Page 1

Operating Guide

VLT® Soft Starter MCD 600

Page 2

Page 3

Operating Guide | VLT® Soft Starter MCD 600

Contents

Contents

1 Introduction 8

1.1 Product Description 8

1.2 Document Version 8

1.3 Additional Resources 8

1.4 Approvals and Certifications 8

2 Safety 9

2.1 Safety Symbols 9

2.2 Qualified Personnel 9

2.3 Safety Precautions 9

3 System Design 12

3.1 Feature List 12

3.2 Type Code 13

3.3 Selection of Soft Starter Size 14

3.4 Current Ratings (IEC Ratings) 14

3.5 Dimensions and Weight 16

3.6 Physical Installation/Cooling Clearances 17

3.7 Accessories 17

3.7.1 Expansion Cards 17

3.7.1.1 Smart Card 17

3.7.1.2 Communication Expansion Cards 18

3.7.2 Remote LCP 601 18

3.7.3 Finger Guard Kit 18

3.7.4 Soft Starter Management Software 18

3.8 Main Contactor 18

3.9 Circuit Breaker 19

3.10 Power Factor Correction 19

3.11 Short-circuit Protection Devices 20

3.11.1 Type 1 Coordination 20

3.11.2 Type 2 Coordination 20

3.12 IEC Coordination with Short-circuit Protection Devices 20

3.13 UL Coordination with Short-circuit Protection Devices 21

3.13.1 Standard Fault Short-circuit Current Ratings 21

3.13.2 High Fault Short-circuit Current Ratings 22

3.14 Fuse Selection for Type 2 Coordination 23

4 Specifications 25

4.1 Supply 25

4.2 Short-circuit Capability 25

AQ262141844215en-000202 / 175R1174 | 3Danfoss A/S © 2018.10

Page 4

Operating Guide | VLT® Soft Starter MCD 600

4.3 Electromagnetic Capability (Compliant with EU Directive 2014/35/EU) 25

4.4 Inputs 25

4.5 Outputs 25

4.6 Environmental 26

4.7 Heat Dissipation 26

4.8 Motor Overload Protection 26

4.9 Certification 26

4.10 Operational Life (Internal Bypass Contacts) 26

Contents

5 Installation 27

5.1 Safety Instructions 27

5.2 Command Source 27

5.3 Setting up the Soft Starter 28

5.4 Inputs 28

5.4.1 Input Terminals 29

5.4.2 Motor Thermistor 29

5.4.3 Start/Stop 29

5.4.4 Reset/Starter Disable 30

5.4.5 Programmable Inputs 30

5.4.6 USB Port 30

5.5 Outputs 31

5.5.1 Output Terminals 31

5.5.2 Analog Output 31

5.5.3 Main Contactor Output 31

5.5.4 Programmable Outputs 32

5.6 Control Voltage 32

5.6.1 Control Voltage Terminals 32

5.6.2 UL Compliant Installation 32

5.7 Power Terminations 33

5.7.1 Wiring Connectors 34

5.7.2 Motor Connection 34

5.7.2.1 In-line Installation 35

5.7.2.2 Inside Delta Installation 35

5.8 Typical Installation 36

5.9 Quick Set-up 37

6 Set-up Tools 39

6.1 Introduction 39

6.2 Setting Date and Time 39

6.3 Command Source 39

6.4 Commissioning 39

6.5 Run Simulation 39

AQ262141844215en-000202 / 175R11744 | Danfoss A/S © 2018.10

Page 5

Operating Guide | VLT® Soft Starter MCD 600

6.6 Load/Save Settings 40

6.7 USB Save & Load 41

6.7.1 Save and Load Procedure 42

6.7.2 File Locations and Formats 42

6.8 Auto-start/Stop 43

6.9 Network Address 43

6.9.1 Setting a Network Address 44

6.10 Digital I/O State 44

6.11 Analog I/O State 45

6.12 Serial Number & Rating 45

6.13 Software Versions 46

6.14 Thermistor Reset 46

6.15 Reset Thermal Model 46

Contents

7 Logs 47

7.1 Introduction 47

7.2 Event Log 47

7.3 Counters 47

7.3.1 Viewing the Counters 47

8 LCP and Feedback 48

8.1 Local LCP and Feedback 48

8.2 Remote LCP 48

8.3 Adjusting the Display Contrast 50

8.4 Soft Starter Status LEDs 50

8.5 Displays 51

8.5.1 Soft Starter Information 51

8.5.2 Configurable Feedback Screens 51

8.5.3 Operating Feedback Screens 52

8.5.4 Performance Graph 52

9 Operation 54

9.1 Start, Stop, and Reset Commands 54

9.2 Command Override 54

9.3 Auto-start/Stop 54

9.3.1 Clock Mode 54

9.3.2 Timer Mode 54

9.4 PowerThrough 55

9.5 Emergency Mode 55

9.6 Auxiliary Trip 56

9.7 Typical Control Methods 56

9.8 Soft Start Methods 57

9.8.1 Constant Current 57

AQ262141844215en-000202 / 175R1174 | 5Danfoss A/S © 2018.10

Page 6

Operating Guide | VLT® Soft Starter MCD 600

9.8.2 Constant Current with Current Ramp 58

9.8.3 Adaptive Control for Starting 59

9.8.3.1 Fine-tuning Adaptive Control 60

9.8.4 Constant Current with Kickstart 60

9.9 Stop Methods 61

9.9.1 Coast to Stop 61

9.9.2 Timed Voltage Ramp 61

9.9.3 Adaptive Control for Stopping 61

9.9.4 DC Brake 62

9.9.5 DC Brake with External Zero-speed Sensor 64

9.9.6 Soft Brake 64

9.10 Pump Clean 65

9.11 Reverse Direction Operation 66

9.12 Jog Operation 67

9.13 Inside Delta Operation 68

9.14 Secondary Motor Set 69

Contents

10 Programmable Parameters 70

10.1 Main Menu 70

10.2 Changing Parameter Values 70

10.3 Adjustment Lock 70

10.4 Parameter List 70

10.5 Parameter Group 1-** Motor Details 77

10.6 Parameter Group 2-** Motor Start/Stop 79

10.7 Parameter Group 3-** Motor Start/Stop-2 81

10.8 Parameter Group 4-** Auto-Start/Stop 85

10.9 Parameter Group 5-** Protection Levels 88

10.10 Parameter Group 6-** Protection Action 91

10.11 Parameter Group 7-** Inputs 96

10.12 Parameter Group 8-** Relay Outputs 100

10.13 Parameter Group 9-** Analog Output 102

10.14 Parameter Group 10-** Display 102

10.15 Parameter Group 11-** Pump Clean 106

10.16 Parameter Group 12-** Communication Card 106

10.17 Parameter Group 20-** Advanced 110

10.18 Parameter Group 30-** Pump Input Configuration 111

10.19 Parameter Group 31-** Flow Protection 113

10.20 Parameter Group 32-** Pressure Protection 114

10.21 Parameter Group 33-** Pressure Control 115

10.22 Parameter Group 34-** Depth Protection 116

10.23 Parameter Group 35-** Thermal Protection 116

10.24 Parameter Group 36-** Pump Trip Action 117

AQ262141844215en-000202 / 175R11746 | Danfoss A/S © 2018.10

Page 7

Operating Guide | VLT® Soft Starter MCD 600

Contents

11 Application Examples 121

11.1 Smart Card - Pump Control and Protection 121

11.2 Smart Card - Level-controlled Pump Activation 122

12 Troubleshooting 124

12.1 Protection Responses 124

12.2 Trip Messages 124

12.3 General Faults 138

13 Appendix 141

13.1 Symbols and Abbreviations 141

13.2 Conventions 141

AQ262141844215en-000202 / 175R1174 | 7Danfoss A/S © 2018.10

Page 8

Operating Guide | VLT® Soft Starter MCD 600

Introduction

1 Introduction

1.1 Product Description

The VLT® Soft Starter MCD 600 is an advanced digital soft start solution for 11–315 kW motors. The soft starters provide a complete

range of motor and system protection features and are designed for reliable performance in the most demanding installation

situations.

1.2 Document Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

Table 1: Document Version

Edition Remarks

AQ262141844215 Model range extended. Parameter numbering changed.

1.3 Additional Resources

Other resources are available to understand advanced soft starter functions and programming.

• Operating guides for operation with optional equipment.

• Installation guides for installing various accessories.

• WinStart Design Tool to help with selecting the right soft starter for an application.

Supplementary publications and manuals are available from www.danfoss.com/en/search/?filter=type%3Adocumentation.

1.4 Approvals and Certifications

8 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 9

Operating Guide | VLT® Soft Starter MCD 600

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

DANG ER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WA RN IN G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CA UT IO N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Safety

NO TI CE

Indicates a property damage message.

2.2 Qualified Personnel

Correct and reliable transport, storage, installation, operation, and maintenance are required for the trouble-free and safe operation of

the soft starter. Only qualified personnel are allowed to install or operate this equipment.

Qualified personnel are defined as trained staff, who are authorized to install, commission, and maintain equipment, systems, and

circuits in accordance with pertinent laws and regulations. Also, the qualifed personnel must be familiar with the instructions and

safety measures described in this manual.

2.3 Safety Precautions

Safety precautions cannot cover every potential cause of equipment damage, but can highlight common causes of damage. It is the

installer's responsibility to:

• Read and understand all instructions in this manual before installing, operating, or maintaining the equipment.

• Follow good electrical practice including applying appropriate personal protective equipment.

• Seek advice before operating this equipment in a manner other than described in this manual.

NO TI CE

The VLT® Soft Starter MCD 600 is not user serviceable. The unit should only be serviced by authorized service personnel.

Unauthorized tampering with the unit voids the product warranty.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 9

Page 10

Operating Guide | VLT® Soft Starter MCD 600

WA RN IN G

PROPER GROUNDING

It is the responsibility of the installer of the soft starter to provide proper grounding and branch circuit protection according to

local electrical safety codes. Not providing proper grounding and branch circuit protection may lead to death, personal injury,

or equipment damage.

Disconnect the soft starter from mains voltage before carrying out repair work.

-

WA RN IN G

UNINTENDED START

When the soft starter is connected to AC mains, DC supply, or load sharing, the motor can start at any time. Unintended start

during programming, service, or repair work can result in death, serious injury or property damage. The motor can start with an

external switch, a fieldbus command, an input reference signal from the LCP, or after a cleared fault condition.

Press [Off/Reset] on the LCP before programming parameters.

-

Disconnect the soft starter from the mains.

-

Completely wire and assemble the soft starter, motor, and any driven equipment before connecting the soft starter to AC

-

mains, DC supply, or load sharing.

Fit the power supply to the soft starter with an isolating switch and a circuit-breaking device (for example a power

-

contactor) controllable through an external safety system (for example an emergency stop or a fault detector).

Safety

CA UT IO N

POWER FACTOR CORRECTION

Connecting power factor correction capacitors to the output side will damage the soft starter.

Do not connect power factor correction capacitors to the output of the soft starter. If static power factor correction is

-

employed, it must be connected to the supply side of the soft starter.

CA UT IO N

SHORT CIRCUIT

The VLT® Soft Starter MCD 600 is not circuit proof.

After severe overload or short circuit, the operation of the MCD 600 should be fully tested by an authorized service agent.

-

CA UT IO N

MECHANICAL DAMAGE FROM UNEXPECTED RESTART

The motor could restart after the causes of a shutdown are rectified, which may be dangerous for certain machines or

installations.

Ensure that appropriate arrangements are made against restarting after unscheduled stops of the motor.

-

10 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 11

Operating Guide | VLT® Soft Starter MCD 600

WA RN IN G

SAFETY OF PERSONNEL

The soft starter is not a safety device and does not provide electrical isolation or disconnection from the supply.

If isolation is required, the soft starter must be installed with a main contactor.

-

Do not rely on the start and stop functions for safety of personnel. Faults occurring in the mains supply, the motor

-

connection, or the electronics of the soft starter can cause motor starts or stops.

If faults occur in the electronics of the soft starter, a stopped motor may start. A temporary fault in the mains supply or loss

-

of motor connection can also cause a stopped motor to start.

To provide safety of personnel and equipment, control the isolation device through an external safety system.

-

NO TI CE

Before changing any parameter settings, save the current parameter set to a file using MCD PC Software or the Save User

-

Set function.

Safety

NO TI CE

Use the Auto-start feature with caution. Read all the notes related to auto-start before operation.

-

Disclaimer

The examples and diagrams in this manual are included solely for illustrative purposes. The information contained in this manual is

subject to change at any time and without prior notice. Responsibility or liability is never accepted for direct, indirect, or consequential

damage resulting from the use or application of this equipment.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 11

Page 12

Operating Guide | VLT® Soft Starter MCD 600

3 System Design

3.1 Feature List

Streamlined set-up process

• Configuration profiles for common applications.

• Built-in metering and inputs/outputs.

Easy-to-understand interface

• Multi-language menus and displays.

• Descriptive option names and feedback messages.

• Real-time performance graphs.

Supports energy efficiency

• IE3 compatible.

• 99% energy efficient when running.

• Internal bypass.

• Soft start technology avoids harmonic distortion.

System Design

Extensive range of models

• 20–579 A (nominal).

• 200–525 V AC.

• 380–690 V AC.

• Inside delta installation.

Extensive input and output options

• Remote control inputs (2 x fixed, 2 x programmable).

• Relay outputs (1 x fixed, 2 x programmable).

• Analog output.

Versatile starting and stopping options

• Scheduled start/stop.

• Adaptive control.

• Constant current.

• Current ramp.

• Pump clean.

• Timed voltage ramp soft stop.

• Coast to stop.

• DC brake.

• Soft brake.

• Reverse direction.

