Page 1

Contents

Contents

VLT® Metasys

1 Overview

1.1.1 Software Version 2

1.1.2 Introduction 2

1.1.3 About this Manual 2

1.1.4 References 2

2 Instructions

2.1.1 Abbreviations and Definitions 3

2.1.2 Network Connection 3

2.1.3 Hardware Set-up 3

2.1.5 VLT Parameters 4

3 Appendix

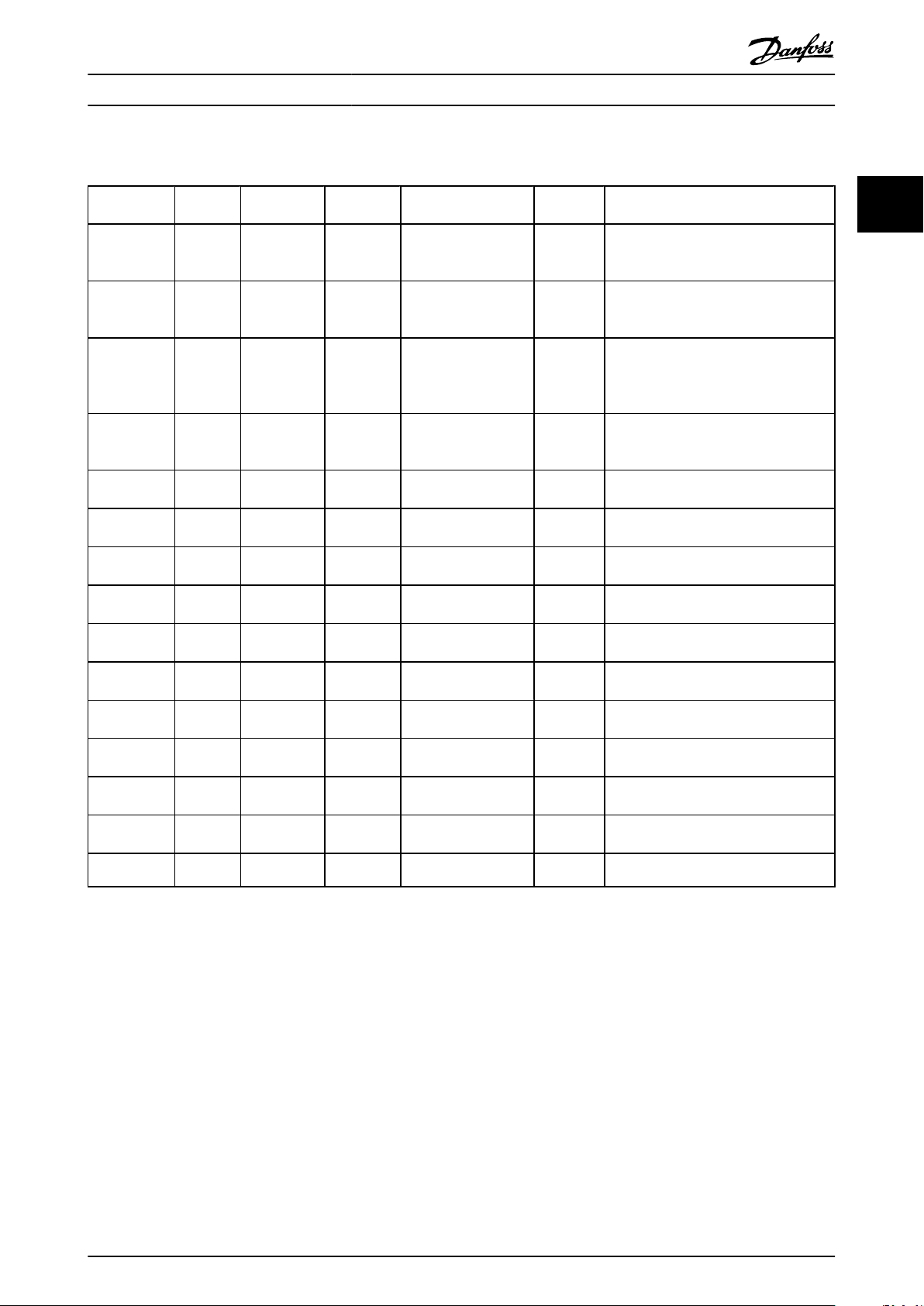

3.1.1 Analog Inputs (AI) 18

3.1.2 Binary Inputs (BI) 19

3.1.3 Analog Outputs (AO) 23

3.1.4 Binary Outputs (BO) 24

3.1.5 Internal Floating Point (ADF) 25

2

3

18

3.1.6 Internal Integers (ADI) 27

Index

29

MG.11.G2.02 - VLT® is a registered Danfoss trademark 1

Page 2

Overview

VLT® Metasys

11

1 Overview

1.1.1 Software Version

VLT HVAC Drive

FC 102 Series

Software version: 3.4x

and VLT AQUA Drive FC 202 Series

Software version: 1.7x

This guide can be used with all VLT HVAC Drive frequency converters with

software version 3.4x and VLT AQUA Drive frequency converters with

software version 1.7x.

The actual software version number can be read from

par. 15-43 Software Version.

1.1.2 Introduction

The frequency converter control board is program selectable

for use with the Johnson Controls Metasys N2 protocol.

Metasys N2 is a master/slave control network. The physical

layer is RS-485 compatible, half duplex 9600 baud shielded

twisted pair. The N2 software protocol is designed to be

general in nature to accommodate the unique properties each

device type may have. Every device connection to the N2

network can be thought of as a small data manager. Data

points in the database are classified as analog I/O (floating

point), binary I/O or integer data points - floats, integers or

bytes. Each data type has its own unique structure defined in

the Metasys N2 system Protocol Specification for Vendors.

The information in this manual is intended to provide you with

comprehensive information on how to install and set up the

frequency converter for communication over a Metasys

network.

For specific information on operation of the drive, refer to the

VLT HVAC Drive Operating Instructions, MG.11.Ax.yy or the VLT

AQUA Drive Operating Instructions, MG.20.Mx.yy.

1.1.3 About this Manual

This manual is for both instructional and for reference

purposes. This manual can also serve as a guideline when you

specify and optimize your communication system.

It is highly recommended that you read this manual in its

entirety before initiating any programming. It is assumed that

the user has full knowledge of the capabilities and limitation

of the controller node in addition to full knowledge of the

frequency converter.

References

1.1.4

In addition to this manual, the following two manuals should

be consulted: VLT HVAC Drive Operating Instructions, MG.

11.Ax.yy, VLT AQUA Drive Operating Instructions, MG.20.Mx.yy

and Johnson Controls METASYS N2 System Protocol Specification

for Vendors, Johnson Controls number 04-3402-22, rev A.

2 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 3

130BA060.11

68 69 68 69 68 69

RS 485

RS 232

USB

+

-

1 2

S801

ON

130BA272.11

Instructions

VLT® Metasys

2 Instructions

2.1.1 Abbreviations and Definitions

ACK Acknowledge

ADF Internal Floating Points

ADI Internal Integers

AI Analog Inputs

AO Analog Outputs

BI Binary Inputs

BO Binary Outputs

COS Change Of State

FC Frequency Converter

HPFB High Performance Field Bus

JCI Johnson Controls Inc. developers of the METASYS N2 protocol

N2 METASYS N2

N2

A N2 master is either a PC with JCI software or a dedicated JCI

mast

controller

er

NAK Not acknowledged

NPA N2 Point Address (Each N2 Point Type has a address range

from 0 to 255)

NPT N2 Point Type

PAR Parameter Number

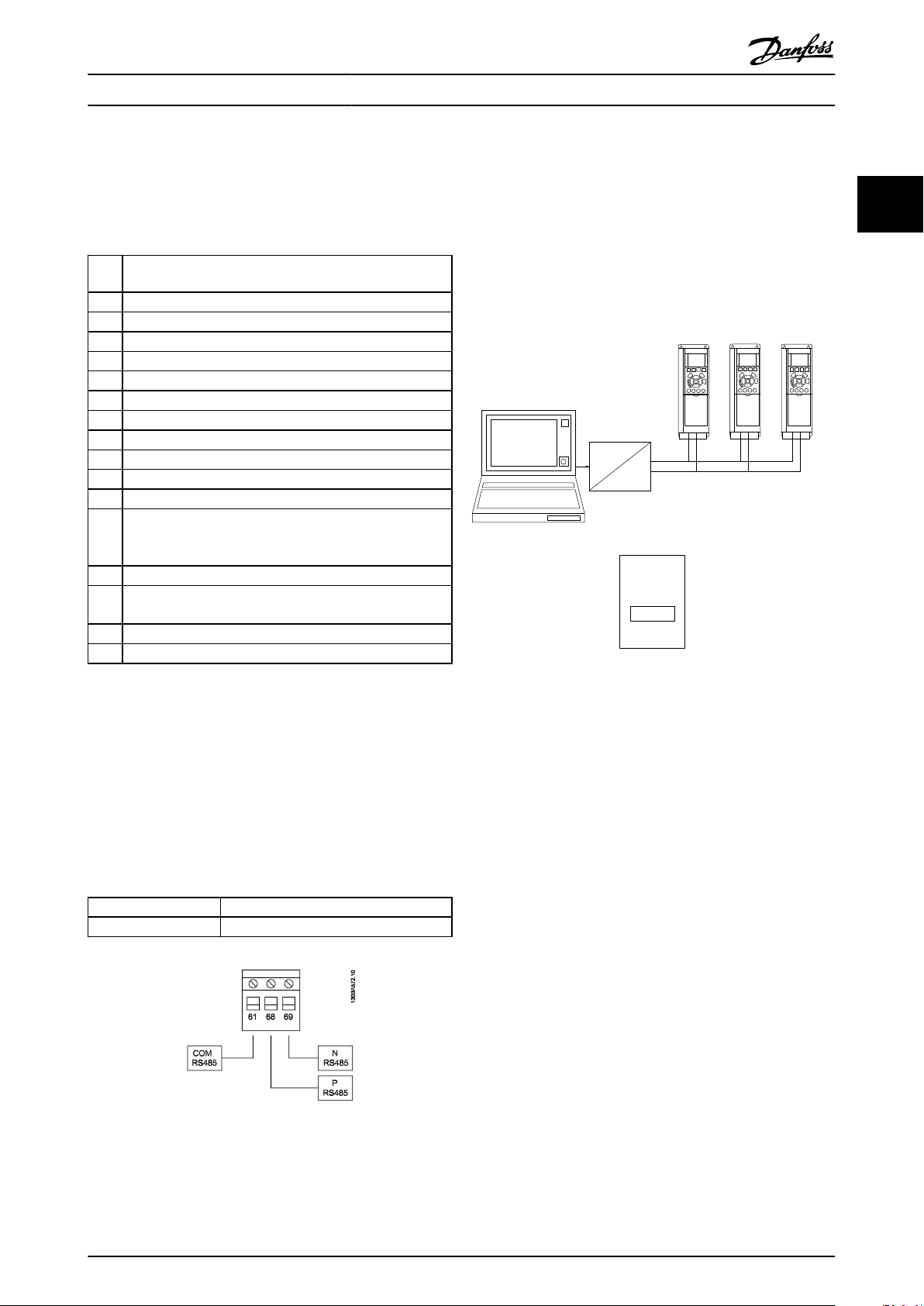

2.1.3 Hardware Set-up

RS-485 Bus Connection:

One or more frequency converters can be connected to a

control (or master) using the RS-485 standardized interface.

Terminal 68 is connected to the P signal (TX+, RX+), while

terminal 69 is connected to the N signal (TX-,RX-). If more than

one frequency converter is connected to a master, use parallel

connections.

Illustration 2.1: Bus termination switch

2 2

2.1.2 Network Connection

Connect signal wires to terminal 68 (N+) and terminal 69 (N-)

on main control board of the drive. If shielded cabling is used,

connect one end of the shield to terminal 61. This terminal is

connected to ground via an internal RC link. It is highly

recommended to use shielded twisted-pair cables to reduce

the differential mode interference between the conductors.

Danfoss do not take any responsibility for consequences, if

unshielded or untwisted cables are used.

Torque Specifications:

Control wire: 18 - 24 AWG, shielded, twisted pair

4.5 in.lb. (0.5 Nm) if screw terminal is used

NOTE

The factory setting for the dip switch is OFF.

