Page 1

Electric Heating

Vineyards

Frost Protection

Application guide

Intelligent solutions

with lasting effect

Visit devi.com

Page 2

Page 3

Index

Our quality management

system

and compliances

Along with full compliance with EU

directives and product approvals

ISO 9001 TS 16949

ISO 14001 PED

1. Application overview 4

2. System description 5

3. System design 6

3.1 Heat loss calculation 6

3.2 System output 6

3.3 Product selection 7

3.3.1 Heating cable selection 7

3.3.2 Thermostats/controllers 9

3.3.3 Accessories 11

3.4 Installation guide 12

4. Safety instruction 13

4.1 DO's 13

4.2 DON'Ts 13

Solve the challenge of vine

growers with an Electric

Heating system

Electric Heating by Danfoss is a symbiosis of long history formed by 2 brands

DEVI and Danfoss united under 1 company umbrella.

It derives from DEVI brand that was established in Copenhagen, Denmark, in

1942. As from January 1st 2003 DEVI has become a part of the Danfoss Group Denmark's largest industrial Group.

Danfoss is one of the world's leading companies within heating, cooling and air

conditioning. The Danfoss Group has more than 23.000 employees and serves

customers in more than 100 countries. The development of electric heating

systems takes place in Denmark, where the head office is situated while

heating elements (cables and mats) are manufactured by Danfoss in EU.

5. Case stories 14

6. Technical support 14

Electric Heating is an energy efficient system

using electric heating cables to protect vines

against frost damage

This design guide presents our recommendations for design and installation

of Vineyards Frost Protection system. It provides guidance for a heating cable

layout, electric data and system configurations.

Following our recommendations will ensure energy efficient,

reliable and maintenance free solution for constant wattage

heating cables with 20 year warranty.

Page 4

1. Application

overview

Every year vine growers from

different regions face a problem

of late frosts. They often happen

in April - May when buds start

blossoming.Late spring frosts are

one of the greatest challenges vine

growers are facing. Non-heated vines

can suffer considerable inflorescence

damages (up to 50%), whilst heated

vines will have dramatically

improved protection of harvest loss

or damage and reduce the losses to

approximately 13-20%.

Worldwide, the grape and wine

industry rely on three main

alternatives for frost protection: frost

fans, sprinklers, and candles.

Electric Heating solves the challenge

with energy efficient systems using

Electric Heating cables to protect

vines against frost damage.

Benefits

• An energy-efficient solution with electric

heating cables.

• Easy, fast and reliable installation.

• A customized approach to meet client’s needs,

area of vinery and number of rows.

• Proven high saving compared to the existing

methods.

• A sustainable solution for a green and clean

future through low energy consumption during

the frost period.

• Tough cable outer sheath (resistant to weather

and UV)

A green (without CO2 emissions)

and sustainable lifetime solution.

Highly economic due to low energy

consumption during the frosts

period.

• Protected against chemical

fertilizers;

• Extremely-high pulling strength

(special tractors coward the

vineyards, while knocking the

fruits);

• Accurate power design (W)

according to requested needs;

• 5 or 20 years warranty.

Heating system can provide frost

protection ONLY in spring season

when the bud grows and NOT in

wintertime!

