Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

Safety Option MCB 150/151

www.danfoss.com/drives

Page 2

Page 3

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Overview of Documentation

1.3 Abbreviations and Definitions

2 Legal Information and Safety

2.1 Legal Information

2.1.1 Copyright and Revisions 8

2.1.2 Warranty and Liability 8

2.2 Safety

2.2.1 Safety Precautions 8

2.2.2 Risk Assessment 8

2.2.3 Safety Regulations 9

2.2.4 Qualified Personnel 9

3 Functions and System Overview

3.1 System Overview

3.1.1 Behaviour of Holding Brake 10

5

5

5

6

8

8

8

10

10

3.1.2 Safety Certification 11

3.1.3 Implementation in Control Systems 11

3.2 Functions

3.2.1 Specification of Safety Functions 11

3.2.1.1 Performance Level (PL) and Safety Integrity Level (SIL) 11

3.2.2 Validation of Performance Level 11

3.2.3 Activation of Safety Functions 12

3.2.4 Simultaneous Activation of Safety Functions 12

3.2.5 Functional Proof Tests 13

3.2.6 PFD and PFH Definitions 13

3.2.7 Intended Use of the Safety Option 13

3.2.8 MCT 10 Set-up Software with Safe Plug-in 13

3.3 Unit Features

3.4 Front View

3.5 Categories of Safe Stop

3.5.1 Operation and Requirements 14

3.5.2 Safety Functions 14

11

13

14

14

3.5.3 Safe Torque Off - STO 15

3.5.4 Safe Stop 1 - SS1 15

3.5.4.1 SS1 Delay 15

3.5.4.2 SS1 Delay with S-ramp Stop Profile 16

3.5.4.3 SS1 Ramp 17

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 1

Page 4

Contents Operating Instructions

3.5.4.4 SS1 Ramp Slope 17

3.5.4.5 SS1 Ramp Time 18

3.5.5 Safely Limited Speed (SLS) 18

3.5.5.1 SLS without Ramp 19

3.5.5.2 SLS with Ramp 20

3.6 Inputs and Output

3.6.1 Inputs 21

3.6.2 Reset Input (DI2) 21

3.6.3 Output 22

3.6.4 Permitted Sensor Types on Digital Inputs 22

3.6.5 Reset 22

3.6.6 Signal Filtering 22

3.6.7 Stable Signal Time from Safe Outputs 23

3.6.8 Zero Speed Time Error Detection 23

3.6.9 Yearly Test 23

3.6.10 Safety Parameter Settings 23

3.6.11 Encoder Interface 24

3.7 Limitations

3.7.1 Exceeded Limit Value and Internal Errors 24

3.7.2 Compatibility between Safety and Frequency Converter Functions 24

4 Installation

4.1 Installing the Safety Option

21

24

25

25

4.1.1 Requirements for Safe Use 25

4.1.2 Protected Cable Installation 25

4.1.3 Installation 25

4.1.4 General Wiring Guidelines 27

4.1.5 Connector Pin Assignment 28

4.2 Encoder

4.2.1 Permissible Encoder Cable Length 30

4.2.2 Encoder Wiring Examples 30

4.2.3 Proximity Switch 30

4.3 Application Examples

4.3.1 Connecting Safe Digital Inputs 31

5 Commissioning

5.1 Before Commissioning

5.1.1 Safety Guidelines 33

5.1.2 Commissioning Requirements 33

5.2 Initial Commissioning

5.2.1 Power-up/Self-test 33

30

31

33

33

33

2 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 5

Contents Operating Instructions

5.2.2 Initial Commissioning 34

5.2.3 Safety Option Customisation 34

5.2.4 Setting up the Encoder 34

5.2.5 Commissioning Test 35

5.3 Operation

6 General Parameter Set-up

6.1 Configuration

6.1.1 General Parameter Set-up 36

6.1.2 Safety Functions Configuration 36

6.1.3 Password Protection 36

6.1.3.1 Password Forgotten 37

6.2 Reset and Status over Fieldbus

6.2.1 Reset of Safety Option and Pending Safe Function 37

6.2.2 Retrieving Safety Option Status 37

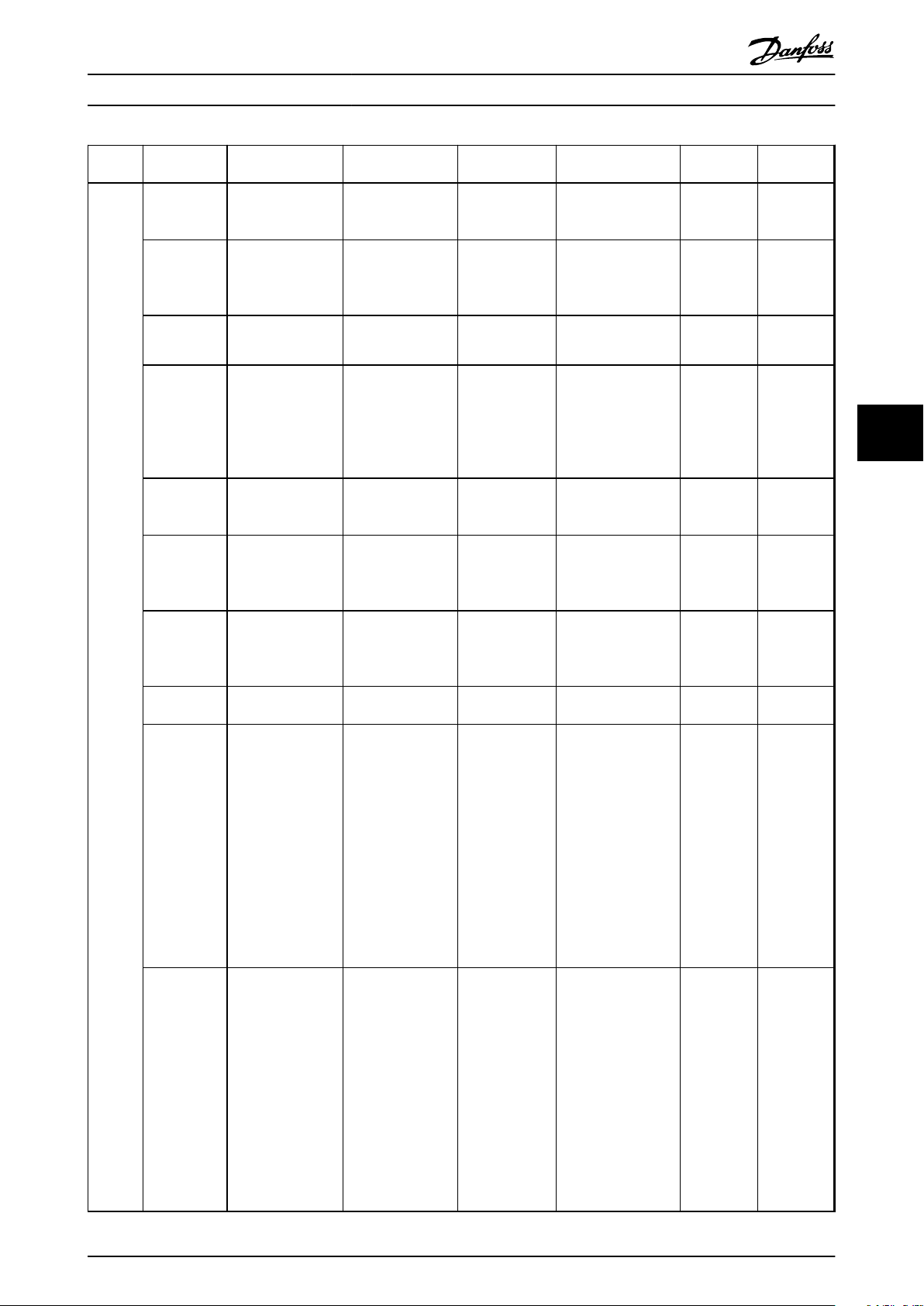

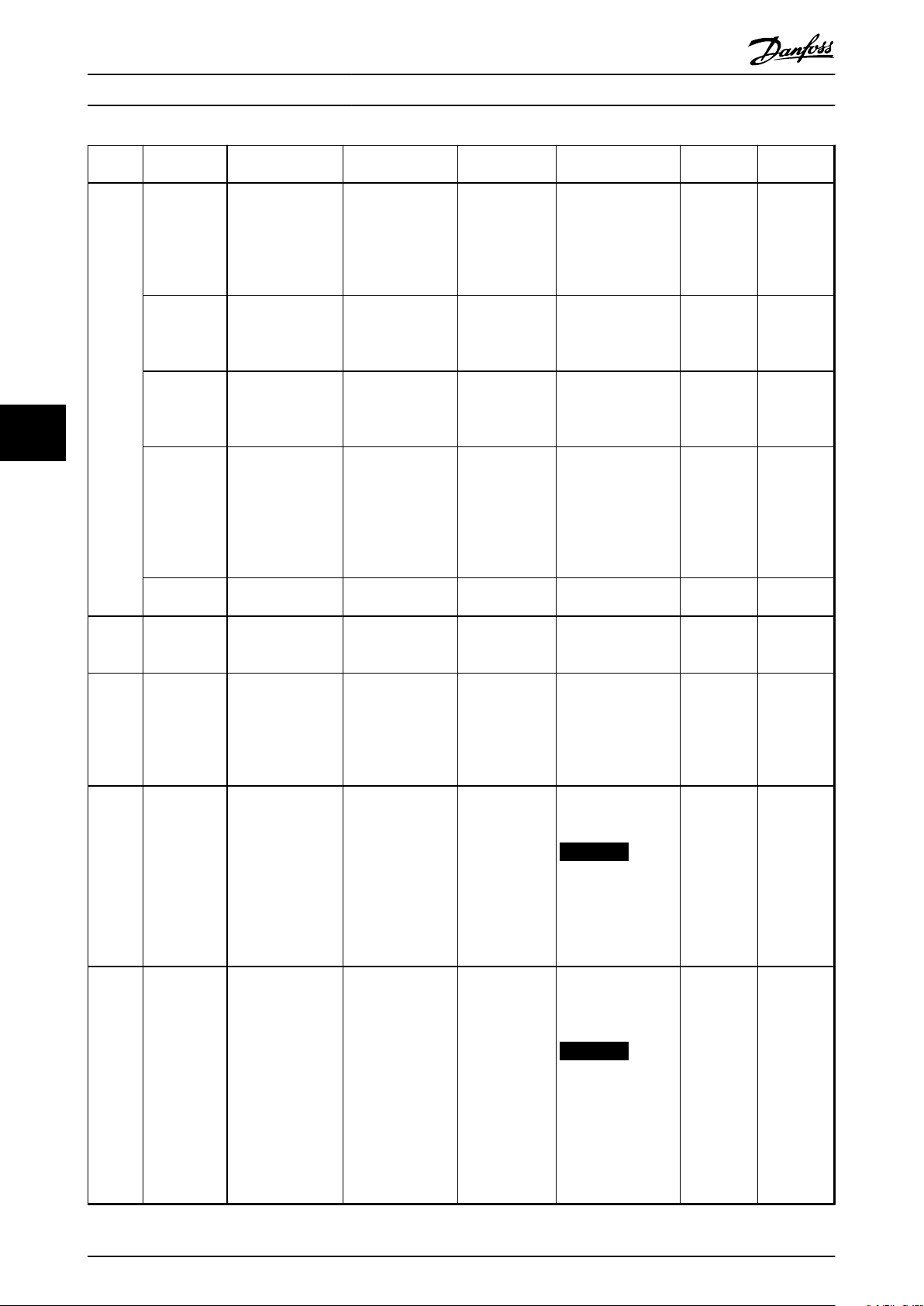

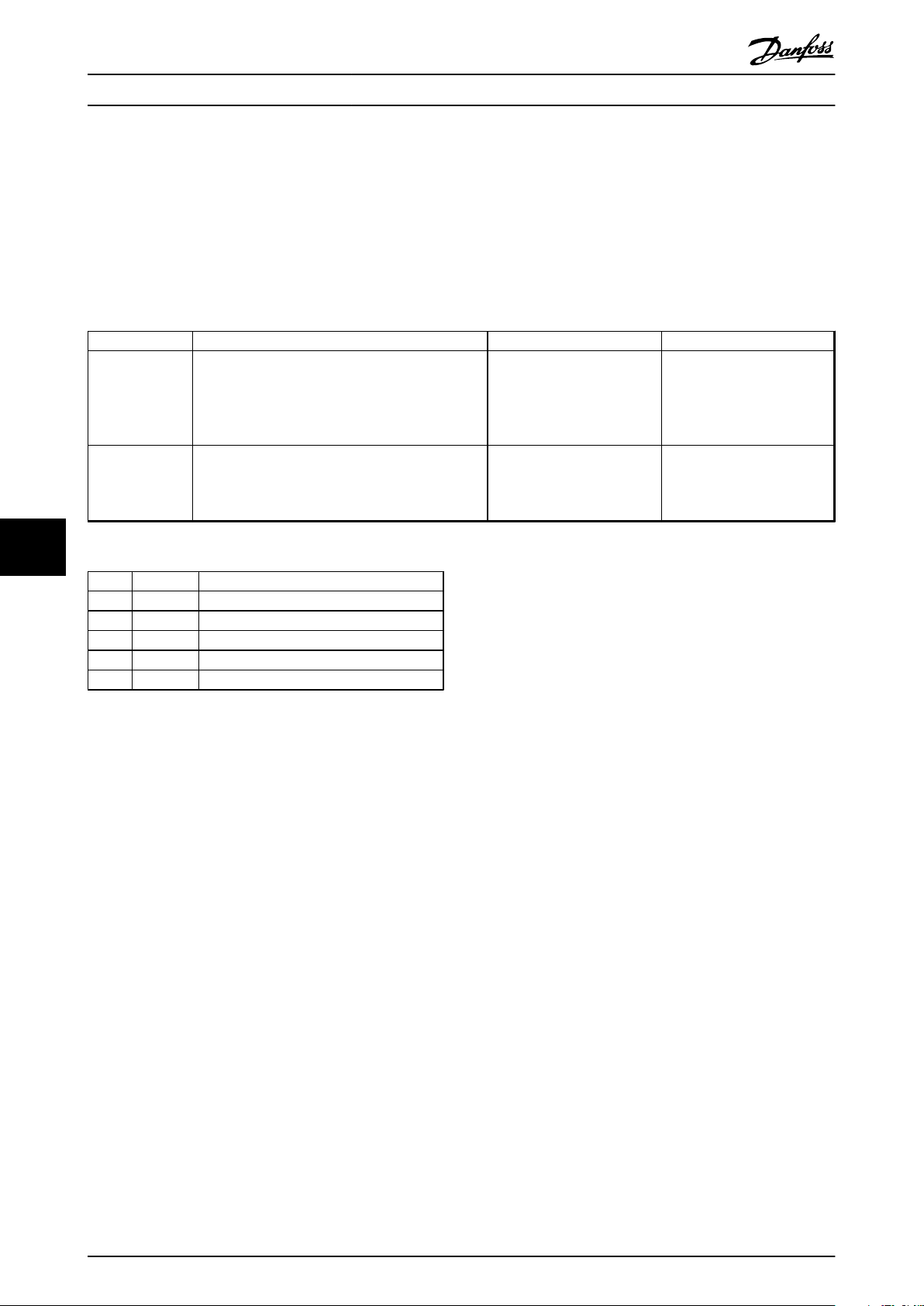

6.3 Parameter List

7 Service and Repair

7.1 Updates, Servicing and Modifications

7.2 Repair

7.3 Replacing

7.3.1 Removing the Safety Option 46

35

36

36

37

40

46

46

46

46

7.3.2 Replacing the Safety Option 46

7.3.3 Copying Safe Parameter Set-up 47

7.4 Commissioning Test

7.4.1 Safety Guidelines 51

7.4.2 Condition before Performing the Commissioning Test 51

7.4.3 Safety Functions of the Frequency Converter 53

7.5 Disposal

8 Warnings and Alarms

8.1 Fault Types and Messages

8.1.1 Messages 60

8.2 Warnings and Alarms

8.2.1 Safety Option Warning 68

8.2.2 Safety Option Reset Message 68

9 Technical Specifications

9.1 Consumption

9.2 Inputs

51

59

60

60

61

70

70

70

9.3 Outputs

9.4 Other Specifications

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 3

71

71

Page 6

Contents Operating Instructions

9.5 Safety Characteristic Data

Index

72

73

4 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 7

Introduction Operating Instructions

1 Introduction

1

1

1.1 Purpose of the Manual

NOTICE

Retain this documentation for instruction and for future

reference.

These Operating Instructions explain the function and

operation and provide installation and wiring guidelines

for the safety option.

Also refer to the following documents from the motion

control range:

MCT 10 Set-up Software Operating Instructions

•

describe the configuration of the safety option.

VLT® AutomationDrive FC 301/FC 302 Operating

•

Instructions describe the frequency converter.

The online help for the MCT 10 Set-up Software

•

describes how to set the parameters for the

frequency converter and the safety option.

Be conversant with the information in these documents to

fully understand this manual.

Chapter 2 Legal Information and Safety

Provides information on the most important product

features.

Chapter 4 Installation

Explains how to install and wire the product.

Chapter 5 Commissioning

Describes how to commission the product.

Chapter 6 General Parameter Set-up

Describes the basic parameters for setting.

Chapter 7 Service and Repair

Describes how to replace a defective safety option and

how to update, service and modify its firmware.

Chapter 8 Warnings and Alarms

Contains a table overview of the warnings and alarms.

Troubleshooting tips are also part of the overview.

Chapter 9 Technical Specifications

Specifies the technical details of the safety option.

