Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Page 2

VLT ® Series 2000 Table of Contents

Page

Specification Chart 2

Installation

Safety 4

Dimensions 5

Cooling 7

Wiring 8

Quick Setup 10

Operation 11

Programming

Group 0 -- Operation and Display 16

Group 1 -- Load and Motor 18

Group 2 -- Reference and Limits 22

Group 3 -- Functions and Timers 25

Group 4 -- Inputs and Outputs 27

Group 5 -- Serial Data Interface 31

Group 6 -- Service and Display 38

Appendix

Motor Coil and Filter Options 41

PI Regulation 42

Parameter Groups

Factory Default Settings 46

Customer Settings Chart 47

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Page 3

Installation; Safety

VLT ® Series 2000

The VLT® Series 2000 Adjustable

Frequency Drive (AFD) contains

dangerous voltages when connected to

line voltage. Only a competent electrician

should carry out the electrical installation.

WARNING

Improper installation of the motor or the AFD may cause

equipment failure, serious injury or death. Follow this

manual and local and national safety codes.

Caution:

The motor may start without warning during operation

and programming of the parameters. Activate the STOP

key on the VLT keypad when changing data.

Danfoss VLT® and CE Marking

Danfoss CE marks our VL T® Adjustable Frequency

Drives (AFD) according to the Electro Magnetic

Compatibility (EMC) Directive 89/336/EEC and LowVoltage Directive 73/23/EEC.

It is possible for the VLT to start upon application of AC

power. DO NOT attempt any maintenance on the VLT,

motor or system machinery without verifying that the AC

power has been disconnected.

DO NOT touch any electrical parts after the AC line has

been disconnected for at least 14 minutes. This allows

for capacitor discharge.

NOTE: The STOP key on the VLT keypad DOES NOT

disconnect the AC line.

It is the responsibility of the user or the person installing

the AFD to provide proper grounding and branch circuit

protection for incoming power and motor overload

protection according to the National Electrical Code

(NEC) and local codes.

Upon request we will issue a declaration of conformity to

the EMC and low-voltage directives. A manufacturer's

declaration for the Machinery Directive 89/392/EEC is

also available.

When the installation specification is followed and

shielded motor cables are used per instruction manuals

provided with the drive, we guarantee the AFD complies

with the EMC Directive 89/336/EEC.

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

VLT ® Series 2000

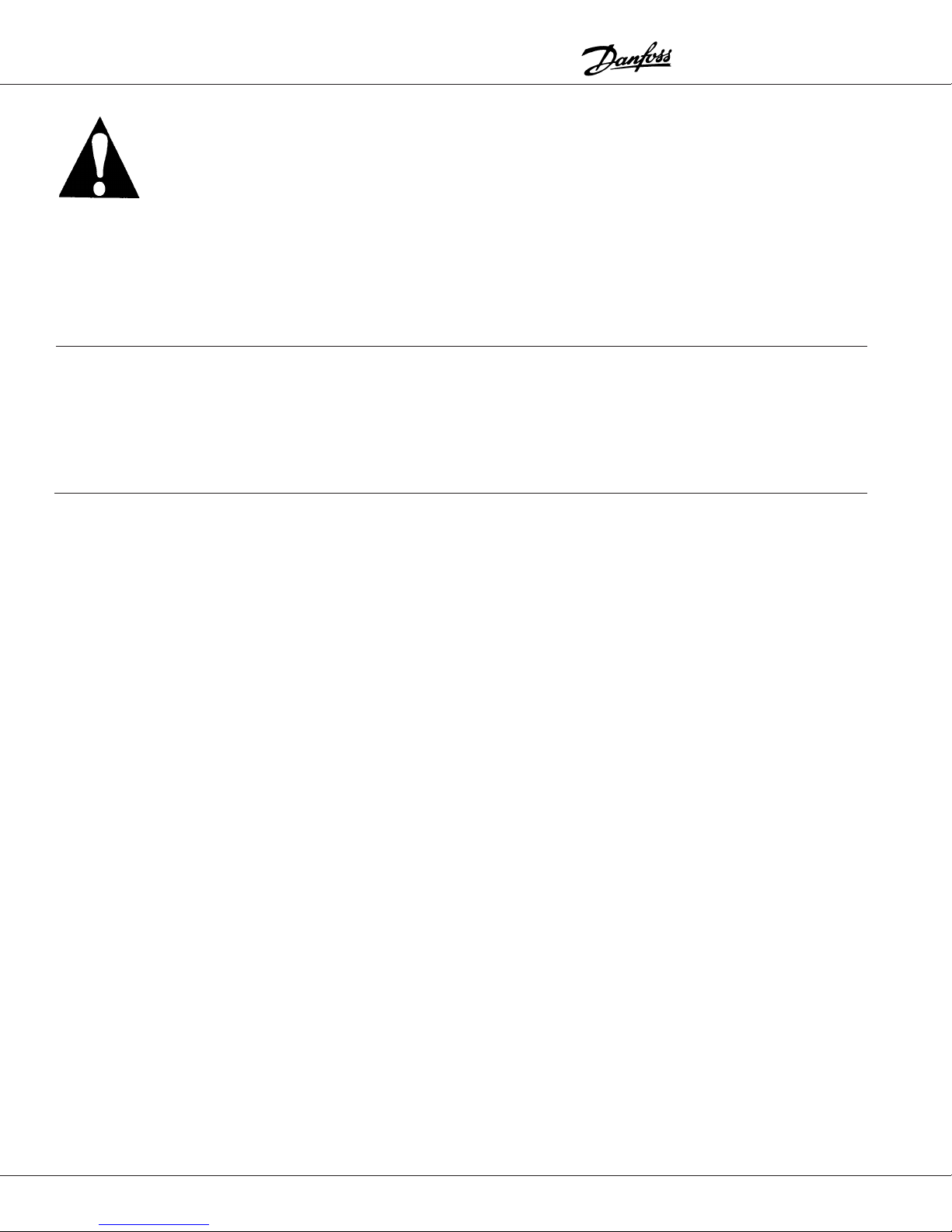

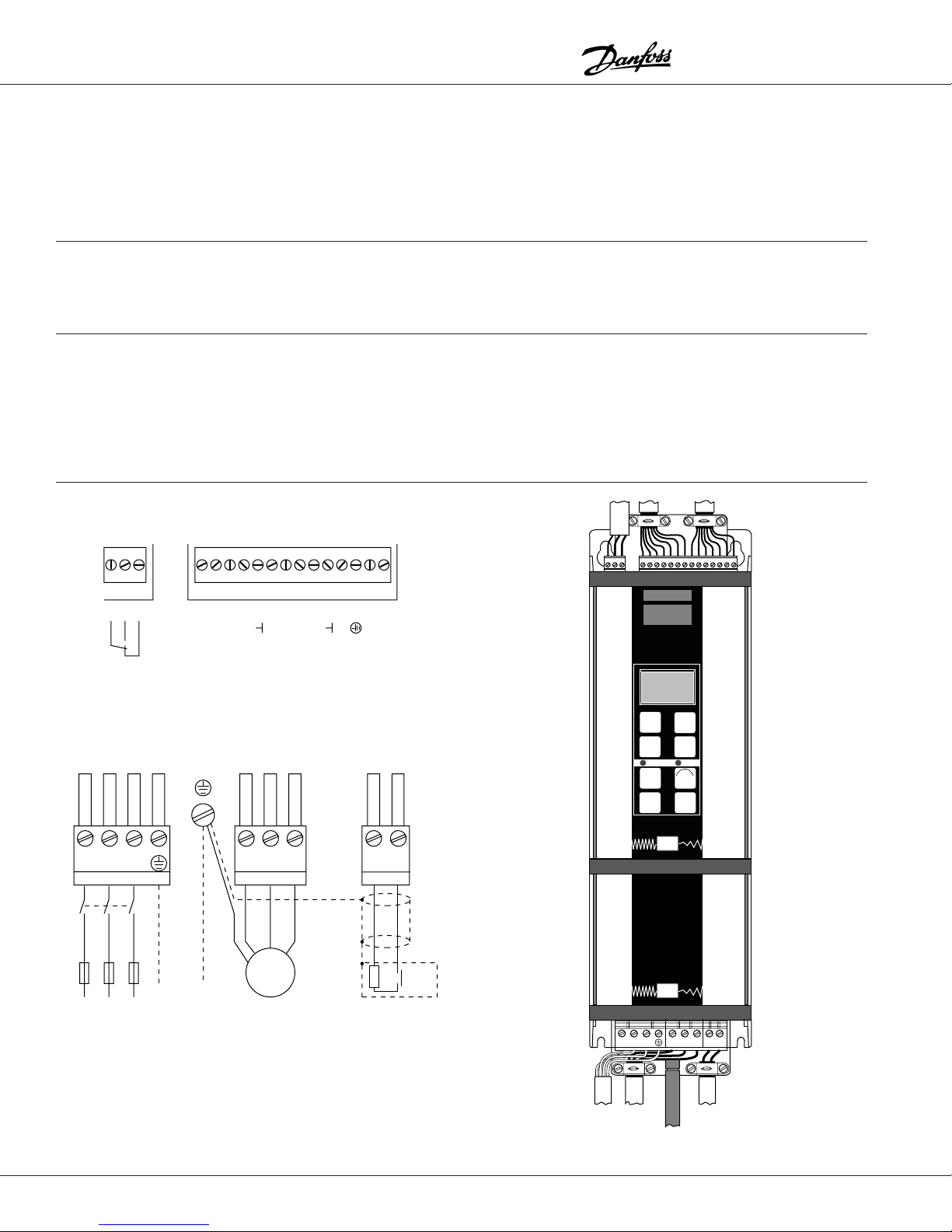

VLT 2010-2030

Single-phase, 220-240 V

Three-phase, 208-240 V

NOTE:

Minimum space above and below the unit is 4 inches.

Minimum space to the sides of the unit is 0 inches.

7.1

(180)

Installation; Dimensions

4.3

(110)

3.5

(90)

9.3

(235)

10.2

(260)

0.21

(5.5)

0.29

(7.5)

0.43

(11)

0.21

(5.5)

0.17

(4.5)

VLT 2010-2030 with module

Single-phase, 220-240 V

Three-phase, 208-240 V

NOTE:

Minimum space above and below the unit is 4 inches.

Minimum space to the sides of the unit is 0 inches.

7.1

(180)

4.3

(110)

3.5

(90)

14.3

(338)

14.3

(363)

0.21

(5.5)

0.29

(7.5)

0.43

(11)

0.21

(5.5)

0.17

(4.5)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

Page 5

Installation; Dimensions

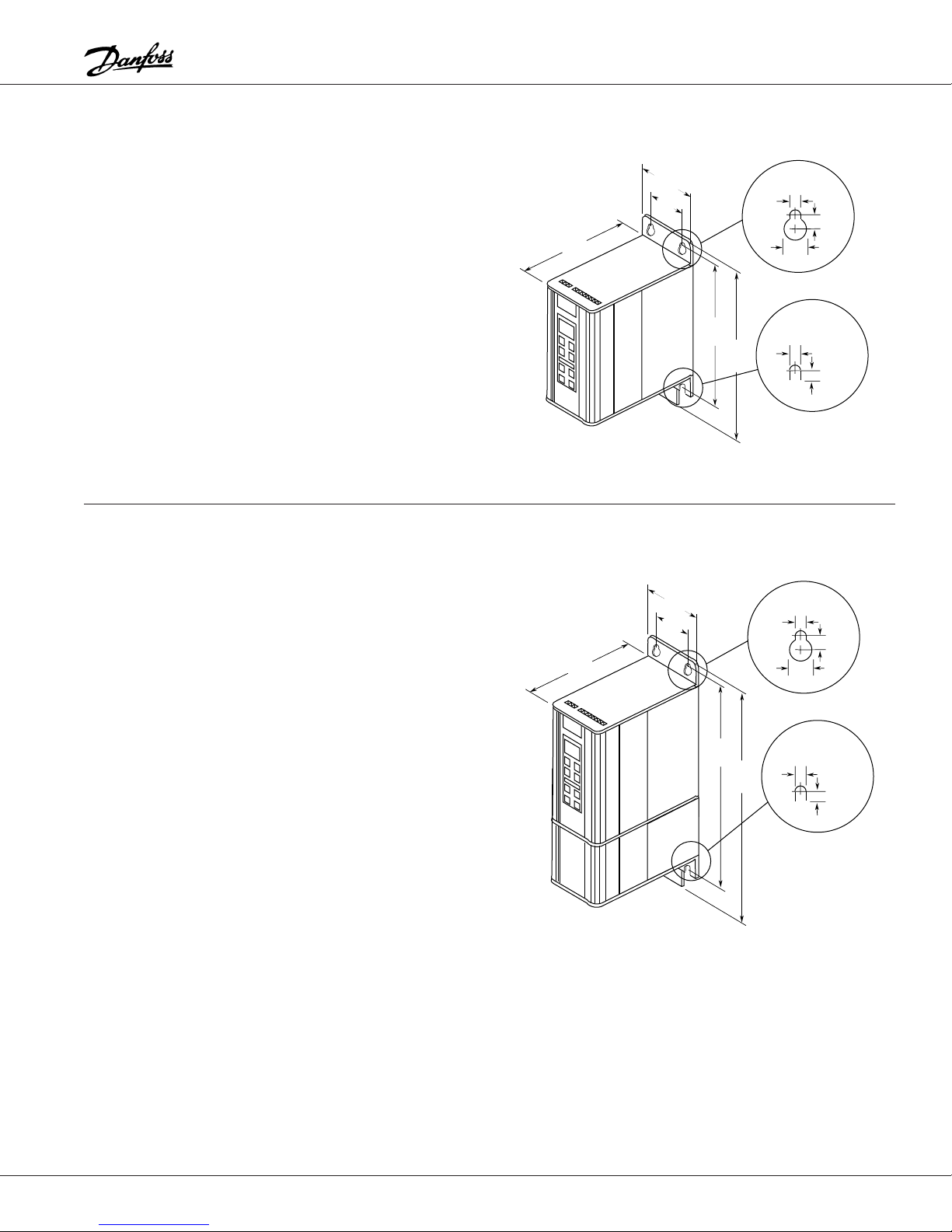

VLT 2020-2050

Three-phase, 380-415/460 V

VLT 2040-2050

Three-phase, 208-240 V

7.1

(180)

4.3

(110)

3.5

(90)

VLT ® Series 2000

0.21

(5.5)

0.29

(7.5)

0.43

(11)

NOTE:

Minimum space above and below the unit is 4 inches.

