Page 1

User Guide

Visual Chiller

for small units ready to be customized

Software Version 1.07

Page 2

C ontents

User Interface ...............................................................................3

Main screen, Keyboard, Status, Alarm, Login, Start, Parameters,

I/O display, I/O Config, Service, Language, About ........................ 3

Regulation set point ................................................................................ 3

Parameters ...................................................................................8

SetUp: ...........................................................................................8

Parameter: y01, y03, y07,Cid ................................................................ 8

Buzzer and relay ..........................................................................9

Parameter: BUZ, Adl, AOF ..................................................................... 9

Serial setting ................................................................................9

Parameter: Cid, Ser, bAU, COM ............................................................ 9

Password ......................................................................................9

Parameter: L01, L02, L03 ........................................................................ 9

Unit Configuration .....................................................................10

Parameter: H06, H40, HEA ...................................................................10

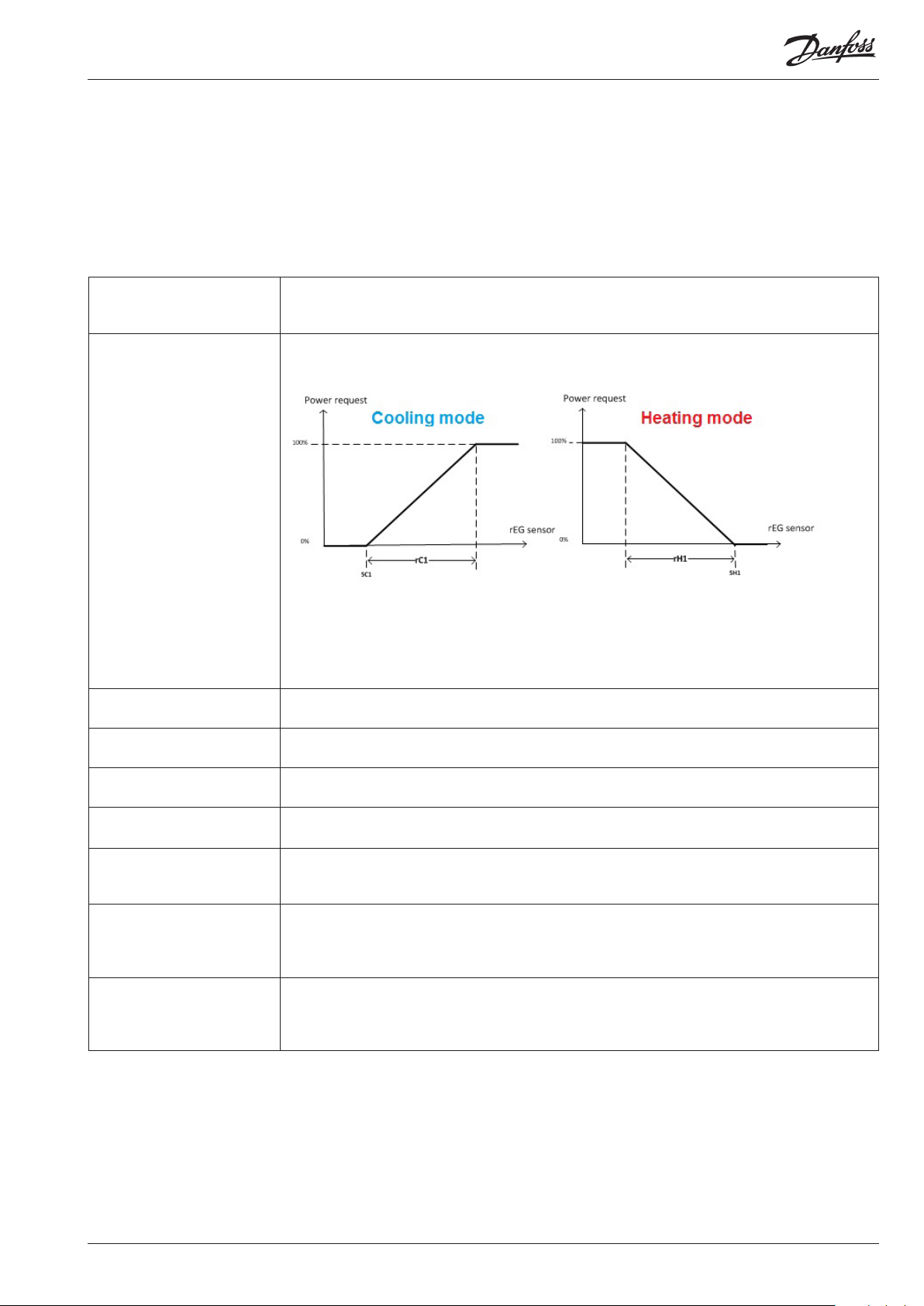

Temperature Control .................................................................11

Parameter: rEG, rET, Sc1, rC1, SH1, rH1, SdC, SdH, rin, SOE, SOO

11

Maximum number of compressor starts per hour: .................13

Parameter: CT0, CT1, CT2, CT3, CT4, CT5, CT6, CT7 ...................13

Inverter compressor ..................................................................14

Parameter: IV0, IV1, IV2, IV4, IV5 ........................................................14

Pump for the internal coil: ........................................................15

Parameter: P01, P02, AFr ......................................................................15

Valve in the liquid line ...............................................................16

Parameter: Pd1, Pd2, Pd3, Pd4............................................................16

Reversing cycle valve (4-way valve): ........................................17

Parameter: rE1 ..........................................................................................17

Compressor’s status ...............................................................................17

Defrost: .......................................................................................18

Parameter: d01, d02, d09, d10, d13, d14, d15, d16, d20, d21 18

Stepper motor valve setting for SuperHeat control: ..............19

Parameter: EEN, bAt, v10, EV0, EV1, EV2, EV3, EV4, EV5, EV6,

EV7, EV8, EV9 ........................................................................................... 19

SuperHeat control:: ...................................................................20

Parameter: SH0, N22, N10, N09, N19, N04, N20, N05, N11, N18,

N32, N17, N15, N21, o30 ...................................................................... 20

External coil ...............................................................................22

Parameter: F01, F02, FCS, FCD, FCi, FCd, FHS, FHD, FHi, FHd, .22

Stepless regulation of the fan: .................................................23

Parameter: F11, F12, F13 .....................................................................23

Heaters: ......................................................................................24

Parameter: HE1, HE2, HE3, HE4, HE5 ................................................24

ICE alarm: ...................................................................................25

Parameter: AIT, AID, AIA ........................................................................25

High pressure alarm: .................................................................26

Parameter: HPE, HPS, HPD ...................................................................26

Pressure alarms from analogue input:.....................................27

Parameter: Alr, AL1, LPC, ALE, LPS, LPD ..........................................27

Compressor high temperature alarms: ...................................28

Parameter: HT0, HT1, HT2 ....................................................................28

How to log data into SD card: ...................................................28

Parameter: SDL ........................................................................................28

Status variables: ........................................................................32

Software status: ....................................................................................... 32

Status: V01,…,V08, …, V11, …,V20, V22, V24, V26, V28, V29,V31,

V34, …, V37,…, V40,V43, V44,V53, …,V57, V59, …, V61, V65,

V67, V68, V72, V75, V81,…, V83, V85 C01,…, C04 ........................ 32

Preparatory, see

MCX Shape user guide: DKRCC.PS.RJ0.E3.02

MCXDesign manual: DKRCC.PS.RI0.Y3.02

2 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 3

User Interface

Main screen, Keyboard, Status, Alarm, Login, Start,

Parameters, I/O display, I/O Config, Service, Language,

About

The user interface has been developed for LCD displays.