The manuals listed below contain important information

about safety systems that must be used to mount and set

up the speed monitoring safety functions of the safety

option module.

VLT® is a registered trademark.

1.2

Overview of Documentation

Chapter 1 Introduction

Explains the contents, structure and specific order of this

manual.

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 5

Page 8

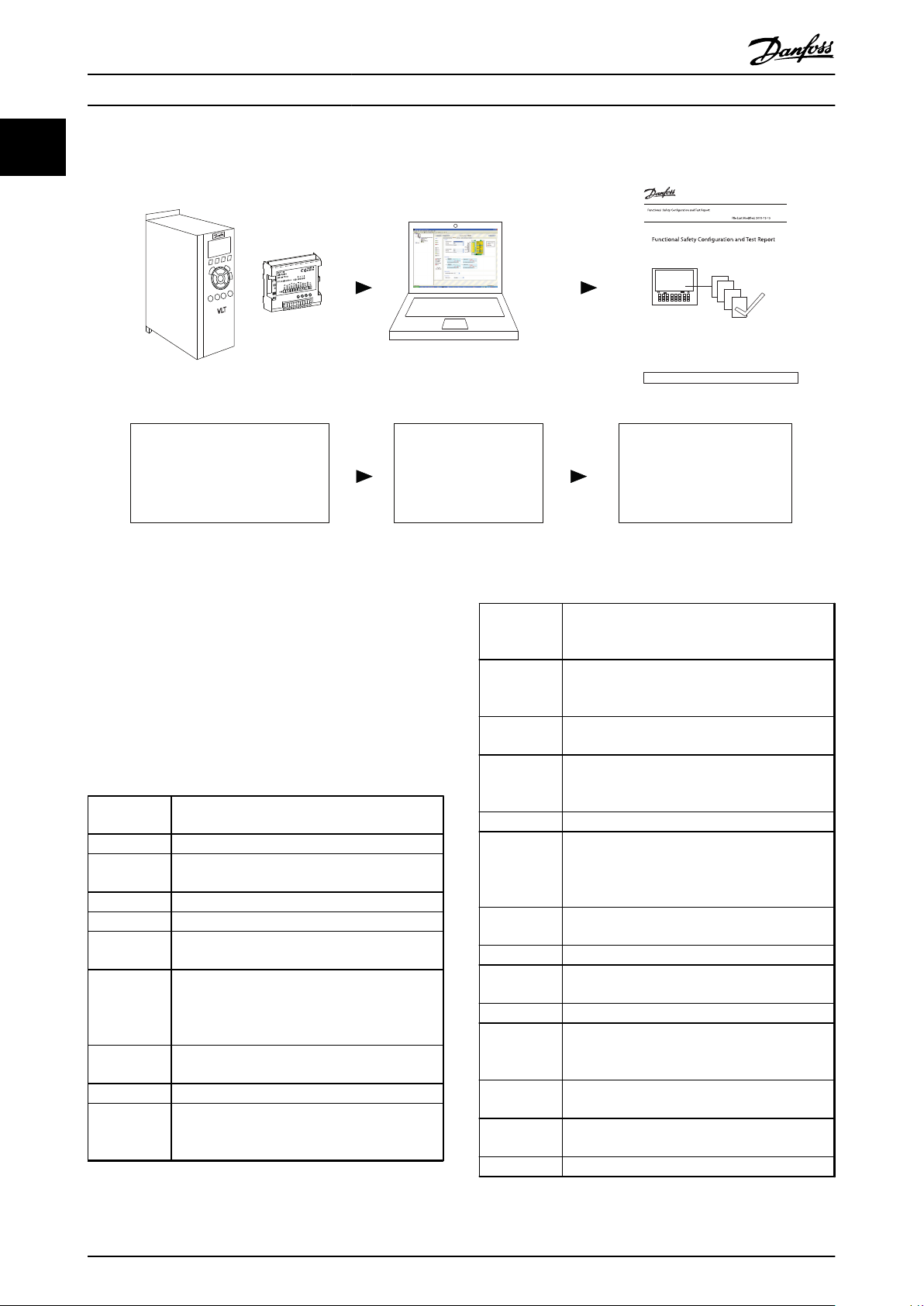

130BC961.11

+ MCT 10 + Safe Plug-in Commis sioning Report

Install

Use Manual for FC

Use Manual for MCB 150/151

Paramete rize

Use Manual for

MCT 10 Safe

Plug-in

Test

Use Commissioning

Report ge nerated via

MCT 10 Safe Plug-in

Report

Rev.Sequence: A, 3

MCT 10

Commisioning report

3 February 2012

Property of Danfoss A/S. Not to be handed over to, copied, or used by third party. Two - or three - dimensional

reproduction of contents to be authorized by Danfoss A/S.

302

FC 302 MCB 15x

1

Introduction Operating Instructions

Illustration 1.1 System Overview

Referenced literature

Error Discrepancy between a computed, observed or

measured value or condition and the specified or

VLT® AutomationDrive FC 301/FC 302 Operating

•

Instructions

MCT 10 Set-up Software Operating Instruction

•

Also refer to www.danfoss.com/drives for additional

information.

1.3 Abbreviations and Definitions

Blank Initial

State

Cat. Category (EN ISO 13849-1)

Factory settings

Error class Classification of errors into groups. The different

Factory

setting

Fatal error In the case of fatal error, the product is no

Fault Fault is a state that can be caused by an error

Fault reset A function used to restore the frequency

CCF Common Cause Failure (IEC 61508, IEC 62061, EN

61511-1, EN ISO 13849-1)

CCW Counter Clockwise

CW Clockwise

DC Diagnostic Coverage (EN ISO 13849-1, IEC

62061(IEC 61508-2))

Degree of

protection

The degree of protection is a standardized

specification for electrical equipment that

describes the protection against the ingress of

foreign objects and water (for example: IP20).

MTTF/MTTFd Mean time to failure/Mean time to dangerous

OSSD Output Signal Switching Device (EN 61496-1)

Parameter Device data and values that can be read and set

PDS(SR) Power Drive System (Safety Related)

PELV Protective Extra Low Voltage, low voltage with

DIx DI1: Digital Input 1

DI2: Digital Input 2

EMC Electromagnetic compatibility

PFD Probability of Failure on Demand (IEC 61508, IEC

Encoder Sensor for detection of the angular position of a

rotating component. Installed on/in a motor, the

PFH Probability of Failure per Hour (IEC 62061 and

encoder shows the angular position of the rotor.

theoretically correct value or condition.

error classes allow for specific responses to

errors, for example by severity.

Factory settings when the product is shipped

longer able to control the motor so that the

power stage must be immediately disabled.

converter to an operational state after a detected

error is cleared by removing the cause of the

error so that the error is no longer active.

failure (EN ISO 13849-1)

(to a certain extent) by the user

isolation. For more information: IEC 60364-4-41

or IEC 60204-1.

62061)

IEC61508)

PLC Programmable logic controller

6 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 9

Introduction Operating Instructions

PL/

Performance

Level

PUST Power Up Self Test. Internal self test on the

RS-485 Fieldbus interface as per EIA-422/485 Bus

Safe state If a safe state fault is detected, the safety option

SF Safe Function

SIL Safety Integrity level (IEC61508, IEC61800-5-2,

SLS - Safely

limited speed

SO Safety Option

SRECS Safety Related Electrical Control System (IEC

SRP/CS Safety related parts of control systems (EN ISO

SS1 - Safe

Stop 1

STO - Safe

Torque Off

TM Mission Time (EN ISO 13849-1)

Warning If the term is used outside the context of safety

Discrete level used to specify the ability of

safety-related parts of control systems to perform

a safety function under foreseeable conditions

(EN ISO 13849-1)

safety option.

Description, which enables serial data

transmission with multiple devices.

goes into safe state. This includes faults related

to integrity of hardware or firmware.

IEC62061)

Safety function in accordance with EN IEC

61800-5-2, monitors the frequency converter to

check that it stays within a defined speed limit.

SLS is the abbreviation for safely limited speed.

62061)

13849-1)

Safety function in accordance with EN IEC

61800-5-2, ensures that the motor decelerates in

the expected way. SS1 is the abbreviation for

safe stop 1.

Safety function in accordance with EN IEC

61800-5-2, prevents torque from being

generated by the motor. This function is

integrated within the frequency converter as

standard. STO is the abbreviation for safe torque

off.

instructions, a warning alerts to a potential

problem that was detected by a monitoring

function. A warning is not an error and does not

cause a transition of the operating state.

1

1

Table 1.1 Abbreviations and Definitions

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 7

Page 10

Legal Information and Safet...

Operating Instructions

2 Legal Information and Safety

22

2.1 Legal Information

2.2

Safety

According to the Machinery Directive regulation, it is

hereby stated that the original language of these

Operating Instructions is English UK.

2.1.1 Copyright and Revisions

This publication contains information proprietary to

Danfoss and is protected by Copyright laws of Denmark,

international treaties and most other countries. All

trademarks in this publication are property of the

respective companies. Danfoss and the Danfoss logotype

are trademarks of Danfoss A/S. All rights reserved.

Although Danfoss has tested and reviewed the correctness,

completeness and documentation of this publication,

Danfoss makes no warranty or representation, neither

express or implied, with respect to this publication,

including but not limited to its quality, correctness,

completeness, performance, or fitness for a particular

purpose.

Danfoss reserves the right to revise, update and change

this publication at any time without prior notice or specific

obligation to inform former or present users of such

revisions or changes.

Warranty and Liability

2.1.2

All claims to warranty and liability are rendered invalid if

2.2.1 Safety Precautions

WARNING

HIGH VOLTAGE!

Frequency converters contain high voltage when

connected to AC mains input power. Installation, start

up, and maintenance should be performed by qualified

personnel only. Failure to perform installation, start up,

and maintenance by qualified personnel could result in

death or serious injury.

WARNING

UNINTENDED START!

When the frequency converter is connected to AC mains,

the motor may start at any time. The frequency

converter, motor, and any driven equipment must be in

operational readiness. Failure to be in operational

readiness when the frequency converter is connected to

AC mains could result in death, serious injury,

equipment, or property damage.

CAUTION

This option is suitable for performing mechanical work

on the frequency converter system or affected area of a

machine only. It does NOT provide electrical safety. This

option should NOT be used as a control for starting

and/or stopping the frequency converter. See the

requirements for those applications in ISO 12100.

the product was used contrary to the purpose for

•

which it is intended.

damage can be attributed to not having followed

•

the guidelines in the manual.

operating personnel are not suitably qualified.

•

any type of modification has been made (e.g.

•

exchanging components on the PCB boards,

soldering work etc.).

8 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

2.2.2 Risk Assessment

CAUTION

The safety option is intended to be part of the safetyrelated control system of a machine. Before installation,

a risk assessment shall be performed to determine

whether the specifications of this safety option are

suitable for all foreseeable operational and environmental characteristics for the system in which it will be

installed.

The system user is responsible for

the set-up, safety rating and validation of any

•

sensors or actuators connected to the system.

completing a system-level risk assessment and

•

reassessing the system any time a change is

made.

Page 11

Legal Information and Safet...

Operating Instructions

providing supposition (as needed for the

•

application) that the system fulfills desired safety

rating.

project management and proof testing.

•

programming the application software and the

•

safety option configurations in accordance with

the information in this manual.

access to the control system.

•

analysing all configuration settings and selecting

•

the proper setting to achieve the required safety

rating.

Safety Regulations

2.2.3

Check that the mains supply has been discon-

•

nected and that the necessary time has elapsed

before removing motor and mains supply plugs

and before commencing any repair work.

The [Off] key on the LCP does not disconnect

•

mains supply and must never be used as a safety

switch.

Ensure the following in accordance with national

•

and local regulations:

The equipment must be properly

-

earthed

The user must be protected against

-

supply voltage

The motor must be protected against

-

overload

The earth leakage current exceeds 3.5 mA.

•

Protection against motor overload is not included

•

in the factory setting. If this function is desired,

set 1-90 Motor Thermal Protection to data value [4]

ETR trip 1 or data value [3] ETR warning 1.

Do not remove the plugs for the motor and

•

mains supply while the frequency converter is

connected to mains.

NOTICE

The frequency converter has more voltage sources than

L1, L2 and L3, when load sharing (linking of DC

intermediate circuit) or external 24 V DC are installed.

engineers and are suitably experienced to

operate devices, systems, plant and machinery in

accordance with the general standards and

guidelines for safety technology.

are familiar with the basic regulations concerning

•

health and safety/accident prevention

have read and understood the safety guidelines

•

given in this description and also the instructions

given in the VLT® AutomationDrive FC 301/FC 302

Operating Instructions.

have a good knowledge of the generic and

•

specialist standards applicable to the specific

application.

Users of PDS(SR)s are responsible for

hazard and risk analysis of the application.

•

identifying safety functions required and

•

allocating SIL or PLr to each of the functions.

other subsystems and the validity of signals and

•

commands from them.

designing appropriate safety-related control

•

systems (hardware, software, parameterisation,

etc.).

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations that

may result in damage to equipment or property.

Approvals

2 2

2.2.4 Qualified Personnel

The products may only be assembled, installed,

programmed, commissioned, maintained and decommissioned by persons with proven skills. Persons with proven

skills

are qualified electrical engineers, or persons who

•

have received training from qualified electrical

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 9

Page 12

130BC308.10

Field bus

Interface

MCB 150/151

Safety Option

Option A

Option B

Inte rnal Bus 1

Inte rnal Bus 2

μ C

Control Card

IGBT

STO

37

E

M

PLC

E

M

E

R

E

N

C

Y

G

S

T

O

P

Functions and System Overvi...

