ENGINEERING TOMORROW

Installation Guide

VLT® Parallel Drive Modules

250–1200 kW

vlt-drives.danfoss.com

Contents Installation Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Document and Software Version

1.4 Approvals and Certications

1.5 Disposal

2 Safety

2.1 Safety Symbols

2.2 Qualied Personnel

2.3 Safety Precautions

3 Product Overview

3.1 Intended Use

3.2 Drive Modules

3.3 Control Shelf

3.4 Wire Harness

3.5 DC Fuses

4

4

4

4

4

4

5

5

5

5

7

7

8

9

10

10

4 Mechanical Installation

4.1 Receiving and Unpacking the Unit

4.1.1 Items Supplied 11

4.1.2 Lifting the Unit 12

4.1.3 Storage 12

4.2 Requirements

4.2.1 Environmental 14

4.3 Installing the Drive Modules

4.4 Installing the Control Shelf

5 Electrical Installation

5.1 Safety Instructions

5.2 Electrical Requirements for Certications and Approvals

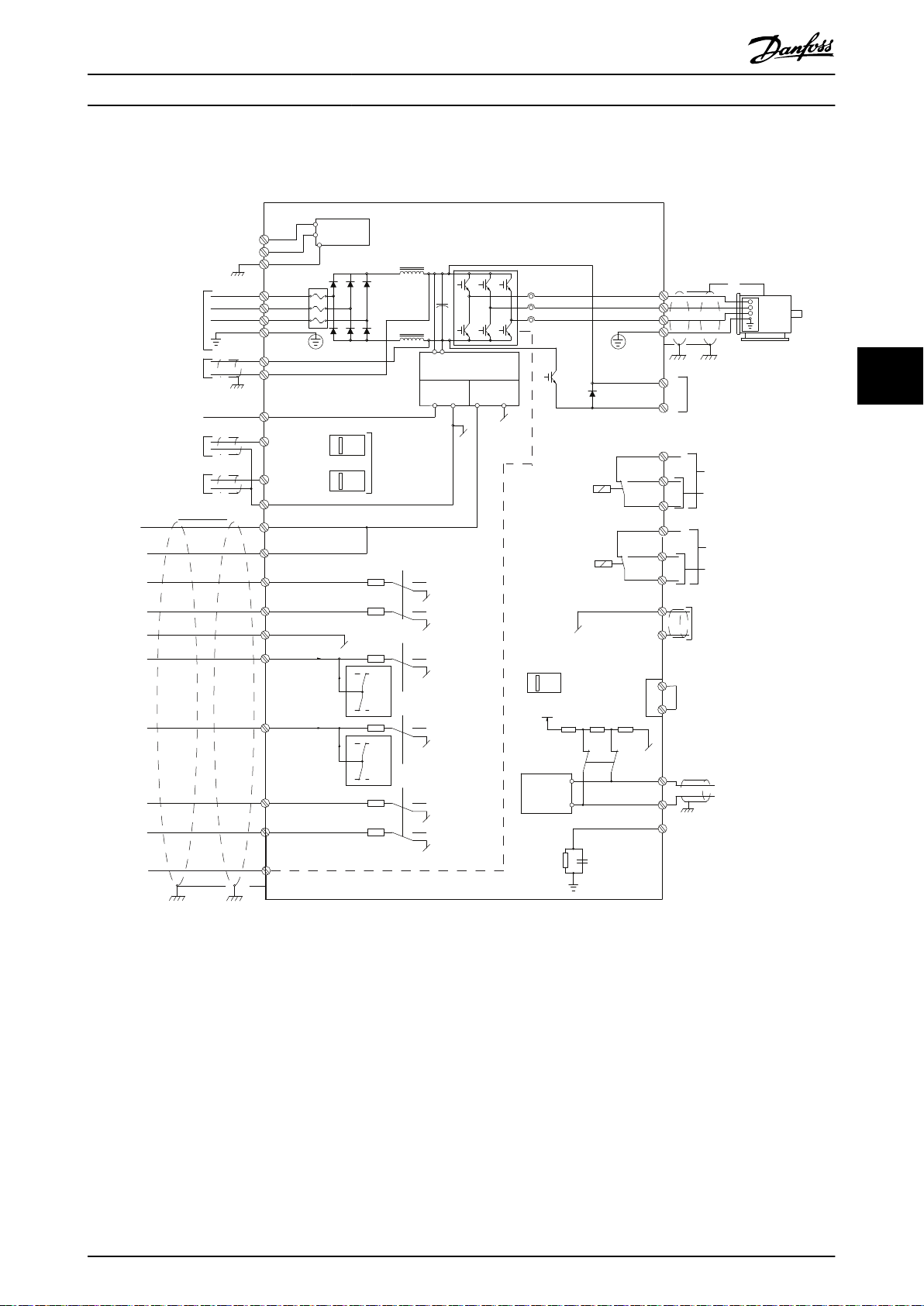

5.3 Wiring Diagram

5.4 Fuses

5.5 Electrical Kit Installation

5.6 DC Bus Fuse Installation

5.7 Motor Connections

11

11

14

16

18

19

19

20

21

22

24

24

24

5.7.3 Motor Terminal Connections 26

5.7.3.1 Motor Cable 26

5.7.3.2 Motor Terminal Connections in 2-Drive Module Systems 27

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 1

Contents

VLT® Parallel Drive Modules

5.7.3.3 Motor Terminal Connections in 4-Drive Module Systems 27

5.8 Mains Connections

5.8.1 AC Mains Terminal Connections 28

5.8.1.1 Mains Terminal Connections in 2-Drive Module Systems 28

5.8.1.2 Mains Terminal Connections in 4-Drive Module Systems 29

5.8.2 12-Pulse Disconnector Conguration 29

5.8.3 Discharge Resistors 30

5.9 Control Shelf Installation

5.10 Control Wiring Connections

5.10.1 Control Cable Routing 32

5.10.2 Control Wiring 33

5.10.2.1 Control Terminal Types 33

5.10.2.2 Wiring to Control Terminals 35

5.10.2.3 Enabling Motor Operation (Terminal 27) 35

5.10.2.4 Voltage/Current Input Selection (Switches) 35

5.10.2.5 RS485 Serial Communication 36

5.10.3 Safe Torque O (STO) 36

5.11 Relay Output

28

31

31

36

5.12 EMC Recommendations

6 Initial Start-up

6.1 Pre-start Check List

6.2 Safety Instructions

6.3 Applying Power

6.4 Conguring the Drive System

6.5 Testing the Motor Operation

7 Specications

7.1 Power-dependent Specications

7.2 Mains Supply to Drive Module

7.3 Motor Output and Motor Data

7.4 12-Pulse Transformer Specications

7.5 Ambient Conditions for Drive Modules

7.6 Cable Specications

7.7 Control Input/Output and Control Data

7.8 Kit Dimensions

37

41

41

42

42

43

44

45

45

59

59

59

59

60

60

64

7.9 Fastener Tightening Torques

7.9.1 Tightening Torques for Terminals 66

8 Appendix

8.1 Disclaimer

2 Danfoss A/S © 08/2017 All rights reserved. MG37K302

66

67

67

Contents Installation Guide

8.2 Symbols, Abbreviations, and Conventions

8.3 Block Diagrams

Index

67

68

79

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 3

Introduction

VLT® Parallel Drive Modules

11

1 Introduction

1.1 Purpose of the Manual

This manual provides requirements for mechanical and

electrical installation of the VLT® Parallel Drive Modules

basic kit. Separate installation instructions for optional

components - bus bars and back-channel cooling - are

provided with those kits.

This guide includes information on:

Wiring of mains and motor connections.

•

Wiring of control and serial communications.

•

Control terminal functions.

•

Detailed tests that must be performed before

•

start-up.

Initial programming to verify proper functioning

•

of the drive system.

The installation guide is intended for use by

personnel.

To install the drive modules and paralleling kit safely and

professionally, read and follow the installation guide. Pay

particular attention to the safety instructions and general

warnings. Always keep this installation guide with the

panel containing the VLT® Parallel Drive Modules

components.

VLT® is a registered trademark.

Additional Resources

1.2

Other resources are available to understand functions and

programming of the VLT® Parallel Drive Modules.

qualied

The VLT® FC Series, D-frame Service Manual

•

contains detailed service information, including

information applicable to the VLT® Parallel Drive

Modules.

The VLT® Parallel Drive Modules DC Fuses Instal-

•

lation Instructions contain detailed information

about installing the DC fuses.

®

The VLT

•

lation Instructions contain detailed information

about installing the bus bar kit.

The VLT® Parallel Drive Modules Duct Kit Instal-

•

lation Instructions contain detailed information

about installing the duct kit.

Refer to other supplemental publications and manuals,

available from Danfoss. See drives.danfoss.com/knowledge-

center/technical-documentation/ for listings.

Parallel Drive Modules Bus Bar Kit Instal-

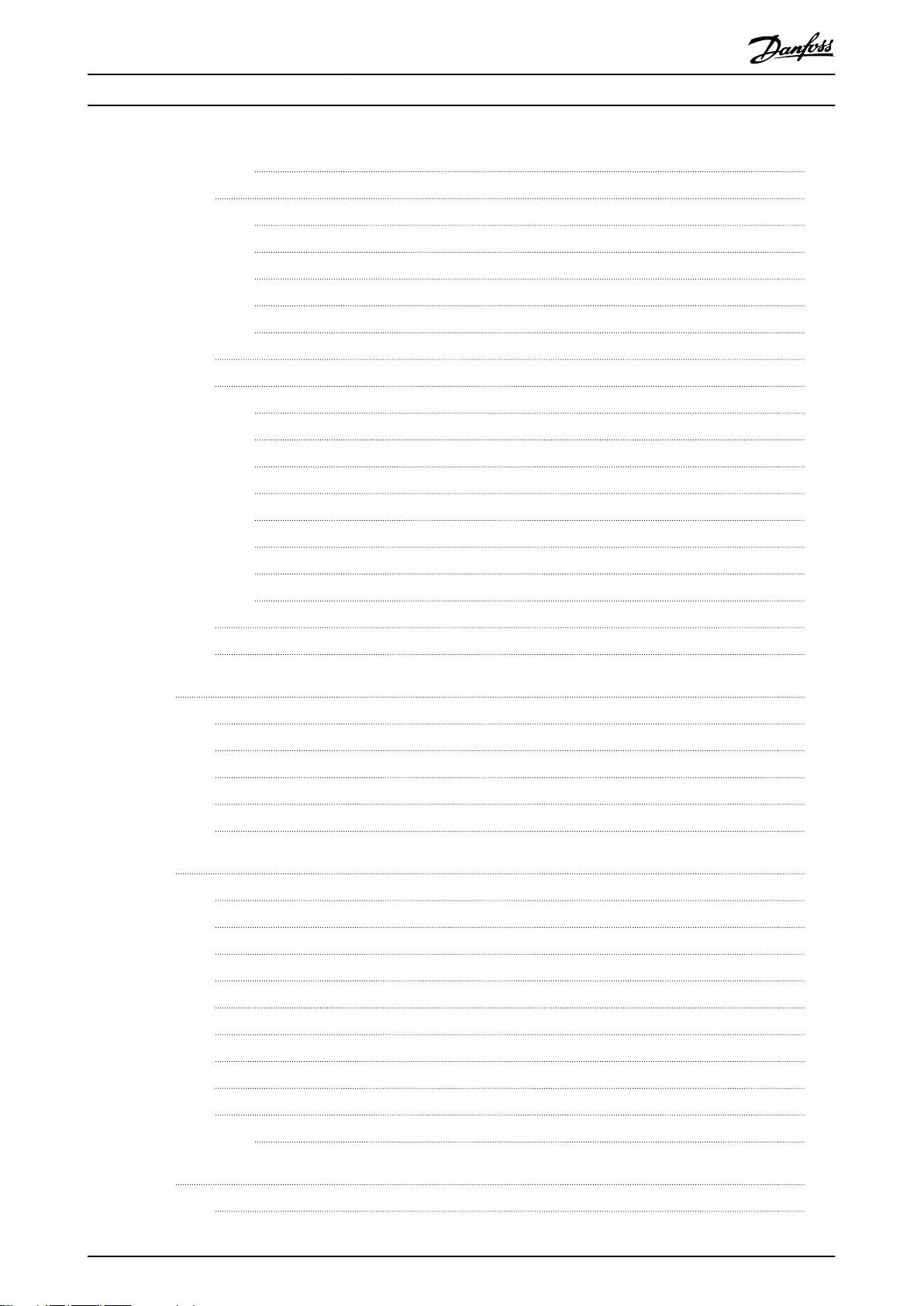

1.3 Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

Edition Remarks Software

version

MG37K3xx Added 230 V external

power supply content

Table 1.1 Document and Software Version

Approvals and Certications

1.4

FC 102 (5.0x),

FC 202 (3.0x),

FC 302 (7.6x)

The VLT® Parallel Drive Modules Design Guide

•

contains detailed information about the

capabilities and functionality of motor control

systems using these drive modules, and provides

guidance for designing this type of system.

The VLT® Parallel Drive Modules User Guide

•

contains detailed procedures for start-up, basic

operational programming, and functional testing.

Additional information describes the user

interface, application examples, troubleshooting,

and specications.

Refer to the Programming Guide applicable to the

•

particular series of VLT® Parallel Drive Modules

used in creating the drive system. The

programming guide describes in greater detail

how to work with parameters and provides

application examples.

4 Danfoss A/S © 08/2017 All rights reserved. MG37K302

Table 1.2 Approvals and Certications

Disposal

1.5

Do not dispose of equipment containing

electrical components together with

domestic waste.

Collect it separately in accordance with

local and currently valid legislation.

Safety Installation Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

WARNING

UNINTENDED START

When the drive system is connected to AC mains, the

motor can start at any time. Unintended start during

programming, service, or repair work can result in death,

serious injury, or property damage. The motor can start

via an external switch, a eldbus command, an input

reference signal from the LCP, a cleared fault condition,

or remote operation using MCT 10 Set-up Software.

To prevent unintended motor start:

Disconnect the drive system from AC mains.

•

Press [O/Reset] on the LCP, before

•

programming parameters.

The drive system, motor, and any driven

•

equipment must be fully wired and assembled

when the drive is connected to AC mains.

2 2

2.2 Qualied Personnel

Correct and reliable transport, storage, and installation are

required for the trouble-free and safe operation of the

VLT® Parallel Drive Modules. Only qualied personnel are

allowed to install this equipment.

Qualied personnel are dened as trained sta, who are

authorized to install equipment, systems, and circuits in

accordance with pertinent laws and regulations. Also, the

personnel must be familiar with the instructions and safety

measures described in this manual.

Safety Precautions

2.3

WARNING

HIGH VOLTAGE

The drive system contains high voltage when connected

to AC mains input. Failure to ensure that only qualied

personnel install the drive system can result in death or

serious injury.

Only qualied personnel are allowed to install the

•

drive system.

CAUTION

POTENTIAL HAZARD IN THE EVENT OF

INTERNAL FAILURE

There is a risk of personal injury when the drive modules

are not properly closed.

Before applying power, ensure that all safety

•

covers are in place and securely fastened.

WARNING

DISCHARGE TIME

The drive module contains DC-link capacitors. Once

mains power has been applied to the drive, these

capacitors can remain charged even after the power has

been removed. High voltage can be present even when

the warning indicator lights are o. Failure to wait 20

minutes after power has been removed before

performing service or repair work can result in death or

serious injury.

1. Stop the motor.

2. Disconnect AC mains and remote DC-link

supplies, including battery back-ups, UPS, and

DC-link connections to other drives.

3. Disconnect or lock the PM motor.

4. Wait 20 minutes for the capacitors to discharge

fully before performing any service or repair

work.

WARNING

UNINTENDED MOTOR ROTATION

WINDMILLING

Unintended rotation of permanent magnet motors

creates voltage and can charge the capacitors in the

drive system, resulting in death, serious injury, or

equipment damage.

Ensure that permanent magnet motors are

•

blocked to prevent unintended rotation.

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 5

Safety

VLT® Parallel Drive Modules

WARNING

LEAKAGE CURRENT HAZARD (>3.5 mA)

22

Leakage currents exceed 3.5 mA. Failure to ground the

drive system properly can result in death or serious

injury. Follow national and local codes regarding

protective earthing of equipment with a leakage current

>3.5 mA. Frequency converter technology implies high

frequency switching at high power. This switching

generates a leakage current in the ground connection. A

fault current in the drive system at the output power

terminals sometimes contain a DC component, which can

charge the lter capacitors and cause a transient ground

current. The ground leakage current depends on various

system congurations including RFI ltering, shielded

motor cables, and drive system power.

If the leakage current exceeds 3.5 mA, EN/IEC 61800-5-1

(Power Drive System Product Standard) requires special

care.

Grounding must be reinforced in 1 of the following ways:

Ensure the correct grounding of the equipment

•

by a certied electrical installer.

Ground wire of at least 10 mm2 (6 AWG).

•

Two separate ground wires, both complying

•

with the dimensioning rules.

See EN 60364-5-54 § 543.7 for further information.

WARNING

HEAVY LOAD

Unbalanced loads can fall and loads can tip over. Failure

to take proper lifting precautions increases risk of death,

serious injury, or equipment damage.

