Page 1

Data sheet

Butterfly valves with gear box

VFY-WG, VFY-LG

Description

Features:

• Spline driven one piece shaft connected to

spherically machined disc allows high torque

transmission i.e. quick response and minimum

back-lash

• Long term reliability due to upper and lower

anti-friction bearings

• Safe maintenance: shaft blow out protection

with circlip

• Position indicator

Main Data:

• DN 50-350

• kVS 79-8520 m3/h

• PN 16

• EPDM Liner

• Stainless steel or Ductile iron Epoxy

Coated disc

• Medium:

- Circulation water, drinking water or chilled

glycolic water up to 50 %

• Medium Temperature:

−10 … 120 °C (EP disc)

−10 … 130 °C (SS disc)

• Wafer or Lug connection

• Approvals:

Ordering

Wafer type VFY-WG

XX

X

k

DN

50 79

65 174 06 5B7441

80 275 06 5B744 2

100 496 0 65B74 43

125 883 065B7444

150 1212 065B744 5

200 2500 06 5B744 6

250 3948 0 65B74 57

300 5635 0 65B74 58

350 8520 065B7449

50 79

65 174 065B 8421

80 275 065B8422

100 496 065B8423

125 883 065B8424

150 1212 065B8425

200 2500 065B8426

250 3948 065B8427

300 5635 065B8 428

350 8520 065B8429

VS

(m3/h)

PN

16 130 Stainless Steel

16 120

T

(°C)

max

Disc Code No.

06 5B744 0

065B8420

Ductile iron Epoxy

Coated

© Danfoss | 2020.11 AI176286477249en-010903 | 1

Page 2

Data sheet VFY-WG, VFY-LG

Ordering

Lug type VFY-LG

DN XX

XX XX

XX

XX

DN

(m3/h)

50 79

k

VS

PN

T

(°C)

max

Disc Code No.

