Page 1

1MG.30.A7.02 - VLT® is a registered Danfoss trademark

VLT® 3000 Series

Product Manual

Software version: 3.0 and 3.11

Warning:

Touching the electrical parts, even when the mains supply

has been switched off, can cause serious injury or death.

When using VLT

®

types 3002-3052: Wait 4 minutes

When using VLT

®

types 3060-3250: Wait 14 minutes

This product manual applies to all VLT® 3000 frequency converters with software

version 3.0 and 3.11:

* Version 3.0 covers VLT

®

3002-3022, 200/400/500 V and VLT® 3032-3052, 400/500 V.

* Version 3.11 covers VLT

®

3032-3052, 230 V, and VLT® 3060-3250, 380/500 V.

Where version 3.11 deviates from version 3.0 this is described.

The size and voltage of the frequency converter will be identified automatically on

start-up.

Page 2

2 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Electrical safety

The frequency converter contains

dangerous voltages when connected

to the mains. Improper connection of

the motor or frequency converter may

cause equipment failure, serious injury or death.

Therefore follow the directions in this

manual, as well as local and national

safety codes.

Touching the electrical parts, even

when the power supply has been

switched off, can cause serious injury

or death.

When using VLT® 3002-3052:

Wait 4 minutes.

When using VLT® 3060-3250:

Wait 14 minutes.

Warning

These rules concern

your safety

1. When repairs are undertaken, the mains

supply to the VLT

®

must be disconnected.

2. The “Stop/Reset” key on the frequency

converter’s keyboard does not

disconnect the power supply and may

therefore not be used as a safety

switch.

3. The unit must be properly grounded,

the user must be protected against

supply voltage and the motor against

overload according to national and local

codes.

4. The leakage currents to ground are

higher than 3 mA.

5. The factory setting does not incorpor-

ate protection against motor overload.

For this function parameter 315 is set

at data value

“trip”

[2] or data value

“warning”

[1].

Note:

This function is initialised at 1.16 x rated

motor current (parameter 107).

Warning against

improper start

1. The motor can be stopped using digital commands, bus commands,

references or local stop, while the

frequency converter is connected to

the mains. If personal safety requires

elimination of any possibility of unintended start, these stops will not be

sufficient.

2. The motor can start during parameter

operation. Therefore always activate

the ”Stop/Reset” key, after which

data can be changed.

3.

A stopped motor can start if a fault

occurs in the frequency converter’s

electronics or after a temporary

overload, mains fault or faulty motor

connection.

CAUTION: It is the responsibility of the user or person installing the drive to provide

proper grounding and branch circuit protection for incoming power and motor

overload according to National Electrical Codes (NEC) and local codes.

For the

North American

market

The Electronic Thermal Relay (ETR) in UL listed VLT®'s provides class 20 motor

overload protection in accordence with NEC in single motor applications, when

parameter 315 is set for "TRIP" and parameter 107 is set for nominal motor

rated (nameplate) current. Effective from software version 1.10.

Page 3

3MG.30.A7.02 - VLT® is a registered Danfoss trademark

Contents

Product description

Quick setup

How to use this manual ........................ 5

For first-time Danfoss VLT® users ........ 5

For experienced Danfoss VLT® users... 5

Available documentation ...................... 5

In most cases ....................................... 6

Programming keys ............................... 6

External operation ................................ 6

Start-up ................................................ 6

If the factory setting has been changed 7

Quick setup .......................................... 7

Introduction .......................................... 8

Technology ........................................... 9

Sizing ................................................... 12

Product range....................................... 14

Technical data ...................................... 23

Dimensions........................................... 28

Description of terminals........................ 31

Connection examples........................... 32

About this manual

Installation

Mechanical installation ......................... 40

Electrical installation............................. 45

Connection of VLT

®

......................................................

46

Connection of motor ............................. 50

EMC installation ................................... 51

What is CE-labelling? ........................... 51

The control panel.................................. 60

Display layout ....................................... 61

Initialization........................................... 63

Avoid unwanted data change ............... 64

Menu build-up....................................... 65

Group description ................................. 66

Parameter description .......................... 82

Display messages ................................ 123

Operational instructions

Page 4

4 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Special conditions

Galvanic isolation -

Earth leakage current ........................... 128

Extreme running conditions.................. 129

du/dt and peak voltage on motor.......... 130

Acoustic noise ...................................... 130

Thermal motor protection ..................... 130

Derating................................................ 131

EMC testresults .................................... 134

Vibration and shock.............................. 137

Air humidity .......................................... 137

Efficiency .............................................. 138

Mains supply

interference / harmonics....................... 139

Power factor ......................................... 139

Service

Fault messages ................................... 140

Electrostatic discharge (ESD)............... 141

Fault location ........................................ 142

Accessories

External mounting

of display .............................................. 146

Connection of brake resistors............... 146

Connection of option cards................... 146

Mounting of bonding plate for

UL approval.......................................... 148

Mounting of fan option.......................... 148

Factory settings

Factory settings .................................... 149

Index

Index .................................................... 154

Page 5

5MG.30.A7.02 - VLT® is a registered Danfoss trademark

About this manual

How to use this manual This manual has sections on the VLT®’s

performance and on installation and operation of the VLT®, as well as a section on

special conditions.

There is also a section on service and an

appendix for quick referral to factory settings. The index can be a help if you wish

to look up a specific item in the manual.

For first-time Danfoss

VLT® users

If you have not used a Danfoss VLT® before, “Quick setup” will be a help, and also

“Installation” and “Operational instructions”.

Pay attention to the safety rules on page

2 before start-up.

If you already have experience with the

Danfoss VLT

®

, you will find the “Quick

setup” section most useful.

For experienced Danfoss

VLT

®

users

For more information see the other sections, of which “EMC-correct installation”

and “Special conditions” will be particularly

useful.

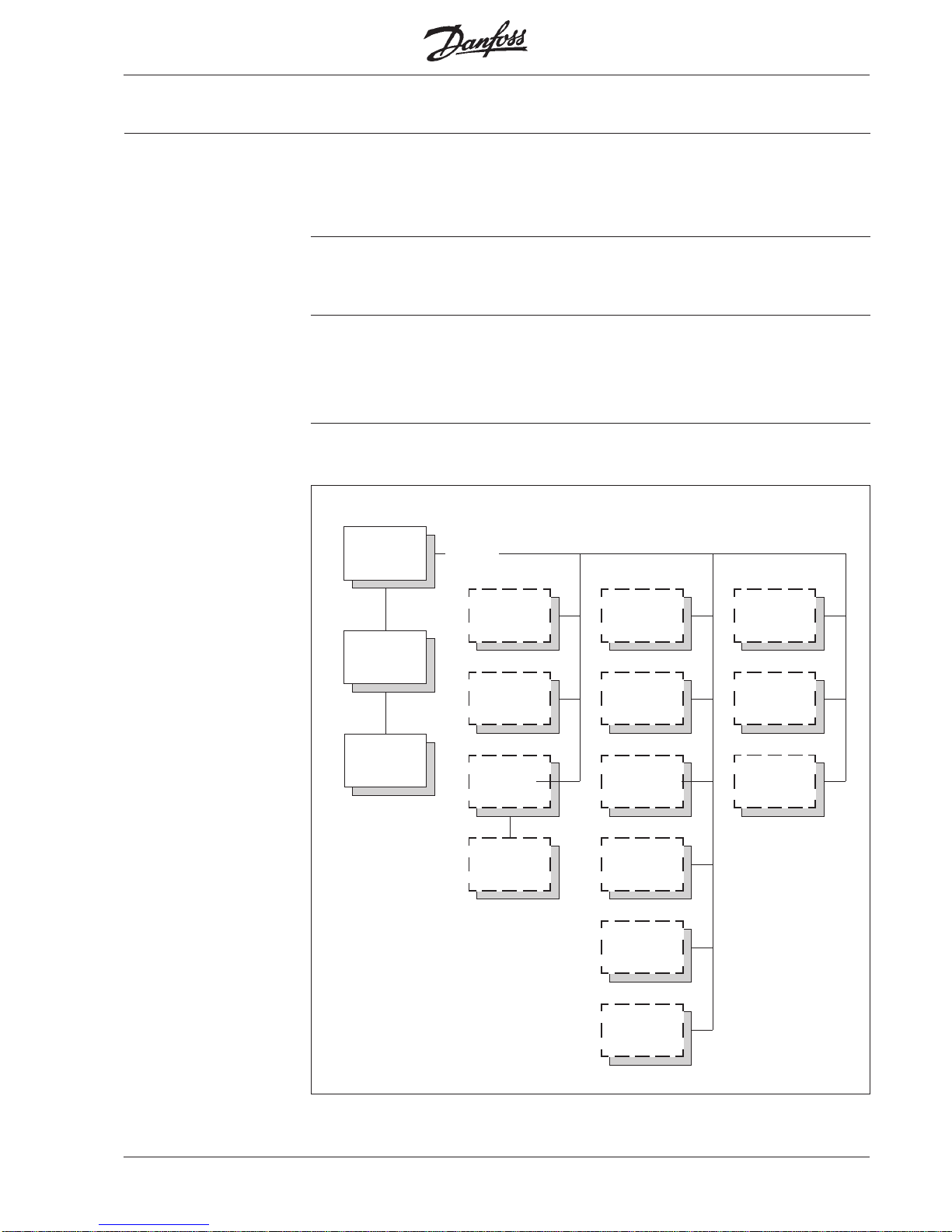

Available

documentation

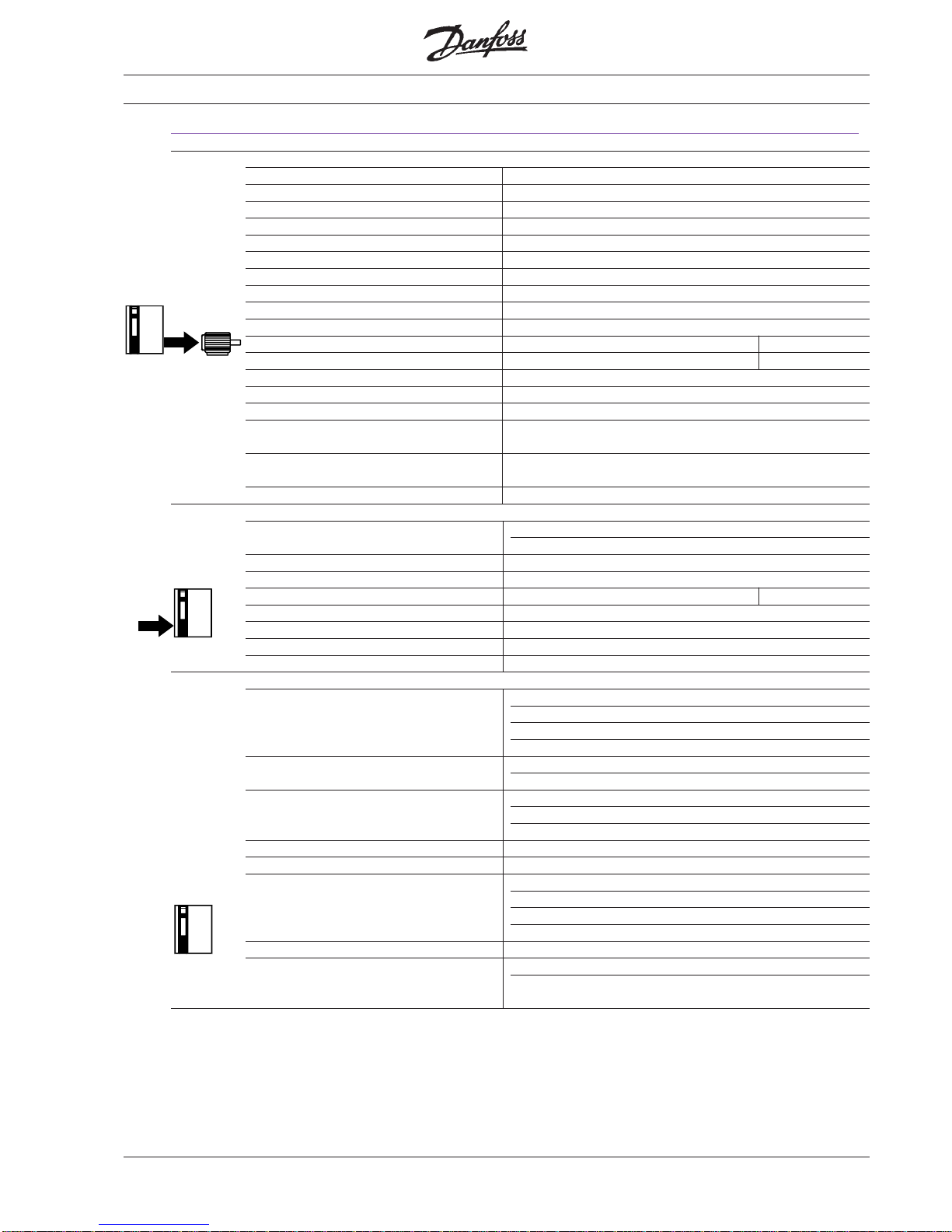

The following chart shows what literature

is available on the VLT® 3000 Series.

Note that there can be deviations between different countries.

Option

Product

manual

MG.30.AX.02

Data sheet

MD.30.AX.02

All

users

Relay

option

MI.10.AX.YY

PC

Software

MZ.64.FX.YY

PROFIBUS

manual

MG.10.AX.YY

PROFIBUS

data sheet

MD.10.AX.YY

RFI

module

MI.62.FX.YY

RFI

option

MI.62.GX.YY

RFI - LC

module

MI.65.FX.YY

Clamp

module

MI.65.IX.YY

Brake

module

MI.62.GX.YY

LC

module

MI.65.FX.YY

RFI

option

MI.60.AX.YY

RFI

option

MI.60.BX.YY

Brake

resistor

MI.65.BX.YY

X = Revision of edition

YY = Language version

Page 6

6 MG.30.A7.02 - VLT® is a registered Danfoss trademark

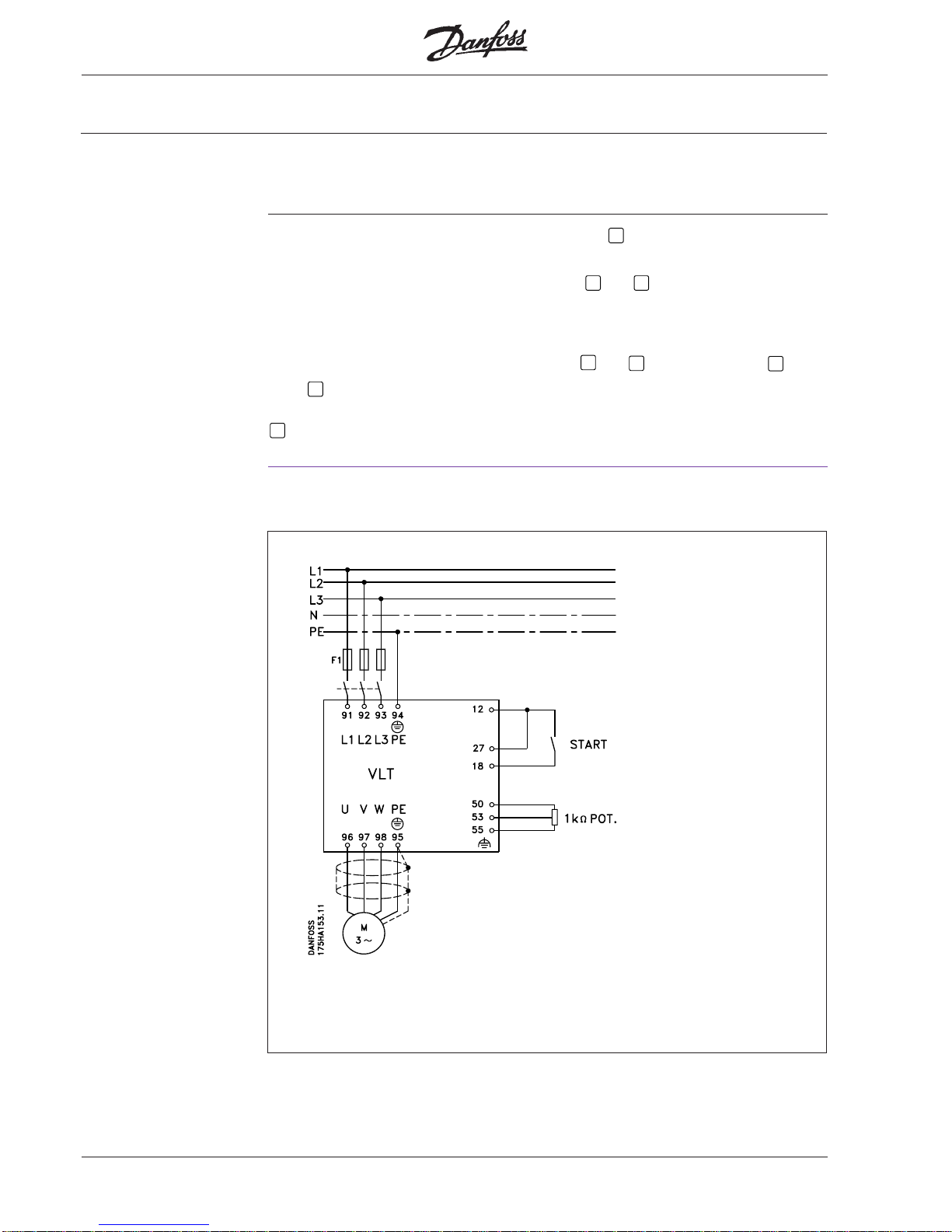

In most cases In most cases it is sufficient to program

the VLT® according to items 1-10 (see

next page).

Note: All settings are based on factory settings, but the following must

be selected: 103, 104 and 105.

Screen for control cables, is mounted under terminal clamp according to

instructions on p. 57.

Connection example

Programming keys When the supply voltage is connected, the

VLT® is automatically in DISPLAY MODE

after start-up. Please note that the size and

voltage of the VLT

®

are shown on the

display during start-up. If the VLT® voltage

and size shown do not correspond to the

actual VLT

®

/mains voltage, the correct VLT

®

size and mains voltage can be selected in

parameter 650.

A potentiometer 1 kΩ is connected to

terminals 50, 53 and 55, see connection

example.

External operation

Start the frequency converter by connecting

+24 V D.C. (terminal 12) to start (terminal 18)

and freewheel stop (terminal 27).

Start-up

Press once to switch to MENU GROUP

MODE. From MENU GROUP MODE press

Menu

Menu

once to switch to MENU PARAMETER

MODE.

Use the

Data

key to switch to DATA MODE.

Data can now be changed.

The+and–keys are used to select a

group of parameters, one particular parameter or a data value.

Data values can only be changed using

the

+

and–keys. Pressing the

Menu

key

stores the new data value in the memory.

This also takes place automatically after 20

seconds if data values have been changed.

Quick setup

Page 7

7MG.30.A7.02 - VLT® is a registered Danfoss trademark

Item Parameter Description Settings Display

1 000 Language Select: "English" ENGLISH

2 103 Motor output See nameplate and select closest setting

3 104 Motor voltage See nameplate

4 105 Motor frequency See nameplate

Items 1-4 must be carried out first.

5 106 Automatic Select: "On". ON

motor adaption The compensation menus 109-113 are now tuned automatically.

During automatic motor adaption the motor should be unloaded or

loaded at max. 50%.

Automatic motor adaption is not possible in connection with

parallel running of several motors on one VLT

®

. This also applies

to motor outputs which cannot be set in parameter 103, and

synchronous, reluctance and other specialised motors.

After tuning the VLT

®

is reset by pressing the Stop/Reset key and

restarted by pressing the Start key.

Note: During automatic motor adaption the motor will start

for a short period.

6 201 Min. frequency Set required frequency

7 202 Max. frequency Set required frequency

8 215 Ramp-up 1 Set required ramp time

9 216 Ramp-down 1 Set required ramp time

10 Start frequency converter This is by supplying terminals 18 and 27 with 24 V D.C. from

terminal 12 or by using an external 24 V D.C. voltage.