In order to avoid potential equalizing currents in the screen,

earth the cable screen via terminal 61, which is connected to

the frame via an RC-link.

Bus termination: The RS-485 bus must be terminated by a

resistor network at both ends. For this purpose, set switch

S801 on the control card to "ON". For more information, see

the paragraph: Switches S201, S202 and S801.

MG.11.G2.02 - VLT® is a registered Danfoss trademark 3

Page 4

Instructions

2.1.4 Error Codes

VLT® Metasys

22

Error Code 00 is issued after power up or after a time out where all overridden points were released, as long as no Identify yourself

command has been issued by the master.

Error Code 01 is issued if the command is not supported or not known by the drive.

Error Code 02 is issued if the received telegram has a checksum error.

Error Code 03 is issued if the N2 telegram receive buffer exceeds 256 characters.

Error Code 05 is issued if the received N2 telegram is too long.

Error Code 10 is issued the data is out of expected range

Error Code 11 is issued when:

1. A point attributes or attribute bit is unused.

2. A point attributes or attribute bit is for JCI use only.

3. An internal data point attribute for current value can not be changed while running

Error Code 12 is issued when:

1. The N2 master tries to change attribute 2 bit 6 "Current State" on a BO and the drive is tripped.

2. The N2 master tries to change attribute 2 bit 6 "Current State" on a BO and the drive is trip locked except for BO 5

"reset"

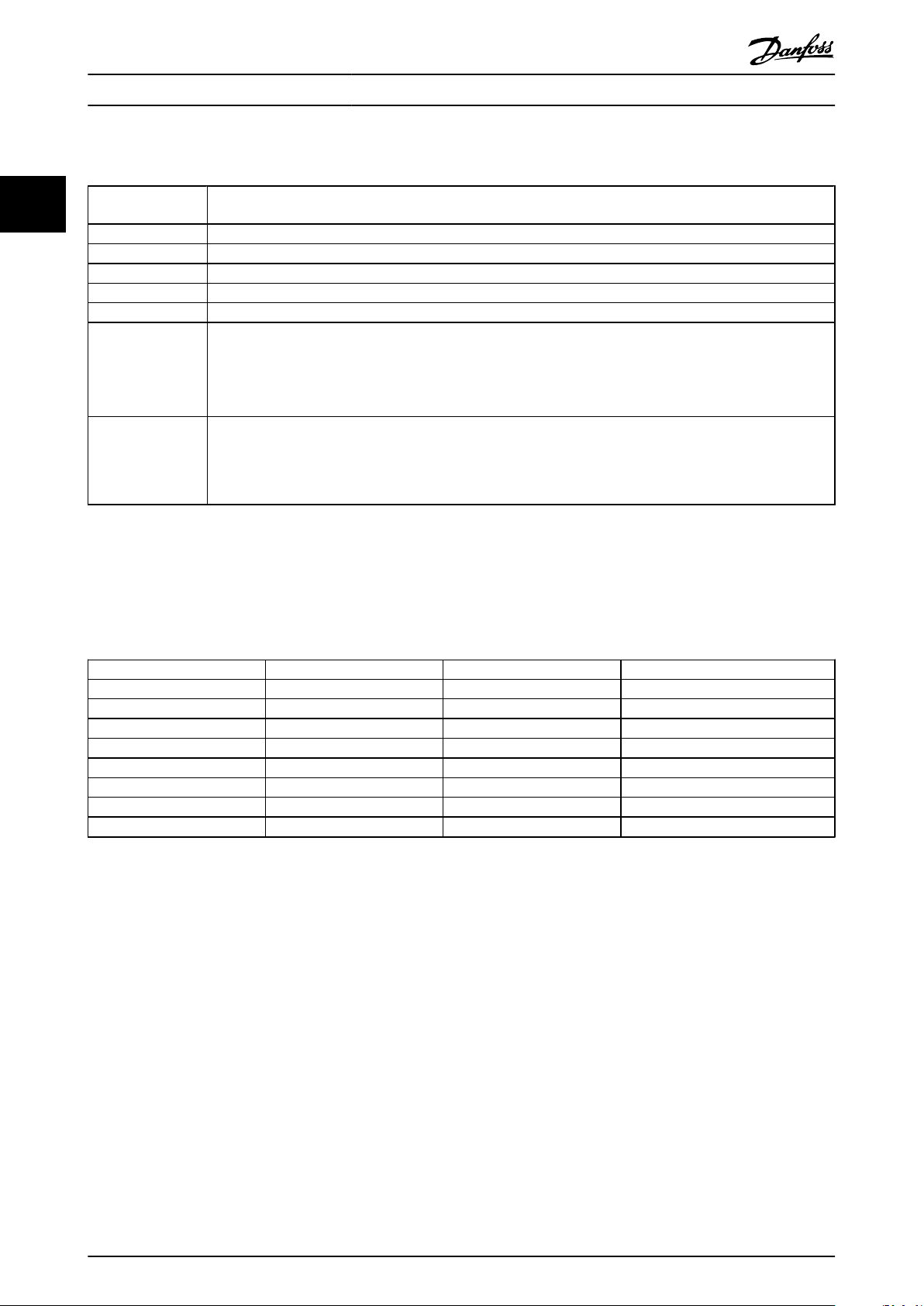

2.1.5 VLT Parameters

The following parameters may need to be manually set for each drive in the Metasys N2 network. Refer to the VLT HVAC Drive

Design Guide, MG.11.Bx.yy, or VLT AQUA Drive Design Guide, MG.20.Nx.yy, for the frequency converter for programming.

