VLT® types 5001-5011

■ Description of the brake system ...................Page 3

■ Application - conveyor belt ........................... Page 3

General formulas ........................................... Page 4

Brake performance examples ......................Page 4

■ Selection of brake resistor ............................Page 5

■ How to setup the brake function ..................Page 6

Basic setup ...................................................Page 6

Power monitoring ..........................................Page 6

Brake check .................................................Page 7

Protection properties ....................................Page 7

Readout of brake power...............................Page 7

DC hold ......................................................... Page 7

■ Installation .....................................................Page 7

Mechanical ................................................... Page 7

Electrical ....................................................... Page 8

EMC (twisted cables/shielding) ................. Page 8

■ Dimensions ................................................... Page 9

Warning:

Do not touch the brake resistors

during braking. They can be very

hot.

MI.50.S1.02 – VLT is a registered Danfoss trademark 1

VLT® types 5001-5011

■■

Introduction

■

■■

The flatpack brakeresistors for the VLT 5000 series is

a safe and compact solution for the customer.

At a constant load and free convection the resistor is

selfprotecting as a fuse. This means short circuit

proof, no fault to frame, no melting of casing and self

extinguishing. The casing is made of anodized

aluminum and is IP54 tight.

■■

Description of the brake system

■

■■

When the speed of a frequency converter is reduced, the motor acts as a generator and brakes.

When a motor acts as a generator, it supplies energy

to the intermediate circuit in the frequency converter.

The brake resistor loads the intermediate circuit, ensuring that the brake power is absorbed by the

brake resistor.

If a brake resistor was not used, the intermediate circuit voltage of the frequency converter would continue to increase, until it cuts out for protection.

The advantage of using a brake resistor is that it

enables braking of heavy load quickly, e.g. on a conveyor belt.

With the compact flatpack resistor, it is possible to

mount the resistor on the rear of a VLT 5000

bookstyle frequency converter.

In addition, VLT5000 incorporates brake monitoring

to ensure that the average power dissipated to the

brake resistor does not exceed a given limit. The

brake monitor calculates the mean brake power

within the last 120 seconds and compares this

value with a programmed limit. If the limit is exceeded the drive can give a warning or trip. Monitoring of short circuiting of the brake resistor or

brake IGBT and disconnection of the brake resistor

is also possible.

Increased performance at low speeds can be

achieved by using the DC brake in VLT5000.

Application - conveyor belt

■■

■

■■

The brake resistor program covered in this instruction

is for horizontal conveyor applications. The resistors

are chosen for use with small drives, this means up

to VLT5011.

The premises for the application is:

● The energy of the system is assumed to be deter-

mined by two times the motor inertia.

● Values for braking are calculated at 160% torque.