06 5B746 0

65 174 06 5B7461

80 275 065B7462

100 496 0 65B74 63

125 883 0 65B74 64

150 1212 065B7465

16 130 Stainless Steel

200 2500 065B7406

250 3948 065B7407

300 5635 0 65B74 08

350 8520 065B7469

50 79

065B8430

65 174 065B 8431

80 275 065B8432

100 496 065B8433

125 883 065B8434

150 1212 065B8435

16 120

Ductile iron Epoxy

Coated

200 2500 065B8436

250 3948 065B 8437

300 5635 065B8438

350 8520 065B8439

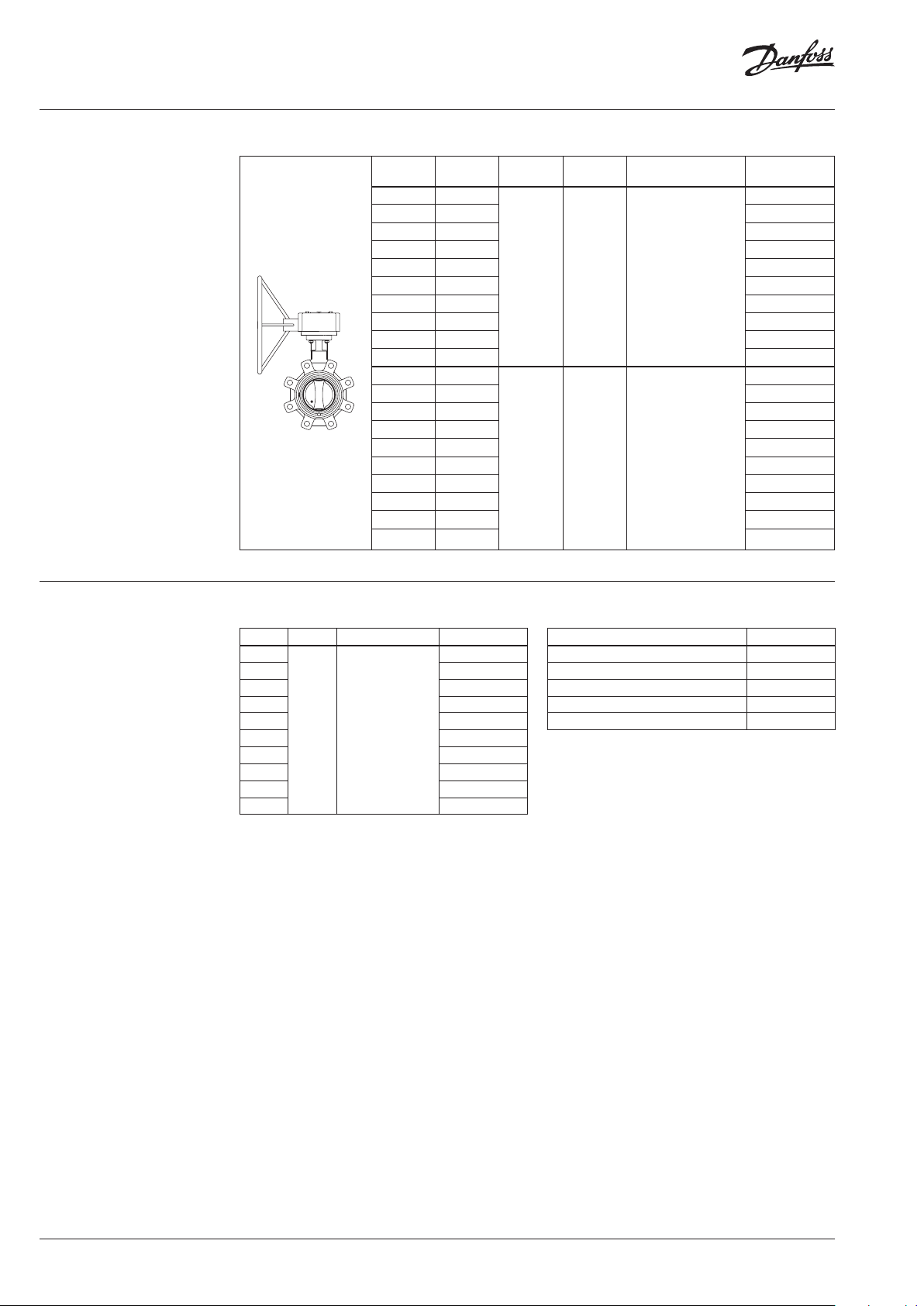

Spare parts

Replacement Liner VFY-W Liner

DN PN Liner Code No.

50

65 065B7583

80 065B7584

100 065B7585

125 065B7578

150 06 5B7579

16 EPDM

200 065B7592

250 065B7593

300 065B7594

350 06 5B7591

065B7582

Replacement gearbox VFY-G earbox

for DN Code No.