Quick setup

If the factory setting

has been changed

If the factory setting has been changed

initialisation must be carried out.

In most cases it is sufficient to program

the VLT

®

according to items 1-10.

Quick setup

Standard motor running in constant torque application without a brake module on the frequency converter

The following settings are also used for specialised motors and parallel coupled motors, or variable torque

application or when a brake module is mounted

Item Parameter Description Settings Display

1 100 Load For normal applications with

constant torque:

Select: “Constant torque compensated”

CT WITH COMP

For

centrifugal pumps and fans:

Select: “VT medium” VT MODE-MED

For

centrifugal pumps and fans with heavy start:

Select: “VT Medium CT Start” VT MED W/CT

For

synchronous motors, parallel coupled motors or specialised motors

Select: “Constant torque”

CT MODE

2 300 Brake option If

brake option/module

is used:

Select: “Applied” APPLIED

3 Start frequency converter This is by applying 24 V D.C. to terminals 18 and 27 from

terminal 12 or by using external 24 V D.C. voltage.

The following settings are used for local operation and start

Item Parameter Description Settings Display

1 003 Operation mode Select: “Local” LOCAL

2 004 Local reference Set required output frequency using the "+" or "−" keys.

Page 8

8 MG.30.A7.02 - VLT® is a registered Danfoss trademark

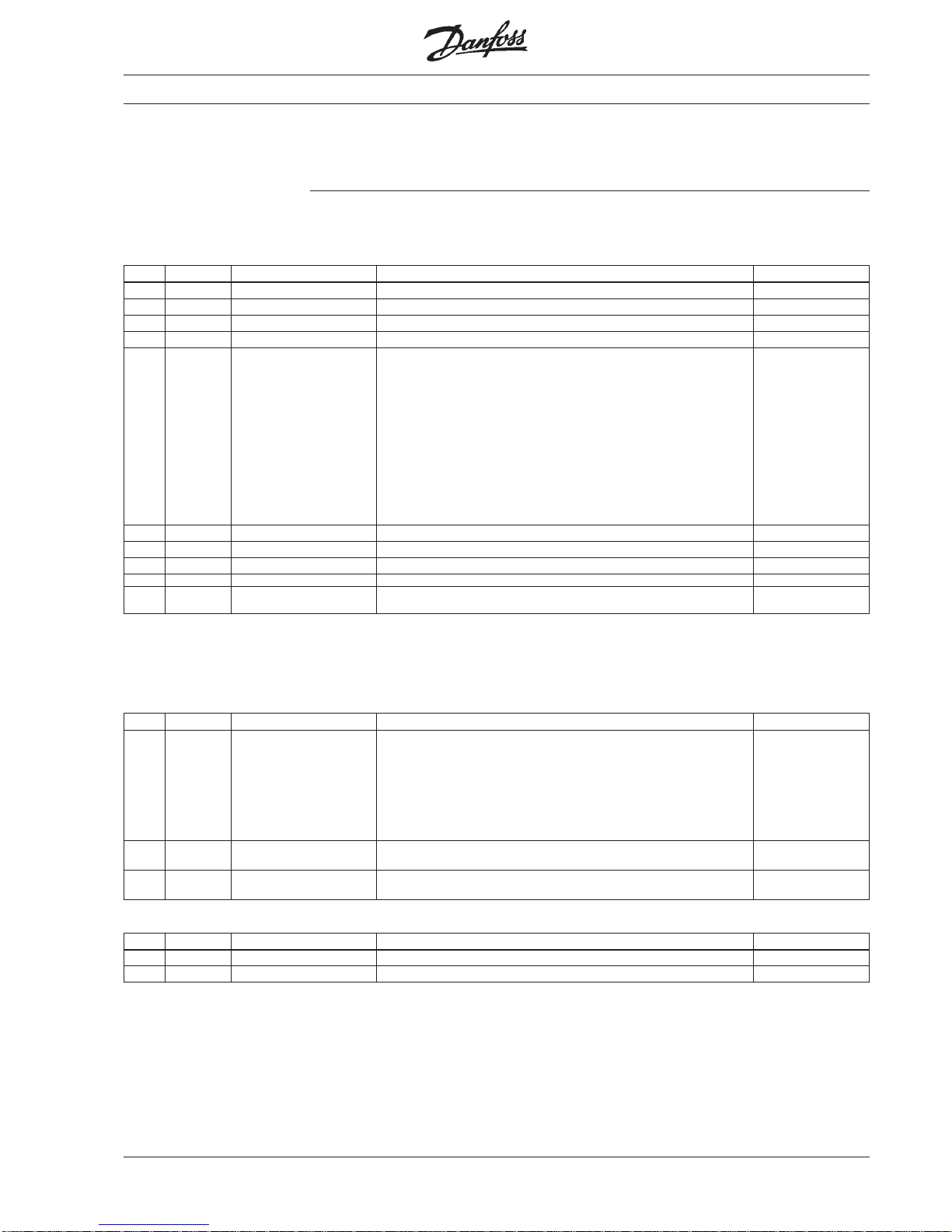

A frequency converter rectifies the a.c.

voltage to D.C. voltage and then converts

this D.C. voltage to A.C. voltage with

variable amplitude and frequency.

The variable voltage and frequency

supplying the motor make possible infinite

speed control of standard three-phase

asynchronous motors.

Control principle

1.

Mains supply

3 x 200 / 220 / 230 V A.C., 50/60 Hz

3 x 380 / 400 / 415 V A.C., 50/60 Hz

3 x 440 / 460 / 500 V A.C., 50/60 Hz

2.

Rectifier

Three-phase rectifier bridge rectifies

A.C. to D.C..

3.

Intermediate circuit

D.C. voltage = √2 x supply voltage.

4.

Coils in the intermediate circuit

Smooth the D.C. voltage and limit

the mains supply harmonics.

5.

Capacitors in the intermediate circuit

Smooth- the D.C. voltage.

6.

Inverter

Converts D.C. voltage to variable A.C.

voltage and variable frequency.

7.

Motor coils

Advantages of motor coils:

• You can use longer motor cables

• 100% short-circuit and earth-fault

protected

• Unlimited switching at the output of

the frequency converter.

• Reduces du/dt.

8.

Output

Variable A.C. voltage, 10 -100% of

the supply voltage.

Variable frequency: 0.5-120 / 0.5-500 Hz.

9.

Control card

This section controls and monitors the

power and inverter section, which

generates the pulse pattern by means

of which the D.C. voltage is converted

to variable A.C. voltage and variable

frequency.

Introduction

Page 9

9MG.30.A7.02 - VLT® is a registered Danfoss trademark

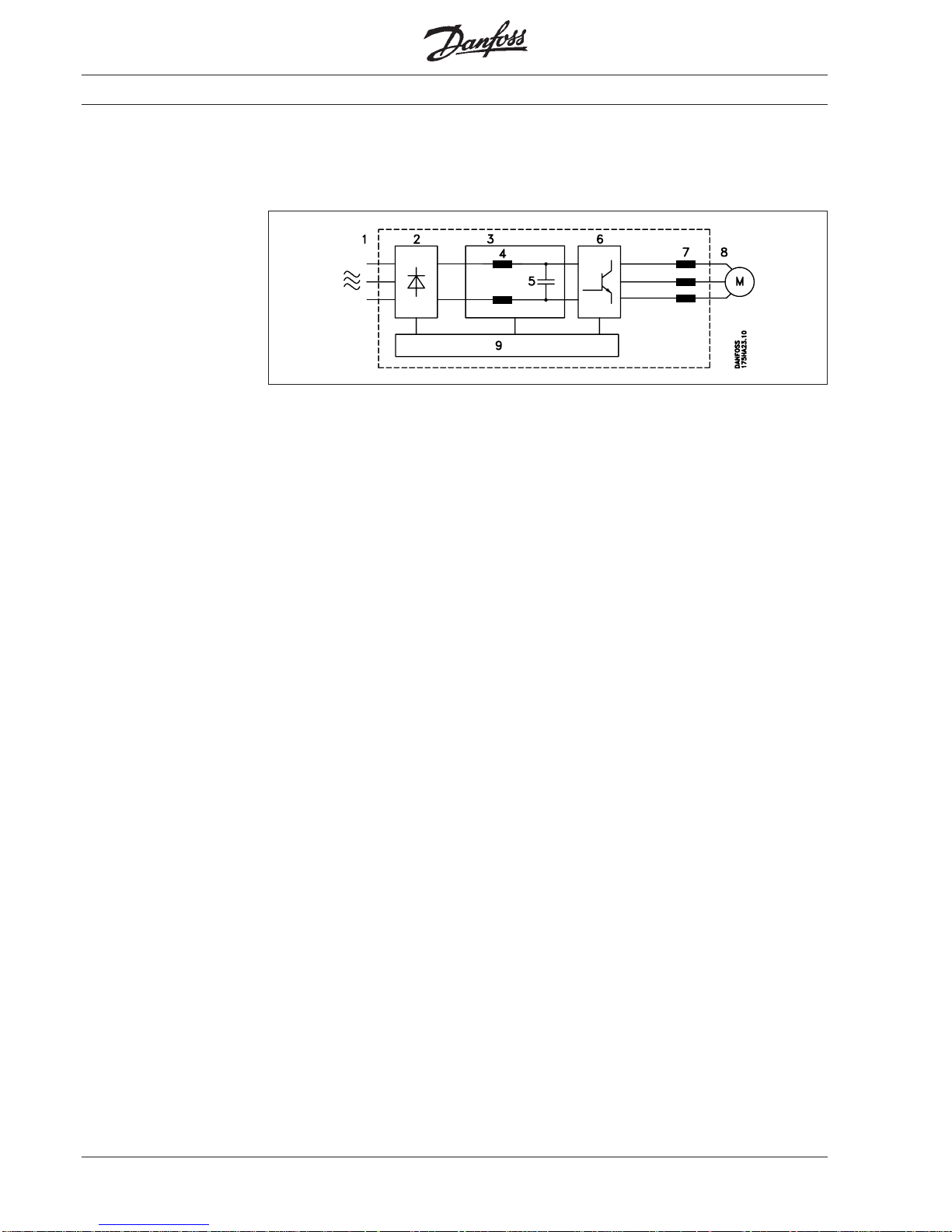

The features are obtained through a

special switching pattern: the switching

intervals are very short, which means high

switching frequency, and the six semiconductors of the inverter section are

alternately held inactive, in pairs, throughout a 60° sine period. The current wave

form of the motor current closely resembles

that obtained on mains operation. The

switching pause in 60° of the sine period

also means that full-rated motor voltage

can be obtained – and inverter switching

losses are reduced by about one third.

The figures below show the switching

pattern and the maximum motor voltage in

relation to the mains voltage according to

the VVC principle and the traditional PWM

principle, respectively.

The full-rated motor voltage and the

perfect current wave form mean that the

Danfoss VLT

®

3000 Series allows full motor performance without any derating –

just like running the motor on the mains.

Technology

VLT® 3000 Series frequency converters

use an inverter control system known as

the Voltage Vector Control (VVC)

developed by Danfoss.

The VVC principle is superior to the

traditional PWM (

Pulse Width Modulation)

principle used in most modern frequency

converters in the following ways:

• Full-rated motor voltage at rated motor

frequency

• Near perfect resemblance to the

sinusoidal mains supply

• Extremely low switching losses, resulting

in high converter efficiency

U

V

W

U

W

V

0,50

0,00

1,00

-0,50

-1.00

0 60 120 180 300 360240

U-V U-W W-U

0,50

0,00

1,00

-0,50

-1.00

0 60 120 180 300 360240

0,866

U-V V-W W-U

Motor voltage and switching pattern with the traditional PWM principle

Motor voltage and simplified switching pattern with the Danfoss VVC principle

Switching pattern for phase U Single-phase voltage Phase-phase voltage for motor

Page 10

10 MG.30.A7.02 - VLT® is a registered Danfoss trademark

The VLT® 3000 Series is delivered with a

number of standard components which

you would normally have to buy separately

such as motor coils, mains reactor DC link

coil and galvanic insulation (PELV).

These components built-in as standard

give you the following advantages:

• Save space and reduce costs

• Simplify the installation as the

VLT

®

3000 will meet most demands.

Factory programmed

U/f characteristics

Technology

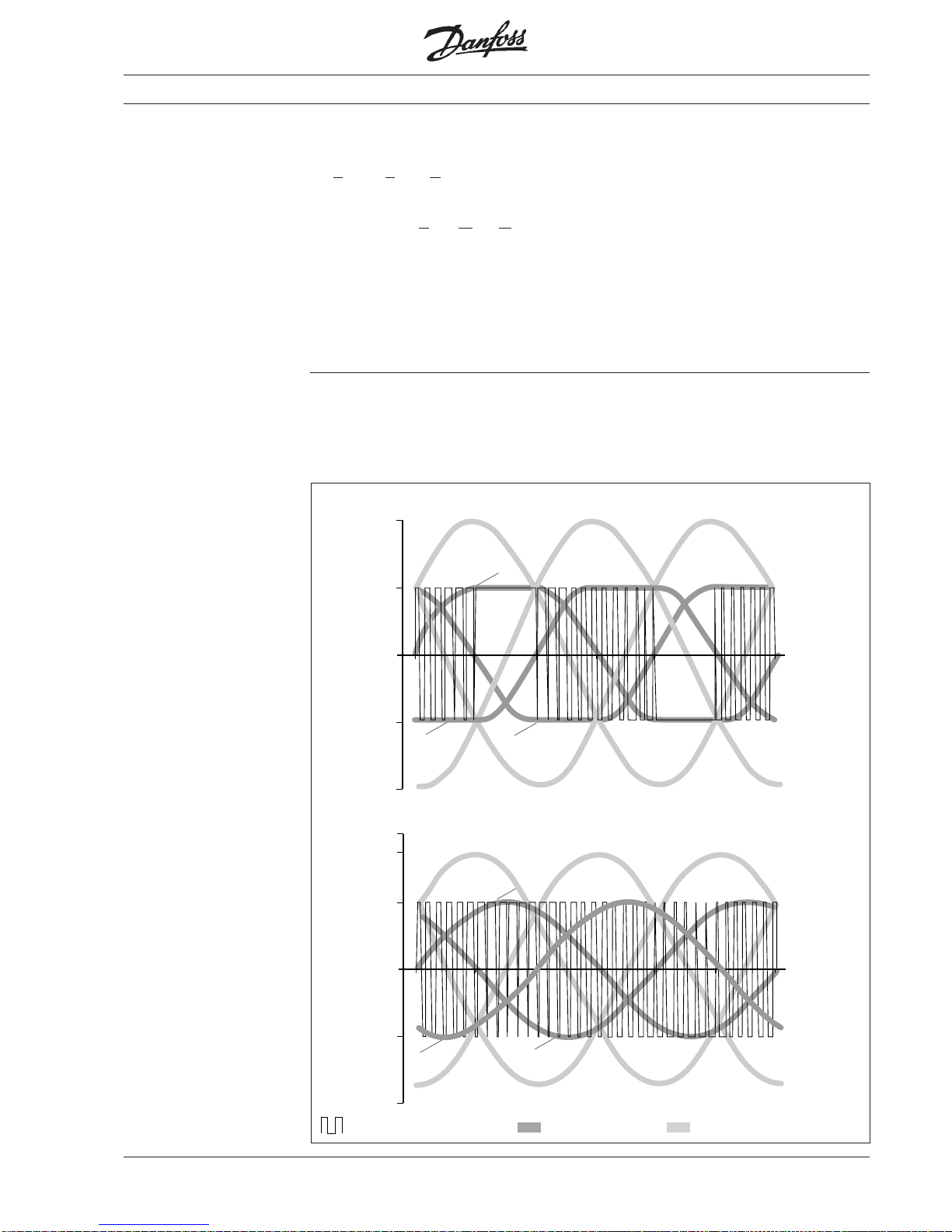

Depending on the type of load, the

VLT® 3000 Series has dynamic adapting or

factory programmed U/f characteristics

(motor voltage/frequency) giving the

correct magnetisation of the motor, thus

ensuring optimum dynamic, accuracy or

efficiency.

It is possible to choose between 3 U/f

characteristics for VT operation, offering

the choice of optimising the start torque or

reducing the noise level or power losses

from the motor. A new parameter (106)

called “Automatic motor tuning” optimizes

the motor parameters at constant load

torque.

Constant torque CT

(Parameter 100)

1: VT low

2: VT medium

3: VT high

Quadratic torque VT

(Parameter 100)

Control accuracy

Slip-compensated ±0.5% 5-50 Hz: VLT® 3011-3052

(depending on motor size) 10-50 Hz: VLT

®

3004-3008

±1.0% 5-50 Hz: VLT

®

3004-3052 (10-140% load change)

PID (closed loop) ±0.1% 5-50 Hz: (−140 - +140% load change)

Open loop (digital) ±0.01% 0.5-120 Hz

0.5-500 Hz

±0.05% Frequency resolution (digital)

(10-90% load change)

(frequency stability)

Page 11

11MG.30.A7.02 - VLT® is a registered Danfoss trademark

It is easy for the user to program the

required functions on the keyboard of the

VLT® 3000 Series or via the terminals or

the RS 485 interface.

The digital technique used in the VLT

®

3000 Series makes it possible to program

the different control inputs and signal

outputs, and to select 4 different userdefined setups.

Programmable

control inputs and

signal outputs

in 4 setups

Protected against mains

disturbance

The VLT® 3000 Series is protected against

transients arising on the mains, e.g. when

you switch in power factor phase correction

capacitors or when the supply is subject to

lightning strikes.

Rated motor voltage and full torque can be

maintained down to 10% undervoltage on

the supply mains.

Low disturbance on

the mains

As the VLT

®

3000 Series has coils in the

intermediate circuit built-in as standard the

harmonic generation is low.

This gives a good power factor, thus

reducing the harmonic load on the mains

supply.

Effective radio

frequency interference

suppression (EMC)

Technology

As standard the VLT® 3000 Series is

delivered with built-in motor coils. This

means that it is possible to install a long

Current measurement in all three motor

phases gives perfect protection of the VLT

®

3000 series in the event of short circuits or

earth faults on the motor terminals.

The continuous monitoring of the three

motor phases makes switching on the

motor cables possible e.g. by opening/

closing a contactor.

Long motor cables

Advanced

VLT® protection

cable between motor and frequency

converter without any additional coils.

Galvanic isolation

With the VLT® 3000 Series safety isolation

is standard, as the high-voltage parts of

the power section are galvanically isolated

from the low-voltage parts of the control

section in accordance with VDE 0160/0106

(PELV).

Advanced

motor protection

The VLT® 3000 Series has a built-in electronic thermal motor protection.

The frequency converter calculates the

motor temperature on the basis of voltage,

current, frequency and time.

Therefore it is superior to the traditional

bi-metallic protection where the altered

cooling conditions due to the speed control

are not taken into consideration.

The thermal motor protection is comparable with thermal relay in the motor cables.

To achieve optimum protection against

overheating of the motor when covered or

blocked, or in case the ventilation should

fail, it is possible to build in a thermistor

and connect this to the frequency converter thermistor input (terminal 16, see

page 102).

The effective monitoring of the three supply

phases means that the VLT

®

3000 Series

stops in the event of a missing phase. In

this way overloading of the inverter and the

capacitors of the intermediate circuit, which

would reduce the lifetime of the frequency

converter drastically, can be avoided.

The VLT

®

3000 Series has built-in thermal

protection of the unit as standard. The

function turns off the inverter on thermal

overload.

The VLT

®

3000 Series can be delivered with

an RFI filter complying with EN 55011.

Filters are available as options or modules.

Some VLT

®

types have a mains filter as

standard in compliance with grade 1, class A.

