Page 1

Fact Sheet

VLT® No Flow Feature

The VLT® AQUA Drive provides a new

No Flow detection feature for pump

systems. This feature is useful for

detecting conditions where a pump is

producing no flow – a condition that

can cause pump damage if not

detected and corrected.

No ow based on motor

power and frequency

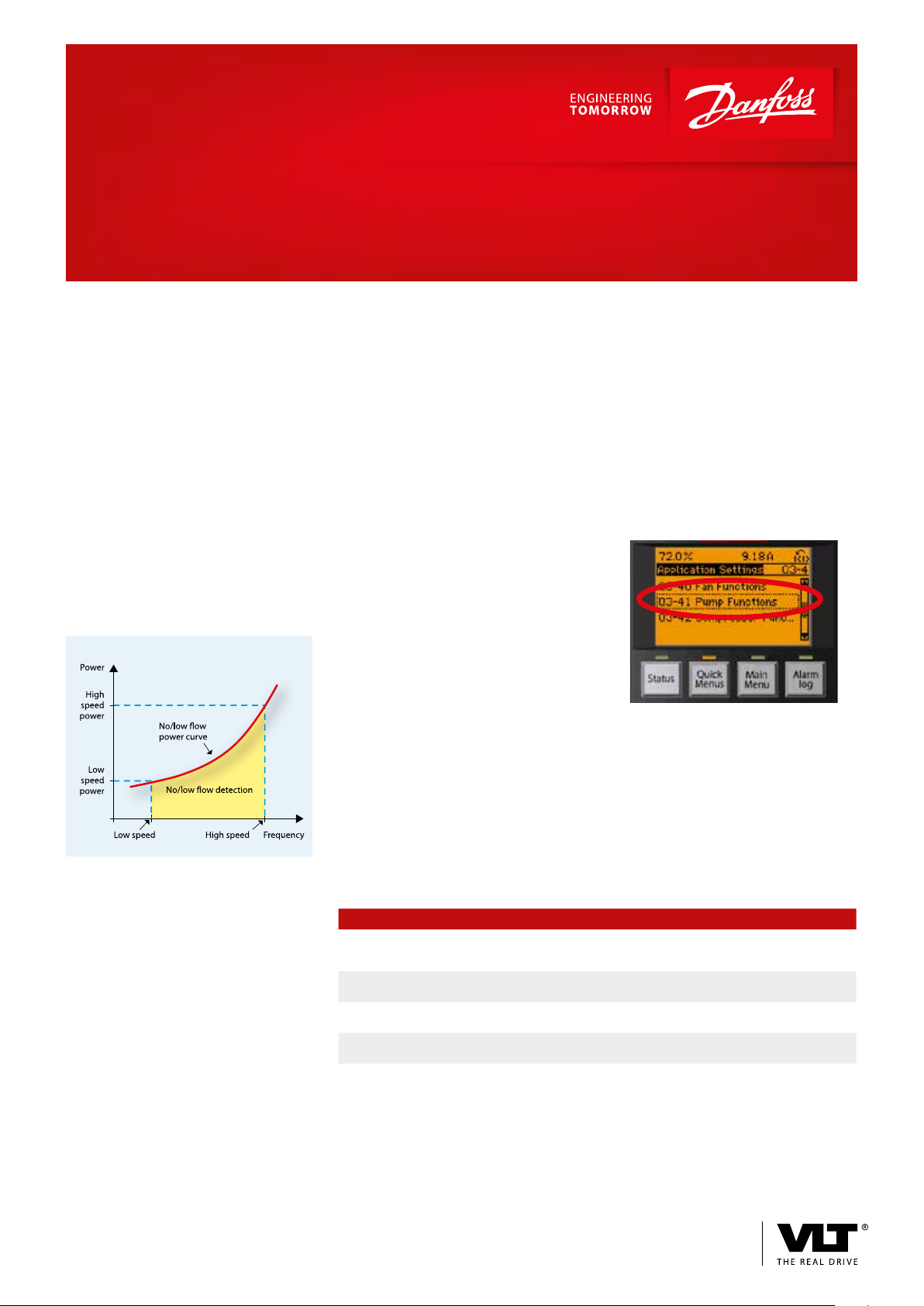

No Flow Detection is based on the

measurement of power at specific

motor speeds. The drive monitors

actual power and motor frequency and

compares it to the calculated no-flow

power at specific speeds. If the power

measured at a specific frequency is

greater than the no-flow power

calculated by the drive, the pump is

producing flow. If the power measured

is less than the no-flow power calculated by the drive, a warning or alarm is

generated to notify the operator of the

condition.