Minimum space to the sides of the unit is 0 inches.

VLT 2020-2050 with module

Three-phase, 380-415/460 V

7.1

(180)

4.3

(110)

3.5

(90)

13.2

(335)

14.2

(360)

0.21

(5.5)

0.17

(4.5)

0.21

(5.5)

0.29

(7.5)

0.43

(11)

NOTE:

Minimum space above and below the unit is 4 inches.

Minimum space to the sides of the unit is 0 inches.

6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17.2

(437)

18.2

(462)

0.21

(5.5)

0.17

(4.5)

Page 6

VLT ® Series 2000

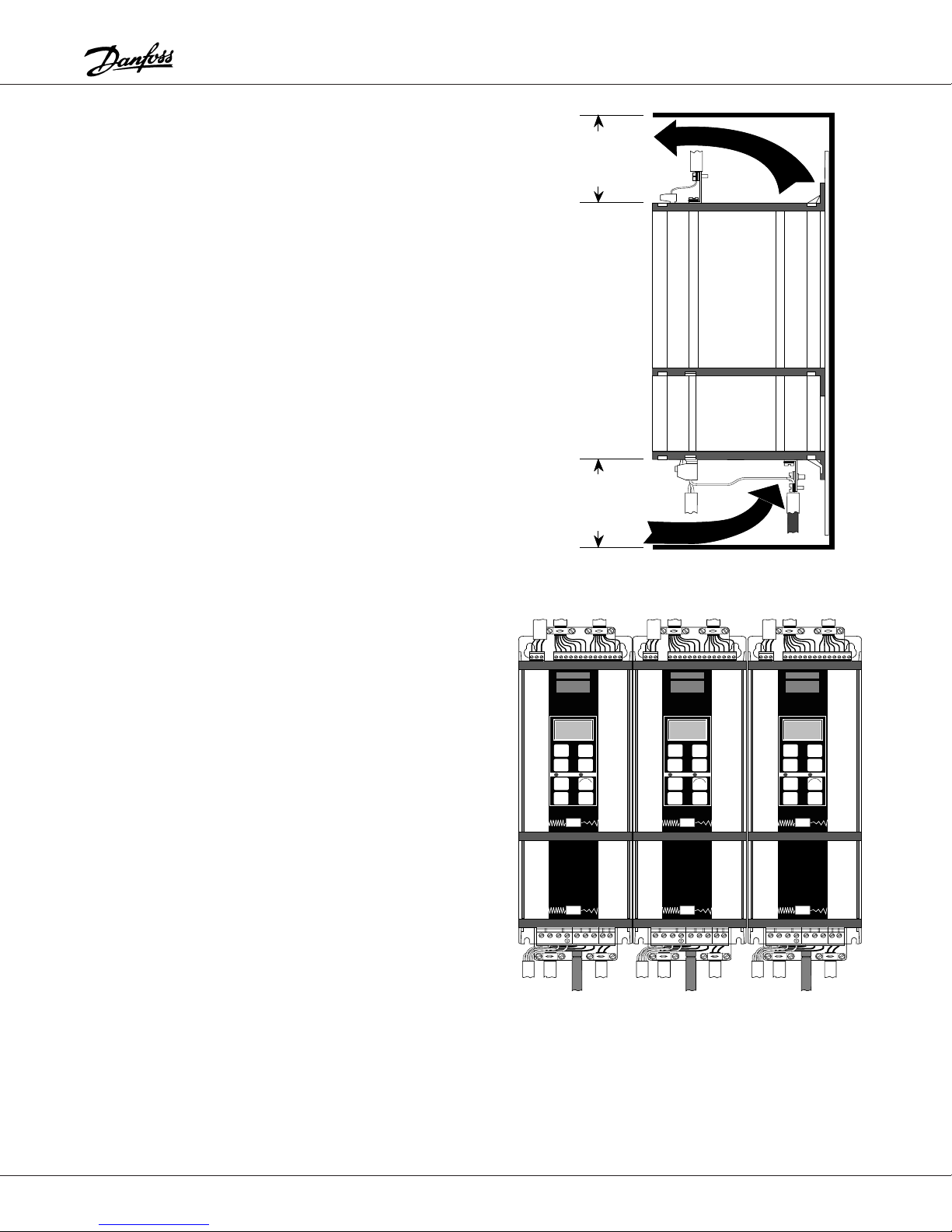

Mechanical Installation

The VLT Series 2000 is cooled by natural or forced air

convection. Therefore air must be able to pass freely

under and over the unit

The VLT adjustable frequency drive must be mounted on

a flat vertical surface.

To enable the VLT to get rid of the cooling air, you must

allow free air space both above and below the adjustable

frequency drive.

The ambient temperature must not exceed 40°C so that

the VLT can dispose of its power loss.

Installation; Cooling

Minimum

Clearance

4 Inches

(100 mm)

Minimum

Clearance

4 Inches

(100 mm)

Side by Side Mounting

The VLT Series 2000 adjustable frequency drive can be

installed side by side. There is no need for any space for

cooling along the side of the enclosure.

Variable Speed Drive

Menu

+

Data

–

Alarm

On

Fwd.

Jog

Rev.

Stop

Start

Reset

®

VLT

®

VLT

BR

MOTOR

LINE

Variable Speed Drive

Menu

+

Data

–

Alarm

On

Fwd.

Jog

Rev.

Stop

Start

Reset

®

VLT

®

VLT

BR

MOTOR

LINE

Variable Speed Drive

Menu

+

Data

–

Alarm

On

Fwd.

Jog

Rev.

Stop

Start

Reset

®

VLT

®

VLT

BR

MOTOR

LINE

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

Page 7

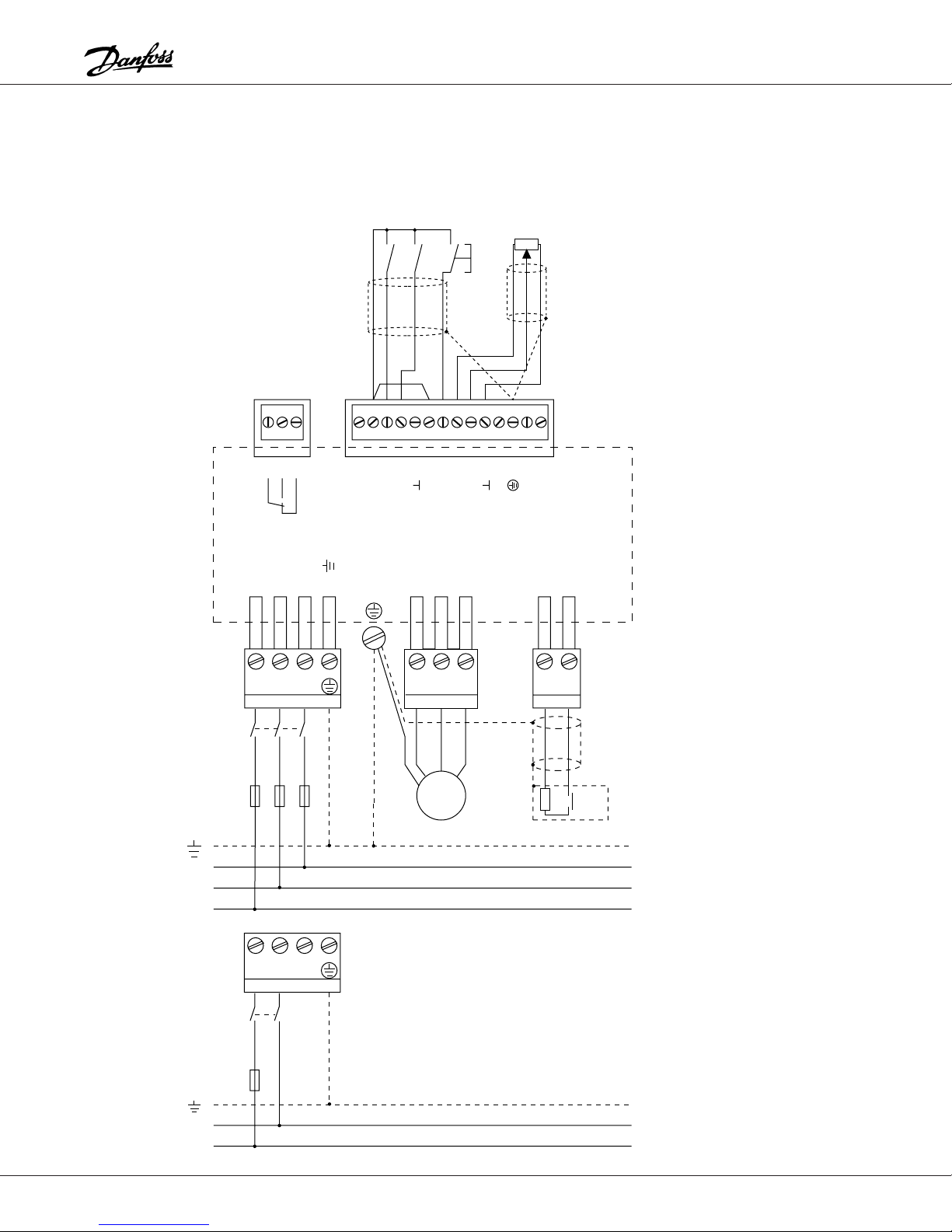

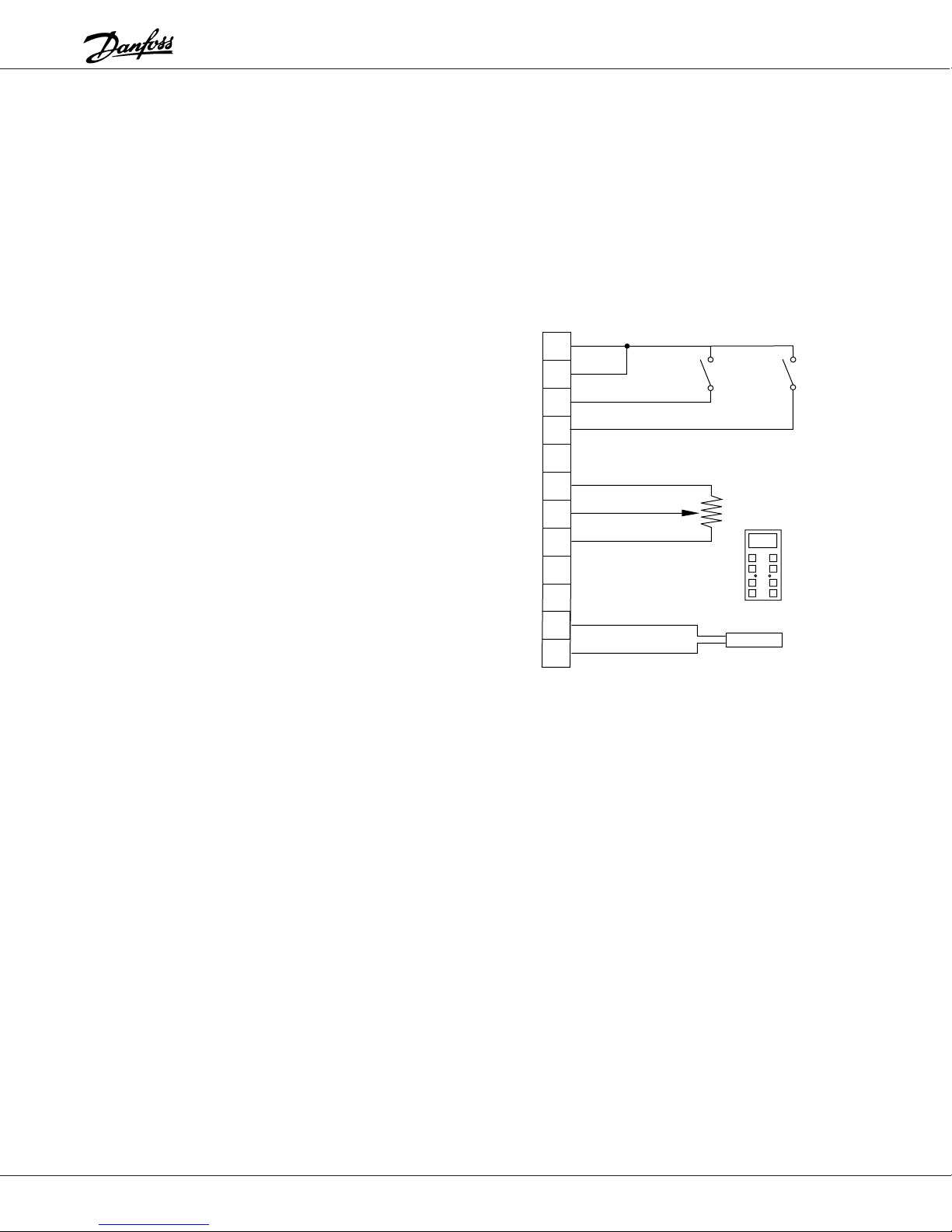

Installation; Wiring

VLT

VLT

®

®

Menu

Data

Stop

Reset

Jog

Start

Fwd.

