Page 1

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

1

Contents

Chapter 1 ■ Introduction .............................................................. 2

Chapter 2 ■ Interbus introduction ................................................ 4

Chapter 3 ■ Technical Data ......................................................... 5

Chapter 4 ■ Ordering number ...................................................... 6

Chapter 5 ■ Cable routing and Connectors ................................. 7

Chapter 6 ■ Process Data ......................................................... 13

Chapter 7 ■ Drivecom 21 Profile & Interbus objects ................... 15

Chapter 8 ■ FC Profile ................................................................ 23

Chapter 9 ■ VLT Parameters ...................................................... 26

Chapter 10 ■ Timming ................................................................. 30

Chapter 11 ■ Warning and Allarm messages................................ 31

Chapter 12 ■ Abreviations & definitions ........................................ 32

Chapter 13 ■ VLT5000 Parameter list .......................................... 33

Copyrights, Limitation of Liability and Revision Rights.

This publication contains information proprietary to Danfoss A/S. By accepting and using this manual the user

agrees that the information contained herein will be used solely for operating equipment of Danfoss A/S or

equipment from other vendors provided that such equipment is intended for communication with Danfoss

equipment over a INTERBUS serial communication link. This publication is protected under the Copyright laws

of Denmark and most other countries.

Danfoss A/S does not warrant that a software program produced according to the guidelines provided in this

manual will function properly in every physical, hardware or software environment.

Although Danfoss A/S has tested and reviewed the documentation within this manual, Danfoss A/S makes no

warranty or representation, either express or implied, with respect to this documentation, including its quality,

performance, or fitness for a particular purpose.

In no event shall Danfoss A/S be liable for direct, indirect, special, incidental, or consequential damages arising

out of the use, or the inability to use information contained in this manual, even if advised of the possibility of

such damages. In particular, Danfoss A/S is not responsible for any costs including but not limited to those

incurred as a result of lost profits or revenue, loss or damage of equipment, loss of computer programs, loss of

data, the costs to substitute these, or any claims by third parties.

Danfoss A/S reserves the right to revise this publication at any time and to make changes in its contents

without prior notice or any obligation to notify previous users of such revisions or changes.

Page 2

MG.10.O1.02 VLT is a registered Danfoss trademark

2

VLT® 5000 INTERBUS

■ About this manual

This manual is intended to be used both as an

instructional and as a reference manual. It only

briefly touches on the basics of the INTERBUS

protocol whenever it is necessary for gaining an

understanding of the DRIVECOM implementation of

the DRIVECOM Profile 21

The manual is also intended to serve as a guideline

when you specify and optimize your communication

system.

If you are not completely familiar with INTERBUS,

PCP or the Profile for Variable Speed Drives, it may

be advisable to read some of the material provided

on these subjects.

Even if you are an experienced INTERBUS

programmer, we suggest that you read this manual

in its entirety before you start programming, since

important information can be found in all chapters.

Chapter 5 gives details on the INTERBUS Option

Card and how to establish the physical connection.

In chapter 6 you will find information about VLT

Process Data.

Chapter 7 and 8 describe the two different

statemachine, implemented in the INTERBUS option:

Drivecom 21 and FC Drive.

Chapter 9 has all the relevant VLT and INTERBUS

parameters listed.

Chapter 10 contains information on Timing on a

INTERBUS system and on the INTERBUS option

Chapter 11 describes display messages, warning and

alarm messages.

In chapter 12 you will find a glossary explaining

abbreviations, words and phrases you must know to

understand this manual. This chapter also contains

a complete parameter list with parameter

designations, default settings, setting ranges etc.

Chapter 13 lists the VLT5000 Parameters.

If you want to know more about the INTERBUS

protocol in general, please refer to the vast amount

of literature provided for this purpose.

■ Assumptions

This manual assumes that you are using a

DANFOSS INTERBUS Option Card in conjunction

with a DANFOSS VLT 5000 Series. It is also

assumed that you, as a master, are using a PLC or

PC that is equipped with a serial communication

card supporting all the INTERBUS communication

services required by your application, and that all

requirements stipulated in the INTERBUS standard

as well as those set up in the DRIVECOM Variable

Speed Drives Profile and its company-specific

implementation, as well as those pertaining to the

VLT Variable Speed Drive are strictly observed as

well as all limitations therein fully respected.

■ What you should already know

The DANFOSS INTERBUS Option Card is designed

to communicate with any master abiding by the

INTERBUS standard. It is therefore assumed that

you have full knowledge of the PC or PLC you

intend to use as a master in your system. Any

questions pertaining to hardware or software

produced by any other manufacturer is beyond the

scope of this manual and is of no concern to

DANFOSS.

If you have questions about how to set up master master communication or communication to a nonDanfoss slave, the appropriate manuals should be

consulted.

Introduction

Page 3

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

3

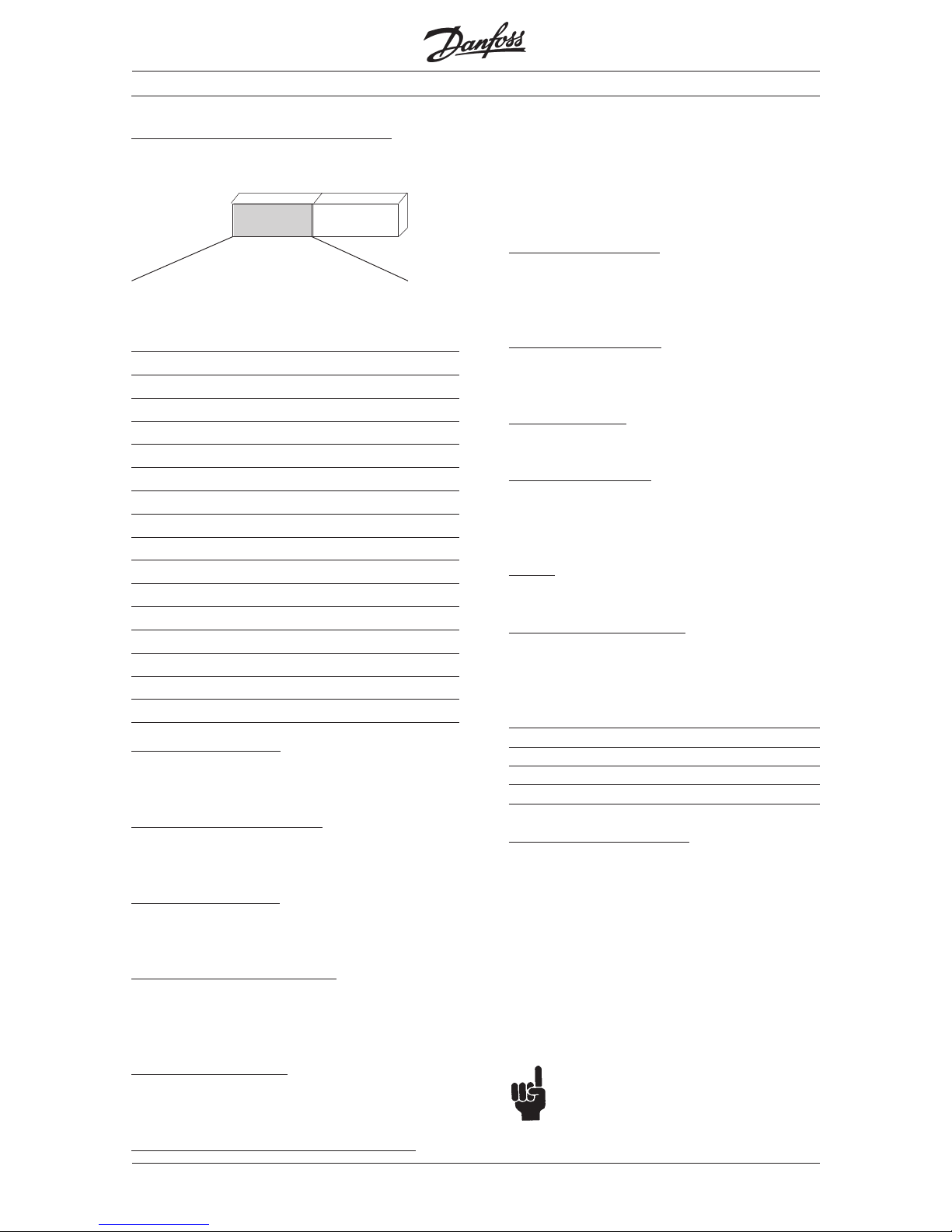

Available literature

The chart below gives an overview of the literature

available for the VLT 5000 Series.

Please note that variations may occur from one

country to the next.

■

X = version number

YY = language

01 = Danish

02 = English

03 = German

04 = French

05 = Spanish

06 = Italian

07 = Swedish

10 = Dutch

20 = Finnish

28 = Brazilian Portuguese

51,52 = Danish, English, German

Design

Guide

MG.50.CX.YY

Operating

Instructions

MG.50.AX.YY

Instructions

for VLT

5000 Series

VLT Software

Dialog

MG.50.EX.YY

PROFIBUS

Manual

MG.10.EX.YY

Quick

Setup

MG.50.FX.YY

LCP remotemounting kit

IP 20

MI.56.AX.51

Brake

instructions

MI.50.DX.YY

LC-filter

VLT 5001-5011

MI.56.DX.51

IP 20 terminal

cover

MI.56.CX.51

Syncron. and

positioning

MG.10.JX.02

MG.10.JX.03

Gateway

InterBus

MG.10.G1.51

Quick

Setup

MG.50.DX.YY

Quick

Setup

MG.50.GX.YY

Bookstyle IP 20

Compact IP 20

Compact IP 54

VLT 5000

Data sheet

MD.50.AX.YY

Loadsharing

instructions

MI.50.NX.YY

Var. literature

for VLT 5000

Series

Instructions

for VLT 5000

Series

Communication

for VLT 5000

Series

LonWorks

Manual

DeviceNet

Manual

RCD

Instructions

MI.66.AX.YY

Modbus Plus

Manual

LC-filter

VLT 5016-5250

MI.56.FX.51

LCP remotemounting kit

IP 54

MI.56.GX.52

VLT 5300-5500

Installation guide

MG.56.AX.YY

Interbus

Manual

Page 4

MG.10.O1.02 VLT is a registered Danfoss trademark

4

VLT® 5000 INTERBUS

Technical overview.

