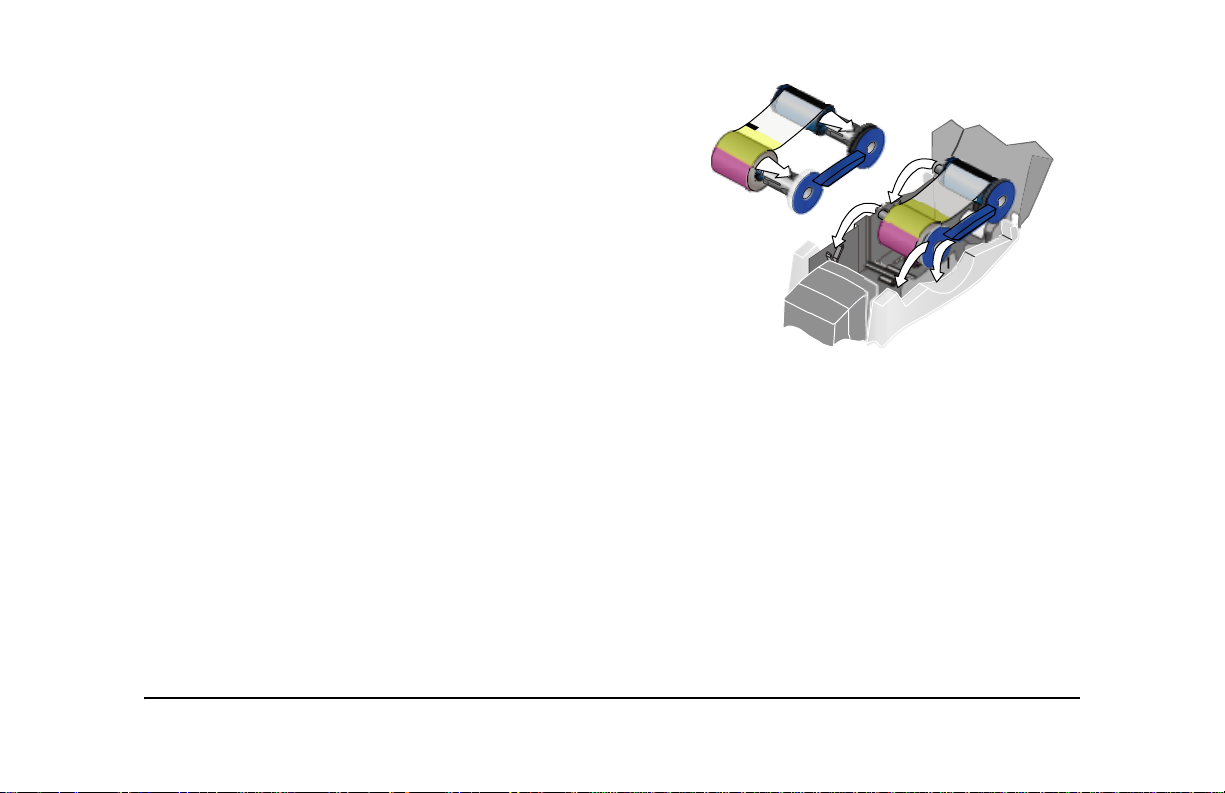

5 Load the new roll of print ribbon on the cartridge.

— Put the full spool of ribbon on the supply spindle of the

ribbon cartridge. Push until the spool clicks onto the

spindle.

— Put the empty take-up spool on the spindle with the solid

black gear. Push until the spool clicks onto the spindle.

6 Replace the loaded ribbon cartridge in the printer.

— Make sure both spindles rest in the black supports on the

left side of the printer.

— Make sure the ribbon ca rtridge handle rests in the

supports on the right side of the printer.

— Make sure to install the full, new spool toward the input

hopper of the printer.

Close the printer cover. Press down firmly to latch it.

Page 8

Page 14

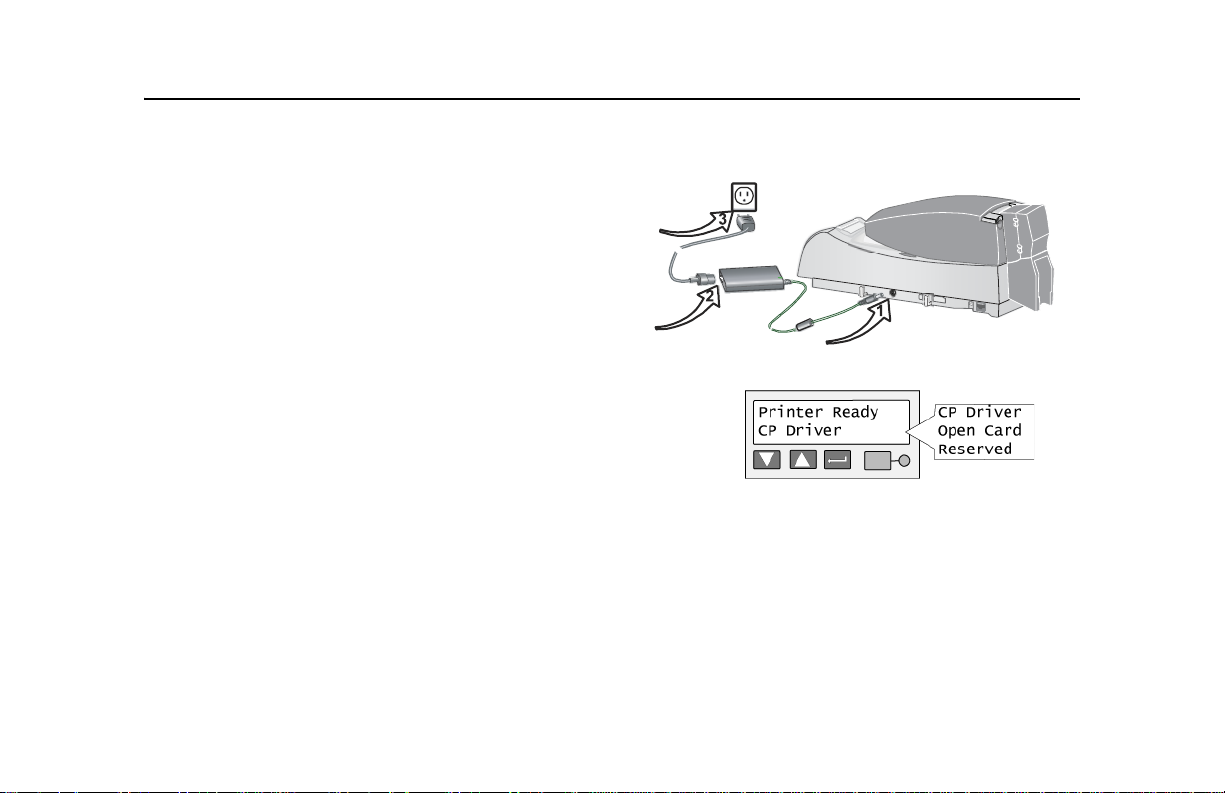

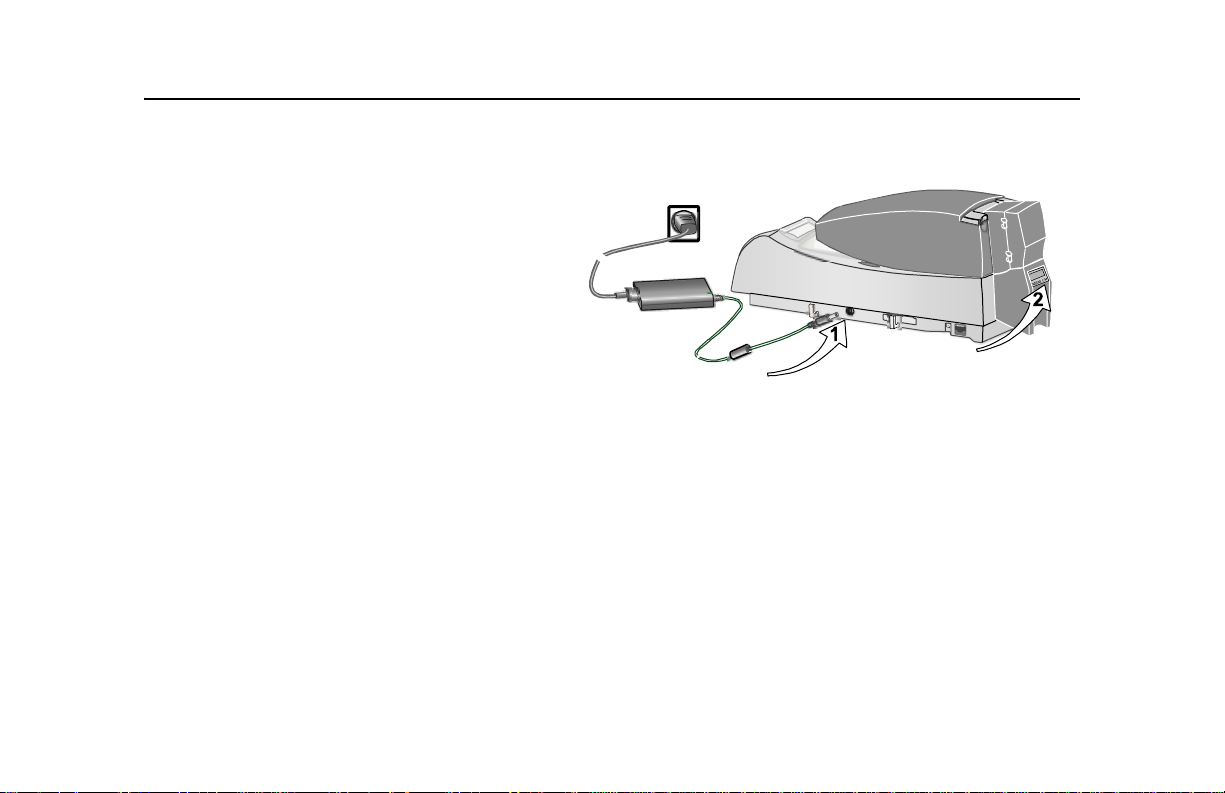

Power on the printer

Plug in the printer to power it on. The printer does not

have a power switch.

1 Make sure the power supply cord connects to the

printer power receptacle (1).

2 Connect the power cord to the power supply (2).

3 Connect the power cord to the power outlet (3).

4 The printer powers on and the Status Light is amber.

5 When the printer is ready to print cards, the Status Light displays

steady green.