Rev.

+

–

Variable Speed Drive

MOTOR

BR

LINE

Alarm

On

CAUTION:

It is the responsibility of the user or the person installing

the drive to provide proper grounding and branch circuit

protection for incoming power and motor overload.

National Electrical Codes (NEC) and local codes must be

observed.

Prefuses

Prefuses must be installed in the AC line feeding the

adjustable frequency drive.

Wiring

Cables for the control signals and the brake cable must

be shielded in order to comply with EMC specifications.

The maximum cable length and the maximum cable

cross section is listed in the Specification Chart.

Signal Wiring

VLT ® Series 2000

The Electronic Thermal Relay (ETR) in UL listed VLT's

provides class 20 motor overload protection in

accordance with NEC in single motor applications, when

parameter 315 is set to

to nominal motor (nameplate) current.

The correct sizes and ratings can be found in the

Specification Chart.

Any motor cable shielding is connected to the ground

terminals in the adjustable frequency drive and the motor.

If non-shielded cables are used, the control inputs can

occasionally be subject to signal disturbances. Normally

such a disturbance will not affect the VLT.

Trip

[2] and parameter 107 is set

03

02

01

0UT 46

DIN1 18

+24V 12

Line and Motor Wiring

L1 L2

L3 PE

20

DIN2 19

U

V

M

55

61

10V 50

A IN 53

DIN3 27

DIN4 29

W81

A IN 60

RS 232 TXD 72

RS 232 RXD 71

82

Tmax

8

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

VLT ® Series 2000

Typical Wiring Example

START/STOP

(par. 402)

REVERSING

(par. 403)

JOGGING

(par. 405)

Installation; Wiring

1k

L3

L2

L1

LINE

01

91 L1

L1 L2

03

02

92 L2

L3 PE

93 L3

94

0UT 46

DIN1 18

+24V 12

94 / 95

20

DIN2 19

DIN3 27

96

U

V

M

55

61

10V 50

A IN 53

DIN4 29

97

A IN 60

RS 232 TXD 72

RS 232 RXD 71

98

MOTOR

W81

81

82

82

BRAKE

Tmax

Three-phase connection

LINE

L1 L2

N

L1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

L3 PE

Single-phase connection

9

Page 9

Installation; Quick Setup

Quick Setup

VLT ® Series 2000

If you know how to operate the VLT Series and and are

familiar with the menus and parameters, go directly to the

How to Program section of this manual.

How to Program

This setup is based on the assumption that you want

your VLT to operate with the following:

1. External start/stop

2. Potentiometer connected for external speed control

3. Option to change rotation direction

4. Option to select a fixed speed (Jog)

If you are not familiar with the VLT Series Adjustable

Frequency Drive refer first the Operation section of this

manual.

NOTE: If you use a brake module, you must program

parameter 300. If you want local operation via the display

keys you must program parameters 003 and 004. To

store the data press the "Menu" key.

If you have connected your VLT as shown in the Typical

Wiring Example, you must program the parameters as

listed in the chart below.

Standard motor with constant torque load without a brake module on the adjustable frequenct drive

Step Parameter Designation Settings Display Indication

1 000 Language Choose

2 103 Motor output Read motor plate

3 104 Motor voltage Read motor plate

4 105 Motor frequency Read motor plate

5 201 Minimum frequency Set wanted frequency

6 202 Maximum frequency Set wanted frequency

7 215 Ramp up 1 Set wanted ramping time

8 216 Ramp down 1 Set wanted ramping time

9 Start the This is done by supplying terminals 18 and 27 with 24 VDC from

adjustable frequency the adjustable frequency drive's terminal 12 or by using an

drive external 24 VDC voltage.

English

ENGLISH

If a brake module is mounted, program the following parameters

Step Parameter Designation Settings Display Indication

1 300 Brake function If a brake module is used, choose

2 Start the This is done by supplying terminals 18 and 27 with 24 VDC from

adjustable frequency the adjustable frequency drive's terminal 12 or by using an

drive external 24 VDC voltage.

If you want local operation and start, program the following parameters

Step Parameter Designation Settings Display Indication

1 003 Operation site Choose

2 004 Local reference Record wanted output frequency by means of the "+" and "–" keys

10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loc/ext stop

Applied

APPLIED

LOC/EXT STOP

Page 10

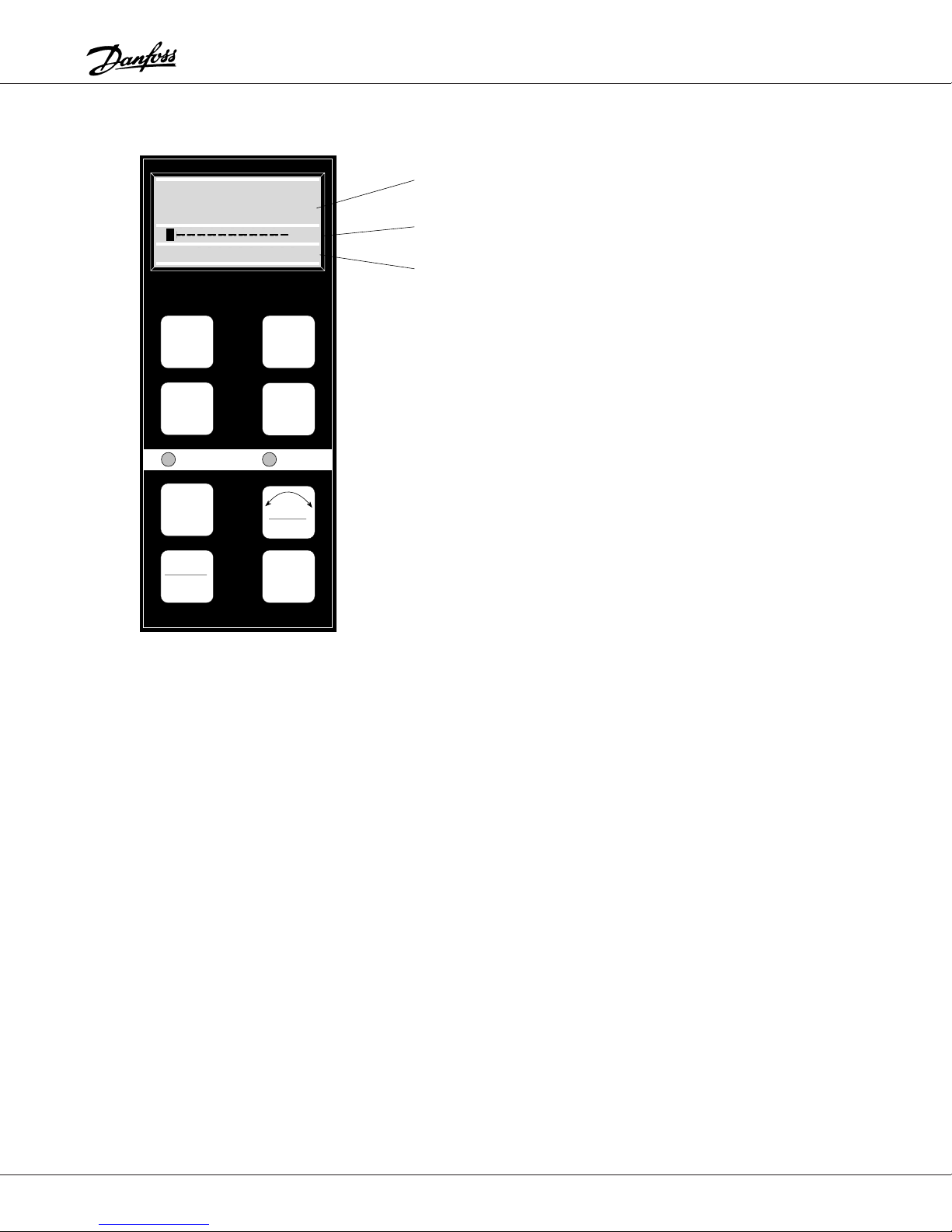

VLT ® Series 2000

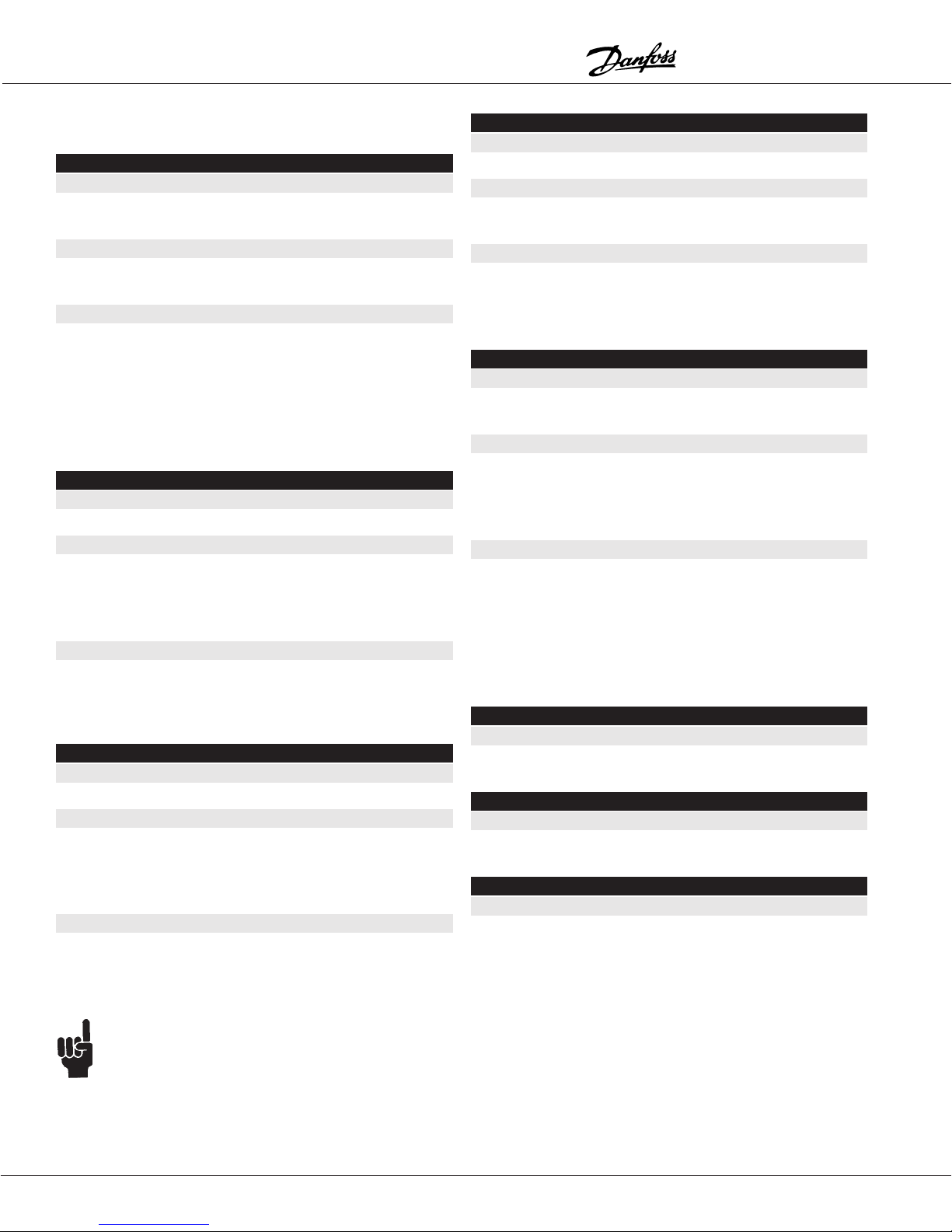

Operation

VLT Control Panel

60 Hz

0000000000000060

USE±000000000015

Menu

Data

Alarm On

Jog

Stop

Reset

+

–

Fwd.

Rev.

Start

A

B

C

All Danfoss VLT Series 2000 AC drives utilize the same

control card throughout the entire HP range. The VL T control

panel consists of a keyboard and a display.

The keyboard is used for two purposes: local control and

programming. The display communicates VLT, motor and

application information to the operator.

Located on the control panel is a red and green status LED.

When the green status LED is illuminated, there is AC power

applied to the VL T . The red LED is used for alarm indications.

In an ALARM MODE, the LED will flash.

The display is a three-line LCD display. Line A is used for

operating displays. It shows the value corresponding to the

setting in DISPLAY MODE. The set value remains in the

display line during programming of parameters. Line B

shows information about parameters and direction of motor

operation. Line C shows information about status and setup

or data value.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Page 11

Operation

Programming Keys

VLT ® Series 2000

Menu

is used to enter MENU MODE from either DATA

MODE or DISPLA Y MODE. MENU is also used for entering

a specific group of parameters.

Data

is used for entering DATA MODE or DISPLAY

MODE from MENU MODE. DA T A is also used to move the

cursor in data values.

Operator Keys

Four keys are provided for local control:

Start

Stop

Reset

Jog

With theexception of the Start key the keys can be

programmed to be enabled or disabled to prevent unwanted

use in certain applications.