Parameter list

VLT Parameter Description Default Desired Setting

8-01 Control Side Digital & Ctrl. Word

8-02 Control Source FC Port FC Port

8-03 Control Word Timeout 60 s 1-18000 s

8-30 Protocol FC Metasys N2

8-31 Address 1 1-255

8-32 Baud Rate 9600 Fixed to 9600

8-33 Parity Even, 1stop Fixed to No Parity, 1stop

8-37 Maximum Inter-char Delay 25 s for Metasys N2

4 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 5

Instructions

VLT® Metasys

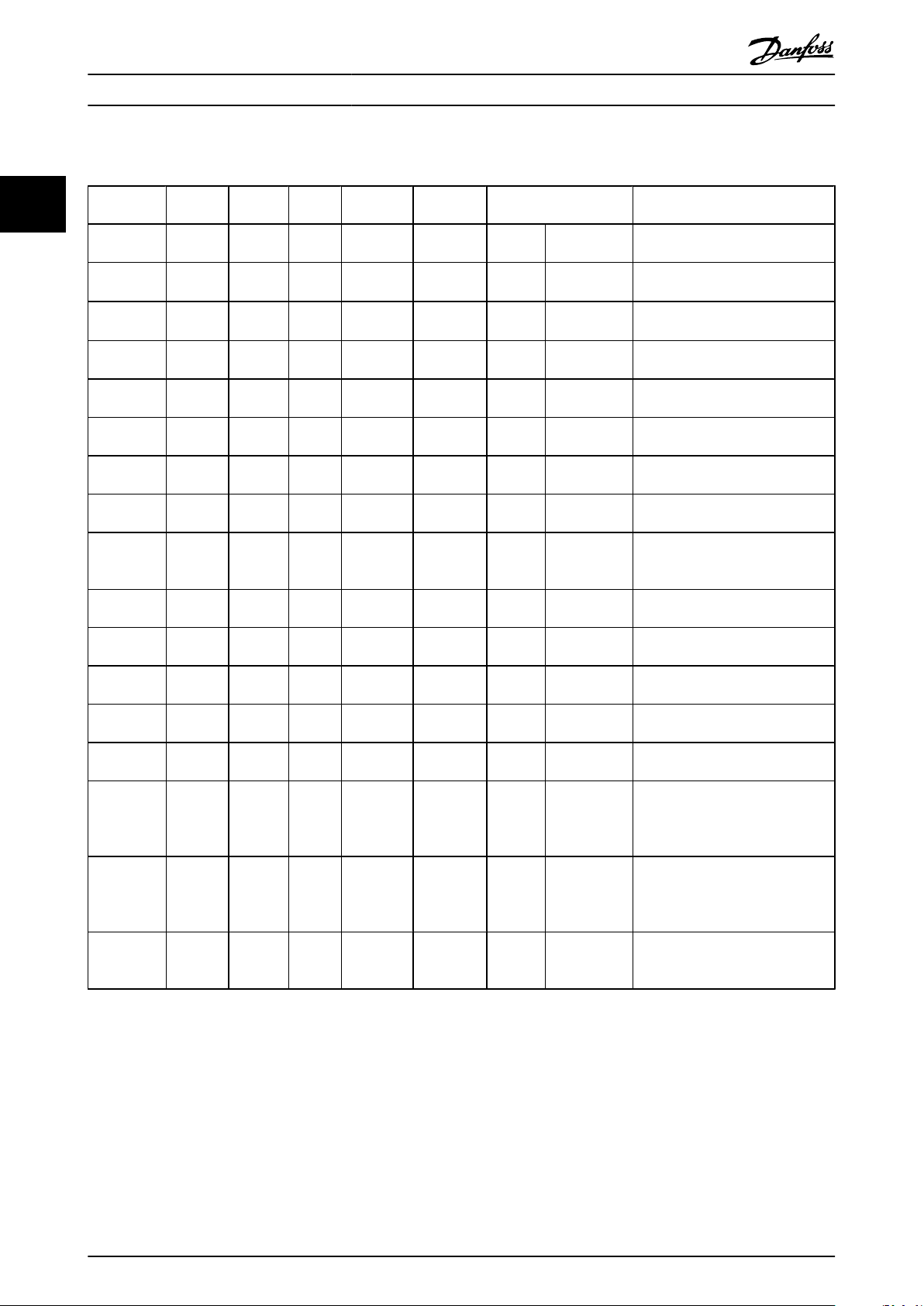

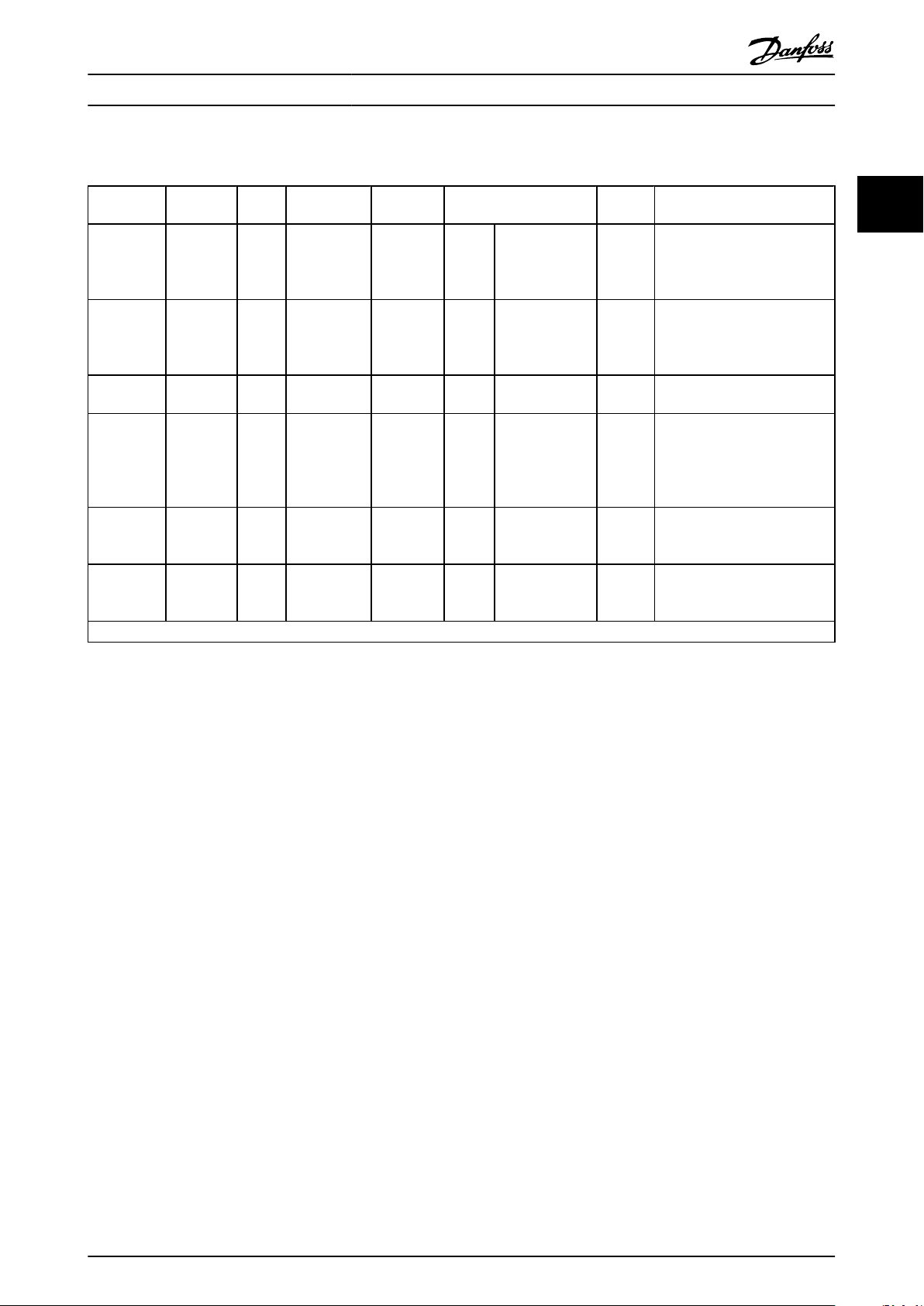

2.1.6 General Commands (Acknowledged)

VLT Response Command Subcommand

ACK 0 4 -

ACK 0 5 -

ACK 0 9 - Status update Message -

ACK F - - Identify Device Type -

ACK 0 0 - Synch Time -

ACK, no action 8 0 - Upload -

ACK, no action 8 1 - Upload -

ACK, no action 8 3 - Upload Record -

ACK, no action 8 4 - Upload Complete -

ACK, no action 9 0 - Download -

ACK, no action 9 1 - Download -

ACK, no action 9 3 - Download -

ACK, no action 9 4 - Download Complete -

NAK 0 1 - Read Memory 01

NPA Object

no.

Attribute Message Type Error Code Comments

Poll Message

No Acknowledge

Poll message

With Acknowledge

The slave is to respond with any data

-

-

points, analog or binary I/O that have

been flagged for COS

The slave is to respond with any data

points, analog or binary I/O that have

been flagged for COS

Slave device must respond with device

manufacturing model number (Par. 6-21),

days in service (Par. 6-00) and device

status

Slave device responds with an identifica-

tion number of 10H to indicate non JCI

device

The internal clock is syncronized by this

command

Optional, no support in the frequency

converter

Optional, no support in the frequency

converter

Optional, no support in the frequency

converter

Optional, no support in the frequency

converter

Optional, no support in the frequency

converter

Optional, no support in the frequency

converter

Record optional, no support in the

frequency converter

Optional, no support in the frequency

converter

Slave device memory read based on

memory addresses

2 2

NAK 0 8 - Warm Start 01 JCI use only

MG.11.G2.02 - VLT® is a registered Danfoss trademark 5

Page 6

Instructions

VLT® Metasys

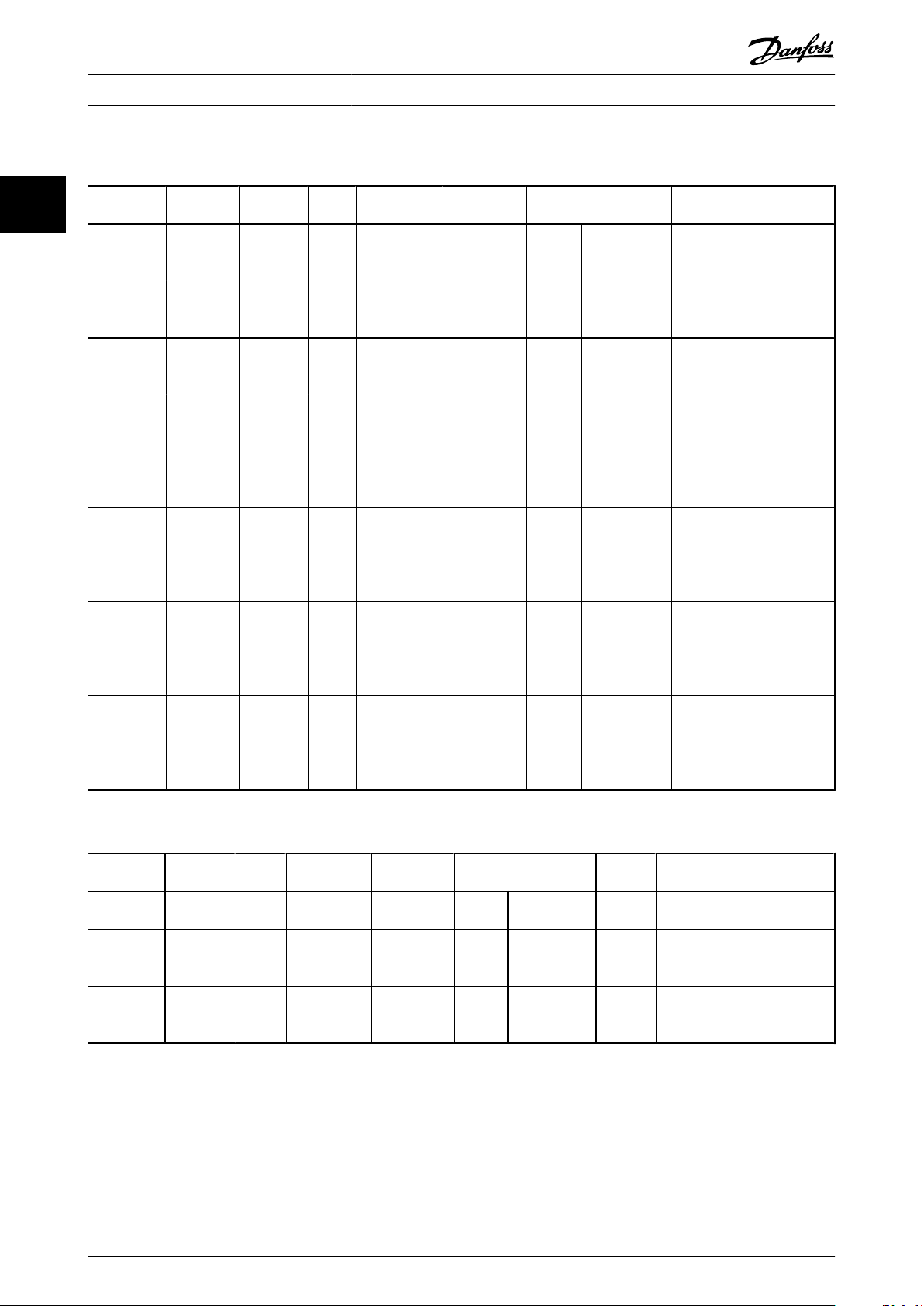

2.1.7 Analog Input Commands (Acknowledged)

22

VLT

Response

ACK 1 - 1 0-23 1 Byte

ACK 1 - 1 0-23 2 Byte

ACK 1 - 1 0-23 3 Float

ACK 1 - 1 0-23 8 Float

ACK 1 - 1 0-23 9 Float

ACK 1 - 1 0-23 10 Float

ACK 1 - 1 0-23 11 Float

ACK 1 - 1 0-23 12 Float

ACK 2 - 1 0-23 1 Byte

ACK 2 - 1 0-23 8 Float

ACK 2 - 1 0-23 9 Float

ACK 2 - 1 0-23 10 Float

ACK 2 - 1 0-23 11 Float

ACK 2 - 1 0-23 12 Float

ACK, no

action

ACK, no

action

ACK, no

action

Command Subcom-

mand

7 2 1 0-23 - Float

7 3 1 0-23 - -

7 7 1 0-23 - -

Region

NPA Object

no.

Attribute

No.

Attribute Message Type Comments

Read Analog

Input

Read Analog

Input

Read Analog

Input

Read Analog

Input

Read Analog

Input

Read Analog

Input

Read Analog

Input

Read Analog

Input

Write Analog

Input

Write Analog

Input

Write Analog

Input

Write Analog

Input

Write Analog

Input

Write Analog

Input

Override

Analog inputs

Override

Analog Release

Write Analog

Input Attrib-

utes

Read Object Configuration attribute

associated with each individual point

1)

Read Object Status attribute

associated with each individual point

2)

Read Analog Input Value attribute

associated with each individual point

Read Low Alarm attribute associated

with each individual point

Read Low Warning attribute associ-

ated with each individual point

Read High Warning attribute associ-

ated with each individual point

Read High Alarm attribute associated

with each individual point

Read Differential attribute associated

with each individual point

Write to Object Configuration attrib-

ute associated with each individual

point

Write to Low Alarm Limit attribute

associated with each individual point

Write to Low Warning Limit attribute

associated with each individual point

Write to High Warning Limitattribute

associated with each individual point

Write to High Alarm Limit attribute

associated with each individual point

Write to Differential attribute associ-

ated with each individual point

Analog inputs are "outputs" from the

frequency converter and should not

be written over by the network

controller

Analog inputs are "outputs" from the

frequency converter and should not

be written over by the network

controller

Optional command for slave devices.

Only used for N2

commissioning purposes

6 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 7

Instructions

VLT® Metasys

2.1.8 Analog Input Commands (Not Acknowledged)

VLT

Response

Comm and Region NPA Object no. Attribute

No.

Attribute Message Type Error

NAK 1 1 0-23 4 Float Read Analog

Input

NAK 1 1 0-23 5 Float Read Analog

Input

NAK 2 - 0-23 2 Byte Write Analog

Input

NAK 2 - 0-23 3 Float Write Analog

Input

NAK 2 - 0-23 4 Float Write Analog

Input

NAK 2 - 0-23 5 Float Write Analog

Input

NAK 2 - 0-23 6 Float Write Analog

Input

NAK 2 - 0-23 7 Float Write Analog

Input

NAK 2 - 0-23 13 Integer Write Analog

Input

NAK 2 - 0-23 14 Float Write Analog

Input

1)

Error code 11 is used because attributes are considered as fields/records in the point map database.

Comments

Code

1 )

Read Linear Ranging Parameter 1

11

attribute associated with each

individual point. (JCI use only)

1)

Read Linear Ranging Parameter 2

11

attribute associated with each

individual point. (JCI use only)

11

11

11

1)

1)

1)

Object Status writeable

Analog Input Value not writeable

Write to Linear Ranging Parame-

ter 1 attribute associated with

each individual point. (JCI use

1)

Write to Linear Ranging Parame-

11

ter 2 attribute associated with

each individual point. (JCI use

1)

Write to Linear Ranging Parame-

11

ter 3 attribute associated with

each individual point. (JCI use

1)

Write to Linear Ranging Parame-

11

ter 4 attribute associated with

each individual point. (JCI use

1)

11

Write to Filter Weight attribute

associated with each individual

point. (JCI use only)

1)

Write to AI Offset attribute associ-

11

ated with each individual point.

(JCI use only)

2 2

only)

only)

only)

only)

MG.11.G2.02 - VLT® is a registered Danfoss trademark 7

Page 8

Instructions

VLT® Metasys

2.1.9 Analog Output Commands (Acknowledged)

22

VLT

Response

ACK 1 - 3 0-2 1 Byte Read Analog

ACK 1 - 3 0-2 2 Byte Read Analog

ACK 0 9 - - - - Status update

ACK 1 - 3 0-2 3 Float Read Analog

ACK 2 - 3 0-2 1 Byte Write Analog

ACK 7 2 3 0-2 - Float Override Analog

ACK 7 2 3 0-2 - Float Override Analog

ACK 7 3 3 0-2 - - Override Release Set the current value, the value

ACK, no

action

ACK, no

action

Command Sub

command

7 7 3 0-2 - - Write Analog

7 8 3 0-2 - - Read Analog

Region NPA Object no. Attribute

No.

Attribute Message Type Comments

Output Attributes

Output

Output

Message

Output

Output

Output

Output

Output

Read Object Configuration

attribute associated with each

individual point

Read Object Status attribute

associated with each individual

point

Slave device must respond

with device manufacturing

model number (Par. 6-21), days

in service (Par. 6-00) and

device status

Read Current Value attribute

associated with each individual

point

Write to Object Configuration

attribute associated with each

individual point

Write to analog output current

value (frequency setpoint)

Write to analog output current

value (frequency setpoint)

that it was before the 1.