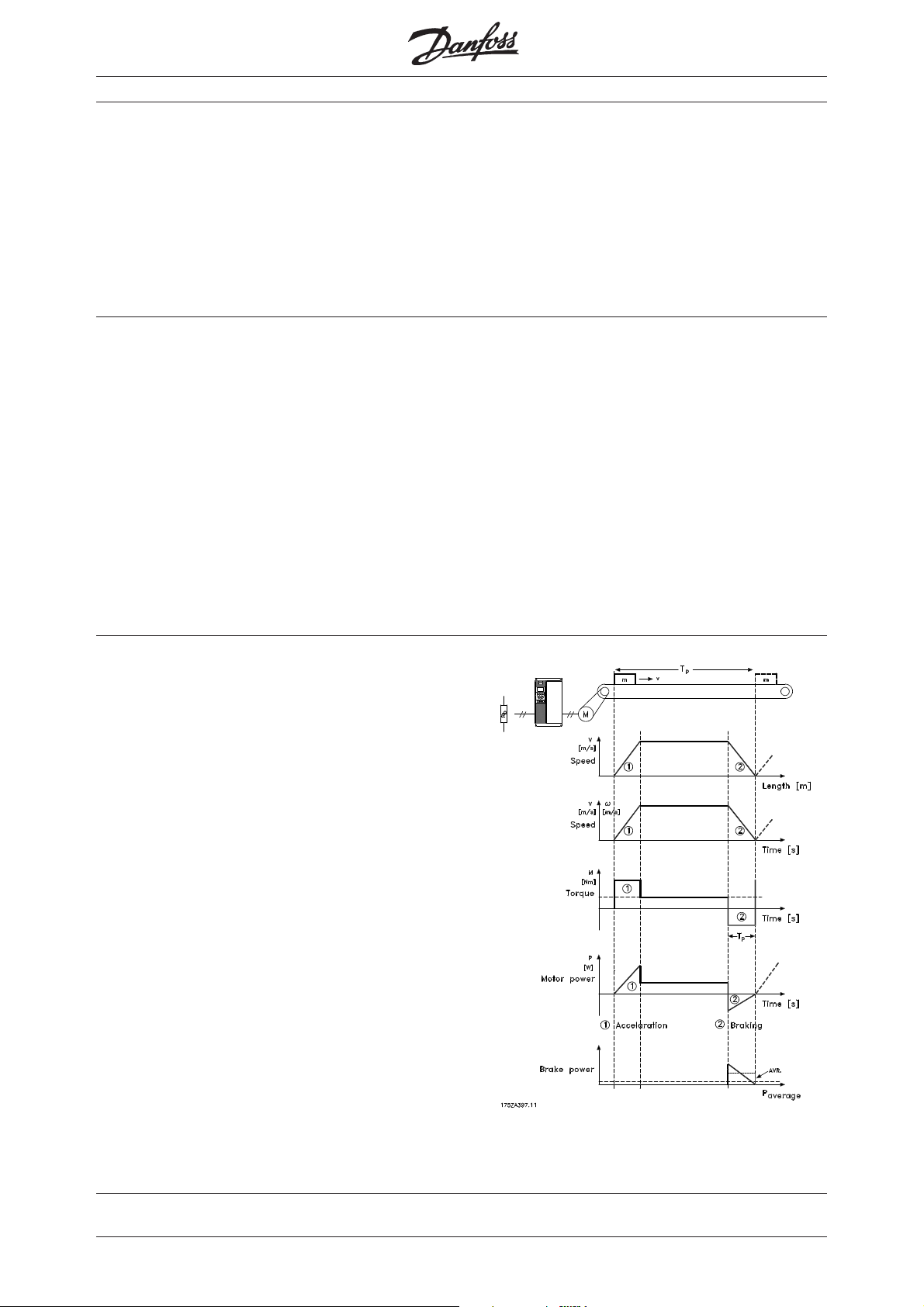

Figure 1 shows the relation between the braking

power and the acceleration/braking of the conveyor

belt. During braking the motor power is negative,

since the torque on the motor shaft is negative. The

braking power is to be dissipated in the brake resistor, and corresponds almost to the negative motor

power taking the losses into the motor and VLT frequency converter into account.

Figure 1

Typical characteristic of a

horizontal brake application

MI.50.S1.02 – VLT is a registered Danfoss trademark 3

■■

■

■■

General fomulas

The general formulas for calculation of the brake in a

system are stated below.

An example is shown with the following values:

Motor inertia: j = 0.0021 kgm2

Motor speed (at 50 Hz): n = 1500 rpm

Average power dissipated in resistor: P

Nominal motor power: P

average

= 750 W

motor

= 120 W

The kinetic energy in the system is:

2

E = ½ × j' × ω

= j × ω2 = 0.011 × j × n2 [Ws]

E = 0.011 × 0.0021 × 1500 × 1500 = 52 Ws

2

j = inertia of motor and gear box (kgm

]

j' = inertia of the system ≈ 2 × j

ω = motor speed = (n × 2 × π)/60 [rad/s]

n = motor speed [rpm]

The maximum number of stops per time unit

for the resistor is calculated as:

f

= P

stop

resistor/Esystem

f

= 120/52 = 2.3 s-1 = 138,5 min

stop

[s-1]

-1

VLT® types 5001-5011

The minimum time for stop is calculated as:

= E

t

stop

t

= 52/750 = 0.069 s

stop

P

motor

The maximum duty cycle of the system is:

Duty cycle = t

Duty cycle = 0.069 × 2.3 × 100 = 16%

The resistor values must be calculated using the formulas from the general brake instruction (resistance

based on minimum acceptable resistance). When

choosing a standard resistor, it is necessary to

choose a value higher than the calculated

240 Volt units: R

500 Volt units: R

system

/ P

motor

[s]

= nominal motor power (100% torque)