Fwd

Rev

The and keys are used for scrolling through

+

–

Groups, Parameters and Data V alue selections. Additionally

these keys are used for speed up and down when operating

in Local mode.

Local Stop: Local Stop is accomplished by pressing the

Stop/Reset key on the front control panel. The local stop

command has been designed to override all run signals

whether local or remote. When a local stop has been made

the top line of the display will flash. The only way to resume

running from a local stop condition is to initiate a local start.

Local Forward/Reverse: Local Forward/Reverse will be

automatically disabled if remote operation is selected. In

remote, it is not possible to make direction changes from

the keypad.

Operational Modes

The VLT will be in DISPLAY MODE when the motor is

running in normal operation. DISPLAY MODE provides

various information concerning the current status of the VLT

and motor.

The and keys are used to scroll among

+

the 12 main display readouts:

• Reference

• Frequency Hz

• Display Feedback unit

• Current A

• Torque %

• Power kW

• Power HP

• Energy kWH

• Output voltage V

• DC voltage V

• Motor ETR value %

• Inverter ETR value %

–

The MENU MODE is used to select and change operating

parameters. The and keys are used in the

+

–

MENU MODE to select a parameter group or an individual

parameter or the data value of a given parameter.

Group Description Parameters

0 Operation and Display 000-099

1 Load and motor 100-199

2 Reference and limits 200-299

3 Functions and timers 300-399

4 Input and Output 400-499

5 Serial data interface 500-599

6 Service and diagnostics 600-699

12

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

VLT ® Series 2000

Operation

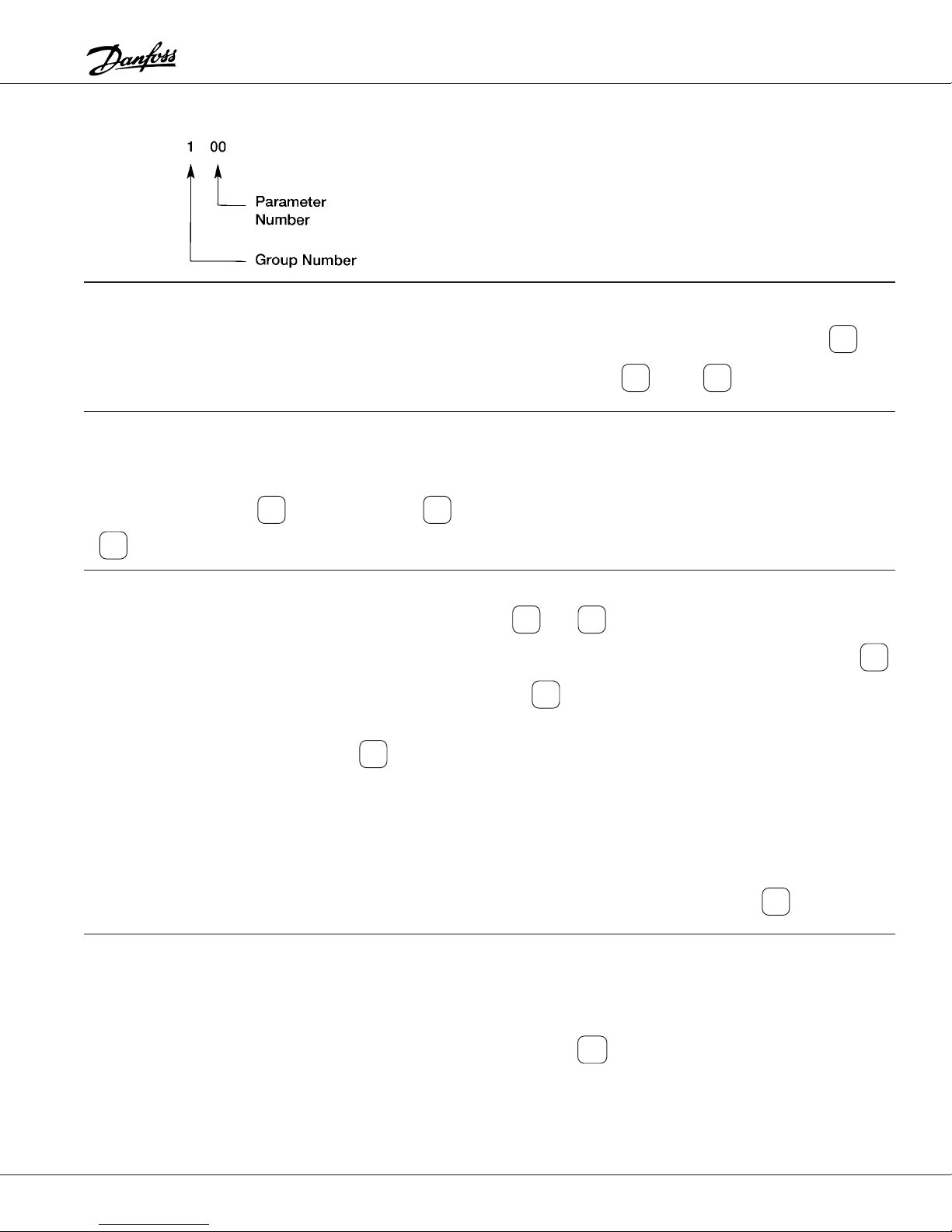

Parameter Numbering

Moving through the Program

After the first power up, the drive is in DISPLA Y MODE. To

program the VLT's various Groups, use the MENU key to

enter the MENU GROUP MODE.

Changing a Parameter number in a Group

Parameters in each group can be entered in the selected

group by also using the key followed by or

Menu

key.

+

–

The parameter number consists of three digits as shown.

The left digit indicates the Group, and the two digits at the

right specify the parameter number in the specific Group.

T o travel through the available Groups, use the key

followed by the or keys.

+

–

Menu

Changing a Numerical Data Value

The Data Value can be a continuous (numerical) value of

figures within a specified range (i.e., volts, Hz, etc.), or it

can be a discrete value represented by the text.

The new data value will be stored in the software when

leaving the DATA MODE.

Please Note: It is necessary to press to stop the

Stop

Reset

motor before changing the data value of some parameters.

If the data value of the chosen parameter is a discrete value,

a text will appear in the display . The text shown represents

the chosen parameter. In order to change it, press

Time-out

If the VLT is left in DATA MODE, a 20 second time-out will

prevent unwanted change of data.

+

or . All the other data value words that can

be chosen will be shown one at a time by using the

or key.

–

–

+

Due to space considerations, several words have been

abbreviated on the display.

When leaving the DATA MODE, the word shown in the

display will be stored.

Please Note: In order to change the data value of some

parameters, it is necessary to press .

Stop

Reset

It is possible to return to DATA MODE and program the

parameter that was blocked by the time-out with a single

The software leaves DATA MODE after 20 seconds if no

operation is recorded.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

stroke on .

Data

Note: The 20 second time-out does not occur in parameter

004, Local Reference.

13

Page 13

Operation

Operational Modes

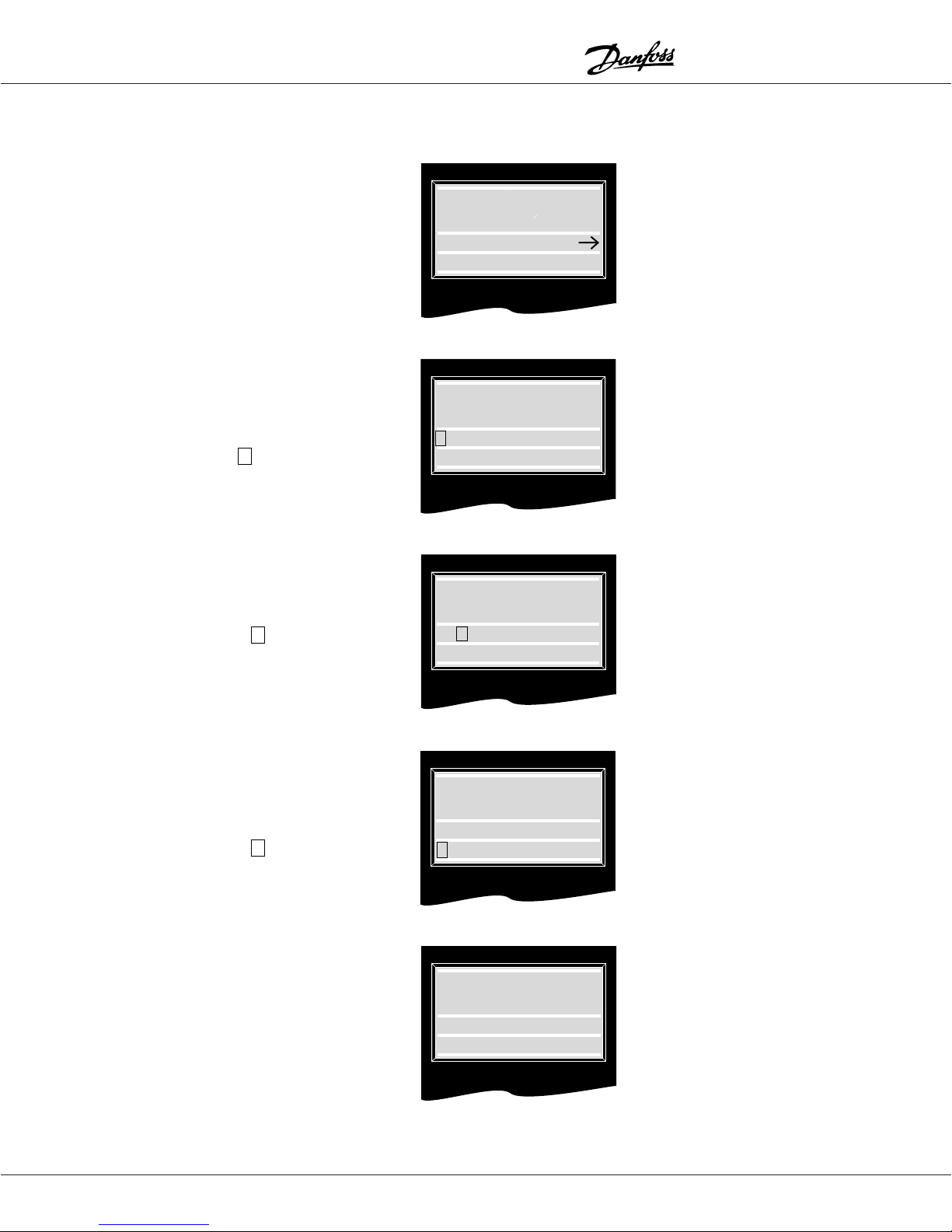

Display Mode

VLT ® Series 2000

Status, and source of control —

Menu Mode

Parameter number flashes —

Parameter Mode

Flashing parameter numbe —

Shows value and unit —

Defines the display —

0.. = Cursor flashes

0 = Cursor flashes —

Selected data value —

15.0 Hz

FREQUENCY

RUN OK LOCAL. 1

0.0 Hz

0 . .OPERATION

AND0DISPLAY 0000

0.0 Hz

0000LANGUAGE0000

ENGLISH000000001

— Direction of rotation

— Setup number

— Parameter group

— Name

— Parameter name

— setup number

Data Mode

E = Cursor flashes —

Selected data value

NOTE: To store the newly selected data value,

you must quit Data group, by pressing "Menu".

Alarm Mode

Reset mode —

Cause of alarm —

NOTE: If TRIP is displayed the operation has

stopped and you must press the "Reset" key to

reset the VLT.

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

0.0 Hz

LANGUAGE0ENGLISH

ENGLISH000000001

ALARM

TRIP000000000000

MOTOR TRIP000000

— Parameter name

— Setup number

NOTE: If TRIP LOCKED is

dispalyed you must switch off the

VLT and switch it on again. Press

the "Reset" key to reset the VLT.

