Page 1

MG.20.B6.02 – VLT is a registered Danfoss trademark

1

VLT® 2000 Series

Section 1 Section 2 Section 3

Contents

Section 1

■■

■■

■

InstallationInstallation

InstallationInstallation

Installation

Section 2

■■

■■

■

After installationAfter installation

After installationAfter installation

After installation

Section 3

■■

■■

■

Facts about VLFacts about VL

Facts about VLFacts about VL

Facts about VL

TT

TT

T

Page 2

Page 3

MG.20.B6.02 – VLT is a registered Danfoss trademark

3

VLT® 2000 Series

Section 1 Section 2 Section 3

Installation has been written for personnel who will unpack the VLT frequency converter and carry out mechanical and electrical installation.

Installation makes it easy and safe for you to install the VLT frequency converter, just

follow the instructions on the next pages.

After Installation has been written for personnel who are to set up the VLT

frequency converter, when it is to be commissioned. The VLT has a number of factory

settings. You can choose the settings to match your plant (application). The

initial settings are described in chapter 1.

When you start your setting the mechanical and electrical installation has been done.

If you want to check the electrical installation you can do that on the basis of the survey of terminals.

To go on with the settings you must know the values of the different parameters.

Typically it is the planning engineer or technician who determines the values on the

basis of the information given in the section

Facts about VLT.

Facts about VLT is written for users of VLT frequency converters for large plants.

In

Facts about VLT you can read how to size a plant, how to select the right VLT on

the basis of the technical data, how to carry out the electrical installation, the

mechanical installation, etc.

It will also appear what standards the VLT frequency converter complies with and

what safety measures you should take before you start.

Facts about VLT is your work of reference, so do keep it within reach.

When you read the manual please note the following symbols:

About this manual

Section 1

Section 2

Section 3

General warning

Pay special attention here.

Page 4

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

4

■

Safety rules

Warning against improper start

1. The motor can be stopped using digital commands,

bus commands, references or local stop, while the

frequency converter is connected to the mains.

If personal safety requires elimination of any

possibility of unintended start,

these stops will not

be sufficient.

2. The motor can start during parameter operation.

Therefore

always activate the “Stop/Reset” key

before changiing data.

3.

A stopped motor can start if a fault occurs in the

electronics of the frequency converter or after a

temporary overload, mains fault or faulty motor

connection.

For the North American market

CAUTION: It is the responsibility of the user or person

installing the drive to provide proper grounding and

branch circuit protection for incoming power and motor

overload according to National Electrical Codes (NEC)

and local codes.

The Electronic Thermal Relay (ETR) in UL listed VLTs

provides class 20 motor overload protection in

accordance with NEC in single motor applications,

when parameter 315 is set to Trip [2] and parameter

107 is set to nominal motor (nameplate) current.

The frequency converter contains dangerous

voltages when connected to the mains.

Improper connection of the motor or the frequency

converter may cause equipment failure, serious injury

or death.

Therefore follow the directions in this manual, as well as

local and national safety rules.

Touching the electrical parts, even when the power

supply has been switched off, can cause serious injury

or death.

Wait at least 4 minutes after switching off before

touching any electrical parts.

These rules concern your safety

1. When repairs are undertaken the power supply to

the frequency converter must be disconnected.

2. The

“Stop/Reset” key on the keyboard of the

frequency converter does not disconnect the power

supply and may therefore not be used as a safety

switch.

3. The unit must be properly grounded, the user must

be protected against supply voltage and the motor

against overload according to national and local

codes.

4. The leakage currents to ground are higher than

3 mA.

5. The factory setting does

not incorporate protection

against motor overload. For this function parameter

315 is set to data value Trip [2] or data value

Warning [1]. Note: This function is initialised at

1.16 x rated motor current and rated motor

frequency (see page 63).

6. Do

not remove the motor and mains terminals,

when the unit is connected to the mains. Ensure

that the power supply has been switched off,

before you remove the motor and mains terminals.

■

■

■

Page 5

MG.20.B6.02 – VLT is a registered Danfoss trademark

5

VLT® 2000 Series

Section 1 Section 2 Section 3

Installation

Chapter 1 ■ Before you start ........................................... Page 6

■ Mechanical installation................................. Page 6

■ Electrical installation .................................... Page 6

■ EMC-correct installation .............................. Page 9

■ General.......................................................Page 9

■ Instructions for installation .......................... Page 9

■ For further information ............................... Page 11

■ Installation guide

VLT 2000 with built-in compact RFI filter ... Page 12

■ Technical data

VLT 2000 with built-in compact RFI-filter ... Page 12

Page 6

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

6

Before you start

Read the safety rules on

pagepage

pagepage

page 4 before you start.

Mechanical installation

Item 1 Drilling template (enclosed in box)

For sizing and drilling of holes you can use the

enclosed Drilling Template.

Ensure min. 100 mm (10 cm) free air space

above and below the VLT frequency converter. This

also applies when a module has been mounted.

Make sure that the ambient temperature does not

exceed 40°C.

Item 2 Side by side mounting

VLT frequency converters can be mounted side by

side, without any space between them.

Item 3 Module

If you want to use a module (to be placed underneath)

you must take the physical dimensions into account.

Electrical installation

Item 1 Prefuses

Choose the right prefuses:

Mains supply 1 x 220/230/240 V

3 x 208/220/230/240 V

VLT 2010 Max. 10A

VLT 2015 Max. 16 A

VLT 2020 Max. 20 A

VLT 2030 Max. 20 A

VLT 2040 Max. 20 A

VLT 2050 Max. 25 A

See Special conditions: Cut-in current

That I have done

That I have done

Mains supply 3 x 380-460 V

VLT 2020 Max. 16 A

VLT 2025 Max. 16 A

VLT 2030 Max. 16 A

VLT 2040 Max. 16 A

VLT 2050 Max. 16 A

VLT 2060 Max. 20 A

Installation

■

■

■

Page 7

MG.20.B6.02 – VLT is a registered Danfoss trademark

7

VLT® 2000 Series

Section 1 Section 2 Section 3

Electrical installation (continued)

Item 2 Extra protection

If you want extra protection, pay attention to the

following:

As extra protection, error voltage relays or neutral

grounding can be used. However, the installation

must comply with local health and safety standards.

An earth fault can introduce a direct current in the

discharge current. Any ELCB relay used must comply

with local regulations. The relays must be suitable to

protect three-phase equipment with bridge rectifier

and short discharge on power-up.

Item 3 Motor, mains and brake cables

To comply with the stated EMC emission

specifications, screened motor cable must

not be

used. However, a precondition is that an RFI filter

module is installed to comply with the EMC emission

specifications.

Observe the following max. cross sections for motor,

mains and brake cables:

■

That I have done

Mains supply 1 x 220/230/240 V

3 x 208/220/230/240 V

VLT 2010 Max. 4 mm

2

VLT 2015 Max. 4 mm

2

VLT 2020 Max. 4 mm

2

VLT 2030 Max. 4 mm

2

VLT 2040 Max. 4 mm

2

VLT 2050 Max. 4 mm

2

Installation

▲▲

▲▲

▲

Cable relief fitting

195H6129

Option

Mains supply 3 x 380-460 V

VLT 2020 Max. 4 mm

2

VLT 2025 Max. 4 mm

2

VLT 2030 Max. 4 mm

2

VLT 2040 Max. 4 mm

2

VLT 2050 Max. 4 mm

2

VLT 2060 Max. 4 mm

2

Page 8

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

8

Electrical installation (continued)

Item 4 Control cables

The cables used for control cables must be

screened to comply with the stated EMC emission

specifications. Connect the screen from the control

cables to terminal 61 (ground).

Observe the following max. cross sections for control

cables:

That I have done

Mains supply 1 x 220/230/240 V

3 x 208/220/230/240 V

VLT 2010 Max. 1.5 mm

2

VLT 2015 Max. 1.5 mm

2

VLT 2020 Max. 1.5 mm

2

VLT 2030 Max. 1.5 mm

2

VLT 2040 Max. 1.5 mm

2

VLT 2050 Max. 1.5 mm

2

Mains supply 3 x 380-460 V

VLT 2020 Max. 1.5 mm

2

VLT 2025 Max. 1.5 mm

2

VLT 2030 Max. 1.5 mm

2

VLT 2040 Max. 1.5 mm

2

VLT 2050 Max. 1.5 mm

2

VLT 2060 Max. 1.5 mm

2

Installation

Cable relief fitting

195H6129

▲▲

▲▲

▲

■

Page 9

MG.20.B6.02 – VLT is a registered Danfoss trademark

9

VLT® 2000 Series

Section 1 Section 2 Section 3

Installation

EMC correct installation

A number of factors must be considered in order to

achieve EMC correct installation of the VLT 2000

frequency converter.

General

The basic VLT 2000 units do not comply with any

EMC emission specifications, since no EMC filter (RFI

filter) is incorporated in the basic units.

Therefore it is necessary to install an

RFI and motor

filter module to comply with EMC emission

specifications.

VLT Series 2000 is available with built-in RFI filter that

fulfils the EMC emission requirements.

In addition to reducing the mains interference, the filters also reduce the interference radiating from the

unscreened motor cable. As far as the motor cable is

concerned, only interference above 30 MHz is

reduced (ref. EN 55011-1A).

To reduce the electromagnetic noise level from the total system as far as possible (frequency converter and

motor installation), it is important to make the motor

and brake cables as short as possible.

Cables having a sensitive noise level may not be led

together with motor and brake cables.

How to install

Units with RFI and motor filter module:

When the RFI and motor filter module is installed it is

recommended to use

unscreened motor cable, since

this gives the lowest electromagnetic noise level.

Control cable:

The control cable must be screened. The screen must

be installed under the screen clamp on the screen

termination bracket. Mounting with twisted screen

ends (Pigtails) should be avoided, as this will destroy

the screen effect at high frequencies.

Normally, the screen should also be connected to the

base of the controlling appliance (follow the

instructions for use of the appliance in question). In

connection with very long control cables and

analogue signals, 50 Hz ripple loops may occur in

rare cases, depending on the installation. This is

because of interference coupling from the mains

supply cables. In this connection it can be necessary

to break the screen or possible insert a 100nF condenser between screen and base.

■

■

■

Cable for serial communication:

The cable for serial communication should be

screened. The screen should be installed using a

screen clamp on the VLT frequency converter (see the

instruction for installation, page 10, point B ).

Motor cable:

For the motor either screened or unscreened cable

can be used. In connection with installation of the RFI

and motor filter module it is recommended to use

unscreened motor cable. With screened motor cable,

the screen must be installed under the cable clamp

on the cable relief fitting. Mounting with twisted

screen ends (Pigtails) should be avoided as this will

destroy the screen effect at high frequences. In

principle the motor cable screen may not be

interrupted and it may not be earth connected. If it is

necessary to interrupt the screen to mount a motor

starter or motor relays, the screen must continue with

an impedance which is as low as possible.

The EMC emission specifications are complied with

by using up to 100 m of unscreened motor cable.

If screened cable is used the demand for conducted

noise (150 kHz - 30 MHz) cannot be observed.

Brake cable:

Screened cable must be used for the brake resistor.

The screen must be installed under the cable clamp

on the cable relief fitting. (See page 10 point E ).

Avoid using screen pigtails.

Use brake cable lengths of up to 5 m.

Sensitive signal cables:

Cables having a sensitive noise level may not be led

together with motor and brake cables.

Equalising currents:

Efforts should be made to avoid possible equalising

currents that may occur when the control cable

screen is connected to the base (earthed) at both

ends. Equalising currents occur because of voltage

differences between the VLT frequency converter

base and the base of the controlling appliance. They

can be avoided by making a tight fit with the cabinet

base rear plate, thereby ensuring that any equalising

currents will run via the base rear plates and their

joints, not via the cable screens.

