Page 1

Operating Instructions

VLT® 5000 Crane

Page 2

■ Contents

VLT® 5000 Crane

Introduction

Safety ....................................................................................................................... 4

General Instructions ................................................................................................. 5

Abbreviations and Definitions .................................................................................... 6

Brief Product Description .......................................................................................... 9

Function and System Description ............................................................................. 9

Key Diagram for VLT 5000 Crane 5042, 5102 400-500 V ....................................... 14

Key Diagram for VLT 5000 Crane 5122-5202 400-500 V ....................................... 15

......................................................................................................... 3

Technical Data .................................................................................................. 16

General Technical Data ........................................................................................... 16

Mains Supply 400 - 500 V ...................................................................................... 20

Mains supply 3 x 400 - 500 V ................................................................................. 20

Fuses ..................................................................................................................... 22

Mechanical Dimensions .......................................................................................... 23

Installation ......................................................................................................... 24

General Warning before Installation ........................................................................ 24

Mechanical Installation ........................................................................................... 24

Installation of VLT 5042–5062 400-500 V Compact IP20/IP00 ............................... 24

Installation of VLT 5072-5202 400-500 V Compact IP20/IP00 ................................ 25

Electrical Installation ............................................................................................... 26

RFI switch .............................................................................................................. 33

LCP - Local Control Panel .......................................................................... 36

Control Panel ......................................................................................................... 36

Display ................................................................................................................... 37

Parameter programming ........................................................................................ 39

Programming .................................................................................................... 42

General Advice on Programming ............................................................................ 42

Operation & Display ................................................................................................ 50

Load and Motor ..................................................................................................... 54

References & Limits ................................................................................................ 58

Inputs & Outputs .................................................................................................... 61

Application Functions ............................................................................................. 68

Service Functions ................................................................................................... 70

Crane Functions ..................................................................................................... 74

Serial communication .................................................................................. 80

Factory Settings ..................................................................................................... 81

Defined Parameters ................................................................................................ 85

All About VLT 5000 Crane .......................................................................... 86

Status Messages .................................................................................................... 86

List of Warnings and Alarms ................................................................................... 87

Warnings ................................................................................................................ 87

MG.50.N4.02 - VLT is a registered Danfoss trademark

1

Page 3

VLT® 5000 Crane

Appendix ............................................................................................................. 92

Trouble-shooting .................................................................................................... 92

Derating for air pressure ......................................................................................... 94

Efficiency .............................................................................................................. 113

General aspects of EMC emissions ...................................................................... 114

2

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 4

VLT® 5000 Crane

VLT 5000 Crane

175ZA522.12

Operating instructions

Software version: 20.3x

These operating instructions can be used for VLT 5000

Crane frequency converters with software version 20.3x.

See software version number in parameter 624.

Introduction

MG.50.N4.02 - VLT is a registered Danfoss trademark

3

Page 5

VLT® 5000 Crane

■Safety

The voltage of the frequency converter

is dangerous whenever the equipment is

connected to mains. Incorrect installation

of the motor or the frequency converter may cause

damage to the equipment, serious personal injury

or death. Consequently, the instructions in this

manual, as well as national and local rules and safety

regulations, must be complied with

■Safety Regulations

1. The frequency converter must be disconnected

from mains if repair work is to be carried out. Check

that the mains supply has been disconnected

and that the necessary time has passed before

removing motor and mains plugs.

2. The [STOP/RESET] key on the control panel of

the frequency converter does n

the equipment from mains and is thus n

be used as a safety switch.

3. Correct protective earthing of the equipment

must be established, the user must be protected

against supply voltage, and the motor must be

protected against overload in accordance with

applicable national and local regulations.

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is n

in the factory setting. If this function is desired,

set parameter 128 to data value ETR trip or

data value ETR warning.

N

ote: The function is initialised at 1.16 x rated

motor current and rated motor frequency. For

the North American market: The ETR function

ot disconnect

ot to

ot included

provide class 20 motor overload protection

in accordance with NEC.

6. Do n

7. Please note that the frequency converter has more

■Warning Against Unintended Start

1. The motor can be brought to a stop by means

2. While parameters are being changed, the

3. A motor that has been stopped may start if faults

4. Immediate stop. Direct stop input (term. 37). When

s

ot remove the plugs for the motor and mains

supply while the frequency converter is connected

to mains. Check that the mains supply has been

disconnected and that the necessary time has

passed before removing motor and mains plugs.

voltage inputs than L1, L2 and L3, when loadsharing

terminals (linking of DC intermediate circuit) and

external 24 V DC have been installed. Check

that all voltage inputs have been disconnected

and that the necessary time has passed before

repair work is commenced.

of digital commands, bus commands, references

or a local stop, while the frequency converter

is connected to mains. If personal safety

considerations make it necessary to ensure

that no unintended start occurs, these stop

functions are not sufficient.

motor may start. Consequently, the stop key

[STOP/RESET] must always be activated, following

which data can be modified.

occur in the electronics of the frequency converter,

or if a temporary overload or a fault in the supply

mains or the motor connection ceases.

contact is open, the drive will stop (coast).

Warning:

Touching the electrical parts may be fatal - even after the

equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected, such as external 24 V DC, load-sharing (linkage of

DC intermediate circuit), as well as the motor connection for

kinetic back-up.

Using VLT 5042-5062: wait at least 15 minutes.

Using VLT 5072-5202: wait at least 20 minutes.

175ZA523.11

4

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 6

VLT® 5000 Crane

■General Instructions

These Operating Instructions are intended for

persons who are to install, operate and program

the VLT 5000 Crane.

They comprise the specific technical publications on

the VLT 5000 Crane and are delivered with the product.

When reading these Operating Instructions you come across different symbols that require special attention:

The symbols used are the following:

Indicates a general warning

Indicates a high-voltage warning

NB!:

Indicates something to be noted by the reader

Introduction

MG.50.N4.02 - VLT is a registered Danfoss trademark

5

Page 7

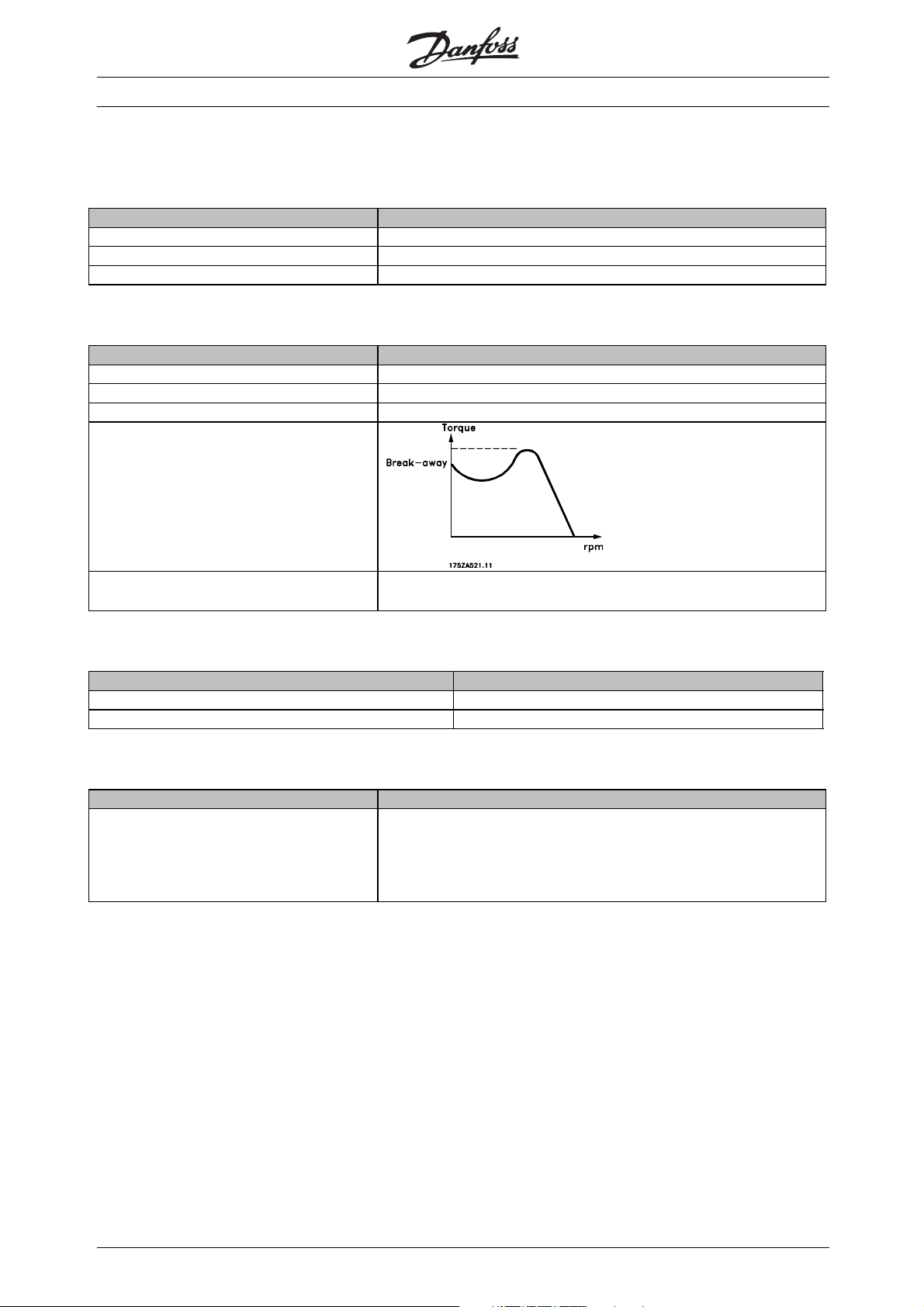

■Abbreviations and Definitions

■Frequency converter

Abbreviation/Definition Description

I

VLT,MAX

I

VLT,N

U

VLT,MAX

■Output

Abbreviation/Definition Description

I

M

U

M

f

M

Break-away torque

VLT® 5000 Crane

The maximum output current

The rated output current supplied by the frequency converter

The maximum output voltage

The current transmitted to the motor

The voltage transmitted to the motor

The frequency transmitted to the motor

η

VLT

The efficiency of the frequency converter is defined as the ratio between the

power output and power input

■NO/NC

Abbreviation/Definition Description

NO Normally open

NC Normally closed

■Input

Abbreviation/Definition Description

Control command

Immediate stop

Stop command

By means of LCP and the digital inputs, it is possible to start and stop the

connected motor.

6

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 8

■Motor

I

M,N

f

M,N

U

M,N

P

M,N

n

M,N

T

M,N

■References

VLT® 5000 Crane

Abbreviation/Definition Description

The rated motor current (nameplate data)

The rated motor frequency (nameplate data)

The rated motor voltage (nameplate data)

The rated power delivered by the motor (nameplate data)

The rated motor speed (nameplate data)

The rated torque (motor)

Abbreviation/Definition Description

Analogue ref. A signal transmitted to input 53, 54 or 60. Can be voltage or current

Binary ref. A signal transmitted to the serial communication port

Ref

MAX

The maximum value which the reference signal may have. Set in parameter 205

■Miscellaneous

Abbreviation/Definition Description

ELCB Earth Leakage Circuit Breaker

Trip A state which occurs in different situations, eg. if the frequency converter is subject to a live zero warning.

A trip can be cancelled by pressing Reset

Trip locked A state which occurs in different situations, eg. if the frequency converter is subject to an overtemperature.

A locked trip can be cancelled by cutting off mains and restarting the frequency converter and pressing

Reset

Initializing If initializing is carried out (see parameter 620), the frequency converter returns to the factory setting

LCP The Local Control Panel, which makes up a complete interface for control and programming of VLT 5000

Crane. The control panel is detachable and may, as an alternative, be installed up to 3 metres away from

the frequency converter, ie. in a front panel, by means of the installation kit option

Flux Vector If compared with standard voltage/frequency ratio control, Flux Vector improves the dynamics and the

stability, both when the speed reference is changed and in relation to the load torque

Thermistor A temperature-dependent resistor placed where the temperature is to be monitored (frequency converter

or motor)

Analogue inputs The analogue inputs can be used for controlling various functions of the frequency converter. There are

two types of analogue inputs:

Current input and voltage input

Analogue outputs There are two analogue current outputs

Digital inputs The digital inputs can be used for controlling various functions of the frequency converter

Digital outputs There are four digital outputs, two of which activate relay switches.

Brake resistor The brake resistor is a module capable of absorbing the brake power that is generated in regenerative

braking. This regenerative braking power increases the intermediate circuit voltage and a brake chopper

ensures that the power is transmitted to the brake resistor

Incremental encoder An external, digital pulse transmitter used for feeding back information on motor speed. The encoder is

used in applications where high accuracy in speed control is required

AWG Means American Wire Gauge, ie. the American measuring unit for cable cross-section

Introduction

MG.50.N4.02 - VLT is a registered Danfoss trademark

7

Page 9

VLT® 5000 Crane

■Miscellaneous- continued

Abbreviations/Definitions Description

Manual initialisation Press the [CHANGE DATA] + [MENU] + [OK] keys at the same time to carry out

manual initialisation. See also Parameter 620.

Note that manual initialisation is only to be used if the reset function does not work!

SFAVM Switching pattern called Stator Flux oriented Asynchronous Vector Modulation

On-line/off-line parameters On-line parameters are activated immediately after the data value is changed.

Off-line parameters are not activated until OK has been entered on the control unit

CT characteristics Constant torque characteristics, used for all applications, such as conveyor belt

and cranes.

MCM Stands for Mille Circular Mil, an American measuring unit for cable cross-section

1 MCM=0.5067mm

ETR Electronic thermal relay is a thermal load calculation based on present load and

time. Its purpose is to estimate the motor temperature

CP Constant power

2

s

8

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 10

■Brief Product Description

The VLT 5000 Crane frequency converter supplies

a motor with variable voltage and frequency and

thereby enables infinitely variable speed control of

three-phased standard AC-motors.

The VLT 5000 Crane features the Flux Vector

control system.

The VLT 5000 Crane uses a digital technique

making it possible to program the different control

inputs and signal outputs.

The user can easily program the desired functions

by means of the VLT 5000 Crane control panel or

the user interfaces RS485 and RS232.

The VLT 5000 Crane is protected against the transients

occurring in the mains supply. Furthermore, a

good power factor and low peak current, reducing

the load on the mains installation, are ensured

through intermediate circuit coils.

Current measurement on all three motor phases

perfectly protects VLT 5000 Crane against earthing and

short-circuiting faults on the motor connenction.

VLT® 5000 Crane

Introduction

VLT 5000 Crane offers:

• Full utilisation of control range

• 130% torque for acceleration

• Fine adjustment at standstill + full load possible

without activating the system brake

■System Description

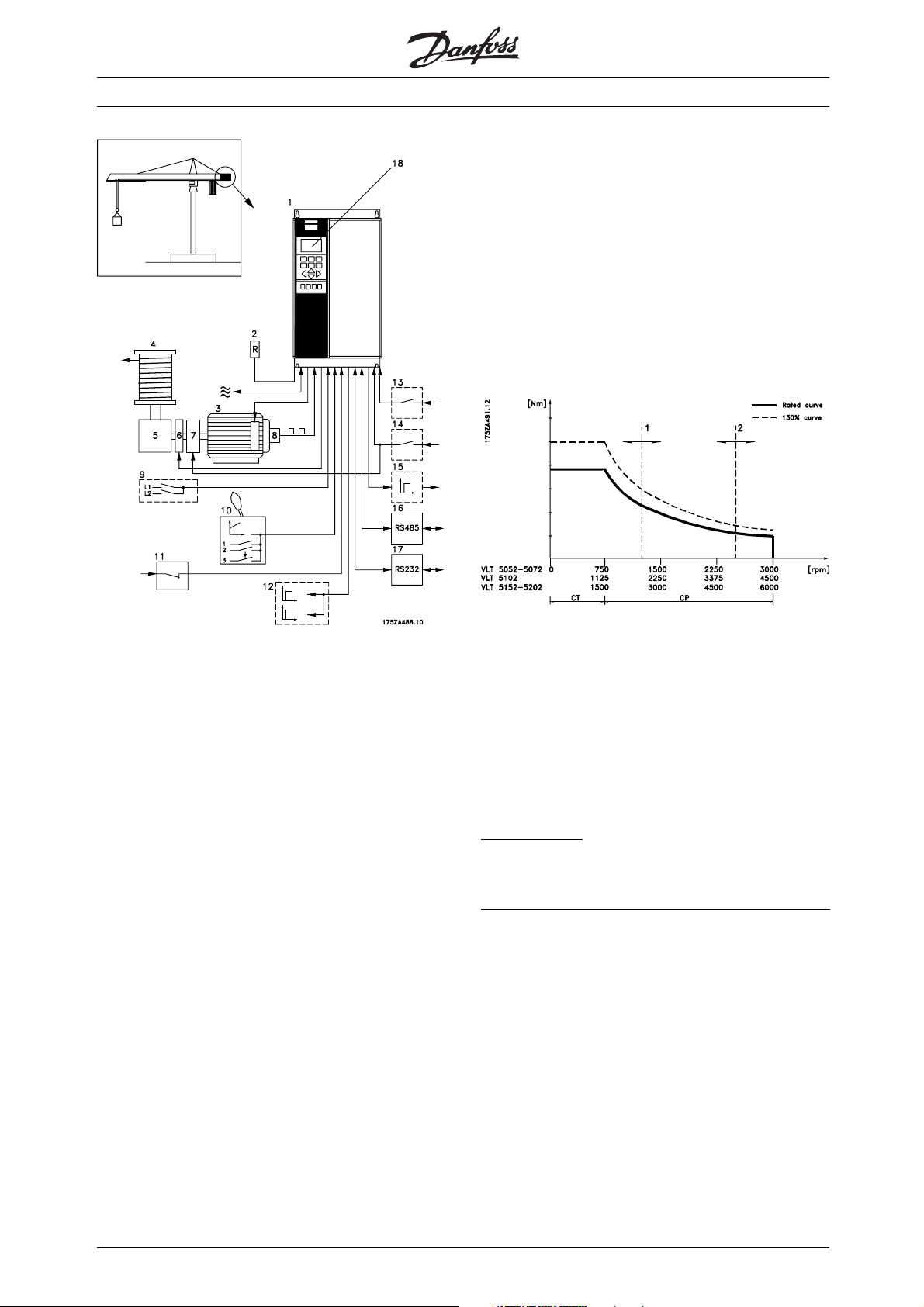

The sketch on next page shows how a tower crane

works together with VLT Crane Control.

The system consists of the following:

Efficient monitoring of the mains supply phases

ensures that the unit stops in case of phase failure.

This eliminates the risk of overloading the inverter an

the capacitors in the intermediate circuit and thereby

prolongs the service life of the frequency converter.

As standard, VLT 5000 Crane features integral

thermal protection. If a situation of thermal overload

occurs, this function cuts out the inverter.

The VLT 5000 Crane features reliable galvanic isolation

on all control terminals and integrated electronic

thermal protection on the motor.