Page 14

VLT ® Series 2000

Operation

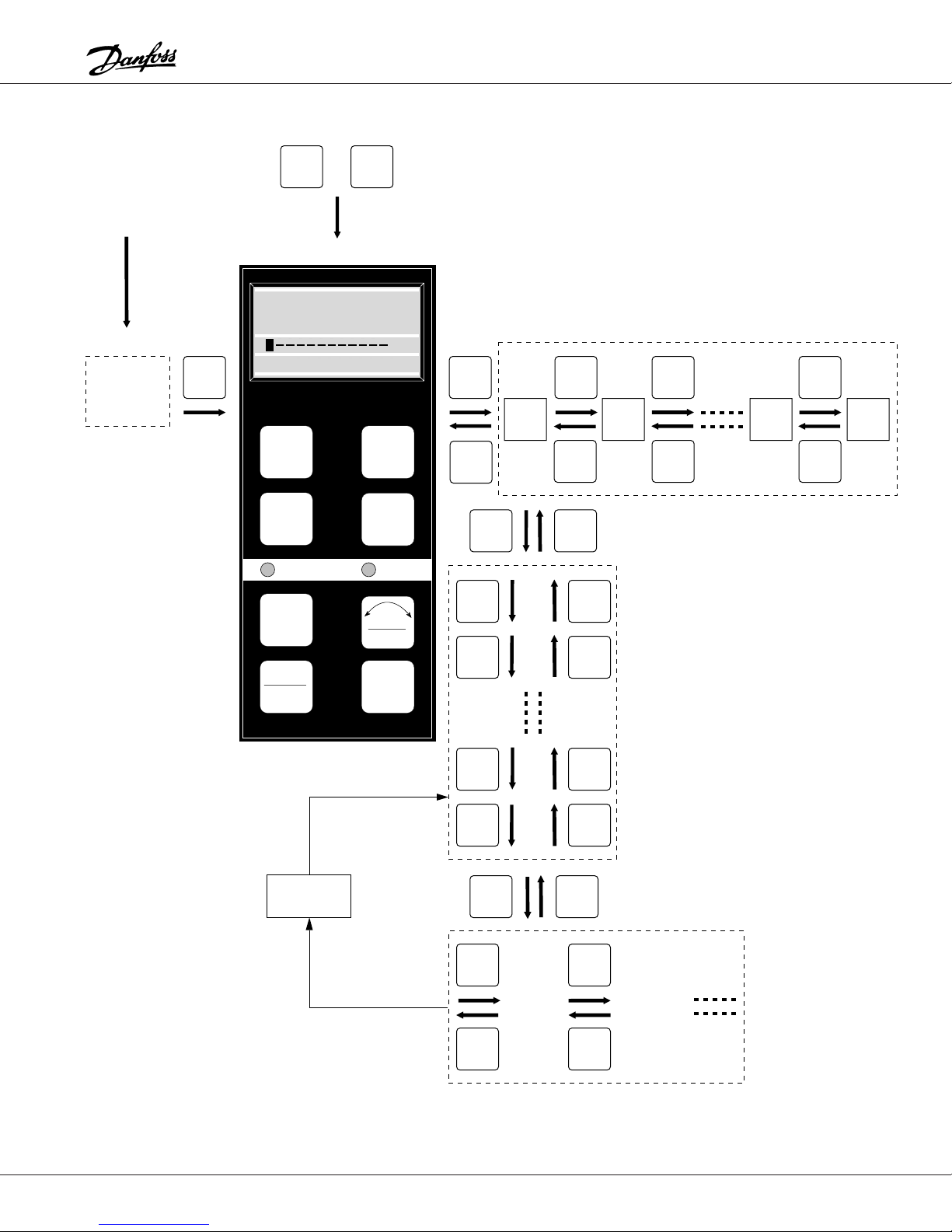

From any state

Alarm Mode

Stop

Reset

From any state

Menu

Display Mode

+

Data

60 Hz

0000000000000060

USE±000000000015

Menu

Data

Alarm On

+

–

The figure below shows how to switch

between the different groups.

Menu Mode

Menu

Data

Menu

Grou

0

p

+

–

Menu

Group

1

+

6

–

+

0

–

Time Out

Jog

Stop

Reset

20 Sec.

No Action

Fwd.

Rev.

Start

+

+

+

+

Data

+

000

001

00X

000

English

Menu

Parameter Mode

–

–

–

–

+

Deutsch

Data Mode

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

–

–

15

Page 15

Programming VLT® Series 2000

Group 0 -- Operation and Display

000 Language (LANGUAGE)

Value:

★ English (ENGLISH) [0]

German (DEUTSCH) [1]

French (FRANCAIS) [2]

Danish (DANSK) [3]

Function and Description:

Determines the language of the display.

You can choose between

Danish.

001 Menu Setup Select (MENU SETUP)

Value:

★ Setup 1 (SETUP 1) [1]

Setup 2 (SETUP 2) [2]

Multi-setup (MULTI SETUP) [5]

Setup Terminal 29

10

21

Function:

You can select a menu setup which is different from the

factory setting and store it in

Description:

You start by selecting the setup you want to make or alter.

You can choose between

alter any data value you like. Your alterations make a setup

different from the factory setting. If you choose

you can switch between the two setups via terminal 29. The

parameters which can be chosen for the two setups have

been specially selected. Refer to the Parameter/Default

Settings chart in the back of this manual.

English, German, French and

Setup 1 or Setup 2

Setup 1 or setup 2.

.

Then you can

Multi-setup

002 Setup Copy ((MENU SET COPY)

Value

★ No copying (DO NOT COPY) [0]

Copy setup 1 to 2 (COPY 1 TO 2) [6]

Copy to 2 to 1 (COPY 2 TO 1) [7]

Copy from fact. setting to 1 (Fact. setting ➔1) [8]

Copy from fact. setting to 2 (Fact. setting ➔2) [9]

Function:

You can copy

always copy the factory setting back to

Description:

The copying starts when you have entered the desired

copying function and Data mode is left by pressing the

“Menu” key, or after 20 seconds of no activity. Line 3 in the

display flashes while copying is in progress. Time out does

not activate the copying function.

003 Operation Site (LOCAL /REMOTE)

Value:

★ Remote (REMOTE) [0]

Local with external stop (LOC/EXT./STOP) [1]

Local (LOCAL) [2]

Local and remote (LOCAL - REMOTE) [3]

Function:

You can choose four different operation sites:

Local with external stop, Local and Local and remote

Description:

If you choose

frequency drive via the control terminals. However, you can

still use the stop key of the control panel (provided you

have not chosen to disable this function in parameter (007).

If you choose

the connection between terminals 12 and 27 to activate

stop.

Local with external stop

coasting

have been chosen in parameter 404 (terminal 27).

Choose

keyboard (must be activated in parameter 007).

remote

selected for access to local reference even when the unit is

operated remotely.

Setup 1 to Setup 2

and vice versa. You can

Setup 1 or Setup 2.

Remote,

.

Remote

Local with external stop

,

Quick stop, Reset and motor coasting or Stop

Local

if you want to operate the unit via the

, you can control the adjustable

you must disconnect

can only be chosen if

Motor

Local and

adds local and external reference. This function is

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

16

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

VLT® Series 2000 Programming

004 Local Reference (LOCAL SPEE)

Value:

0 to f

MAX

Function:

You choose

Local reference

if you want to set the speed

(frequency) via the control panel.

Description of choice:

To use this parameter you must choose

stop or Local and remote

in parameter 003. the output

Local with external

frequency of the adjustable frequency drive can be

changed by means of the "+" and "–" keys. If the AC line is

disconnected the value changes to 0.00. Parameter 004

cannot be controlled via the serial bus, RS 232.

There is no automatic switch back to Parameter Group from

this parameter. In parameter 010 you can lock data

changes in parameter 004.

005 Display Value (VALUE AT M)

Value:

1 to 9999 ★ 1000

Function:

Yoy can choose to have the speed/frequency displayed

without the unit Hz behind the value.

Description of choice:

The value will only be read out if

Display

is selected in

Display Group.

It is not possible to change Hz to another unit.

006 Local Reset (LOCAL RESE)

Value:

Disable (DISABLE) [0]

★ Enable (ENABLE) [1]

010 Local Reference (LOC REFERE)

Value:

Disable (DISABLE) [0]

★ Enable (ENABLE) [1]

Enable and save (ENABLE AND SAVE) [2]

Function:

You can enable/disable the function via the control panel.

You also can choose whether it must be possible to change

the output frequency via parameter 004.

Description:

If you choose

Disable

in parameter 006, 007, 008 or 009

you cannot activate the function via the control panel.

If you choose

Disable

in parameter 010 the output

frequency cannot be changed via parameter 004.

You can prevent data change by setting parameter 013 to

Locked.

If you choose

Enable

and savs a change of local speed

reference will be saved automattically after 15 sec.

013 Data Change Lock (DATA CHC. LOCK)

Value:

★ Not locked (NOT LOCKED) [0]

Locked (LOCKED) [1]

Function:

There is a way to avoid unintended programming.

Description:

If you choose Locked you cannot make any data change in

any parameter. However, it is still possible to change the

local reference.

If data change is attempted with data change lock, the

display shows: DATA LOCKED.

007 Local Start/Stop (LOCAL START/STOP)

Value:

Disable (DISABLE) [0]

★ Enable (ENABLE) [1]

008 Local Reversing (LOCAL/FWD/REV)

Value:

★ Not possible (DISABLE) [0]

Possible (ENABLE) [1]

009 Local Jog (LOCAL JOG)

Value:

Disable (DISABLE) [0]

★ Enable (ENABLE) [1]

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

Page 17

Programming VLT® Series 2000

Group 1 -- Load and Motors

101 Speed Control (SPEED CONT)

Value:

Open loop (OPEN LOOP) [0]

★ Slip comp. (SLIP COMP) [1]

Closed loop (CLOSED LOOP) [2]

Function:

You can choose among three different kinds of speed

control:

Choose

speed must be constant no matter what the load is. Choose

Open loop

when synchronous motors are used.

Choose Closed loop when you want operation with process

feedback. For closed loop opereation you must choose the

feedback type in parameter 114 (current, voltage or pulses).

★ Pre-programmed value (VALUE SET) [0]

You can choose to control the speed by means of the

current limit. This makes indirect torque control possible.

The current limit is set in parameter 209, or by means of a

current or voltage signal in parameter 412 or parameter

413.

Choose between controlling the current limit via parameter

209 or one of the analog inputs, terminal 53 0r 60.

mA

Do not select the same signal for PI control.

★ Nom. size [1]

This parameter allows a choice of the kW value that best

matches the rated motor power.

The factory setting will be for the nominal kW equivalent of

the horsepower size on the drive nameplate.

Open loop, Slip compensated

Description:

Slip compensation

when the motors used are parrellel connected or

102 Setting of Current Limit (SET CUR.LI)

Value:

Voltage signal (10VDC SIGNAL) [1]

Current signal (20 mA SIGNAL) [2]

Function:

Description:

corresponds to 160% current (2030: 140%).

103 Motor Power (MOTOR POWE)

Value:

Under size [0]

Over size [2]

Function:

for normal operation , where the

and

Closed loop

.

10V/20

103 (continued)

Description:

Check the rated motor power on the motor nameplate. If it

is not equal to the nominal horsepower rating on the drive

nameplate, select the most appropriate size (1 HP = 0.746

kW). Parameters 107, 108, 109, 110, 111 and 112 change

automatically when the value in parameter 103 is changed.

104 Motor Voltage (U

Value:

)(MOTOR VOLT)

M,N

Only 200-230 V units

200 V [0]

208 V [1]

★ 220 V [2]

230 V [3]

240 V [4]

Only 380-460 V units

380 V [0]

★ 400 V [1]

415 V [2]

440 V [3]

460 V [4]

Function:

The rated voltage that most closely matches the motor

nameplate voltage can be selected.

Description:

You can choose among different voltage values. The value

is selected on the basis of the data on the motor plate.

Parameters 107, 108, 109, 110, 111 and 112 change

automatically when the value in parameter 104 is changed.

105 Motor Frequency (fN)(MOTOR FREQ)

Value:

★ 50 Hz (50 Hz) [0]

60 Hz (60 Hz) [1]

87 Hz (87 Hz) [2]

100 Hz (100 Hz) [3]

Function:

Choose the frequency that corresponds to the rated motor

frequency.

Description:

You can choose among 4 different frequency values. The

value is selected on the basis of the data on the type plate

of the motor.

The U/f ratio in parameter 111 is changed automatically.

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

18

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

VLT® Series 2000 Programming

107 Motor Current (MOTOR CURR)

Value:

I

MAG (par. 108)

Function:

It is important to specify the rated motor current because it

is used in part to calculate torque and thermal motor

protection, (ETR),

Description:

The rated motor current, which can be seen from the motor

nameplate, must be entered. This is also chosen in Quick

Set Up Menu step 2.

108 Motor Magnetizing Current (MOTOR MAG AMP)

Value:

0.3 - I

Function:

The VLT uses the value for different calculations such as

compensation.

Description:

If the factory setting is unsuitable, the motor current on

running idle should be measured with suitable

amperemeter (RMS). The magnetizing current is then set to

the measured value.

109 Start Voltage (START VOLT)

Value:

0 to (V

Function:

By increasing the start voltage, a high start torque can be

obtained. Small motors (<1 HP) normally require a high

start voltage. When motors are connected in parallel, it

may be desirable to increase the starting torque.

Description:

Do not forget to consider that the motor must be able to

start with the required torque:

1. Choose a value to make start possible with the load in

question.

2. Reduce value until starting up with the given

load is just possible.

3. Choose a value where operation in the rest of the

frequency range is possible at the lowest possible

current consumption.

If the start voltage makes normal operation impossible, you

can change the V/f ratio in parameter 111.

- I

VLT, MAX (par. 209)

M,N (par. 107)

+ 10%)

M,N

110 Start Compensation (START COMP)

Value:

0.00 - 99 V/A

Function:

Using this parameter you acn make a load dependent

torque adaptation. This is for example used for motors and

applications where there is a large difference between the

motor's full-load current (parameter 107) and no-load

current (parameter 108).

Description:

If the factory setting is not sufficient, you can set the

parameter so that the motor can start at the actual load.

You can also combine start compensation with parameter

109.

WARNING: Should not be used with

synchronous motors and parallel-coupled motors

and where quick load changes may occur. To

!

∆

111 V/f Ratio (V/F RATIO)

Value:

Function:

Using this parameter you can change the linear ratio

between voltage (V) and frequency (f) to correct motor

magnetization, optimal dynamics, accuracy or efficiency.

Description:

Use this parameter only if you cannot record the correct

motor data in parameters 104 and 105.

The value can be calculated as follows:

The value of the factory setting is based on no-load

operation. Therefore it is lower than the value calculated.

The compensation will give the necessary voltage

supplement.

For factory settings refer to the Parameter Chart in the back

of this manual.

avoid instability do not increase the value more

than necessary.

0.00 - 20 V/Hz

Motor voltage (para. 104)

V/f =

Motor frequency (para. 105)

WARNING: If the use of start voltage is

excessive, it can lead to magnetic saturation and

motor overheating.

!

∆

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

Page 19

Programming VLT® Series 2000

112 Slip Compensation (SLIP COMP.)

Value:

0.0 - 20 Hz

Function:

Slip Compensation

voltage of the VLT adjustable frequency drive with an

increasing load to compensate for the motor's increasing

slip (loss). This achieves a load-independent speed.

