Page 1

Data sheet

Seated valve for steam (PN 25)

VFS 2 – Two way valve, flange

Description

VFS 2 valve is a range of 2 port flanged valve

for chilled water, LPHW, MPHW, HPHW (low,

medium or high pressure hot water) and steam

applications.

The valve is designed to be combined with

following actuators:

• DN 15-50 AMV(E) 25 (SU/SD), AMV(E) 35,

AMV(E) 56 (with clutch "065Z7551")

• DN 65-100 AMV(E) 55, AMV(E) 56, AMV(E) 85,

AMV(E) 86, AMV (E) 65x

Features:

• Logarithmic characteristic

• Rangeability R= >100:1 by DN 20-100

• Suitable for steam applications

Main data:

• DN 15-100

• kVS 0.4 -145 m3/h

• PN 25

• Down to close

• Medium:

Circulation water/glycolic water up to 50 % /

steam (max. p = 6 bar)

• Temperature:

1)

At temperature s from −10 °C up to +2 °C use stem heater

2 (10

1)

) … 200 °C

• Logarithmic characteristic

• Flange PN 25 connections

• Compliance with Pressure Equipment Directive

2014/6 8/EU.

Ordering

Example:

Two way valve, DN 15, kVS 1.6, PN 25,

T

200 °C, flange connection

max

- 1× VFS 2 DN 15 valve

Code No.: 0 65B1513

Two way valve VFS 2

k

DN

15

20 6.3 06 5B1520

25 10 06 5B1525

32 16 0 65B1532

40 25 06 5B1540

50 40 065B1550

65 63 065B3365

80 100 0 65B3380

100 145 065B3400

VS

(m3/h) (°C)

0.4

0.63 06 5B1 511

1.0 06 5B1512

1.6 06 5B1513

2.5 06 5B1514

4.0 06 5B1515

PN

25 200

T

max.

065 B1510

Code No.

Spare parts – stuffing box

DN Description Co de No.

15

20

25

32

40

50

65

100

Four PTFE rings

Seal for valve cover

Gland ring

Washer

Instructions

Three PFTE rings

Gland ring

Instructions

065B0001

065B000680

Accessories

Typ e Code No.

Stem heater 24 V AC/DC

(AMV(E) 25, 35 and VFS 2 valves DN 15-50)

Stem heater 24 V AC/DC

(AMV(E) 56 and VFS 2 valves DN 15-50)

Stem heater 24 V AC/DC

(AMV(E) 85, 86 and and VFS 2 valves DN

65-100)

Stem heater 24 V AC/DC

(AMV(E) 55, 56, 655, 658, 659 and VFS 2

valves DN 65-100)

Adapter AMV(E) 25 (SU/SD), AMV(E) 35

and VFS 2 DN 15-50

(for media temperatures over 150 °C)

Clutch

(AMV(E) 56 and VFS 2 valves DN 15-50)