Page 12

12 MG.30.A7.02 - VLT® is a registered Danfoss trademark

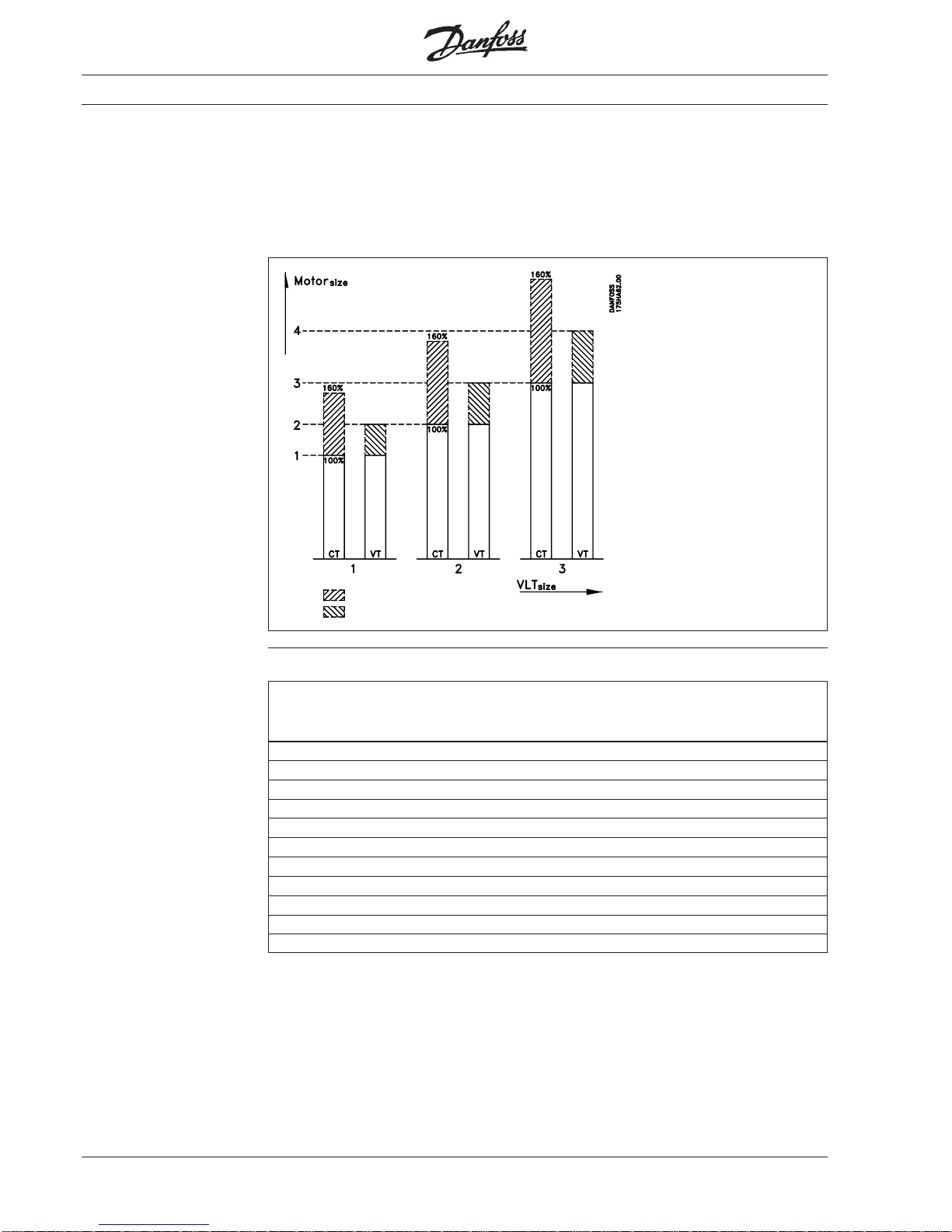

Choice of frequency

converter size

The frequency converter must be chosen

on the basis of the actual motor current I

M

at maximum load of the plant.

The rated continuous output current I

VLT,N

must be equal to or higher than the

required motor current.

Sizing

Example:

In a heating plant (quadratic load) the

pump motor is a 7.5 kW, 3 x 380 V, which

at max. load takes up 14 A.

Choose a VLT

®

3008 which can supply

16 A (I

VLT,N

) continuously.

Mains: 3 x 200/220/230 V and 3 x 220/230/240 V (see technical data)

Which one

to choose?

The

VLT

®

types larger

than 3004 (3008 at 500 V) have

a higher output when using

quadratic load,

referred to as VT load

(variable torque).

Some technical specifications

might change from

CT to VT mode (e.g. the max.

motor cable length

decreases).

: Intermittent operation

: In continuous operation some specifications might change

CT VT CT VT CT VT

Typical shaft Constant output Constant output

VLT

®

type output current I

VLT.N

power at 230 V

[kW] [A] [kVA]

3002 1.1 5.4 2.1

3003 1.5 7.8 3.1

3004 2.2 10.5 4.2

3006 4.0 5.5 19 25 7.6 10.0

3008 5.5 7.5 25 32 10.0 12.7

3011 7.5 11 32 46 12.7 18.3

3016 11 15 46 61 18.3 24.3

3022 15 22 61 88 24.3 35.1

3032 22 30 80 104 31.9 41.4

3042 30 37 104 130 41.4 51.8

3052 37 45 130 154 51.8 61.3

CT: Constant torque

VT: Variable torque (quadratic load)

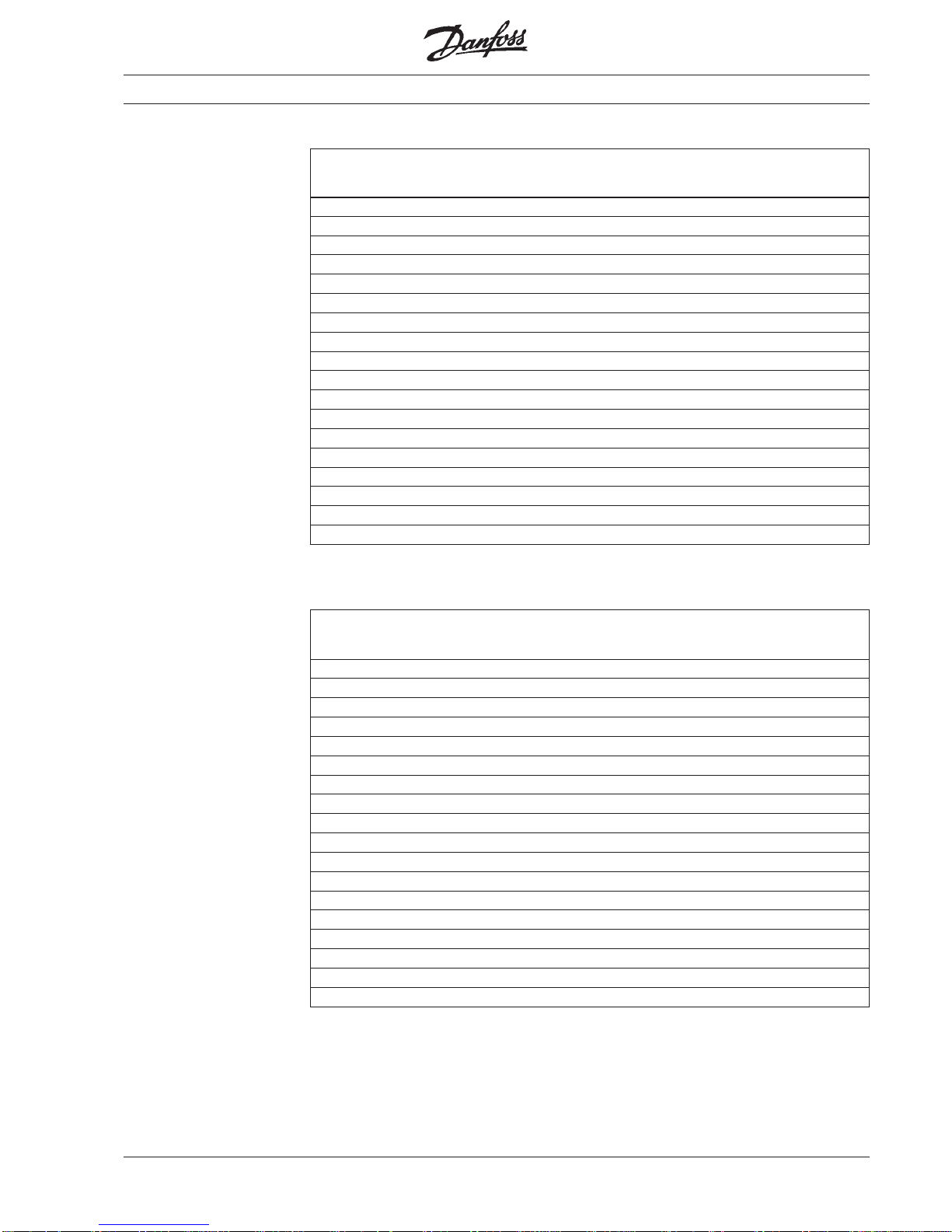

Page 13

13MG.30.A7.02 - VLT® is a registered Danfoss trademark

Mains: 380/400/415 V

Typical shaft Constant output Constant output

VLT

®

type output current I

VLT,N

power at 415 V

[kW] [A] [kVA]

3002 1.1 2.8 2.0

3003 1.5 4.1 2.9

3004 2.2 5.6 4.0

3006 4.0 5.5 10.0 13.0 7.2 9.3

3008 5.5 7.5 13.0 16.0 9.3 11.5

3011 7.5 11 16.0 24.0 11.5 17.3

3016 11 15 24.0 32.0 17.3 23.0

3022 15 22 32.0 44.0 23.0 31.6

3032 22 30 44.0 61.0 31.6 43.8

3042 30 37 61.0 73.0 43.8 52.5

3052 37 45 73.0 88.0 52.3 63.3

3060 45 55 86.0 105 61.8 75.5

3075 55 75 105 139 75.5 99.9

3100 75 90 139 168 99.9 120

3125 90 110 168 205 120 147

3150 110 132 205 243 147 174

3200 132 160 243 302 174 217

3250 160 200 302 368 217 264

CT VT CT VT

CT: Constant torque

VT: Variable torque (quadratic load)

CT VT CT VT

CT VT

CT: Constant torque

VT: Variable torque (quadratic load)

Sizing

Typical shaft Constant output Constant output

VLT

®

type output current I

VLT,N

power at 500 V

[kW] [A] [kVA]