■Function and System Description

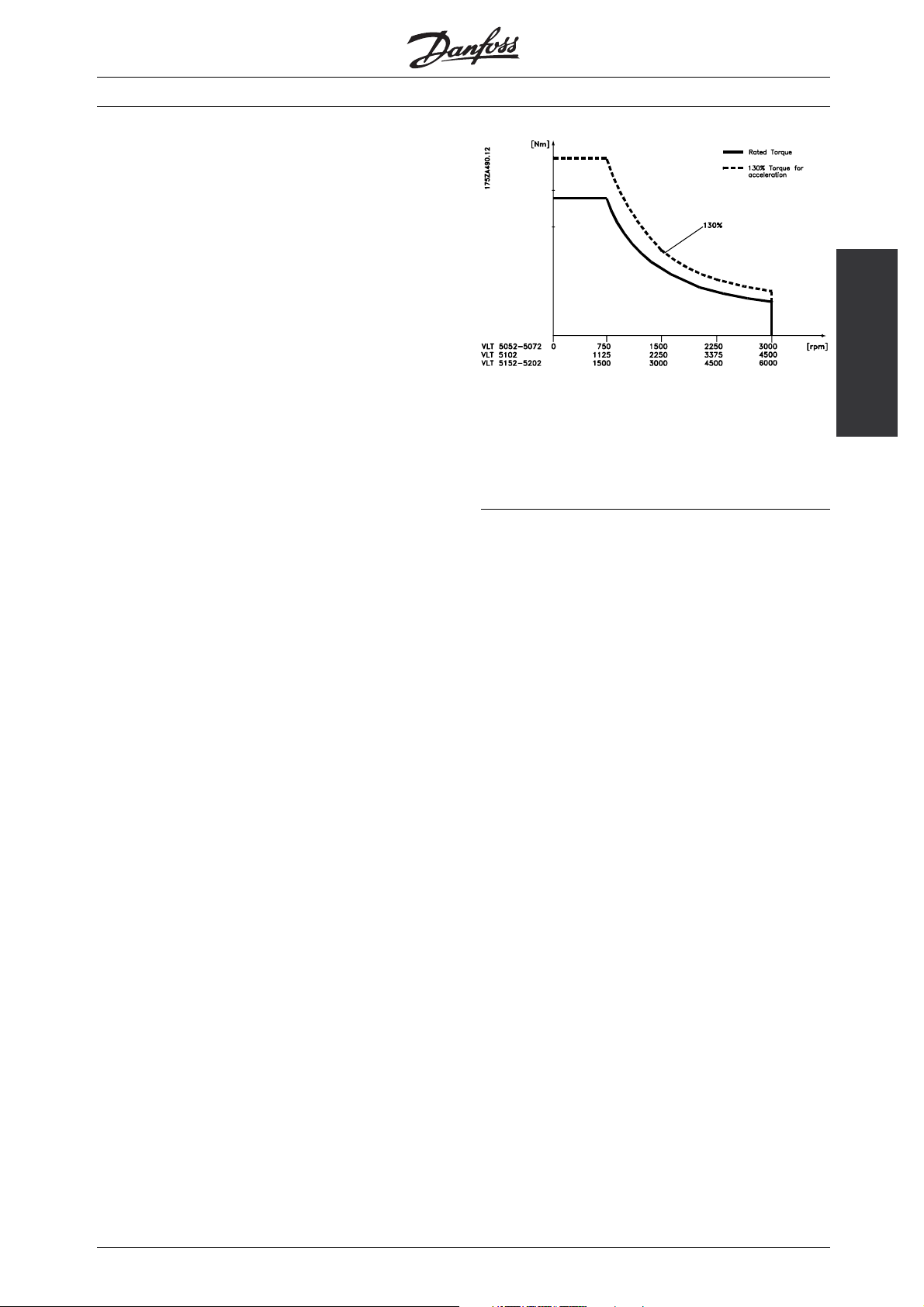

With VLT 5000 Crane the speed is infinitely varied in the

whole speed range from standstill (0 RPM) until rated

speed (750 RPM for VLT 5052-5072, 1125 RPM for

VLT 5102) according to the CT characteristic and rated

power up to max. speed (3000 or 4500 RPM).

There is full torque in the whole speed range.

1. VLT 5000 Flux Vector Control

2. Brake resistor

d

3. Motor

4. Cable drum

5. Angular gear box

6. NC system brake

7. Electric 2-step-gears: Normal load and heavy load

8. Optical encoder: Motor speed information for

flux vector control with closed loop

9. Load signals: VLT 5000 Crane checks on the basis of

load signals that the working range is not exceeded

10. Control signal: Analogue reference as well as

hoist, lowering and position operation

11. Quick stop with brake

12. Digital outputs: For combination of warning

and alarm at your operation

13. Crane ready signal

14. Gear step selection signal

15. VLT ready signal

16. RS 485 bus

17. RS 232 bus

18. Local control panel

MG.50.N4.02 - VLT is a registered Danfoss trademark

Installation and mains connection of brake resistor

and motor are described in Electrical installation

9

Page 11

VLT® 5000 Crane

■Description of Functions

With Danfoss VLT 5000 Crane the hoist/lower function

can be infinitely varied in the whole speed range.

Up to 750 RPM for VLT 5052-5072, 1125 RPM for

VLT 5102, 1500 RPM for VLT 5152-5202, respectively

themax. torquecurveappliesandabove750

RPM for VLT 5052-5072, 1125 RPM for VLT 5102,

1500 RPM for VLT 5152-5202, respectively the

max. power curve. There is up to 130% torque for

acceleration in the whole speed range.

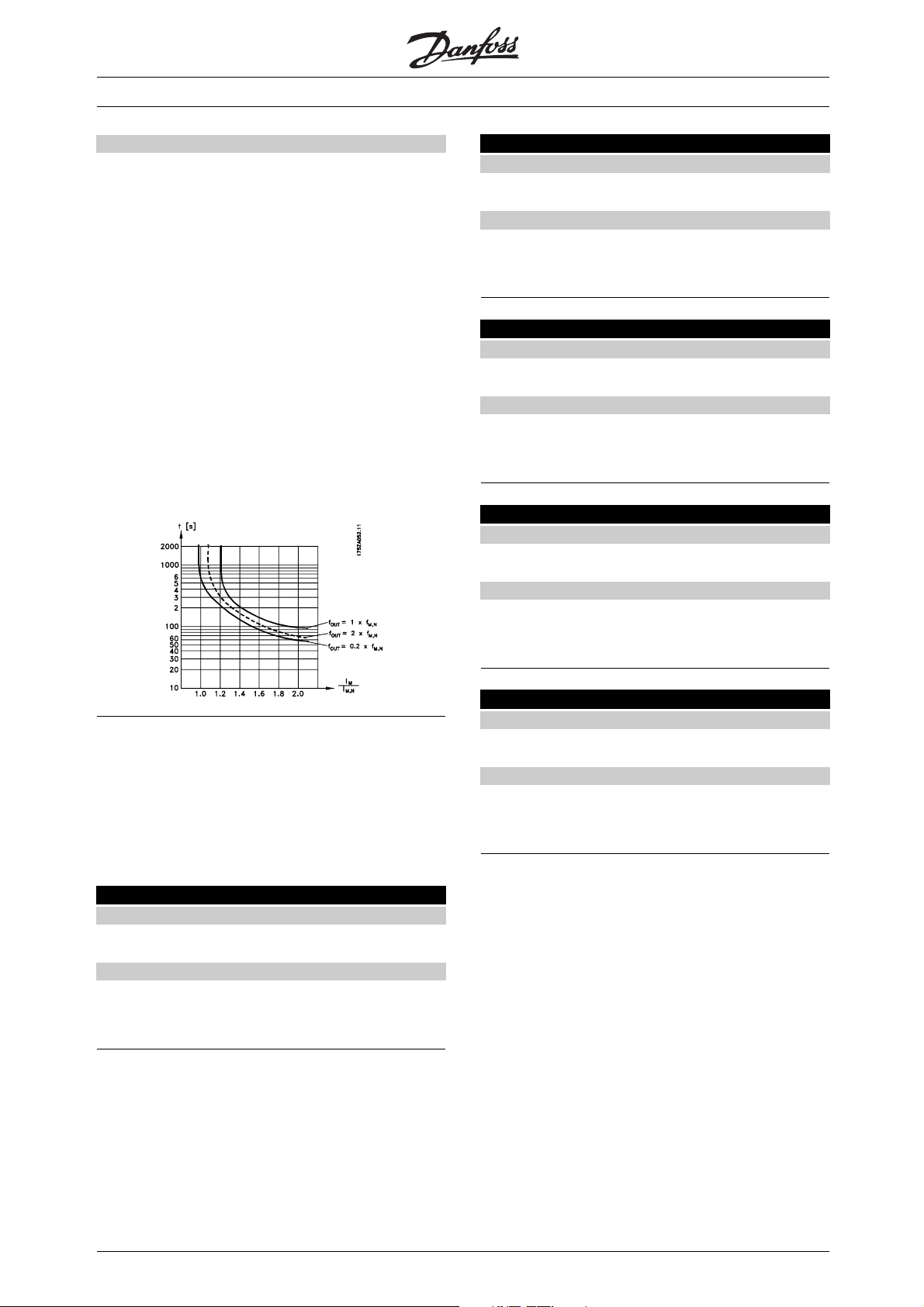

Working curve, motor:

1: Speed limit at heavy load (parameter 702)

2: Speed limit at normal load (parameter 701)

The 2-step gear box (see System description )

increases the working range, as it is possible to switch

between normal load and heavy load.

VLT 5000 will optimise the motor control to the selected

gear stage on the basis of the signal on terminal

29, see System Description, position 14.

ignal definition

S

24 V signal: Normal load

0 V signal: Heavy load

■Operating Status at Remote Control

Control ready

Voltage on VLT 5000 Crane. The frequency

converter is ready for use and the control card

receives supply voltage.

No faults were found during initialisation.

Inverter section disabled.

10

Normal operation

The reference signal is higher than minimum. Up to

750 RPM the working range is limited by max. torque.

Above 750 RPM it is working in field weakening range.

Here the working range is limited by constant power.

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 12

VLT 5000 Crane controls the mechanical brake

of the crane. It holds the load when speed is

below the set minimum value.

VLT 5000 Crane monitors that the system brake

holds and releases the load as required. In case

of faults, Brake fault 2 is displayed.

Load determination and speed measuring will ensure

that the working range is not exceeded. For each

load contact the max. allowed motor speed is set

(parameters 701 and 702). VLT 5000 Crane cuts off

automatically when motor speed for the activated

load contact exceeds the value recorded

Positioning

The reference signal is higher than minimum. The

condition for VLT ready is fulfilled. 24V is applied

to terminal 17 (parameter 301).

During positioning the speed is limited to 750 RPM

for VLT 5052-5072, 1125 RPM for VLT 5102, 1500

RPM for VLT 5152-5202, respectively, and system

brake is not activated at 0 RPM.

Quick stop with brake

If control signal to terminal 27(parameter 304)

is removed, the motor ramps down according

to the alternative ramp (parameter 212) and the

brake is activated momentarily.

■Operating Status at Local Operation

It is only possible to change to local operation from

Control Ready. Besides, parameter 003 must be

set for Local and parameter 010 for Enable.VLT

5000 Crane can be operated over the control panel

or over parameters 004 - 009. This state acts

as Normal operating state, however there are no

load functions and monitoring of system brake.

This means that the whole working range from 0

- 3000 RPM can be used and the crane system

brake is controlled at approx. 0 RPM.

VLT® 5000 Crane

Brake fault 2

VLT 5000 Crane monitors in the state normal operation,

that the system brake releases the load as required.

If that is not the case Brake fault 2 applies. The unit

will cut in the system brake again. This means that the

system brake signal is deactivated. This ensures that

the load is held. Then the inverter section is disabled.

Brake fault 2 may also occur during commissioning

if the encoder connection is not correct.

Atreference0theunitgoesbacktothestateVLTready.

Function fault

VLT 5000 Crane monitors several functions. Should

severe faults occur, the unit will trip automatically.

For fault types, see Trouble-shooting

To reset the fault switch off/switch on the mains

supply and press the stop/reset button.

■System Components

Motor

Select the motor type for the rated output in question

in parameters 102-106, 150-155..

Incremental Encoder

The encoder must meet the following requirements:

• Pulses pr. revolution, see parameter 329

• Out puts: A (0º ), inv. A, B ( 9 0 º), inv. B, Z, i nv. Z

• Supply: +5 V ±5%

• Max. current (5V supply): 200mA

Note that outputs must be compatible with RS 422!

Brake resistor

See data for calculation in Control with brake function.

Introduction

■Fault Status at Remote and Local Control

Brake fault 1

VLT 5000 Crane monitors in the state VLT ready that

the system brake holds the load as required. If that is

not the case, Brake fault 1 appliesandtheloadisslowly

lowered according to the speed set in parameter 704.

MG.50.N4.02 - VLT is a registered Danfoss trademark

11

Page 13

VLT® 5000 Crane

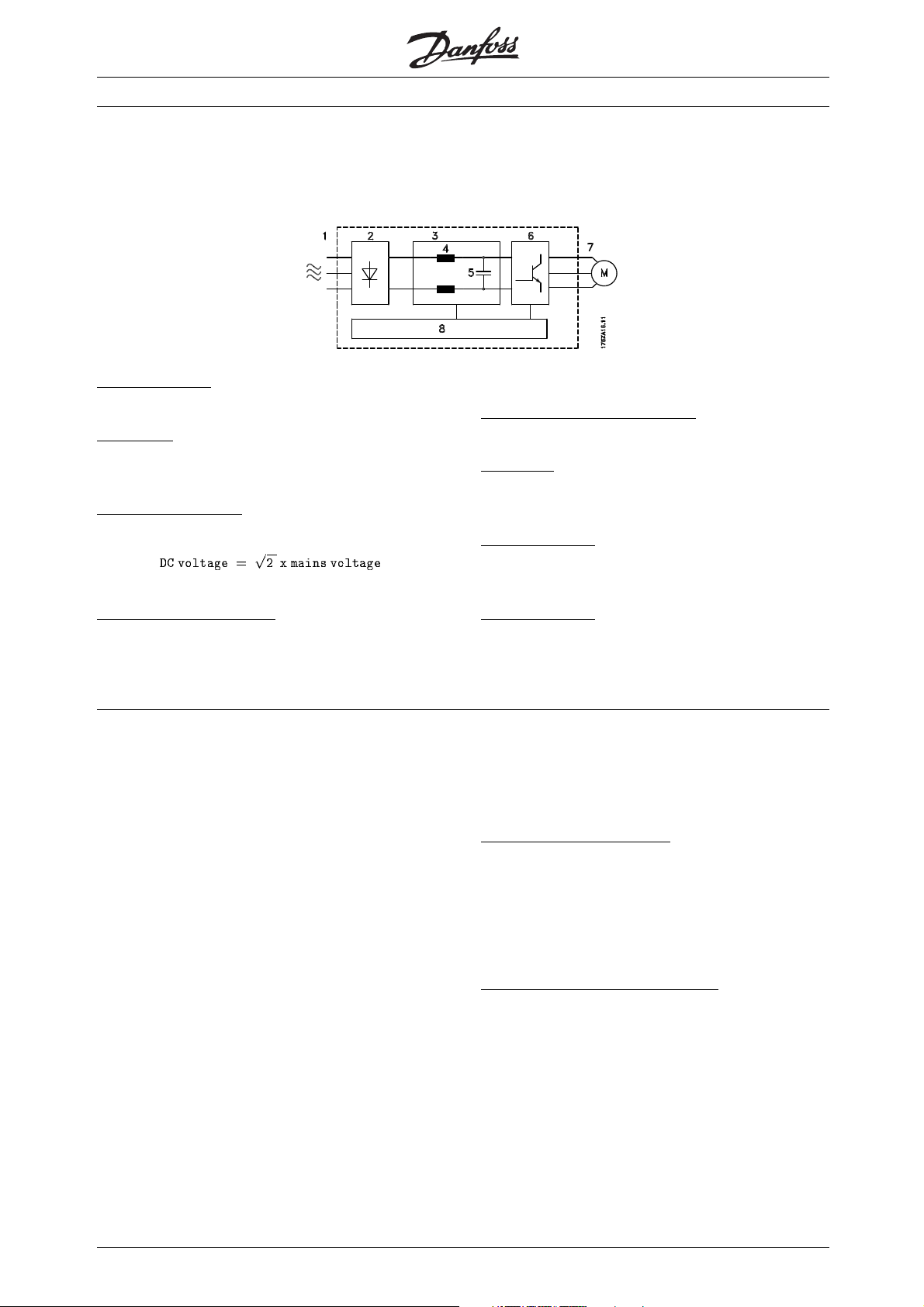

■Control Principle

A frequency converter rectifies AC voltage from mains

into DC voltage. This DC voltage is then converted into

aACvoltagewithavariableamplitudeandfrequency.

1. Mains voltage

3 x 400 - 500 V AC, 50 / 60 Hz.

2

. Rectifier

A three-phase rectifier bridge that rectifies AC

voltage into DC voltage.

3

. Intermediate circuit

The motor is thus supplied with variable voltage and

frequency, which enables infinitely variable speed

control of three-phased, standard AC motors.

5

. Intermediate circuit capacitors

Smooth the intermediate circuit voltage.

. Inverter

6

Converts DC voltage into variable AC voltage

with a variable frequency.

. Motor voltage

7

Variable AC voltage, 0-100% of mains supply voltage.

Variable frequency: 0 - 300 Hz.

4. Intermediate circuit coils

Smooth the intermediate circuitcurrent and limit the

load on mains and components (mains transformer,

wires, fuses and contactors).

■Flux Vector Control Principle

TheaimofdevelopingtheFluxVectorcontrol

principle has been to obtain a robust motor control

that is tolerant to different motor characteristics

without motor derating being required.

The current is split into magnetising and

torque-generating parts and provides for much

better and quicker estimation of the actual motor

loads. It is now possible to compensate for rapid

load changes. Full torque as well as extremely

accurate speed control can now be obtained even

at low speeds or even at standstill.

Good torque control properties and smooth transitions

to and from current limit operation are ensured.

Advantages of the Flux Vector control system:

- Accurate speed control down to 0 speed

- Quick response from received signal to

full motor shaft torque

- Good compensation for step loads

- Controlled transition from normal operation to

current limit operation (and vice versa)

. Control circuit

8

On basis of parameters, reference settings and input

signals, pulse patterns are generated for forming

thevariablemotorvoltageandfrequency.

- Torque control, comprising control of both

the torque-generating and the magnetising

component of the current

- Full holding torque

P

rogrammable signal outputs

VLT 5000 Crane uses a digital technique which makes

it possible to program the signal outputs.

For the user, it is easy to program the desired functions

by means of the control panel on VLT 5000 Crane

or the RS 485/RS 232 user interfaces.

rotection against mains interference

P

VLT 5000 Crane is protected against the transients

that occur in the mains supply, eg. when switching

power factor correction or when fuses blow.

The rated motor voltage and full torque can be

maintained all the way down to 10% undervoltage

in the mains supply.

12

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 14

VLT® 5000 Crane

Minor interference on mains

Since as standard the VLT 5000 Crane features

intermediate circuit coils, there is only a small amount

of harmonic mains supply interference. This ensures

a good power factor and lower peak current, which

reduces the load on the mains installation.

A

dvanced VLT protection

Current measurement on all three motor phases

provides perfect protection of VLT 5000 Crane

against earthing and short-circuiting faults on

the motor connection.

Efficient monitoring of the three mains supply phases

ensures that the unit stops in the case of phase failure.

This avoids overloading the inverter and the capacitors

in the intermediate circuit, which would dramatically

reduce the service life of the frequency converter.

As standard, VLT 5000 Crane features integral

thermal protection. If a situation of thermal overload

occurs, this function cuts out the inverter.

ncoder supervisory circuit

E

The signals from the incremental encoder and hence

the cabling are continuously supervised.

The encoder signals are made up of three channels,

each of which are supervised, and status is given

on LEDs placed near the encoder terminals for each

channel as well as for the supply voltage for the encoder.

Green LED turned on means channel or voltage OK.

fan fails, a thermistor can be integrated and connected

to the thermistor input of the frequency converter

(terminals 53), see parameters 128 and 308.