Never walk under suspended loads.

•

To guard against injury, wear personal

•

protective equipment such as gloves, safety

glasses, and safety shoes.

Be sure to use lifting devices with the

•

appropriate weight rating. The lifting bar must

be able to handle the weight of the load.

The load’s center of gravity may be in an

•

unexpected location. Failure to locate the center

of gravity correctly, and position the load

accordingly before lifting the load, can cause

the unit to fall over or tilt unexpectedly during

lifting and transport.

The angle from the top of the drive module to

•

the lifting cables has an impact on the

maximum load force on the cable. This angle

must be 65° or greater. Attach and dimension

the lifting cables properly.

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

perform the installation.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this document.

•

WARNING

DISCONNECT POWER BEFORE SERVICING

Sometimes during installation, AC mains power is

applied but then must be disconnected to change the

line connections. Failure to follow these steps can result

in death or serious injury.

Disconnect the frequency converters from the

•

AC mains, 230 V supply, and motor lines.

After the lines have been disconnected, wait 20

•

minutes for the capacitors to discharge.

6 Danfoss A/S © 08/2017 All rights reserved. MG37K302

Product Overview Installation Guide

3 Product Overview

3.1 Intended Use

A frequency converter is an electronic motor controller that uses 1 or more drive modules to convert AC mains input into a

variable AC waveform output. The frequency and voltage of the output are regulated to control the motor speed or torque.

The frequency converter varies the motor speed based on system feedback, such as position sensors on a conveyor belt.

The frequency converter also regulates the motor in response to remote commands from external controllers.

The VLT® Parallel Drive Modules basic kit described in this guide is UL 508 C compliant. The kit is used to create drive

systems of 2 or 4 drive modules. These drive modules are based on the D4h frequency converter and can provide a greater

power range in a smaller enclosure. The basic kit is designed to allow the exibility to either order components through

Danfoss or fabricate custom components.

The basic kit contains the following components:

Drive modules

•

Control shelf

•

Wire harnesses

•

- Ribbon cable with 44-pin connector (on both ends of the cable)

- Relay cable with 16-pin connector (on 1 end of the cable)

- DC fuse microswitch cable with 2-pin connectors (on 1 end of the cable)

DC fuses

•

Microswitches

•

Other components, such as bus bar kits and back-channel cooling duct kits, are available as options to customize the drive

system.

3 3

NOTICE

EXTERNAL 230 V SUPPLY

An external 230 V supply is needed to power the SMPS

(switch mode power supply) and any cabinet fans.

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 7

130BE561.11

2

3

4

1

5

6

7

8

9

12

13

11

10

Product Overview

VLT® Parallel Drive Modules

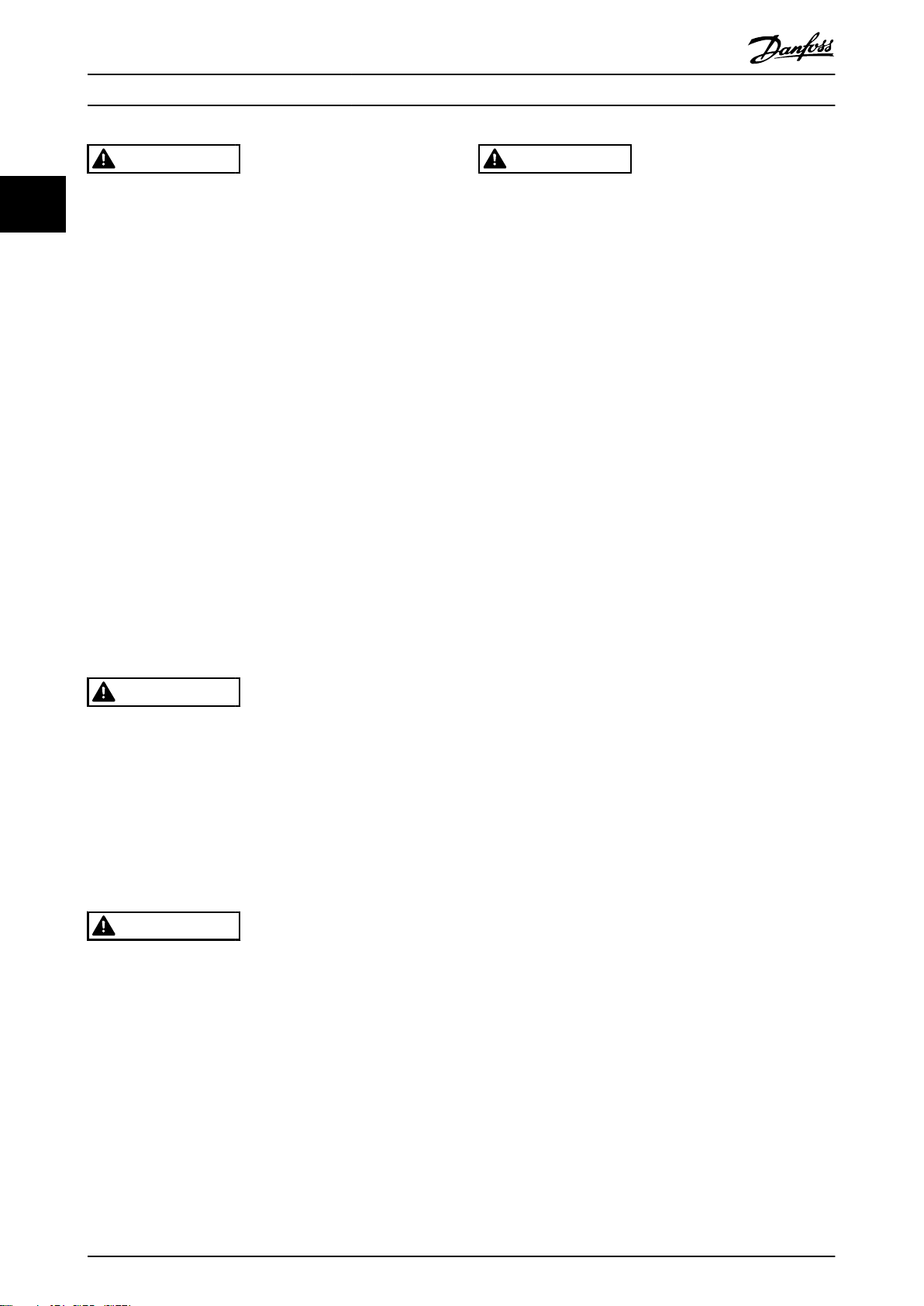

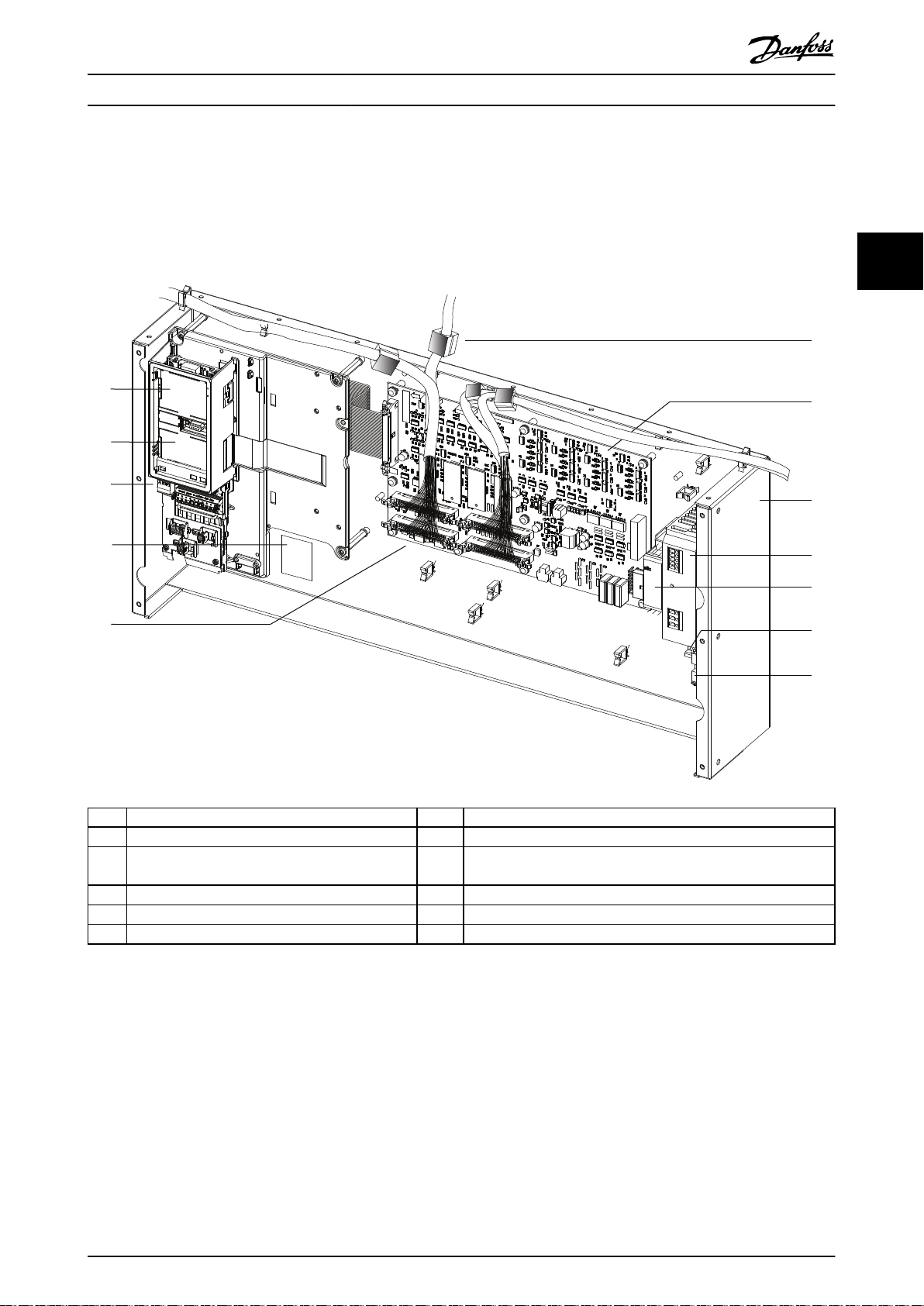

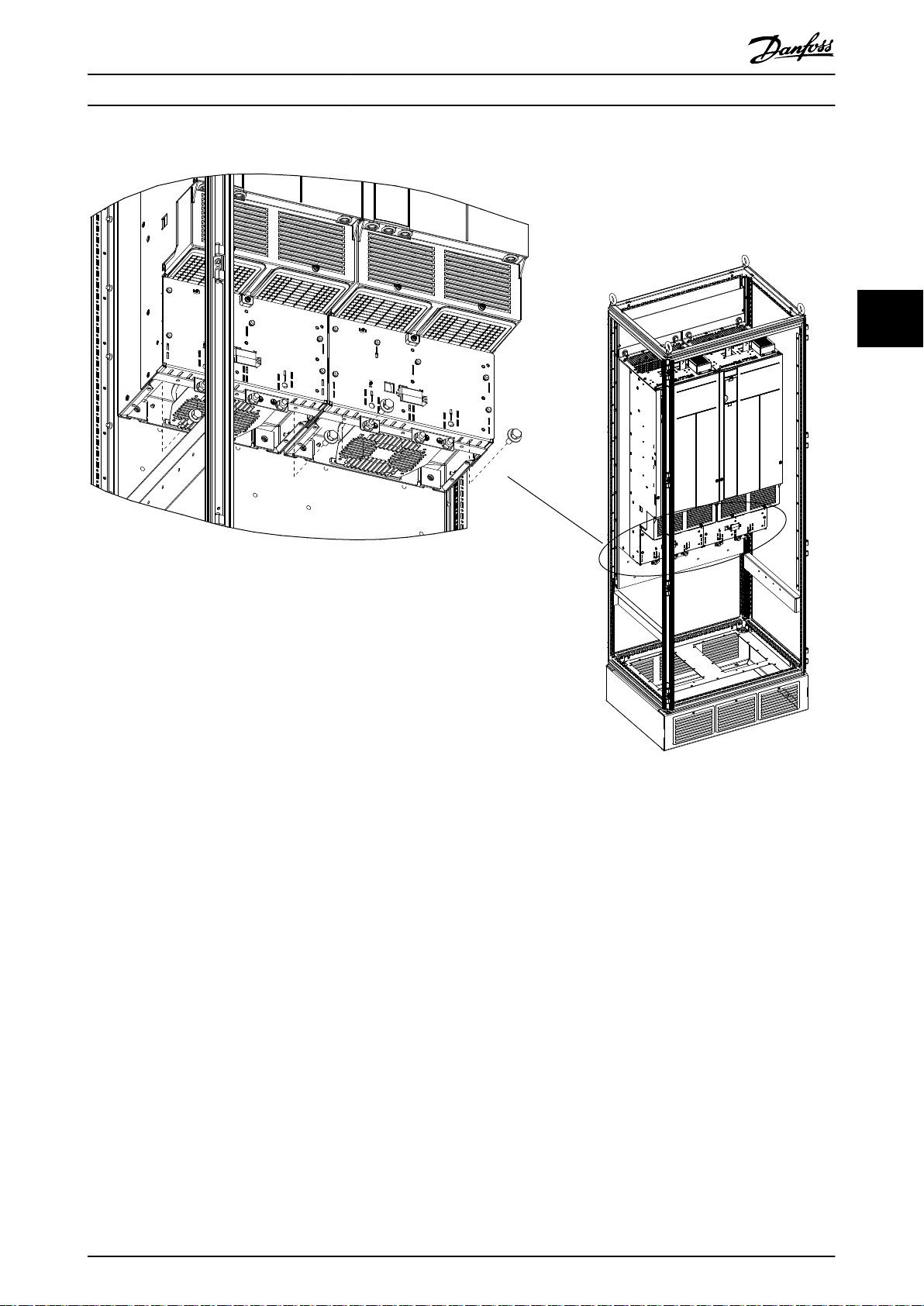

3.2 Drive Modules

Each drive module has an IP00 protection rating. Either 2 or 4 drive modules can be connected in parallel to create a drive

system, based on power requirements.

