Page 1

Installation Guide

Butterfly valves VFH2-WAO/VFH2-WAM

蝶阀VFH2-WAO/VFH2-WAM

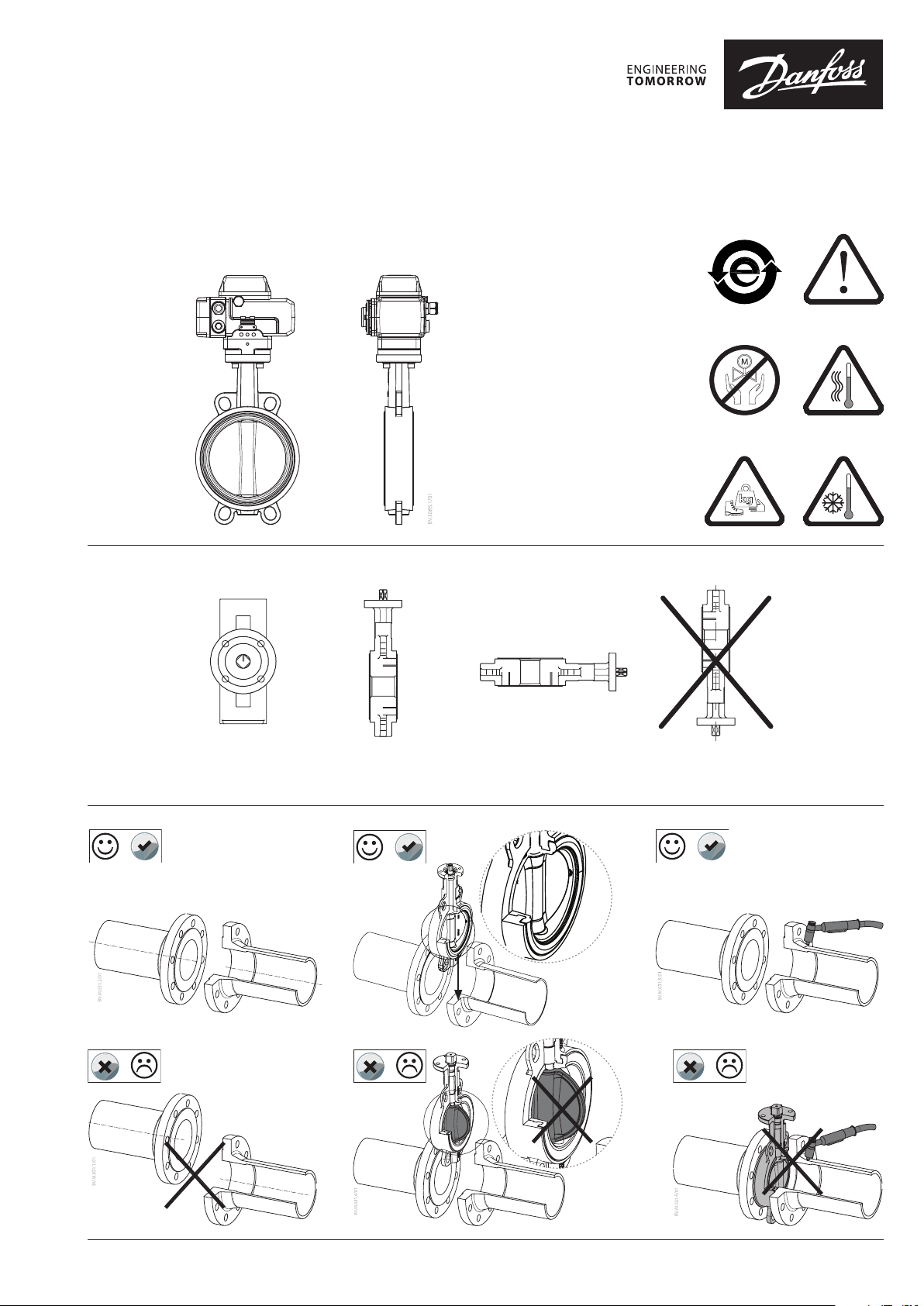

Installation Direction/阀门安装方向

220 V ± 10 %

MAINTENANCE

FREE

Installation Demand/安装要求

RecommendedRecommended

Not recommendedNot recommended for DN35 - 600

不允许推荐安装方向 推荐安装方向 DN350-600 不推荐

© Danfoss | 2021.05

AN337070523500zh-010202 | 1

Page 2

VFH2-WAO/VFH2-WAM

EN

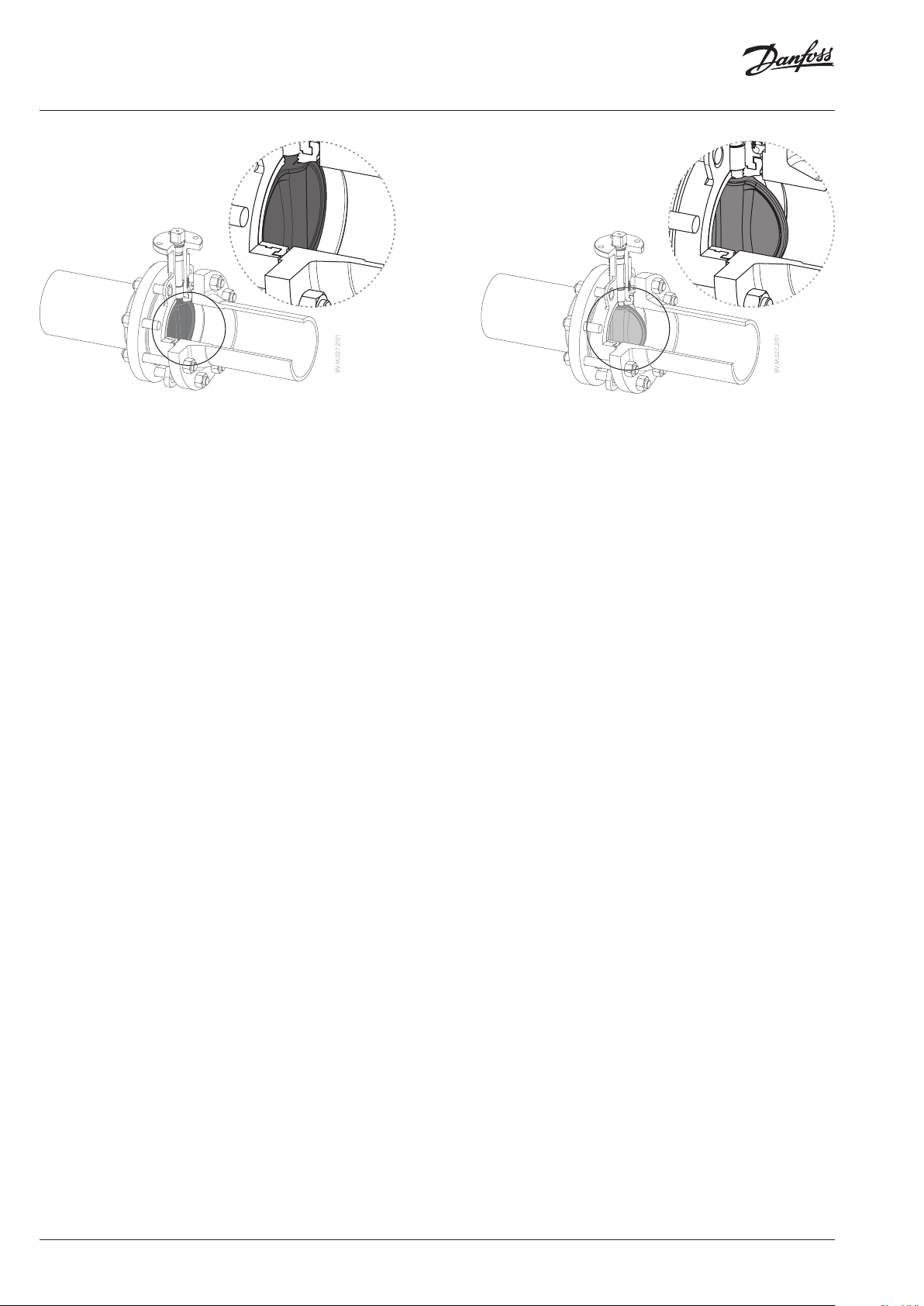

The valve is no leakage in both direction in shut off position. When

installing, leave the butterfly valve partly open. Make sure there is enough

distance between pipeline flanges to place the valve. Don’t add sealing

gaskets between the flange and the valve.

Insert bolts into flange and tighten opposing nuts sequentially. Make sure

that valve is aligned with the flange.

Fully open the valve. Make sure that the disc is centered and there is no

jam between the valve and the disc.

Pipeline flange standard should be consistent with the butterfly valve

flange standard. Make sure that the pipeline flange has enough surface

for sealing. It is necessary to ensure that the butterfly valve plate does not

collide with the inner diameter of the pipe during the opening process.

Avoid oil and impurity in the pipeline.

The butterfly valve must not be installed at the corner of the pipeline.

Don’t use the valve as a tool to increase the space between the pipeline

flanges.