12 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 13

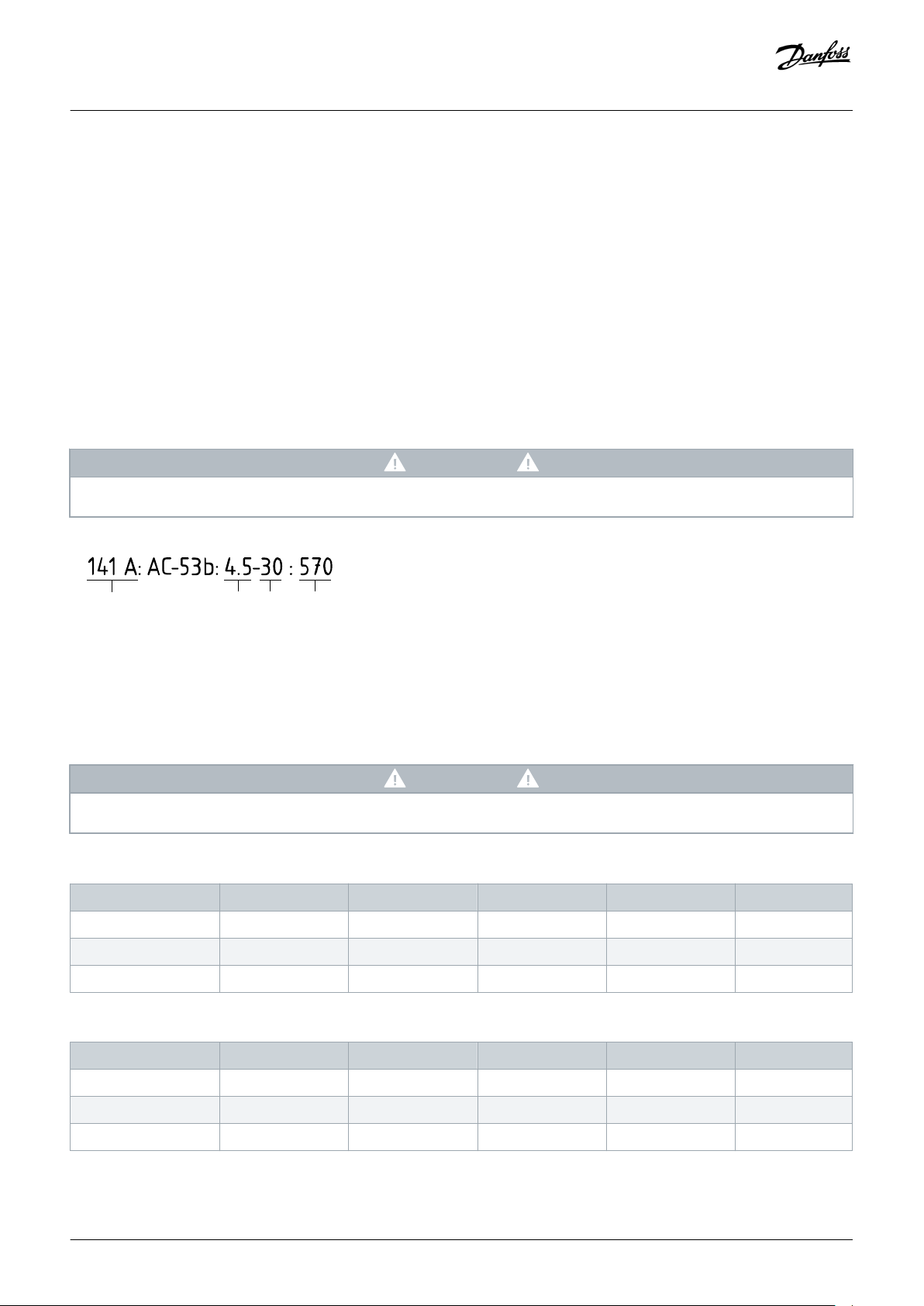

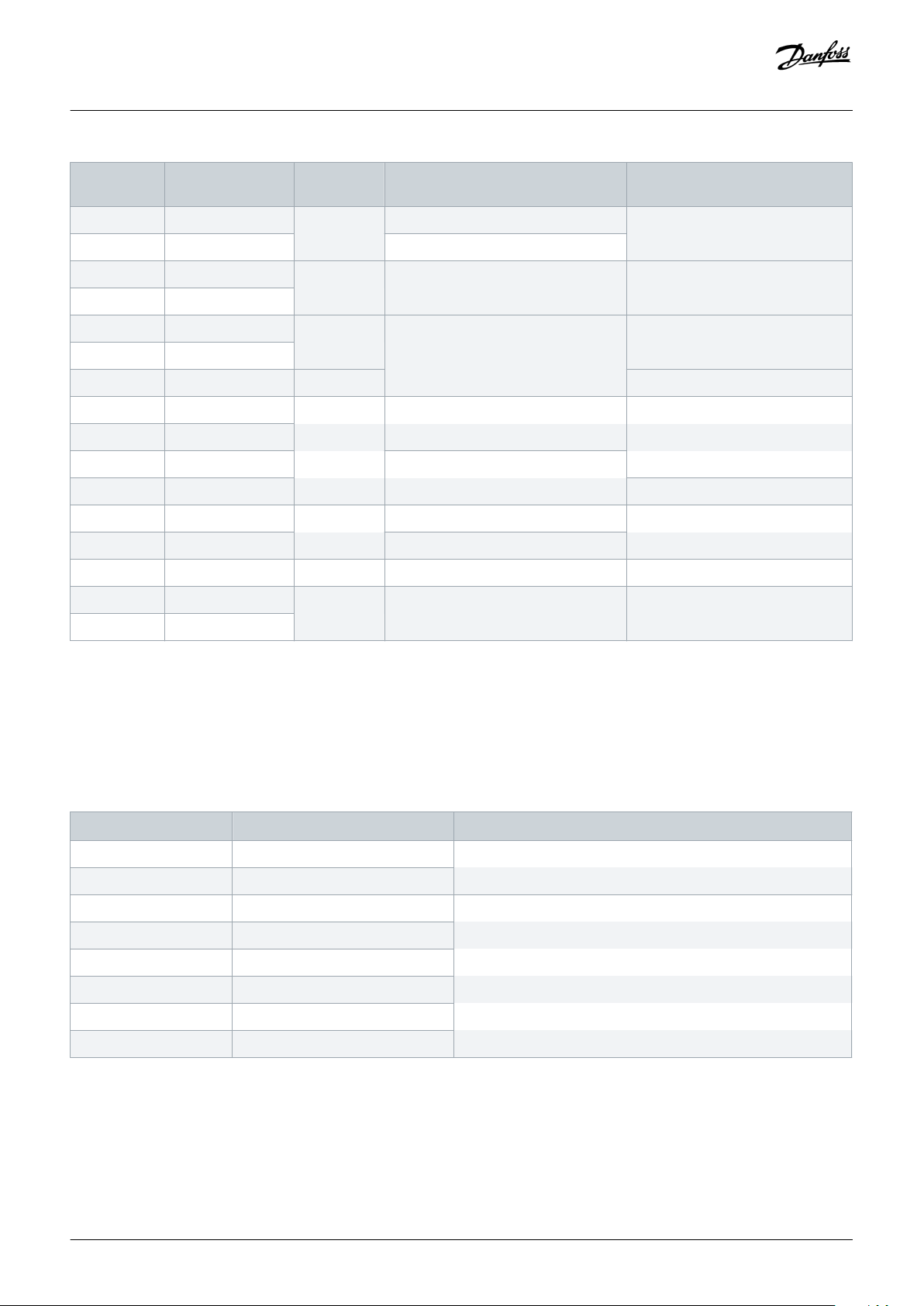

0 014

B T 5

Control voltage

CV1 = 24 V AC/V DC

CV2 = 110~120 V AC or

220~240 V AC

Protection

00 = IP00 (open frame)

20 = IP20 (enclosed)

Frame size

S1X = Frame size 1

S2X = Frame size 2

Mains voltage

T5 = 200~525 V AC

T7 = 380~690 V AC

Bypass

B = Internally bypassed

Nominal current rating

e77ha788.10

MCD6-

––

– –

Operating Guide | VLT® Soft Starter MCD 600

Customizable protection

• Motor overload.

• Excess start time.

• Undercurrent/overcurrent.

• Underpower/overpower.

• Current imbalance.

• Input trip.

• Motor thermistor.

Optional features for advanced applications

• Smart cards.

• Communication options:

- DeviceNet.

- EtherNet/IP.

- Modbus RTU.

- Modbus TCP.

- PROFIBUS.

- PROFINET.

System Design

3.2 Type Code

Illustration 1: Type Code String

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 13

Page 14

e77ha281.12

Starter current rating

Start current (multiple of FLC)

Start time (seconds)

Off time (seconds)

Operating Guide | VLT® Soft Starter MCD 600

System Design

3.3 Selection of Soft Starter Size

The size of the soft starter must match the motor and the application.

Select a soft starter that has a current rating at least equal to the motor's full load current rating (see motor nameplate) at the start

duty.

The soft starter's current rating determines the maximum motor size it can be used with. The soft starter's rating depends on the

number of starts per hour, the length and current level of the start, and the amount of time the soft starter is off (not passing current)

between starts.

The soft starter's current rating is only valid when used in the conditions specified in the AC53b code. The soft starter may have a

higher or lower current rating in different operating conditions.

3.4 Current Ratings (IEC Ratings)

NO TI CE

Contact the local supplier for ratings under operating conditions not covered by these rating charts.

Illustration 2: AC53b Format

NO TI CE

All ratings are calculated at an altitude of 1000 m (3280 ft) and an ambient temperature of 40 °C (104 °F).