06 5B2171

065Z7020

065Z7021

065Z7022

065Z 7548

065Z7551

© Danfoss | 2022.01 AI094186477177en-010404 | 1

Page 2

Data sheet Two way valve VFS 2

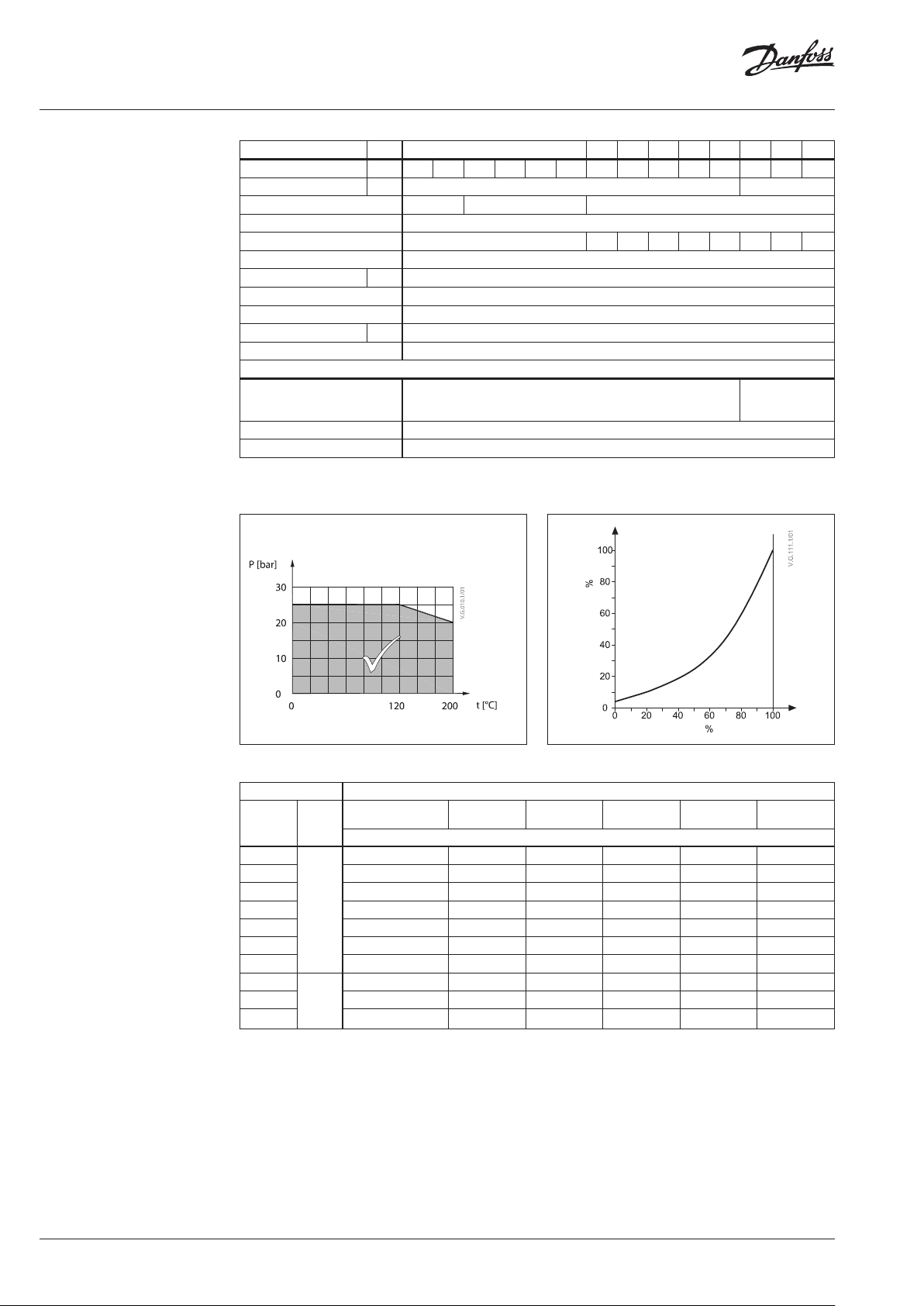

Technical data

Nominal diameter DN 15 20 25 32 40 50 65 80 100

kVS value m3/h 0.4 0.63 1.0 1.6 2.5 4.0 6.3 10 16 25 40 63 100 145

Stroke mm 15 40

Rangeability > 3 0:1 > 50:1 > 10 0:1

Control characteristic Logarithmic

Cavitation factor z 0.5 0.5 0.5 0.5 0. 5 0.5 0.4 0.3 0.3

Leakage acc. to standard IEC 534

< 0.05 % of k

VS

Nominal pressure PN 25

Medium Circulation water/glycolic water up to 50 % /steam (max. ∆p = 6 bar)

Medium pH Min. 7, max. 10

Medium temperature °C 2 (–101)) … 200

Connections Flange ISO 7005-2

Materials

Ductile iron

Body and cover Ductile iron EN- GJS-400 -18-LT (GGG 40.3)

EN-GJS-400-15

(GGG 40)

Cone, seat and spindle Stainless steel

Gland seal Replaceable PTFE rings

1)

At temperature s from -10 °C … +2 °C use stem heater .