Description:

Choose a value so that the speed remains constant when

the load increases. If the value is too high the speed

increases with the load. This may lead to unstable motor

operation.

When you use synchronous motors and motors connected

in parallel, set slip compensation to 0 Hz. Slip

compensation should be avoided in case of high dynamics.

114 Feedback Signal (FEEDBACK T)

Value:

Voltage (VOLTAGE) [0]

★ Current (CURRENT) [1]

Pulses (PULSES) [2]

Function:

This parameter allows a choice of process feedback signal

in a closed loop system, as chosen in parameter 101. It has

no effect if parameter 101 is set to OPEN LOOP.

For further information, see the section on the PID

controller.

Description of choice:

If a PID controller is used, one of the inputs on terminal 29

(parameter 405), terminal 53 (parameter 412) or terminal

60 (parameter 413) must be used for the feedback signal.

The same type of signal cannot be the reference signal.

119 FF Factor (FEED FWD F)

Value:

0 to 500% ★ 100%

Function:

This parameter is used in connection with a PI controller.

The FF factor makes a large or small part of the reference

signal around the PID controller so that the PI controller

only affects part of the control signal. Any change of the

setpoint will affect the motor rpm directly. The FF factor

gives high dynamics at changes of the setpoint and less

overswing.

Description of choice:

You can choose the required % value in the interval f

Choose a value above 100% if the setpoint variations are

only minor.

increases the output frequency and

MIN-fMAX

120 Control Range (CONTRL RAN)

Value:

0 to 100% ★ 100%

Function:

The regulator range (bandwidth) limits the output from the

PID controller as a % of f

Description of choice:

A desired % value of f

range is reduced, speed variations will become smaller

during initial adjustment.

WARNING: The output frequency is limited by

0.9 x f

width setting is. The controller can therefore be

!

∆

121 Proportional Gain (PROPRT/L G)

Value:

Function:

The proportional gain sets the amplification factor of the

error (the difference between the feedback signal and the

setpoint).

Description of choice:

Quick regulation is obtained at a high amplification, but if

the amplification is too high, the process may become

unstable due to overshoot.

122 Integral Time (INTEGRAL T)

Value:

Function:

The integral time determines how long the PI controller

takes to correct the fault. The integral time results in a delay

of the signal, and therefore has a dampening effect that will

improve stability.

Description of choice:

Quick regulation is obtained through a short integral time.

However, if this time is set too short, the process will

become unstable. If the integral time is set long, regulation

becomes unnecessarily slow.

inactive.

active without affect the output frequency can

exceed f

0.01 to 10.00 ★ 0.01

0.01 to 7200 sec. ★ OFF

and 1.1 x f

MIN

MAX

.

MAX

can be selected. If the regulator

MAX

no matter what the band

MAX

by 10%.

Off

means that the function is

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

VLT® Series 2000 Programming

125 Feedback Factor (FEEDBACK F)

Value:

0 to 500% ★ 100%

Function:

The feedback factor is used if the transmitter cannot be

selected optimally for the scale range of the setpoint.

Description of choice:

This parameter is only used if the feedback signal in

parameter 114 is not of a suitable level. If you choose

the feedback signal is not changed.

100%

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

21

Page 21

Programming VLT® Series 2000

Group 2 -- References and Limits

200 Frequency Range (FREQUE RANGE)

Value:

★ 0 to 120 Hz [0]

0 to 500 Hz [1]

Function:

Using this parameter you can set and thus limit the output

frequency range of the VLT adjustable frequency drive.

Description:

In most cases you can use 0-120 Hz.

WARNING: Only choose 0-500 Hz if you use

special motors designed for high speeds.

!

∆

201 Minimum Frequency (MIN FREQUE)

Value:

0.0 to f

MAX

Function:

Choose the minimum frequency that corresponds to the

minimum speed at which the motor is to run. The minimum

frequency can never be higher than the maximum

frequency, f

MAX

.

Description:

A value from 0.0 Hz to the max. frequency (f

parameter 202 can be chosen. This is also chosen in Quick

Set Up Menu step 5.

202 Maximum Frequency (MAX FREQUE)

Value:

0.0 - value in para. 200 ★ 60 Hz

Function:

Choose a maximum frequency that corresponds to the

maximum speed at which the motor is to run. The maximum

frequency can never be lower than the minimum frequency,

f

.

MIN

Description:

A value from f

f

(

120 Hz or 500 Hz

MAX

to the value selected in parameter 200 for

MIN

) This is also chosen in Quick Set

Up Menu step 6.

★ 0

) selected in

MAX

203 Jog Frequency (JOG FREQUE)

Value:

0.0 to f

MAX

★10 Hz

Function:

The jog frequency is the fixed output frequency at which the

drive runs when the jog function is activated.

Description:

The jog frequency can be selected to be lower than f

MIN

(parameter 201) but the highest output frequency is limited

(parameter 202).

by f

MAX

204 Digital Reference Type (DIG. REF.)

Value:

★ Sum (SUM) [0]

Relative (RELATIVE) [1]

Function:

The digital references are generated internally in the unit

and presented as a percentage of the difference between

the f

to f

MIN

MAX

and f

.

selected in parameters 201 and 202, added

MIN

Description:

If

Sum

is selected, one of the digital references (parameters

205-208) is added as a percentage of the difference

between f

MAX

and f

with the other references. If

MIN

Relative

is selected, one of the digital references )parameters 205-

208) is added as a percentage of the sum of the other

references.

205 Digital Reference 1 (REF. 1 DIG)

Value:

-100.00% to +100.00% ★ 0 % of f

MAX .

- f

MIN

206 Digital Reference 2 (REF. 2 DIGI)

Value:

-100.00% - +100.00% ★ 0 % of f

MAX .

- f

MIN

207 Digital Reference 3 (REF. 3 DIG)

Value:

-100.00% - +100.00% ★ 0 % of f

MAX.

- f

MIN

When the PI controller is active the maximum

frequency can be exceeded by 10%. The same

applies when slip compensation is active.

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

22

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

VLT® Series 2000 Programming

208 Digital Reference 4 (REF. 4 DIG)

Value:

-100.00% - +100.00% ★ 0 % of f

MAX - fMIN

Function:

The digital speed references are generated internally in the

unit and presented as a percentage of the difference

between the f

202, added to f

MAX

and f

MIN

selected in parameters 201 and

MIN

.

Description:

By means of terminal 29 you can switch between the other

references (terminal 29 = 0 V) and the sum of the other/

digital references (terminal 29 = 24 V).

You must select Digital reference in parameter 402 and 403

to file one of the digital references:

Terminal 18/27 Terminal 19

0 0 Digital reference 1

1 0 Digital reference 2

0 1 Digital reference 3

1 1 Digital reference 4

209 Current Limit (CURRENT LI)

Value:

0.3 to I

VLT,MAX

Function:

Use this parameter to set the maximum intermittent output

current. If the current limit is exceeded, the output

frequency is reduced until the current falls to below the

current limit. The output frequency will not increase to the

reference level until the current has fallen below the current

limit.

Description of choice:

The value set at the factory corresponds to a load which is

160% (VLT 2030, 3Ø 208-240 V: 140%) of the rated output

current. If the current limit is to be used as motor protection,

the rated motor current must be programmed. Parameter

310 determines the length of time that the drive will run in

current limit before an overcurrent fault. The load range

between 100 and 160% can be programmed, but it is only

intended for intermittent operation therefore the unit can

only give an output of 160% (VLT 2030, 3Ø 208-240 V:

140%) for 60 seconds. The intermittent operating time will

be extended as the load drops below 110%, and becomes

unlimited at 100%.

If the switching frequency is higher than 4.5 kHz

this period will be shorter.

210 Warning: Low Frequency (LO FREQ. W)

Value:

0 to 500 Hz ★ 120 Hz

Function:

Set the low frequency (f

) at which the warning is to

LOW

occur.

Description:

If the output frequency falls below the frequency set (f

LOW

),

the display shows LO FREQ. WARN.

You can also choose to program the signal outputs in

parameters 408 and 409 to give a signal.

211 Warning: High Frequency (HI FREQ. W)

Value:

0 to 500 Hz ★ 120 Hz

Function:

Set the high frequency (f

) at which the warning is to

HIGH

occur.

Description:

If the output frequency increases above the frequency set

(f

), the display will read HI FREQ. WARN.

HIGH

You can also choose to program the signal outputs in

parameters 408 and 409) to give a signal.

213 Warning: High Current (HI CURR. W)

Value:

0.0 to I

VLT,MAX

★ I

VLT,MAX

Function:

Set the current (I

) at which the warning is to occur.

HIGH

Description of choice:

If the motor current rises above the I

programmed, the

HIGH

display will read HI CURR. WARN.

You can also choose to program the signal outputs in

parameters 408 and 409 to give a signal.

215 Accel (ramp-up) Time (RAMP UP TI)

Value:

0.1 to 800 sec. ★ 5 s

Function:

Using this parameter you can record the required

acceleration time from 0.1 Hz to the rated output frequency

(parameter 105).

Description:

To ensure the fastest possible start, choose a value for the

ramp-up time so that the current limit is not activated. The

ramp-up time is always defined as the acceleration time

from 0 Hz to the rated motor frequency.

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

23

Page 23

Programming VLT® Series 2000

216 Decel (ramp-down) Time (RAMP DOWN)

Value:

0.1 to 800 sec. ★ 5 s

Function:

Using this parameter you can record the required

deceleration time from rated output frequency to 0 Hz.

Description:

The ramp-down time can be selected in the range 0.1-800

seconds. If the ramp-down time is too short the VLT's

voltage limit becomes active, which will extend the rampdown time. Short ramp-down times will require a VLT unit

with a brake function and installation of a brake resistor.

The ramp-down time is always defined as the deceleration

time from the rated motor frequency to 0 Hz.

218 Quick Stop Ramp (QUICK STOP RAMP)

Value:

0.1 - 800 sec. ★ 1 s

Function:

Using this parameter you can choose an alternative

deleceration ramp - a programmable quick stop ramp.

Description of choice:

The ramp-down time can be selected in the range 0.1 - 800

seconds, calculated from the rated frequency to 0 Hz. If the

ramp-down time is too short the VLT's voltage limit

becomes active, which will extend the ramp-down time.

Short ramp-down times will require a VLT unit with a brake

function and installation of a brake resistor.

230 Digital Speed Up/Down (DIG. SPEED UP/DOWN)

Value:

★ Disable (DISABLE) [0]

Enable (ENABLE) [1]

Enable and Save (ENABLE and SAVE) [2]

Function:

Using this parameter you can make the VLT adjustable

frequency drive lock the output frequency to the latest

indicated speed reference.

Description:

You can choose to have either digital speed up/down

(terminal 18/27 and 19) or other speed references. When

you have chosen

(terminal 18) and

402/404 and 403.

When Enable and Save is selected a speed will be saved

automatically after new start-up.

The other references will not be active so that the digital

references cannot be combined with other references.

Enable

you must choose

Speed Down

Speed Up

(terminal 19) in parameters

224 Carrier Frequency (CARRIER FR)

Value:

2.0 to 14.0 kHz ★ 4.5 kHz

Function:

The set value determines the carrier frequency of the

inverter. Changing the carrier frequency may minimize

acoustic noise from the motor.

Description:

It is possible to change the carrier frequency between 2

and 14 kHz. The disadvantages of operating at a high

carrier frequency are:

- reduced continuous output current

- reduced efficiency

- higher capacitive leakage current

- increased RFI radiation from the VLT

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

24

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

VLT® Series 2000 Programming

Group 3 -- Functions and Timers

300 Brake Function (START FREQ)

Value:

★ Not Applied (NOT APPLIED) [0]

Applied (APPLIED) [1]

Function:

Using this parameter you can inform the VLT adjustable

frequency drive that a brake function and a brake resistor

have been connected.

Description:

Choose Applied if you use a brake function and a brake

resistor.

306 DC Braking Time (DC-BRAKE T)

Value:

0 to 60 sec. ★ 0 sec.

Function:

Using this parameter you can record how long the DC

braking must be active

Description:

When you choose the braking time you must consider if you

want to maintain the braking torque or if you want to use a

stop function.

The DC braking time must be ≠ 0 to activate DC braking.

307 DC Brake Cut-in Frequency (DC-BRK ON)

Value:

0 to 500 Hz ★ 1 Hz.

Function:

Using this parameter you can record the output frequency

at which DC braking must start when ramping down to

standstill.

Description:

The cut-in frequency depends on the application. The cut-in

frequency must be ≠ 0 to activate DC braking. Instaed of

using this parameter you can activate DC braking via

terminal 27 if a DC braking time and a DC brake voltage

have been recorded.

308 DC Brake Voltage (DC-BRK VOL)

Value:

0 to 50 V ★ 10 V

Function:

Using this parameter you can record the DC brake voltage

for the motor.

Description:

The size of the voltage depends on the motor size. The

bigger the motor the lower the DC brake voltage.

WARNING: At frequent DC-braking the DC brake

voltage should not be too high. This is to avoid

!

∆

309 Reset Function (RESET MODE)

Value:

★ Manual reset (MANUAL) [0]

Automatic reset 1 (AUTO 1) [1]

Automatic reset 5 (AUTO 5) [5]

Function:

Using this parameter you can choose how you want to

reset an alarm

Description:

If you choose

adjustable frequency drive via the keyboard or via terminals

19, 27, or 29. The display shows TRIP.

If you choose

reset once after alarm. The display shows AUTO START.

