Fact Sheet

VLT® OneGearDrive®

VLT® OneGearDrive® comprises a

high-efficiency permanent magnet

(PM) motor coupled to an optimized

bevel gearbox. As part of the

Danfoss VLT® FlexConcept® the VLT®

OneGearDrive® is an energy- efficient

drive system that helps to optimize

plant productivity and reduce

energy costs.

With only one motor type and three

available gear ratios, the motor concept

covers all typical versions of conveyor

drives commonly used in the food and

beverage industry.

Furthermore, the restricted range of

physical configurations of the VLT®

OneGearDrive® simplifies spares holding and makes it more cost efficient,

easing engineering and installation

thanks to uniform mechanical dimensions.

Flexible plant design

In combination with the VLT® AutomationDrive FC 302 or the VLT® Decentral

Drive FCD 302 the VLT® OneGearDrive®

is equally suited to central and decentral installations, giving the plant

designer complete flexibility from the

outset. As a whole, the system can

reach energy savings of up to 40%

compared with conventional systems.

Achieve up to

70%

variant reduction with VLT®

OneGearDrive® together

with VLT® AutomationDrive

FC 302 or VLT® Decentral

Drive FCD 302.

Two versions

The VLT® OneGearDrive® comes in

two versions, the VLT® OneGearDrive®

Standard for use in dry and wet

VLT® OneGearDrive® Hygienic for use

in wet areas, areas with high cleaning

intensity and aseptic and clean room

production areas.

production areas and the

VLT® OneGearDrive® Standard with brakeVLT ® OneGearDrive® Hygienic

Feature Benefit

High system efficiency including drive

High-efficiency permanent-magnet

three-phase synchronous 10-pole motor

with bevel gear drive

Available hollow shaft diameters:

30, 35, 40 mm and 3 impertial shaft sizes

Completely smooth enclosure leaves

no crevices or dirt traps

Motor connection with Danfoss CleanConnect®

stainless steel circular connector

Motor and brake connections via terminal box

with CageClamp® technology

Aseptic coating

Gearbox without breather vents and use of food

grade lubricants compliant with FDA and NSF

requirements

High degrees of protection:

– IP67 and IP69K (OGD- H)

– IP67 (OGD-S)

Fan-free operation

Only 3 gearbox ratios in one common design

Compatible with all Danfoss drives, FC 302 and

FCD 302 from 0.75 to 3 kW

– Save money and energy – up to 40% energy

savings compared to conventional systems

– Better than Super Premium Efficiency

class IE4 (comparing to induction motor only).

Will comply to highest IES2 class with FC 302

– Flexible adaption to customer standards

– Easy to clean

– Safe production

– Safe connection in wet areas

– Fast installation and replacement

– High cleanability

– Fast, reliable connection

– Lower installation cost

– Resistant to detergents and

disinfectants (pH 2..14)

– Up to 35,000 operating hours in partial load

between oil change

– Unrestricted use in wash down areas

– High protection in wash down areas

– Less noise emission

– No airborne germs and dirt particles are drawn

into the motor and then expelled back into the

surrounding air

– Up to 70% reduction in variants

reduces spare part stock

– Free choice of central or decentral installation

www.danfoss.com/flexconcept

In both versions, the completely

smooth, easy-to-clean surface free of

cooling fins, prevents pockets of dirt

from forming and allows detergents

to drain off freely. The fan-free motor

avoids the risk of airborne germs and

dirt particles being drawn in and then

expelled back into the surrounding air.

Hygienic design

The VLT® OneGearDrive® Hygienic

complies with the requirements for

best cleaning and hygienic design. It

is certified as usable for clean rooms

and aseptic filling by IPA (Fraunhofer

institute) according to the dedicated

“Air Cleanliness Classification“ DIN EN

ISO 14644-1.