33

1 DC-link terminal and DC fuse 8 Ground terminals

2 MDCIC plug 9 Top fan

3 Microswitch to DC fuse 10 Drive module label. See Illustration 4.2.

4 Relays 1 and 2 11 Motor output terminals (inside the unit)

5 Brake fault jumper and connector 12 Heat sink and heat sink fan

6 Mains input terminals (inside the unit) 13 Ground plate

7 Terminal cover – –

Illustration 3.1 Drive Module Overview

8 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BE597.11

1

2

3

5

7

8

4

9

11

6

10

12

Product Overview Installation Guide

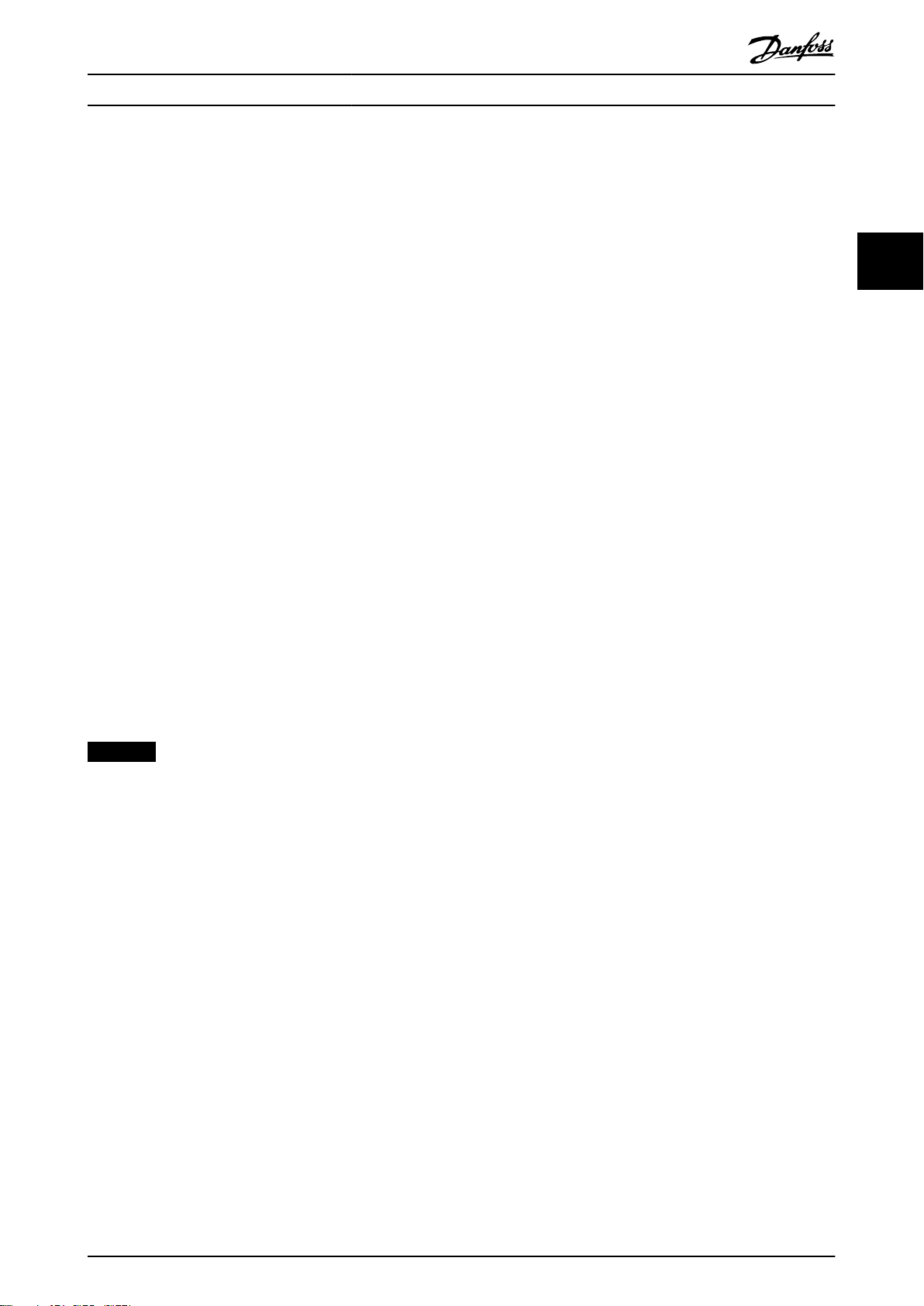

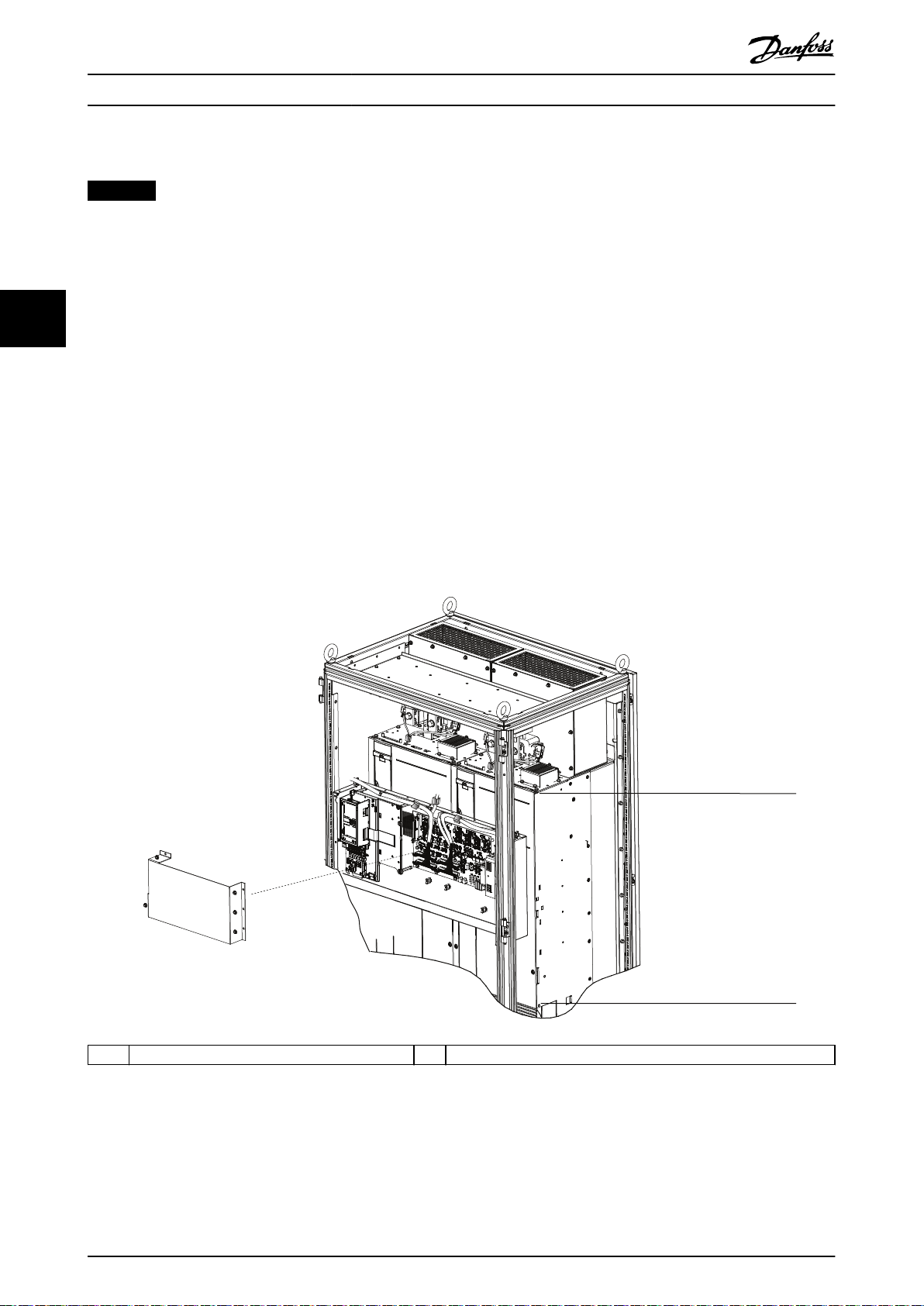

3.3 Control Shelf

The control shelf contains the LCP, MDCIC, and control card. The LCP provides access to the system parameters. The MDCIC

is connected to each of the drive modules via a ribbon cable and communicates to the control card. The control card

controls the operation of the drive modules.

3 3

1 LCP cradle 7 MDCIC card

2 Control card (underneath cover) 8 Control shelf

3 Control terminal blocks 9 Switch mode power supply (SMPS). Note that an external 230 V

supply is needed to power the SMPS.

4 Top-level drive system label. See Illustration 4.1. 10 Pilz relay

5 44-pin cables from MDCIC board to drive modules 11 DIN rail

6 Ferrite core 12 Terminal block mounted on DIN rail

Illustration 3.2 Control Shelf

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 9

130BE750.10

1

2

Product Overview

VLT® Parallel Drive Modules

3.4 Wire Harness

The VLT® Parallel Drive Modules basic kit contains the following wire harnesses:

Ribbon cable with 44-pin connector (on both ends of the cable)

•

Relay cable with 16-pin connector (on 1 end of the cable)

•

DC fuse microswitch cable with 2-pin connectors (on 1 end of the cable)

33

•

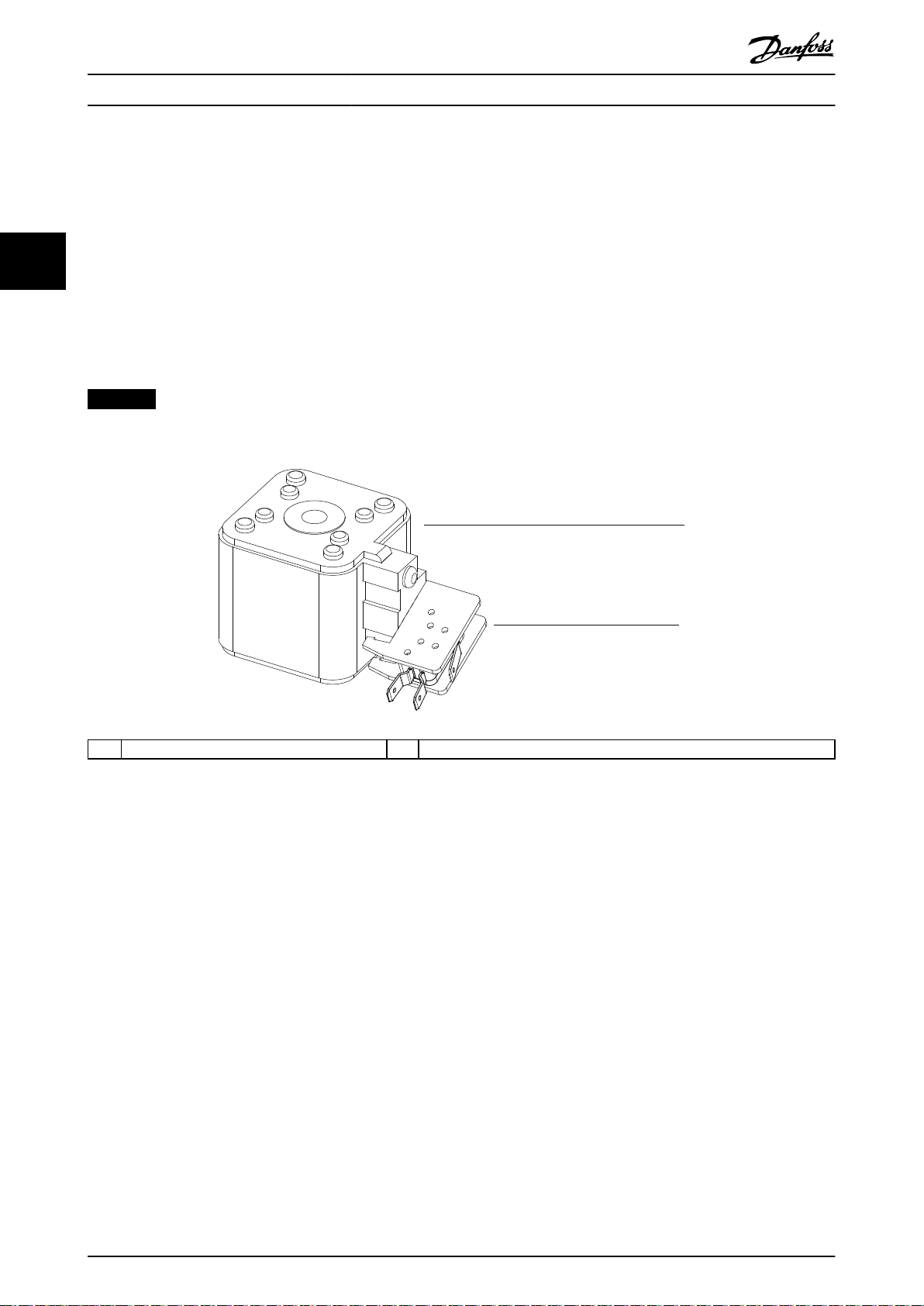

3.5 DC Fuses

The VLT® Parallel Drive Modules kit contains 2 DC fuses per drive module. These fuses on the supply side ensure that any

damage is contained to inside the drive modules.

NOTICE

Use of fuses on the supply side is mandatory for IEC 60364 (CE) compliant installations.

1 DC fuse 2 Microswitch connector

Illustration 3.3 DC Fuse and Microswitch Connector

10 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BE710.12

OUT: 3x0-Vin 0-590Hz 1260/1160 A

IN: 3x380-500V 50/60Hz 1227/1129 A

710 kW / 1000 HP, High Overload

OUT: 3x0-Vin 0-590Hz 1460/1380 A

IN: 3x380-500V 50/60Hz 1422/1344 A

800 kW / 1200 HP, Normal Overload

VLT

T/C: FC-302N710T5E00P2BGC7XXSXXXXAXBXCXXXXDX

P/N: 134X4109 S/N:

R

AutomationDrive

www.danfoss.com

1

2

3

4

5

6

ASSEMBLED IN USA

CAUTION - ATTENTION:

Stored charge, wait 20 min.

Charge residuelle, attendez 20

See manual for special condition / prefuses

Voir manuel de conditions speciales / fusibles

WARNING - AVERTISSEMENT:

`

`

Tamb. 45

˚

C/113

˚

F at Full Output Current

CHASSIS (OPEN TYPE) / IP00

SCCR 100 kA at UL Voltage range 380-500 V

Listed 36U0 E70524 IND. CONT. EQ.

UL Voltage range 380-500 V

Max. Tamb. 55

˚

C/131

˚

F w/ Output Current Derating

123456H123

130BE711.14

Intended use - The Individual Base Drive

Modules are intended for use in Parallel Drive

Module system only. Specic electrical

ratings are not applicable. Name plate of

Parallel Drive Module system should

be referred for actual drive ratings.

VLT

ASSEMBLED IN USA

T/C: FC-BDMN250T5E00H2SXC7XXSXXXXAXBXCXXXXDX

P/N: 178N0025 S/N: 123456H123

CAUTION - ATTENTION:

Stored charge, wait 20 min.

Charge residuelle, attendez 20

See manual for special condition / prefuses

Voir manuel de conditions speciales / fusibles

WARNING - AVERTISSEMENT:

R

AutomationDrive

www.danfoss.com

`

`

CHASSIS (OPEN TYPE) / IP00

SCCR 100 kA at UL Voltage range 380-500 V

Listed 36U0 E70524 IND. CONT. EQ.