As long as the display shows AUTOSTART the unit will try

to reset every 20 minutes.

If you choose Auto Reset 5 thr VLT will automatically try to

reset 5 times after alarm. The display shows AUTO START.

!

∆

motor overload. The DC brake voltage must be ≠

0 to activate DC braking.

Manual Reset

Auto Reset 1

WARNING: The motor may start without warning.

you must reset the VLT

the VLT will automatically try to

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

25

Page 25

Programming VLT® Series 2000

310 Trip Delay at Current Limit (TRIP DLY@C)

Value:

0 to 60 secs.

★ Infinite at 61

Function:

Using this parameter you can record how long the current

limit may be active before trip.

Description:

Record the delay time.

WARNING: If you choose Infinite, and your load

is between 105% and 160%, trip may occur after

!

∆

315 Motor Thermal Protection (MOTOR THER)

Value:

★ Off (PROTECT-OFF) [0]

Only Warning (ONLY WARNING) [1]

Trip (TRIP) [2]

Function:

The VLT adjustable frequency drive calculates whether the

motor temperature exceeds the permissible limits. The

calculation is based on 1.16 x rated motor current, as set in

parameter 107.

Description:

Select

Select

the motor is overloaded. The drive can be programmed to

give an external warning through the signal outputs set by

parameters 408 through 409.

Select

a given interval.

Off

(OFF) if no warning or tripping is required.

Warning

Trip

if only a warning is to be displayed when

if you want warning and trip to be displayed.

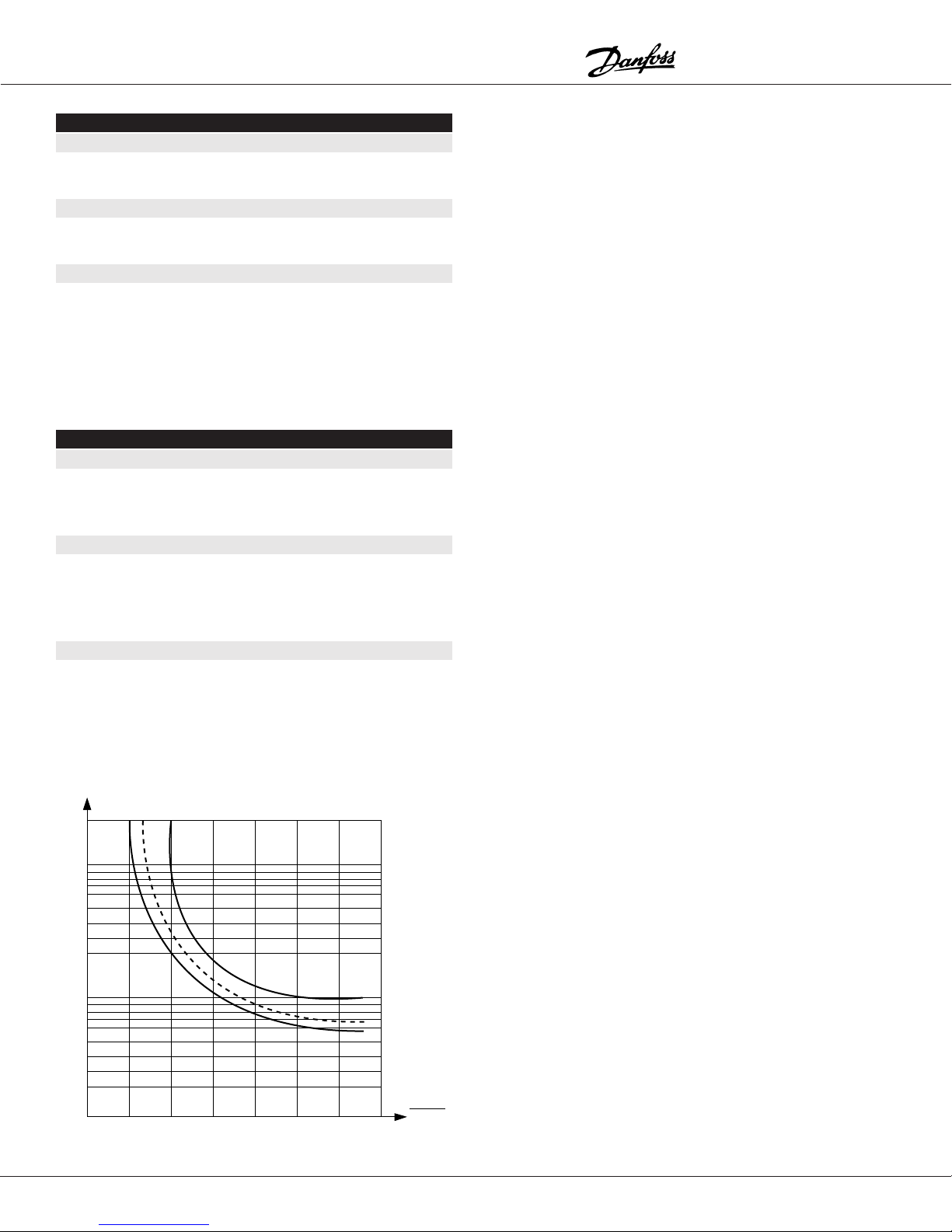

t [s]

2000

1000

6

5

4

3

2

100

60

50

40

30

20

10

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

1.0 1.2 1.4 1.6 1.8 2.0

26

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PAR 105

2xPAR 105

0.2xPAR 105

M

I

I

M NOM

MENU 107

Page 26

VLT® Series 2000 Programming

Group 4 -- Inputs and Outputs

402 Terminal 18 (TERMINAL 18 START)

Value:

★ Start (START) [0]

Pulse Start (PRESS CONT.) [1]

No Function (NO FUNCTION) [2]

Speed Up (SPEED UP) [3]

Digital Reference Select (SPEED SELECT) [4]

Reversing (REVERSING) [5]

Reset and Start (RESET&START) [6]

Motor Coasting & Start (COASTING/START) [7]

Function:

This parameter gives the motor various start signals.

Description:

Start :

[0]

24 V on terminal 18 will make the motor ramp up to the set

reference. 0 V will make the motor ramp down to stop.

[1]

Pulse Start

On selection of Press Cont. in parameter 402 and

application of a pulse (24 V) to terminal 18, the motor will

ramp up to the set reference. Futher pulses do not have

any effect. (Therefore the motor must be stopped via

terminal 27 (parameter 404).

[2]

No Function

Locks the input.

[3]

Speed Up

This is used together with parameter 230. It is possible to

make the output frequency increase towards fMAX as long

as 24 V is applied to terminal 18.

At 0 V on terminal 18 the output frequency is maintained.

Also refer to parameter 403).

[4]

Digital Reference Select

Together with parameter 403 you can choose between four

different digital references:

Terminal 18/27 Terminal 19

[5]

Reversing

If the motor reverses when 24 V is applied to terminal 18, it

will change direction again when 0 V is applied.

[6]

Reset and Start

The function can be used as start when terminals 27 and

19 are used to select between the digital references and

terminal 29 to change setup (8 digital speeds). 24 V applied

to terminal 18 resets the VLT adjustable frequency drive

and the motor ramps up to the set reference according to

the ramp-up time set in parameter 215.

:

:

:

:

0 0 Digital reference 1

1 0 Digital reference 2

0 1 Digital reference 3

1 1 Digital reference 4

:

:

[7]

Motor Coasting and Start

24 V applied to terminal 18 makes the motor ramp up to the

set reference..

0 V applied to terminal 18 sets the motor coasting, running

freely until it stops. This can be used in connection with a

mechanical brake.

403 Terminal 19 Reversing (TERM 19 REVERSING)

Value:

★ Reversing (REVERSING) [0]

Start Reversing (START REV) [1]

No Function (NO FUNCTION) [2]

Speed Down (SPEED DOWN) [3]

Digital Reference Select (SPEED SELECT) [4]

Reset (RESET) [5]

Function:

Using this parameter (terminal 19) you can e.g. change the

motor's direction.

Description:

[0]

Reversing

Reverses the motor, when 24 V is applied to terminal 19

and changes the rotation direction again when 0 V is

applied to the terminal.

[1]

Start Reversing

Reverses the motor, when 24 V is applied to terminal 19.

The motor stops when 0 V is applied to the terminal.

[2]

No Function

Locks the input.

[3]

Speed Down

This is used together with parameter 230. It is possible to

make the output frequency drop towards f

V is applied to terminal 19.

At 0 V applied to terminal 19, the output frequency in

question is maintained. Also refer to parameter 402.

[4]

Digital Reference Select

Together with parameter 402 you can choose between four

different digital references:

Terminal 18/27 Terminal 19

[5]

Reset

Incase of alarm the VLT can be reset by applying 24 V to

terminal 19.

:

:

:

:

0 0 Digital reference 1

1 0 Digital reference 2

0 1 Digital reference 3

1 1 Digital reference 4

:

:

, as long as 24

MIN

:

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

27

Page 27

Programming VLT® Series 2000

404 Terminal 27 Stop (INPUT 27)

Value:

Motor Coasting Stop (MTR. COAST) [0]

Quick-Stop (Q-STOP) [1]

DC Braking (DC-BRAKE) [2]

★ Reset and Motor Coasting (RST & COAST) [3]

Stop (STOP=PRESS) [4]

Reset and Start (RST & START) [5]

Speed Down (SPEED DOWN) [6]

Digital Reference Select (SPEED SELECT) [7]

Function:

Using this parameter (terminal 27) you can give the motor

various stop signals.

Description:

[0]

Motor coasting stop

:

If 0 V is applied to terminal 27 the motor will coast to a stop.

[1]

Quick Stop

:

If 0 V is applied to terminal 27 the motor will brake to a stop

according to the ramp-down time set in parameter 218.

A DC current brakes the motor after ramping down to 0,

according to the setting of parameters 306-308.

[2]

DC Brake

:

If 0 V is applied to terminal 27 the motor will brake to a stop

according to the settings of parameters 306 and 308.

[3]

Reset and Motor Coasting

:

If 0 V is applied to terminal 27 the motor will start coasting

and the VLT adjustable frequency drive is reset.

[4]

Stop = Press

:

A circuit breaker between terminals 12 and 27, when

opened briefly causes ramp-down to stop.

[5]

Reset and Start

:

This can be used as a start function when you use

terminals 18 and 19 to select a digital reference. 24 V

applied to terminal 27 will make the adjustable frequency

drive reset and the motor ramp up to the set reference

according to the ramp-up time set in parameter 215.

[6]

Speed Down

:

This is used together with parameter 230. It is possible to

make the output frequency drop towards f

, as long as 24

MIN

V is applied to terminal 27.

At 0 V applied to terminal 27, the output frequency in

question is maintained. Also refer to parameter 402.

[7]

Digital Reference Select

:

Together with parameter 402 you can choose between four

different digital references:

Terminal 18/27 Terminal 19

0 0 Digital reference 1

1 0 Digital reference 2

0 1 Digital reference 3

1 1 Digital reference 4

405 Terminal 29 Jog (TERMINAL 29 JOG)

Value:

★ Jog (JOG) [0]

Start (START) [1]

Digital Reference (DIGITAL REF.) [2]

Pulse Input, 100 Hz (PULSES 100 Hz) [3]

Pulse Input, 1 KHz (PULSES 1 KHz) [4]

Pulse Input, 10 KHz (PULSES 10 KHz) [5]

Setup Select (SETUP SELECT) [6]

Reset (RESET) [7]

Reversing (REVERSING) [8]

Speed Down (SPEED DOWN) [9]

Function:

Using this parameter (terminal 29) you can give the motor

different jog signals.

Description:

You can set the output frequency to a pre-programmed

value (jog in parameter 203). Recording Digital reference

you can enable/disable values stored in parameters 205-

208.

If terminal 29 is used for either pulse signal reference (open

loop) or pulse signal feedback (closed loop) choose one of

the pulse inputs [3] - [5].

If Multi Setup is selected in parameter 001, the terminal can

be used to switch between setups 1 and 2.

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

28

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

VLT® Series 2000 Programming

408 Terminal 46 Output (TERMINAL 46 OUTPUT)

Value:

Unit Ready (UNIT READY) [0]

★ Unit Ready Remote Control (UNT RDY RCTL) [1]

Enabled not Warning (ENABLED no WR) [2]

Running (RUNNING) [3]

Running, no warning (RUNNING noWR) [4]

Running in range, no warning (RUNinRANGE) [5]

Speed = reference, no warning (RUN@REF noWR) [6]

Alarm (ALARM) [7]

Alarm or warning (ALARM or WARN) [8]

Current limit (CURRENT LIMIT) [9]

Out of frequency range (OUT FREQ RGE) [10]

Out of current range (OUT CURR RGE) [11]

Reversing (REVERSING) [12]

Pulse output 15 Hz - 1.5 kHz (PULSEOUT 1500) [13]

Pulse output 15 Hz - 3.0 kHz (PULSEOUT 3000) [14]

Pulse output 15 Hz - value par. 005 (PULSPAR005) [15]

Send/receive RS485 (CTS/RTS-RS485) [18]

Receive/send RS485 (CTS/RTS-RS485) [19]

Function:

Using this parameter you can choose between different

output signals. The output is an open collector output and

therefore a pull-up resistor must be connected to terminal

12 (+24 V).

Description:

For the pulse output the lowest output frequency is 15 Hz

and the highest output frequency is 5 Hz.

RS 485 send/receive control is used when the serial port is

connected to the RS 485 network via a RS 232/RS 485

adapter.