The installation and commissioning of the valve actuator are completed

in the factory. Commissioning and dismounting should not be done on

site.

Connect the terminal according to the terminal number as shown on the

wiring diagram.

CN

阀门为双向密封结构。安装阀门时,蝶板应处于接近全关的位置。确定

管道法兰间有足够的距离将阀门插入法兰中间。蝶阀安装时无须再加密

封垫,蝶阀端面自带软密封面。

将螺栓穿入法兰盘,用手或扳手对称轮流预紧螺栓,以法兰盘端面凸台

或外圆及阀体外圆为相互参照物,确认阀门是否与法兰盘对中。

谨慎地,轻轻地将阀门开启到全开位置,检查阀板是否对中,检查阀板

与法兰内孔有无磕碰现象。

管道对夹法兰标准需与蝶阀法兰标准相符,管道法兰端面与蝶阀软密封

端面需保证足够的接触面积用于密封,需保证蝶板在开启过程中与管路

法兰内径无磕碰。

管道内避免含有油及杂质。

蝶阀不得安装于管道拐角处。

不得使用阀门做撬杠,撬撑法兰。

阀门的驱动装置在出厂前已经安装调试完成,现场不得对其调试拆装。

按照接线图所示的端子号进行端子连接。

电动蝶阀若安装在室外,建议加装防雨水的防护罩

Recommend to install a protective cover against rain, if the motorized

butterfly valve is installed outdoors.

2 | © Danfoss | 2021.05

AN337070523500zh-010202

Page 3

VFH2-WAO/VFH2-WAM

VFH2-WAO for DN32-DN350 VFH2-WAO for DN400-DN600

Cable specifications must be 9-11mm2. Recommended cross-sectional area of the wiring is 1.5 mm2.

线缆规格必须是9-11mm2 。每根线芯推荐线径1.5mm

2

VFH2-WAO

Heater for DN32-DN100

加热电阻适用于DN32-DN100

Y & G

加热电阻

Heater

Grey 灰

Brown 棕

White 白

Brown 棕

Grey 灰

Black 黑

Full-close signal (Pasive contact)

无源反馈全关信号

Full-open signal

无源反馈全开信号

COM

公共端

Full-open signal (Active contact)

有源反馈全开信号

Full-close signal

Open 开

有源反馈全关信号

only for input signal of PLC

只用于做PLC输入采集信号

only for indicator lamp

只用来接指示灯

ON/OFF

Feedback signals cannot be connected with control loop.

反馈信号不能串联到控制回路中。

AN337070523500zh-010202

Red 红

Blue 蓝

Close 关

PE / 外壳接地

© Danfoss | 2021.05 | 3

Page 4

Danf

VFH2-WAO/VFH2-WAM

1

–

1

2

2

SC

–

–

VFH2-WAM for DN32-DN350 VFH2-WAM for DN400-DN600

Control panel 控制面板

Power supply and modulating signal must through

different entrance, with well locked cable gland. Cable

specifications must be 9-11mm2 . Recommended

cross-sectional area of the wiring is 1.5 mm2.

推荐电源线缆与模拟量信号控制线缆走不同的穿线

孔并用穿线护口锁死。线缆规格必须是9-11mm2。

每根线芯推荐线径1.5mm2。

࢛

2

2

3

1

SB

૿ҵ

+

3

૿ӟ

– +

DN32-DN100

SB DIP control signal missing setting: 1,To fully open position; 2

Keep current position; 3, To fully close position.

SB DIP 丢信号响应设定:当输入信号丢失时,1档为阀门回到全

开位;2档为阀门保持在当前位置;3档为阀门回到全关位。

VFH2-WAM

Pink 粉

RP

Purple 紫

1K

Orange 橙

Black 黑

Red 红

Blue

蓝

SC DIP: left, 2-10V ; Right 4-20mA

SB DIP control signal missing setting: 1, To fully open position; 2,

Keep current position; 3,To fully close position.

SC DIP 开关:向左2-10V 输入信号;向右 4-20mA输入信号。

SB DIP 丢信号响应设定:当输入信号丢失时,1档为阀门回到全

开位;2档为阀门保持在当前位置;3档为阀门回到全关位。

+

Output Signal 输出信号

−

+

Input Signal 输入信号

−

L

Power 电源

Servo controller 电子控制器

N

Heater 加热电阻

3

1

SB

૿ҵ ૿ӟ

+

3

DN125-DN600

+

MOD

oss Danfoss

4 | © Danfoss | DHS-SRMT/SI | 2021.05

PE / 外壳接地

Danfoss ઼ᡰᴹ Danfoss Danfoss A/S( )

AN337070523500zh-010202

Loading...

Loading...