4 Application guide · Vineyards Frost Protection · ©DEVI

Page 5

2. System description

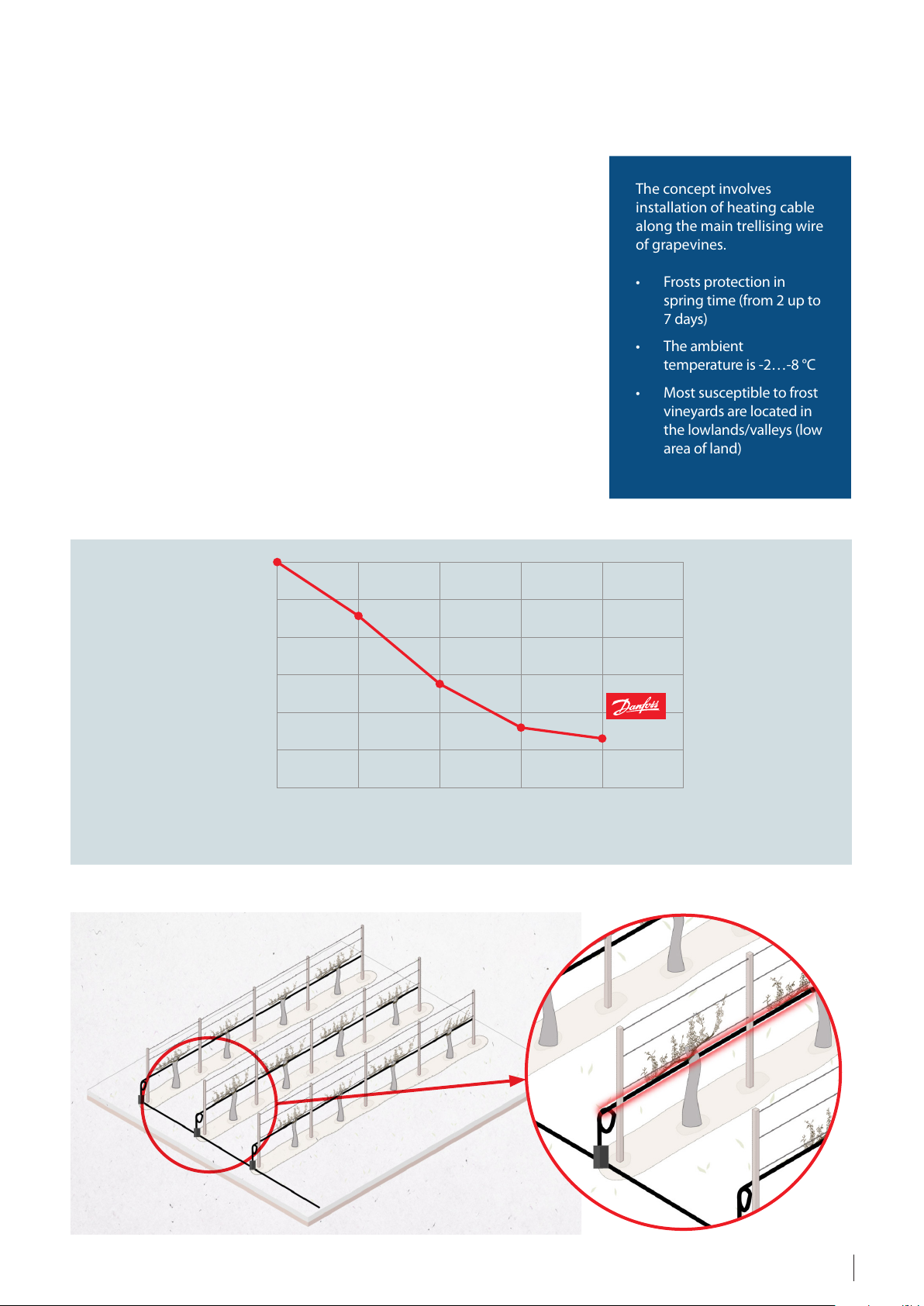

The concept involves

installation of heating cable

along the main trellising wire

of grapevines.

• Frosts protection in

spring time (from 2 up to

7 days)

• The ambient

temperature is -2…-8 °С

• Most susceptible to frost

vineyards are located in

the lowlands/valleys (low

area of land)

50%

100%

40%

30%

20%

10%

Electric Heating solves the challenge

with energy efficient systems using

Electric Heating cables to protect

A dormant bud is reasonably frost

hardy, it can survive frost down to

-3,5 °С (Pinot Noir).

vines against spring frost damage.

The heating cables by DEVI are installed and fixed on metal wire along

the grapes. The system is controlled

automatically by temperature sensors

As the bud grows the water contents

raise in the bud and it becomes more

susceptible to frost -1,1 °С can damage it (Pinot Noir).

connected to the controller.

We offer an energy-efficient solution

Non-heated vines can suffer considerable inflorescence (bud) losses.

with our electric heating cables for

frost protection of the vines.

Number of berries can decrease by 3

times or completely disappear!