Connection example where the signal is active high:

VLT

12

20

I

Imp

max

min

= 600

= 40mA

Connection example where the signal is active low:

VLT

12

46

I

max

Imp

min

= 600

= 40mA

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

20

Connection example using RS 232/485 adapter:

VLT

12

46

20

12V

I

Imp

max

min

= 600

= 30mA

SND/RCV

29

Page 29

Programming VLT® Series 2000

409 Terminal 01 Relay Output (RELAY 01)

Value:

★ Unit ready (UNIT READY) [0]

Unit ready - remote control (UNT RDY RCTL) [1]

Enabled no warning (ENABLED noWR) [2]

Running (RUNNING) [3]

Running, no warning (RUNNING noWR) [4]

Running in range, no warning (RUNinRANGE) [5]

Running on reference, no warn (RUN@REF noWR) [6]

Alarm (ALARM) [7]

Alarm or warning (ALARM or WARN) [8]

Current limit (CURRENT LIMIT) [9]

Out of frequency range (OUT FREQ RGE) [10]

Out of current range (OUT CURR RGE) [11]

Reversing (REVERSING) [12]

Description:

You can use the relay output 01 to indicate selected status

and warnings. The relay is activated when the conditions

for the selected data values are fulfilled.

When relay output 01 is not active, there is no connection

between terminal 01 and 02. The relay output is potentialfree and the maximum load is 2 A at 24 VDC or 250 VAC.

411 Analog Input Current (ANALOG REFTYPE)

Value:

★ Linear between minimum and maximum (LINEAR) [0]

Proportional with lower limit (PROP W/LIMIT) [1]

Function:

Is used to determine which frequency converter is to follow

an analog reference signal.

Description:

When you select [1] the reference signal will not affect the

output frequency until it reaches a value equivalent to the

set minimum frequency (parameter 201).

412 Terminal 53 Analog Input Voltage

(INPUT #53)

Value:

No Function (NO FUNCTION) [0]

★ 0 to 10 V (0 to 10 V DC) [1]

10 to 0 V (10 to 0 V DC) [2]

Description:

Record the polarity of analog control signals to inputs 53

and 60. You can choose between voltage, current and

polarity.

If you use both inputs for reference signals the total

reference signal will be a summation.

413 Terminal 60 Analog Input Current

(INPUT #60)

Value:

No Function (NO FUNCTION) [0]

★ 0 to 20 mA (0 to 20 mA) [1]

4 to 20 mA (4 to 20 mA) [2]

20 to 0 mA (20 to 0 mA) [3]

20 to 4 mA (20 to 4 mA) [4]

Description:

If you are using a PI controller one of the inputs or the pulse

input must be used for the feedback signal.

If you are using current control, one of the inputs must be

used to set a current limit.

Naturally these choices block the same type of reference

signal.

Output

Frequency

MAX

0

1

MIN

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

30

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Ref.

Page 30

VLT® Series 2000 Programming

Group 5 -- Serial Data Interface

500 Address (ADDRESS)

Value:

01 to 99 (echo)

101 to 199 ★ 01

Function:

Using this parameter you set the bus address for each VLT

via the control panel. Howeve,r the first telegram after the

voltage connection can change the bus address. This

means that address change from the bus is no longer

possible. The echo function enables connection of several

VLT 2000 adjustable frequency drives to the same PC.

Description:

Specify an address of each unit connected. If the PC/PLC

addresses 00, all drives connscted will be written to at the

same time. The units in this case not give a reply to the

master.

address change via bus enables address change on units

without display.

The echo function is active on address 101-199, shown as

01-99 ECHO. The ring is built up by connecting Tx on the

first VLT to Rx on the next VLT.

501 Bits/Sec. Baud Rate (BAUD RATE)

Value:

300, 600, 1200 ★1200

Function:

Using this parameter you can set the speed at which a

character is transmitted via the RS 232 port. It is defined as

the number of bits transmitted per second.

Description:

The transmission rate of the VLT must be set in accordance

with the transmission rate of the PLC/PC applied. The

transmission rate can only be altered via the control panel.

502 Data Readout (DATA READO)

Value:

★ [0] Reference (REFERENCE %) %

[1] Frequency (FREQUENCY Hz) Hz

[2] Display/Feedback (FDBK UNIT) “unit”

[3] Current (CURRENT A) A

[4] Torque (TORQUE %) %

[5] Power (POWER kW) kW

[8] Motor voltage (OUTPUT VOLT.V) V

[9] DC voltage (DC BUS V) V

[10] Motor thermal load (ETR (MOT) %) %

[11] Thermal inverter load (ETR (VLT) %) %

[12] Digital input (DIG IN CODE) binary code

[13] Analog input 1 (ANALOG IN 53) in terminal 53

[14] Analog input 2 (ANALOG IN 60) in terminal 60

[15] Warning parameter (WARN CODE) binary code

[16] Control word (CONTROL WORD)

[17] Status word (STATUS WORD)

[18] Alarm parameter (ALARM CODE) binary code

[19] Software version no. 4 digits

The last unit's Tx is connected to Rx on the PC. Terminal 20

(frame) must be connected throughout, but with the PC

connected at only one end.

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Description:

NOTE: Menu 502 can only be selected from the bus.

These values are read-only values.

The PC/PLC may prompt for a value from an index

between 0 and 19.

31

Page 31

Programming VLT® Series 2000

502 Data Read-Out (DATA READOUT) continued

[15] Warning parameter messages:

Frequency low re; parameter 210 value: 32768

Frequency high re; parameter 211 value: 16384

Current limit, re; power section value: 8192

Key blocked value: 2048

Motor overload value: 1024

Inverter overload value: 512

Outside frequency range value: 256

Current higher than par. 213 value: 128

Data locked value: 64

Read only value: 32

Current limit re; control card value: 16

Overvoltage value: 8

Undervoltage value: 4

Can only be changed in stop mode value: 2

Parameter limit value: 1

Usually only one warning occurs at a time, so one of the

figures in parameter 502, index 15, will show. In the event

of several simultaneous warnings, e.g. Motor overload and

Current limit, re; control card, the two values are added;

Motor overload: 512

Current limit re; control card:

Reading in par. 502, index 15: 528

[16] Alarm parameter messages:

Excess temperature, re; power section value: 16384

Ground connection value: 4096

Overvoltage value: 1024

Undervoltage value: 512

Unspecified inverter fault value: 236

Inverter overload value: 128

Motor overload value: 64

Short circuit value: 16

VLT attempts restart value: 8

Overcurrent value: 4

Trip locked value: 1

In contrast to warnings, alarms will always be combined,

i.e. at least 2 of the alarm parameters apply, e.g.

Unspecified inveter fault will usually occur with another

alarm, e.g. Inverter overload. It will give the following

reading:

Unspecified inverter fault: 256

Inverter overload:

Reading in par. 502, index 18: 384

In case of Short circuit Ground connection and Excess

temperature, re; power section, Trip locked will also occur.

This will give a typical reading:

Groung connection: 4096

Unspecified inverter fault: 256

Trip locked

Reading in par. 502, index 18: 4353

+ 16

+ 128

+ 1

503 Coasting (COAST)

Value:

Digital (DIGITAL) [0]

Bus (BUS) [1]

Logical and (AND) [2]

★ Logical or (OR) [3]

Description:

In parameters 503 to 510 you can choose to control the

VLT adjustable frequency drive via the control unit's

terminals (digitally) and or via the bus.

When using

the digital control terminals are either dependent on or

overruled by the bus commands.

504 Quick-Stop (Q-STOP)

Value:

Digital (DIGITAL) [0]

Bus (BUS) [1]

Logical and (AND) [2]

★ Logical or (OR) [3]

Description:

In parameters 503 to 510 you can choose to control the

VLT adjustable frequency drive via the control unit's

terminals (digitally) and or via the bus.

When using

the digital control terminals are either dependent on or

overruled by the bus commands.

505 DC Brake (DC-BRAKE)

Value:

Digital (DIGITAL) [0]

Bus (BUS) [1]

Logical and (AND) [2]

★ Logical or (OR) [3]

Description:

In parameters 503 to 510 you can choose to control the

VLT adjustable frequency drive via the control unit's

terminals (digitally) and or via the bus.

When using

the digital control terminals are either dependent on or

overruled by the bus commands.

506 Start (START)

Value:

Digital (DIGITAL) [0]

Bus (BUS) [1]

Logical and (AND) [2]

★ Logical or (OR) [3]

Description:

In parameters 503 to 510 you can choose to control the

VLT adjustable frequency drive via the control unit's

terminals (digitally) and or via the bus.

Logical

Logical

Logical

and

and

and

Bus

values in parameters 503-510,

Bus

values in parameters 503-510,

Bus

values in parameters 503-510,

★ = ROM default setting. Text in ( ) = display text. Figures in [ ] are used when communicating with the bus.

32

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

VLT® Series 2000 Programming

When using

Logical

and

Bus

values in parameters 503-510,

the digital control terminals are either dependent on or

overruled by the bus commands.

507 Direction of Rotation (DIRECTION)

Value:

★ Digital (DIGITAL) [0]

Bus (BUS) [1]

Logical and (AND) [2]

Logical or (OR) [3]

Description:

In parameters 503 to 510 you can choose to control the

VLT adjustable frequency drive via the control unit's

terminals (digitally) and or via the bus.

When using

Logical

and

Bus

values in parameters 503-510,

the digital control terminals are either dependent on or

overruled by the bus commands.

508 Reset (RESET)

Value:

Digital (DIGITAL) [0]

Bus (BUS) [1]

Logical and (AND) [2]

★ Logical or (OR) [3]

Description:

In parameters 503 to 510 you can choose to control the

VLT adjustable frequency drive via the control unit's

terminals (digitally) and or via the bus.

When using

Logical

and

Bus

values in parameters 503-510,

the digital control terminals are either dependent on or

overruled by the bus commands.

509 Selection of Setup (SETUP SELE)

Value:

Digital (DIGITAL) [0]

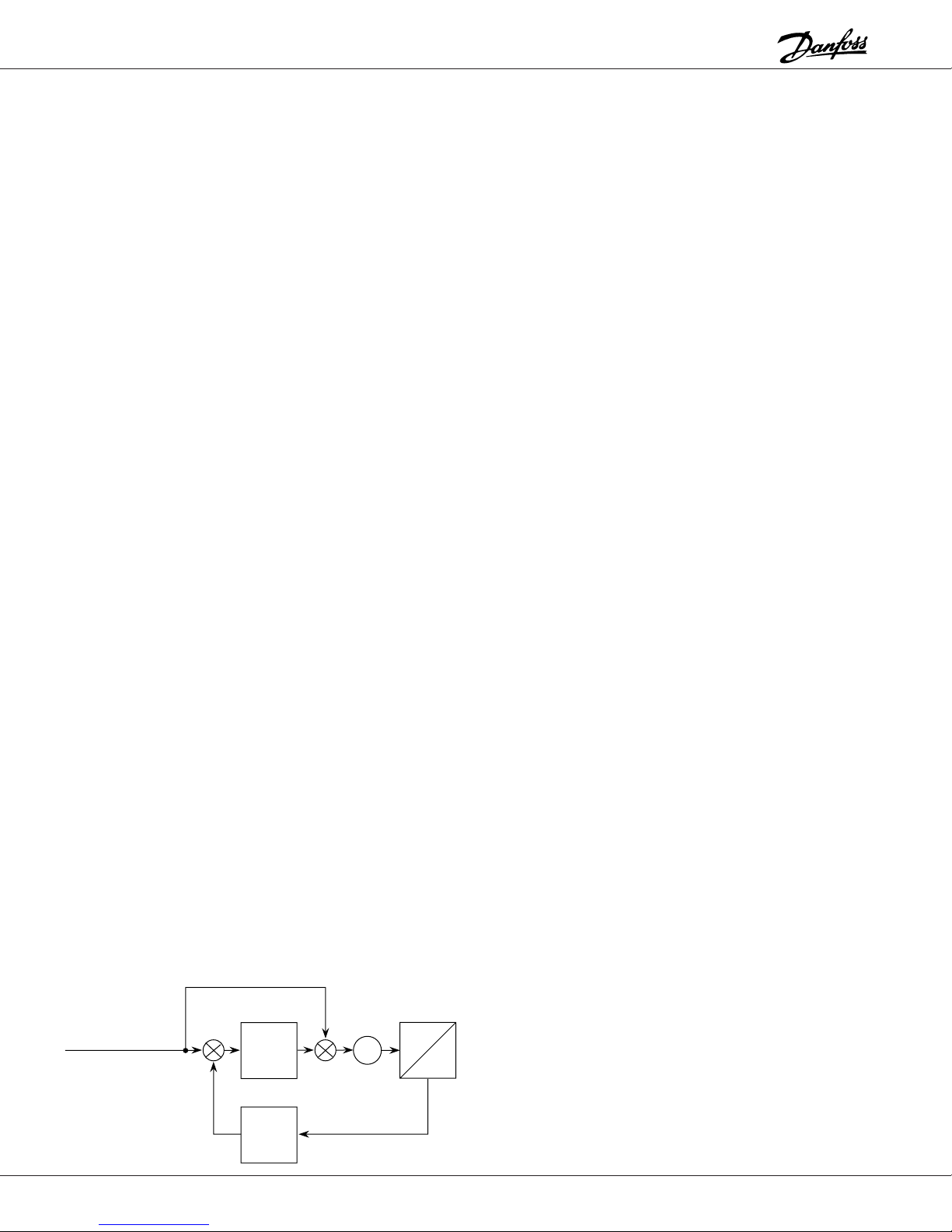

Bus (BUS) [1]