Note: playing with MCXShape, it is very easy to customize

the structure and the visibility of the menu: so the following

indication cannot match with all the compiled software

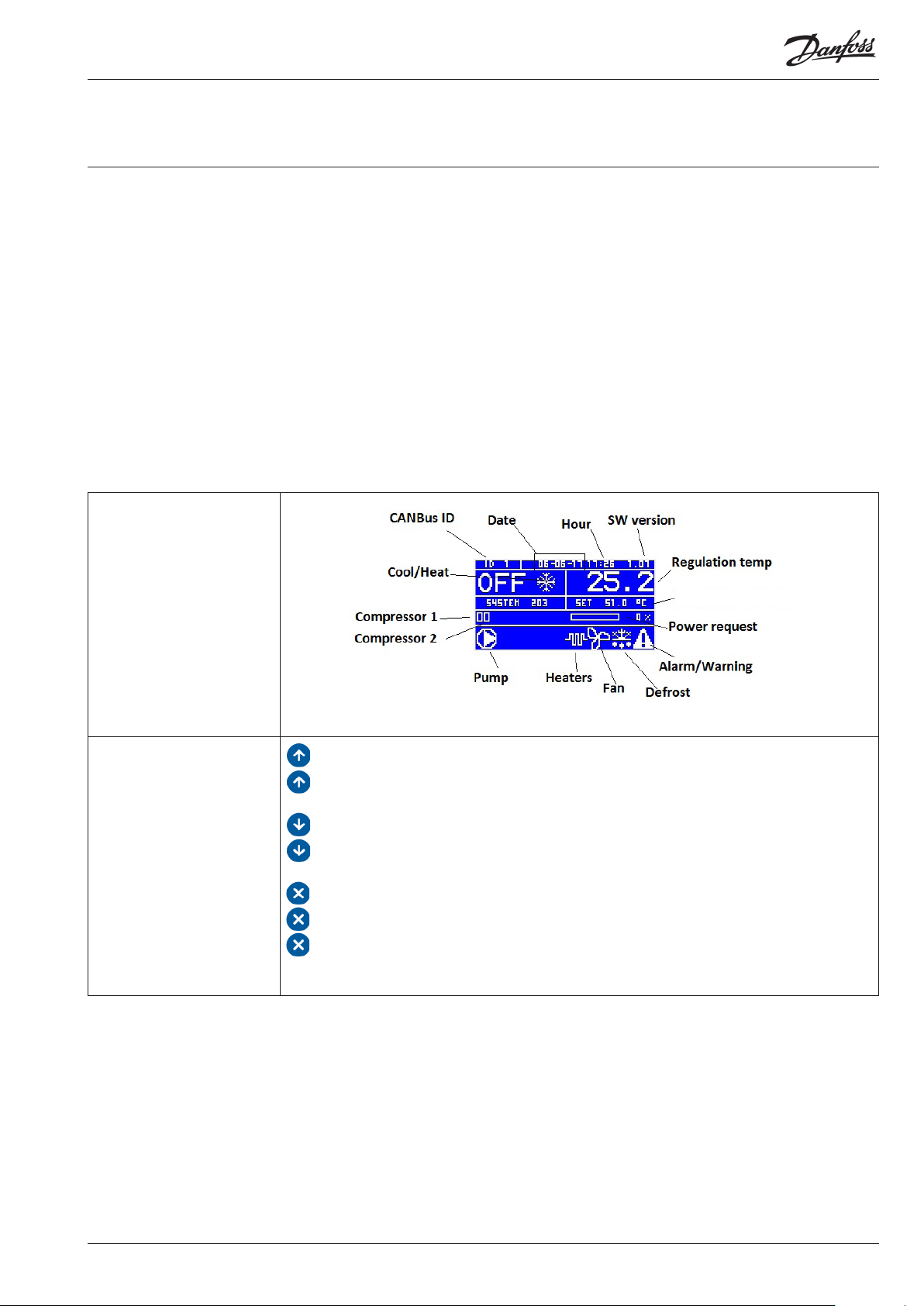

Main screen

Keyboard

Regulation set point

: Scroll UP, increase a value

: 3s when in main screen: toggle ON/OFF

: Scroll down, decrease a value

: 3s when in main screen: toggle Heat/Cool mode

: exit and save,

: when in main screen: access the active alarm list

: 3s when in Alarm screen: manual reset

The LEFT and RIGHT keys, if present, allow you to move the cursor to the desired option

Visual Chiller RS8KB102 © Danfoss 2018-06 3

Page 4

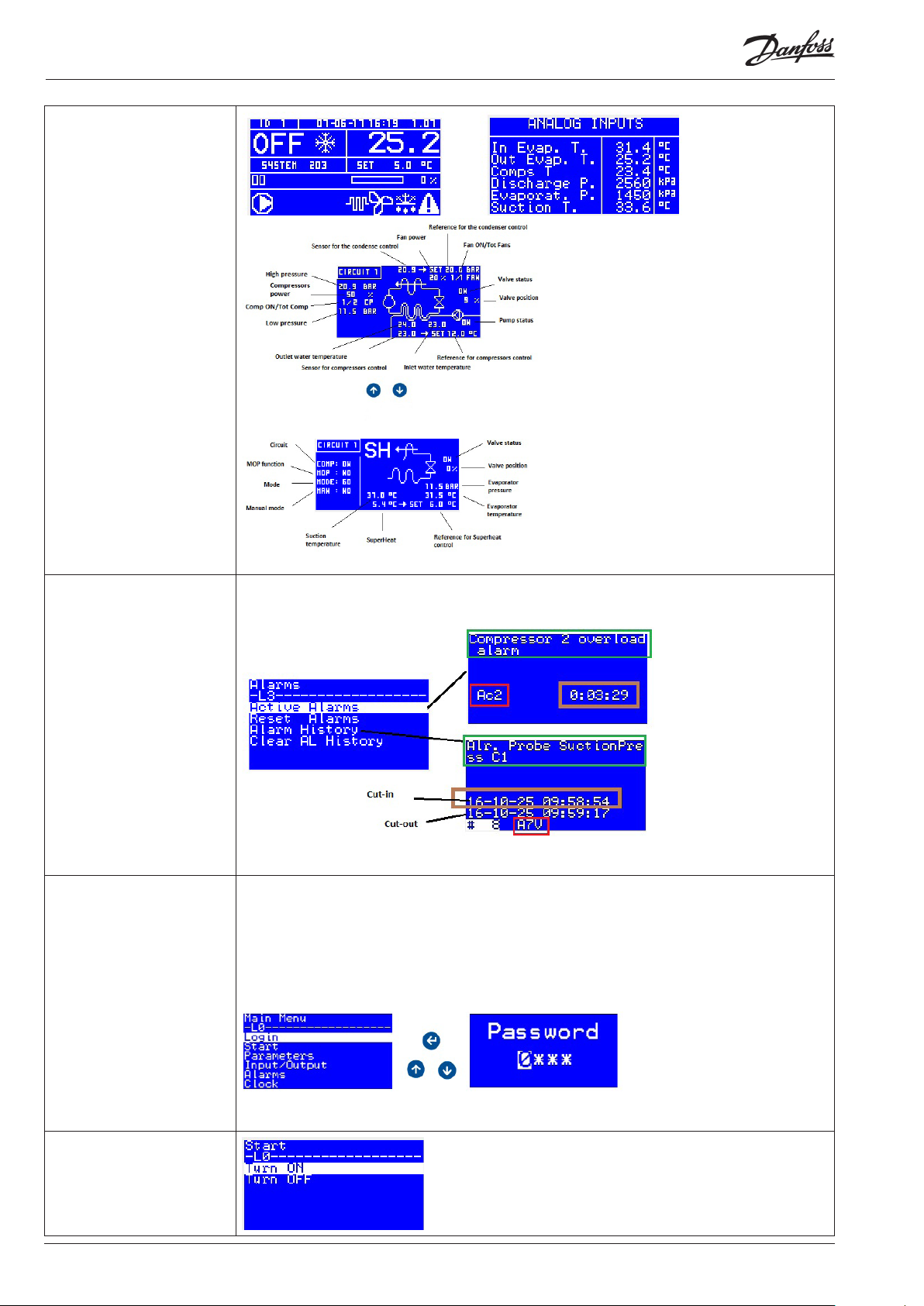

Menu Screen: Status

Menu: Alarm Each alarm is described through an alarm description (for LCD display only), an alarm code and

the time since its activation in the format hours:minutes:seconds (seconds for LCD display only).

Note: You can also access alarm visualization by pressing the ESC key from the main screen.

The alarm is only reset if the alarm has ended and it will return you to the main screen.

Note: Alarms can also be reset by pressing ESC for 3 seconds on the alarm screens

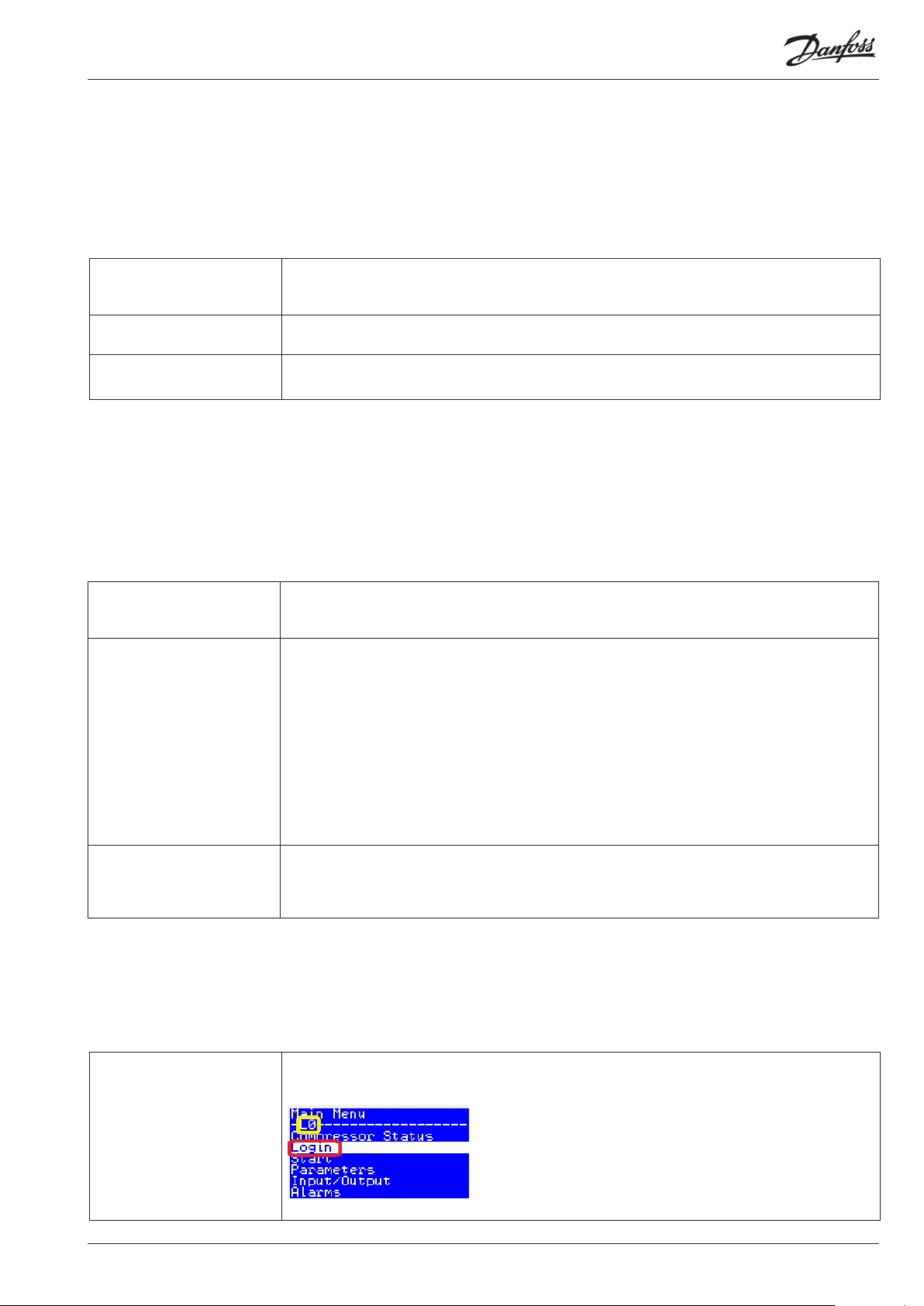

Menu: Login Parameters and Menu are organized into 4 access levels. Levels from 1 to 3 are linked to a password.