1

2

3

4

5

UL Voltage range 380-500 V

Mechanical Installation Installation Guide

4 Mechanical Installation

4.1 Receiving and Unpacking the Unit

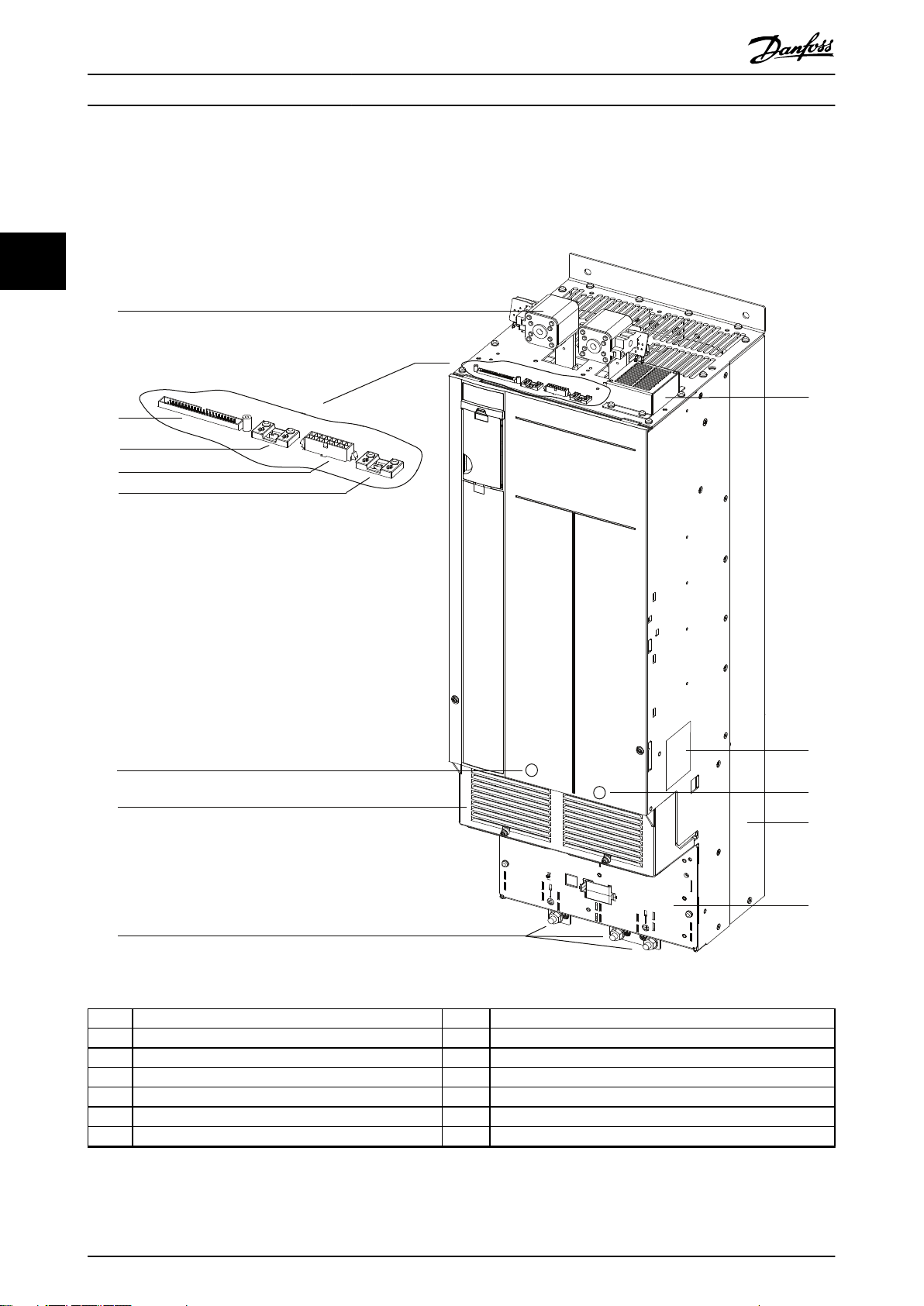

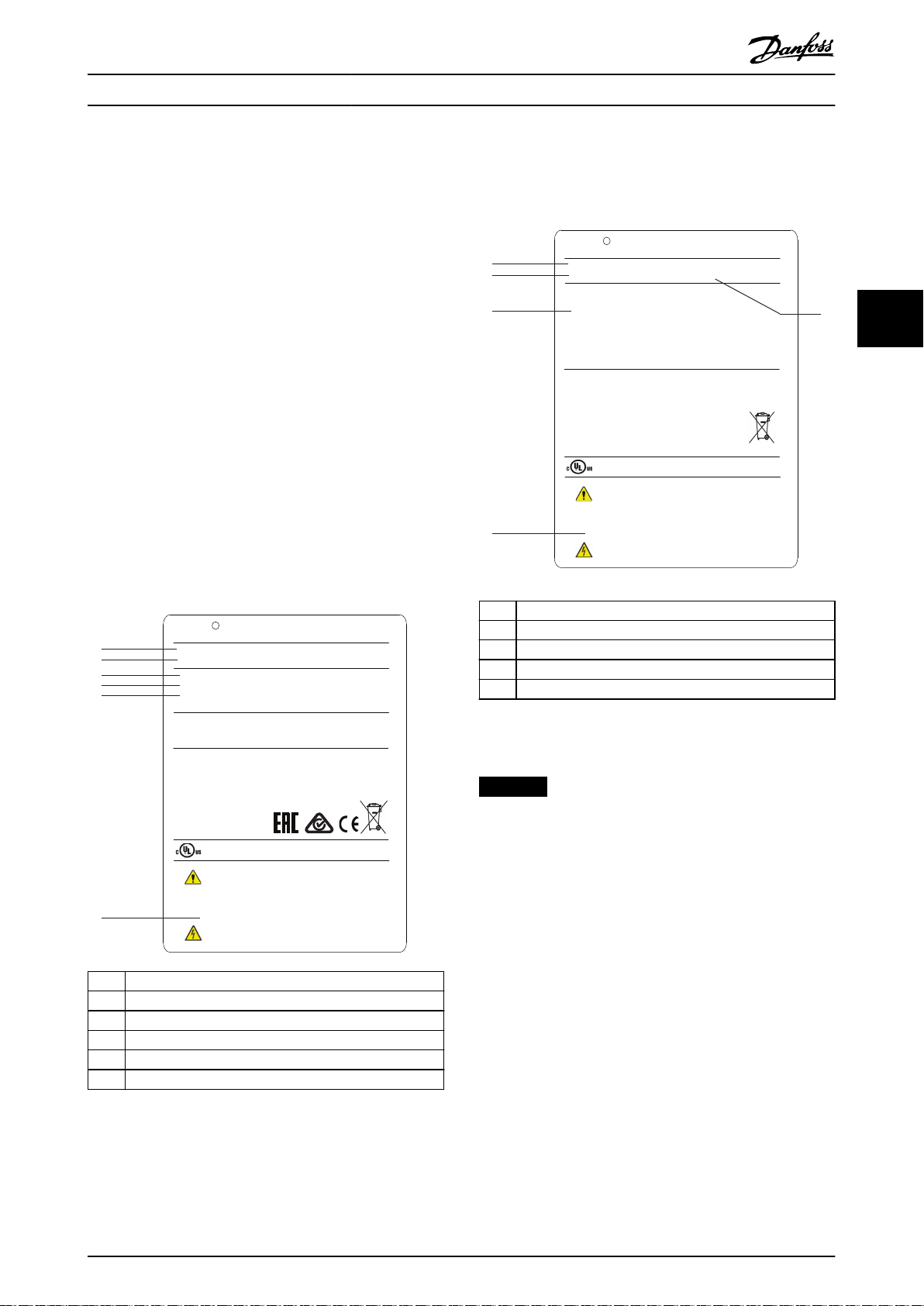

4.1.1 Items Supplied

Make sure that the items supplied and the

•

information on the labels correspond to the

order.

- Top-level drive system. This label is

found on the control shelf, lower right

side of the LCP. See Illustration 3.2.

- Drive module. This label is found inside

the drive module enclosure, on the right

side panel. See Illustration 3.1.

Visually check the packaging and the VLT

•

Parallel Drive Modules components for damage

caused by inappropriate handling during

shipment. File any claim for damage with the

carrier. Retain damaged parts, in case

is needed.

®

clarication

4 4

1 Type code

2 Code number

3 Intended use disclaimer

4 Discharge time

5 Serial number

Illustration 4.2 Drive Module Label (Example)

NOTICE

LOSS OF WARRANTY

Removing the labels from the VLT® Parallel Drive

Modules can result in loss of warranty.

1 Type code

2 Code number

3 Power rating

4 Input voltage, frequency, and current

5 Output voltage, frequency, and current

6 Discharge time

Illustration 4.1 Top-level Drive System Label (Example)

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 11

Mechanical Installation

Receiving and unloading

I-beam and hooks rated to lift a drive module having a weight of 125 kg (275 lb), with the necessary safety

•

margins.

Crane or other lifting aid rated to lift the minimum weight specied in the documentation package supplied with

•

the drive module.

Crowbar to disassemble the wooden shipping container.

•

Installation

Drill with 10 mm or 12 mm drill bits.

44

•

Tape measurer.

•

Screwdriver.

•

Wrench with relevant metric sockets (7–17 mm).

•

Wrench extensions.

•

Torx T50 tool.

•

Cabinet construction

Acquire the tools necessary for assembly of the panel - according to the design plans and established practices.

VLT® Parallel Drive Modules

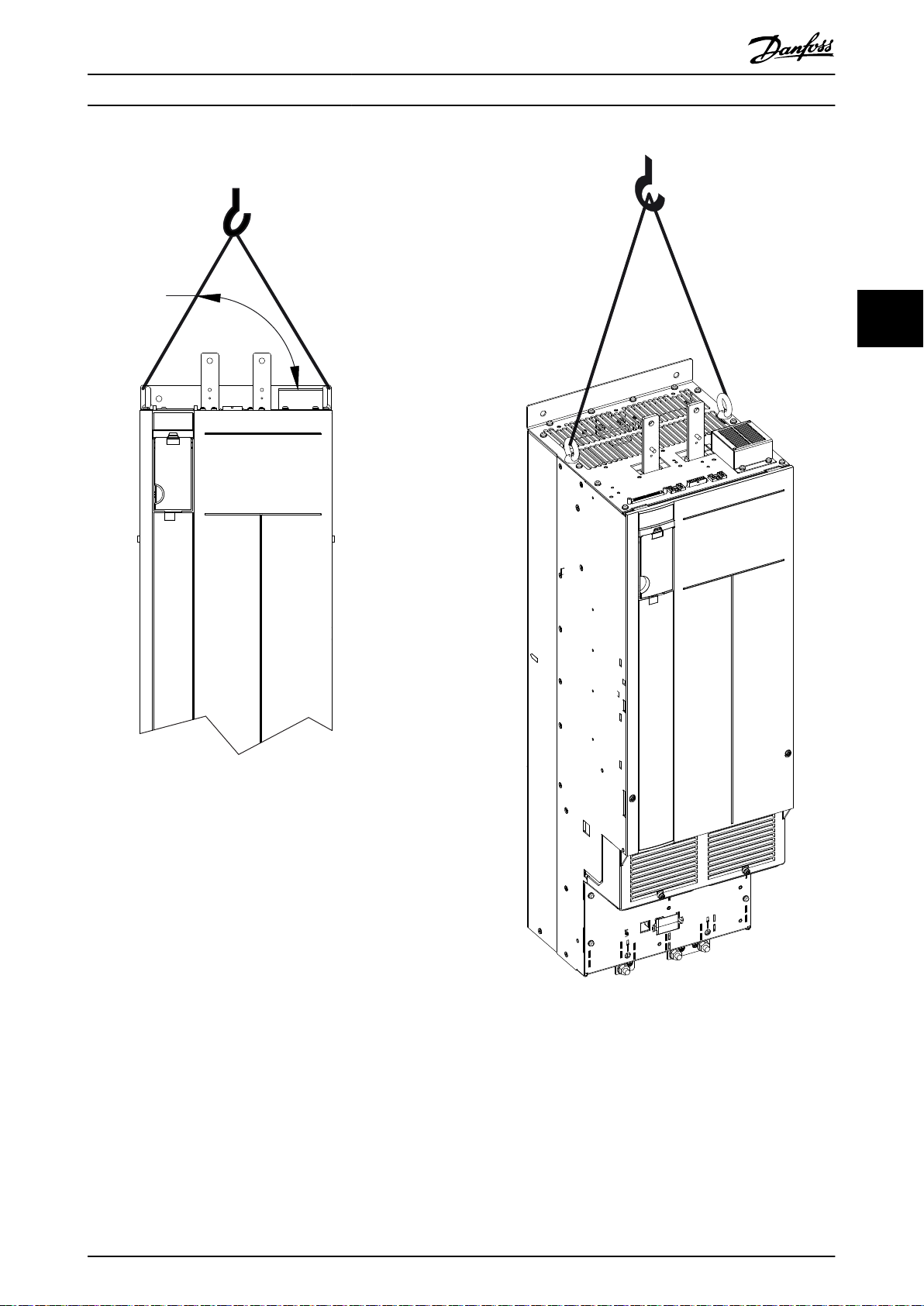

4.1.2 Lifting the Unit

For measurements and center of gravity, see chapter 7.8 Kit Dimensions.

Ensure that the lifting device is suitable for the task.

•

Move the unit using a hoist, crane, or forklift with the appropriate rating.

•

Always use the dedicated lifting eye bolts. See Illustration 4.3.

•

CAUTION

HEAVY LOAD

Unbalanced loads can fall and loads can tip over. Failure to take proper lifting precautions increases risk of death,

serious injury, or equipment damage.

Never walk under suspended loads.

•

To guard against injury, wear personal protective equipment such as gloves, safety glasses, and safety shoes.

•

Be sure to use lifting devices with the appropriate weight rating. The lifting bar must be able to handle the

•

weight of the load.

The load’s center of gravity may be in an unexpected location. Failure to locate the center of gravity correctly

•

and position the load accordingly before lifting the load can cause the unit to fall over or tilt unexpectedly

during lifting and transport.

The angle from the top of the drive module to the lifting cables has an impact on the maximum load force on

•

the cable. This angle must be 65° or greater. Refer to Illustration 4.3. Attach and dimension the lifting cables

properly.

4.1.3 Storage

Store the kit in a dry location. Keep the equipment sealed in its packaging until installation. Refer to chapter 7.5 Ambient

Conditions for Drive Modules for recommended ambient conditions.

12 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BE566.10

65° min

Mechanical Installation Installation Guide

4 4

Illustration 4.3 Lifting the Drive Module

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 13

Mechanical Installation

VLT® Parallel Drive Modules

4.2 Requirements

This section describes the minimum recommended

requirements for mechanical installation. For UL and CE

requirements, see chapter 5.2 Electrical Requirements for

Certications and Approvals.

4.2.3 Busbars

If the Danfoss busbar kit is not used, see Table 4.2 for the

cross-section measurements that are required when

creating customized busbars. For terminal dimensions, refer

to chapter 7.8.2 Terminal Dimensions and chapter 7.8.3 DC

Bus Dimensions.

4.2.1 Environmental

44

Refer to for information on required operating

temperature, humidity, and other environmental

conditions.

4.2.2 Cabinet

The kit consists of either 2 or 4 drive modules, depending

on the power rating. The cabinets have to meet the

following minimum requirements:

Description Width [mm (in)] Thickness [mm (in)]

AC motor 143.6 (5.7) 6.4 (0.25)

AC mains 143.6 (5.7) 6.4 (0.25)

DC bus 76.2 (3.0) 12.7 (0.50)

Table 4.2 Cross-section Measurements for Customized Busbars

NOTICE

Align busbars vertically to provide maximum airow.

4.2.4 Thermal Considerations

Width [mm (in)] 2-drive: 800 (31.5), 4-drive: 1600 (63)

Depth [mm (in)] 600 (23.6)

Height [mm (in)]

Weight capacity

[kg (lb)]

Ventilation openings See chapter 4.2.5 Cooling and Airow

Table 4.1 Cabinet Requirements

1) Required if Danfoss busbar or cooling kits are used.

2000 (78.7)

2-drive: 450 (992), 4-drive: 910 (2006)

Requirements.

1)

NOTICE

EXTERNAL 230 V SUPPLY

An external 230 V supply is required for the SMPS

(switch mode power supply). Danfoss recommends using

a 6 A, 10 A, or 16 A slow-blow fuse when installing the

external supply.

For heat dissipation values, refer to chapter 7.1 Powerdependent Specications. The following heat sources must

be considered when determining cooling requirements:

Ambient temperature outside enclosure.

•

Filters (for example, sine-wave and RF).

•

Fuses.

•

Control components.

•

For required cooling air, refer to chapter 4.2.5 Cooling and

Airow Requirements.

14 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BE569.10

Mechanical Installation Installation Guide

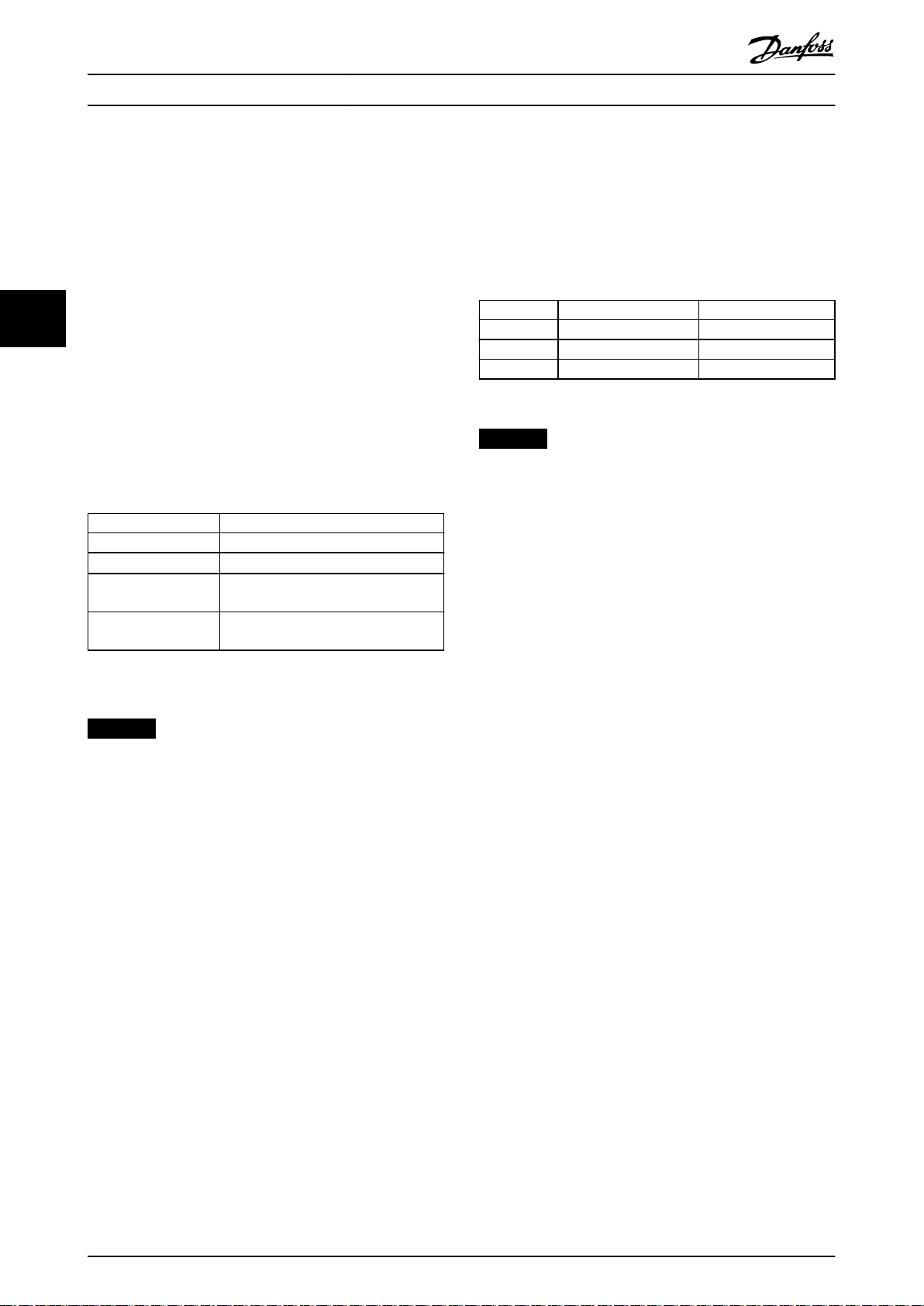

4.2.5 Cooling and Airow Requirements

The recommendations provided in this section are necessary for eective cooling of the drive modules within the panel

enclosure. Each drive module contains a heat sink fan and a mixing fan. Typical enclosure designs utilize door fans along

with the drive module fans to remove waste heat from the enclosure.

Danfoss provides several back-channel cooling kits as options. These kits remove 85% of the waste heat from the enclosure,

reducing the need for large door fans.

NOTICE

Make sure that the total ow of the cabinet fans meets the recommended airow.

Drive module cooling fans

The drive module is equipped with a heat sink fan, which provides the required

heat sink. Also, there is a cooling fan mounted on the top of the unit, and a small 24 V DC mixing fan mounted under the

input plate that operates any time the drive module is powered on.

In each drive module, the power card provides DC voltage to power the fans. The mixing fan is powered by 24 V DC from

the main switch mode power supply. The heat sink fan and the top fan are powered by 48 V DC from a dedicated switch

mode power supply on the power card. Each fan has a tachometer feedback to the control card to conrm that the fan is

operating correctly. On/o and speed control of the fans help reduce unnecessary acoustical noise and extend the life of the

fans.