Interbus introduction

The INTERBUS system is divided into two different

system: remote and local. The remote system

enables the user to connect up to 256 stations on a

single system wiht a maximum of 400m Cable

between each station.

The locale bus system enables the user to establish

communication to Input/output devices throuhgt a

single twisted pair of Cables. This type of

comunication is typical used the simple devices E.g.

Digital I/O devices.

For Communication on the remote bus the

INTERBUS system provides two different types of

communication Process Data and PCP (Peripherals

Communication Protocol). The Process Data is

cyclic communication to devices with high priority.

This type of communication typically takes between

few milliseconds and up to 100 milliseconds,

depending on the size of the system. Example of

this type of communication is digital & analogue I/O

or control word & reference to frequency

converters.

PCP communication are used for communications

needs that does not require high speed and and

typically only are activated on request from the user

writen program. Typical time to read/write a single

value is 100 to 200 millisecond. Example of this type

of communication is configurating Data, read of

service parameter such as running hours, number

power up and KWh.

Page 5

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

5

Technical Data

Technical Data

Topology Ring system - one dual

twisted pair

Physics RS-485

Protocol InterBus, total frame

message transfer

Method Master/Slave

Transmission Asynchronous, full duplex

Trans. Rate 500 Kbits/sec.

Error Check CRC-16

Hamming distance 4

Number of I/O Max. 4096 bits

No. of Nodes Max. 256

Scan Speed 1024 I and 1024 O in less

than 4 ms

Total Distance Max.12.8 km (Cu)

Segm. Length Max. 400 m(~1200 ft.)

between 2 nodes

Cable Belden #8103 or

equivalent

Cable lengths/number of nodes

The maximum length of the Cable is only

provided, if the bus cable has the following

properties :

- Impedance: 135 to 165 ohm at a measuring

frequency from 3 to 20 MHz

- Resistance: < 110 ohm/km

- Capacity: < 30 pF/m

- Damping: max. 9 dB over the

whole wire length

-Cross sect. max. 0.34mm

2,

corresponding to AWG 22

-Cable type: twisted in pairs,

3 x 2, wires

-Screening: Copper-braided screen

or braided screen and foil screen

It is recommended to use the same cable type in

the entire network to avoid impedance

mismatch.

Page 6

MG.10.O1.02 VLT is a registered Danfoss trademark

6

VLT® 5000 INTERBUS

Ordering number.

■

Ordering number.

The Interbus option for the VLT®5000, is available in 2

different versions, one option that serves the purpose

of enabling a VLT®5000 to communicate on a

INTERBUS remote bus as a slave, and one version

that enables the VLT®5000 that is equip with a

Syncronising and positioning option to communicate

on a INTERBUS remote bus as a slave. As upgrade

kit there is also a set of Eproms available.

Field installation:

INTERBUS Option for field installation, complete set

including Interbus Communication unit, Memory

option, EMC Bracket, installation instruction,

manuals. This kit is intended for field installation in

VLT5000 series, that enables a VLT5000 to

communicate on a INTERBUS remote bus.

Ordering number: 175Z3122

Synchronizing and positioning option:

INTERBUS Communication Option, as above, but

wihtout memory option. This option is intended as

and INTERBUS Option to the Synchronizing and

positioning option, that does not need a memory

option and as a spare part for damaged INTERBUS

Option.

Ordering number: 175Z2900

Upgrade Kit:

INTERBUS Memory set. This set contains a full

memory set (3 Pcs.) for the INTERBUS option and

the Memory board. This Option serves as an

upgrade to the latest version of the VLT5000

software and the INTERBUS Communication

option.This options will not upgrade of the

Synchronising and positioning option. Please refere to

the Synchronising and positioning option Manual for

detailed information on how to upgrade this option.

Ordering number: 175Z3123

Factory Installed:

The INTERBUS option can be ordered from Danfoss

Drives, factory installed in a VLT®5000. Please

consult your Danfoss representive for order number of

a given VLT5000 and INTERBUS combination.

Page 7

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

7

Cable routing and connectors

recommended to keep the greatest possible

distance between the cables,or use fiber optic

Cables, especially where cables are running in

parallel over long distances.

If the INTERBUS cable has to cross a motor or

brake resistor cable they must cross each other

at an angle of 90° to ensure the minimum of

interfrence.

- Connection of the cable screen

The screen of the INTERBUS cable must

always be connected to ground at both ends,

that means the screen must be connected to

ground in all stations connected to the

INTERBUS network. It is of high importance

to have a low impedance ground connection

of the screen, also at high frequencies.This

can be obtained by connecting the surface of

the screen to ground, for example by means

of a cable clamp or a conductive cable gland.

The INTERBUS Option Card is connected to the

remote bus line via MK 100A or MK 101A for the

incomming INTERBUS cable. terminals 62, 63, 64,

65, and 66. to the bus line via MK 100B or MK 101B

for the outcomming INTERBUS, terminals 62, 63, 64,

65, 66 and RB.

EMC precautions

The following EMC precautions are recommended to

obtain interference free operation of the INTERBUS

network. Additional information on EMC can be found

in the VLT 5000 Series design guide (MG.50.CX.YY).

Please also consult the manual of the INTERBUS

master for further installation guidelines.

Relevant national and local regulations, for

example regarding protective earth connection,

must be observed.

- Cable routing

The INTERBUS communication cable must be

kept away from motor and brake resistor

cables to avoid coupling of high frequency

noise from one cable to the other. Normally a

distance of 200 mm is sufficient, but it is generally

Page 8

MG.10.O1.02 VLT is a registered Danfoss trademark

8

VLT® 5000 INTERBUS

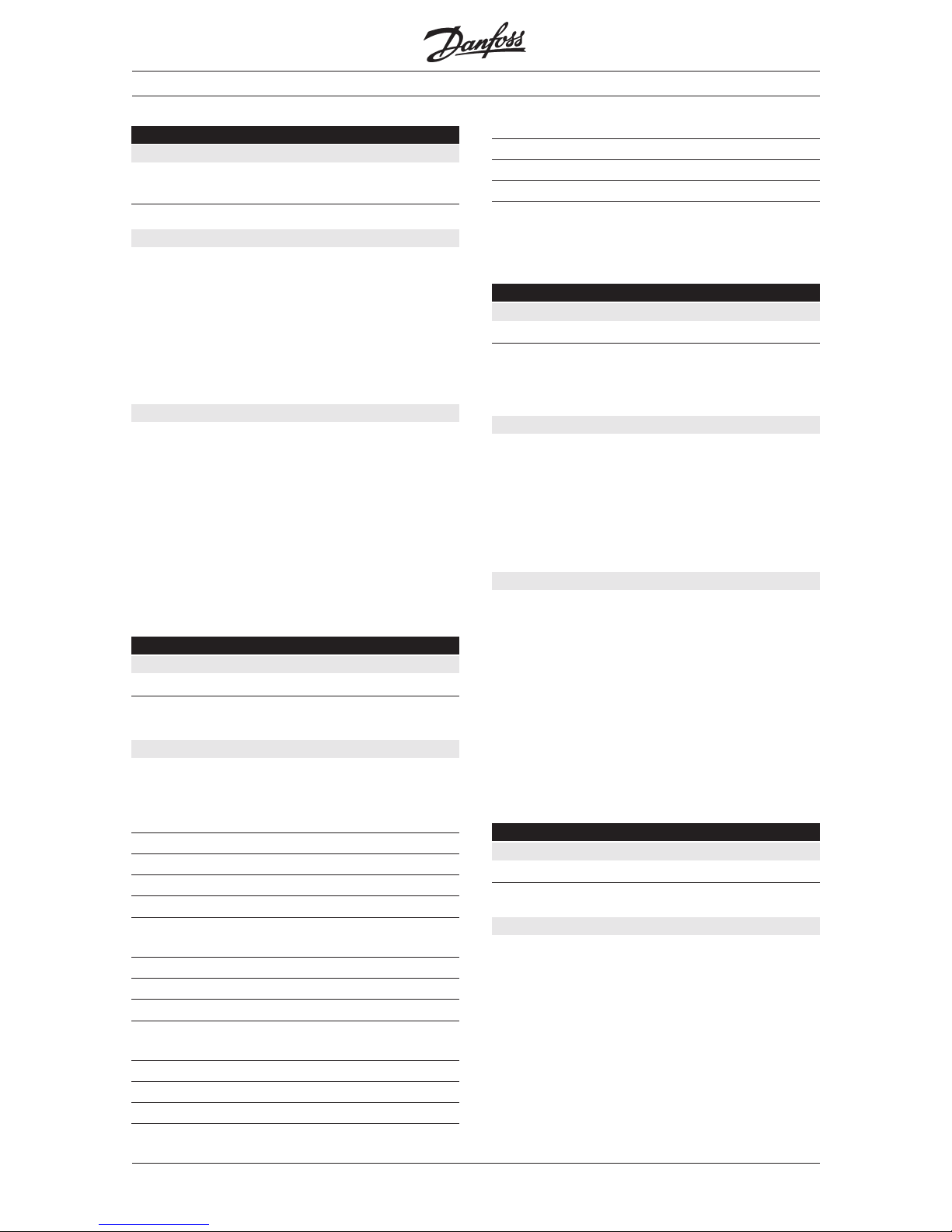

■ LEDs

There are 10 LEDs on the INTERBUS option card.

The LEDs are organized in two sets each having 5

LEDs. One set is visible through the top air outlet if

installed in a VLT®5000 bookstyle, the second set is

visible if installed in a VLT5000 Compact version.

TR

TR

UL

UL

CC/CR

CC/CR

RD

RD

BA

BA

IBS in IBS Out

IBS in

IBS Out

MK 100A MK 100B

MK 101A MK 101B

Name Indicates Color On OFF

CC/CR: Cable Check. Green Incomming bus active Incomming bus swicthed off

BA Bus Active. Green Bus active Bus stopped

RD: Status of outgoing bus. Red Outgoing bus stopped Outgoing bus active

TR: Transmit/Receive. Green PCP Communication running NO PCP Communication running

UL: Power OK. Green Voltage within permissable range No Voltage

VLT 5000 Series is provided with different clamps and

brackets to enable a proper ground connec-aLso at

high frequency. low HF (high frequency) impedance.

