Page 1

Operating Instructions

Positioning Controller

VLT® 5000

VLT® 5000 FLUX

Page 2

Positioning Controller

Table of contents

Safety regulations _______________________________________________________________ 3

Introduction____________________________________________________________________ 4

Hardware ........................................................................................................................................................................ 5

VLT control card terminals.........................................................................................................................................5

Technical data............................................................................................................................................................. 5

Option card terminals..................................................................................................................................................5

Supply voltages........................................................................................................................................................... 6

Encoder monitor.........................................................................................................................................................7

Option card layout......................................................................................................................................................8

Technical Data.............................................................................................................................................................. 10

Description of the electrical and field bus interface ___________________________________ 12

Electrical interface VLT ...............................................................................................................................................12

Option card MK3A................................................................................................................................................... 14

Option card MK3C................................................................................................................................................... 15

Option card MK3B (secondary position feedback for absolute encoders when using VLT 5000 Flux)................... 15

Option card MK3D (primary position feedback)......................................................................................................16

Field bus interface.........................................................................................................................................................17

Data layout................................................................................................................................................................ 17

Description of the available parameters_____________________________________________ 20

Special LCP functions...................................................................................................................................................20

Description of parameters............................................................................................................................................. 21

An application example!_________________________________________________________ 35

Wiring diagram............................................................................................................................................................. 36

Basic set-up................................................................................................................................................................... 36

Parameter settings.........................................................................................................................................................38

Troubleshooting _______________________________________________________________ 41

Frequently asked questions........................................................................................................................................... 41

Appendix _____________________________________________________________________ 44

Binary selection of reference positions using digital control........................................................................................ 44

Binary selection of reference positions using fieldbus control...................................................................................... 44

Glossary of key terms ................................................................................................................................................... 46

Index............................................................................................................................................................................. 48

MG.50.P3.02 - VLT is a registered Danfoss trademark 1

Page 3

Positioning Controller

Positioning Controller for

VLT 5000 and VLT 5000Flux

Software Version 2.1X

Software Version number: See Parameter 779.

2 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 4

Positioning Controller

The voltage of the frequency converter is dangerous whenever the equipment is

connected to mains. Incorrect installation of the motor or the frequency converter may

cause damage to the equipment, serious personal injury or death. Consequently, the

instructions in this manual, as well as national and local rules and safety regulations, must

be complied with.

Safety regulations

1. The VLT frequency converter must be disconnected from mains if repair work is to be carried out.

Check that the mains supply has been disconnected and that the necessary time has passed before

removing motor and mains plugs.

2. The [STOP/RESET] key on the control panel of the frequency converter does not disconnect the

equipment from mains and is thus not to be used as a safety switch.

3. Correct protective earthing of the equipment must be established, the user must be protected against

supply voltage, and the motor must be protected against overload in accordance with applicable national

and local regulations.

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is not included in the factory setting. If this function is desired, set

parameter 128 to data value ETR trip or data value ETR warning.

Note:

For the North American market: The ETR functions provide class 20 motor overload protection in

6. Do not

7. Please note that the frequency converter has more voltage inputs than L1, L2 and L3, when load sharing

1. The motor can be brought to a stop by means of digital commands, bus commands, references or a

2. While parameters are being changed, the motor may start. Consequently, the stop key

3. A motor that has been stopped may start if faults occur in the electronics of the VLT frequency

The function is initialized at 1.16 x rated motor current and rated motor frequency.

accordance with NEC.

remove the plugs for the motor and mains supply while the frequency converter is connected to

mains. Check that the mains supply has been disconnected and that the necessary time has passed

before removing motor and mains plugs.

(linking of DC intermediate circuit) and external 24 V DC have been installed.

Check that all voltage inputs have been disconnected and that the necessary time has passed before

repair work is commenced.

Warning against unintended start

local stop, while the frequency converter is connected to mains.

If personal safety considerations make it necessary to ensure that no unintended start occurs, these

stop functions are not sufficient.

must always be activated, following which data can be modified.

converter, or if a temporary overload or a fault in the supply mains or the motor connection ceases.

[STOP/RESET]

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, such as external 24 V DC, load sharing

(linkage of DC intermediate circuit), as well as the motor connection for kinetic back-up.

Using VLT 5001-5006 220 and 500 V units: wait at least 4 minutes

Using VLT 5008-5500 220 and 500 V units: wait at least 15 minutes

Using VLT 5001-5005 550-600 V units: wait at least 4 minutes

Using VLT 5006-5022 550-600 V units: wait at least 15 minutes

Using VLT 5027-5250 550-600 V units: wait at least 30 minutes

MG.50.P3.02 - VLT is a registered Danfoss trademark 3

Page 5

Positioning Controller

Introduction

The Positioning Controller is an application option for the VLT 5000 and VLT 5000 Flux Series. It is

based on the SyncPos option card.

The positioning controller can be used in a wide range of applications where a frequency converter is

used for positioning. The controller holds information of up to 32 (64 in field bus mode) fixed positions.

Relative positions can be added to each other by triggering a new relative positioning command when

the controller is already executing a relative positioning command.

Full field bus support is now included meaning starting and stopping etc can be done via bus.

In field bus mode a “quickbus” mode is introduced to enable writing a target position directly. Hence an

unlimited number of positions can be reached.

Positions are defined either relative to a fixed home position (absolute positions) or relative to other

positions, or relative to a movable “touch probe” sensor.

An advanced mechanical brake controller is included. It is strongly advised to use this brake function

as suppose to the VLT mechanical brake handler.

If absolute encoders must be used for positioning feedback in conjunction with VLT 5000 Flux this is

now possible. Encoder input MK 3B can be programmed as option feedback input allowing the

feedback encoder input MK 3D to be used for VLT 5000 Flux.

The encoder(s) connected can now hardware wise be monitored for open or short-circuits.

Last but not least VLT manual run mode is introduced. It is selected via parameter 711.

This manual consists of the following parts:

Hardware

Description of the electrical interface

Description of the available parameters

An application example!

Troubleshooting

Appendix

4 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 6

Positioning Controller

Hardware

VLT control card terminals

The terminals on the control card are allocated for positioning controller functions the following

parameter settings should therefore not be changed in positioning mode (set-up 1):

Digital inputs 16, 17, 18, 19, 27, 29, 32 and 33

Parameters 300–303 and 305–307 are set to ”No operation” (default setting), then the inputs are

ignored by the control card but used as inputs to the positioning controller.

Analogue inputs 53, 54 and 60

Parameters 308, 311 and 314 are set to ”No operation”, then the inputs are ignored by the control card

but used as inputs to the positioning controller.

Digital/analogue outputs 42 and 45 (VLT 5000)

Parameters 319 and 321 are set to:

OPTION 0 … 20 mA [91] analogue output

(default setting)

Digital outputs 26 and 46 - Analogue outputs 42 and 45(VLT 5000 Flux)

Parameters 319 and 321 are set to:

OPTION 0 … 20 mA [90] analogue output

(default setting)

Parameters 341 and 355 are set to:

OPTION digital [90] digital output

(default setting)

Technical data

Technical data on the control card terminals can be found in the VLT 5000 design guide.

Option card terminals

There are two encoder interfaces, which are covering the following functions:

• Primary Feedback encoder input

• Secondary encoder input

There are 8 digital inputs, 8 digital output and terminals for 5 V and 24 V supply. The functions and

technical data of the terminals are described in the following.