Cabinet fans

When the back-channel option is not used, fans mounted in the cabinet must remove all the heat generated inside the

enclosure.

For each enclosure housing 2 drive module, the cabinet fan ow recommendation is as follows:

When back-channel cooling is used, 680 m3/h (400 cfm) ow is recommended.

•

When back-channel cooling is not used, 4080 m3/h (2400 cfm) ow is recommended.

•

ow rate of 840 m3/h (500 cfm) across the

4 4

Illustration 4.4 Airow, Standard Unit (Left), Bottom/Top Cooling Kit (Middle), and Back/Back Cooling Kit (Right)

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 15

130BE571.10

Mechanical Installation

VLT® Parallel Drive Modules

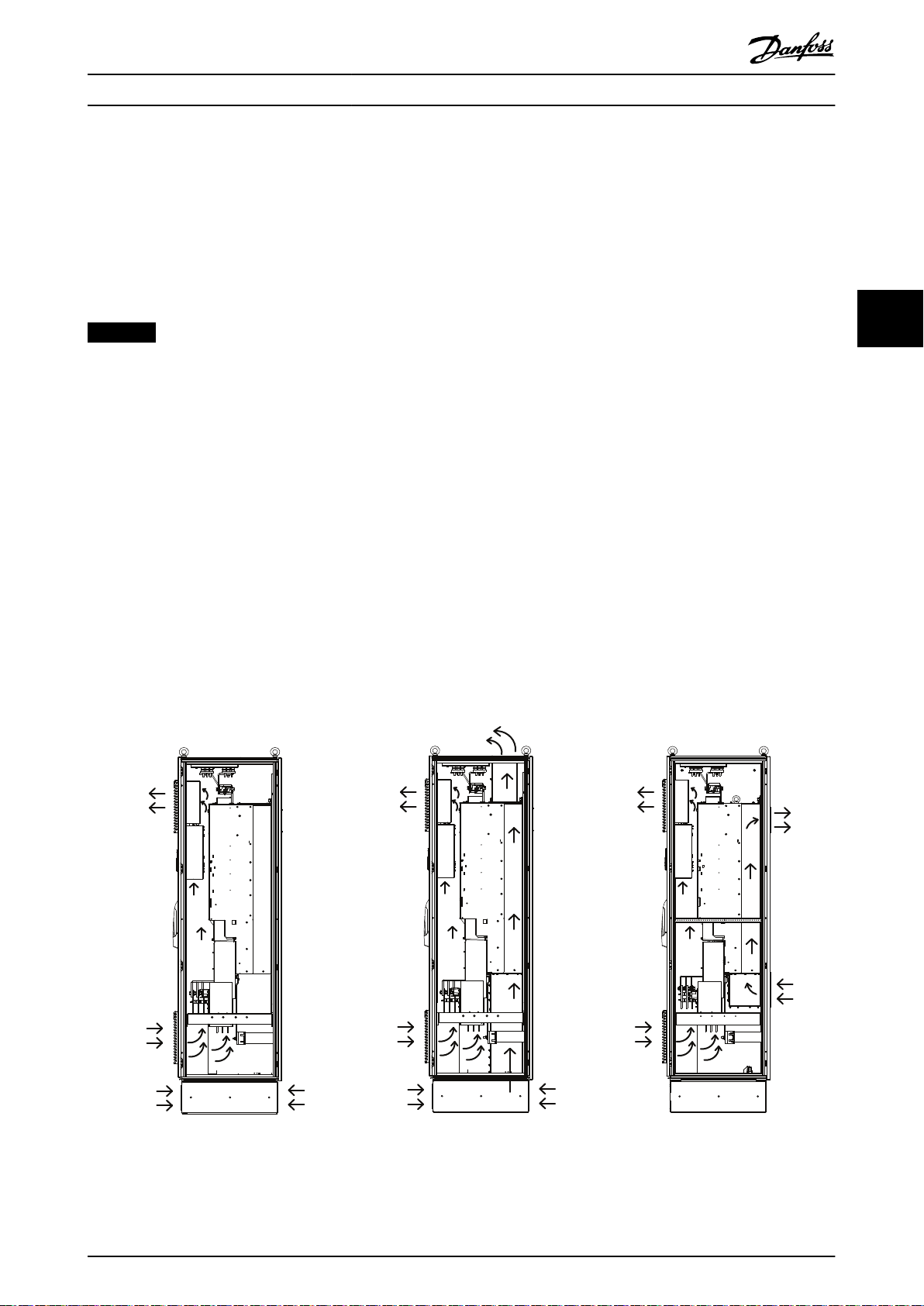

4.3 Installing the Drive Modules

Install the drive modules into the cabinet frame as described in the following steps.

1. Unpack the drive modules from the packaging. See chapter 4.1 Receiving and Unpacking the Unit.

2. Install 2 eye bolts in the top of the

lifting harness and an overhead hoist or crane with the necessary lifting capacity. See chapter 4.1.2 Lifting the Unit.

rst drive module. Prepare the drive module for lifting, using an appropriate

44

Illustration 4.5 Installation of Eye Bolts

3. Install the 2 bottom mounting screws and gaskets onto the mounting panel.

4. Using the crane or hoist, lift the drive module and then lower the unit through the top of the cabinet frame. Align

the bottom mounting holes of the unit with the 2 bottom mounting screws on the mounting panel.

5. Verify that the drive module is correctly aligned on the mounting panel and then secure the bottom of the unit to

the panel with the 2 hex nuts. See Illustration 4.6. Torque the hex nuts. Refer to chapter 7.9 Fastener Tightening

Torques.

6. Secure the top of the unit to the mounting panel with M10x26 screws, and then torque the screws.

7. Line up the groove on the microswitch with the edges on each DC fuse and press rmly until the microswitch

clicks into place.

8. Install 2 DC fuses with microswitches onto the tops of the DC-link terminals on each drive module. The

microswitches should be installed on the outer side of each terminal. Refer to Illustration 3.1.

9. Secure each fuse with 2 M10 screws and torque the screws.

10. Install the next drive module.

16 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BE572.10

Mechanical Installation Installation Guide

4 4

Illustration 4.6 Installation of Bottom Mounting Bolts

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 17

130BE713.11

1

2

Mechanical Installation

VLT® Parallel Drive Modules

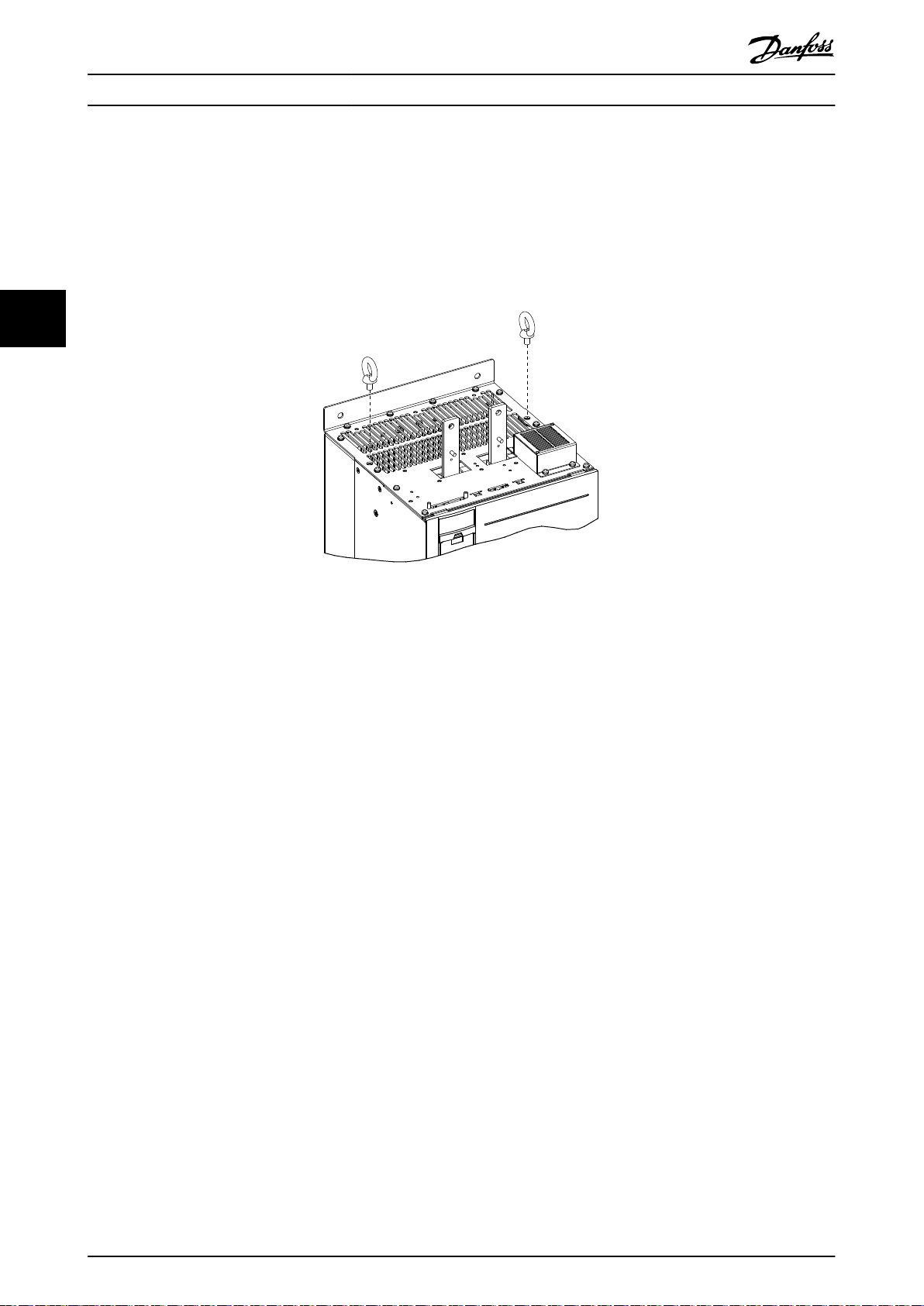

4.4 Installing the Control Shelf

NOTICE

To avoid RFI, do not route control wiring together with power cables or bus bars.

1. Remove the control shelf assembly from its package.

2. Remove the LCP from the control shelf.

3. Use some type of mounting bracket to install the control shelf. Danfoss does not supply the mounting brackets for

44

the control shelf. For EMC-correct installation, refer to Illustration 4.7.

4. Remove the MDCIC cover from the control shelf assembly.

5. Connect the 44-pin ribbon cables from the MDCIC card to the top of the drive modules, following the sequence

numbers indicated next to the connectors on the MDCIC.

6. Route the 44-pin ribbon cables inside the cabinet.

7. Connect the external brake fault wiring harness between the microswitch terminals and the brake jumper

connector on the top of the drive module.

8. Connect the relay wiring between relay 1 or 2 on the control shelf and the corresponding relay connector on the

top of the drive module.

9. Connect the microswitch to the microswitch connector provided on the top of the drive module. Refer to

Illustration 3.1 and Illustration 3.3.

1 Control shelf must stay below this point 2 Control shelf must stay above this point

Illustration 4.7 Positioning the Control Shelf for EMC-correct Installation

18 Danfoss A/S © 08/2017 All rights reserved. MG37K302

Electrical Installation Installation Guide

5 Electrical Installation

5.1 Safety Instructions

See chapter 2 Safety for general safety instructions.

WARNING

INDUCED VOLTAGE

When output motor cables from dierent frequency

converters are run together, induced voltage can charge

equipment capacitors even with the equipment turned

o and locked out.

To avoid death or serious injury:

Run output motor cables separately or use

•

shielded cables.

Simultaneously lock out all the frequency

•

converters.

CAUTION

SHOCK HAZARD

The drive system can cause a DC current in the

protective earth (PE) conductor.

When a residual current-operated protective

•

device (RCD) is used for protection against

electrical shock, only an RCD of Type B is

allowed on the supply side.

Failure to follow this recommendation could prevent the

RCD from providing the intended protection.

NOTICE

MOTOR OVERLOAD PROTECTION

The drive modules are supplied with Class 20 overload

protection for single motor applications.

Overcurrent protection

Extra protective equipment, such as short-circuit

•

protection or motor thermal protection between

the drive modules and the motors, is required for

applications with multiple motors.

The correct input fusing is required to acquire

•

approvals and meet certication requirements,

and to provide short circuit and overcurrent

protection. These fuses are not factory-supplied,

and must be provided by the installer. See

maximum fuse ratings in chapter 7.1 Power-

dependent Specications.

Wire type and ratings

All wiring must comply with local and national

•

regulations regarding cross-section and ambient

temperature requirements.

Power connection wire recommendation:

•

minimum 75 °C rated copper wire.

See chapter 7.6 Cable Specications for recommended wire

sizes and types.

5 5

CAUTION

PROPERTY DAMAGE

Electronic thermal relay (ETR) protection against motor

overload is not included in the default setting. To

program the LCP for this function, refer to the VLT

Parallel Drive Modules User Guide.

®

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 19

Electrical Installation

VLT® Parallel Drive Modules

5.2 Electrical Requirements for Certications and Approvals

The standard conguration provided in this guide (drive

modules, control shelf, wire harnesses, fuses, and

microswitches) is UL and CE certied. The following

conditions must be met apart from the standard congu-

ration to obtain UL and CE regulatory approval

requirements. For a list of disclaimers, see

chapter 8.1 Disclaimer.

Use the frequency converter in a heated, indoor-

•

controlled environment. Cooling air must be

55

clean, free from corrosive materials, and

electrically conductive dust. See for specic limits.

Maximum ambient air temperature is 40 °C

•

(104 °F) at rated current.

The drive system must be assembled in clean air,

•

according to enclosure classication. To obtain UL

or CE certication regulatory approvals, drive

modules must be installed according to the

standard conguration provided in this guide.

Maximum voltage and current must not exceed

•

the values provided in chapter 7.1 Powerdependent

conguration.

The drive modules are suitable for use on a

•

circuit capable of delivering not more than

100 kA rms symmetrical amperes at the drive

Specications for the specied drive

nominal voltage (600 V maximum for 690 V units)

when protected by fuses with the standard

conguration. Refer to chapter 5.4.1 Fuse Selection.

The ampere rating is based on tests done

according to UL 508C.

The cables located within the motor circuit must

•

be rated for at least 75 °C (167 °F) in ULcompliant installations. The cable sizes have been

provided in chapter 7.1 Power-dependent Speci-

cations for the specied drive conguration.

The input cable must be protected with fuses.

•

Circuit breakers must not be used without fuses

in the U.S. Suitable IEC (class aR) fuses and UL

(class L or T) fuses are listed in chapter 5.4.1 Fuse

Selection. In addition, country-specic regulatory

requirements must be adhered to.

For installation in the U.S., branch circuit

•

protection must be provided according to the

National Electrical Code (NEC) and any applicable

local codes. To fulll this requirement, use UL-

classied fuses.

For installation in Canada, branch circuit

•

protection must be provided according to the

Canadian Electrical Code and any applicable

provincial codes. To fulll this requirement, use

the UL-classied fuses.

20 Danfoss A/S © 08/2017 All rights reserved. MG37K302

230 V AC

50/60 Hz

1

2

Brake Temp

(NC)

91 (L1)

L

N

230 V/24 V Power supply

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24 V OUT)

13 (+24 V OUT)

18 (D IN)

20 (COM D IN)

15 mA

200 mA

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

0/4–20 mA

03

+10 V DC

0 V DC - 10 V DC

0/4-20 mA

24 V DC

02

01

05

04

06

240 V AC, 2A

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27

24 V

0 V

(D IN/OUT)

0 V (PNP)

24 V (NPN)

(D IN/OUT)

0 V

24 V

29

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

A53 U-I (S201)

ON

21

A54 U-I (S202)

ON=0–20 mA

OFF=0–10 V

95

400 V AC, 2A

P 5-00

(R+) 82

(R-) 81

+ - + -

(P RS485) 68

(N RS485) 69

(COM RS485) 61

0 V

5 V

S801

RS485

RS485

21

ON

S801/Bus Term.