Table 2: In-line Installation, MCD6-0020B ~ MCD6-0042B

3.0-10:350 3.5-15:345 4.0-10:350 4.0-20:340 5.0-5:355

MCD6-0020B 24 20 19 16 17

MCD6-0034B 42 34 34 27 32

MCD6-0042B 52 42 39 35 34

Table 3: In-line Installation, MCD6-0063B ~ MCD6-0579B

3.0-10:590 3.5-15:585 4.0-10:590 4.0-20:580 5.0-5:595

MCD6-0063B 64 63 60 51 54

MCD6-0069B 69 69 69 62 65

MCD6-0086B 105 86 84 69 77

14 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 15

Operating Guide | VLT® Soft Starter MCD 600

3.0-10:590 3.5-15:585 4.0-10:590 4.0-20:580 5.0-5:595

MCD6-0108B 115 108 105 86 95

MCD6-0129B 135 129 126 103 115

MCD6-0144B 184 144 139 116 127

MCD6-0171B 200 171 165 138 150

MCD6-0194B 229 194 187 157 170

MCD6-0244B 250 244 230 200 202

MCD6-0287B 352 287 277 234 258

MCD6-0323B 397 323 311 263 289

MCD6-0410B 410 410 410 380 400

MCD6-0527B 550 527 506 427 464

MCD6-0579B 580 579 555 470 508

Table 4: Inside Delta Installation

System Design

3.0-10:350 3.5-15:345 4.0-10:350 4.0-20:340 5.0-5:355

MCD6-0020B 36 30 28 24 25

MCD6-0034B 63 51 51 40 48

MCD6-0042B 78 63 58 52 51

3.0-10:590 3.5-15:585 4.0-10:590 4.0-20:580 5.0-5:595

MCD6-0063B 96 94 90 76 81

MCD6-0069B 103 103 103 93 97

MCD6-0086B 157 129 126 103 115

MCD6-0108B 172 162 157 129 142

MCD6-0129B 202 193 189 154 172

MCD6-0144B 276 216 208 174 190

MCD6-0171B 300 256 247 207 225

MCD6-0194B 343 291 280 235 255

MCD6-0244B 375 366 345 300 303

MCD6-0287B 528 430 415 351 387

MCD6-0323B 595 484 466 394 433

MCD6-0410B 615 615 615 570 600

MCD6-0527B 825 790 759 640 696

MCD6-0579B 870 868 832 705 762

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 15

Page 16

4/T2

READY RUN

TRIP

LOCAL

Exit

Reset

Menu

Store

2/T1

6/T3

1/L1

3/L2

5/L3

READY RUN TRIP LOCAL

Exit

Reset

Menu

Store

VLT

®

Soft Starter

VLT

®

Soft Starter

A

B

C D

E

A

B

C

D

E

e77ha713.10

Operating Guide | VLT® Soft Starter MCD 600

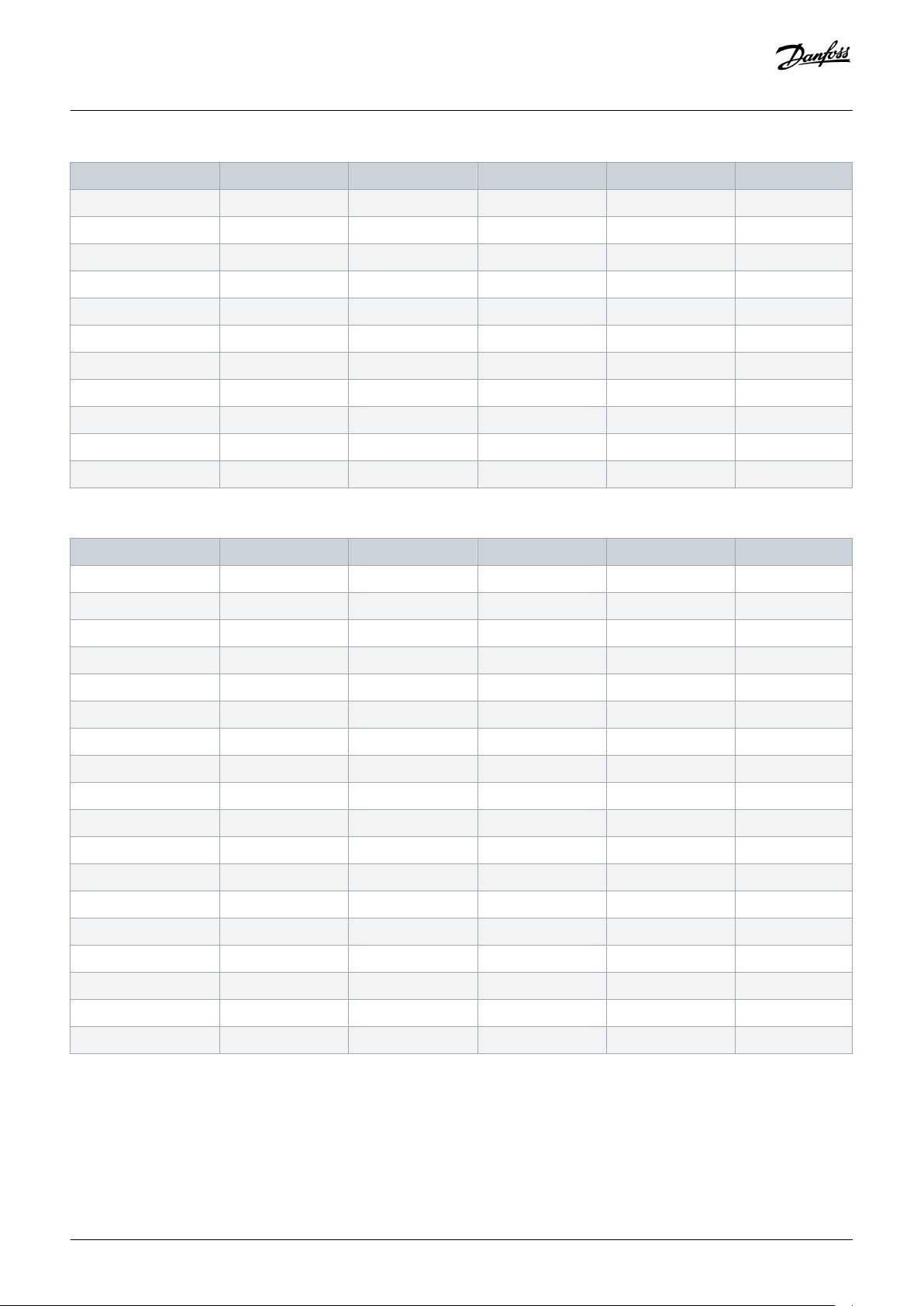

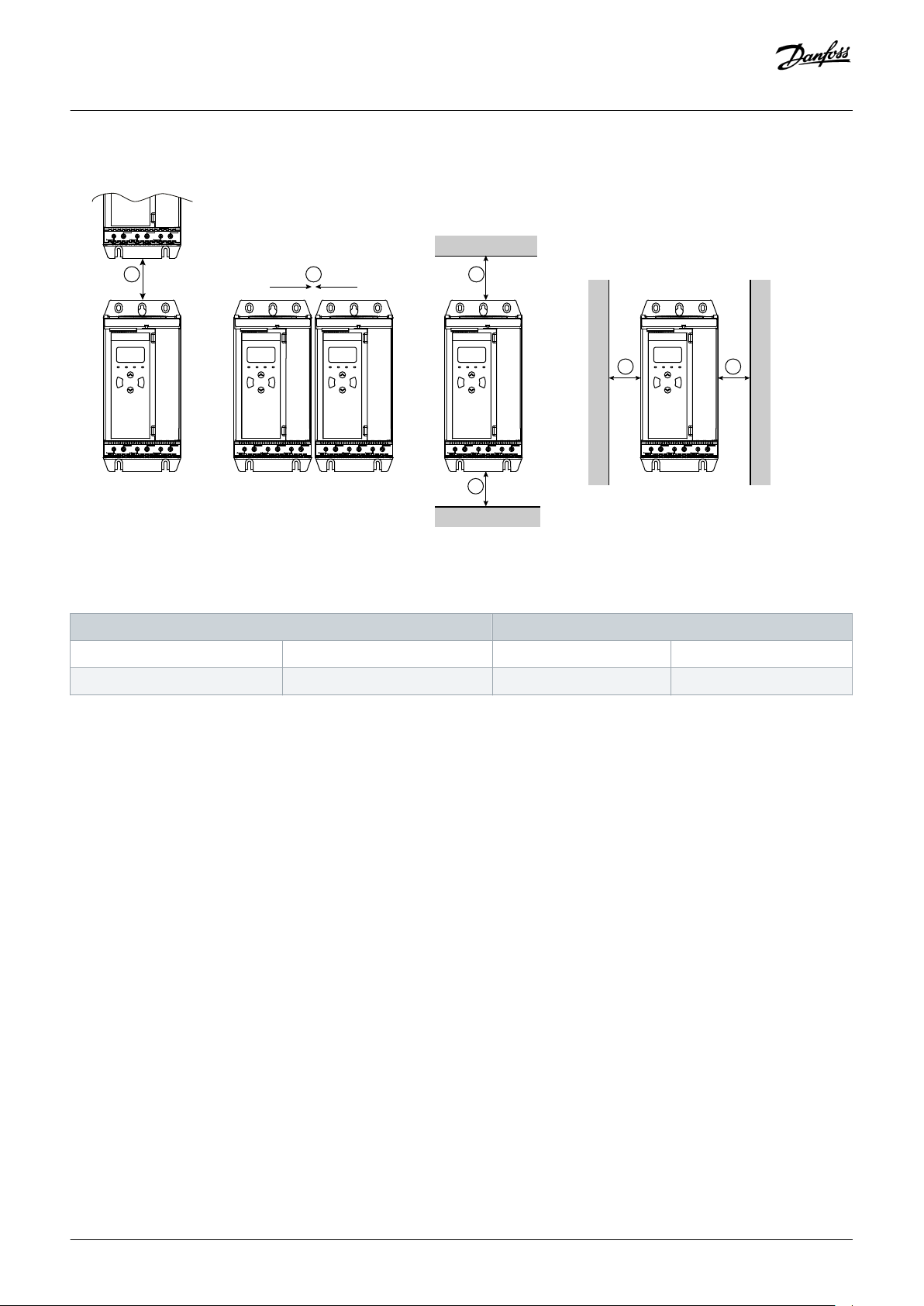

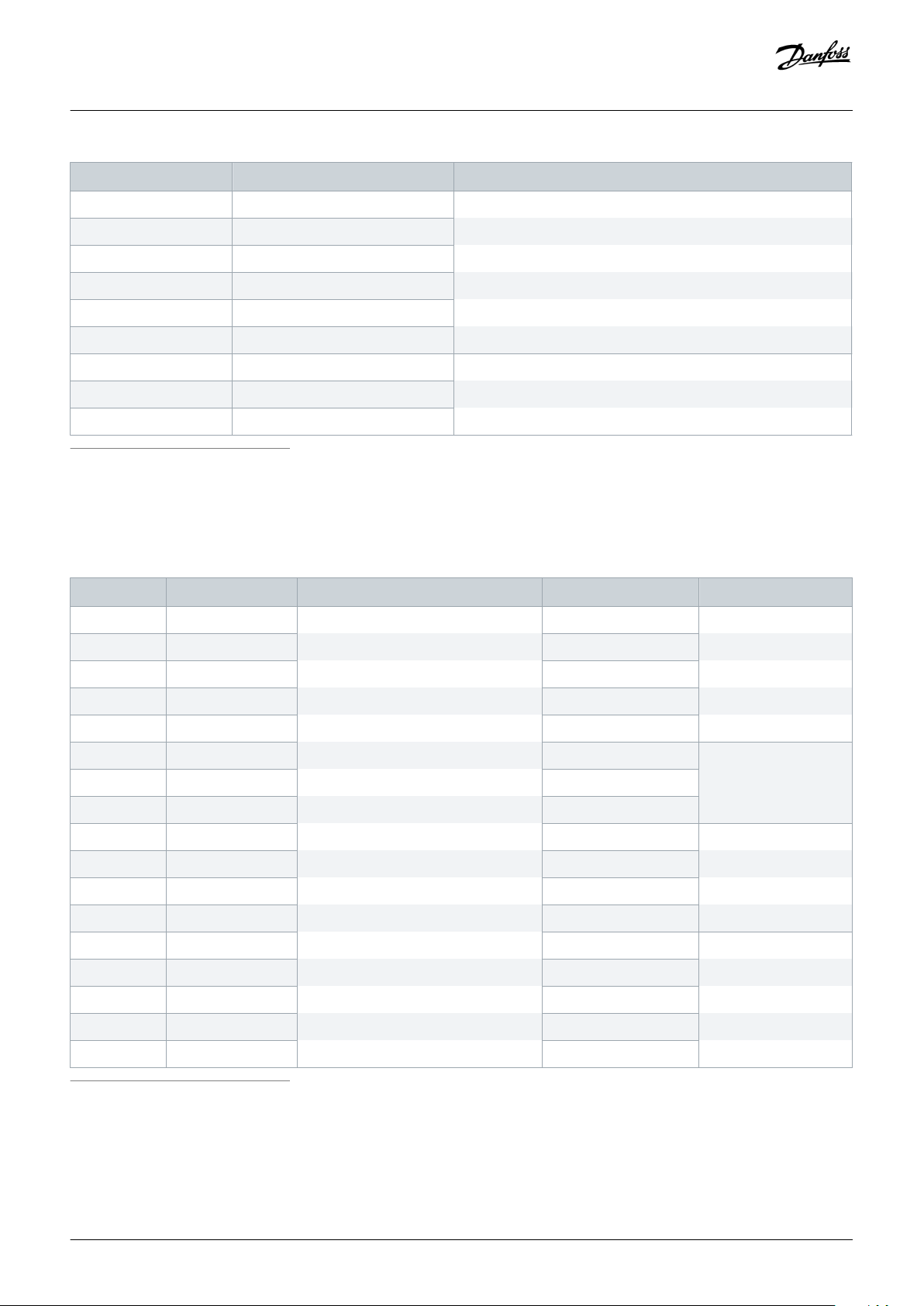

3.5 Dimensions and Weight

System Design

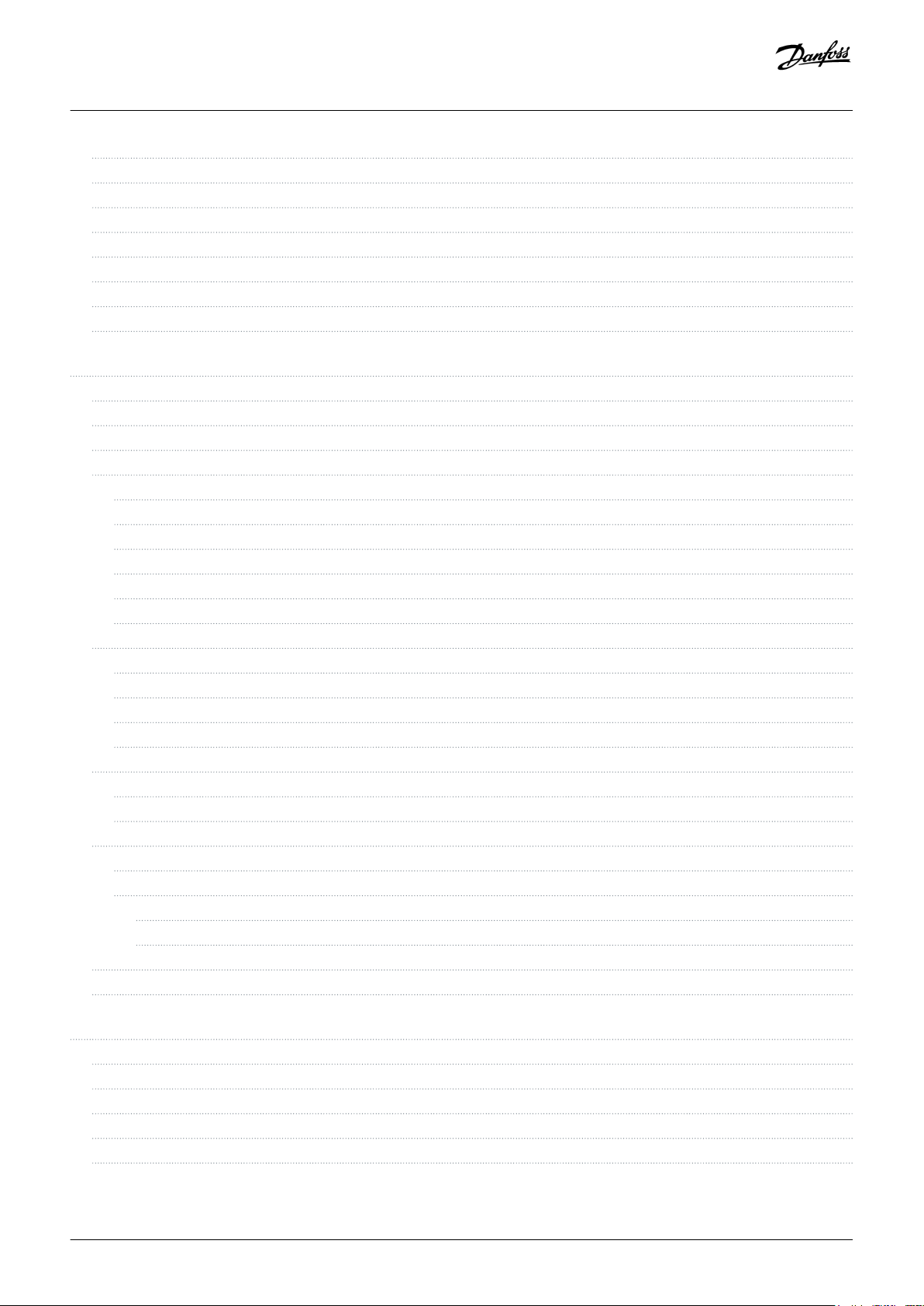

Illustration 3: Dimensions, Frame Sizes S1 (Left) and S2 (Right)

Table 5: Dimensions and Weight

Width [mm (in)] Height [mm (in)] Depth [mm (in)] Weight [kg (lb)]

A B C D E

MCD6-0020B 152 (6.0) 92 (3.6) 336 (13.2) 307 (12.1) 231 (9.1) 4.8 (10.7)

MCD6-0034B

MCD6-0042B

MCD6-0063B 4.9 (10.9)

MCD6-0069B

MCD6-0086B 5.5 (12.1)

MCD6-0108B

MCD6-0129B

MCD6-0144B 216 (8.5) 180 (7.1) 495 (19.5) 450 (17.7) 243 (9.6) 12.7 (28)

MCD6-0171B

MCD6-0194B

MCD6-0244B 15.5 (34.2)

MCD6-0287B 523 (20.6)

MCD6-0323B

MCD6-0410B

MCD6-0527B 19 (41.9)