Page 10

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

10

Installation

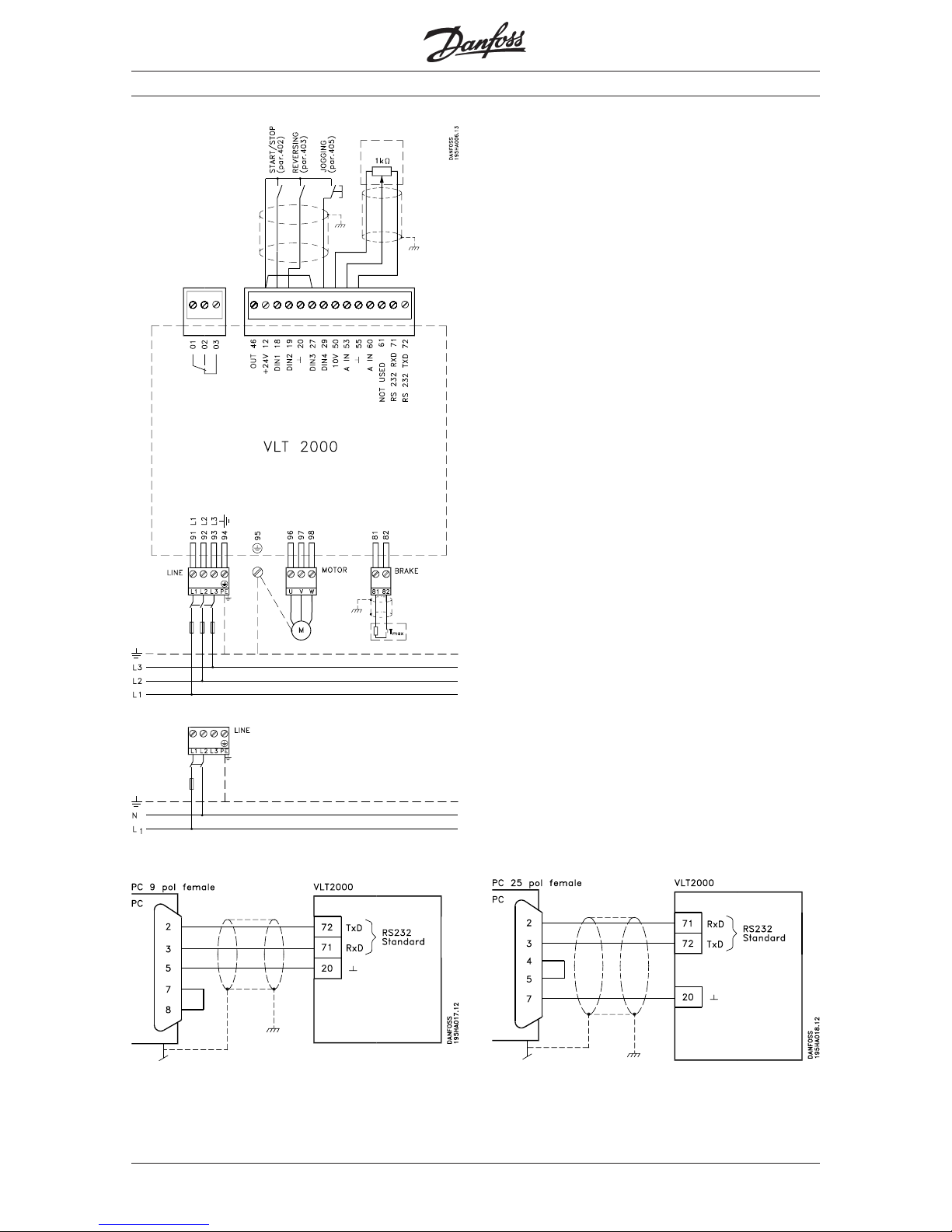

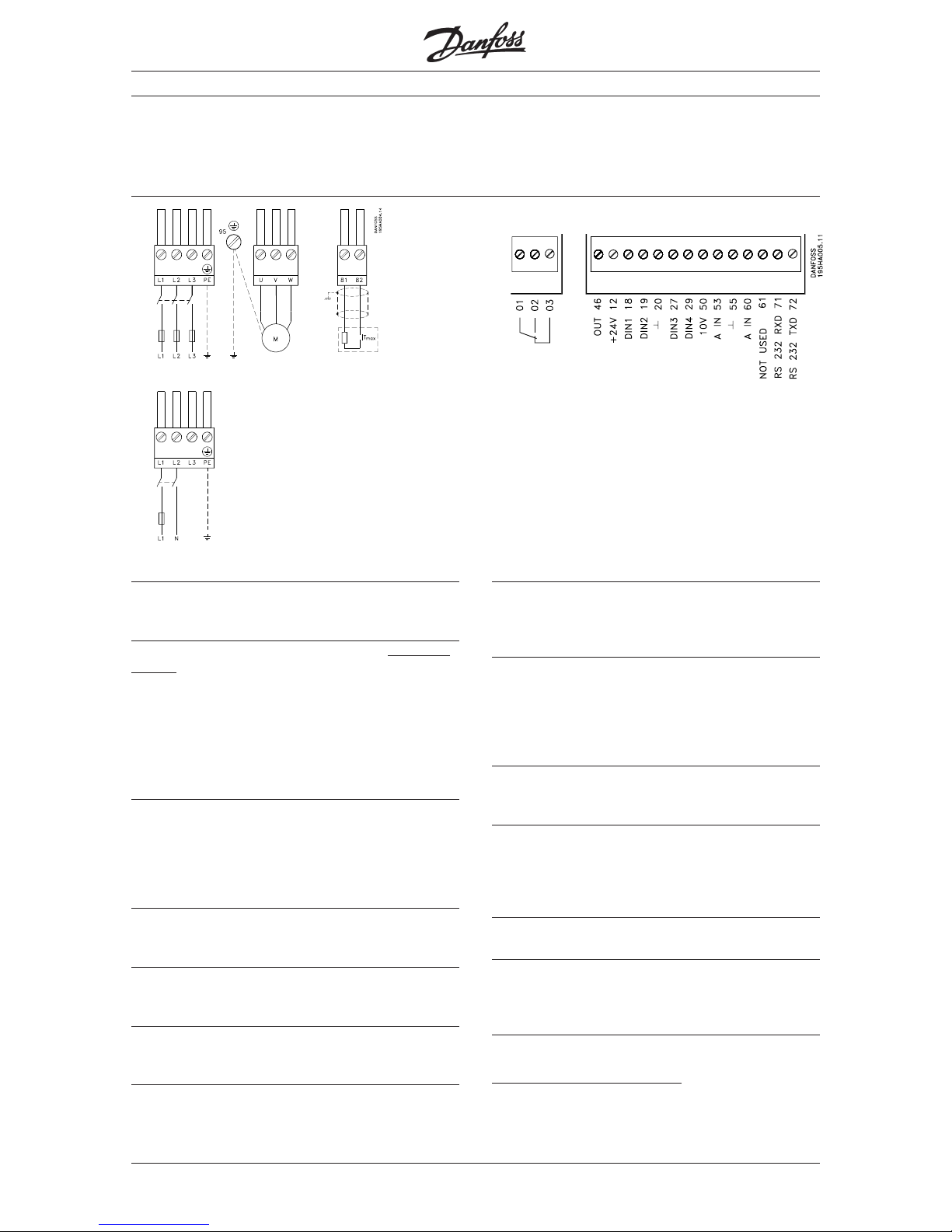

Three-phase mains connection

Single-phase mains connection

Between PC and VLT frequency converter

Page 11

MG.20.B6.02 – VLT is a registered Danfoss trademark

11

VLT® 2000 Series

Section 1 Section 2 Section 3

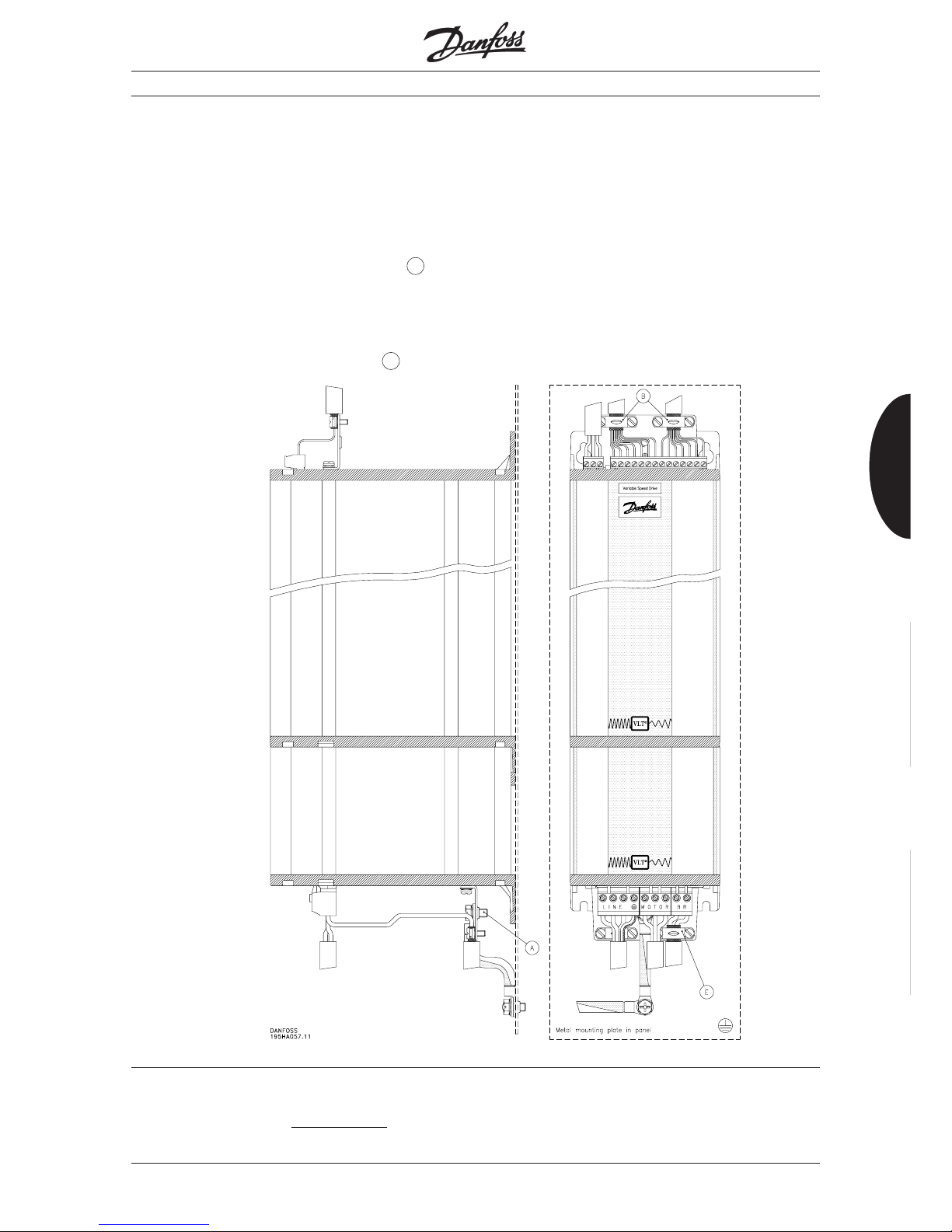

VLT 2010-2030, 1/3 x 208-240 V and VLT 20202060* 3 x 380-460 V with RFI and motor filter

module or LC and RFI filter module:

If VLT frequency converters are mounted on an

electrically conductive, metal rear plate, good

electrical connection between the VLT and the rear

plate is to be ensured (use earth screw (item A in

the drawing)).

If the VLT frequency converter is mounted on a nonconductive rear plate, it is to be ensured that there is

good grounding to the earth screw (item A in the

drawing).

For further information

When you have finished installing the VLT frequency

converter, see the section

After installation for infor-

mation about how to operate the VLT frequency

converter. You will also get information about what

parameters to choose to ensure optimum operation.

*) VLT 2060 Max. 415 V

Installation

■

Page 12

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

12

Following this installation guide the VLT® 2000 units

with built-in compact RFI filter comply with the EMC

requirements according to EN 55011 group 1A.

Technical data

The technical data on this page only apply to VLT

®

2010, 0.37 kW, VLT® 2015, 0.55 kW and VLT

®

2020,0.75 kW.with built in compact RFI filter.

■■

■■

■

Cable type: Screened

Max. length: 20 m

Mains supply: 1 x 220-240 V

Installation guide

Clamp to secure cables and cable screen type

195H6129 is delivered with the above units.

Mains supply connection:Mains supply connection:

Mains supply connection:Mains supply connection:

Mains supply connection:

Cable is secured in cable relief fitting.

Earth wire is secured in the earth screw on the

frequency converter.

Motor cable connection:Motor cable connection:

Motor cable connection:Motor cable connection:

Motor cable connection:

Motor cable and screen is secured in cable relief fitting

and the wires are connected in the motor plug.

■■

■■

■

Installation

Page 13

MG.20.B6.02 – VLT is a registered Danfoss trademark

13

VLT® 2000 Series

Section 1 Section 2 Section 3

After installation

Chapter 1 ■ Quick Setup,

If you are familiar with a VLT ...................... Page 14

■ Quick Setup,

If you are not familiar with a VLT ................ Page 14

■ A simple connection example .................... Page 14

■ How to program ........................................ Page 15

■ Survey of terminals .................................... Page 16

■ Description of connection terminals............ Page 16

■ How to check connection of

control cables ............................................. Page 17

■ Prefuses .................................................... Page 17

■ Cables ....................................................... Page 17

■ Check grounding ....................................... Page 17

■ Commissioning and testing ....................... Page 18

■ Basic settings ............................................ Page 18

Page 14

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

14

Quick Setup

If you are familiar with a VLT

If you know the VLT and how to move round in the

menus and parameters, you can go directly to steps

1-9 overleaf to get started.

Quick Set

If you are not familiar with a VLT

If you have never operated a VLT frequency converter

before, you can learn it on the basis of the

instructions on page 15.

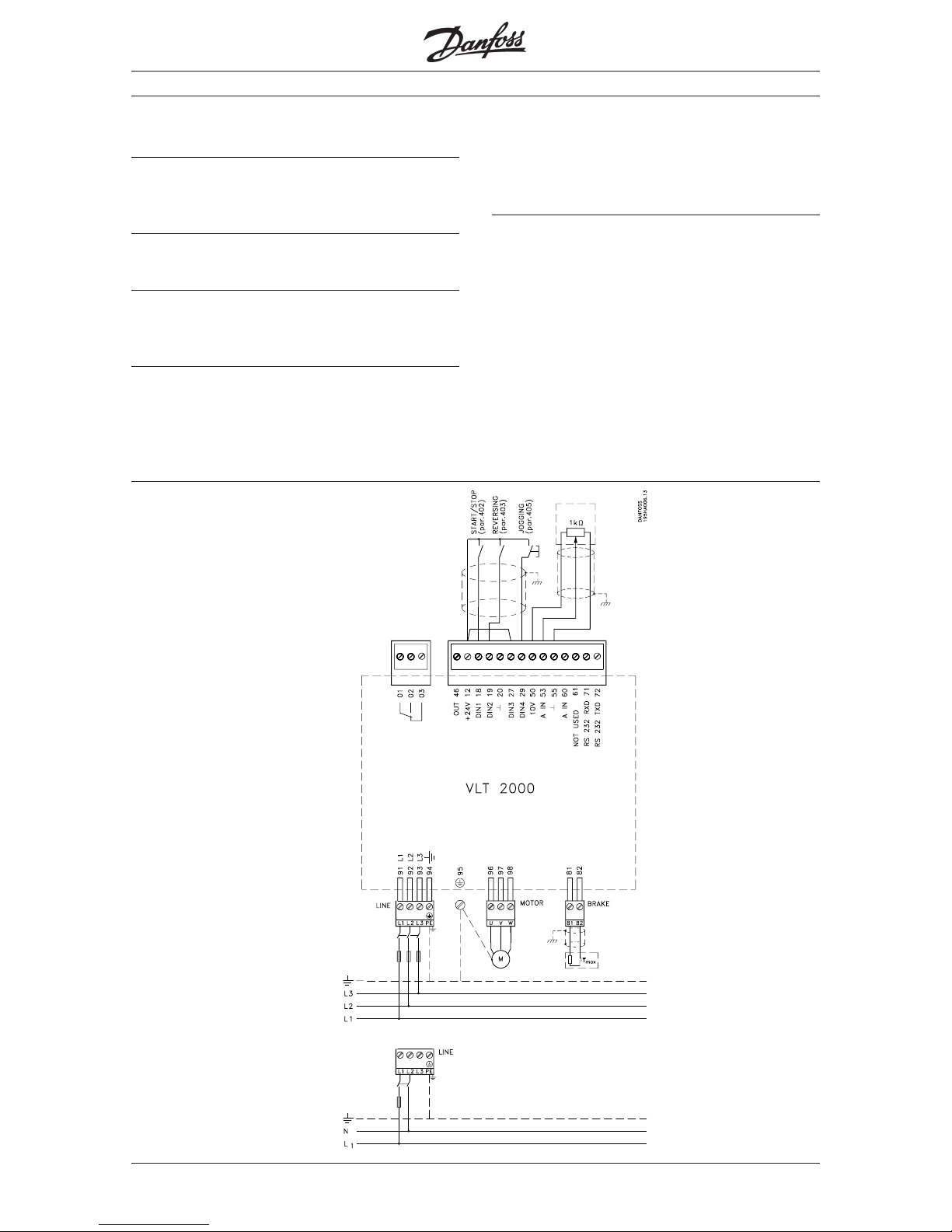

Connection example

■

A simple connection example

In the figure below you can see a simple connection

example based on the Quick Setup programming

overleaf.