OFF-ON

3-phase

power

input

Switch mode

Power supply

Motor

Analog output

Interface

Relay1

Relay2

ON=Terminated

OFF=Open

Brake

resistor

(NPN) = Sink

(PNP) = Source

240 V AC, 2A

400 V AC, 2A

0 V DC - 10 V DC

10 V DC

37 (D IN) - option

130BE752.10

Regen

terminals

Electrical Installation Installation Guide

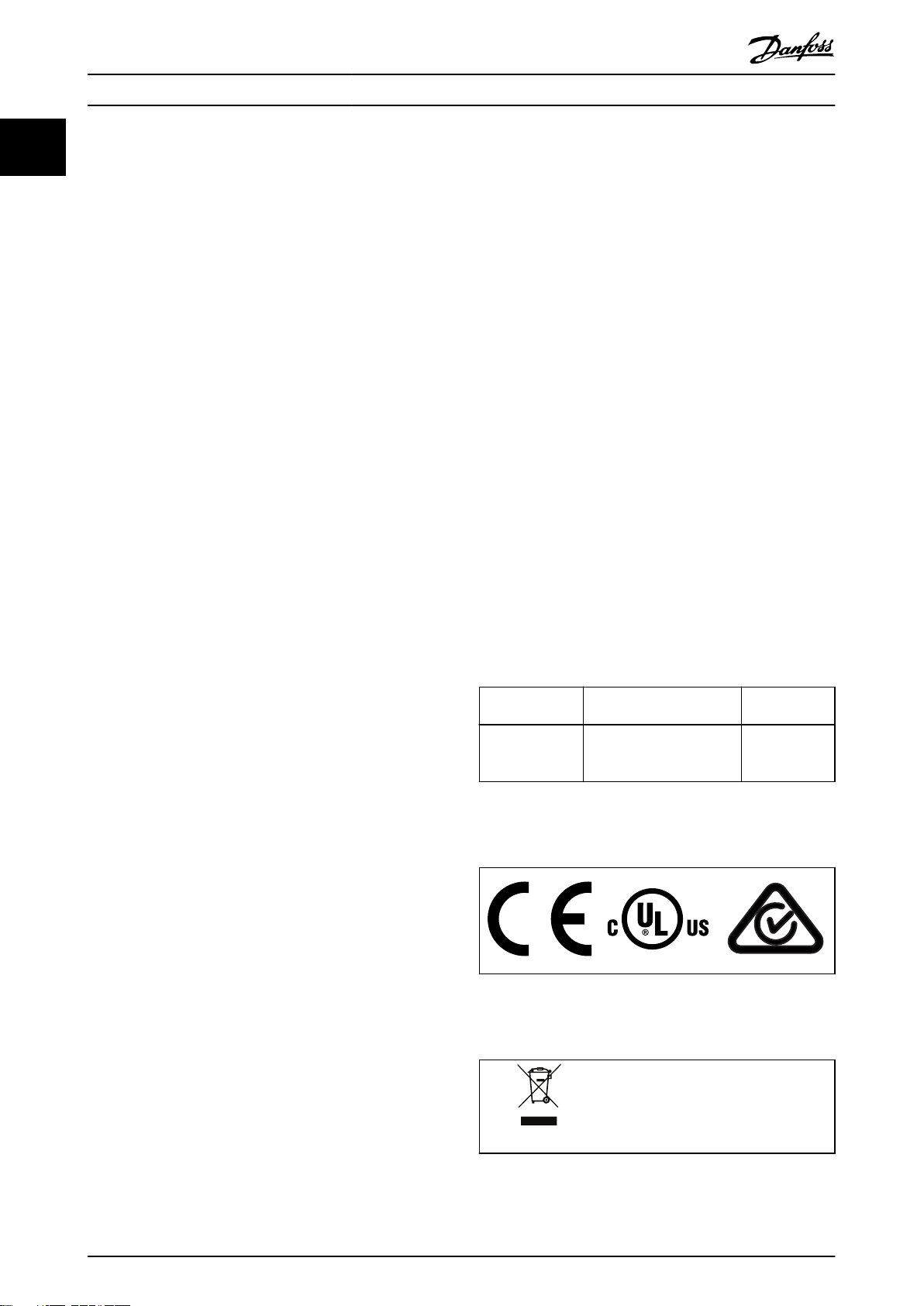

5.3 Wiring Diagram

5 5

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 21

Illustration 5.1 Wiring Diagram

Electrical Installation

VLT® Parallel Drive Modules

5.4 Fuses

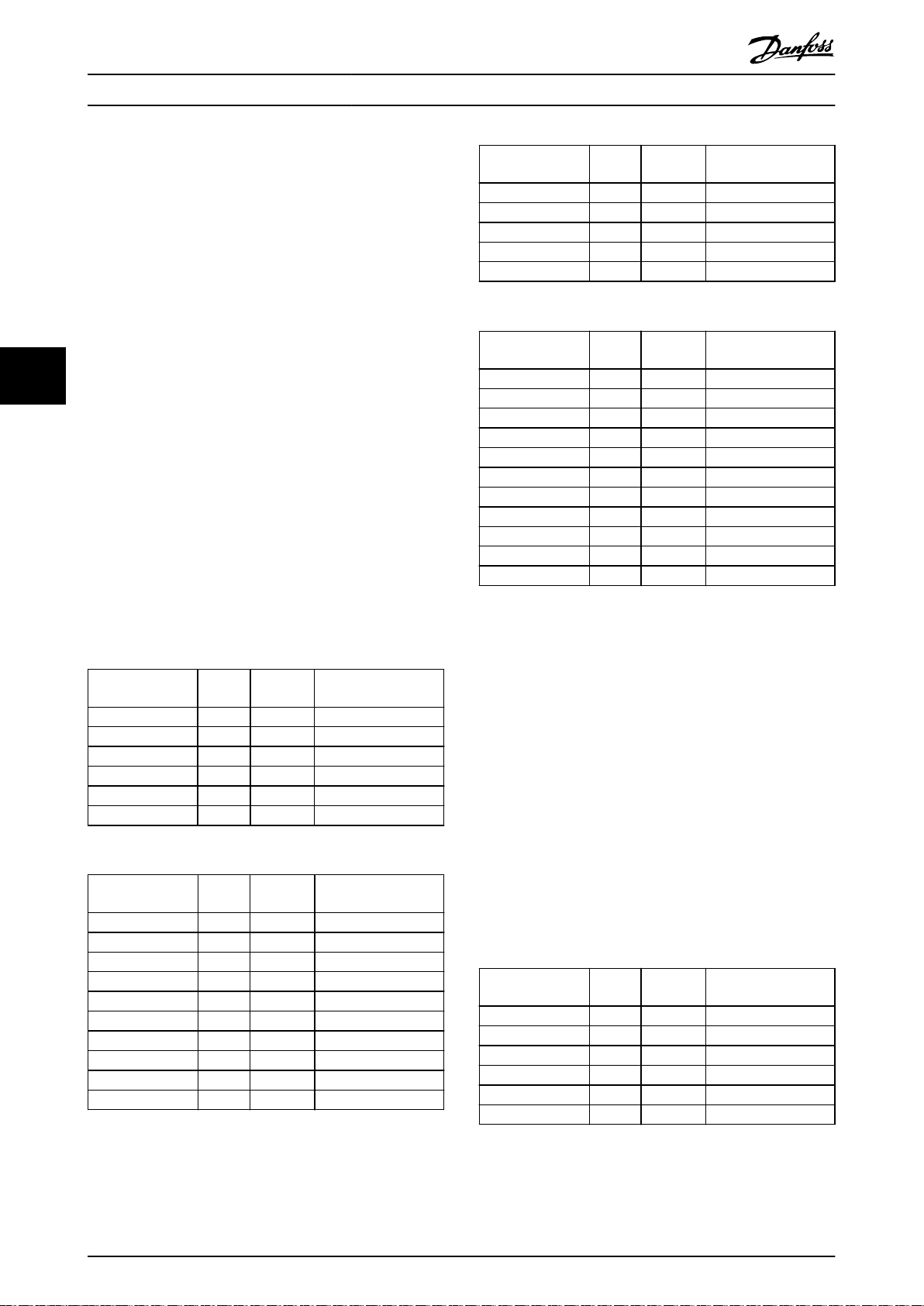

5.4.1 Fuse Selection

To protect the drive system in case 1 or more internal

components break down within a drive module, use fuses

and/or circuit breakers at the mains supply side.

5.4.1.1 Branch Circuit Protection

To protect the installation against electrical and re

hazards, protect all branch circuits in an installation against

55

short circuit and overcurrent according to national and

international regulations.

5.4.1.2 Short-circuit Protection

Danfoss recommends the fuses listed in

chapter 5.4.1.3 Recommended Fuses for CE Compliance and

chapter 5.4.1.4 Recommended Fuses for UL Compliance to

achieve CE or UL Compliance in the protection of service

personnel and property against the consequences of

component breakdown in the drive modules.

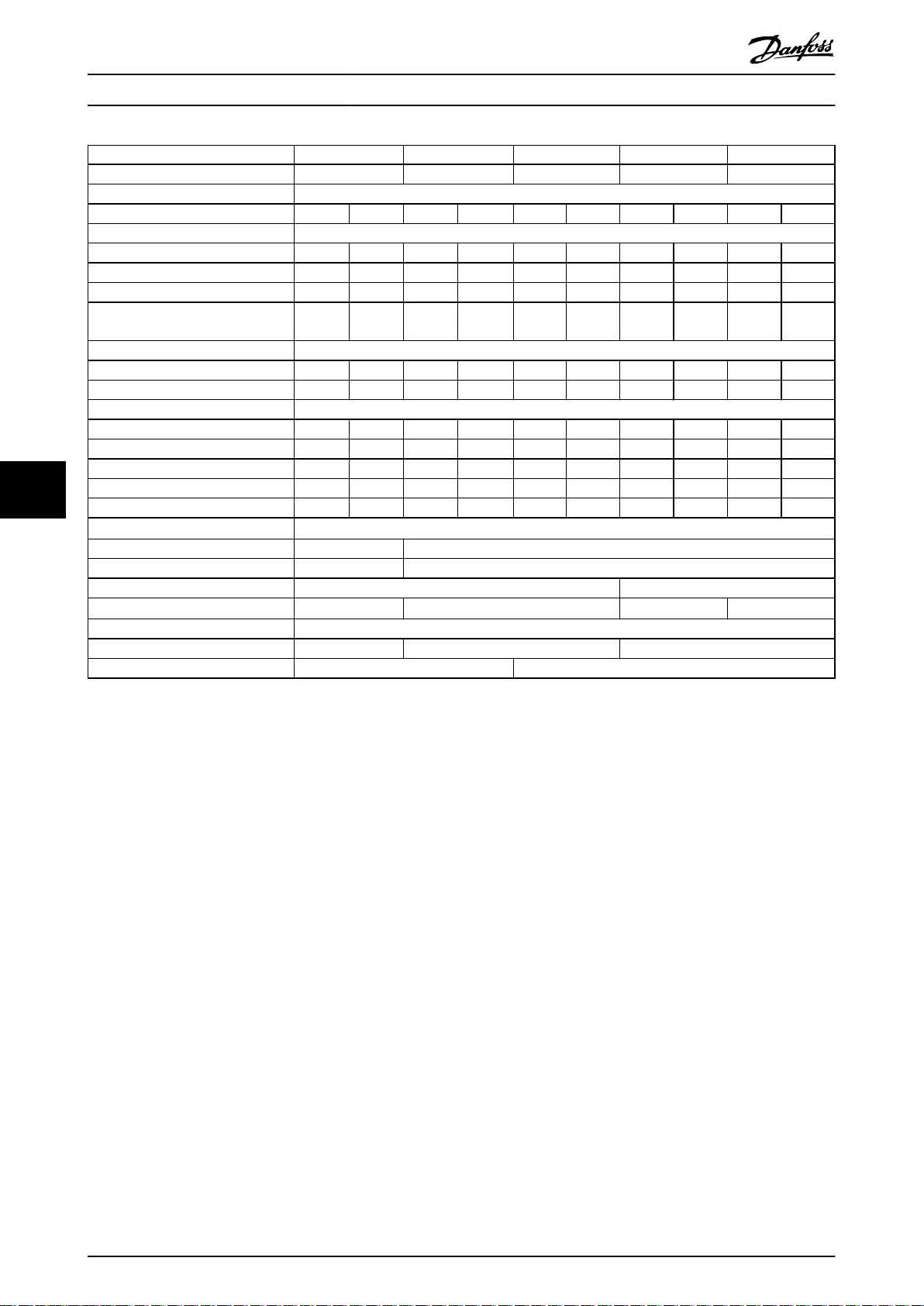

Number of drive

modules

4 N630 N710 aR-1600

4 N710 N800 aR-2000

4 N800 N900 aR-2500

4 N900 N1M0 aR-2500

4 N1M0 N1M2 aR-2500

Table 5.3 6-Pulse Drive Systems (525–690 V AC)

Number of drive

modules

2 N250 N315 aR-550

2 N315 N355 aR-630

2 N355 N400 aR-630

2 N400 N500 aR-630

2 N500 N560 aR-630

2 N560 N630 aR-900

4 N630 N710 aR-900

4 N710 N800 aR-900

4 N800 N900 aR-900

4 N900 N1M0 aR-1600

4 N1M0 N1M2 aR-1600

FC 302 FC 102/

FC 202

FC 302 FC 102/

FC 202

Recommended fuse

(maximum)

Recommended fuse

(maximum)

5.4.1.3 Recommended Fuses for CE

Compliance

Number of drive

modules

2 N450 N500 aR-1600

4 N500 N560 aR-2000

4 N560 N630 aR-2000

4 N630 N710 aR-2500

4 N710 N800 aR-2500

4 N800 N1M0 aR-2500

Table 5.1 6-Pulse Drive Systems (380–500 V AC)

Number of drive

modules

2 N250 N315 aR-630

2 N315 N355 aR-630

2 N355 N400 aR-630

2 N400 N450 aR-800

2 N450 N500 aR-800

4 N500 N560 aR-900

4 N560 N630 aR-900

4 N630 N710 aR-1600

4 N710 N800 aR-1600

4 N800 N1M0 aR-1600

Table 5.2 12-Pulse Drive Systems (380–500 V AC)

FC 302 FC 102/

FC 202

FC 302 FC 102/

FC 202

Recommended fuse

(maximum)

Recommended fuse

(maximum)

Table 5.4 12-Pulse Drive Systems (525–690 V AC)

5.4.1.4 Recommended Fuses for UL

Compliance

The drive modules are supplied with built-in AC

•

fuses. The modules have been qualied for

100 kA short-circuit current rating (SCCR) for the

standard busbar congurations at all voltages

(380–690 V AC).

If no power options or extra busbars are

•

connected externally, the drive system is qualied

for 100 kA SCCR with any Class L or Class T ULlisted fuses connected at the input terminals of

the drive modules.

Do not exceed the listed fuse rating in Table 5.6

•

to Table 5.7 with the current rating of the Class L

or Class T fuses.

Number of drive

modules

2 N450 N500 1600 A

4 N500 N560 2000 A

4 N560 N630 2000 A

4 N630 N710 2500 A

4 N710 N800 2500 A

4 N800 N1M0 2500 A

Table 5.5 6-Pulse Drive Systems (380–500 V AC)

FC 302 FC 102/

FC 202

Recommended fuse

(maximum)

22 Danfoss A/S © 08/2017 All rights reserved. MG37K302

Electrical Installation Installation Guide

Number of drive

modules

2 N250 N315 630 A

2 N315 N355 630 A

2 N355 N400 630 A

2 N400 N450 800 A

2 N450 N500 800 A

4 N500 N560 900 A

4 N560 N630 900 A

4 N630 N710 1600 A

4 N710 N800 1600 A

4 N800 N1M0 1600 A

Table 5.6 12-Pulse Drive Systems (380–500 V AC)

Any minimum 500 V UL-listed fuse can be used for the 380–500 V AC

drive systems.

Number of drive

modules

4 N630 N710 1600 A

4 N710 N800 2000 A

4 N800 N900 2500 A

4 N900 N1M0 2500 A

4 N1M0 N1M2 2500 A

FC 302 FC 102/

FC 202

FC 302 FC 102/

FC 202

Recommended fuse

(maximum)

Recommended fuse

(maximum)

5 5

Table 5.7 6-Pulse Drive Systems (525–690 V AC)

Number of drive

modules

2 N250 N315 550 A

2 N315 N355 630 A

2 N355 N400 630 A

2 N400 N500 630 A

2 N500 N560 630 A

2 N560 N630 900 A

4 N630 N710 900 A

4 N710 N800 900 A

4 N800 N900 900 A

4 N900 N1M0 1600 A

4 N1M0 N1M2 1600 A

Table 5.8 12-Pulse Drive Systems (525–690 V AC)

Any minimum 700 V UL-listed fuse can be used for the 525–690 V AC

drive systems.

FC 302 FC 102/

FC 202

Recommended fuse

(maximum)

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 23

Electrical Installation

VLT® Parallel Drive Modules

5.5 Electrical Kit Installation

This section describes how the electrical kit is used to

connect 2 or 4 drive modules in parallel - to provide

controlled power to an AC motor. A diagram is provided

for each of the 4 congurations which, if followed, meet

specic agency approvals and certications. If designing

and building other congurations, seek agency approvals

or certications apart from Danfoss.

Read this section for guidance in making electrical

connections when assembling the drive modules into a

55

panel.

5.6 DC Bus Fuse Installation

DC fuses are provided in the basic kit. Install the DC fuses

at the available DC terminals at individual drive modules,

using the recommended bolts. Each DC fuse has a xture

for mounting the microswitches, which are used to detect

a fuse failure. See Illustration 3.3. Install the supplied

harness between the microswitch terminals and the brake

fault jumper port on the top of the drive modules. If the

jumper is not installed properly, the unit does not power

up and the error Brake IGBT Fault is shown. The

microswitch has 3 terminals: NO, NC, and COM. Connect

the wire harness between the NC and COM terminals. If it

is connected between any other terminals, the unit does

not power up, and the error Brake IGBT Fault is shown.