Elements cannot be accessed when they are on a higher level than the entry level. The level of each

parameter and menu is defined with MCXShape

• Level 0 is accessible without password

• Levels 1-3 are linked to a password (Check parameters L01, L02 and L03)

• Level 4 is not linked to a password, which can be used to make a menu or parameters

never accessible.

You can log in from the menu:

if the password provided is not correct you remain on the login screen. Otherwise you return to the

main menu.

Menu: Start

4 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 5

Menu: Parameter This menu contains all the parameters.

The meanings of the parameters are explained in the last part of this manual

Menu: I/O Display Display input and output values

You have access to three screens showing all the input and output values; each screen shows a group

of 8 I/Os. Use UP and DOWN keys to scroll.

The second and third screens are used with MCX15 and MCX20 only.

The example below shows the first screen.

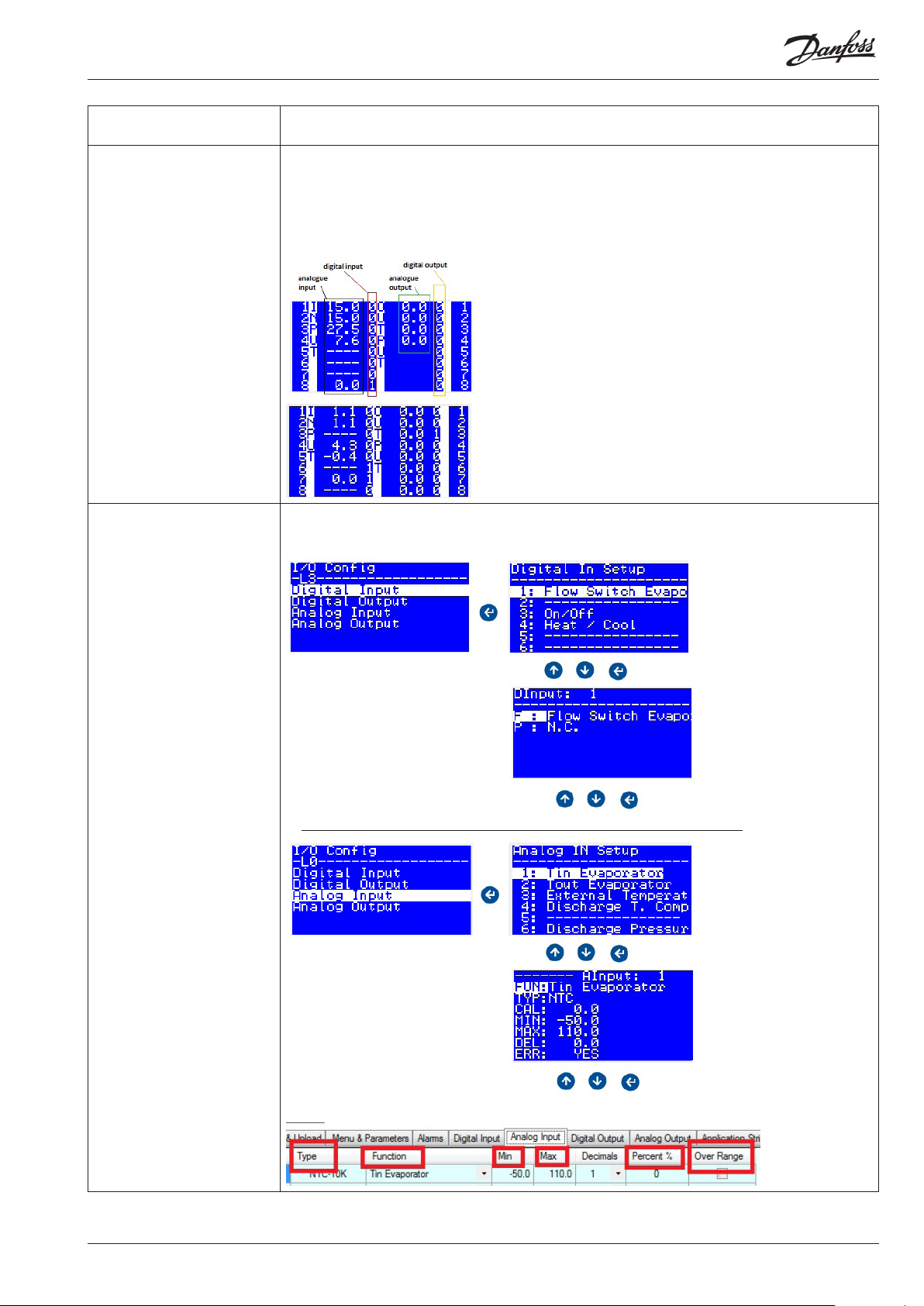

Menu: I/O Config From the menu I/0 Config it is possible to change the position of all the inputs and outputs used

in the software

Note: “CAL”is the offset to add of the reading, the other items are the ones available in the MCXShape

Visual Chiller RS8KB102 © Danfoss 2018-06 5

Page 6

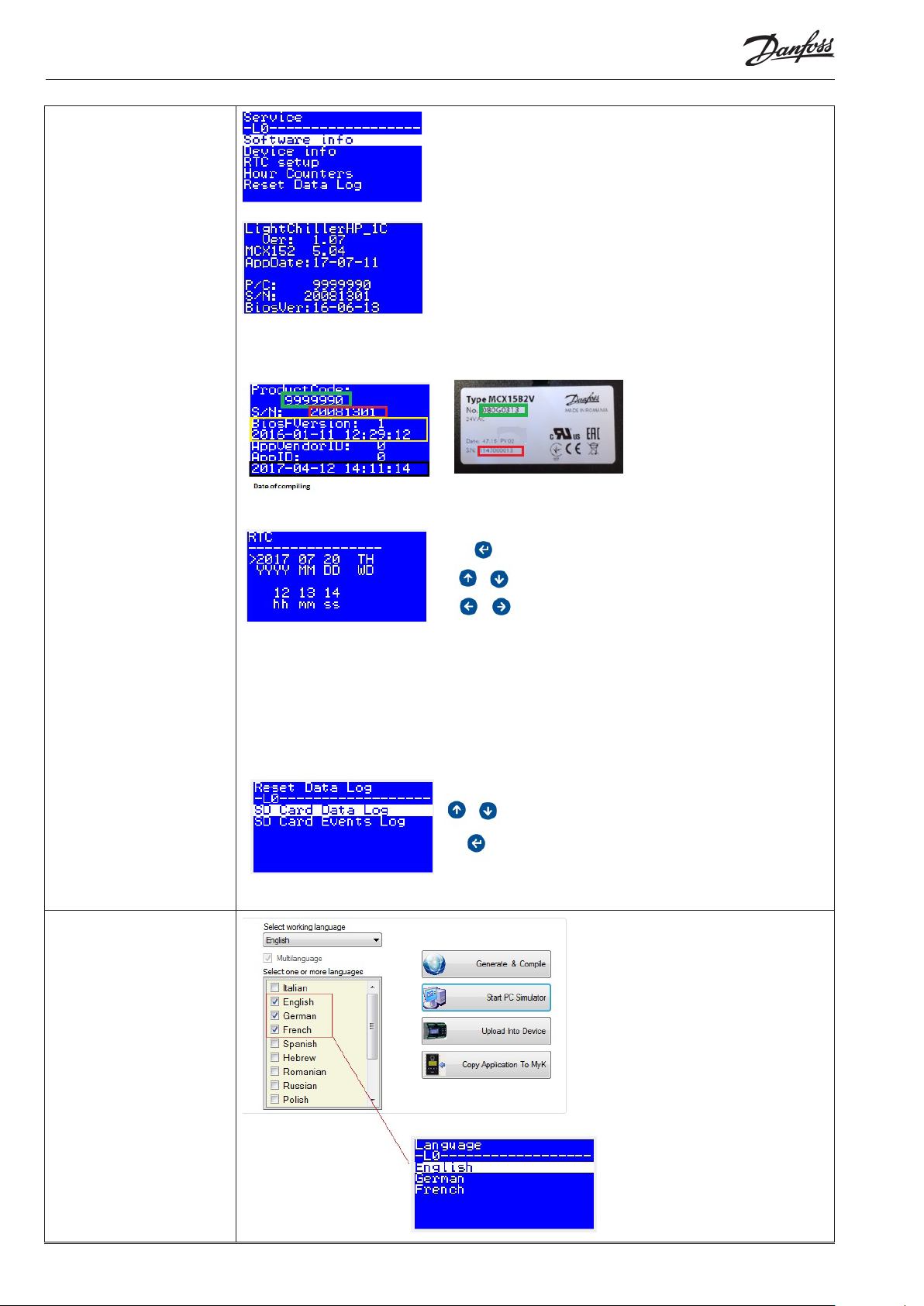

Menu: Service

Software info:

Note: This menu is shown for few seconds just after the power on

Device info:

RtC Setup:

Menu: Language

Hour Counters:

Note: Entering the “Reset Hour Counter” menu will set to zero both the compressors’ hour counters

Reset Data Log:

The Log data is available only for MCXxxxV; about how define the variable to log check parameter

SDL_ Enable SD Card Log

Note: Entering these menus will delete the Data log or the Events log in the SD card memory

6 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 7

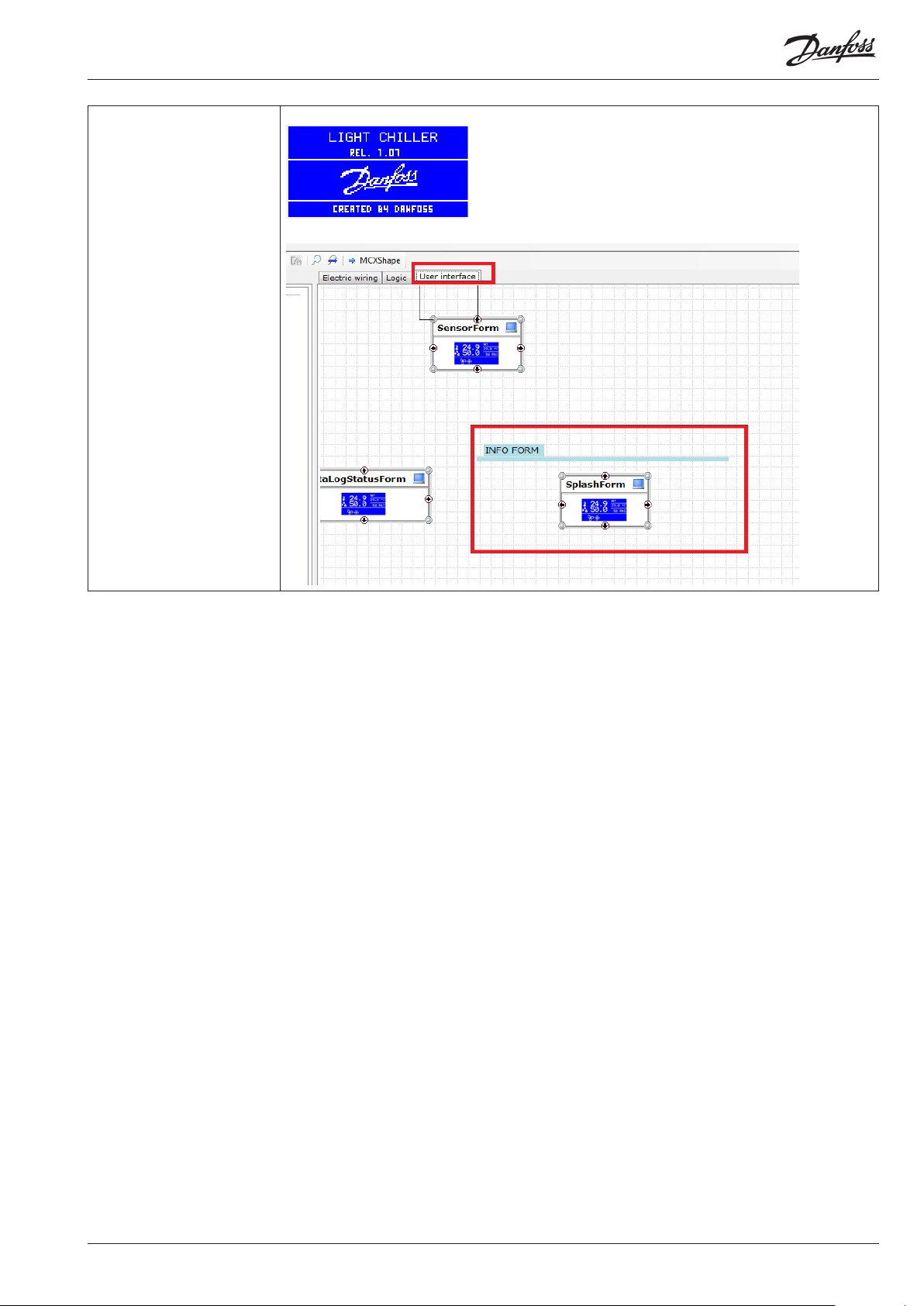

Menu: About This menu is shown for some seconds after the power is turned on

Note: it can be customized from the tab “User Interface” in MCXDesign part

Visual Chiller RS8KB102 © Danfoss 2018-06 7

Page 8

Parameters

SetUp:

Parameter: y01, y03, y07,Cid

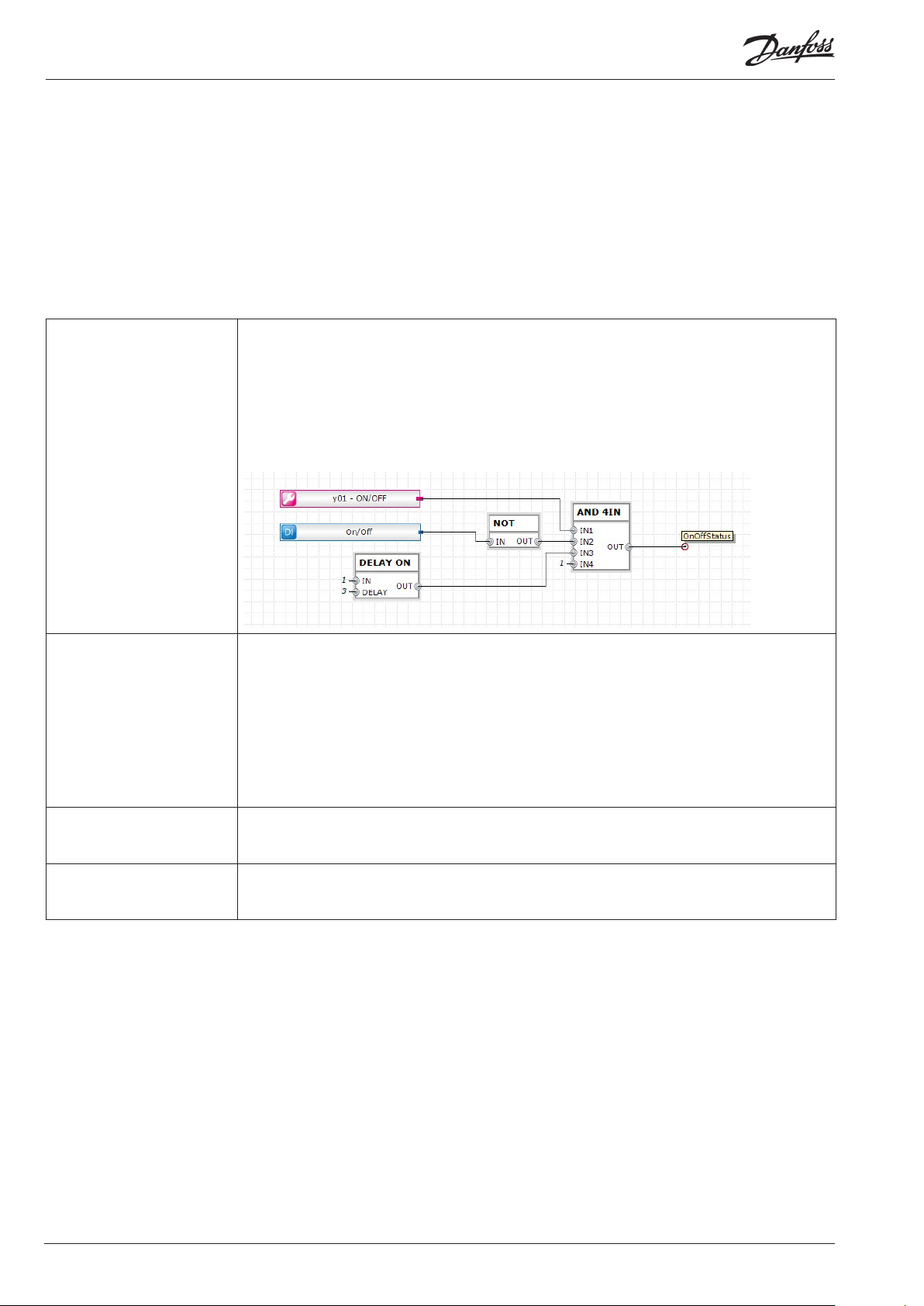

How to switch ON-OFF and change the application mode from the

parameters.

y01- System ON/OFF O=OFF

1=ON

Together with the digital input ON_On/Off the parameter y01 defines whether the machine is in the

ON or OFF state

The parameter y01 can be also changed from the menu/Start, by Modbus or CANBUS and from the

start screen by holding the up-arrow key.