× f

stop

× 100 [%]

stop

= 111684 / P

rec

R

= 111684 / 750 = 149

rec

= 478801 / P

rec

= 478801 / 750 = 638

R

rec

motor

motor

[Ω]

[Ω]

t

.

rec

Ω

Ω

P

= Average power dissipated in the resistor [W]

resistor

■■

■

■■

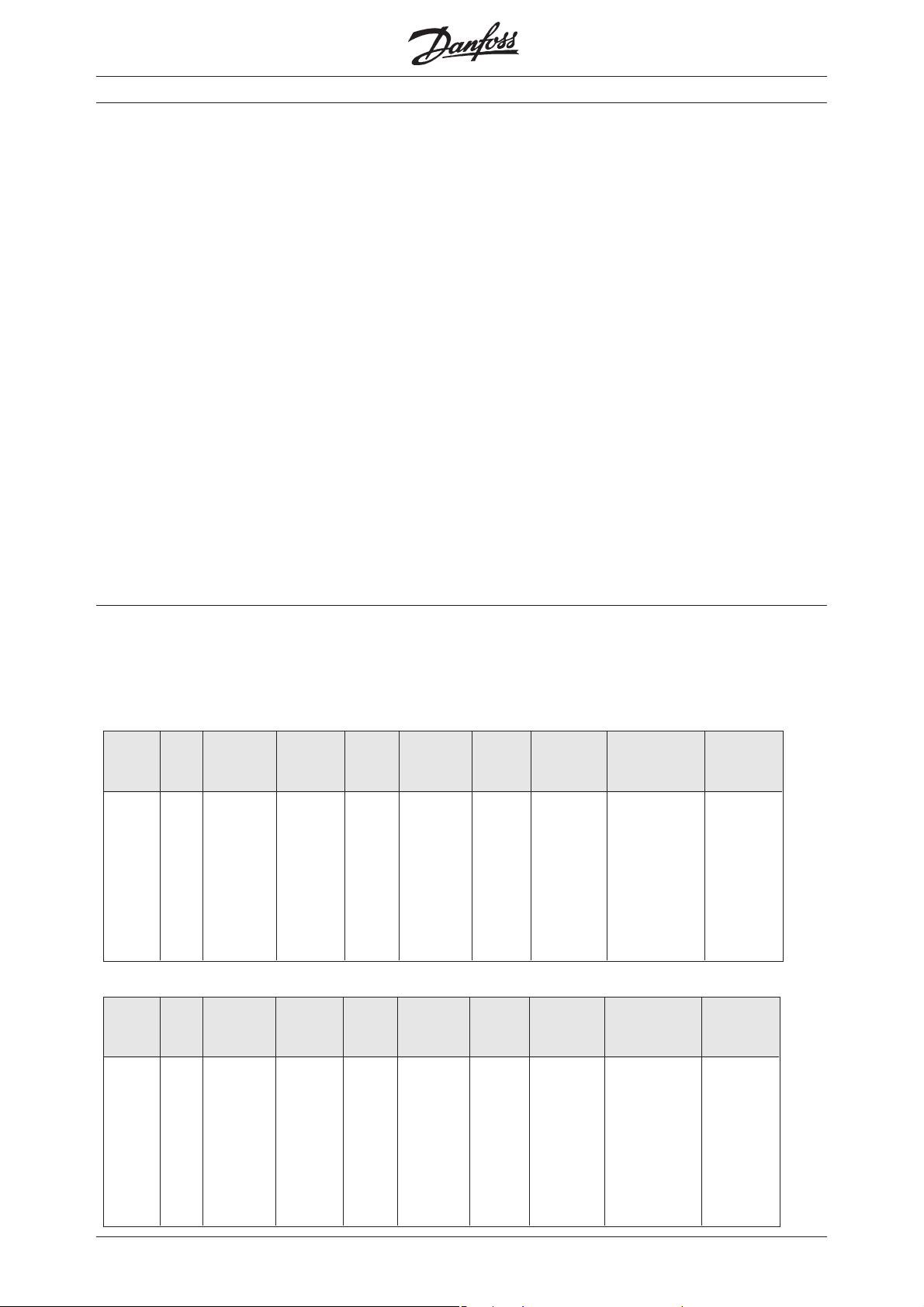

Brake performance examples

The figures below show typical data for a horizontal

application. At other frequencies please use the for-

All are calculated at a nominal motor speed of

1500 rpm at 50 Hz.

mulas above to calculate the values.