After installation

■

■

Page 15

MG.20.B6.02 – VLT is a registered Danfoss trademark

15

VLT® 2000 Series

Section 1 Section 2 Section 3

How to program

The Quick Setup shown is based on the assumption

that you want your VLT to operate with the following

setup:

1. External start/stop

2. Potentiometer connected for external speed control

3. Option to change rotation direction

4. Option to select a fixed speed (Jog)

If you use a brake module, you must program

one parameter more, and two more if you

want local operation via the display keys.

This will appear from the two tables at the bottom.

To store the data press the “menu” key!

When you have connected your VLT, as described on

the previous page, you must program a few parameeters.

Perform steps 1-9 for Quick Setup.

After installation

Standard motor with constant torque load without brake module on the frequency converter

Step Parameter Designation Settings Display indication

1 000 Language Choose English ENGLISH

2 103 Motor power Read motor plate

3 104 Motor voltage Read motor plate

4 105 Motor frequency Read motor plate

5 201 Min. frequency Set wanted frequency

6 202 Max. frequency Set wanted frequency

7 215 Ramp up 1 Set wanted ramping time

8 216 Ramp down 1 Set wanted ramping time

9 Start This is done by supplying terminals 18 and 27

the frequency with 24 V DC from the frequency converter’s terminal 12

converter or by using an external 24 V DC voltage

If a brake module is mounted, make the following settings

Step Parameter Designation Settings Display indication

1 300 Brake function If a brake module is used, choose Applied APPLIED

2 Start This is done by supplying terminals 18 and 27

the frequency with 24 V DC from the frequency converter’s terminal 12,

converter or by using an external 24 V DC voltage

If you want local operation and start, make the following settings

Step Parameter Designation Settings Display indication

1 003 Operation site Choose Local LOCAL

2 004 Local reference Record wanted output frequency by means

of the “+” and “−” keys

■

Page 16

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

16

Survey of terminals

Below you will see a survey of all the terminals of a

VLT frequency converter (3 x 380-460 V).

After installation

Description of connection terminals

Terminal 12: Internal voltage supply

24 V DC activates digital inputs such as Start/stop,

Jog or Quick stop.

Terminal 18: Start/stop (Digital input)

When 24 V DC is applied the motor starts

on condit-

ion that

− digital input 27 (Quick stop) is connected

to 24 V DC.

− you have made no local stop command

(“Stop/reset” key).

− f

Max

is > 0 Hz.

− a reference signal has been given (see para. 402).

Terminal 19: Reversing (Digital input)

When 24 V DC is applied to terminal 19, the motor

starts reversing, either at once or after a stop command. If you have chosen pulse start in para. 402

(terminal 18), the start reversing function of para.

403 is automatically a pulse-activated function.

Terminal 20: Digital common

This terminal is the reference for all digital signals,

including bus.

Terminal 27: Stop (Digital input)

When you apply 0 V you can give different stop signals. See also para. 404.

Terminal 29: Jogging (Digital input)

This terminal allows you to activate a fixed

preprogrammed speed. See para. 405.

Terminal 46: Output

Using parameter 408 you can choose between

different output signals. The output is an open collector

output, and a pull-up resistor of min. 600 ohm must

therefore be connected to terminal 12 (+24 V).

Terminal 50: Internal voltage supply

With 10 V DC voltage you can set an analogue

control signal using a 1 kohm potentiometer with terminal 55 as reference.

Terminal 53: Analogue control voltage

Using parameter 412 you can choose between 0 +10 V DC or +10 - 0 V DC analogue voltage. The terminal is used together with terminals 50 and 55. The

voltage value determines the output frequency and

thus also the speed of the motor.

Terminal 55: Analogue common

Is used together with terminals 50 and 53 or together

with terminal 60.

Terminal 60: Analogue control current

Using parameter 413 you can choose between four

different input signals:

0-20 mA, 4-20 mA, 20-0 mA or 20-4 mA.

The current value determines the output frequency.

Terminal 61: Not used

Terminals 71-72: RS 232 port

Connect the terminals to a PC, if you want to control

the VLT frequency converter via PC software. Terminal

20 acts as digital common.

Terminals 81-82: Brake resistor

By means of these terminals you can connect the

brake resistor on units with brake function.

Note the live voltage 550 V DC.

The control signals and the terminals for the brake

module are described at the bottom of this page.

Mains Motor

Br.

■

■

Page 17

MG.20.B6.02 – VLT is a registered Danfoss trademark

17

VLT® 2000 Series

Section 1 Section 2 Section 3

How to check connection of control cables

The VLT frequency converter must be connected so

that it is possible to control it via the different signal

inputs at the top of the enclosure.

Terminals 01-03: Relay output Max. 250 V, max. 2 A. Relay: Not activated

Terminal 12: Supply to digital inputs 24 V DC, max. 140 mA

Terminals 18-19: Digital inputs 0-24 V, Ri=2 kohm (max. 37 V for 10 sec.)

27-29 (min. on-time 80 ms.)

Terminal 46: Digital output signal (open collector) Max. 24 V DC, max. 40 mA, min. 600 ohm

Terminal 50: Supply to 1 kohm potentiometer 10 V DC, max. 12 mA

Terminal 53 Analogue control voltage +0 - 10 V DC, Ri=10 kohm, +10 - 0 V

Terminal 60: Analogue control current 0/4-20 mA, Ri=226 ohm, 20-0/4 mA

Terminals 71/72: RS 232 standard bus 71 RXD, 72 TXD, 20 dig. ref.

Terminals 81/82: Used in connection with brake resistor

Terminal 20: Digital common Must be used as reference for all digital

signals

Terminal 55: Analogue common Must be used as reference for all analogue

signals.

Prefuses

Prefuses must be installed in the mains supply to the

frequency converter.

Cables

The cables to control signals and brake resistor must

be screened. It is recommended to use unscreened

motor cable.

Motor/mains cables (max. cable cross-section)

Mains supply 1/ 3 x 208/220/230/240 V Mains supply 3 x 380-460 V

2010 2015 2020 2030 2040 2050 2020 2025 2030 2040 2050 2060*

4 mm2 for all VLT 2000 Series types 4 mm2 for all VLT 2000 Series types

Control cables (max. cable cross-section)

Mains supply 1/ 3 x 208//220/230/240 V Mains supply 3 x 380-460 V

2010 2015 2020 2030 2040 2050 2020 2025 2030 2040 2050 2060*

1.5 mm2 for all VLT 2000 Series types 1.5 mm2 for all VLT 2000 Series types

How to check the grounding

The grounded line must be connected to terminal 94

(PE). If you use a thick cable this must be connected

to the 6 mm large screw (terminal 95) in the bottom of

the VLT frequency converter.

If you use screened cables, the screen must be connected to the screen termination bracket of the VLT

frequency converter and brake resistor.

(Max. sizes)(Max. sizes)

(Max. sizes)(Max. sizes)

(Max. sizes)

Mains supply 1/3 x 208/220/230/240 V Mains supply 3 x 380-460 V

2010 2015 2020 2030 2040 2050 2020 2025 2030 2040 2050 2060*

10 A 16 A 20 A 20 A 20 A 25 A 16 A 16 A 16 A 16 A 16 A 20 A

After installation

*) VLT 2060: Max. 415V

■

■

■

■

Page 18

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

18

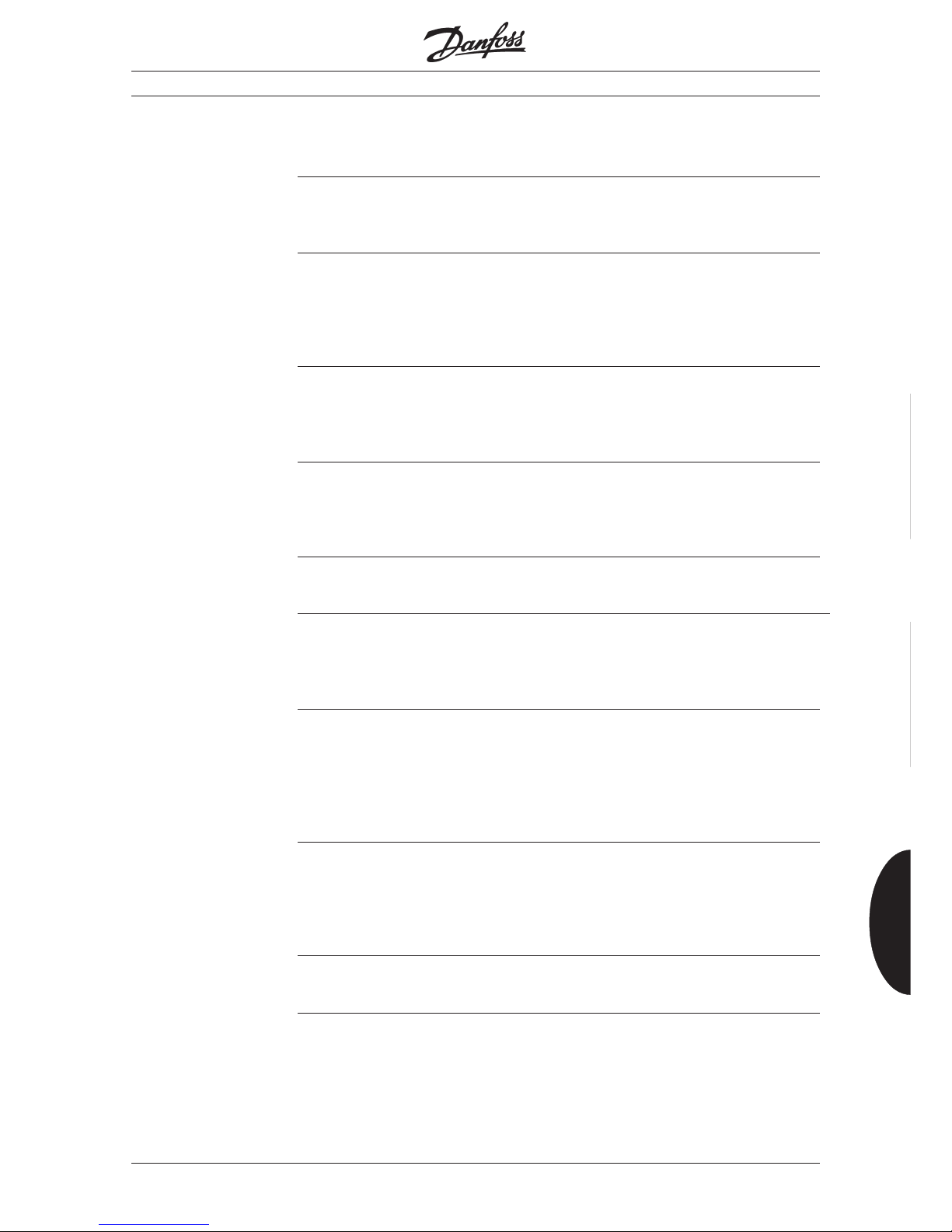

c) Make a quick stop by means of disconnecting

between terminal 27 and terminal 12.

Example of display indication:

During the simulation you can see that the VLT

frequency converter reacts by watching the

display indications.

If no external control has been

connected, you can choose to simulate

the function of the VLT frequency converter

locally via the keyboard. See description at

the bottom of page 31.

5. Press the “Stop” key to stop the VLT frequency

converter

before you connect the motor.

6. Test the whole system (repeat steps 4 and 5) with

the motor connected to check the direction of

rotation.

Commissioning and testing

When the VLT frequency converter has been connected to

control signals, you may want to test the system.

This following test is not suitable if you use the built-in

PI controller.

1. Disconnect the motor from the VLT frequency

converter.

2. Connect the VLT frequency converter to the mains.

3. Make the necessary settings such as min./max.

frequency and connect the necessary control

signals, possibly via PLC.

As a minimum you must set the parameters

and connect the control signals as described

in chapter 1, Quick Setup.

4. Make a simulation without motor:

a) Give a start signal via a contact to terminal 18.

Example of display indication:

b) The speed (frequency) can be changed by

means of the potentiometer connected.

Example of display indication:

After installation

00,0 Hz

FREQUENCY

STOP 1

23,7 Hz

FREQUENCY ➜

FUNCTION OK 1

30,0 Hz

FREQUENCY ➜

FUNCTION OK 1

Basic settings

The VLT frequency converter has been preset from

the factory so that normally it will function after a few

data values are recorded/changed.

See Quick Setup on page 15.

The factory settings of the VLT frequency

converter are listed on page

105.

.

.

.