This can be achived by connecting a large surface

area of the cabinet to Ground, for example by

mounting the VLT 5000 series on a conductive rear

plate.

Especially when having long distances between

the stations in a INTERBUS network it can be

necessary to use additional potential equalizing

cables, connecting the individual stations to the

same Ground potential.

Connectors

There are 4 connectors, arranged in groups of two.

MK100A and MK100B is to be used if installed in a

VLT®5000 Compact. MK101A and MK101B is used

if the INTERBUS Option is installed in a VLT®5000

Bookstyle. Only one group of connectors may be

used at a time.

Cable routing and connectors

Page 9

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

9

Preperation of the Cable for the VLT5000 Connector.

Step 1:

Step 2:

Cable routing and connectors

Interbus Cable DB9 to VLT5000:

Interbus Cable VLT5000 to DB9:

30 mm.

Interbus Cable VLT5000 to VLT5000:

/DO

DO

/DI

DI

COM

RBST

RB

65

66

62

63

64

65

66

62

63

64

/DO

DO

/DI

DI

COM

/DO

DO

/DI

DI

COM

RBST

1

9

6

5

/DO

DO

/DI

DI

COM 3

6

1

7

2

RB

65

66

62

63

64

/DO

DO

/DI

DI

COM

65

66

62

63

64

/DO

DO

/DI

DI

COM

6

3

2

7

1

9

5

1

9

6

5

Green

Yellow

Pink

Gray

Brown

Green

Gray

Pink

Yellow

Brown

Brown

Gray

Pink

Yellow

Green

IBS Out

IBS Out

(Male)

IBS Out

IBS In

IBS In

IBS In

(Female)

Page 10

MG.10.O1.02 VLT is a registered Danfoss trademark

10

VLT® 5000 INTERBUS

Interbus Cable VLT©5000 Bookstyle:

Interbus Cable VLT©5000 Compact:

Note: Only ingoing connector set is showed.

Cable routing and connectors

IBS In IBS Out

Page 11

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

11

Routing the bus Cable VLT©5060-VLT©5300 IP20 :

Note: Only ingoing cable set is showed.

Cable routing and connectors

Page 12

MG.10.O1.02 VLT is a registered Danfoss trademark

12

VLT® 5000 INTERBUS

Routing the bus Cable VLT©5060-VLT©5300 IP54

Note: Only ingoing cable set is showed.

Cable routing and connectors

Page 13

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

13

■ Process Data.

The VLT®5000 INTERBUS option, offers a flexible

way for the user to customize the number of

Process Data. The process Data of the VLT®5000

is split in two main parts: The first two words that is

reserved for the Drive profile and the user

definable Process data (PCD1 to PCD7).

Process Data

The first two words are fixed on the VLT®5000

option, whereas the input and output PCD1 to

PCD7 can be selected by the user. The number of

PCDs active in a system is user selectable from 0

(zero) up to 7 words. The number of PCDs is

always selected in pairs (input and output).

For the first 2 fixed words of Data, in the PQ and PI

Data, the Danfoss VLT®5000 offers two different

types of profiles: Drivecom and Danfoss. The

Drivecom profile fullfills the requirement of Drivecom

21, speed setting 1. The Drivecom and Danfoss

profiles will be explained in detail in chapter 7 & 8.

PCD1 to PCD7 can be used in a flexible way to read

and write the VLT®5000 parameters, or high speed

transfer of data to the Syncronizing and positioning

Card (Sync/Pos Card).

Changing the number of PCDs can be done by

accesing the VLT®5000s Parameter 807. The

Parameter can be changed at any time, but the

changes wil first take place at the next powerup, or if

the Master sends out a Bus reset command.

Please note that changing the number of

PCDs also may change the mapping of the

Masters I/O Area (PC/PLC).

The VLT®5000 INTERBUS option features the

disabling of PQ Data. PQ can be made inactive,

this means that the VLT®5000 ingnores the content

of all PQ Data, but the VLT®5000 continues to

update the PI Data. This feature is used during

reconfiguration of a running VLT®5000 system and

ensures that no parameter is changed by mistake.

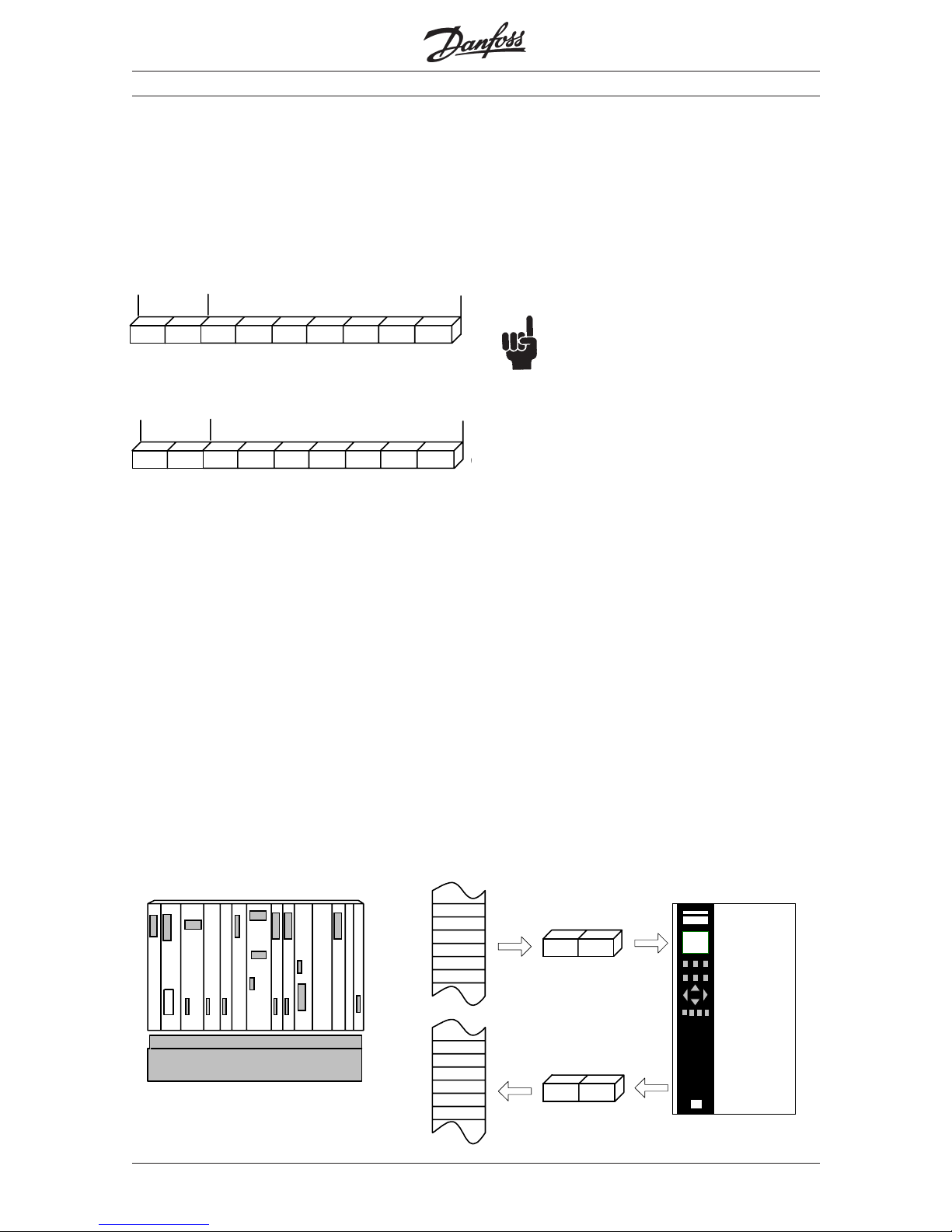

The drawing below shows the default setting of a

system with no PCD words. The system only

consist of control word and main reference for the

PQ Data, and status word and main actual value

for the PI Data. In this system the Control word is

mapped into the PLCs output memory QW000

and the reference is mapped to the output memory

QW002. The status word of the VLT®5000 is

mapped into the input word IW000 of the PLC and

the feedback (main actual value) is mapped to

IW002.

Fixed

Fixed

User definable

User definable

PI

PQ

STW

MAV

STW MAV

MRVCTW

CTW

MRV

QW 000

QW 002

IW 000

IW 002

PLC VLT®5000INTERBUS

CTW MRV PCD1 PCD2 PCD3 PCD4 PCD5 PCD

STW MAV PCD1 PCD2 PCD3 PCD4 PCD5 PCD

6

Page 14

MG.10.O1.02 VLT is a registered Danfoss trademark

14

VLT® 5000 INTERBUS

■ Process Data, PCD.

To enable the use of PCD data, of the VLT®5000

INTERBUS option, the amount of PCD Datawords

has to be configured in Parameter 807, where as the

contents of each single PCD word has to be

configured in Parameter 915 and 916. This can be

done in two different ways: setting parameter 915

and 916, or by using the the INTERBUS object

6000

H

and 6001H.

After setting parameter 807 to match the desired

amount of PCD Data, the VLT®5000 needs to be

configured, for assigning Parameters to each single

PCD words. The VLT®5000 stores this information

in Parameter 915 and 916. The INTERBUS objects

6000

H

and 6001H are images of the two Parameters.

Changing Parameter 915/916 has immidiatly effect

on the PCD data.

The drawing below shows the relation between the

INTERBUS object 6000

H

/6001H and VLT®5000

Parameter 915/916.

The INTERBUS Object 6000

H

and 6001H is an Array of

words that has following structure:

The sub Index number 1 contains the number of

process data bytes. For each byte of process data

2 sub indexes are used. Sub index 2 contains the

Object number, sub index 3 is the index of the object,

if the object is of type array. The next two indexes are

for the next byte of process data. If a Object is of type

Word it uses 4 Sub indexes, wheras the three last Sub

indexes are not used, and must be set to zero.