Different grape varieties can withstand frosts different.

Depending on heating level, vintage losses may be decreased

. . .

46%

Common view of electric heating system for vineyards

Vintage losses, %

0%

Non heated

Slightly

heated

28%

heated

Averagely

16%

13%

heated

Efficiently

Well-heated

5Application guide · Vineyards Frost Protection · ©DEVI

Page 6

3. System design

• Tolerance of heating cable resistance: +10%...-5%;

• Cable length tolerance: +2%...-2%;

• Supply voltage: +5%...-5%.

Totally can be up to 30%

Following pages provide an easy design guide for selection of a Vineyards frost protection system.

The recommendations are provided relates to heating cables, as well as thermostats and accessories.

3.1 Heat loss calculation

Linear output of a heating cable

(W/m), which is installed for main

vine branch, should be at least the

same as heat loss (Q, W/m).

In order to calculate heat losses and

design the system, we need to know:

• Minimum ambient temperature in

spring frost period (-2…-8 °С);

• Grape sort. For different sorts

we need to maintain different

temperature (+1…+5 °С). The

temperature must be checked with

vineyard owner and specified for

the project calculation;

• Length and numbers of vineyard

rows;

• Available total load on site, kW;

• Voltage (230, 400 V).

For medium weather conditions*,

In average can be installed from 10 up

to 20 W/m for each main branch of

grapevine.

Example.

Location is France and ambient

temperature during frosts period is

-8 °С. Grape sort is Pinot Noir and we

can maintain +2 °С near the main

vine branch.

According to the data above:

q

= Δt

sys

q

t

Δt

sys

main

= t

main.-amb.

- t

main.

amb.

q

= 10 · 1 = 10 W/m

sys

– heat loss of the system, W/m.

. – maintain temperature near the

· p

main.-amb.

= +2 – (–8) = 10 °С

vines, °С.

t

– ambient temperature, °С.

amb.

p – output coefficient, W/(m · °С).

in order to increase temperature by

1 °С needs power of approx. 1 Watt.

* Medium conditions are the following: wind velocity is from 4-6 m/s. But it always depends on local weather conditions!

3.2 System output

The heat required for vineyards frost

protection depends on the following

main factors:

- Weather conditions (min.

temperature, wind speed, humidity,

altitude)

- Electrical data (voltage, power,

control requirements)

- System performance expectations

- Safety factor

With data from previous example

will calculate linear output of heating

cable:

p

= q

· 1,3

sys

sys

p

= 10 · 1,3 = 13 W/m

sys

However, in some locations the wind

is present at any time of the day. I

such cases we need to add influences

of wind velocity.

Heat transfer coefficient should

be considered according to wind

velocity.

Safety factor is very important

and depends on the following

parameters:

Average values of linier outputs depending on different wind velocity:

Wind

velocity

Linear

output*

* Note that values in the table above are calculated without influence of altitude, Nusselt and Prandtl

criterions. For more info: EH@danfoss.com

2 m/s 3 m/s 4 m/s 5 m/s 6 m/s

10,8 W/m 11,4 W/m 14 W/m 16,6 W/m 19,2 W/m

Total system output depends on numbers and length of vine rows and should

be calculated in order to choose appropriate load equipment.

P

= p

· n · L

tot

sys

P

= 13 · 10 · 100 = 13000 Watts

p

– total output of the system, W;

tot

p

– linear output of the system, W/m;

sys

tot

r

n – vine row numbers;

Lr – vine rows length, m.

6 Application guide · Vineyards Frost Protection · ©DEVI

Page 7

3.3 Product selection

This section will show how to choose the correct heating element, control device and what accessories to use for the installation.

The electric heating system product

portfolio for the Vineyards Frost

protection consists of three major

components:

• Heating element – heating cable

with constant wattage ready-made

units or drum goods;

• Controller with a temperature

sensor or a controller with both

temperature and moisture sensors;

• Fixing elements and accessories.

3.3.1 Heating cable selection

Most of cables are manufactured as

ready-made heating elements with

a specific length, with connecting

power supply cable (cold lead or cold

tail) and sealed joints (connection

muffs or end terminals).