3002 1.1 2.6 2.3

3003 1.5 3.4 2.9

3004 2.2 4.8 4.1

3006 4.0 8.2 7.1

3008 5.5 11.1 9.6

3011 7.5 11 14.5 21.7 12.6 18.8

3016 11 15 21.7 27.9 18.8 24.1

3022 15 22 27.9 41.4 24.1 36.0

3032 22 30 41.4 54.0 36.0 46.8

3042 30 37 54.0 65.0 46.8 56.3

3052 37 45 65.0 78.0 56.3 67.5

3060 55 75 77.0 96.0 66.7 83.1

3075 75 90 96.0 124 83.1 107

3100 90 110 124 156 107 135

3125 110 132 156 180 135 156

3150 132 160 180 240 156 208

3200 160 200 240 302 208 262

3250 200 250 302 361 262 313

CT VT

Mains: 440/460/500 V

Page 14

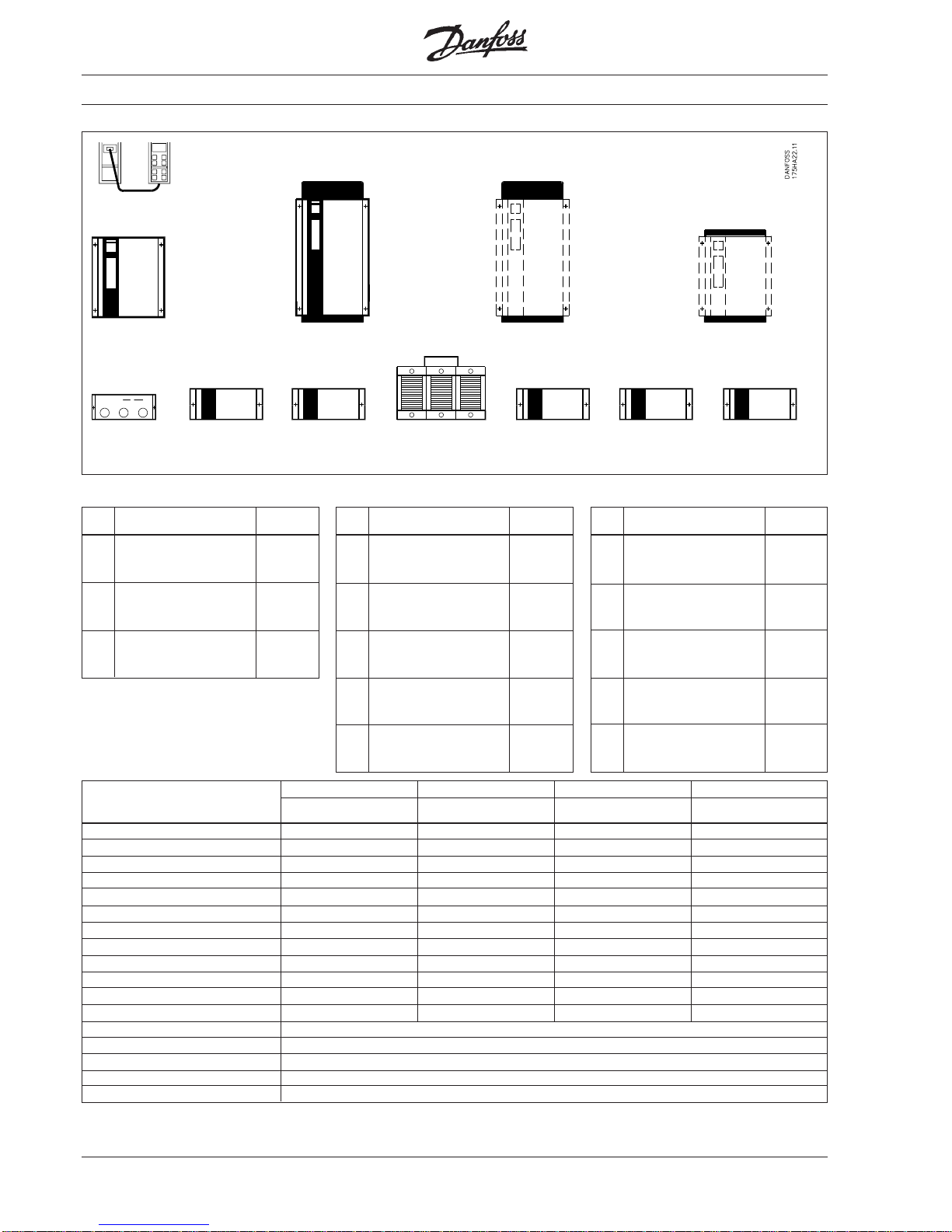

14 MG.30.A7.02 - VLT® is a registered Danfoss trademark

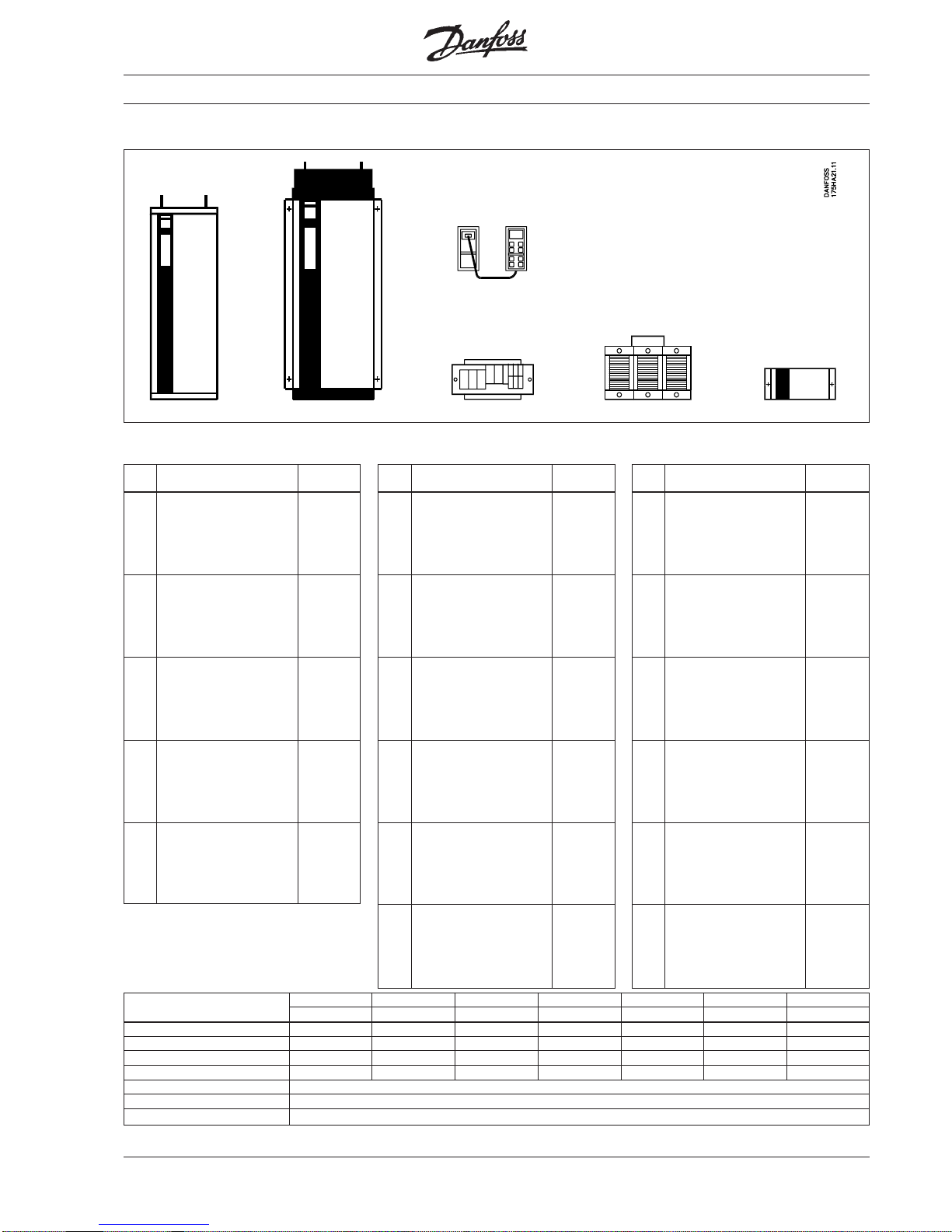

VLT

®

type 3002 - 3004, 200/230 V /

VLT

®

type 3002 - 3008, 380/415 V /

VLT

®

type 3002 - 3008, 440/500 V

Product range

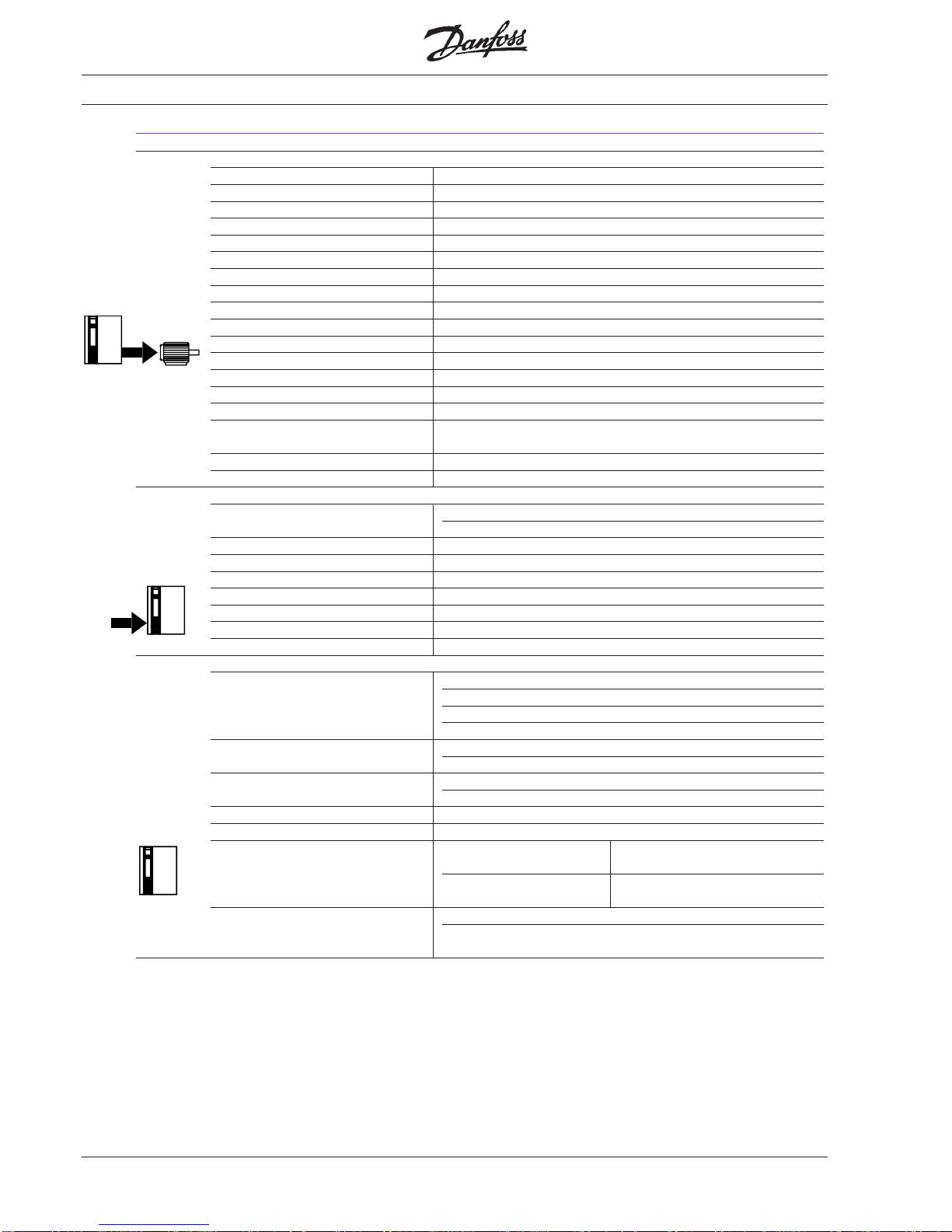

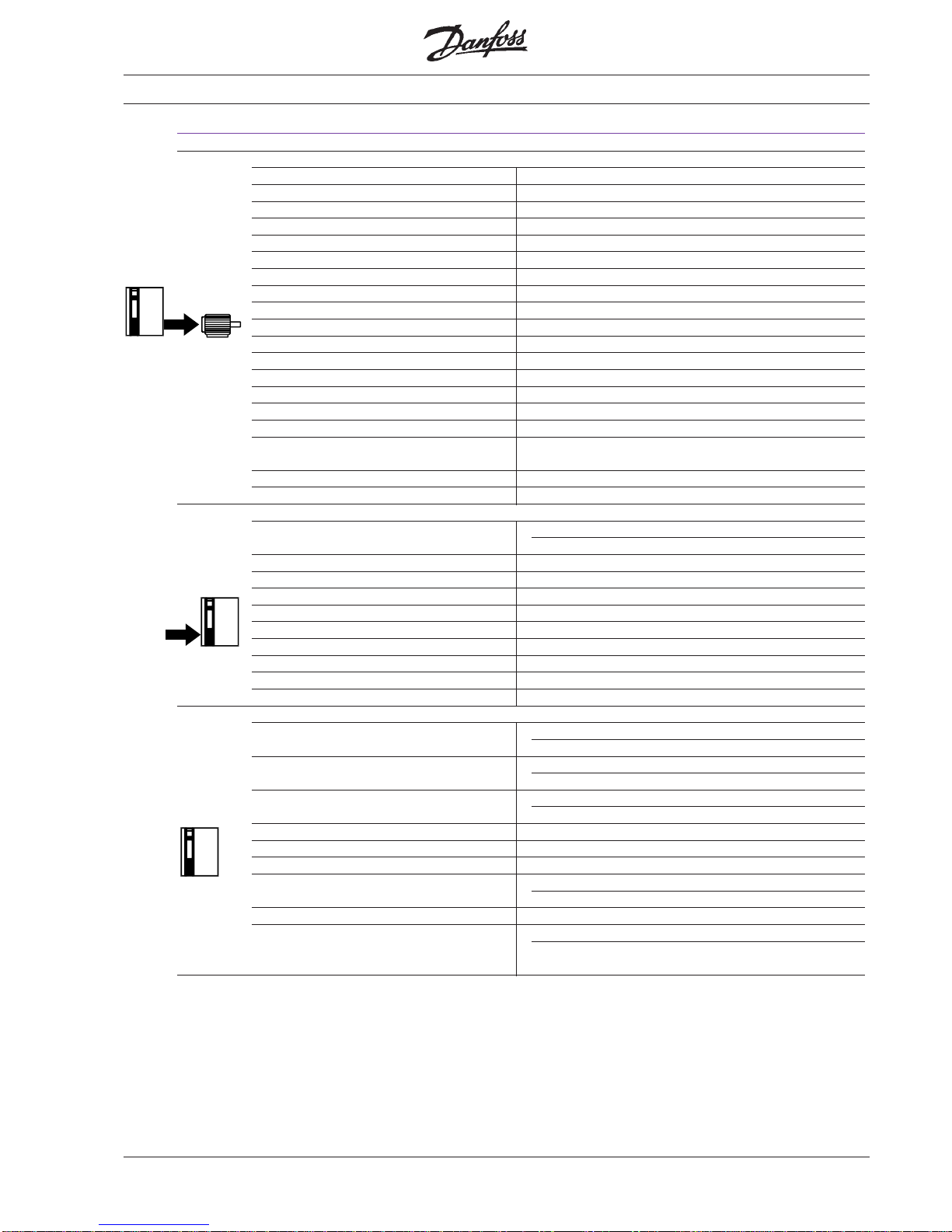

RFI option RFI module RFI-LC module LC motor filter *) LC module Brake module Clamp module

175U0253 175U0252 175H6198/6199 175H5147

*) Made for Danfoss A/S by the firm Platthaus

Remote box

175H1788

IP 00 IP 54 IP 21 option IP 21 option

with fan without fan

175H7040/7008 175H1007/7007

1IP 21 option H1007 H1007 H1007 H7040 H1007 H1007 H1007 H7040 H1007 H1007 3) H1007 3) H1007 3)

IP 21 option with UL approval H7007 - H7007 H7008 - H7007 - - H7007 - - H7007

3

)

RFI module for IP 00 / 21 H7037 H7037 H7037 H7037 H7037 H7037 H7037

2

) H7037 2) H7037 2) H7037 2) H7037 2) H7037 2)

RFI option for IP 00 / 21 H7038

1

) H7038 1) H7038 1) H7038 1) H7038 1) H7038 1) H7038 H7038 H7038 H7038 H7038 H7038

RFI option for IP 54 H7038 H7038 H7038 H7038 H7038 H7038 H7038 H7038 H7038 H7038 H7038 H7038

RFI-LC module for IP 00 - U0253 U0253 - U0253

4

) U0253 -----RFI motor filter option for unscreened motor cable H7083 H7083 H7083 H7083 H7083 H7083 H7083 H7083 H7083 H7083 H7083 H7083

RFI motor filter module for unscreened motor cable H7084 H7084 H7084 H7084 H7084 H7084 H7084 H7084 H7084 H7084 H7084 H7084

LC module for IP 00 U0252 U0252 - U0252 U0252 - U0252 U0252 - U0252 U0252 LC motor filter for IP 00 191G0216 - 191G0209 191G0217 - 191G0209 - - 191G0209 - - 191G0210

Clamp module for IP 00 H5147 H5147 H5147 H5147 H5147 H5147 H5147 H5147 H5147 H5147 H5147 H5147

Brake module for IP 00 / 21 H6198 H6199 H6199 H6198 H6199 H6199 H6199 H6199 H6199 H6199 H6199 H6199

Remote box H1788 H1788 H1788 H1788 H1788 H1788 H1788 H1788 H1788 H1788 H1788 H1788

Relay option H7063 H7063 H7063 H7063 H7063 H7063 H7063 H7063 H7063 - - PROFIBUS option H4696

Modbus Plus option contact Danfoss

PC software ( GB 175H2850) ( D 175H2876) ( DK 175H2877)

3002 / 3003 3004 3006 3008

Description 220 V 380 V 500 V 220 V 380 V 500 V 380 V 380 V 500 V 380 V 380 V 500 V

CT VT CT VT

All code numbers: 175XXXXX. CT: Constant torque / VT: Variable torque (quadratic load)

1

) Can only be mounted in units with brake function.2) The RFI filter option (175H7038) may be beneficial.3) Only bottom can be used.4) Forced cooling

needed.

"-" Cannot be delivered.

200 / 220 / 230 V 380 / 400 / 415 V

440 / 460 / 500 V

VLT

®

Description kW Code no.

type

VLT

®

Description kW Code no.

type

VLT

®

Description kW Code no.

type

IP 00 1,1 175H4131

IP 00 with brake 1,1 175H4132

3002 IP 21 (as option) 1,1 175H1007

IP 54 1,1 175H4133

IP 54 with brake 1,1 175H4134

IP 00 1,5 175H4135

IP 00 with brake 1,5 175H4136

3003 IP 21 (as option) 1,5 175H1007

IP 54 1,5 175H4137

IP 54 with brake 1,5 175H4138

IP 00 2,2 175H4139

IP 00 with brake 2,2 175H4140

3004 IP 21 (as option) 2,2 175H7040

IP 54 2,2 175H4141

IP 54 with brake 2,2 175H4142

IP 00 1,1 175H7238

IP 00 with brake 1,1 175H7239

3002 IP 21 as option) 1,1 175H1007

IP 54 1,1 175H7240

IP 54 with brake 1,1 175H7241

IP 00 1,5 175H7242

IP 00 with brake 1,5 175H7243

3003 IP 21 (as option) 1,5 175H1007

IP 54 1,5 175H7244

IP 54 with brake 1,5 175H7245

IP 00 2,2 175H7246

IP 00 with brake 2,2 175H7247

3004 IP 21 (as option) 2,2 175H1007

IP 54 2,2 175H7248

IP 54 with brake 2,2 175H7249

IP 00 4,0 175H7264

IP 00 with brake 4,0 175H7265

3006 IP 21 (as option) 4,0 175H7040

IP 54 4,0 175H7266

IP 54 with brake 4,0 175H7267

IP 00 5,5 175H7268

IP 00 with brake 5,5 175H7269

3008 IP 21 (as option) 5,5 175H1007

IP 54 5,5 175H7270

IP 54 with brake 5,5 175H7271

IP 00 1,1 175H1729

IP 00 with brake 1,1 175H1730

3002 IP 21 (as option) 1,1 175H1007

IP 54 1,1 175H1731

IP 54 with brake 1,1 175H1732

IP 00 1,5 175H1733

IP 00 with brake 1,5 175H1734

3003 IP 21 (as option) 1,5 175H1007

IP 54 1,5 175H1735

IP 54 with brake 1,5 175H1736

IP 00 2,2 175H1737

IP 00 with brake 2,2 175H1738

3004 IP 21 (as option) 2,2 175H1007

IP 54 2,2 175H1739

IP 54 with brake 2,2 175H1740

IP 00 4,0 175H1741

IP 00 with brake 4,0 175H1742

3006 IP 21 (as option) 4,0 175H1007

IP 54 4,0 175H1743

IP 54 with brake 4,0 175H1744

IP 00 5,5 175H1745

IP 00 with brake 5,5 175H1746

3008 IP 21 (as option) 5,5 175H1007

IP 54 5,5 175H1747

IP 54 with brake 5,5 175H1748

Page 15

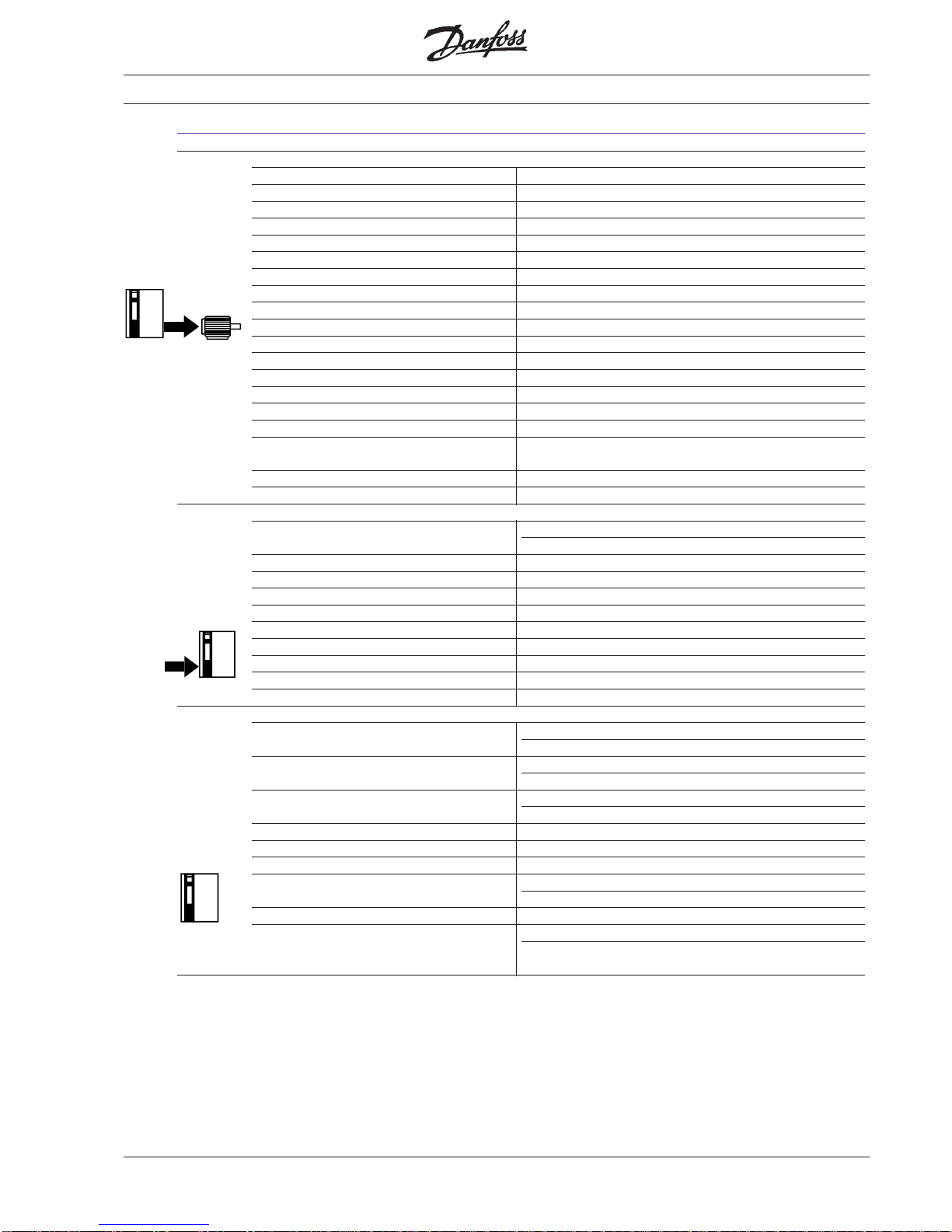

15MG.30.A7.02 - VLT® is a registered Danfoss trademark

VLT

®

type 3006 - 3022, 200/230 V /

VLT

®

type 3011 - 3052, 380/415 V /

VLT

®

type 3011 - 3052, 440/500 V

Product range

IP 20 IP 54 RFI option LC filter *) Clamp module

*) Made for Danfoss A/S by the firm Platthaus

IP 20 4.0 175H4449

IP 20 with RFI 4.0 175H4450

IP 20 with brake 4.0 175H4451

IP 20 with RFI + brake 4.0 175H4452

3006

IP 54 4.0 175H4453

IP 54 with RFI 4.0 175H4454

IP 54 with brake 4.0 175H4455

IP 54 with RFI + brake 4.0 175H4456

IP 20 5.5 175H4457

IP 20 with RFI 5.5 175H4458

IP 20 with brake 5.5 175H4459

IP 20 with RFI + brake 5.5 175H4460

3008

IP 54 5.5 175H4461

IP 54 with RFI 5.5 175H4462

IP 54 with brake 5.5 175H4463

IP 54 with RFI + brake 5.5 175H4464

IP 20 7.5 175H4465

IP 20 with RFI 7.5 175H4466

IP 20 with brake 7.5 175H4467

IP 20 with RFI + brake 7.5 175H4468

3011

IP 54 7.5 175H4469

IP 54 with RFI 7.5 175H4470

IP 54 with brake 7.5 175H4471

IP 54 with RFI + brake 7.5 175H4472

IP 20 11.0 175H4473

IP 20 with RFI 11.0 175H4474

IP 20 with brake 11.0 175H4475

IP 20 with RFI + brake 11.0 175H4476

3016

IP 54 11.0 175H4477

IP 54 with RFI 11.0 175H4478

IP 54 with brake 11.0 175H4479

IP 54 with RFI + brake 11.0 175H4480

IP 20 15.0 175H4520

IP 20 with RFI 15.0 175H4521

IP 20 with brake 15.0 175H4522

IP 20 with RFI + brake 15.0 175H4523

3022

IP 54 15.0 175H4524

IP 54 with RFI 15.0 175H4525

IP 54 with brake 15.0 175H4526

IP 54 with RFI + brake 15.0 175H4527

200 / 220 / 230 V 380 / 400 / 415 V

440 / 460 / 500 V

VLT

®

Description kW Code no.

type

IP 20 7.5 175H7272

IP 20 with RFI 7.5 175H7273

IP 20 with brake 7.5 175H7274

IP 20 with RFI + brake 7.5 175H7275

3011

IP 54 7.5 175H7276

IP 54 with RFI 7.5 175H7277

IP 54 with brake 7.5 175H7278

IP 54 with RFI + brake 7.5 175H7279

IP 20 11.0 175H7280

IP 20 with RFI 11.0 175H7281

IP 20 with brake 11.0 175H7282

IP 20 with RFI + brake 11.0 175H7283

3016

IP 54 11.0 175H7284

IP 54 with RFI 11.0 175H7285

IP 54 with brake 11.0 175H7286

IP 54 with RFI + brake 11.0 175H7287

IP 20 15.0 175H7288

IP 20 with RFI 15.0 175H7289

IP 20 with brake 15.0 175H7290

IP 20 with RFI + brake 15.0 175H7291

3022

IP 54 15.0 175H7292

IP 54 with RFI 15.0 175H7293

IP 54 with brake 15.0 175H7294

IP 54 with RFI + brake 15.0 175H7295

IP 20 22.0 175H1671

IP 20 with RFI 22.0 175H1672

IP 20 with brake 22.0 175H1673

IP 20 with RFI + brake 22.0 175H1674

3032

IP 54 22.0 175H1675

IP 54 with RFI 22.0 175H1676

IP 54 with brake 22.0 175H1677

IP 54 with RFI + brake 22.0 175H1678

IP 20 30.0 175H1679

IP 20 with RFI 30.0 175H1680

IP 20 with brake 30.0 175H1681

IP 20 with RFI + brake 30.0 175H1682

3042

IP 54 30.0 175H1683

IP 54 with RFI 30.0 175H1684

IP 54 with brake 30.0 175H1685

IP 54 with RFI + brake 30.0 175H1686

IP 20 37.0 175H1687

IP 20 with RFI 37.0 175H1688

IP 20 with brake 37.0 175H1689

IP 20 with RFI + brake 37.0 175H1690

3052

IP 54 37.0 175H1691

IP 54 with RFI 37.0 175H1692

IP 54 with brake 37.0 175H1693

IP 54 with RFI + brake 37.0 175H1694

VLT

®

Description kW Code no.