Introduction

R

eliable galvanic isolation

In the VLT 5000 Crane all of the control circuits are

separated from mains potential through isolation

meeting the PELV requirements.

One set of relay contacts, terminals 01 - 03, is

separated from the remaining control circuits through

isolation also complying with PELV.

Furthermore, the control circuits are placed in blocks

individually separated through functional isolation

(< 100 V), see General Technical Data.

A

dvanced motor protection

VLT 5000 Crane features integrated

thermal motor protection.

The frequency converter calculates the motor

temperature on the basis of current, frequency and time.

As opposed to the traditional bimetallic protection,

electronic protection takes ac

cooling at low frequencies that comes from reduced

fan speed (motors with internal ventilation).

To obtain maximum protection against overheating of

the motor if the motor is covered or blocked, or if the

count of the reduction in

electronic,

MG.50.N4.02 - VLT is a registered Danfoss trademark

13

Page 15

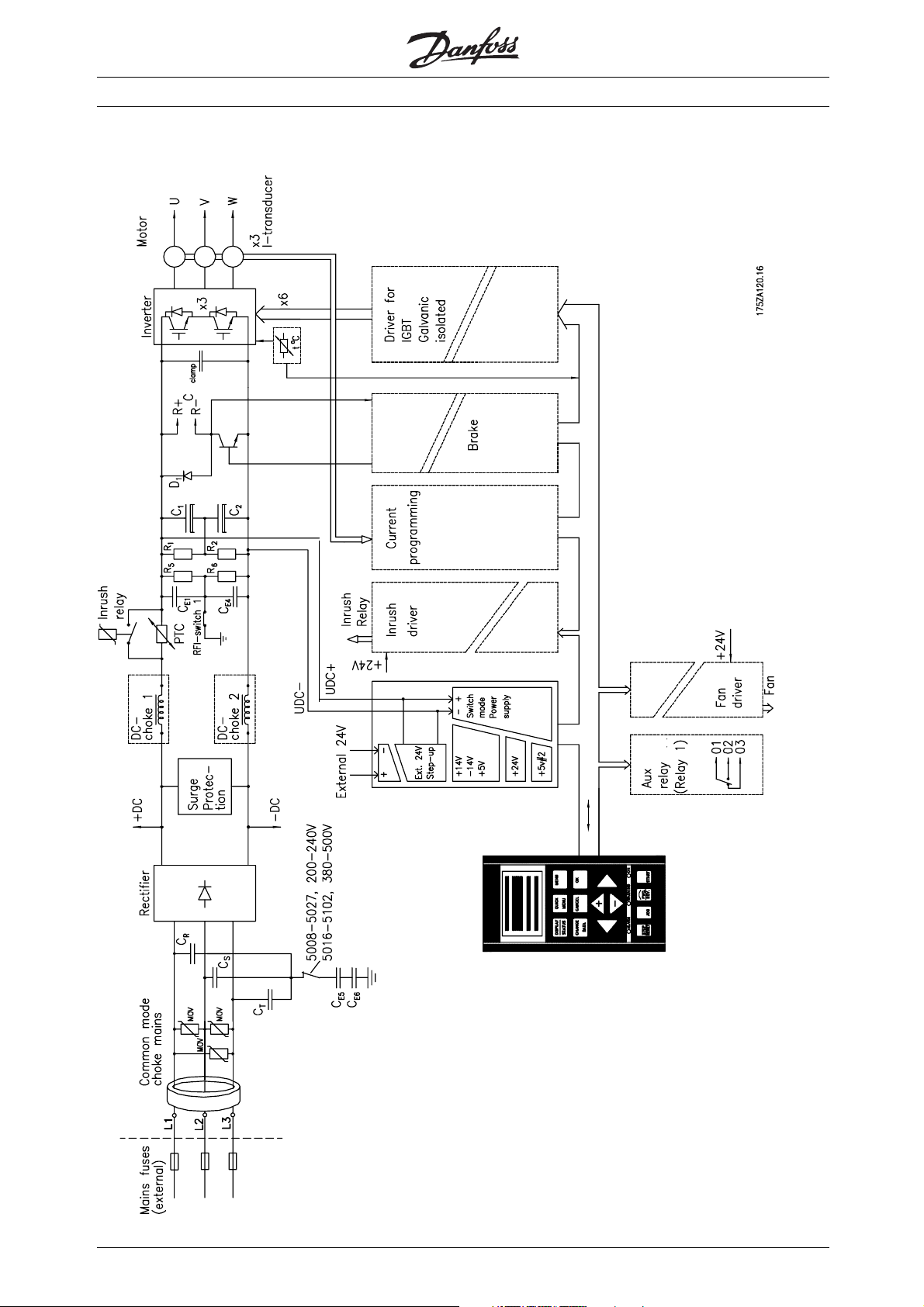

■Key Diagram for VLT 5000 Crane 5042,

5102 400-500 V

VLT® 5000 Crane

14

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 16

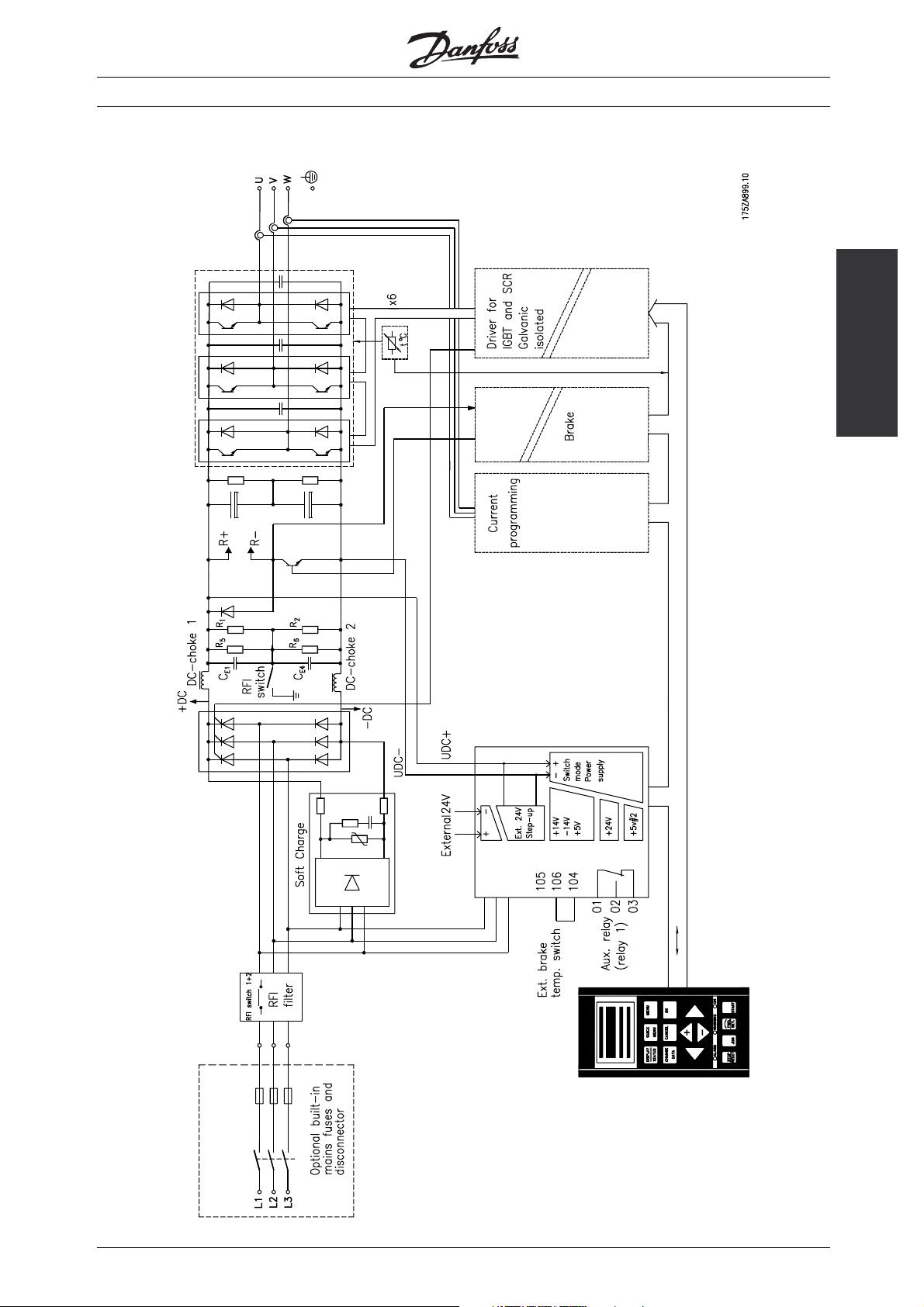

■Key Diagram for VLT 5000 Crane 5122-

5202 400-500 V

VLT® 5000 Crane

Introduction

MG.50.N4.02 - VLT is a registered Danfoss trademark

15

Page 17

VLT® 5000 Crane

■General Technical Data

Mains Supply (L1, L2, L3)

Supply voltage 400 - 500 V units 3 x 400/415/440/460/500 V ± 10%

Supply frequency 50/60 Hz ± 1%

Max. imbalance of supply voltage

VLT 5052 - 5062/400 - 500 V

VLT 5072 - 5202/400 - 500 V

Power factor/cos ϕ

No. of switches on supply input L1, L2, L3 Appr. 1 time/minute

Max. short-circuit rating 100.000 A

Output voltage 0-100% of supply voltage

Output frequency 0-160 Hz

Rated motor voltage 400 - 500 V units 315 V

Rated motor frequency 25/37 Hz

Ramp times 0.05 - 3600 Seconds

Starting torque, VLT 5042–5202, 400 - 500 V 160%

Acceleration torque, VLT 5042–5302, 400 - 500 V 160%

Overload torque, VLT 5042-5302, 400 - 500 V 160%

Holding torque at 0 rpm (closed loop), VLT 5042–5302, 400 - 500 V 160%

1

VLT Data Output (U, V, W)

Torque Characteristics

of rated supply voltage

1.5%

3%

0.90/1 at rated load

for 1 minute

for 1 minute

for 1 minute

for 1 minute

Digital Inputs

Number of digital inputs 9

Voltage level 0-24 V DC (PNP positive logics)

Voltage level, logical ’0’ <5 V DC

Voltage level, logical ’1’ >10 V DC

Max. voltage on input 28 V DC

Input resistance, Ri(terminal 29) Appr. 4 K /2 K (2 K )

Scanning time per input 3msec

NOTE: All digital inputs are galvanic isolated from the mains voltage (PELV). In addition, the digital inputs can be isolated from the other

terminals on the control card by connecting an external 24 V DC supply and opening switch 4, see Electrical installation.

Analogue Inputs

Number of programmable analogue voltage inputs/thermistor inputs 1

Voltage level 0- ± 10 V DC (Scalable)

Input resistance, R

Number of programmable analogue current inputs 2

Current range 0/4- 20 mA (Scalable)

Input resistance, R

Resolution 10 + sign bit

Accuracy on input Max. error: 1% of full scale

Scanning time per input 3msec

NOTE: Analogue inputs are galvanic isolated from the mains voltage (PELV) and functionally isolated from all other inputs

i

i

Appr. 10 K

200

16

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 18

VLT® 5000 Crane

Incremental/Encoder Input

Number of encoder input terminals 6

Max. frequency 205 kHz

Voltage level 0-5 V (RS422)

Voltage level, logical ’0’ <0.5V

Voltage level, logical ’1’ >2.5V

Max. voltage on input 7VDC

Input resistance, R

Supply voltage 5V+/-5%

Supply current 200 mA

NOTE: Encoder input terminals are galvanic isolated from the supply voltage (PELV) and functionally isolated from all other inputs

and outputs.

Number of programmable digital outputs 2

Number of programmable analogue outputs 2

Voltage level at digital/pulse output 0-24 V DC

Min. load to ground (terminal 39) at digital/pulse output 600

Frequency ranges (digital output used as pulse output) 0-50 kHz

Resolution

<5kHz

<50 kHz

Current ranges at analogue output 0/4-20 mA

Max. load to ground (terminal 39) at analogue output 500

Accuracy of analogue output Max error: 1.5% of full scale

Resolution on analogue output 8bit

NOTE: All digital and analogue outputs are galvcanic isolated from the supply voltage (PELV) and functionally isolated from all other inputs

NB: Digital and analogue outputs have one common ground terminal (39)

i

Digital/Pulse and Analogue Outputs

Appr. 120

0.1%

1%

Data

Technical

24 V DC Output

Max. load (short-circuit protection) 200 mA

Terminal numbers, ground (with switch 4 closed) 39 (20)

NOTE: The 24 V DC supply is galvanic isolated from the supply volta

outputs

RS 485 Serial Communication

Terminal numbers 68 (TX+, RX+), 69 (TX-,RX-)

NOTE: The signal input is galvanic isolated from the mains volta

RS 232 Serial Communication (Peer to Peer)

Connection RJ 11

NOTE: The signal input is galvanic isolated from mains supply (PELV) but not from RS 485

ge (PELV), but has the same potential as analogue and digital

ge (PELV) but not from RS 232

MG.50.N4.02 - VLT is a registered Danfoss trademark

17

Page 19

VLT® 5000 Crane

Relay Outputs

Number of programmable relay outputs 2

Terminal numbers, control cards 4-5 NO

Max. terminal load (AC) on 4-5 control card 50 V AC, 1A, 60 VA

Max. terminal load (DC) on 4-5, control card 75 V DC, 1A, 30W

Max. terminal load (DC) on 4-5, control card

UL applications

cUL applications

Terminal numbers, power card 1-3 NC, 1-2 NO

Max. terminal load (AC) on 1-3, 1-2, power card 240 V AC, 2A, 60 VA

Max. terminal load on 1-3, 1-2, power card 50 V DC, 2 A

Min. terminal load on 1-3, 1-2, power card 24 V AC/24 V DC, 10/100mA

Brake Resistor Terminal

Terminal numbers 81, 82

Cable Lenghts and Cross-Sections

Max. motor cable length, screened cable 25m

Max. brake cable length, screened cable 5m

Max. cable cross-section for control cables 0.75mm2/AWG

Max. cross-section for serial communication 0.75mm2/AWG

NOTE: Max. cable cross-section for motor and brake, see Installation

30 V AC, 1A

1A, 42.5 V DC

Accuracy of Display Readout (Parameters 009 - 012)

Motor Current [6] 0 - 140% load Max error: 2% of rated output current

Torque % [7] -100 - 140% load Max error: 5% of rated motor size

Output [8], power HP [9] 0 - 90% load Max error: 5% of rated output

Control Caracteristics

Frequency range 0-160 Hz

Resolution on output frequency ± 0.003 Hz

System response time* <5msec

Speed, control range 1:1000 of synchro speed

Speed, accuracy

<1500 rpm

>1500 rpm

Torque control accuracy (Speed feedback) Max error: ± 5% of rated torque

NOTE: All control caracteristics are based on 4-pole asynchronous motors

Max error:

±1.5rpm

0.1% of actual speed

*The system response time is the time passing

from the input receives a signal to a reaction

occurs on the VLT output.

18

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 20

VLT® 5000 Crane

Externals

Enclosure Ty pe IP 20 /I P 0 0

Vibration Test: 0.7 g RMS 18 - 100 Hz random, 3

directions for 2 hrs (IEC 68-2-34/35/36)

Max. relative humidity for storage/transport 93% (IEC 68-2-3)

Max. relative humidity non-condensing for operation 95% (IEC 721-3-3; Class 3K3)

Ambient temperature 55°C

Ambient temperature, 24-hour average Max 50°C

Min. ambient temperature in full operation 0°C

Min. ambient temperature at reduced performance -10°C

Temperature during storage/transport -25 - +65/70°C

Max. altitude above sea level, without derating* 1000m

NOTE: EMC standards used:

Emission: EN50081-1/2, EN61800-3, EN55011,

Immunity: EN50082-2, EN61000-4-2,, EN61000-4-4,ENV50204, EN61000–4–3, EN61000–4–5, EN61000–4–6, VDE0160/1990.12

Derating for high ambient temperature, see Special Conditions in Appendix

*For more information on derating, see Special

Conditions in Appendix.

■VLT 5000 Crane Protection

• Electronic motor thermal protection against overload

• Electronic thermal protection against overload

• Temperature monitoring of heat-sink ensures that the frequency converter cuts out if the temperature reaches

90°C. An overtemperature fault can only be reset when the temperature of the heat-sink has fallen below 60°C

• The frequency converter is protected against short-circuiting on motor terminals U, V, W

• The frequency converter is protected against earth fault on motor terminals U, V, W

• Monitoring of the intermediate circuit voltage ensures that the frequency converter cuts out if

the intermediate circuit voltage gets too high or too low

• If a motor phase is missing, the frequency converter cuts out, see parameter 234 Motor Phase Monitor

• If a mains phase is missing, the frequency converter will cut out when a load is applied to the motor

Data

Technical

MG.50.N4.02 - VLT is a registered Danfoss trademark

19

Page 21

VLT® 5000 Crane

■Mains Supply 400 - 500 V

According to international requirements VLT type 5042 5052 5062

I

(S3 60%) [A]

Output current

Output

Typical shaft output P

Typical shaft output P

Max. cable cross-section to motor and

brake [mm

2

Rated input current I

Max. cable cross-section

power[mm2]/[AWG]

Max. pre-fuses [-]/UL1)[A] 100/100 125/125 150/50

Efficiency 0.96 0,96 0.96

Weight IP 20 SB [kg] 41 42 43

Power loss at max. load. 1004 1210 1500

Enclosure IP20 IP20 IP20

1. For type of fuse see section Fuses.

2. American wire gauge.

3. Connection stud 1 x M8/2 x M8.

]/[AWG]

I

VLT, MAX

2)3)

2)3)

VLT,N

(400-500 V)

58 69 85

(60 s) [A] (400-500 V) 97.6 116.8 135

S

(S3 60%) [kVA]

VLT,N

(400-500 V)

VLT,N

VLT,N

39.2

46.6 57.4

[kW] 22 30 37

[HP] 30 41 50

IP20 50/0 50/0

(S3 60%) [A] (400 V) 51 62 76

L,N

35/2 50/0 50/0

20

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 22

VLT® 5000 Crane

■Mains supply 3 x 400-500 V

According to international

requirements VLT type 5072 5102 5152 5202

Output

current

Output

Typical shaft output P

Typical shaft output P

Max. cable cross-section to motor

(400-500 V) [mm

Max. cable cross-section to brake

(400-500 V) [mm2]

Max. cable cross-section to motor

(400-500 V) AWG]

Max. cable cross-section to brake

(400-500 V) AWG]

Max input current I

Max. cable cross-section to power

(400-500 V) [mm

Max. cable cross-section to power

(400-500V) [AWG]

Efficiency

Weight IP 20 EB/IP 00 [kg] 109 109 89 134

Power loss at max. load [W] 1860 2250 2828 3231

Enclosure IP20 IP20 IP00 IP00

1. For type of fuse see section Fuses.

2. American wire gauge.

3. Connection Dual M10 screws.

4. Connection Dual M8 screws.

I

[A] (S3 60%) (400-500 V) 100 139 201 246

VLT,N

I

VLT, MAX

(60 s) [A] (400-500 V) 159 221 301 369

S

(S3 60%) [kVA]

VLT,N

(400-500 V) 67.5 93.9 135.8 166.2

[kW] 45 65 90 110

VLT,N

[HP] 61 89 125 150

VLT,N

2]3)

2) 3)

2) 4)

2]3)

4)

2) 3)