Terminal A1

Incremental input A in in A B in in B Z in in Z

Absolute input Clk out out Clk Data in inData Not used Not used

Fig. 1

Terminal A2

Incremental input A in in A B in in B Z in in Z

Absolute input Clk out out Clk Data in inData Not used Not used

Fig. 2

A1 B1 B1 Z1 Z1

A2 B2 B1 Z2 Z2

MG.50.P3.02 - VLT is a registered Danfoss trademark 5

Page 7

Positioning Controller

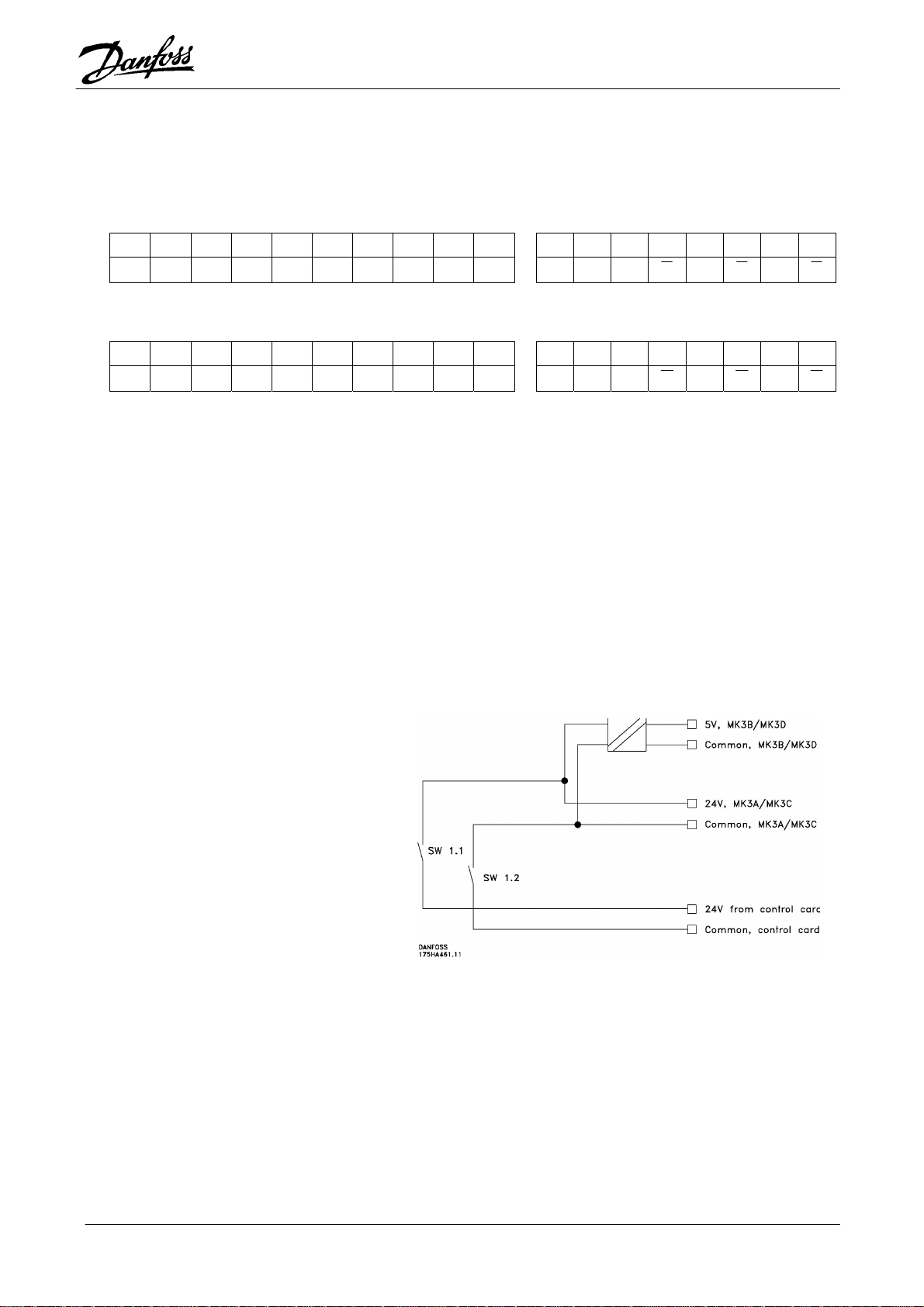

Terminal description

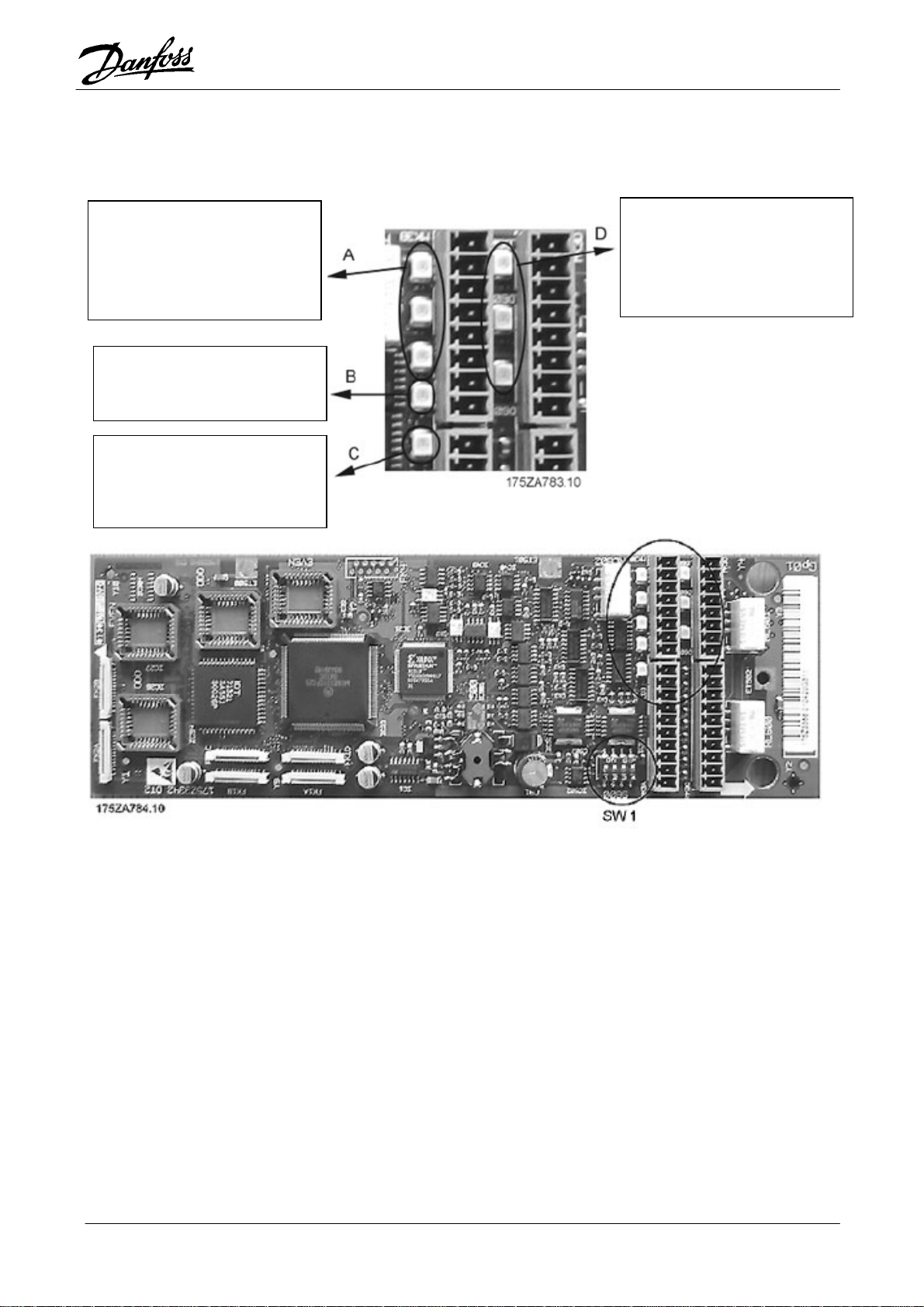

There are 4 terminal blocks, 2 with 10 poles and 2 with 8 poles. (See figure below)

MK3A Digital Inputs

MK3B Secondary feedback

I1 I2 I3 I4 I5 I6 I7 I8 24V

COM 5V COM A1

A1

B1

B1

MK3C Digital Outputs

MK3D Primary feedback

O1 O2 O3 O4 O5 O6 O7 O8 24V COM 5V COM A2

A2

B2

B2

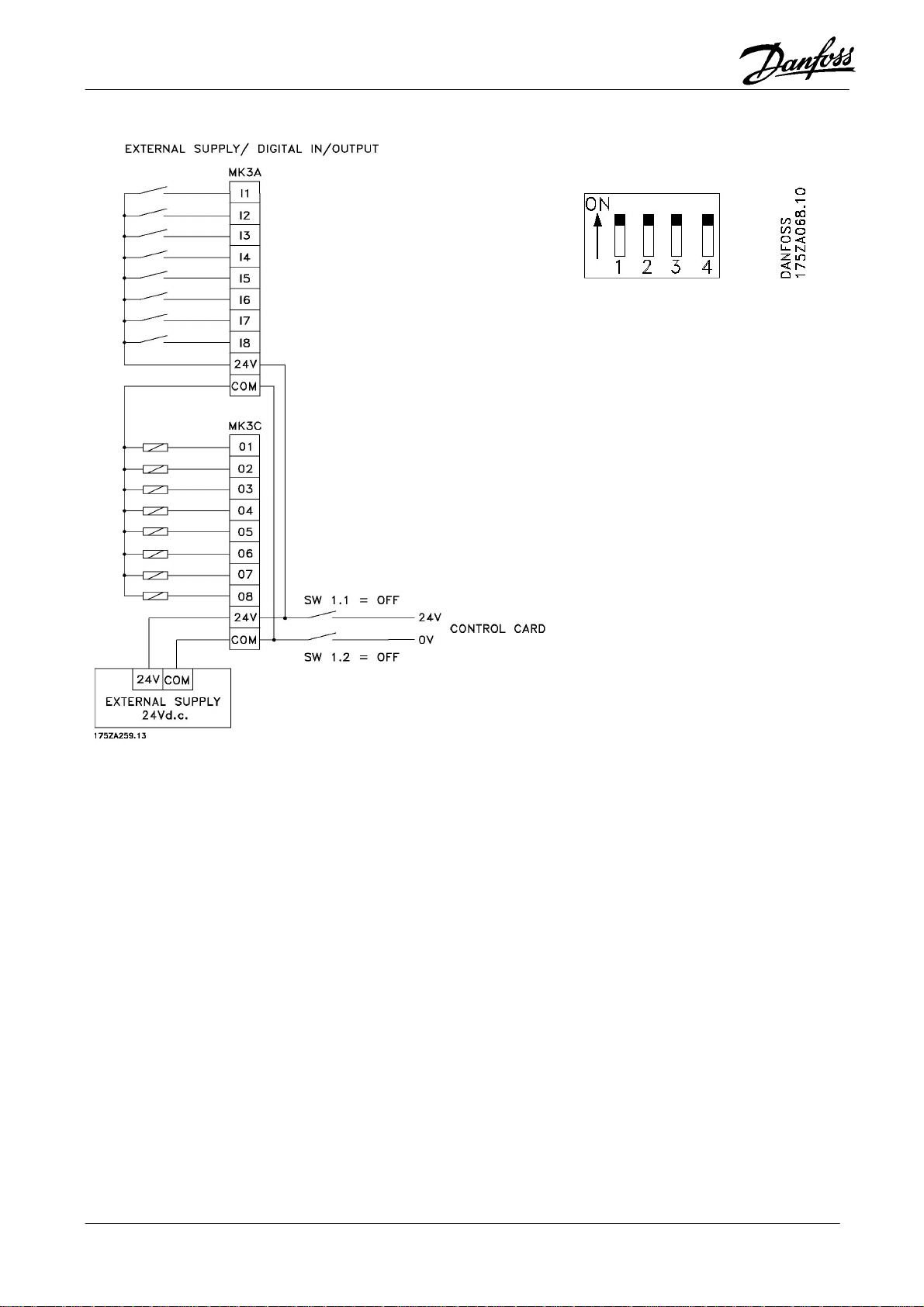

Supply voltages

The option card is supplied by the internal 24 V DC supply of VLT 5000, but as the available power is

limited it can be necessary to use an external 24 V DC supply.

The 24 V DC supply of VLT 5000 can supply a total of 420 mA including the load on the control card

(terminal 12, 13 and output 42 and 45 + 26 and 46 for VLT 5000 Flux).