Pressure temperature diagram Valve characteristics-logarithmic

DN 15-50: EN-GJS -400-18-LT (GGG-4 0.3) PN 25

DN 65-100: EN- GJS-400 -15 (GGG-40) PN 25

Max. closing pressure1) and recommended Δp

Capacity

2)

-way

2

Stroke

AB

A

Valve Actuator

DN

15

Stroke

(mm)

AMV(E) 25

[AMV(E) 25 SU/SD]

25 [223)] 25 -

15 (kVS 4.0) 25 [163)] 20 -

20 25 [103)] 13 -

25 16 [53)] 8 -

15

32 9 [2.53)] 5 -

40 6 [23)] 3 -

50 3 [0.53)] 2 -

65

80 - - 3 2 8 3

40

- - 4.5 3 13 4.5

AMV(E) 35 AMV(E) 55 AMV(E) 56 AMV(E) 85, 86 AMV(E) 65x

3)

max. closing pressure 1) (bar)

4)

25

4)

25

4)

25

4)

21

4)

12

4)

8

4)

5

- -

- -

- -

- -

- -

- -

- -

100 - - 1.5 1 5 1. 5

Note:

1)

Max. Δp is t he physical limit of diffe rential pressure the valve will cl ose against. Max. Δp for ste m application is 6 bar.

2)

The recommen ded Δp is based on the generati on of noise, plug erosion e tc.

Max. re commended Δp is 4 bar.

If max. c losing pressure is smaller tha n 4 bar than the recommended Δ p is the same as closing Δp.

3)

Values in parenth eses [ ] are based on the force of the ac tuator AMV(E) 25 SU/SD only.

4)

With stem connec tor (On request)