(S3 60%) [A] (400 V) 89 124 186 224

L,MAX

95 120 2x70 2x185

95 120 2x35 2x70

3/0 4/0 2x2/0

3/0 4/0 2x3 2x2/0

95 120 2x70 2x185

3/0 4/0 2x2/0

0.96-

0.97

0.96-

0.97

0.97-

0.98

2x350

MCM

Data

Technical

2x350

MCM

0.97-

0.98

MG.50.N4.02 - VLT is a registered Danfoss trademark

21

Page 23

VLT® 5000 Crane

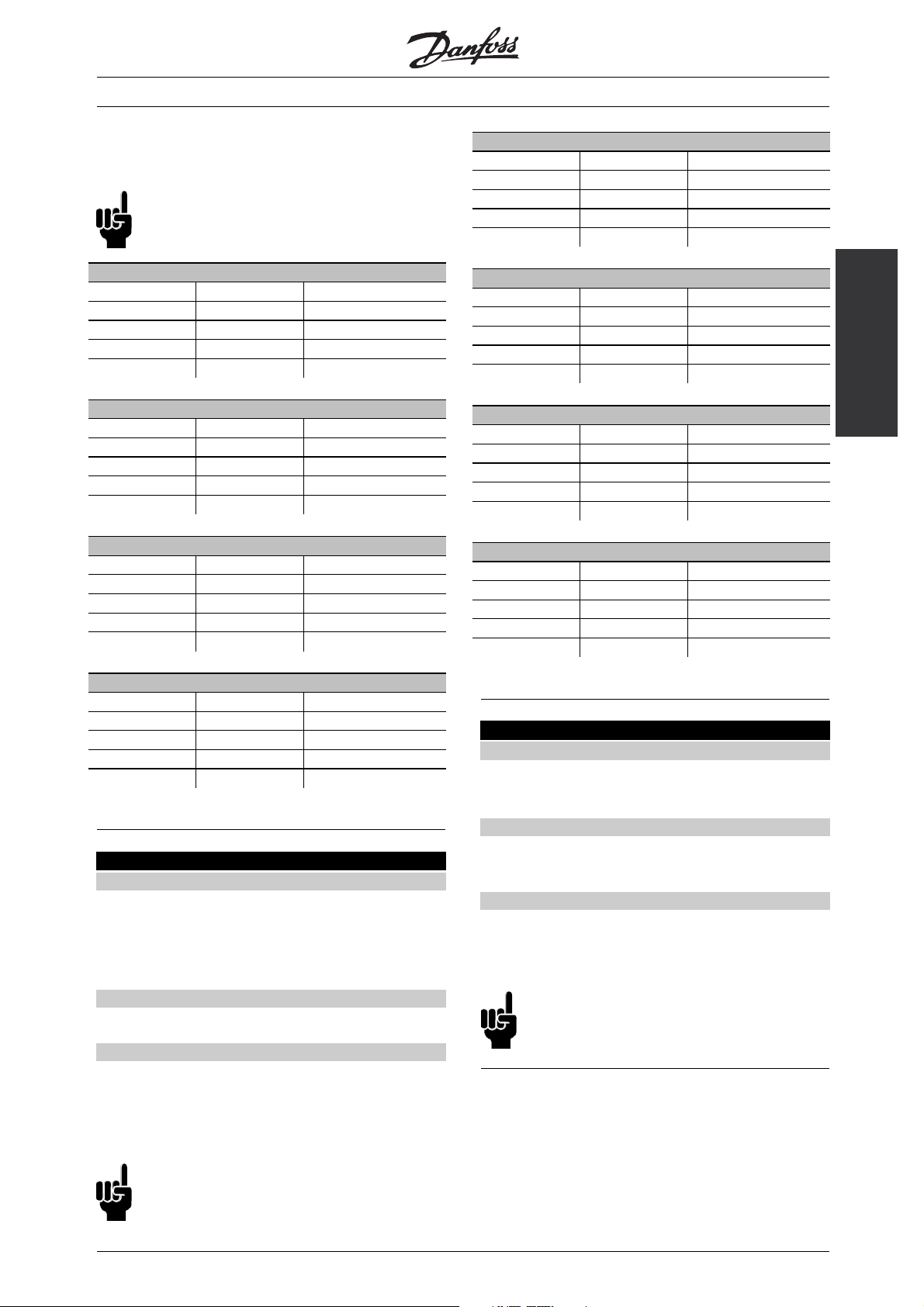

■Fuses

UL compliance

Bussmann SIBA Littel fuse Ferraz-Shawmut

5042 KTS-R100 2028220-125 KLS-R100 A6K-100R

5052 KTS-R125 2028220-125 KLS-R125 A6K-125R

5062 KTS-R150 2028220-160 KLS-R150 A6K-150R

5072 FWH-220 2028220-200 L50S-225 A50-P225

5102 FWH-250 2028220-250 L50S-250 A50-P250

5122 FWH-300 2028220-315 L50S-300 A50-P300

5152 FWH-350 2028220-315 L50S-350 A50-P350

5202 FWH-400 206xx32-400 L50S-400 A50-P400

KTS-fuses from Bussmann may substitute KTN for 240 V drives.

FWH-fuses from Bussmann may substitute FWX for 240 V drives.

KLSR fuses from LITTEL FUSE may substitute KLNR fuses for 240 V drives.

L50S fuses from LITTEL FUSE may substitute L50S fuses for 240 V drives.

A6KR fuses from FERRAZ SHAWMUT may substitute A2KR for 240 V drive

A50X fuses from FERRAZ SHAWMUT may substitute A25X for 240 V drives.

Non UL

compliance

380-500 V

s.

If UL/cUL is not to be complied with, we recommend the above mentioned fuses or:

VLT 5001-5027 200-240 V type gG

VLT 5001-5062 380-500 V type gG

VLT 5032-5052 200-240 V type gR

VLT 5072-5500 380-500 V type gR

Not following the recommendation may result

in unnecessary damage of the drive in case of

malfunction. Fuses must be designed for protection in

a circuit capable of supplying a maximum of 100000

A

(symmetrical), 500/600 V maximum.

rms

22

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 24

VLT® 5000 Crane

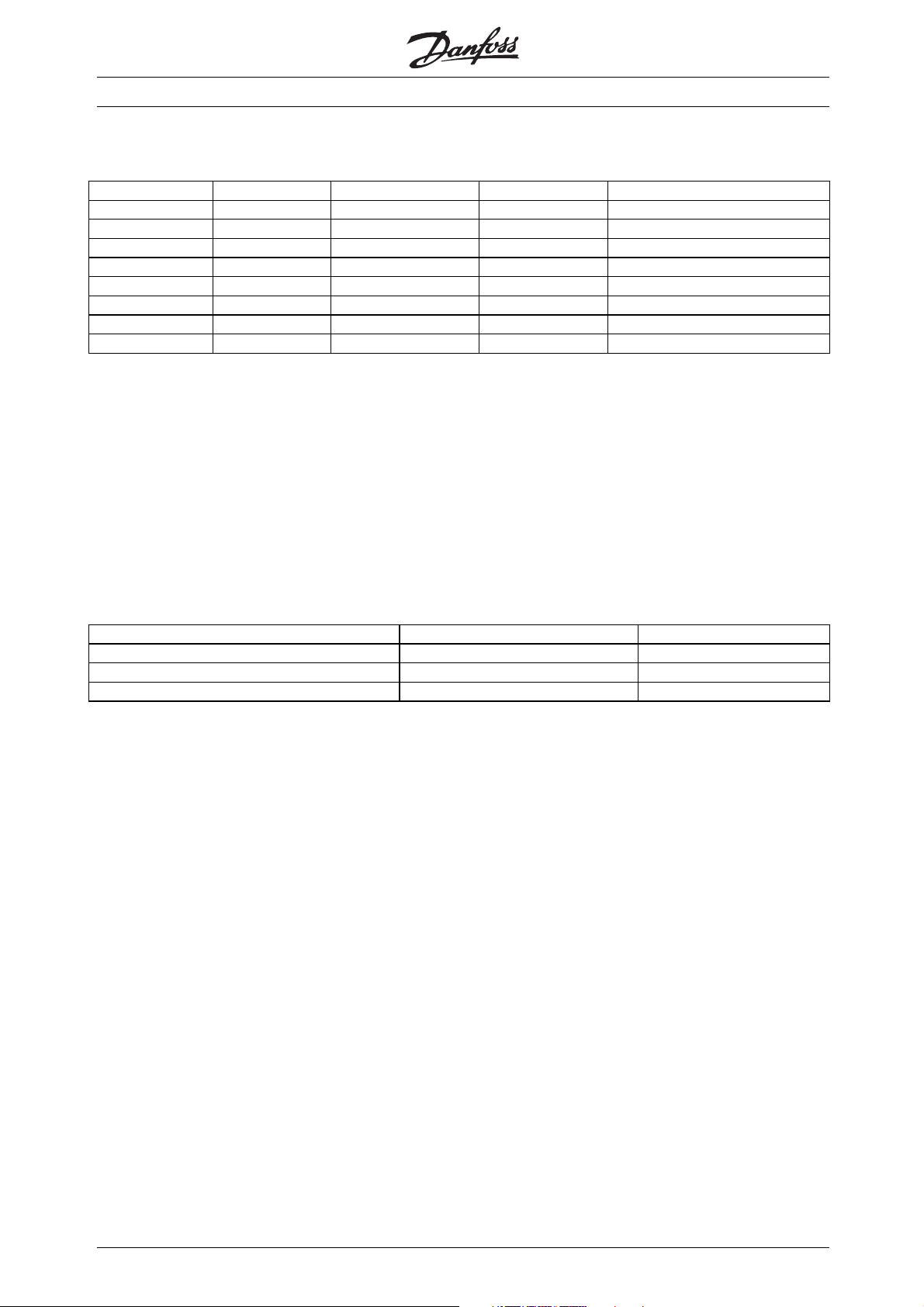

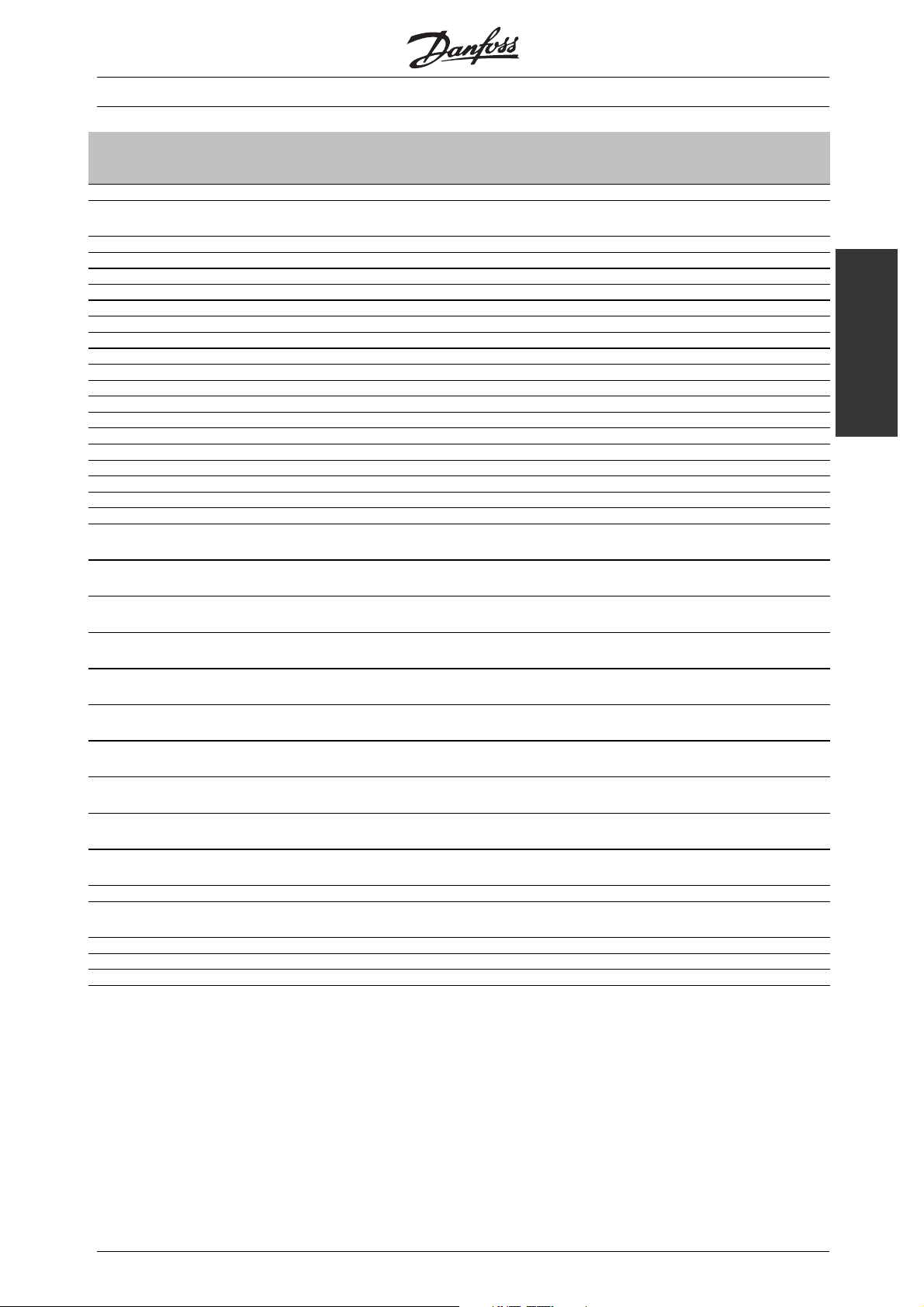

■Mechanical Dimensions

■Compact IP 00 and IP 20

IP 00 enclosure 400-500 V

VLT type A (mm) B (mm) C (mm) a (mm) b (mm) ab/be (mm) l/r (mm)

5152 - 5202 1400 420 400 1380 350 225 0

IP 20 enclosure 400-500 V

VLT type A (mm) B (mm) C (mm) a (mm) b (mm) ab/be (mm) l/r (mm)

5042 - 5062 800 308 296 780 270 200 0

5072 - 5102 800 370 335 780 330 225 0

ab: Min. space above enclosure.

be: Min. space below enclosure.

l/r: Min. distance between frequency converter and

other plant components, left and right sides.

VLT 5042-5102/400-500 V

Data

Technical

VLT 5152-5202/400-500 V

MG.50.N4.02 - VLT is a registered Danfoss trademark

23

Page 25

VLT® 5000 Crane

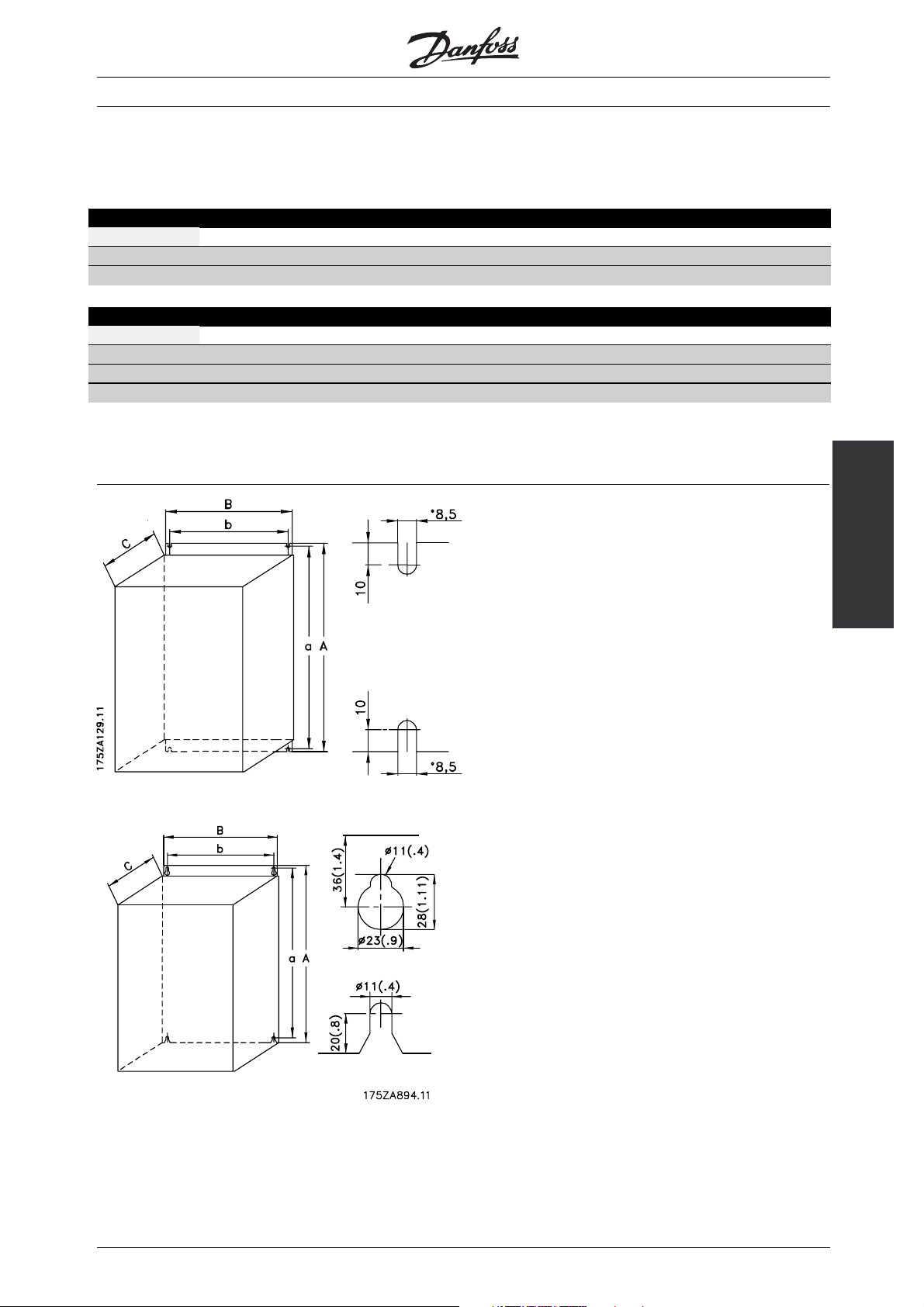

■General Warning before Installation

Before starting the installation, please

be aware of heavy weight and sharp

edges. Furthermore, make sure that

no mains are connected

■Mechanical Installation

The frequency converter must be installed vertically.

The frequency converter is cooled by means of air

circulation. For the unit to be able to release its cooling

air, the minimum distance over and below the unit

must be as shown in the illustration below. To protect

■Installation of VLT 5042–5062 400-500 V

Compact IP20/IP00

Cooling

the unit from overheating, it must be ensured that the

ambient temperature does not rise above the max.

temperature stated for the frequency converter and

that the 24-hour average temperature is not exceeded.

The max. temperature and 24-hour average can be

seen from the General Technical Data.

■Enclosure Protection

Compact

VLT 5042 - 5102 400-500 V IP 20

VLT 5152 - 5202 400-500 V IP 00

Side-by-side

All Compact units in the above-mentioned series

require a minimum space of 200 mm above and

below the enclosure and must be installed on a

plane, vertical surface (no spacers).

Compact IP 00/IP20

All units in the above-mentioned series can be installed

side by side without any space between them, since

these units do not require cooling on the sides.

24

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 26

■Installation of VLT 5072-5202 400-500 V

Compact IP20/IP00

Cooling

All Compact units in the above-mentioned series

require a minimum space of 225 mm above and

below the enclosure and must be installed on a

plane, vertical surface (no spacers).

VLT® 5000 Crane

Side-by-side

Compact IP 00/IP20

All units in the above-mentioned series can be installed

side by side without any space between them.