Override Command was issued

Optional command for slave

devices. Only used for N2

Attributes commissioning

purposes. Not to be implemen-

ted at this time

Optional command for no

action slave devices. Only used

for N2 commissioning

purposes. Not to be implemen-

ted at this time

8 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 9

Instructions

VLT® Metasys

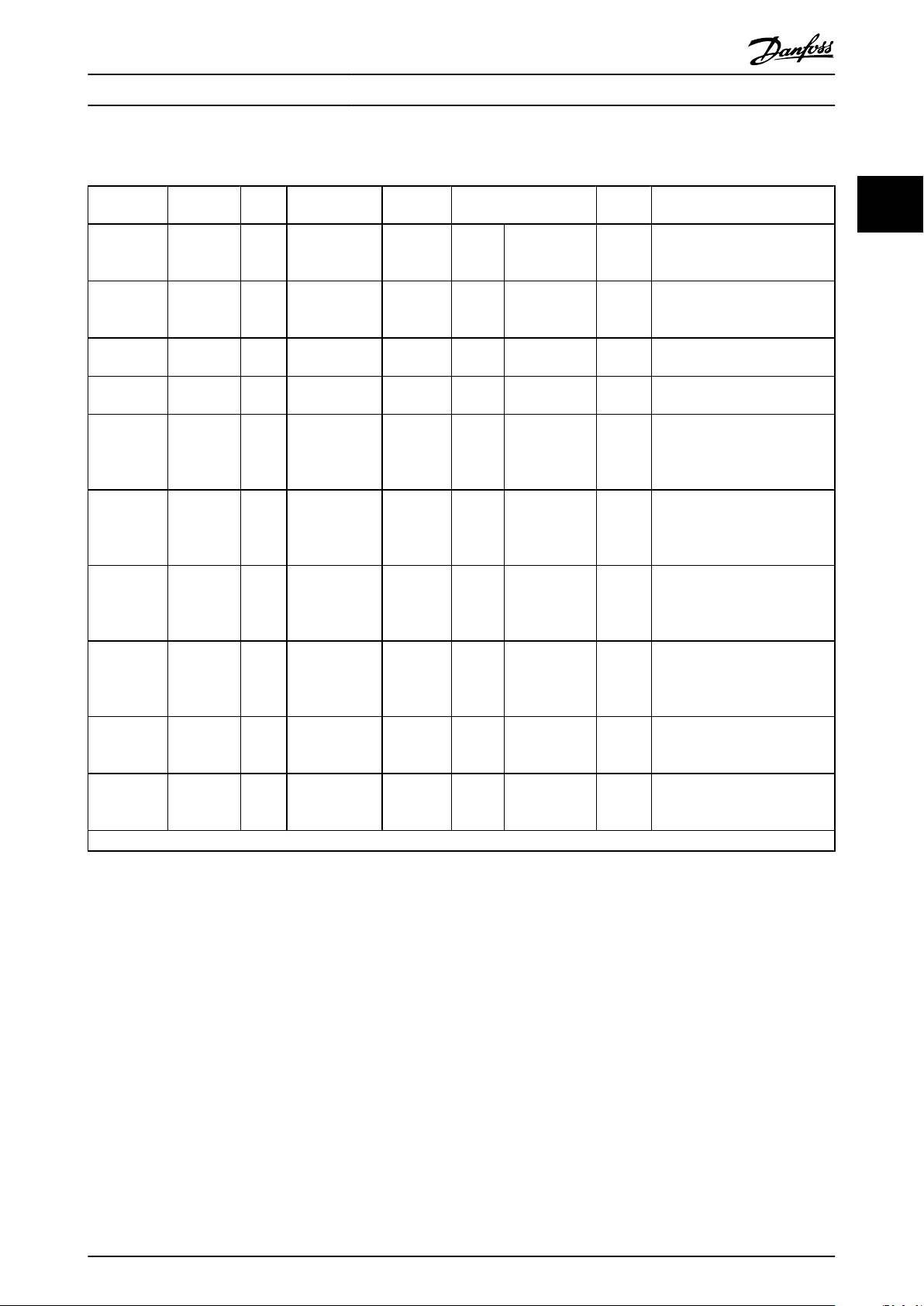

2.1.10 Analog Output Commands (Not Acknowledged)

VLT

Response

0-2 1 3 0-2 4 Float Read Analog

NAK 1 3 0-2 5 Float Read Analog

NAK 2 3 0-2 2 Byte Write Analog

NAK 2 3 0-2 3 Float Write Analog

NAK 2 3 0-2 4 Float Write Analog

NAK 2 3 0-2 5 Float Write Analog

Command Region NPA Object

no.

1)

Error code 11 is used because attributes are considered as fields/records in the point map database.

Attribute

No.

Attribute Message Type Error

Output

Output

Output

Output

Output

Output

Comments

Code

11

11

11

11

11

11

1

1

1

1

1

1

Read Low Linear Ranging

Parameter attribute associated

with each individual point. (JCI

use only)

Read High Linear Ranging Parameter attribute associated with

each individual point. (JCI use

Object Status not writeable

Write to Current Value structure

attributes associated with each

individual point. (N2 does not

support this, override function

must be used)

Write Debouncing Value in msec

attribute associated with each

individual point.(JCI use only)

Write Accumulator value attrib-

ute associated with each individ-

ual point. (JCI use only)

2 2

only)

MG.11.G2.02 - VLT® is a registered Danfoss trademark 9

Page 10

Instructions

VLT® Metasys

2.1.11 Binary Input (BI) Commands (Acknowledged)

22

VLT

Response

ACK 1 - 2 0-135 1 Byte Read Binary

ACK 1 - 2 0-135 2 Byte Read Binary

ACK 2 - 2 0-135 1 Byte Write Binary

ACK, no

action

ACK, no

action

ACK, no

action

ACK, no

action

Command Subcom-

mand

7 2 2 0-135 - Byte(0/1) Override Binary

7 3 2 0-135 - - OverrideRe-

7 7 2 0-135 - - Write Binary

7 8 2 0-135 - - Read Binary

Region NPA Object no. Attribute No. Attribute Message Type Comments

Input

Input

Input

Input

lease

Input

Input

Read Object Configuration

attribute associated with

each individual point

Read Object Status attribute

associated with each individ-

ual point

Write to Object Configuration

attribute associated with

each individual point

Binary inputs are "outputs"

from the frequency converter

and should not be written

over by the network control-

ler. (Status word, Warnings,

and Alarms)

Binary inputs are "outputs"

from the drive and should

not be written over by the

network controller. (Status

word, Warnings and Alarms)

Optional command for slave

devices. Only Attributes used

for N2 commissioning

purposes. Not to be

implemented at this time

Optional command for Attrib-

utes slave devices. Only used

for N2 commissioning

purposes. Not to be

implemented at this time

2.1.12 Binary Input (BI) Commands (Not Acknowledged)

VLT

Response

NAK 2 2 0-135 2 Byte Write Binary

NAK 2 2 0-135 3 Integer Write Binary

NAK 2 2 0-135 4 Integer32Write Binary

10 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Command Region NPA Object

no.

Attribute No. Attribute Message Type Error

Input

Input

Input

Comments

Code

1

11

11

11

Object Status not writeable

1

Write Debouncing Value in msec

attribute associated with each

individual point.(JCI use only)

1

Write Accumulator value attrib-

ute associated with each individ-

ual point (JCI use only)

Page 11

Instructions

VLT® Metasys

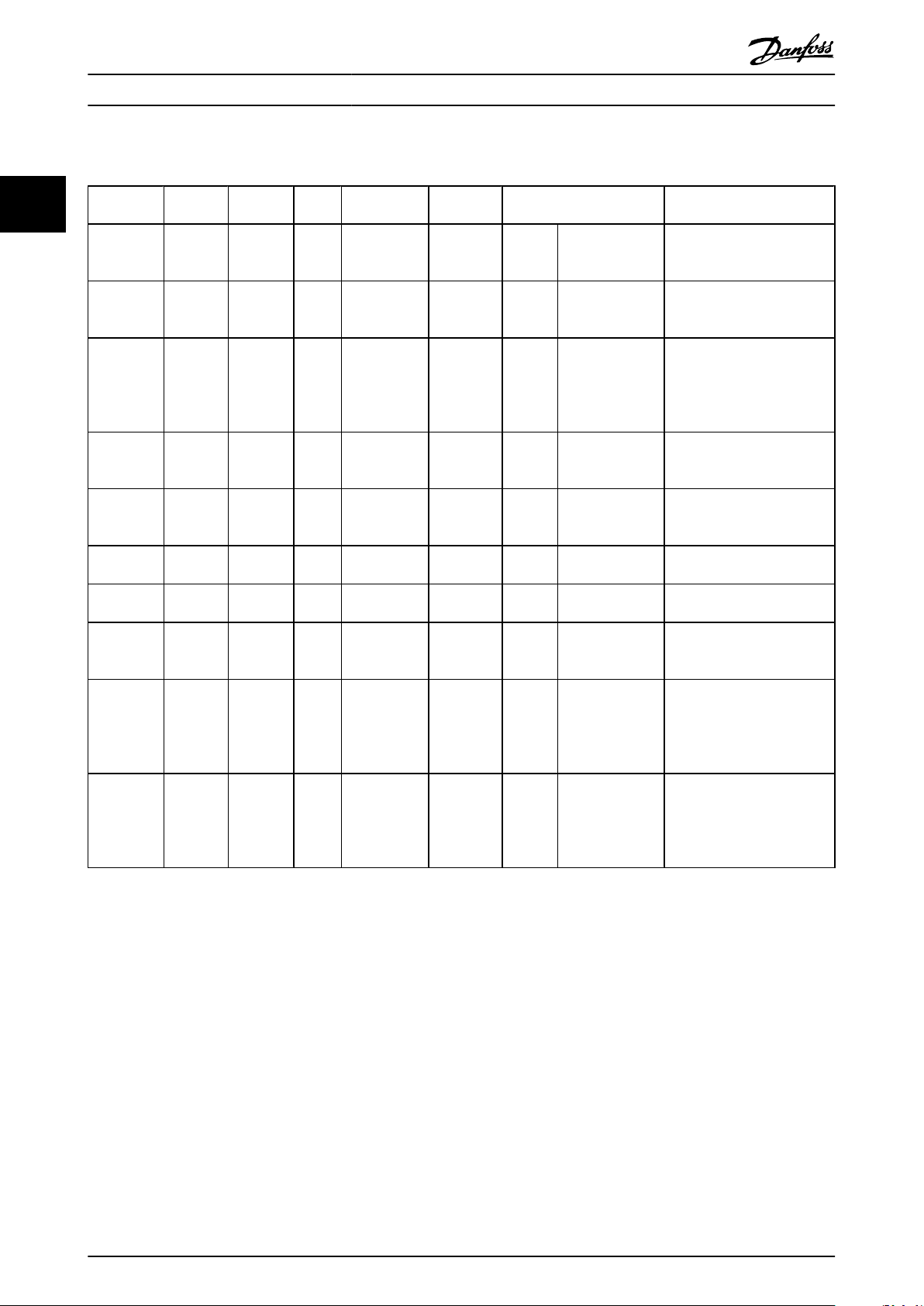

2.1.13 Binary Output Commands (Acknowledged)

VLT

Response

ACK 1 - 4 0-10 1 Byte Read Binary

ACK 1 - 4 0-10 2 Byte Read Binary

ACK 2 - 4 0-10 1 Byte Write Binary

ACK 7 2 4 0-10 - Byte(0/1) Override Binary

ACK 7 2 4 0-10 - Byte(0/1) Override Binary

ACK 7 3 4 0-10 - - Override Release Set the current value, the value that

ACK, no

action

ACK, no

action

ACK, no

action

ACK, no

action

ACK, no

action

ACK, no

action

ACK, no

action

ACK, no

action

Command Subcom-

mand

1 - 4 0-10 3 Integer Read Binary

1 - 4 0-10 4 Integer Read Binary

1 - 4 0-10 5 Integer Read Binary

2 - 4 0-10 3 Integer Write Binary

2 - 4 0-10 4 Integer Write Binary

2 - 4 0-10 5 Integer Write Binary

7 7 4 0-10 - - Write Binary

7 8 4 0-10 - - Read Binary

Region NPA Object

no.