The 6000

H

6001H Objects can have from 9 up to 37

Sub indexes depending on how many PCD words

there has been assigned. The drawing below shows a

configuration with 2 PCD words assign for reading

parameter 520 (Current) and parameter 528 (digital

input). For writing parameter 204 (minimum reference)

and parameter 221 (Torque limit) is used.

The output data to the VLT®5000 can be disabled by

Interbus Object 6002

H

. By setting the Interbus object

6002H to 00H all imcomming process data wil not be

transimitted to the VLT5000. Setting Interbus object

6002

H

to FFH reactivates the updating of output data.

After a power up the option always sets objects 6002

H

to FFH .

Writing to Interbus Object 6001

H

automaticly sets object 6002H to 00H an

thereby disables the inputs. The user has

to write 0FF

H

to Object 6002

H

manually.

Process Data

Bytes of PQ/PI Data

Description

Object number

Object number

Sub Index

Object number

Sub Index

Sub Index

Object number

Sub Index

Data type

Unsigned 8

Unsigned 8

Unsigned 16

Unsigned 16

Unsigned 16

Unsigned 8

Unsigned 8

Unsigned 16

Unsigned 8

Sub index

1

2

3

4

6

5

9

8

7

37 Unsigned 8

Sub Index

STW

MAV

PCD2

PCD1

CTW

MRV

PCD2

PCD1

6001

17

6040

00

0000

00

6042

00

0000

00

56BC

00

0000

00

56CD

00

0000

00

6000

17

6041

00

0000

00

6044

00

0000

00

57F8

00

0000

00

5900

00

0000

00

204

0

0

0

0

0

221

915 [1]

520

0

0

0

0

0

528

916

MRV PCD1

PCD2CTW

STW MAV PCD1

PCD2

915 [2]

{

PCD2

{

PCD1

{

MRV

{

CTW

{

STW

{

MAV

{

PCD1

{

PCD2

Interbus objects

VLT5000

Parameters

916 [1]

916 [2]

IW 000

IW 002

QW 002

QW 000

Page 15

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

15

Drivecom State machine

The state machine describes the device status and

the possible control sequence of the drive. A status

represents a specific internal and external response.

By means of device control commands and/or

internal events, the status can be changed and a

control sequence thus executed. The current status

can be read out by way of the VLT®5000 status word.

In the flowchart to the right, this explanation may help

you understanding the

drawing: to change from

state A to state B, the condition Controlword bit 1

has to be set equal to 0. The coarses the

transition 0 to be exequted. In state B the

statusword is equal to xx01

H

.

Drivecom 21 Profile.

Not ready to switch on

STW = xx00h

Switched on

0

1

2

11

7

3

4 5

6

9

8

12

10

STW = xx33h

Disable Voltage

xxxx xx0x or

Qiuck stop

xxxx x01x

Shutdown

xxxx x110

Disable Voltage

xxxx xx0x

Switch on

xxxx x111

Stop

xxxx x110

Enable

operation

xxxx 1111

Disable

operation

xxxx x01x

Shutdown

xxxx x110

Qiuck stop

xxxx x01x

Disable voltage

xxxx xx0x

Disable voltage

xxxx xx0x or

Quick stop

xxxx x01x

Reset malfunction

0xxx xxxx

1xxx xxxx

↓

Operation enabled

STW = xx37h

Enabled Ramp

STW = xx37h

No Freeze

STW = xx37h

Start

STW = xx37h

Quick stop active

STW = xx17h

13

14

15

STW = xx38h

STW = xxxx xxxx x1xx 1xxx

JOG 1

STW = xx37h

Malfunction reaction

active

Malfunction

Ready to switch on

STW = xx31h

Switch on disabled

STW = xx40h

Power on

Drivecom 21

Danfoss specific

State B

STW = xx01h

0

State A

condition

xxxx xx0x

transition 0

Page 16

MG.10.O1.02 VLT is a registered Danfoss trademark

16

VLT® 5000 INTERBUS

Data transitions of the device control

The following describes each transaction that the

Drivecom statemachine follows, by a given

command.

0 Input of the state machine ➠ NOT READY TO

SWITCH ON

Event: - Reset

Action: - Start self test

- Start initialisation

1 NOT READY TO SWITCH ON ➠ SWITCH ON

DISABLED

Event: - Error-free self test

- Initialisation completed without errors occurring

Action: - Activate communication and process data

monitoring

2 SWITCH ON DISABLED ➠ READY TO SWITCH

ON

Event: - Shutdown command

Condition: - Depending on the manufacturer-specific

requirements (e.g. power section ready)

Action: - None

3 READY TO SWITCH ON ➠ SWITCHED ON

Event: - Switch-on command

Action: - The power section is switched on if it is not

already switched on.

4 SWITCHED ON ➠ OPERATION ENABLED

Event: - Enable-Operation command

Action: - Enable drive function

5 OPERATION ENABLED ➠ SWITCHED ON

Event: - Disable-Operation command

Action: - Execute the parameter-definable DriveDisable-Function

6 SWITCHED ON ➠ READY TO SWITCH ON

Event: - Shutdown command

Action: - The power section can be switched off

7 READY TO SWITCH ON ➠ SWITCH ON DISABLED

Event: - Quick-Stop or Disable-Voltage command

Action: - None

8 OPERATION ENABLED ➠ READY TO SWITCH

ON

Event: - Shutdown command

Action: - Execute the parameter definable DriveDisable-Function

- The power section can be switched off

9 OPERATION ENABLED ➠ SWITCH ON DISABLED

Event: - Disable-Voltage command

Action: - Disable drive function

- The power section can be switched off

10 SWITCHED ON ➠ SWITCH ON DISABLED

Event: - Disable-Voltage command

or

- Quick-Stop command

Action: - The power section can be switched off

11 OPERATION ENABLED ➠ QUICK STOP ACTIVE

Event: - Quick-Stop command

Action: - Trigger the parameter-definable QuickStop-Function

12 QUICK STOP ACTIVE ➠ SWITCH ON DISABLED

Event: - Quick stop has been completed

or

- Disable-Voltage command

Action: - Disable drive function

- The power section can be switched off

13 All states ➠ MALFUNCTION REACTION ACTIVE

Event: - Drive malfunction detected

Action: - Trigger malfunction reaction depending on

the fault

14 MALFUNCTION REACTION ACTIVE ➠ MALFUNCTION

Event: - Malfunction reaction concluded

Action: - Disable drive function

- The power section can be switched off

15 MALFUNCTION ➠ SWITCH ON DISABLED

Event: - Malfunction-Reset command

Condition: - Malfunction is no longer present

Action: - Malfunction reset is executed

Drivecom 21 Profile.

Page 17

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

17

Control word as per Drivecom 21 Standard

(parameter 512 = Drivecom)

Master➝Slave

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Bit

no.

Bit Bit = 0 Bit =1

00 Switch off Switch on

01 Disable voltage Enable voltage

02 Quick stop Run

03 Disable operation Enable operation

04 Disable Ramp Enable Ramp

05 Freeze Run enable

06 Ramp stop Start

07 No function Reset

08 Drivecom reserved

09 Drivecom reserved

10 Drivecom reserved

11 Jog 1 OFF Jog 1 ON

12 Danfoss reserved

13 Choice of Setup 1 (lsb)

14 Choice of Setup 2 (msb)

15 Forward Reversing

Bit 00, Switch OFF/ON:

Bit 00= "0" execute transition 2, 6 or 8

Bit 00 = "1" execute transition 3

Bit 01, Disable/Enable Voltage:

Bit 01= "0" execute transition 9, 10 or 12

Bit 01 = "1" = Enable Voltage

Bit 02, Quick stop/Run:

Bit 02= "0" execute transition 7, 10 or 11.

Bit 02 = "1" = Quick stop not active.

Bit 03, Disable/enable Operation:

Bit 03= "0" execute transition 5.

Bit 03 = "1" = Enable operation

Bit 04, Quick-stop/ramp:

Bit 04= "0" execute transition 7 or 11, Quick stop

Bit 04 = "1" = Enable ramp.

Bit 05, Freeze output frequency/ramp enable:

Bit 05 = "0" means that the given output frequency is

maintained even if the reference is changed.

Bit 05 = "1" means that the frequency converter is

again able to regulate, and the given reference is

followed.

Bit 06, Ramp stop/start:

Bit06= "0" The VLT controls the motor down to

stop.

Bit 01 = "1" = Start command to the VLT is given

Bit 07, No function/reset

Reset of trip. Bit 07 = "0" means that there is no

reset. Bit 07 = "1" means that a trip is reset.

Bit 08, 09 and 10 :

Drivecom reserved.

Bit 11, Jog 1 OFF/ON:

Activation of pre-programmed speed in

parameter 509 (Bus JOG 1). JOG 1 is only

possible when Bit 04 = "0" and bit 00-03 = "1".

Bit 12,:

Danfoss reserved.

Bits 13/14, Choice of Setup:

Bits 13 and 14 are used for choosing among the

four menu Setups in accordance with the

following table:

Setup Bit 14 Bit 13

10 0

20 1

31 0

41 1

Bit 15, No function/reversing:

Reversing of the direction of rotation of the motor.

Bit 15 = "0" leads to no reversing, bit 15 = "1"

leads to reversing.

Please note that, in the factory setting, reversing

has been chosen as digital in parameter 506,

which means that bit 15 will only lead to reversing

if bus, logic or or logic and (however, logic and

only together with terminal 19) has been

selected.

NB!

Unless otherwise mentioned, the control

word bit is combined (gated) with the

corresponding function on the digital

inputs as a logical "or" function.

Drivecom 21 Profile.

Control

word

Bus

reference

Page 18

MG.10.O1.02 VLT is a registered Danfoss trademark

18

VLT® 5000 INTERBUS

Status word (according to Drivecom standard)

The status word is used for informing the master

(e.g. a PC) of the condition of the VLT 5000.

Slave➝Master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Bit

no.