The 5 V output on the option card is generated from the 24 V supply. The maximum power on the 5 V

side is 5 V * 280 mA = 1.4 W, this corresponds to app. 60 mA on the 24 V side.

When an external 24 V DC voltage source is used the internal 24 V supply from the control card must

be disconnected, this is done by opening switch 1.1 and 1.2

Each digital input on the option card takes 8 mA. Each digital output on the option card can supply up

to 0.7 A (external 24V-supply) depending on the load. The load from the 24 V supply (internal or

external) can be calculated as follows:

8 mA * number of digital inputs

+

Load on digital outputs

(mk3 C, O1 – O8)

+

load on 5 V supply

(mk3 B/D, 5 V/com)

+

Load on control card

(24 V supply, terminal 12/13 and

outputs, terminal 42/45, 26/46)

Z1

Z2

Z1

Z2

6 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 8

Positioning Controller

Encoder monitor

Both encoder interfaces are equipped with a monitoring circuit that can detect open circuit as well as

short circuit of each encoder channel. Each encoder channel has a LED showing the status: Green

light means ok, no light means fault.

Zero channel monitoring can be switched off by means of switch 1.4, this is necessary when using

incremental encoders without Zero channel or absolute encoders. Switch 1.4 disables monitoring of

both Zero channels. If disabling of only one of the two Zero channels is required (e.g. when using

incremental Flux feedback encoder and absolute option feedback encoder) the unused Zero channel

input must be connected to 5V/common as shown below.

An encoder fault will only result in an ”Option error” 92 if encoder monitoring is activated via parameter

713.

Note: Monitoring of the secondary feedback encoder is disabled when switch 1.3 is ”OFF”.

MG.50.P3.02 - VLT is a registered Danfoss trademark 7

Page 9

y

Positioning Controller

Option card layout

Option card layout showing the position of connectors and dip switch.

Encoder monitor secondary

input,

channel A, B and Z:

LED off = Short or open circuit

LED green = Ok.

5V monitor:

LED off = no 5V

LED Green = 5V ok.

CPU monitor:

LED must flash at 1 Hz to

indicate a running CPU

s

stem

Encoder monitor primary

input,

channel A, B and Z:

LED off = Short or open circuit

LED green = Ok

.

SW 1.1: Connect(ON)/disconnect(OFF) 24 V from control card (see description of supply voltages).

SW 1.2: Connect(ON)/disconnect(OFF) 24 V common from control card.

SW 1.3: Connect(ON)/disconnect(OFF) termination resistor for secondary encoder.

Note: When OFF the secondary encoder monitor is disabled.

SW 1.4: Switch Z-channel encoder monitor ON/OFF for both encoder inputs.

Default setting of switch 1.1. - 1.4 is ON.

8 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 10

Positioning Controller

MG.50.P3.02 - VLT is a registered Danfoss trademark 9

Page 11

Positioning Controller

Technical Data

Terminals:

Type..............................................................................................................Plugs with screw connections

Maximum cable size......................................................................................................1.3 mm

Digital inputs, MK3A:

Terminal designations .......................................................................................................................I1 – I8

Voltage level............................................................................................0 – 24 V DC (PNP positive logic)

Voltage threshold logical “0”............................................................................................................5 V DC

Voltage threshold logical “1”..........................................................................................................10 V DC

Maximum voltage .......................................................................................................................... 28 V DC

Input impedance..................................................................................................................................4 kΩ

Min. pulse duration (ON INT)...........................................................................................................1 msec

Galvanic isolation: All digital inputs are galvanically isolated by means of optocouplers,

but with the same common as the digital outputs.

Digital outputs, MK3C:

Terminal designations ...................................................................................................................O1 – O8

Voltage level............................................................................................................................0 – 24 V DC

Maximum load ........................................................................................0.7A (with external power supply)

Update rate......................................................................................................................................1 msec

Galvanic isolation: All digital outputs are galvanically isolated by means of optocouplers,

but with the same common as the digital inputs.

External 24 V DC supply:

(see VLT 5000 manual)

Encoder input 1, MK3B (secondary):

Terminal designations ..........................................................................................A1, A1, B1, B1, Z1, Z1.

Incremental:

Signal level ...........................................................................................................................5 V differential

Signal type.....................................................................................................................Linedriver, RS 422

Input impedance.............................................................................................120 Ω (Dip switch 1.3 = ON)

...................................................................................................................> 24 kΩ (Dip switch 1.3 = OFF)

Maximum frequency......................................................................................220 kHz (at 50 % duty cycle)

Phase displacement between A and B..........................................................................................90° ±30°

Absolute:

Signal level ...........................................................................................................................5 V differential

Signal type.............................................................................................................................................SSI

Data coding ................................................................................................................................ Gray code

Data length .........................................................................................................................................25 bit

Parity....................................................................................................................................................none

Clock frequency.................................................................................................................. 105 or 260 kHz

Protocol ...............................................................................................................................................Gray

Maximum positions per revolution.......................................................................................................8192

Maximum number of revolutions.........................................................................................................4096

2

(AWG 16)

10 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 12

Positioning Controller

Encoder input 2, MK3D (primary)

Terminal designations .........................................................................................A2, A2, B2, B2 , Z2, Z2

Incremental:

Signal level ...........................................................................................................................5 V differential

Signal type......................................................................................................................Linedriver, RS422

Input impedance................................................................................................................................120 Ω

Maximum frequency......................................................................................220 kHz (at 50 % duty cycle)

Phase displacement between A and B..........................................................................................90° ±30°

Absolute:

Signal level ...........................................................................................................................5 V differential

Signal type.............................................................................................................................................SSI

Protocol ......................................................................................................................................Gray code

Data length .........................................................................................................................................25 bit

Parity....................................................................................................................................................none

Clock frequency.................................................................................................................. 105 or 260 kHz

Maximum positions per revolution.......................................................................................................8192

Maximum number of revolutions.........................................................................................................4096

Encoder cable:

Cable type...Twisted pair and screened. Note: Please observe the prescriptions of the encoder supplier

Cable length.................................................................Observe the prescriptions of the encoder supplier.

Absolute encoder is tested ok up to 150 meter cable at 105 kHz clock and 100 m at 260 kHz clock.

(Tested with TR electronic encoder type CE-65 M 8192*4096 and appropriate cable prescribed by TR

electronic.)

Maximum allowed time delay between clock and data signal measured at the controller terminals...........

................................................................................................................................ 105 kHz clock = 9µsec

............................................................................................................................ 260 kHz clock = 3.5 µsec

MG.50.P3.02 - VLT is a registered Danfoss trademark 11

Page 13

Positioning Controller

Description of the electrical and field bus interface

Electrical interface VLT

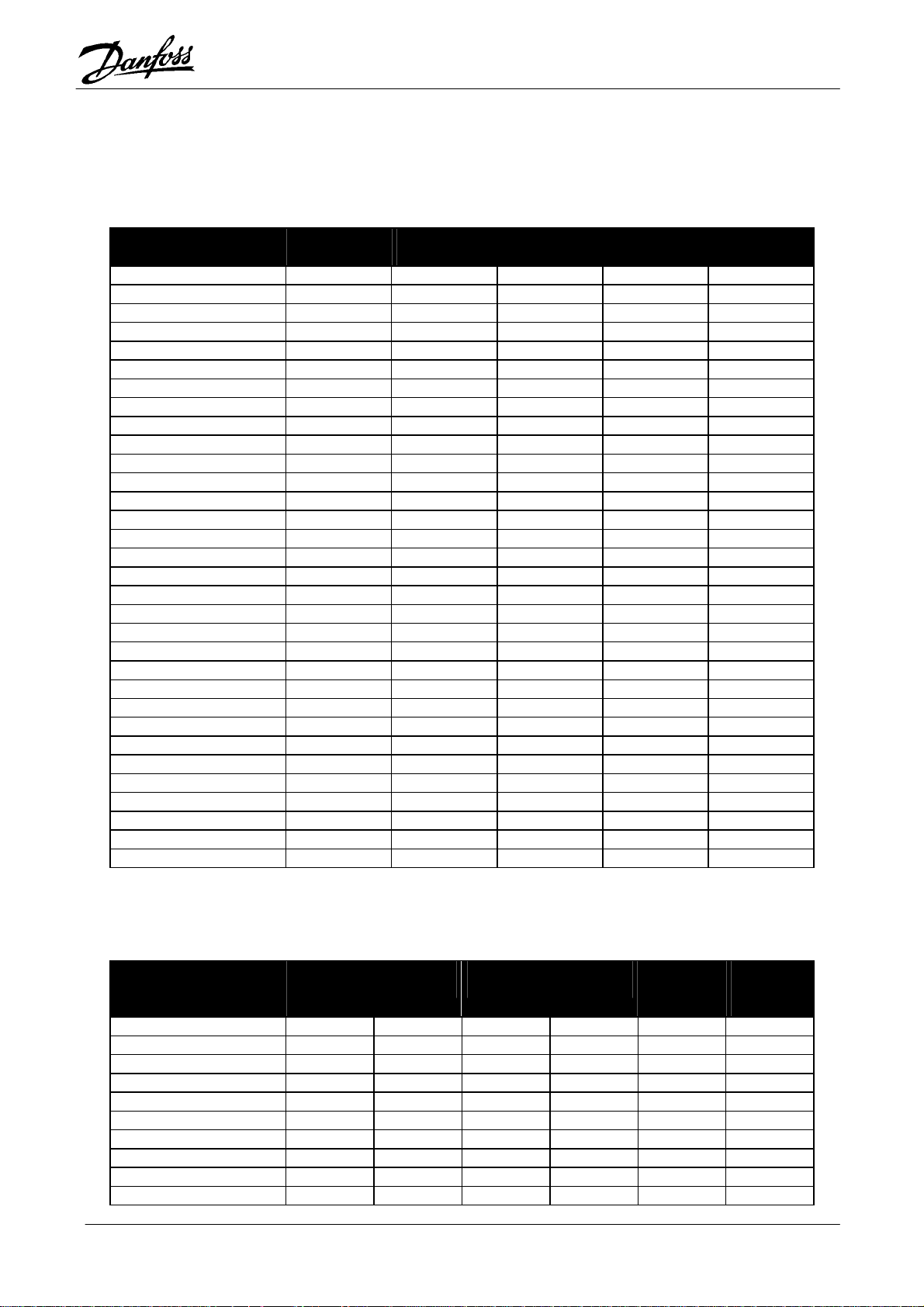

Terminal Designation Description

12 24V DC

13 24V DC

16 Reference index Bit 0

(LSB)

17 Reference index Bit 1

18 Reference index Bit 2

19 Reference index Bit 3

20 GND

27 Reset / ENABLE (error

clear)

29 Reference index Bit 4

(MSB)

24V power supply for switches etc. maximum load 200 mA

24V power supply for switches etc. maximum load 200 mA

Reference position index number bit 0 (least significant bit).