Below the logic that manages the ON-OFF status, the ON status is always delayed by 3 seconds from

the power ON

y03- System heat/cool O=Cool

1=Heat

Together with the digital input DHC_Heat/Cool, the parameter y03 defines whether the machine is in

Cool or Heat mode:

The digital input DHC_Heat/Cool is without predefined meaning, each time that it’ s switched, the

parameter y03 is automatically changed.

Note: It works for H40<> 0

y07- Restore default

parameters

Cid – Serial address (CAN) It defines the ID in the CANBUS communication

0=No means no action

1=Yes means that the default parameters (the ones used in the MCXShape) are loaded

Note: after the restore parameters process, the parameter y07 will be reset to zero

Note: the baud rate and the settings of the CANBUS communication are tuned through the bios

menu or through the MYK

8 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 9

Buzzer and relay

Parameter: BUZ, Adl, AOF

How to set it up.

BUZ- Buzzer activation time

number

Adl- Alarm relay activation

delay

AOF- Alarm relay active if unit

in off

It is in minutes. It defines the maximum time that the buzzer can work;

BUZ=15 means that there is no limit to the active time of buzzer

It is in seconds. It defines the delay of the alarm relay when there is an alarm

It defines whether the alarm relay works in OFF state of the chiller

Serial setting

Parameter: Cid, Ser, bAU, COM

How to configure the communication port.

SEr – Serial address (Modbus) Defines the ID in the Modbus communication

bAU – Serial baud rate

(Modbus)

COM – Serial settings

(Modbus)

Defines the baud rate in the Modbus communication

0 means Reserved: do not use

1 means 1200 bits/sec

2 means 4200 bits/sec

3 means 4800 bits/sec

4 means 9600 bits/sec

5 means 14400 bits/sec

6 means 19200 bits/sec

5 means 28800 bits/sec

8 means 38400 bits/sec

9 means 57600 bits/sec

8 means 115200 bits/sec

Defines the serial settings of the Modbus communication

0 means 8N1

1 means 8E2

2 means 8N2

Password

Parameter: L01, L02, L03

How to change the password

L01, L02, L03-

Level x password

Visual Chiller RS8KB102 © Danfoss 2018-06 9

Typing the parameter L0x, in the login screen, you will be able to see all the parameters and menu

with level <= of X;

The level of access is highlighted in the yellow square;

Page 10

Unit Configuration

Parameter: H06, H40, HEA

General setting of the fridge circuit

Digital input: C11, C21

Digital output: C11, C21, HC1, HEA

Analogue output: CI1

H06 – Number of compressors

per circuit

H40 – Heat pump type 0=No means that the software doesn’t perform the heating mode

HEA – Enable Heater 0=No means that the heater is not used

It defines the number of compressors in the circuit;

Note: the software manages only one circuit

1=GAS means that the software performs the heating mode, the internal coil acts as evaporator in

cooling mode and condenser in heating mode

1=H2O means that the software performs the heating mode, the coils keep the same function in

both heating and cooling mode

Note: one digital output “HC1_Reverse Valve C1” is reserved for controlling the reverse flow valve

1=Heat the heater is managed by parameters HE1 end HE2

2=Defrost the heater works only during defrost and is managed by parameters HE3 end HE4

3=Both the heater works like HEA=1 and HEA=2

10 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 11

Temperature Control

Parameter: rEG, rET, Sc1, rC1, SH1, rH1, SdC, SdH, Rin, SOE, SOO

Digital input: SE2

Analogue input: Tin, TOE, SOV

rEG – Analogue input for

temperature regulation

rET – Regulation Type It defines the relation between the temperature gap and the power request to the circuits.

SC1- Cooling temperature

set point

rC1- Cooling temperature

differential.

SH1- heating temperature set

point

rH1- Heating temperature

differential.

Rin- Ti

SdC- Offset for set point in

cooling

SdH- Offset for set point in

heating

0= Tin : reference sensor is Tin_Tin Evaporator

1= TOUT : reference sensor is TOE_Tout Evaporator

0=P : Power request to the circuits increases proportionally with the regulation error, it is 100% when

the regulation error (the gap between set point and the reference sensor ) is equal to rC1 (rH1)

1=PI : the power request is the sum of P regulation (rET=0) more a component (Integral part) that

increases time by time in relation to the regulation error; the speed of the Integral part depends on

the parameter Rin.

In the PI regulation the balance is reached only when the regulation sensor gets to the set point.

It defines the set point in cooling mode

See parameter rET

It defines the set point in heating mode

See parameter rET

It is the integral time of the PI regulation, the bigger the value of Rin slower is the action of the Integral

part.

See parameter rET

In economy status and cooling mode the regulation set point is shift of SdC.

Note: the digital input SE2_Second set point defines if use comfort set point (SC1 or SH1) or the

economy set point (SC1+SdC or SH1-SdH);

In economy status and heating mode the regulation set point is shift of SdH.

Note: the digital input SE2_Second set point defines whether the comfort set point (SC1 or SH1)

or the economy set point (SC1+SdC or SH1-SdH) is used;

Visual Chiller RS8KB102 © Danfoss 2018-06 11

Page 12

SOE- Set point override enable 0=NO means that the function is not enabled

1=Yes means that the regulation set point is defined through the analogue input SOV_Setpoint

Override

set point = main set point + offset from analogue input (SOV_Setpoint Override)

Note: the analogue input SOV has to be mA or Volt type (4-20mA or 0-10V or etc.) and the range

has to be 0-1000

This is because inside the logic we compare AI_SOV within a range of 0-1000

SOO- Set point override offset It is in °C

Check parameter SOE

12 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 13

Maximum number of compressor starts per hour:

Parameter: CT0, CT1, CT2, CT3, CT4, CT5, CT6, CT7

How to set it up

Digital output: C11, C21

CT0- Minimum time between

2 ON

CT1- Minimum time between

2 OFF

CT2- Minimum OFF time It’s in seconds

CT3- Minimum ON time It’s in seconds

CT4- Minimum time between

2 ONs for same compressor

CTA- Automatic rotation It defines the start order of the compressors

CT5- Max difference in

running hours

CT6- Delay from evaporator

pump/fan

It’s in seconds

It defines the minimum time in between the switch-on of different compressors

It’s in seconds

It defines the minimum time in between the switch-off of different compressors

It does not work for the inverter compressor (IV0=1)

It defines the minimum time that the compressor has to stay switched - OFF

It does not work for the inverter compressor (IV0=1)

It defines the minimum time that the compressor has to stay switched – ON

It’s in seconds

It defines the minimum time in between two starts of the same compressor:

It means that if the compressor started at the 8:00:00, it will be allowed to start again after 8:00:00

past CT2 sec

Note: it’s used for define the maximum number of starts/hour of the compressor

0=No: LIFO means that there is not rotation and the last compressor cut in is the first compressor

cut out, the cut in order is C1,C2…Cn, the cut out order is Cn…C2, C1

2=Yes: tIME means running hours control; the compressor to start is the one with the lowest number

of run hours; the compressor to stop is the one with the highest number of run hours.

It’s in minutes

It works only for “time” rotation (C01=tIME).

If a compressor that is running becomes older than a compressor switched off by more than CT5

minutes, the logic will switch off the oldest compressor running; It will cause the other compressor

to be switched on.

The compressors’ timing (CT0,…CT4) is respected

It’s in seconds

It defines the minimum delay from the evaporator’s pump before allowing the compressors to be

switched on.

Visual Chiller RS8KB102 © Danfoss 2018-06 13

Page 14

Inverter compressor

Parameter: IV0, IV1, IV2, IV4, IV5

The inverter compressor will be switched on first and switched

off last.

The inverter compressor will provide a large range of power.

Below shows the inverter behaviour singly or combined with

another ON-OFF compressors

Digital input: C11

Digital output: C11

Analogue output: CI1

IV0- Inverter enable It enables control of the inverter compressor in the compressor C1

0=No

1=Yes

IV1- Minimum speed It’s in %

It defines the minimum speed of the inverter compressor

IV2- Maximum speed It’s in %

It defines the maximum speed of the inverter compressor

IV4- Minimum ON time It’s in seconds

It works only for inverter compressor (IV0=1)

It defines the minimum time that the compressor has to stay switched - ON

IV5- Minimum OFF time It’s in seconds

It works only for inverter compressor (IV0=1)

It defines the minimum time that the compressor has to stay switched – OFF

14 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 15

Pump for the internal coil:

Parameter: P01, P02, AFr

The pump EP1_Evaporator pump 1 is switched on when the

chiller is switched on (check parameter y01) or for ice alarm

(check parameter AIA).

The pump EP2_Evaporator pump 2 can be used as backup pump.

Digital output: EP1, EP2

Digital input: P1E, P2E

Alarms: AP1, AP2, A06

Warning: AP3

PO1- Number of evaporator

pumps

PO2- Pump OFF delay from

comp OFF

AFr- Flow switch alarm

reset type

1 means that there is only the pump P1E (back-up pump is not managed)

2 means that in case of alarm of pump P1E the pump P2E is switched-on

It’s in seconds.

It defines the minimum time that the pump has to work after compressor is cut off.

Note: It works after the switch OFF of the machine only if the compressor was running

It ‘s used in the alarm tab in order to set the reset type from the UI

Visual Chiller RS8KB102 © Danfoss 2018-06 15

Page 16

Valve in the liquid line

Parameter: Pd1, Pd2, Pd3, Pd4

Pump down before the circuit’s stop and equalization of

the pressure before circuit’s startup

Digital output: LV1

Digital input: LP1

Analogue input: EP1

Pd1-Pump down enable and

max time

It’s in seconds

0=Disable

>0 defines the maximum pump down time.