Bit Bit = 0 Bit =1

00 Not ready to Ready to

switch on switch on

01 Switched off Switched on

02 Operation disabled Operatin enabled

03 No malfunction Malfunction

04 Voltage disabled Voltage Enable

05 Quick stop Run

06 Switch on disable Switch on

enable

07 No warning Warning

08 Danfoss reserved

09 Remote disabled Remote enabled

10 Setpoint not reached Setpoint reached

11 Speed limit Speed limit

not active active

12 Drivecom reserved

13 Drivecom reserved

14 Not running Running

15 Danfoss reserved

Bit 00, Not ready to switch on/Ready to switch on:

Bit 00 = "0" state less than ´´Ready to switch on

Bit 00 = "1" state at least = ´´Ready to Switch on

Bit 01, Switch off/Switch on:

Bit 00 = "0" state less than ´´Switched on

Bit 00 = "1" state at least = ´´Switched on

Bit 02, Operation disable/Operation enable:

Bit 00 = "0" state less than ´´Operation enable

Bit 00 = "1" state at least = ´´Operation enable

Bit 03, No fault/trip:

Bit 03 = "0" means that VLT 5000 Series is not in a

fault condition. Bit 03 = "1" means that VLT 5000

Series has tripped and needs a reset signal in order

to run.

Bit 04, Voltage disable/Voltage enable:

Output

frequency

Status

word

Bit 04 = "0" means that control word bit 01 = "1".

Bit 04 = "1" means that control word bit 01 = "0".

Bit 05, Quick stop/Run:

Bit 05 = "0" means that control word bit 02 = "1".

Bit 05 = "1" means that control word bit 02 = "0".

Bit 06, Start enable/start disable:

Bit 06 = "0" state not ´´Switch on disable

Bit 06 = "1" state = ´´Switch on enable

Bit 07, No warning/warning:

Bit 07 = "0" means that there is no unusual

situation. Bit 07 = "1" means that an abnormal

condition has arisen for the VLT 5000 Series. All

warnings are described in the Operating

Instructions.

Bit 08, Danfoss reserved:

Bit 09, Remote disable/ Remote enable:

Bit 09 = "0" means that VLT 5000 Series has been

stopped by means of the stop key on the control

panel, or that Local operation has been selected in

parameter 002. Bit 09 = "1" means that it is

possible to control the frequency converter via the

serial port.

Bit 10, Setpoint not reached/Setpoint reached:

Bit 10 = "0" means that the actual motor speed is

different from the speed reference set. This can be

the case i.a. while the speed is ramped up/down

during start/stop. Bit 10 = "1" means that the

present motor speed equals the speed reference

set.

Bit 11, Speed limit not active/speed limit active:

Bit 11 = "0" means that the output frequency is out

of the range set in parameter 225 (Warning: Low

frequency) and parameter 226 (Warning: High

frequency). Bit 11 = "1" means that the output

frequency lies within the mentioned range.

Bit 12, Drivecom reserved

Bit 13, Drivecom reserved

Bit 14, Running/Not running:

Bit 14 = "0" means that the motor is not running.

Bit 14 = "1" means that VLT 5000 Series has a start

signal or that the output frequency is greater than 0

Hz.

Bit 15, Danfoss reserved.

Drivecom 21 Profile.

Page 19

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

19

Bus reference value (Drivecom Profile):

Master➝Slave

1514131211109876543210Bit no.

The bus reference value is transmitted to the frequency

converter in the form of a 16-bit word. The value is

transmitted as a whole number (-32768 to 32767). The

value is handled as RPM.

Actual output RPM

Slave➝Master

1514131211109876543210Bit no.

The value of the actual output RPM of the Motor, is

transmitted in the form of a 16-bit word. The value is

transmitted as a whole number (-32768 to 32767).

Drivecom 21 Profile.

Status

word

Output

frequency

Control

word

Bus

reference

Page 20

MG.10.O1.02 VLT is a registered Danfoss trademark

20

VLT® 5000 INTERBUS

■ Drivecom 21 objects.

The VLT®5000 supports 9 Drivecom specific objects.

The objects can be access by PCP communication.

4 of these objects can also be accessed as process

data.

Object 6040H, Control Word:

This object is the same as the Drivecom Control Word

Object 6041H, Status Word:

This object is the same as the Drivecom status word .

Object 6042H, Nominal-Speed-Value :

This object is the same as the Bus reference (MRV).

Object 6043H, Reference-Speed-Variable:

This is the reference after the Ramp. This value is read

only (-32768 to 32767) .

Object 6044H, Actual-Speed-Value:

This object is the same as the Actual output RPM.

The value of the actual output RPM of the Motor, is

transmitted in the form of a 16-bit word. The value is

transmitted as a whole number (-32768 to 32767).

Object 6046H, Speed-min-max-amount:

The Speed-Min-Max-Amount Object is composed of

the Speed-Min-Amount and Speed-Max-Amount sub

objects. These subobjects have no unit and have values within a range from 0 to 4 294 967 295 (unsigned

32).The Interbus Option translates these two indexes

into the VLT®5000 parameter 204 and 205. Based on

Parameter 106 (Motor Norminal Speed) the option

calculation new values for P.204 & P.205.

Object 6048H, Speed-Acceleration:

The Speed-Acceleration object specifies the slope of

the acceleration ramp (α) The object has 2 indexes

where: Index 1, is the Delta-Speed (unsigned 32) and

index 2 is Delta-Time (unsigned 16). If Delta-Time is

set to 0 (zero) the ramp is disabled. The VLT®5000

Interbus Option translate these two values into the

VLT®5000 parameters 106, Motor norminal speed

and parameter 207, ramp up time.

Object 6049H, Speed-Deceleration:

The Speed-deceleration object specifies the slope of

the deceleration ramp (α) The object has 2 indexes

where: Index 1, is the Delta-Speed (unsigned 32) and

index 2 is Delta-Time (unsigned 16). If Delta-Time is

set to 0 (zero) the ramp is disabled. The VLT®5000

Interbus Option translate these two values into the

VLT®5000 parameters 106, Motor norminal speed

and parameter 208, ramp down time.

T, time

N, Rpm

∆∆

∆∆

∆n

∆∆

∆∆

∆t

αα

αα

α

T, time

N, Rpm

∆∆

∆∆

∆n

∆∆

∆∆

∆t

αα

αα

α

The VLT®5000 will first activate the

changes when both indexes are written.

Since the VLT®5000 translates the two

indexes into VLT®5000 paramters, the

value written to Object 6048

H

may be dif-

ferent from a following read, but the slope

(α) is correct !

The VLT®5000 will first activate the changes

when both indexes are written. Since the

VLT®5000 translates the two indexes into

VLT®5000 paramters, the value written to

Object 6049

H

may be different from a follow-

ing read, but the slope (α) is correct !

Object 603FH, Malfunction:

This is the errors reported back to the Master system.

A detailed list is on the next page.

Object 6052H, Normial-Percentage :

This object is the Normial setpoint in %. . The value is

transmitted as a whole number ±100% = ±4000

H.

This value is read only.

Object 6054H, Actual-Percentage :

This object is the actual speed of the motor . The

value is transmitted as a whole number ±100% =

±4000

H

Drivecom 21 Objects

Page 21

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

21

Meaning VLT-Code Drivecom Drivecom

Alarmword Malfunc. Malfunc group

(Hex) Code

No alarm 0000 0000 0 No malfunction

Brake test Failed 0000 0001 7110 brake chopper

Trip locked 0000 0002 1000 general malfunction

Auto-optimisation not OK 0000 0004 5210 measurement circuit

Auto-optimisation OK 0000 0008 0 no error

Power-up fault 0000 0010 1000 general malfunction

ASIC fault 0000 0020 5200 hardware control fault

HPFB bus timeout 0000 0040 8100 monitoring communication

Standard bus timeout 0000 0080 8100 monitoring communication

Short circuiting 0000 0100 2130 short circuit

Switch mode fault 0000 0200 5115 U5 supply

Earth fault 0000 0400 2240 earth leakage

Overcurrent 0000 0800 2310 continuous over-current

Torque limit 0000 1000 8311 excess torque

Motor thermistor 0000 2000 4310 excess temperature drive

Motor overloaded 0000 4000 2312 continuous over-current 2

Inverter overloaded 0000 8000 2316 continuous over-current 1

DC Link undervoltage 0001 0000 3220 internal under-voltage

DC Link overvoltage 0002 0000 3210 internal over-voltage

Phase fault 0004 0000 3130 phase failure

Live zero fault 0008 0000 7300 sensor

Heat sink temperature too high 0010 0000 4210 excess temperature device

Motor phase U missing 0020 0000 3131 phase failure L1

Motor phase V missing 0040 0000 3132 phase failure L2

Motor phase W missing 0080 0000 3133 phase failure L3

Quick discharge not OK 0100 0000 9000 External malfunction

Interbus Error codes:

Interbus Error Codes

Page 22

MG.10.O1.02 VLT is a registered Danfoss trademark

22

VLT® 5000 INTERBUS

■ PCP Communication.

For acyclical read and writting of VLT®5000

parameters and Interbus Objects, the PCP-Channel

has to be used. The Danfoss VLT®5000 option

supports following services:

Initiate

Establish connection between master and

VLT®5000

Abort

Cancel Connection between Master and VLT®5000

Read

Read VLT®5000 Parameter or Interbus Objects.

Write

Write VLT®5000 Parameter or Interbus Objects.

Get OD, both short and long are supported

Get Object dictionary from VLT®5000.

and

Identify

Identification of the VLT®5000 to the Master.

Following entries has to be done in the Master for

PCP communication:

All parameters in the VLT®5000 are mapped to the

Danfoss specific objects starting from object 22000

D

=

55F0

H

. The first object is 22001D, which corresponds

to read VLT®5000 parameter 001, language. 22002

D

corresponds to VLT®5000 parameter 2 and so on.

This means that all VLT®5000 parameters simply can

be accessed by using PCP communication, just

adding 22000

D

to the VLT®5000 parameter.

To access the VLT®5000 objects for reading and

writing, it is necesarry to set up the correct data size

and index for the parameter. The option board can

provide the complete list of objects to the user by

using the GET OD command. Alternally the user can

set up the command for the object manualy.

Communication referens

Transmitt buffer lengh

Receive buffer lengh

Supported Service request

Supported Service response

2

246

246

80 30 00

H

00 00 00

H

Page 23

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

23

Control word under VLT standard (parameter 512 =

FC Drive)

The control word is used for sending commands

from a master (e.g. a PC) to a slave (VLT 5000

Series).

