Page 1

Installation and Instruction

PLRCA.PI.BZO.D1.02 / 520H3015

© Danfoss Saginomiya

取 扱 説 明 書

IIII NNNN TTTT RRRR OOOO DDDD UUUU CCCC TTTT IIII OOOO NNNN

Thank you for purchasing the 4-way reversing valve type VHV.

TTTToooo eeeennnnssssuuuurrrreeee tttthhhhaaaatttt yyyyoooouuuu wwwwiiiillllllll ooooppppeeeerrrraaaatttteeee tttthhhheeee pppprrrroooodddduuuucccctttt ccccoooorrrrrrrreeeeccccttttllllyyyy,,,, rrrreeeeaaaadddd aaaallllllll iiiinnnnssssttttrrrruuuuccccttttiiiioooonnnnssss ccccaaaarrrreeeeffffuuuullllllllyyyy bbbbeeeeffffoooorrrreeee uuuusssseeee....

Keep this instructions handy for future reference.

SSSSAAAAFFFFEEEETTTTYYYY PPPPRRRREEEECCCCAAAAUUUUTTTTIIIIOOOONNNNSSSS

WWWWAAAARRRRNNNNIIIINNNNGGGG

Do not energize coil unless it is attached to the valve body.

This may result in a coil burnout (fumes or fire).

Do not use with voltage which does not match that on the coil label.

This could result in a coil burnout (fumes or fire),or malfunction.

Coil gets hot (approx.90℃)while energized.

To prevent burns,do not touch the coil cover while energized.

Do not subject coil to a shock or a heavy load.

This could deform the tube and result in an inoperative valve,a coil burnout

(fumes or fire),or fluid leakage.

Do not wrap up coil with thermal insulation. This could result in a coil burnout.

Keep inflammable things away from coil. They could catch fire by coil heat.

SSSSPPPPEEEECCCCIIIIFFFFIIIICCCCAAAATTTTIIIIOOOONNNN

Body Test Pressure 6.23MPa{62.3bar}

Max.Working Pressure 4.15MPa{41.5bar}

Min. Operating Pressure Diff. 0.3MPa{3bar}

Applicable fluids Fluorocarbon refrigerants(Contact us if other fluids are used.)

Fluid Temperature -20 ~ +120℃

Ambient Temperature -20 ~ + 55℃ Ambient Humiidity Less than 95%RH

Note:If there are contents to differ between this specification sheet and the approval drawing,

those in the approval drawing take precedence.

CCCCOOOONNNNSSSSTTTTRRRRUUUUCCCCTTTTIIIIOOOONNNN AAAANNNNDDDD FFFFEEEEAAAATTTTUUUURRRREEEESSSS

The valve is a 4-way reversing valve for heat-pump air conditioners,composed of three components:

a pilot valve,a valve body and a solenoid coil assembly.

Internal parts are resistant to fluorocarbon refrigerants.

VVVVAAAALLLLVVVVEEEE SSSSEEEELLLLEEEECCCCTTTTIIIIOOOONNNN

Selection of proper valves is important for good control.See the above specifications

concerning general specifications of the valve.

Verify compatibility of specifications to the system by referring to our catalog.If the valve is not compatible,

such as its use with liquid flow,pressure rise on high pressure side or incapability of valve changeover could occur.

IIIINNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONNNN IIIINNNNSSSSTTTTRRRRUUUUCCCCTTTTIIIIOOOONNNNSSSS

<BEFORE INSTALLATION>

Verify that the voltage on the label on the coil cover matches the source voltage.

Do not flaw connections(brazed portion).This could result in external leskage.

Clear dust and foreign material from the inside of piping.They could cause valve failure.

In case dust or foreign material could flow into the valve, install an 80 to 100 mesh strainer at the valve inlet.