50/65/80/100 065B7595

125/150/200 065B7596

250 065B7598

300 065B7599

350 065 B7600

2 | AI176286477249en-010903 © Danfoss | 2020.11

Page 3

Data sheet VFY-WG, VFY-LG

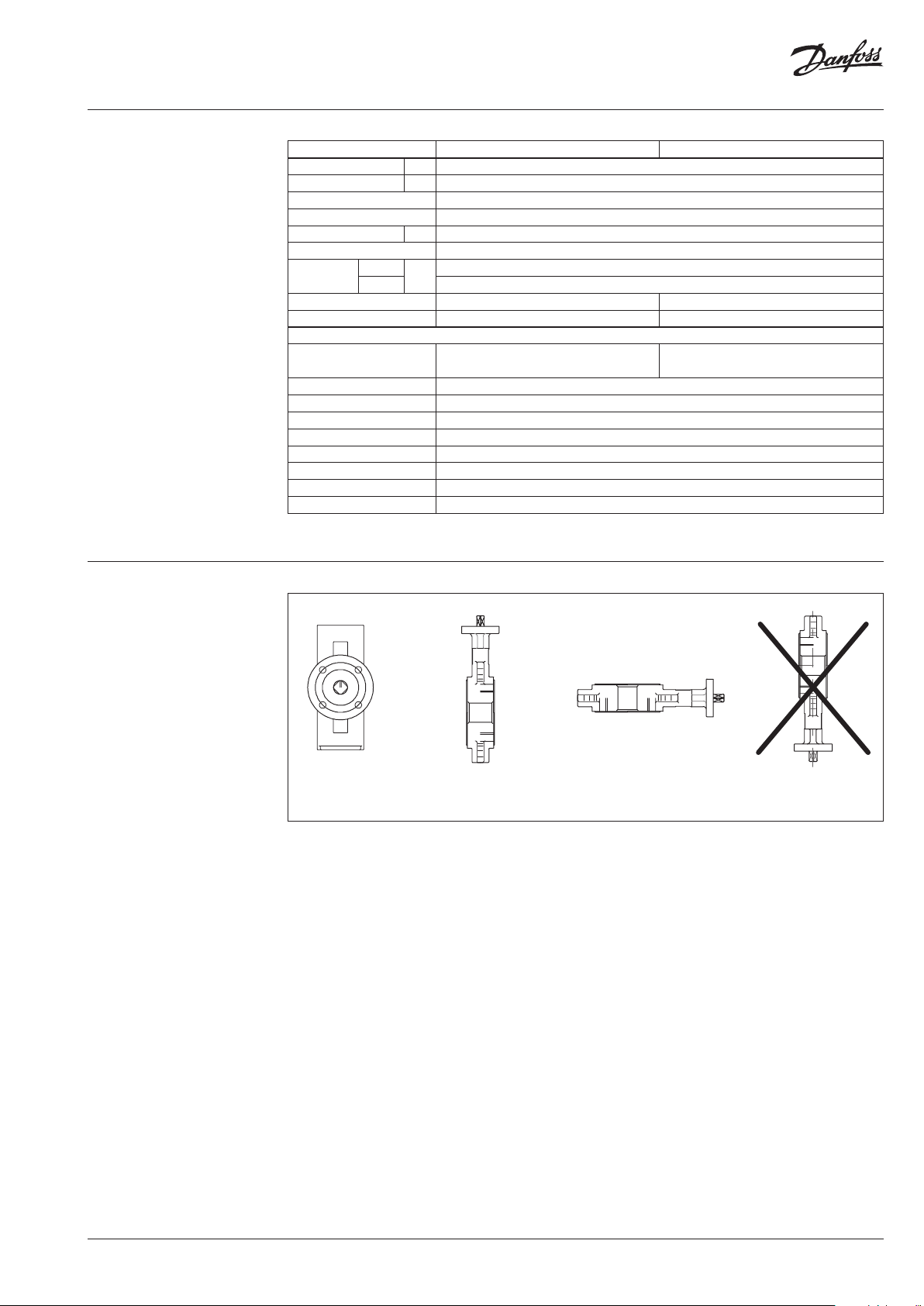

mounting between flanges

mounting deadline

Technical data

Typ e VF Y-WG VFY- LG

Nominal diameter DN 50-350

kVS value m3/h 79-8520

Rotation angle 90 °

Leakage rate Acc. to PED 2014/68/EU, EN 12266-1, Rate A

Nominal pressure PN 16

Medium Circulation water, Glycolyc water up to 50 % or drinking water

Medium

temperature

Connection Wafer (centering lugs) Lug (Tapped lugs)

Mounting

Material

Body

Disc Ductile iron EN GJS 400 -15 (DIN GGG 40) with Epox y coating or Stainless Steel

Shaft Stainless steel AISI 420

Liner EPDM

Circlip Steel XC 75 / Stainless steel

O-ring Nitrile/Viton

Upper guide bush Zinc coated S. + PTFE

Lower guide bush Zinc coated S. + PTFE

Gear box Aluminium

1)

No visible detec table leakage during the te sting procedure

EP disc

SS disc −10 ... 130 (see p-T diagram)

°

C

Cast iron EN GJL 250 (DIN GG25) DN 50 -300 Cast iron EN GJL 250 (DIN GG25) DN 50 -150

Ductile iron (DIN GGG40) DN 350 Ductile iron (DIN GGG40) DN 200-350

−10 ... 120 (see p-T diagram)

1)

Installation positions

Not recommendedPossiblePossibleRecommended

AI176286477249en-010903 | 3© Danfoss | 2020.11

Page 4

Data sheet VFY-WG, VFY-LG

1 DN

1 DN

1 DN

10

15

20

25

30

Installation conditions

It is recommended that distances indicated

below are respected in order to prolong lifetime

of the valve. Mounting the valve close to

pipework junctions (turbulent zones) increases

wear.