Master➝Slave

1514131211109876543210Bit

no.

Bit Bit = 0 Bit = 1

00 Preset reference choice lsb

01 Preset reference choice msb

02 DC brake Ramp

03 Coasting Enable

04 Quick-stop Ramp

05 Hold Ramp

enable

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data not valid Valid

11 No function Relay 01

activated

12 No function Relay 04

activated

13 Choice of Setup lsb

14 Choice of Setup msb

15 No function Reversing

Bit 00/01:

Bits 00 and 01 are used for choosing among the

four pre-programmed references (parameters 215-

218) in accordance with the following table:

Preset ref. Parameter Bit 01 Bit 00

1 215 0 0

2 216 0 1

3 217 1 0

4 218 1 1

NB!

Parameter 508 is where to choose the

way bits 1/12 are to be combined (gated)

with the corresponding function on the

digital inputs.

Bit 02, DC BRAKE:

Bit 02 = "0" leads to DC braking and stop. Braking

current and duration are set in parameters 125 and

126. Bit 02 = "1" leads to ramping.

Bit 03, Coasting/enable:

Coasting stop. Bit 03 = "0" leads to a stop. Bit 03 =

"1" means that the frequency converter is able to

stop, provided the other conditions for starting are

fullfilled. Note: In parameter 502 the choice is made

as to how bit 03 is to be combined (gated) with the

corresponding function in the digital inputs.

Bit 04, Quick-stop/ramp:

Quick-stop which uses the ramp time in parameter

212. Bit 04 = "0" leads to a quick-stop. Bit 04 = "1"

means that the frequency converter is able to start,

provided the other conditions for starting are fulfilled.

Note: In parameter 503 the choice is made as to

how bit 04 is to be combined (gated) with the

corresponding function on the digital inputs.

Bit 05, Freeze output frequency/ramp enable:

Bit 05 = "0" means that the given output frequency is

maintained even if the reference is changed.

Bit 05 = "1" means that the frequency

converter is again able to regulate, and the

given reference is followed.

Bit 06, Ramp stop/start:

An ordinary ramp stop that uses the ramp time in

parameters 207/208 or 209/210; in addition, output

relay 01 or 04 will be activated when the output

frequency is 0 Hz, provided Relay 123 has been

selected in parameter 323 or 326. Bit 06 = "0" leads

to a stop. Bit 06 = "1" means that the frequency

converter is able to start, provided the other

conditions for starting are fulfilled. Note: In

parameter 505 the choice is made as to how bit 06

is to be combined (gated) with the corresponding

function on the digital inputs.

Bit 07, No function/reset

Reset of trip. Bit 07 = "0" means that there is no

reset. Bit 07 = "1" means that a trip is reset.

Bit 08, Activation of Jog speed in parameter 213:

Bit 08 = "0": Jog speed not activated. Bit 08 = "1"

means that the motor is running at Jog speed.

Bit 09, Choice of ramp 1/2:

Bit 09 = "0" means that ramp 1 is active

(parameters 207/208). Bit 09 = "1" means that

ramp 2 (parameters 209/210) is active.

Bus

reference

Control

word

FC Profile

Page 24

MG.10.O1.02 VLT is a registered Danfoss trademark

24

VLT® 5000 INTERBUS

Status word under VLT standard

The status word is used for informing the master

(e.g. a PC) about the condition of the slave (VLT

5000 Series).

Slave➝Master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Bit

no.

Bit Bit = 0 Bit = 1

00 Control not ready Ready

01 VLT not ready Ready

02 Coasting Enable

03 No fault Trip

04 Reserved

05 Reserved

06 Reserved

07 No warning Warning

08 Speed ≠ ref. Speed = ref.

09 Local control Bus control

10 Out of range Frequency OK

11 Not running Running

12 VLT OK Stalling, autostart

13 Voltage OK Above limit

14 Torque OK Above limit

15 Timer OK Above limit

Bit 00, Control not ready/ready:

Bit 00 = "0" means that the frequency converter

has tripped.

Bit 00 = "1" means that the frequency converter

controls are ready, but that the power component is

not necessarily receiving any power supply (in case

of external 24 V supply to controls).

Bit 01, VLT not ready/ready:

Same meaning as bit 00; however, there is also a

supply to the mains component, and the frequency

converter is ready to run when it receives the

necessary start signals.

Bit 02, Coasting/enable:

Bit 02 = "0" means that the control word bit 03 is

"0" (Coasting) or that VLT 5000 Series has tripped.

Bit 02 = "1" means that control word bit 03 is "1"

and that VLT 5000 Series has not tripped.

Bit 03, No fault/trip:

Bit 03 = "0" means that VLT 5000 Series is not in a

fault condition. Bit 03 = "1" means that the VLT

Output

frequency

Status

word

Bit 10, Data not valid/valid:

Used for telling VLT 5000 whether the control word is

to be used or ignored. Bit 10 = "0" means that the

control word is ignored. Bit 10 = "1" means that the

control word is used. This function is relevant because

the control word is always contained in the telegram,

regardless of the type of telegram used, i.e. it is

possible to disconnect the control word if it is not to be

used in connection with updating or reading of

parameters.

Bit 11, Relay 01:

Bit 11 = "0": Relay 01 not activated. Bit 11 = 1:

Relay 01 activated, provided Control word bit has

been chosen in parameter 323.

Bit 12, Relay 04:

Bit 12 = "0": Relay 04 has not been activated. Bit

12 = "1": Relay 04 has been activated, provided

Control word bit has been chosen in parameter 326.

NB!

Unless otherwise mentioned, the control

word bit is combined (gated) with the

corresponding function on the digital inputs

as a logic "or" function.

Bits 13/14, Choice of Setup:

Bits 13 and 14 are used for choosing among the

four menu Setups in accordance with the following

table:

Setup Bit 14 Bit 13

10 0

20 1

31 0

41 1

This function is only possible if Multi-Setup has been

selected in parameter 004.

NB!

Parameter 507 is used for choosing how bits 13/14

are to be combined (gated) with the corresponding

function on the digital inputs.

Bit 15, No function/reversing:

Reversing of the direction of rotation of the motor.

Bit 15 = "0" leads to no reversing, bit 15 = "1" leads

to reversing.

Please note that, in the factory setting, reversing

has been chosen as digital in parameter 506, which

means that bit 15 will only lead to reversing if bus,

logic or or logic and (however, logic and only

together with terminal 19) has been selected.

FC Profile

Page 25

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

25

5000 Series has tripped and needs a reset signal in

order to run.

Bit 04, Reserved.

Bit 05, Reserved.

Bit 06, Reserved.

Bit 07, No warning/warning:

Bit 07 = "0" means that there is no unusual

situation. Bit 07 = "1" means that an abnormal

condition has arisen for the VLT 5000 Series. All

warnings are described in the Operating

Instructions.

Bit 08, Speed ≠ ref/speed = ref.:

Bit 08 = "0" means that the actual motor speed is

different from the speed reference set. This can be

the case i.g. while the speed is ramped up/down

during start/stop. Bit 08 = "1" means that the

present motor speed equals the speed reference

set.

Bit 09, Local control/Bus control:

Bit 09 = "0" means that VLT 5000 Series has been

stopped by means of the stop key on the control

panel, or that Local operation has been selected in

parameter 002. Bit 09 = "1" means that it is

possible to control the frequency converter via the

serial port.

Bit 10, Out of operating range/Frequency limit OK:

Bit 10 = "0" means that the output frequency is out

of the range set in parameter 225 (Warning: Low

frequency) and parameter 226 (Warning: High

frequency). Bit 10 = "1" means that the output

frequency lies within the mentioned range.

Bit 11, Does not run/running:

Bit 11 = "0" means that the motor is not running.

Bit 11 = "1" means that VLT 5000 Series has a start

signal or that the output frequency is greater than 0

Hz.

Bit 12, VLT OK/stalling, autostart:

Bit 12 = "0" means that there is no temporary overtemperature on the inverter. Bit 12 = "1" means

that the inverter has stopped because of overtemperature, but that the unit has not tripped and

will continue, once the overtemperature stops.

Bit 13, Voltage OK/above limit:

Bit 13 = "0" means that the voltage limits of VLT

5000 Series have not been exceeded. Bit 13 = "1"

means that the DC voltage of the VLT 5000 Series

intermediate circuit is too low or too high.

Bit 14, Torque OK/above limit:

Bit 14 = "0" means that the motor current is lower

than the torque limit selected in parameter 221. Bit

14 = "1" means that the torque limit in parameter

221 has been exceeded.

Bit 15, Timers OK/above limit:

Bit 15 = "0" means that the timers for motor

thermal protection (described on page 67) and VLT

thermal protection, respectively, have not exceeded

100%. Bit 15 = "1" means that one of the timers

has exceeded 100%.

Bus reference value (FC Profile):

Master➝Slave

1514131211109876543210Bit no.

The frequency reference value is transmitted to the

frequency converter in the form of a 16-bit word.

The value is transmitted as a whole number (0-

32767). 16384 (4000 Hex) corresponds to 100%.

(Negative figures are formed by means of 2's

complement.)

The bus reference has the following format:

Parameter 203 = "0"

"ref

MIN

-ref

MAX

"

0-16384 (4000 Hex) ~ 0-100% ~ ref

MIN

- ref

MAX

Parameter 203 = "1"

-ref

MAX

- +ref

MAX

-16384 (C000 Hex) - +16384 (4000 Hex) ~

-100- +100% ~ -ref

MAX

- +ref

MAX

Actual output frequency

Slave➝Master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Bit no.

The value of the actual output frequency of the

frequency converter is transmitted in the form of a

16-bit word. The value is transmitted as a whole

number (0-32767). 16384 (4000 Hex) corresponds

to 100%. (Negative figures are formed by means of

2's complement).

Status

word

Output

frequency

Control

word

Bus

reference

FC Profile

Page 26

MG.10.O1.02 VLT is a registered Danfoss trademark

26

VLT® 5000 INTERBUS

Parameters

■ INTERBUS specific VLT parameters

Only the INTERBUS specific parameters (800 - 807

and 915, 916, 9 . . ) are described in this manual.