The printer must be connected to a computer (locally or through a

network) to print cards. See

Tips for printer power

• Wait while the printer initializes.

• Follow the guidelines for your organization about when to power

the printer on and off.

"Printer Installation" on page 21.

Page 9

Page 15

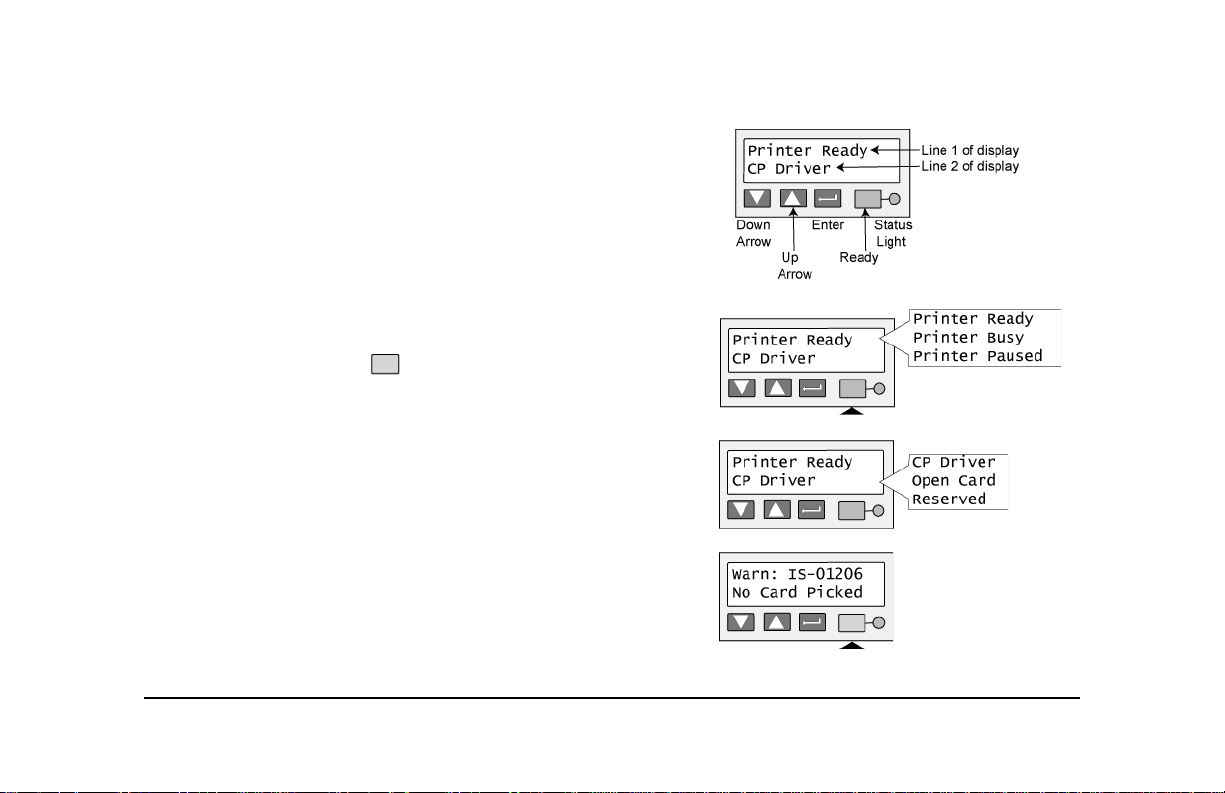

The LCD panel

The CP60 Card Printer with built-in Ethernet includes an LCD panel.

The LCD panel has a 2-line display, four keys, and the Status light.

This section describes what you need to know when printing cards.

See

"Printer LCD settings" on page 45 for detailed information about

viewing and changing network settings.

The LCD panel provides the following:

• Current State (line 1): Shows whether the printer is ready to

print, is busy, or is paused.

— Press the Ready key to pause or resume the printer

(undo pause).

• Data format (line 2): The type of data the printer is ready to

accept.

• Printer messages: The display shows the message number

and a short description of the problem.

— Fix the problem and then press the Ready key to clear the

message. Repeat if another message is displayed.

Page 10

Page 16

— See "Printer messages" on page 65 for details about messages.

• Status: Information about the printer, including printer card

counts and network settings. To view status details:

— Press the Enter key to move to the Main Menu.

— Press the Enter key again to enter the Status Menu.

— Press the Up Arrow or Down Arrow key to

scroll through the Status Menu choices.

— Press the Enter key to view the data.

Page 11

Page 17

— Press the Enter key again to return to the menu.

— Scroll to “Exit” and press the Enter key to leave a choice.

Repeat as needed to leave the menus.

See "Printer LCD settings" on page 45 for details about viewing

and changing settings.

Page 12

Page 18

Make a printer test card

1 Power off the printer.

2 Confirm that cards and print ribbon are

loaded in the printer.

— If the printer has a magnetic stripe

module, the card for a printer test card

must have a magnetic stripe.

— If it is a three-track module, be sure to use

blank cards with the correct coercivity (the

default is high coercivity cards, which are

shipped in the Starter Kit.)

— If the printer has been installed previously and has used a

custom magnetic stripe format, you might need to set the printer

to use the default encoding format for the module. See Info

Central for information on Magnetic stripe setup.

3 Power on the printer (1). Within 5 seconds, press and hold the

Ready key (2), as shown in the illustration. Hold the Ready key

firmly until the printer sounds three tones and displays “Printer Test

Card” on the LCD panel, usually about

4 Release the Ready key and observe the printer. You hear the

internal components initialize and the printer starts processing the

card.

15 to 30 seconds.

Page 13

Page 19

5 After it is printed, remove the card from the output hopper.

Tips for success

• Allow 30 to 60 seconds for the printer to begin printing the test card.

• The status light will flash green while the printer is processing the data.

• If the status light is steady amber and the printer beeps, the printer is paused. Press the Ready key once to

un-pause the printer.

• If the printer test card did not print successfully, try the procedure again, making sure you follow the

instructions. If the test card does not print, or if the printer does not initialize, contact your service provider.

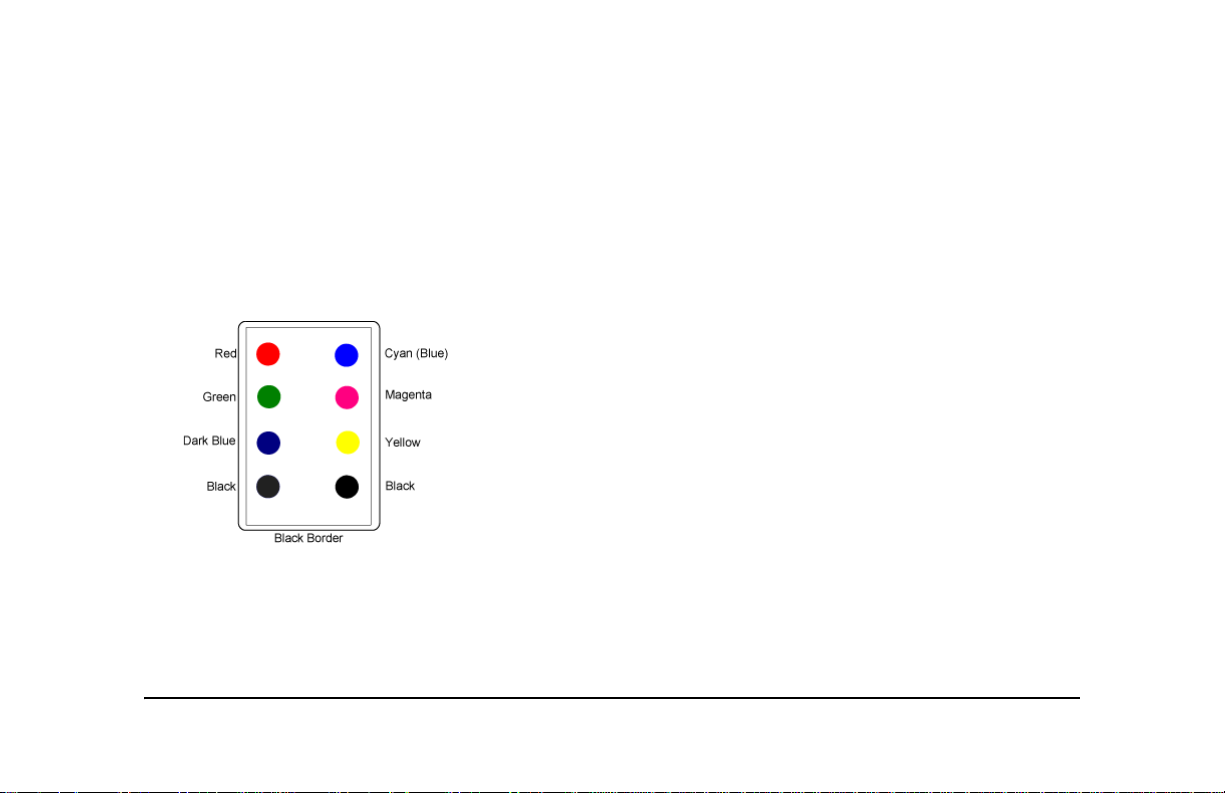

• The test card has the pattern shown. (The pattern will be monochrome dots, not colored dots, if the printer

uses a monochrome ribbon.)

Page 14

Page 20

Data formats for the CP60 Card Printer

All CP60 printers are shipped with the CP Driver CD-ROM, and can print cards sent by the CP Driver (when the

Data Format is set to CP Driver). The printer can also be purchased with the Open Card option. Printers with the

Open Card option can also print cards using the Open Card data format (when the Data Format is set to Open

Card). This section describes the requirements and functionality of each format.

Page 15

Page 21

CP Driver data

The printer can be used with the CP Driver installed on a PC. The CP Driver receives

data from your Windows application and formats it for the printer. The printer can print

one or both sides of the card (duplex printing), print in landscape or portrait

orientation, and print in full color or one color.

The driver formats (renders) the data for each card. It can accept text, photos,

backgrounds, logos and other elements such as bar codes if they are supported by

the Windows application. With the corresponding options, the printer can encode a

magnetic stripe on the front or back of the card and read or program a smart card.

