High Performance FieldBus cards

Profibus card VLT 5000/5000 Flux/6000 HVAC/8000 AQUA ..................... 3

Interbus card VLT 5000 ................................................................................. 6

DeviceNet card VLT 5000/5000 Flux/6000 HVAC/8000 AQUA .................. 8

Modbus+ card VLT 5000 ............................................................................. 10

Modbus RTU card ........................................................................................ 12

Lonworks card VLT 5000/6000 HVAC/8000 AQUA Free Topology ........ 14

Lonworks cards VLT 5000/6000 HVAC 78 kbps and 1.25 Mbps ............ 16

VLT 2800 Fieldbus cards ............................................................................. 18

FCD 300 Fieldbus cards .............................................................................. 20

DMS 300 Profibus card ............................................................................... 23

Adap-Kool Lon card ..................................................................................... 23

Miscellaneous, Accessories to Fieldbus

VLT 3000 to 5000 converter software ............................................. 24

Profibus SUB D9 connector ............................................................ 25

Fieldbus options ordering number for VLT 5000: ................................... 26

Fieldbus options ordering number for VLT 6000: ................................... 27

Fieldbus options ordering number for VLT 8000: ................................... 27

Previous produce fieldbus cards: .............................................................. 28

MI.90.I1.02 - VLT is a registered Danfoss trademark

1

■■

■ Introduction:

■■

This instruction can be used in conjunction with

Danfoss Drives High Performance Fieldbus cards. It

briefly shows the most important Technical data for

each Fieldbus we support. For more information or

Technical data please consult the representative

Operating Instruction.

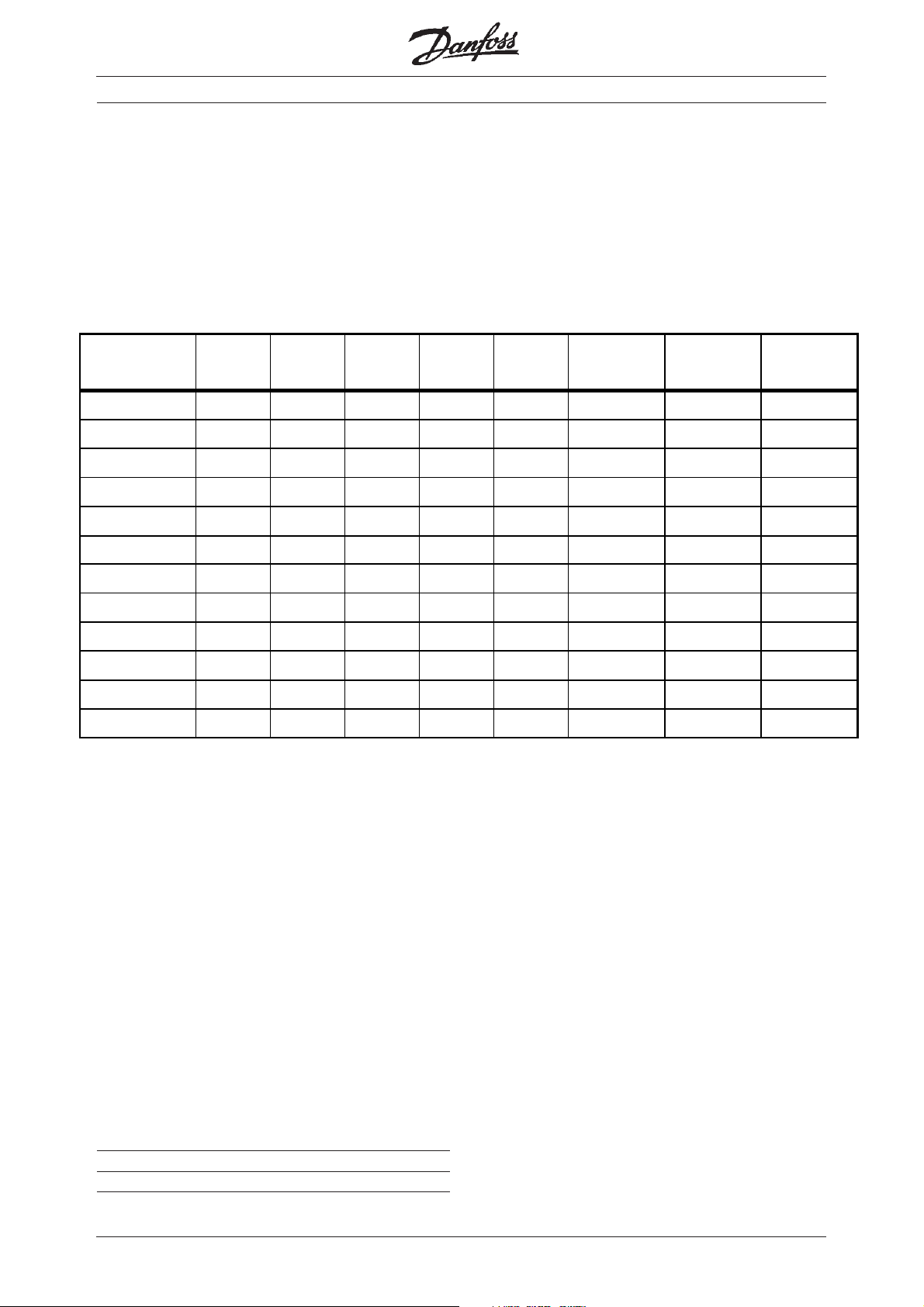

The table shows the supported Fieldbusses:

High Performance FieldBus cards

Profibus DPV0

Profibus DPV1

DMS

300

9Ø9ØØ 9 Ø Ø

FCD

300

FCM

300

999 99

Profibus FMS

Interbus

DeviceNet

AS- i

99

999999

Modbus+

Modbus RTU

9

d

9

e

LonWorks

FC protocol

9999 9 9 9

Metasys N2

L&S FLN

Ø These products still support Profibus DPV0, but

have now been replace with Profibus DPV1.

VLT

2800

VLT

5000

c

9

d

9

VLT

5000

Flux

c

9

VLT 6000

HVAC

c

9

VLT 8000

Aqua

c

9

9

9

e

9

99

9

e

99

f

9

99

9

c Note that the Profibus FMS card has a new

ordering number, see page 26-27.

d Note that the previous Interbus gateway to

Profibus is not available anymore.

e The Modbus RTU need to be install in an external

box by these products. The box is not included.

f VLT 8000 Aqua supports only the LonWorks FTP

card.

Issued by: John Bargmeyer, DD-OSE

Revision: 3.11

Date: 2003-08-13

2

MI.90.I1.02 - VLT is a registered Danfoss trademark

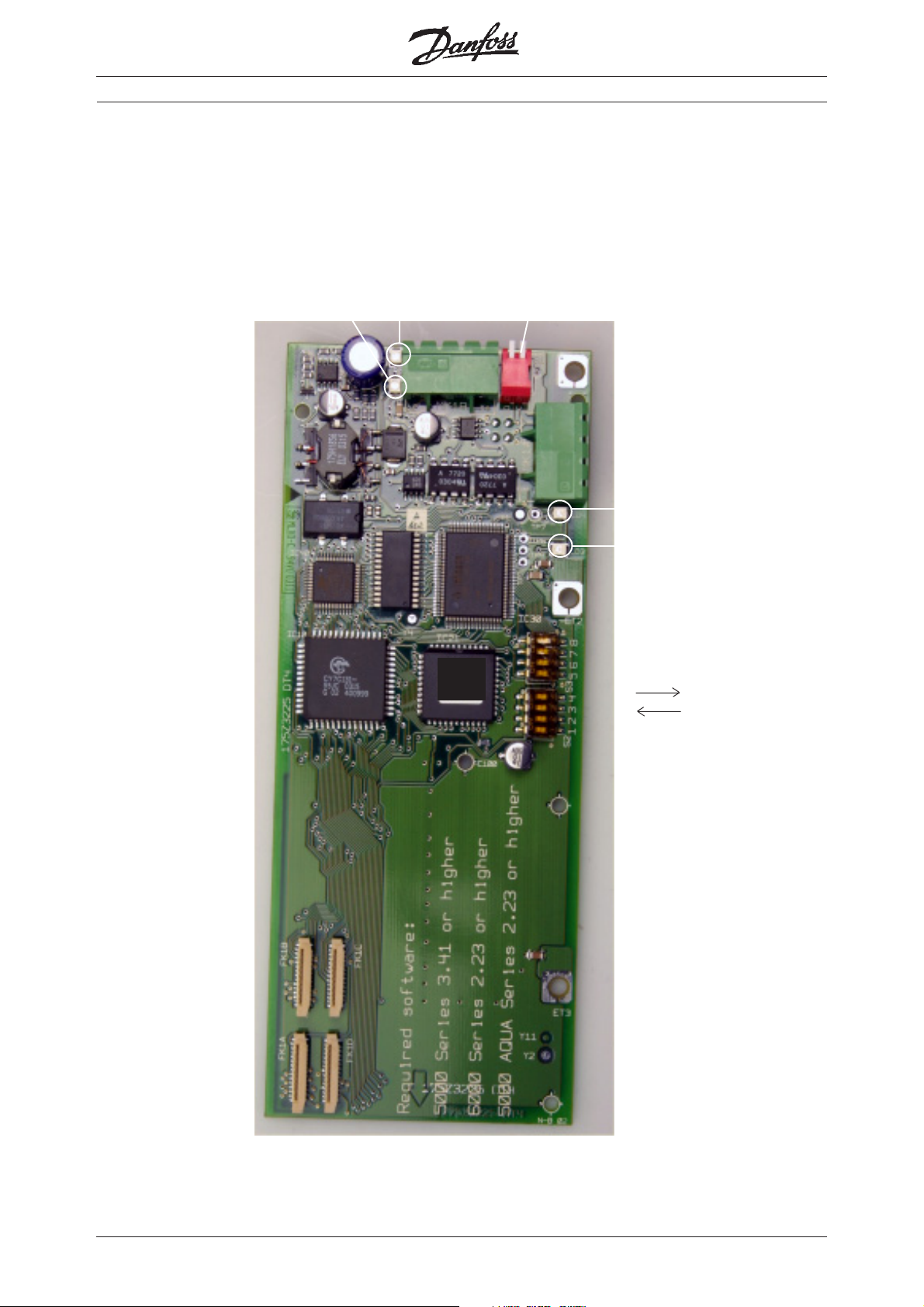

■■

■ Profibus DP V0/V1 card for VLT 5000/6000/8000

■■

This Profibus DP V0/V1 card is only available as a

build in, i.e. if the VLT was produce with a Profibus

card.