■Ventilation when Panelmounted

The quantity of air needed to cool VLT 5000 Crane

can be calculated as follows:

1. Add up the values of P

to be installed at the same panel (

2. Determine the air inlet temperature (t

air outlet temperature (t

for all VLT 5000 Crane

P )[W]

)andthe

IN

)[ºCorK]

OUT

3. Calculate the necessary air quantity in m

Insert t

OUT-tIN

in Kelvin

• The output from the fan must be located above

the highest mounted frequency converter

• Remember to take pressure drops over filters

into account and that the pressure decreases

as the filters are choked

• The max. cooling air temperature (t

)must

IN

be lower than 55ºC. The average of day/night

temperature may be 5ºC lower than that stated

in VDE 160. The cooling outlet temperature

(t

) may not exceed 60ºC

OUT

3

/h:

Installation

MG.50.N4.02 - VLT is a registered Danfoss trademark

25

Page 27

■Electrical Installation

The voltage on the frequency converter is

dangerous when the unit is connected to

mains. Incorrect installation of the motor

or frequency converter may lead to material damage

or serious injury or it may be fatal. Consequently, the

instructions in this manual as well as national and

local rules and safety regulations must be complied

with. Touching the electrical parts may be fatal, even

after the mains supply has been disconnected. Wait

at least 15 minutes if using VLT 5052-5102.

NB!:

It is the user’s or certified electrician’s

responsibility to ensure correct earthing and

protection in accordance with applicable

national and local norms and standards.

All terminals for the control cables are located under

the protective cover of the frequency converter. The

protective cover (see drawing) can be removed by

means of a pointed object - a screwdriver or similar.

VLT® 5000 Crane

Once the protective cover has been removed, the

actual EMC-correct installation can start.

26

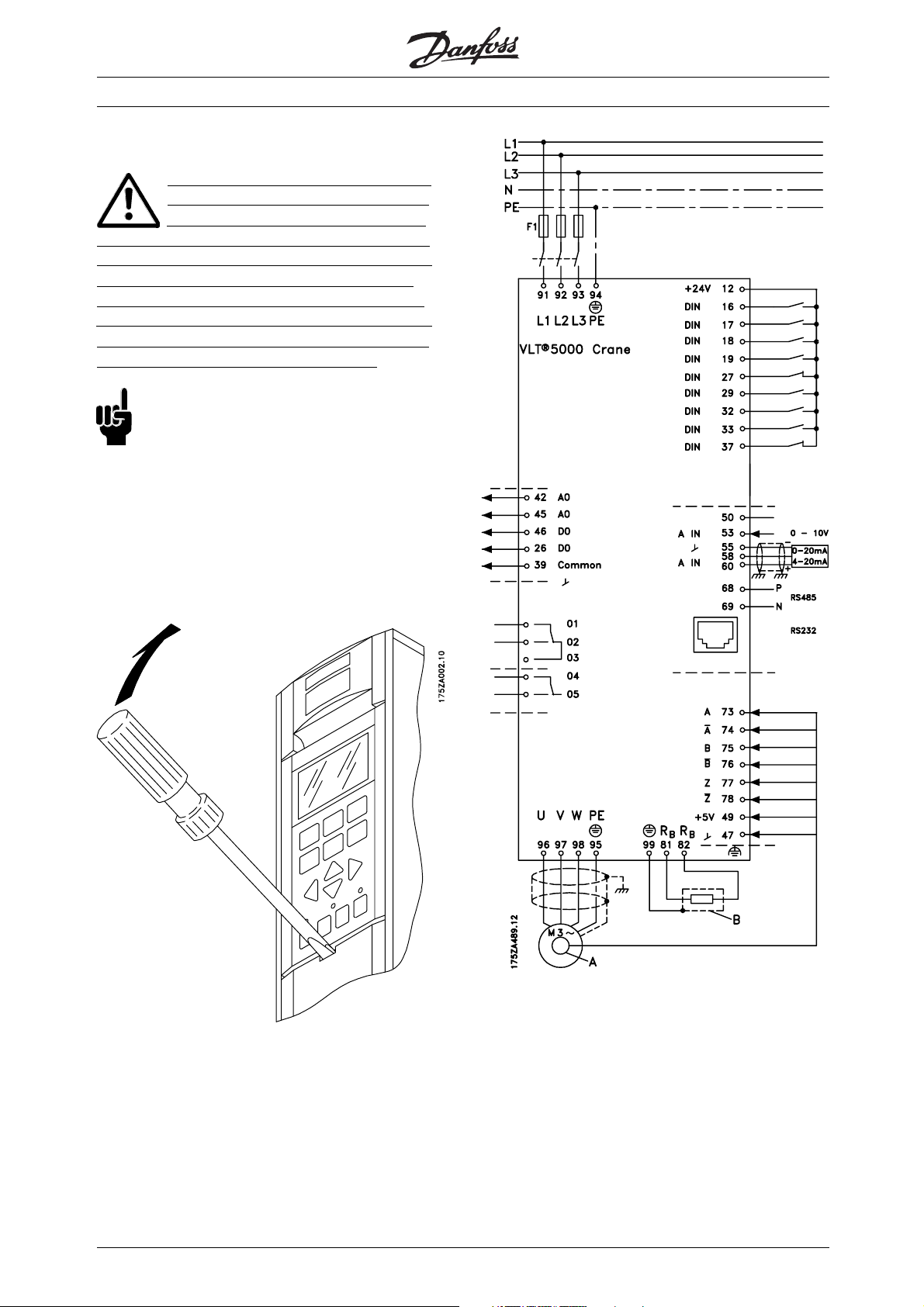

Wiring diagram VLT 5000 Crane

A: Encoder

B: Brake resistor

12: +24 V

16 Crane ready (NO)

17: Positioning (NO)

18: Lower (NO)

19: Hoist (NO)

20: Ground for digital inputs

26: Digital output

27: Quick stop (NC)

29: Gear ratio select (NO)

32: Load low (NO)

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 28

33: Load high (NO)

37: Hardware coast (NC)

39: Ground for analogue/digital outputs

42: Analogue output warning/alarm

45: Analogue output warning/alarm

46: Digital output

50: 10 V supply

53: Reference voltage

55: Common for anal. ref.

60: Reference current

68, 69: RS 485

01, 02: System brake signal

04, 05: Ready signal

73: Pulse signal A from encoder (0°)

74: Inverted pulse signal from encoder (0°)

75: Pulse signal B from encoder (90°)

76: Inverted pulse signal B from encoder (90°)

77: Zero pulse signal from encoder

78: Inverted zero pulse signal from encoder

49: 5 V supply to encoder

47: Common for encoder supply

VLT® 5000 Crane

■Electrical Installation, Power Cables

Compact IP 20 VLT Type 5042–5062

Compact IP 00 VLT 5125-5250 400-500 V

■Connection of Mains

Connect the three mains phases to terminals L

■Connection of Motor

All types of 3-phased asynchronous standard motors

can be used with the VLT 5000 Crane.

1,L2,L3

.

Installation

Compact IP 20/IP 00 VLT Types 5072-5102

MG.50.N4.02 - VLT is a registered Danfoss trademark

27

Page 29

Normally, small motors are star-connected.

Large motors are delta-connected.

Note the voltage value at the type plate.

■Installation of Motor Cables

NB!:

If an unscreened cable is used, some EMC

requirements are not complied with, see

Special conditions in Appendix.IftheEMC

specifications regarding emission are to be complied

with, the motor cable must be screened, unless

otherwise stated for the RFI filter in question. It is

important to keep the motor cable as short as possible

to reduce the noise level and leakage currents to a

minimum. The motor cable screen must be connected

to the metal cabinet of the frequency converter and to

the metal housing of the motor. The screen connections

are to be made with the biggest possible surface

(cable clamp). This is enabled by different installation

devices in the different frequency converters.

Mounting with twisted screen ends (pigtails) is to

be avoided, since these spoil the screening effect

at higher frequencies. If it is necessary to break

the screen to install a motor isolator or motor

contactor, the screen must be continued at the

lowest possible HF impedance.

VLT® 5000 Crane

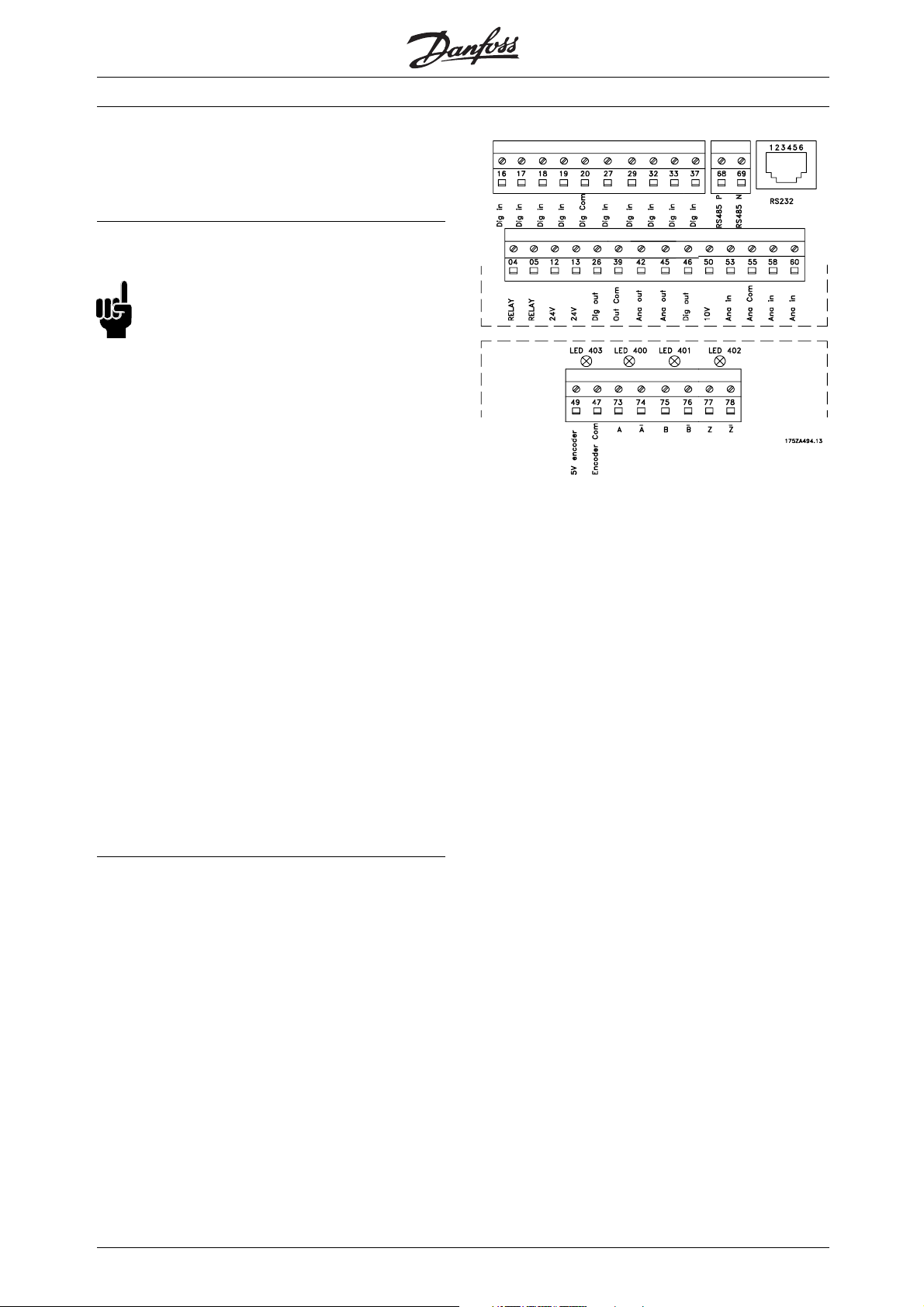

LEDs on encoder board:

When all LEDs are on the connection to encoder

and encoder condition are OK.

LED 403 OFF: 5 V supply missing

LED 400 OFF: Channel A or inv. A missing

or shortcircuited

LED 401 OFF: Channel B or inv. B missing

or shortcircuited

LED 402 OFF: Channel Z or inv. Z missing

or shortcircuited.

The frequency converter has been tested with a given

length of cable and a given cross-section of that cable.

If the cross-section is increased, the cable capacitance

- and thus the leakage current - increases, and the

cable length must be reduced correspondingly.

■Installation of Control Cables

Tightening-up torque: 0.22 - 0.25 Nm

Screw size: M2

Screw driver type: 0.4 x 2.5 x 80 mm

See Earthing of Braided Screened/Armoured

Control Cables for correct earthing.

28

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 30

Connection of shield:

VLT® 5000 Crane

The connection cable to the brake resistor must

be screened/armoured. Connect the screen to the

metal cabinet of the frequency converter and to

the metal cabinet of the brake resistor by means of

cable clamps. Dimension the cross-section of the

brake cable to match the brake torque.

NB!:

Please note that voltages up to 850 V DC

occur on the terminals.

No. Function

12, 13 Voltage supply to digital inputs.

Forthe24VDCtobeusable

for the digital inputs, switch 4 on

the control card must be closed

position "ON".

Max. current 350 mA

16-33 Digital inputs

37 Digital inputs. Hardware coast

20 Ground for digital inputs

39 Ground for analogue/digital

outputs

26, 46 Digital outputs for output

functions (messages)

42, 45 Analogue outputs for indicating

frequency, reference, current and

torque

47, 49 Supply 5 V, 200 mA for

incremental encoder

50 Supply voltage to potentiometer

and thermistor 10 V DC.

Max. current 12 mA

53 Analogue reference input, voltage

0-±10V

55 Ground for analogue reference

inputs

58, 60 Analogue reference input, current

0/4-20 mA

68, 69 RS 485 interface, serial

communication.

73, 78 Encoder input

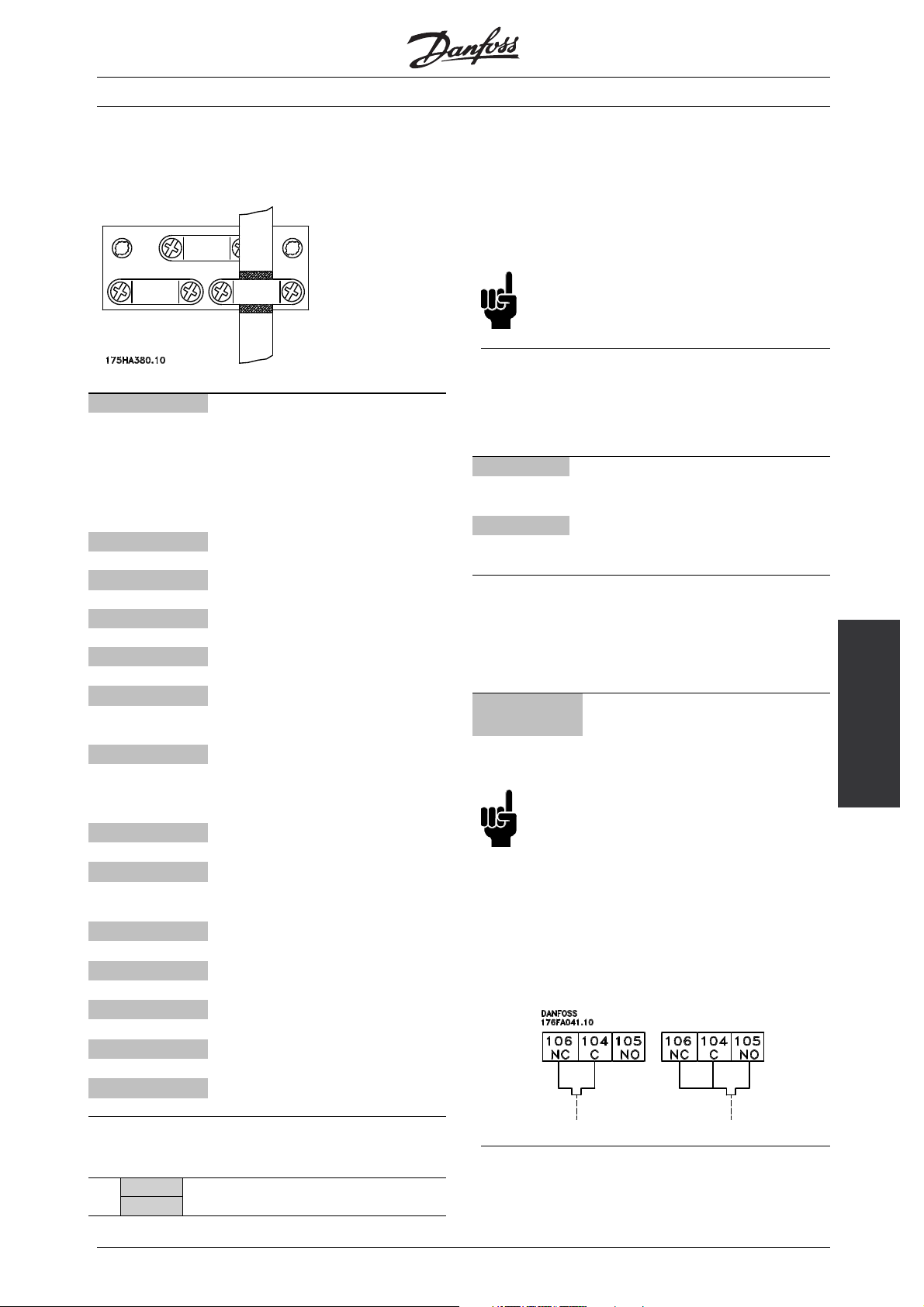

■Installation of Relay Terminals

Tightening-up torque: 0.22 - 0.25 Nm

Screw size: M3/M2

No. Function

1-3 Relay output, 1+3 NC, 1+2 NO See

parameter 323. See also General

technical data.

4, 5 Relay output, 4+5 NO See parameter

326. See also General technical

data.

■Installation of Brake Resistor Temperature Switch

Torque: 0.5-0.6 Nm

Screw size: M3

No. Function

106, 104,

Brake resistor temperature switch.

105

NB!:

This function is only available on VLT

5072-5202 400-500 V.

If the temperature of the brake resistor gets too high and

the terminal switch drops out, the frequency converter

will stop braking. The motor will start coasting.

A terminal switch must be installed that can either be

‘normally closed’ or ‘normally open’. If this function is

not used, 106 and 104 must be short-circuited together.

Installation

■Brake Connection

No. 81 82 Brake resistor

R- R+ terminals

MG.50.N4.02 - VLT is a registered Danfoss trademark

29

Page 31

VLT® 5000 Crane

■EMC-Correct Electrical Installation

General points to be observed to ensure

EMC-correct electrical installation.

- It is important to ensure good electrical contact from

the installation plate through the installation screws

to the metal cabinet of the frequency converter.

- Use toothed discs and galvanic conductive

- Use only screened/armoured motor cables and

screened/armoured control cables.

- Connect the screen to earth at both ends.

installation plates.

- Do not use unscreened/unarmoured motor

cables in the installation cabinets.

- Avoid installation with twisted screen ends (pigtails),

since this ruins the screening effect at high

frequencies. Use cable clamps instead.

■Tightening-up Torques and Screw Sizes

Mains terminals Nos 91, 92, 93

The table shows the torque required when fitting

terminals to the frequency converter. For VLT

5042-5302 400-500 V, the cables must be fastened

Motor terminals Nos 96, 97, 98

with screws. For VLT 5122-5500 400-500 V, the

cables must be fastened with bolts.