Operating Instructions

3 Functions and System Overview

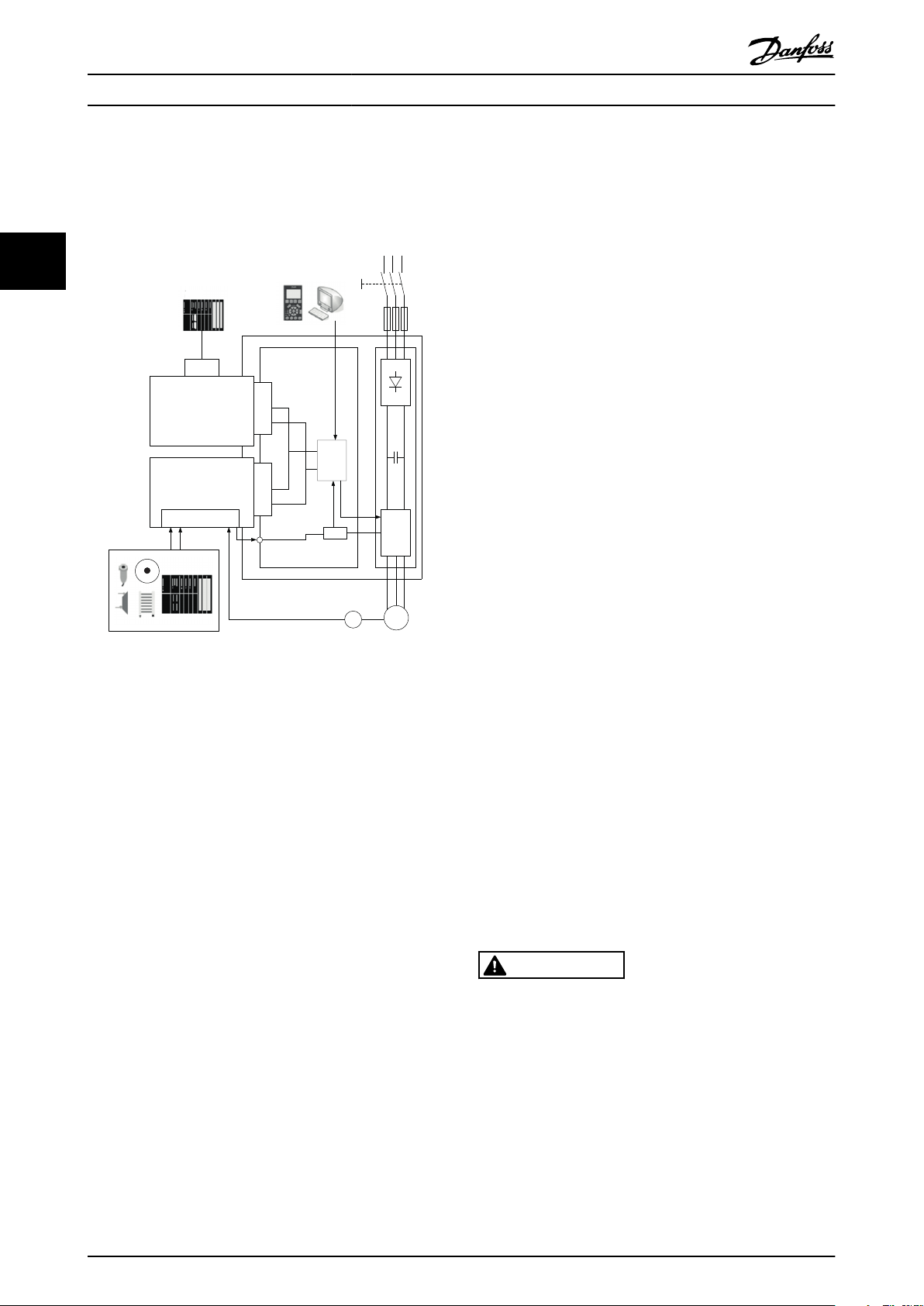

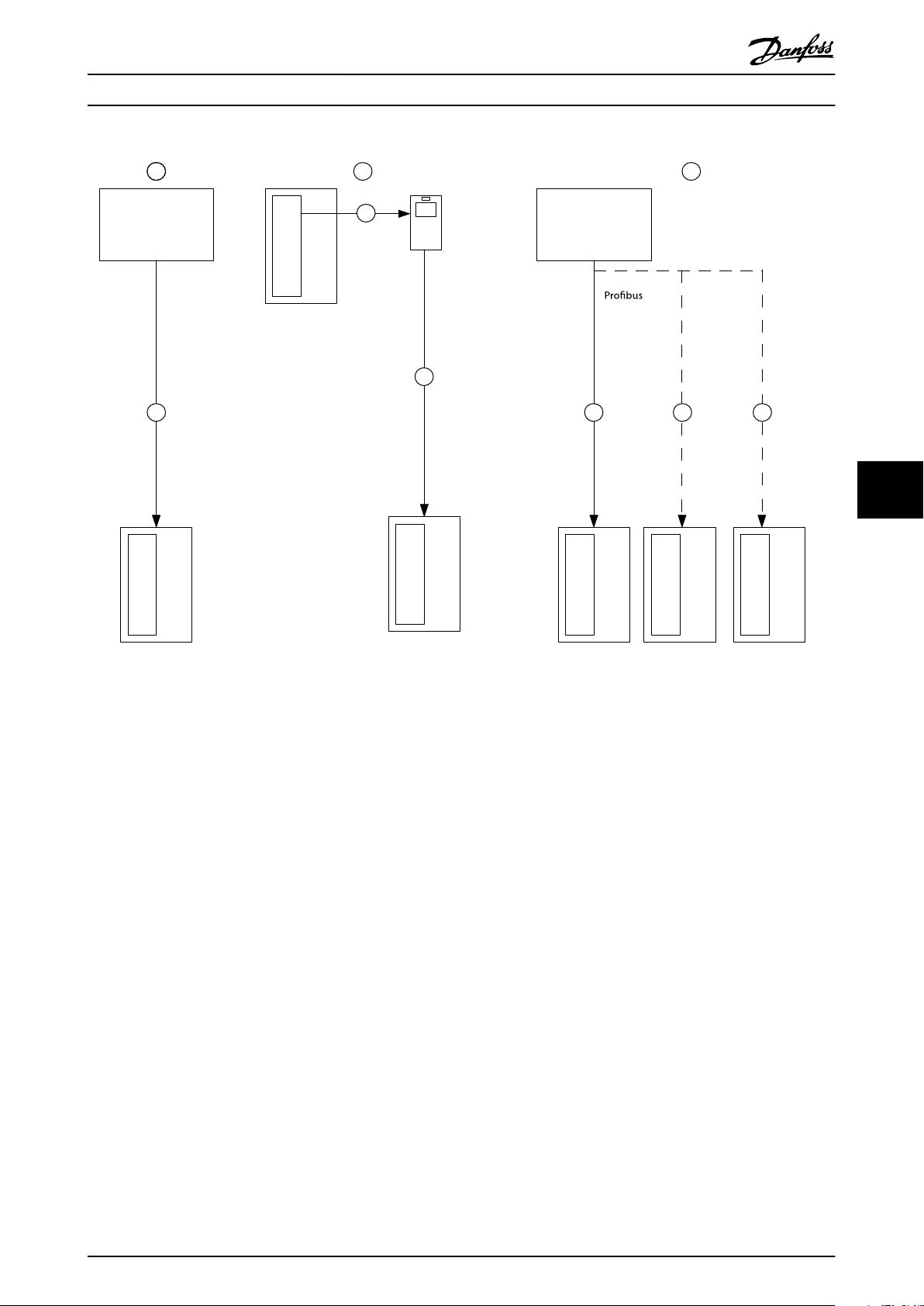

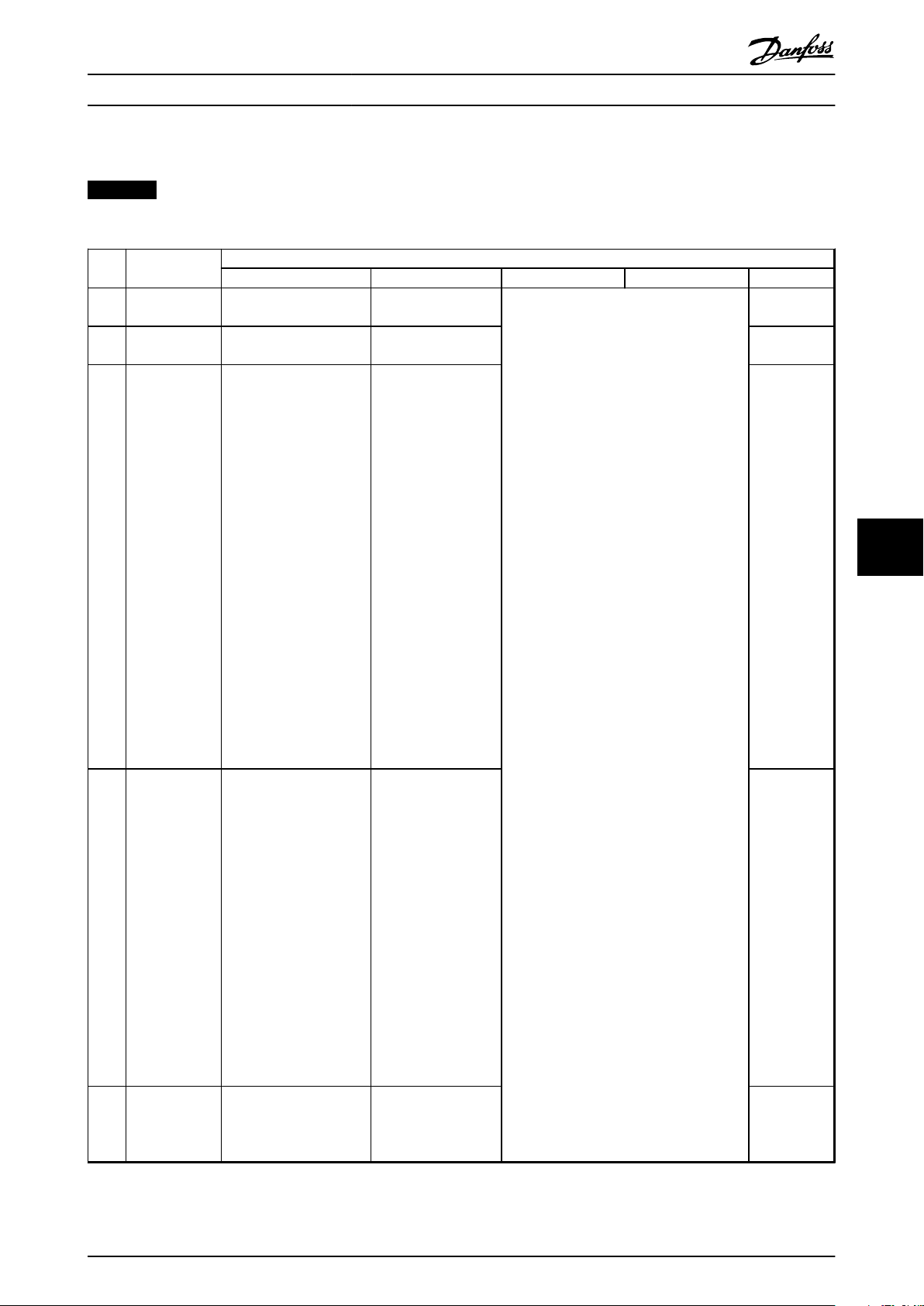

3.1 System Overview

with hard guarding, access doors, and safety gates with

solenoid-lock or -unlock safety switches. When the speed

33

of the monitored device drops below the set switch point

(where its speed is no longer considered dangerous), the

safety option sets S37 output low. This allows the operator

to open the safety gate. In speed monitor applications, the

safety output S37 is high for operation (when the motor

speed of the monitored device is below the set switch

point). When the speed exceeds the set value, indicating a

too-high (dangerous) speed, the safety output is low.

The frequency converter

removes the power to the motor,

•

switches the motor to torque-free, if Safe Torque

•

Off is activated

The safety control system

activates the safety functions via inputs on the

•

safety option

evaluates signals from safety devices, such as

•

Illustration 3.1 FC 302 with Safety Option and Fieldbus Option

The safty option performs safety functions in accordance

with EN IEC 61800-5-2. It monitors safe motion sequences

on frequency converters, which are safely brought to a

stop and shut down in the event of an error.

The safety option

activates safety functions

•

monitors safe motion sequences

•

signals the status of safety functions to the safety

•

control system via possible connected Profibus

fieldbus

activates the selected failure reaction Safe Torque

•

Off or Safe Stop 1, in the event of an error

There are 2 variants of the safety option, one with HTL

encoder interface (MCB 151) and one with TTL encoder

interface (MCB 150).

The safety option is constructed as a standard option for

the VLT® AutomationDrive FC 302 and is automatically

detected after mounting.

The safety option can be used to monitor the stopping,

starting or speed of a rotating or laterally moving device.

As speed monitor, the option is often used in combination

10 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

3.1.1

RISK OF HAZARD!

If external forces act on the motor (vertical axis) and an

unwanted movement, for example caused by gravity,

could cause a hazard, add measures for fall protection

before operating the motor.

Triggering the Safe Torque Off safety function means that

the delay time for motors with holding brake is not

effective. The motor cannot generate holding torque to

bridge the time to application of the holding brake. Check

whether additional measures have to be taken; for

example, this may cause the load of vertical axes to lower.

processes the safety option status function

•

provides safe connection between safety option

•

and safety control system

provides fault detection at activation of safety

•

functions (shorts across contacts, short circuit) on

signal between the safety control system and

safety option

Behaviour of Holding Brake

CAUTION

E-STOP push buttons

-

Non Contact Magnetic switch

-

Interlocking switch

-

Light curtain devices

-

Page 13

130BC962.10

Detect

Sensor

E.g. lightcurtain

Process Switch

Logic

E.g. MCB 15x

Actuator

E.g. FC 302

Functions and System Overvi... Operating Instructions

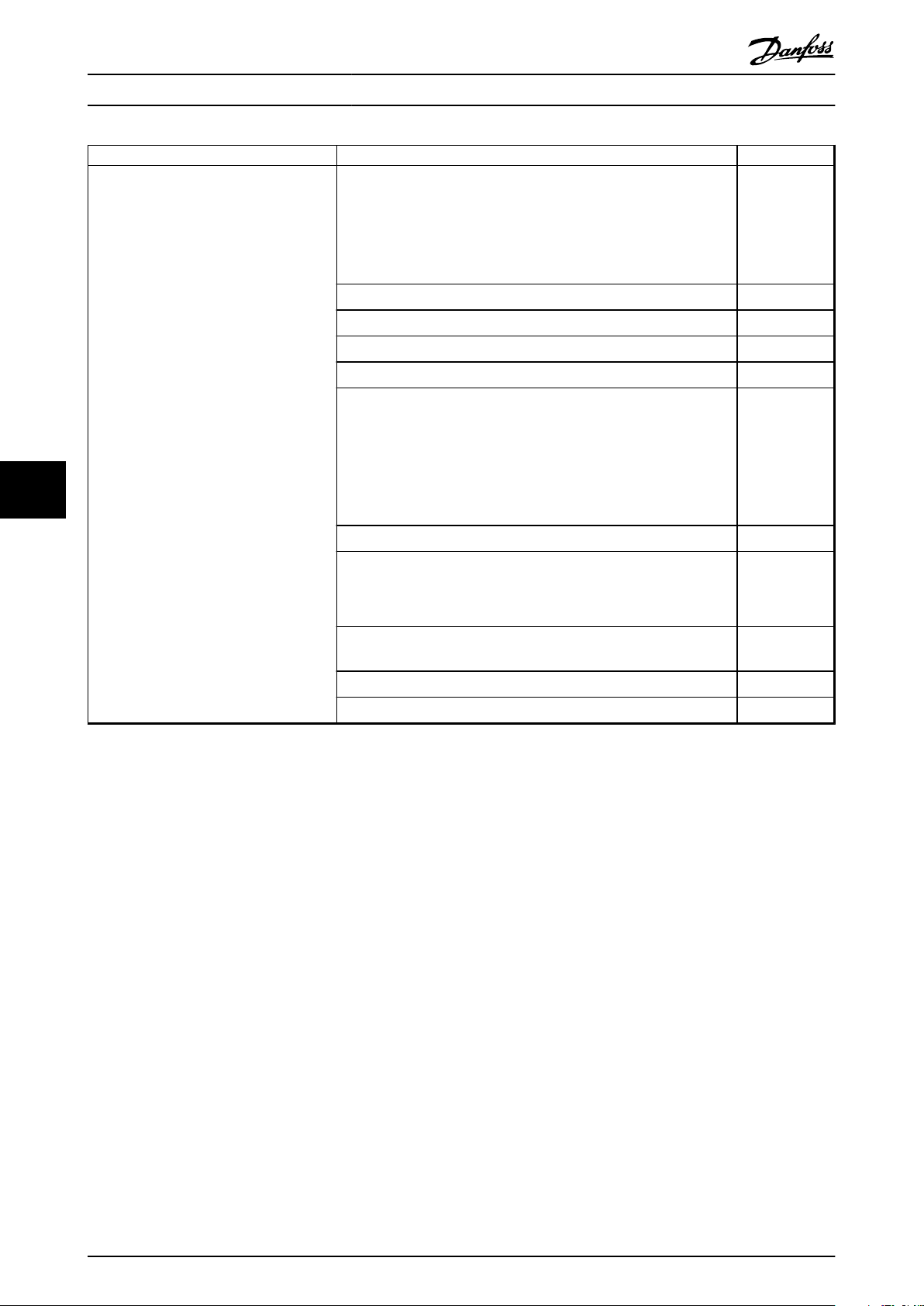

3.1.2 Safety Certification

The safety option is certified for use in safety applications up to and including SIL 2 according to EN IEC 61508 and EN IEC

62061, Performance Level PL d and Category 3 according to EN ISO 13849-1. Safety requirements are based on the

standards valid at the time of certification. The IFA (Institute for Occupational Safety & Health) has approved the safety

option for use in safety-related applications where the de-energised state is considered to be the safe state. All of the

examples related to I/O included in this manual are based on achieving de-energisation as the safe state.

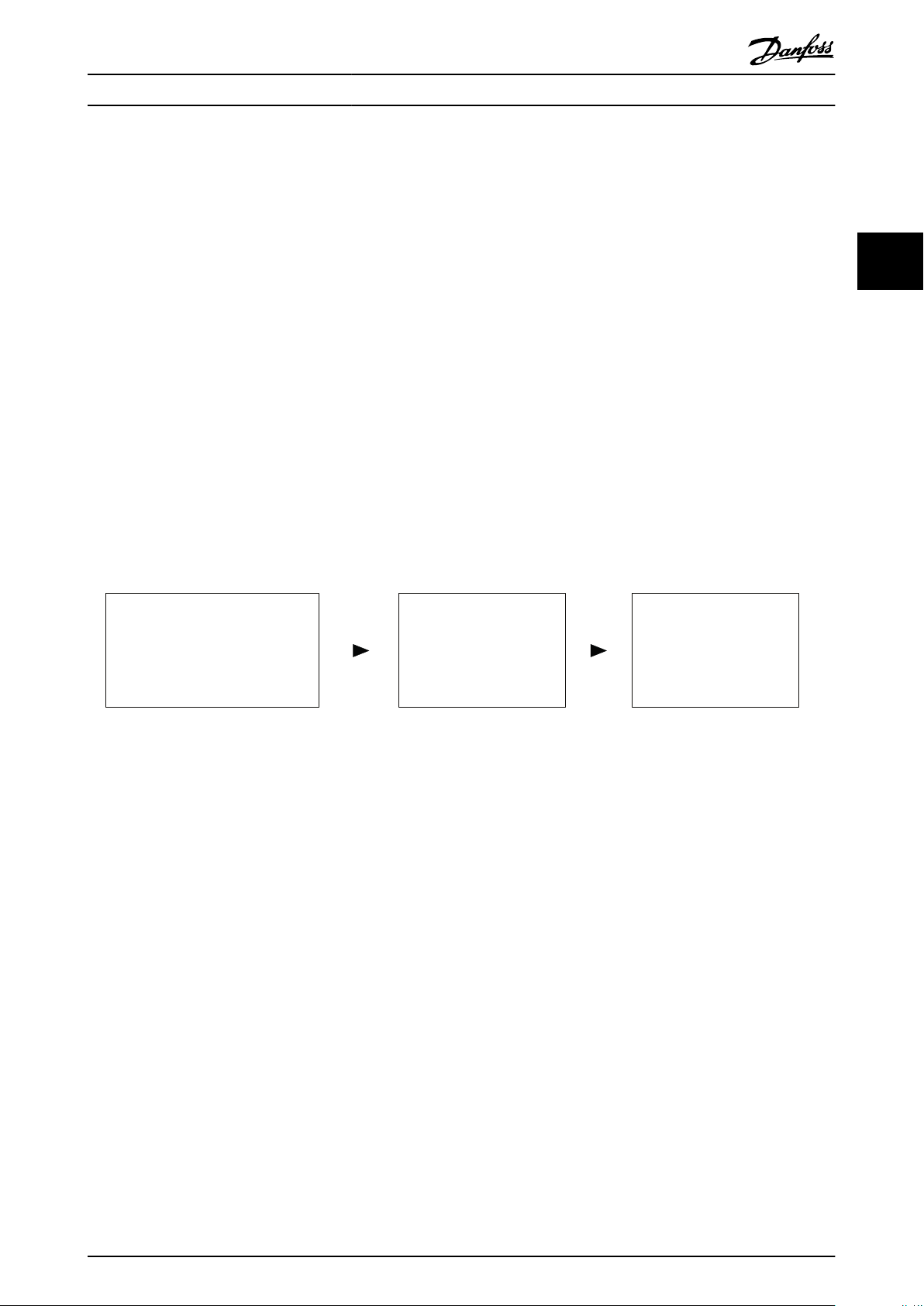

3.1.3 Implementation in Control Systems

In many cases design measures are not sufficient and protective devices are needed to minimise risk. In this context, safety

functions executed by SRP/CS (safety related parts of control systems) are defined. SRP/CS includes the entire safety chain

with sensor (detect), logic (process) and actuator (switch).