2 | AI094186477177en-010404 © Danfoss | 2022.01

Page 3

Data sheet Two way valve VFS 2

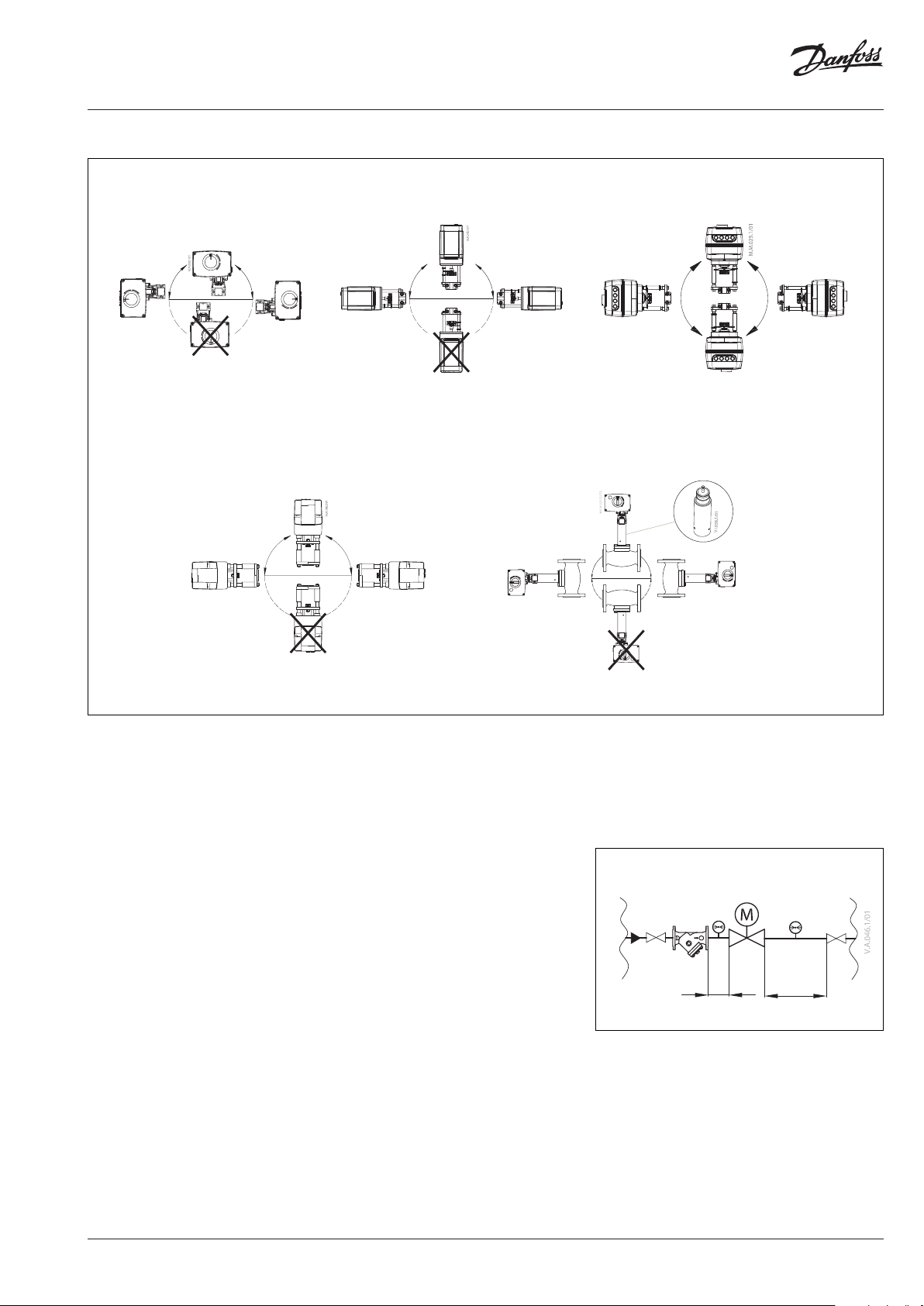

Installation

T

≤150 °C for AMV(E) 25 (SU/SD), 35

max

T

≤200 °C for other AMV(E)

max

AMV(E) 25(SU/SD)/35

AMV(E) 55/56 AMV(E) 65x

T

= 150 ... 200 °C AMV(E) 25 (SU/SD), 35

max

AMV(E) 85/8 6

Valve mounting

Before mounting the valve be sure that the pipes

are clean and free from abrasion.

It is essential that the pipes are lined up squarely

with the valve at each connection and that they

are free from vibrations.

Adapter for

VFS 2 DN 15 -50

Always install the valve with the arrow on the

body in the same direction as the ow. In order to

avoid turbulence, which will aect the measuring

accuracy, it is recommended to have a straight

length of pipe up and down stream from the

valve as shown (D - diameter of pipe).

Install the motorized control valves with the

actuator in a vertical or horizontal position in

accordance to recommendations described in

Installation above.

Note that the actuator may be rotated up to 360°

with respect to the valve body by loosening the

retaining fixture. After this operation retighten.

Leave sufficient clearance to facilitate the

dismantling of the actuator from the valve body

for maintenance purposes.

Note that the actuator may be rotated up to 360°

with respect to the valve body by loosening the

retaining fixture. After this operation retighten.