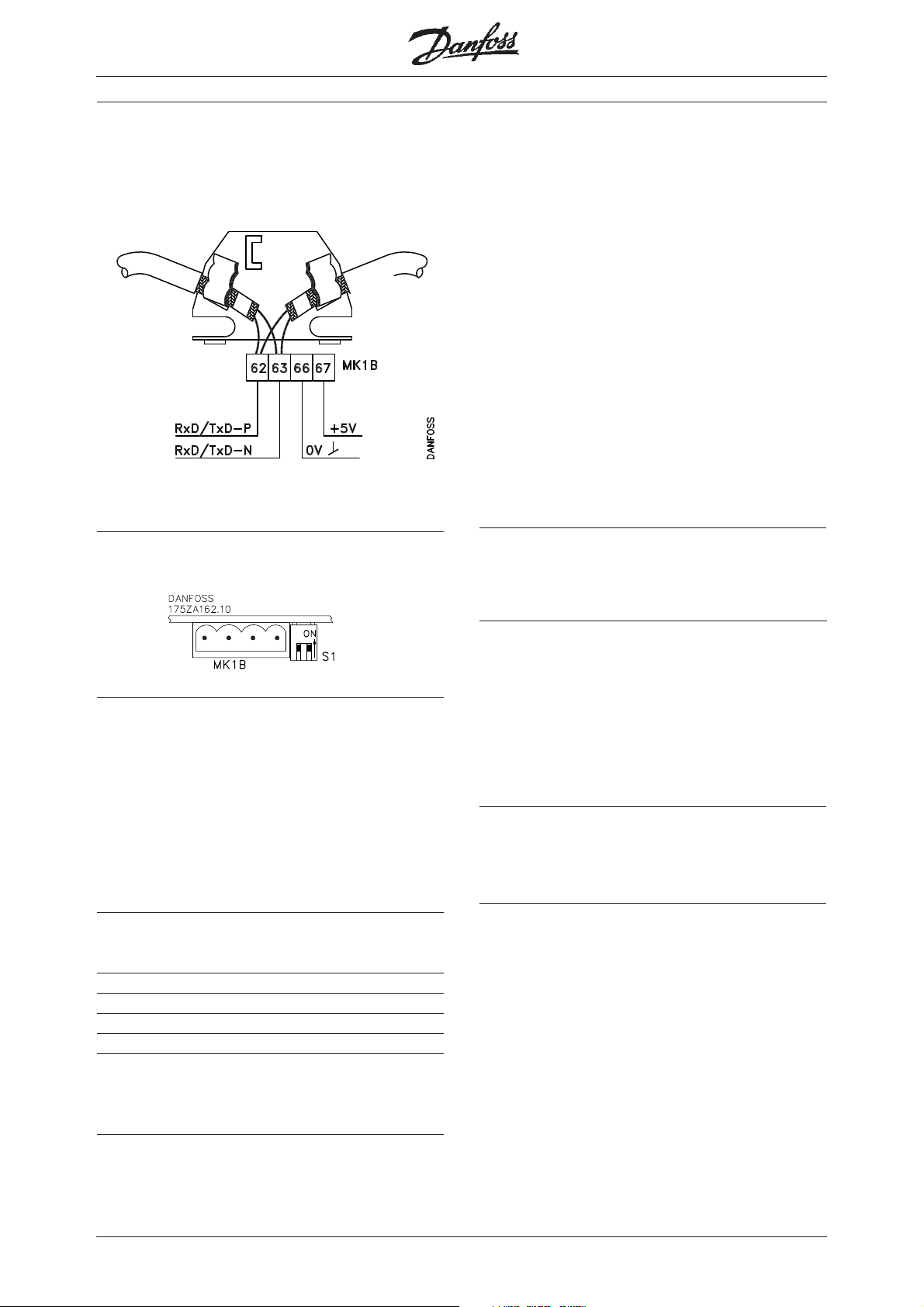

Profibus connection for Bookstyle

LD1LD2

High Performance FieldBus cards

Termination of

Profibus

Profibus connection for Compact

LD4

LD3

Address switch

OFF = 0

ON = 1

MI.90.I1.02 - VLT is a registered Danfoss trademark

3

■■

■ Profibus DP V0/V1 card for VLT 5000/6000/8000

■■

This Profibus DP V0/V1 card is used in conjunction

with a memory card or Sync./Pos card.

High Performance FieldBus cards

■■

■ Profibus DPV0 card for FMS support

■■

This Profibus DPV0 card is available to support

installations that use the Profibus FMS protocol.

4

MI.90.I1.02 - VLT is a registered Danfoss trademark

Profibus data

■■

■ Profibus connection

■■

High Performance FieldBus cards

■■

■ Cable specification

■■

- Impedance: 135 to 165 ohm at a measuring

frequency from 3 to 20 MHz

- Resistance: < 110 ohm/km

- Capacitance: < 30 pF/m

- Damping: max. 9 dB over the whole wire

length

- Cross section: max. 0.34 mm

corresponding to AWG 22

- Cable type: twisted in pairs,

1 x 2, or 2 x 2, or 1 x 4 wires

- Screening: Copper-braided screen

or braided screen and foil screen

2

,

62 = RxD/TxD-P red cable

63 = RxD/TxD-N green cable

■■

■ Profibus termination

■■

By 'ON' is the bus termination active.

■ LEDs

There are 4 LEDs on the PROFIBUS option card:

LD1 and LD4: Flashes when the card is

communicating.

LD2 and LD3: Lights up when the card is initialized

and ready to communicate. They will

flash while auto baudrate detection is

attempting to detect the actual

baudrate.

It is recommended to use the same cable type in

the entire network to avoid impedance mismatch.

■■

■ Technical data

■■

Baudrate ..................................... 9.6 - 12000 kBaud

Adress area .................................................... 0 - 125

■■

■ Profibus literature

■■

Operating Instruction .......................... MG.90.G1.02

DPV1 Design Guide ............................. MG.90.E2.02

Siemens S7 PLC .................................. MC.50.A2.02

Siemens S5 IM 308C ...........................MC.50.C1.02

SST-PFB-PLC5 Profibus master .......... MN.51.U1.02

GE Fanuc Series 90-30 ......................... MI.50.X1.02

■■

■ GSD files

■■

GSD files are available on the internet at:

http://www.danfoss.com/drives

■ Cable length

Transmission speed Max. total cable length [m]

9.6 - 187.5 kBaud 1000

500 kBaud 400

1.5 MBaud 200

3-12 MBaud 100

Note that theese cable lengths are for 1 segment

with 31 VLT frequency converter.