Attribute

No.

Attribute Message Type Comments

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Read structure attributes associated

with each individual point

Read structure attributes associated

with each individual point

Write to Object Configuration attrib-

ute associated with each

individual point

Write to binary output current state

(VLT control word)

Write to binary output current state

(VLT control word)

it was before the 1. Override

Command was issued

Read Minimum On-time attribute

associated with each

individual point. Return value = 0

Read Minimum Off-time attribute

associated with each

individual point. Return value = 0

Read Maximum Cycles/ Hour attrib-

ute associated with each

individual point. Return value = 0

Write Minimum On-time attribute

associated with each individual

point

Write Minimum Off-time attribute

associated with each individual

point

Write Maximum Cycles/ Hour attrib-

ute associated with each

individual point

Optional command for slave

devices. Only Attributes used for N2

commissioning purposes

Optional command for slave

devices. Only Attributes used for N2

commissioning purposes

2 2

MG.11.G2.02 - VLT® is a registered Danfoss trademark 11

Page 12

Instructions

VLT® Metasys

2.1.14 Binary Output (BO) Commands (Not Acknowledged)

22

VLT

Response

NAK 1 4 0-10 6 Integer Read Binary

NAK 1 4 0-10 7 Integer Read Binary

NAK 2 4 0-10 2 Byte Write Binary

NAK 2 4 0-10 6 Integer Write Binary

NAK 2 4 0-10 7 Integer Write Binary

Command Region NPA Object

no.

1)

Error code 11 is used because attributes are considered as fields/records in the point map database.

Attribute No. Attribute Message Type Error Code Comments

1)

Read Interstage on delay attrib-

11

Output

individual point. (JCI use only)

1)

Read Interstage off delay attrib-

11

Output

individual point. (JCI use only)

1)

11

Output

11

Output

11

Output

Object Status not writeable

1)

Write Interstage on delay attrib-

individual point. (JCI use only)

1)

Write Interstage off delay attrib-

individual point. (JCI use only)

ute associated with each

ute associated with each

ute associated with each

ute associated with each

2.1.15 Internal Integers (ADI) Commands (Acknowledged)

VLT

Response

ACK 1 - 6 0-254 1 Integer Read Internal

ACK 1 - 6 0-254 2 Integer Read Internal

ACK 2 - 6 0-254 - Integer Write Internal

ACK 7 2 6 0-254 - Integer Override Internal

ACK 7 3 6 0-254 - - Override Release Set the current value, the

Command Subcom-

mand

Region NPA Object no. Attribute No. Attribute Message Type Comments

Read Object Status associ-

Parameter of

object type

integer (16 bit)

Parameter of

object type

integer (16bit)

Parameter of

object type

integer (16bit)

Parameter of

object type

Integer (16 bit)

ated with each individual

point

Read Current Value attrib-

ute associated with each

individual point

Write to Current Value

attribute associated with

each individual point

Write to internal parame-

ter current value (set-up

parameters for VLT)

value that it was before

the 1. Override Command

was issued

12 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 13

Instructions

VLT® Metasys

2.1.16 Internal Floating Point Commands (Acknowledged)

VLT

Response

ACK 1 - 5 0-101 1 Byte Read Internal

ACK 1 - 5 0-101 2 Float Read Internal

ACK 2 - 5 0-101 - Float Write Internal

ACK 2 - 5 0-101 - Float Write Internal

ACK 7 2 5 0-101 - Float Override Internal

ACK 7 3 5 0-101 - - Override Release Set the current value, the

Command Subcom-

mand

Region NPA Object no. Attribute No. Attribute Message Type Comments

Read Object Status

Parameter of

object type float

Parameter of

object type float

Parameter of

object type float

Parameter of

object type float

Parameter of

object type float

associated with each

individual point

Read Current Value

attribute associated with

each individual point

Write to Current Value

attribute associated with

each individual point

Write to Current Value

attribute associated with

each individual point

Write to internal parame-

ter current value (set-up

parameters for VLT)

value that it was before

the 1. Override

Command was issued

2 2

MG.11.G2.02 - VLT® is a registered Danfoss trademark 13

Page 14

Instructions

VLT® Metasys

2.2.1 Start-up of the Frequency Converter

22

drive or remote. Use the Extended Menu key to access the 8-**

group parameters (serial communication). The settings shown

below are typical. Some settings may be changed to meet the

application requirements. The settings below will serve as a

good starting reference. Refer to the operating instruction

manual for instructions on changing parameters and programming the drive.

Examples of typical settings. Program the following:

Parameter: Setting:

Use the frequency converter keypad mounted either on the

Par. 8-30 Protocol

Par. 8-31 Address

Par. 8-32 Baud Rate

Par. 8-50 Coasting Select

Par. 8-52 DC Brake Select

Par. 8-53 Start Select

Par. 8-54 Reversing Select

Par. 8-55 Set-up Select

Par. 8-56 Preset Reference Select

Par. 8-94 Bus Feedback 1

Par. 8-95 Bus Feedback 2

[3] Metasys N2

1 (Default)

[2] 9600 Baud (fixed at 9600 for

N2 protocol)

[3] Logic OR

[3] Logic OR

[3] Logic OR

[0] Digital input

[3] Logic OR

[3] Logic OR

0

0

Telegram code:

>XX72040401YY <CR>

Issue a frequency reference through the master, to the device:

Example 3:

Over-ride analog output, speed

(50%) change command:

Device address XX

Char1 command 7

Char1 subcommand 2

Char2 region 03

Char2 object number (NPA) 00

Char8 override value * 4E 00 00 00 override value = 50%

Checksum YY

Setting:

speed (IEEE floating point,

format)

Telegram code:

>XX7203004E000000<CR>

To calculate override value for speed: refer to Scaling of Bus

Reference and Bus Feedback. Issue an override release

command through the master to the device:

NOTE

Send an F command to begin communications between

the master and the drive

Example 1:

F command

Device address XX

Char1 command F

Checksum YY

Telegram code:

>XXFYY <CR>

Issue a run command through the master, to the device:

Example 2:

start, BO override command: Setting:

Bus

Device address XX

Char1 command 7

Char1 subcommand 2

Char2 region 04

Char2 object number (NPA) 04 (Start)

Char2 override value 01 (Active)

Checksum YY

Setting:

Example 4:

Bus stop, BO over-ride release

command:

Device address XX

Char1 command 7

Char1 subcommand 2

Char2 region 04

Char2 object number (NPA) 04 (Start)

Char8 override value * 00 (Not active)

Checksum Y

Setting:

Telegram code:

>XX72040400YY <CR>

If the preceding commands were issued, the drive should have

accelerated to 50% after the speed reference was issued. After

the override release, the drive should have stopped.

14 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 15

Instructions

VLT® Metasys

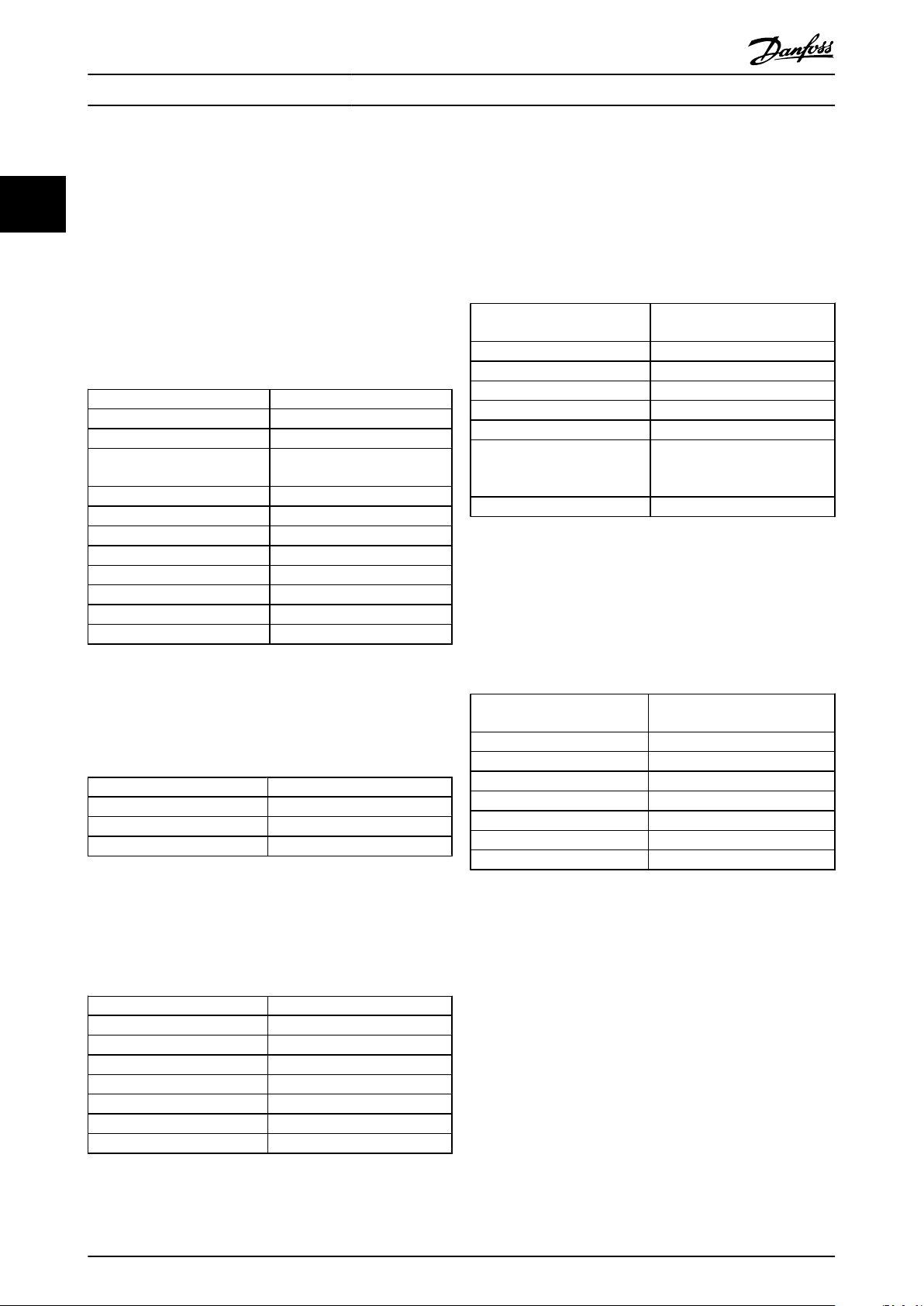

2.2.2 Scaling of Bus Reference and Feedback

Reference/

feedback

20% 20 * 16384/100 3276.8 454C CCCD

50% 50 * 16384/100 8192 4600 0000

100%

200%

-100%

-200%

Table 2.1: Reference/feedback values

Scaling Float IEEX hex

100 *

16384/100

200 *

16384/100

-100 *

16384/100

-200 *

16384/100

16384 4680 0000

32767 46FF FE00

-16384 C680 0000

-32768 C700 0000

The reference/feedback value is the percentage of the range

of parameter 3-02 and 3-03. Values within the ranges 100% to

200% and -200% to -100% applies only to the reference. The

Float representation of the value 200% must be limited to

maximum 32767 and minimum -32768.

Status Update Request

2.2.3

A Status Update Request will cause the drive to report its

current operating status. The status codes, descriptions and

associated alarms are shown in the chart below.

The Device Status Code consists of two parts. The Least Significant Byte, (LSB) of the hex number is the Alarm Number. The

Most Significant Byte (MSB) indicates if the alarm is a normal

trip (01) that can be reset automatically or manually, or if the

alarm is a trip lock (02) requiring cycling power to the drive.