The perfect solution for

n

Intelligent control

n

Water and wastewater system

protection

n

Remote status reporting

To determine the no-flow power level

throughout the speed range, the drive

generates a power vs. frequency curve

that represents the no-flow condition.

This curve is generated by the drive

from two data points. These power/

frequency points can be entered into

the drive automatically or manually.

Manual or Auto Set Up are available

The Auto Set Up automatically steps

the user through the commissioning

process, storing the data measured.

When the automatic set-up is selected

the output frequencies used are 50%

and 85% of maximum. Manual set-up

can be used when a different pair of

frequencies is desired.

Programming is quick and easy

The drive software makes programming the No Flow feature quick and

easy by choosing Pump Functions and

then No Flow Function under the Quick

Menu.

Feature Benet

Eliminates an external differential

pressure switch or flow meter

Eliminates wiring for external sensors Reduce installation and maintenance cost

A warning or alarm can alert operator

of the problem

Programming is quick and easy with

pre-programmed software

Reduce installation and maintenance cost

Provides proper operation of equipment and

increases occupant comfort

Saves time and increases reliablity

www.vlt-drives.danfoss.com

Page 2

Programming No Flow detection

Programming for No Flow detection

is simplified with a number of para-

Par.# Description

1-00 Configuration mode Open loop VLT® AQUA Drive must be set in Open Loop for Auto Set-up.

22-20 Low Power Auto Set-up Disable Enable Close the outlet valve for the pump before starting Auto Set-up.

The following parameters are accessed through the Main Menu and will be stored after pressing the [OK] key to save the results after the auto-tuning:

22-33 Low Speed

[Hz]

22-34 Low Speed Power [kW] When Low Power Auto Set-up is used, the output power

22-37 High Speed

[Hz]

22-38 High Speed Power [kW ] When Low Power Auto Set-up is used, the output power

1-00 Configuration mode Open loop Closed loop Return the VLT® AQUA Drive to Closed Loop operation if required.

Factory

setting

meters that are pre-programmed into

the drive. Prior to programming this

feature, commission the drive by using

Settings

Recommended setting

Comments

Select Enable and follow the instruction on the LCP. After Auto Set-up

is complete, open the pump outlet valve.

When Low Power Auto Set-up is used, 50% of the drive’s

maximum frequency will be stored here. This can be

manually edited, if desired.

measured under no flow conditions at 50% speed will be

stored here. This can be manually edited, if desired.

When Low Power Auto Set-up is used, 85% of the drive’s

maximum frequency will be stored here. This can be manually edited,

if desired.

measured under no flow conditions at 85% speed will be

stored here. This can be manually edited, if desired.

the parameters in the Quick Menu.

Then perform the following steps for

programming No Flow detection:

These parameters are used after Auto Set-up and the No Flow feature is operating:

22 - 30 No Flow Power When the drive is running, this parameter will show the power

22 - 31 Power Correction Factor 100% 110% This parameter is used to raise or lower the no flow power curve

The following parameters determine the action that the drive will take if a no flow condition is detected:

22-21 Low Power

Detection

22-23 No Flow Function Off Sleep Mode/Warning/Alarm Select action

22-24 No Flow Delay 10 sec. Set the time delay before the drive will perform the No Flow Function.

The following parameters give an indication to a SCADA system if a no flow condition is detected:

5-40 Function Relay [190] No Flow

Digital Output [190] No Flow

The following are used if No Flow is reported via serial communications:

Protocol Alarm Word Warning Word

Profibus/Profinet Parameter 1691 bit 5=1 Parameter 1693 bit 5=1

DeviceNet/Ethernet IP Class 116, Instance 1, Attribute 193, bit 5=1 Class 116, Instance 1, Attribute 193, bit 5=1

Modbus RTU/TCP Register 16910 Bit 5=1 Register 16930 Bit 5=1

Disable Enable To activate no flow based on power

level that will be interpreted as producing no flow at the current

motor speed.

to the percentage entered here. Values above 100% help ensure the

drive reliably detects no flow.

Generally set longer than the decel ramp time.

Program one of the relays to selection [190], No Flow.

The selected relay will be activated when No Flow occurs.

A digital output can be used to indicate a no flow condition. Use the

parameter that sets the function of the desired digital output.

Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.vlt-drives.danfoss.com, E-mail: info@danfoss.com

DEDD.PFF.400.A2.02 © Copyright Danfoss Drives | 2015.10

Loading...

Loading...