AMV(E)

FVR/FVF

2D

5D

Note:

Install a strainer upstream of the valve

(e.g. Danfoss FVR/FVF)

AI094186477177en-010404 | 3© Danfoss | 2022.01

Page 4

Data sheet Two way valve VFS 2

2p1p

1p

a authority, Valve

∆+∆

∆

=

5.0

p2

p

a

1

1

62.0

557.90

7.90

authority valve hence =

+

=

395.0

5536

36

authority valve hence =

+

=

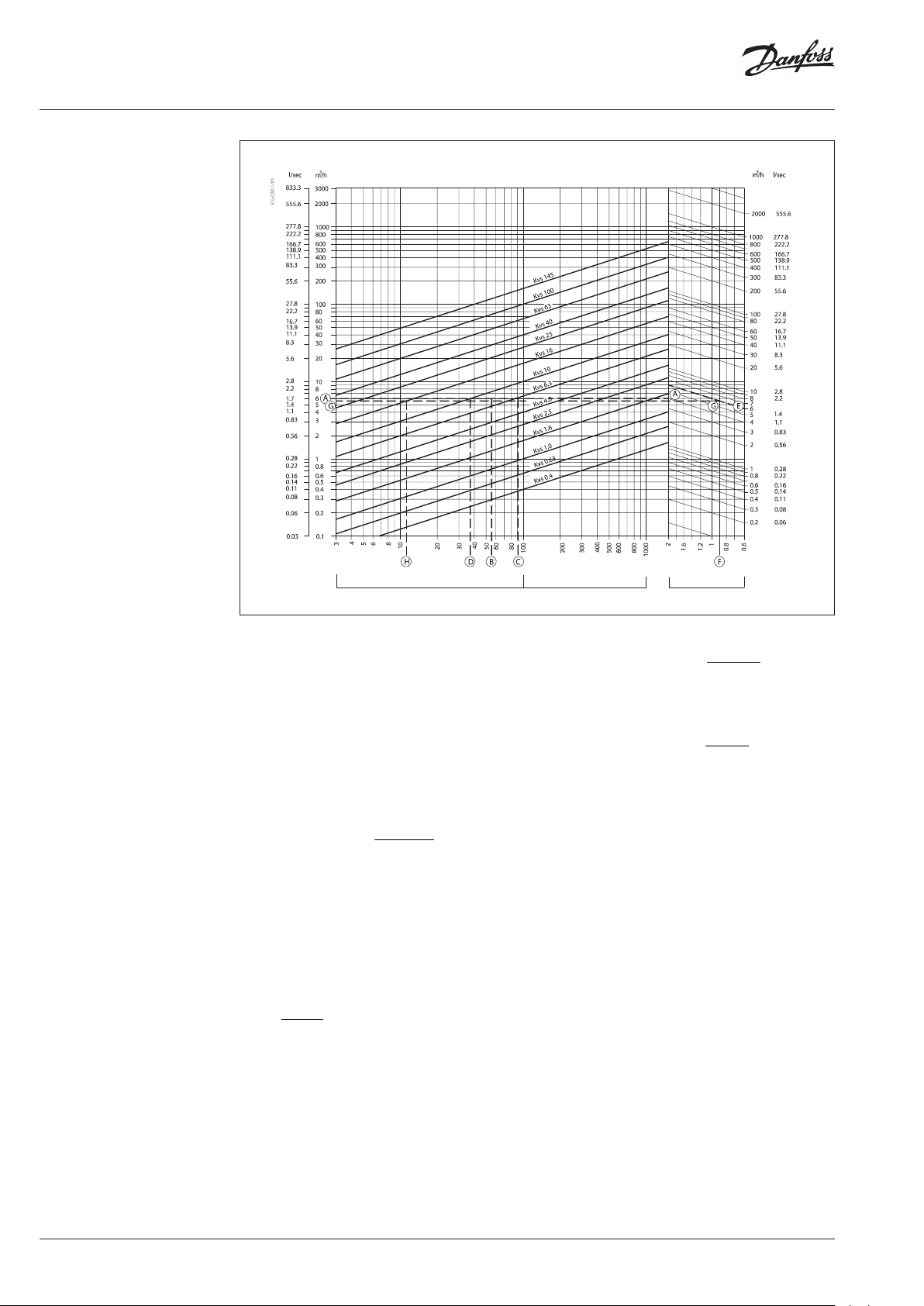

Control valve sizing diagram

for fluids

Flow liqui d with specific

gravit y of 1

Flow liqui d with specific

gravity different to 1

FLOW Pressure d rop kPa (100 kPa = 1 bar = ~10 m H2O) Specif ic gravity

Examples:

1 For fluids with specific gravity of 1

(e.g. water)

Design data:

Flow rate: 6 m3/h

System pressure drop: 55 kPa

Locate the horizontal line representing a flow

rate of 6 m3/h (line A-A). The valve authority is

given by the equation:

Where:

p1 = pressure drop across the fully open valve

p2 = pressure drop across the rest of the circuit

with a full open valve

The ideal valve would give a pressure drop equal

to the system pressure drop (i.e. an authority of

0.5):

If p1 = p2

In this example an authority of 0.5 would be

given by a valve having a pressure drop of 55

kPa at that flow rate (point B). The intersection

of line A–A with a vertical line drawn from B lies

between two diagonal lines; this means that no

ideally-sized valve is available. The intersection

of line A–A with the diagonal lines gives the

pressure drops stated by real, rather than ideal,

valves. In this case, a valve with kVS 6.3 would give

a pressure drop of 90.7 kPa (point C):

The largest valve, with kVS 10, would give a

pressure drop of 36 kPa (point D):

Generally, the smaller valve would be selected

(resulting in a valve authority higher than 0.5

and therefore improved control). However, this

will increase the total pressure and should be

checked by the system designer for compatibility

with available pump heads, etc. The ideal

authority is 0.5 with a preferred range of

between 0.4 and 0.7.

2 For fluids with specific gravity (S.G. )

different from 1

Design data:

Flow rate: 6 m3/h of fluid, S.G. 0.9

System pressure drop: 10 kPa

For this example, the left hand axis of the

diagram must be ignored. Starting from the

right hand axis, the flow rate of 6 m3/h is located

(point E). The intersection of the diagonal line

from point E with a vertical line from S.G. = 0.9

(point F) gives the starting point for the effective

flow rate line G-G. The process then continues as

for Example 1, so 10 kPa intersects G-G nearest

to the kVS 16 diagonal. The intersection of G-G

with kVS 16 gives a valve pressure drop of 12.7 kPa

(point H).

4 | AI094186477177en-010404 © Danfoss | 2022.01

Page 5

Data sheet Two way valve VFS 2

Control valve sizing diagram for steam

Max. p in low pressure steam application variance from 0.5 bar to 6 bar (see page 2)

mass flow of saturated water steam (kg/h)

Critical Pressure Drop (kPa)

Critical Pressure Drop (kPa)

Absolute Inlet Pressure

Saturated Sream Temperature

Superheat °C

mass flow of superheated water steam (kg/h)

Steam valve sizing is based on 40 % of the

absolute steam pressure (immediately upstream

of the valve), being dropped across the valve

when fully open. At this condition the steam

is travelling at or close to its critical velocity

(approx. 300 m/s) and throttling will occur over

the full valve stroke. If the steam is travelling

slower than this then the first part of the valve

stroke will merely increase the velocity of the

steam without reducing the volumetric flow.

AI094186477177en-010404 | 5© Danfoss | 2022.01

Page 6

Data sheet Two way valve VFS 2

Control valve sizing diagram

for steam

(continued)

1 For saturated steam

Design data:

Flow rate: 1000 kg/h

Absolute inlet pressure: 5 bar (500 kPa)

- follow dashed line -

The absolute inlet pressure is 500 kPa. 40% of

this is 200 kPa.

Locate the diagonal line corresponding to the

pressure drop of 200 kPa (line A-A).

Read the absolute inlet pressure on the lower left

hand scale (point B), and draw a horizontal line

across until it meets the pressure drop diagonal

(A-A) at point C.

From this point extend a vertical line upwards

until it meets the horizontal line representing

the steam flow of 1000 kg/h from point D. The

intersection of this is point E.

