Page 1

Installation Instructions

Control Cassettes

®

VLT

Midi Drive FC 280

There are 6 types of control cassettes for VLT® Midi Drive FC

280:

Standard control cassette.

•

Control cassette with PROFIBUS.

•

Control cassette with PROFINET.

•

Control cassette with CANopen®.

•

Control cassette with EtherNet/IP™.

•

Control cassette with POWERLINK.

•

The installation instructions in this manual apply to all control

cassettes. For all control cassettes, except for the standard

cassette, mount the decoupling kit after mounting the control

cassette. Find the instructions on mounting the decoupling kit

in the kit package.

For information on how to program the control card, refer to:

VLT® Midi Drive FC 280 Programming Guide.

•

VLT® Midi Drive FC 280 PROFIBUS Programming Guide.

•

VLT® Midi Drive FC 280 PROFINET Programming Guide.

•

VLT® Midi Drive FC 280 CANopen® Programming Guide.

•

VLT® Midi Drive FC 280 EtherNet/IP™ Programming

•

Guide.

Safety Instructions

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. High voltage can be present even when the

warning LED indicator lights are

specied time after power has been removed before

performing service or repair work can result in death or

serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and DClink connections to other frequency converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum duration of waiting time is specied in

Tabl e 1. 1 .

Before performing any service or repair work, use

•

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

Failure to wait the

o.

VLT® Midi Drive FC 280 POWERLINK Programming

•

Guide.

®

VLT

is a registered trademark.

®

CANopen

international users and manufacturers group e. V.

EtherNet/IP™ is a trademark of ODVA, Inc.

is a registered trademark for CAN IN AUTOMATION

Items Supplied

One of the 6 types of control cassettes:

Standard control cassette (132B0345).

•

Control cassette with PROFIBUS (132B0347).

•

Control cassette with PROFINET (132B0348).

•

Control cassette with CANopen® (132B0346).

•

Control cassette with EtherNet/IP™ (132B0349).

•

Control cassette with POWERLINK (132B0378).

•

Voltage [V] Minimum waiting time (minutes)

415

200–240 0.37–3.7 kW

(0.5–5 hp)

380–480 0.37–7.5 kW

(0.5–10 hp)

Tab le 1 .1 D isc h arg e Time

Refer to the VLT® Midi Drive FC 280 Operating Guide for detailed

information about safe installation of the frequency converter.

–

11–22 kW

(15–30 hp)