MI.90.I1.02 - VLT is a registered Danfoss trademark

5

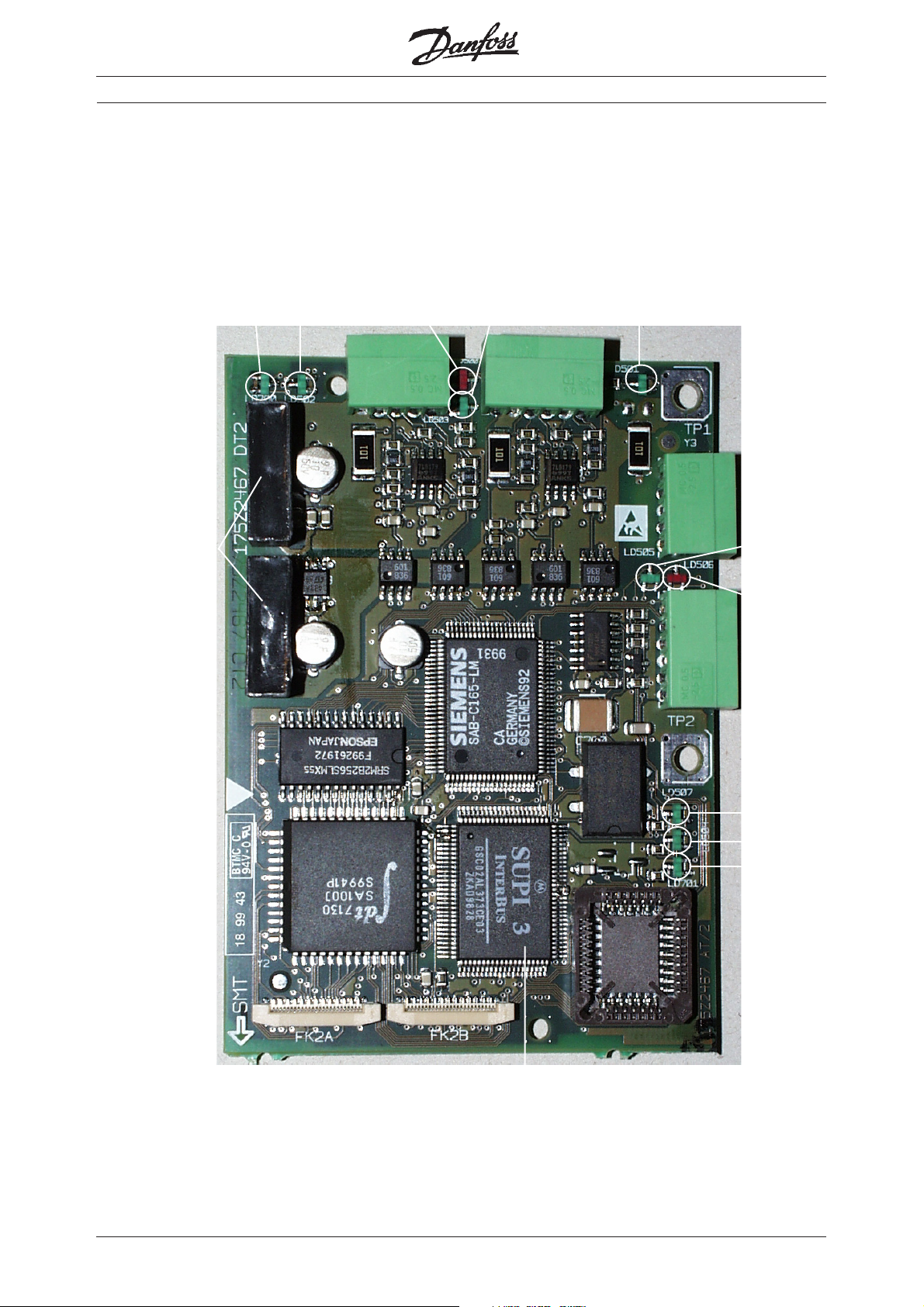

■■

■ Interbus card VLT 5000

■■

High Performance FieldBus cards

Interbus connection for Bookstyle

IBS IN IBS OUT

DC/DC

converter

TR

CC/CR

UL

RD

BA

UL

RD

Interbus connection for Compact

SUPI component for

Interbus communication

IBS OUT IBS IN

BA

CC/CR

TR

6

MI.90.I1.02 - VLT is a registered Danfoss trademark

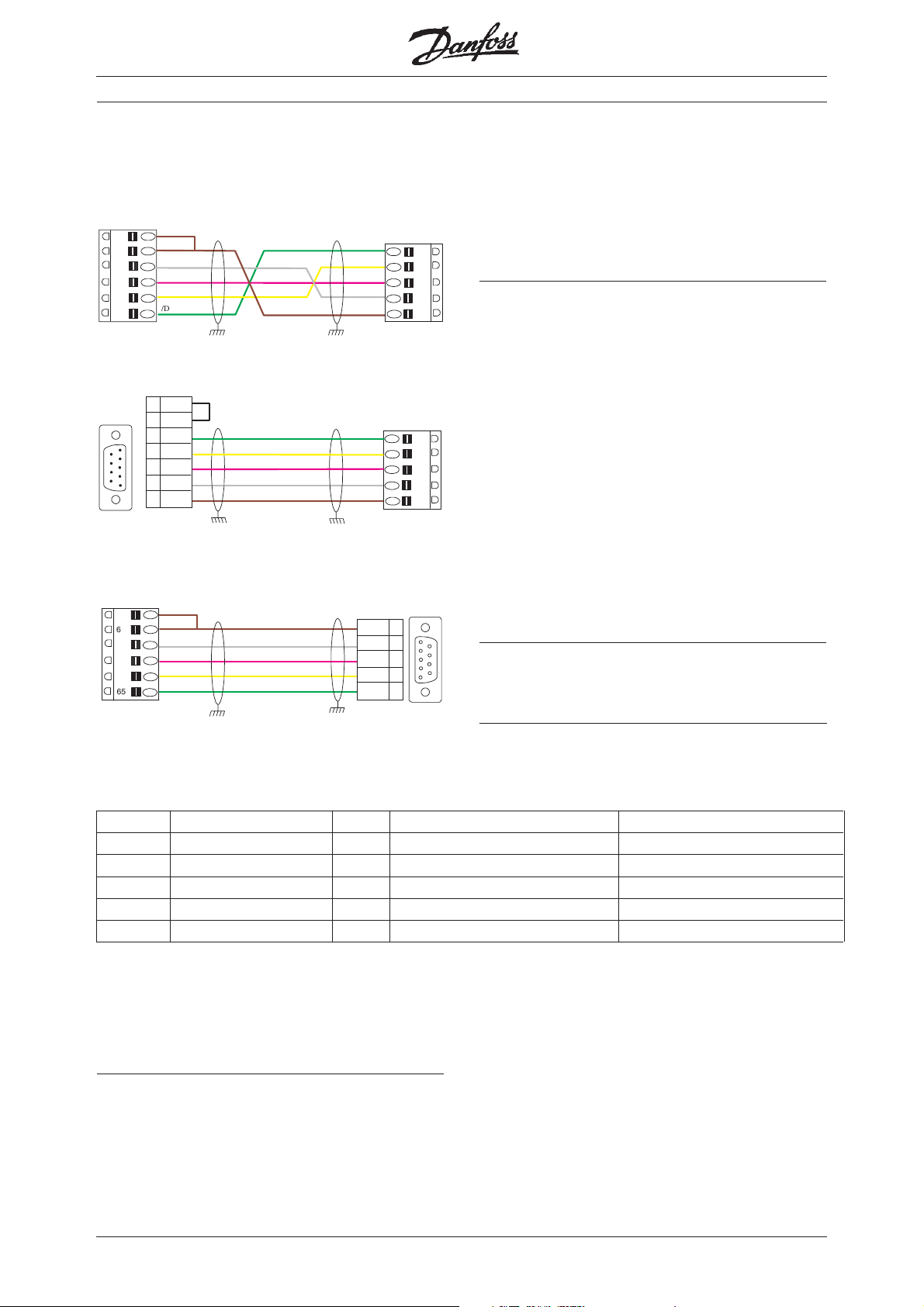

Interbus data

■■

■ Interbus connection

■■

RB

66

62

63

64

65

VLT 5000 to VLT 5000

6

9

DB9 (male) to VLT 5000

RBST

COM

DI

/DI

DO

/DO

9

5

/DO

6

1

1

DO

7

/DI

2

DI

5

3

COM

GreenGreen

Green

GreenGreen

GrayGray

Gray

GrayGray

PinkPink

Pink

PinkPink

YY

ellowellow

Y

ellow

YY

ellowellow

BrownBrown

Brown

BrownBrown

GreenGreen

Green

GreenGreen

YY

ellowellow

Y

ellow

YY

ellowellow

PinkPink

Pink

PinkPink

GrayGray

Gray

GrayGray

BrownBrown

Brown

BrownBrown

/DO

DO

/DI

DI

COM

/DO

DO

/DI

DI

COM

High Performance FieldBus cards

■ Cable length

Max. total cable length ........................ 12.8 km (Cu)

65

64

63

62

66

65

64

63

62

66

Max. length between nodes ........................... 400 m

■■

■ Cable specification

■■

- Impedance: 135 to 165 ohm at a measuring

- Resistance: < 110 ohm/km

- Capacitance: < 30 pF/m

- Damping: max. 9 dB over the whole wire

- Cross section: max. 0.34 mm

- Cable type: twisted in pairs,

- Screening: Copper-braided screen

frequency from 3 to 20 MHz

length

2

,

corresponding to AWG 22

3 x 2 wires

or braided screen and foil screen

RB

66

62

63

64

65

RBST

COM

DI

/DI

DO

/DO

BrownBrown

Brown

BrownBrown

GrayGray

Gray

GrayGray

PinkPink

Pink

PinkPink

YY

ellowellow

Y

ellow

YY

ellowellow

GreenGreen

Green

GreenGreen

COM 3

DI

/DI

DO

/DO

the entire network to avoid impedance mismatch.

1

6

2

7

1

5

6

■■

■ Technical data

■■

9

Baudrate ..................................................500 kBaud

VLT 5000 to DB9 (female)

■ LEDs

It is recommended to use the same cable type in

NameName

Name

NameName

IndicatesIndicates

Indicates

IndicatesIndicates

ColorColor

Color

ColorColor

OnOn

On

OnOn

OFFOFF

OFF

OFFOFF

CC/CR: Cable Check. Green Incomming bus active Incomming bus swicthed off

BA Bus Active. Green Bus active Bus stopped

RD: Status of outgoing bus. Red Outgoing bus stopped Outgoing bus active

TR: Transmit/Receive. Green PCP Communication running NO PCP Communication running

UL: Power OK. Green Voltage within permissable range No Voltage

■■

■ Interbus literature

■■

Operating Instruction .......................... MG.10.O2.02

Interbus CMD ......................................MN.50.U1.02

MI.90.I1.02 - VLT is a registered Danfoss trademark

7

■■

■ DeviceNet card for VLT 5000/6000/8000

■■

DeviceNet connection

High Performance FieldBus cards

for Bookstyle

Device status

LED

Network status

LED

DeviceNet connection

for Compact

Device status LED

Network status LED

Address switch and

baud rate setting

OFF = 1

ON = 0

8

MI.90.I1.02 - VLT is a registered Danfoss trademark

High Performance FieldBus cards

5 V+

4 CAN_H

3 drain

2 CAN_L

1 V–

red

white

bare

blue

black

1 2 3 4 5

DeviceNet data

■■

■ DeviceNet connection

■■

■■

■ DeviceNet termination

■■

Termination resistors should be installed at each end

of the bus line.

