Page 1

Installation Guide

AFP/VFG 2(21) DN 15-250

ENGLISH

DANSK

DEUTSCH

SVENSKA

FRANCAIS

ČESKY

SPANISH

SUOMI

POLSKI

ROMÂNĂ

MAGYAR

Differential Pressure Controller AFP/VFG 2(21) www.danfoss.com Page 6

Differenstrykregulator AFP/VFG2 (21) www.danfoss.dk Side 7

Differenzdruckregler AFP / VFG 2 (21) www.danfoss.de Seite 8

Differenstrycksregulator AFP VFG2 (21) www.danfoss.se Page 9

Régulateur de pression différentielle AFP / VFG 2 (21) www.danfoss.fr Page 10

Regulátoru diferenčního tlaku AFP / VFG 2 (21) www.danfoss.cz Page 11

Controlador de presión diferencial AFP / VFG 2 (21) www.danfoss.es Page 12

Paine-erosäädin AFP / VFG 2(21) www.danfoss.fi Sivu 13

Regulator różnicy ciśnień AFP / VFG 2(21)

Regulator de presiune diferenţială AFP/VFG 2(21) www.danfoss.ro Page 15

Nyomáskülönbség-szabályozó AFP / VFG 2 (21) www.danfoss.hu Page 16

www.danfoss.pl Page 14

РУССКИЙ

District Energy VI.CA.K2.1I DEN-SMT/SI

Регулятор перепада давления AFP/VFG 2 (21) www.danfoss.ru Page 17

1

Page 2

Installation Guide AFP/VFG 2(21) DN 15-250

DN 15-125

t

= 150 °C

max

VFG 2 (21)

AFP

DN 150-250

t

= 140 °C

max

DN 15-125

t

max

❶ ❷

= 200 °C

V1, V2

VFG 2

AFP

DN 150-250

t

= 200 °C

max

2×

①

②

❸

AF (2×)

*)

AF (2×)

*)

①

② ②

①

District Energy VI.CA.K2.1I DEN-SMT/SI

22

Page 3

Installation Guide AFP/VFG 2(21) DN 15-250

❹

❼

②

①

①

③

❺

❻

①

③

①

②

②

G ⁄

①

AF

❽

❾

②

①

②

①

②

③

⑤

④

District Energy VI.CA.K2.1I DEN-SMT/SI

33

Page 4

Installation Guide AFP/VFG 2(21) DN 15-250

❿

①

⓬

②

⓫

VFG 2(21)

DN

15 130 212 7

20 150 238 9

25 16 0 238 10

32 180 240 13

40 200 240 17

50 230 275 22

65 290 275 33

80 310 380 41

100 350 380 60

125 400 380 79

150 480 326 85

200 600 354 145

250 730 404 228

L B Weight

mm (kg)

⓭

⊕

①

①

②

VFG 2 t

= 200 °C

max

DN

150 630 480 14 0

200 855 600 210

250 120 5 730 300

AFP A H Weight

(mm2) mm (kg)

80 17 2 430 7, 5

250 263 470 13

630 380 580 28

B

L Weight

1

mm (kg)

4

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 5

Installation Guide AFP/VFG 2(21) DN 15-250

⓮

②

⑤

⓯

∆ps = 0,5-3 bar

∆p

%050

②

⑥

④

①

③

①

④

⑤

36 mm

⑥

xam

V

③

⑦

District Energy VI.CA.K2.1I DEN-SMT/SI

55

Page 6

Installation Guide AFP/VFG 2(21) DN 15-250

LANGUAGEENGLISH

Safety Notes

Prior to assembly and commissioning to

avoid injury of persons and damages of

the devices, it is absolutely necessary to

carefully read and observe these instructions.

Necessary assembly, start-up, and maintenance

work must be performed only by qualified,

trained and authorized personnel.

Prior to assembly and maintenance work on the

controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Disposal instructions

This product should be

dismantled and its components

sorted, if possible, in various

groups before re cycling or

disposal.

Always follow the local disposal regulations.

Definition of Application

The controller is used for diffe rential pressure

control of water and water glycol mixtures for

heating, district heating and cooling systems.

The technical data on the ra ting plates

determine the use.

Scope of Delivery ❶

*) Impulse tube AF, accessory

Assembly

Admissible Installation Positions ❷

DN 15-80 ①:

medium temperatures up to 120 °C:

Can be installed in any positi on.

DN 100-250 and DN 15-80 ②:

medium temperatures > 120 °C.

Installation permitted only in horizontal

pipelines with the actuator oriented

downwards.