Status codes with associated alarms and descriptions

Device Status

Code1

0x0000 - Device OK

0x0102 2 Live zero error

0x0204 4 Phase fault (Trip lock)

0x0107 7 Over voltage

0x0108 8 Under voltage

0x0109 9 Inverter overloaded

0x010A 10 Motor overloaded

0x010B 11 Motor thermistor

0x010C 12 Current limit

0x020D 13 Over current (Trip lock)

0x020E 14 Earth fault (Trip lock)

0x020F 15 Switch mode fault (Trip lock)

0x0210 16 Short circuit (Trip lock)

0x0111 17 Standard bus time out

0x0112 18 HPFB time out

0x0116 22 Auto optimization not OK

0x021D 29 Heat sink temperature to high (Trip

0x011E 30 Motor phase U missing

0x011F 31 Motor phase V missing

0x0120 32 Motor phase W missing

0x0122 34 Profibus communication error

0x0225 37 Inverter fault (Trip lock)

0x013C 60 Safety interlock

0x0263 99 Unknown fault (Trip lock)

Alarm

No.

Description

lock)

Read/write notes

A write command to an ADF (Internal Floating Point) or BD

(Internal Byte) point type will be stored in the drive's EEPROM.

2 2

NOTE

If write command is issued to an overridden point, the

new value will not be stored in the drive's EEPROM.

MG.11.G2.02 - VLT® is a registered Danfoss trademark 15

Page 16

Instructions

VLT® Metasys

2.2.4 Override/Override Release Commands

Handling of Poll Message Commands

2.2.6

and Time Out, 8-04 (Setting [20], N2

Override release)

22

The way the overridden points are released is very important

to the way the drive will behave during the override release

time out or for release commands issued by the N2 master.

This is due to the fact that the active setup can be changed to

a different setup. If one would release the active setup before

the values that have been overridden in that setup, the

backup values would then be restored to the wrong setup,

leaving the overridden values in the old setup unchanged.

The release after override time out:

During an override release time-out, all points which are

overridden, will be released in the order, which they are

specified in Appendix POINTMAP:

1. Release Analog Outputs from point address (NPA) 0

to 255.

2. Release Binary Outputs from point address (NPA) 0

to 255.

3. Release Internal Floating Points from point address

(NPA) 0 to 255.

4. Release Internal Integer Points from point address

(NPA) 0 to 255.

5. Release Internal Byte points from point address

(NPA) 0 to 255.

The Identity Command will cause the drive to report all AI, AO,

BI and BO points, which are available when the next Poll (0/4)

is received. The drive also supports COS for AI and BI point

types. The drive is limited to responding with up to 200 ASCII

characters, so multiple messages may need to be sent before

all available points have been reported.

Upon receiving the Poll (0/4), the frequency converter will

begin exporting the requested information. The frequency

converter will continue to export new information upon

receiving the 0/5 Poll until it has sent all requested information. Then it will respond to a new 0/5 Poll with an ACK

response to indicate all information has been transmitted and

complete the Poll sequence receiving a 0/4 Poll before

sending the ACK response will cause the frequency converter

to re-transmit its latest response.

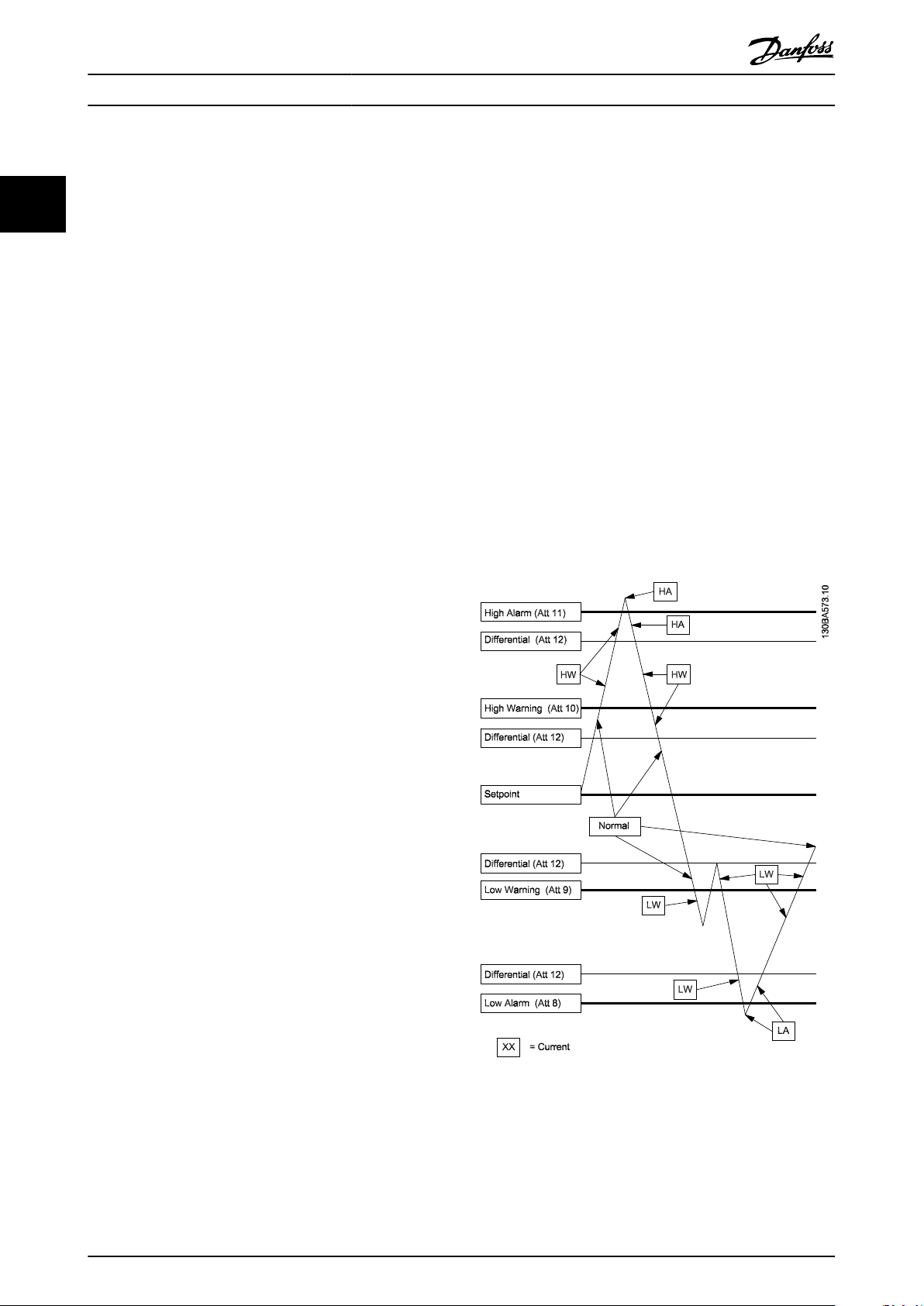

The drawing below illustrates the AI COS handling.

Change of State (COS)/POLLING

2.2.5

A change of state occurs when a new command has been

issued for the drive. This command can be issued through the

bus or through a drive related status change or command. The

master can issue a series of poll commands to the network

devices to get an update on any status changes from the time

of the last polling. When polling a frequency converter for the

first time after a network has been powered up after an F

command has been issued, a 0/4 poll command must be

issued.

16 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 17

Instructions

For AI:

Alarm Enable or Warning Enable must be set in the Object

Configuration Attribute (Attribute 1). Low/High Alarm limits

(Attribute 8, 11) or Low/High Warning limits (Attribute 9, 10)

must be programmed. Differential Value (Attribute 12) must

also be programmed.

For BI:

Alarm Enable must be set in the Object Configuration Attribute (Attribute 1).

Normal state must be programmed in the Object Configuration Attribute (Attribute 1)

Att XX = Attribute number, HA = High alarm, LA = Low alarm,

HW = High Warning, LW = Low Warning

The AI COS alarms will only be cleared when the point value

goes below the high alarm/warning or above the low alarm/

warning limit by more than the programmed differential value

(Attribute 12).

The BI COS will set the Alarm (Object Status bit 4) if COS

enabled (Object Configuration Bit 0) is set, Alarm Enabled

(Object configuration bit 3) is set, and Current State (Object

Status bit 6) is different from Normal State (Object Configuration bit 1).

VLT® Metasys

2 2

MG.11.G2.02 - VLT® is a registered Danfoss trademark 17

Page 18

Appendix

3 Appendix

3.1.1 Analog Inputs (AI)

VLT® Metasys

3

NPA Unit Description Range FC Par. Number

0 % Reference [%] - 16-02

1 - Reference [Unit] - 16-01

2 - Feedback - 16-52

3 Hz Frequency - 16-13

4 - User defined readout - 16-09

5 A Current - 16-14

6 kW Power - 16-10

7 hp Power - 16-11

8 V Output Voltage - 16-12

9 V DC Voltage - 16-30

10 % Motor Thermal Protection - 16-18

11 % Inverter Thermal Protection - 16-35

12 V Terminal 53 analog - 16-62

13 V Terminal 54 analog - 16-64

16 % External reference - 16-50

17 C Heat sink temperature - 16-34

18 Hour Operating hours - 15-00

19 Hour Running hours - 15-01

20 kWh kWh counter - 15-02

21 - Power-ups - 15-03

22 - Over temps - 15-04

23 - Over voltages - 15-05

24 - Start Ups - 15-08

25 - Torque [%] - 16-22

26 - Speed [rpm] - 16-17

27 - Analog Input, GPIO X30/11 - 16-75

28 - Analog Input, GPIO X30/12 - 16-76

29 - Analog Input, IO option X42/1 -20.000 to +20.000 18-20

30 - Analog Input, IO optionX42/3 -20.000 to +20.000 18-21

31 - Analog Input, IO optionX42/5 -20.000 to +20.000 18-22

32 - Analog Out X42/7 - 18-33

33 - Analog Out X42/9 - 18-34

34 - Analog Out X42/11 - 18-35

40 - ECB: Bypass Running Hours

45 - Feedback 1 [Unit] - 16-54

46 - Feedback 2 [Unit] - 16-55

47 - Feedback 3 [Unit] - 16-56

48 - Ext. 1 Feedback [Unit] - 21-18

49 - Ext. 2 Feedback [Unit] - 21-38

0-232/10

31-11

The default values are shown in bold on the following pages. Any point not listed on the following pages is reserved for future

use.

Some Metasys software uses an object number range from 0 to 255, other Metasys software uses the range 1 to 254. The latter

software will interpret object number 0 as 1, and 1 as 2, etc. To access the proper point with this Metasys software, add 1 to the

NPA number in the tables.

18 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 19

Appendix

3.1.2 Binary Inputs (BI)

NPA Unit Description Range FC Par. Number

0 15 Timers Status 0=OK, 1=Limit

1 14 Current Status 0=OK, 1=Limit

2 13 Voltage Status 0=OK, 1=Limit

3 12 Inverter Status 0=OK, 1 =Stall, Auto-start

4 11 Running Status 0=Not Running, 1=Running

5 10 Frequency Status 0=Out of Range, 1=In Range

6 9 Control Status 0=Local, 1= Bus

7 8 Reference Status 0=Not on Ref., 1=On Ref.

8 7 Warning Status 0=No Warning , 1= Warning

9 3 Tripped Status 0=No Trip , 1=Tripped

10 2 Drive Enabled Status 0=Not Enabled , 1=Enabled

11 1 Drive Ready Status 0=Not Ready, 1=Ready

12 0 Drive Controller Status 0=Not Ready, 1=Ready

16 31 Reserved

17 30 Reserved

18 29 Unused

19 28 Unused

20 27 Voltage Limit 0=OK, 1=Warning

21 26 Low Temperature 0=OK, 1=Warning

22 25 Current Limit 0=OK, 1=Warning

23 24 Mains Failure 0=OK, 1=Warning

24 23 24V Supply Low 0=OK, 1=Warning

25 22 Fieldbus Fault 0=OK, 1=Warning

26 21 Speed Limit 0=OK, 1=Warning

27 20 Brake IGBT 0=OK, 1=Warning

28 19 Brake Resistor 0=OK , 1=Warning

29 18 Brake Overload 0=OK, 1=Warning

30 17 10V low 0=OK, 1=Warning

31 16 Live Zero Error 0=OK, 1=Warning

32 15 No Motor 0=OK, 1=Warning

33 14 Mains Phase Loss 0=OK, 1=Warning

34 13 DC Voltage High 0=OK, 1=Warning

35 12 DC Voltage Low 0=OK, 1=Warning

36 11 DC Overvoltage 0=OK, 1=Warning

37 10 DC Undervoltage 0=OK, 1=Warning

38 9 Inverter Overload 0=OK, 1=Warning

39 8 Motor ETR Overload 0=OK, 1=Warning

40 7

41 6 Torque Limit 0=OK, 1=Warning

42 5 Over Current 0=OK, 1=Warning

43 4 Ctrl. Word Timeout 0=OK, 1=Warning

44 3 Ctrl. Card Temp. 0=OK, 1=Warning

45 2 Earth Fault 0=OK, 1=Warning

46 1 Pwr. Card Temp 0=OK,1=Warning

47 0 Brake Check 0=OK1=Warning

VLT® Metasys

Motor Thermal

Overload

0=OK, 1=Warning

Par. 16-03 Status Word

Par. 16-92 Warning Word

3

3

MG.11.G2.02 - VLT® is a registered Danfoss trademark 19

Page 20

3

Appendix

Binary Inputs (BI), continued..