The liquid valve LV1 is closed before switching off the last compressor in the circuit.

The compressor will switch off for the following reasons:

• Low pressure switch LP1

• Suction pressure EP1 goes below Pd4 (SPx< Pd4)

• Pd1 seconds have elapsed from LVx closing

• The digital input PDx is closed (manual pump down)

Note: Pump down is not executed in case of alarm

Note: if the sensor SPx is not present it is not considered

Pd4- Pump down pressure set It’s in bar G

If the pressure of the circuit (SPx) goes below Pd4 during the pump down process the compressor is

switched off

Pd2- Compressor ON delay

from liquid valve

Pd3- Start up suction pressure

set

It’s in seconds

Before starting the first compressor in the circuit, the liquid valve is opened in order to decrease the

pressure ratio of the circuit.

The compressor will start for:

• The suction pressure goes above Pd3

• At the maximum after Pd2 seconds from liquid line valve opening

It’s in barG

See parameter Pd2

16 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 17

Reversing cycle valve (4-way valve):

Parameter: rE1

The working mode of the chiller is defined by parameter y03.

The reversing cycle valve will switch with rE1 seconds delay

from the cut off of the last compressor running

Digital input: DHC

Digital output: HC1

rE1- Change over delay It’s in seconds

rE1=0 means that the compressors are not switched off for switching the 4-way valve

rE1<>0 means that the change of the working mode is performed in 3 steps:

• Switch off all the compressors running

• After rE1 seconds the 4-way valve is switched

• After rE1 seconds the compressors are enabled to work

Compressor’s

status

Visual Chiller RS8KB102 © Danfoss 2018-06 17

Page 18

Defrost:

Parameter: d01, d02, d09, d10, d13, d14, d15, d16, d20, d21

The circuit suction pressure detects the condition to start the

defrost ;

Note: dripping is not performed

Digital output: HC1

Analogue input: dP1, EP1, EXT

d01- Defrost enable 0=NO: disable

1=Yes: means that the defrost is enabled

d02- Defrost type 0=SpEp: means that the defrost is detected and stopped in relation to the pressure sensors

1=SpEt: means that the defrost is detected in relation to the pressure sensor and the defrost is

stopped only after d15 seconds (Defrost maximum time)

d09- Defrost start set point It’s in barG

If the the suction pressure stays below d09 for more than d13 seconds, defrost is detected

d10- Defrost stop set point It’s in barG

If the discharge pressure goes above d10 defrost is completed

Note: it works for d02=0

d13- Defrost temp start

verifying time

d14- Defrost minimum time It’s in sec

d15- Defrost maximum time It’s in minutes

d16- Minimum time 2 defrost

same circuit

d21- Start verifying time It’s in seconds

d22- Start set point It’s in bar

It’s in seconds

Check parameters d09

Counting is stopped but it is not reset when temperature goes beyond that limit d09. Counter is

reset at power ON or when the defrost cycle starts.

The defrost can be switched off only after d14 seconds.

It represents the defrost’s maximum duration, beyond which defrost is stopped and the A13 warning

occurs. This warning is reset after a correct defrost cycle.

Note: If d02=1, parameter d15 defines the defrost duration.

It’s in minutes

It defines the minimum time in between 2 defrost

It’s used to force the start of the defrost

If the pressure stays d21 seconds below d22 the defrost can start

It’s used to force the start of the defrost

If the pressure stays d21 seconds below d22 the defrost can start

18 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 19

Stepper motor valve setting for SuperHeat control:

Parameter: EEN, bAt, v10, EV0, EV1, EV2, EV3, EV4, EV5, EV6, EV7, EV8, EV9

Internal valve driver (for MCX152V or MCX061V) for the Superheat

control is available.

Note: the superheat algorithm is the same as the EXD external

driver.

Analogue output: ST1, ST2

Alarm: E10, E11

EEN-Electronic Expansion

Valve

v10-Valve 1 type 0=ETS 25

bAt- Enable battery check 0=No

EV0- Valve steps Number of steps from 0% to 100% open

EV1- Valve Nominal Speed Spindle stroke speed (number of steps per second)

EV2- Valve Min Speed It’s in step/sec

EV3- Valve Max Speed It’s in step/sec

EV4- Valve Run Current It’s in mA

EV5- Valve Acceleration

Current

EV6- Valve Hold Current It’s in mA

EV7- Valve Acceleration Rate It’s in Step/sec2

EV8- Valve Decay type 0= Fast

EV9- Valve Stepping type 0=Full Step

0= No means that the MCX stepper motor driver is disabled

1= Yes means that the MCX stepper motor driver is enabled to control the Superheat

It only works for MCX152V or MCX061V

1= ETS 50

2= ETS 100

3= ETS 250

4= ETS 400

5=Custom

6=UKV

It defines the type of valve that will be used.

Only if v10 =5, the valve’s drive setting is by the parameters EV0,…., EV9

1= Yes: if the voltage of the battery goes below 12 V, the alarm E11 EXV battery Fault is generated

Note: Max. steps (100 to 5000 step)

Note: it only works for v10=5

Note: Steps/sec (10 to 500 step/sec)

Note: it only works for v10=5

Note: it only works for v10=5

Note: it only works for v10=5

Note: it only works for v10=5

It’s in mA

Note: it only works for v10=5

Note: it only works for v10=5

Note: it only works for v10=5

Note: we suggest around 5000 steps/sec2

1=Slow

2=Mixed

Note: it only works for v10=5

1=Half Step

2=1/4

3=1/8

4=1/16

Note: it only works for v10=5

Visual Chiller RS8KB102 © Danfoss 2018-06 19

Page 20

SuperHeat control::

Parameter: SH0, N22, N10, N09, N19, N04, N20, N05, N11, N18, N32, N17, N15, N21, o30

Internal valve driver (for MCX152V or MCX061V) for the Superheat

control is available.

Note: the superheat algorithm is the same of EXD external driver.

Analogue input: ET1, ST1

Analogue output: ST1

SH0- Superheat offset It’s in °C

It is an offset that will be added to the Superheat reference (that is calculated in between N09

and N10)

Note: we’ve left it as parameters but please consider also replacing it with a piece of logic in the event

you want to compensate the superheat in special condition

N22- Min superheat ref per

load under 10%

N10- Min superheat reference Warning! Due to the risk of liquid flow, the setting should not be lower than approx. 2-4K.

N09- Max superheat reference

N19- Damping of

amplification factor N04

N04- P Amplification factor Kp The regulation becomes slower if the Kp value is reduced.

N05-Integration time Tn The regulation becomes slower if the tn (N05) value is increased.

N20- Amplification factor for

the SH

N11- MOP point in press

(barG)

20 RS8KB102 © Danfoss 2018-06 Visual Chiller

The value must be smaller than ”N10”

This setting damps the normal amplification Kp (N04), but only just around the reference value.

A setting of 0.5 will reduce the Kp (N04) value by half.

The value should only be changed by specially trained staff.

This setting determines the valve’s opening degree as a function of the change in evaporating

pressure. An increase of the evaporating pressure will result in a reduced opening degree. When

there is a drop-out on the low-pressure thermostat during start-up the value must be raised a bit.

If there is fluctuation during start-up the value must be reduced a little.

The value should only be changed by specially trained staff.

It’s in barG

Page 21

N18- Stability factor for

superheat control

N32- Max valve opening

degree

N17- Signal safety during

start-up

N15- Start-up time for safety

signal

N21- Definition of superheat

control mode

o30 – Gas type 0=---

With a higher value the control function will allow a greater fluctuation of the superheat before the

reference is changed. The value should only be changed by specially trained staff.

The valve’s opening degree can be limited. The value is set in %

The control function uses the value as start value for the valve’s opening degree at each thermostat

cut-in. The controller continuously calculates a new value using adaptive control.

The value should only be changed by specially trained staff.

If the controller does not obtain a reliable signal within this period of time it will try to establish a

stable signal in other ways. (A too high value may result in a flooded evaporator).

The value should only be changed by specially trained staff.

0: The superheat reference is N10

1: Lowest permissible superheat (MSS). Adaptive regulation.

2: Load-defined superheat. The reference is established based on the line formed by the three points:

N09, N10 and N22.

1=R12

2=R22

3=R134a

4=R502

5=R717

6=R13

7=R131b1

8=R23

9=R500

10=R503

11=R114

12=R142b

13=-14=R32

15=R227

16=R401a

17=R507

18=R402a

19=R404a

20= R407c

21= R407a

22= R407b

23= R410a

24= R170

25= R290

26=R600

27= R600a

28= R744

29= R1270

30=R417a

31=R422a

Note: the gas definition is used when the translation of the pressure in temperature is required;

ReG=SPT1 and for the “internal” super heat control

Visual Chiller RS8KB102 © Danfoss 2018-06 21

Page 22

External coil

Parameter: F01, F02, FCS, FCD, FCi, FCd, FHS, FHD, FHi, FHd,

Digital output: IC1

Digital input: FC1

Analogue input: dP1, EP1

Analogue output: FC1

Alarms: AF1, E03, E04

F01- Codensation regulation

type

F02- Regulation type It works for F01=3

FCS- Cooling set point It’s in barG

FCD- Cooling differential It’s in barG

FCI- Cooling integral time It’s in seconds

FCd- Cooling derivate time It’s in seconds

FHS- Heating set point It’s in barG

FHD- Heating differential It’s in barG

FHI- Heating integral time It’s in seconds

FHd- Heating derivate time It’s in seconds

0=OFF means that the fans will not controlled

1= ON means that the fans are always ON. They are switched OFF only when the unit is OFF;

this setting doesn’t work for the analogue output

2=ON_C means that if the circuit is operating, the relevant fans are switched on.