Installation Location and Installation

Scheme ❸

Return mounting ①

Flow mounting ②

Valve Installation ❹

1. Install strainer ① before the controller.

2. Rinse system prior to installing the valve.

3. Observe flow direction ② on valve body.

Flanges ③ in the pipeline must b e in

parallel position and sealing surfaces

must be clean and wi thout any damage.

4. Install valve.

5. Tighten screws crosswise in 3 steps up to the

max. torque.

Valve Actuator Installation

Valves DN 150-250

The actuator ste m must be screwed into

the valve stem.

Observe the Installation In structions for the

valves DN 150-250.

Valves DN 15-125 ❺

1. Place actuator at the valve.

2. Align actuator, observe position of impulse

tube connection to the valve ①

3. Tighten union nut ② Torque 100 Nm

Impulse Tube mounting

When installing sea l pots ❻①, please

observe the Installati on Instructions for

the seal pots.

• Whichimpulsetubestouse?

The impulse tube set AF (2×) ❻② can be

used: Order No.: 003G1391

or use the following pipes:

Stainless steel Ø 10×0 ,8

Steel Ø 10×1 DIN 2391

Copper Ø 10×1 DI N 1754

• Connection❼ of impulse tubes ① in the

system

Installation in return flow ②

Installation in supply flow ③

• Connection❽ to the pipeline ①

No connection downwards ② , could be

chocked by dirt.

• ImpulseTubeInstallation(Copper)❾

1. Cut pipe into rectangular sections ① and

deburr.

2. Insert sleeves ② on both sides.

3. Verify the correct position of the cutting

ring ③.

4. Press impulse tube ④ into the threaded

joint up to its stop.

5. Tighten union nut ⑤. Torque 40 Nm

DI N 1745 8,

DIN 2391

Insulation ❿

For medium temperatures up to 100 °C the

pressure actua tor may be insulated ①.

Dimensions ⓫

Flanges: connection dimensi ons acc. to

DIN 2501, seal form C

Dismounting ⓬

Danger

Danger of inju ry by hot water

Valve without actuator is open ①, Seal ② is in

the ac tuator.

Prior to dismounting depres surize system!

Carry out dismounting in re verse order to

mounting.

Leak and Pressure Test ⓭

Pressure must be constantly increased

at the +/ connec tion ①. Never increase

− pressure above + pressure.

Observe max. permitted pressure, see below.

Non-compliance may cause damages at the

actuator or valve.

Max. test pressure [bar] with connected

impulse tu bes

2

AFP cm

bar 25 25 16

In case of higher test pressu res, remove impulse

tubes at the pipelines ①.

Close connections with plugs G ¼ ISO 228.

Observe nominal pressure ② of the valve.

Max. test pres sure is 1,5 × PN

80 250 630

Filling the System, Start-up ⓮

The return flow pressure ① must not

exceed the suppl y flow pressure ②.

Non-compliance may cause damages at the

controller ③.

1. Open shut-off devices ④ that are possibly

available at the impulse tubes.

2. Slowly open valves in the system.

3. Slowly open shut-off devices ⑤ in the

supply flow.

4. Slowly open shut-off devices ⑥ in the return

flow.

Putting out of Operation

1. Slowly close shut-off devices ⑤ in the supply

flow.

2. Slowly close shut-off devices ⑥ in the return

flow.