NPA Unit Description Range FC Par. Number

48 31 Reserved

49 30 Reserved

50 29 Drive Initialized 0=OK, 1=Alarm

51 28 Option Change 0=OK, 1=Alarm

52 27 Brake IGBT 0=OK, 1=Alarm

53 26 Brake Resistor 0=OK, 1=Alarm

54 25 1.8V Supply Low 0=OK, 1=Alarm

55 24 Mains Failure 0=OK, 1=Alarm

56 23 24V Supply Low 0=OK, 1=Alarm

57 22 Fieldbus Fault 0=OK, 1=Alarm

58 21 W Phase Loss 0=OK, 1=Alarm

59 20 V Phase Loss 0=OK, 1=Alarm

60 19 U Phase Loss 0=OK, 1=Alarm

61 18 Brake Overload 0=OK, 1=Alarm

62 17 Internal Fault 0=OK, 1=Alarm

63 16 Live Zero Error 0=OK, 1=Alarm

64 15 AMA not ok 0=OK, 1=Alarm

65 14 Mains Phase Loss 0=OK, 1=Alarm

66 13 Inrush Fault 0=OK, 1=Alarm

67 12 Short Circuit 0=OK, 1=Alarm

68 11 DC Overvoltage 0=OK, 1=Alarm

69 10 DC Undervoltage 0=OK, 1=Alarm

70 9 Inverter Overload 0=OK, 1=Alarm

71 8 Motor ETR Overload 0=Trip, 1=Trip lock

72 7 Motor Thermal Overload 0=OK, 1=Alarm

73 6 Torque Limit 0=OK,1=Alarm

74 5 Over Current 0=OK,1=Alarm

75 4 Ctrl. Word Timeout 0=OK,1=Alarm

76 3 Ctrl. Card Temp 0=OK,1=Alarm

77 2 Earth Fault 0=OK,1=Alarm

78 1 Pwr. Card Temp 0=OK,1=Alarm

79 0 Brake check 0=OK,1=Alarm

80 31 0=FALSE, 1=TRUE

81 30 0=FALSE, 1=TRUE

82 29 0=FALSE, 1=TRUE

83 28 0=FALSE, 1=TRUE

84 27 0=FALSE, 1=TRUE

85 26 0=FALSE, 1=TRUE

86 25 0=FALSE, 1=TRUE

87 24 0=FALSE, 1=TRUE

88 23 0=FALSE, 1=TRUE

89 22 0=FALSE, 1=TRUE

90 21 0=FALSE, 1=TRUE

91 20 0=FALSE, 1=TRUE

92 19 0=FALSE, 1=TRUE

93 18 0=FALSE, 1=TRUE

94 17 0=FALSE, 1=TRUE

95 16 0=FALSE , 1=TRUE

96 15 OVC Active 0=FALSE , 1=TRUE

97 14 Out of Speed Reange 0=Auto mode, 1=Hand mode

VLT® Metasys

Par. 16-90 Alarm Word

Par. 16-94 Ext. Status Word

20 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 21

Appendix

Binary Inputs (BI), continued..

NPA Unit Description Selection FC Par. Number

98 13 Braking 0=FALSE, 1=TRUE

99 12 Braking Max 0=Remote ref., 1=Local ref.

100 11 Brake Check Ok 0=FALSE, 1=TRUE

101 10 Output Frequency Low 0=FALSE, 1=TRUE

102 9 Output Frequency High 0=FALSE, 1=TRUE

103 8 Output Current Low 0=FALSE, 1=TRUE

104 7 Output Current High 0=FALSE, 1=TRUE

105 6 Feedback Low 0=FALSE, 1=TRUE

106 5 Feedback High 0=FALSE, 1=TRUE

107 4 Catch Up 0=FALSE, 1=TRUE

108 3 Slow Down 0=FALSE, 1=TRUE

109 2 Start CW/CCW 0=FALSE, 1=TRUE

110 1 AMA Running 0=FALSE, 1=TRUE

111 0 Ramping 0=FALSE, 1=TRUE

112 9 Ramp 0=RAMP 1, 1=RAMP 2

113 15 Reverse 0=No function, 1=reverse

114 14 Setup MSB 0=FALSE, 1=TRUE

115 13 Setup LSB 0=FALSE, 1=TRUE

116 12 Relay02 0=Relay04 off, 1=Relay04 on

117 11 Relay01 0=Relay01 off, 1=Relay01 on

118 10 Res., always 0 (data valid) 0=FALSE

119 8 Jog 0=No Function, 1=Jog

120 7 Reset 0=No Function, 1=Reset

121 6 Start 0=start, 1=stop

122 5 Freeze Output 0=Freeze output, 1=Ramping

123 4 Q-stop 0=Q-stop, 1=Ramping

124 3 Coast 0=Coasting, 1=no Coast

125 2 DC Brake 0=DC Brake, 1=Ramp stop

126 1 Preset ref. MSB 0=FALSE, 1=TRUE

127 0 Preset ref. LSB 0=FALSE, 1=TRUE

128 0 Terminal 33 0=FALSE, 1=TRUE

129 1 Terminal 32 0=FALSE, 1=TRUE

130 2 Terminal 29 0=FALSE, 1=TRUE

131 3 Terminal 27 0=FALSE, 1=TRUE

132 4 Terminal 19 0=FALSE, 1=TRUE

133 5 Terminal 18 0=FALSE, 1=TRUE

134 6 GPIO Term X30/2 0=FALSE, 1=TRUE

135 7 GPIO Term X30/3 0=FALSE, 1=TRUE

136 8 GPIO Terminal X30/4 0=FALSE, 1=TRUE

VLT® Metasys

Par. 16-94 Ext. Status Word

Par. 16-00 Control Word

Par. 16-60 Digital Input

3

3

MG.11.G2.02 - VLT® is a registered Danfoss trademark 21

Page 22

3

Appendix

Binary Inputs (BI), continued..

NPA Unit Description

150 10

151 9 ECB External Interlock 0=FALSE, 1=TRUE

152 8 ECB M3 Contactor Fault 0=FALSE, 1=TRUE

153 7 ECB M2 Contactor Fault 0=FALSE, 1=TRUE

154 6 ECB Overload Trip 0=FALSE, 1=TRUE

155 5

156 4 ECB Reserved 0=FALSE, 1=TRUE

157 3 ECB Bypass Mode 0=FALSE, 1=TRUE

158 2

159 1 ECB Drive Mode 0=FALSE, 1=TRUE

160 0 ECB Test Mode 0=FALSE, 1=TRUE

187 31 - 0=FALSE, 1=TRUE

188 30 - 0=FALSE, 1=TRUE

189 29 - 0=FALSE, 1=TRUE

190 28 - 0=FALSE, 1=TRUE

191 27 - 0=FALSE, 1=TRUE

192 26 - 0=FALSE, 1=TRUE

193 25 Fire Mode 0=FALSE, 1=TRUE

194 24 Drive Bypass 0=FALSE, 1=TRUE

195 23 Running 0=FALSE, 1=TRUE

196 22 Sleep Boost 0=FALSE, 1=TRUE

197 21 Sleep 0=FALSE, 1=TRUE

198 20 Start Delay 0=FALSE, 1=TRUE

199 19 Start Applied 0=FALSE, 1=TRUE

200 18 Start 0=FALSE, 1=TRUE

201 17 Start Request 0=FALSE, 1=TRUE

202 16 Jog 0=FALSE, 1=TRUE

203 15 Jog Request 0=FALSE, 1=TRUE

204 14 Freeze Output 0=FALSE, 1=TRUE

205 13 Freeze Output Request 0=FALSE, 1=TRUE

206 12 Standby 0=FALSE, 1=TRUE

207 11 Stop 0=FALSE, 1=TRUE

208 10 DC Brake 0=FALSE, 1=TRUE

209 9 Quick Stop 0=FALSE, 1=TRUE

210 8 Drive Ready 0=FALSE, 1=TRUE

211 7 Control Ready 0=FALSE, 1=TRUE

212 6 Start Prevented 0=FALSE, 1=TRUE

213 5 Relay 123 Active 0=FALSE, 1=TRUE

214 4 Profibus OFF3 Active 0=FALSE, 1=TRUE

215 3 Profibus OFF2 Active 0=FALSE, 1=TRUE

216 2 Profibus OFF1 Active 0=FALSE, 1=TRUE

217 1 Auto/Hand 0=AUTO, 1=TRUE

218 0 OFF 0=AUTO, 1=TRUE

VLT® Metasys

ECB Manual Bypass

ECB Motor Running from

Bypass/Drive

ECB Automatic Bypass

Override

Mode

Selection

0=FALSE, 1=TRUE

0=FALSE, 1=TRUE

0=FALSE, 1=TRUE

1)

FC Par. Number

Par. 31-10 Bypass Status

Word

Par. 16-95 Ext. Status Word

2

1)

The values in bold are the default values

22 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 23

Appendix

3.1.3 Analog Outputs (AO)

NPA Unit Description Range FC Par. Number

0 %

1 Bus Feedback 1 8-94

2 Bus Feedback 2 8-95

3 Bus Feedback 3 8-96

4 Analog Output 42 6-53

5 Pulse Output 27 5-93

6 Pulse Output 29 5-95

7

8

9

10

VLT® Metasys

Bus reference

Analog Output, GPIOTer-

minal X30/8

Analog Output, IO Option

Analog Output, IO Option

Analog Output, IO Option

X42/7

X42/9

X42/11

1

-200 to 200 Proportionally

mapped into the range

-32768 to 32767

Shared Variable

6-63

26-53

26-63

26-73

3

3

MG.11.G2.02 - VLT® is a registered Danfoss trademark 23

Page 24

Appendix

3.1.4 Binary Outputs (BO)

VLT® Metasys

3

NPA Unit Description

0 2 DC Brake Inverse 0=Active, 1=Not Active

1 3 Coast Inverse 0=Active, 1=Not Active

2 4 Stop Inverse 0=Active, 1=Not Active

3 5 Freeze Output Inverse 0=Active, 1=Not Active

4 6 Start 0=Not active, 1=Active

5 7 Stop 0=Not active, 1=Active

6 8 Jog 0=Not active, 1=Active

8 11 Relay01 0=Not active, 1=Active

9 12 Relay02 0=Not active, 1=Active

10 15 Reversing 0=Not active, 1=Active

11 13 Setup LSB 0=Not active, 1=Active

12 14 Setup MSB 0=Not active, 1=Active

13 0 Preset ref. LSB 0=Not active, 1=Active

14 1 Preset ref. MSB 0=Not active, 1=Active

20 0 Output Terminal 27 0=Not active, 1=Active

21 1 Output Terminal 29 0=Not active, 1=Active

22 2 Output Terminal X30/6 0=Not active, 1=Active

23 3 Output Terminal X30/7 0=Not active, 1=Active

24 4 CC Relay 1 0=Not active, 1=Active

25 5 CC Relay 2 0=Not active, 1=Active

26 6 Option B Relay 1 0=Not active, 1=Active

27 7 Option B Relay 2 0=Not active, 1=Active

28 8 Option B Relay 3 0=Not active, 1=Active

29 9 Reserved 0=Not active, 1=Active

30 10 Reserved 0=Not active, 1=Active

31 11 Reserved 0=Not active, 1=Active

32 12 Reserved 0=Not active, 1=Active

33 13 Reserved 0=Not active, 1=Active

34 14 Reserved 0=Not active, 1=Active

35 15 Reserved 0=Not active, 1=Active

36 16 Option C Relay 1 0=Not active, 1=Active

37 17 Option C Relay 2 0=Not active, 1=Active

38 18 Option C Relay 3 0=Not active, 1=Active

39 19 Option C Relay 4 0=Not active, 1=Active

40 20 Option C Relay 5 0=Not active, 1=Active

41 21 Option C Relay 6 0=Not active, 1=Active

42 22 Option C Relay 7 0=Not active, 1=Active

43 23 Option C Relay 8 0=Not active, 1=Active

44 24 Reserved 0=Not active, 1=Active

45 25 Reserved 0=Not active, 1=Active

46 26 Reserved 0=Not active, 1=Active

47 27 Reserved 0=Not active, 1=Active

48 28 Reserved 0=Not active, 1=Active

49 29 Reserved 0=Not active, 1=Active

50 30 Reserved 0=Not active, 1=Active

52 ECB Activate 31-19

60 No Flow Detection 0=Not active, 1=Active 22-21

61

Enable Interval

between starts

0=Disable, 1=Enable 22-75

Range

1)

FC Par. Number

Par. 16-00 Control Word

Par. 5-90 Digital & Relay Bus

Control

1)

The values in BOLD are the default values.