type

IP 20 7.5 175H4401

IP 20 with RFI 7.5 175H4402

IP 20 with brake 7.5 175H4403

IP 20 with RFI + brake 7.5 175H4404

3011

IP 54 7.5 175H4405

IP 54 with RFI 7.5 175H4406

IP 54 with brake 7.5 175H4407

IP 54 with RFI + brake 7.5 175H4408

IP 20 11.0 175H4409

IP 20 with RFI 11.0 175H4410

IP 20 with brake 11.0 175H4411

IP 20 with RFI + brake 11.0 175H4412

3016

IP 54 11.0 175H4413

IP 54 with RFI 11.0 175H4414

IP 54 with brake 11.0 175H4415

IP 54 with RFI + brake 11.0 175H4416

IP 20 15.0 175H4417

IP 20 with RFI 15.0 175H4418

IP 20 with brake 15.0 175H4419

IP 20 with RFI + brake 15.0 175H4420

3022

IP 54 15.0 175H4421

IP 54 with RFI 15.0 175H4422

IP 54 with brake 15.0 175H4423

IP 54 with RFI + brake 15.0 175H4424

IP 20 22.0 175H4425

IP 20 with RFI 22.0 175H4426

IP 20 with brake 22.0 175H4427

IP 20 with RFI + brake 22.0 175H4428

3032

IP 54 22.0 175H4429

IP 54 with RFI 22.0 175H4430

IP 54 with brake 22.0 175H4431

IP 54 with RFI + brake 22.0 175H4432

IP 20 30.0 175H4433

IP 20 with RFI 30.0 175H4434

IP 20 with brake 30.0 175H4435

IP 20 with RFI + brake 30.0 175H4436

3042

IP 54 30.0 175H4437

IP 54 with RFI 30.0 175H4438

IP 54 with brake 30.0 175H4439

IP 54 with RFI + brake 30.0 175H4440

IP 20 37.0 175H4441

IP 20 with RFI 37.0 175H4442

IP 20 with brake 37.0 175H4443

IP 20 with RFI + brake 37.0 175H4444

3052

IP 54 37.0 175H4445

IP 54 with RFI 37.0 175H4446

IP 54 with brake 37.0 175H4447

IP 54 with RFI + brake 37.0 175H4448

VLT

®

Description kW Code no.

type

RFI option for IP 20 / 54 H5353 H5355 H5353 H5355 H5353 H5355 H5355

Clamp module for IP 00 H5147 H5147 H5147 H5147 H5147 H5147 H5147

Remote box H1788 H1788 H1788 H1788 H1788 H1788 H1788

LC motor filter IP 00 191G0218-219-220 - 191G0202-203-204 191G0205-206-207 191G0210-211-212 191G0213 191G0214-215

PROFIBUS option H4696

Modbus Plus option contact Danfoss

PC software ( GB 175H2850) ( D 175H2876) ( DK 175H2877)

3006-3011 3016-3022 3011-3022 3032-3052 3011-3022 3032 3042-3052

Description

220 V 220 V 380 V 380 V 500 V 500 V 500 V

Remote box

175H1788

All code numbers: 175XXXXX.

"-" Cannot be delivered.

Page 16

16 MG.30.A7.02 - VLT® is a registered Danfoss trademark

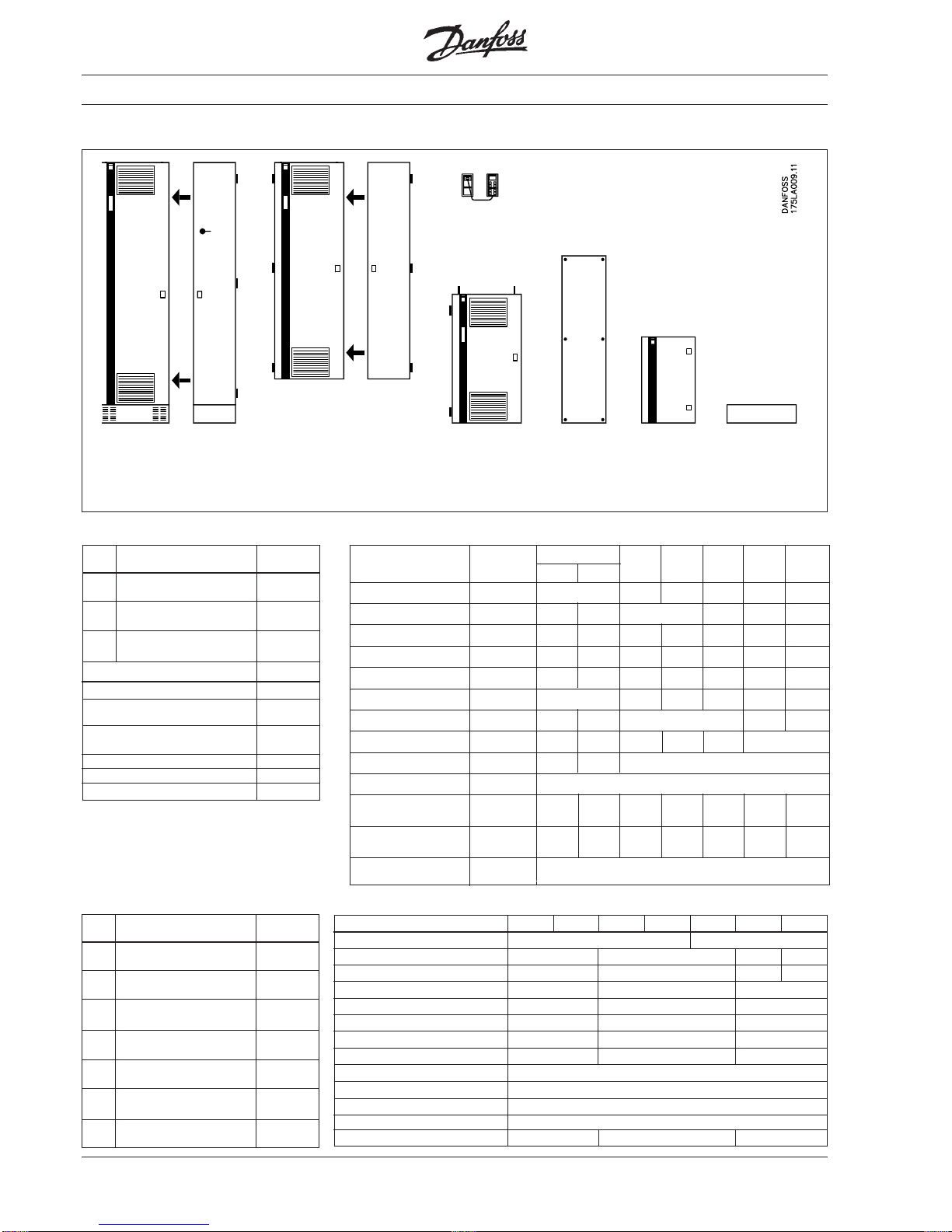

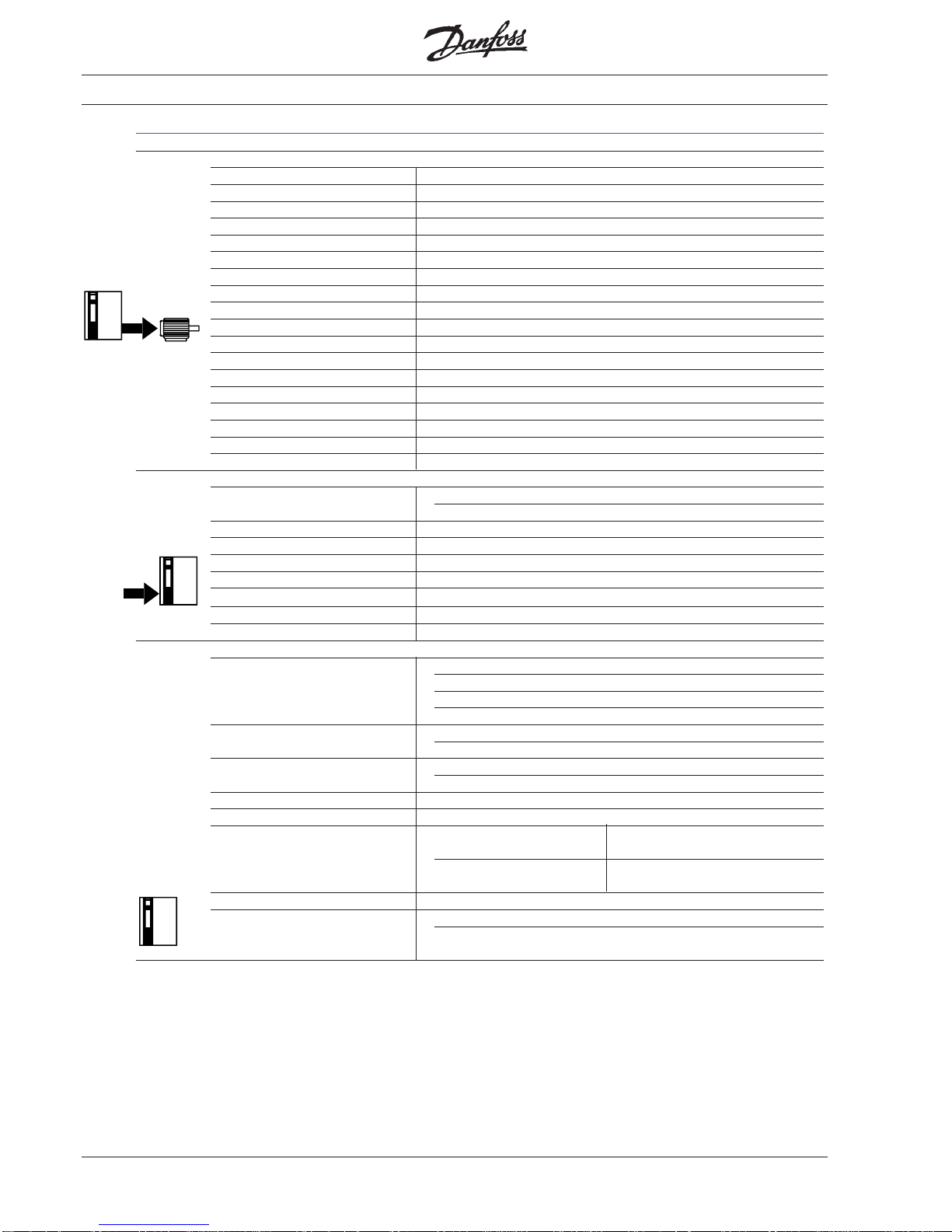

VLT® type 3032 - 3052, 220/440 V, VLT® type 3060 - 3250, 380/440/500 V

Product range

NEMA 1/12

IP 21/54

only wall

mounting

Base

IP 20

RFI filter

NEMA 1/12

IP 21/54

including

base

NEMA 12

IP 54

RFI mounted

with filter,

including base

Optional

base for VLT

®

3100-3150

mounting cabinet/

RFI filter

Brake module

NEMA 12

IP 54

NEMA 1/12

IP 21/54

without base

(option)

NEMA 12

IP 54

RFI mounted

with filter

without base

(option)

Remote box

175H1788

IP 21 45 175L3000

3060

IP 54 45 175L3007

IP 21 55 175L3001

3075

IP 54 55 175L3008

IP 21 75 175L3002

3100

IP 54 75 175L3009

IP 21 90 175L3003

3125

IP 54 90 175L3010

IP 21 110 175L3004

3150

IP 54 110 175L3011

IP 21 132 175L3005

3200

IP 54 132 175L3012

IP 21 160 175L3006

3250

IP 54 160 175L3013

380/440/500 V

VLT

®

Description kW Code no.

type

175L3535

175L3437

175L3490

175L3489

175L3414

175L3415

175L3534

175L3432

175L3419

175L3462

175L3563

175L3475

175L3439

Fuses

Description Amp Bussmann 3100 3125 3150 3200 3250

name 3060 3075

Input fuse 150 T-Tron JJS

Input fuse 250 T-Tron JJS

Input fuse 300 T-Tron JJS

Input fuse 450 T-Tron JJS

Input fuse 500 T-Tron JJS

Charge fuse 9 KT-9

Charge fuse 10 KT-10

Charge fuse 12 KT-12

Fuse for fan 1.5 FNQ-R-1-1/2

Voltage supply 5 KTK-5

Fuse 250 170L5021

1BK/75

Fuse 315 170L5015

1BK/75

Fuse, dynamic

brake 20 KTK-20

IP 21 22 175L4500

3032

IP 54 22 175L4503

IP 21 30 175L4501

3042

IP 54 30 175L4504

IP 21 37 175L4502

3052

IP 54 37 175L4505

Options

Brake module IP54 175L3656

Mounting cabinet with main switch, IP 54 175L3038

(175A)

Mounting cabinet with main switch, IP 54 175L3039

(200A)

Mounting cabinet without main switch IP 54 175L3653

RFI module IP20 VLT 3032-3052 175L3665

RFI module IP54 VLT 3032-3052 175L3666

220/230/240 V

VLT

®

Description kW Code no.

type

Description 3060 3075 3100 3125 3150 3200 3250

Brake module IP 54 175L3030 175L3031

RFI module IP20 175L3657 175L3658 175L3659 175L3660

RFI module IP54 175L3661 175L3662 175L3663 175L3664

Mounting cabinet IP54 with main switch 175L3038(175A) 175L3040(200A) 175L3042(400A)

Mounting cabinet IP54 with main switch 175L3039(200A) 175L3041(400A) 175L3043(600A)

Mounting cabinet IP54 without main switch 175L3653 175L3654 175L3655

Base for floor installation for VLT

®

- 175L3047 Included

Base for RFi/mounting cabinet IP54 - 175L3048 Included

PROFIBUS option 175H4754

Modbus Plus option Contact Danfoss

PC software ( GB 175H2850) ( D 175H2876) ( DK 175H2877)

Remote box 175H1788

Terminal adapter kit 175L3640 175L3641 175L3642

3032 - 3052

Page 17

17MG.30.A7.02 - VLT® is a registered Danfoss trademark

Product range

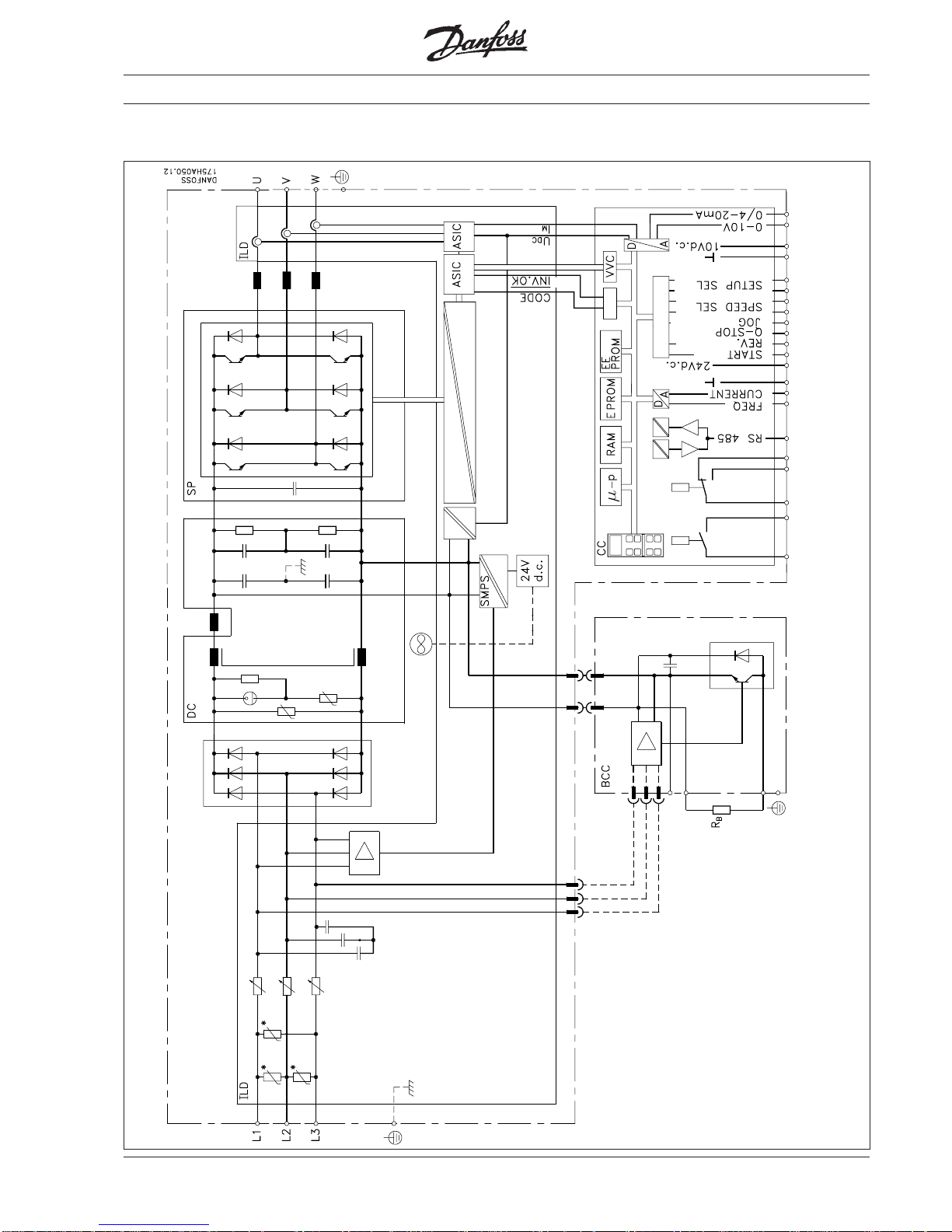

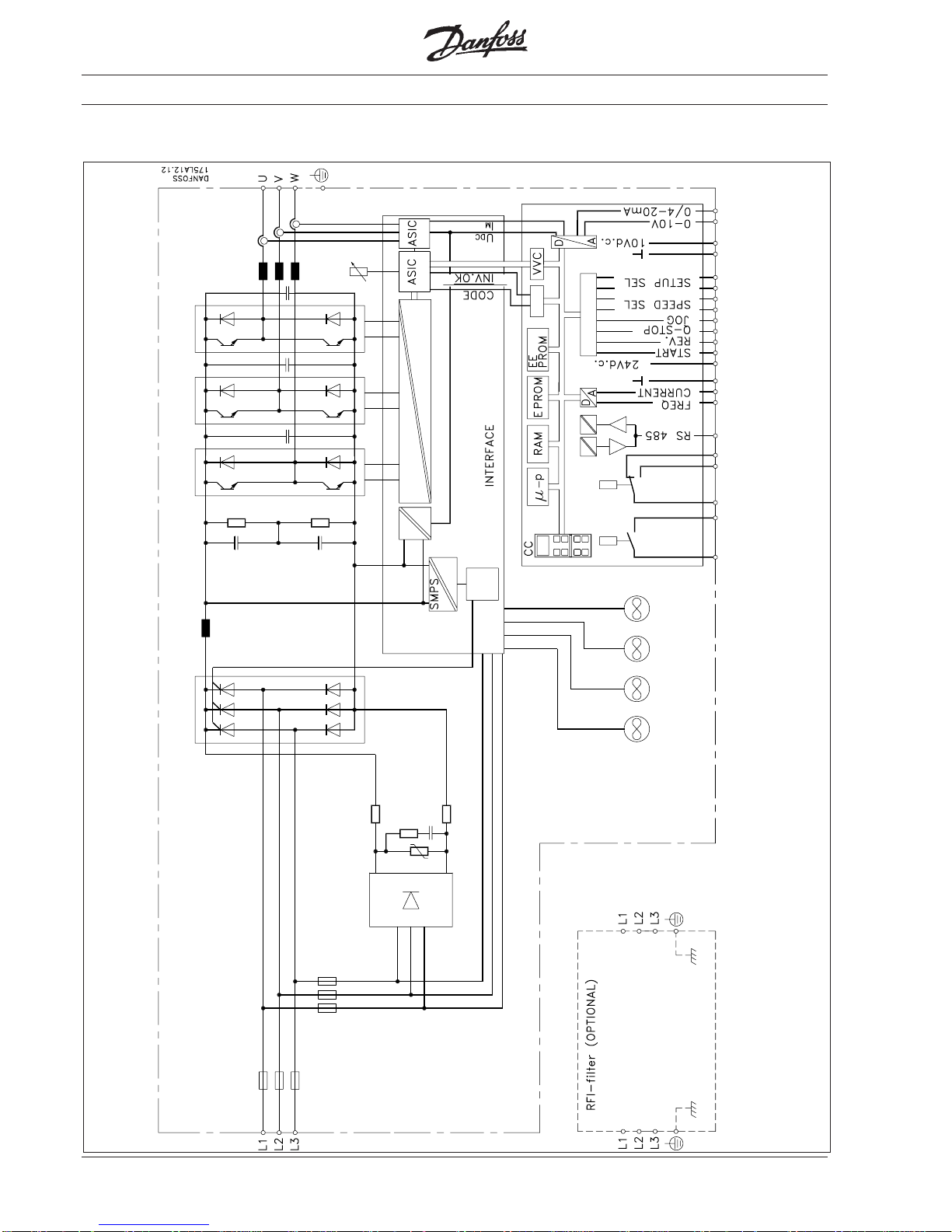

Function diagram for

VLT® type 3002 - 3006 380/415 V, VLT® type 3002 - 3008 440/500 V and VLT® type 3002 - 3004 200/230 V

*) Only 220/230 V and 440/500 V.