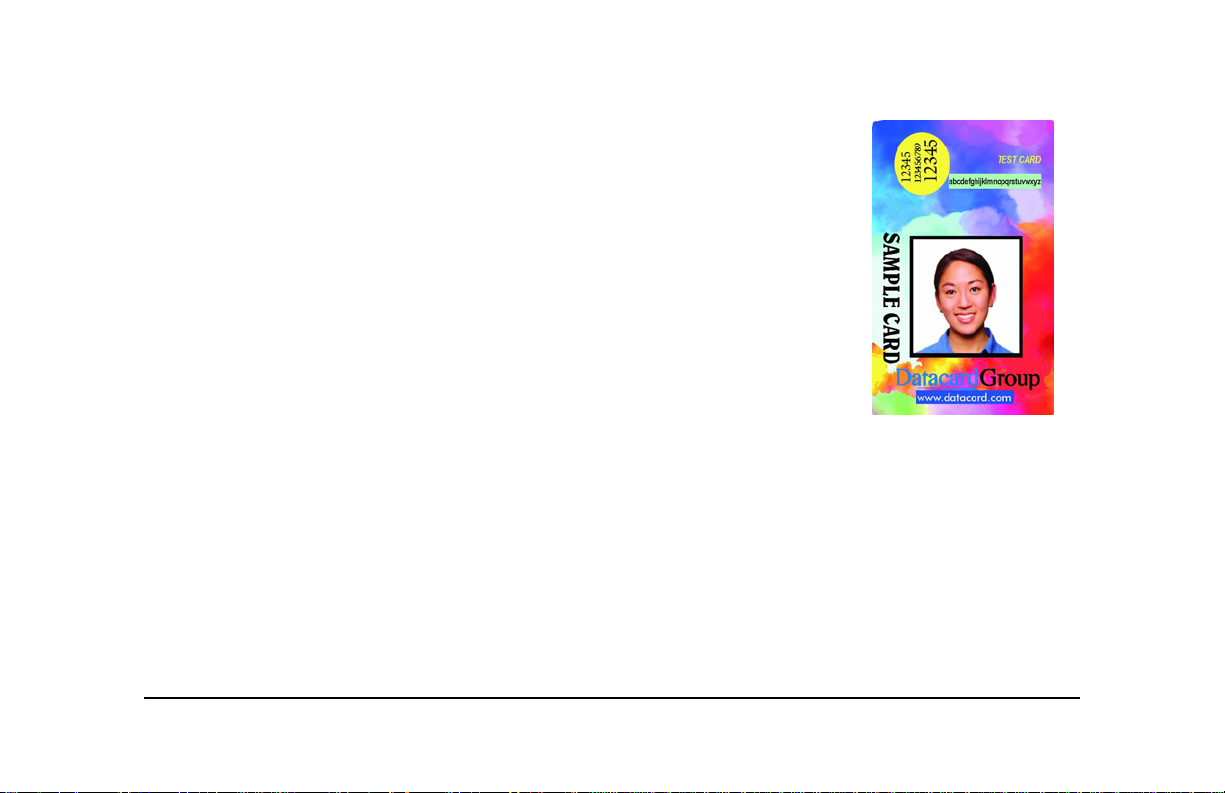

The sample card on this page is printed when you use the “Print Sample Card” button

of the Printer Toolbox, which is part of the CP Driver. It shows typical features of a

card printed using the CP Driver and the printer (with a full-color ribbon).

When you print from the CP Driver, any errors on the printer cause a message to be

displayed on the PC, in addition to being displayed on the printer LCD panel. For best

results, use buttons on the message box to clear the message from the printer and driver. (This also clears the

message from the LCD panel.) Using the driver provides you with adva nced features including retrying the card.

Page 16

Page 22

Open Card data format

The Open Card data format uses ASCII data. Any host computer that can generate an ASCII (text) data stream

and send it to the printer using TCP/IP (or TCP/IP with LPD/LPR) can send card data using the Open Card data

format. Organizations that use operating systems other than Windows can print cards without inserting a PC

between the host computer and the printer (provided that the systems can generate an ASCII data stream).

The Open Card feature provides two methods for specifying the format of the data; supported Open Card

commands and Card Layout menus in the printer. For organizations that currently send data tagged with Open

Card commands to a printer or embosser, the printer can produce printed cards from the same data stream. Or,

you can use the Card Layout menus to define card designs that reside in the printer and format the data.

The Open Card feature supports printing text, printing bar codes, printing logos, and encoding magnetic stripe

data on a card. For text, you can choose from several fonts and sizes that are printer-resident. For bar codes, you

can also choose from several bar code fonts (for different types of bar codes) and sizes. For graphics, you can

download up to four black-and-white logo files to the printer and choose where to place the files on the card. The

printer does not provide the ability to download a different graphic for each card. Each text or graphic field can be

rotated independently. In addition, the entire card design can be rotated to change the relationship of printing to

the magnetic stripe.

For magnetic stripe data, you can define encoding formats in the printer (using Printer Diagnostics) and then

send up to three tracks of data (with a magnetic stripe option). For some features, you must use a PC running the

CP Driver and Printer Diagnostics to configure the printer. After configuring, you can use the host computer to

send Open Card data and print cards.

Page 17

The Open Card format supports printing with one color on one side of the card in landscape mode. If you use a

full-color ribbon in a full-color printer when you send Open Card data, the printer will use only the K panel in the

Page 23

ribbon and ignore the color and topcoat panels. The magnetic stripe (if it is encoded) must be located on the side

of the card opposite the printing.

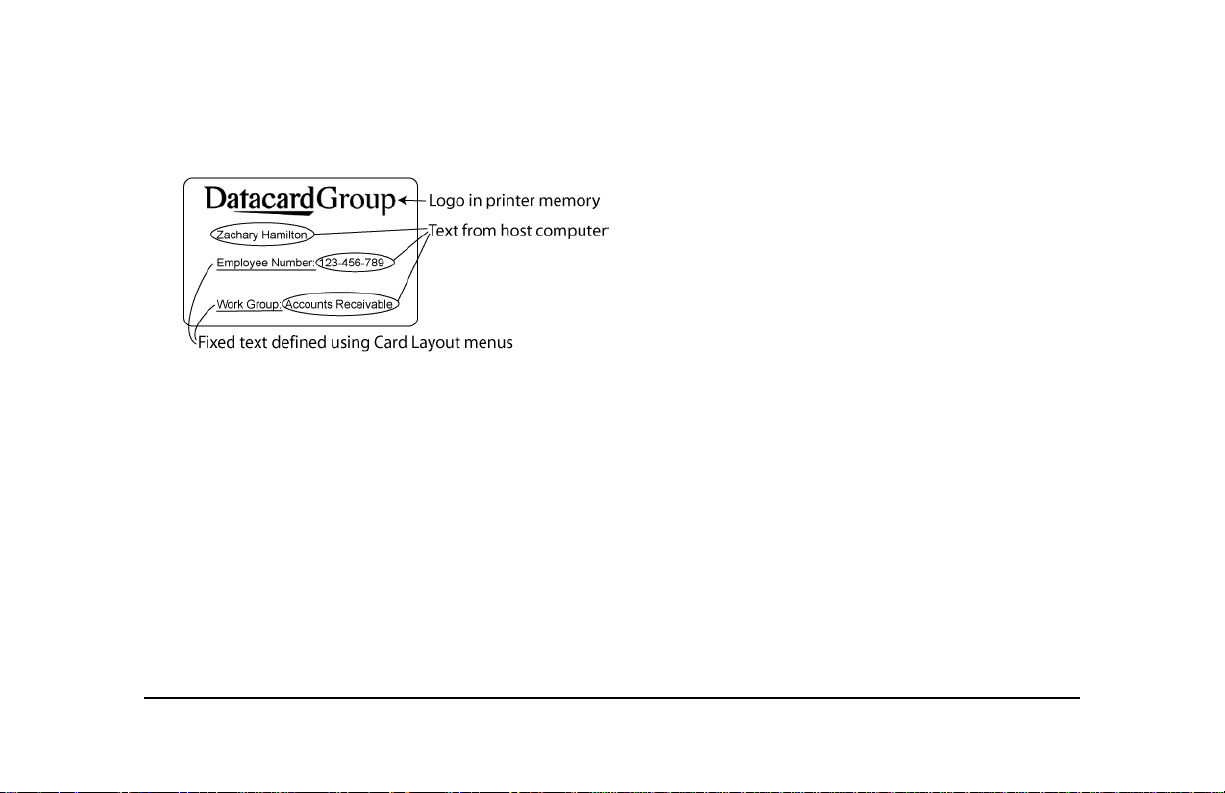

The following card shows some of the features available using the Open Card forma t.

When you use the Open Card format, messages are displayed on the printer LCD panel. This guide provides

information for fixing problems. Use the Ready key on the LCD panel to clear the message from the printer.

The Open Card features are typically used with an Ethernet connection and a network. You can also use the

Open Card data format through the printer USB port when using a print server. See the Data Formatting Guide

for details on using the Open Card format.

See "Network installation" on page 25 for details on installing and setting up the printer for the data format you

choose.

Page 18

Page 24

Data formats summary

The following table summarizes the requirements and features for each data format.

Open Card CP Driver

Page 19

Source of data Any host computer that produces

an ASCII data stream and uses

TCP/IP (RAW or LPD/LPR)

Data formatted by Open Card commands or Card

Layout menus

Type of connection Ethernet port Ethernet or USB ports

Printer Messages Displayed on LCD panel Displayed in Windows message

Configuration tools • Network configuration utility

and LCD panel

• Telnet to use Card Layout

menus (optional)

• Text editor or batch process

to insert Open Card

commands in data (optional)

• Printer Diagnostics (on PC

with CP Driver))

Windows application (with the

CP Driver running on a Windows

PC)

CP Driver running on a Windows

PC

boxes and on LCD panel

• Network configuration utility

and LCD panel

• Printer Toolbox

• Printer Properties and

Printing Preferences

• Printer Diagnostics (on PC)

Page 25

Features:

• Print on both sides

• Portrait or landscape

orientation

• Rotate card 180 degrees

• Rotate fields

• Full-color or monochome

printing

• Unique graphics on each

card

• Different design for each card

• Magnetic stripe encoding

• Smart Card programming

Example:

Open Card CP Driver

•No

• Landscape only

•Yes

•Yes

• Monochrome only

• Up to 4 downloaded logos on

a card

•No

•Yes

•No

•Yes

•Both

•Yes

• Yes (using an application)

• Yes (with full-color printing

feature)

•Yes

•Yes

•Yes

•Yes

Page 20

Page 26

Printer Installation

This section describes the following:

• Site requirements

• Useful tools for network installation and setup

• Preparing the printer for installation

• Connecting the printer to the network

• Setting up the printer on the network

• Setting up the printer for your card design

• SNMP (Simple Network Management Protocol) support

Page 21

Page 27

Site requirements

Operating environment

• Relative humidity: 20% to 80% non-condensing

• Temperature: 60° F to 95° F (15° C to 35° C)

Electrical requirements

• The power supply is rated at 100-240 VAC, 50-60

Hz, 1.8 amp. (It adjusts to any power within this

range.)