P

, 120 W

average

VLT type Motor Motor System E (50Hz) Number of E (100 Hz) Number of Stop time [s] Stop time [s]

5001 0.75 0.00210 0.00420 52.0 138.5 207.9 34.6 0.069 0.277

5002 1.1 0.00320 0.00640 79.2 90.9 316.8 22.7 0.072 0.288

5003 1.5 0.00430 0.00860 106.4 67.7 425.7 16.9 0.071 0.284

5004 2.2 0.00690 0.01380 170.8 42.2 683.1 10.5 0.078 0.311

5005 3 0.00820 0.01640 203.0 35.5 811.8 8.9 0.068 0.271

5006 4 0.01200 0.02400 297.0 24.2 1188.0 6.1 0.074 0.297

5008 5.5 0.01800 0.03600 445.5 16.2 1782.0 4.0 0.081 0.324

5011 7.5 0.02300 0.04600 569.3 12.6 2277.0 3.2 0.076 0.304

P

average

VLT type Motor Motor System E (50Hz) Number of E (100 Hz) Number of Stop time [s] Stop time [s]

4 pol. inertia inertia Ws stops 1/min Ws stops 1/min (50 Hz) (100 Hz)

kg

× m × m kg × m × m from 50 Hz. from 100 Hz. 160 % torque 160% torque

, 250 W

4 pol. inertia inertia Ws stops 1/min Ws stops 1/min (50 Hz) (100 Hz)

kg

×

m × m kg × m × m from 50 Hz. from 100 Hz. 160 % torque 160% torque

5001 0.75 0.00210 0.00420 52.0 254.0 207.9 63.5 0.069 0.277

5002 1.1 0.00320 0.00640 79.2 166.7 316.8 41.7 0.072 0.288

5003 1.5 0.00430 0.00860 106.4 124.0 425.7 31.0 0.071 0.284

5004 2.2 0.00690 0.01380 170.8 77.3 683.1 19.3 0.078 0.311

5005 3 0.00820 0.01640 203.0 65.0 811.8 16.3 0.068 0.271

5006 4 0.01200 0.02400 297.0 44.4 1188.0 11.1 0.074 0.297

5008 5.5 0.01800 0.03600 445.5 29.6 1782.0 7.4 0.081 0.324

5011 7.5 0.02300 0.04600 569.3 23.2 2277.0 5.8 0.076 0.304

4

MI.50.S1.02 – VLT is a registered Danfoss trademark

VLT® types 5001-5011

■■

■

■■

Selection of a brake resistor

Danfoss brake resistors for horizontal applications are

rated to the performance mentioned in the table below.

In parameter 402 the brake power limit is set. It is

calculated as described in the manual for the VLT

5000 series. The maximum values to put in must be

calculated as follows:

2

For 200-240 V units: P=397

For 380-500 V units: P=822

× Max. dutycycle / R

2

× Max. dutycycle / R

Units for supply 200 to 240 VAC

VLT Type Motor Resistor Size Ordernumber Max. duty Max. limit in

[kW] [ohm] cycle [%] par. 402

5001 0.75 150 150 Ω 100 W 175U1005 14.0 0.15

5001 0.75 150 150 Ω 200 W 175U0989 40.0 0.43

5002 1.1 100 100 Ω 100 W 175U1006 8.0 0.13

5002 1.1 100 100 Ω 200 W 175U0991 20.0 0.32

5003 1.5 72 72 Ω 200 W 175U0992 16.0 0.36

5004 2.2 47 50 Ω 200 W 175U0993 9.0 0.31

5005 3 35 35 Ω 200 W 175U0994 5.5 0.25

5005 3 35 72 Ω 200 W 2 x 175U0992

5006 4 25 50 Ω 200 W 2 x 175U0993

5008 5.5 20 40 Ω 200 W 2 x 175U0996

5011 7.5 13 27 Ω 200 W 2 x 175U0995

*1

12.0 0.55

*1

11.0 0.70

*1

6.5 0.52

*1

4.0 0.49

[kW]

Units for supply 380 to 500 VAC

VLT Type Motor Resistor Size Ordernumber Max. duty Max. limit in

[kW] [ohm] cycle [%] par. 402

[kW]