Most VLT 5000 Series parameters and their

functions are unaffected by the INTERBUS option.

Refer to the parameter description in the VLT 5000

Series product manual.

Special attention must be given to the following

parameters that are not described in this manual:

- 002: If operation site = Local, then control via

INTERBUS is not possible

- 100: If parameter 512 is set to DRIVECOM, it is

only possible to select speed open

loop or speed closed loop.

- 502 - 508: Selection of how to gate INTERBUS

control commands with control card

digital inputs.

- 512: Control word profile, selects a control word

according to DRIVECOM or a

Danfoss specified control word.

- 515 - 540: Data readout parameters that can be

used to read various actual data from

the VLT, for example actual status of

the analog and digital inputs of the

control card thus using these as

inputs to the master.

801 Baud rate select (BAUD RATE SELECT)

Selection:

✭ 500 kBaud (500 KBAUD) [30]

Function:

Selection of the INTERBUS transmission speed.

Description of selections:

- 500 kBaud: The INTERBUS transmission speed

is fixed to 500 kBaud at this time.

803 Bus time out (BUS TIME OUT)

Selection:

1 - 99 sec ✭ 1 sec

804 Bus time out function (TIME OUT FUNCT.)

Selection:

✭ Off (OFF) [0]

Freeze output frequency (FREEZE OUTPUT) [1]

Stop with auto restart (STOP) [2]

Output frequency = JOG freq. (JOGGING) [3]

Output freq. = Max. freq. (MAX SPEED) [4]

Stop with trip (STOP AND TRIP) [5]

Control without INTERBUS [6]

(NO COM OPT CONTROL)

Select setup 4 (SELECT SETUP 4) [7]

Function:

The time out counter is triggered at the first reception

of a valid control word. When process data is used.

Acyclical PCP will not trigger the time out counter.

The time out function will be activated if CTW is not

updated within the specified time, set in parameter

803.

The VLT remains in the time out state until one of the

following four conditions is true:

1. Valid control word is received

and reset (Bus,

terminals or local control panel) is activated (reset

is only necessary when the time out function

Stop w. trip is selected) ⇒ control via INTERBUS

is resumed with the actual control word.

2. Parameter 002 = Local ⇒ Local control via local

control panel is enabled.

3. Parameter 928 = Disabled ⇒ Normal control via

terminals and RS485 is enabled.

The time out counter is reset and must be

trigged by a valid control word before a new time

out can be activated.

4. Parameter 804 = Off ⇒ control via INTERBUS is

resumed and the most recent control word is

used.

Description of selections:

- Freeze output frequency: Freeze output

frequency until communication is resumed.

- Stop with auto restart: Stop with auto restart

when communication is resumed.

- Output frequency = JOG freq.: Motor will run at

JOG frequency until communication is resumed.

- Output frequency = Max. freq.: Motor will run at

max. frequency until communication is resumed.

- Stop with trip: Motor is stopped, reset needed for

restart, see explanation above.

- Control without INTERBUS: Control via

INTERBUS is disabled and control is only possible

via standard RS485 interface, until communication

is resumed.

- Select setup 4: Setup 4 is selected if timeout

occurs. If communication is resumed the VLT will

not cange back to the setup it used before the

timeout occured.

Page 27

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

27

Description of selections:

807 PCD size select (PCD SIZE SELECT)

Selection:

✭ 0 Word (0 WORDS) [0]

1 Word (1 WORDS) [1]

2 Word (2 WORDS) [2]

3 Word (3 WORDS) [3]

4 Word (4 WORDS) [4]

5 Word (5 WORDS) [5]

6 Word (6 WORDS) [6]

7 Word (7 WORDS) [7]

Function:

The PCD size select assigns the number of Process

data words, the VLT is using.

Change of parameter 807 is first executed at next

power up, or alarmstop from the INTERBUS Master.

915 PCD config. write (PCD IN WR-)

Selections:

Sub index 1 ([1] 000) Parameter #

Sub index 2 ([2] 000) Parameter #

Sub index 3 ([3] 000) Parameter #

Sub index 4 ([4] 000) Parameter #

Sub index 5 ([5] 000) Parameter #

Sub index 6 ([6] 000) Parameter #

Sub index 7 ([7] 000) Parameter #

Sub index 8 ([8] 000) Parameter #

Function:

Different parameters can be assigned to PCD 1-7 of

the PA data (the number of PCDs depends on the

setting in parameter 807). The values in PCD 1-7 will

be written to the selected parameters as

data values.

Description of selections:

The order of the subindexes corresponds to the order

of the PCDs in the PQ + 2, i.e. subindex 1 ≈ PCD 3,

subindex 2 ≈ PCD 3 and so on. Each subindex can

hold the number of any of the VLT parameters.

Parameters

916 PCD config. read(PCD IN RD-)

Selections:

Sub index 1 ([1] 000) Parameter #

Sub index 2 ([2] 000) Parameter #

Sub index 3 ([3] 000) Parameter #

Sub index 4 ([4] 000) Parameter #

Sub index 5 ([5] 000) Parameter #

Sub index 6 ([6] 000) Parameter #

Sub index 7 ([7] 000) Parameter #

Sub index 8 ([8] 000) Parameter #

Function:

Different parameters can be assigned to PCD 1-7 of

the PPOs (the number of PCDs depends on the

PPO type). PCD 1-7 will hold the actual data value of

the selected parameters.

Description of selections:

The order of the subindexes corresponds to the order

of the PCDs in the PI + 2, i.e. subindex 1 ≈ PCD 3,

subindex 2 ≈ PCD 3 and so on. Each subindex can

hold the number of any of the VLT parameters.

927 Parameter edit

Selections:

Disabled [0]

✭ Enabled [1]

Function:

Editing parameters is possible via either INTERBUS

or the standard RS485 interface, but not both at the

same time. Parameter read is always possible via

the local control panel.

Description of selections:

- Disabled: Parameter edit via INTERBUS is

disabled. Parameter edit via standard RS485 is

possible.

- Enabled: Parameter edit via INTERBUS is

enabled. Parameter edit via standard RS485 port

is blocked

Page 28

MG.10.O1.02 VLT is a registered Danfoss trademark

28

VLT® 5000 INTERBUS

Parameters

928 Process control

Selections:

Disabled [0]

✭ Enabled [1]

Function:

Process control (setting of control word and speed

reference) is possible via either INTERBUS or the

standard RS485 interface, but not both at the same

time. Local control is always possible via the local

control panel. Control via control card terminals is

possible with either bus depending on the setting of

parameters 502-508.

Description of selections:

- Disabled: Process control via INTERBUS is

disabled. Process control via standard RS485 is

possible.

- Enabled: Process control via INTERBUS is

enabled. Process control via standard RS485 is

blocked.

The motor may start without notice when

parameter 928 is changed and start commands are

present.

953 Warning parameter 1 (WARN. PARA)

Selections:

Read only

No LCP access

Function:

A 16 bit bitstring where each bit is associated with a

specific warning according to the list below.

Bit = 0 when: Bit = 1 when:

0 Bus active Bus not Active

1 Not used

2 Not used

3 Not used

4 Actual value updated Actual value not

updated

5 Not used

6 Not used

7 No init error Init error

8 Remote bus OK Remote bus

disable

9 Not used

10 Not used

11 Not used

12 Internal SW error LSB

13 Internal SW error

14 Internal SW error

15 Internal SW error MSB

Bit 12-15 describes the Internal option error code.

971 Store data values (STORE DATA VALUE)

Selections:

✭ No action (NO ACTION) [0]

Store active setup (STORE ACTIVE SETUP) [1]

Store all setups (STORE ALL SETUPS) [2]

Store edit setup (STORE EDIT SETUP) [3]

Function:

Parameter values changed via INTERBUS are only

stored in RAM meaning that the changes are lost at

power down. This parameter is used to activate a

function that stores all parameter values in the

EEPROM thus retaining changed parameter values at

power down.

Description of selections:

No action: The store function is inactive.

Store active setup: All parameter values in the

active setup will be stored in the EEPROM. The

value returns to No action when all parameter

values have been stored.

Store all setups: All parameter values will be stored

in the EEPROM. The value returns to No action

when all parameter values have been stored.

Store edit setup: All parameter values in the setup

you are editing will be stored in the EEPROM. The

value returns to No action when all parameter

values have been stored.

980-982 Defined parameters (DEFINED PNU'S)

Selections:

Read only

Function:

These three parameters hold a list of all the

parameters that are defined in the VLT. Each of the

three parameters can be read as an array by means of

the PCP read service. It is also possible to read single

elements of the list by PCP Communication, by using

the corresponding subindex. The subindexes start at

1 and follow the order of the parameter numbers.

Page 29

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

29

Parameters

-

Each parameter holds up to 116 elements (parameter

numbers). The number of parameters (980, 981 and

982) in use depends on the actual VLT configuration.

When a 0 is returned as parameter number the list

ends.

990-992 Modified parameters

(MODIFIED PNU'S)

Selections:

Read only

Function:

The three parameters holds a list of all the VLT

parameters that have been changed from factory

setting. Each of the three parameters can be read

as an array by means of the acyclical PCP read

service. The subindexes start at 1 and follow the order

of the parameter numbers. Each parameter hold up to

116 elements (parameter numbers). The number of

parameters (990, 991 and 992) in use depends on

how many parameters have been changed from

factory setting.

Read only parameters, as for example data read out

parameters, will not be registered as modified

eventhough they are changing.

When a 0 is returned as parameter number the list

ends.

Page 30

MG.10.O1.02 VLT is a registered Danfoss trademark

30

VLT® 5000 INTERBUS

■■

■■

■ VLT response time

The update time via the INTERBUS connection can

be divided in two parts:

1) The communication time, which is the time it

takes to transmit data from the master to the slave

(VLT 5000 with INTERBUS option), and 2) the

internal update time, which is the time it takes to

transmit data between the VLT 5000 control card

and the INTERBUS option card.

Communication time (t

com

) depends on the type of

master in use, the total number of bytes transmitet to

all slaves and the total length of the INTERBUS Cable.