It is also possible to choose special

drum goods which can be customized

for the specific project.

DEVI frost protection systems can be

fully automated which eliminates the

need for field personnel during frost

events.

Also, the prefabricated cold

connections in DEVI factories offer

considerable time savings in the

deployment of frost protection

systems. Connection to the electrical

cabinet is pretty easy due to DIN rail

construction.

Main rules how to choose suitable

heating cable:

• Calculate heat loss;

• Add safety factor to heat loss (usually

+ 30% or 1,3);

• Outer sheath of heating cable MUST

be UV protected;

• Check voltage supply and choose

suitable heating cable: 230 V or 400 V;

• Choose product type: ready-made

units or drum goods (usually

depends on specific row length and

linear output).

Range of the heating cables linear

output for vineyards frost protection

is usually between 10 and 20 W/m

(Watt per linear meter).

Ready-made heating cables

The heating cable offered for the

Twin conductor cable

application is constant wattage cable

with an extremely high-quality. Its

round profile and robust construction

ensures a fast, simple and safe

installation in multiple applications.

1 cold lead

Heating part

1 connection muff

Product

DEVIsafe™ 20T 20 Twin conductor 60 6,9 XLPE

DEVIsnow™ 20T 20 Twin conductor 70 7 FEP

Linear

output,

W/m

Type

Max.

permissible

use temp., °C

Cable

dimensions,

mm

Conductor

insulation

1 end muff

Outer sheath Cold lead IP class

PVC

UV protected

PVC

UV protected

One

2,3 m DTCL

One

2,3 m DTCL

IPX7

IPX7

7Application guide · Vineyards Frost Protection · ©DEVI

Page 8

Drum goods

• not ready-made cables, only

heating part;

• shielded/screened cables;

• MUST be done separate calculation

depending on cable length, linear

output, voltage, ohmic value before

offering the cables to customers;

• please use calculation tool or

contact local sales representative

or EH@danfoss.com.

Drum goods can be customized for

the specific project depending on

voltage, required output, length of

heating cable and length of cold leads.

Cable calculation formulas:

L = U / √(p · r)

r = U² / (L² · p)

p = U² / (L² · r)

where:

L – length of heating cable (m);

U – supply voltage (V);

p – linear output (W/m);

r – linear resistance (Ohm/m).

Heating part

Product

DEVIsnow™ Drum

Goods

Linear

output,

W/m

Separate

calculation

Type

Twin conductor 60 7 FEP

Max.

permissible

use temp., °C

Cable

dimensions,

mm

Conductor

insulation

Outer sheath Cold lead IP class

PVC

UV protected

No IPX7

Note: It is the full responsibility of the installer/designer to use proper cold lead dimensioned for the purpose and assembly sets that

establish sufficient mechanical strength, flammability resistance and water tightness - and to design the heating unit with correct

output for the specific application to avoid overheating of the cable or building materials.

To ensure a long life-time, all cables

are minutely inspected including tests

for Ohmic resistance, high voltage and

material controls to ensure the quality.

Possible solutions for drum goods

are already presented in the table

below. Cable lengths depend on

ambient temperature, linear output

and voltage. Always contact technical

department in order to check your

own calculations.

How to use the table below?

Based on known minimum protected

temperature, linear output of the

cable, voltage and resistance, the

actual length of the cable can be

found (and opposite):

1. Find minimum protected

temperature in the top bar of the

table (e.g. -4 °С);

2. Choose suitable linear output

of the cable based on heat loss

3. Find suitable voltage (e.g. 400 V);

4. Choose resistance value (e.g. 1,519

Ohm/m);

5. Follow the vertical and horizontal

lines, until they meet.

calculation (e.g. 9 W/m);

Minimum protected temperature

Description

DEVIsnow 9,36 ohm/m 9,36 27 46 25 44 24 41 23 39 22 38 21 36 20 35 19 34

DEVIsnow 4,19 ohm/m 4,19 40 69 37 65 36 62 34 59 32 56 31 54 30 52 29 50

DEVIsnow 2,368 ohm/m 2,368 53 92 50 87 47 82 45 78 43 75 41 72 40 69 39 67

DEVIsnow 1,519 ohm/m 1,519 66 115 62 108 59 103 56 98 54 94 52 90 50 87 48 84

DEVIsnow 1,057 ohm/m 1,057 79 138 75 130 71 123 67 117 65 112 62 108 60 104 58 100