5001 0.75 630 620 Ω 100 W 175U1001 14.0 0.15

5001 0.75 630 620 Ω 200 W 175U0982 40.0 0.43

5002 1.1 430 430 Ω 100 W 175U1002 8.0 0.13

5002 1.1 430 430 Ω 200 W 175U0983 20.0 0.32

5003 1.5 320 310 Ω 200 W 175U0984 16.0 0.34

5004 2.2 215 210 Ω 200 W 175U0987 9.0 0.29

5005 3 150 150 Ω 200 W 175U0989 5.5 0.25

5005 3 150 300 Ω 200 W 2 x 175U0985

5006 4 120 240 Ω 200 W 2 x 175U0986

5008 5.5 82 160 Ω 200 W 2 x 175U0988

5011 7.5 65 130 Ω 200 W 2 x 175U0990

*1

: Connect in parallel.

*1

12.0 0.54

*1

11.0 0.62

*1

6.5 0.54

*1

4.0 0.42

MI.50.S1.02 – VLT is a registered Danfoss trademark 5

General technical data:General technical data:

General technical data:

General technical data:General technical data:

■■

■

■■

VLT® types 5001-5011

Max. permissible operating voltage V

Insulation voltage V

Casing temperature J

B

ISO

C

≤ 700 VAC always considering

≤ 1000 VDC the self protection

≤ 4000 V

≤ 250 °C free convection

Weight m about 280 g Small 100 W

about 550 g Large 200 W

Enclosure IP54

ImpulseloadImpulseload

Impulseload

ImpulseloadImpulseload

■■

■

■■

Duty cycle [%]Duty cycle [%]

Duty cycle [%]

Duty cycle [%]Duty cycle [%]

100 W resistor100 W resistor

100 W resistor

100 W resistor100 W resistor

Duty cycle [%]Duty cycle [%]

Duty cycle [%]

Duty cycle [%]Duty cycle [%]

200 W resistor200 W resistor

200 W resistor

200 W resistor200 W resistor

Power [W]Power [W]

Power [W]

Power [W]Power [W]

Figure 2

■■

■

■■

How to setup the brake function

To use the brake function it is necessary to set up

some parameters. It is always necessary to perform

the Basic Setup. Further settings are available for

monitoring the brake power, protection of the brake

resistor and brake IGBT and readout of brake power.

Basic setupBasic setup

Basic setup

Basic setupBasic setup

To enable the brake function it is necessary to set

one parameter.

- Activate the brake function

● Set parameter 400 (Brake function/overvoltage

control) to Resistor brake [1].

Power monitoringPower monitoring

Power monitoring

Power monitoringPower monitoring

To monitor the power to the brake resistor it is nec-

essary to set the following:

- Set the value of the brake resistor

● Set parameter 401 to the present resistor

value [ohm].

- Set the limit for the power transmitted to the resistor

● Set parameter 402 to the maximum accept

able power [kW] transmitted to the resistor dur

ing 120 seconds.

Power [W]Power [W]

Power [W]

Power [W]Power [W]

- Choose the power monitoring function

● Set parameter 403 to Warning [1] or Trip [2]

● If the circuit in figure 4 is used, set parameter

323 to Brakefault [30]

The monitor function calculates the power transmitted to the brake resistor. The power is calculated on

the basis of the resistor ohm value (parameter 401),

the intermediate circuit voltage and the resistor run

ning time.

If the power transmitted over 120 seconds exceeds

100% of the monitoring limit (parameter 402) and

Warning [1] (parameter 403) has been selected, a

warning will come up on the display. The warning

will disappear when the power goes below 80%.

If Trip [2] (parameter 403) has been selected, the

converter will trip and give an alarm when the power

limit is reached.

If the power monitoring is set to Off [0]or Warning

[1], the brake function remains active, even if the

monitoring limit has been exceeded. This may

lead to thermal overload of the resistor

6

MI.50.S1.02 – VLT is a registered Danfoss trademark

VLT® types 5001-5011

Brake checkBrake check

Brake check

Brake checkBrake check

To protect the brake resistor and IGBT during

operation, it is possible to activate a brake check

function.

- Activate the brake check

● Set parameter 404 to Warning [1] or Trip [2],

depending on which level of protection You

need.

If Off [0] is selected, the brake resistor and brake

IGBT will be monitored with respect to short

circuiting during operation. In case of short circuit, a

warning will be given.