■

■

Page 19

MG.20.B6.02 – VLT is a registered Danfoss trademark

19

VLT® 2000 Series

Section 1 Section 2 Section 3

Chapter 1 ■ How the VLT works ................................... Page 21

Technology

Chapter 2 ■ How to size your VLT ................................. Page 29

Product range, sizing, technical data

Chapter 3 ■ How to install your VLT .............................. Page 41

The connection terminals, dimensions,

mechanical installation, electrical installation,

and motor connection

Chapter 4 ■ How to operate your VLT ........................... Page 45

The control panel and

the structure of the menus

Chapter 5 ■ The control possibilities of the VLT ............. Page 51

The menu groups and

the various parameters

Chapter 6Chapter 6

Chapter 6Chapter 6

Chapter 6 ■ Description of parameters ......................... Page 59

Chapter 7 ■ Display messages ..................................... Page 81

Status, alarm and warning and

reset messages

Chapter 8 ■ Special conditions ..................................... Page 85

CE-labelling

EMC, extreme operational conditions,

electrical noise, air humidity, efficiency and

du/dt measurements

Chapter 9 ■ Factory settings and service ...................... Page 97

Factory settings and fault location

Form to note down the VLT

parameter settings

Chapter 10 ■ Subject index .......................................... Page 107

Contents

Page 20

Page 21

MG.20.B6.02 – VLT is a registered Danfoss trademark

21

VLT® 2000 Series

Section 1 Section 2 Section 3

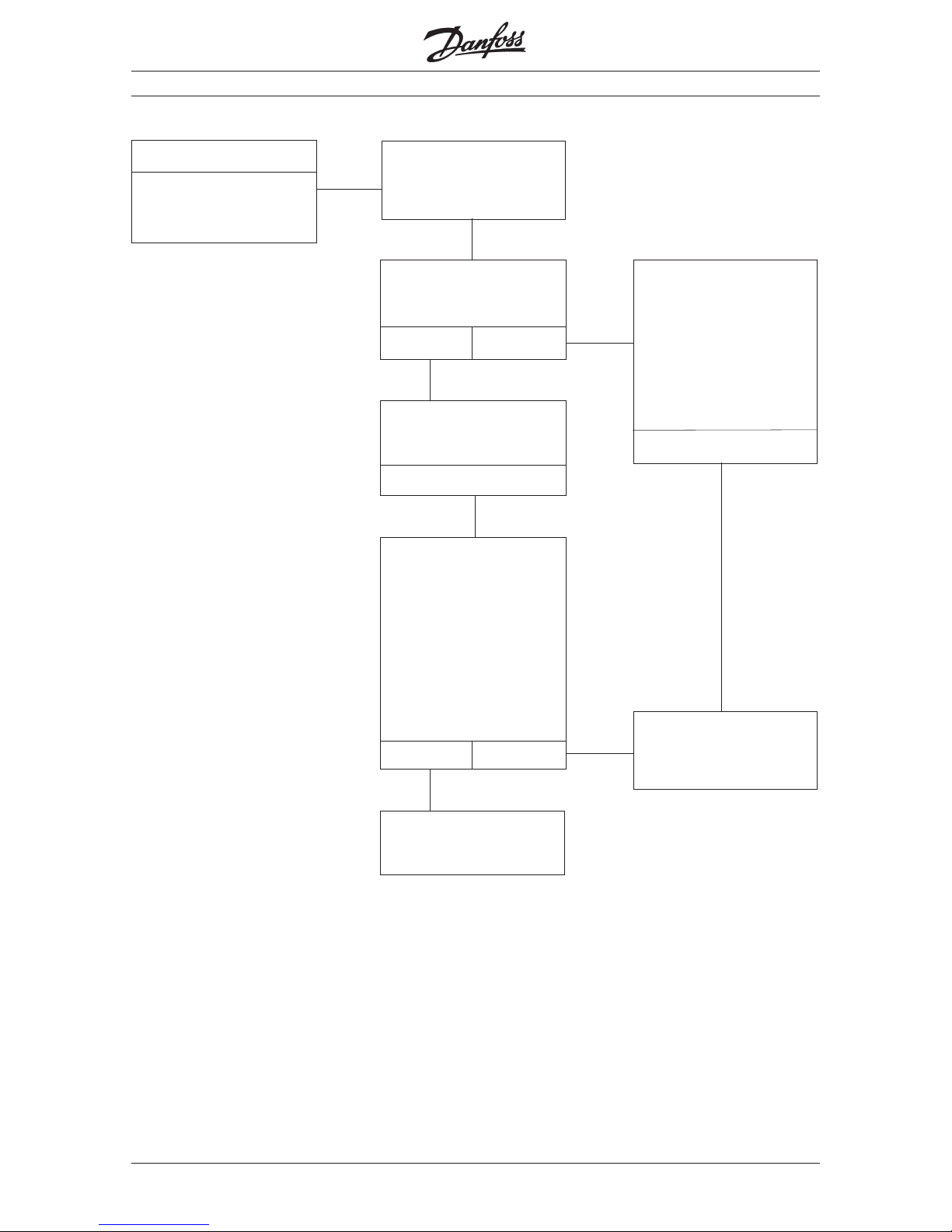

Chapter 1 ■ How the VLT is built up .............................. Page 22

■ The Danfoss VVC principle ........................ Page 23

■ Factory-programmed optimization............. Page 24

■ Control accuracy ....................................... Page 25

■ Protection against mains disturbance........ Page 25

■ Galvanic isolation....................................... Page 25

■ Advanced motor protection ....................... Page 25

■ Long motor cables .................................... Page 25

■ Functional diagrams .................................. Page 26

How the VLT works

Page 22

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

22

Saved energy

Energy is saved when the motor runs at a speed

which is continually matched to the momentary

requirement. An example is a pump and ventilating

plant, where a frequency converter can reduce energy

consumption by the cube of the speed.

Improved process

Matching the speed to the production process has

several advantages: an increase in production and a

decrease in the consumption of materials and the

scrapping rate.

Improved quality

The number of starts and stops is reduced. This avoids

unnecessarily hard treatment of machine parts.

Less maintenance

The frequency converter requires no maintenance.

In water supply plants there are no pressure surges

which might damage the water pipes.

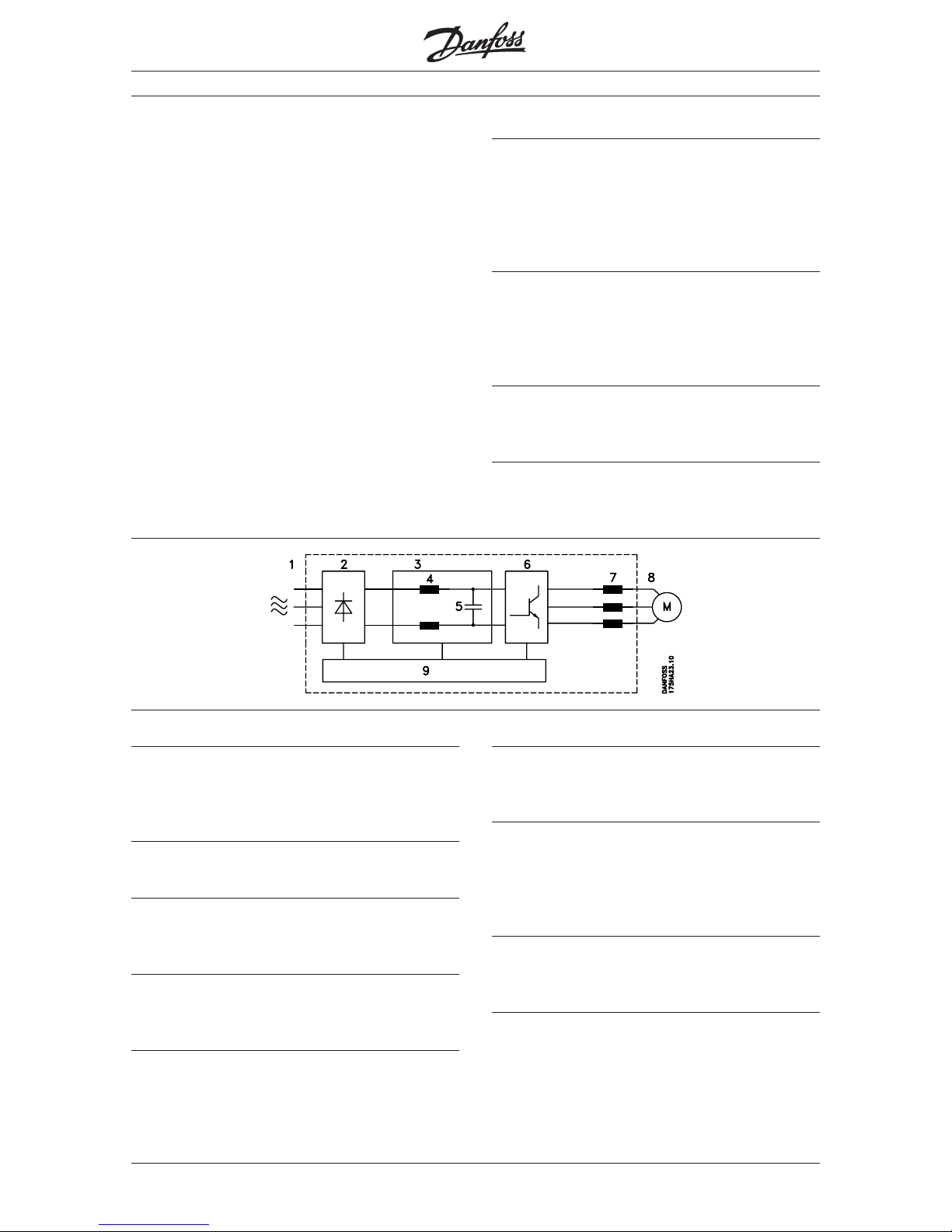

1. Mains supply

1 × 220/230/240 V AC, 50/60 Hz

3 × 208/220/230/240 V AC, 50/60 Hz

3 × 380/400/415/440/460 V AC, 50/60 Hz

2. Rectifier

Three-phase rectifier bridge rectifies AC to DC.

3. Intermediate circuit

DC voltage = √2 × supply voltage

4. Coils in the intermediate circuit

(not all VLT 2000 units)

Smoothen DC voltage and limit mains

supply interference (mains harmonics).

5. Capacitors in the intermediate circuit

Smoothen the voltage of the intermediate circuit

(energy store).

6. Inverter

Converts DC voltage to variable a.c.voltage and

variable frequency.

7. Motor coils (as module)

Advantages of motor coils:

− You can use long motor cables.

− Unlimited switching at the output of

the frequency converter (trip may occur).

8. Output

Variable a.c. voltage,10-100% of the supply voltage.

Variable frequency: 0-120/0-500 Hz.

9. Control card

The integrated computer controls the inverter, which

generates the pulse pattern by means of which DC

voltage is converted to variable a.c. voltage and

variable frequency.

How the VLT works

How the VLT is built up

A frequency converter is an electronic unit for infinite

speed control of a.c. motors. The frequency converter

controls the motor speed by converting the fixed voltage and frequency of the supply mains, e.g. 400 V/

50 Hz, to variable values. The frequency converter

does this by rectifying a.c. voltage to DCvoltage and

converting this to a.c. voltage with variable amplitude

and frequency.

The variable voltage and frequency supplying the motor

make infinite speed control of standard three-phase,

asynchronous motors possible.Today the a.c. motor

controlled by a frequency converter is a natural part of

all automised plants. Apart from utitilizing the good features of the a.c. motor, the infinite speed control gives

the user a multitude of additional advantages:

■■

■■

■

Page 23

MG.20.B6.02 – VLT is a registered Danfoss trademark

23

VLT® 2000 Series

Section 1 Section 2 Section 3

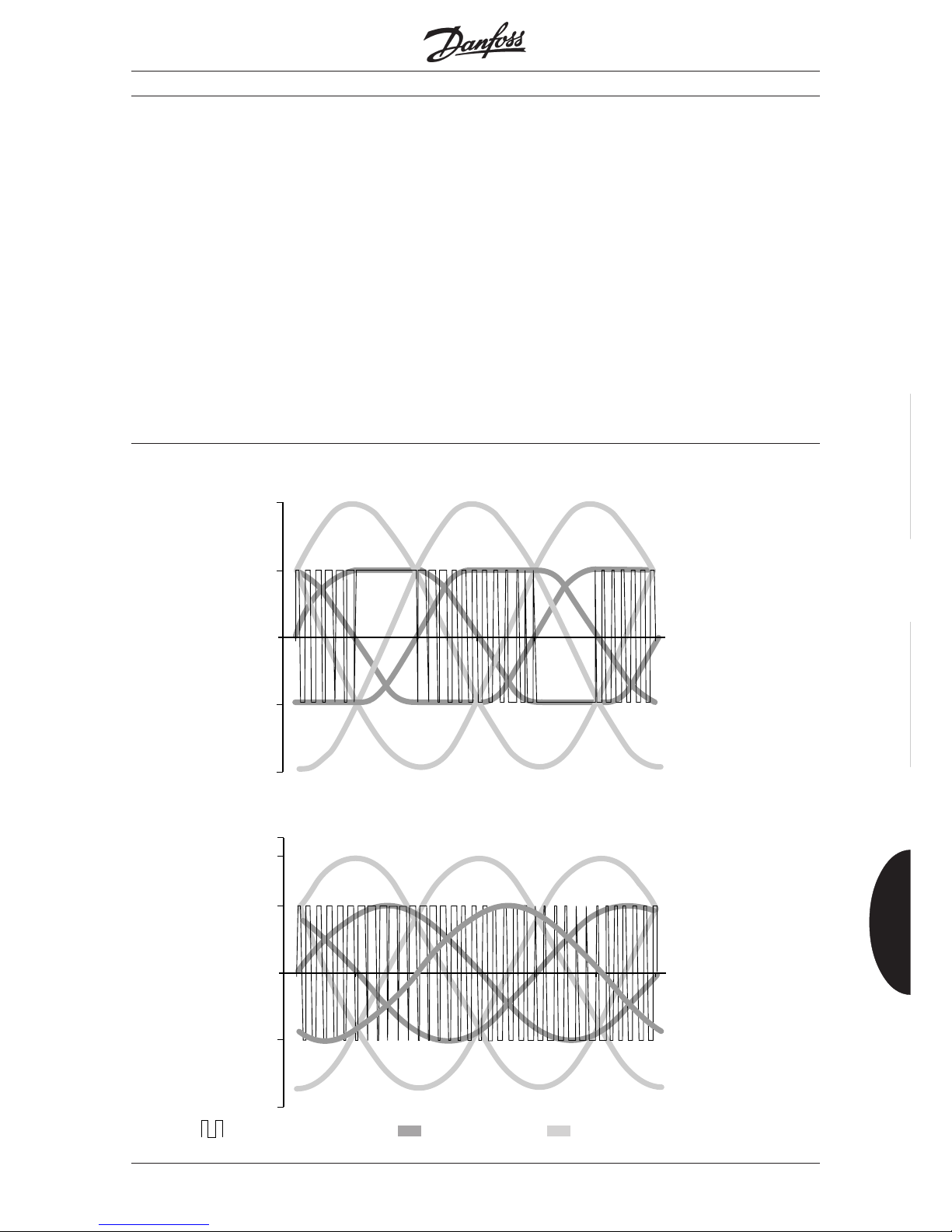

The Danfoss VVC principle

VLT 2000 Series frequency converters use an inverter

control system known as the Voltage Vector Control

(VVC) developed by Danfoss.

The VVC principle is superior to the traditional PWM

(Pulse Width Modulation) principle used in most

modern frequency converters in the following ways:

− Full-rated motor voltage at rated motor frequency.

− Near perfect resemblance to the sinusoidal

mains supply.

− Extremely low switching losses, resulting in high

converter efficiency.

The features are obtained through a special switching

pattern: the switching intervals are very short, which

means high switching frequency, and the six

semiconductors of the inverter section are alternately

held inactive in pairs, throughout a 60° sine period.

The current wave form of the motor current closely

resembles that obtained on mains operation. The

switching pause in 60° of the sine period also means

that full-rated motor voltage can be obtained - and

inverter switching losses are reduced by about

one third.

The figures below show the switching pattern and

maximum motor voltage according to the VVC

principle and the traditional PWM principle

respectively.

The full-rated motor voltage and the perfect current

wave form mean that the Danfoss VLT 2000 Series

allows full motor performance without any derating just like running the motor on the mains.