Danfoss A/S © 01/2017 All rights reserved. MI07J202

Page 2

Installation Instructions

Mounting

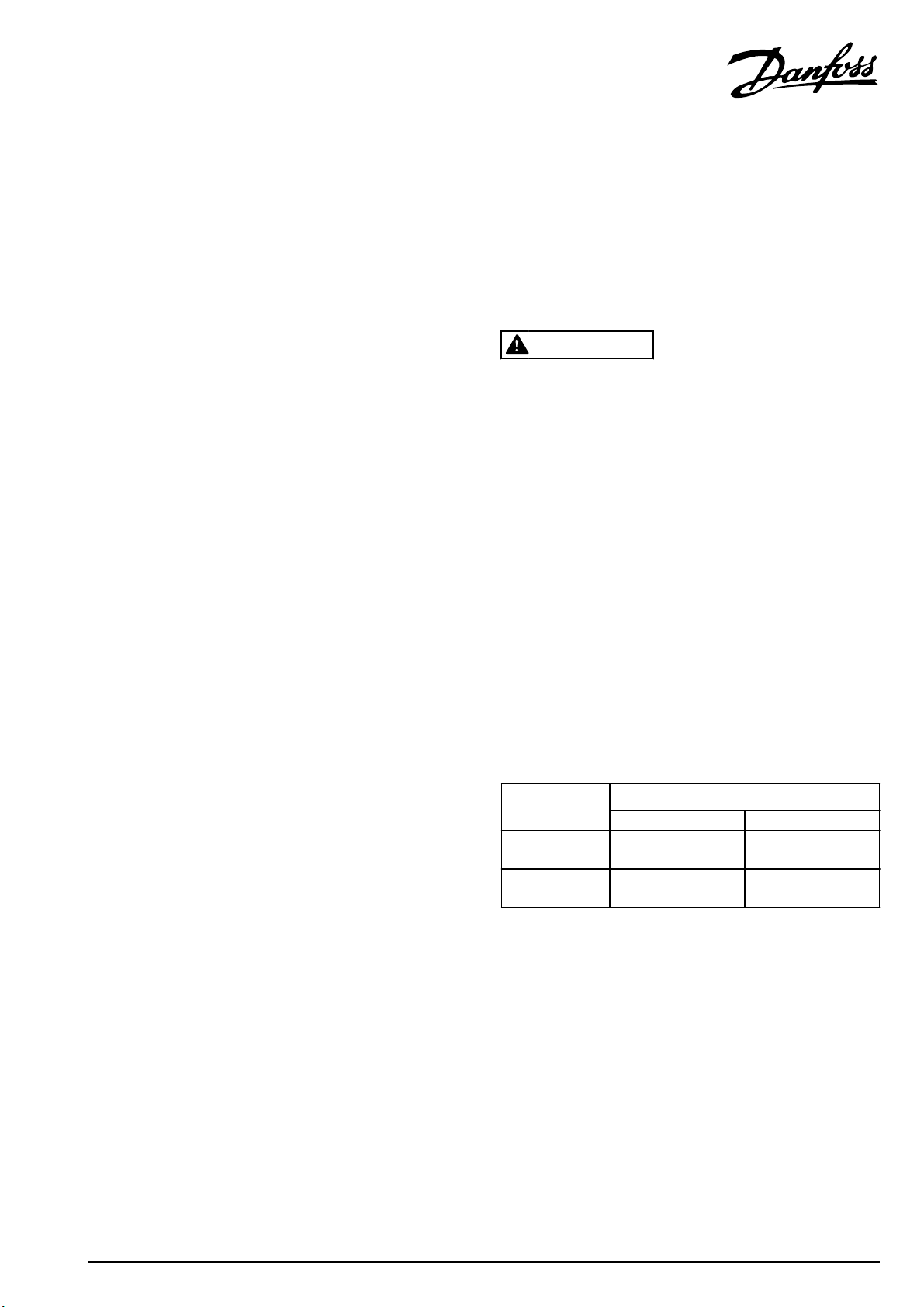

1. Remove the LCP with a at-edged screwdriver

(accessed from the top), as shown in Illustration 1.1.

Illustration 1.1 Remove LCP

Control Cassettes

®

Midi Drive FC 280

VLT

2. Remove the plastic cover beneath the LCP by

pushing down the lock lever with a at-edged

screwdriver and lift the plastic cover upwards, as

shown in Illustration 1.2.

Illustration 1.2 Remove Cover

3. Loosen the old control card cassette by removing the

2 screws (T10, M3x6) on the left side, as shown in

Illustration 1.3.

Illustration 1.3 Loosen the Old Control Card Cassette

4. Slide the old control card cassette upwards to release

it from the power section.

5. Connect the new control cassette with the frequency

converter as shown in Illustration 1.4.