DEVIsnow 0,735 ohm/m 0,735 95 165 89 156 85 148 81 141 77 135 74 129 72 125 69 120

DEVIsnow 0,567 ohm/m 0,567 108 188 102 177 97 168 92 160 88 153 85 147 82 142 79 137

DEVIsnow 0,451 ohm/m 0,451 121 211 114 199 108 188 103 180 99 172 95 165 92 159 88 154

DEVIsnow 0,367 ohm/m 0,367 134 233 127 220 120 209 114 199 110 191 105 183 101 176 98 170

DEVIsnow 0,257 ohm/m 0,257 160 279 151 263 143 250 137 238 131 228 126 219 121 211 117 204

DEVIsnow 0,19 ohm/m 0,19 187 324 176 306 167 290 159 277 152 265 146 255 141 245 136 237

DEVIsnow 0,146 ohm/m 0,146 213 370 201 349 190 331 181 316 174 302 167 290 161 280 155 270

DEVIsnow 0,115 ohm/m 0,115 240 417 226 393 214 373 204 356 196 341 188 327 181 315 175 305

DEVIsnow 0,092 ohm/m 0,092 268 466 253 440 240 417 229 398 219 381 210 366 203 352 196 341

DEVIsnow 0,07 ohm/m 0,07 307 535 290 504 275 478 262 456 251 436 241 419 232 404 224 390

DEVIsnow 0,055 ohm/m 0,055 347 603 327 569 310 539 296 514 283 492 272 473 262 456 253 440

Resistance

Ohm/m

4

-3°С -4°С -5°С -6°С -7°С -8°С -9°С -10°С

Cable length at

8 W/m (-3°С)

230 V 400 V 230 V 400 V 230 V 400 V 230 V 400 V 230 V 400 V 230 V 400 V 230 V 400 V 230 V 400 V

Cable length at

9 W/m (-4°С)

1

Cable length at

2

3

10 W/m (-5°С)

Cable length at

11 W/m (-6°С)

Cable length at

12 W/m (-7°С)

Cable length at

13 W/m (-8°С)

Cable length at

14 W/m (-9°С)

Cable length at

15 W/m (-10°С)

Table can be used in opposite way where, based on length, voltage and linear output, a suitable cable from the product range

can be found.

8 Application guide · Vineyards Frost Protection · ©DEVI

Page 9

3.3.2 Thermostats/controllers

Temp. sensor

Twin conductor cable 230 VTwin conductor cable 230 V

Temp. sensor

Twin conductor cable 400 VTwin conductor cable 400 V

400 V AC

Thermostats and controllers are fitted

with a complete set of control functions for frost protection systems. It is

a combination of multi functionality

and temperature control.

The product range of controls is

designed for frost protection systems

including the following:

• simple electronic thermostats;

• digital controllers.

Line of simple electronic thermostats

to be installed in electric cabinets

with DIN rail attachment. To measure

and control the desired temperature

either a wire sensor (in the set) or an

external indoor/outdoor air sensor

must be used. The thermostat must

be installed via an all-pole disconnection switch. It has a LED indicating

showing standby (green light) and

heating (red light) periods.

or

To control simple or low output (less

than 3000 Watts) systems, simple

thermostats are recommended as a

standard solution.

DEVIreg™ 330 (+5…+45 °C) and

DEVIreg™ 330 (-10…+10 °C) can be

used for such purposes.

Wire sensors should be installed

according to specific project data.

Minimum one sensor must be used

for one heated zone (could be one

vineyard row or few rows depending

on field size and location). Always

contact local sales representative

or EH@danfoss.com in order to get

technical help.

Find basic thermostat connections below.

Thermostat connection of twin conductor heating

cables (max. 3680 Watts at 230 V).