24 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 25

Appendix

VLT® Metasys

3.1.5 Internal Floating Point (ADF)

NPA Unit Description Range FC Par. Number

0 - Max value of custom readout 0-32

1 - Min value of custom readout 0-31

13 A

14 RPM Motor nom. Speed 1-25

16 % Resonance damping 1-64

18 Sec Start delay 1-71

19 % Preheat DC-current 2-00

20 % DC brake current 2-01

21 Sec DC braking time 2-02

22 Hz DC brake cut-in frequency 2-03

29 - Max output Frequency 4-19

34 Sec Ramp Up Time 3-41

35 Sec Ramp Down Time 3-42

36 Hz Jog Frequency 3-11

37 % Digital Reference 1 3-10:0

38 % Digital Reference 2 3-10:1

39 % Digital Reference 3 3-10:2

40 % Digital Reference 4 3-10:3

41 A Current Limit 4-18

42 Hz Frequency 1. Bypass start 4-61:0

43 Hz Frequency 1. Bypass stop 4-63:0

44 Hz Frequency 2. Bypass start 4-61:1

45 Hz Frequency 2. Bypass stop 4-63:1

46 Hz Frequency 3. Bypass start 4-61:2

47 A Frequency 3. Bypass stop 4-63:2

48 A Frequency 4. Bypass start 4-61:3

49 Hz Frequency 4. Bypass stop 4-63:3

50 A

51 A

52 Hz

53 Hz

54 Unit

55 Unit

56 Unit

57 Unit

60 V Terminal 53 min scale V 6-10

61 V Terminal 53 max scale V 6-11

62 V Terminal 53 min scale mA 6-12

63 V Terminal 53 max scale mA 6-13

64 A Terminal 54 min. scale V 6-20

65 V Terminal 54 max. scale V 6-21

66 V Terminal 54 min. scale mA 6-22

67 A Terminal 54 max. scale mA 6-23

68 Hz Terminal 42 output puls scale 5-62

69 Hz Terminal 45 output puls scale 5-65

70 mSec CC Relay 1 ON Delay 5-41:0

71 mSec CC Relay 1 ON Delay 5-42:0

72 mSec CC Relay 1 ON Delay 5-41:1

73 Sec CC Relay 1 ON Delay 5-42:1

Motor Current(I

Warning Current Low(I

Warning Current High (I

Warning Freq. Low(F

Warning Freq. High(F

Warning Low Ref.(Ref

Warning High Ref.(Ref

Warning Low FB.(FB

Warning High FB.(FB

M.N

)

LOW

HIGH

LOW

HIGH

LOW

HIGH

LOW

HIGH

)

)

)

)

)

)

)

)

1-24

4-50

4-51

4-52

4-53

4-54

4-55

4-56

4-57

3

3

MG.11.G2.02 - VLT® is a registered Danfoss trademark 25

Page 26

3

Appendix

VLT® Metasys

Internal Floating Point (ADF), continued..

NPA Unit Description Range FC Par. Number

80 Sec No Flow Timer 0-600 22-24

81 Sec Dry Pump Timer 0-600 22-27

82 Sec Minimum Run Time 0-600 22-40

83 Hz Minimum Sleep Time 0-600 22-41

84 % Boost setpoint -100% - +100% 22-45

85 Hz Wake-up Speed Par. 4-12 to 4-14 22-43

86 Sec Max Boost Time 0-600 22-46

87 kHz Switch Frequency 14-01

88 Unit Set point 1 20-21

89 Unit Set point 2 20-22

90 Hz PID Start Frequency 20-83

91 - PID Proportional Gain 20-93

92 Sec PID Integration Time 20-94

93 Sec PID Differentiation Time 20-95

94 - PID D-gain Limit 20-96

95 Unit Set Point 3 20-23

100 - Control Timeout Function 8-04

101 - Control Timeout Time 8-03

110 Sec Option B Relay 1 ON Delay 0.01 to 600.00 5-41:6

111 Sec Option B Relay 1 OFF Delay 0.01 to 600.00 5-42:6

112 Sec Option B Relay 2 ON Delay 0.01 to 600.00 5-41:7

113 Sec Option B Relay 2 OFF Delay 0.01 to 600.00 5-42:7

114 Sec Option B Relay 3 ON Delay 0.01 to 600.00 5-41:8

115 Sec Option B Relay 3 OFF Delay 0.01 to 600.00

120 V Analogue Input, GPIO option X30/11, Low Voltage 6-30

121 V Analogue Input, GPIO option X30/11, High Voltage 6-31

122 V Analogue Input, GPIO option X30/12 Low Voltage 6-40

123 V Analogue Input, GPIO option X30/12, High Voltage 6-41

124 V Analogue Input, IO X42/1, Low Voltage 0.07 to 10.00 26-10

125 V Analogue Input, IO option X42/1, High Voltage 0.07 to 10.00 26-11

126 V Analogue Input, IO option X42/3, Low Voltage 0.07 to 10.00 26-20

127 V Analogue Input, IO option, X42/3, High Voltage 0.07 to 10.00 26-21

128 V Analogue Input, IO option X42/5, Low Voltage 0.07 to 10.00 26-30

129 V Analogue Input, IO option X42/5, High Voltage 0.07 to 10.00 26-31

130 % Analogue Output 42 Timeout Preset 6-54

131 % Analogue Output, GPIO option X30/8, Timeout Preset 6-64

132 % Analogue Output, IO option X42/7, Timeout Preset 0.00 to 100.00 26-54

133 % Analogue Output, IO option X42/9, Timeout Preset 0.00 to 100.00 26-64

134 % Analogue Output, IO option X42/11, Timeout Preset 0.00 to 100.00 26-74

140 Ext. 1 Setpoint 21-15

141 Ext. 1 Proportinal Gain 21-21

142 Ext. 1 Integral Gain 21-22

143 Ext. 1 Differentation Time 21-23

144 Ext. 2 Setpoint 21-35

145 Ext. 2 Proportinal Gain 21-41

146 Ext. 2 Integral Time 21-42

147 Ext. 2 Differentation Time 21-43

26 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 27

Appendix

VLT® Metasys

3.1.6 Internal Integers (ADI)

NPA Unit Description Range FC Par. Number

0 - Language Selection 0-01

1 - Setup Copy Function 0-51

2 - Custom Readout Unit 0-30

3 - Large Readout 0-23

4 - Small Readout 1 0-20

5 - Small Readout 2 0-21

6 - Small Readout 3 0-22

7 - Unit of Local Reference 0-05

8 - Hand Start Button 0-40

9 - Off/Stop Button 0-41

10 - Auto Start Button 0-42

11 - Reset Button 0-43

13 - Operating State at Power Up 0-04

21 - Torque Characteristics 1-03

23 - Motor Preheat 2-00

24 - Motor Thermal Protection 1-90

31 - Reference Site 3-13

32 - Over Volt Control 2-17

33 - Reference Function 3-04

40 - Digital Input 18 5-10

41 - Digital Input 19 5-11

42 - Digital Input 27 5-12

43 - Digital Input 29 5-13

44 - Digital Input 32 5-14

45 - Digital Input 33 5-15

51 Sec Live Zero Time Out 6-00

52 - Live Zero Function 6-01

53 - Signal Output 42 6-50

55 - CC Relay 1 Function 0 to 255 5-40:0

56 - CC Relay 2 Function 0 to 255 5-40:1

57 - Option B Relay 1 Function 0 to 255 5-40:6

58 - Option B Relay 2 Function 0 to 255 5-40:7

59 - Option B Relay 3 Function 0 to 255 5-40:8

60 - Reset Function 14-20

61 - Flying Start 1-73

62 - Noise Reduction Method 14-04

63 - Broken Belt Function 22-60

3

3

MG.11.G2.02 - VLT® is a registered Danfoss trademark 27

Page 28

3

Appendix

VLT® Metasys

Internal Integers (ADI), continued..

NPA Unit Description Range FC Par. Number

64 Sec Trip Delay on Overload 14-25

68 - PID Normal/Inverse 20-81

69 - PID Anti Windup 20-91

70 - Feedback 1 Conversion 20-01

71 - Feedback 1 Source Unit 20-02

72 - Feedback 2 Conversion 20-04

73 - Feedback 2 Source Unit 20-05

75 - Two Feedback Calculation 20-20

80 - Coasting 8-50

81 - DC Brake 8-52

82 - Start 8-53

83 - Reversing 8-54

84 - Selection of Setup 8-55

85 - Selection of Speed 8-56

90 - Reset kWh Counter 15-06

91 - Reset Running Hours Counter 15-07

92 - Operation Mode 14-22

101 -

102 -

103 -

104 -

105 -

106 -

107 -

110 - ECB Bypass Mode 0 - 4 31-00

111 - ECB Bypass Start Timer Delay 0 - 60 31-01

112 - ECB Bypass Trip Bypass Delay 0 - 300 31-02

120 - Dry Pump Function 0 - 2 22-26

121 - Broken Belt Action 0 - 2 22-60

122 % Broken Belt Torque 0 - 100% 22-61

123 sec Broken Belt Timer 0 - 600 22-62

124 sec Interval Between Starts Par. 22-76 - 36-00 22-76

125 sec Minimum Run Time Par. 22-77 - 36-00 22-77

254 - Active Setup 0-10

Analogue Input, IO option X42/1

Mode

Analogue Input, IO option X42/3

Mode

Analogue Input, IO option X42/5

Mode

Analogue Input, GPIO option X30/8

Mode

Analogue Input, IO option X42/7

mode

Analogue Input, IO option X42/9

Mode

Analogue Input, IO option X42/11

Mode

0 - 3 26-00

0 - 3 26-01

0 - 3 26-02

0 -145 26-50

0 -145 26-60

0 -145 26-70

6-60

28 MG.11.G2.02 - VLT® is a registered Danfoss trademark

Page 29

Index

VLT® Metasys

Index

A

Abbreviations And Definitions 3

Analog Input Commands (acknowledged) 6

Analog Input Commands (not Acknowledged) 7

Analog Inputs (ai) 18

Analog Output Commands (acknowledged) 8

Analog Output Commands (not Acknowledged) 9

Analog Outputs (ao) 23

B

Binary Input (bi) Commands (acknowledged) 10

Binary Input (bi) Commands (not Acknowledged) 10

Binary Inputs (bi) 19

Binary Output (bo) Commands (not Acknowledged) 12

Binary Output Commands (acknowledged) 11

Binary Outputs (bo) 24

C

Change Of State (cos)/polling

V

VLT Parameters 4

16

E

Error Codes

G

General Commands (acknowledged)

H

Handling Of Poll Message Commands

Hardware Set-up 3

I

Internal Floating Point (adf)

Internal Floating Point Commands (acknowledged) 13

Internal Integers (adi) 27

Internal Integers (adi) Commands (acknowledged) 12

N

Network Connection

O

Override/override Release Commands And Time Out

R

Reference/feedback Values

References 2

4

5

16

25

3

16

15

S

Scaling Of Bus Reference And Feedback

Software Version 2

Start-up Of The Frequency Converter 14

Status Update Request 15

T

Typical Settings

MG.11.G2.02 - VLT® is a registered Danfoss trademark 29

15

14

Loading...

Loading...