The internal update time (t

int

) depends on the type of

data in question as there are different channels for

the data transfer where time critical data e.g.

control word has highest priority. The internal update

time for the different types of data are stated below.

Update

Data time, t

int

Control word/Main reference 2 msec

Status word/Actual speed 2 msec

Parameter read via PCD-part 2 msec

Parameter write via PCD1-2 83 msec

Parameter write via PCD3-4 165 msec

Parameter write via PCD5-7 325 msec

Parameter read via PCP XXY msec

Parameter write via PCP YYX msec

Timing

■■

■■

■ System update time

The system update time is the time it takes to

update all the slaves in the network when using

cyclical communication.

Actual master station delay:

- The information must be supplied by the

manufacturer of the actual INTERBUS master.

Example:

- INTERBUS G4 master using 4 words of

Process Data and 1 Word of PCP Data to 12

Slaves on the INTERBUS. The total length of

the INTERBUS Cable is 250m.

Following Formula can be used for calculation the

Cycle-time:

tz = [15*(8+n) + 3*m] * t

Bit

+ tSW + 2*t

PH

where

n the register size

m the total number of stations

t

Bit

the Bit time = 2µ at 500 kBit/sec

tSW software time 0,34 ms for G3 Master

0,70 ms for G4 Master

t

PH

the delay of the medium,

for Cu = 0,016ms*l/Km; Lenght in Km

tz = [15*(8+n) + 3*m] * t

Bit

+ tSW + 2*t

PH

tz = [15*104 + 3*13] *2*10

-6

+ 0,7+

0,016 * 0,250

t

z

= 3.902 ms

VLT®5000

Control

Card

Interbus

option

Master

t

com

t

int

Page 31

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

31

■ Warning and alarm messages

There is a clear distinction between alarms and

warnings. In the case of an alarm, the VLT will enter

a fault condition and act as defined in the Control

Word. After the cause for the alarm has been

cleared, the master will have to acknowledge the

alarm message for the VLT to start operating again.

A warning, on the other hand may come when a

warning condition appears, and disappear when

conditions return to normal without interfering with

the process.

Warnings

Any warning within the VLT is represented by a

single bit within a warning word. A warning word is

always an action parameter. Bit status FALSE [0]

means no warning, while bit status TRUE [1] means

warning. To each bit and each bit status there is a

corresponding text string.

Any bit change in the warning word will result in a

Spontaneous / Event Notification being issued.

In addition to the warning word message the master

will also be notified through a change of bit 7 in the

Status Word.

Alarms

Following an Alarm message the VLT will enter Fault

condition. Only after the fault has been alleviated

and the master has acknowledged the alarm

message by setting bit 7 in the Control word, can the

VLT resume operation.

Any warning within the VLT is represented by a

single bit within a warning word. A warning word is

always an action parameter. Bit status FALSE [0]

means no fault, while bit status TRUE [1] means

fault. To each bit and each bit status there is a

corresponding text string.

Any bit change in the alarm word will result in a

Spontaneous / Event Notification being issued.

Since several alarms may be issued as a result of a

fault condition (e.g. Overcurrent inverter trip Current limit trip - Motor trip) it is important for

subsequent troubleshooting to store the alarm

messages in the sequence they occur. Parameter

615, 616 and 617 provide this service.

Warning and alarm messages

■■

■■

■ Additional display messages

When VLT

®

5000 is equipped with a INTERBUS

interface it can display the following messages in

addition to the display messages described in the

VLT 5000 product manual:

Warnings

WARN. 34

INTERBUS COMM. FAULT

- There is no connection to the master. The

reason could be that the master is stopped (or

in a fault condition) or the INTERBUS

connection to the VLT is interrupted.

Alarms

ALARM

INTERBUS OPT. FAULT

- The option card is disturbed by electrical noise

or there is a fault on the option card and it

must bereplaced.

Page 32

MG.10.O1.02 VLT is a registered Danfoss trademark

32

VLT® 5000 INTERBUS

■ Abbriviations.

English German Elaboration Page

CTW STW Control Word

EIA - Electronic Industries Association: Specifiers of the EIA Standard RS 485-A

EMC EMV Electromagnetic Compatibility

FIFO - First In First Out

Hd - Hamming distance

HPFB - High Performance Field Bus

IND - Subindex

I/O E/A Input/Output

ISO - International Standards Organization

LSB - Least Significant Bit

MSB - Most Significant Bit

MAV HIW Main Actual Value

MRV HSW Main Reference Value

OD OV Object Directory

PI PE Peripherial input

PQ PA Peripherial output

PC - Personal Computer

PCD PZD Process Data

PCP Peripherials Communication Protocol

PDU - Protocol Data Unit

PLC SPS Programmable Logic Control

STW ZSW Status Word 32

TRT - Target Rotation Time 49

VDE - Association of German Electrical Technicians 4

VDI - Association of German Electrical Engineers 4

VSD FU Variable Speed Drive 18

Abreviations

Page 33

VLT® 5000 INTERBUS

MG.10.O1.02 VLT is a registered Danfoss trademark

33

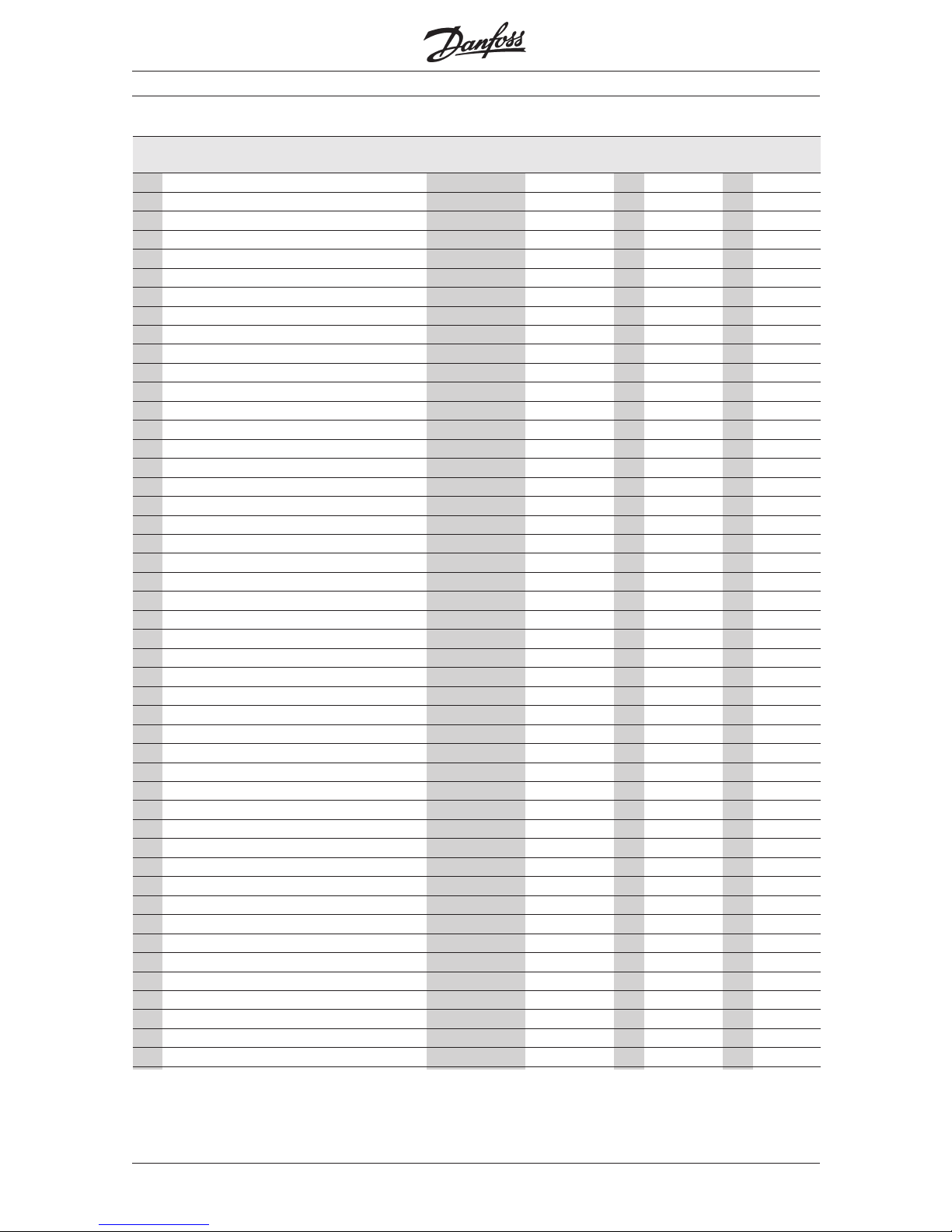

VLT5000 parameter list

■ VLT5000 parameter list.

The parameters setting in this list are valid for VLT

software version 3.22.

Conversion

index

Data

type

PNU Parameter Factory setting Range Changes 4-Setup

# description during operation

001 Language English Yes No 0 5

002 Local/remote control Remote control Yes Yes 0 5

003 Local reference 000.000 Yes Yes -3 4

004 Active setup Setup 1 Yes No 0 5

005 Programming setup Active setup Yes No 0 5

006 Copying of setups No copying No N o 0 5

007 LCP copy No copying No No 0 5

008 Display scaling of motor frequency 1 0.01 - 100.00 Yes Yes -2 6

009 Display linie 2 Frequency [Hz] Yes Yes 0 5

010 Display line 1.1 Reference [%] Yes Yes 0 5

011 Display line 1.2 Motor current [A] Yes Yes 0 5

012 Display line 1.3 Power [kW] Yes Yes 0 5

013 Local control/configura LCP digital control/as par.100 Yes Yes 0 5

014 Local stop Possible Yes Yes 0 5

015 Local jog Not possible Yes Yes 0 5

016 Local reversing Not possible Yes Yes 0 5

017 Local reset of trip Possible Yes Yes 0 5

018 Lock for data change Not locked Yes Yes 0 5

019 Operating state at Forced stop, use saved ref. Yes Yes 0 5

power-up, local control

100 Configuration Speed control, open loop No Yes 0 5

101 Torque characteristics High - constant torque Yes Yes 0 5

102 Motor power Depends on the unit 0.18-500 kW No Yes 1 6