Not used in field bus mode.

Reference position index number bit 1.

Not used in field bus mode.

Reference position index number bit 2.

Not used in field bus mode.

Reference position index number bit 3.

Not used in field bus mode.

Ground for 24V is normally bridged with Terminal 39, but can be

set to “OFF” by means of Switch SW 4 on the control card.

Errors are cleared on the rising edge (must be “0” min. 1 ms. to

guarantee edge detection). Not used in field bus mode.

To enable operation, this input must be maintained at “1” in

either digital control mode or field bus control mode.

Reference position index number bit 4 (most significant bit).

Not used in field bus mode.

32 Go to HOME position

33 LATCH new reference

position index number

While this input is high the drive executes the homing sequence.

While this input is high no position or jog operations are carried

out. Any homing sequence is interrupted by a low state on this

input.

Not used in field bus mode.

Active on the rising edge (must be “0” min. 1 ms. to guarantee

edge detection):

Latches reference position index number specified on terminal

16, 17, 18, 19, 29 into memory. Digital output MK3C 4 – 8 is

changed to mirror the new reference index specified when using

digital input control.

Not used in field bus mode.

12 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 14

Positioning Controller

Terminal Designation Description

01 COM; 240V AC/2A

02 Connect to electro

mechanical brake

NO

03 NC

04 COM; 50V AC/1A; 75V

DC/1A

05 Brake activated

NC

26 Touch probe position

locked in (VLT 5000

Flux only)

Common terminal for Relay 01-03.

Normal Open

Relay 01-03 is open (brake activated) during power off, and

start-up of the VLT 5000. It is always open after a “Quick Stop”

procedure or in connection with an error situation. Relay 01-03

only closes in connection with motion procedures or if specified

in P715.

Normal Closed

Common terminal for Relay 04-05.

Normal Closed

Relay 04-05 is closed to indicate an activated electromechanical

brake. It is open to indicate a deactivated electromechanical

brake.

Not used in field bus control mode.

A high “1” signal is present when a rising edge has been

detected on digital input 1 (terminal MK3A) and a target position

is fixed in memory.

A low signal is present when no target position has yet been

determined.

39 GND

42 Touch probe position

locked in (VLT 5000

Process only)

45 Watchdog output in

(VLT 5000 Process

only)

46 Watchdog output in

(VLT 5000 Flux only)

50 10V DC 17mA

53

± 10V-In

Manual jog positive

Not used in field bus mode.

Ground for analogue inputs/outputs is normally bridged with

Terminal 20, but can be set to “OFF” by means of Switch SW 4

on the control card.

A high “1” signal is present when a rising edge has been

detected on digital input 1 (terminal MK3A) and a target position

is fixed in memory.

A low signal is present when no target position has yet been

determined.

Not used in field bus mode.

This output toggles continually as long as the program is active.

This output toggles continually as long as the program is active.

Power supply for manual JOG inputs (terminal 53 and 54)

When high (above 5V), the drive will travel with jogging speed

(P723) and ramp (P724) in the positive direction.

When low (below 5V), the drive will ramp down and stop if no

other motion procedure is activated.

Jog positive has higher priority than Jog negative

Not used in field bus mode.

MG.50.P3.02 - VLT is a registered Danfoss trademark 13

Page 15

Terminal Designation Description

Positioning Controller

54

60

± 10V-In

Manual jog negative

± 20mA-In

When high (above 5V), the drive will travel with jogging speed

(P723) and ramp (P724) in the negative direction. When low

(below 5V), the drive will ramp down and stop if no other motion

procedure is activated.

Not used in field bus mode.

Not used

Option card MK3A

Terminal Designation Description

1 Touch probe switch

input

2 Positive HW limit

switch input

3 Negative HW limit

switch input

4 HOME reference

switch input

Interrupt triggered on the rising edge. If this signal goes high

when no touch probe target position is currently locked (VLT 5000

Process: terminal 42 low, VLT 5000 Flux: terminal 26 low), a new

touch probe target position is calculated and locked in memory.

Interrupt triggered on the falling edge. Triggers a HW limit error

and the drive is stopped according to P725.

Interrupt triggered on the falling edge. Triggers a HW limit error

and the drive is stopped according to P725.

Active high. Marks the HOME position in the application.

5 Go to the referenced

target position

6 Reset home flag

7 Reset touch probe

position

8 Quick stop

9 24V DC

10 COM

Active high. Upon activation the drive goes to the specified target

position. A low signal interrupts any positioning sequence.

Not used in field bus mode.

Active high. This input clears the home flag. This allows the user

to perform a second homing sequence.

Not used in field bus mode.

Active high. This input clears the touch probe position flag. The

reset is necessary to carry out a touch probe positioning

command to a new target position.

Not used in field bus mode.

Active low. This input activates the Quick Stop function. The drive

is stopped according to the setting of P725. After that the

electromechanical brake is always activated when the “Quick

stop” input is activated regardless of the P715 setting.

14 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 16

Option card MK3C

Positioning Controller

1 Homing completed

2 Referenced position

reached

3 Error occurred

4 Reference index bit 0

5 Reference index bit 1

6 Reference index bit 2

7 Reference index bit 3

8 Reference index bit 4

Active high. This output is always high if an absolute encoder is

specified in P713

Active high. This output is set when the target position is reached

according to the setting of P746.

Active high. This output is set every time an error occurs. It is

cleared every time a successful error clear is carried out. This

output will remain high as long as the Power recovery function is

selected (P736) and active.

Active high. Mirror of the currently locked-in reference index bit 0.

Not used in field bus mode.

Active high. Mirror of the currently locked-in reference index bit 1.

Not used in field bus mode.

Active high. Mirror of the currently locked-in reference index bit 2.

Not used in field bus mode.

Active high. Mirror of the currently locked-in reference index bit 3.

Not used in field bus mode.

Active high. Mirror of the currently locked-in reference index bit 4.

Not used in field bus mode.

9 24V DC

10 COM

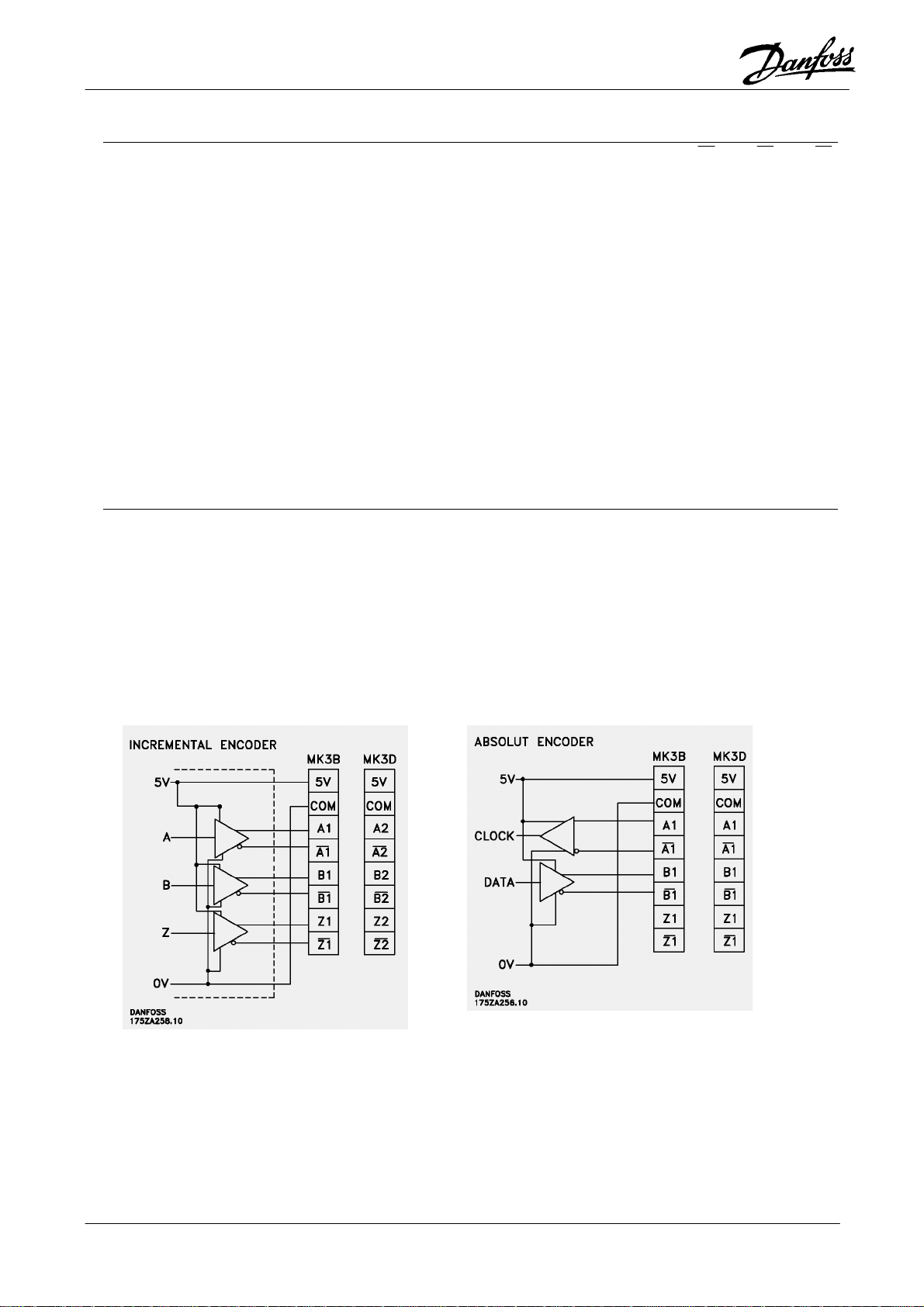

Option card MK3B (secondary position feedback for absolute encoders when using VLT 5000 Flux)