Safety functions are defined on the basis of both the application and the hazard. They are often specified in a Type C

standard (a product standard) which provides precise specifications for special machines. If a C standard is not available, the

machine designer defines the safety functions. Typical safety functions are described in more detail in EN ISO 13849-1,

section 5, Specification of Safety Functions. The safety functions for frequency converter systems are described in IEC

61800-5-2.

3 3

Illustration 3.2 Sensor-Logic-Actuator Safety Chain

3.2 Functions

3.2.1 Specification of Safety Functions

The standards require a specification of functional

requirements. The specification must contain details about

each safety function that should be executed. Also define

the

necessary interfaces with other control functions

•

required error responses

•

performance level required PLr or achievable SIL

•

level

3.2.1.1

Performance Level (PL) and Safety

Integrity Level (SIL)

For safety-related control systems, Performance Level (PL),

according to EN ISO 13849-1, and SIL levels, according to

EN IEC 61508 and EN IEC 62061, include a rating of the

system's ability to perform its safety functions.

All of the safety-related components of the control system

must be included in both a risk assessment and the

determination of the achieved levels. Refer to EN ISO

13849-1, EN IEC 61508 or EN IEC 62061 standards for

complete information on requirements for PL and SIL

determination.

3.2.2 Validation of Performance Level

Check whether the required Performance Level “PLr”,

determined in the risk assessment, is achieved by the

selected system for each safety function used.

Check the calculation using the SISTEMA SW Tool of IFA

(Institute for Occupational Safety & Health). Danfoss

provides a component library which can be used for the

calculation. Danfoss offers corresponding services to

support the system check by calculation. Library can be

downloaded from www.dguv.de/ifa/en/pra/softwa/sistema.

If using another validation method for the performance

level, use the characteristic safety values specified.

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 11

Page 14

130BC373.11

time

frequency

time

frequency

A

B

C

Functions and System Overvi...

Operating Instructions

3.2.3 Activation of Safety Functions

The safety functions are activated using the dual-

•

pole safe inputs on the safety option.

These inputs operate in accordance with the fail-

•

33

safe principle (on switching off). The safety

control system activates the safety functions via a

1/0 transition.

Deactivate the safety functions before applying

•

any changes to them.

3.2.4 Simultaneous Activation of Safety

Functions

All safety functions can be active at the same time.

However, Safe Torque Off has priority over all other safety

functions. Functions already started (e.g. Safe Stop 1 or

Safely Limited Speed) are canceled and the frequency

converter coasts.

Safe Torque Off has the highest priority. If the

•

Safe Torque Off function is triggered, a Safe

Torque Off is managed no matter what other

If 2 Safe Stop 1 functions are active at the same time, the

function with the steepest ramp has higher priority than

the function with less steep ramp.

If 2 Safely Limited Speed functions are active at the same

time, the function with the lowest speed limit has higher

priority than the function with higher speed limit.

If 2 equal safety functions have to be configured, they

must be parameterised as SS1-a and SS1-b or SLS-a and

SLS-b.

functions are active.

Safe Stop 1 has medium priority to the other safe

•

functions.

Safely Limited Speed has the lowest priority.

•

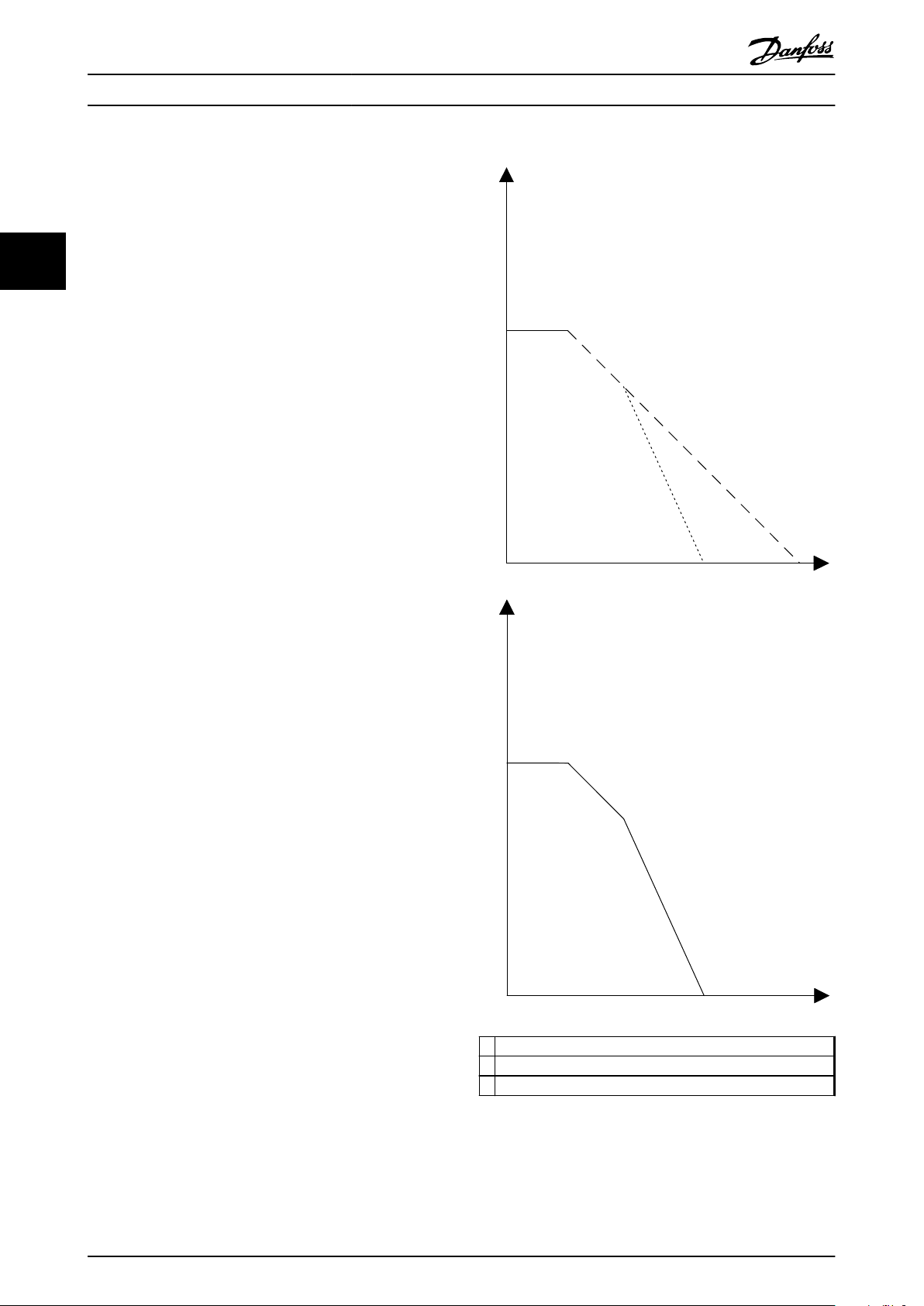

Ramp stop function 1

A

12 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

B Ramp stop function 2

C Actual ramp stop function

Illustration 3.3 2 Safe Stop 1 Safety Functions Active

Illustration 3.3 shows the result of activating first a Safe

Stop 1 function with a given ramp and afterwards

Page 15

Functions and System Overvi...

Operating Instructions

activating a second Safe Stop 1 function with a steeper

ramp. The lower graph shows the actual ramp function.

3.2.5 Functional Proof Tests

The functional safety standards require that functional

proof tests are performed on the equipment used in the

system. Proof tests are performed at user-defined intervals

and are dependent on PFD and PFH values.

3.2.6 PFD and PFH Definitions

Safety-related systems can be classified as operating in

either a Low Demand mode, or in a High Demand/

Continuous mode.

Low demand mode

The frequency of demands for operation made on a safetyrelated system is no greater than once per year.

High Demand/Continuous mode

The frequency of demands for operation made on a safetyrelated system is greater than once per year.

The SIL value for a low demand safety-related system is

directly related to order-of-magnitude ranges of its average

probability of failure on demand (PFD). The SIL value for a

High Demand/continuous mode safety-related system is

directly related to the probability of a dangerous failure

per hour (PFH).

Intended Use of the Safety Option

3.2.7

CAUTION

RISK OF PERSONAL INJURY AND EQUIPMENT

DAMAGE!

To avoid personal injury and equipment damage, only

use the safety option for its intended purpose.

The following is considered as improper use

any component, technical or electrical modifi-

•

cation to the frequency converter

use of the frequency converter outside the

•

allowed electrical and environmental conditions

specified in chapter 9 Technical Specifications

and in the VLT® AutomationDrive FC 301/FC 302

Operating Instructions.

The safety option is designed for use in safety-related

applications. It meets the requirements for safety functions

in accordance with IEC 61800-5-2, regarding safe motion

monitoring.

3.2.8

MCT 10 Set-up Software with Safe

Plug-in

Use MCT 10 Set-up Software to configure the safety

functions supported in safety option.

Configuration of the safety functions is required

•

for safe motion sequences. In the event of an

error or fault, these functions shut down the

frequency converter's power element in a safe

and controlled way.

Setting of limit values, braking ramps for the

•

safety functions, monitoring of motion sequences.

The software

runs in full with a license key. All functions are

•

available from MCT 10 Set-up Software version

3.18.

supports the configuration of applications with

•

up to max. 256 safety options per project

has a simple language setting for the user

•

interface.

A PDF file and a commissioning report can be generated

for documentation of the project and all its settings.

3.3

Unit Features

The safety option has the following features

2 Dual-pole, digital inputs to activate the safety

•

functions in accordance with EN IEC 61800-5-2

Safe Torque Off (STO)

-

Safe Stop 1 (SS1)

-

Safely Limited Speed (SLS)

-

Reset function

•

Digital input 2 can be used for resetting

-

the safety option after an error or after

deactivation of a safety function.

Status indicators

•

Safe input status (LED 1 and LED 2)

-

Safe output status (LED 4)

-

LED 3 reserved for future use (always in

-

off state)

By Fault or warning the LEDs indicate a

-

failure via flash pattern, see Table 8.2

Supply voltage

•

Internally supplied by the frequency

-

converter.

24 V DC output for safety sensors and

-

encoder available.

3 3

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 13

Page 16

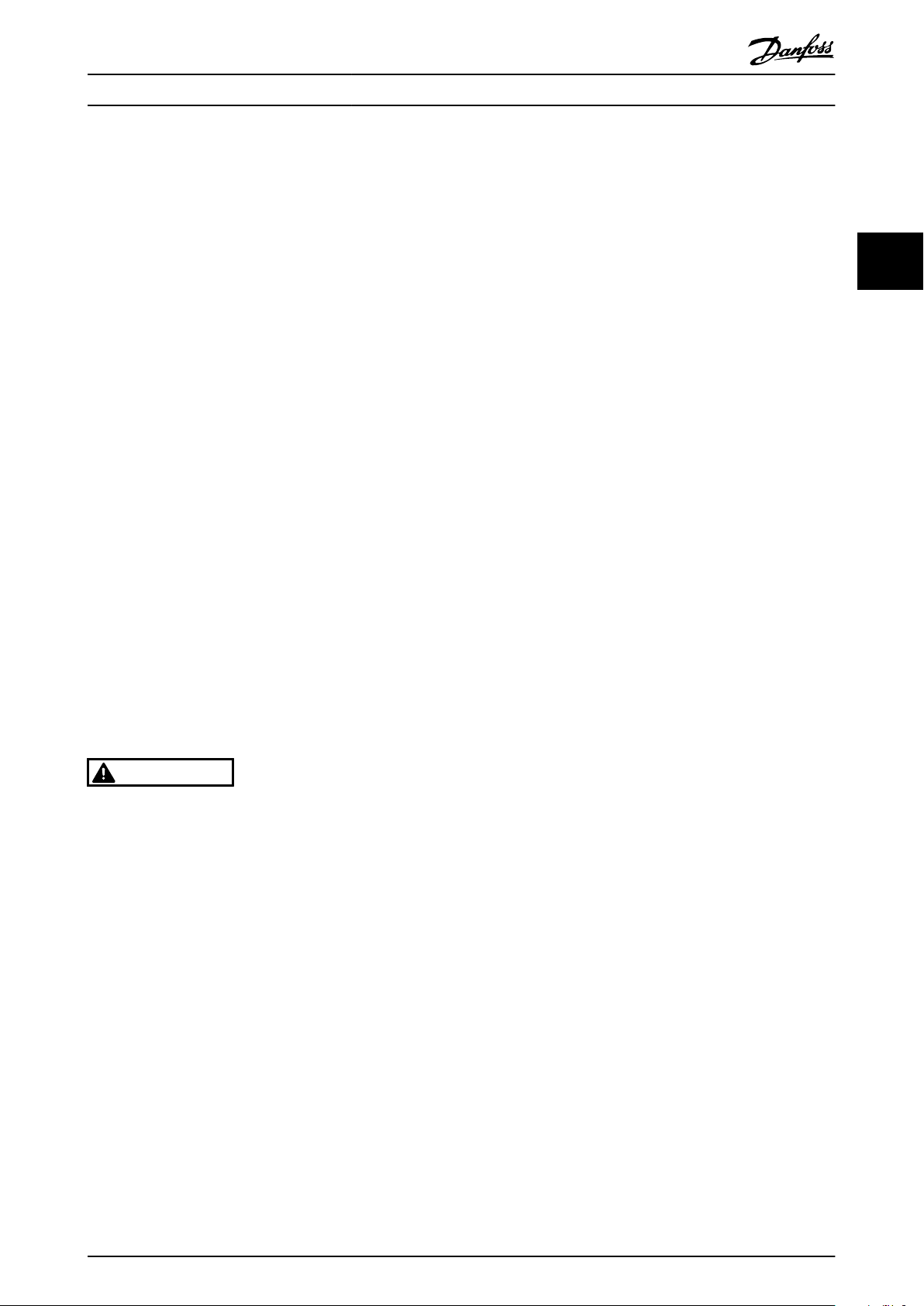

E30BC325.11

MCB 150

Safe Option

SW. ver. xx. xx

Option B

130B3280

LED:

123 4

TTL Enc. interface

Y30/

DI1 A

GND

DI1 B

ENC A

DI2 A

ENC nA

ENC B

DI2 B

ENC nB

24V

GND

S37

1 2 3 4 5 6 7 8 9 10 11 12

E30BC326.11

MCB 151

Safe Option

SW. ver. xx. xx

Option B

130B3290

LED:

1

2

3 4

HTL Enc. interface

Y31/

DI1 A

GND

DI1 B

ENC A

DI2 A

ENC B

DI2 B

24V

GND

S37

1 2 3 4 5 6 7 8 9 10 11 12

GND

GND

Functions and System Overvi...

Operating Instructions

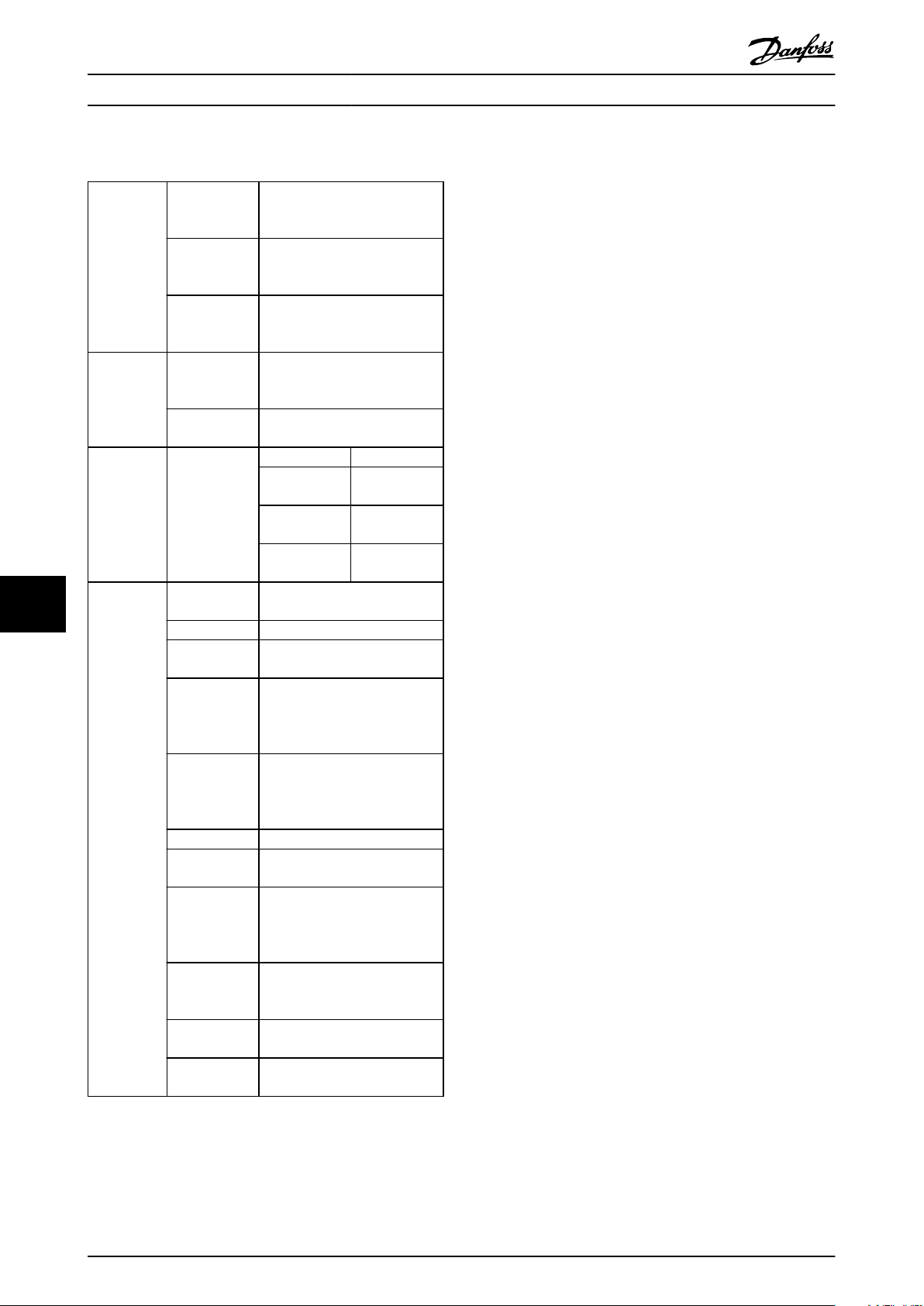

3.4 Front View

Refer to EN IEC 61800-5-2:2007 (4.2.2.2) for a definition of

Safe Torque Off (STO).