MCD6-0579B

16 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 17

4/T2

2/T1

6/T3

1/L1

3/L2

5/L3

4/T2

READY

RUN

TRIP

LOCAL

Exit

Reset

Menu

Store

2/T1

6/T3

1/L1

3/L2

5/L3

VLT

®

Soft Starter

4/T2

READY

RUN

TRIP

LOCAL

Exit

Reset

Menu

Store

2/T1 6/T3

1/L1 3/L2 5/L3

VLT

®

Soft Starter

4/T2

READY RUN TRIP

LOCAL

Exit

Reset

Menu

Store

2/T1 6/T3

1/L1

3/L2

5/L3

VLT

®

Soft Starter

4/T2

READY RUN TRIP LOCAL

Exit

Reset

Menu

Store

2/T1 6/T3

1/L1 3/L2 5/L3

VLT

®

Soft Starter

4/T2

READY RUN TRIP LOCAL

Exit

Reset

Menu

Store

2/T1 6/T3

1/L1 3/L2 5/L3

VLT

®

Soft Starter

177HA714.10

A

B

C

D D

C

Operating Guide | VLT® Soft Starter MCD 600

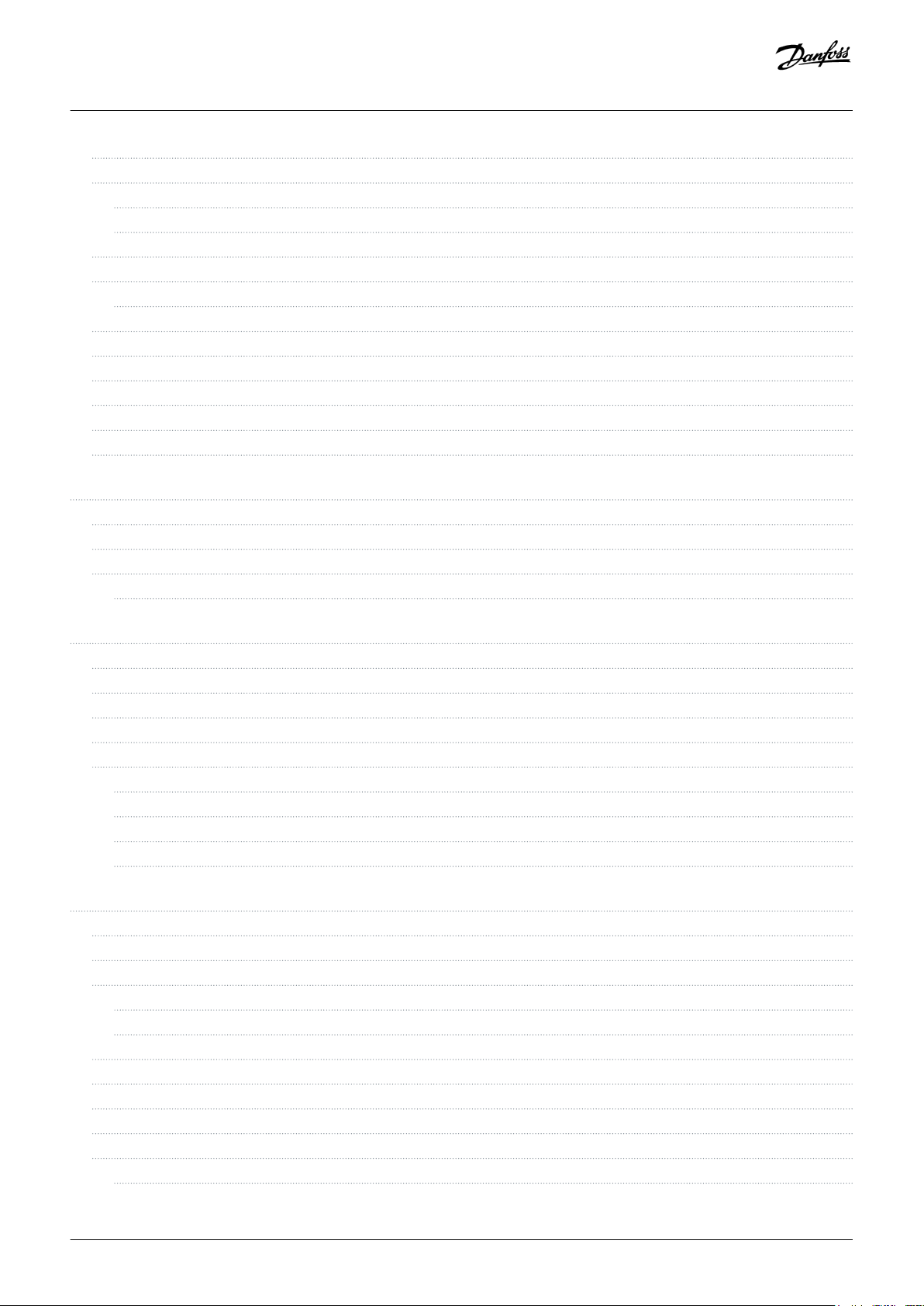

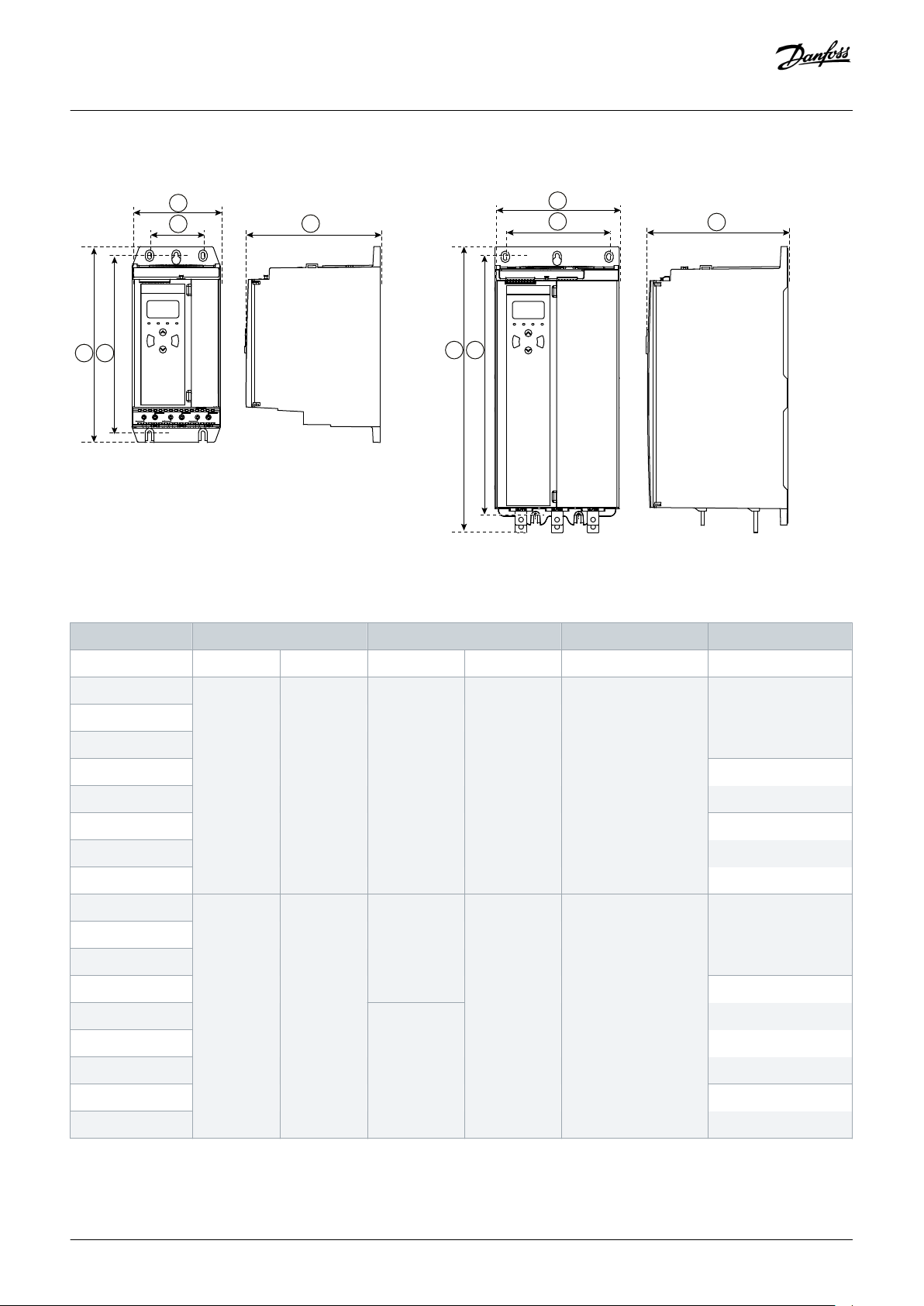

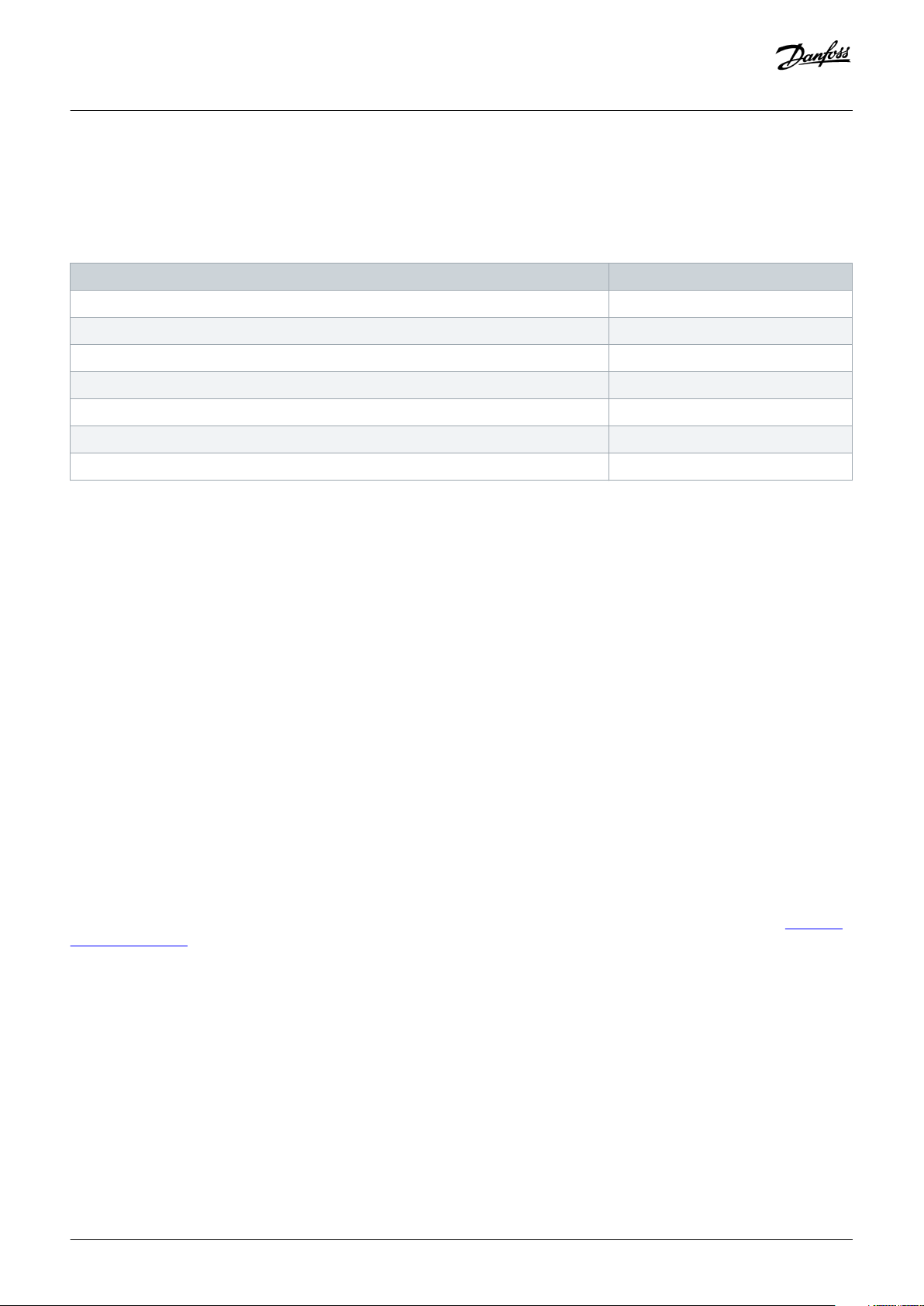

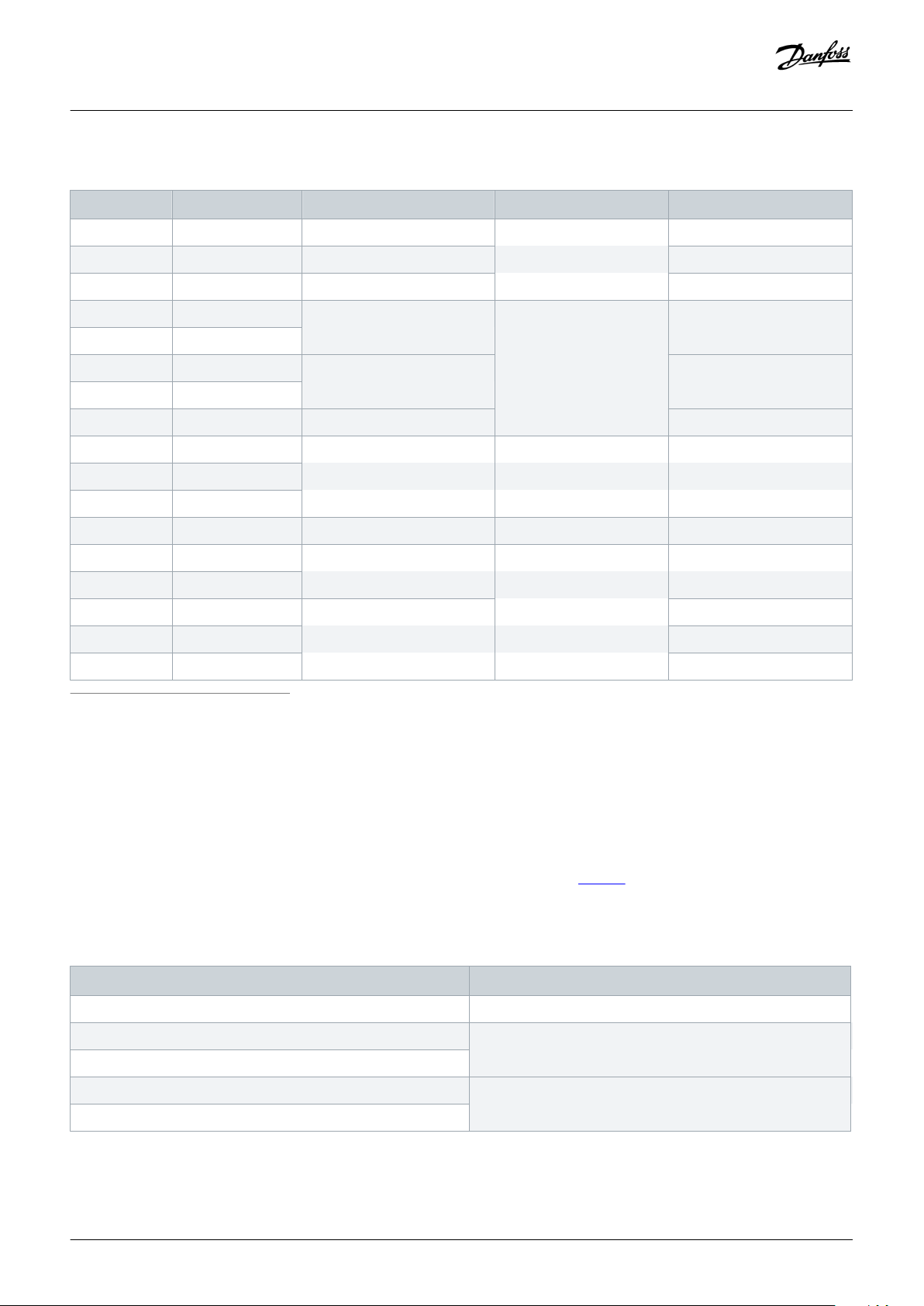

3.6 Physical Installation/Cooling Clearances

System Design

Illustration 4: Clearances

Table 6: Cooling Clearances

Clearance between soft starters Clearance to solid surfaces

A [mm (in)] B [mm (in)] C [mm (in)] D [mm (in)]

>100 (3.9) >10 (0.4) >100 (3.9) >10 (0.4)

3.7 Accessories

3.7.1 Expansion Cards

The VLT® Soft Starter MCD 600 offers expansion cards for users requiring additional inputs and outputs or advanced functionality. Each

MCD 600 can support a maximum of 1 expansion card.

3.7.1.1 Smart Card

The smart card has been designed to support integration with pumping applications and provides the following additional inputs and

outputs:

• 3 x digital inputs.

• 3 x 4–20 mA transducer inputs.

• 1 x RTD input.

• 1 x USB-B port.

• Remote LCP connector.

Ordering number: 175G0133

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 17

Page 18

Operating Guide | VLT® Soft Starter MCD 600

System Design

3.7.1.2 Communication Expansion Cards

The VLT® Soft Starter MCD 600 supports network communication via easy-to-install communication expansion cards. Each

communication card includes a remote LCP 601 connector port.

Table 7: Fieldbus Expansion Cards with Ordering Numbers

Option Card Ordering Number

VLT® Soft Starter MCD 600 Modbus RTU 175G0127

VLT® Soft Starter MCD 600 PROFIBUS 175G0128

VLT® Soft Starter MCD 600 DeviceNet 175G0129

VLT® Soft Starter MCD 600 Modbus TCP 175G0130

VLT® Soft Starter MCD 600 EtherNet/IP 175G0131

VLT® Soft Starter MCD 600 PROFINET 175G0132

VLT® Soft Starter MCD 600 Pump Application 175G0133

3.7.2 Remote LCP 601

The VLT® Soft Starter MCD 600 soft starters can be used with a remote LCP mounted up to 3 m (9.8 ft) away from the soft starter. Each

expansion card includes an LCP connection port, or a dedicated LCP connector card is available.

Ordering number for the Remote LCP 601 expansion card: 175G0134.

3.7.3 Finger Guard Kit

Finger guards may be specified for personal safety. Finger guards fit over the soft starter terminals to prevent accidental contact with

live terminals. Finger guards provide IP20 protection when used with cable of diameter 22 mm or greater.

Finger guards are compatible with models MCD6-0144B ~ MCD6-0579B.

Ordering number for the finger guard kit: 175G0186.

3.7.4 Soft Starter Management Software

The VLT® Soft Starter MCD 600 has an installed USB flash interface. The USB flash must be formatted to FAT32 format. To format the

flash, follow the instructions on a PC when connecting a standard flash stick (minimum 4 MB) to a USB port. VLT® Motion Control Tool

MCT 10 transfers the set-up files to the USB flash stick. To load the set-up files to the soft starter, use the LCP as described in 6.7.1 Save

and Load Procedure.

The VLT® Motion Control Tool MCT 10 can help manage the soft starter. Contact the local supplier for more information.

Documentation for the VLT® Motion Control Tool MCT 10 can be downloaded from www.danfoss.com/en/search/?filter=type

%3Adocumentation.

3.8 Main Contactor

A main contactor is recommended to protect the soft starter from voltage disturbances on the network while stopped. Select a

contactor with an AC3 rating greater than or equal to the FLC rating of the connected motor.

18 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 19

K1

K1

1

2

4

3

e77ha794.10

Operating Guide | VLT® Soft Starter MCD 600

Use the main contactor output (13, 14) to control the contactor.

For wiring of the main contactor, see illustration 12 in 5.8 Typical Installation.

System Design

WA RN IN G

SHOCK HAZARD

When the soft starter is wired in inside delta configuration, it results in a portion of the motor windings being connected to line

power at all times (even when the soft starter is switched off). This situation may cause death or serious personal injury.

Always install a main contactor or shunt trip circuit breaker when connecting the soft starter in inside delta configuration.

-

3.9 Circuit Breaker

A shunt trip circuit breaker may be used instead of a main contactor to isolate the motor circuit if a soft starter trips. The shunt trip

mechanism must be powered from the supply side of the circuit breaker or from a separate control supply.