The resistors shall be mount between terminal 2

CAN_L and terminal 4 CAN_H and should have the

following specification:

121 Ohm, 1 % Metal film and 1/4 Watt

■ Cable length

Transmission speed Max. total cable length [m]

125 kBaud 500

250 kBaud 250

500 kBaud 100

■■

■ Cable specification

■■

- Cross section: max. 0.78 mm

2

,

corresponding to AWG 18

- Cable type: twisted in pairs, 2 x 2 wires with

drain wire in center

- Screening: Copper-braided screen

or braided screen and foil screen

It is recommended to use the same cable type in

the entire network to avoid impedance mismatch.

■■

■ Address and baud rate setting

■■

Dip switch 1-6 set the VLT frequency converters

address and 7-8 the baud rate.

If the address shall be set to 3 the dip switches

should be set as follow:

■ LEDs

For the device status LED:

1. when the LED is off, the device is off

2. when the LED is green, the device is

operational

3. When the LED is flashing green, the device

is in standby

4. when the LED is flashing red, the device

detects a minor fault

5. when the LED is red, the device detects

an unrecoverable fault

6. when the LED is flashing red/green, the

device is self testing

For the network status LED:

1. when the LED is off, the network is non-

powered/not online

2. when the LED is flashing green, the

network is online but not connected

3. when the LED is green, the network is

4. when the LED is flashing red, the network

online and connected

has a connection time-out

5. when the LED is red, the network has a

critical link failure.

ON

ON = 0

OFF = 1

8

12345

6

7

Switch Settings for DeviceNet Module Baud Rate:

Baud Switch Switch

Rate Setting Setting

87

125 kBPS 0 0

250 kBPS 0 1

500 kBPS 1 0

125 kBPS 1 1

■■

■ DeviceNet literature

■■

Operating Instruction .......................... MG.50.H4.22

Allen-Bradley SLC 500 .........................MC.50.D1.02

Allen-Bradley Control logix ................... MN.51.T1.02

■■

■ EDS files

■■

EDS files for each product series are available on

the internet at:

http://www.danfoss.com/drives

MI.90.I1.02 - VLT is a registered Danfoss trademark

9

High Performance FieldBus cards

■■

■ Modbus+ card VLT 5000 Bookstyle

■■

Network LED

Top connector

Address switch

■■

■ Modbus+ card VLT 5000 Compact

■■

Network LED

Side connector

Address switch

10

MI.90.I1.02 - VLT is a registered Danfoss trademark

High Performance FieldBus cards

E

Modbus Plus data

■■

■ Modbus connection

■■

3 Blue

2 Drain

3 2 1

NOTE: Drain wire and shield should be

insulated.

■■

■ Modbus termination

■■

It is essential that the bus line be terminated

properly. A mismatch of impedance may result in

reflections on the line that will corrupt data

transmission.

The Modbus Plus Option card is provide with a

pluggable screw connector for 176F1551 (Compact

units) and a DB9 connector for 176F1550 (Bookstyle units).

An adaptor cable number 190703 is required for use

with 176F1551.

Mating network connectors should be ordered from

MODICON:

P/N AS-MBKT-085, (1) in-line connector

P/N AS-MBKT-185, (2) terminating connectors

1 White

■ LEDs

• Three flashes, then OFF for 1.7 seconds;

The node is not hearing any other nodes. It

is periodically claiming the token, but finding

no other node to which to pass it. Check

the network for an open circuit or defective

termination.

• Four flashes, then OFF for 1.4 seconds;

The node has heard a valid message from

another node that is using the same

address as this node. The node remains in

this state as long as it continues to hear the

duplicate address. If the duplicate address

is not heard for five seconds, the node then

changes to the pattern of one flash every

second.

NOTE: LED patterns other than those shown

above indicate a possible hardware problem.

■■

■ Cable specification and length

■■

The recommended Modbus Plus cable is Belden

9841, shielded twisted pair.

Minimum length between nodes ........................ 3 m

Maximum length without repeaters ................ 450 m

■■

■ Address and baud rate setting

■■

Dip switch 1-6 set the VLT frequency converters

address. Dip switch are not 7-8 used.

ON

ON = 0

OFF = 1

1234567

8

■ LEDs

Modbus Plus status is shown by flashing a

repetitive pattern on the network indicator (green

LED). The patterns are:

• Six flashes per second;

The node's normal operating state. The

node is successfully receiving and passing

the token. All nodes on the network should

be flashing this pattern.

• One flash per second;

The node is off-line after just being powered

up, or after exiting the four flashes per

second mode.

• Two flashes, then OFF for two seconds;

The node is hearing the token being passed

among other nodes, but is never receiving

the token. Check the network for an open

circuit or defective termination.

MI.90.I1.02 - VLT is a registered Danfoss trademark

The address of the VLT frequency converter will be

L

one higher than the binary value. With the above

settings of the dip switches the address will be 4.

NOTE: Changes in switch settings are only active

after power up.

■■

■ Modbus Plus literature

■■

Operating Instruction .......................... MG.10.M1.22

Modbus ............................... Modbus Plus Tech note

11

■■

■ Modbus RTU card

■■

The Modbus RTU option card is a gateway that

translates Modbus RTU telegrams to Danfoss FC

protocol. As the FC protocol is integrated in all VLT

frequency converts as standard, the Modbus RTU

can interface to all our drives except for the DMS

300.

The Modbus RTU can be built into the control

cassette of the following products:

High Performance FieldBus cards

● VLT 5000

● VLT 6000 HVAC

● VLT 8000 AQUA

With VLT 5000 Flux, VLT 2800, FCM 300 the

Modbus RTU card must be mounted into an

external box.

The code number for the Modbus RTU option card

is 175Z3362.

Modbus RTU

connector

Modbus LED

Modbus RTU

connector

VLT LED

Address and

termination

Baud rate

and Parity

12

Connector to

VLT terminals

MI.90.I1.02 - VLT is a registered Danfoss trademark

High Performance FieldBus cards

Modbus RTU data

■■

■ Modbus RTU connection

■■

RT xD' (-)

Com

RTxD (+)

■■

■ Connector from Modbus RTU to VLT

■■

24V in

RTxD

Com

RTxD'

■ LEDs

There are 2 LEDs on the Modbus RTU option card.

Both LEDs use the same communication pattern:

• Flashing Green (1 Hz): Communication online

(VLT LED) or receiving data (Modbus LED).

to terminal 12 or 13

to terminal 69 (+)

to terminals 39 and 61

to terminal 68 (-)

(spare)

(spare)

■ Baud rate and parity Dip switch

This Dip switch sets the baud rate and the parity on

the Modbus network.

The baud rate can be set to 4800, 9600 (default) or

19200 baud by switches 1-3.

The parity bit can be set to None, Odd or Even

(default) by switches 4-5.

See the Modbus manual for the Dip switch settings.

Switches 6-8 are reserved switches.

■ Address and termination Dip switch

This Dip switch sets the Modbus address and the

termination.

The address can be set by switches 1-8. Default

address is 1.

The termination can be set by switch 9. Default

termination is ON.

See the Modbus manual for the Dip switch settings.

• Flashing Red (1 Hz): Communication time out

• Solid Red: Major fault, communication stopped

■ VLT parameter settings

As the Modbus RTU card interface to the built-in

RS-485 FC profile the following parameters must be

set in the VLT:

VLT 5000/VLT 2800/FCD 300/FCM 300:

Parameter 500 Address: 001

Parameter 501 Baud rate: 9600 baud

Parameter 512 Profile: FC protocol

VLT 6000/VLT 8000

Parameter 500 Profile: FC protocol

Parameter 501 Address: 001

Parameter 502 Baud rate: 9600 baud

MI.90.I1.02 - VLT is a registered Danfoss trademark

13

■■

■ Lonworks cards VLT 5000/6000/8000 Free Topology

■■

High Performance FieldBus cards

Termination of

LonWorks

Status and

Service LED

LonWorks connection

for Bookstyle

Service Pin

Status and

Service LED

LonWorks connection

for Compact

Service Pin

14

MI.90.I1.02 - VLT is a registered Danfoss trademark

LonWorks data for FTP

■■

■ LonWorks connection

■■

High Performance FieldBus cards

Flashing 5 times per secondFlashing 5 times per second

Flashing 5 times per second

Flashing 5 times per secondFlashing 5 times per second

The response to the network management “Wink”

command. The VLT LonWorks node must be reset

to leave the wink state.

61

80

Net B 80

79

Net A 79

Connect signal wires to terminal 79 and to 80 of the

terminal connector. In free topology model,

connections can be reversed.

■■

■ Lonworks termination

■■

The option card has a termination resistor built-in

which is activated by a terminator switch. Use of

the terminator is optional, depending upon the

network configuration. If termination is provided

elsewhere in the network, the termination function

should be OFF. Terminator switch position functions

are provided in the table below.

TT

erminationermination

T

ermination

TT

erminationermination

No termination Net Term Off Don’t Care

Single termination Net Term On Net Term Off

Double termination Net Term On Net Term On

■ LEDs

There are 2 LEDs on the LonWorks option card:

Green LED: Status LED

Red LED: Service LED, see LonWorks manual.

Pos 1Pos 1

Pos 1

Pos 1Pos 1

Pos 2Pos 2

Pos 2

Pos 2Pos 2

OFF

No power on board or hardware fault.

■ Cable length

Free Topology Specifications

Maximum Maximum

node-to-node distance total wire length

Belden 85102 500 m 500 m

Belden 8471 400 m 500 m

Level IV, 22AWG 400 m 500 m

JY (St) Y 2x2x0.8 320 m 500 m

Maximum bus length for segments with FTT-10

transceivers and with both FTT-10 and LPT-10

transceivers.