Connection

mu End mu End mu

Fuse

Connection

mu

Thermostats connections of twin conductor heating

cables (400 V) via contactor.

L1

L2

L3

N

PE

Fuse

QF2

Fuse

contactor

Connection

mu End mu End mu

Connection

mu

For more connection schemes please contact EH@danfoss.com.

9Application guide · Vineyards Frost Protection · ©DEVI

Page 10

Line of digital controllers have

+

special functions which can be

programmed for different purposes.

DEVIreg™ Multi is 7 channel

electronic programmable controller

to be installed on DIN rail.

Every channel can be individually set

up with three control modes – with

temperature sensor, time proportional power regulation without

sensor and manually on/off with time

limitation.

Main functions of it are next:

• 3 control modes:

- with temperature sensor

- time proportional regulation

- manual On/Off with time limitation

• 7 channel controller;

• DIN rail;

• Modbus interface for BMS control;

• Cable failure monitoring (alarm);

• The wide temp range.

Find basic thermostat connections below.

Thermostat connection of twin conductor heating cables (230 V).

+

…

Up to 7

or

…

Up to 7

+

For more connection schemes please contact EH@danfoss.com.

10 Application guide · Vineyards Frost Protection · ©DEVI

Page 11

The ECL Comfort 310 is an electronic

weather compensated temperature

controller. The weather compensated

heating system increases the comfort

level and saves energy.

Main functions and benefits:

• Easy installation;

• Optimized performance;

Interface example:

• Easy modifications;

• Alarm function;

• Different configurations;

• 24/7 overview of the system;

• Ability to make log of the individual

sensors;

• Remote control;

• For mounting on wall and DIN rail.

Product

DEVIreg™ 330 (-10…+10 °С) 16 Wire -10…+10 ±0,2 No IP20 DIN rail

DEVIreg™ 330 (+5…+45 °С) 16

DEVIreg™ Multi

ECL Comfort 310 4 (2 x CO and 2 x NC) Wire -50…+200 Yes On wall

Resistive load,

at 230V, Amps

10 (2 channels)

6 (5 channels)

Sensor type

Wire/Air

optional

Wire/Air

optional

Temperature

range, °С

+5…+45 ±0,2 No IP20 DIN rail

-50…+200 ±0,2…9 Yes IP40 DIN rail

Hysteresis, °С BMS IP class Installation

3.3.3 Accessories

DEVI range has all necessary accessories for fixing, measurement and

connection in order to provide full

project specification.

Cable ties Wire sensors Air sensor Plastic conduit pipe DTCL Cold leads

Plastic ties for fixing

heating cables.

End termination repair set Heating cable to cold

Wire sensors for different

temperature range.

lead repair set

In order to find all accessories please

refer to Product Catalogue or visit

www.devi.com.

Outdoor air sensor with

IP44

Heating cable to heating

cable repair set

Plastic conduit pipe for wire

sensors

Heating cable to cold lead/

heating cable repair set

Different cold leads with

different cross sections and

construction are available

for ordering

DEVIcrimp™ CS-2C

assembly kit dk 2-cond.

Note: always use only authorized accessories!

For more details please use Product Catalogue or EH@danfoss.com.

DEVIcrimp™ for

DEVIsnow™

DEVIcrimp™ ass/repair kit

2-cond. CS-2A/CS-2B

Repair kit cables 2 cond.

Concrete/støbesæt

11Application guide · Vineyards Frost Protection · ©DEVI

Page 12

3.4 Installation guide

After product selection proper

installation should be done. Always

use the following rules during the

installation process:

• Heating cable should be installed

on metal wire near the main branch

of grapevines, the closer the cable

is to the buds the more heat it will

exert on the buds;;

• One cable line for one row of

vineyard. All cables should be

connected in parallel;

1. Fix one line of the heating cable to metal wire by plastic ties.

• Heating cable can be fixed by

plastic ties;

• Distance between cable and vines

branch is maximum 0-4 cm;

• Control system should have

temperature sensors (wire sensors);

• Install sensors where the temperature

is estimated to be representative

for the whole installation, where

2 sensors are needed for the

thermostat/controller please install

at the estimated extreme points

(coldest and hottest);

• Wire sensors should be installed in

plastic conduit pipe (avoid direct

contact of sun rays) near the main

branch of grapevines;

• Alarm should be installed in order

to check all cables which can be

damaged by grape secateurs,

tractors, etc.