Motor voltage and simplified switching pattern according to the Danfoss VVC principle

Motor voltage and simplified switching pattern according to the traditional PWM principle

0,50

0,00

1,00

-0,50

-1.00

0 60 120 180 300 360240

U-V U-W W-U

U-V V-W W-U

0,50

0,00

1,00

-0,50

-1.00

0 60 120 180 300 360240

0,866

U-V V-W W-U

Switching pattern for phase U

Single phase voltage

Phase-phase voltage

for motor

How the VLT works

■

Page 24

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

24

How the VLT works

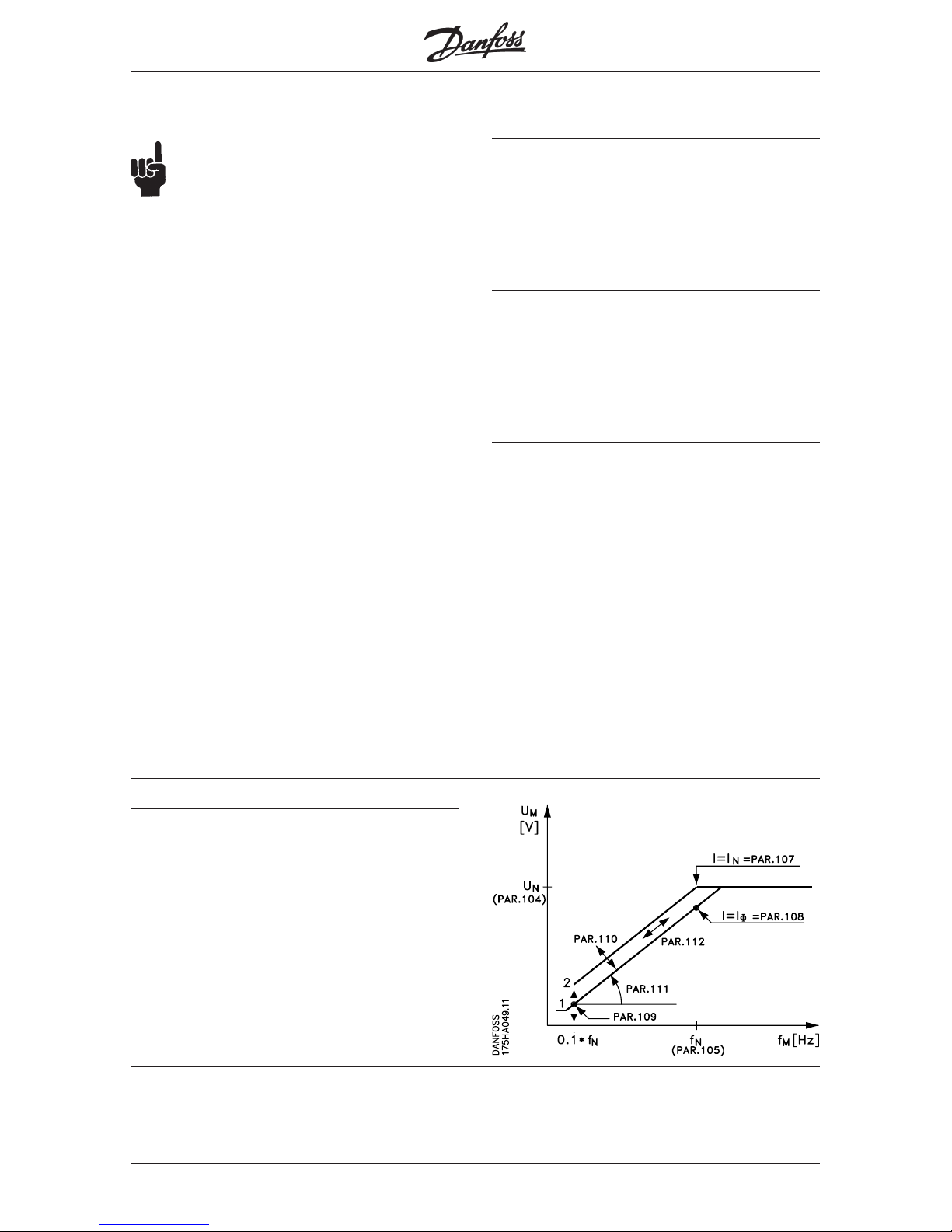

Factory-programmed optimization

VLT Series 2000 has dynamic adaptation of the

motor voltage and frequency. This ensures

correct magnetisation of the motor, thus

providing optimum dynamics, accuracy or efficiency.

VLT has been designed for operation of the most

common types of motors and loads.

Once parameters 103,104, 105, 107 and 108 have

been set according to the motor type plate, your

motor operation will be optimum in most cases.

Individual adaptation of VLT and motor is done via

parameters 109-112.

Start voltage

increases the motor voltage at a given frequency. This

increases the motor magnetization. The motor can yield

a higher torque, but the disadvantage is that the motor

losses are increased too. The result is a higher motor

temperature. Excessive start voltage can cause a trip

(cut-out).

Start compensation

changes the motor voltage as a function of the load.

The voltage will increase with higher motor current.

Over-compensation will overheat the motor and give

the risk of instability and can cause trip (cut-out). As

the name indicates, the function is most effective at

low motor speed.

U/f ratio

This describes the pre-programmed U/f characteristics

which indicate the relation between motor voltage (U)

and frequency (f).

The U/f ratio can be adjusted to ensure correct

excitation of the motor, thereby helping to

obtain optimal dynamism, accuracy or efficiency.

Slip compensation

adds both frequency and voltage and compensates for

the varying slip at varying load so that the motor speed

is kept constant at varying load. Over-compensation

may make the speed increase at increasing load. This

means motor overload and risk of unstable motor

operation.

Constant torque CT

Par. 104 = Rated motor voltage

Par. 105 = Rated motor frequency

Par. 107 = Rated motor current

Par. 108 = Motor no-load current

Par. 109 = Start voltage

Par. 110 = Start compensation

Par. 111 = U/f ratio

Par. 112 = Slip compensation

■

Page 25

MG.20.B6.02 – VLT is a registered Danfoss trademark

25

VLT® 2000 Series

Section 1 Section 2 Section 3

How the VLT works

Control accuracy

Basically we distinguish between open loop and

closed loop control.When the control is an open loop

type the motor current acts as process feedback. The

final result is therefore highly dependent on the

characteristics of the motor.

Note that large motors give a better result than small

motors.

Open loop (depending on motor size) ±2.0 % 3-100 Hz (10-90% of max. torque)

PI (closed loop) ±0.5% 1.2-100 Hz (-90 - +90% of max. torque)

A closed loop control incorporates a direct process

feedback, which substantially improves the control

accuracy.

The stated maximum torque follows the power hyperbola in the frequency range across the motor’s rated

frequency.

Galvanic isolation

With the VLT 2000 Series safety isolation is standard,

as the high-voltage parts of the power section are

galvanically isolated from the low-voltage parts of the

control section according to VDE 0160/0106 (PELV).

Therefore PCs and the like will not be disturbed.

Advanced motor protection

The VLT 2000 Series has a built-in electronic thermal

motor protection. The frequency converter calculates

the motor temperature on the basis of voltage,

current, frequency and time.

The thermal motor protection is comparable with a

thermal relay in the motor cables. Therefore it is

superior to the traditional bi-metallic protection, where

the altered cooling conditions due to the speed

control are not taken into consideration.

Long motor cables

For the VLT 2000 Series motor coils in an IP 00 or IP

10 enclosure are available as modules.

This makes it possible to install a long cable between

motor and frequency converter.

Motor coils are also included in the RFI and motor

filter module in IP 20 enclosure. See page 34 for a

speciffication of maximum cable length.

Programmable control inputs and

signal outputs in 2 setups

The digital technique used in the VLT 2000 Series

makes it possible to redefine the different control

inputs and signal outputs and to program 2 different

user defined setups.

It is easy for the user to program the required

functions on the keyboard of the VLT 2000 Series or

via the RS 232 user interface.

Protection against mains disturbance

The VLT 2000 Series is protected against transients

arising on the mains, e.g. when you switch in power

factor phase-correction capacitors or when the

supply is subject to lightning strikes.

Adequate motor voltage and full torque can be maintained down to 10% under-voltage on the supply

mains.