5-6 DN

DN

5-6 DN

DN

2-3 DN

DN

P-T diagram

2-3 DN

DN

DN

Pressure (bar)

5

0

30 50 70 90 100 110 120 130

10 -10 0

Temperature (°C)

DN

1 DN

4 | AI176286477249en-010903 © Danfoss | 2020.11

Page 5

Data sheet VFY-WG, VFY-LG

∆PP

0

2777,8

1111,1

1666,7

2222,2

1388,9

FLOW Pressure drop kPa (100 kPa = 1 bar = ~ 10m HFLOW Pressure drop kPa (100 kPa = 1 bar = ~ 10m H

2

O)O)

Headloss diagram

For water at 20 °C

2,8

5,6

8,3

11,1

16,7

22,2

27,7

41,7

55,6

69,4

83,3

111,1

138,9

166,7

222,2

277,8

417,7

555,6

694,4

833,3

10

20

30

40

60

80

100

150

200

250

300

400

500

600

800

1000

1500

2000

2500

3000

4000

5000

6000

8000

10000

2

10020 30 401072345 60 8015681,5

∆

DN

50

65

80

10

125

150

200

250

300

350

l/sec m3/h

Flow Rate

(liquid with specific a gravity of 1)

AI176286477249en-010903 | 5© Danfoss | 2020.11

Page 6

Data sheet VFY-WG, VFY-LG

Design

1. Body

2. Disc

3. Shaft

4. Liner

5. Circlip

6. O-ring

7. Upper guide bush

8. Lower guide bush

9. Gear box

9

5

6

7

3

2

4

8

1

6 | AI176286477249en-010903 © Danfoss | 2020.11

Page 7

Data sheet VFY-WG, VFY-LG

C

B

A

Ø E

A B

C

Dimensions

Ø

XX

X

D

C

Waffer type VFY-WG

Ø A B C D ØE

DN

50 54 62 225.5 120 43 125 3.6

65 70 70 234.5 120 46 12 5 4

80 85 89 240.5 120 46 125 4.3

100 100 106 264.5 120 52 12 5 6.3

125 12 5 120 279.5 120 56 125 7.4

150 150 131 292.5 120 56 12 5 8.5

200 200 166 315 120 60 12 5 12. 3

250 250 196 429 239 70 250 25.2

300 300 238 453 239 77 250 28.9

350 340 270 468 239 78 250 41.4

mm

Weight

(kg)

ØE

B

Ø

Lug type VFY-LG

Ø A B C D ØE

DN

50 54 62 225.5 120 43 125 4

65 70 70 234.5 120 46 12 5 4.5

mm

Weight

(kg)

A

D

Ø E

Lug type VFY-LG

Ø A B C D ØE

DN

DN XX

XX XX

Ø

XX

XX

80 85 89 240.5 120 46 125 5.4

100 100 103 264.5 120 52 125 7. 9

125 12 5 119 279.5 12 0 56 125 9.9

150 150 133 292. 5 120 56 12 5 11 .9

mm

D

ØEC

Weight

(kg)

Lug type VFY-LG

Ø A B C D ØE

BA

Ø

D

DN

200 200 162 315 120 60 125 17

250 250 198 429 239 68 250 30.8

300 300 227 453 239 77 250 38.3

350 340 24 8 468 239 78 250 49.7

mm

AI176286477249en-010903 | 7© Danfoss | 2020.11

Weight

(kg)

Page 8

Data sheet VFY-WG, VFY-LG

© Danfoss | DHS-SMDBT/SI | 2020.118 | AI176286477249en-010903

Loading...

Loading...