If Warning [1] is selected, the brake resistor and

brake IGBT will be monitored with respect to short

circuiting and on power-up it will be checked if the

brake resistor has been disconnected.

In case of Trip [2], the VLT frequency converter will

cut out while giving an alarm (trip locked) if the

brake resistor has short-circuited or been disconnected or if the brake IGBT has short-circuited.

It is possible to readout the result of the brake

check via the outputs 42, 45, 01 (relay) or 04 (relay).

Protective propertiesProtective properties

Protective properties

Protective propertiesProtective properties

For protection of the installation, one of the outputs

from the drive can be used to control a protection

circuit. For connections, see page 8 Electrical.

● Set one of the outputs 42, 45, 01 (relay) or 04

(relay) (parameters 319, 321, 323 or 326) to

Brake Fault [30].

If there is a fault on the brake, the output will be activated and activate the protection circuit.

Readout of brake powerReadout of brake power

Readout of brake power

Readout of brake powerReadout of brake power

To readout the brake power in the display set parameters as follows:

- Mean brake power during the latest 2 minutes.

● Set parameter 009, 010, 011 or 012 to Brake

energy/2 min [23].

- Instantaneous brake power

● Set parameter 009, 010, 011 or 012 to Brake

energy/s [24].

For large readouts set parameter 009 and for small

readout set parameters 010, 011 or 012.

DC brakingDC braking

DC braking

DC brakingDC braking

To increase brake performance at low speed, the

DC brake function can be used.

● The DC brake cuts in when the output fre-

quency is below a set cut-in frequency, and no

start signal is present.

Define a DC brake cut-in frequency.

Set parameter 127 to the desired DC brake

cut-in frequency

● or control the DC brake function by activating

digital input 27. Logical low activates the brake.

Define digital input 27 to DC brake Inverse

Set parameter 304 to DC-braking, Inverse [3]

DC braking can also be controlled via the bus. See

parameter 504.

It is possible to optimise the performance of the

DC brake by changing the parameters 125 (DC

braking current) and 126 (DC braking time).

InstallationInstallation

Installation

InstallationInstallation

■■

■

■■

MechanicalMechanical

Mechanical

MechanicalMechanical

NB!:NB!:

NB!:

The brake resistor can be installed beside the drive

using different fittings. It is possible to mount the

bookstyle drives on the enclosure of the brake resis-

NB!:NB!:

The brake resistor is to be fitted on a nonflammable material.

tor. See figure.

Figure 3

Mechanical measurements and necessary space around

MI.50.S1.02 – VLT is a registered Danfoss trademark 7

ElectricalElectrical

Electrical

ElectricalElectrical

The brake resistor must be connected to the terminals 81 and 82.

For protection of the installation, a thermal relay

should be fitted that cuts off the frequency converter if the brake current becomes too high. See

Instruction MI50Dxyy (x is the version and yy is the

language).

Alternatively the built in monitoring functions can be

used, see page 7 Protective properties. To protect

the drive and brake resistor from overload, a circuit

breaker can be placed in the mains supply. One of

the relay outputs on the VLT 5000 are setup as

alarm or warning signal and controls a shunt trip. If

an alarm or warning occurs, the mains supply will

be cut out.

VLT® types 5001-5011

Figure 4

VLT5000 with integrated monitoring

EMC (twisted cables/shielding)EMC (twisted cables/shielding)

EMC (twisted cables/shielding)

EMC (twisted cables/shielding)EMC (twisted cables/shielding)

To reduce the electrical noise from the wires between the brake resistor and the VLT frequency

converter, the wires must be twisted.

For enhanced EMC performance a metal screen

can be used.

Figure 5

8

MI.50.S1.02 – VLT is a registered Danfoss trademark

■■

■

■■

Dimensions

All dimensions in mm.

VLT® types 5001-5011

175U0003

Wide - 2 resistors

175U0004

Slim - 2 resistor

A 90 130 90

175U0002

Slim - 1 resistors

Figure 6

B 65 65 38

175U0009

for 200 W resistor

175U0011

for 100 W resistor

C 110 216

Figure 7

MI.50.S1.02 – VLT is a registered Danfoss trademark 9

VLT® types 5001-5011

Dimensions - 100 W:

Dimensions - 200 W:

Figure 8

10

MI.50.S1.02 – VLT is a registered Danfoss trademark

Loading...

Loading...