■

■

■

■

■

■

Page 26

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

26

How the VLT works

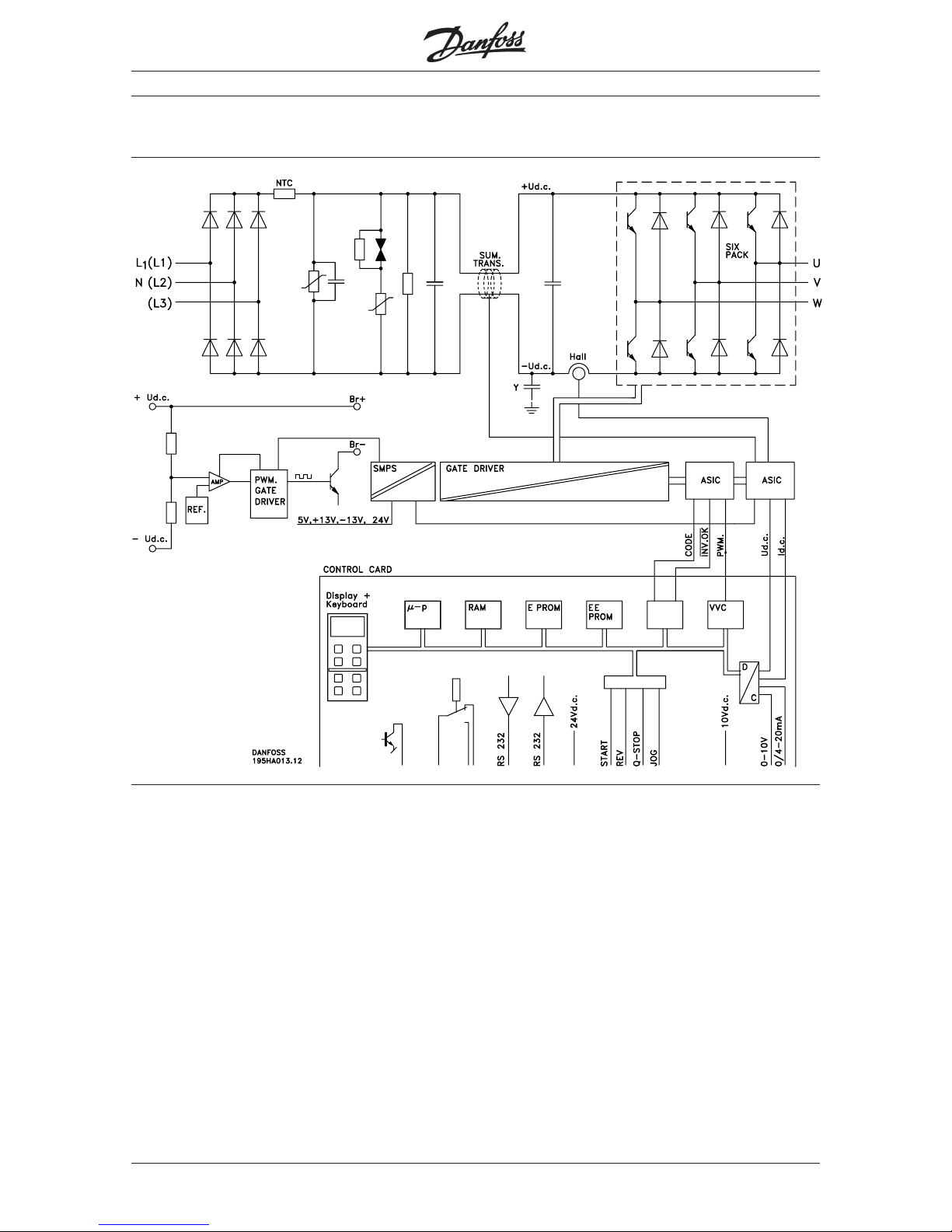

Functional diagram VLT 2010-2030 single-phase/three-phase 208-240 V

■

Page 27

MG.20.B6.02 – VLT is a registered Danfoss trademark

27

VLT® 2000 Series

Section 1 Section 2 Section 3

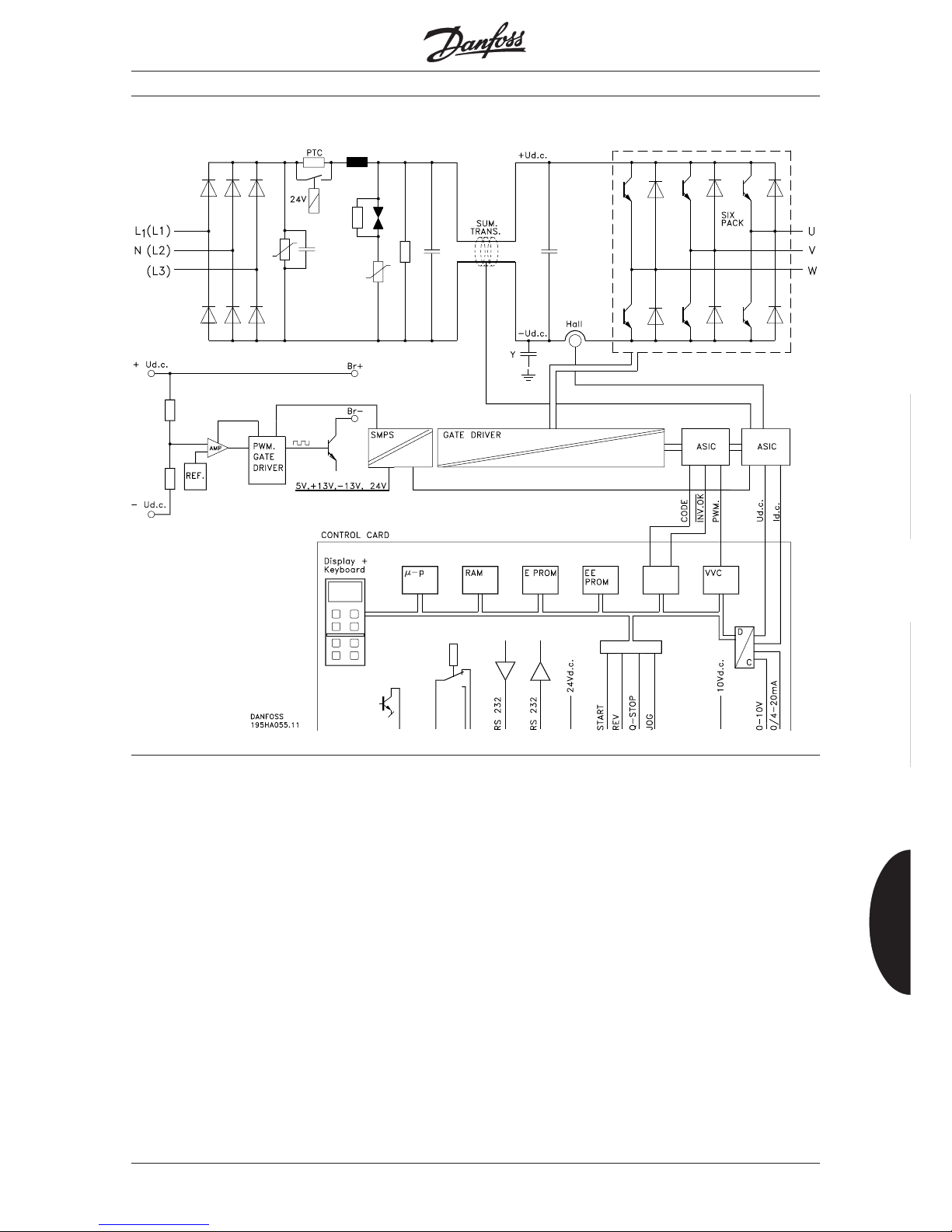

Function diagram VLT 2040-2050, 3-phase 208-240 V

How the VLT works

■

Page 28

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

28

How the VLT works

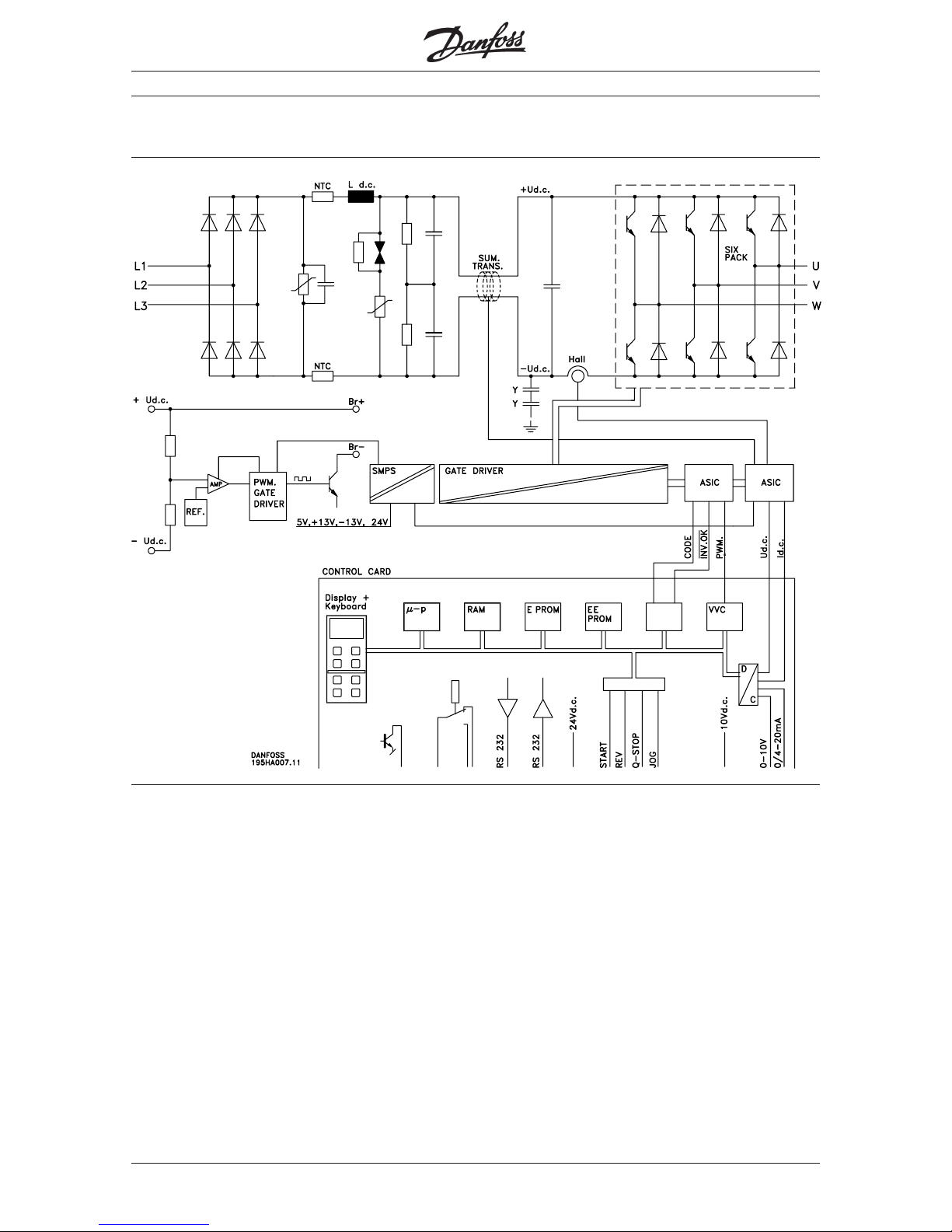

Functional diagram VLT 2020-2060 three-phase 380-460 V

■

Page 29

MG.20.B6.02 – VLT is a registered Danfoss trademark

29

VLT® 2000 Series

Section 1 Section 2 Section 3

Chapter 2 ■ Selection of frequency converter ............... Page 30

Sizing ....................................................... Page 30

■ Product range ........................................... Page 31

■ Brake function ........................................... Page 33

■ Motor coils (module) .................................. Page 34

■ RFI and motor filter (module) ..................... Page

34

■ LC and RFI filter (module) .......................... Page 34

■ Dimensions ............................................... Page 35

■ Technical data ........................................... Page 38

How to size your VLT

■

■

■

Page 30

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

30

How to size your VLT

Selection of frequency converter

Usually the size of frequency converter is chosen on

the basis of the shaft output, as this may be the only

value known. However, if the data are known for both

the application, the motor and the frequency converter,

it is recommended to make a more accurate sizing.

The values must be based on the rated motor speed.

VLT 2000 only operates according to the CT

(constant torque) characteristic

Sizing when you know the motor current

Exercise

Conveyor plant with a 1.1 kW, 3 × 380 V motor. At

continuous operation the motor current is 2.5 A

( 3 × 415 V).

Solution

From the table on the next page you can see that a

VLT type 2025 can yield 2.8 A at continuous operation. The right solution is therefore VLT 2025.

Sizing on the basis of the apparent power S

M

[kVA] consumed by the motor

Exercise

A motor must yield constant torque at continous

operation. Usually the necessary values will appear

from the motor plate or from the motor catalogue.

Solution

From the table on the next page you can see that VLT

type 2025 can yield 2.0 kVA (415 V) at continuous

operation. The solution is therefore VLT type 2025.

Read values

Motor current = 2.5 A (3 × 415 V)

s

M

=

U × I × √3

[kVA]

1000

=

415 × 2.5 × √3

[kVA]

1000

= 1.8 kVA

Sizing on the basis of the power requirement

P

VLT

[kW] of the motor

Exercise

A machine tool is driven by a 3 kW motor. The power

requirement is indicated to be 2.4 kW. The motor

efficiency η is 0.80, cos ϕ = 0.81 and the motor voltage is 3 x 415 V.

η and cos ϕ are measured at 3 kW output. We

estimate η and cos ϕ to be approximately the same

at 80 % load.

Solution

From the table on the next page you can see that VLT

type 2040 can yield 4.0 kVA (415 V) at continuous

operation. The right solution is therefore VLT type 2040.

S

VLT

=

P

m

η × cos ϕ

=

2.4 kW

0.80 × 0.81

= 3.7 kVA

■

■

■

■

Page 31

MG.20.B6.02 – VLT is a registered Danfoss trademark

31

VLT® 2000 Series

Section 1 Section 2 Section 3

Which one to choose?

Mains: 1 × 220/230/240 V, 3 × 208/220/230/240 V

VLT type Typical shaft output Constant output current I

VLT,N

Constant output power at 230 V

[kW] [A] [kVA]

2010 0.37 2.2 0.9

2015 0.55 3.1 1.3

2020 0.75 4.0 1.6

2030 1.5 7.5 3.1

2040 *) 2.2 10.6 4.4

2050 *) 3.0 16.7 6.9

*) VLT types 2040 and 2050: only three-phase mains supply.

Mains: 3 × 380/400/415/440/460 V *)

VLT type Typical shaft output Constant output current I

VLT,N

Constant output power at 415 V

[kW] [A] [kVA]

2020 0.75 2.4 1.7

2025 1.1 2.8 2.0

2030 1.5 4.0 2.9

2040 2.2 5.6 4.0

2050 3.0 7.6 5.5

2060 *) 4.0 9.7 7.0

*) VLT type 2060: 3 × 380/400/415 V

How to size your VLT

■

Page 32

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

32

How to size your VLT

Product range

The VLT 2000 Series is available in a single-phase/

three-phase version (1 x 220-240 V or 3 x 208-240V)

in the power range 0.37-1.5 kW and a three-phase

version (3 x 208-240 V) in the power range 2.2-3.0

kW. A three-phase version (3 x 380-460 V) in the

power range 0.75-4.0 kW is also available.

All units are delivered in an IP 20 enclosure.

How to find the right code number

When you have found the right VLT size you can find

the code number to be ordered in the table below.

Example:

VLT type 2020 (3 x 380-460 V) three-phase without

display with brake has the code number 195H3400.

As appears from the table a VLT 2000 single/three

phase can be delivered with various options and

modules such as brake function, RFI filter and motor

coils.

VLT 2000 Series, single-phase/three-phase (1

× ×

× ×

× 220-240 V / 3

× ×

× ×

× 208-240 V) (3 x 208-240 V)

VLT 2010 VLT 2015 VLT 2020 VLT 2030 VLT 2040 VLT 2050

Without display 195H3100 195H3102 195H3104 195H3106 195H3108 195H3110

With display 195H3101 195H3103 195H3105 195H3107 195H3109 195H3111

Without display with brake 195H3200 195H3202 195H3204 195H3206 195H3208 195H3210

With display with brake 195H3201 195H3203 195H3205 195H3207 195H3209 195H3211

RFI and motor filter module 195H6523 195H6524 195H6524 195H6525

IP 20 1-phase

RFI and motor filter module 195H6522 195H6522 195H6522 195H6522

IP 20 3-phase

RFI-filtermodul IP 20 (VBG-4)* - - - - 195H6528 195H6528

Motor coil module IP 00 195H6510 195H6510 195H6510 195H6510

Motor coil module IP 10 (VBG-4) 195H6521 195H6521 195H6521 195H6521

LC and RFI filter module 195H6527 195H6526 195H6526 195H6526

IP 20 3-phase

* Schaffner RFI-filter type FN351 - 16/29

VLT 2000 Series, three-phase (3

× ×

× ×

× 380/460 V). Note: VLT 2060: 380/415 V

VLT 2020 VLT 2025 VLT 2030 VLT 2040 VLT 2050 VLT 2060

Without display 195H3300 195H3302 195H3304 195H3306 195H3308 195H3310

With display 195H3301 195H3303 195H3305 195H3307 195H3309 195H3311

Without display with brake 195H3400 195H3402 195H3404 195H3406 195H3408 195H3410

With display with brake 195H3401 195H3403 195H3405 195H3407 195H3409 195H3411

RFI and motor filter module IP 20** 195H6522 195H6522 195H6522 195H6522 195H6522 195H6522

Motor coil module IP 10 (VBG-4) 195H6521 195H6521 195H6521 195H6521 195H6521 195H6521

LC and RFI filter module IP 20** 195H6527 195H6527 195H6527 195H6526 195H6526 195H6526

**Only 380/415 V

■

■

Page 33

MG.20.B6.02 – VLT is a registered Danfoss trademark

33

VLT® 2000 Series

Section 1 Section 2 Section 3

How to size your VLT

Brake function

All units can be delivered with built-in brake function

(factory-mounted). The brake resistors for the brake

function must be connected according to the connection diagram on page 42.

Specifications VLT 2010-2030 VLT 2040-2050 VLT 2020-2050 VLT 2060

208-240 V 208-240 V 380-460 V 380-415 V

Max. current 5.5 A 16 A 5.5 A 7.5 A

Min. brake voltage 372 V DC 372 V DC 747 V DC 646 V DC

Max. brake voltage 382 V DC 382 V DC 764 V DC 661 V DC

P-band 4 V 8 V 8 V 8 V

Overcurrent fuse None None None None

Min. brake resistance 70 Ohm 25 Ohm 140 Ohm 90 Ohm

The VLT

®

2000 with built-in RFI filter in IP 20 enclosure,

is designed to be built directly into control panels.

,

EMC demands are fulfiled without any extra

component.

- RFI filter to reduce electromagnetic interference.

- The VLT

®

2000 units meet all necessary EMC

immunity standards as laid down in the IEC 1000-4.

- The VLT

®

2000 units meet the EMC emission

requirements as laid down in the EN 55011,

Group 1 Class A. The EMC emission specifications

are complied with by using up to 40 m unscreened

cable, see page 88.

VLT Series 2000, single-phase (1 x 220-240 V)

VLT 2010 VLT 2015 VLT 2020 VLT 2030

Without display 195H3600 195H3602 195H3604 195H3606

With display 195H3601 195H3603 195H3605 195H3607

Without display / With brake 195H3700 195H3702 195H3704 195H3706

With display / with brake 195H3701 195H3703 195H3705 195H3707

Motor coils, IP20, three-phase 195H6529 195H6529 195H6529 195H6529

VLT Series 2000, three-phase (3 x 380-415 V)

VLT 2020 VLT2025 VLT2030 VLT 2040 VLT 2050 VLT 2060

Without display 195H3800 195H3802 195H3804 195H3806 195H3808 195H3810

With display 195H3801 195H3803 195H3805 195H3807 195H3809 195H3811

Without display / With brake 195H3900 195H3902 195H3904 195H3906 195H3908 195H3910

With display / with brake 195H3901 195H3903 195H3905 195H3907 195H3909 195H3911

Motor coils, IP20, three-phase 195H6529 195H6529 195H6529 195H6529 195H6529 195H6529

VLT 2000 Series built-in RFI filter EN 55011 1A:

■

■

VLT Series 2000, single-phase (1 x 220-240 V)

VLT 2010 VLT 2015 VLT 2020

With display / without brake 195H3112 195H3113 195H3114

VLT 2000 Series built-in compact RFI filter

For technical data, see page 12.