Page 18

18 MG.30.A7.02 - VLT® is a registered Danfoss trademark

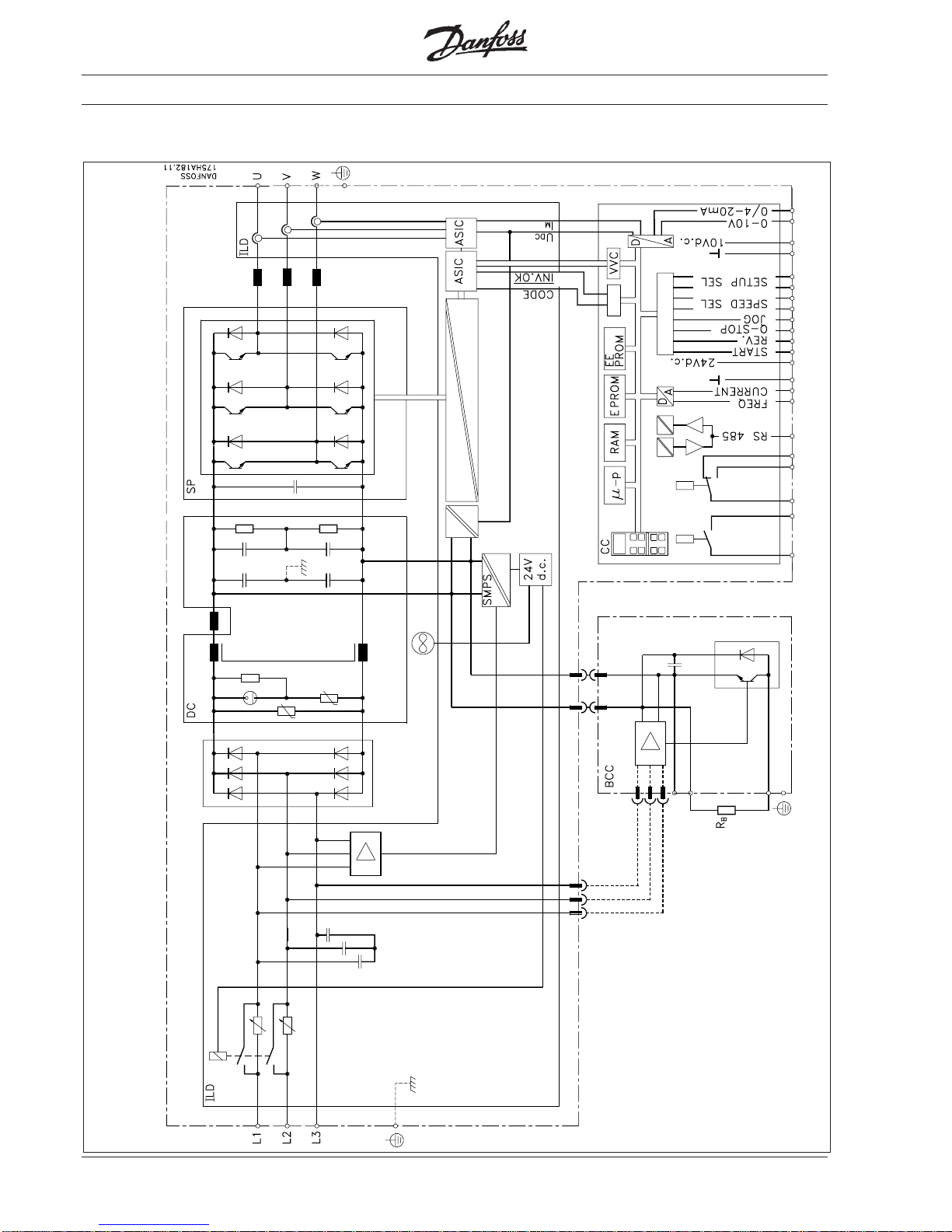

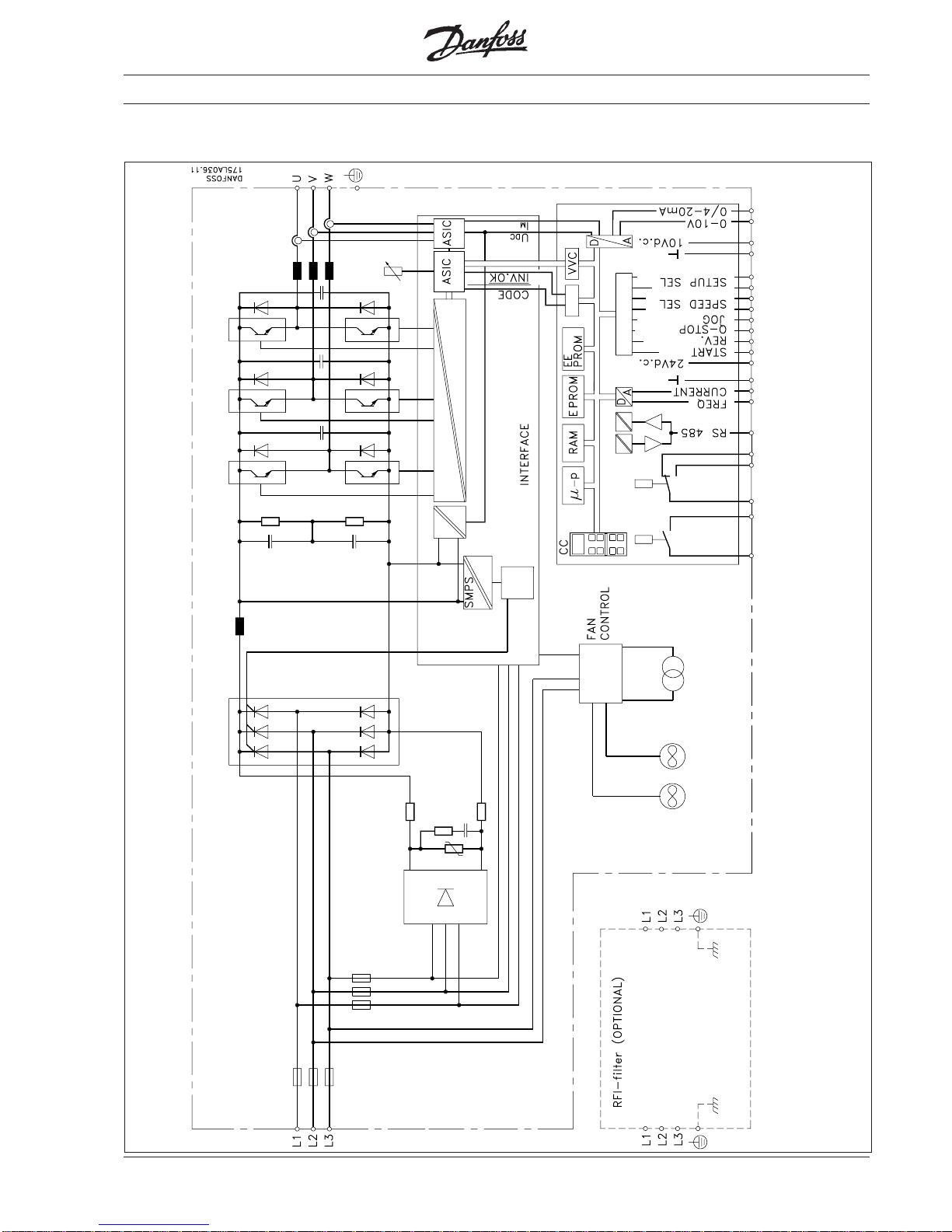

Function diagram for VLT® type 3008, 385/415 V

Product range

Page 19

19MG.30.A7.02 - VLT® is a registered Danfoss trademark

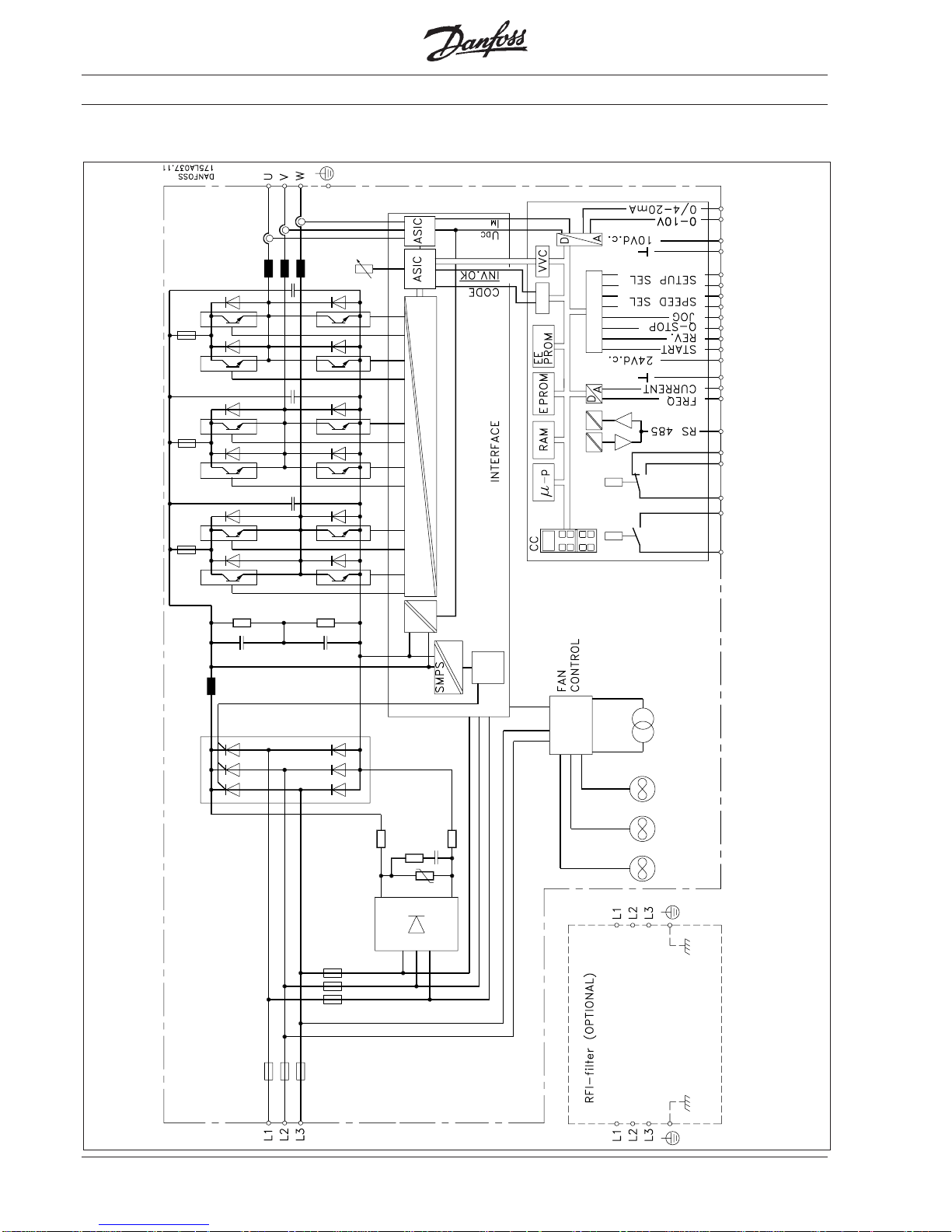

Function diagram for VLT® type 3011 - 3052 380/500 V, VLT® type 3006 - 3022 200/230 V

Product range

Page 20

20 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Function diagram for VLT® type 3032 - 3052, 220/240 V, VLT® type 3060 - 3075 (380/500 V)

Product range

Page 21

21MG.30.A7.02 - VLT® is a registered Danfoss trademark

Function diagram for VLT® type 3100 - 3150 ( 380-500 V)

Product range

Page 22

22 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Function diagram for VLT® type 3200 - 3250 ( 380-500 V)

Product range

Page 23

23MG.30.A7.02 - VLT® is a registered Danfoss trademark

Mains supply 3 x 200/220/230 V and 3 x 220/230/240 V Technical data

According to international VDE and UL/CSA requirements VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Constant torque (CT):

Output current I

VLT,N

[A] 5.4 7.8 10.5 19.0 25.0 32.0 46.0 61.0 80.0 104.0 130.0

I

VLT,MAX

[A] (60 s) 6.7 12.5 17.0 30.0 40.0 51.2 73.6 97.6 120.0 156.0 195.0

Output S

VLT,N

[kVA] 2.1 3.1 4.2 7.6 10.0 12.7 18.3 24.3 31.9 41.4 51.8

S

VLT,MAX

[kVA] (60 s) 2.7 4.9 6.7 12.0 15.9 20.4 29.2 38.9 47.8 62.1 77.7

Typical shaft output P

VLT,N

[kW] 1.1 1.5 2.2 4.0 5.5 7.5 11.0 15.0 22.0 30.0 37.0

Quadratic torque (VT):

Output current I

VLT,N

[A] 5.4 7.8 10.5 25.0 32.0 46.0 61.0 88.0 104.0 130.0 154.0

Output S

VLT,N

[kVA] 1.9 2.9 4.0 10.0 12.7 18.3 24.3 35.1 41.4 51.8 61.3

Typical shaft output P

VLT,N

[kW] 1.1 1.5 2.2 5.5 7.5 11,0 15,0 22.0 33.0 37.0 45.0

Max. cable cross-section [mm2] 2.5 2.5 2.5 16.0 16.0 16.0 35.0 50.0 70.0 70.0 70.0

Max. motor cable length [m] 300, with screened cables: 150 m 300

Output voltage UM [%] 0-100, of mains voltage max. 230 V

Output frequency fM [Hz] 0-120 or 0-500; programmable

Rated motor voltage U

M,N

[V] 200/220/230

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal protection during operation Integrated thermal motor protection (electronic);

thermistor to DIN 44081

Switching on output Unlimited (frequent switching on output may result

in fault message)

Ramp times [s] 0.1 - 3600

VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Max. input current const. load I

L,N

[A] 6.8 9.1 13.3 17.5 22.2 26.4 41.7 52.2 78.0 102.0 128.0

quad. load I

L,N

[A] 6.8 9.1 13.3 23.1 29.6 42.0 56.8 72.3 102.0 128.0 152.0

Max. cable cross-section [mm2] 2.5 2.5 2.5 16.0 16.0 16.0 35.0 50.0 120.0 120.0 120.0

Max. pre-fuses

1)

[A] 16.0 16.0 25.0 40.0 50.0 60.0 80.0 125.0 150.0 150.0 150.0

Supply voltage (VDE 0160) [V] 3 x 200/220/230 ±10% 3 x 220/230/240

Supply frequency [Hz] 50/60

Power factor / cos. ϕ

1

0.9/1.0

Efficiency 0.96 at 100% load

Switching on input times/min. times/min. 2

VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Weight (kg)

IP 007.4 7.4 7.4-------IP 20 - - - 24.0 26.0 32.0 49.0 51.0 - - IP 218.0 8.0 8.0-----143.0 145.0 147.0

IP 54 11.0 11.0 11.0 34.0 37.0 48.0 63.0 65.0 143.0 145.0 147.0

Power loss CT [W] 60.0 100.0 130.0 270.0 425.0 399.0 615.0 935.0 760.0 910.0 1110

at max. load VT [W] 60.0 100.0 130.0 425.0 580.0 651.0 929.0 1350 950.0 1110 1290

Enclosure

VLT type 3002-04: IP 00 / IP 21 / IP 54

VLT type 3006-22: IP 20 / IP 54

VLT type 3032-52: NEMA 1 / 2, IP 21 / 54

Vibration test [g] 0.7

Relative humidity [%] VDE 0160 5.2.1.2.

Ambient temperature (to VDE 0160)

[°C] VLT 3002-3004: -10→ +40, operation at full load

2)

VLT 3006-3052: -10→ +45/40(CT/VT) at full load

2)

[°C] VLT 3002-3004: -30/25→ +65/70, in storage/transport

VLT 3006-3052: -25→ +65/70, in storage/transport

Frequency converter protection Protection against earthing and short-circuiting

Emission EN 55011, EN 55014

EMC standards

EN 50082-2, IEC 1000-4-2, IEC 1000-4-3, IEC 1000-4-4,

(See section “EMC test results”)

Immunity IEC 1000-4-5 VDE 0160, ENV 50140, ENV 50141

+10%+10%

+10%+10%

+10%

-15%-15%

-15%-15%

-15%

1) VLT 3022: Only semi-conductor fuses; VLT 3032-3052: Bussman rapid type JJS built-in (see list)

2) In the range -10 to 0°C, the equipment can start and run; however, the display values and certain operating characteristics will not fulfil the

specifications.