• Single phase, 3-wire, grounded receptacle only.

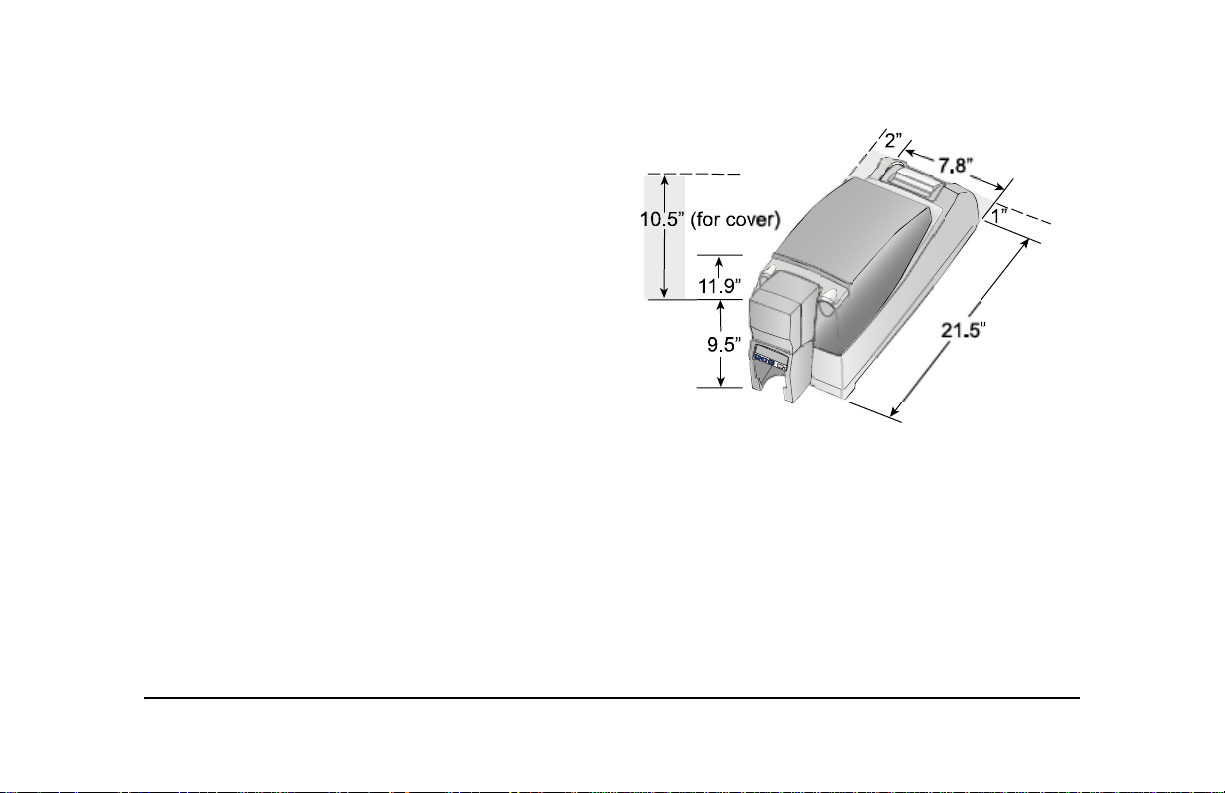

Physical requirements

• The printer weighs less than 11.5 pounds (5.3 kg).

The weight depends on the supplies and options

installed.

• Printer dimensions are 21.5 inches (546 mm) long, and 7.8 inches (198 mm) wide. The 100-card input hopper

is 9.5 inches (241 mm) high and the 200-card hopper is 11.9 inches (302 mm) high.

• The clearances required are 1 inch (25 mm) at the back, 2 inches (51 mm) on the left side, and 10.5 inches

(267 mm) above the printer latch to open the cover.

Page 22

Page 28

Useful tools

When you set up a CP60 Card Printer with Built-in Ethernet feature, you might use several tools. These tools are

part of the network operating system and a computer operating system; they are not provided with the printer.

• Network configuration utility

When the printer is set up on the network where cards are produced, network support personnel use one or

more utilities to view and monitor the network. The CP60 printer was tested with HP® Web Jetadmin® on

Windows XP (service pack 2).

• Command prompt

If you are not using the CP Driver, you can use a command prompt to type commands and use utilities to set

up the printer. You might also find a command prompt helpful for network testing.

•Ping

Ping is a network utility that obtains a response from a device connected to the network. It is a quick way to

query an IP address to verify that it is functioning on the network. The printer responds to Ping.

If the printer includes the Open Card option and you plan to send Open Card data, you might use several

additional tools, including the following:

•Telnet

Most operating systems include a telnet utility. The CP60 printer with the Open Card option provides Card

Layout menus through a telnet interface.

Page 23

Page 29

• tiff2opencard

The Open Card CD-ROM includes the tiff2opencard utility, which you use to prepare logos (graphics) before

sending then to the printer.

• file2prn

The Open Card CD-ROM includes the file2prn utility, which you use to send files, including logo files or

sample card files, to the printer.

See the Data Formatting Guide for more information about them.

Page 24

Page 30

Network installation

A networked printer is connected to a network without a computer (PC) between the printer and network.

Depending on printer options and your needs, the printer can be connected to a print server and then to the

network. A PC can connect to several networked printers at a time, and several PCs can connect to one

printer. To connect a printer to a network, you need the following:

• An Ethernet network that uses the TCP/IP protocol and can run at 10 megabits per second (also called

10base-T), or a faster network (such as 100 megabits per second) that automatically switches to the printer

speed of 10 megabits per second

• A CP60 Card Printer with the Built-In Ethernet feature.

•An Ethernet cable to connect the printer or print server to the network. An Ethernet cable is not supplied with

the printer.

• Network configuration utility. Network support personnel use utilities to set up and monitor the network and

devices on the network.

• PC connected to and communicating with the network.

— From the PC, you will set up the printer on the network and verify that the printer is connected to and

communicating with the network. The printer was tested with PCs running the Windows XP operating

systems and the CP Driver. CP60 printers with the Open Card option were also tested with a PC running

the Knoppix Linux Boot CD-ROM (version 3.3).

— When setting up the printer using an operating system with permissions, such as Windows XP, 2000, or

NT, make sure you are logged in as the Administrator. If networking is set up on the PC, log into the

network.

.

Page 25

Page 31

— When using the printer from an operating system with permissions, such as Windows XP, 2000, or NT,

users must have the same permissions as for a locally attached printer.

Y ou can connect a CP60 Card Printer using a print server if you choose. See "Connect the printer to the network"

on page 27 for details about supported print servers, additional equipment that might be needed, an d how to

install the printer using a print server.

Prepare the printer for installation

Make sure you have done the following to prepare the printer:

1 Load print ribbon. See "Loading print ribbon" on page 7.

2 Load cards. See "Loading cards" on page 5.

3 Power on the printer. See "Power on the printer" on page 9.

— If the printer was previously installed on a network, it might take a few moments for the printer to initialize.

— If you power on the printer, if the Address Mode is DHCP (dynamic host configuration protocol), and if the

printer is not connected to a network, the IP Address will be blank. You can change the Address Mode to

Static IP, or you can connect it to a DHCP network after power on and wait a moment while the printer

obtains an IP Address.

4

View the LCD panel to make sure that the printer has powered on correctly. See

5 Make a printer test card. See "Make a printer test card" on page 13.

6 Work with network support personnel to understand whether the network uses DHCP or static IP addressing.

If it uses static IP addressing, obtain the IP address, subnet mask, and gateway address from network

support personnel. (You can also use the default IP address in the printer.) DHCP is the printer default.

When you have successfully completed these steps, continue with installing the printer on a network.

"The LCD panel" on page 10

.

Page 26

Page 32

Connect the printer to the network

To connect the printer to the network, use one of the following methods:

• Connect the printer using the Ethernet port (requires a CP60 Card Printer with the Built-in Ethernet feature).

• Connect the printer using the USB port and a wired print server. The HP Jetdirect® 175x has been tested in

this usage.

• Connect the printer using the USB port and a wireless print server. The HP Jetdirect 380x has been tested in

this usage.

On operating systems with permissions, such as Windows XP, 2000, or NT, make sure you are logged in as the

Administrator during setup. If networking is set up on the PC, log into the network.

Use the Ethernet port

1 Attach the Ethernet cable to the Ethernet port on the printer and to

the port for the network.

2 Continue with "Set up the network printer" on page 30.

Page 27

Page 33

Use the USB port and a wired print server

1 Connect the print server to the printer using a USB

cable.

2 Connect the print server to the network using an

Ethernet cable. See the setup information provided with

the print server.

3 Follow the instructions provided with the print server to

set it up on the network, and then see "Set the Data

Format" on page 34.

Tips for Success

• Be sure to record the print server name or IP address,

which you need to send print jobs from a PC. Work with

your network support personnel if needed to obtain the

print server name and IP address.

• You do not need to perform the steps in "Set up the

network printer" on page 30. Instead, set up the print

server on the network (step 3 above).

Page 28

Page 34

Use the USB port and a wireless print server

1 Install the wireless network adapter,

including the driver files, to a nearby

PC. Follow the instructions provided

with the adapter to install it.

2 Change settings in the utility for the

wireless network adapter (if needed)

to match the default settings for the

wireless print server. Find the settings

in the print server information.

3 Power on the wireless print server. Do

not connect the print server to the

printer at this time.

4 Insert the wireless print server CD-ROM in the PC with the wireless

network adapter. Follow the instructions provided with the print server to

set it up on the network, and then see

Tips for Success

• Network support personnel can provide the network settings to use.

• Be sure to record the print server name or IP address, which you need to

send print jobs from a PC.

You do not need to perform the steps in "Set up the network printer" on page

30. Instead, set up the print server on the network (step 4 above).

"Set the Data Format" on page 34.