Danfoss GmbH

OneGearDrive Hygienic

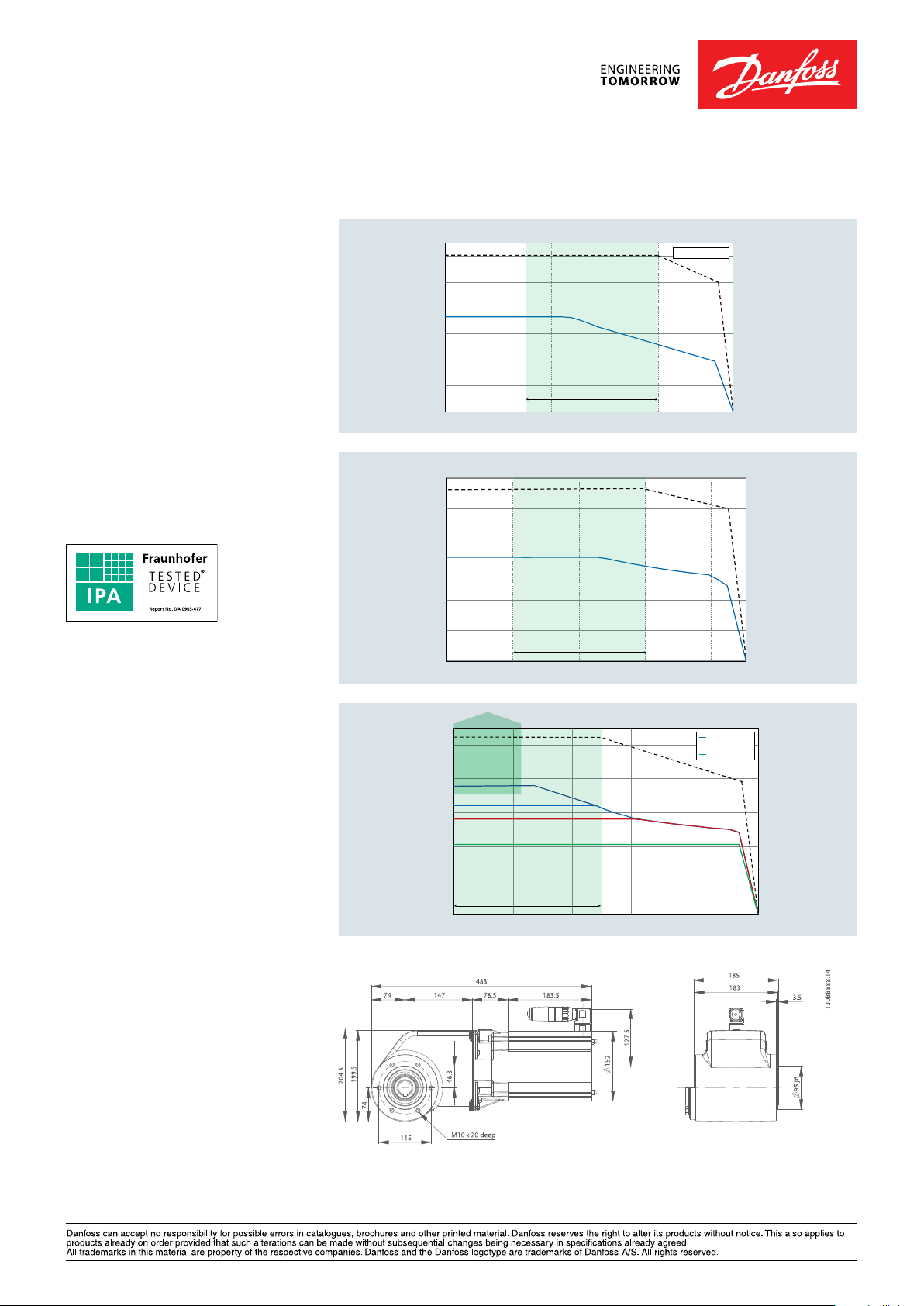

Speed/ torque characteristics

Gear ratios 5.92; i = 14.13 and i = 31.13

Max. high starting torque M

Max. constant torque M

Max. high starting torque M

Max. constant torque M

HST

n

Typical operating range

HST

n

120

100

80

Torque [Nm]

60

40

20

0

0 100 200 300 400 500

300

250

200

150

Torque [Nm]

100

i = 5.92

FC 302 2.2 kW (V210)

Speed [RPM]

i = 14.13

Specifications

Power rating ...................................0.75-2.2 kW

Speed max ...........................................3000 rpm

Frequency max. ......................................250 Hz

Nominal current ..........................................5.5 A

Torque .................................................. 2.35 Nm/A

Voltage .................................... 155 V/1000 rpm

Weight .......................................... Approx. 22 kg

Dimensions

50

ExtensionBox

Typical operating range

Max. high starting torque M

Max. torque in part load operation

Max. constant torque M

Typical operating range

Speed [RPM]

i = 31.13

(max 3s, max 10 cycles/h)

HST

n

Speed [RPM]

FC 302 2.2 kW (V210)

FC 302 1.5 kW

FC 302 1.1 kW

0

0 50 100 150 200

up to 1,000 Nm

500

400

300

Torque [Nm]

200

100

0

0 20 40 60 80 100

Dimensions of Danfoss VLT® OneGearDrive® Hygienic in mm

Danfoss Drives Salg Danmark, Jegstrupvej 3, 8361 Hasselager. Tlf. +45 6991 8080, drives.danfoss.dk, E-mail: kundeservice.dk@danfoss.com

DKDD.PFP.700.B1.02 © Copyright Danfoss Drives | 2018.10

Loading...

Loading...