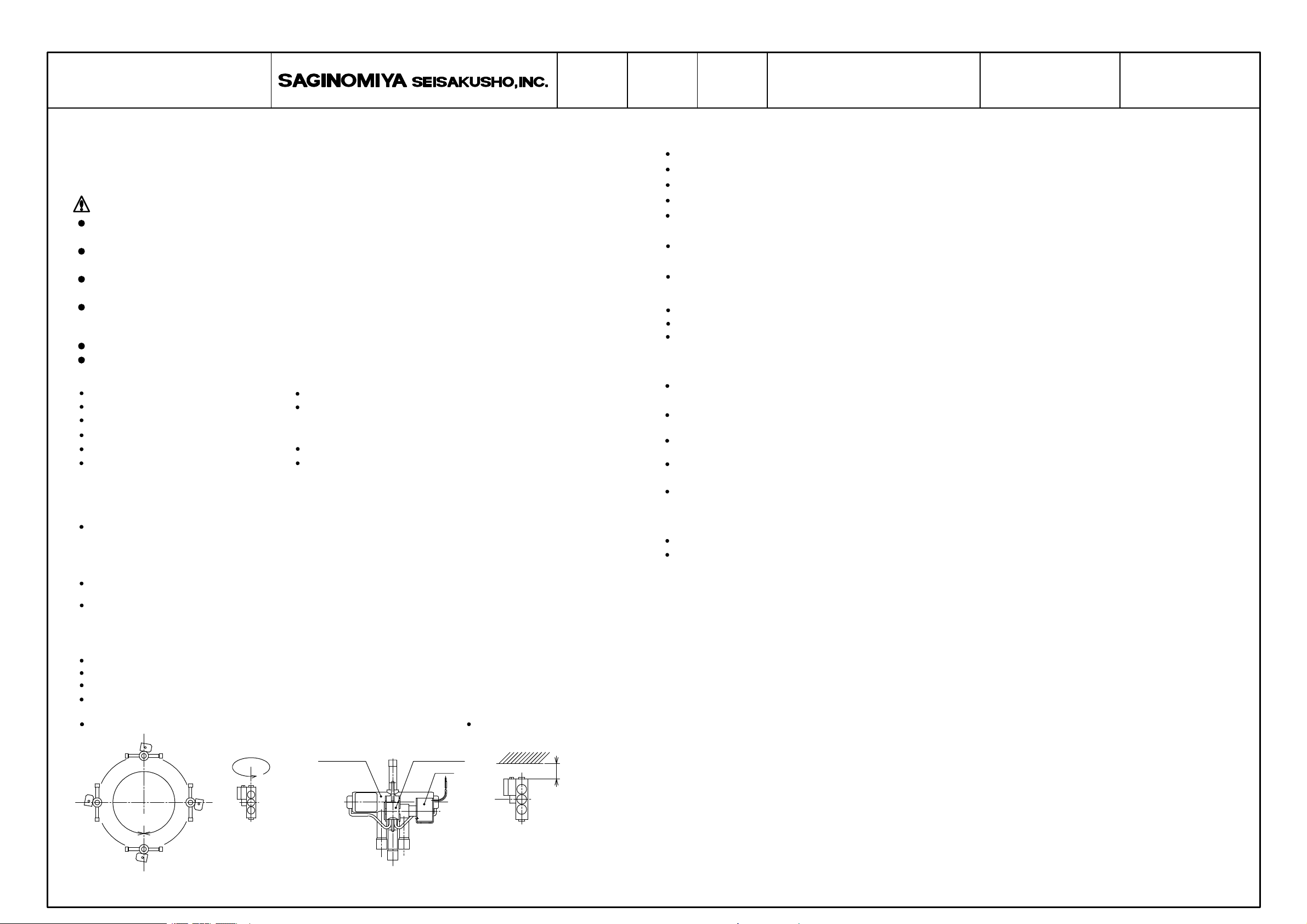

Mounting positions should be in the below range.

Airtight Test Pressure 4.15MPa{41.5bar}

Max. Operating Pressure Diff. 3.1MPa{31bar} (at Rated Voltage)

Class of Insulation Class B

Be sure to ensure space for

maintenance above coil.