FTT-10 FTT-10 and

transceivers only LPT-10 transceivers

Belden 85102 2700 m 2200 m

Belden 8471 2700 m 2200 m

Level IV, 22AWG 1400 m 1150 m

JY (St) Y 2x2x0.8 900 m 750 m

Danfoss recommends the use of shielded LonWorks

communication cable for instance Belden 8719.

The Status LED patterns are:

ONON

ON

ONON

There is power on the board but there has not been

any communication to an input network variable in

the last 2 seconds.

Flashing 10 times per secondFlashing 10 times per second

Flashing 10 times per second

Flashing 10 times per secondFlashing 10 times per second

There is regular network communication to the

VLT’s input network variables.

Flashing intermittentlyFlashing intermittently

Flashing intermittently

Flashing intermittentlyFlashing intermittently

There is network communication to the VLT’s input

network variables but input network variables are

received at a period greater than 2 seconds.

MI.90.I1.02 - VLT is a registered Danfoss trademark

■■

■ LonWorks literature

■■

Operating Instruction .......................... MG.60.N1.02

LonMaker .............................................. MI.60.L1.02

■■

■ Xif files

■■

Xif files are available on the internet at:

http://www.danfoss.com/drives

15

High Performance FieldBus cards

■■

■ Lonworks cards VLT 5000/6000 78 kbps and 1.25 Mbps

■■

Terminator

switch

Status LED

Service pin

Status LED

Service pin

16

MI.90.I1.02 - VLT is a registered Danfoss trademark

LonWorks data for 78 kbps and

1.25 Mbps

■■

■ LonWorks connection

■■

High Performance FieldBus cards

Flashing 5 times per secondFlashing 5 times per second

Flashing 5 times per second

Flashing 5 times per secondFlashing 5 times per second

The response to the network management “Wink”

command. The VLT LonWorks node must be reset

to leave the wink state.

61

80

Net B 80

79

Net A 79

Connect signal wires NET A to terminal 79 and NET

B to 80 of terminal connector.

■■

■ Lonworks termination

■■

The option card has a termination resistor built-in

which is activated by a terminator switch. Use of

the terminator is optional, depending upon the

network configuration. If termination is provided

elsewhere in the network, the termination function

should be OFF. Terminator switch position functions

are provided in the table below.

Switch 1:

Network TNetwork T

Network T

Network TNetwork T

The VLT LonWorks node is terminated.

ermination ONermination ON

ermination ON

ermination ONermination ON

OFFOFF

OFF

OFFOFF

No power on board or hardware fault.

■ Cable length

78 kbps and 1.25 Mbps Specifications

78 kbps 1.25 Mbps

Network bus lenght, Typical 2000 m 500 m

Network bus lenght, Worst case 1330 m 125 m

■■

■ Cable specification

■■

Network Bus Wiring UL Level IV, 22 AWG (0.65 mm)

twisted pair

Network Stub Wiring UL Level IV, 22 or 24 AWG (0.5

mm) twisted pair

Danfoss recommends the use of shielded LonWorks

communication cable for instance Belden 8719.

Network TNetwork T

Network T

Network TNetwork T

The VLT LonWorks node is not terminated.

■ LEDs

There are 2 LEDs on the LonWorks option card:

Green LED: Status LED

Red LED: Service LED, see LonWorks manual.

The Status LED patterns are:

ONON

ON

ONON

There is power on the board but there has not been

any communication to an input network variable in

the last 2 seconds.

Flashing 10 times per secondFlashing 10 times per second

Flashing 10 times per second

Flashing 10 times per secondFlashing 10 times per second

There is regular network communication to the

VLT’s input network variables.

Flashing intermittentlyFlashing intermittently

Flashing intermittently

Flashing intermittentlyFlashing intermittently

There is network communication to the VLT’s input

network variables but input network variables are

received at a period greater than 2 seconds.

ermination OFFermination OFF

ermination OFF

ermination OFFermination OFF

■■

■ LonWorks literature

■■

Operating Instruction ........................... MG.60.E4.02

LonMaker .............................................. MI.60.L1.02

■■

■ Xif files

■■

Xif files are available on the internet at:

http://www.danfoss.com/drives

MI.90.I1.02 - VLT is a registered Danfoss trademark

17

■■

■ VLT 2800 fieldbus cards.

■■

High Performance FieldBus cards

18

Profibus card DeviceNet card

MI.90.I1.02 - VLT is a registered Danfoss trademark

Plugable DeviceNet

connector.

High Performance FieldBus cards

VLT 2800 Profibus card

■■

■ VLT 2800 Profibus connection

■■

68 = RxD/TxD-P red cable

69 = RxD/TxD-N green cable

■■

■ Technical data

■■

Baudrate ........................................ 9.6 - 3000 kbaud

Adress area .................................................... 0 - 125

VLT 2800 DeviceNet card

■■

■ VLT 2800 DeviceNet connection

■■

■■

■ Drop cable

■■

An alternative to splicing two trunk lines in the connector on the control card, is using a DeviceNet

connection box or a T-connector. For this kind of installation a drop cable is available as an option.

■■

■ 12 M baud Profibus card

■■

VLT 2800 can also be delivered with a 12 M baud

Profibus control card.

Order number: .......................................... 195N0603

The order number is only for the control card with

12 M baud Profibus. The power part should be order

separately.

For other technical data on Profibus, see page 5

Profibus Data.

Drop cable ordering number: 195N3113

For other technical data on DeviceNet, see page 9

DeviceNet Data.

MI.90.I1.02 - VLT is a registered Danfoss trademark

19

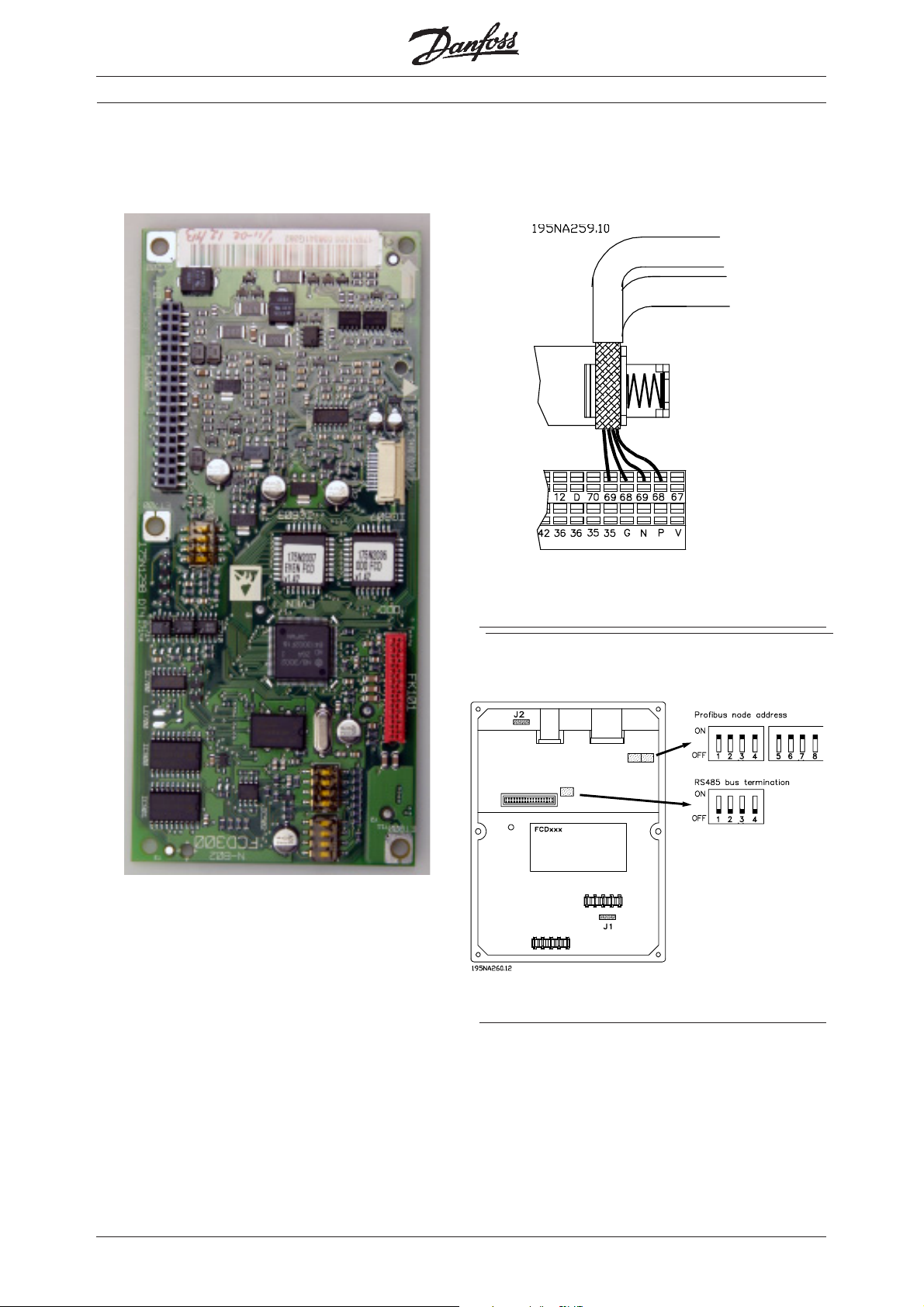

■■

■ FCD 300 Profibus card

■■

High Performance FieldBus cards

■■

■ FCD 300 Profibus connection

■■

Profibus card

68 = RxD/TxD-P red cable

69 = RxD/TxD-N green cable

■■

■ FCD 300 DIP switches

■■

20

MI.90.I1.02 - VLT is a registered Danfoss trademark

■■

■ FCD 300 DeviceNet card

■■

High Performance FieldBus cards

■■

■ FCD 300 DeviceNet connection

■■

Terminal Colour Func tion

67 Red 24 Volt

68 White Can_high

69 Blue Can_low

70 Black GND

DBar Drain

DeviceNet card

■■

■ FCD 300 Plug 175N2279

■■

The DeviceNet bus connection can be performed

through a plug, that is to be mounted in the

FCD 300 housing (M16 gland hole) and wired

to the inside terminal strip.

