VLT® Lift Drive

Developed specically for lifts to provide reliable and excellent ride comfort. Operates without motor contactors and can be commissioned in less than 10 minutes.

Designed specically for lifts

The VLT® Lift Drive’s compact, rugged

design is optimized for easy installation. Built in features ensure a long life

of reliable operation, a smooth ride,

and low total costs.

Easy commissioning

with customized software

Setup and service is easily handled

using the drive’s dedicated software,

which can be accessed at your convenience via the graphical display,

VLT® Control Panel LCP 102. Read-outs

are simple and clear, including the

scope function that presents analog

and digital data.

With parameterization tailored specifically for lifts all settings use “elevator

language”. This means that specialists

are not required, as owners can set up

and service their lift themselves in the

shortest possible time.

Operates without motor contactors

The patented Safe Stop function

eliminates the need for motor contactors, increasing the reliability of

the elevator installation, which is at

least as safe as a solution with motor

contactors.

An integrated RFI lter and DC coils

eliminate the costly installation of

external components. This reduces

space requirements and eliminates a

complex EMC-compliant wiring.

Reliable in all environments

The Lift Drive can be installed in challenging ambient conditions outside

the control of the variety of available

housing and protection classes. For

example, a unique feature of the Lift

Drive means that when the temperature rises, the drive maintains the output current so that only the switching

frequency is derated.

2.1 million

Load cycles

Is the minimum life

time of the VLT®

Lift Drive at 16 KHz

frequency and 45 °C

ambient temperature.

Product range

n 4 – 55 kW (380-400 V) IP 20/21/55

Feature Benet

– Save space

Patented Safe Stop technology

IP 20, 21, 55, 66 protection rating

Dedicated lift functionality

Integrated RFI lter and DC coils

– Reduce costs for materials

– No switching noise

– Higher reliability

– Flexible installation options

– Mount the drive outside the lift cabinet

– Increases comfort during start-up,

operation, and passenger entry/exit

– Very little noise from the lift shaft

– Reduces total system costs

– Reduces space requirements

– Lowers installation costs

– Easy compliance with EMC and harmonics

standards

Facts about our products

Specications

Mains supply (L1, L2, L3)

Supply voltage 380 – 400 V ±10%

Motor and Motor Feedback

Load prole and lifetime expectancy 2.1 million load cycles

Motor feedback supported types

Acoustics

Acoustic noise 55 dB

Maximum switching frequency 16 kHz

Environment

Temperature operation 0 to 45

Enclosure IP protection IP 20/21, IP 55

RFI lter Included as standard

Incremental: 5V TTL (RS422)