1

2

3

4

5

6

7

8

5V DC

COM

A1

/A1

B1

/B1

Z1

/Z1

Encoder supply

Encoder supply

Incremental encoder Absolute encoder

A-track Clock out

A-track inverted Clock out inverted

B-track Data in

B-track inverted Data in inverted

Zero-track Not used

Zero-track inverted Not used

MG.50.P3.02 - VLT is a registered Danfoss trademark 15

Page 17

Positioning Controller

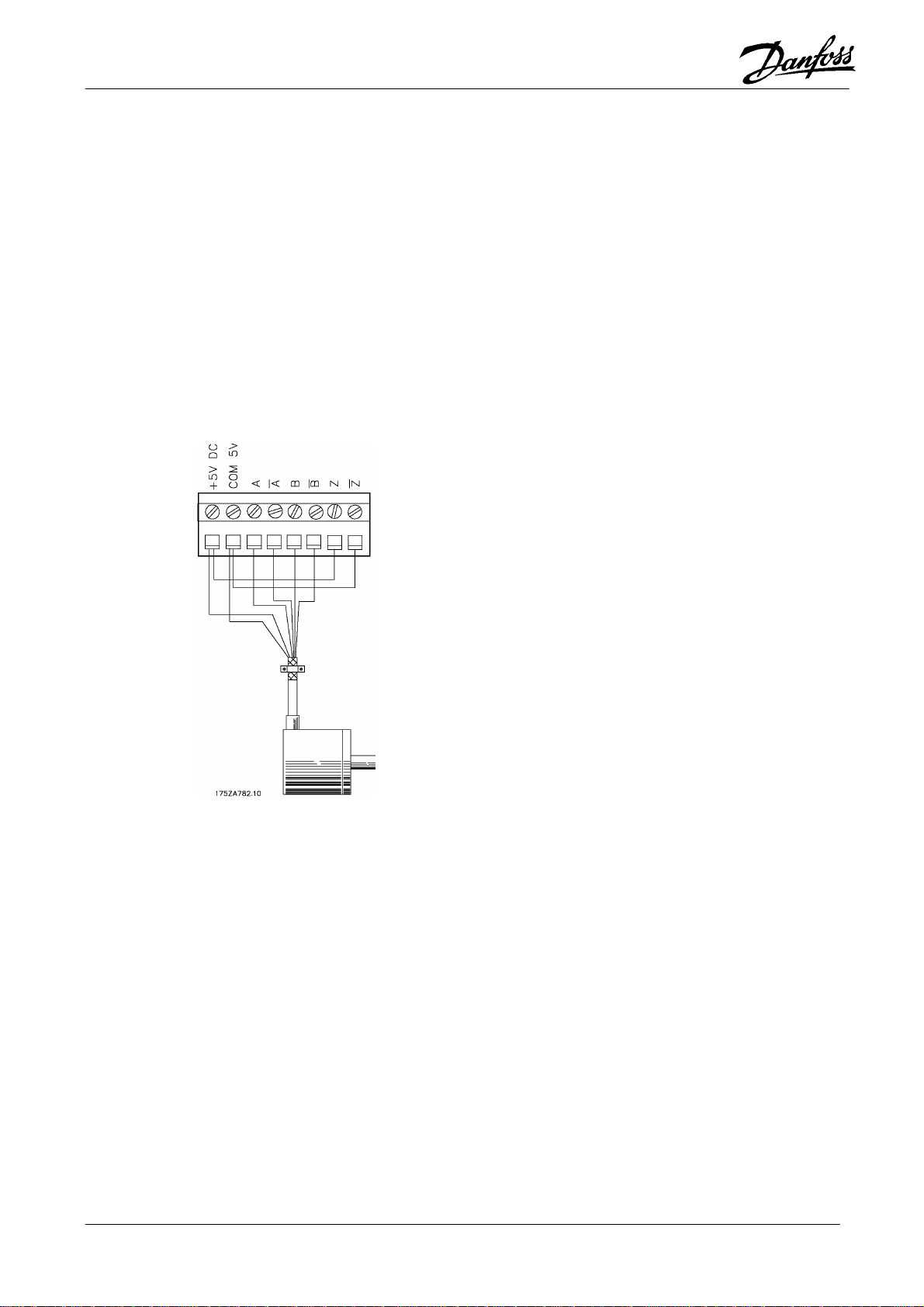

Option card MK3D (primary position feedback)

1

2

3

4

5

6

7

8

5V DC

COM

A1

/A1

B1

/B1

Z1

/Z1

Encoder supply

Encoder supply

Incremental encoder Absolute encoder

A-track Clock out

A-track inverted Clock out inverted

B-track Data in

B-track inverted Data in inverted

Zero-track Not used

Zero-track inverted Not used

Fig.: Encoder connection for positioning applications

16 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 18

Positioning Controller

Field bus interface

NOTE: This section is only relevant if the VLT is equipped with a Field bus interface (option) as well as

the Positioning controller.

The Positioning controller can be controlled via the digital/analogue inputs or via field bus. The control

source can be selected in parameter 749. There can only be one control source at a time meaning that

the digital/analogue inputs are inactive when Field bus is selected as control source and visa versa. The

only exceptions are listed in the digital interface section.

In field bus mode it is possible to specify only the target position and velocity. If the acceleration and

deceleration PCDs are left blank then the last used acceleration and deceleration chosen via an index is

used. This enables the use of PPO type 4

Data layout

Control and status signals are transferred via the so-called process data channel (PCD) of the various

field bus interfaces. The telegram structure and the available number of data words depends on the

Field bus used, please refer to the manual of the Field bus option in use for further details. The below

example is based on the layout of a PROFIBUS telegram, the so-called PPO:

Example using PROFIBUS PPO type 5:

Field bus control signals:

Field bus

[word.bit]

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

Go to home / Stop positioning (↑) / Go to position (↓)

Field bus mode Corresponding input

Quick bus go to target(↑)

Reset error (↑)

Read new trajectory index (↑)

Automatic (↑) / manual (↓) mode

Reset home status (↑)

Reset touch probe position (↑)

Quick stop (↓)

Positive jog (↑)

N\A

27

32

33

5

6

7

8

53

1.10

MG.50.P3.02 - VLT is a registered Danfoss trademark 17

Negative jog (↑)

54

Page 19

Positioning Controller

Field bus

[word.bit]

1.11

1.12

1.13

1.14

1.15

1.16

2

3

4

5

Field bus mode Corresponding input

Quick Bus Type Absolute (↑)

Quick Bus Type Relative (↑)

Quick Bus Type Touch Probe positive (↑)

Quick Bus Type Touch Probe negative (↑)

Teach in(via LCP or fieldbus) (↑)

Change sign on Quick Bus Target Position (↑)

Quick Bus Target Position(MSB) N\A

Quick Bus Target Position(LSB) N\A

Quick Bus Target Velocity N\A

Quick Bus Target Acceleration N\A

N\A

N\A

N\A

N\A

KEYPAD “JOG” &

“FWD\REW”

N\A

6

7.1

7.2

7.3

7.4

7.5

7.6

Quick Bus Target Deceleration N\A

Reference index bit 0 (LSB) (↑)

Reference index bit 1 (↑)

Reference index bit 2 (↑)

Reference index bit 3 (↑)

Reference index bit 4 (Digital MSB) (↑)

Reference index bit 5 (Fieldbus MSB) (↑)

16

17

18

19

29

N\A

18 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 20

Field bus status signals:

Positioning Controller

Field bus

[word.bit]

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.1

2.2

Field bus mode Corresponding

output / parameter

Homing done (↑)

Referenced position reached (↑)

Error occurred (↑)

Electro-mechanical brake output (↑)

Touch probe position locked (↑)

Watchdog output (toggling) 45(46 Flux)

Positive hardware limit (↑)

Negative hardware limit(↑)

Current index bit 0 (LSB) (↑)

Current index bit 1 (↑)

42(26 Flux)

1

2

3

04

N\A

N\A

4

5

2.3

2.4

2.5

2.6

3

4

5

Current index bit 4 (Digital MSB) (↑)

Current index bit 5 (Fieldbus MSB) (↑)

Current index bit 2 (↑)

Current index bit 3 (↑)

Actual Position (MSB) 795 (MSB)

Actual Position (LSB) 795 (LSB)

Error Status 798

6

7

8

N\A

MG.50.P3.02 - VLT is a registered Danfoss trademark 19

Page 21

p

Positioning Controller

Description of the available parameters

Special LCP functions

Multiple parameters display: To have multiple read-only parameters displayed at once on the LCP simply

press the [DISPLAY/STATUS] button after start-up. This will prompt the top line of the LCP to display up

to three read-only parameters that can be specified in P010, P011, and P012. The default settings will

bring up the following display:

Figure text: To the left: P798 –

the error status. In the middle:

P797 - the PID tracking error.

To the right: P795 – the actual

osition.

Holding down the [DISPLAY/STATUS] button will display which parameters are shown in the top line of

the display.

The TEACH-IN function: Pressing the [JOG] and [FWD./REV.] buttons at the same time will cause the

target position P739 to be updated with the actual position. This provides an easy way of programming

several positions. Simply jog to the desired position, then press the [JOG] and [FWD./REV.] buttons to

store that position in memory.

20 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 22

Description of parameters

Positioning Controller

No. Parameter Default

value

701 Operating mode

POSITIONING

MODE

702 Proportional gain

PROP. GAIN

703 Derivative gain

DER. GAIN

1 1 = POSITIONING This parameter never needs changing.