Page 24

24 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Mains supply 3 x 380/400/415 V Technical data

Acc. to international VDE and UL/CSA requirements VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Constant torque (CT):

Output current I

VLT,N

[A] 2.8 4.1 5.6 10.0 13.0 16.0 24.0 32.0 44.0 61.0 73.0

I

VLT,MAX

[A] (60 s) 3.5 6.5 9.0 16.0 20.8 25.6 38.4 51.2 70.4 97.6 117.0

Output S

VLT,N

[kVA] 2.0 2.9 4.0 7.2 9.3 11.5 17.2 23.0 31.6 44.0 52.5

S

VLT,MAX

[kVA] (60 s) 2.5 4.6 6.4 11.5 15.0 18.4 27.6 36.8 50.5 70.2 84.1

Typical shaft output P

VLT,N

[kW] 1.1 1.5 2.2 4.0 5.5 7.5 11.0 15.0 22.0 30.0 37.0

Quadratic torque (VT):

Output current I

VLT,N

[A] 2.8 4.1 5.6 13.0 16.0 24.0 32.0 44.0 61.0 73.0 88.0

Output S

VLT,N

[kVA] 2.0 2.9 4.0 9.3 11.5 17.2 23.0 31.6 44.0 52.5 63.3

Typical shaft output P

VLT,N

[kW] 1.1 1.5 2.2 5.5 7.5 11.0 15.0 22.0 30.0 37.0 45.0

Max. cable cross-section [mm2] 2.5 2.5 2.5 2.5 2.5 16.0 16.0 16.0 35.0 35.0 50.0

Max. motor cable length [m] 300, with screened cables: 150 m

Output voltage UM [%] 0-100, of mains voltage

Output frequency fM [Hz] 0-120 or 0-500; programmable

Rated motor voltage U

M,N

[V] 380/400/415

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal protection during operation

Integrated thermal motor protection (electronic);

thermistor to DIN 44081

Switching on output Unlimited (frequent switching on output may result in fault message)

Ramp times [s] 0.1 - 3600

VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Max. input current const. load I

L,N

[A] 2.8 4.8 7.0 10.0 13.0 13.8 21.8 30.7 41.9 55.6 66.5

quad. load. I

L,N

[A] 2.8 4.8 7.0 13.0 17.0 22.0 31.0 41.5 57.5 66.5 80.0

Max. cable cross-section [mm2] 2.5 2.5 2.5 2.5 2.5 16.0 16.0 16.0 35.0 35.0 50.0

Max. pre-fuses [A] 16.0 16.0 16.0 25.0 25.0 50.0 63.0 63.0 80.0 1001)125

1)

Supply voltage [V] 3 x 380/400/415 ±10% (VDE 0160)

Supply frequency [Hz] 50/60 Hz

Power factor / cos. ϕ

1

0.9/1.0

Efficiency 0,96 at 100% load

Switching on input times/min. 2

VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Weight (kg)

IP 00 7.4 7.4 7.4 12.0 14.0 - - - - - IP 20-----24.0 26.0 32.0 49.0 54.0 54.0

IP 21 8.0 8.0 8.0 13.0 15.0 - - - - - -

IP 54 11.0 11.0 11.0 14.0 15.0 34.0 37.0 48.0 63.0 69.0 69.0

Power loss CT [W] 60 100 130 195 200 270 425 580 880 1390 1875

at m ax. l oad VT [ W] 60 100 130 280 300 425 580 880 1390 1875 2155

Enclosure VLT type 3002-08: IP 00 / IP 21 / IP 54

VLT type 3011-52: IP 20 / IP 54

Vibration test [g] 0.7

Relative humidity [%] VDE 0160 5.2.1.2.

[°C] -10→ +40 -10→ +45/40 (CT/VT)

Ambient temperature operation at full load

2)

at full load

2)

(to VDE 0160) [°C] -25→ +65/70, -25→ +65/70,

in storage/transport in storage/transport

EMC standards Emission EN 55011, EN 55014, EN 61000-3-2

(See section “EMC test results”) Immunity EN 50082-2, IEC 1000-4-2, IEC 1000-4-3, IEC 1000-4-4,

IEC 1000-4-5, VDE 0160, ENV 50140, ENV 50141

1) Only semi-conductor fuses.

2) In the range -10 to 0°C, the equipment can start and run; however, the display values and certain operating characteristics will not fulfil the

specifications.

Page 25

25MG.30.A7.02 - VLT® is a registered Danfoss trademark

Mains supply 3 x 380/400/415 V Technical data

According to international VDE and UL/CSA requirements VLT

type 3060 3075 3100 3125 3150 3200 3250

Constant torque (CT):

Output current I

VLT,N

[A] 86 105 139 168 205 243 302

I

VLT,MAX

[A] (60s) 129 158 209 252 308 365 453

Output S

VLT,N

[kVA] 61.8 73 96 116 142 168 209

S

VLT,MAX

(60s) 89 109 144 175 213 253 314

Typical shaft output P

VLT,N

[kW] 45 55 75 90 110 132 160

Quadratic torque (VT):

Output current I

VLT,N

[A] 105 139 168 205 243 302 368

I

VLT,MAX

[A] (60s) 116 153 185 226 267 332 405

Output S

VLT,N

[kVA] 73 96 116 142 168 209 255

Typical shaft output P

VLT,N

[kW] 55 75 90 110 132 160 200

Max. cable cross-section [mm2] 70 70 150 150 150 2x95 2x95

Max. motor cable length [m] 300

Output voltage UM [%] 0-100 of mains voltage

Output frequency fM [Hz] 0-120 or 0-500, programmable

Rated motor voltage U

M,N

[V] 380/400/415/440/460/500

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal protection during operation Integrated thermal motor protection (electronic);

thermistor to DIN 44081

Switching on output Unlimited (frequent switching on output may result in fault message)

Ramp times [s] 0.1 - 3600

VLT Type 3060 3075 3100 3125 3150 3200 3250

Input current I

L,N

[A] 84.6 103.3 138.4 167.2 201.7 241.9 307.6

I

L,MAX

(60s) [A] 129.0 158.0 209.0 252.0 308.0 365.0 453.0

Quadratic load I

L,N

[A] 103.3 138.4 167.2 201.7 241.9 293.3 366.3

I

L,MAX

(60s) [A] 116.0 153.0 185.0 226.0 267.0 332.0 405.0

Max. cable cross-section [mm2] 120.0 120.0 2 x 120 2 x 120 2 x 120 2 x 240 2 x 240

Pre-fuses

1)

[A] 150.0 150.0 250.0 250.0 300.0 450.0 500.0

Supply voltage (VDE 0160) [V] 3 x 380/400/415/440/460/500 ±10%

Supply frequency [Hz] 50/60

Power factor / cos. ϕ

1

0.9/1.0

Efficiency 0,96 at 100% load

Switching on input times/min. 1

VLT type 3060 3075 3100 3125 3150 3200 3250

Weight (kg)

IP 21 147 147 211 211 220 306 306

IP 54 147 147 211 211 220 306 306

Power loss at max. load CT [W]

Front 423 529 713 910 1091 1503 1812

Heat sink 859 1074 1447 1847 2216 3051 3679

Power loss at max. load VT [W]

Front 529 713 910 1091 1503 1812 2209

Heat sink 1074 1447 1847 2216 3051 3679 4485

Enclosure IP 21 / IP 54 NEMA 1/12

Vibration test [g] 0.7

Relative humidity [%] VDE 0160 5.2.1.2.

Ambient temperature [°C] -10→ +40 operation at full load (VT) -10→ +45 (CT)

2)

(to VDE 0160) [°C] -30/25→ +65/70 in storage/transport

Frequency converter protection Protection against earthing and short-circuiting

EMC standards Emission EN 55011, EN 55014

(See section “EMC test results”) Immunity EN 50082-2, IEC 1000-4-2, IEC 1000-4-3, IEC 1000-4-4,

IEC 1000-4-5, VDE 0160

1) Bussman rapid type JJS integrated.

2) In the range -10 to 0°C, the equipment can start and run; however, the display values and certain operating characteristics will not fulfil the

specifications.

Page 26

26 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Mains supply 3 x 440/460/500 V

Technical data

Acc. to international VDE and UL/CSA requirements VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Constant torque (CT):

Output current I

VLT,N

[A] 2.6 3.4 4.8 8.2 11.1 14.5 21.7 27.9 41.4 54.0 65.0

I

VLT,MAX

[A] (60s) 3.4 5.5 7.7 13.1 17.6 23.2 34.7 44.6 67.2 86.4 104.0

Output S

VLT,N

[kVA] 2.3 2.9 4.1 7.1 9.6 12.6 18.8 24.2 36.0 46.8 56.3

S

VLT,MAX

[kVA] (60s) 2.9 4.7 6.7 11.3 15.2 20.1 30.1 38.6 58.2 7.8 90.1

Typical shaft output P

VLT,N

[kW] 1.1 1.5 2.2 4.0 5.5 7.5 11.0 15.0 22.0 30.0 37.0

Quadratic torque (VT):

Output current I

VLT,N

[A] 2.6 3.4 4.8 8.2 11.1 21.7 27.9 41.4 54.0 65.0 78.0

Output S

VLT,N

[kVA] 1.6 2.9 4.1 7.1 9.6 18.8 24.2 35.9 46.8 56.3 67.5

Typical shaft output P

VLT,N

[kW] 1.1 1.5 2.2 4.0 5.5 11.0 15.0 22.0 30.0 37.0 45.0

Max. cable cross-section [mm2] 2.5 2.5 2.5 2.5 2.5 16.0 16.0 16.0 35.0 35.0 50.0

Max. motor cable length [m] 300, with screened cables: 150 m (3011-3052 in VT: 150 m and 40 m)

Output voltage UM [%] 0-100, of mains voltage

Output frequency fM [Hz] 0-120 eller 0-500, programmable

Rated motor voltage U

M,N

[V] 440/460/500

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal protection during operation Integrated thermal motor protection (electronic); thermistor to DIN 44081

Switching on output Unlimited (frequent switching on output may result in fault message)

Ramp times [s] 0.1 – 3600

VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Max. const. load. [A] 2.6 3.4 4.8 8.2 11.1 12.6 20.1 26.8 37.3 50.2 61.3

input current quadratic load [A] 2.6 3.4 4.8 8.2 11.1 19.6 26.0 34.8 48.6 60.3 72.0

Max. cable cross-section [mm2] 2.5 2.5 2.5 2.5 2.5 16.0 16.0 16.0 35.0 35.0 50.0

Max. pre-fuses [A] 16.0 16.0 16.0 25.0 25.0 30.0 40.0 50.0 60.0 100.01)125.0

1)

Supply voltage (VDE 0160) [V] 3 x 440/460/500 ±10% (VDE 0160)

Supply frequency [Hz] 50/60

Power factor / cos. ϕ

1

0.9/1.0

Efficiency 0.96 at 100% load

Switching on input times/min. 2

VLT type 3002 3003 3004 3006 3008 3011 3016 3022 3032 3042 3052

Weight (kg)

IP 007.47.47.41214 - ---- IP 20 - - - - - 25 26 31 49 54 54

IP 218.08.08.01315 - ---- IP 54 11 11 11 14 15 34 37 48 63 69 69

Power loss at max. load

CT [W] 60 100 130 160 200 174 287 580 958 1125 1467

VT [W] 60 100 130 160 200 281 369 880 1133 1440 1888

Enclosure

VLT type 3002-08: IP 00 / IP 21 / IP 54 VLT type 3011-52: IP 20 /IP54

VLT type 3042-52: IP 20 / IP 54

Vibration test [g] 0.7

Relative humidity [%] VDE 0160 5.2.1.2.

[°C] -10→ +40 -10→ +45/40(CT/VT)

Ambient temperature at full load

2)

at full load

2)

(to VDE 0160) [°C] -25→ +65/70 -25→ +65/70

in storage/transport in storage/transport

Frequency converter protection Protection against earthing and short-circuiting

EMC standards

Emission EN 55011, EN 55014

(See section “EMC test results”)

Immunity EN 50082-2, IEC 1000-4-2, IEC 1000-4-3, IEC 1000-4-4,

IEC 1000-4-5, VDE 0160, ENV 50140, ENV 50141

1) Semi-conductor fuses.

2) In the range -10 to 0°C, the equipment can start and run; however, the display values and certain operating characteristics will not fulfil the specifications.

Page 27

27MG.30.A7.02 - VLT® is a registered Danfoss trademark

Mains supply 3 x 440/460/500 V Technical data

According to international VDE and UL/CSA requirements VLT type 3060 3075 3100 3125 3150 3200 3250

Constant torque (CT):

Output current I

VLT,N

[A] 77 96 124 156 180 240 302

I

VLT,MAX

[A](60s) 116 144 186 234 270 360 453

Output S

VLT,N

[kVA] 67 83 107 135 156 208 262

S

VLT,MAX

(60s) [kVA] 100 125 161 203 234 312 392

Typical shaft output P

VLT,N

[kW] 55 75 90 110 132 160 200

Quadratic torque (VT):

Output current I

VLT,N

[A] 96 124 156 180 240 302 361

I

VLT,MAX

[A](60s) 106 136 172 198 264 332 397

Output S

VLT,N

[kVA] 83 107 135 156 208 262 313

Typical shaft output P

VLT,N

[kW] 75 90 110 132 160 200 250

Max. cable cross-section [mm2] 70 70 150 150 150 2 x 95 2 x 95

Max. motor cable length [m] 300

Output voltage UM [%] 0-100 of mains voltage

Output frequency fM [Hz] 0-120 or 0-500; programmable

Rated motor voltage U

M,N

[V] 380/400/415/440/460/500

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal protection during operation Integrated thermal motor protection (electronic); thermistor

to DIN 44081

Switching on output Unlimited (frequent switching on output may result in fault message)

Ramp times [s] 0.1 - 3600

VLT type 3060 3075 3100 3125 3150 3200 3250

Input current I

L,N

[A] 75.8 94.4 123.4 155.3 177.1 238.9 307.6

I

L,MAX

(60s)[A] 113.7 141.6 185.1 233.0 265.7 358.4 461.4

Quadratic load I

L,N

[A] 94.4 123.4 155.3 177.1 238.9 307.6 359.3

I

L,MAX

(60s)[A] 106.0 136.0 172.0 198.0 264.0 332.0 397.0

Max. cable cross-section [mm2] 120.0 120.0 2 x 120 2 x 120 2 x 120 2 x 240 2 x 240

Max. pre-fuses

1)

[A] 150.0 150.0 250.0 250.0 300.0 450.0 500.0

Supply voltage (VDE 0160) [V] 3 x 380/400/415/440/460/500 ±10%

Supply frequency [Hz] 50/60

Power factor / cos. ϕ

1

0.9/1.0

Efficiency 0.96 at 100% load

Switching on input times/min. 1

VLT type 3060 3075 3100 3125 3150 3200 3250

Weight (kg)

IP 21 147 147 211 211 220 306 306

IP 54 147 147 211 211 220 306 306

Power loss at max. load CT [W]

Front 423 529 713 910 1091 1503 1812

Heat sink 859 1074 1447 1847 2216 3051 3679

Power loss at max. load VT [W]

Front 529 713 910 1091 1503 1812 2209

Heat sink 1074 1447 1847 2216 3051 3679 4485

Enclosure IP 21 / IP 54, NEMA 1/12

Vibration test [g] 0.7

Relative humidity [%] VDE 0160 5.2.1.2.

Ambient temperature [°C] -10→ +40 at full load

2)

(VT) -10→ +45 (CT)

2)

(to VDE 0160) [°C] -30/25→ +65/70 in storage/transport

Frequency converter protection Jord- og kortslutningssikker

EMC standards Emission EN 55011, EN 55014

(See section “EMC test results”) Immunitet EN 50082-2, IEC 1000-4-2, IEC 1000-4-3, IEC 1000-4-4,

IEC 1000-4-5 VDE 0160

1) Bussman rapid type JJS integrated.

2) In the range -10 to 0°C, the equipment can start and run; however, the display values and certain operating characteristics will not fulfil the

specifications.