These figures apply to the following terminals:

400-500 V

5042 IP20 3 M5 4 mm Allen wrench

3)

5042

5052-5062 6 M6 5 mm Allen wrench

5072-5102 IP20 15 M6 6 mm Allen wrench

5122-5302

4)

IP54 3 M5 4 mm Allen wrench

IP54

2)

24 M8 8 mm Allen wrench

19 M10 bolt

Earth terminal No 94, 95, 99

Brake resistor terminals 81, 82

Loadsharing 88, 89

L1, L2, L3

U, V, W

1) Brake terminals: 3,0 Nm, Nut: M6

2) Brake and loadsharing: 14 Nm, M6 Allen screw

3) IP54 with RFI - Line terminals 6Nm, Screw: M6 - 5 mm Allen wrench

4) Loadshare and brake terminals: 9,5 Nm; Bolt M8

5) Brake terminals: 11,3 Nm; Bolt M8

■High Voltage Test

A high voltage test can be carried out by shortcircuitingterminalsU,V,W,L

1,L2

and L3and

energizing by max. 2.15 kV DC for one second

between this short-circuit and the chassis.

■Extra Protection (RCD)

ELCB (Earth Leakage Circuit Breaker) relays,

multiple protective earthing or earthing can be

used as extra protection, provided that local

safety regulations are complied with. In case

of an earth fault, a DC content may develop in

NB!:

the faulty current. If ELCB relays are used:

The RFI switch must be closed (position ON)

when high voltage tests are carried out.

- Local regulations must be complied with

- Suitable for protecting equipment with a DC content

■Motor Thermal Protection

The electronic thermal protection function in

UL-approved frequency converters has received

the UL-approval for single motor protection when

in the faulty current (3-phase bridge rectifier)

- Suitable for a pulse-shaped, brief discharge

on power-up

- Suitable for a high leakage current.

parameter 128 has been set for ETR Trip and

parameter 105 has been programmed to the rated

motor current (see motor nameplate).

NB!:

Never use an RCD (ELCB relay), type A, as it

is not suitable for DC faulty currents.

30

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 32

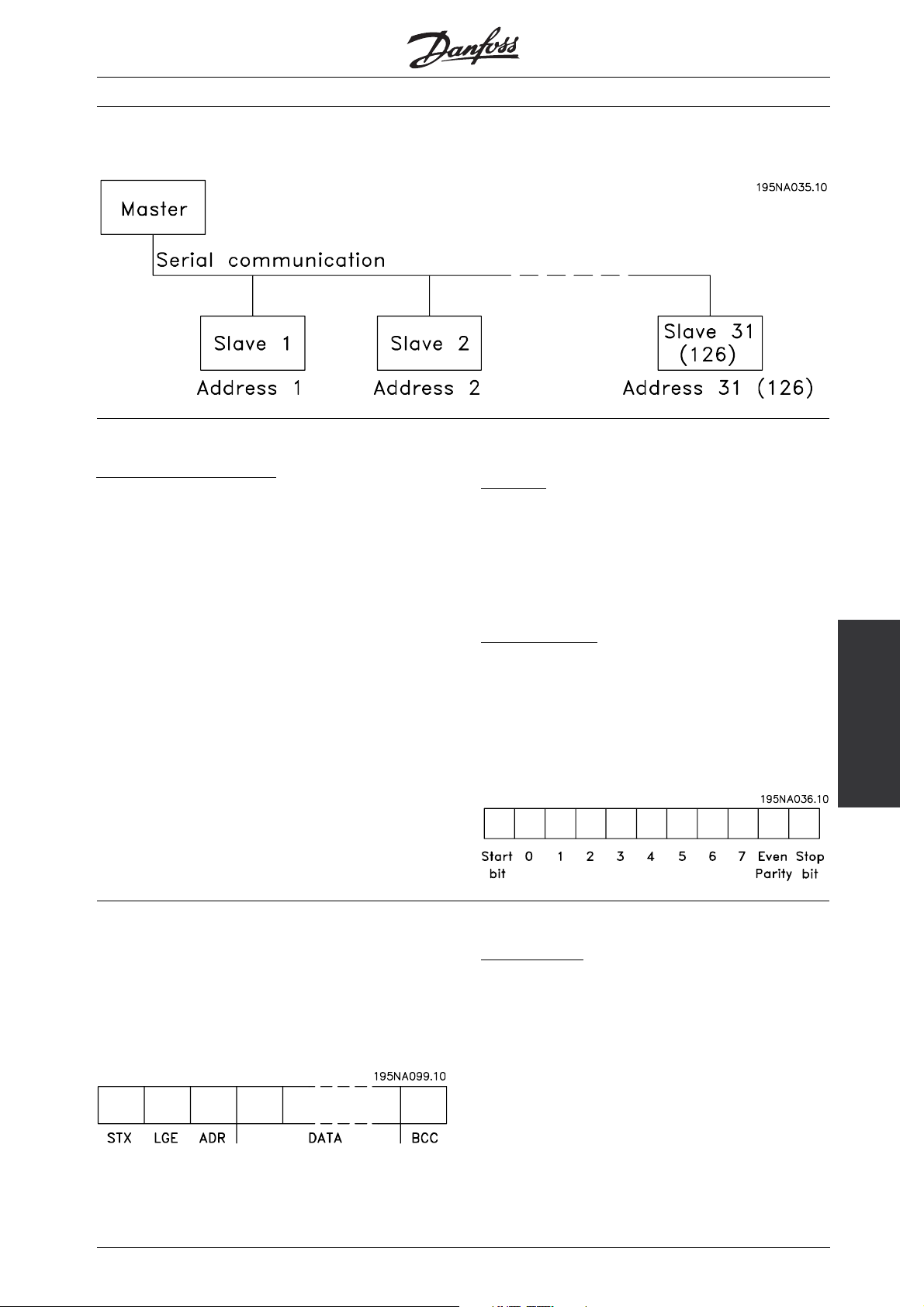

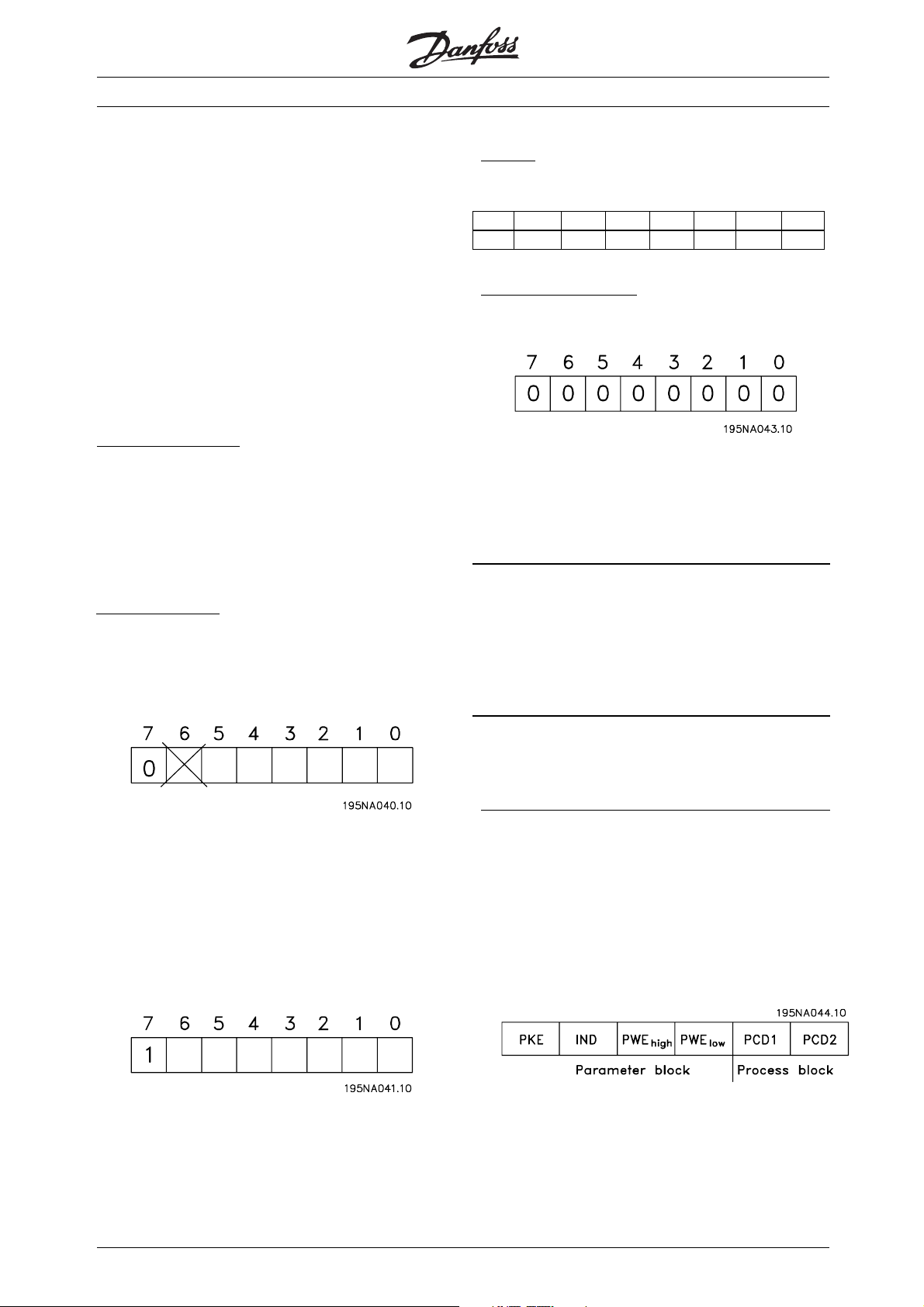

■Switches 1-4:

The dipswitch is located on the control card.

It is used for serial communication, terminals 68 and 69.

The switching position shown is the factory setting.

Switch 1 has no function.

Switches 2 and 3 are used for terminating an RS

485 interface, serial communication.

Switch 4 is used for separating the common potential

for the internal 24 V DC supply from the common

potential of the external 24 V DC supply.

NB!:

Please note that when Switch 4 is in position

"OFF", the external 24 V DC supply is galvanic

isolated from the frequency converter.

VLT® 5000 Crane

■Electrical Installation, Enclosures

Compact IP 20 VLT 5042-5102, 400-500 V

Installation

MG.50.N4.02 - VLT is a registered Danfoss trademark

Compact IP 20 VLT 5042-5062, 400-500 V

31

Page 33

Compact IP 20 VLT 5072-5102, 400-500 V

VLT® 5000 Crane

Compact IP 00 without disconnect and fuse

VLT 5202-5302 400-500 V

Compact IP 00 without disconnect and fuse

VLT 5122-5302 400-500 V

32

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 34

■RFI switch

ains supply isolated from earth:

M

If the frequency converter is supplied from an isolated

mainssource(ITmains),theRFIswitchcanbe

turned off (OFF). In OFF position, the internal RFI

capacities (filter capacitors) between the chassis and

the intermediate circuit are cut off to avoid damage

to the intermediate circuit and to reduce the earth

capacity currents (according to IEC 61800-3).

NB!:

TheRFIswitchisnottobeoperatedwith

mains connected to the unit. Check that

the mains supply has been disconnected

before operating the RFI switch.

NB!:

Open RFI switch is only allowed at factory

set switching frequencies.

NB!:

The RFI switch disconnects the capacitors

galvanically to ground.

VLT® 5000 Crane

P

osition of RFI switches

The red switches are operated by means of e.g. a

screwdriver. They are set in the OFF position when

they are pulled out and in ON position when they are

pushed in (see drawing below). Factory setting is ON.

Mains supply connected to earth:

The RFI switch must be in ON position in order for the

frequency converter to comply with the EMC-standard.

Compact IP 20/NEMA 1

VLT 5042 - 5062 400 - 500 V

Installation

MG.50.N4.02 - VLT is a registered Danfoss trademark

33

Page 35

VLT® 5000 Crane

■Use of EMC compliant cables

In order to comply with requirements for EMC immunity

of the control cables and EMC emissions from the

motor cables screened/armoured cables must be used.

The ability of a cable to reduce the amount of ingoing

and outgoing radiation of electric noise depends

on the transfer impedance (Z

). The screen of a

T

cable is normally designed to reduce the transfer of

electric noise, and a screen with a lower Z

effective than a screen with a higher Z

is rarely stated by cable manufacturers, but it

Z

T

is often possible to estimate Z

by looking at and

T

is more

T

.

T

assessing the physical design of the cable.

Z

can be assessed on the basis of the following factors:

T

- the contact resistance between the individual

screen conductors.

- Screen coverage, i.e. the physical area of the

cable covered by the screen. Is often stated as a

percentage and should be no less than 85%.

- The screen type, i.e. braided or twisted pattern. A

braided pattern or closed pipe is recommended.

34

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 36

VLT® 5000 Crane

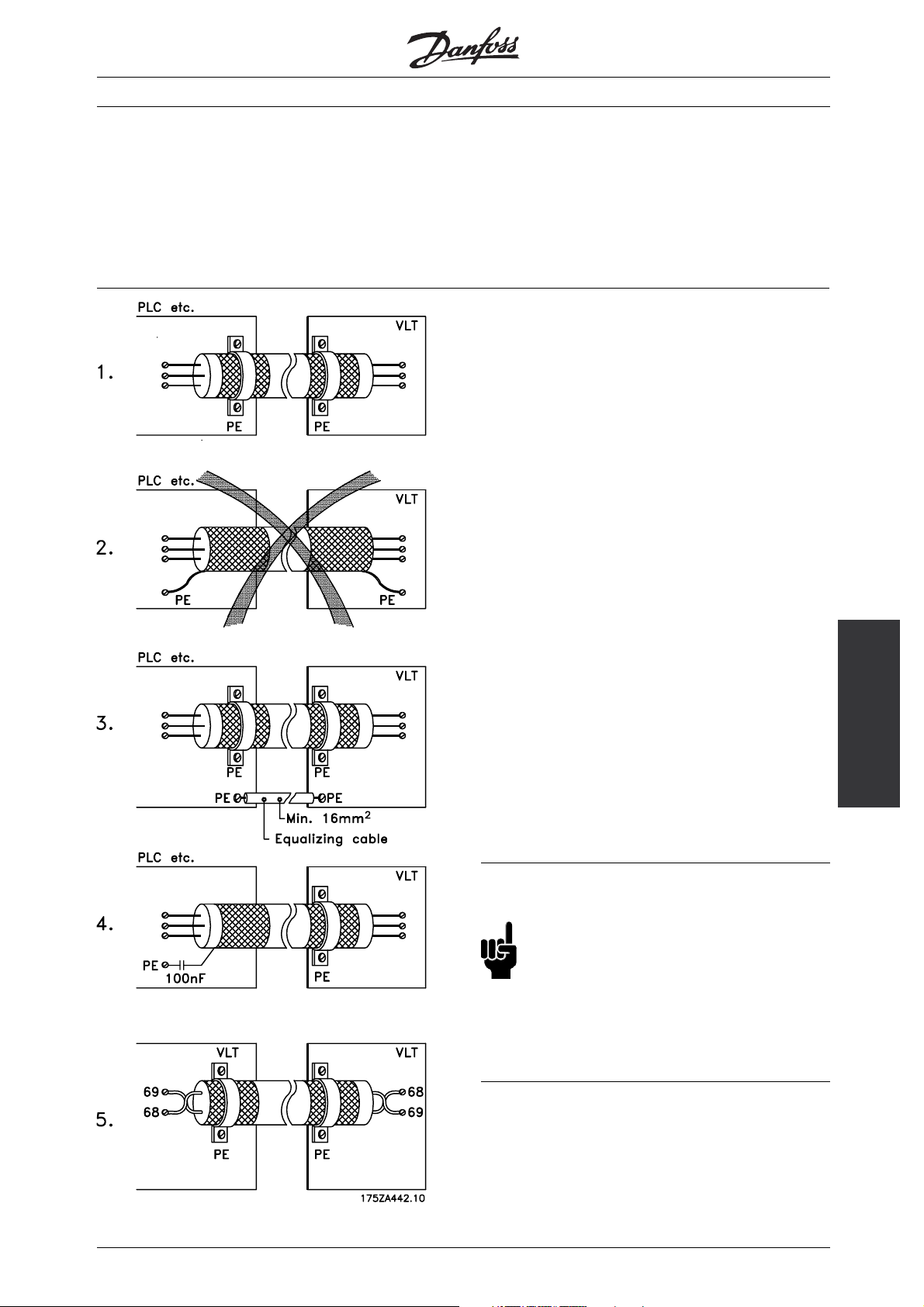

■Earthing of Braided Screened/armoured

Control Cables

Generally speaking, control cables must be braided screened/armoured and the screen must be connected

by means of a cable clamp at both ends to the metal cabinet of the unit.

The drawing below indicates how correct earthing is carried out and what to be done if in doubt.

1. Correct earthing

Control cables and cables for serial

communication must be fitted with cable

clamps at both ends to ensure the best

possible electrical contact.

2. Wrong earthing

Do not use twisted cable ends (pigtails), since these increase the screen

impedance at high frequencies.

3. Protection with respect to earth potential

between PLC and frequency converter

If the earth potential between the frequency

converter and the PLC (etc.) is different, electric

noise may occur that will disturb the whole system.

This problem can be solved by fitting an equalising

cable, to be placed next to the control cable.

Minimum cable cross-section: 16 mm

4. For 50/60 Hz earth loops

If very long control cables are used,

50/60 Hz earth loops may occur. This problem can

be solved by connecting one end of the screen to

earth via a 100nF capacitor (keeping leads short).

5. Cables for serial communication

It is recommended to use twisted-pair

cables to reduce the differential mode interference

between the conductors.

2

Installation

MG.50.N4.02 - VLT is a registered Danfoss trademark

■Safety Earthing

NB!:

The frequency converter has a leakage

current and must be earthed appropriately

for safety reasons. Use earth terminal,

which enables reinforced earthing.

Apply national safety regulations.