30 1 … 65,000 The proportional gain is the factor that is

0 0 … 65,000 The derivative gain is the factor that is

Range Description

multiplied with the PID tracking error to

produce the proportional part of the output

frequency.

The higher the setting of this parameter

the “harder” is the resulting control.

NB! Too high a setting of this parameter

will cause the controller to become

unstable.

multiplied with the change in the PID

tracking error to produce the derivative

part of the output frequency.

The higher the setting of this parameter

the “harder” is the resulting control.

704 Integral gain

INT. GAIN

The derivative gain has best effect if the

encoder is mounted directly on the motor

and an encoder with good resolution

(4096 pulses/rev) is used.

NB! Too high a setting of this parameter

will cause the controller to become

unstable.

0 0 … 65,000 The integral gain is the factor that is multi-

plied with the integrated PID tracking error

to produce the integral part of the output

frequency. The main function of the integral part is to provide zero steady-state

tracking error.

The higher the setting, the faster the

application will reach a zero steady-state

tracking error. The dynamic tracking error

however increases with increasing setting

of this parameter.

NB! Too high a setting of this parameter

will cause the controller to become

unstable.

705 Limit integral part

INT. LIMIT

MG.50.P3.02 - VLT is a registered Danfoss trademark 21

1,000 0 … 65,000 Here it is possible to clamp the integral

part of the PID output. A setting of 1000

corresponds to 100% of the maximum

allowed reference specified in parameter

205.

Page 23

No. Parameter Default

Positioning Controller

value

Range Description

706 Limit PID output

PID LIMIT

707 Feed-forward

velocity gain

F-FWD. VEL.

GAIN

708 Feed-forward

acceleration gain

F-FWD. ACC.

GAIN

1,000 0 … 1,000 Here it is possible to clamp the total output

of the PID controller. A setting of 1000

corresponds to 100 % of the maximum

allowed reference specified in parameter

205.

0 0 … 65,000 The velocity feed-forward gain is the factor

that is multiplied with the set-point (desired

trajectory) velocity to produce the feedforward part of the output frequency. The

function of the feed-forward part is to provide a fast (and fairly accurate) starting

point for the calculation of the output frequency.

NB! To get the fastest and most stable

controller response this parameter should

be set optimally. For this purpose

parameter 710 gives access to a function

that automatically calculates the optimal

setting of this parameter.

0 0 … 65,000 The acceleration feed-forward gain is the

factor that is multiplied with the set-point

acceleration to produce the feed-forward

part of the output frequency.

709 PID sample interval

SAMPLE

INTERVAL

710 FFVEL auto-

calculation

AUTOCALC.

FFVEL

1 ms 1 … 100 ms The sampling frequency of the controller

can be adjusted in this parameter. Normally, the fastest possible setting (1 ms) is

preferable, but in cases with low resolution

of the feedback signal it is a good idea to

set this parameter at a slightly higher

value.

0 0 = disabled

1 = FFVEL enabled

2 = FFVEL + PID

enabled

Setting this parameter to “1” will prompt

the program to calculate the optimal

setting of parameter 707. Setting this

parameter to “2” will prompt the program to

calculate the optimal setting of parameter

702, 703, 704 and 707. For VLT 5000

Process the following parameters

influence the result and must be set

correctly beforehand:

P104 nominal motor frequency

P106 nominal motor speed

P205 maximum reference frequency

P713 encoder type

P714 encoder resolution

P721 motor/encoder gear ratio numerator

22 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 24

No. Parameter Default

value

Positioning Controller

Range Description

P722 motor/encoder gear ratio denominator

For VLT 5000 Flux the following

parameters influence the result and must

be set correctly beforehand:

P205 maximum reference rpm

P713 encoder type

P714 encoder resolution

P721 motor/encoder gear ratio numerator

P722 motor/encoder gear ratio

denominator

NB! If you change any one of these para-

meters you should prompt a recalculation,

since the optimum value of 702, 703, 704

and 707 will have changed.

711 VLT local mode

VLT MANUAL

712 Positive direction

POS. DIRECTION

0 0 = Pos control

1 = VLT control

1 -2 = right rotation

-1 = left rotation

1 = right rotation

2 = left rotation

By setting this parameter to 1 the VLT

changes to setup “2” Manual running of the

VLT is now possible.

Here you specify which encoder direction

is considered positive. If you change this

setting the current actual position (P795)

will also change sign.

1 = standard, position is counting positive

when the drive is running forward.

-1 = position is counting negative when the

drive is running forward.

2 = as “1”, but with opposite sign of the

reference to the drive. This can be

used as alternative to swapping two

motor phases if direction of motor

rotation is wrong.

-2 = as “-1”, but with opposite sign of the

reference to the drive. This can be

used as alternative to swapping two

motor phases if direction of motor

rotation is wrong.

MG.50.P3.02 - VLT is a registered Danfoss trademark 23

Page 25

No. Parameter Default

Positioning Controller

value

Range Description

713 Encoder type

ENCODER TYPE

0 0 = incremental

1 = absolute

260kHz clock

2 = absolute

105kHz clock

3 = absolute

260kHz clock

& error

correction

4 = absolute

105kHz clock

& error

correction)/

+100 enable

hardware

encoder

monitor.

It is possible to use two types of encoder. If

you select any absolute encoder the home

flag is instantly set high, thus no homing is

required preceding a positioning

command.

Type 3 and 4 are to be used for linear

absolute encoder. A possible leap in the

position data can be detected if it is larger

than the encoder resolution/2. The correction is made by means of an artificial

position value which is calculated from the

last velocity. If the error continues for more

than 100 read-outs (> 100 ms), there will

be no further correction which will then

lead to a tolerated position error exceeded.

Type 3 and 4 are only available if encoder

feedback is via MK 3 D (see description of

parameter 748) type.

100 … 104 = like 0 … 4, however, hardware monitoring of the encoder will be

activated. Error 92 will be issued in case of

open or short circuit.

714 Encoder resolution

ENCODER RES.

715 Automatic brake

control

AUTO. BRAKE

CTRL

4.096 ps. 1 … 1,000,000

pulses

1 0 = disabled

1 = enabled

NB! When switching from a setting of absolute encoder to a setting of incremental

encoder, the home flag is automatically

cleared. A homing procedure afterwards is

necessary before any positioning commands can be executed.

The encoder resolution must be entered in

pulses per revolution (not quad-counts per

revolution).

When the automatic brake control function

is enabled, the electromechanical brake is

automatically activated every time the

application has been at standstill for a time

period specified in parameter 718. This is

especially useful in hoist applications

where the motor could overheat if it has to

deliver full torque at standstill for a prolonged period of time.

When the automatic brake control function

is disabled, the drive controls the application also at standstill.

24 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 26

No. Parameter Default

value

Positioning Controller

Range Description

716 Coast delay

COAST DELAY

717 Brake delay

BRAKE DELAY

718 Hold delay

HOLD DELAY

200 ms 0 … 1,000 ms Used in conjunction with the automatic

brake control function. The coast delay is

the delay after activating the electromechanical brake before disabling the controller

and coasting the drive.

Useful in hoisting applications where the

load would otherwise have a tendency to

drop a little after each stop because the

activation of the brake is slower than the

deactivation of the drive.

200 ms 0 … 1,000 ms Used in conjunction with the automatic

brake control function. The brake delay is

the delay after activating the control and

magnetizing the motor before the brake is

deactivated.

Useful in applications with (typically large)

motors that take a longer time to be fully

magnetized than the time it takes for the

electro mechanical brake to deactivate.

0 s 0 … 10,000 s Used in conjunction with the automatic

brake control function. The hold delay is a

waiting period in which the brake is not

activated even though the application is at

standstill.

719 Quick ramp time

QUICK RAMP

TIME

720 Ramp type

RAMP TYPE

721 Motor/encoder gear

nominator

MOT/ENC GEAR

NUM

5,000 ms 50 … 65,535 ms The quick ramp time is defined as the time

0 0 = trapezoidal

1 1 … 1,000 If the encoder is mounted on a gear where

1 = sinusoidal

Useful in applications where a sequence of

fast positioning commands is followed by

longer standstill periods.

to ramp down from the maximum velocity

to standstill.

The quick ramp time is used when the

quick stop function is activated or an error

has occurred.

Select trapeze shaped ramps to get the

optimal acceleration.

5 revolutions of the motor correspond to 2

revolutions of the encoder, P721 should be

set to “5” (the number of motor revolutions)

and P722 should be set to “2” (the number

of encoder revolutions).

If the encoder is mounted directly on the

motor shaft this parameter setting should

remain at “1”.

MG.50.P3.02 - VLT is a registered Danfoss trademark 25

Page 27

No. Parameter Default

Positioning Controller

value

Range Description

722 Motor/encoder gear

denominator

MOT/ENC GEAR

DEN

723 Maximum jog

velocity

MAX.JOG

VELOCITY

724 Jog ramp time

JOG RAMP TIME

725 Error behaviour

ERROR

BEHAVIOUR

1 0 … 1,000 See the description of P721.

100 ERPM 1 …

5,000 ms 50 … 100,000 ms This parameter specifies both the ramp-up

0 0 = electronic

999,999 ERPM

brake

1 = mechanical

brake

If the encoder is mounted directly on the

motor shaft this parameter setting should

remain at “1”.

The maximum speed allowed while jogging

the application is specified in terms of

Encoder Revolutions Per Minute (ERPM).

NB! This setting must never exceed a

value that is approx. 5% lower than the

value calculated in P799.

time as well as the ramp-down time used

during jogging.

The ramp time is defined as the time in

milliseconds it would take to ramp from

standstill to the maximum allowed velocity

(P799).

This parameter determines the behaviour

of the drive after an error is detected.

If “0” is selected the drive will ramp down to

standstill with the shortest possible ramp

(P719). After achieving standstill it will

activate the electronic brake according to

the setting of P716. If the drive is coasted at

any point during ramp down (e.g. due to an

OVER CURRENT trip – ALARM 13) the

drive will immediately activate the brake and

coast the drive.