Page 29

Page 35

Set up the network printer

Set the CP60 Card Printer with the Built-in Ethernet feature for the type of network addressing you plan to use.

Do not perform these steps if you use a print server to connect the printer to the network. First, view the current

mode of addressing:

1 Press the Enter key to enter the menu system.

2 Make sure “Status” appears on the second line and press the

Enter key.

3 Press the Up or Down Arrow key to scroll to “Network,” and

then press the Enter key.

4 Press the Up or Down Arrow key if needed to scroll to “Address

Mode,” and then press the Enter key.

5 The display shows the address mode, which can be DHCP

(default) or Static IP.

— If the address mode setting is the one you want to use, use

the Network Status submenus to retrieve the IP address,

subnet mask, gateway address, and, if needed, the MAC

address values from the printer:

Page 30

Page 36

— Press the Enter key to leave the current value.

— Press the Up or Down Arrow key to scroll to a value

and press Enter to view the value.

— Exit to the Main Menu and continue with "Set the Data

Format" on page 34.

— If you need to change the address mode, continue with

these steps.

6 Exit from the Network Status menu and from the St atus Menu

to return to the Main Menu. Press the Up or Down Arrow key

to scroll to “Configuration,” and then press the Enter key.

7 Press the Up or Down Arrow key to scroll to “DHCP/Static IP”

and then press the Enter key.

8 Press the Up or Down Arrow key to choose the address mode

you want and then press the Enter key.

— If you choose DHCP, the display shows “Apply/Restart” on

line 2. If you are not connected to a DHCP network, the IP

address will be blank until you connect the printer to the

network. Continue with step 9.

Page 31

Page 37

— If you choose Static IP, the second line of the LCD panel

shows “IP Address.”

— Work with your network personnel to obtain the IP

address, subnet mask, and gateway address. Enter

these as described next.

— Press the Enter key to choose “IP Address.” The printer

shows the current IP address and a cursor appears

under the first byte of the address. (The address byte

shows 3 digits when it can be changed and the cursor

appears under the right-most digit.)

— Press the Up or Down Arrow key to change the address.

(Press and hold the Up or Down Arrow key to change

the value quickly.)

— When the first byte is correct, press the Enter key to

move to the second byte.

— Repeat for the third and fourth byte of the IP address.

When you press the Enter key after the fourth byte of the

address, “Subnet Mask” appears on the second line of

the LCD panel.

Page 32

Page 38

— Press the Enter key. The current value appears with the

cursor under the first byte. Use the same process as for the

IP address to set the subnet mask. When you press the

Enter key after the fourth byte, “Gateway Addr” appears.

— Press the Enter key. The current value appears with the

cursor under the first byte. Use the same process as for the

IP address to set the gateway address. When you press the

Enter key after the fourth byte of the gateway address,

“Apply/Restart” appears.

9 Press the Enter key to apply the value(s) and restart the printer.

The Status light shows amber (yellow) and then blinks green.

Internal printer components move and the LCD panel changes

to show “Printer Ready” on the first line.

Page 33

Page 39

Set the Data Format

This section applies only to the CP60 printer with the Built-in Ethernet and Open Card features. Before you send

any data to the printer, set the data format so the printer can receive the data you send.

1 Press the Enter key to enter the menu system.

2 Press the Up or Down Arrow key to scroll to “Configuration”

and press the Enter key.

3 Press the Up or Down Arrow key to scroll to “Data Format”

and press the Enter key.

4 Press the Up or Down Arrow key to display the data format

you want on the second line of the display and press the

Enter key.

5 The “Apply/Restart” prompt appears on the second line of the

display. Press the Enter key to confirm the dat a format choice

and restart the printer.

6 Y ou can choose Exit to leave without changing the data format.

Press the Enter key repeatedly to leave the menu system.

Page 34

Page 40

Set up for your card design

The steps to set up for your card design depend on the Data Format you use.

Set up for CP Driver

1 Install the CP Driver. Choose “Direct Network” when installing the printer.

2 Install Info Central.

3 Open Info Central. In the contents list, locate the “Network Installation” topic in the “Installation” book. Scroll

down to the steps for your type of connections—wired or wireless—to complete driver installation.

4 In Info Central, locate the “Setting up for your card design” book. Follow the guidance provided to complete

driver and printer setup.

Set up for the Open Card data format

The Open Card option is required to use the Open Card data format. See "Features and options" on page 3 to

determine whether you have the Open Card option.

1 Prepare the data by using Open Card commands. (At a minimum, use the Start and End Data commands.)

2 Use the Card Layout menus available through the printer Telnet interface to set up a card design.

3 See the Data Formatting Guide for more information.

Page 35

Page 41

SNMP Support

The CP60 Card Printer with the Built-in Ethernet feature supports the following SNMP (simple network

management protocol) features:

• The printer has an SNMP agent which supports the printer MIB (management information block) and MIB-II.

The agent supports SNMPv1 and SNMPv2c.

• If you connect the printer to the network using a print server, the print server can p r ovide SNMP data about

itself (if supported). You cannot obtain SNMP data about the printer through a print server. SNMP data about

the printer is only available through the printer Ethernet port; if you require SNMP data about the printer and

use a print server to send data, you must also connect the printer Ethernet port to the network to provide the

SNMP data.

• The MIB-II is described in RFC (request for comment) 1213 and includes RFC 2233, the Interfaces Group

MIB using SMI v2.

• The printer MIB is described in RFC 1759 (which requires inclusion of part of the Host Resources MIB, RFC

1514).

• For more information about SNMP standards, see the RFC pages of the Internet Engineering Task Force

Web site at

http://www.ietf.org/rfc.html.

Page 36

Page 42

Print a card

First, make sure the printer is installed and ready (see "Printer Installation" on page 21). Then, see "Data formats

for the CP60 Card Printer" on page 15 for features of each format.

From the CP Driver

The CP60 printer can receive card data from the CP Driver running on a Windows PC.

1 Using the LCD panel, select “CP Driver” as the data format. See "Set the Data

Format" on page 54 for the steps to follow.

2 In the application, select the CP Driver as the current printer. (Your printer might

have a different name .)

3 Choose the printer settings that correspond to the cards.

4 Set the paper size to CR80 Card 2.13" x 3.38." Set margins to match the driver.

5 Capture, format, and save the card data.

— Format the text to print us ing TrueType fonts.

— Text formatted as Black will print using the K (solid black) ribbon panel.

— Other colors are printed using th e color panels (if you use a full-color print ribbon).

6 When the card data is ready, choose Print to send the card to the printer.

The card shown is the sample card printed from the Printer Toolbox. It shows the features available when printing

from the CP Driver using a full-color ribbon. (The card has less printing if using a monochrome ribbon.) See Info

Central for detailed information about set up and printing using the CP Driver.

Page 37

Page 43

Using the Open Card data format

A printer with the Open Card feature can receive card data from any host computer that sends an ASCII (text)

data stream using TCP/IP. Usually, you use an application on a host computer to collect and prepare the data

and then send it.

1 Using the LCD panel, select “Open Card” as the data format. See "Set the

Data Format" on page 54 for the steps to follow.

— The Open Card value does not appear in the list if the printer does not

have the Open Card option.

2 Define the card design or format. This step is part of setup, done before

the operator prints cards. Do one of the following:

— Use an application that sends Open Card commands and data to the

printer.

— Set up a card design using the Card Layout menus, and then use an

application that sends data to the printer.

3 Capture and save the data.

4 Choose Print to send the card to the printer.

See the Data Formatting Guide for details about Open Card commands and menus.

The card shown is a sample Open Card design. It shows features available when printing Open Card data.

Page 38

Page 44

Cleaning the printer

Page 39

Run a cleaning card and change the cleaning sleeve when

changing the print ribbon. Make sure that all cards sent to the

printer have completed printing before cleaning.

1 Open the printer cover (1).

2 Remove the replaceable cleaning roller and the ribbon

cartridge (2).

3 Open the input hopper cover (3).

4 Remove unprinted cards from the input hopper (4).

5 Open the cleaning card package and remove the cleaning

card.

6 Insert the cleaning card into the input hopper (5), just past the

roller.

7 On the LCD panel, press the Enter key to view the Main

Menu.

8 Press the Up Arrow or Down Arrow key to display

“Diagnostics” and then press the Enter key.

1

1

1

1

2

2

2

3

5

4

Page 45

9 Make sure “> Cleaning Card” is displayed on the second line of

the LCD panel and press the Enter key.

The printer moves the card through the printer several times

and ejects the card. Wait a few minutes to allow the rollers to

dry for best printer operation and print quality.

10 Slide the used cleaning sleeve off the spindle.

11 Discard the used cleaning card and used sleeve.

12 Place a new cleaning sleeve on the spindle (1).

13 Remove the protective cover from the sleeve (2).

14 Insert the replaceable cleaning roller (with a new cleaning sleeve) into

the printer (3).

15 Replace the ribbon cartridge, close the printer cover, load cards, and

resume printing.

Cleaning tips

• Use the cleaning card as soon as you open the package. The cleaning

solution on the card evaporates after a few minutes.

• Some card features, such as signature panels and magnetic stripes, can

require more frequent cleaning of the printer.

• If you use StickiCard™ adhesive-backed cards, use a cleaning card

more often, such as after printing every 100 cards. The printer might also

need additional cleaning. See

“Cleaning the printer rollers” on page 41.

1

2

3

Page 40

Page 46

Cleaning the printer rollers

The printer rollers move the card during printing or cleaning

operations. Clean the rollers when problems occur such as:

• Repeated card jams

• Cards are not being picked, repeatedly

• Colors are not aligned on the printed card

Use the cleaning pen to clean printer rollers.

1 Clean the pick roller:

a Open the input hopper and remove all cards from the input

hopper.

b Remove the cap from the cleaning pen. Hold the end of the

cleaning pen against the pick roller.

c Use the LCD panel to run a cleaning card. See "Cleaning

the printer" on page 39. Do not insert a cleaning card! The

printer moves the rollers when it attempts to pick the card.

d Slowly move the pen over the surface of the pick roller.

e Lightly wipe any dirt from the end of the cleaning pen onto a

clean cloth or paper. Move the cleaning pen to another area

of the roller.

f Repeat steps c through e until no more dirt appears on the

pen.

Page 41

Page 47

2 Clean the permanent cleaning rollers (at location 1),

transport area rollers (at locations 2, 3, 4, 5), and duplex

rollers (at location 6) following the same procedure

used for the pick rollers.