The nearest diagonal kVS line above this is line F-F

with a kVS of 25 (point E’). If the ideal valve size

is not available the next largest size should be

selected to ensure design flow.

The pressure drop through valve at the flow rate

is found by the intersection of the 1000kg/h

line with F-F (point E’) and dropping a vertical;

this actually hits the horizontal line for 500 kPa

(point E’’) inlet pressure at a pressure drop

diagonal of 70 kPa. This is only 14 % of the inlet

pressure and the control quality will not be

good until the valve has partially closed. As with

all steam valves this compromise is necessary

since the next smaller valve would not pass the

required flow (maximum flow would have been

about 600 kg/h).

The maximum flow for same inlet pressure

is found by extending the vertical line (C-E)

through point E until it crosses the kVS 25 line F-F

(point E’’’) and reading off the flow (1700 kg/h).

2 For superheated steam

Design data:

Flow rate: 500 kg/h

Absolute inlet pressure: 5 bar (500 kPa)

Steam temperature: 190 °C

The procedure for superheated steam is much

the same as for saturated steam, but uses a

different flow scale which slightly elevates the

readings according to the degree of superheat.

- follow dotted line -

As before, the diagonal pressure drop line

A-A is located as before for 40 % of 500

(200 kg/h). The horizontal inlet pressure line

through point B is now extended to the left to

read off the corresponding saturated steam

temperature at point G (150 °C). The difference

between the saturated steam temperature and

the superheated steam temperature is

190 °C - 150 °C = 40 °C.

The superheated steam flow is found on the

upper right hand scale, point H, and the diagonal

line is followed down from here until it meets

a vertical line from the steam temperature

elevation (40 °C) at point J.

As before, the horizontal line through point B is

drawn to cut line A-A at point C and the point

where the vertical line from this point meets the

horizontal line from point J is the operating point

(point K). This horizontal line, J-K, is the corrected

flow line. The nearest diagonal line above this is

for kVS 10 (point K’). A vertical line

the intersection of J-K with the 10 kVS line intersects

the 500 kPa inlet pressure line (point K’’) at a

pressure drop diagonal of about 150 kPa. This

is about 30% of the inlet pressure which will

give reasonable control quality (compared to

recommended ratio of 40%).

dropped from

6 | AI094186477177en-010404 © Danfoss | 2022.01

Page 7

Data sheet Two way valve VFS 2

Dimensions

118 .5

Adapter

065Z7548

mi n. 150

min . 100

1

H

H

k

n

d

L

VFS 2 (DN 15-50) +

AMV(E) 25, 35 (SU/SD)

L

VFS 2 (DN 15-50) +

AMV(E) 56 +

clutch 065Z7551

DN

L H H

1

mm

k d

n

(number)

Valve weight

15 13 0 237 383 65 14 4 3.6

20 150 237 383 75 14 4 4.3

25 16 0 237 383 85 14 4 5.0

32 180 259 405 100 18 4 8.7

40 200 259 405 110 18 4 9.5

50 230 259 405 125 18 4 11. 7

mi n. 118

mi n. 150

min . 81

1

H

2

H

k

d

n

L

VFS 2 (DN 65-100) +

AMV(E) 55, 56

L

VFS 2 (DN 65-100) +

AMV(E) 65X

L

VFS 2 (DN 65-100) +

AMV(E) 85, 86

(kg)

3

H

DN

L H

1

H

2

mm

H

3

k d

n Valve weight

(number) (kg)

65 290 484 525 568 14 5 18 8 23.0

80 310 503 544 587 160 18 8 28 .1

100 350 530 571 614 19 0 22 8 40.7

AI094186477177en-010404 | 7© Danfoss | 2022.01

Page 8

Data sheet Two way valve VFS 2

© Danfoss | DCS-SGDPT/SI | 2022.018 | AI094186477177en-010404

Loading...

Loading...