The fans will be switched off F03 seconds after the cut off of the last compressor in the circuit.

3=Prb means that the fans are controlled in relation to the pressure inside the external coil:

Note: check parameters H42 ,ex2 and F10

It defines the type of logic used to manage the fan

0=P means proportional logic

0=PI means proportional logic more an integral part

0=PID means proportional logic more an integral part and more a derivative part

Note: the PID components are defined by the parameters FCi, FCd, FCD, FHi, FHd, FHD,

It’s the set point used for the PID control of the fan, in chiller mode.

Note: it works for F01=Prb

It’s the proportional band of the fan’s PID control, in chiller mode.

Note: it works for F01=Prb

It’s the integral part of the fan’s PID control, in chiller mode.

Note: it works for F01=Prb

It’s the derivate part of the fan’s PID control, in chiller mode.

Note: it works for F01=Prb

It’s the set point used for the PID control of the fan, in heat pump mode.

Note: it works for F01=Prb

It’s the proportional band of the fan’s PID control, in heat pump mode.

Note: it works for F01=Prb

It’s the integral part of the fan’s PID control, in heat pump mode.

Note: it works for F01=Prb

It’s the derivate part of the fan’s PID control, in heat pump mode.

Note: it works for F01=Prb

22 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 23

Stepless regulation of the fan:

Parameter: F11, F12, F13

Digital output: IC1

Digital input: FC1

Analogue input: dP1, EP1

Analogue output: FC1

Alarms: AF1, E03, E04

F11- Minimum speed It’s in %

It defines the minimum speed of the fan InverterFanCondx (external coil)

Note: check picture above

F12- Maximum speed It’s in %

It defines the maximum speed of the fan InverterFanCondx (external coil)

Note: check picture above

F13- Starting speed It’s in %

The fan is switched ON when the regulation request goes above F13 %;

in the same time it also defines the starting speed of the fan

Visual Chiller RS8KB102 © Danfoss 2018-06 23

Page 24

Heaters:

Parameter: HE1, HE2, HE3, HE4, HE5

The heaters work:

• For regulation (HEA=1 or 3, HE1,HE2)

• For defrost (HEA=2 or 3, HE3,HE4)

• If the unit is switched on

• If the regulation temperature is not in alarm

MCXDesign location:

Digital output: HEA

Analogue input: TIN or TOE

HE1- Heater set point in

heating

HE2- Heater differential in

heating

HE3- Heater set point in

defrost

HE4- Heater differential in

defrost

It’s in °C.

It’s used for parameter HEA=1 or 3.

In heating mode, the heater HEA is switched on when the regulation temperature

(defined by parameter rEG) goes below HE1-HE2

The heater HEA is switched off above HE1

It’s in °C.

Check parameter HE1

It’s in °C.

It’s used for parameter HEA=2 or 3.

In defrost mode, the heater HEA is switched on when the regulation temperature

(defined by parameter rEG) goes below HE3-HE4

The heater HEA is switched off above HE3

It’s in °C.

Check parameter HE3

HE5- Compressor off with

heater in heating

24 RS8KB102 © Danfoss 2018-06 Visual Chiller

0=NO

1=Yes means that when heater is switched on the compressor is switched off

Page 25

ICE alarm:

Parameter: AIT, AID, AIA

Analogue input: TOE

Alarms: A06

AIT- Ice alarm Threshold It’s in °C

If the TOE_ Tout Evaporator temperature goes below AIT °C the alarm A06 is detected.

It the TOE_ Tout Evaporator temperature goes above AIT+AID °C the alarm A06 can be reset

(check the tuning of the alarm in the “Alarm” tab)

Note: The alarm is delayed 4 seconds from the power-on

Note: the alarm is always detected when the chiller is switched off, when the chiller is switched on

the alarm start will be detected after the pump is switched on

Note: check parameter AIA

AID- Differential It’s in °C

Check parameter AIT

AIA- Ice alarm Action With

Unit Off

0=NO : When the ice alarm and machine are in the OFF state the circulation pump is not switched ON

1=PON: When the ice alarm and machine are in the OFF state the circulation pump is switched ON

Visual Chiller RS8KB102 © Danfoss 2018-06 25

Page 26

High pressure alarm:

Parameter: HPE, HPS, HPD

Digital input: HP1

Analogue input: dP1

Alarms: HP1

HPE- Enable HP alarm from

sensor

HPS- High pressure alarm set

point

HPD- High pressure alarm

differential

0=NO: HP1 alarm depends only from the digital input HP1_High Pressure Circuit1

1=Yes: HP1 alarm is triggered by the digital input HP1 or when the analogue input dP1 goes above

HPS bar (check also HPD)

It’s in bar

It’s in bar

If the high pressure dP1 goes below HPS-HPD bar the alarm HP1 is resettable

26 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 27

Pressure alarms from analogue input:

Parameter: Alr, AL1, LPC, ALE, LPS, LPD

Digital input: LP1

Analogue input: EP1

Alarms: LP1.

Alr- Reset type It ‘s used in the alarm tab in order to set the reset type from the UI

AL1- Delay from compressor

starting

LPC- Enable when compressor

OFF

ALE- Enable LP alarm from

Sensor

LPS- Low pressure alarm set

point

ALd Low pressure alarm

hysteresisLPD- Low pressure

alarm differential

It's in sec

It ‘s used in the alarm tab in order to set the start-up delay from the UI

0=NO means that low pressure alarm is triggered when at least one compressor is switched ON

1=YES means that low pressure alarm is always triggered

0=NO: LP1 alarm depends only from the digital input LP1_High Pressure Circuit1

1=Yes: LP1 alarm is triggered by the digital input HP1 or when the analogue input LP1 goes below

LPS bar (check also LPD)

It’s in bar

It’s in bar

If the low pressure EP1 goes above LPS+LPD bar the alarm LP1 is resettable

Visual Chiller RS8KB102 © Danfoss 2018-06 27

Page 28

Compressor high temperature alarms:

Parameter: HT0, HT1, HT2

Analogue input: DT1, DT2

Alarms: HT1, HT2, E08, E09

Note: the trip alarms of the compressors are generated through

the digital input C11 and C21

HT0- Enable high temperature

alarms

HT1- High temperature

Set point

HT2- High temperature Diff It’s in °C

0= No: the alarms HT1 and HT2 are disabled

1=Yes: when the discharge temperature of the compressor DTx goes above HT1 °C the alarm HTx

is generated

It’s in °C

Note: check parameter HT0

when the discharge temperature of the compressor DTx goes below HT1-HT2 °C the alarm HTx

can be resettable

How to log data into SD card:

Parameter: SDL

It is available only for SD-card-compatible MCXs (MCX152V and

MCX061V).

1-It is possible to start/stop data logging through the parameter

EDL_Enable SD Card Log. If you want to restart the data logger

from zero, it is enough deleting the file into the SD card memory.

The parameter EDL is read just after the power ON, so the

changes of it will have effect only after the power-off of the unit

2-It’ s possible to define the variables to store with the inputs “IN

1-32” of the brick SDCardLog32

28 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 29

3-The “number of records” for the “Sample time (seconds)”

will define the period covered from the log data

4-For alarms reset of the data log check the menu service

5-The files saved on the SD card can be read through a WEB

connection or using a batch file; however, the file saved on

the internal memory can be read only through WEB.

6- To read the files on the SD card using a decode program,

download the “DecodeLog” folder available on the MCX site

and save it to the C disk.

7- Extract the memory card from the MCX and copy and paste the

files to the SD card in the “DecodeLog/Disck1” folder.

8-

From the “DecodeLog” folder, run the batch file “decodeSDCardLog

it will generate the .csv files with encoded data

”;

Visual Chiller RS8KB102 © Danfoss 2018-06 29

Page 30

9- Events are recorded in the events.csv file. There are six columns:

a. Event time: the time of the event (start alm, stop alm,

parameters change and RTC change)

b. EventNodeID: the ID of the MCX

c. EventType: a numerical description of the event type

i. -2: Reset of MCX history alarm

ii. -3: RTC set

iii. -4: Start alarm

iv. -5: Stop alarm

v. 1000: Parameters change (note: the change can be

detected only when it is made through a user interface)

d. Var1: a numerical description of the variable. To decrypt it, open

the “AGFDefine.c” file in the “App” folder of the MCXDesign

software. In this file there are two sections with an ID indication:

one is for the parameters and the other is for the alarm. If the

event type is 1000, refer to the index parameters list; if the

event type is -4 or -5, refer to the index alarms list. These lists

contain the variable names corresponding to each ID (not to

the variable description – for the variable description, refer to

MCXShape).

30 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 31

f. Var2: used to record the parameter value before and after

the change. This number is a double integer; in the high part

there is the new parameter value and in the low part there is

the old value.

g. Var3: not used

10- Recorded in the hisdata.csv file are all the variables defined in

MCXDesign in relation to the sample time in the order defined

in the brick.