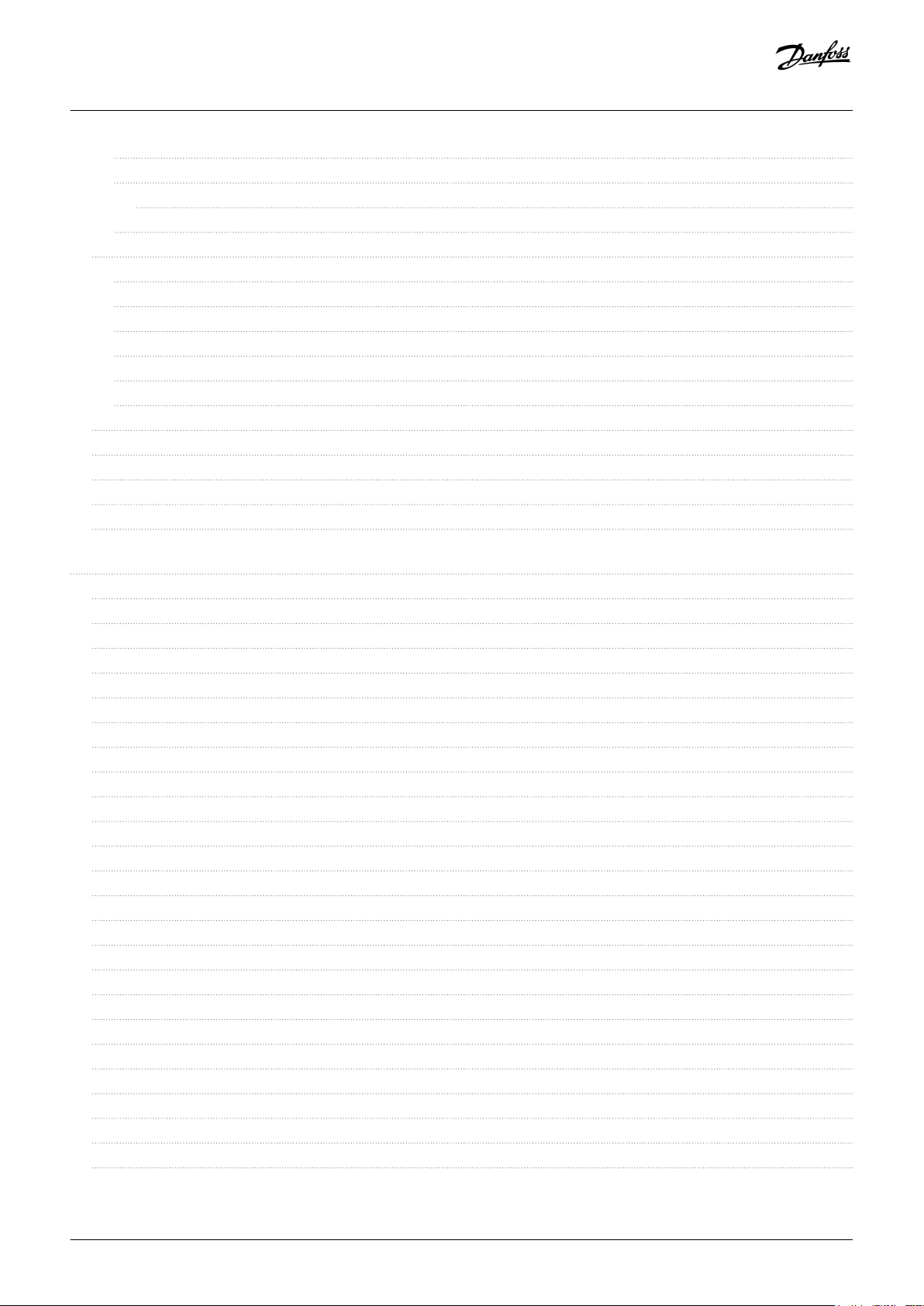

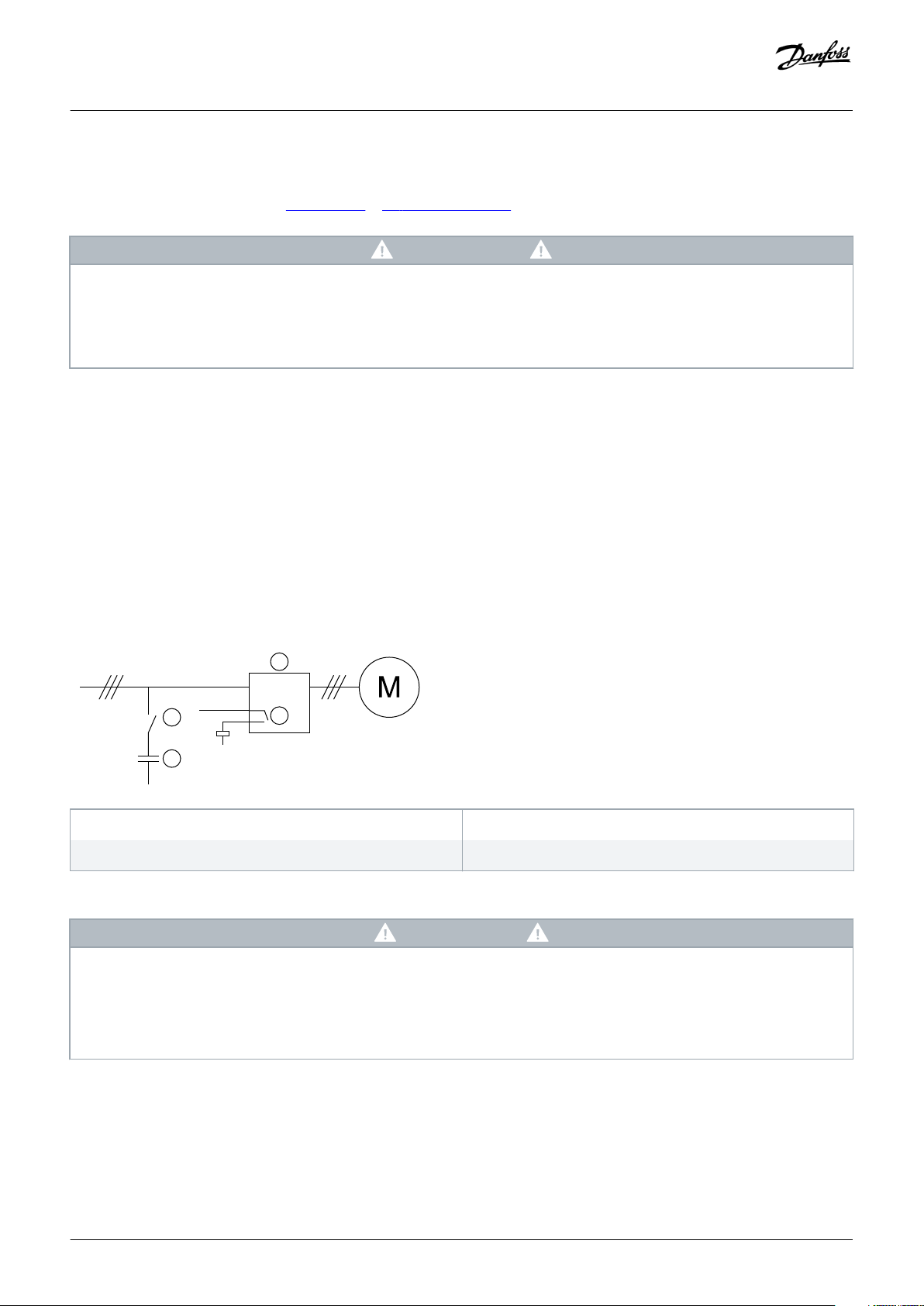

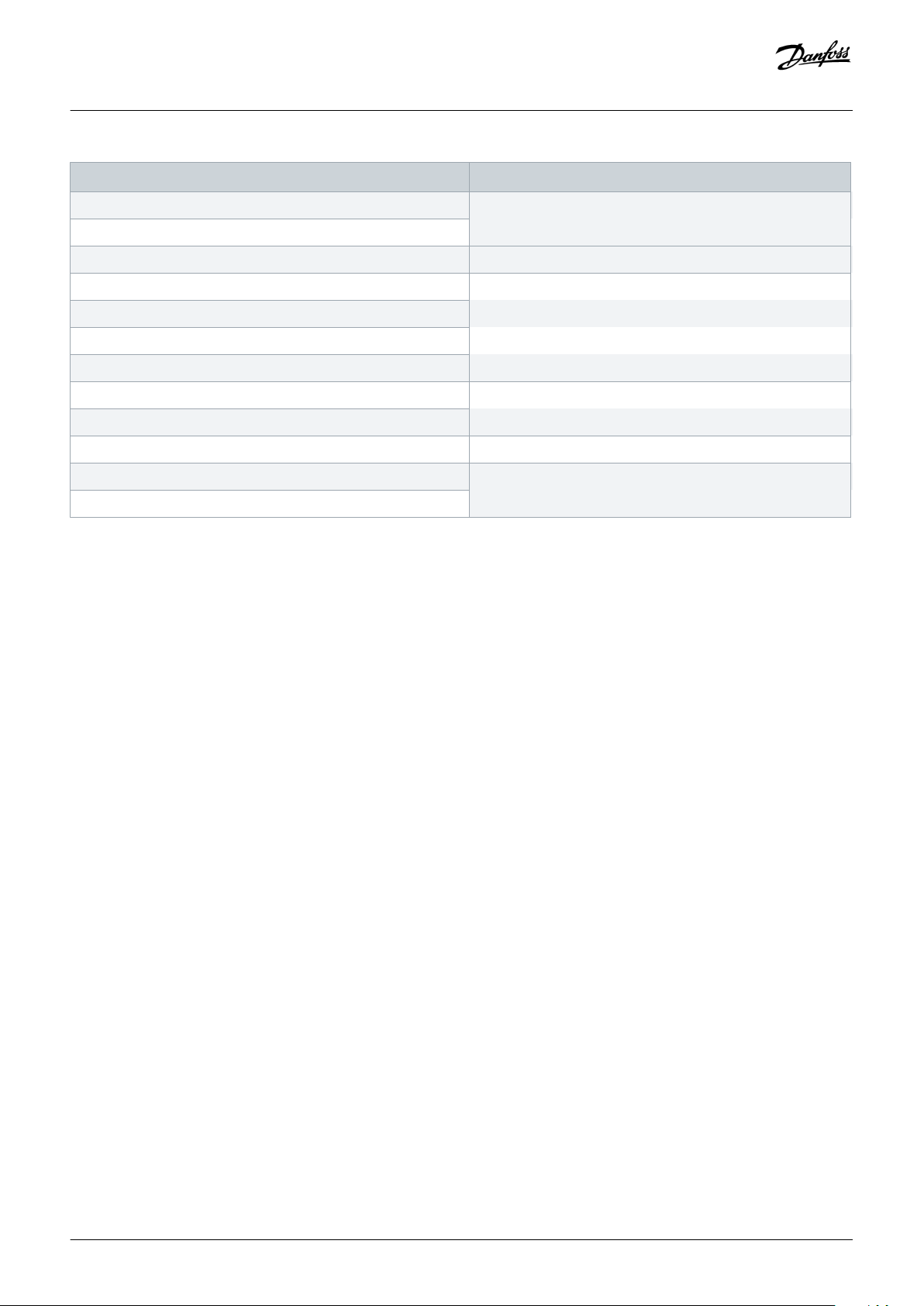

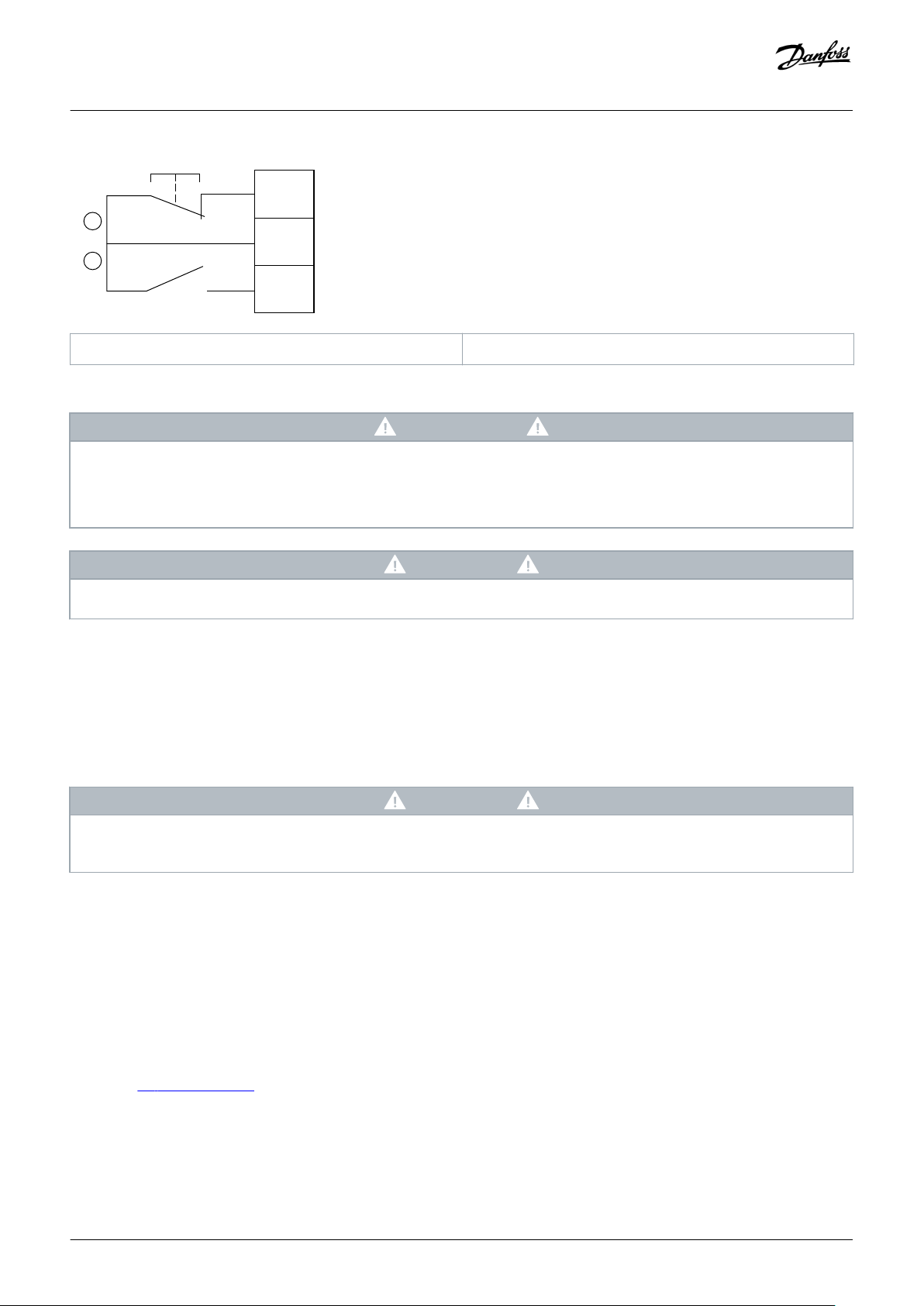

3.10 Power Factor Correction

If power factor correction is used, use a dedicated contactor to switch in the capacitors.

To use the VLT® Soft Starter MCD 600 to control power factor correction, connect the PFC contactor to a programmable relay set to

Run. When the motor reaches full speed, the relay closes and power factor correction is switched in.

1 Soft starter

3 Power factor correction contactor

Illustration 5: Connection Diagram

2 Programmable output (set=Run)

4 Power factor correction

CA UT IO N

EQUIPMENT DAMAGE

Connecting power factor correction capacitors to the output side damages the soft starter.

Always connect power factor correction capacitors to the input side of the soft starter.

-

Do not use the soft starter relay output to switch in power factor correction directly.

-

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 19

Page 20

Operating Guide | VLT® Soft Starter MCD 600

System Design

3.11 Short-circuit Protection Devices

When designing motor circuit protection schemes, the IEC 60947-4-1 standard on soft starters and contactors defines 2 types of

coordination regarding soft starters:

• Type 1 coordination.

• Type 2 coordination.

3.11.1 Type 1 Coordination

Type 1 coordination requires that, if there is a short circuit on the output side of a soft starter, the fault must be cleared without risk of

injury to personnel and damage to installations. There is no requirement that the soft starter must remain operational after the fault.

For the soft starter to become operational again, repair and replacement of parts are required.

HRC fuses (such as Ferraz/Mersen AJT fuses) can be used for Type 1 coordination according to the IEC 60947-4-2 standard.

3.11.2 Type 2 Coordination

Type 2 coordination requires that, if there is a short circuit on the output side of a soft starter, the fault must be cleared without risk of

injury to personnel or damage to the soft starter.

Type 2 coordination has the advantage that, after the fault is cleared, authorized personnel can replace the blown fuses and check

contactors for any welding. The soft starter is then operational again.

Semiconductor fuses for Type 2 circuit protection are extra to HRC fuses or MCCBs that form part of the motor branch circuit

protection.