A Category 1 stop triggers a controlled stop. The safety

option monitors the controlled stop. If a power outage or

an error occurs, a controlled stop is impossible. Trigger the

33

safety function Safe Torque Off after the stop to shut off

the motor torque.

Refer to EN IEC 61800-5-2:2007 (4.2.2.3) for a definition of

Safe Stop 1 (SS1).

An evaluation of the machine-related risks determines

Illustration 3.4 MCB 150

which of the 2 stopping methods to use.

NOTICE

When designing the machine application, consider

timing and distance for a coast to stop (Stop Category 0

or Safe Torque Off). For more information regarding stop

categories, refer to EN IEC 60204-1.

3.5.1 Operation and Requirements

3.5 Categories of Safe Stop

International standard EN/ISO 13850 specifies the

functional requirements and design principles of

emergency stop devices.

It applies to all machines, whatever type of energy is used

to control this function.

The standard allows 2 types of stop

During a category 0 stop, the motor coasts down in an

uncontrolled way. If access to the machine coasting down

involves a hazard (results of the hazard and risk analysis),

take protective measures to avoid the hazard.

Illustration 3.5 MCB 151

Category 0 stop: Stopping by immediately

•

cutting-off power or mechanical disconnection

between the dangerous components

Category 1 stop: Controlled stopping with power

•

maintained to the actuator to achieve stopping

(braking for example), then cut-off of power

when zero speed is reached.

The safety option is redundant and self-checking. It

requires digital input signals from an input sensor (e.g.,

PNP proximity switch) or higher resolution TTL or HTL

encoders to monitor for either safe stop or speed

conditions.

Safety Functions

3.5.2

Safety functions maintain a safe condition or prevent

hazardous conditions from arising. The safety functions for

frequency converters are defined in EN IEC 61800-5-2.

The safety option implements the following safety

functions

Safe Torque Off (STO)

•

No power is being fed to the motor

-

which can generate a rotation. Stop

category 0 to EN IEC 60204-1

Safe stop 1 (SS1)

•

Motor decelerates. Monitoring of

-

deceleration ramp and Safe Torque Off

following zero speed, or Safe Torque Off

at the end of a deceleration time. Stop

category 1 to EN IEC 60204-1

Safely limited speed (SLS)

•

Prevents exceeding a defined speed

-

value

14 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 17

frequency

130BC318.10

time

1

2

A

Functions and System Overvi...

Operating Instructions

3.5.3 Safe Torque Off - STO

The safety function Safe Torque Off disconnects power to

the motor. It is implemented via the frequency converter's

shutdown path and the safety option’s safe outputs.

Features of the safety function

The motor becomes torque-free and no longer

•

generates any hazardous movements

To prevent the frequency converter from running

•

down in an uncontrolled manner. In normal

operation, activate the safety function Safe

Torque Off via the safety function Safe Stop 1

Safe Torque Off is only activated directly when

•

There is an internal error on the safety

-

option

The Safe Stop 1 delay time is set to 0

-

One of the inputs DI1 or DI2 has been

-

selected as Safe Torque Off function

The safety function Safe Torque Off corresponds

•

to a category 0 stop (uncontrolled stop) in

accordance with EN IEC 60204-1.

Prerequisites for normal operation

Input DI1 or DI2: "1" Signal (+24 V DC)

•

S37 output: "1" Signal (+24 V DC).

•

Safety function is activated

By an error after limit values have been exceeded

•

for Safe Stop 1 and Safely Limited Speed

By an internal error on the safety option or

•

frequency converter, if the frequency converter

can no longer be controlled

By executing the safety function Safe Stop 1 (1/0

•

transition). In this case the frequency converter is

monitored before it is switched to torque-free.

By download of parameterisation via MCT 10 Safe

•

Plug-in if the current frequency converter is

running.

By executing the safety function Safe Torque Off

•

(1/0 transition). This function ensures that no

torque-generating energy can continue to affect a

motor and prevents unintentional start-ups.

WARNING

If any external forces influence the motor axis (e.g.

suspended loads), additional measures (e.g. a safety

holding brake) are required to eliminate hazards.

The Safe Torque Off (STO) may be used where power

removal is required to prevent an unintended start. The

function disables the control voltage of the frequency

converter output stage. Thus, it prevents the frequency

converter from generating the voltage required to rotate

the motor (see Illustration 3.6). The function allows for

performing maintenance work on non-electrical parts of

the machinery without switching off the power supply to

the frequency converter.

A Actual frequency

1 Activation of Safe Torque Off

2 Motor standstill

Illustration 3.6 Safe Torque Off

Safe Stop 1 - SS1

3.5.4

The safety function Safe Stop 1 monitors the deceleration

to zero speed in a controlled manner and activates Safe

Torque Off after detection of stop. The Safe Stop 1 can

either be configured as SS1 Delay or SS1 Ramp.

Features of the safety function

The safety function Safe Stop 1 corresponds to a

•

category 1 stop (controlled braking) in

accordance with EN IEC 60204-1

Monitoring the speed deceleration after which

•

the energy supply to the motor is safely

interrupted

The motor becomes torque-free and removes

•

hazardous movements

3.5.4.1

Select SS1 Delay to activate Safe Stop 1 function while a

parameterised safety delay timer expires.

SS1 Delay

3 3

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 15

Page 18

130BC321.10

1 2

time

frequency

3

4

A

Functions and System Overvi...

Safe Torque Off is activated immediately when the

configured Stop Delay has expired, regardless of speed,

see chapter 6.1 Configuration for parameter settings.

Selecting the SS1 settings

1.

Enter 42-41 Ramp Profile

33

2. Select

2a

[0] Linear, if the ramp must follow a

linear curve

2b

[2] S-ramp Const Time, if the ramp

should follow an S-ramp

By using SS1 Delay, the frequency converter attempts to

follow the selected ramp. After a specified delay time, Safe

Torque Off is activated and the motor is made torque free.

Operating Instructions

CAUTION

Using SS1 Delay may result in the motor still spinning

when the Safe Torque Off is activated. The risk analysis

for the machine must indicate that this behaviour can be

tolerated. An interlock may be required.

Default value in 42-40 Type is [0] Delay. If this value is

selected, the Safe Stop 1 function activates a braking ramp

defined from a selected time delay in 42-42 Delay Time.

This means that the braking ramp is linear. Select the value

of 42-43 Delta T (the % of the delay time), which is a

reasonable tolerance after the SS1 Delay Time has expired.

NOTICE

The SS1 delayu function does not monitor the stopping

of the frequency converter!

The safety relevant time, Delta T, allows the frequency

converter to come to a stop before Safe Torque Off is

activated. Thus ensuring that the system is also stopped

before Safe Torque Off is activated. If a fault occurs, the

frequency converter does not come to a stop. It coasts

after the time delay no matter of the speed of the

frequency converter.

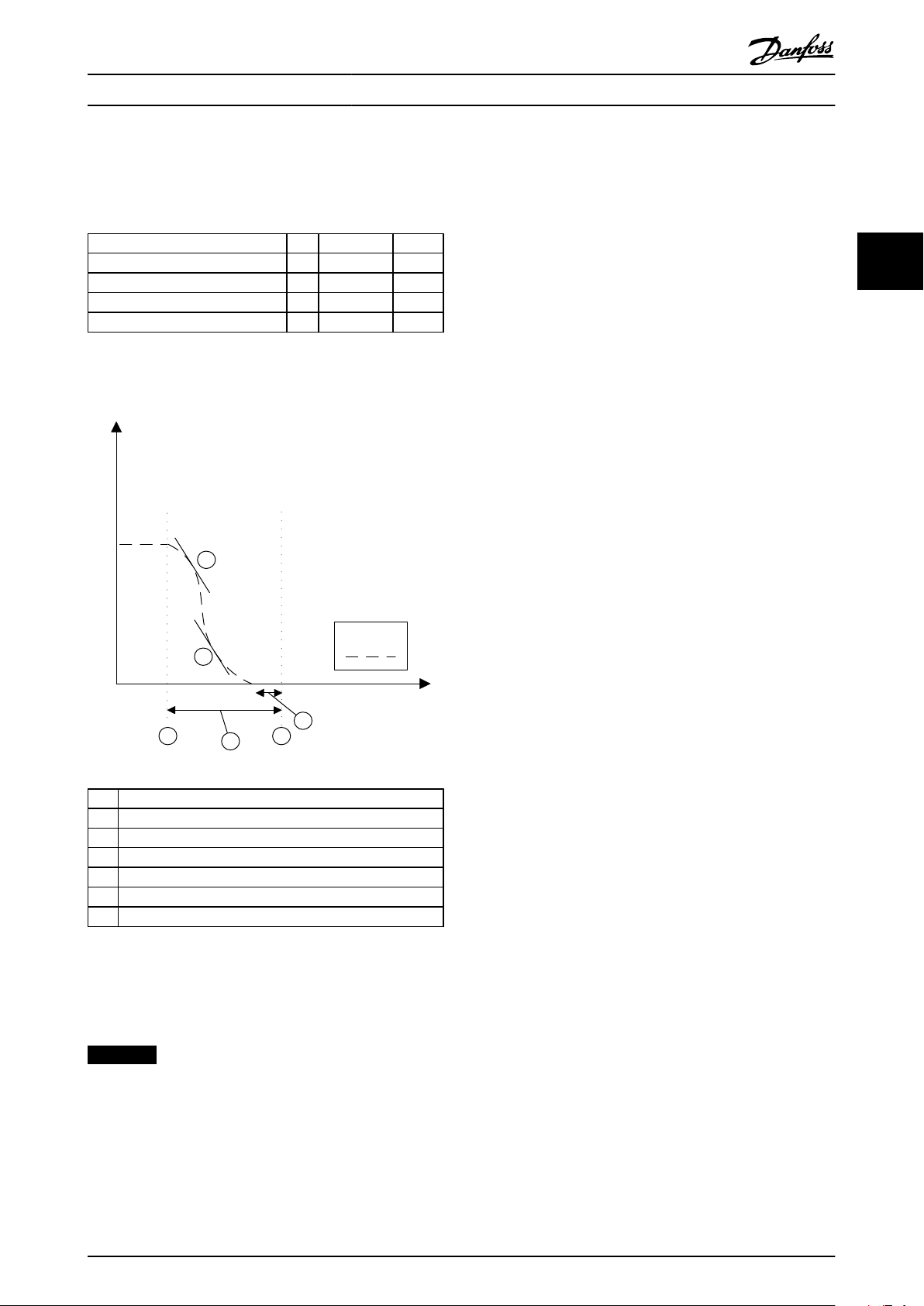

A Actual frequency

1 Activation of SS1 Delay Timer

2 Activation of Safe Torque Off

3 42-42 Delay Time

4 42-43 Delta T

Illustration 3.7 SS1 Delay

When Safe Stop 1 function is active, the frequency

converter brings the motor to zero speed. The Safe Torque

Off function is triggered after a specified safety-relevant

time. This safety function corresponds to a controlled stop

of the frequency converter according to EN IEC 60204-1,

stop category 1.

3.5.4.2

An S-ramp gives non-linear deceleration, compensating for

jerks in the application.

SS1 Delay with S-ramp Stop Profile

1. Define a speed profile by a delay (a ”worst case”

delay from actual frequency to zero speed) and a

delay tolerance. The safety relevant time, Delta T,

allows the frequency converter to come to a stop

before Safe Torque Off is activated. Thus ensuring

that the system is also stopped before Safe

Torque Off is activated. If a fault occurs, the

frequency converter does not come to a stop. It

coasts after the time delay regardless of the

frequency converter speed.

2. Define an S-ramp configuration, which achieves

zero speed within the delay.

16 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 19

130BC322.11

1

2

time

frequency

3

4

actual

frequency

5

6

Functions and System Overvi...

Operating Instructions

3. Configure the S-Ramp ratio at deceleration start

in 42-48 S-ramp Ratio at Decel. Start and set

42-49 S-ramp Ratio at Decel. End for S-Ramp ratio

at deacceleration end.