2. Heating cables should be connected

to thermostat/controller according to

local norms and regulations.

Contact EH@danfoss.com for

all technical information about

connections.

3. Install wire sensor in plastic conduit

pipe and place it in coldest place near

main branch of grapevines.

4. It is strongly recommended to

install alarm system in order to check

the integrity of the cables in real-time

and before the frost season

As a result you will get reliable frost

protection heating system providing

a stable harvest.

12 Application guide · Vineyards Frost Protection · ©DEVI

Page 13

4. Safety instruction

Heating cables must always be installed

according to local regulations and

wiring rules as well as the guidelines in

this installation manual.

De-energize all power circuits before

installation and service.

Residual current device (RCD)

protection is required.RCD trip rating

is max.30 mA.

The screen from each heating cable

must be connected to earthing

terminal in accordance with local

electricity regulations.

4.1 DO's

• For installation of cable and

thermostat/controller, always refer

to the local regulations/legislations

and respective manuals;

• Remember to fill out the warranty

certificate with the required

information as this will not be valid

otherwise;

• Carefully complete the installation,

the cable can break when

overloaded;

• If any doubt arises consult you

manual or local DEVI department;

• Ensure that the cable is sufficiently

fixed and mounted according to

the manual;

Heating cables must be connected

via a switch providing all pole

disconnection.

The heating cable must be equipped

with a correctly sized fuse or circuit

breaker according to local regulations.

Never exceed the maximum heat

density (W/m or W/m²) for the actual

application.

It is strongly recommended to use

the heating cable together with an

appropriate thermostat to secure

against overheating.

• Ensure that warning labels and

stickers (potentially tape) with

warning text is used to inform

about the heat traced cable;

• Install sensors where the

temperature is estimated to be

representative for the whole

installation, where 2 sensors

are needed for the thermostat/

controller please install at the

estimated extreme points (coldest

and hottest);

• To get the best performance of

the system and avoid failures it is

necessary to follow the installation

descriptions;

The presence of a heating cable

must be made evident by affixing

caution signs in the fuse box and in

the distribution board or markings

at the power connection fittings

and/or frequently along the circuit

line where clearly visible (tracing)

must be stated in any electrical

documentation following the

installation.

• To get the best performance of the

system it is strictly necessary to

calculate the correct heat losses.

Using this knowledge the cable

with right output can be chosen;

• Plan every installation step and

fixing point of the frost protection

system ahead of time and ensure

that the "run" is proper and

possible;

• Ensure sensors are connected

according to the applicable

installation guide and/or

application guide.

4.2 DON'Ts

• Never make an installation without

thermostat/controller;

• Never install cables where the heat

can't be dissipated, even with a

self-limiting cable the output will

never become zero and the cable

can overheat;

• Never let unauthorized personnel

install controllers/thermostats or

heating elements;

• Never use unauthorized

accessories;

• Never use our products (cables,

controllers, sensors, etc.) outside

provided temperature range.

13Application guide · Vineyards Frost Protection · ©DEVI

Page 14

5. Case stories

https://devi.danfoss.com/en/case-stories/?page=1

6. Technical support

The Electric Heating team is offering

valuable support to professionals

when it comes to preparing your new

projects.

We offer support for:

• Calculation of Electric Heating

system;

• Development of drawings for

projects;

• Preparation of the BoM (Bill of

Material);

• Recommendations for the

installation and operation of the

system;

• Technical trainings.

In order to clarify the project data

for different applications use the

following technical request forms, fill

in with your specifications and send it

to: EH@danfoss.com

https://devi.danfoss.com/en/support/

14 Application guide · Vineyards Frost Protection · ©DEVI

Page 15

15Application guide · Vineyards Frost Protection · ©DEVI

Page 16

08098000 & AB392433138239en-010103 | 25.11.2021

Intelligent solutions

with lasting effect

Visit devi.com

Loading...

Loading...