35

Page 37

VLT® 5000 Crane

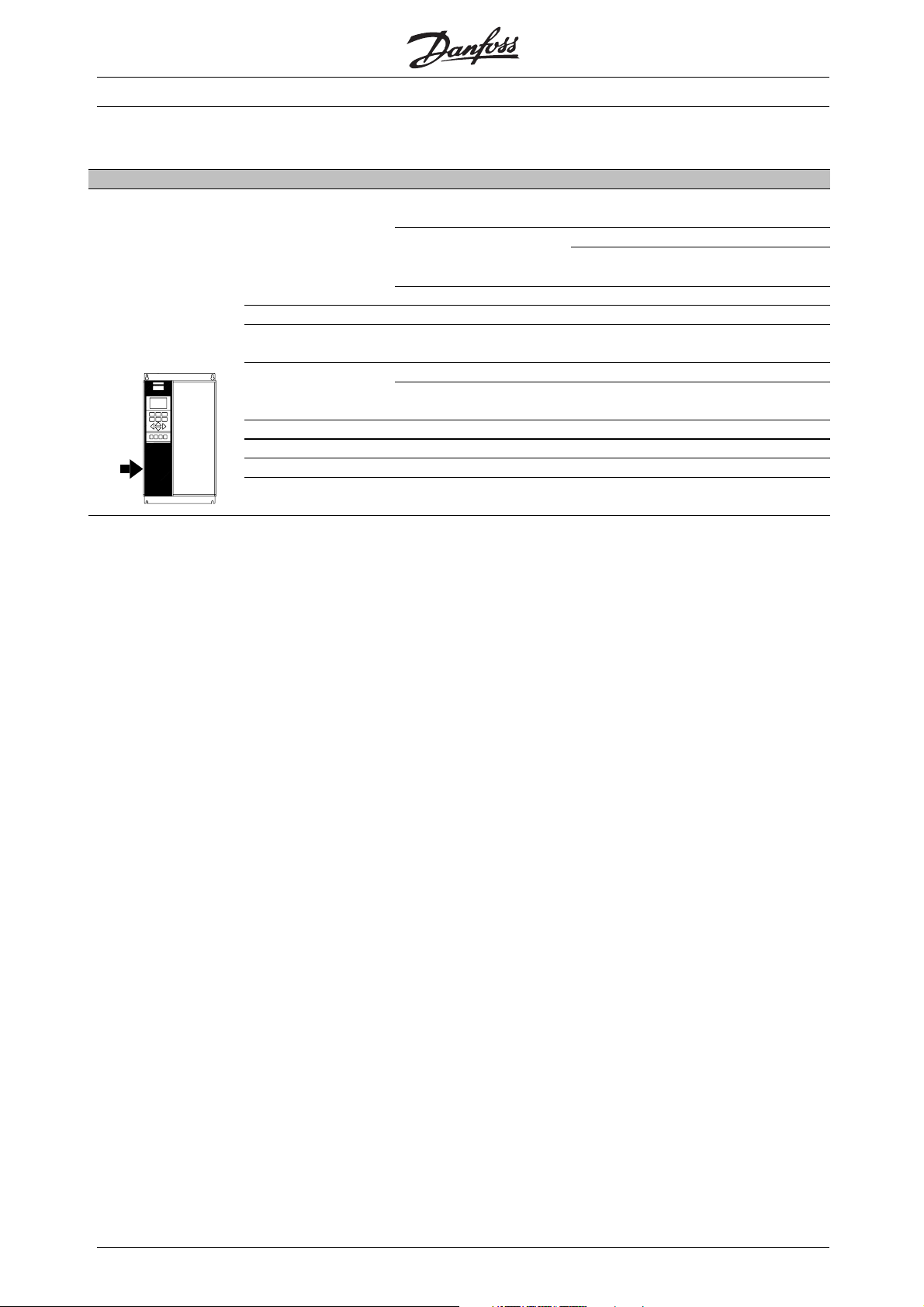

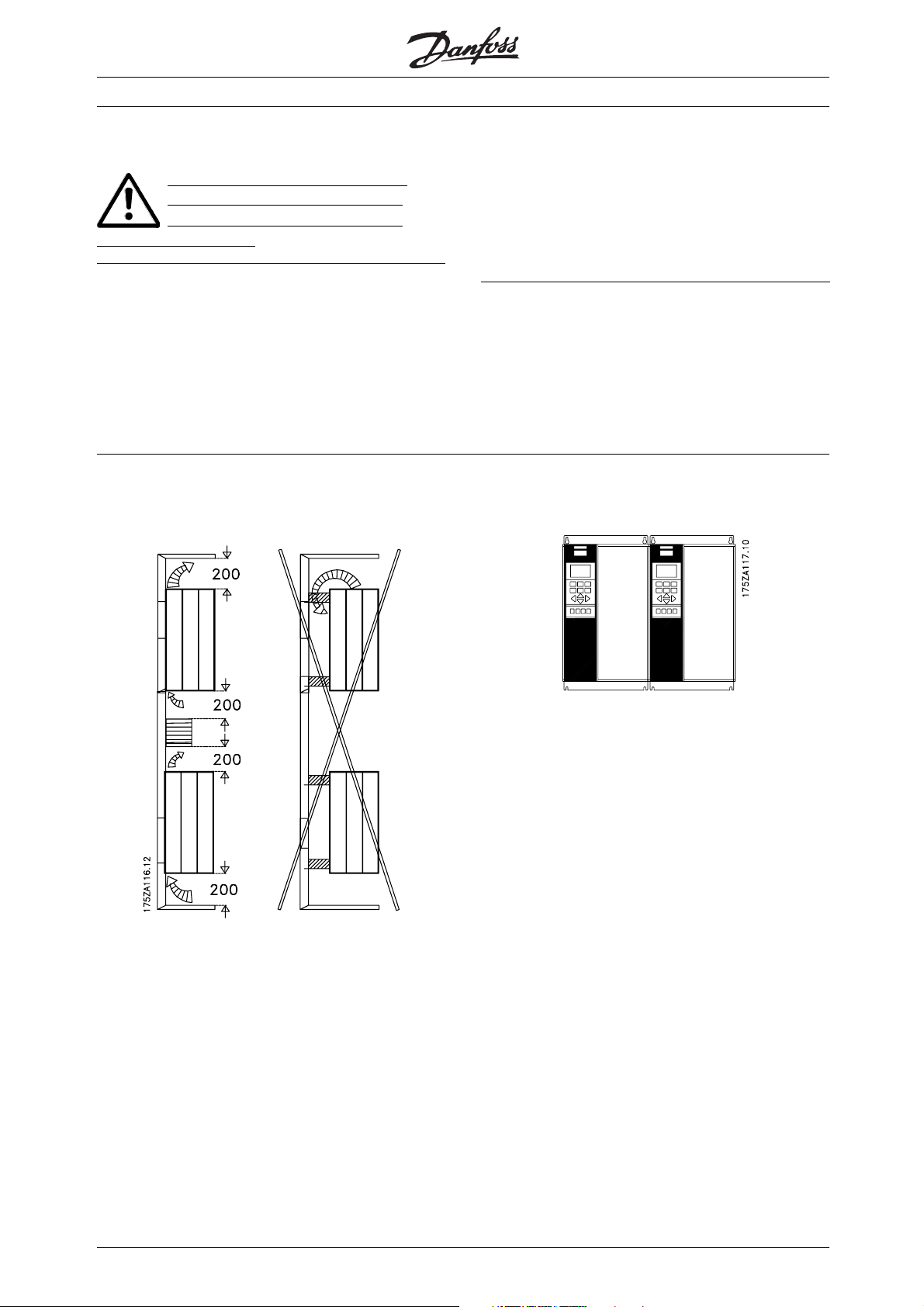

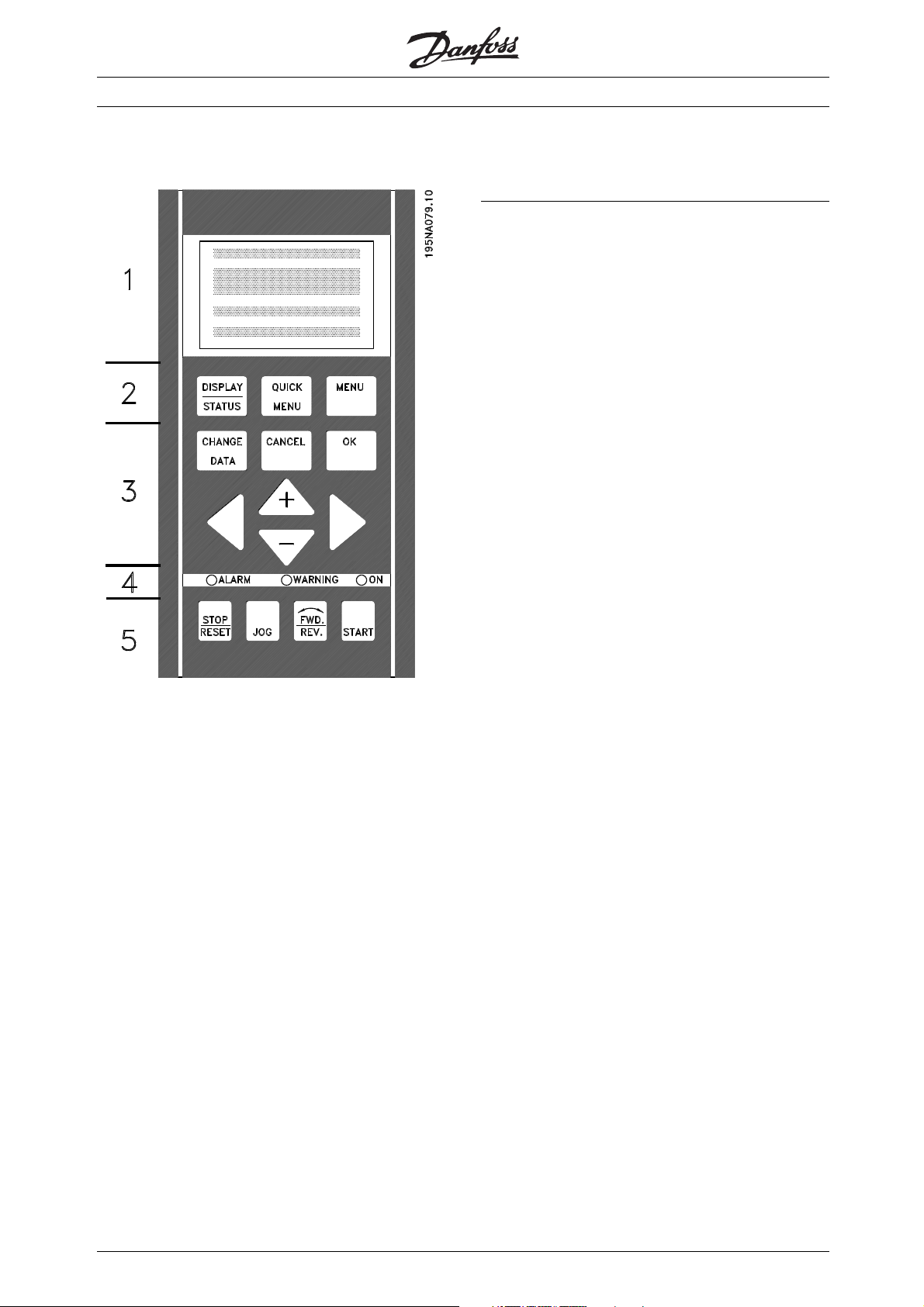

■Control Panel

the correct password in parameter 650 and if in

parameter 018 Not Locked [0] is selected.

The VLT 5000 Crane can be combined with an LCP

control unit (Local Control Panel) which makes up a

complete interface for operation and programming

of the frequency converter. The LCP control panel

can be installed up to 3 metres away from the

frequency converter, eg. on a front panel, by

means of the additional mounting kit.

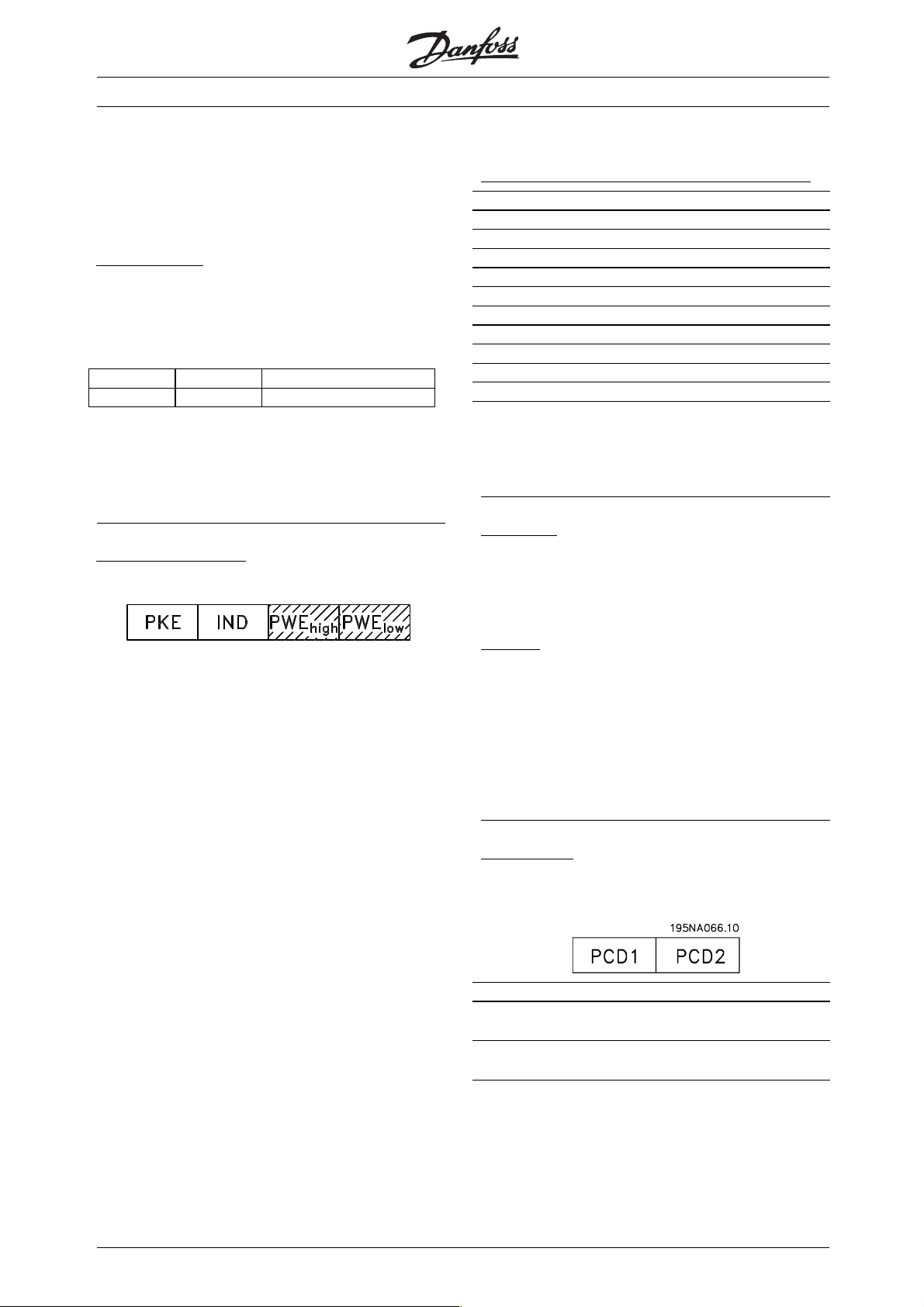

The control panel is divided into five functional groups:

1. Display.

2. Keys used to change the display function.

3. Keys used to change the programme parameters.

4. Indicator lamps.

5. Local control keys.

Alldataisdisplayedviaa4-linealphanumeric

display, which during normal operation will be able

to continuously display 4 items of operating data

and 3 operating modes. During programming all

information needed for quick, effective parameter

setup of the frequency converter will be displayed.

As a supplement to the display there are three

indicator lamps for voltage indication (ON), warning

(WARNING) and alarm (ALARM) respectively. All

frequency converter parameter Setups can be changed

immediately from the control panel, after entering

✭ = factory setting. () = display text [] = value for use in communication via serial communication port

36

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 38

VLT® 5000 Crane

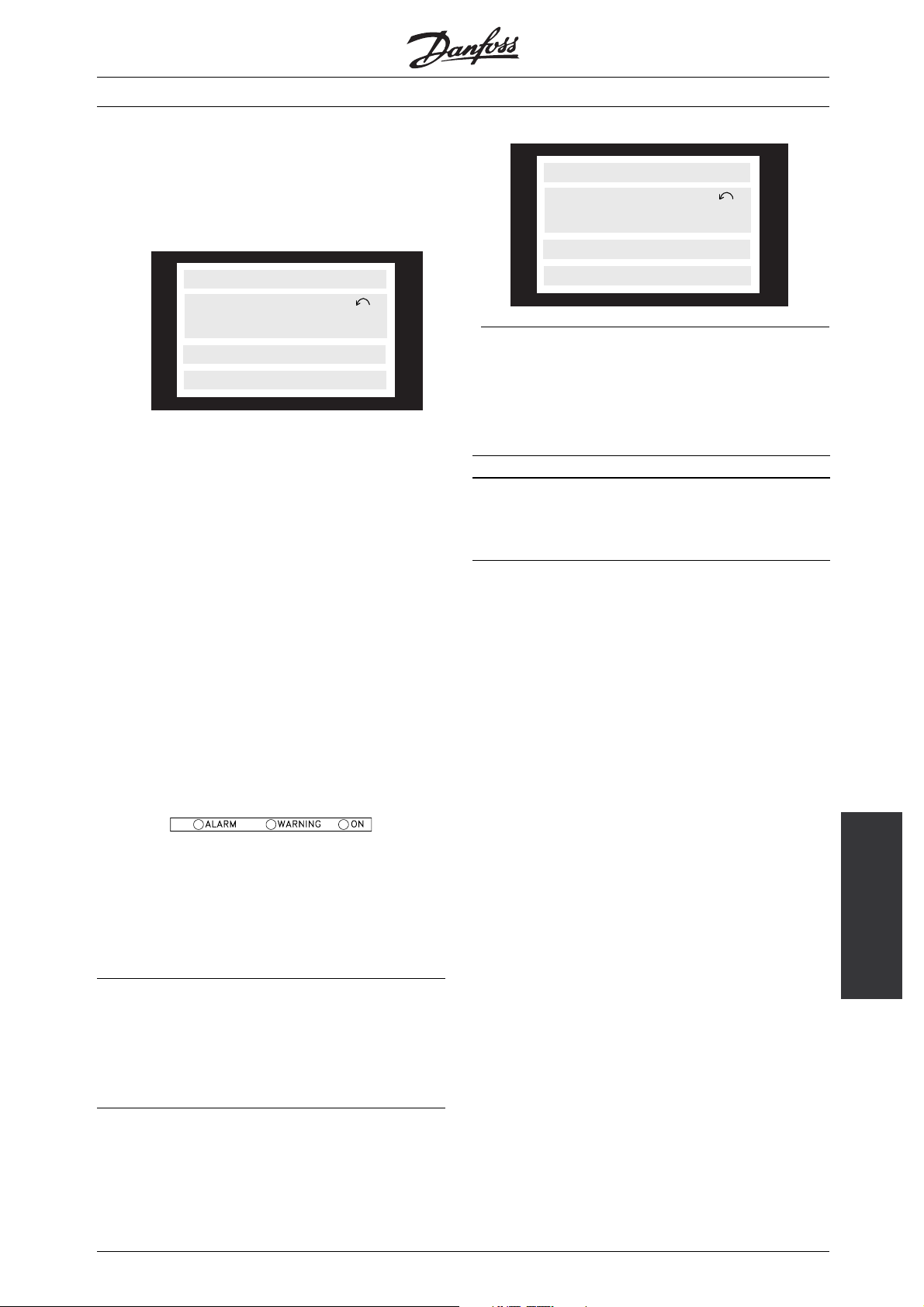

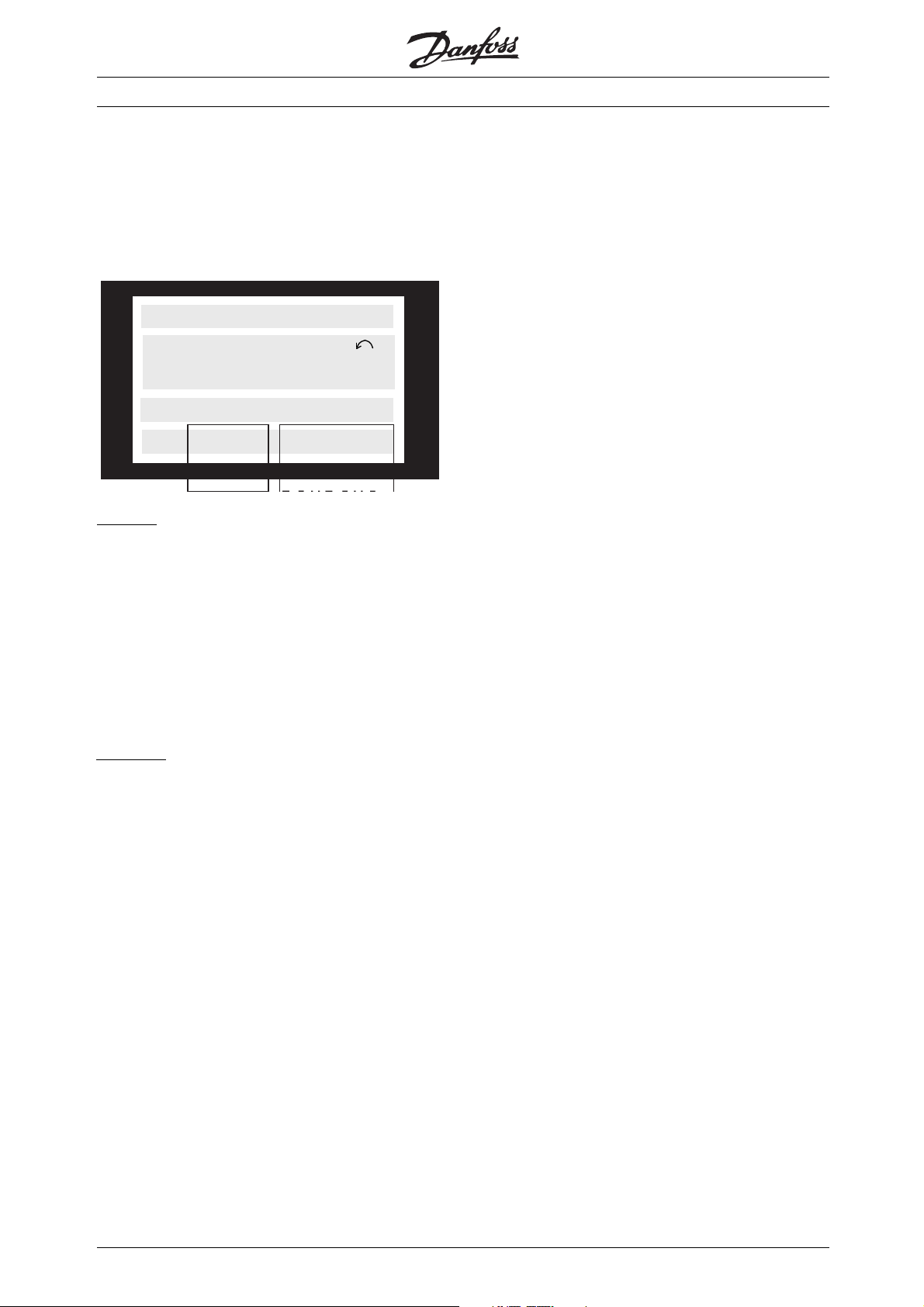

■Display

The LCD-display has back lighting and a total of

4 alpha-numeric lines including a box showing the

direction of rotation (arrow) and the chosen set-up as

well as the set-up in which programming is taking place.