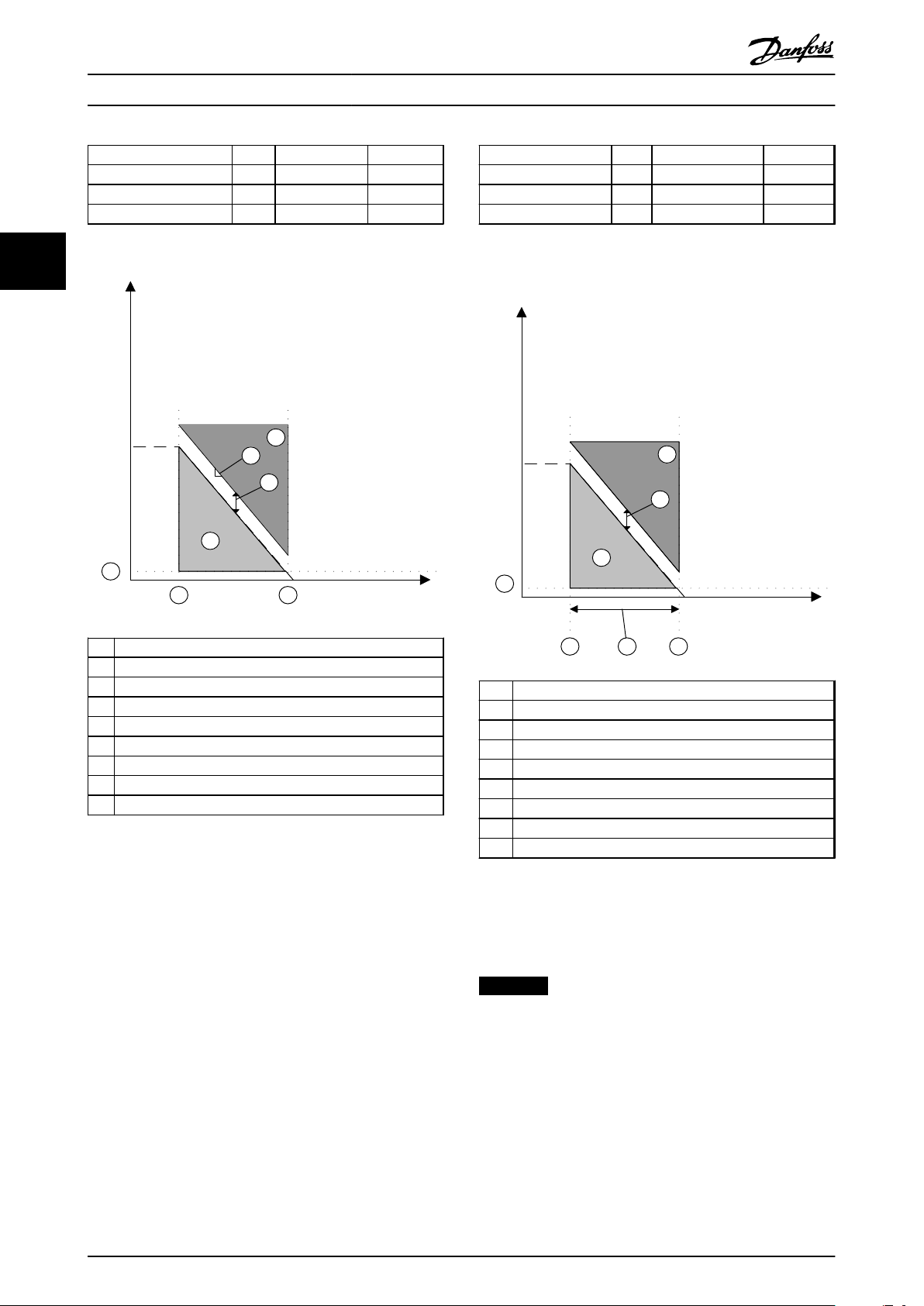

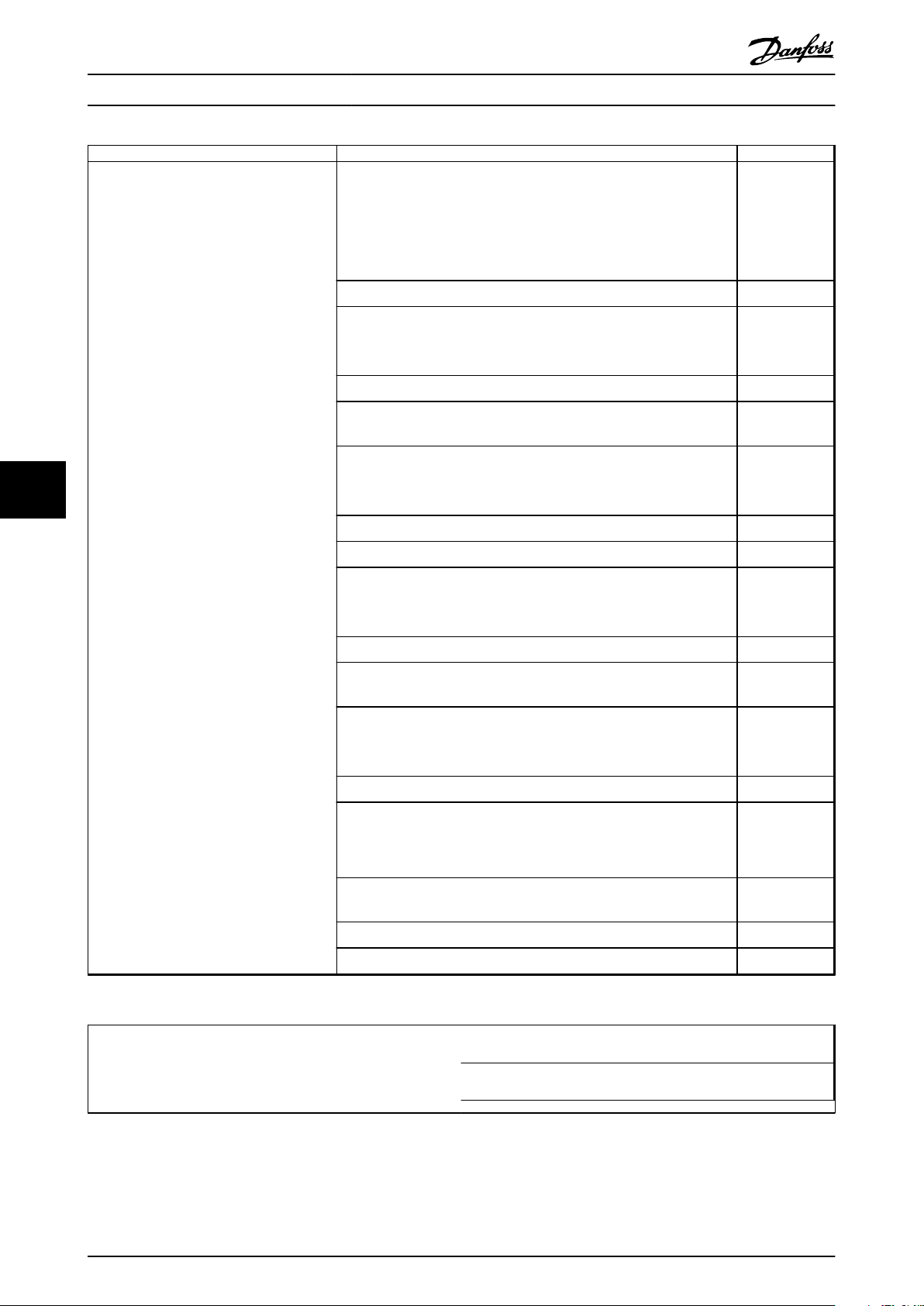

Parameter Unit Range Default

42-42 Delay Time s 0.1-3600.0 s 1.0 s

42-43 Delta T % 0-50% 5%

42-48 S-ramp Ratio at Decel. Start % 1-99 50

42-49 S-ramp Ratio at Decel. End % 1-99 50

Table 3.1 Parameters for SS1 Delay with S-ramp Stop Profile

A Actual frequency

1 Activation of SS1 Ramp Delay

2 Activation of Safe Torque Off

3 42-42 Delay Time

4 42-43 Delta T

5 42-48 S-ramp Ratio at Decel. Start

6 42-49 S-ramp Ratio at Decel. End

Illustration 3.8 SS1 Delay with S-ramp Stop Profile

3.5.4.3

SS1 Ramp

NOTICE

The SS1 Ramp function can only be used when an

encoder is connected to the safety option.

This Safe Stop type allows access to the hazard area

immediately after motion is detected as stopped rather

than waiting until a specific time has elapsed.

The safety option monitors the following functions

Braking ramp

•

In the MCT 10 Set-up Software Safe

-

Plug-in, the braking ramp is specified

and monitoring is activated. The braking

period depends on the speed of the

motor when braking is started. The

braking ramp can be monitored via a

maximum speed error specified in the

MCT 10 Set-up Software tolerable in

42-45 Delta V.

Braking ramp in normal operation

•

The frequency converter starts with the

-

configured braking ramp when safety

function Safe Stop 1 has been activated.

Once the speed is at zero speed limit,

Safe Torque Off is activated.

Safety function Safe Torque Off is activated when

•

the configured limit value for the position error is

exceeded

A standstill threshold Zero speed (42-46 Zero Speed) for

activating the safety function Safe Torque Off can be

specified in MCT 10 Set-up Software.

Safety function Safe Torque Off is activated when zero

speed is achieved.

Prerequisites for normal operation

Input DI1 or DI2: "1" Signal (+24 V DC)

•

S37 output: "1" Signal (+24 V DC). The safety

•

option is ready for operation

A 1/0 transition at the selected DI1 or DI2 input activates

the safety function.

Signal status of the inputs DI1 and DI2

The Safe Stop 1 ramp starts when one of the 2 inputs is

set to “0”. The safety function Safe Torque Off is activated

once the braking ramp has reached zero speed.

3.5.4.4

For the stopping process, the safety option initiates a stop

signal to the frequency converter and monitors the

controlled braking by monitoring the braking ramp. The

admissible deceleration ramp is specified in

42-44 Deceleration Rate. The frequency converter must

decelerate at least with the steepness of this deceleration

ramp in the event of a Safe Stop 1 request from the safety

option, even under heavy load. If the frequency converter

does not fulfill the admissible deceleration ramp during a

Safe Stop 1 requested by the safety option, a Safe Torque

Off is triggered immediately. The motor then performs an

uncontrolled stop. This action prevents the frequency

converter from continuing to run or even accelerating in

the event of an error.

SS1 Ramp Slope

3 3

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 17

Page 20

130BC319.10

6

4

3

7

1 2

5

time

frequency

6

A

B

130BC320.10

6

4

7

1 2

5

time

frequency

6

3

A

B

Functions and System Overvi...

Operating Instructions

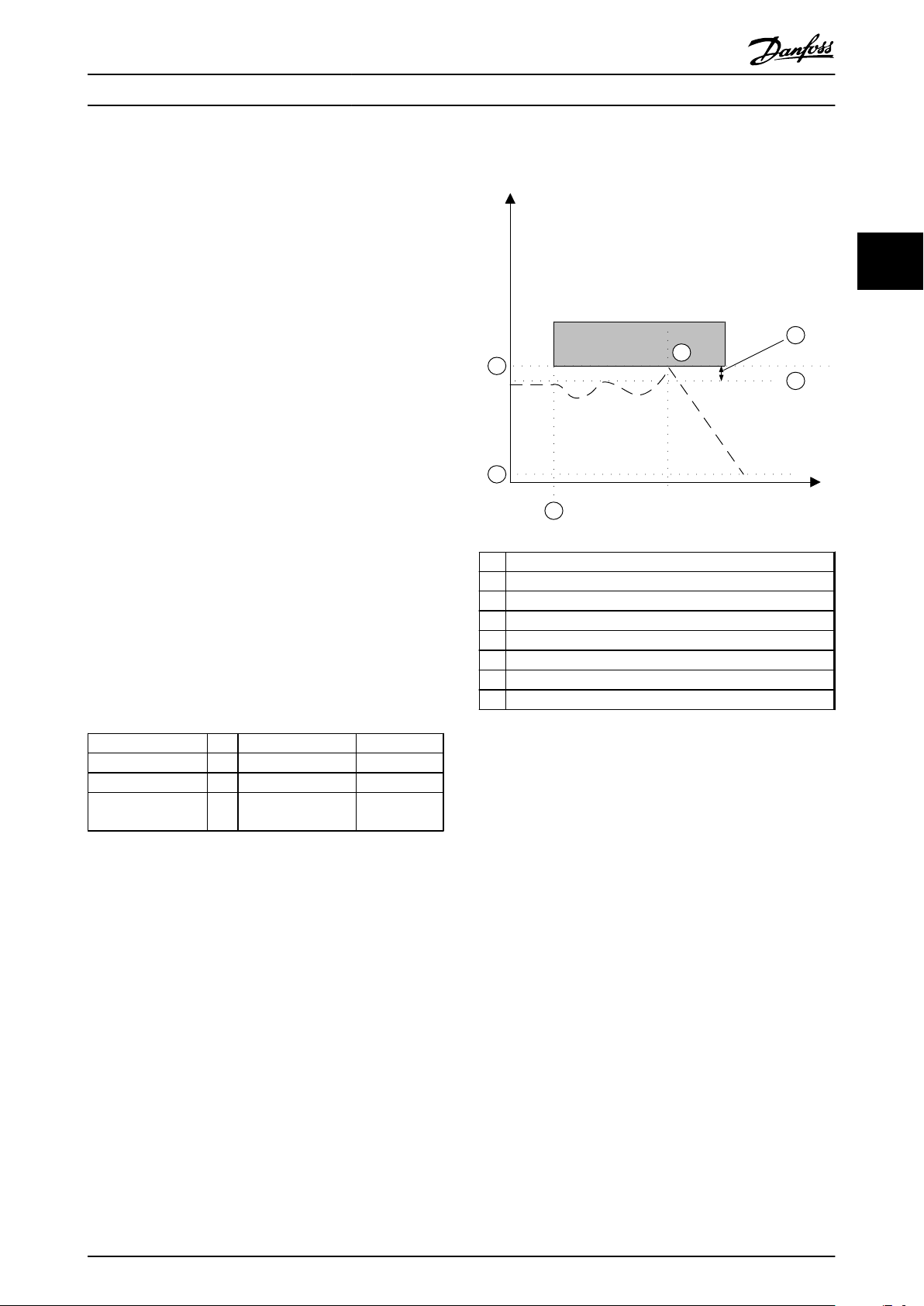

Parameter Unit Range Default

42-44 Deceleration Rate RPM/s 1-30000 RPM/s 1500 RPM/s

42-45 Delta V RPM 1-10000 RPM 120 RPM

42-46 Zero Speed RPM 1-600 RPM 10 RPM

Table 3.2 Parameters for SS1 Ramp Slope

Parameter Unit Range Default

42-47 Ramp Time s 0.1 - 3600.0 s 1.0 s

42-45 Delta V RPM 1 - 10000 RPM 120 RPM

42-46 Zero Speed RPM 1 - 600 RPM 10 RPM

Table 3.3 Parameters for SS1 Ramp Time

33

A Actual frequency

B SS1 Ramp

1 Activation of SS1 Ramp Slope

2 Activation of STO

3 42-44 Deceleration Rate

4 42-45 Delta V

5 42-46 Zero Speed

6 Safety function monitors

7 Activation of failure function

Illustration 3.9 SS1 Ramp Slope

A Actual frequency

B SS1 ramp

1 Activation of SS1 Ramp Time

2 Activation of STO

3 42-47 Ramp Time

4 42-45 Delta V

5 42-46 Zero Speed

6 Safety function monitors

7 Activation of failure function Safe Torque Off

Illustration 3.10 SS1 Ramp Time

When the Safe Stop 1 function is active, the frequency

converter brings the motor to zero speed. The deceleration

is monitored. If the monitored deceleration is slower than

expected or at zero speed, Safe Torque Off is triggered.

This safety function corresponds to a controlled stop of the

frequency converter according to EN IEC 60204-1, stop

category.

3.5.4.5

Define a speed monitoring profile by a deceleration time

and a tolerable speed (Delta V).

18 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

SS1 Ramp Time

Safely Limited Speed (SLS)

3.5.5

NOTICE

The Safely Limited Speed function can only be used

when an encoder is connected to the safety option.

This function is used to limit a machine speed. The main

goal is to monitor the motor speed and to adjust the

speed to a set point. There are 2 types of Safely Limited

Speed

SLS without ramp: Monitors the motor speed and,

•

depending on the setting of 42-52 Fail Safe

Page 21

time

1

2

4

5

3

6

frequency

130BC324.10

A

B

Functions and System Overvi... Operating Instructions

Reaction, trips in Safe Torque Off or Safe Stop 1 if

an overspeed occurs

SLS with ramp: Limits the motor speed to a set

•

point and, depending on the setting of 42-52 Fail

Safe Reaction, trips in Safe Torque Off or Safe

Stop 1, if an overspeed occurs

The Safe Limited Speed is given as speed limit in

42-51 Speed Limit. The value for the cut-off speed partly

depends on the motor that is being used. A suggested

value from MCT 10 Set-up Software calculates a value for

which Danfoss guarantees functionality. This value is called

delta speed limit and is added to the selected speed limit

and suggested as value in 42-50 Cut Off Speed.

3 3

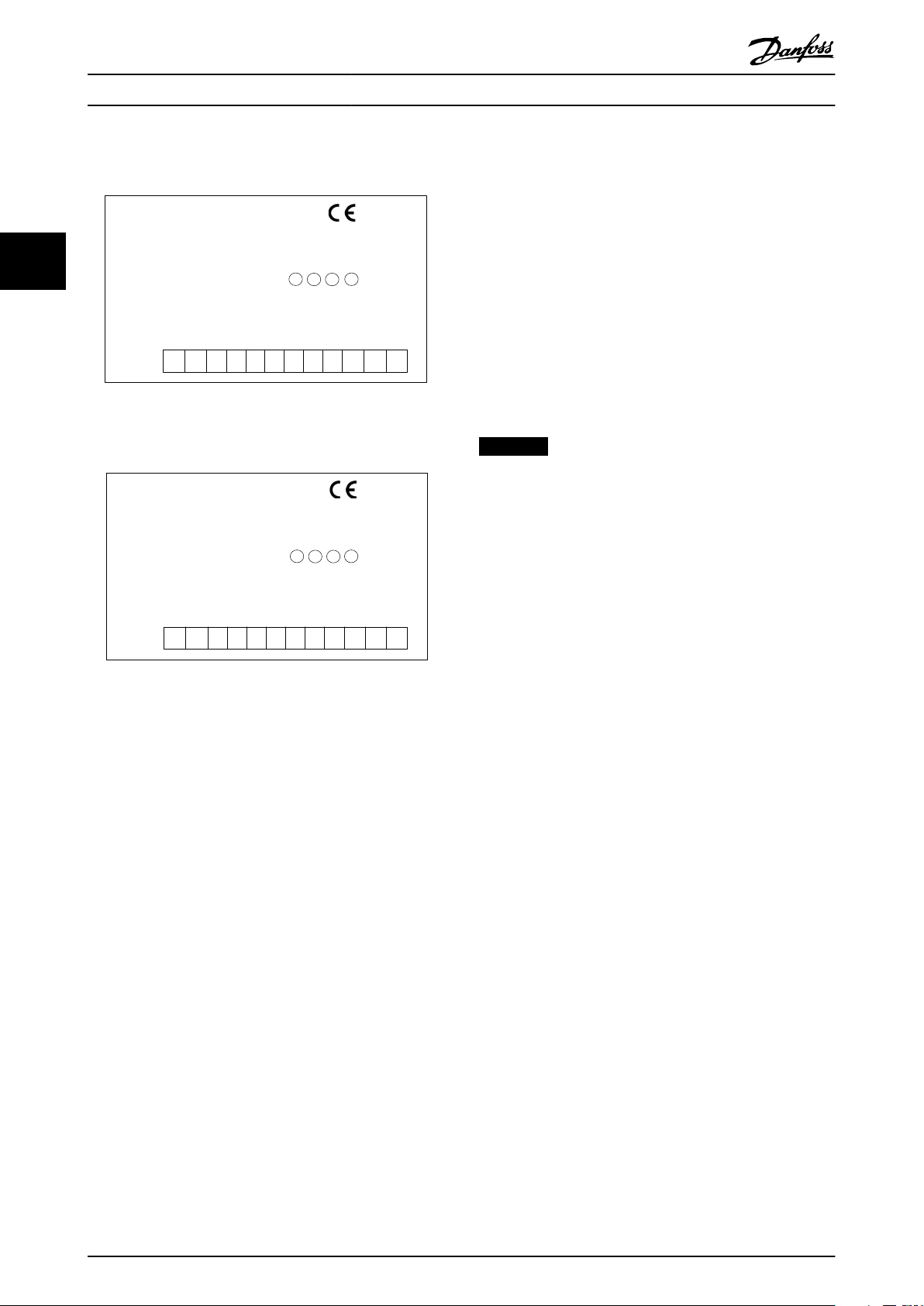

3.5.5.1

SLS without Ramp

The safety function Safely Limited Speed monitors whether

a specified velocity value is exceeded since it was activated

via DI1 or DI2. The function is active until the selected

input has been put to high again.

If 2 Safe Speed limits must be monitored, set one of the 2

Safe Digital Inputs DI1 or DI2 in 42-20 Safe Function to SLSa or SLS-b. Then select the input type under 42-21 Type.

The cut-off speed represents the maximum allowed

frequency of the actual motor frequency. If the motor

frequency accelerates above that value, the safety option

enters external fault selected (STO or SS1 Ramp), and the

error is given. The frequency value at which a shutdown is

realised should be parameterised in 42-50 Cut Off Speed.