CA UT IO N

DC BRAKE

A high brake torque setting can result in peak currents up to motor DOL being drawn while the motor is stopping.

Ensure that protection fuses installed in the motor branch circuit are selected appropriately.

-

CA UT IO N

NO BRANCH CIRCUIT PROTECTION

Integral solid-state short-circuit protection does not provide branch circuit protection.

Provide branch circuit protection in accordance with the National Electrical Code and any additional local codes.

-

3.12 IEC Coordination with Short-circuit Protection Devices

These fuses were selected based on a start current of 300% FLC for 10 s.

Table 8: IEC Fuses

Nominal rating [A]

MCD6-0020B 24 1150 40NHG000B 170M3010

20 | Danfoss A/S © 2018.10

SCR I2t (A2s)

Type 1 coordination 480 V AC, 65 kA

Bussmann NH fuse links

Type 2 coordination 690 V AC,

65 kA Bussmann DIN 43 653

AQ262141844215en-000202 / 175R1174

Page 21

Operating Guide | VLT® Soft Starter MCD 600

System Design

Nominal rating [A]

MCD6-0034B 42 7200 63NHG000B 170M3013

MCD6-0042B 52 80NHG000B

MCD6-0063B 64 15000 100NHG000B 170M3014

MCD6-0069B 69

MCD6-0086B 105 80000 160NHG00B 170M3015

MCD6-0108B 115

MCD6-0129B 135 125000 170M3016

MCD6-0144B 184 320000 250NHG2B 170M3020

MCD6-0171B 200

MCD6-0194B 229 315NHG2B

MCD6-0244B 250 170M3021

MCD6-0287B 352 202000 355NHG2B 170M6009

MCD6-0323B 397 400NHG2B

MCD6-0410B 410 320000 425NHG2B 170M6010

MCD6-0527B 550 781000 630NHG3B 170M6012

SCR I2t (A2s)

Type 1 coordination 480 V AC, 65 kA

Bussmann NH fuse links

Type 2 coordination 690 V AC,

65 kA Bussmann DIN 43 653

MCD6-0579B 579

3.13 UL Coordination with Short-circuit Protection Devices

3.13.1 Standard Fault Short-circuit Current Ratings

Suitable for use on a circuit capable of delivering not more than the stated level of amperes (symmetrical rms), 600 V AC maximum.

Table 9: Maximum Fuse Rating [A] - Standard Fault Short-Circuit Current

Model Nominal rating [A]

MCD6-0020B 24 5 kA

MCD6-0034B 42

MCD6-0042B 52 10 kA

MCD6-0063B 64

MCD6-0069B 69

MCD6-0086B 105

MCD6-0108B 120

MCD6-0129B 135

3 cycle short cct rating @600 V AC

(1)

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 21

Page 22

Operating Guide | VLT® Soft Starter MCD 600

System Design

Model Nominal rating [A]

3 cycle short cct rating @600 V AC

(1)

MCD6-0144B 184 18 kA

MCD6-0171B 225

MCD6-0194B 229

MCD6-0244B 250

MCD6-0287B 352

MCD6-0323B 397

MCD6-0410B 410 30 kA

MCD6-0527B 550

MCD6-0579B 580

1

Suitable for use in a circuit with the prospective current noted, when protected by any listed fuses or listed circuit breakers sized according to the NEC.

3.13.2 High Fault Short-circuit Current Ratings

Table 10: Maximum Fuse Rating [A] - High Fault Short-circuit Current

Model Nominal rating [A] Short cct rating @480 V AC maximum

Listed fuse rating [A]

(1)

Fuse class

MCD6-0020B 24 65 kA 30 Any (J, T, K-1, RK1, RK5)

(1)

MCD6-0034B 42 50

MCD6-0042B 52 60

MCD6-0063B 64 80

MCD6-0069B 69 80

MCD6-0086B 105 125 J, T, K-1, RK1

MCD6-0108B 115 125

MCD6-0129B 135 150

MCD6-0144B 184 200 J, T

MCD6-0171B 200 225

MCD6-0194B 229 250

MCD6-0244B 250 300

MCD6-0287 352 400 Any (J, T, K-1, RK1, RK5)

MCD6-0323B 397 450

MCD6-0410B 410 450

MCD6-0527B 550 600

MCD6-0579B 580 600

1

Suitable for use on a circuit capable of delivering not more than 65000 rms symmetrical amperes, 480 V AC maximum, when protected by fuses of the stated class and rating.

22 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 23

Operating Guide | VLT® Soft Starter MCD 600

Table 11: Circuit Breakers - High Fault Short-circuit Current

System Design

Model Nominal rating [A]

Breaker 1: Eaton (rating, A)

(1)

Breaker 2: GE (rating, A)

(1)

Breaker 3: LS (rating, A)

MCD6-0020B 24 HFD3030 (30 A) SELA36AT0060 (60 A) UTS150H-xxU-040 (40 A)

MCD6-0034B 42 HFD3050 (50 A) UTS150H-xxU-050 (50 A)

MCD6-0042B 52 HFD3060 (60 A) UTS150H-xxU-060 (60 A)

MCD6-0063B 64 HFD3100 (100 A) SELA36AT0150 (150 A) UTS150H-xxU-100 (100 A)

MCD6-0069B 69

MCD6-0086B 105 HFD3125 (125 A) UTS150H-xxU-125 (125 A)

MCD6-0108B 115

MCD6-0129B 135 HFD3150 (150 A) UTS150H-xxU-150 (150 A)

MCD6-0144B 184 HFD3250 (250 A) SELA36AT0250 (250 A) UTS150H-xxU-250 (250 A)

MCD6-0171B 200

MCD6-0194B 229

MCD6-0244B 250 HFD3300 (300 A) SELA36AT0400 (400 A) UTS150H-xxU-300 (300 A)

MCDF6-0287B 352 HFD3400 (400 A) SELA36AT0600 (600 A) UTS150H-xxU-400 (400 A)

MCD6-0323B 397

MCD6-0410B 410 HFD3600 (600 A) UTS150H-xxU-600 (600 A)

MCD6-0527B 550 UTS150H-xxU-800 (800 A)

(1) (2)

MCD6-0579B 580 UTS150H-NG0-800

1

Suitable for use on a circuit capable of delivering not more than 65000 rms symmetrical amperes, 480 V AC maximum, when protected by circuit breaker models listed in this table.

2

For LS circuit breakers, xx represents FM, FT, or AT.

3.14 Fuse Selection for Type 2 Coordination

Type 2 coordination is achieved by using semiconductor fuses. These fuses must be able to carry motor start current and have a total

clearing I2t less than the I2t of the soft starter SCRs.

When selecting semiconductor fuses for VLT® Soft Starter MCD 600, use the I2t values in table 12.

For further information on selecting semiconductor fuses, contact the local distributor.

Table 12: SCR Values for Semiconductor Fuses

Model

MCD6-0020B 1150

MCD6-0034B 7200

MCD6-0042B

MCD6-0063B 15000

SCR I2t [A2s]

MCD6-0069B

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 23

Page 24

Operating Guide | VLT® Soft Starter MCD 600

System Design

Model

MCD6-0086B 80000

MCD6-0108B

MCD6-0129B 125000

MCD6-0144B 320000

MCD6-0171B

MCD6-0194B

MCD6-0244B

MCD6-0287B 202000

MCD6-0323B

MCD6-0410B 320000

MCD6-0527B 781000

MCD6-0579B

SCR I2t [A2s]

24 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 25

Operating Guide | VLT® Soft Starter MCD 600

Specifications

4 Specifications

4.1 Supply

Mains voltage (L1, L2, L3)

MCD6-xxxxB-T5 200–525 V AC (±10%)

MCD6-xxxxB-T7 380–690 V AC (±10%)

Control voltage (A7, A8, A9)

MCD6-xxxxB-xx-CV2 (A8, A9) 110–120 V AC (+10%/-15%), 600 mA

MCD6-xxxxB-xx-CV2 (A7, A9) 220–240 V AC (+10%/-15%), 600 mA

MCD6-xxxxB-xx-CV1 (A8, A9) 24 V AC/V DC (±20%), 2.8 A

Mains frequency 50–60 Hz (±5 Hz)

Rated insulation voltage 690 V AC

Rated impulse withstand voltage 6 kV

Form designation Bypassed or continuous, semiconductor motor starter form 1

4.2 Short-circuit Capability

Coordination with semiconductor fuses Type 2

Coordination with HRC fuses Type 1

4.3 Electromagnetic Capability (Compliant with EU Directive 2014/35/EU)

EMC Immunity IEC 60947-4-2

EMC Emmissions IEC 60947-4-2 Class B

4.4 Inputs

Input rating Active 24 V DC, 8 mA approximately

Motor thermistor (TER-05, TER-06) Trip >3.6 kΩ, reset >1.6 kΩ

4.5 Outputs

Relay outputs 10 A @ 250 V AC resistive, 5 A @ 250 V AC AC15 pf 0.3

Main contactor (13, 14) Normally open

Relay output A (21, 22, 23) Changeover

Relay output B (33, 34) Normally open

Analog output (AO-07, AO-08)

Maximum load 600 Ω (12 V DC @ 20 mA)

Accuracy ±5%

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 25

Page 26

Operating Guide | VLT® Soft Starter MCD 600

Specifications

4.6 Environmental

Operating temperature -10 to +60 °C (14–140 °F), above 40 °C (104 °F) with derating

Storage temperature -25 to +60 °C (-13 to +140 °F)

Operating altitude 0–1000 m (0–3280 ft), above 1000 m (3280 ft) with derating

Humidity 5–95% relative humidity

Pollution degree Pollution degree 3

Vibration IEC 60068-2-6

Protection

MCD6-0020B~MCD6-0129B IP20

MCD6-0144B~MCD6-0579B IP00

4.7 Heat Dissipation

During start 4.5 W per ampere

During run

MCD6-0020B~MCD6-0042B ≤ 35 W approximately

MCD6-0063B~MCD6-0129B ≤ 50 W approximately

MCD6-0144B~MCD6-0244B ≤ 120 W approximately

MCD6-0287B~MCD6-0579B ≤ 140 W approximately

4.8 Motor Overload Protection

The default settings of parameters 1-4 to 1-6 provide motor overload

protection.

Class 10, trip current 105% of FLA (full load amperage) or

equivalent

4.9 Certification

CE EN 60947-4-2

UL/C-UL UL 508

Marine Lloyds Marine No 1 specification

ABS

DNV

4.10 Operational Life (Internal Bypass Contacts)

Expected operational lifetime 100000 operations

26 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 27

Operating Guide | VLT® Soft Starter MCD 600

Installation

5 Installation

5.1 Safety Instructions

See 2.3 Safety Precautions for general safety instructions.

WA RN IN G

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the equipment

turned off and locked out. Failure to run output motor cables separately or to use shielded cables could result in death or

serious injury.

Run output motor cables separately.

-

Use shielded cables.

-

WA RN IN G

UNINTENDED START

When the soft starter is connected to AC mains, DC supply, or load sharing, the motor can start at any time. Unintended start

during programming, service, or repair work can result in death, serious injury or property damage. The motor can start with an

external switch, a fieldbus command, an input reference signal from the LCP, or after a cleared fault condition.

Press [Off/Reset] on the LCP before programming parameters.

-

Disconnect the soft starter from the mains.

-

Completely wire and assemble the soft starter, motor, and any driven equipment before connecting the soft starter to AC

-

mains, DC supply, or load sharing.

Fit the power supply to the soft starter with an isolating switch and a circuit-breaking device (for example a power

-

contactor) controllable through an external safety system (for example an emergency stop or a fault detector).

5.2 Command Source

Start and stop the soft starter via the digital inputs, remote LCP 601, communication network, smart card, or scheduled auto-start/stop.

Set up the command source via Set-up Tools or via parameter 1-1 Command Source.

If the remote LCP is installed, the [CMD/Menu] key provides shortcut access to the Command Source function in Set-up Tools.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 27

Page 28

Operating Guide | VLT® Soft Starter MCD 600

5.3 Setting up the Soft Starter

Procedure

1. Mount the soft starter, see 3.6 Physical Installation/Cooling Clearances.

2. Connect control wiring, see 5.4.1 Input Terminals.

3. Apply control voltage to the soft starter.

4. Configure the application (listed in the Quick Set-up):

A Press [Menu].

B Press [Menu/Store] to open the Quick Set-up menu.

C Scroll through the list to find the application.

D Press [Menu/Store] to begin the configuration process, see

5. Configure the application (not listed in the Quick Set-up):

A Press [Back] to return to the Menu.

B Press [▿] to scroll to the Main Menu and press [Menu/Store].

C Scroll to Motor Details, press [Menu/Store] twice, and edit parameter 1-2 Motor Full Load Current.

D Set parameter 1-2 Motor Full Load Current to match the motor full load current (FLC).

E Press [Menu/Store] to save the setting.

6. Press [Back] repeatedly to close the Main Menu.

7. (Optional) Use the built-in simulation tools to check that the control wiring is connected correctly, see

8. Power off the soft starter.

9. Connect the motor cables to the soft starter output terminals 2/T1, 4/T2, 6/T3.

10. Connect mains supply cables to the soft starter input terminals 1/L1, 3/L2, 5/L3, see

The soft starter is now ready to control the motor.

5.9 Quick Set-up.

5.7 Power Terminations.

Installation

6.5 Run Simulation.

5.4 Inputs

CA UT IO N

The control inputs are powered by the soft starter. Do not apply external voltage to the control input terminals.

NO TI CE

Cables to the control inputs must be segregated from mains voltage and motor cabling.

28 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 29

READY

RUN

TRIP

LOCAL

Exit

Reset

Menu

Store

VLT

®

Soft Starter

2/T1

4/T2

6/T3

1/L1 3/L2

5/L3

AO-08

AO-07

DI-B

DI-A

COM+

START

COM+

RESET

TER-06

TER-05

e77ha718.10

Operating Guide | VLT® Soft Starter MCD 600

5.4.1 Input Terminals

Installation

TER-05, TER-06 Motor thermistor input

START, COM+ Start/stop input

DI-B, COM+ Programmable input B (default = Input trip (N/O))

RESET, COM+ Reset input

DI-A, COM+ Programmable input A (default = Input trip (N/O))

USB port (for flash, no direct PC connection)

Illustration 6: Input Terminals

5.4.2 Motor Thermistor

Motor thermistors can be connected directly to the VLT® Soft Starter MCD 600. The soft starter trips when the resistance of the

thermistor circuit exceeds approximately 3.6 kΩ or drops below 20 Ω.

The thermistors must be wired in series. The thermistor circuit should be run in shielded cable and must be electrically isolated from

ground and all other power and control circuits.

The thermistor input is disabled by default, but activates automatically when a thermistor is detected. If thermistors have

previously been connected to the MCD 600 but are no longer required, use the Thermistor Reset function to disable the

thermistor. Thermistor reset is accessed via Set-up Tools.

5.4.3 Start/Stop

NO TI CE

The VLT® Soft Starter MCD 600 requires 2-wire control.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 29

Page 30

RESET

COM+

START

A

B

e77ha721.10

Operating Guide | VLT® Soft Starter MCD 600

A Reset B Start/stop

Illustration 7: Start/Stop Control Wiring

CA UT IO N

ATTEMPTED START

If the start input is closed when control voltage is applied, the soft starter attempts to start.

Check that the start/stop input is open before applying control voltage.

-

Installation

NO TI CE

The MCD 600 only accepts command from the control inputs if parameter 1-1 Command Source is set to Digital Input.

5.4.4 Reset/Starter Disable

The reset input (RESET, COM+) is normally closed by default. The soft starter does not start if the reset input is open. The display then

shows Not ready.

If the reset opens while the soft starter is running, the soft starter removes power and allows the motor to coast to stop.

NO TI CE

The reset input can be configured for normally open or normally closed operation. Make the selection in parameter 7-9 Reset/

Enable Logic.