MI.90.I1.02 - VLT is a registered Danfoss trademark

21

■■

■ FCD 300 AS-i bus card

■■

High Performance FieldBus cards

■■

■ FCD 300 AS-i connection

■■

The AS-I bus lines are to be connected to terminals

68 and 69 of the internal terminal strip. A round drop

cable can be wired directly into the terminals by

using a cable gland. A sealed M12 connector can

be mounted into one of the M16 gland holes in the

FCD enclosure. The M12 connector is to be wired

to the terminals 68, 69 on the control terminal

block. The connection is in the following way:

AS-i + to 68

AS-i - to 69.

■■

■ FCD 300 AS-i Plug 175N2281

■■

The AS-i bus connection can be performed

through a plug, that is to be mounted in the

FCD 300 housing (M16 gland hole) and wired

to the inside terminal strip.

Pin 1 (Brown) to AS-i + (68)

Pin 3 (Blue) to AS-i - (69)

22

AS-i bus card

MI.90.I1.02 - VLT is a registered Danfoss trademark

■■

■ DMS 300 Profibus card

■■

High Performance FieldBus cards

■■

■ AKD Lon card

■■

Profibus connection

Profibus termination

The AKD Lon card can only be used together with

AKD 2800 and AKD 5000.

Adap-Kool

Lon connector

Connector to

VLT terminals

MI.90.I1.02 - VLT is a registered Danfoss trademark

23

■■

■ Miscellaneous, Accessories to Fieldbus

■■

VLT 3000 to 5000 converter software (17.1x):

The VLT 3000 to 5000 converter is a special

software version which is intended to convert a VLT

3000 to a VLT 5000, which replaces the VLT 3000.

The converter software is typical used to replace a

VLT 3000 with a Profibus interface, but it can also

replace a VLT 3000 in a RS-485 network.

With the converter software we only support

Profibus DP Norm, so a replaced VLT 3000 should

have a software version 3.00 or higher.

The software version number can be read out in

parameter 603, choice 3.

To purchase (obligatory):

● VLT 5000 ................................................ 175XXXXX

● Converter software 17.1x ....................... 175z3389

High Performance FieldBus cards

Optional:

● Profibus option excl. memory option ...... 175z0402

● Backplate for 5001-5005 Compact IP 20

ordering no. ................................................ 175Z2349

● Separate relay card ................................. 175Z1814

If two high voltage relays are needed in VLT 5000 a

separate relay card must be purchased.

● Ordering number ..................................... 176F1814

See also the VLT 3000 to 5000 converter manual

MG.50.Q1.02.

24

MI.90.I1.02 - VLT is a registered Danfoss trademark

■■

■ Miscellaneous, Accessories to Fieldbus

■■

High Performance FieldBus cards

Profibus kit for SUB D9 connection:

This kit can be mounted together with a VLT 5000/

6000/8000 Profibus card and the standard SUB D9

Profibus connector can be used.

Product Ordering number

VLT 5001-5027 230 V ............................... 175Z3568

VLT 5032-5052 230 V ............................... 176F1822

VLT 5001-5102 400 V ............................... 175Z3568

VLT 5125-5500 400 V ............................... 176F1822

VLT 6002-6032 230 V ............................... 175Z3568

VLT 6042-6072 230 V ............................... 176F1822

VLT 6002-6122 400 V ............................... 175Z3568

VLT 6150-6550 400 V ............................... 176F1822

VLT 8002-8032 230 V ............................... 175Z3568

VLT 8042-8072 230 V ............................... 176F1822

VLT 8002-8122 400 V ............................... 175Z3568

VLT 8150-8550 400 V ............................... 176F1822

Top connection of Fieldbus by IP 20 Unit:

It is now possible to make a top connection of the

Fieldbus cable by all IP 20 units by VLT 5000/6000/

8000. The connection will be similar to a book style

connection.

The top connection can be done on all VLT 5000/

6000/8000 IP 20 unit that are produce from the

week 15 2003 (G363) except VLT 5032-5052 230 V,

VLT 5125-5500 400 V, VLT 6042-6072 230 V, VLT

6150-6550 400 V, VLT 8042-8072 230 V and VLT

8150-8550 400 V.

Top connection on VLT 5072-5102, 6102-6122 and

8102-8122 is available from week 36 2003.

It is also possible to retrofit VLT 5000/6000/8000 IP

20 unit with a clamp (175Z3477), so that a top

connection can be done.

In this case the Drive need to be produce after

week 23 2002 (G232)

By VLT 5072-5102, 6102-6122 and 8102-8122 can

the kit first by install from week 36 2003 (G363).

MI.90.I1.02 - VLT is a registered Danfoss trademark

Ordering number 175Z3477

25

High Performance FieldBus cards

Fieldbus options ordering number for VLT 5000:

■

Profibus DPV1:

Type Description Ordering no. Ordering no. with conformal coating

Profibus option DPV1 Incl. memory option 175Z0404 175Z2625

Profibus option DPV1 excl. memory option 175Z0402 175Z4363

Profibus FMS:

Type Description Ordering no. Ordering no. with conformal coating

Profibus option FMS Incl. memory option 175Z3722 175Z3723

Interbus:

Interbus option Incl. memory option 175Z3122 175Z3191

Interbus option excl. memory option 175Z2900

DeviceNet:

DeviceNet option Incl. memory option 176F1580 176F1581

DeviceNet option excl. memory option 176F1584

Modbus Plus:

Modbus Plus for Compact units Incl. memory option 176F1551 176F1553

Modbus Plus for Compact units Excl. memory option 176F1559

Modbus Plus for Bookstyle units Incl. memory option 176F1550 176F1552

Modbus Plus for Bookstyle units Excl. memory option 176F1558

LonWorks:

LonWorks option, Free topology Incl. memory option 176F1500 176F1503

LonWorks option, Free topology excl. memory option 176F1512

LonWorks option, 78 KBPS Incl. memory option 176F1501 176F1504

LonWorks option, 78 KBPS excl. memory option 176F1513

LonWorks option, 1.25 MBPS Incl. memory option 176F1502 176F1505

LonWorks option, 1.25 MBPS excl. memory option 176F1514

26

MI.90.I1.02 - VLT is a registered Danfoss trademark

High Performance FieldBus cards

■

Fieldbus options ordering number for VLT 6000 HVAC:

Profibus DPV1:

Type Description Ordering no. Ordering no. with conformal coating

Profibus option DPV1 Incl. memory option 175Z7800 175Z2905

Profibus option DPV1 excl. memory option 175Z0402 175Z4363

Profibus FMS:

Type Description Ordering no. Ordering no. with conformal coating

Profibus option FMS Incl. memory option 175Z4207 175Z4208

LonWorks:

LonWorks option, Free topology Incl. memory option 176F1515 176F1521

LonWorks option, Free topology excl. memory option 176F1512

LonWorks option, 78 KBPS Incl. memory option 176F1516 176F1522

LonWorks option, 78 KBPS excl. memory option 176F1513

LonWorks option, 1.25 MBPS Incl. memory option 176F1517 176F1523

LonWorks option, 1.25 MBPS excl. memory option 176F1514

DeviceNet:

DeviceNet option Incl. memory option 176F1586 176F1587

DeviceNet option excl. memory option 176F1584

■

Fieldbus options ordering number for VLT 8000 Aqua:

Profibus DPV1:

Type Description Ordering no. Ordering no. with conformal coating

Profibus option DPV1 Incl. memory option 175Z3685 175Z3686

Profibus option DPV1 excl. memory option 175Z0402 175Z4363

LonWorks:

LonWorks option, Free topology Incl. memory option 176F0225 LonWorks option, Free topology excl. memory option 176F1512

DeviceNet:

DeviceNet option Incl. memory option 176F0224 DeviceNet option excl. memory option 176F1584