Parameter Unit Range Default

42-50 Cut Off Speed RPM 120-10000 RPM 270 RPM

42-51 Speed Limit RPM 1-9999 RPM 150 RPM

42-52 Fail Safe

Reaction

Table 3.4 Parameters for SLS without Ramp

n/a Safe Torque Off/Safe

Stop 1

Safe Torque

Off

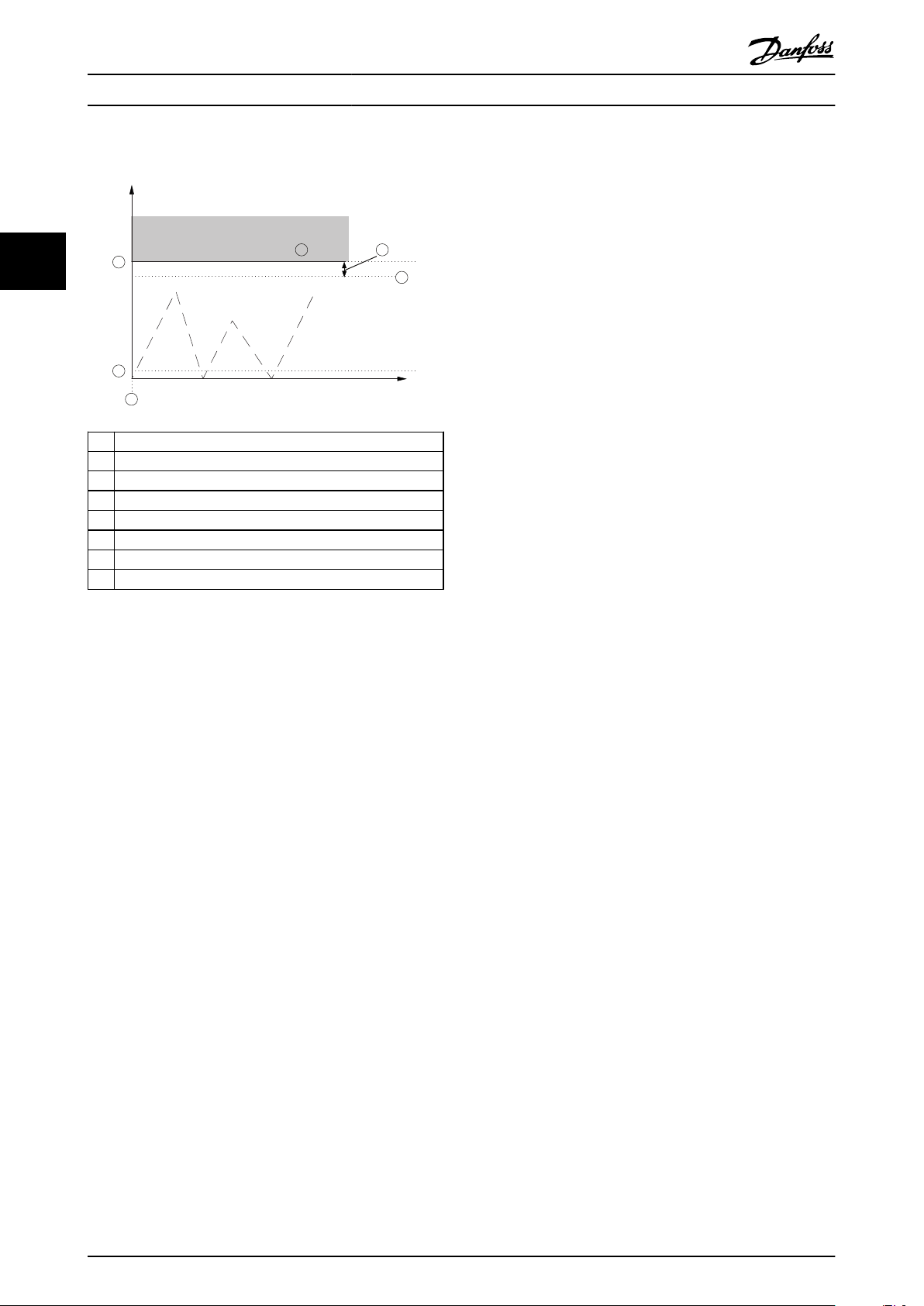

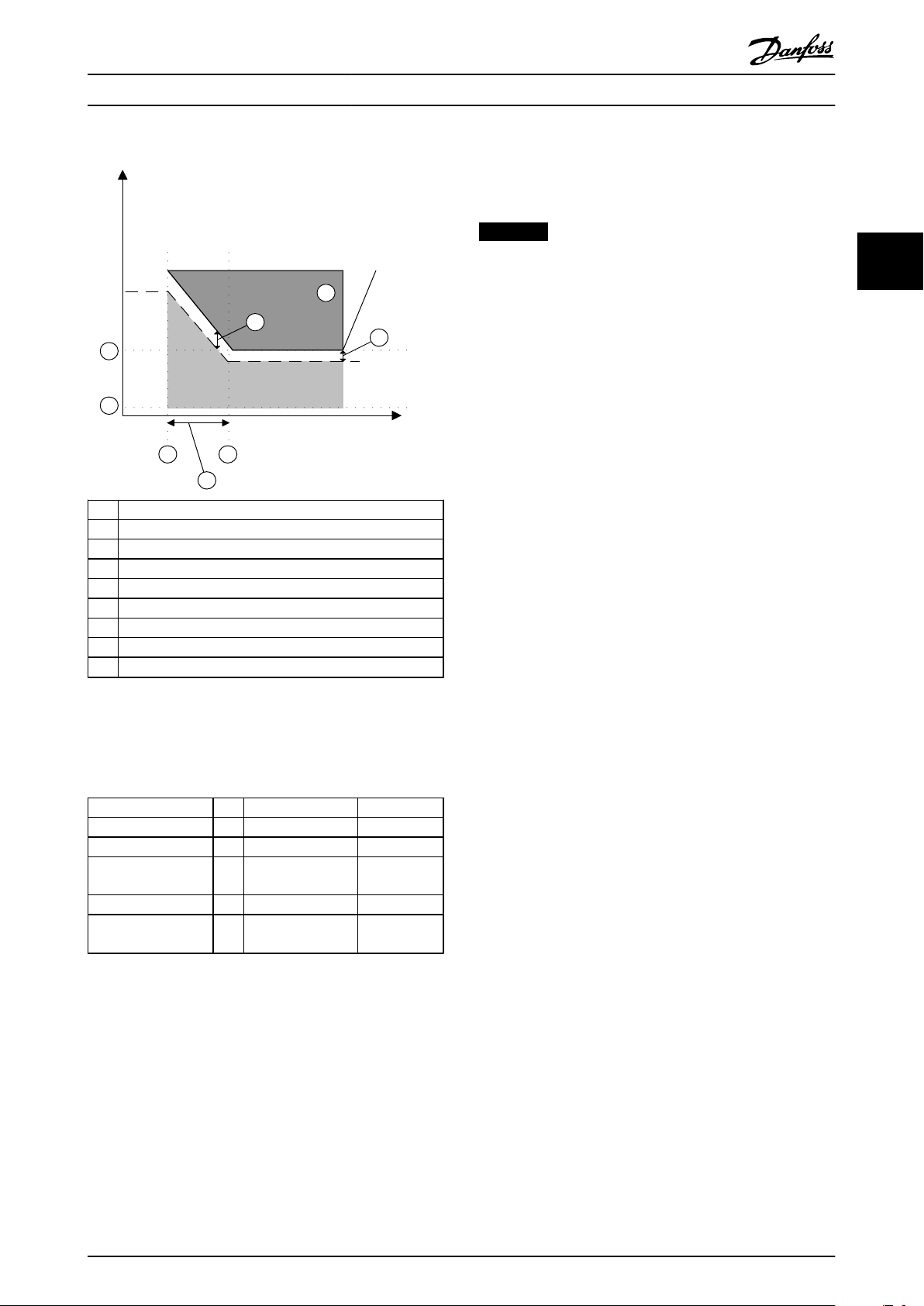

Actual frequency

A

B SLS limit

1 SLS is activated

2 42-51 Speed Limit

3 42-50 Cut Off Speed

4 Delta speed limit

5

Activation of failure function set in 42-52 Fail Safe Reaction

6

Fixed value of 120 RPM in 42-19 Zero Speed Limit

Illustration 3.11 SLS without Ramp

If speed exceeds the limit, 42-52 Fail Safe Reaction is

activated. The safety function can either be Safe Torque

Off or SS1 Ramp Time. Safe Stop 1 can only be triggered

as error response if one Safe Stop 1 function has been set

as Safe Stop 1 with ramp time function, set in 42-40 Type.

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 19

Page 22

130BC959.10

4

2

3

6

1

5

frequency

time

A

B

Functions and System Overvi... Operating Instructions

Safe jog in combination with SLS

Limited Speed limit, the limit comes into effect

immediately without ramping. When the Safely Limited

Speed function is deactivated, the speed limits are ramped

up back to the values defined in parameter group 3-1*

References, and the actual speed returns to the reference

value if it was limited by this function.

33

Follow these steps to configure the Safely Limited Speed

operation

1. If a safe speed limit must be monitored, set one

of the 2 safe digital inputs, DI1 or DI2, to [1] SLS-a

or [2] SLS-b in 42-20 Safe Function.

2.

Select input type in 42-21 Type.

3.

Select 42-53 Start Ramp to run Safely Limited

Speed with monitored braking ramp. The default

A Actual frequency

B SLS limit

1 SLS is activated

2 42-51 Speed Limit

3 42-50 Cut Off Speed

4 Delta speed limit

5

Activation of failure function set in 42-52 Fail Safe Reaction

6

Fixed value of 120 RPM in 42-19 Zero Speed Limit

Illustration 3.12 Safe Jog

When the safety option actively monitors Safely Limited

Speed, and the motor speed is at or below the configured

safe speed limit, the function monitors the speed until the

function is deactivated.

value is [0] No for applications without SLS Ramp

control.

4. Set the time allowed to reach Safe Limited Speed

in 42-54 Ramp Down Time.

5.

Set the value in 42-50 Cut Off Speed.

Access under specific conditions of reduced risk

Under specific conditions of reduced risk, safe jog allows

for access to areas for fault-finding, commissioning, etc. On

machines where safe jog (jogging or inching) is needed,

this is also possible from zero speed setpoint.

By activating Safely Limited Speed, the motor can be

moved at safe jog resulting in a number of cycles and with

safely monitored movements. The motor can be started

and stopped continuously also from zero speed.

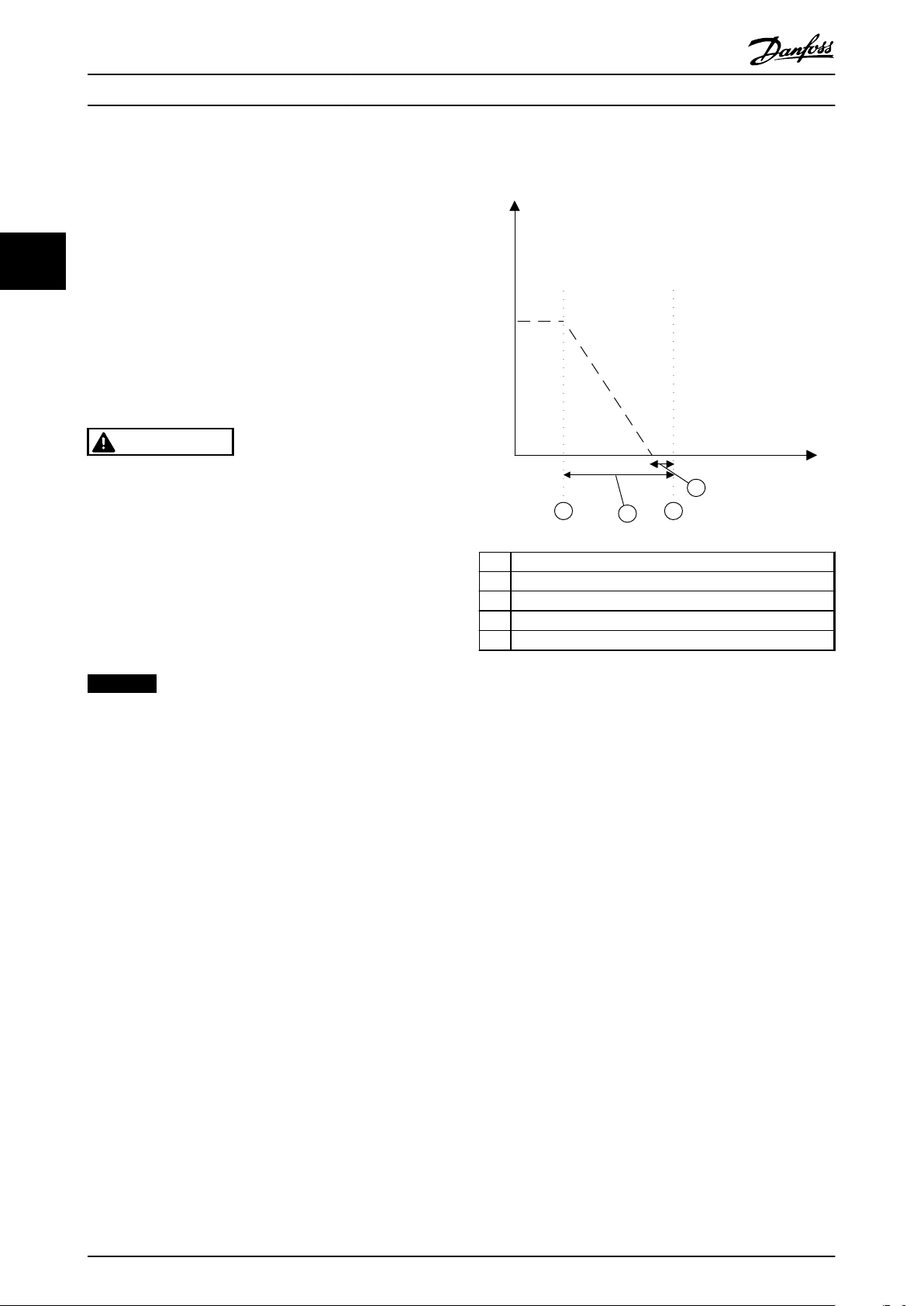

3.5.5.2

SLS with Ramp

If this safety function is needed, configure the safety

option for Safely Limited Speed (SLS). When the inputs DI1

or DI2 are selected as SLS, input is OFF, feedback velocity

is monitored and compared against a configurable safe

speed limit.

Select 42-53 Start Ramp to configure an SLS Monitoring

Ramp. The ramping begins when SLS monitoring is

requested by the selected input for SLS transition from ON

to OFF. The safety option starts monitoring for safe limited

speed when the ramp-down times out. If the system speed

exceeds or is equal to the configured safe speed limit

during Safely Limited Speed monitoring, a Safely Limited

Speed fault occurs and the safety option initiates the

configured Safe Stop type selected in 42-52 Fail Safe

Reaction.

The ramping begins at the absolute value of the actual

speed. If the actual speed is already below the Safely

20 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 23

130BC323.10

1 2

frequency

3

5

6

4

time

4

7

A

B

Functions and System Overvi...

Operating Instructions

Shorts between the 2 lines of a dual channel input are not

detected. Therefore the cables of the channels must be

routed separately to exclude short circuits.

NOTICE

A Actual frequency

B SLS limit

1 Safely Limited Speed is activated with SS1 Ramp

2 Safely Limited Speed speed limit reached

3 Ramp down time

4 Delta speed limit

5 Zero speed limit, fixed value of 120 RPM

6 Cut-off speed

7

Activation of failure function set in 42-52 Fail Safe Reaction

Illustration 3.13 SLS with Ramp

Routing of the sensor cables

All proximity switch sensor/encoder cables must be

shielded when laid. The shielding must be connected to

chassis at both ends.

3.6.1 Inputs

The Dual-pole digital inputs are used to activate the safety

functions. DI 1 can be

STO: Safe Torque Off

•

SS1: Safe stop 1

•

SLS: Safely limited speed

•

Signals at DI 1

1/0 transition at the input: Activates the safety

•

function

“0” signal (0 V) at the input: Activates the safety

•

function

“1” signal (+24 V) at the input: Does not activate

•

the safety function

DI 2 can be

3 3

STO: Safe Torque Off

Activation of failure function set in 42-52 Fail Safe Reaction.

Parameter Unit Range Default

42-50 Cut Off Speed RPM 120-10000 RPM 270 RPM

42-51 Speed Limit RPM 1-9999 RPM 150 RPM

42-52 Fail Safe

Reaction

42-53 Start Ramp n/a No/Yes No

42-54 Ramp Down

Time

Table 3.5 Parameters for SLS with Ramp

If the speed exceeds the limit, 42-52 Fail Safe Reaction is

activated. The safety function can either be Safe Torque

Off or SS1 Ramp Time. SS1 can only be triggered as error

response if one digital input is selected as SS1 with ramp

time function, set in 42-40 Type.

3.6

Inputs and Output

An internal diagnostic function in the safety option

cyclically tests the correct function of the output. A

detected fault sets the safety option into an alarm status.

At the same time, the option output S37 goes low.

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 21

n/a Safe Torque Off/

Safe Stop 1

s 0.1-3600.0 s 1.0 s

Safe Torque

Off

•

SS1: Safe stop 1

•

SLS: Safely limited speed

•

Reset: Additional safe input to reset the safety

•

option after an error, or after deactivating a

safety function on input DI1

Signals at DI 2

1/0 transition at the input: Activates the safety

•

function

“0” signal (0 V) at the input: Activates the safety

•

function

“1” signal (+24 V) at the input: Does not activate

•

the safety function

0/1 transition at the DI2 input if configured to

•

reset: Resets the safety option

3.6.2

Reset Input (DI2)

The reset input is for resetting the safety circuit selected

on DI1. Configure the reset input for automatic or manual

reset types. If manual reset is configured, wire the DI2A

reset input terminal to a 24 V DC via an NO switch.