If “1” is selected the drive will immediately

activate the brake and coast the drive.

NB! The brake is always activated after an

error situation (or quick stop) regardless of

the P715 setting.

726 Maximum tolerated

PID error

MAX. TRACK

ERROR

26 MG.50.P3.02 - VLT is a registered Danfoss trademark

20,000 qc 0 …

1,000,000,000 qc

The PID track error is defined as the difference between the internal controller setpoint and the actual position. The better

tuning of the PID controller (P702-709) the

lesser the PID track error.

At every sample time the current track

error is compared with the setting of P726.

It is defined as an error situation (“PID

track error too big” - P798 = 9) if the track

error is bigger than the setting of P726.

Page 28

No. Parameter Default

value

Positioning Controller

Range Description

After tuning the PID controller optimally

this parameter should be set to a value

approx. 50 % larger than the maximum

observed value of P797.

NB! The unit is quad-counts (QC) not user

units (UU).

727 Error reset

RESET ERROR

728 Home offset

HOME OFFSET

[UU]

729 Home ramp time

HOME RAMP TIME

730 Home velocity

HOME VELOCITY

731 Home type

HOME TYPE

0 0 = no reset

1 = reset error

0 UU -33,554,432 …

33,554,431 UU

5,000 ms 50 … 100.000 ms The home ramp time is defined as the time

100 ERPM -20,000 … 20,000

ERPM

0 -2 … 3 There are six types of homing sequences.

By setting this parameter to “1” it is possible to clear the error flag (provided that

the reason for the error is not still present).

The parameter automatically resets to “0”

when the error is successfully cleared.

This parameter defines an offset to the

“zero” (HOME) position. Any change in this

setting will immediately affect the actual

position displayed in P795.

in milliseconds it would take to ramp from

standstill to the maximum allowed velocity

(P799).

The home velocity is entered here. Notice

that the sign of the velocity determines the

direction in which the homing sequence

will be performed.

-2 = No homing is needed, the actual position (when using an incremental encoder) after power-up is set in

parameter 750.

-1 = No homing is needed, the actual

position (when using an incremental

encoder) after power-up is zero.

0 = The drive moves to the reference

switch (MK3A 4) with home velocity

(P730), then reverses and slowly (at

30% of home velocity) leaves the

switch, subsequently moves to the

next index pulse. The HOME position

is defined as that index position.

1 = Like “0” but without the search for the

index position. Instead the HOME

position is defined as the position at

which the reference switch goes low.

After defining the HOME position the

drive is then ramped down with the

home ramp (P729) and stopped.

MG.50.P3.02 - VLT is a registered Danfoss trademark 27

Page 29

No. Parameter Default

Positioning Controller

value

Range Description

2 = Like “0” but without reversing before

leaving the reference switch. Rather

the movement is slowly continued in

the same direction out of the switch.

3 = Like “1” but without reversing before

leaving the reference switch. Rather

the movement is slowly continued in

the same direction out of the switch.

732 User unit numerator

USER UNIT NOM.

733 User unit

denominator

USER UNIT DEN.

1,000 1 … 100,000 P732 and P733 together define the ratio

between User Units (UU) and quad-counts

(QC).

Let’s illustrate this parameter with the following example: By measurement it has

been determined that 1000 mm. of travel

correspond to 16345 QC (quad-counts).

Now instead of defining the target positions

in QC but rather in mm, the setting of P732

must be 16345, and the setting of P733

must be 1000.

NB! The target positions stored in memory

is defined according to the settings of

P732/P733, so changing the P732/P733

ratio might require that up to 32 positions

must be reprogrammed to achieve the

same result as before the change.

1,000 1 … 100,000 P732 and P733 together define the ratio

between User Units (UU) and quad-counts

(QC).

The setting of this parameter is illustrated

in the description of P732.

NB! The target positions stored in memory

is defined according to the settings of

P732/P733, so changing the P732/P733

ratio might require that up to 32 positions

must be reprogrammed to achieve the

same result as before the change.

734 Block reversal

BLOCK

DIRECTION

28 MG.50.P3.02 - VLT is a registered Danfoss trademark

0 0 = no blocking

1 = block reverse

2 = block forward

By selecting “1” it is defined as an error

situation (“Reverse operation prohibited” –

P798 = 12) if the drive is moving in reverse

direction.

By selecting “2” it is defined as an error

situation (“Forward operation prohibited” –

P798 = 13) if the drive is moving in forward

direction.

Selecting “0” disables the function.

Page 30

No. Parameter Default

value

Positioning Controller

Range Description

735 Brake wear limit

BRAKE WEAR

LIMIT

736 Power-recovery

POWER RECOVERY

0 0 ( = disabled) …

1,073,741,824 UU

1 0 = disabled

1 = enabled

Setting a value higher than “0” (disabled)

the drive defines an error situation (“Brake

wear limit exceeded” – P798 = 7) if the

drive moves more than the number of UU

specified in this parameter while the electronic brake is activated.

When the power recovery function is disabled (0), it is not possible to drive the

application by any means (neither jogging

nor positioning) as long as the application

is outside the HW or SW limits. The only

way to recover from this situation is to

move the application by hand.

When the power recovery function is

activated (1) however it is possible to

make a “partial reset“ of the limit error

(P798 = 2/3/4/5) whereby it will be possible

to use the jogging function to drive the

application out of the HW or SW limit area.

It is not possible to drive the application

otherwise by means of homing, positioning

or jogging (in the wrong direction), as long

as the application is still within the HW or

SW limit area.

737 Link LCP input to

index

LINK INDEXINPUT

0 0 = disabled

1 = enabled

The “error occurred” output (MK3C 2) will

remain high to indicate that these

restrictions are in effect. As soon as the

application is moved outside the HW or

SW limit area the error is automatically

cleared and the “error occurred” signal

goes low to indicate that normal operation

is now restored.

When activating this function (1) P738 will

be automatically updated with the last position reference number that has been loaded into memory. This enables to operator

to see what position reference is currently

given by the PLC system.

The function is deactivated when set to “0”.

This is necessary when programming a

position number different from the one

loaded into the PLC memory.

MG.50.P3.02 - VLT is a registered Danfoss trademark 29

Page 31

No. Parameter Default

Positioning Controller

value

Range Description

738 Index number

INDEX NUMBER

739 Index target

position

TARGET

POSITION

0 0 … 31

0 … 63 in field bus

mode

0 -1,073,741,824 …

1,073,741,824 UU

Here it is possible to specify which position

data that should be displayed in P739-743.

Whenever this number is changed the

current values of P739-P743 are stored in

memory under the previously specified

index number. After that, the value of

P739-743 is updated with the data stored

in memory relevant to the newly specified

index number.

The meaning of this parameter depends

on the position type specified in P743.

If P743 = 0, the value of this parameter

refers to an absolute position (relative to

the fixed HOME position).

If P743 = 1 and the last position was obtained through jogging, the value of this parameter is a position relative to that position.

If the last position was reached as a result

of a positioning command, then the value

of this parameter specifies a position relative to the last target position (whether it

was reached or not).

If P743 = 2 the application will move in the

positive direction until a touch probe position is defined. If a touch probe position is

already defined the application will move

directly to that position.

A touch probe position is defined as the position at which the “touch probe switch” input

(MK3A 1) goes high plus the value of P739.

A touch probe position is cleared by a high

signal on the “reset touch probe position”

input (MK3A 7) input.

The output “Touch probe position locked”

(VLT5000 Terminal 42) is high if a touch

probe position is defined.

If P743 = 3 the application will move in the

negative direction until a touch probe posi-

30 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 32

No. Parameter Default

value

Positioning Controller

Range Description

tion is defined. If a touch probe position is

already defined the application will move

directly to that position.

NB! This parameter is automatically updated depending on P738.

740 Index ramp up time

RAMP UP TIME

741 Index ramp down

time

RAMP DOWN TIME

742 Index maximum

velocity

MAX. VELOCITY

5,000 50 … 100,000 ms This setting is relevant during positioning

with the current trajectory index.

The index ramp up time is defined as the

time in milliseconds it would take to ramp

from standstill to the maximum allowed

velocity (P799).

NB! This parameter is automatically updated depending on P738.

5,000 50 … 100,000 ms This setting is relevant during positioning

with the current trajectory index.

The index ramp down time is defined as

the time in milliseconds it would take to

ramp from the maximum allowed velocity

(P799) to standstill.

NB! This parameter is automatically updated depending on P738.

100 ERPM 1 … 999.999

ERPM

This setting is relevant during positioning

with the current trajectory index.

NB! This parameter is automatically

updated depending on P738.

The setting should never exceed a value

that is approx. 5% lower than the value

calculated in P799.

743 Index trajectory

type

TRAJECTORY

TYPE

744 Positive software

limit

POS. SW. LIMIT

MG.50.P3.02 - VLT is a registered Danfoss trademark 31

0 0 = absolute

1 = relative

2 = touch probe

positive

3 = touch probe

negative

1,073,000,000

-1,073,000,000 …

1,073,000,000 UU

The function of this parameter setting is

described under P739.

NB! This parameter is automatically

updated depending on P738.

If the actual position (P795) exceeds the

value specified in this parameter an error

situation is defined (P798 = 4) and handled

according to the setting of the “Error

behaviour” parameter (P725).

Page 33

No. Parameter Default

745 Negative software

limit

NEG. SW. LIMIT

Positioning Controller

value

–1,073,000,000

Range Description

–1,073,000,000 …

1,073,000,000 UU

If the actual position (P795) goes below

the value specified in this parameter an

error situation is defined (P798 = 5) and

handled according to the setting of the

“Error behaviour” parameter (P725).

746 Target position

window

TARGET WINDOW

747 Touch probe delay

PROBE DELAY

748 Feedback input

SWAP ENCODER

0 0 UU (< P726) …

1,073,741,824 UU

0 0 …100,000 ms This parameter enables for compensation

0 0 … 1 Choose feedback input for positioning con-

During a positioning sequence the “Referenced position reached” output (MK3C 2)

is set according to this parameter.