1st line

2nd line

3rd line

4th line

1st line shows up to 3 measurements continuously in

normal operating status or a text explaining the 2nd line.

2nd line shows a measurement with related

unit continuously, regardless of status (except

in case of an alarm/warning).

3rd line is normally blank and is used in the

menu mode to show the selected parameter

group number and name

12345678901234567890

SETUP

12345678

1

12345678901234567890

12345678901234567890

VAR 1.1 VAR 1.2 VAR 1.3

VAR 2

175ZA443.10

STATUS

■Display Mode - Selection of Read-Out State

There are three options in connection with the

choice of read-out state in the Display mode - I, II

and III. The choice of read-out state determines the

number of operating variables read out.

Read-out state: I: II: III:

Line 1 Description

for operating

variable in line 2

The table below gives the units linked to the variables

in the first and second line of the display.

Data value for

3operating

variables in line

1

195NA113.10

SETUP

1

Description for

3operating

variables in line

1

4th line is used in operating status for showing a

status text or in data change mode for showing the

mode or value of the selected parameter.

An arrow indicates the direction of the motor rotation.

■LEDs

At the bottom of the control panel is a red alarm

LED, a yellow LED and a green voltage LED.

red yellow green

If certain threshold values are exceeded, the alarm

and/or warning LED lights up concurrently with a

status and alarm text on the control panel.

■Display Read-Out State

The display read-out state can be varied - see the list

below - depending on whether the frequency converter

is in normal operation or is being programmed.

Panel

LCP - Local Control

■Display Mode

In normal operation, up to 4 different operating

variables can be indicated continuously: 1.1 and 1.2

and 1.3 and 2, and in line 4 the present operating

status or alarms and warnings that have arisen.

= factory setting. () = display text [] = value for use in communication via serial communication port

✭

MG.50.N4.02 - VLT is a registered Danfoss trademark

37

Page 39

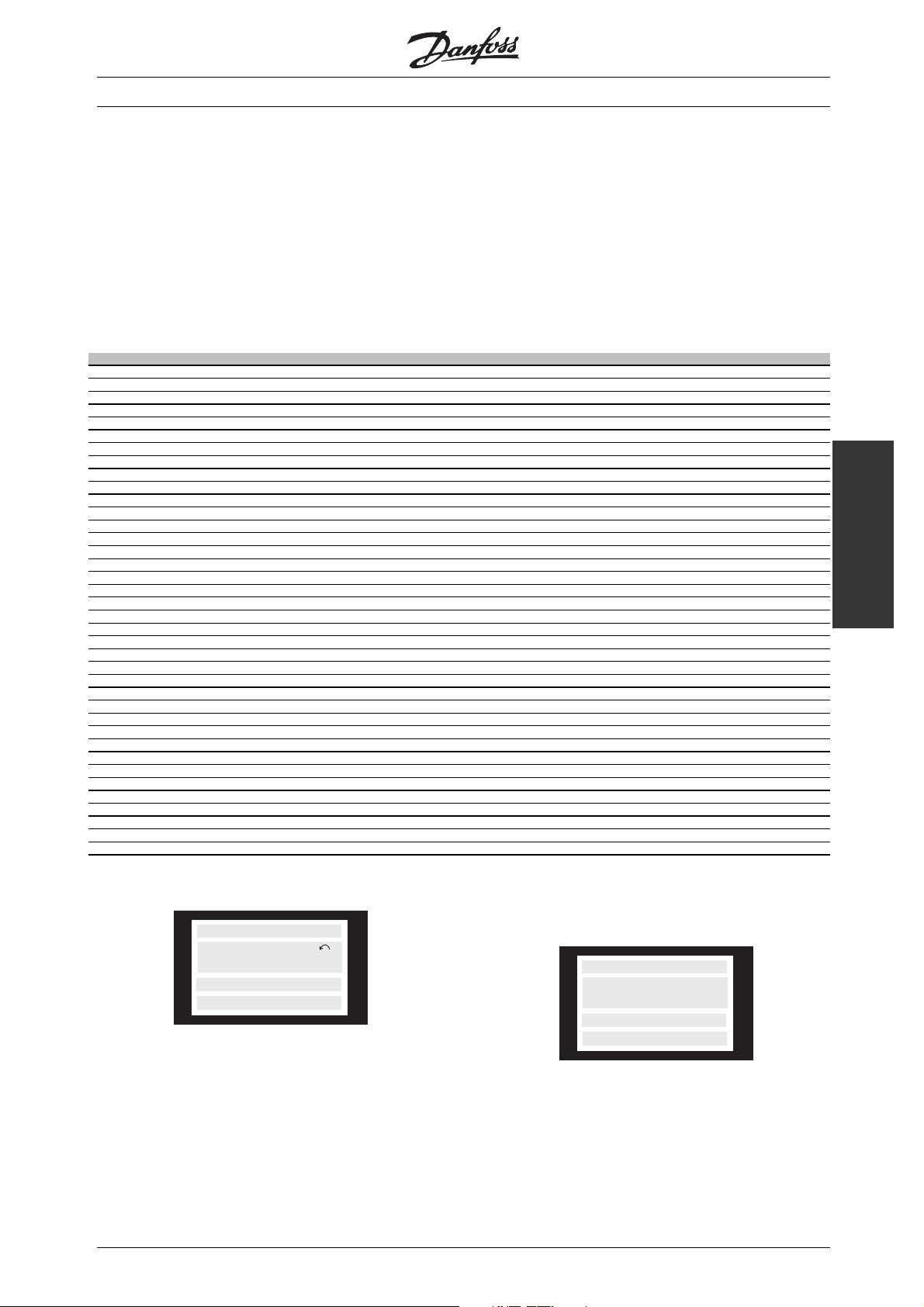

VLT® 5000 Crane

Operating variable: Unit:

Reference [%]

Reference [unit]

Feedback [unit]

Frequency [Hz]

Speed RPM [rpm]

Current [A]

To rq ue [ %]

Power [kW]

Power [HP]

Output energy [kWh]

Motor voltage [V]

DC-link voltage [V]

Motor ETR value [%]

Inverter ETR value [%]

Hours run [Hours]

Digital input [Bin]

Input status, analogue terminal 53 [V]

Input status, analogue terminal 58 [mA]

Input status, analogue terminal 60 [mA]

Exter nal reference [%]

Status word [Hex]

Brake energy/2 min. [kW]

Brake energy/sec. [kW]

Heat sink temp. [ºC]

Alarm word [Hex]

Control word [Hex]

Warning word 1 [Hex]

Extended status word [Hex]

Operating variables 1.1, 1.2 and 1.3 in the first line,

and operating variable 2 in the second line are selected

via parameter 009, 010, 011 and 012.

normal operation another variable can immediately

be read out by using the [+/-] keys.

• Read-out state II:

Switching between read-out states I and II is effected

by pressing the [DISPLAY / STATUS] key.

24.3% 30.2% 13.8A

50.0 Hz

MOTOR IS RUNNING

In this state, data values for four operating values

are shown at the same time, giving the related

unit, cf. table. In the example, Reference, Torque,

Current and Frequency are selected as variables

in the first and second line.

• Read-out state III:

This read-out state can be held as long as the

[DISPLAY/STATUS] key is pressed. When the

key is released, the system switches back to

Read-out state II, unless the key is pressed for

less that approx. 1 sec., in which case the system

always reverts to Read-out state I.

REF% TORQUE CURR A

SETUP

50.0 Hz

MOTOR IS RUNNING

1

• Read-out state I:

This read-out state is standard after starting

up or after initialisation.

This is where parameter names and

variables in the first and second line are given operating variable 2 remains unchanged.

FREQUENCY

50.0 Hz

MOTOR IS RUNNING

Line 2 gives the data value of an operating variable with

related unit, and line 1 provides a text which explains

line 2, cf. table. In the example, Frequency has

been selected as variable via parameter 009. During

✭ = factory setting. () = display text [] = value for use in communication via serial communication port

38

MG.50.N4.02 - VLT is a registered Danfoss trademark

units for operating

Page 40

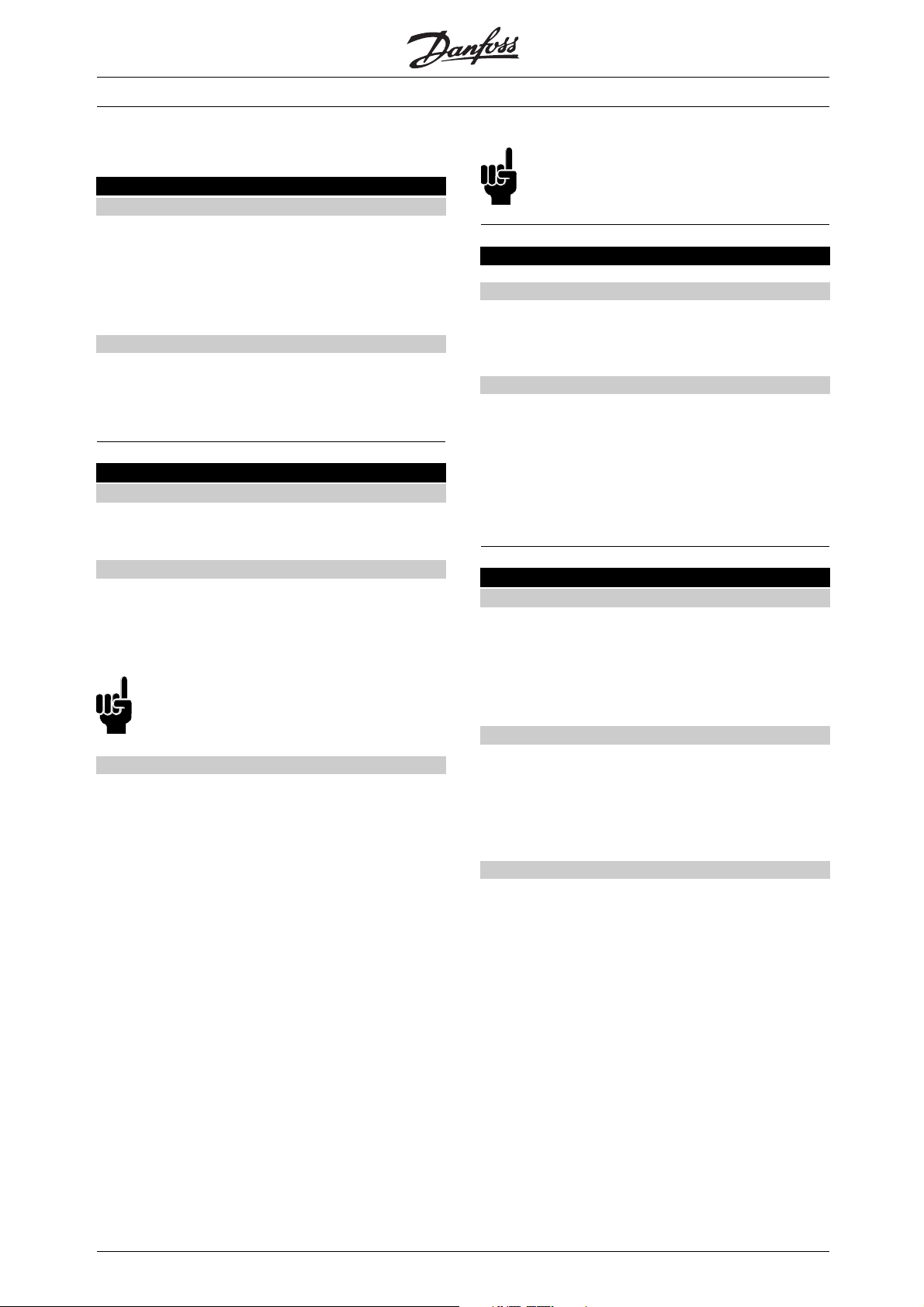

■Parameter programming

Menu mode is started by pressing the [MENU] key,

which produces the following readout on the display:

FREQUENCY

50.0 Hz

0 KEYB.&DISPLAY

VLT® 5000 Crane

Changing data

Regardless of whether a parameter has been

selected under the Quick menu or the Menu mode,

the procedure for changing data will be the same.

Pressing the [CHANGE DATA] key gives access

to changing the selected parameter, following

which the underlining in line 4 will flash on the

display. The procedure for changing data depends

on whether the selected parameter represents a

numerical data value or a text value.

Line 3 on the display shows the parameter

group number and name.

In Menu mode, the parameters are divided

into groups. Selection of parameter group is

effected using the [< >] keys.

The following parameter groups will be accessible:

Group no. Parameter group

0xx Operation & Display

1xx Load & Motor

2xx References & Limits

3xx Inputs & Outputs

4xx Special functions

5xx Serial communication

6xx Technical functions

7xx Crane functions

When the required parameter group has been

selected, each parameter can be chosen by

means of the [+ / -] keys:

FREQUENCY

Changing a data value

If the selected parameter is a text value, the text value

is changed by means of the [+ / -] keys.

FREQUENCY

50.0 Hz

001 LANGUAGE

ENGLISH

The bottom display line will show the value that will be

entered (saved) when acknowledgment is given [OK].

Change of numeric data value

If the selected parameter is represented by a numerical

data value, a digit is first chosen using the [< >] keys.

FREQUENCY

SETUP

50.0 Hz

130 START FREQUENCY

09.0 HZ

1

Panel

50.0 Hz

001 LANGUAGE

ENGLISH

The3rdlineofthedisplayshowstheparameter

number and name, while the status/value of the

selected parameter is shown in line 4.

MG.50.N4.02 - VLT is a registered Danfoss trademark

The selected digit can then be changed infinitely

variably using the [+ / -] keys:

FREQUENCY

SETUP

50.0 Hz

1

130 START FREQUENCY

10.0 HZ

LCP - Local Control

39

Page 41

VLT® 5000 Crane

The chosen digit is indicated by the digit flashing. The

bottom display line shows the data value that will be

entered (saved) when signing off with [OK].

■Manual initialization

Manual initialization is performed as follows:

Cut mains. Hold the [DISPLAY STATUS] + [CHANGE

DATA] + [OK] keys down, and simultaneously

reconnect the mains. Release the keys; the frequency

converter has now been programmed for the

factory setting. The following parameters are not

reset during manual initialization:

- par. 600 Operating hours

- par. 601 Hours run

- par. 602 kWh counter

- par. 603 Number of power-ups

- par. 604 Number of overtemperatures

- par. 605 Number of overvoltages

■Changing of datavalue, step-by-step

Certain parameters can be changed step by step

or infinitely variably. This applies to Motor power

(parameter 102), Motor voltage (parameter 103)

and Motor frequency (parameter 104).

This means that the parameters are changed

bothasagroupofnumericdatavaluesandas

numeric data values infinitely variably.

■Infinitely Variable Change of NumericData Value

If the chosen parameter represents a numeric data

value, a digit is first selected by means of the [<>] keys.

FREQUENCY

SETUP

50.0 HZ

1

102 MOTOR POWER

0.37 KW

Then the chosen digit is changed infinitely variably

by means of the [+/-] keys:

FREQUENCY

SETUP

50.0 HZ

102 MOTOR POWER

1

SETUP

1

0.55 KW

The chosen digit is indicated by the digit flashing. The

bottom display line shows the data value that will be

entered (saved) when signi

40

ng off with [OK]

MG.50.N4.02 - VLT is a registered Danfoss trademark

Page 42

■Menu Structure

DISPLAY MODE

VAR 1.1 VAR 1.2 VAR 1.3

▲

VAR 2

STATUS

VLT® 5000 Crane

▲

▲

MENU MODE

FREQUENCY

1500 RPM

0 KEYB.&DISPLAY

Choice of

parameter

DATA MODE

FREQUENCY

1500 RPM

001 LANGUAGE

ENGLISH

▲

Choice of

group

▲

QUICK MENU MODE

QUICK MENU 1 OF 13

▲

▲▲

1500 RPM

001 LANGUAGE

ENGLISH

▲

DATA CHANGE MODE

FREQUENCY

1500 RPM

001 LANGUAGE

ENGLISH

175ZA721.10

✭ = factory setting. () = display text [] = value for use in communication via serial communication port

MG.50.N4.02 - VLT is a registered Danfoss trademark

Choice of

data value

DATA CHANGE MODE

QUICK MENU 1 OF 13

1500 RPM

001 LANGUAGE

ENGLISH

Panel

LCP - Local Control

41

Page 43

VLT® 5000 Crane

■General Advice on Programming

On the following pages the control keys for parameter

set-up and the local control keys will be explained.

First, however, please draw attention to the difference

between the [+]/[-] keys and the [<]/[>] keys.

The [+]/[-] keys are used for:

• Changing parameter numbers within a

parameter group

• Changing parameter values

The [<]/[>] keys are used for:

• Shifting between parameter groups

• Moving the cursor when changing numeric values

For further details on the parameter groups, please

refer to the table in Parameter Programming.

Example:

The configuration mode in parameter 100 is to

be set to SPEED CLOSED LOOP.

1. Press Menu to get access to the parameters

2. Press the [>] key to enter parameter group 100

3. Press [Change Data]

4. Press the [+] key twice to select the data value

[1] for SPEED CLOSED LOOP

5. Press [OK]

6. The parameter is now set

■Control keys for parameter Setup

The control keys are divided into functions, in such a

way that the keys between the display and the indicator

lamps are used for parameter Setup, including selection

of the display’s view mode during normal operation.

[DISPLAY/STATUS] is used to select the display’s