11- The log of the data can be read directly form the MCXWEB

(Check MCXWeb guide)

EDL- Enable SD card log 0=NO means that the log is stopped

1=YES means that the log is started

Note: If you want to restart the data logger from zero, you only have to delate the file in the SD card

memory

Note: The parameter EDL is read just after the power ON, so the changes of it will have effect only

after the power-off of the unit

Visual Chiller RS8KB102 © Danfoss 2018-06 31

Page 32

Status variables:

The following variables are available through Modbus,

they are the state of the software.

The variables which can work as command are set as

R/W variable

Software status: Status: V01,…,V08, …, V11, …,V20, V22, V24, V26, V28, V29,V31, V34, …, V37,…, V40,V43, V44,V53, …,V57, V59, …, V61, V65, V67, V68, V72, V75, V81,…, V83, V85 C01,…, C04

V01- SystemOnOFF (R)(R) 0: means that the application is switched-OFF

1: means that the application is switched-ON

V02- ActiveDefrostIndex (R)(R) 0: means that defrosting is not needed

1: means that there is request for defrosting or the defrosting is running

V03- ChillerHeatPumpMode(R)(R) 0: means that the heat pump is performing cooling

1: means that the heat pump is performing heating

V04- Enable

CompressorFromInvValve(R)(R)

V05- TinEvaporatorValue (R) It is in °C (*10)

V06

TinEvaporator

Error(R)

V07- Regulation TemperatureValue (R) It is in °C (*10)

V08- Regulation

TemperatureError(R)

V09- Sensor

AlmStatus

(R)

V10- Active

WarningStatus (R)

V11- Active

AlarmStatus (R)

V12- Evaporator

PumpStatus (R)

V13- Current

SetpointValue (R)

V14- Current

DifValue (R)

V15- Enable

Regulation (R)

0: means that the compressors are disabled cause the inversion of the fridge cycle

1: means normal operation

It is the value of the analogue input TIN_Tin Evaporator

0: means no sensor fault

1: means sensor fault

It is the value of the analogue input used for the regulation

Note: Check parameter rEG

0: means no sensor fault

1: means sensor fault

0: means no alarms from DI_General Alarm or DI_External Alarm

1: means that there is an alarm from DI_General Alarm or DI_External Alarm

0: means no warning is active

1: means that there is a warning active

0: means no alarm is active

1: means that there is an alarm active

0: means that the pump is switched off

1: means that the pump is switched on

It is in °C (*10)

It is the value of the set point used for the regulation

It is in °C (*10)

It is the value of the proportional band used for the regulation

0: means that the compressors cannot work

1: means that compressor can work

Note:

Status V15 depends on the variables “SystemOnOff, EvaporatorPumpStart,

EnableCompressorFromInValve and EvapAlarmStopAllOutput”

32 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 33

V16- DemandValue (R) It is in ‰

It is the power request for the compressors

V17- Compressor

Status (R)

V18- LiquidValve StatusC1 (R) 0: DO_LV1 is Closed

V19- Compressor

1C1Status (R)

V20- Working secCompr1C1(R) It is in seconds

V21- Valve PositionValueC1(R) It is in ‰

V22- EventLog

StatusCode (R)

V23- SDCardDatalog

StatusCode (R)

V24- ExternalCoil

C1Demand (R)

V25- ExtCoil

Status (R)

V26- SuctionTemperatureC1Value (R) It is in °C (*10)

V27- SuctionTemperatureC1Error(R) 0: means no sensor fault

V28- TOutEvaporatorValue (R) It is in °C (*10)

V29- TOutEvaporatorError(R) 0: means no sensor fault

V30- Discarge

PressureC1Value (R)

V31- Discarge

PressureC1Error (R)

V32- Evaporating

PressureC1Value (R)

V33- Evaporating PressureC1Error (R) 0: means no sensor fault

V34- Defrost StatusValue (R)

0: means no compressors are working

1: means that at least one compressor is working

1: DO_LV1 is Opened

0: DO_C11 is Switched off

1: DO_C11 is Switched on

It’s the amount of seconds that the compressor 1 (digital output C11) is been kept switched-on

It’s the requested position of the expansion valve for the Superheat control

Note: it can be different from V42 because of the valve physical movement

It is in ‰

It is the power request for the fan (AO_FC1)

0: DO_IC1 is switched off

1: DO_ IC1 is switched on

It is the value of the AI_ ST1

1: means sensor fault

It is the value of the AI_ TOE

1: means sensor fault

It is in bar (*10)

It is the value of the AI_dP1

0: means no sensor fault

1: means sensor fault

It is in bar (*10)

It is the value of the AI_EP1

1: means sensor fault

V35- MainLoop TimeValue (R) It is in mSeconds

It is the loop time of the software

V36- EvapAlarmStopAllOutput(R) 0: means normal operation

1: means that all the pumps available are in alarm or there is a flow alarm (DI_FSE)

V37- Condenser

SetpointValue (R)

V38- Condenser

SensorValue (R)

V39- SuperHeat ValueC1 (R) It is in °C (*10)

V40- SuperHeat ReferenceC1 (R) It is in °C (*10)

V41- MOP

StatusC1 (R)

V42- ActualValve

PositionEXV1(R)

V43- Cooling serious alarm status (R) 0: means normal operation

Visual Chiller RS8KB102 © Danfoss 2018-06 33

It is in bar (*10)

It is the value of the set point used for the regulation of the external coil

It is in bar (*10)

It is the value of the sensor used for the regulation of the external coil

It is the value of the sensor Superheat

It is the reference of the Superheat

0: means normal operation

1: means that the superheat control is following the MOP

It is in ‰

It’s the position of the expansion valve for the Superheat control

Check also status V26

1: means that the alarm A06_Evaporator ice alarm is active

Page 34

V44- Force Evaporatore pump on (R) 0: means normal operation

1: means that the pump is forced ON cause A06 alarm

Check also parameter AIA

V45- Working secCompr2C1(R) It is in seconds

It’s the amount of seconds that the compressor 2 (digital output C21) is been kept switchedon

V46- Compressor 2C1 status (R) 0: DO_C21 is Switched off

1: DO_C21 is Switched on

V47- Inverter status (R) 0: Inverter compressor DO_C11 is switched off

1: Inverter compressor DO_C11 is switched on

Check also parameters IV0- IV5

V48- Inverter Demand value (R) It is in ‰

It’s the power request for the inverter compressor (analogue output FC1)

Check also parameters IV0- IV5

V49- UI Actual power C1 (R) It is in ‰

It’s the total power request for the compressors

V50- Stage ON C1 (R) 0: No compressors switched on

1: One compressor is switched on

2: Two compressors are switched on

V51- Condensing TemperatureC1

value (R)

V52- Condensing TemperatureC1

error (R)

V53- Evaporating TemperatureC1

value (R)

V54- Evaporating TemperatureC1

error (R)

V55- Discharge Temperature Compr1

value (R)

V56- Discharge Temperature Compr1

error (R)

V57- Discharge Temperature Compr2

value (R)

V58- Discharge Temperature Compr2

error (R)

V59- Forced From heaters

Compr OFF (R)

V60- Heater status (R) 0: DO_HEA is Switched off

V61- External Temperature value (R) It is in °C (*10)

V62- External Temperature error (R) 0: means normal operation

V63- Set point Override value (R) It is in ‰

V64- Set point Overide error (R) 0: means normal operation

V65- Alarm Condenser Fan status (R) 0: DO_IC1 is Switched off

C01- Reset Alarms (R/W) 0: means normal operation, after the writing of 1 or 2 the software will reset zero

It is in °C (*10)

It’s the calculated temperature from the reading of the analogue input dp1_Discharge Pres-

sure C1

0: means normal operation

1: means the fault of the analogue input dp1_Discharge Pressure C1

It is in °C (*10)

It’s the calculated temperature from the reading of the analogue input EP1_Evaporating Pres-

sure C1

0: means normal operation

1: means the fault of the analogue input EP1_Evaporating Pressure C1

It is in °C (*10)

It’s the temperature of the analogue input DT1_Discharge T. Compr. 1

0: means normal operation

1: means the fault of the analogue input DT1_Discharge T. Compr. 1

It is in °C (*10)

It’s the temperature of the analogue input DT2_Discharge T. Compr. 2

0: means normal operation

1: means the fault of the analogue input DT2_Discharge T. Compr. 2

0: means normal operation

1: means that the compressors are not allowed to work because of the heater

1: DO_HEA is Switched on

It’s the temperature of the analogue input EXT_External Temperature

1: means fault in the analogue input EXT_External Temperature

It’s the reading of the analogue input SOV_Set point Override

Check also parameters SdH-SOO

1: means the fault of the analogue input SOV_Set point Override

1: DO_IC1 is Switched on

1: Write 1 to reset the buzzer

2: Enter 2 to reset the active alarms

34 RS8KB102 © Danfoss 2018-06 Visual Chiller

Page 35

C02- Reset hour counters (R/W) 0: means normal operation, after entering 1 the software will reset to zero

1: Enter 1 to reset the hour counters

C03- Event Log Reset (R/W) 0: means normal operation, after entering 1 the software will reset to zero

1: Enter 1 to reset the event log in the SD card

C04- External Log Reset (R/W) 0: means normal operation, after entering 1 the software will reset to zero

1: Enter 1 to reset the data log in the SD card

Visual Chiller RS8KB102 © Danfoss 2018-06 35

Page 36

36 RS8KB102 © Danfoss 2018-06 Visual Chiller

ADAP-KOOL®

Loading...

Loading...