NOTICE

The microswitch is a snap t onto the fuse. Ensure that

the switch is properly installed on the fuses.

5.7 Motor Connections

5.7.1 Motor Cables

See chapter 7.6 Cable Specications for more information on

wire type and sizes.

NOTICE

SHIELDED CABLE LENGTH

With a standard VLT® Parallel Drive Modules drive

system, shielded cables up to 150 m (492 ft) long or

unshielded up to 300 m (984 ft) long provide full voltage

at the motor. If this cable length is exceeded, use a

dU/dt lter. For information on the selection of a dU/dt

lter, refer to the VLT® Parallel Drive Modules Design

Guide.

motor cable. Use motor cables with rated voltage specication of at least 0.6/1 kV. Cables in this range provide

good resistance to insulation breakdown.

5.7.1.2 Dimensions

Follow local codes for current capacity data for cables and

conductors. Widely used codes include: NFPA 70, EN

60204-1, VDE 0113-1, and VDE 0298-4. Overdimensioning

for harmonics is not required.

5.7.1.3 Length

Keep cables as short as possible. Voltage drop and heat

dissipation depends on the frequency and is approximately

proportional to cable length. Consult the cable

manufacturer specications regarding the length and

expected voltage drop when connected to the drive

system. See chapter 7.6 Cable Specications.

5.7.1.4 Shielding

The following factors are important for eective shielding:

Make sure that the amount of cable surface

•

covered by the shield is at least 80%.

Use a single-layer braided copper shield. Ensure

•

that the shield is braided to reduce surface area

for leakage currents.

Use cables with double shielding to improve the

•

attenuation of interference further. Twisted

conductors reduce magnetic elds.

Use cables that are shielded at both ends

•

between the drive system and the motor.

To comply with radio frequency interference

•

limits, shield the cables between the drive system

and the motor at both ends.

Ensure that the shield fully surrounds the cable.

•

Route cable glands or cable clamps directly to

•

the grounding point.

Keep connections as short as possible at each

•

end of the cable.

Bridge shield gaps such as terminals, switches, or

•

contactors by using connections with the lowest

possible impedance and the largest possible

surface area.

NOTICE

TWISTED SHIELD ENDS (PIGTAILS)

5.7.1.1 Voltage Rating

Peak voltages up to 2.8 times the mains voltage of the

VLT® Parallel Drive Modules drive system can occur in the

motor cable. High peak voltages can severely stress the

Twisted shield ends increase the shield impedance at

higher frequencies, which reduces the shield eect and

increases the leakage current. To avoid twisted shield

ends, use integrated shield clamps. Refer to

Illustration 5.2.

24 Danfoss A/S © 08/2017 All rights reserved. MG37K302

1

2

130BE747.10

PE

PEPE

PE

PTC / Thermistor

R

OFF

ON

<800 Ω

+10V

130BA152.10

>2.7 kΩ

12 13 18 37322719 29 33 20

5550

39 42 53 54

555039 42 53 54

R

<3.0 k Ω

>3.0 k Ω

+10V

130BA153.11

PTC / Thermistor

OFF

ON

PTC / Thermistor

OFF

ON

+24V

12 13 18 3732

A

2719 29 33B20

GND

R<6.6 k Ω >10.8 k Ω

130BA151.11

Electrical Installation Installation Guide

1 Correct grounding of shielded ends

2 Incorrect grounding using twisted shield ends (pigtail)

Illustration 5.2 Example of Shield Ends

Using a digital input and 24 V as supply

Illustration 5.5 PTC Thermistor Connection - Digital Input with

24 V Supply

5 5

Check that the selected supply voltage follows the specication of the used thermistor element.

5.7.2 Types of Thermal Protection

5.7.2.1 PTC Thermistor

Using a digital input and 10 V supply

Illustration 5.3 PTC Thermistor Connection - Digital Input with

10 V Supply

Using an analog input and 10 V supply

Input digital/

analog

Supply

voltage [V]

Trip resistancekΩReset

Digital 10 >2.7

Analog 10 >3.0

Digital 24 >10.8

Table 5.9 PTC Thermistor Resistance Parameters

resistance

<800 Ω

<3.0 kΩ

<6.6 kΩ

Illustration 5.4 PTC Thermistor Connection - Analog Input with

10 V Supply

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 25

0

500

1000

1500

2000

2500

3000

3500

4000

4500

-25 0 25 50 7 5 100 125 150

Temperature [°C]

Resistance [Ohm]

KTY type 1 KTY type 2 KTY type 3

130BB917.10

Electrical Installation

VLT® Parallel Drive Modules

5.7.2.2 KTY Sensor

The frequency converter handles 3 types of KTY sensors:

KTY Sensor 1: 1 kΩ at 100 °C (212 °F). Philips KTY

•

84-1 is an example.

KTY Sensor 2: 1 kΩ at 25 °C (77 °F). Philips KTY

•

83-1 is an example.

KTY Sensor 3: 1 kΩ at 25 °C (77 °F). Philips

•

KTY-10 is an example.

55

Illustration 5.6 KTY Type Selection

NOTICE

NOTICE

Danfoss is not responsible for the failure of any Klixon

thermal switch.

5.7.3 Motor Terminal Connections

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables from dierent

frequency converters that are run together can charge

equipment capacitors even with the equipment turned

o and locked out. Failure to run output motor cables

separately or use shielded cables could result in death or

serious injury.

Run output motor cables separately.

•

Or

Use shielded cables.

•

Simultaneously lock out all the frequency

•

converters.

Comply with local and national electrical codes

•

for cable sizes. For maximum cable sizes, see

chapter 7.1 Power-dependent Specications.

Follow motor manufacturer wiring requirements.

•

Do not wire a starting or pole-changing device

•

(for example, Dahlander motor or slip ring

induction motor) between the drive system and

the motor.

5.7.3.1 Motor Cable

PELV COMPLIANCE

If short circuits occur between motor windings and the

sensor, PELV compliance is not achieved when the motor

temperature is monitored via a thermistor or KTY sensor.

Ensure that the sensor is isolated better.

5.7.2.3 Brake Resistor Thermal Switch

Installation

Each drive module has a brake fault jumper connector on

the top plate, which is used to connect the Klixon thermal

switch on the brake resistors. This connector has a preinstalled jumper as shown in Illustration 8.3. The brake fault

jumper must always be in place to ensure proper

operation of the drive module. Without this jumper

connection, the drive module does not allow the inverter

to operate, and a brake IGBT fault is shown.

The thermal switch is a normally-closed type. If the brake

resistor temperature exceeds recommended values, the

thermal switch opens. Use 1 mm2 (18 AWG), reinforced and

doubly insulated wire for the connection. See

Illustration 8.5.

All types of 3-phase asynchronous standard motors can be

used with the drive system.

Connect the motor to the following terminals:

U/T1/96

•

V/T2/97

•

W/T3/98

•

Ground to terminal 99

•

Factory setting is for clockwise rotation with the drive

system output connected as follows:

Terminal number Function

96 Mains U/T1

97 V/T2

98 W/T3

99 Ground

Table 5.10 Motor Cable Terminals

26 Danfoss A/S © 08/2017 All rights reserved. MG37K302

175HA036.11

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

Electrical Installation Installation Guide

Changing motor rotation

Terminal U/T1/96 connected to U-phase

•

Terminal V/T2/97 connected to V-phase

•

Terminal W/T3/98 connected to W-phase

•

5.7.3.2 Motor Terminal Connections in 2Drive Module Systems

Illustration 8.9 and Illustration 8.10 show the bus bar

connections for 6-pulse and 12-pulse 2-drive systems,

respectively. If a common terminal design is used, there is

1 set of motor terminals.

NOTICE

MULTIPLE MOTOR CABLES

If connecting more than 1 set of motor terminals, use

the same number, size, and length of cables for each set

of terminals. For example, do not use 1 cable on one

motor terminal and 2 cables on another motor terminal.

1. Measure between the common terminals and the

rst common point of a phase, typically the

motor terminals.

2. Strip a section of the outer cable insulation.

3. Connect the ground wire to the nearest

protective earth terminal.

4. Connect the 3-phase motor wiring to terminals

U/96, V/97, and W/98 using M10 screws.

5. Tighten the motor terminals. See

chapter 7.9.1 Tightening Torques for Terminals.

5 5

Illustration 5.7 Changing Motor Rotation

The direction of rotation can be changed by switching 2

phases in the motor cable, or by changing the setting of

parameter 4-10 Motor Speed Direction.

Motor rotation check can be performed using

parameter 1-28 Motor Rotation Check and following the

steps shown in Illustration 5.7.

5.7.3.3 Motor Terminal Connections in 4Drive Module Systems

Illustration 8.11 shows the bus bar connections for a 4-drive

system. If a common terminal design is used, there is 1 set

of motor terminals in each cabinet.

NOTICE

MULTIPLE MOTOR CABLES

If connecting more than 1 set of motor terminals, use

the same number, size, and length of cables for each set

of terminals. For example, do not use 1 cable on one

motor terminal and 2 cables on another motor terminal.

1. Measure between the common terminals and the

rst common point of a phase, typically the

motor terminals.

2. Strip a section of the outer cable insulation.

3. Connect the ground wire to the nearest

protective earth (ground) terminal.

4. Connect the 3-phase motor wiring to terminals

U/96, V/97, and W/98 using M10 screws.

5. Tighten the motor terminals. See

chapter 7.9.1 Tightening Torques for Terminals.

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 27

Electrical Installation

VLT® Parallel Drive Modules

5.8 Mains Connections

5.8.1.1 Mains Terminal Connections in 2Drive Module Systems

There are several types of AC mains systems for supplying

power to frequency converters. Each aects the EMC

characteristics of the system. The 5-wire TN-S systems are

regarded as best regarding EMC, while the isolated IT

system is the least preferred.

System

type

TN mains

systems

55

TN-S A 5-wire system with separate neutral (N) and

TN-C A 4-wire system with a common neutral and

TT mains

systems

IT grid

system

Table 5.11 AC Mains Systems and EMC Characteristics

Description

There are 2 types of TN mains distribution systems:

TN-S and TN-C.

protective earth (PE) conductors. It provides the

best EMC properties and avoids transmitting

interference.

protective earth (PE) conductor throughout the

system. The combined neutral and PE conductor

results in poor EMC characteristics.

A 4-wire system with a grounded neutral conductor

and individual grounding of the drive system. It has

good EMC characteristics when grounded properly.

An isolated 4-wire system with the neutral

conductor either not grounded or grounded via an

impedance.

5.8.1 AC Mains Terminal Connections

When making mains connections, observe the following:

Size the wiring based on the input current of the

•

frequency converter. For maximum wire sizes, see

chapter 7.1 Power-dependent Specications.

Comply with local and national electrical codes

•

for cable sizes.

Illustration 8.9 and Illustration 8.10 show the bus bar

connections for 6-pulse and 12-pulse 2-drive systems,

respectively.

If a common terminal design is used with a 6-

•

pulse, 2-drive system, there is 1 set of mains

terminals.

Common terminal design cannot be used with

•

12-pulse mains connections in a 2-drive module

systems. The mains cables are connected directly

to the drive input terminals.

There are individual brake terminals available in

•

each drive module. Connect an equal number of

recommended cables to the individual brake

terminals.

NOTICE

MULTIPLE MAINS CABLES

If connecting more than 1 set of mains terminals, use the

same number, size, and length of cables for each set of

terminals. For example, do not use 1 cable on one mains

terminal and 2 cables on another mains terminal.

1. Measure between the common terminals and the

rst common point of a phase, typically the

mains terminals.

2. For 12-pulse drive modules, the set of cables from

the 1st drive module connects to the starsecondary winding of the 12-pulse transformer.

The set from the 2nd drive module connects to

the delta-secondary winding of the 12-pulse

transformer.

3. Strip a section of the outer cable insulation.

4. Connect the ground wire to the nearest ground

terminal.

5. Connect the 3-phase mains wiring to terminals

R/91, S/92, and T/93 using M10 screws.

6. Tighten the mains terminals. See

chapter 7.9.1 Tightening Torques for Terminals.

28 Danfoss A/S © 08/2017 All rights reserved. MG37K302

Electrical Installation Installation Guide

5.8.1.2 Mains Terminal Connections in 4Drive Module Systems

Illustration 8.11 shows the bus bar connections for 4-drive

systems. If a common terminal design is used, there is 1

set of mains terminals in each cabinet.

NOTICE

MULTIPLE MAINS CABLES

If connecting more than 1 set of mains terminals, use the

same number, size, and length of cables for each set of

terminals. For example, do not use 1 cable on one mains

terminal and 2 cables on another mains terminal.

1. Measure between the common terminals and the

1st common point of a phase.

1a For 6-pulse modules, it is typically the

mains terminals.

1b For 12-pulse drive modules, the set of

cables from the 1st cabinet connects to

the star-secondary winding of the 12pulse transformer. The set from the 2

cabinet connects to the delta-secondary

winding of the 12-pulse transformer.

2. Strip a section of the outer cable insulation.

3. Connect the ground wire to the nearest ground

terminal.

4. Connect the 3-phase mains wiring to terminals

R/91, S/92, and T/93 using M10 screws.

5. Tighten the mains terminals. See

chapter 7.9.1 Tightening Torques for Terminals.

nd

NOTICE

Danfoss is not responsible for any failure or malfunction

in the disconnector/contactor switch.

5 5

5.8.2 12-Pulse Disconnector Conguration

This section describes how to use a disconnector for a 12pulse drive system. When using disconnectors or

contactors, make sure to install an interlock. When

installed, both contactors or disconnectors should close to

avoid 1 set of rectiers not working. See Illustration 8.1 for

a diagram of these connections.

The selected contactors or mains disconnectors should

have NC auxiliary contacts routed as shown. Connect the

interlock in series with the Klixon switch of the brake. If

only 1 contactor/disconnector has closed, the LCP shows

the error Brake IGBT Fault and does not allow the drive

system to power the motor. Illustration 8.2 shows a BRF

connection with 12-pulse disconnector and interlock.

NOTICE

If the brake option is not selected, the Klixon switch can

be bypassed.

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 29

Electrical Installation

VLT® Parallel Drive Modules

5.8.3 Discharge Resistors

There are common positive and negative DC terminals on each drive module. If a shorter time to achieve the reduced run

functionality is wanted, connect the external discharge resistor for quicker discharge of DC-link voltage. It is possible to

connect a discharge resistor in an additional cabinet, through a contactor. This discharge contactor should have an interlock

with the mains contactor/disconnector’s auxiliary NC contacts to avoid a discharge when the drive system is powered.

Illustration 8.7 shows a 4-drive system with discharge resistor connections.

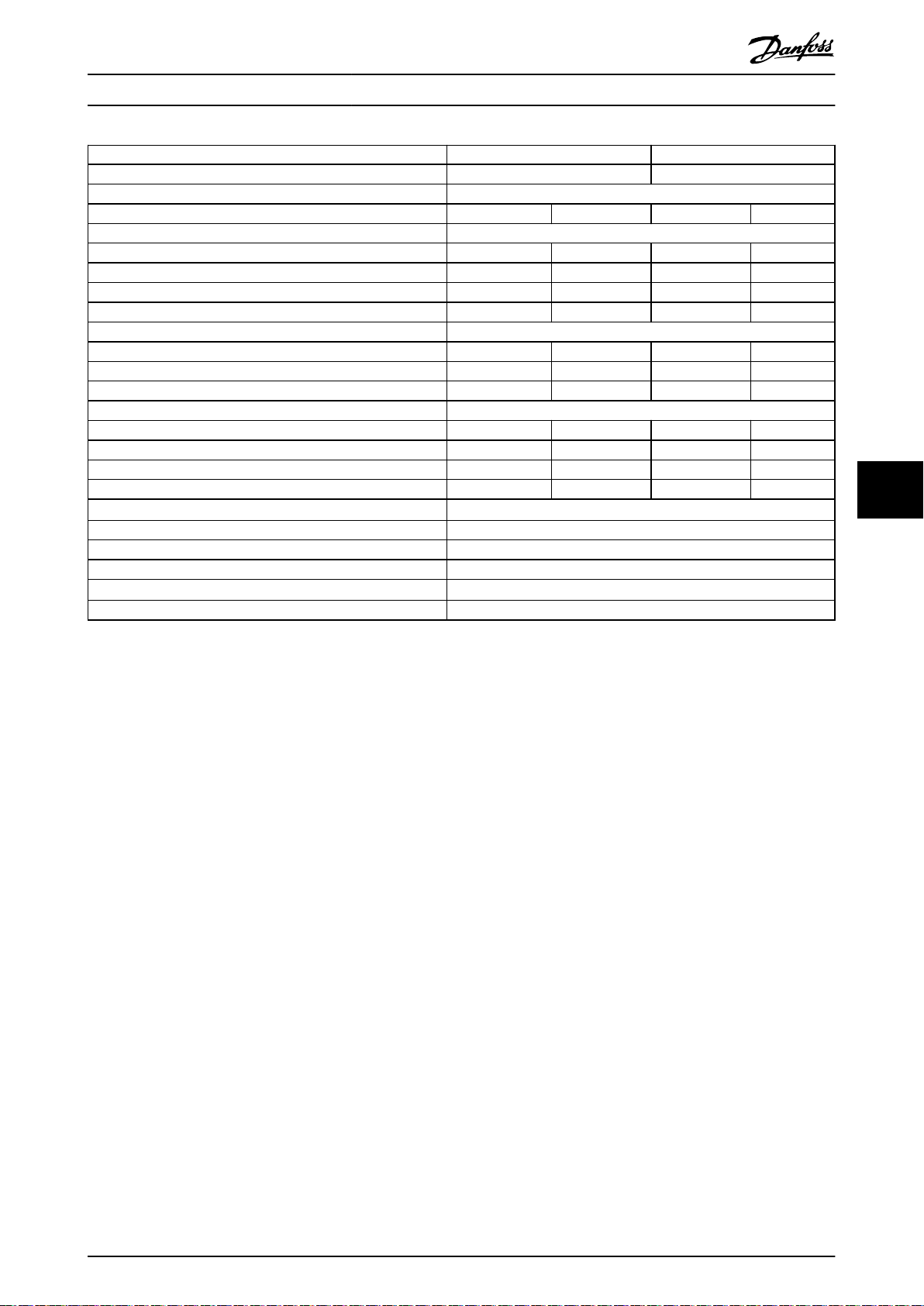

Base the selection of a discharge resistor on the energy and power levels given in Table 5.12 for

dierent power sizes, on

both 12-pulse and 6-pulse systems.