Page 28

28 MG.30.A7.02 - VLT® is a registered Danfoss trademark

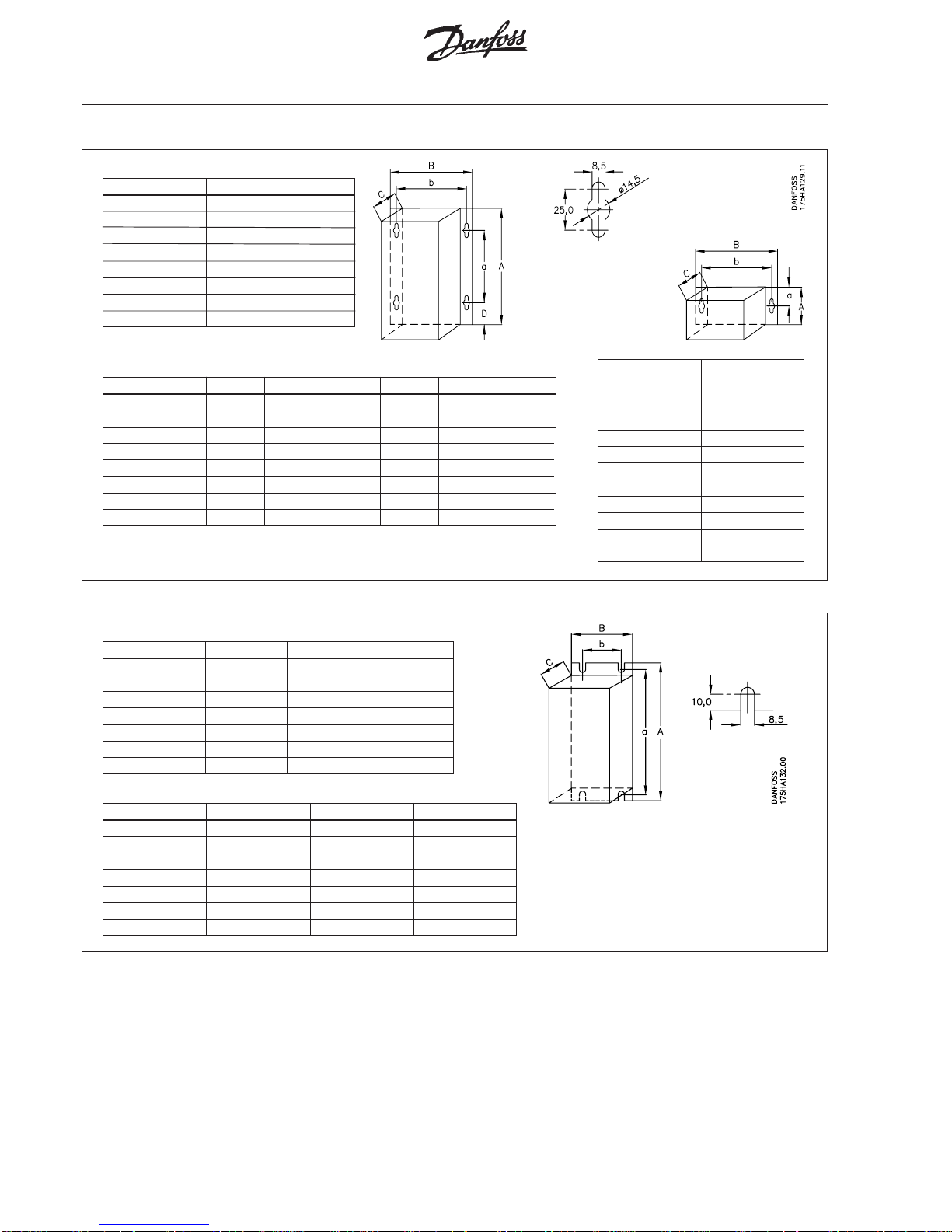

VLT® type 3002-3004 With brake

A (mm) 300 440

B (mm) 281 281

C (mm) 178 178

D (mm) 55 55

a (mm) 191 330

b (mm) 258 258

above/below

(mm) 150 150

left/right (mm) 0 0

Dimensions

IP 00

220 volt

RFI module

RFI-LC filter module

Options LC module

Clamp module

Brake module

A (mm) 115

B (mm) 281

C (mm) 178

D (mm) a (mm) 57.5

b (mm) 258

above/below

(mm) 150

left/right (mm) 0

VLT® type 3011-3016 3022 3032-3052

A (mm) 660 780 950

B (mm) 242 242 308

C (mm) 260 260 296

a (mm) 640 760 930

b (mm) 200 200 270

above/below

(mm) 200 200 200

left/right (mm) 0 0 0

IP 20

220 volt

380 / 500 volt

VLT® type 3006-3008 3011 3016-3022

A (mm) 660 780 950

B (mm) 242 242 308

C (mm) 260 260 296

a (mm) 640 760 930

b (mm) 200 200 270

above/below

(mm) 200 200 200

left/right (mm) 0 0 0

VLT® type 3002-04

With brake

3006

With brake

3008

With brake

A (mm) 300 440 440 550 500 610

B (mm) 281 281 281 281 281 281

C (mm) 178 178 178 178 178 178

D (mm) 55 55 55 55 55 55

a (mm) 191 330 330 440 330 440

b (mm) 258 258 258 258 258 258

above/below

(mm) 150 150 150 150 150 150

left/right (mm) 0 0 0 0 0 0

380 / 500 volt

Page 29

29MG.30.A7.02 - VLT® is a registered Danfoss trademark

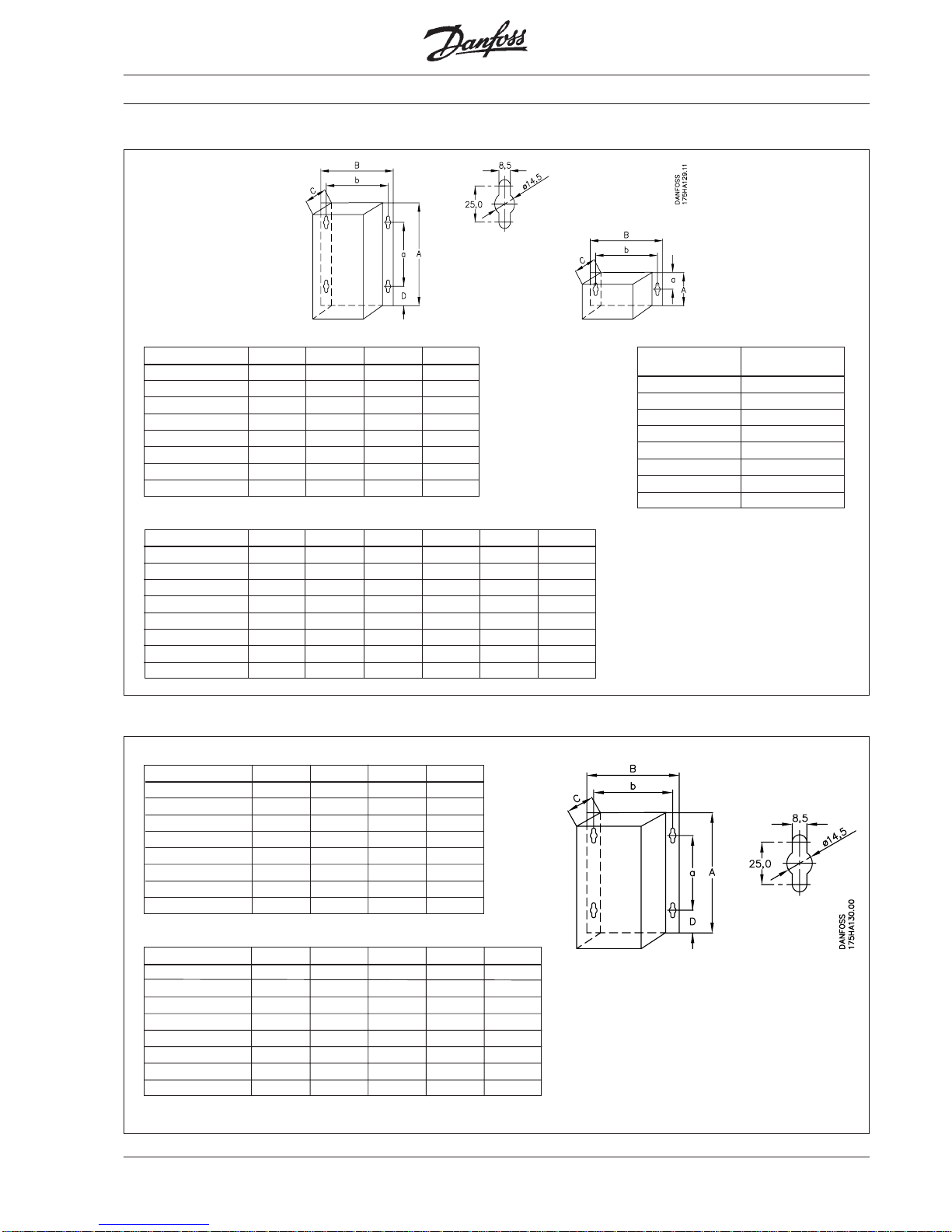

Dimensions

IP 21

VLT® type 3002-04

With brake

3006

With brake

3008

With brake

A (mm) 360 500 500 610 530 640

B (mm) 281 281 281 281 281 281

C (mm) 178 178 178 178 178 178

D (mm) 85 85 85 85 85 85

a (mm) 191 330 330 440 330 440

b (mm) 258 258 258 258 258 258

above/below (mm)

150 150 150 150 150 150

left/right (mm) 0 0 0 0 0 0

VLT® type 3002-03

With brake

3004

With brake

A (mm) 360 500 390 530

B (mm) 281 281 281 281

C (mm) 178 178 178 178

D (mm) 85 85 85 85

a (mm) 191 330 191 330

b (mm) 258 258 258 258

above/below (mm)

150 150 150 150

left/right (mm) 0 0 0 0

380 / 500 volt

220 volt

RFI module

Brake module

A (mm) 115

B (mm) 281

C (mm) 178

D (mm) a (mm) 57.5

b (mm) 258

above/below

(mm) 150

left/right (mm) 0

Options

IP 54

VLT® type 3002-04 *) 3002-08 3006-08 *) 3011-22 3032-52

A (mm) 530 530 640 810 940

B (mm) 281 281 281 355 400

C (mm) 178 178 178 280 280

D (mm) 85 85 85 70 70

a (mm) 330 330 440 560 690

b (mm) 258 258 258 330 375

above/below

(mm) 150 150 150 150 150

left/right (mm) 0 0 0 0 0

*) With brake

380 / 500 volt

220 volt

VLT® type 3002-04

With brake

3006-11 3016-22

A (mm) 530 530 810 940

B (mm) 281 281 355 400

C (mm) 178 178 280 280

D (mm) 85 85 70 70

a (mm) 330 330 560 690

b (mm) 258 258 330 375

above/below (mm) 150 150 150 150

left/right (mm) 0 0 0 0

Page 30

30 MG.30.A7.02 - VLT® is a registered Danfoss trademark

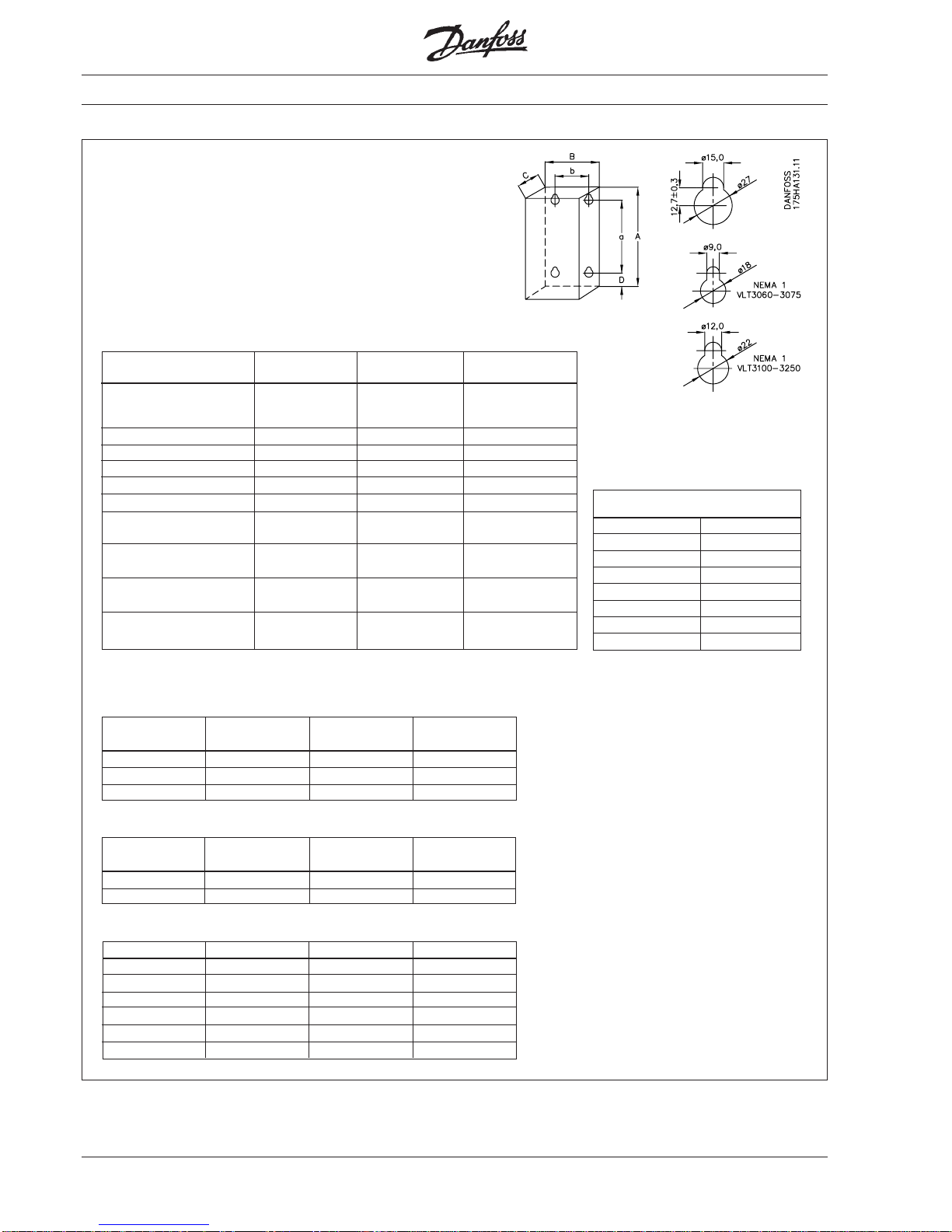

IP 21 / IP 54

Dimensions

RFI module IP21

220 / 230 / 240 / 380 / 500 volt

*) Only limited by hinges on sides.

Note also that the door opens to the left and the option door to the right.

Mounting cabinet IP54

3032-3052, 230 V 3100-3150 3200-3252

3060-3075

A (mm) 900 1515 1695

B (mm) 267 305 349

C (mm) 388 427 554

Internal mounting panel in mounting cabinet IP54

3032-3052, 230 V 3100-3150 3200-3252

3060-3075

A (mm) 845 1459 1640

B (mm) 229 267 311

3060-3075 3100-3150 3200-3252

A (mm) 864 1168 1168

B (mm) 254 317 317

C (mm) 254 254 254

D (mm) 45 52 52

a (mm) 772 1063 1063

b (mm) 174 235 235

VLT® type 3032-3052, 230 V, 3100-3150 3200-3252

3060-3075

A (mm) 954 with ring bolts 1569 with ring bolts 1877 base

1696 with ring bolts and bolts

and optional base

B (mm) 506 with hinges 513 with hinges 513 with hinges

C (mm) IP21 353 394 508

C (mm) IP54 376 417 531

a (mm) 851 1453 placed on base

b (mm) 446 432 placed on base

Floor mounting on base

above (mm) -

230 262

Wall mounting

above/below (mm) 170

230 -

Floor mounting on base

left/right (mm)

- 130 130

Wall mounting

left/right (mm)

*) *) *)

A (mm) 600

B (mm) 380

C (mm) 274

D (mm) 57

a (mm) 485

b (mm) 340

above/below (mm) 80

left/right (mm)

0

Brake module IP54 for VLT

®

3032-3052, 230 V, VLT® 3060-3250

Page 31

31MG.30.A7.02 - VLT® is a registered Danfoss trademark

Control:

Description of terminals

Controls

Terminal 39: Common for analogue/digital outputs

Terminals 42-45: Analogue/digital outputs to display frequency,

reference, current and torque (0-20 mA or 4-20 mA

at max. 470 Ω)/statement of selected status, alarm

or warning (24 V D.C. at min. 600 Ω). See parameters

407 and 408.

Terminal 50: 10 V D.C., max. 17 mA. Supply voltage to

potentiometer and thermistor.

Terminal 53: 0- ±10 V D.C., R

i

= 10 kΩ. Analogue reference input,

voltage. See parameter 412.

Terminal 55: Common for analogue reference inputs.

Terminal 60: 0/4-20 mA, Ri = ~188 Ω.

Analogue reference input, current.

See parameter 413.

Terminal 61: Earth connection, via switch 04, to screen for

communication cable.

See description in parameter group 5.

Terminals 68-69: RS 485 interface. Serial bus communication.

See description of parameter group 5.

Terminal 12: 24 V D.C., max. 140 mA. Supply voltage to digital

inputs (DIN0 - DIN7).

Terminals 16-33: 0/24 V, R

i

= 2 kΩ. < 5 V = logic “0”,

> 10 V = logic “1”. Digital inputs.

See p. 35 and parameters 400-406.

Terminal 20: Common for digital inputs.

Terminal 38: Earth connection to screen for control cables in units

with no terminal clamps for screen.

Terminals 01-03*): Relay output. Max. 250 V A.C., 2 A.

Min. 24 V D.C., 100 mA or 24 V a.c., 100 mA.

See parameter 409.

Terminals 04-05*): Relay output. Max. 250 V A.C., 2 A.

Min. 24 V D.C., 10 mA or 24 V A.C., 100 mA.

See parameter 410.

*) in UL versions: Max. 240 V A.C., 2 A.

NB: On using a thermistor for motor protection, it is connected between terminal 50 and terminal 16

(see description of selection in parameter 400 and outline of thermistor function, page 102).

Page 32

32 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Terminal 16 / par. 400

✭✭

✭✭

✭ Reset Stop *) Freeze reference Thermistor **)

Setup select

Terminal 17 / par. 401 Reset Stop *)

✭✭

✭✭

✭ Freeze ref. Pulse 100 Hz Pulse 1kHz Pulse 10 kHz

Terminal 18 / par. 402

✭✭

✭✭

✭ Start Pulse start No function

Terminal 19 / par. 403

✭✭

✭✭

✭ Reversing Start revers

★★★

) No function

Terminal 27 / par. 404 Quick stop *) DC-brake *) Stop *)

Terminal 29 / par. 405

✭✭

✭✭

✭ Jogging Freeze jogging Freeze reference Digital reference Ramp selection

Terminal 32 / par. 406 Speed up

Speed select Setup select

✭ ✭

✭ ✭

✭ 4

Setup extended

Terminal 33 / par. 406 Speed down

Description of terminals

✭✭

✭✭

✭ Motor

coasting *)

Reset and

motor coasting *)

Cross reference for terminals/parameter functions.

✭✭

✭✭

✭

= Factory setting.

*) Must be with break contact function (NCL), since the function is activated at 0 V on the input.

**) Choose the thermistor function if terminal 50 (10 V

D.C.

) and terminal 16 (parameter 400) are connected.

***) Terminal 19 is pulse start revers if terminal 18 is set to pulse start

Connection examples

The following shows 8 different connection examples with relevant programming suggestions

Example 1:

Connection examples

START/STOP REVERSING Reference: 4-20 mA ~ 0-100% speed

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected.

Page 33

33MG.30.A7.02 - VLT® is a registered Danfoss trademark

The following must be programmed:

Function Parameter no. Parameter value

0-F

MAX

~ 4-20 mA 407 F

MAX

= 4-20 mA

Ref. 4-20 mA 413 4-20 mA

Connection examples

Example 2:

START/STOP REVERSING, 4-20 mA output signal (0-f

MAX

)

Reference: 4-20 mA ~ 0-100% speed

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings,

but motor data (parameters 103-105) must

be set according to the motor connected.

Page 34

34 MG.30.A7.02 - VLT® is a registered Danfoss trademark

The following must be programmed:

Function Parameter no. Parameter value

Thermistor on terminal 16 400 Thermistor

Connection examples

Example 3:

START/STOP REVERSING, thermistor built-in motor connected to VLT® frequency converter.

Reference: 1 kΩ potentiometer, 0-10 V ~0-100% speed

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected

Page 35

35MG.30.A7.02 - VLT® is a registered Danfoss trademark

Connection examples

Example 4:

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected.

The following must be programmed:

Function Parameter no. Parameter value

STOP 404 STOP

START 402 Latched START

0-I

MAX

~ 0-20 mA 407 0-I

MAX

Ref. 0-10 V 412 0-10 V

3 conductor START/STOP, 0-20 mA output signal ~ (0-I

MAX

),

0-10 V Reference: ~ 0-100% speed

Page 36

36 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Digital speed up and down

Relay output:

Indication that the output frequency is outside the range 10-45 Hz.

Connection examples

Example 5:

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected

The following must be programmed:

Function Parameter no. Parameter value

Speed up and down 401 freeze reference

Speed up and down 406 speed up/down

Frequency warning 409 Frequency

on relay too low

Frequency too low 210(F. low) 10 Hz

Frequency too high 211(F. high) 45 Hz

Warning: On power-up the motor will

restart at the last speed that was maintained for 20 sec.

Page 37

37MG.30.A7.02 - VLT® is a registered Danfoss trademark

6 fixed speeds, max. speed 60 Hz

1 speed = 6 Hz (10%), 2 speeds = 12 Hz (20%),

3 speeds = 18 Hz (30%), 4 speeds = 24 Hz (40%),

5 speeds = 42 Hz (70%), 6 speeds = 60 Hz (100%)

Connection examples

Example 6:

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected

The following must be programmed:

Function Parameter no. Parameter value

Setup selection 001 multi setup

Setup selection 400 setup selection

Speed selection 406 digital ref. selection

Select setup 1

Max. frequency 202 60 Hz

Digital reference 1 205 10%

Digital reference 2 206 20%

Digital reference 3 207 30%

Digital reference 4 208 40%

Select setup 2

Max. frequency 202 60 Hz

Digital reference 5 205 70%

Digital reference 6 205 100%

Page 38

38 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Use of the VLT® frequency converter’s internal PID regulator

with internal set-point (digital reference = 50%)

Feedback 0-10 bar ~ 4-20 mA

Min. speed = 10 Hz

Max. speed = 50 Hz

Function Parameter no. Parameter value

Activation of

PID regulator 101 closed loop

Internal setpoint 205 50 %

Feedback type 114 current

Current signal 413 4-20 mA

Min. speed 201 10 Hz

Max. speed 202 50 Hz

Regulator range 120 Depends on

application

Proportional 121 Depends on

amplification application

Integration time 122 Depends on

application

Differentiation time 123 Depends on

application

Example 7:

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected

The following must be programmed:

Connection examples

Page 39

39MG.30.A7.02 - VLT® is a registered Danfoss trademark

Function Parameter no. Parameter value

Activation of

PID regulator 101 closed loop

Feedback type 114 current

Current signal 413 4-20 mA

Min. speed 201 10 Hz

Max. speed 202 50 Hz

Regulator range 120 Depends on

application

Proportional 121 Depends on

amplification application

Integration time 122 Depends on

application

Differentiation time 123 Depends on

application

Use of the VLT® frequency converter’s internal PID regulator

with external set-point (0-10 V)

Feedback 0-10 bar ~ 4-20 mA

Min. speed = 10 Hz

Max. speed = 50 Hz

Example 7:

NB: Screen for control cables must be

connected as described in the chapter on

EMC-correct installation.

All settings are based on factory settings, but

motor data (parameters 103-105) must be set

according to the motor connected

Connection examples

The following must be programmed:

Page 40

40 MG.30.A7.02 - VLT® is a registered Danfoss trademark

Warning The VLT® 3000 Series must always be

attached to the wall or floor before further

installation. This rule must be complied

with, particularly with regard to the very

heavy larger VLT

®

types, to avoid injury to

people and equipment.

As an option for VLT® 3100-3150 a base

for floor installation can be supplied (code

nr. 175L3047).

VLT

®

3200-3250 is only intended for floor

installation, and the base is therefore

supplied as part of the VLT®. The base

must be attached to the floor using 4 bolts

before installation of the VLT

®

. The front

panel of the base is unscrewed so that the

VLT

®

can be secured through the 4 top

holes in the base.

See also section on cooling.

Base VLT

®

3100-3250

VLT® 3060-3150 is supplied with a mounting console placed behind the VLT

®

. This

console also serves as an air channel for

the cooling ribs, and on operation the

console must be mounted on the VLT

®

.

The console does not have to be dismantled for installation, but it can be removed

temporarily by loosening the connecting

bolts from the inside of the VLT

®

.

Remember to attach the console again.

Otherwise there is great danger of cut-out

due to overheating.

The 4 drop-shaped holes in the mounting

console make it possible to attach the

fixing bolts to the wall or in the panel

before suspension of the VLT

®

.

The fixing bolts will be accessible through

the top and bottom of the console to

facilitate tightening.

VLT

®

3060-3075 is only for wall

installation.

VLT

®

3100-3150 is supplied for wall

installation as standard.