Valve body Pilot valve

D

Coil

Checked by drawn by date Name Catalog Number Drawing Number

MAY.2005

4-WAY REVERSING VALVE

VHV

A-HV-01010

<INSTALLATION INSTRUCTIONS>

Do not install in locations where the valve is exposed to rain or gets water dropping from the condenser coil.

Do not press,pull or wrench the valve body.This could result in an inoperative valve.

Do not carry a coil assembly or a complete valve by the coil leads.This could damage coil and result in valve failure.

When wiring coil,make sure that wires do not get tense.

Do not let water enter the inside of piping.

(This could cause freezing and rust that may result in an inoprative valve.)

When brazing,remove coil from the valve body and wrap wet rags around the body to keep its temperature from exceeding 120℃.

(Direct flame away from the valve body)

When brazing,fill the inside of the valve with inert gas,such as nitrogen or carbon dioxide,to prevent oxide scale

formation.Foreign material like oxide scale could result in leakage from the main valve or malfunction.

Give the valve an airtight test after piping.

Be sure to fasten the valve body and piping firmly.

In case that coil is removed or its direction is changed,tighten the fixing bolt fully.If the bolt is tightened

loosely,a coil burnout or abnormal noise could result.

Recommended Torque:1.47~1.96N・m(for M4 screw) 2.45~2.94N・m(for M5 screw)

Body-mounting brackets are attached as accessories to some models.Since the brackets also eliminate vibration

of capillary tubes,do not detach them even if they are not used.

Be careful not to drop the valve derectly on a concrete floor or the like.If the valve is dropped,

check its performance before use.

Install the valve in such a manner that normal working vibration of the valve body does not exceed 19.6 m/s .

Be careful not to add a load on the brazed portion of valve connections.

Do not changeover the valve more than 1 time per 6 minutes.

<DURING OPERATION>

Be sure to shut off the power supply when coil is removed from the valve body.

Energizing only coil may result in a coil burnout.

MMMMAAAAIIIINNNNTTTTEEEENNNNAAAANNNNCCCCEEEE AAAANNNNDDDD IIIINNNNSSSSPPPPEEEECCCCTTTTIIIIOOOONNNNSSSS

Contact SAGINOMIYA SEISAKUSYO,INC.(“SAGINOMIYA”) if maintenance and inspections are required.

Be sure to shut off the power supply during maintenance and inspections.

OOOOPPPPEEEERRRRAAAATTTTIIIIOOOONNNN CCCCHHHHEEEECCCCKKKK

After proper installation,make a trial operation and confirm that the whole system fully operates.

LLLLIIIIMMMMIIIITTTT OOOONNNN AAAAPPPPPPPPLLLLIIIICCCCAAAATTTTIIIIOOOONNNN

The product is not designed and manufactured for such equipment or system that is intended to be used

under such circumstances as involve human life.For application requiring especially high reliability,

please contact SAGINOMIYA first.

LLLLIIIIMMMMIIIITTTTEEEEDDDD WWWWAAAARRRRRRRRAAAANNNNTTTTYYYY

Unless otherwise agreed by parties concerned,the warranty period shall be one (1) year from the date of delivery.

During this period,SAGINOMIYA will repair or replace the product if it has any trouble attributable to SAGINOMIYA.

This warranty does not cover damage resulting from any of the following:

1. Improper handling or application by the user

2. Modification or repair by other than SAGINOMIYA

3. Any act or event beyond the control of SAGINOMIYA including,but not limited to,war,riot,fire,storm or other acts of God.

Min.100㎜

The warranty described herein is for the product itself and does not include warranty for any consequential damage

brought about by a defect or failure of the product.

2

Available to install in any positions

with the body axis held horizontally. 360°

360゚

Available to install in any positions

with the body axis held vertically and

the solenoid coil located above the

center of the valve. 360°

Connections indicated below show at cooling

mode. (When coil is de-energized)

E

C

S

D connection : Discharge

E connection : Evaporator

S connection : Suction

C connection : Condenser

Loading...

Loading...