MI.90.I1.02 - VLT is a registered Danfoss trademark

27

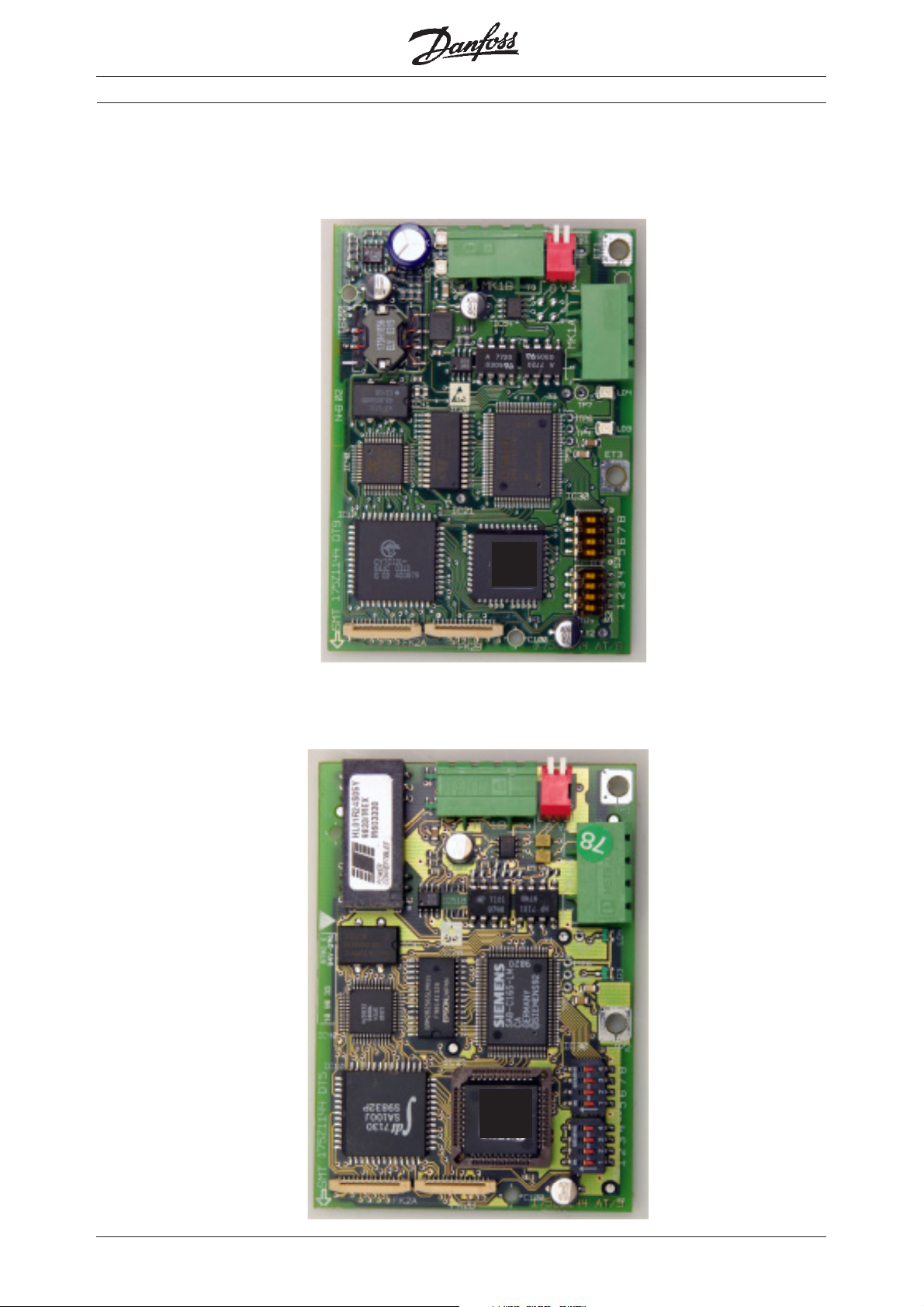

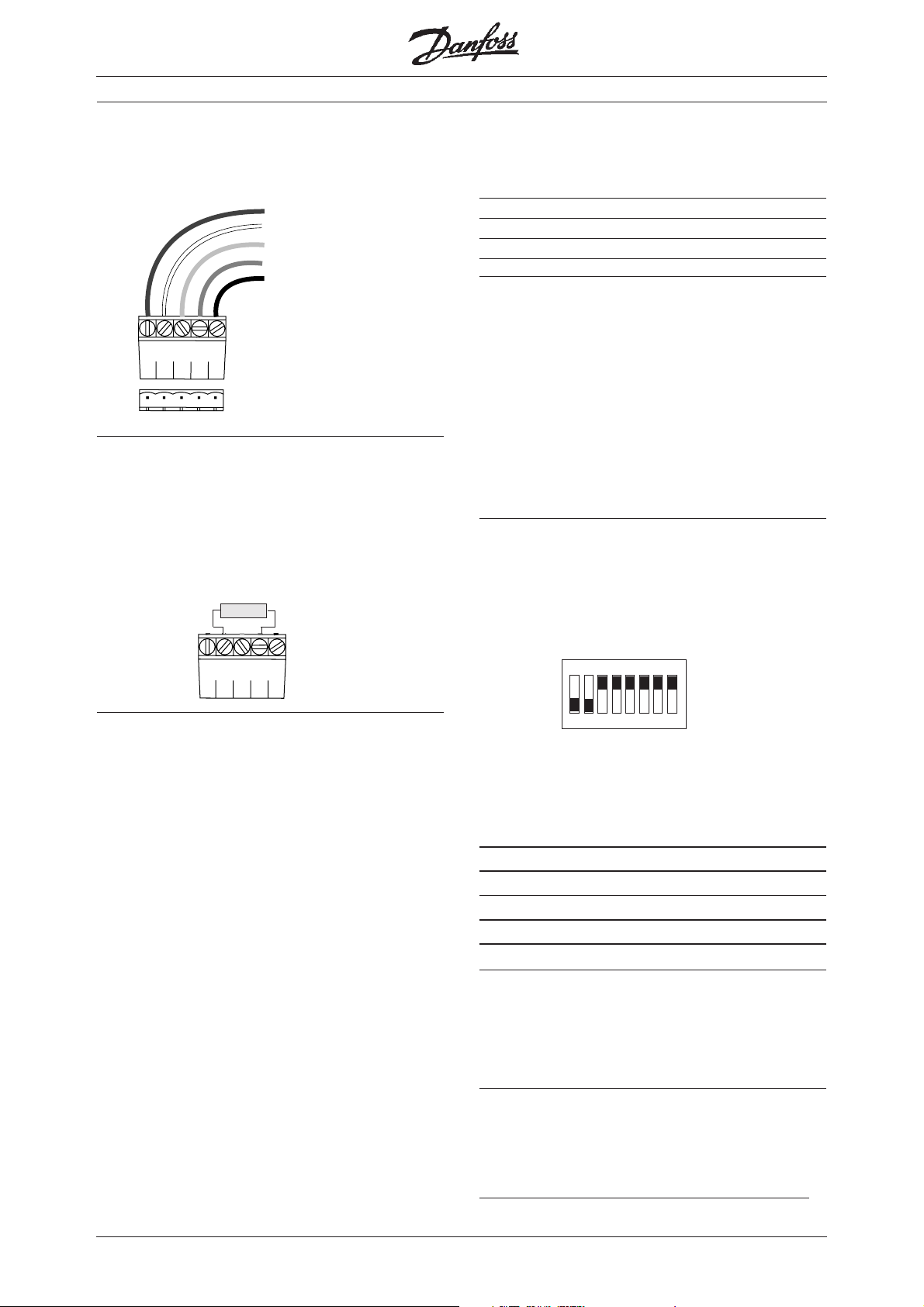

■■

■ Previous produce Profibus ca rds

■■

High Performance FieldBus cards

28

MI.90.I1.02 - VLT is a registered Danfoss trademark

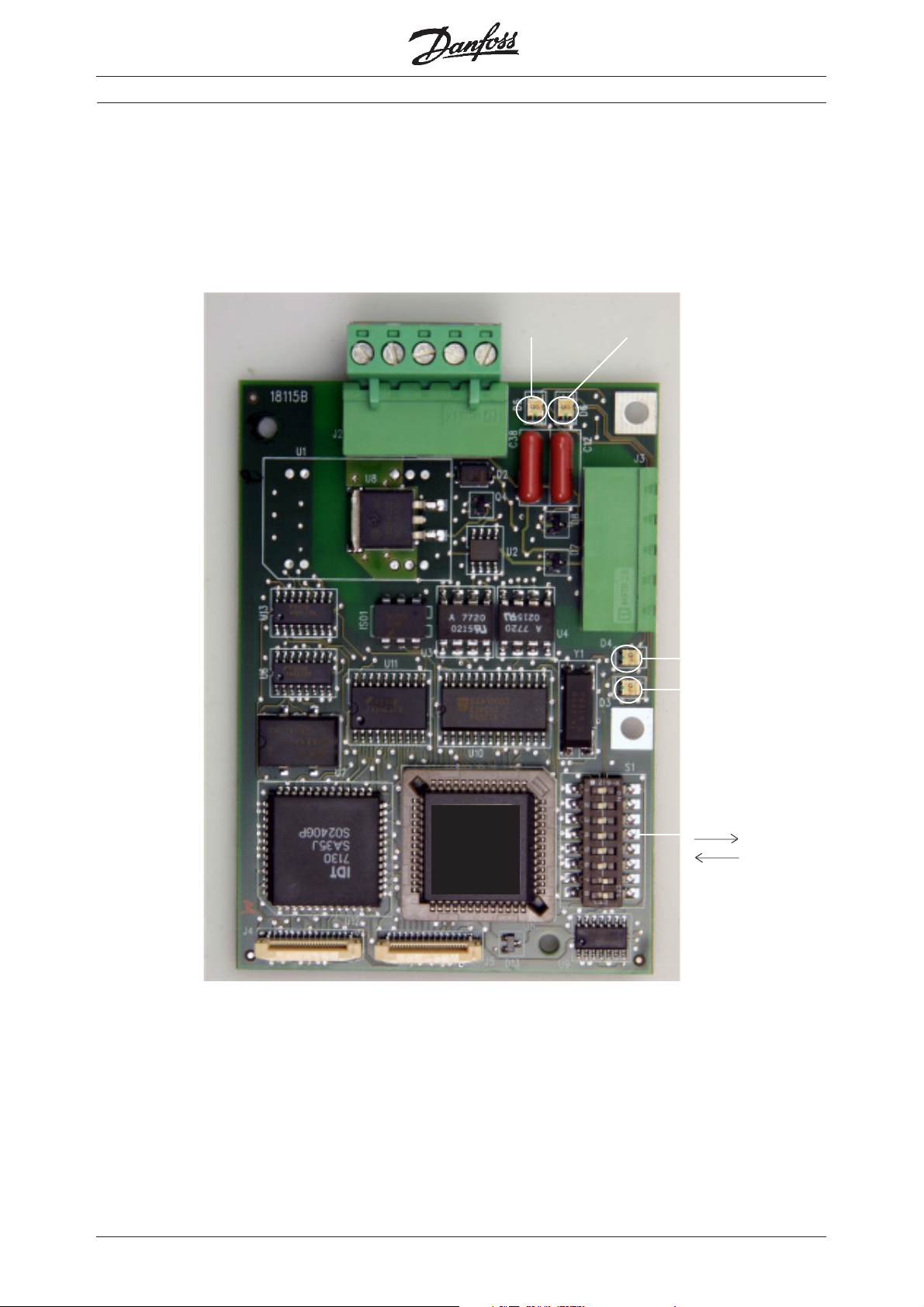

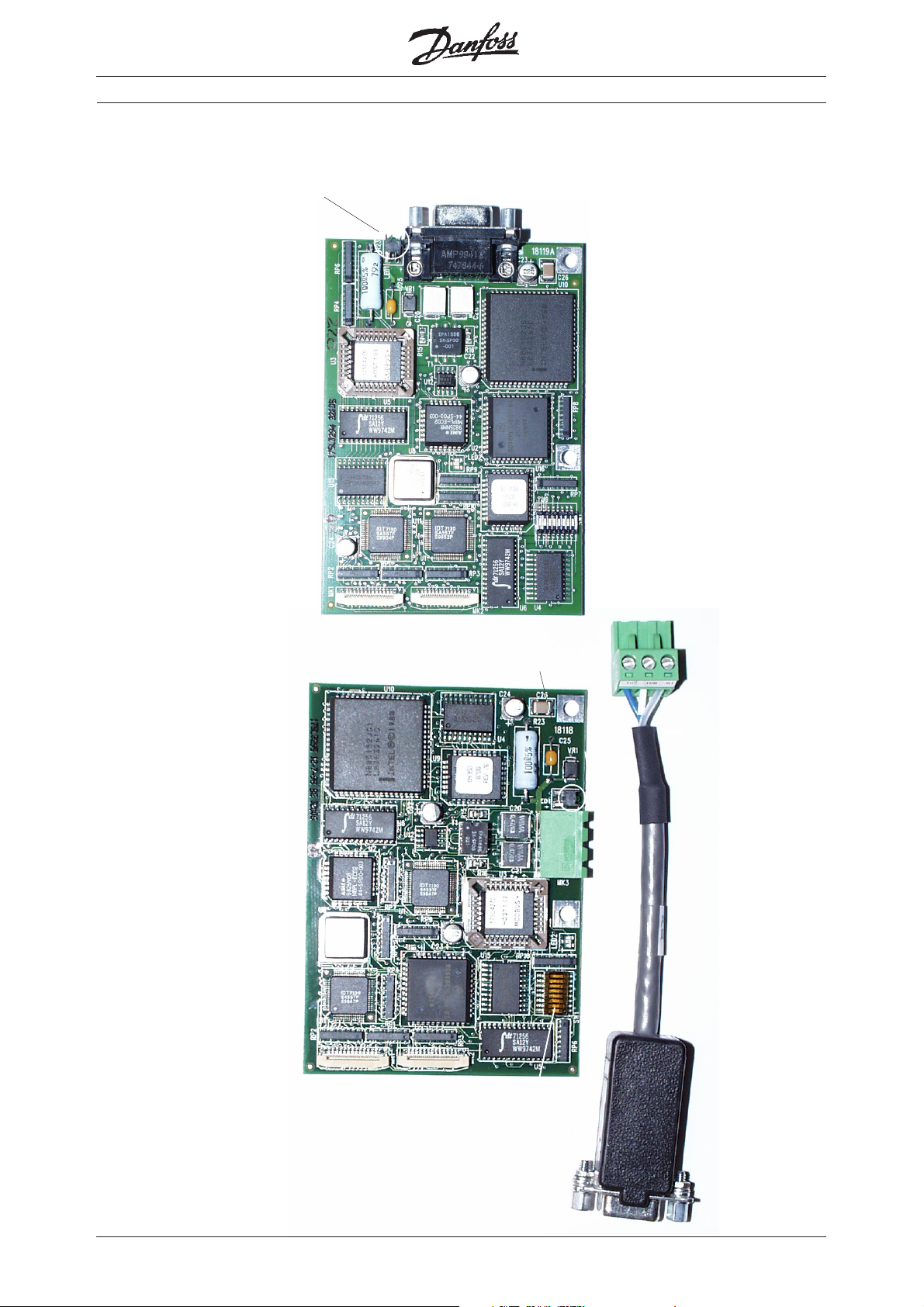

■■

■ Previous produce DeviceNet ca rds

■■

Revisions number

18115A

High Performance FieldBus cards

Revisions number

18115D

MI.90.I1.02 - VLT is a registered Danfoss trademark

29

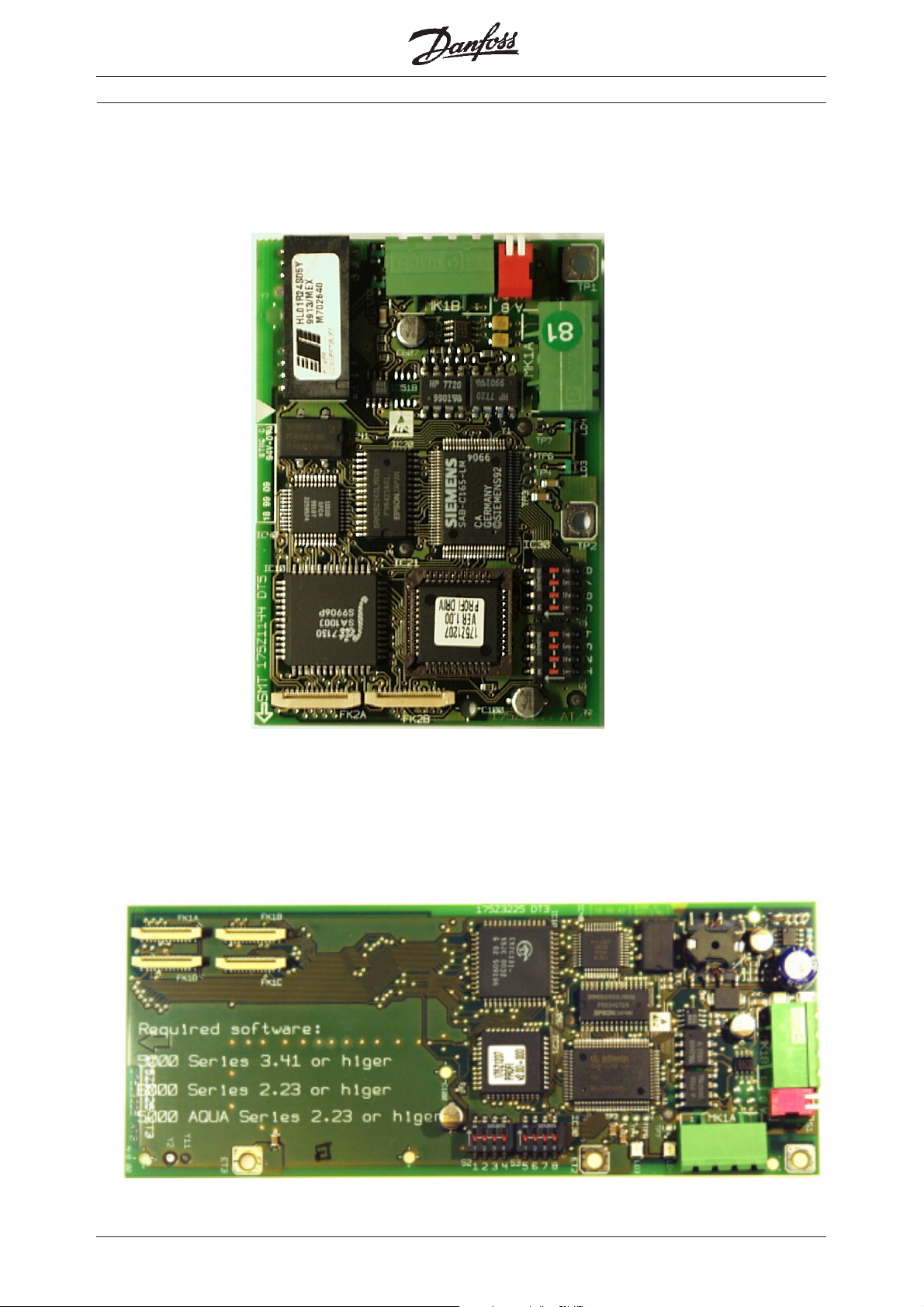

■■

■ Previous produce LonWorks ca rds

■■

High Performance FieldBus cards

Terminator

Switch

Revision number

18110A

Service Pin

Terminator

Switch

Revision number

18110B

Service Pin

Terminator

Switch

This ferrite coil is

only mounted on

revision C

Revision number

18110C

Service Pin

This capacitor is

only mounted on

revision B.

The capacitor can

also be mounted on

revision A card.

30

MI.90.I1.02 - VLT is a registered Danfoss trademark

■■

■ Previous produce Modbus RTU ca rds

■■

High Performance FieldBus cards

Modbus RTU

connector

Modbus RTU LED

VLT LED

6-pin connector to

VLT terminals

Address and termination Dip switch

Pin 1

Baud rate and parity

Dip switch

Pin 1

MI.90.I1.02 - VLT is a registered Danfoss trademark

31

Loading...

Loading...