— Wait a few minutes to allow the rollers to dry for

best printer operation and print quality.

3 Replace the print ribbon cartridge and replaceable

cleaning roller. Close the printer cover.

4 Replace cards in the input hopper.

5 Print a card to verify the quality of printing.

6

2

2

3

3

4

4

5

1

Page 42

Page 48

Getting the most out of your printer

To get the best quality cards and to maintain printer performance, follow these tips for success:

• Use the best quality cards available with a smooth, glossy PVC surface and print them only

once. Make sure options, such as a signature panel or a magnetic stripe, are high quality.

• Match the card design and the supplies you use to obtain the results you want.

— Edge to edge printing requires high-quality cards and can require fine-tuning the printer

(using the CP Driver) and the card design (using ID software).

— Locate bar codes at least 0.25 inches from other printing and from the edge of the card.

Make sure the color used to print the bar code works in your bar code readers.

— Do not print closer than 0.1 inch from a signature panel, magnetic stripe, or smart card

chip. Obtain information from your card manufacturer about card features and placing

design elements on the card.

— Do not apply topcoat over a magnetic stripe, signature panel, or smart card chip.

— Avoid placing an image or important data on the other side of the card from a magnetic

stripe, smart card chip, or signature panel.

• Follow instructions carefully when replacing supplies, correcting problems, cleaning the

printer, and replacing parts.

Page 43

Page 49

• Use cables that meet specifications and connect them correctly.

• Keep cards and Datacard®-certified supplies on hand and store them safely.

• Keep the printer clean and keep the area around the printer clean.

If you use the CP Driver and a PC to print cards, see Info Central for detailed information about:

• Setting up the printer for the card design

• Making cards

If you use the Open Card data format, see the Data Formatting Guide for detailed information

about:

• Card Layout menus in the printer, used to create a card design

• Open Card commands supported by the printer

• Tools to use when using the Open Card data format

For either data format, see Info Central for information about:

• Changing printer settings

• Troubleshooting

• Supplies and parts, and specifications for them

The Data Formatting Guide is available on the Open Card CD-ROM shipped with the Open Card

(SM)

option. It is also available to service providers on the PartnerPage.com

Web site.

Page 44

Page 50

Printer LCD settings

Using the LCD panel, you can:

• View settings and data

• Change settings

• Run a cleaning card

Tips for success

• You can access menus where you can view or change settings when the printer displays “Printer Ready” on

line 1 of the display.

• If you are using the menus and stop pressing keys, the printer will return to the “Printer Ready” display after 2

minutes of inactivity. Any changes not applied will be lost.

• To leave a selection without changing the value, press the Up or Down Arrow key to scroll to Exit and then

press the Enter key.

• If you have the CP Driver installed and communicating with the printer, suspend communication using the

Printer Toolbox before changing values. If you change the data format, unexpected cards might be printed. If

you change IP addresses, communication with the printer can end unexpectedly .

Page 45

Page 51

LCD menu system

The menu system has three major branches. Use the Status menu to view settings and data about the printer.

Use the Configuration menu to change settings. Use the Diagnostics menu to run a cleaning card.

Page 46

Page 52

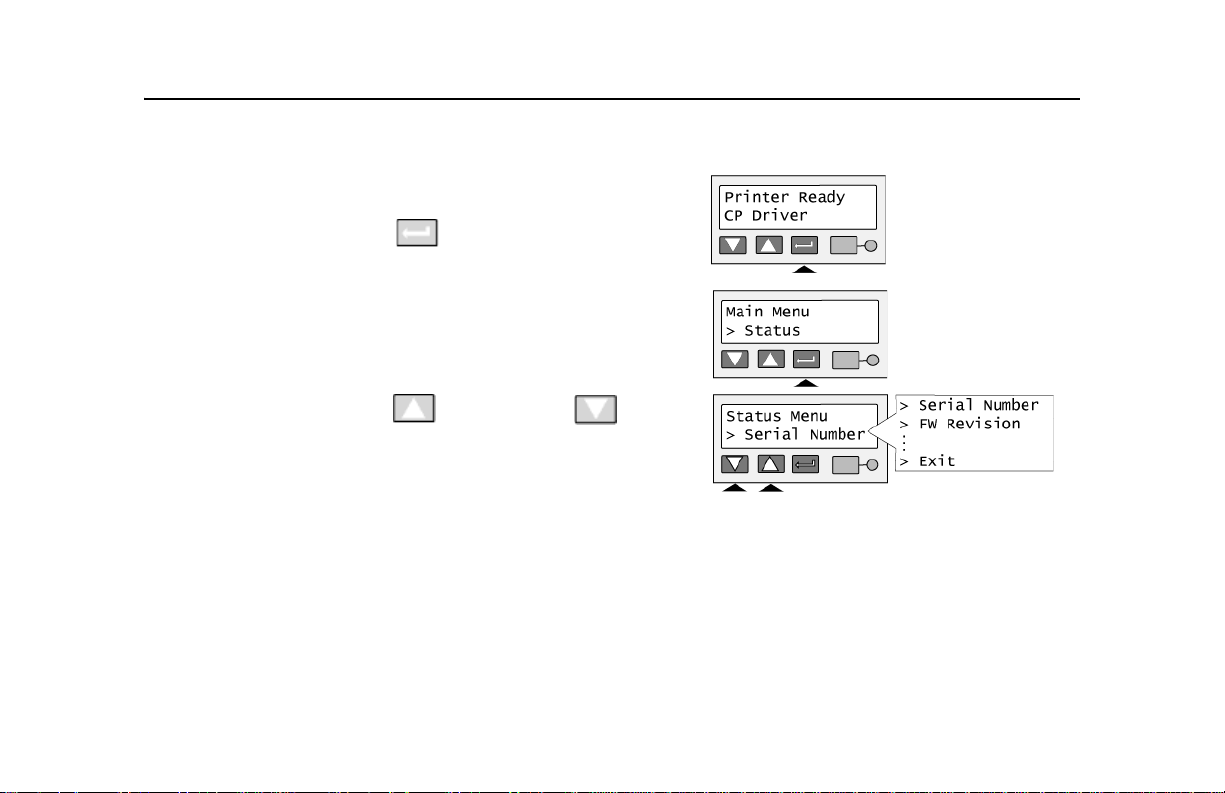

View status settings

Begin when the LCD panel shows “Printer Ready” on line 1 of the display. To view Status information:

1 Press the Enter key to enter the menu system.

2 Make sure “Status” appears on line 2 and press the Enter key. You are now in the

Status Menu.

View the Serial Number

1 With “Status Menu” displayed on line 1, press the Up or Down Arrow key if needed

to display “Serial Number” on line 2.

2 Press the Enter key. The display shows the serial number.

3 Press the Enter key to return to the Status menu.

4 Press the Up Arrow or Down Arrow keys to scroll to “Exit” on line 2.

5 To print cards, press the Enter key repeatedly (with “Exit” displayed on line 2) to

return to the “Printer Ready” display.

Page 47

Page 53

View the Firmware Revision

Use the firmware revision display at the request of your service provider, or to decide whether to use the firmware

update utility to update printer firmware.

1 With “Status Menu” displayed on line 1, press the Up or Down Arrow key if needed

to display “FW Revision” on line 2.

2 Press the Enter key. The display shows the firmware revision.

3 Press the Enter key to return to the Status menu.

4 Press the Up Arrow or Down Arrow keys to scroll to “Exit” on line 2.

5 To print cards, press the Enter key repeatedly (with “Exit” displayed on line 2) to

return to the “Printer Ready” display.

Page 48

Page 54

View Card Counts

1 With “Status Menu” displayed on line 1, press the Up or Down Arrow key to display

“Card Counters” on line 2

2 Press the Enter key. “Card Count” appears on line 2.

3 Press the Enter key to view the total number of cards pri nt e d on this pri n te r.

4 Press the Enter key to return to Card Counters. “Cycle Count” appears on line 2.

5 Press the Enter key to view the cycle count or press the Up or Down Arrow key to

display “Exit” on line 2.

6 To print cards, press the Enter key repeatedly to return to the “Printer Ready”

display.

A cycle is one pass of the printhead. With monochrome (K) ribbon, one cycle prints the

front of the card. A second cycle might print the back of the card. With full-color YMCKT

ribbon, each color panel uses one print cycle; the front of the card uses five print cycles.

Page 49

Page 55

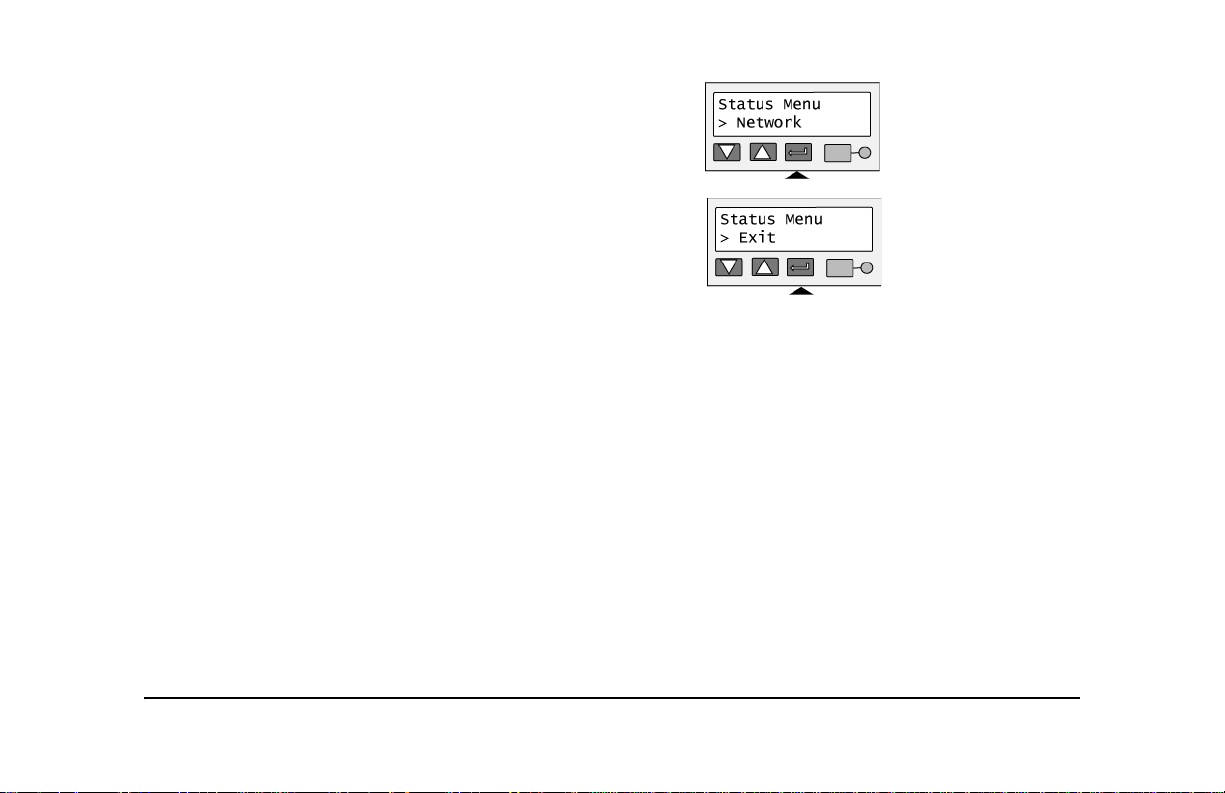

View the Data Format

1 With “Status Menu” displayed on line 1, press the Up or Down Arrow key to display

“Network” on line 2.