■

Accessories/options to the VLT Series 2000:

Remote control (option) 175H1788

PC program (VLS Dialog 2)(

DanishDanish

DanishDanish

Danish) 175H2877

PC program (VLS Dialog 2)(

EnglishEnglish

EnglishEnglish

English) 175H2850

PC program (VLS Dialog 2)(

GermanGerman

GermanGerman

German) 175H2876

■

Page 34

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

34

How to size your VLT

LC and RFI filter (module)

The LC and RFI filter module in IP 20 enclosure is

designed to be built in with the VLT frequency

converter itself. The filter contains the following:

- RFI filter to reduce electro-magnetic

interference

- LC filter to reduce the acoustic noise level from the

motor and make it possible to use long motor

cables up to 300 m.

- Motor filter (motor RFI filter) to reduce the electromagnetic interference from the motor cable.

Equipped with the IP 20 LC and RFI filter

(195H6526 and 195H6527), the VLT 2000 Series

meets the EN 55011, Group 1, Class A requirements

of EMC emission.

The EMC emission specifications are complied with

by using up to 100 m unscreened motor cable.

Code nr. 195H6527 195H6526

VLT basic unit VLT 2020, 2025, 2030 VLT 2040, 2050, 2060

Enclosure IP 20 IP 20

Outside dimensions (H x W x D) 170 x 110 x 180 mm 170 x 110 x 180 mm

Built-in fan Yes No

Mains voltage 380 - 415 V 380 - 415 V

Current (max.) 4.0 A 9.7 A

Cut-out frequency No limit No limit

EMC immunity IEC 801 Series IEC 801 Series

EMC emission EN 55011 Group 1, Class A EN 55011 Group 1, Class A

Max. cable length to fullfill

EN 55011, Group 1, Class A 100 m 100 m

Unscreened

Max. temperature (full load) 40°C 40°C

Motor coils (module)

The IP 20 enclosure (also with mains filter) is available

with integrated motor coils or as an IP 00/IP 10

module for external mounting.

Technical data

208-240 V/IP 20 208-240V/IP 00 380-415 V/IP 20 380-460 V/IP 10

Max. current 3 × 2.2/4.0/7.5 A 3 × 7.5 A 3 × 9.7 A 3 × 10 A

Max. cable length (unscreened) 150 m 300 m 150 m 300 m

Max. cable length to fullfill

EN 55011, Group 1, Class A100 m - 100 m Unscreened

Max. cable length (screened) 75 m 150 m 75 m 150 m

Inductance 3× 75 µH 75 µH 120 µH 240 µH

Outside dimensions 100x110x180 mm - 100x110x180 mm Code no. 195H6523,6524,6525 195H6510 195H6522

195H6521

Additional litterature:

MI.20.CX.02 - Moter coil, IP 10

MI.20.BX.52 - Moter coil, IP 00

MD.65.BX.XX - Brake resistors

Motor coils in IP 00 and IP 10 enclosure contain only

one motor coil, making it possible to use long motor

cables up to 300 m. These motor coils must be

installed separately (not for co-building with the VLT

frequency converter).

RFI and motor filter (module)

The RFI and motor filter module in IP 20 enclosure is

designed to be built in with the VLT frequency

converter itself. The filter contains the following:

- RFI filter to reduce electro-magnetic

interference.

- Motor coils making it possible to use long motor

cables.

- Motor filter (motor RFI filter) to reduce the electromagnetic interference from the motor cable.

The VLT 2000 Series basic units meet EMC immunity

requirements as laid down in the IEC 1000-4

standards, but do not meet any EMC emission

requirements.

Equipped with the IP 20 RFI and motor filter

(195H6522, 195H6523, 195H6524, 195H6525),

the VLT 2000 Series meets the EN 55011, Group 1,

Class A requirements of EMC emission.

The EMC emission specifications are complied with

by using up to 100 m unscreened motor cable.

■

■

■

■

Page 35

MG.20.B6.02 – VLT is a registered Danfoss trademark

35

VLT® 2000 Series

Section 1 Section 2 Section 3

Dimensions

VLT 2010-2030 single-phase, 220-240 V/three-phase, 208-240 V

VLT 2010-2020 built-in compact RFI filter single-phase, 220-240 V

Min. space over and under frequency

converters: 100 mm

Min. space to the left and the right of

frequency converters: 0 mm (side-by-side

mounting).

VLT 2010-2030 with module single-phase, 220-240 V/three-phase, 208-240 V

With 100 mm module: A = 362 mm

a = 337 mm

With 170 mm module: A = 432 mm

a = 407 mm

Min. space over and under frequency

converters: 100 mm.

Min. space to the left and the right of

frequency converters: 0 mm (side-by-side

mounting).

How to size your VLT

■

Page 36

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

36

Dimensions (cont’d)

VLT

2020-2060 three-phase, 380-415/460 V

VLT 2040-2050 three-phase, 208-240 V

Min. space over and under frequency

converters: 100 mm.

Min. space to the left and the right of

frequency converters: 0 mm (side-by-side

mounting)

VLT 2020-2060 with module three-phase, 380-415/460 V

with 100 mm module: A = 462 mm

a = 437 mm

With 170 mm module: A = 532 mm

a = 507 mm

Min. space over and under frequency

converters: 100 mm.

Min. space to the left and the right of

frequency converters: 0 mm (side-by-side

mounting)

How to size your VLT

■

Page 37

MG.20.B6.02 – VLT is a registered Danfoss trademark

37

VLT® 2000 Series

Section 1 Section 2 Section 3

How to size your VLT

Dimensions (cont’d)

VLT 2010-2030 with built-in RFI filter, single-phase, 220-240 V

Min. space over and under frequency

converters: 100 mm.

Min. space to the left and the right of

frequency converters: 0 mm (side-by-side

mounting)

VLT 2020-2060 with built-in RFI filter, three-phase, 380-415 V

Min. space over and under frequency

converters: 100 mm.

Min. space to the left and the right of

frequency converters: 0 mm (side-by-side

mounting)

■

■

Page 38

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

38

How to size your VLT

Technical data

Mains: 1

××

××

× 220/230/240 V, 3

××

××

× 208/220/230/240 V 3 x 208/220/230/240 V

Meets the international standards, UL/ cUL 4) VLT type 2010 2015 2020 2030 2040 2050

Constant load (CT):

Output current I

VLT.N

[A] 2.2 3.1 4.0 7.5 10.6 16.7

I

VLT.MAX

[A] (60 s) 3.5 4.9 6.3 10.5 17.0 26.7

Output S

VLT.N

[kVA] 0.9 1.3 1.6 3.1 4.4 6.9

S

VLT.MAX

[kVA] (60 s) 1.4 2.1 2.6 4.3 7.0 11.0

Typical shaft output P

VLT.N

[kW] 0.37 0.55 0.75 1.5 2.2 3.0

Max. cable cross section [mm2] 44 4444

Max. motor cable length [m] 40 (with motor coils IP 10:

unscreened cables 300 m, screened cables 150 m)

Output voltage UM [%] 0-100% of mains voltage

Output frequency fM [Hz] 0-120 or 0-500; programmable

Rated motor voltage U

M,N

[V] 200/208/220/230/240

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal motor protection during operation Built-in thermal motor protection (electronic)

Switching on the output Unlimited (frequent switching may cause cut-out)

Ramp times [s] 0.1-800

VLT type 2010 2015 2020 2030 2040 2050

Max. input current I

L,N

[A] (5.3/3.5) (8.5/5.6) (10.6/7.1) (18/12) (-/10) (-/16)

Max. cable cross section [mm2] 44 4444

Max. prefuses [A] 10 16 20 20 20 25

Bussmann Fuse type KTN-R 250 V AC 5) [A] 10 15 20 20 20 25

Mains supply voltage [V] 1 x 220/230/240 ±10 % 3 x 208/220/

3 × 208/220/230/240 ±10 % 230/240±10 %

Mains supply frequency [Hz] 50/60

Power factor/cos. ϕ

1

Without mains filter:0.50/0.87 0.90/1.0 0.90/1.0

With mains filter:0.65/1.0

Efficiency >0.94 at rated load

Switching on the input times/min. 5

VLT type 2010 2015 2020 2030 2040 2050

Weight [kg] IP 20 2.0 2.0 2.1 2.1 4.6 4.6

Weight [kg] with built-in RFI filter IP 20 3.7 3.7 3.8 3.8

Power loss at max. load CT [W] 39 53 69 126 136 236

Enclosure IP 20 IP 20 IP 20 IP 20 IP 20 IP 20

Vibration test [g] 0.7

Relative humidity [%] Max. 95 IEC 721 (according to VDE 0160)

Ambient temperature [°C] 0 → +40 at full-load operation

2

)

(according to VDE 0160) [°C] −25 → +70, storage/transport

Frequency converter protection Grounding and short-circuit proof 3)

EMC applied standards Emission EN 55011, Group 1, Class A,

(see page 90) CISPR 11 (with RFI and motor filter)

Immunity IEC 1000-4

UL file-number E134261

2

) In the range -10 - 0 °C the unit can start and run, but the display indications and certain operating characteristics

will not meet the specifications.

3

) Brake option without protection

4

) Units with built-in RFI filter are not UL-approved.

5

) For the North American market

■

Page 39

MG.20.B6.02 – VLT is a registered Danfoss trademark

39

VLT® 2000 Series

Section 1 Section 2 Section 3

Technical data (continued)

Mains: 3

××

××

× 380-460 V (VLT type 2060: 3

××

××

× 380-415 V)

Meets the international standards, UL/cUL 4) VLT type 2020 2025 2030 2040 2050 2060 1)

Constant load (CT):

Output current I

VLT.N

[A] 2.4 2.8 4.0 5.6 7.6 9.7

I

VLT.MAX

[A] (60 s) 3.8 4.5 6.4 9.0 12.2 15.5

Output S

VLT.N

[kVA] 1.91 2.23 3.19 4.46 6.05 6.97

S

VLT.MAX

[kVA] (60 s) 3.06 3.57 5.10 7.14 9.69 11.2

Typical shaft output P

VLT.N

[kW] 0.75 1.1 1.5 2.2 3.0 4.0

Max. cable cross section [mm2]444444

Max. motor cable length [m] 40 (with motor coils IP 10:

unscreened cables: 300 m, screened cables: 150 m)

Output voltage UM [%] 0-100 in % of mains voltage

Output frequency fM [Hz] 0-120 or 0-500; programmable

Rated motor voltage U

M,N

[V] 380/400/415/440/460

Rated motor frequency f

M,N

[Hz] 50/60/87/100

Thermal motor protection during operation Built-in thermal motor protection (electronic)

Switching on the output Unlimited (frequent switching may cause cut-out)

Ramp times [s] 0.1-800

VLT type 2020 2025 2030 2040 2050 2060 1)

Max. input current I

L,N

[A] 2.3 2.7 3.8 5.3 7.2 9.1

Max. cable cross section [mm2]444444

Max. prefuses [A] 16 16 16 16 16 20

Bussmann Fuse type KTN-R 250 V AC 5) [A] 15 15 15 15 15

Mains supply voltage [V] 3 × 380-460 V ±10% 2060: 3 × 380-415 V ±10%

Mains supply frequency [Hz] 50/60

Power factor/cos. ϕ

1

> 0.90/1.0 at rated load

Efficiency > 0.97 at rated load

Switching on the input times/min. 5

VLT type 2020 2025 2030 2040 2050 2060 1)

Weight [kg] IP 20 4.0 4.0 4.0 4.2 4.2 4.2

Weight [kg] with built-in RFI filter IP 20 4.6 4.6 4.6 4.8 4.8 4.8

Power loss at max. load CT [W] 58 64 78 114 153 196

Enclosure IP 20 IP 20 IP 20 IP 20 IP 20 IP 20

Vibration test [g] 0.7

Relative humidity [%] Max. 95 IEC 721 (according to VDE 0160)

Ambient temperature [°C] 0 → +40, at full load operation

2

)

(according to VDE 0160) [°C] −25 → +70, storage/transport

Frequency converter protection Grounding and short-circuit proof 3)

EMC applied standards Emission EN 55011, Group 1, Class A

(see page 90) CISPR 11 (with RFI and motor filter)

Immunity IEC 1000-4

UL file no. E 134261

1

) VLT 2060 has not been UL approved.

2

) In the range -10 - 0 °C the unit can start and run, but the display indications and certain operating characteristics

will not meet the specifications.

3

) Brake option without protection

4

) Units with built-in RFI filter are not UL-approved.

5

) For the North American market

How to size your VLT

■

Page 40

Page 41

MG.20.B6.02 – VLT is a registered Danfoss trademark

41

VLT® 2000 Series

Section 1 Section 2 Section 3

How to install your VLT

Chapter 3 ■ How to connect the VLT to the motor........ Page 42

■ Survey of connection terminals.................. Page 42

■ How to connect control signals ................. Page 43

■ Mechanical installation............................... Page 44

■ High voltage test ....................................... Page 44

■ Extra protection ......................................... Page 44

■ Prefuses .................................................... Page 44

■ What cables to use.................................... Page 44

■ For the North American market ................. Page 44

Page 42

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

42

How to connect the VLT to the motor

With the VLT 2000 Series you can use all standard

three-phase asynchronous motors.

Small motors (230/400 V, ∆/Y) are delta-connected to

230 V and star-connected to 400 V. Large motors are

delta-connected (400/690 V, ∆/Y).

The motor is connected to the VLT frequency converter by means of terminals at the bottom of the enclosure (the module).

The rotation direction can be changed by

swapping the phase motor cables (terminals

97 and 98) or by using the “Fwd/Rev” key, see

also page 47.