Incremental: 1Vpp SinCos

Absolute: ENDAT, Hiperface

o

C

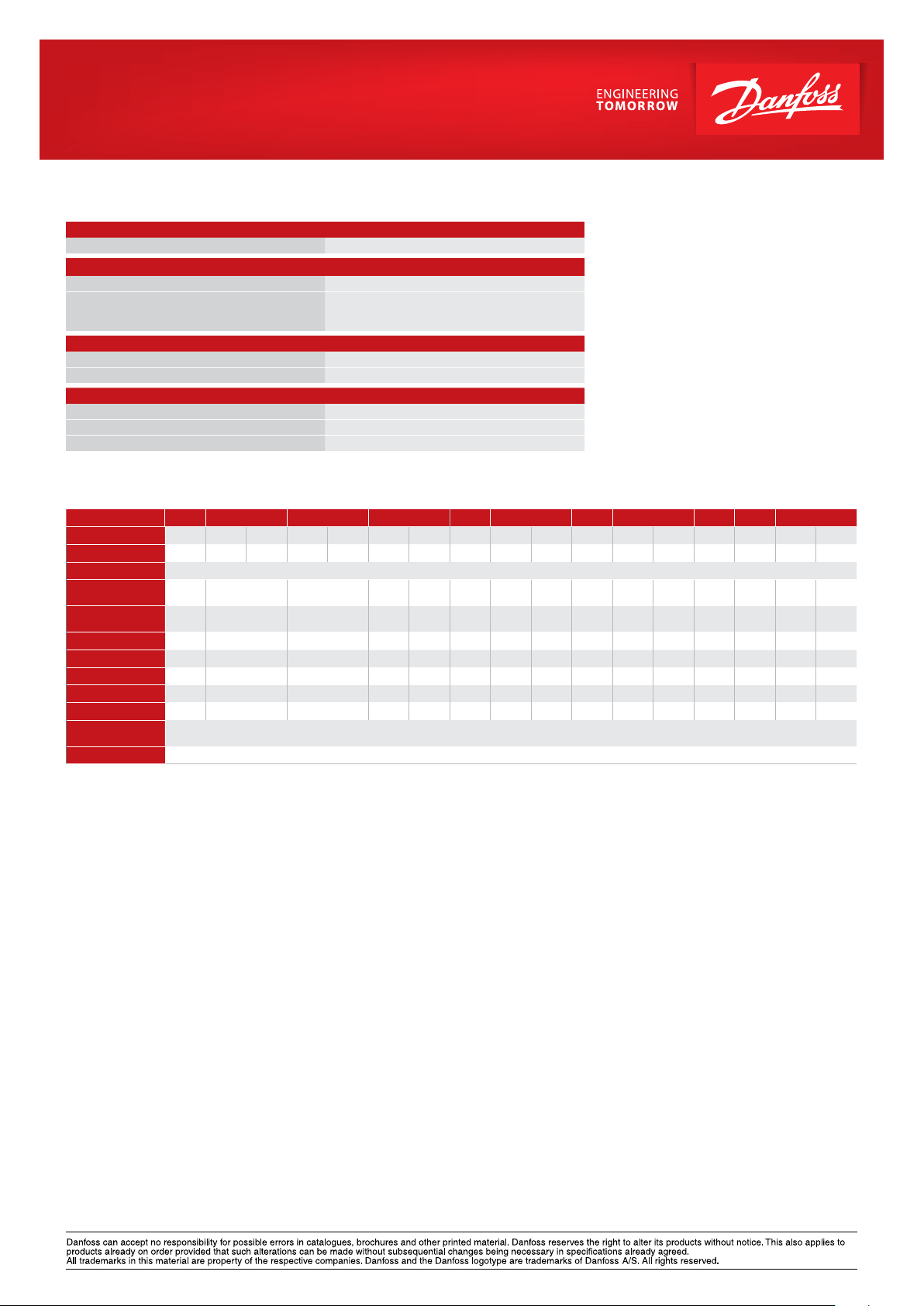

Power rating

IP Class

Frame size A2 A3 A5 A3 A5 B3 B1 B4 B4 B2 B4 C3 C1 C4 C4 C4 C2

Voltage [V]

Continuos output

current 100%

Overload

6s/60s [A]

Current @ 16kHz [A]

Current @ 14kHz [A]

Current @ 12kHz [A]

Current @ 10kHz [A]

Current @ 8kHz [A]

Ambient

temperature

Duty cycle 50%

4 kW 5.5 kW 7.5 kW 11 kW 15 kW 18 kW 22 kW 30 kW 37 kW 45 kW 55 kW

IP 20 IP 20 IP 55 IP 20 IP 55 IP 20 IP 55 IP 20 IP 20 IP 55 IP 20 IP 20 IP 55 IP 20 IP 20 IP 20 IP 55

400 V

10 13 16 26 21 35 44 35 51 60 50 75 90 110 98

16 20.8 26.6

10 13 16 N/A N/A 32 35 35 44 N/A 50 N/A N/A N/A N/A

10 13 16 N/A N/A 32 35 35 44 N/A 50 N/A N/A N/A N/A

10 13 16 21 21 35 44 35 51 60 50 75 83 98 98

10 13 16 26 21 35 44 35 51 60 50 75 90 98 98

10 13 16 26 21 35 44 35 51 60 50 75 90 110 98

46.8/

41.6

33.6

60/

56

74,4 56

45 °C

91.3/

81.6

180/

90

135/

162/

75

112,5

135

198/

165

147

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80

www.danfoss.com/drives • E-mail: info@danfoss.com

DKDD.PFP.302.A4.02 VLT® is a trademark of Danfoss A/S Produced by PE-MMSC 2014.09

Loading...

Loading...