If the setting of this parameter is “0” then

the “Referenced position reached” output

goes high immediately when the internal

PID target position is equal to the requested target position.

If the setting of this parameter is larger

than “0” i.e. “200” then the “Referenced

position reached” output goes high when

the actual position (P795) is within

±200 UU of the requested target position.

in any fixed delay there may be in the

touch probe.

troller. Enter “0” to use MK3D, enter “1” to

use MK3B. This is used to enable the use

of absolute encoders for feedback together

with VLT 5000 Flux in closed loop mode.

In that case input MK3D has an incremental encoder fitted (feedback for Flux) and

MK3B has an absolute encoder fitted for

positioning feedback. The text in parameter 713 and 714 changes accordingly

749 Control source

FIELDBUS MODE

750 User APOS setting

SET APOS

751 Positive SW limit

active

POS SW LIM ACT

752 Negative SW limit

active

NEG SW LIM ACT

32 MG.50.P3.02 - VLT is a registered Danfoss trademark

0 0 … 1 Choose control source for pos. controller.

Enter “0” for digital inputs or “1” for fieldbus

control.

0 -1,073,741,824 …

1,073,741,824

1 0 … 1 Enter “0” to disable positive software limit

1 0 … 1 Enter “0” to disable negative software limit

At power-up if homing type is “-2” (see

parameter 731) the actual position is equal

the value set here.

switch. This should be done only when not

positioning within two fixed limits.

switch. This should be done only when not

positioning within two fixed limits.

Page 34

No. Parameter Default

value

Positioning Controller

Range Description

753 Endless positioning

ENDLESS POS.

776 Factory reset

FACTORY RESET

777 Parameter save

STORE DATA

778 Password

0 0 … 1 Set this parameter to “1” if drive must per-

form positioning continuously in one direction. Remember to also set parameter 751,

752 and 736 to “0”.

0 0 = disabled

1 = enabled

0 0 = no action

1 = SAVE

EEPROM

1,234 0 … 999,999,999 Not used.

By setting this parameter to “1” it is

possible to reset all parameter values to

default. This also resets all trajectory data

(P739-P743).

The parameter automatically resets to “0”

when the reset is successfully carried out.

Parameter and trajectory data is not automatically stored in EEPROM and will thus

not automatically be available after powerdown and power-up.

To permanently store changes made to

parameter values and/or trajectory data

parameter P777 must be set to “1”. This

parameter automatically resets to “0” when

the data is successfully stored.

PASSWORD

779 Software version

VERSION 2.10

795 Actual position

ACTUAL

POSITION

796 Actual inputs

ACTUAL INPUTS

797 PID tracking error

PID TRACK

ERROR

210 210 The text in this parameter shows the

current version number of the Positioning

Controller program.

0 –2,000,000,000 …

2,000,000,000 UU

00000000 00.00.00.00 /

11.11.11.11

0 –2,000,000,000 …

2,000,000,000 UU

READ-ONLY PARAMETER:

This parameter displays the latest position

obtained from the feedback encoder.

READ-ONLY PARAMETER:

This parameter displays the last read

status of the digital input on the option card

(MK3A). The status of the digital inputs on

the VLT5000 control card is accessible via

P528

READ-ONLY PARAMETER:

The current PID tracking error is displayed

in this parameter in user units.

MG.50.P3.02 - VLT is a registered Danfoss trademark 33

Page 35

No. Parameter Default

Positioning Controller

value

Range Description

798 Error status

ERROR STATUS

0 0 = OK

1 = Homing

needed

2 = Pos. HW limit

3 = Neg. HW limit

4 = Pos. SW limit

5 = Neg. SW limit

6 = VLT not

running

7 = Brake wear

limit

8 = Quick stop

9 = PID error too

big

10= Option error

11= VLT Exception

12= Rev. operation

READ-ONLY PARAMETER:

The current error code is displayed in this

parameter.

799 Maximum allowed

velocity

MAX. VELOCITY

1,500

ERPM

13= Fwd. operation

92= Encoder

hardware error

1 … 999,999

ERPM

READ-ONLY PARAMETER:

The maximum velocity allowed is calcula-

ted on the basis of P104, P106, P205,

P721, P722 and the result is presented in

this parameter. To increase this value one

or more of the above mentioned parameters must be changed (usually just P205).

34 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 36

Positioning Controller

An application example!

The drawing below shows a layout of a pallet conveyor system. Loaded pallets are coming from

four different produc t lines via the pallet inlet c onveyors. Each pallet must be transported from one

of the four inlet conveyors to the one of the two outlet conveyors. To do this a movable pallet

conveyor cart is used.

PALLET

INLET #1

PALLET

CART

PALLET

OUTLET

#1

DELIVERY

TRUCK

PALLET

INLET #2

PALLET

INLET #3

PALLET

OUTLET

#2

DELIVERY

PALLET

INLET #4

TRUCK

A typical work process could be;

1) Moving the (empty) pallet conveyor cart to pallet inlet no. 1 to pick up a loaded pallet

2) Waiting until the pallet is successfully transferred to the cart

3) Moving to pallet outlet no. 2.

4) Waiting until the pallet is successfully transferred to the outlet conveyor and so on…

MG.50.P3.02 - VLT is a registered Danfoss trademark 35

Page 37

Wiring diagram

Positioning Controller

Basic set-up

First, check the motor connection:

Please be ware the mechanical brake control cannot be trusted during this basic setup, therefore

control brake externally from the option until setup is finished. Also ensure that the motor can rotate

freely without causing damage or injury to personal.

1. Remove all signals to inputs 16-33 and I1-I8. Only Input 27(coast), I8 (q-stop), I3 (HW

limit) and I2 (HW limit) must be connected and high.

2. Select “Disable syncpos” in P700

3. Select “Local” function in Parameter 002. – VLT 5000 stops (display flashing)

4. Input the motor name plate data in P102-P106 and activate the “Automatic Motor

Adaptation” function in P107.

36 MG.50.P3.02 - VLT is a registered Danfoss trademark

Page 38

Positioning Controller

5. Press the [START] button on the VLT 5000 control panel and wait for the AMA to be

completed.

6. Set the frequency for a low positive value, for example +3 Hz in Parameter 003 please

note that motor should now rotate.

7. Press the [START] button on the VLT 5000 control panel and then the [STOP/Reset]

button watching the direction of rotation on the motor. If the motor rotates in the wrong

(negative) direction then exchange the motor phases.

When you have tested the motor speed direction you test encoder connection as follows, if an

incremental encoder is used go to step 10, if an absolute encoder is used go to step 8:

8. If you are using a VLT 5000 Flux remember to use MK3B as input for the absolute

encoder and enter “1” in parameter 748. Then enter the absolute encoder type and

resolution in parameter 713 and 714.

9. Repeat step 8 to 10 to test the encoder direction.

10. Press the [DISPLAY/STATUS] button on the VLT 5000 control panel. Now the following

values appear in the upper line of the display: Error status, PID tracking error, actual

position.

11. Rotate the slave drive motor shaft manually in the positive direction (you can repeat step

7). Now the display should show an ascending count of the actual position.

12. If the count is descending with an incremental encoder, exchange the feedback encoder

track A by B and A/ by B/. If there is no counting in the display then check the wiring of the

encoder.

When you have tested the encoders and the wiring of motor and encoders, continue as follows:

13. Change parameter 002 back to “Remote” and start the VLT 5000 by pressing the

[START] button on the local control panel (LCP).

14. Select “Enable syncpos” in P700

15. Reset any error by toggling input 27.

Now you come to the test run:

16. Drive the application back and forth by closing the contacts on terminal 53 (positive

direction) or terminal 54 (negative direction). Watch the PID track error via the LCP

display during these tests.

Now you can optimise the controller:

17. Optimise

parameter list for P710 parameter (the FFVEL auto-calculation function).

18. If the track error after entering “2” in parameter 710 is within specification, when jogging,

there is no reason to optimise any further, move to step 21.

19. Increase

right setting. If the drive becomes unstable or if a message is given about over-voltage or

over-current, then reduce the value in parameter 702 to about 70-80% of the set value.

20. Increase

Read the description concerning these parameters in the parameter list.

To store the optimised values

21. Change the value of parameter 777 to “1”. When the value returns to “0” the parameters

have been successfully saved (see the parameter list for a description of how the P777

parameter works).

the Feed forward velocity P707 by following the procedure described in the

the P-portion par. 702. After each change you should make a test run to find the

the other PID parameters P703 (if needed) by following the same approach.

MG.50.P3.02 - VLT is a registered Danfoss trademark 37

Page 39

Positioning Controller

Parameter settings

Now determine the parameter settings fitting this application. The following list of parameters can be

determined right away:

P701 Default (“Positioning mode”)

P702 - P711 Determined during optimising of the PID controller

P712 Default (“1”)

P713 Incremental encoder used (“0”)

P714 Encoder resolution (“4096”)

P720 Trapeze ramps is used for fastest response (“0”)

P721 Default (encoder mounted directly on motor) (“1”)

P722 Default (encoder mounted directly on motor) (“1”)

P723 Default (“100”)

P724 Default (“1500”)

P728 Default (“0”)

P734 Default (“0”)

P747 Default (“0”)

P777 Default (“0”)

P778 “0” – no password protection required

Timing of the electromechanical brake (P715-P718)

If the application is not equipped with an electromechanical brake, P716-P718 are not very important.

Then, however, it is very important to set P715 to “0” to enable the drive also at standstill.

This application is equipped with mechanical brakes to allow it to stop rapidly even if the drive is somehow prevented from stopping the motor (damaged motor cables, damaged or short circuited motor,

inverter overload and so on).

P716-P718 is provided to time the interaction between the mechanical brake and the drive. A description

of these parameters can be found in the parameter list above. In this application the default values of

P716 and P717 is used (200 ms) but the P718 setting is changed to 30 seconds to minimize wear of the

brake.

Setting P732 and P733

Distances are measured in quad-counts (QC) but defined in millimetres. Therefore, it is necessary to

measure how many QC correspond to how many millimetres. To do this the cart is first moved as far to