5.4.5 Programmable Inputs

The programmable inputs (DI-A, COM+ and DI-V, COM+) allow external equipment to control the soft starter. The operation of the

programmable inputs is controlled by parameters 7-1 to 7-8.

5.4.6 USB Port

The USB port can be used to upload a configuration file, or download parameter settings and event log information from the soft

starter. See 6.7 USB Save & Load for details.

30 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 31

READY

RUN

TRIP

LOCAL

Exit

Reset

Menu

Store

VLT

®

Soft Starter

2/T1

4/T2

6/T3

1/L1 3/L2

5/L3

AO-08

AO-07

DI-B

DI-A

COM+

START

COM+

RESET

TER-06

TER-05

34

33

23

22

21

14

13

e77ha719.10

Operating Guide | VLT® Soft Starter MCD 600

5.5 Outputs

5.5.1 Output Terminals

Installation

AO-07, AO-08 Analog output

21, 22, 23 Relay output A (default = Run)

13, 14 Main contactor output

33, 34 Relay output B (default = Run)

Illustration 8: Output Terminals

5.5.2 Analog Output

The VLT® Soft Starter MCD 600 has an analog output, which can be connected to associated equipment to monitor motor

performance. The operation of the analog output is controlled by parameters 9-1 to 9-4.

5.5.3 Main Contactor Output

The main contactor output (13, 14) closes as soon as the soft starter receives a start command and remains closed while the soft starter

is controlling the motor (until the motor starts a coast to stop, or until the end of a soft stop). The main contactor output also opens if

the soft starter trips.

Some electronic contactor coils are not suitable for direct switching with PCB mount relays. Consult the contactor

manufacturer/supplier to confirm suitability.

NO TI CE

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 31

Page 32

READY RUN TRIP LOCAL

Exit

Reset

Menu

Store

VLT

®

Soft Starter

2/T1 4/T2 6/T3

1/L1 3/L2 5/L3

A9

A8

A7

e77ha720.10

Operating Guide | VLT® Soft Starter MCD 600

Installation

5.5.4 Programmable Outputs

The programmable outputs (21, 22, 23 and 33, 34) can report the status of the soft starter or can control associated equipment.

The operation of the programmable outputs is controlled by parameters 8-1 to 8-6.

5.6 Control Voltage

5.6.1 Control Voltage Terminals

Illustration 9: Control Voltage Terminals

Connect the control supply according to the supply voltage being used.

• MCD6-xxxxB-xx-CV2 (110–120 V AC): A8, A9.

• MCD6-xxxxB-xx-CV2 (220–240 V AC): A7, A9.

• MCD6-xxxxB-xx-CV1 (24 V AC/V DC): A8, A9.

5.6.2 UL Compliant Installation

For MCD6-0144B to MCD6-0579B to be UL-compliant, supplementary or branch circuit overcurrent protection must be used on the

control circuit supply (A7, A8, A9) in accordance with the electrical code applicable at the installation location.

32 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 33

e77ha646.11

e77ha648.11

e77ha647.11

e77ha649.11

6 mm

0.24 in

10 mm

0.4 in

20 mm

0.8 in

9 mm

(M8)

e77ha722.10

6 mm

0.24 in

17 mm

0.7 in

34 mm

1.7 in

13 mm

(M12)

e77ha723.10

Operating Guide | VLT® Soft Starter MCD 600

Installation

5.7 Power Terminations

WA RN IN G

SHOCK HAZARD

Models MCD6-0144B ~ MCD6-0579B are IP00 and pose a risk of electrical shock if touching the terminals.

Install a finger guard kit on the soft starter.

-

Install the soft starters inside an enclosure.

-

The power input and output terminals for VLT® Soft Starter MCD 600 are at the bottom of the unit.

• Models MCD6-0020B~MCD6-0129B use cage clamps. Use copper stranded or solid conductors rated for 75 °C (167 °F) or higher.

• Models MCD6-0144B~MCD6-0579B use busbars. Use copper or aluminum conductors, stranded or solid, rated for 60/75 °C

(140/167 °F).

NO TI CE

Some units use aluminum busbars. When connecting power terminations, clean the surface contact area thoroughly (using an

emery or stainless steel brush) and use an appropriate jointing compound to prevent corrosion.

Table 13: Power Terminations, MCD6-0020B~MCD6-0129B

MCD6-0020B~MCD6-0129B

Cable size: 6–

2

70 mm

(AWG 10–2/0)

Torque: 4 Nm

(2.9 ft-lb)

14 mm (0.55 in)

Table 14: Power Terminations, MCD6-0144B~MCD6-0244B and MCD6-0287B~MCD6-0579B

MCD6-0144B~MCD6-0244B MCD6-0287B~MCD6-0579B

19 Nm (14 ft-lb)

Torx T20 x 150

Flat 7 mm x

150

66 Nm (49 ft-lb)

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 33

Page 34

Operating Guide | VLT® Soft Starter MCD 600

Installation

NO TI CE

If the installation requires large diameter cables, it is possible to complete each termination with 2 smaller cables, 1 on each

side of the busbar.

5.7.1 Wiring Connectors

Select a connector according to the wire size, material, and application requirements.

For models MCD6-0144B to MCD6-0579B, a compression connector is recommended. The recommended crimping tool is TBM8-750.

Table 15: Recommended Lugs

Model Example connector - aluminum cable Example connector - copper cable

MCD6-0144B 61162 60150

MCD6-0171B 61165 60156

MCD6-0194B 61171 60165

MCD6-0244B

MCD6-0287B 61162 60150

MCD6-0352B 61165 60156

MCD6-0410B 60156

MCD6-0527B 61178 60171

MCD6-0579B

5.7.2 Motor Connection

The VLT® Soft Starter MCD 600 can be connected to the motor in-line or inside delta (also called 3-wire and 6-wire connection). When

connecting in inside delta, enter the FLC for parameter 1-2 Motor Full Load Current. The MCD 600 automatically detects whether the

motor is connected in-line or inside delta and calculates the correct inside delta current level.

NO TI CE

If the soft starter is not detecting the motor connection correctly, use parameter 20-6 Motor Connection.

34 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 35

e77ha726.10

14

13

K1

K1F1

6/T3

2/T1

5/L3

3/L2

1/L1

4/T2

M

3

M

3

U1(1) U2(4)

V1(2)

V2(5)

W1(3) W2(6)

K1

F1

e77ha727.10

14

13

K1

6/T3

2/T1

5/L3

3/L2

1/L1

4/T2

Operating Guide | VLT® Soft Starter MCD 600

5.7.2.1 In-line Installation

Installation

K1 Main contactor (strongly recommended)

13, 14 Main contactor output

Not using fuses or circuit breakers voids the guarantee.

Illustration 10: Wiring of an In-line Installation

5.7.2.2 Inside Delta Installation

F1

Fuses or circuit breaker (optional

()

)

K1 Main contactor F1

Danfoss A/S © 2018.10

Fuses or circuit breaker (optional

AQ262141844215en-000202 / 175R1174 | 35

()

)

Page 36

22

21

6/T3

2/T1

13

14

4/T2

44

33

23

AO-07

AO-08

TER-06

TER-05

START

COM+

DI-A

DI-B

COM+

A9

A8

A7

5/L3

3/L2

RESET

1/L1

F1

S1

S2

K1

K1

(L/+) (N/# )

A

#

+

M

7

6

5

3

2

1

10

4

9

8

e77ha728.10

Operating Guide | VLT® Soft Starter MCD 600

Installation

13, 14 Main contactor output

Not using fuses or circuit breakers voids the guarantee.

Illustration 11: Wiring of an Inside Delta Installation

5.8 Typical Installation

The VLT® Soft Starter MCD 600 is installed with a main contactor (AC3-rated). Control voltage must be supplied from the input side of

the contactor.

The main contactor is controlled by the main contactor output (13, 14).

1 Three-phase supply

3 Control voltage (soft starter)

2 Motor

4 Digital inputs

36 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 37

Operating Guide | VLT® Soft Starter MCD 600

Installation

5 Motor thermistor input

7 Analog output

9 Pilot lamps

K1 Main contactor

RESET, COM+ (S1) Reset

DI-A, COM+ Programmable input A (default = Input trip (N/O))

TER-05, TER-06 Motor thermistor input

21, 22, 23 Relay output A (default = Run)

AO-07, AO-08 Analog output

Illustration 12: Installation Example

6 Relay outputs

8 Control voltage (external equipment)

10 Communications/smart card expansion port

F1 Semiconductor fuses

START, COM+ (S2) Start/stop

DI-B, COM+ Programmable input B (default = Input trip (N/O))

13, 14 Main contactor output

33, 34 Relay output B (default = Run)

5.9 Quick Set-up

The Quick Set-up makes it easy to configure the soft starter for common applications. The VLT® Soft Starter MCD 600 guides through

the most common installation parameters and suggests a typical setting for the application. Adjust each parameter to suit the exact

requirements.

All other parameters remain at default values. To change other parameter values or review default settings, use the Main Menu (see

10.4 Parameter List for details).

Always set parameter 1-2 Motor Full Load Current to match the motor nameplate FLC.

Table 16: Suggested Settings for Common Applications

Application Start mode Start

ramp

time [s]

Pump centrifugal

Pump bore Adaptive con-

Pump hydraul-icConstant cur-

Fan damped Constant cur-

Fan undamped Constant cur-

Compressor

screw

Compressor recip

Adaptive control

trol

rent

rent

rent

Constant current

Constant current

10 200 500 Early acceler-

3 200 500 Early acceler-

2 200 350 n/a Coast to stop n/a n/a

2 200 350 n/a Coast to stop n/a n/a

2 200 450 n/a Coast to stop n/a n/a

2 200 400 n/a Coast to stop n/a n/a

2 200 450 n/a Coast to stop n/a n/a

Initial

current

[%]

Current

limit

[%]

Adaptive

start profile

ation

ation

Stop mode Stop

time [s]

Adaptive

control

Adaptive

control

15 Late deceler-

3 Late deceler-

Adaptive

stop profile

ation

ation

Conveyor Constant cur-

rent

Danfoss A/S © 2018.10

5 200 450 n/a Coast to stop n/a n/a

AQ262141844215en-000202 / 175R1174 | 37

Page 38

Operating Guide | VLT® Soft Starter MCD 600

Installation

Application Start mode Start

ramp

time [s]

Bow thruster Constant cur-

rent

Bandsaw Constant cur-

rent

5 100 400 n/a Coast to stop n/a n/a

2 200 450 n/a Coast to stop n/a n/a

Initial

current

[%]

Current

limit

[%]

Adaptive

start profile

Stop mode Stop

time [s]

Adaptive

stop profile

NO TI CE

The adaptive start and stop profile settings only apply when using adaptive control. The settings are ignored for all other start

and stop modes.

38 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 39

Operating Guide | VLT® Soft Starter MCD 600

Set-up Tools

6 Set-up Tools

6.1 Introduction

Set-up Tools includes options to load or save parameters to a backup file, set the soft starter's network address, check the status of the inputs and outputs, reset the thermal models, or test operation using the Run Simulation.

To access Set-up Tools, press [Menu] to open the Main Menu and then select Set-up Tools.

6.2 Setting Date and Time

Procedure

1. Press [Menu] to open the menu.

2. Select Set-up Tools.

3. Scroll to Set Date & Time.

4. Press [Menu/Store] to enter edit mode.

5. Press [Menu/Store] and [Back] to select which part of the date or time to edit.

6. Press [▵] and [▿] to change the values.

7. Press [Menu/Store] after the last digit to save the setting.

When the action has been completed, the screen briefly shows a confirmation message, then returns to the previous menu level.

6.3 Command Source

Start and stop the soft starter via the digital inputs, remote LCP 601, communication network, smart card, or scheduled auto-start/stop.

Set up the command source via Set-up Tools or via parameter 1-1 Command Source.

If the remote LCP is installed, the [CMD/Menu] key provides shortcut access to the Command Source function in Set-up Tools.

6.4 Commissioning

Commissioning allows starting and stopping the soft starter via the LCP. Press [▵] [▿] to select a function, then press [Menu/Store] to

send the selected command to the soft starter. The available functions are:

• Quick stop (coast to stop)/reset.

• Start.

• Stop.

6.5 Run Simulation

Context:

The Run Simulation simulates a motor starting, running, and stopping to confirm that the soft starter and associated equipment have

been installed correctly.

NO TI CE

Disconnect the soft starter from mains voltage when using simulation mode.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 39

Page 40

e77ha731.10

Run Simulation

Ready

Apply Start Signal

Operating Guide | VLT® Soft Starter MCD 600

The simulation is only available when the soft starter is in ready state.

Procedure

1. Press [Menu] and select Set-up Tools.

2. Scroll to Run Simulation and press [Menu/Store].

3. Apply a start command from the selected command source.

The soft starter simulates its prestart checks and closes the main contactor relay. The Run LED flashes.

NO TI CE

If mains voltage is connected, an error message is shown.

Set-up Tools

4. Press [Menu/Store].

The soft starter simulates starting. The Run LED flashes.

5. Press Menu/Store.

The soft starter simulates running.

6. Apply a stop command from the selected command source.

The soft starter simulates stopping. The Run LED flashes.

7. Press [Menu/Store].

The Ready LED flashes and the main contactor relay opens.

8. Press [Menu/Store].

The soft starter activates then deactivates each programmable output.

9. Press [Menu/Store].

The soft starter returns to the Set-up Tools.

6.6 Load/Save Settings

Context:

The Load/Save Settings allows:

• Resetting the soft starter parameters to default values.

• Loading parameter settings from an internal file.

• Saving the current parameter settings to an internal file.

The internal file contains default values until a user file is saved.

40 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 41

e77ha732.10

Load/Save Settings

Load Defaults

Load User Set

Save User Set

Operating Guide | VLT® Soft Starter MCD 600

Set-up Tools

Procedure

1. Press [Menu] and select Set-up Tools.

2. Scroll to Load/Save Settings and press [Menu/Store].

3. Scroll to the required function and press [Menu/Store].

4. At the confirmation prompt, select Yes to confirm or No to cancel.

5. Press [Menu/Store] to proceed.

When the action has been completed, the screen birefly shows a confirmation message, then returns to the previous menu level.

6.7 USB Save & Load

The USB Save & Load menu allows:

• Saving parameter settings and all event log entries to an external file (CSV format).

• Saving parameter settings to an external file (proprietary format).

• Loading parameter settings from a previously saved external file.

• Loading custom messages to show on the LCP when a programmable input is active.

NO TI CE

The VLT® Soft Starter MCD 600 supports FAT32 file systems. The MCD 600 USB functions are not compatible with NTFS file

systems.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 41

Page 42

e77ha733.10

USB Save & Load

Save Params and Logs

Save Master Params

Load Master Params

Operating Guide | VLT® Soft Starter MCD 600

Set-up Tools

6.7.1 Save and Load Procedure

Procedure

1. Connect the external drive to the USB port.

2. Press [Menu] and select Set-up Tools.

3. Scroll to USB Save & Load and press [Menu/Store].

4. Scroll to the required function and press [Menu/Store].

5. At the confirmation prompt, select Yes to confirm or No to cancel.

6. Press [Menu/Store] to proceed.

When the action has been completed, the screen briefly shows a confirmation message, then returns to the previous menu level.

6.7.2 File Locations and Formats

Save parameters and logs

The soft starter creates a directory at the top level of the USB drive, named with the soft starter serial number. The event log and

parameter settings are saved as individual CSV files, and the soft starter's software and system information are saved to a text file.

Save master parameters

The soft starter creates a file called Master_Parameters.par and stores it on the USB drive.

Load master parameters

The soft starter loads the file Master_Parameters.par from the top level of the USB drive. The files can be created or edited using VLT®

Motion Control Tool MCT 10. Download the MCT 10 tool from www.danfoss.com/en/service-and-support/downloads/dds/vlt-motioncontrol-tool-mct-10/.

Load custom message

The soft starter loads the files Custom_Message_A.txt and Custom_Message_B.txt from the top level of the USB drive.