How to install your VLT

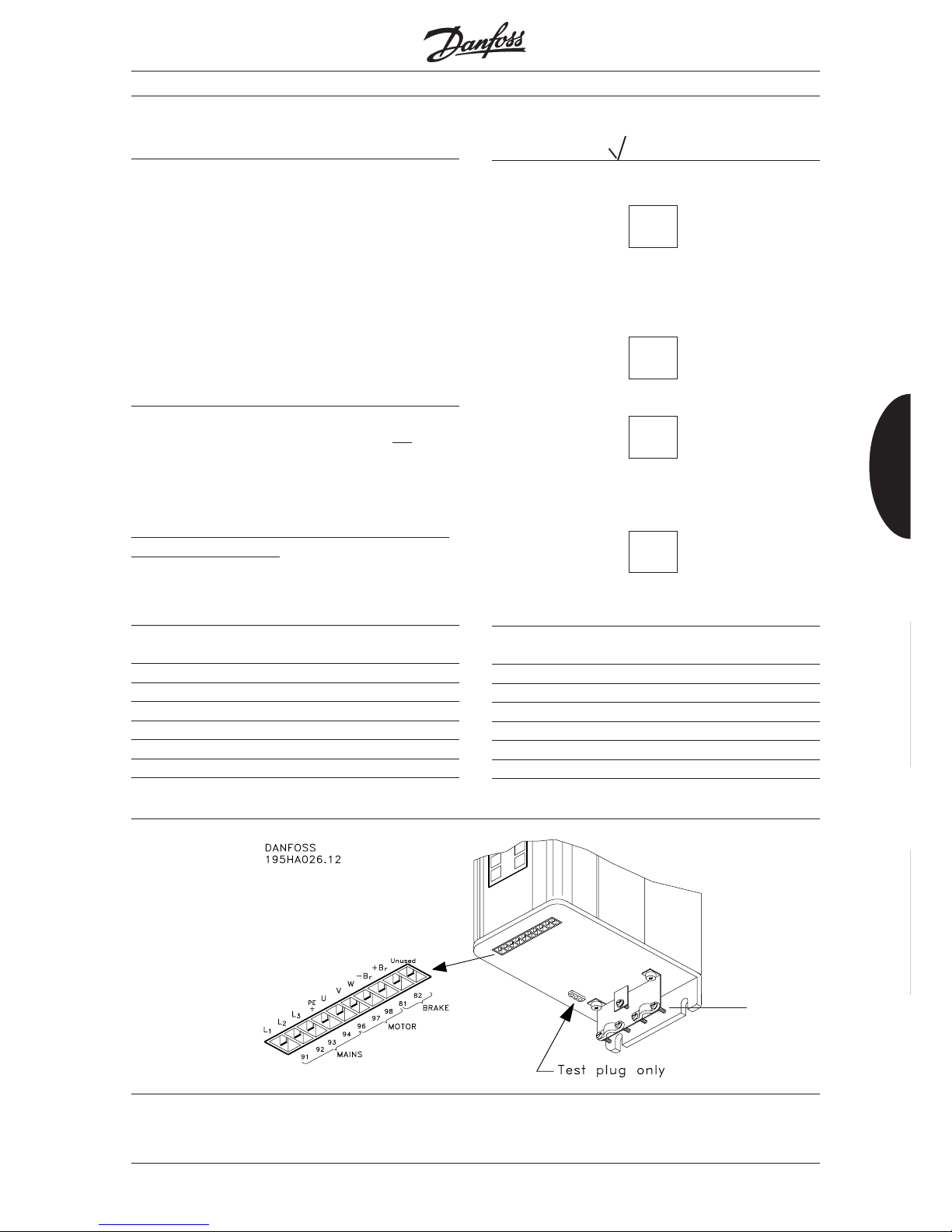

Survey of connection terminals

All the terminals of a VLT frequency converter are

shown below (3 x 380-460 V).

The control signals are described overleaf.

Do

not remove the motor and mains terminals

when the unit is connected to the mains.

Ensure that the power supply has been switched

off before you remove the motor and mains terminals.

■

■

Page 43

MG.20.B6.02 – VLT is a registered Danfoss trademark

43

VLT® 2000 Series

Section 1 Section 2 Section 3

How to install your VLT

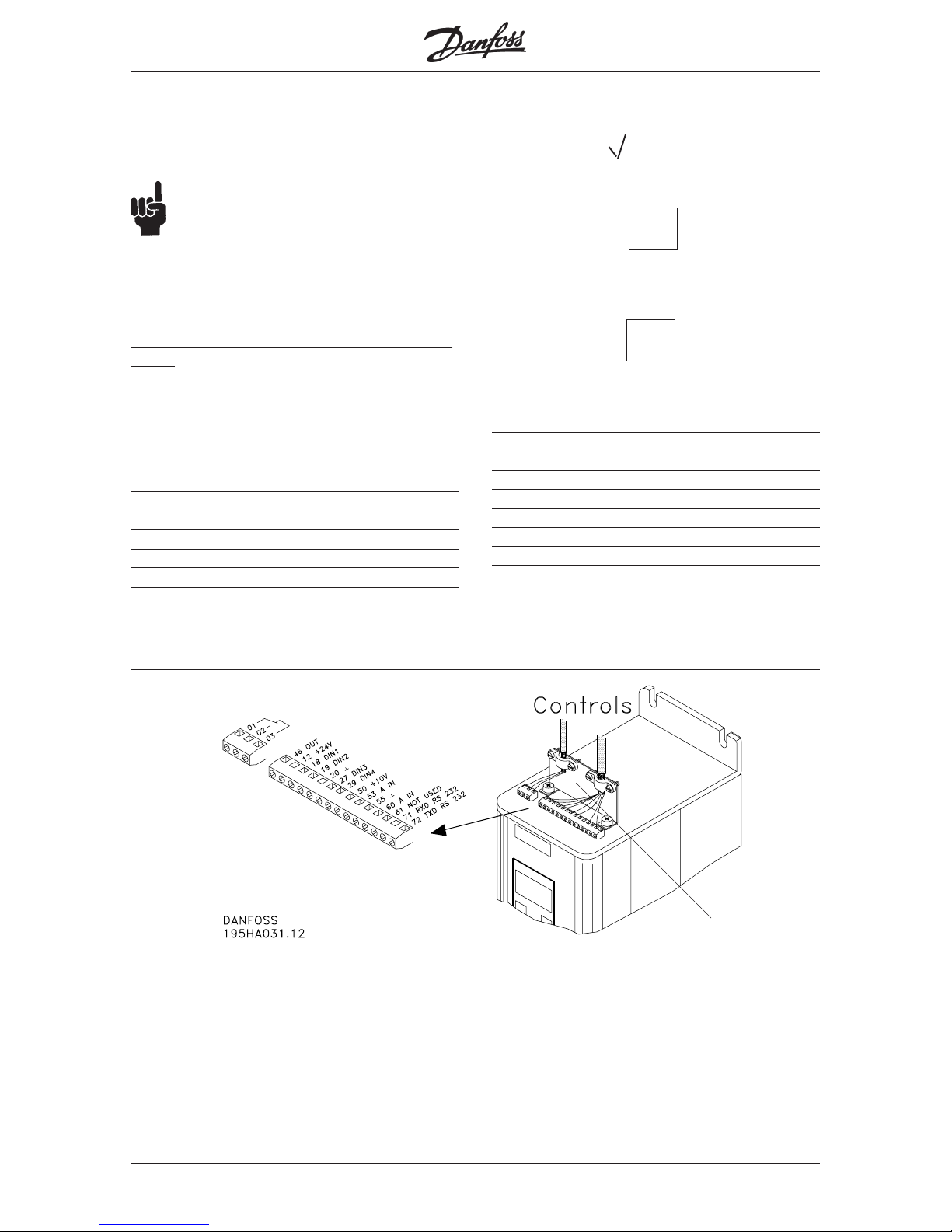

How to connect control signals

You can connect the control signals in different ways

on the VLT frequency converter.

The control signals can be connected to the two

terminal strips at the top of the enclosure.

Each terminal number is based on the survey on page

42.

The control signals can be connected as follows:

Terminal 18/402 ★ Start Latched No Speed Speed Reversing Reset Motor coasting/

start function up select and start start

Terminal 19/403 ★ Reversing Start No Speed Speed Reset

reversing function down select

Terminal 27/404 Motor Quick DC ★ Reset and Stop Reset Speed Speed

coasting stop braking motor coasting and start up select

Terminal 29/405 ★ Jog Start Digital Pulse Pulse Pulse Select Reset Reversing Speed

(Jog) reference 100 Hz 1 kHz 10 kHz setup down

★ For factory setting of terminal function, see page 105.

Terminal 01-03: Relay output Max. 250 V, max. 2 A. Relay: Not activated

Terminal 12: Supply to digital inputs 24 V DC, max. 140 mA

Terminals 18-19: Digital inputs 0-24 V, R

i

= 2 kohm (max. 37 V for 10 sec.)

27-29 (min. on-time 80 millisec.)

Terminal 46: Signal for motor frequency/current Max. 24 V DC, max. 40 mA, min. 600 ohm

Terminal 50: Supply to 1 kohm potmeter 10 V DC, max. 12 mA

Terminal 53: Analogue input voltage +0-10 V DC, Ri = 10 kohm, +10 - 0 V

Terminal 60: Analogue input current 0/4-20 mA, Ri = 226 ohm, 20 - 0/4 mA

Terminals 71/72 RS 232 standard 71 RXD, 72 TXD, 20 dig. ref.

Terminal 20: Digital frame Must be used together with all terminals

except for terminals 50, 53 and 60.

Terminal 55: Analogue frame Must be used together with

terminals 50, 53 and 60

For a description of terminals and how to

program the various parameters, see chapter 4.

■

Page 44

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

44

■

How to install your VLT

Prefuses

Prefuses must be installed in the supply feeding the

frequency converter.

The correct sizes and ratings can be found in the

Technical Data section.

What cables to use

Cables for the control signals and the brake cable

must be screened in order to comply with EMC

specifications.

The maximum cable length and the maximum cable

cross section is specified under Technical Data.

Any motor cable screening is connected to the

screen termination bracket in the frequency converter

(bottom) and the motor.

If non-screened cables are used, the control inputs

can occasionally be subject to signal disturbances.

Normally such a disturbance will not affect the

frequency converter.

For the North American market

CAUTION:

It is the responsibility of the user or person installing the

drive to provide proper grounding and branch circuit

protection for incoming power and motor overload

according to National Electrical Codes (NEC) and local

codes.

The Electronic Thermal Relay (ETR) in UL listed VLT's

provides class 20 motor overload protection in

accordance with NEC in single motor applications,

when parameter 315 is set to Trip [2] and parameter

107 is set to nominal motor (nameplate) current.

■

Mechanical installation

The VLT 2000 Series is cooled by natural convection.

Therefore air must be able to pass freely under and

over the unit.

The frequency converter must be mounted on a flat

vertical surface. This will ensure that the air flow

follows the heat reduction.

To enable the frequency converter to get rid of the

cooling air, you must allow free air space both above

and below the frequency converter.

The ambient temperature must not exceed 40°C so

that the VLT frequency converter can dispose of its

power loss.

Enclosure IP 20 *)

A 100 mm

*) The unit is for panel mounting. It should be placed

so that it is easily accessible according to Pr

EN 50178

Side by side mounting

The VLT frequency converters can be installed side by

side. There is no need for any space for convection

along the side of the enclosure.

High voltage test

You can perform a 2.5 kV DC test for 1 second after

short-circuiting terminals U, V, W, L

1

, L2 and L3. Testing

is according to the unit’s chassis.

It is important to ensure that the filter capacitors have

been discharged after the test.

Extra protection

As extra protection, error voltage relays or neutral

grounding can be used. However, the installation

must comply with local health and safety standards.

A ground fault can introduce a direct current in the

discharge current.

Terminal 95 (earthscrew) intended for reinforced

earthing. Any RCD-relays used must comply with

local regulations.The relays must be suitable to

protect three-phase equipment with bridge rectifier

and short discharge on power-up.

■

■

■

■

■

Page 45

MG.20.B6.02 – VLT is a registered Danfoss trademark

45

VLT® 2000 Series

Section 1 Section 2 Section 3

Chapter 4 ■ Operating your VLT................................... Page 46

■ The display ................................................ Page 46

■ The push buttons ...................................... Page 46

■ Altering a data value (digits) ....................... Page 47

■ Altering a data value (text) ......................... Page 47

■ The light diodes ......................................... Page 48

■ Back to Display group ............................... Page 48

Back to the factory setting ........................ Page 48

■ How to lock programming function ........... Page 48

■ The different groups (modes)..................... Page 49

How to operate your VLT

■

Page 46

MG.20.B6.02 – VLT is a registered Danfoss trademark

VLT® 2000 Series

46

The display

Light in the display indicates that the frequency

converter is connected to the supply voltage.

The display has three lines:

Line A.Text written with capital letters is shown

permanently - also while you are

programming the frequency converter.

Line B.States parameters and the rotation direction

of the motor.

Line C.Indicates the parameter value and what

menu you are in.

The push buttons

There are eight keys on the frequency converter’s

control panel.

The different keys and their functions are described

overleaf.

Operating your VLT

You program and control the frequency converter via

the control panel. The control panel consists of:

− a display allowing you to interface with the

frequency converter.

− push buttons which can have one or several

functions (they are described later in this chapter).

− two light emitting diodes (LEDs):

Green light shows that power is on.

Red light indicates alarm.

How to operate your VLT

Stop

Reset

Menu

Data

–

+

Jog

Fwd.

Rev.

➤

➤

Start

■

■

■

Page 47

MG.20.B6.02 – VLT is a registered Danfoss trademark

47

VLT® 2000 Series

Section 1 Section 2 Section 3

■

The “Stop/Reset” key allows you to stop the

connected motor during operation, provided

you have not chosen to set parameter 007 to Disable.

Line A of the display will flash after you have pressed

the “Stop/Reset” key.

The “Stop/Reset” key does

not disconnect the supply

voltage and may therefore not be used as a safety

switch.

The “Stop/Reset” key can also reset the frequency

converter after trip.

To make the key work, set parameter 006 to Enable.

Press this key to start the connected motor.

This key allows you to change from Display

group (see page 48) to Menu group (see

page 48) and on to Parameter group (see page

49).

Pressing the “Menu” key will return you from Data

group (see page 49) to Parameter group (see page

49) and back to Menu group (see page 48).

Press the “Menu” key in Data group to store altered

data values.

The “Data” key allows you to change from

Parameter group (see page 49) to Data

group (see page 49) and from Menu group (see

page 48) to Display group (see page 48).

■

The “Jog” key allows you to make the motor

run at a fixed, preprogrammed speed or frequency. This frequency is set in parameter 203. Make

sure that parameter 009 is set to Enable first. The VLT

frequency converter is Jogging as long as the “Jog”

key is held down.

This key allows you to change the rotation

direction of the motor. The set ramp times

(up/down) in parameters 215 and 216 will be used

when the key is activated.

For safety reasons the key can only be activated

when the VLT frequency converter is set to local

operation (parameter 003).

To make this key work you must change the factory

setting of parameter 008 from Disable to Enable.

These keys allow you to move round in

5 different groups (modes) in order to

choose a menu, a specific parameter or a data value.

In Display group (see next

pagepage

pagepage

page) you can choose

between 10 different display indications by using the

“+” and ”−” keys.

Altering a data value (digits)

When you press the “Data” key, the digit to the right

flashes (active).The other digits can be activated one

by one by pressing the “Data” key one, two, three or

four times. You can alter the activated digit by

pressing the “+” or “−” key.

It is not possible to delete or alter the values of the

factory settings.

To alter some values, you will have to stop the

motor first by pressing the “Stop/Reset” key.

Altering a data value (text)

If the data value of the chosen parameter is a text,

you can see the chosen text in the display.

The text can be altered by pressing “Data”and then

the “+” or “−” key.

The shown text is stored when you leave Data group