2 Press the Enter key. “Address Mode” appears on line 2.

3 Press the Up or Down Arrow key to display “Data Format” on line 2.

4 Press the Enter key. The data format appears on line 2. Possible values are CP

Driver, Open Card, and Reserved.

5 Press the Enter key to return to the Network Status menu.

6 Press the Up or Down Arrow key to display “Exit” on line 2.

7 To print cards, press the Enter key repeatedly to return to the “Printer Ready”

display.

Page 50

Page 56

View the Network Address Mode, IP Addresses, and MAC Address

1 With “Status Menu” displayed on line 1, press the Up or Down Arrow key to display

“Network” on line 2.

2 Press the Enter key. “Address Mode” appears on line 2. Press the Enter key to

view the address mode. The possible values are DHCP or Static IP.

3 Press the Enter key to return to the Status menu. “Data Format” is displayed on line

2.

4 Press the Up or Down Arrow key to display “IP Address” on line 2.

5 Press the Enter key to display the IP address. If the address mode is DHCP and the

printer is not connected to an active DHCP network, the IP address is blank.

6 Press the Enter key to return to the Status menu. “Subnet Mask” is displayed on

line 2.

Page 51

Page 57

7 Press the Enter key to display the subnet mask.

8 Press the Enter key to return to the Status menu. “Gateway Addr” is displayed on

line 2.

9 Press the Enter key to display the gateway address.

10 Press the Enter key to return to the Status menu. “MAC Address” is displayed on

line 2.

11 Press the Enter key. The MAC address, which is set in the factory, is displayed on

line 2.

If the MAC address needs to be changed, contact your Datacard® service provider.

12 Press Enter to return to the Status menu. “Exit” is displayed on line 2.

13 To print cards, press the Enter key repeatedly to return to the “Printer Ready”

display.

Page 52

Page 58

Change settings

Begin when the LCD panel shows “Printer Ready” on line 1 of the display. To change settings:

1 Press the Enter key to enter the menu system.

2 Press the Up or Down Arrow key to scroll to “Configuration” on line 2.

3 Press the Enter key. You are now in the Configuration menu.

Set LCD Backlighting

1 With “Configuration” displayed on line 1, press the Up or Down Arrow key if needed

to display “LCD Backlight” on line 2.

Page 53

Page 59

2 Press the Enter key to display the current value.

3 Press the Up or Down Arrow key to change the backlighting. The display changes

to show the effect of the new value.

4 When the backlighting reaches the level you want, press the Enter key. The display

remains at the new backlighting level and you return to the Configuration menu.

5 Press the Up or Down Arrow key if needed to scroll to “Exit” on line 2.

6 To print cards, press the Enter key repeatedly to return to the “Printer Ready”

display.

Set the Data Format

Tips for success

• When you choose a data format, the printer might not operate properly if data in another format is sent.

• If you have the CP Driver installed and connected to the printer, suspend communication using the Printer

Toolbox before changing values. If you change the data format, unexpected cards might be printed.

1 With “Configuration” displayed on line 1, press the Up or Down Arrow key if needed

to display “Data Format” on line 2.

2 Press the Enter key. The current data format value is displayed on line 2.

Page 54

Page 60

3 Press the Up or Down Arrow key to display the data format you want. Possible

values are CP Driver, Open Card (requires the Open Card option), and Reserved.

The Reserved value is not supported.

4 Press the Enter key. “Apply/Restart” appears on line 2.

5 Press the Enter key to apply the value(s) and restart the printer.

6 If you did not choose a different data format, the display shows “DHCP/Static IP” on

line 2. Press the Up or Down Arrow key to scroll to “Exit” on line 2 to leave without

making changes.

When the printer restarts, the Ready light shows amber (yellow) and then blinks green.

Internal printer components move and the LCD panel changes to show “Printer Ready” on the first line.

Set the Address Mode

Tips for success

• When you choose an address mode, you determine how the network ad dress of the printer is assigned. The

possible values are DHCP and Static IP. DHCP stands for “Dynamic Host Configuration Protocol” and means

that the network assigns the IP address (and other values) to the printer. Static IP means that the IP address

is entered following the procedure in

Use the address mode requested by your network personnel.

• If you have the CP Driver installed and connected to the printer from any PC, suspend communication using

the Printer Toolbox. If you change IP addresses, communication with the printer can end unexpectedly.

"Set the IP Address, Subnet Mask, and Gateway Address" on page 57.

Page 55

Page 61

1 With “Configuration” displayed on line 1, press the Up or Down Arrow key if needed

to display “DHCP/Static IP” on line 2.

2 Press the Enter key. The current address mode value is displayed on lin e 2.

3 Press the Up or Down Arrow key to display the address mode you want. Possible

values are DHCP and Static IP.

4 Press the Enter key.

5 The next step depends on which address mode you have chosen:

— If you have chosen DHCP, “Apply/Restart” appears on line 2. Press the Enter

key to restart the printer. After the printer restarts, see

Address Mode, IP Addresses, and MAC Address" on page 51 to retrieve the IP

address and other data.

— If you have chosen Static IP, “IP Address” appears on line 2. See "Set the IP Address, Subnet Mask, and

Gateway Address" on page 57 for the steps to follow.

— You must set the IP address, subnet mask, and gateway IP address for the printer. The printer will

restart after you enter thes e val u e s.

— If you have used the DHCP/Static IP menu selection but did not actually change the address mode, “K

Power” appears on line 2. Press the Up or Down Arrow key to display “Exit” on line 2. Press the Enter key

repeatedly to return to the “Printer Ready” display.

"View the Network

Page 56

Page 62

Set the IP Address, Subnet Mask, and Gateway Address

Tips for Success

• The printer address mode must be “Static IP” to set these values. (If the address mode is DHCP, “IP

Addresses” does not appear in the menu.)

• The menu system moves from one value to the next because these values are related and a change in the IP

address usually leads to a change in the subnet mask (and sometimes in the gateway address).

• If you need to change just one value, you can scroll to the value you need to change in step 2 below.

1 With “Configuration” displayed on line 1, press the Up or Down Arrow key if needed

to display “IP Addresses” on line 2.

2 Press the Enter key to choose the “IP Addresses” list. “IP Address” is displayed on

line 2.

3 Press the Enter key. The printer shows the current IP address and a cursor

appears under the first byte of the address. (The address byte shows 3 digits when

it can be changed and the cursor appears under the right-most digit.)

Page 57

Page 63

4 Press the Up or Down Arrow key to change the IP address. (Press and hold the Up

or Down Arrow key to change the value quickly.)

5 When the first byte is correct, press the Enter key to move to the second byte.

6 Repeat for the third and fourth byte of the IP address. When you press the Enter

key after the fourth byte of the address, “Subnet Mask” appears on the second line

of the LCD panel.

7 Press the Enter key. The current value appears with the cursor under the first byte.

Set the subnet mask (using the same process as the IP address). When you press

the Enter key after the fourth byte, “Gateway Addr” appears.

8 Press the Enter key. The current value appears with the cursor under the first byte.

Set the gateway address (use the same process as the IP address). When you

press the Enter key after the fourth byte of the gateway address, “Apply/Restart”

appears.

9 Press the Enter key to apply the value(s) and restart the printer. Or, press the Up

or Down Arrow key to scroll to “Exit” on line 2 to leave without making changes.

The Ready light shows amber (yellow) and then blinks green. Internal printer

components move and the LCD panel changes to show “Printer Ready” on the first

line.

Page 58

Page 64

Set the K Power

Tips for Success

• Set the K Power value to change the darkness—or intensity—of printing with monochrome ribbon (or the

monochrome–K–panel of full-color ribbon). K power affects the thickness of letters and barcodes; higher

intensity prints thicker letters or barcodes.

• A value of “0” for K Power means no change to the factory setting for K power.

• Make small changes in K power and then print a card to view the result. If needed, return to these steps to

make additional changes.

• If you print barcodes, make sure the new setting results in barcodes that can be read by readers at your site.

1 With “Configuration” displayed on line 1, press the Up or Down Arrow key if

needed to display “K Power” on line 2.

2 Press the Enter key to display the current value.

3 Press the Up or Down Arrow key to change the K Power setting. (Press and hold

the Up or Down Arrow key to change the value quickly.) If you press the down

arrow key so the value is less than zero (0), a minus (-) sign appears. A plus (+)

sign indicates a value greater than zero (0).

4 When the K Power reaches the level you want, press the Enter key to return to the

Configuration menu.

5 Press the Up or Down Arrow key if needed to scroll to “Exit” on line 2.

6 To print cards, press the Enter key repeatedly to return to the “Printer Ready” display.

Page 59

Page 65

Turn the page for the next section.

Page 60

Page 66

Troubleshooting

What is the problem? Try this:

1 A message appears on the PC or

LCD panel.

2 The printed cards do not look the

way that was intended.

3 Cards jam often. • The brand of cards might be heavily powdered, dirty, or bowed

4 The ribbon has broken. • Trim the end of the broken ribbon evenly. If ribbon on the take-up

Page 61

• Click the Help button on the message box to see possible causes

and the solution for each cause. See the “Related Topics” to fix

the problem.

• If you moved the ribbon while the printer was powered off, print

another card. If the problem persists, see Info Central for detailed

information about solving card appearance problems.