42 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 43

e77ha730.10

e77ha734.10

Auto-Start/Stop

Start/Stop Mode

Start/Stop Sunday

Start/Stop Monday

Operating Guide | VLT® Soft Starter MCD 600

Illustration 13: USB Directory

Set-up Tools

6.8 Auto-start/Stop

Context:

The soft starter can be configured to automatically start and/or stop the motor at a particular time, or run it in cycles of a specified

duration.

The Auto-Start/Stop function in Set-up Tools gives quick access to the auto-start/stop parameters.

Procedure

1. Press [Menu] and select Set-up Tools.

2. Scroll to Auto-Start/Stop and press [Menu/Store].

3. Scroll to the desired function and press [Menu/Store].

4. Adjust the settings as required:

A Press [Menu/Store] and [Back] to select which information to edit.

B Press [▵] [▿] to change the value.

Press [Menu/Store] to save changes. The soft starter confirms the changes.

Press [Back] to cancel the changes.

6.9 Network Address

To use the VLT® Soft Starter MCD 600 on an Ethernet network, separate addresses must be configured for:

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 43

Page 44

e77ha735.10

Set IP Address

192.168.000.002

e77ha711.10

Digital I/O State

Inputs: 0100

Outputs: 100

Operating Guide | VLT® Soft Starter MCD 600

• IP address.

• Gateway address.

• Subnet mask.

6.9.1 Setting a Network Address

Procedure

1. Press [Menu] and select Set-up Tools.

2. Scroll to Network Address and press [Menu/Store].

3. Scroll to the required function and press [Menu/Store].

Set-up Tools

4. The 1st digit of the address is highlighted.

5. Press [Back] and [Menu/Store] to select which digit to alter.

6. Press [▵] [▿] to change the value.

7. Press [Menu/Store] after the last digit to save the setting.

When the action has completed, the screen briefly shows a confirmation message, then returns to the previous menu level.

NO TI CE

The network address can also be set by using parameters 12-8 to 12-19.

NO TI CE

To configure the soft starter for use with other communication protocols, use parameters 12-1 to 12-7.

6.10 Digital I/O State

Illustration 14: Digital I/O Status Screen

44 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 45

AO-08

AO-07

DI-B

DI-A

COM+

START

COM+

RESET

TER-06

TER-05

3433232221

14

13

e77ha717.10

7

6

5

4

32

1

e77ha736.10

Analog I/O State

Thermistor: 0

4-20 mA Output: 04.0 mA

Operating Guide | VLT® Soft Starter MCD 600

Set-up Tools

1 RESET, COM+: Reset input

3 DI-A, COM+: Programmable input A

5 13, 14: Main contactor output

2 START, COM+: Start/stop input

4 DI-B, COM+: Programmable input B

6 21, 22, 23: Relay output A

7 33, 34: Relay output B

Illustration 15: Location of Digital I/Os

6.11 Analog I/O State

The topline of the screen shows the state of the motor thermistor input. The bottom line of the screen shows the value of the analog

output.

Illustration 16: Analog I/O Status Screen

Thermistor input

S Short

H Hot

C Cold

O Open

6.12 Serial Number & Rating

The top line of the screen shows the product name.

The middle line shows the unit's serial number.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 45

Page 46

e77ha789.10

Serial Number & Rating

MCD 600

123456-123

0410-T5-S1-CV2

Operating Guide | VLT® Soft Starter MCD 600

The bottom line of the screen shows the model number.

Illustration 17: Serial Number & Rating Screen

6.13 Software Versions

The software version screen reports the version of each software component of the soft starter:

• User interface.

• Motor control.

• Remote LCP (if connected).

• Parameter list.

• Bootloader.

• Expansion card (if fitted).

Set-up Tools

NO TI CE

Updated software, including alternative languages, can be loaded into the soft starter via the USB port if required. Contact the

local supplier for further information.

6.14 Thermistor Reset

The thermistor input is disabled by default, but activates automatically when a thermistor is detected. If thermistors have previously

been connected to the soft starter but are no longer required, use the thermistor reset function to disable the thermistor.

6.15 Reset Thermal Model

The thermal modeling software in the soft starter constantly monitors the motor performance. This allows the soft starter to calculate

the motor temperature and ability to start successfully at any time.

The thermal model can be reset if required.

NO TI CE

REDUCED MOTOR LIFETIME

Resetting the motor thermal model compromises thermal model protection and may compromise motor life.

Only reset the thermal model in an emergency.

-

46 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 47

Operating Guide | VLT® Soft Starter MCD 600

7 Logs

7.1 Introduction

The Logs Menu provides information on events, trips, and soft starter performance.

To access the Logs Menu on the local LCP, press [Menu] and select Logs. On the remote LCP, press [Logs].

7.2 Event Log

The Event Log stores details of the most recent trips, warnings, and operations (including starts, stops, and configuration changes).

Event 1 is the most recent and event 384 is the oldest stored event.

NO TI CE

The Event Log can be exported to an external file for analysis away from the soft starter.

See 6.7.2 File Locations and Formats.

Logs

7.3 Counters

The counters store statistics on the soft starter operation:

• Hours run (lifetime and since counter was last reset).

• Number of starts (lifetime and since counter was last reset).

• Number of times the thermal model has been reset.

7.3.1 Viewing the Counters

Procedure

1. Open the Logs, see 7.1 Introduction.

2. Scroll to Counters and press [Menu/Store].

3. Press [▵] and [▿] to scroll through the counters.

4. Press [Menu/Store] to view details.

5. To reset a counter, press [Menu/Store] then press [▵] and [▿] to select Reset/Do Not Reset.

6. Press [Store] to confirm the action.

7. Press [Menu/Store] to close the counter and return to Logs.

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 47

Page 48

READY

RUN

TRIP LOCAL

Menu

Store

Back

Reset

1

2

3

e77ha715.10

Operating Guide | VLT® Soft Starter MCD 600

8 LCP and Feedback

8.1 Local LCP and Feedback

LCP and Feedback

1 Four-line display for status and programming details.

3 Menu

navigation

keys:

Illustration 18: Local LCP

Back: Exit the

menu or

parameter, or

cancel a

parameter

change. This

key also resets

a trip.

Menu/Store:

Enter a menu

or

parameter,

or save a

parameter

change.

Arrows: Scroll

to the next or

previous menu

or parameter,

change the

setting of the

current

parameter, or

scroll through

the status

screens.

2 Status LEDs.

8.2 Remote LCP

The remote LCP can be used to control the soft starter if parameter 1-1 Command Source is set to Remote Keypad.

48 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 49

READY RUN TRIP

LOCAL

RESET

LOGS

Alt

GRAPH

TOOLS

CMD

MENU

MENU

STORE

BACK

e77ha716.10

1

2

3

4

5

6

Operating Guide | VLT® Soft Starter MCD 600

LCP and Feedback

• If the remote LCP is not selected as the command source, [Start], [Stop], and [Reset] have no effect.

• The menu navigation keys and display on the remote LCP are always active.

• If a key is pressed on the remote LCP, the display on the remote LCP updates to match.

NO TI CE

The remote LCP can be safely connected or removed while the soft starter is running. It is not necessary to remove mains or

control voltage.

NO TI CE

If parameter 1-1 Command Source is set to Remote Keypad, removing the remote LCP causes a trip.

1 Four-line display for status and programming details. 2 Status LEDs.

4 Shortcut to the command source menu in Set-up Tools.

6 Shortcut keys

Danfoss A/S © 2018.10

for quick

access to

common tasks:

Logs:

Open the

Logs

Menu.

Graph: Select

which graph to

view, or pause/

restart the graph

(hold longer than

0.5 s).

AQ262141844215en-000202 / 175R1174 | 49

Tools:

Open the

Set-up

Tools.

Page 50

Ready Run Trip Local

e77ha724.10

Operating Guide | VLT® Soft Starter MCD 600

LCP and Feedback

3 Menu

navigation

keys:

5 Local control keys.

Illustration 19: Remote LCP

Back: Exit the

menu or

parameter,

or cancel a

parameter

change.

Menu/Store:

Enter a menu

or parameter,

or save a

parameter

change.

Arrow keys:

Scroll to the

next or previous

menu or

parameter,

change the

setting of the

current

parameter, or

scroll through

the status

screens.

8.3 Adjusting the Display Contrast

Context:

The local and remote LCPs can be adjusted independently.

NO TI CE

1. Press and hold [Back].

2. Press [▵] to lighten the display, or press [▿] to darken the display.

8.4 Soft Starter Status LEDs

Illustration 20: Status LEDs on LCP

Table 17: LED Descriptions

LED name On Flashing

Ready The motor is stopped and the soft start-

er is ready to start.

Run The motor is in run state (receiving full

voltage).

The motor is stopped and the soft starter is not ready to start:

• Waiting for the restart delay (parameter 5-16 Restart Delay).

• The thermal models indicate that the soft starter and/or motor are too

hot to start safely.

• The reset input (RESET, COM+) is open.

The motor is starting or stopping.

50 | Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174

Page 51

e77ha790.10

WELCOME

01.01/01.00/01.00

MCD6-0069B-T5-S1-CV2

1

2

e77ha791.10

69.0 A

Running

69.0 A 415 V

1

2

3

Operating Guide | VLT® Soft Starter MCD 600

LED name On Flashing

Trip The soft starter has tripped. The soft starter is in warning state.

LCP and Feedback

Local The soft starter is controlled via a remote

–

LCP.

If all LEDs are off, the soft starter is not receiving control voltage.

8.5 Displays

8.5.1 Soft Starter Information

At power-up, the soft starter information screen shows details of the soft starter rating, software versions, and serial number.

1 Software versions: User interface, motor control, remote LCP 2 Model code: Current rating, mains voltage, frame size, control

voltage (remote LCP software version is only shown when a

remote LCP is connected)

Illustration 21: Welcome Screen

8.5.2 Configurable Feedback Screens

Select which information to show on the display. To switch between the 2 configurable screens, press [▵] and [▿].

1 Motor running current

3 Parameter 10-8 User Parameter 1 and parameter 10-9 User

Parameter 2

Illustration 22: Soft Starter Status Screen

2 Soft starter status

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 51

Page 52

e77ha792.10

Motor pf

Motor power

1

2

3

Mains Frequency 59.7 Hz

1.01

37.0 kW

4 Motor Temp 85%

e77ha793.10

69.0 A

Last start

350% FLC

1

2

3

010s

D Temp 5%

4

Operating Guide | VLT® Soft Starter MCD 600

LCP and Feedback

1 Parameter 10-10 User Parameter 3 (default: Mains frequency)

3 Parameter 10-12 User Parameter 5 (default: Motor running

power)

Illustration 23: User-configurable Screen

2 Parameter 10-11 User Parameter 4 (default: Power factor)

4 Parameter 10-13 User Parameter 6 (default: Motor

temperature)

8.5.3 Operating Feedback Screens

The operating feedback screens show the motor running current on the top half of the screen. To select which information is shown on

the lower half, press [▵] and [▿].

• Real-time line current on each phase.

• Last start information.

• Date and time.

1 Motor running current

3 Maximum start current drawn (as a percentage of motor full

load current)

Illustration 24: Operating Feedback Screens

8.5.4 Performance Graph

The performance graph provides a real-time display of operating performance. Use parameters 10-2 to 10-5 to format the graph.

The display on the main LCP shows information for motor current.

52 | Danfoss A/S © 2018.10

2 Start duration (seconds)

4 Calculated rise in motor temperature

AQ262141844215en-000202 / 175R1174

Page 53

e77ha757.10

000.0 A 0-400%

Operating Guide | VLT® Soft Starter MCD 600

If a remote LCP is connected, press [Graph] to change the graph data. The graph can show:

• Motor current.

• Motor temperature.

• Motor power factor.

• Analog input data from the smart card (if installed).

LCP and Feedback

Danfoss A/S © 2018.10

AQ262141844215en-000202 / 175R1174 | 53

Page 54

Operating Guide | VLT® Soft Starter MCD 600

Operation

9 Operation

9.1 Start, Stop, and Reset Commands

The VLT® Soft Starter MCD 600 can be started and stopped via the digital inputs, remote LCP, communication network, smart card, or

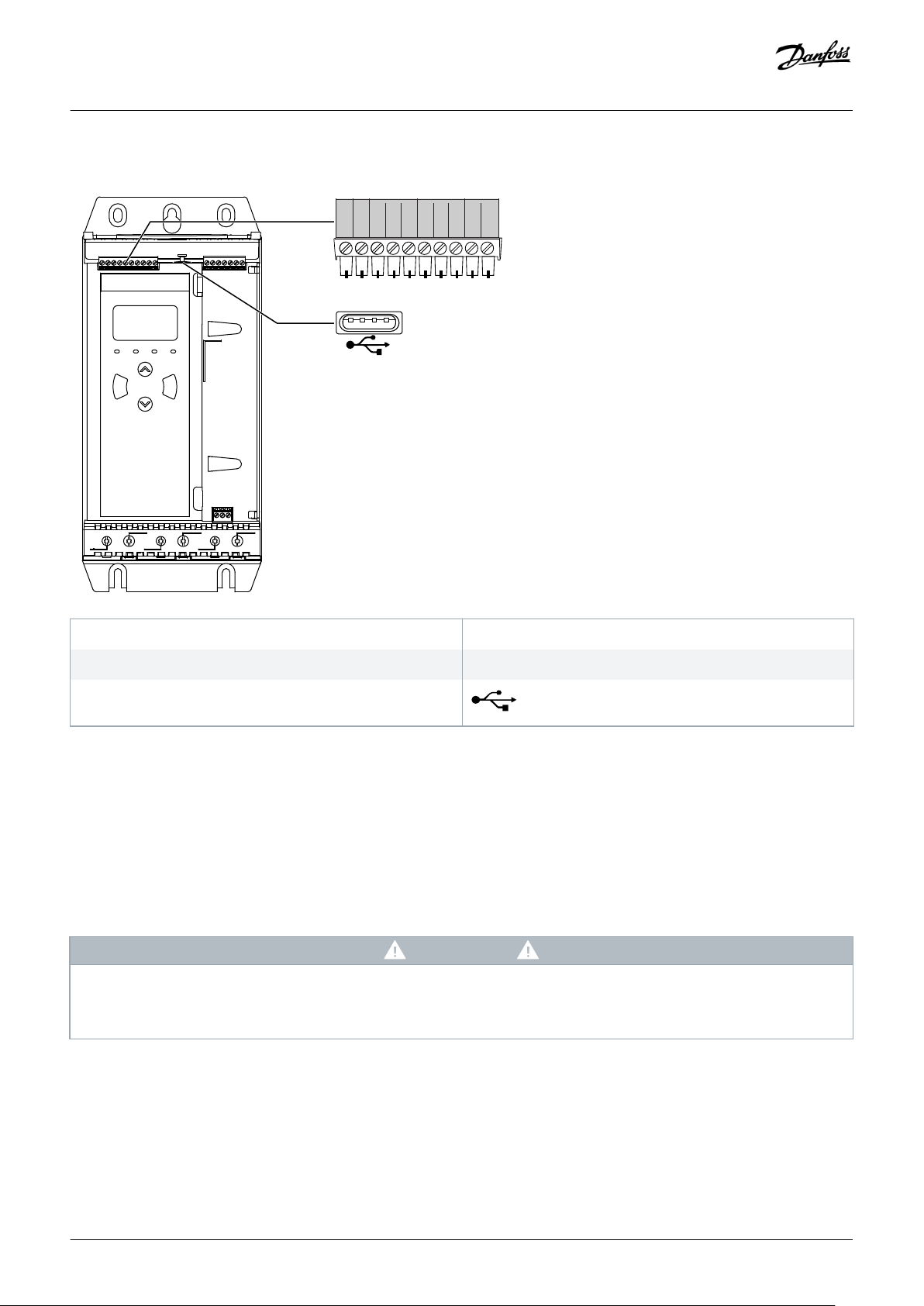

scheduled auto-start/stop. The command source can be set via the Set-up Tools, or using parameter 1-1 Command Source.