55

FC 102

FC 202

FC 302 N450 N500 N560 N630 N710 N800

Drive modules required

(HO rating)

Resistance required to reduce DC

voltage below 50 V within 300 s

(5 minutes), Ω

Power rating of resistor (W) 182 242 303 303 363 363

Energy dissipated by resistor (J) 7773 10365 12956 12956 15547 15547

Table 5.12 Discharge Resistors Recommended for Drive Systems with 380–480 V AC Mains Supply

FC 102

FC 202

FC 302 N560 N630 N710 N800 N900 N1M0

Drive modules required

(HO rating)

Resistance required to reduce DC

voltage below 50 V within 300 s

(5 minures), Ω

Power rating of resistor (W) 230 345 459 459 459 459

Energy dissipated by resistor (J) 8819 13229 17638 17638 17638 17638

N500 N560 N630 N710 N800 N1M0

2xN250 4xN160 4xN200 4xN200 4xN250 4xN250

3036 2277 1822 1822 1518 1518

N630 N710 N800 N900 N1M0 N1M2

2xN315 4xN200 4xN250 4xN250 4xN315 4xN315

4571 3047 2285 2285 2285 2285

Table 5.13 Discharge Resistors Recommended for Drive Systems with 525–690 V AC Mains Supply

NOTICE

Danfoss is not responsible for any failure or malfunction of the resistor, or for any misconnections made by the installer.

NOTICE

The wire used with the brake resistor should be double-insulated or have reinforced insulation.

30 Danfoss A/S © 08/2017 All rights reserved. MG37K302

Electrical Installation Installation Guide

5.9 Control Shelf Installation

The control shelf is preassembled. However, verify its various connections against the connection diagram. Illustration 8.6

shows the various control shelf connections.

NOTICE

INCORRECT CONNECTION ORDER

If the connections are not made in the correct order, the drive modules do not function.

Check the following connections:

Connection of the 44-pin ribbon cable between the MDCIC and the control card.

•

When used, Safe Torque O (STO) jumper connection must be made between the 12th and 27th pins to ensure

•

proper STO operation.

Connect the 44-pin ribbon cable to the MDCIC connectors in the correct order.

•

- For systems with 4 drive modules, connect the ribbon cables to inverter 1, inverter 2, inverter 3, and then

inverter 4.

- For systems with 2 drive modules, connect the ribbon cables to inverter 1, then inverter 2. Leave inverter

3 and inverter 4 terminals unconnected.

5 5

NOTICE

SCALING CARD POSITION

If the scaling cards are not placed in the correct order, the drive modules do not function.

Place the corresponding current scaling card on each respective connector.

•

- For systems with 4 drive modules, Inverter 1, Inverter 2, Inverter 3, and Inverter 4.

- For systems with 2 drive modules, Inverter 1 and Inverter 2. Leave connectors Inverter 3 and Inverter 4

unconnected.

Do not reverse the current scaling card. Check that the PCB spacer is xed on the MDCIC board.

•

Ensure correct installation of the STO relay and the power supply on the DIN rail. Make the connections as shown

•

in Illustration 8.6.

The external supply (100–230 V) must be available at terminals 1 and 2 on the terminal block.

•

Make more checks to ensure that the wiring of the fuse microswitches and the BRF jumpers are properly routed.

•

Check that all the screws on the PCBs are secure.

•

To ensure proper EMC protection, verify that the MDCIC plate is properly attached to the control shelf assembly.

•

Control Wiring Connections

5.10

Make sure to use the provided wire pathway when routing the control wires from the bottom of the drive system cabinet to

the control terminal.

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 31

130BE745.11

1

3

5

4

2

Electrical Installation

VLT® Parallel Drive Modules

5.10.1 Control Cable Routing

Cable routing

Route the cable inside the drive cabinets as shown in Illustration 5.8. Wire routing for a 2-drive conguration is identical,

except for the number of drive modules used.

55

1 Microswitch cable 4 44-pin ribbon cable from MDCIC to drive module 4

2 Ferrite core 5 Bracket to support ribbon cable

3 44-pin ribbon cable from MDCIC to drive modules 1 and 2 – –

Illustration 5.8 Control Cable Routing for a 4-Drive System

32 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BE062.10

2

3

4

1

Electrical Installation Installation Guide

5.10.2 Control Wiring

Isolate the control wiring from the high-power components in the drive modules.

•

When the drive module is connected to a thermistor, ensure that the thermistor control wiring is shielded and

•

reinforced/double insulated. A 24 V DC supply voltage is recommended. See Illustration 5.9.

NOTICE

MINIMIZE INTERFERENCE

To minimize interference, keep control wires as short as possible and separate them from high-power cables.

The control terminals are on the control shelf, directly below the LCP. The control cable is routed at the bottom of the

cabinet.

1. Follow the designated control cable routing as shown in chapter 5.10.1 Control Cable Routing.

2. Tie down all control wires.

3. Ensure optimum electrical immunity by properly connecting the shields.

Fieldbus connection

For details, see the relevant eldbus instructions.

1. Follow the designated control cable routing as shown in chapter 5.10.1 Control Cable Routing.

2. Tie down all control wires.

3. Connect the relevant options on the control card.

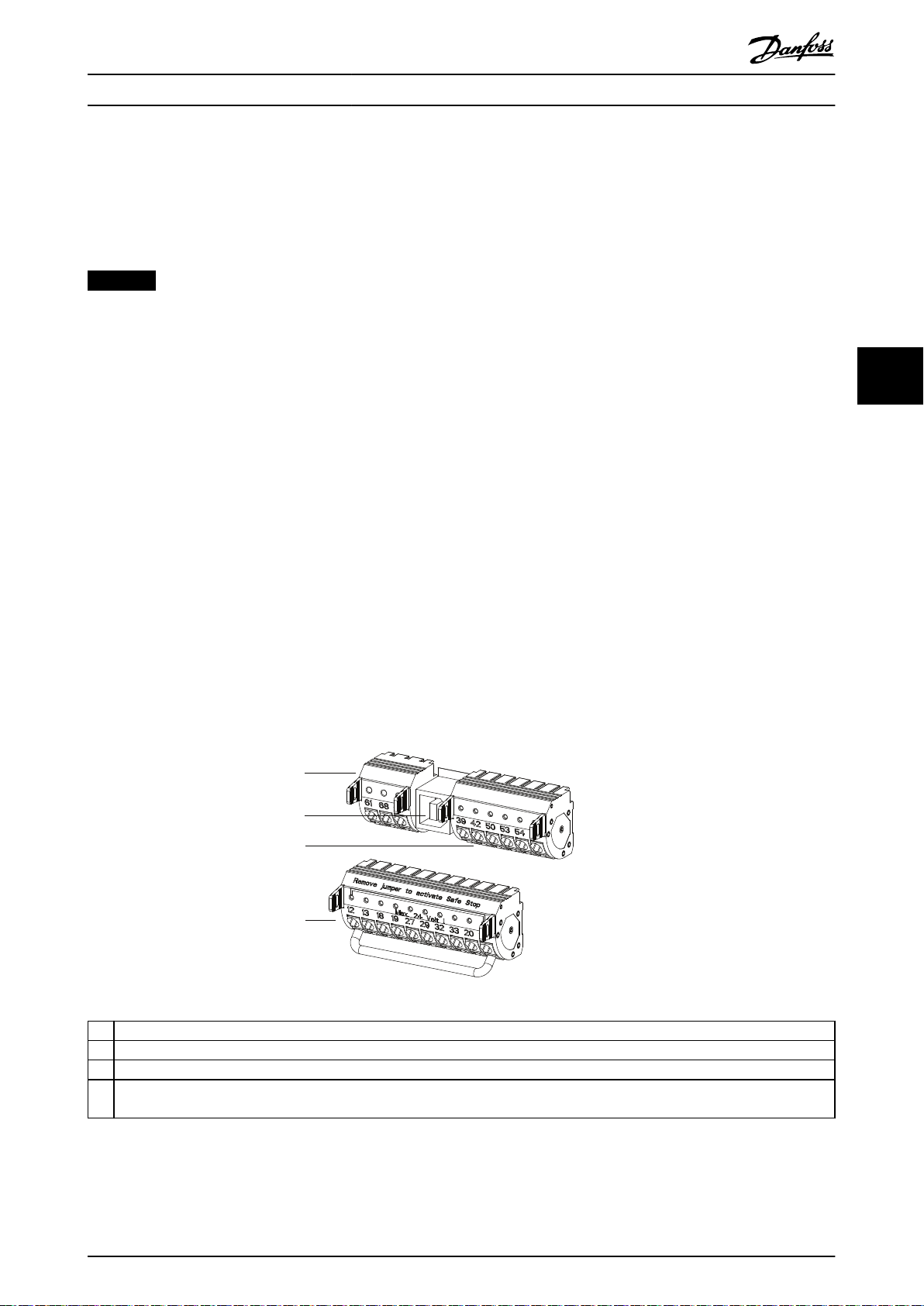

5.10.2.1 Control Terminal Types

Illustration 5.9 shows the removable frequency converter connectors. Terminal functions and default settings are summarized

in Table 5.14. See Illustration 5.9 for the location of the control terminals within the unit.

5 5

1 Terminals (+)68 and (-)69 are for an RS485 serial communication connection.

2 USB port available for use with the MCT 10 Set-up Software.

3 2 analog inputs, 1 analog output, 10 V DC supply voltage, and commons for the inputs and output.

4 4 programmable digital inputs terminals, 2 extra digital terminals programmable as either input or output, a 24 V DC terminal supply

voltage, and a common for optional customer-supplied 24 V DC voltage.

Illustration 5.9 Control Terminal Locations

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 33

Electrical Installation

VLT® Parallel Drive Modules

Terminal Parameter Default

setting

Digital inputs/outputs

12, 13 – +24 V DC

18 Parameter 5-10 Terminal 18 Digital Input [8] Start

19 Parameter 5-11 Terminal 19 Digital Input [10] Reversing

32 Parameter 5-14 Terminal 32 Digital Input [0] No operation

33 Parameter 5-15 Terminal 33 Digital Input [0] No operation

27 Parameter 5-12 Terminal 27 Digital Input [2] Coast inverse Selectable for digital input and

29 Parameter 5-13 Terminal 29 Digital Input [14] Jog

20 – – Common for digital inputs and 0 V

55

37 – Safe Torque O (STO) Safe input (optional). Used for STO.

Analog inputs/outputs

39 – – Common for analog output

42 Parameter 6-50 Terminal 42 Output Speed 0 – high limit

50 – +10 V DC

53 Parameter group 6-1* Analog Input 1 Reference Analog input. Selectable for

54 Parameter group 6-2* Analog Input 2 Feedback

55 – – Common for analog input

Serial communication

61 – – Integrated RC-lter for cable shield.

Digital inputs. 24 V DC supply

voltage. Maximum output current

is 200 mA total for all 24 V loads.

Usable for digital inputs and

external transducers.

output. Default setting is input.

potential for 24 V supply.

Programmable analog output. The

analog signal is 0–20 mA or 4–

20 mA at a maximum of 500 Ω

10 V DC analog supply voltage.

15 mA maximum commonly used

for potentiometer or thermistor.

voltage or current. Switches A53

and A54 select mA or V.

ONLY for connecting the shield

when experiencing EMC problems.

Description

68 (+) Parameter group 8-3 FC Port Settings – RS485 Interface. A control card

69 (-) Parameter group 8-3 FC Port Settings –

Relays

01, 02, 03 Parameter 5-40 Function Relay [0] [9] Alarm Form C relay output. Usable for AC

04, 05, 06 Parameter 5-40 Function Relay [1] [5] Running

Table 5.14 Terminal Description

switch is provided for termination

resistance.

or DC voltage and resistive or

inductive loads.

Extra terminals:

Two form C relay outputs. Location of the outputs depends on frequency converter conguration.

•

Terminals on built-in optional equipment. See the manual provided with the equipment option.

•

34 Danfoss A/S © 08/2017 All rights reserved. MG37K302

130BT306.10

130BE063.10

1

2

3

1

2

N O

Electrical Installation Installation Guide

5.10.2.2 Wiring to Control Terminals

Terminal plugs can be removed for easy access.

Illustration 5.10 Removal of Control Terminals

5.10.2.3 Enabling Motor Operation

(Terminal 27)

A jumper wire is required between terminal 12 (or 13) and

terminal 27 for the frequency converter to operate when

using factory default programming values.

Digital input terminal 27 is designed to receive

•

24 V DC external interlock command.

When no interlock device is used, wire a jumper

•

between control terminal 12 (recommended) or

13 to terminal 27. The jumper provides an

internal 24 V signal on terminal 27.

When the status line at the bottom of the LCP

•

reads AUTO REMOTE COAST, it indicates that the

unit is ready to operate but is missing an input

signal on terminal 27.

When factory installed optional equipment is

•

wired to terminal 27, do not remove that wiring.

5.10.2.4 Voltage/Current Input Selection

(Switches)

The analog mains terminals 53 and 54 allow the setting of

the input signal to voltage (0–10 V) or current (0/4–

20 mA). See Illustration 5.9 for the location of the control

terminals within the drive system.

Default parameter settings:

Terminal 53: Speed reference signal in open loop

•

(see parameter 16-61 Terminal 53 Switch Setting).

Terminal 54: Feedback signal in closed loop (see

•

parameter 16-63 Terminal 54 Switch Setting).

NOTICE

REMOVE POWER

Remove power to the frequency converter before

changing switch positions.

1. Remove the LCP (see Illustration 5.11).

2. Remove any optional equipment covering the

switches.

3. Set switches A53 and A54 to select the signal

type. U selects voltage, I selects current.

5 5

MG37K302 Danfoss A/S © 08/2017 All rights reserved. 35

1 Bus termination switch

2 A54 switch

3 A53 switch

Illustration 5.11 Locations of Bus Termination Switch and

Switches A53 and A54

130BC554.11

Relay 1

Relay 2

03

02

240 V AC, 2 A

01

06

05

04

240 V AC, 2 A

400 V AC, 2 A

400 V AC, 2 A

Electrical Installation

VLT® Parallel Drive Modules

5.10.2.5 RS485 Serial Communication

An RS485 serial communications bus can be used with the

drive system. Up to 32 nodes can be connected as a bus,

or via drop cables from a common trunk line to 1 network

segment. Repeaters can be used to divide network

segments. Each repeater functions as a node within the

segment in which it is installed. Each node connected

within a given network must have a unique node address,

across all segments.

Connect RS485 serial communication wiring to

•

55

terminals (+)68 and (-)69.

Terminate each segment at both ends, using

•

either the termination switch (bus term on/o,

see Illustration 5.11) on the drive module, or a

biased network termination resistor.

Connect a large surface of the shield to ground,

•

for example with a cable clamp or a conductive

cable gland.

Maintain the same ground potential throughout

•

the network by applying potential-equalizing

cables.

Prevent impedance mismatch by using the same

•

type of cable throughout the entire network.

Relay 1

Terminal 01: Common

•

Terminal 02: Normally open 400 V AC

•

Terminal 03: Normally closed 240 V AC

•

Relay 2

Terminal 04: Common

•

Terminal 05: Normally open 400 V AC

•

Terminal 06: Normally closed 240 V AC

•

Relay 1 and relay 2 are programmed in

parameter 5-40 Function Relay, parameter 5-41 On Delay,

Relay, and parameter 5-42 O Delay, Relay.

Use VLT® Relay Card MCB 105 option module for extra

relay outputs.

Cable Shielded twisted pair (STP)

Impedance

Maximum cable length

Station-to-station [m

(ft)]

Total including drop

lines [m (ft)]

Table 5.15 Cable Information

120 Ω

500 (1640)

1200 (3937)

5.10.3 Safe Torque O (STO)