(curved). Consider buying a different brand of cards or clean the

printer more often to use the cards.

• The printer rollers might be dirty. See "Cleaning the printer

rollers" on page 41 for steps to clean the printer rollers.

spool is not wound firmly or is uneven, remove it. Tape the end of

the ribbon onto the same take-up spool, making the edges of the

ribbon and spool even.

• If the ribbon breaks repeatedly, settings might not be correct for

the card design and ribbon. See Setup in Info Central.

Page 67

What is the problem? Try this:

5 The printer does not respond when

printing a card or when clicking

“Resume” on the Printer Toolbox.

6 The printer cover will not close. • Make sure no extra items are inside the printer.

• Make sure the printer is plugged in. See "Power on the printer" on

page 9.

• Make sure the printer is connected to the computer. "Connect the

printer to the network" on page 27.

• If the Status Light on the printer is blinking amber (yellow), press

the Ready .

• Power off the printer and power it on to see if communication

resumes.

• See Info Central for more detailed communication

troubleshooting information.

• Make sure the print ribbon cartridge is installed correctly. See

"Loading print ribbon" on page 7.

• If you installed or bumped the printhead cartridge, make sure it is

installed correctly. See Production in Info Central.

• Push down firmly on the front edge of the cover to latch it.

Page 62

Page 68

Printer supplies

Datacard®-certified ribbon kits and cleaning supplies are available for the printer. Ribbon kits contain a roll of

print ribbon, a cleaning card, and a replaceable cleaning sleeve. For best results, run a cleaning card and replace

the cleaning sleeve each time you change the print ribbon.

Color print ribbon

Color print ribbon for the CP60 printer is available as follows:

• YMCKT Color Ribbon Kit, part number 552854-304, prints up to 250 images

• YMCKT Color Ribbon Kit, part number 552854-604, prints up to 500 images (also for use on SP60 printers)

• YMCKT-KT Color Ribbon Kit, part number 552854-606, prints up to 300 images (for duplex printing on CP60

and SP60 printers)

Color print ribbons are designed for full-color card printing. The ribbons use the following color panels: Y=yellow,

M=magenta, C=cyan/blue, K=black, and T=topcoat (clear). Datacard color print ribbon for CP Series printers

uses Advanced Imaging Technology™ for high quality printing.

Monochrome and Topcoat ribbon

Ribbon with alternating Black (K) and Topcoat (T) panels is available as part of the KT Ribbon Kit, part number

552854-509, which prints up to 1000 images.

Monochrome print ribbon

Several colors of monochrome (single-color) print ribbon are available for the CP60 printer. A roll of ribbon prints

1500 or more images. The Ribbon Saver feature is enabled by Datacard

Saver increases the number of cards printed with each roll of ribbon.

®

-certified monochrome ribbons. Ribbon

Page 63

Page 69

Available monochrome colors include:

Color Part number Color Part Number

Black 552954-501 Gold 552954-508

Dark Blue 552954-502 Scratch-off 552954-513

White 552954-503 Black HQ 552954-701

Red 552954-504 Metallic Silver 552954-607

Green 552954-506 Metallic Gold 552954-608

Silver 552954-507 Metallic Holo Fleck 552954-609

Cleaning supplies

In addition to the cleaning supplies included in the ribbon kit, it is recommended that you order additional cleaning

supplies to have on hand to address unusual situations.

• A package of 5 replaceable cleaning sleeves is available. The part number is 549716-002.

• A package of 10 cleaning cards is available. The part number is 552141-002.

See Info Central for complete information about supplies and replacement parts for CP60 printers.

Page 64

Page 70

Printer messages

The CP60 Card Printer with the Built-in Ethernet displays messages on the LCD panel.

If the Data Format is set to CP Driver, messages (that match up with printer messages) also appear on the PC in

message boxes. Y ou might see messages on the LCD panel that do not appear on the PC, because the LCD

displays all printer messages while the CP Driver shows the most important message if a group of messages

occurs at the same time. In addition, the CP Driver can display messages that begin in the driver (not the printer)

and those messages do not appear on the LCD panel.

When a message appears on the LCD panel, do the following:

1 Find the message number in this section. Messages are listed in numerical order.

2 Use the cause and solution information to fix the problem.

3 Make sure cards are loaded and the ribbon is in the printer. Close the printer

cover (if it was opened).

4 Resume printing:

— Click a button on the message box on the PC, which might allow you to retry

the card.

— Press the Ready key on the LCD panel to clear the message and cancel printing of the card.

5 If another message is displayed, repeat steps 1 through 4. If not, the printer returns to the ready or busy state.

Page 65

Page 71

DM-00760 Duplex Error

The duplex mechanism did not reach the correct

position.

Possible Cause 1: A card or object is jammed in or near the duplex unit.

Solution 1: Open the duplex module cover at the back of the printer (1).

Release any cards or objects stuck in the module (2). Make sure that the

duplex mechanism can move freely in the direction shown (3).

Possible Cause 2: The rollers in the duplex mechanism are dirty.

Solution 2: Run a printer cleaning card, and then clean the printer rollers

including the duplex module rollers.

If you cannot fix the problem, contact your service representative for

assistance.

Related Topics:

"Cleaning the printer" on page 39

1

3

2

Page 66

Page 72

DM-00762 Duplex Jam

The card is stuck in the duplex module.

Possible Cause 1: A card is jammed in or near the duplex unit.

Solution 1: Open the of the printer (1). Release any cards stuck in the

module (2). Make sure that the duplex mechanism can move freely in the

direction shown (3).

Possible Cause 2: The rollers in the duplex mechanism are dirty.

Page 67

Solution 2: Run a printer cleaning card, and then clean the printer rollers

including the duplex module rollers.

If you cannot fix the problem, contact your service representative for

assistance.

Related Topics:

"Cleaning the printer" on page 39

1

3

2

Page 73

DM-00765 No Duplex

The duplex module is not installed or detected.

Possible Cause 1: The driver was set to use automatic duplex and a duplex

module is not installed in the printer.

Solution 1: Send a one-sided card to the printer or set the driver for manual

duplex.

Possible Cause 2: The connection between the duplex module and the rest

of the printer is damaged.

Solution 2: Check the printer to see whether a duplex module is included in

the printer. If it is, power the print off and on; the printer might detect the

module when the printer powers up.

If a duplex module is part of the printer and you receive this message,

contact your service provider for assistance.

Related Topics:

"Features and options" on page 3

Page 68

Page 74

DM-00767 Duplex Jam

The card is lost in the duplex module.

Possible Cause 1: A card is jammed in or near the duplex module.

Solution 1a: Open the of the printer (1). Release any cards stuck in the

module (2). Make sure that the duplex mechanism can move freely in the

direction shown (3).

Solution 1b: If the card is stuck between the upper and lower duplex units,

remove the card from the printer. You might see a “PR 01706” message

after removing the card. Clear the message to continue.

Page 69

Possible Cause 2: The rollers in the duplex mechanism are dirty.

Solution 2: Run a printer cleaning card, and then clean the printer rollers

including the duplex module rollers.

If you cannot fix the problem, contact your service provider for assistance.

Related Topics:

"Cleaning the printer" on page 39

1

3

2

Page 75

IS-01206 No Card Picked

A card was not picked successfully.

Possible Cause 1: The input hopper is empty.

Solution 1: Fan the edges of the cards so the printer picks one card at a

time and then load cards in the input hopper. Push the input hopper cover

closed until it latches.

Possible Cause 2: One or two cards are jammed going into the printer.

Solution 2 a: Release the stuck card(s). Fan the cards in the input hopper

again to separate them.

Solution 2 b: Cleaning liquid is making cards slip on the pick roller. Wait one

or two minutes with the input hopper open to allow the pick roller to dry.

If the problem occurs again, run a cleaning card, change the cleaning

sleeve, and then clean the rollers in the printer.

Related Topics:

"Cleaning the printer" on page 39

"Cleaning the printer rollers" on page 41

2

Page 70

Page 76

SY -01305 Data Error

The setting sent to the printer does not match printer

features.

Possible Cause 1: A setting was sent to the printer for a module that is not

installed or enabled.

Solution 1: Check the printer to see whether options are installed. If the

option is not present in the printer, do not send data for the option.

Possible Cause 2: The printer data format is CP Driver and the printer was

moved from one PC to another PC.

Solution 2: Open the Properties (98 or Me), Printing Preferences (2000 and

XP), or Document Default Properties (NT) dialog box and make sure that

settings match the printer that is currently connected. Click OK to make all

settings take effect.

Related Topics:

"Features and options" on page 3

Page 71

Page 77

SY -01306 Data Error

The setting value you selected is not valid.

Possible Cause 1: The value sent to the printer does not apply to the

printer attached.

Solution 1: Use approved programs, such as the printer’s Properties or

Printing Preferences dialog box, to send values to the printer.

Possible Cause 2: You are using Printer Diagnostics, you have attached

another printer, and have not selected the new printer in Printer Diagnostics.

Solution 2: Wait while the driver updates all printer information. Choose the

new printer in Printer Diagnostics. Wait a moment while Printer Diagnostics

updates to reflect the new printer.

Page 72

Page 78

SY-01310 Flash Error

EEPROM flash data error.

Possible Cause 1: A transmission problem occurred.

Solution 1: Send the file or data again. You can repeat this action several

times.

Possible Cause 2: Data being sent to the printer is corrupted or incorrect.

Solution 2: Obtain the correct update file (or a new update file) and repeat

the process. Be sure to select the correct update file if you are using Printer

Diagnostics or the file2prn utility.

If you cannot fix the problem, contact your service provider for assistance.

Page 73

Page 79

SY-01312 Flash error

EEPROM flash size error.

Possible cause: A logo was downloaded to the printer (using the

file2prn utility) and the logo requires more memory than is available in

the printer.

Solution: Press the Ready key on the LCD panel to clear the logo from

the printer and make the printer ready. Up to 4 logos can be stored in the

printer. Each logo must be smaller than 64K. See the Data Formatting

Guide to delete logos if needed.

Page 74

Page 80

SY-01314 Flash Error

Warning! EEPROM flash write error.

Possible Cause 1: A transmission problem occurred.

Solution 1: Click Retry on the message box to send the file or data again.

You can repeat this action several times.

Possible Cause 2: The printer EEPROM does not accept the data or

setting.

Solution 2: Power off the printer. Wait one minute, and then power on the

printer. Repeat the action again.

Possible Cause 3: The printer EEPROM does not accept the flash file.