Illustration 1.4 Connect the New Control Cassette

2

Danfoss A/S © 01/2017 All rights reserved. MI07J202

Page 3

Installation Instructions

Control Cassettes

®

Midi Drive FC 280

VLT

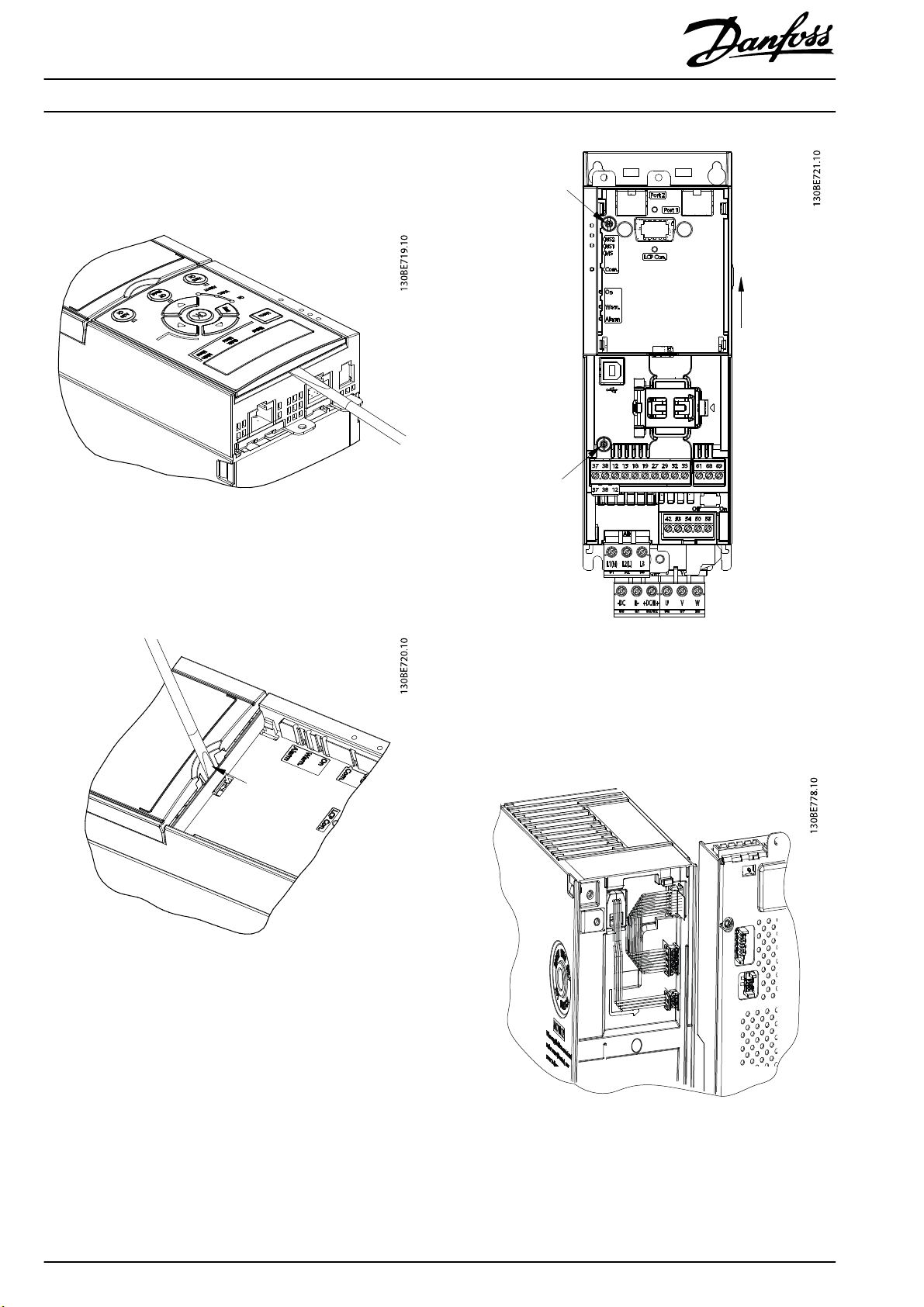

6. Place the new control cassette on the frequency

converter and slide it into place.

Illustration 1.5 Slide the New Control Cassette into Place

7. Fasten the new control cassette on the frequency

converter using 2 screws (supplied). Tightening

torque: 0.7–1.0 Nm (6.2–8.8 lb-in).

NOTICE

For the new control cassette to be properly recognized by

the frequency converter, update the software in the

frequency converter every time a new control cassette is

installed via the MCT 10 Set-up Software.

1. Select MCT 10 Set-up Software in the Start menu.

2. Select Congure bus.

3. Fill in the relevant data in the Serial eldbus congu-

ration-window.

4. Click the Scan bus-icon and

converter.

4a The frequency converter appears in the ID-

view.

5. Click Software upgrader.

6. Select the oss le.

7. In the dialog window, tick Force upgrade and then

click Start upgrade.

7a The rmware ashes.

8. Click Done when the upgrade is complete.

the frequency

nd

1Screws

Illustration 1.6 Tighten Screws

MI07J202 Danfoss A/S © 01/2017 All rights reserved.

3

Page 4

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI07J202132R0249 01/2017

*MI07J202*

Loading...

Loading...