Page 24

130BC316.10

Input Signal

DI1/DI2

D1 x A

D1 x B

Discrepancy time

Safety function

Active

Inactive

Functions and System Overvi...

Operating Instructions

3.6.3 Output

Safe, single-pole output

S37 is the output that goes to the Safe Torque Off input of

the frequency converter.

Safe Torque Off Acknowledge

33

•

Internal error on frequency converter or

-

safety option

Limit values exceeded

-

Activated via SS1

-

PUST (Power Up Self Test)

-

External failure

-

Permitted Sensor Types on Digital

3.6.4

NOTICE

First, trip alarms displayed on the frequency converter

must be acknowledged after which a pending safety

function can be acknowledged. A single reset for the

alarm mode and a second reset for acknowledgment of

the active safety function. Alarms caused by the

frequency converter must be reset before an alarm can

be reset on the safety option.

3.6.6 Signal Filtering

If a sensor with 2NC or 1NC/NO is selected, the safety

option checks the signals of the safe digital input for

consistency. Consistent signals at both inputs always

assume the same signal state (high or low). If 1NC/1NO is

selected, it checks the right state of each input.

Inputs

The following sensor types are applicable

sensors with 2 NC contacts

•

antivalent contacts (1 NO contact and 1 NC

•

contact)

sensor output of type 2xPNP

•

Sensors with 2 NO contacts are not applicable.

With electromechanical sensors (e.g. emergency stop

buttons or door switches), the 2 sensor contacts never

switch at the same time (discrepancy). A long-term

discrepancy points towards a fault in the wiring of a safe

input, for example, a wire break. An adjustable filter in the

safety option prevents faults caused by temporary or shortterm discrepancy. Within the filter tolerance time

42-22 Discrepancy Time, the safety option suppresses the

discrepancy monitoring of the safe inputs.

The safe digital inputs are configured for both directly

connecting safety sensors, e.g. emergency stop control

devices or light curtains, as well as for connecting preprocessing safety relays, e.g. safe controls. See examples of

connecting the safe digital input, in accordance with EN

ISO 13849-1 and EN IEC 62061 in chapter 4.3.1 Connecting

Safe Digital Inputs.

Reset

3.6.5

CAUTION

Both safety inputs must be off after an input fault or

PUST has occurred, before a reset is accepted to branch

into safe monitoring again.

This reset must only be possible at the location where

the safety command has been initiated.

To operate the safety option, the application must send a

reset signal either via the LCP, via a dedicated digital input

or via a control word. When a safety function has been

activated, or an external failure has caused a failure state, a

reset is necessary to enable the safety option again. When

the connected sensor on DI1 or DI2, or both is enabled via

a reset, the safety option can be switched on again. This

deactivates active safety functions or errors.

Illustration 3.14 Discrepancy Time

Parameterise the discrepancy time of the switching

elements connected to the digital inputs. The default value

is 10 ms.

22 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 25

Input Signal

130BC317.10

DI1/DI2

Safety function

Active

Inactive

Test pulse pattern

Stable signal time Stable signal time

Functions and System Overvi...

Operating Instructions

NOTICE

The discrepancy time does not extend the safety option

response time. The safety option activates its safety

function as soon as one of the 2 DI signals changes from

high to low.

3.6.7 Stable Signal Time from Safe Outputs

The safety option normally responds immediately to signal

changes at its safe input DI1 or DI2. This response is not

required in the following cases

When interconnecting the safe input of the

•

option with an electromechanical sensor, contact

bounce may result in signal changes occurring, to

which the option could respond.

Several control modules test their safe outputs

•

using test pulse pattern (on/off tests), to identify

faults due to either short or cross circuiting.

When interconnecting the safe input of the

option with a safe output of a control module,

the option could respond to these test signals.

A signal change during a test pulse pattern usually lasts 1

ms.

Under stable signal time, short pulses, which could lead to

safety functions being incorrectly activated, can be filtered.

NOTICE

The stable signal time extends the safety option

response time. The safety option only activates the

safety function after the response time has expired.

Illustration 3.15 Filter for Suppressing Temporary Signal

Changes

Zero Speed Time Error Detection

3.6.8

Zero Speed Timer monitors if the frequency converter is

operated below 120 RPM during Safely Limited Speed.

42-18 Zero Speed Timer contains the remaining time until

the monitoring responds. The safety option signals Alarm

Ext Fail Prec Thresh Timer Elapsed after the monitoring time

expires.

Define the monitoring time while commissioning the

system depending on the particular application.

Yearly Test

3.6.9

3 3

If the signal to the input on safety option is not stable, the

option responds with a fault.

Definition of a stable signal

Following a change to the DI input signals, the option

triggers an internal monitoring time. Use 42-23 Stable

Signal Time to select an appropriate stable signal time. A

constant signal level is a high or a low state, for at least

42-23 Stable Signal Time.

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 23

According to EN ISO 13849-1, EN IEC 62061 and EN IEC

61508, the safety option must regularly test its safetyrelevant circuits to ensure correct functioning. This test

must be performed at least once every year. After the

power supply has been connected, the safety option

checks its circuits to switch-off the torque each time the

Safe Torque Off function is selected. The safety option

monitors the regular test interval of its safety-relevant

circuits using a time module.

After one year in operation, the frequency converter

displays a message that a yearly test must be performed.

The frequency converter must be power cycled by disconnecting and then reconnecting the supply voltage. Activate

the used inputs on the safety option and check that they

function correctly.

3.6.10

Factory setting for both digital inputs is Safe Torque Off,

meaning that the Safe Output S37 is in low state.

Safety Parameter Settings

Page 26

Functions and System Overvi... Operating Instructions

At the first power up, the option shows Blank Initial State.

3.7.2

Compatibility between Safety and

Frequency Converter Functions

Properties of safety parameters

The safety option is compatible with all VLT

They are kept separate for each monitoring

•

33

A reset of the safety parameters to the factory setting can

be executed via MCT 10 Set-up Software.

channel.

During start-up, a checksum (Cyclic Redundancy

•

Check, CRC) over the safety parameters is

generated and checked. The parameters are

stored on the non-volatile memory on the option.

NOTICE

If the safety option is reinstalled in another frequency

converter, all safety parameters can be selected either

from the safety option or from the frequency converter

in which the option is now installed. A commissioning

test must always be performed to ensure the correct

functionality.

3.6.11 Encoder Interface

CAUTION

Some of the diagnostics performed on the encoder

signals require motion to detect faults. Make sure that

motion occurs at least once every 12 months.

To detect the standstill or the motor speed, the speed

(frequency) is measured using a TTL encoder (MCB 150), an

HTL encoder (MCB 151) or a PNP proximity switch (MCB

151). The HTL encoder uses 2 signal tracks, A and B. TTL

encoders uses 4 signal tracks A, B and their inverted tracks

nA, nB.

Use twisted-pair, individually screened cable to connect

encoders to the safety option.

3.7

Limitations

AutomationDrive FC 302 frequency converters in the range

of 0.37 kW to 75 kW. Compliance to higher power ranges

is to come. Contact the local supplier for latest

information.

MCB150/151 can be combined with the following Aoptions:

PROFIBUS MCB 101

•

DeviceNet MCA 104

•

CanOpen MCA 105

•

PROFINET MCA 120

•

Ethernet/IP MCA 121

•

Modbus TCP MCA 122

•

PowerLink MCA 123

•

EtherCAT MCA 124

•

The safety option is compatible with asynchronous and

synchronous (PM) motors. Asynchronous motors can be

used in U/f and VVC+ in closed and open loop as well as in

FLUX open loop control. Synchronous (PM) motors can be

used in U/f open or closed loop control. Compliance to

further motor types and control modes is to come. Contact

the local supplier for latest information.

The following software versions are required as minimum

for using MCB150/151:

LCP software version 7.0

•

VLT® AutomationDrive FC 302 Firmware Version

•

6.64

All frequency converters, options and control mode

combinations not listed above are not permitted.

®

3.7.1 Exceeded Limit Value and Internal

Errors

Exceeding set limit values activate the stop

•

braking ramp.

Any internal error on the safety option or

•

frequency converter activates the safety function

Safe Torque Off. The frequency converter coasts

the motor.

Internal errors always result in a fault, requiring a power

cycle of the frequency converter to reset the failure.

Alternatively, use 42-90 Restart Safe Option to restart the

safety option after internal failure without power cycling

the frequency converter.

24 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Page 27

Installation

4 Installation

4.1 Installing the Safety Option

Operating Instructions

4.1.2

Protected Cable Installation

WARNING

Before start, disconnect the power supply voltage to the

frequency converter. Never install an option card into

the frequency converter during operation.

Ensure that all dangerous voltages connected from

external control circuits to the inputs and outputs of the

frequency converter are switched off. In addition to

conventional installation tools, have the Operating

Instructions for VLT® AutomationDrive FC 301/FC 302

and MCT 10 Set-up Software available as they contain

important information that is not included in this

manual.

The safety option is exclusively intended for use in

option slot B. The mounting position of B options is

shown in Illustration 4.1.

WARNING

ELECTRICAL HAZARD!

Safe Stop activation (Safe Torque Off) does not provide

electrical safety. The safety device connected to the dual

pole input of the safety option must fulfill the

requirements safety level for the application for

interrupting the voltage/current to safety option. This is

also valid for the connections between the safety

option’s safe output S37 and terminal T37 on the

frequency converter. To connect the safety device

correctly to the safety option, read and follow the

instructions.

If short circuits and cross circuits can be expected with

safety-related signals and if they are not detected by

upstream devices, protected cable installation is required

as per EN ISO 13849-2.

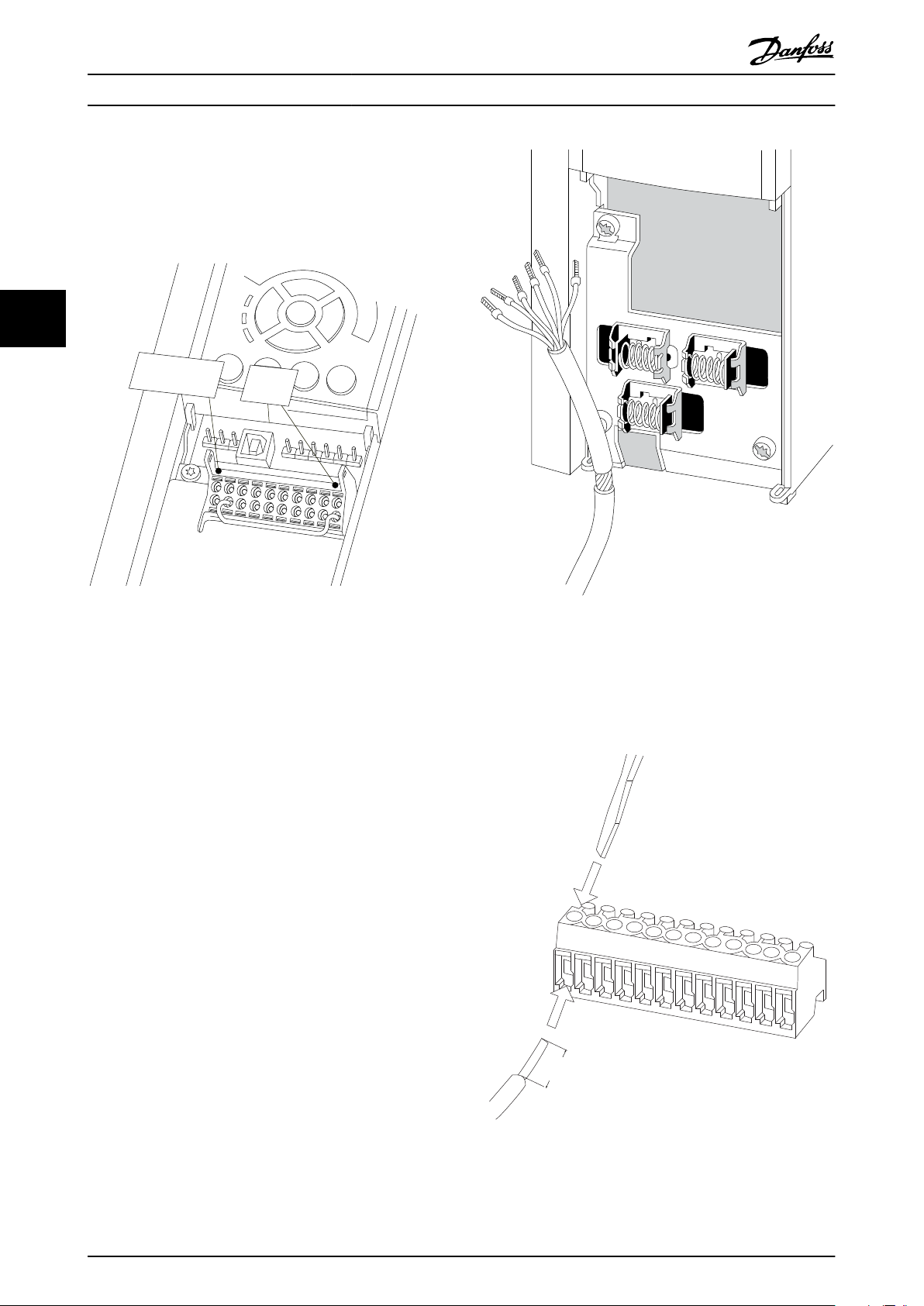

4.1.3 Installation

CAUTION

The VLT® AutomationDrive with safety option (including

the connection between output S37 (Y30/12 or Y31/12)

on MCB150/151 and X44/12 on the control card) must be

placed in an IP54 enclosure as per IEC 60529.

These step-by-step instructions describe how to mount the

control cables

4 4

4.1.1 Requirements for Safe Use

CAUTION

Ensure that the installation and wiring are EMCcompliant to avoid personal injury and damage to the

product.

Refer to the guidelines stated in this manual.

Also ensure compliance with

®

VLT

•

•

The safety option may only be used with the following

frequency converters

•

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 25

AutomationDrive FC 301/FC 302 Operating

Instructions

Tool-Tip help for the configuration tool MCT 10

Safe Plug-in

VLT® AutomationDrive FC 302, power sizes from

0.37 kW to 75 kW, from SW Version 6.64

A A-option slot

B B-option slot

D D-option slot

Illustration 4.1 How to Fit the Safety Option

1. Disconnect power to the frequency converter.

2. Remove the LCP, the terminal cover, and the LCP

frame from the frequency converter.

Page 28

12/13

37

130BA874.10

130BT340.10

1

2

10 mm

130BD009.10

1

2

3

4

7

6

5

10

8

9

11

12

Installation Operating Instructions

3. Fit the safety option in slot B.

4. Remove the jumper wire between control

terminals 37 and 12 or 13.

Cutting or breaking the jumper is not

•

sufficient to avoid short circuiting.

44

Illustration 4.2 Jumper between Terminal 12/13 (24 V) and 37

5. Connect the safe output S37 on the safety option

to terminal 37 on the control card (maximum

length of this wire is 10 cm).

6. Connect the control cables to safety option and

relieve the cable by the enclosed cable strips.

Follow the guidelines in chapter 4.1.4 General

Wiring Guidelines.

Illustration 4.3 Connecting Screened Wire

7. Remove the knock-out in the extended LCP

frame, so that the option fits under the extended

LCP frame.

8. Fit the extended LCP frame and terminal cover.

26 Danfoss A/S © Rev. 2014-02-11 All rights reserved. MG34W302

Illustration 4.4 Connecting Control Wiring

Page 29

Installation Operating Instructions

NOTICE

The connections are not pre-wired from factory.

9. Fit the LCP or blind cover in the extended LCP

frame.

10. Connect power to the frequency converter.

11. Set up the input/output functions in the

corresponding parameters, as mentioned in the

manual for the Safe Plug-in in MCT 10

The commissioning test report is automatically generated

via the Safe Plug-in in MCT 10 after downloading the

parameters to the safety option.

CAUTION

The operator or electrical installer is responsible for

proper grounding and compliance with all applicable

national and local safety regulations.

4.1.4 General Wiring Guidelines

Inputs

Use appropriate wiring to exclude short circuits between

the inputs or to a supply line

Output

Use separate multicore cable for supply voltages to avoid

short circuits between the cable from the output (S37) to

the 24 V DC supply line

interruption with optimum screen support at

both ends

Connect screens at both ends to the grounded

•

enclosures through a good electrical connection

and through a large surface area

Connect cable screens as close as possible to the

•

cabinet cable entry

If at all possible, intermediate terminals should

•

not interrupt cable screens

Retain cable screens for both power cables as

•

well as for signal and data cables using the

appropriate EMC clamps. The screen clamps must

connect the screen to the EMC shield bar or the

screen support element for control cables

through a low inductive connection through a

large surface area.

4 4

CAUTION

As a result of short circuits, it is no longer possible to

switch off the frequency converter terminal 37.

NOTICE

Control cables must be screened/armoured.

See the section Earthing of Screened Control Cables in the

VLT® AutomationDrive Design Guide for detailed specifi-

cations.

Only screened cables are suitable for connecting encoders.

NOTICE

All signals to safety option must be PELV supplied and

comply with EN IEC 60204.

Route sensitive control cables - such as encoder

•

and active safety component cables - without any

MG34W302 Danfoss A/S © Rev. 2014-02-11 All rights reserved. 27

Page 30

1 2 3 4 5 6 7 8 9 10 11 12

130BC315.10

E30BC325.11