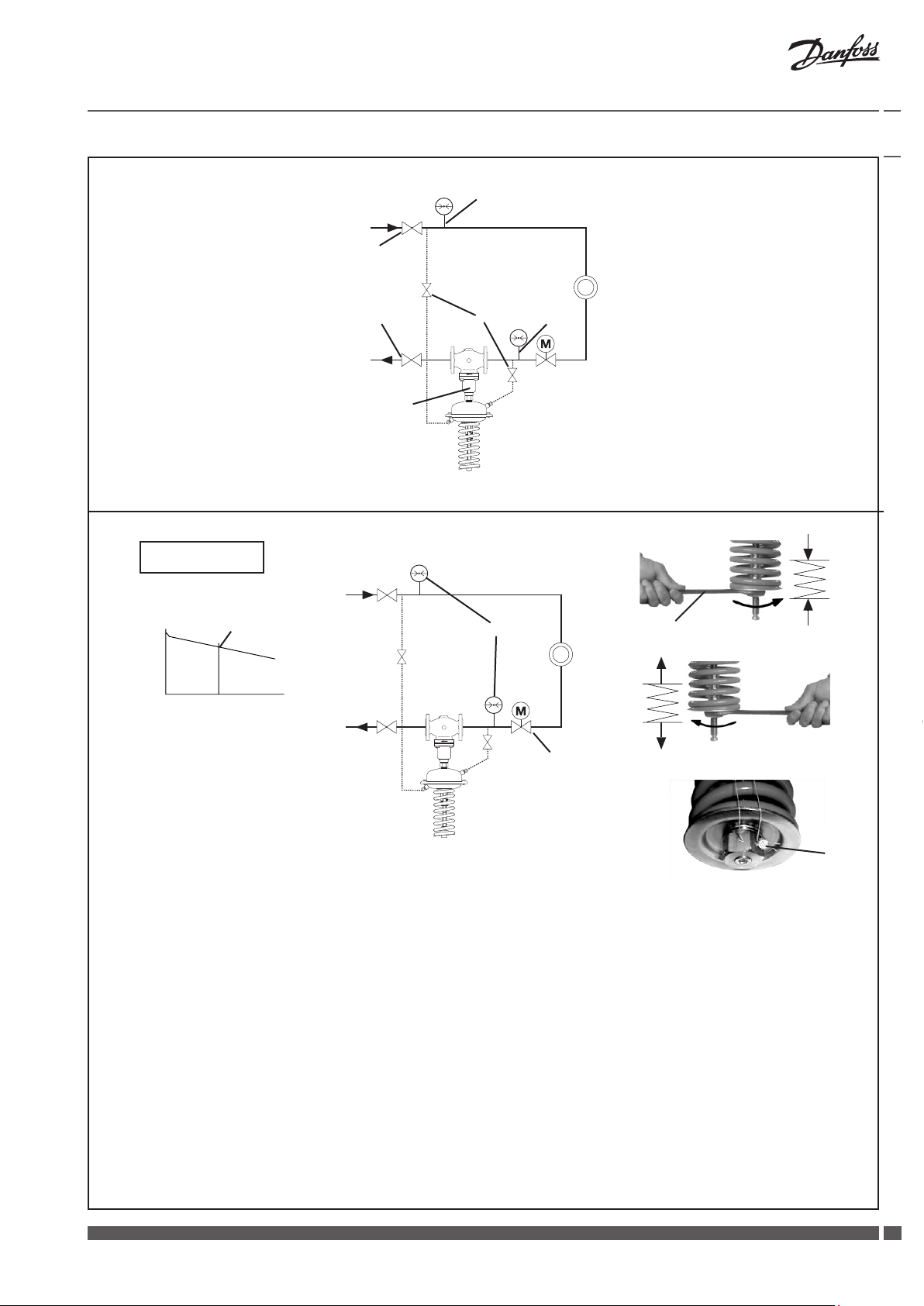

Differential Pressure Setting ⓯

Set-point range see rating plate ①

1. Start-up of system, see section ⓮.

2. Set flow rate on a motorised valve ③ by

which the differential pressure is controlled,

to about 50 % ②

3. Adjustment

• Observepressureindicators④.

• Turningtotheright⑤ increases the set-

point (stressing the spring)

• Turningtotheleft⑥ redu ces the

set-point (unstressing the spring)

4. The set-point adjuster ⑦ may be sealed.

6

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 7

Installation Guide AFP/VFG 2(21) DN 15-250

DANSK

Sikkerhedsbestemmelser

Disse instruktioner skal læses

omhyggeligt forud for montering og

indkøring samt respekteres for at

undgå skader på personer og udstyr.

Nødvendigt monterings-, opstarts- og

vedligeholdelsesarbejde må kun udføres

af faglært og autoriseret personale.

Forud for monterings- og

vedligeholdelsesarbejde på

regulatoren skal systemet være:

- trykløst

- nedkølet

- tømt

- rengjort

Systemproducentens eller -operatørens

instruktioner skal overholdes.

Bortskaffelse

Montage af reguleringsdel

Ventil DN 150-250

Reguleringsspindel skrues sammen med

ventilspindel.

Se ventilinstruktion for DN 150-250.

Ventil DN 15-125 ❺

1. Monter reguleringsdelen på ventilen

2. Drej regulatoren så tilslutning til

impulsledning ① kan monteres

3. Spænd møtrikken ② Moment 100 Nm

Montage af impulsledning

Ved installation af dæmp epotte ❻① se

instruktion for dæmpepotte.

Tætheds- og trykprøvning ⓭

Trykket skal stige jævnt ove r +/- for −

bindelsen ②. Må ikke overstig e max.

tilladeligt tryk se underneden.

Overskridelser kan medføre skader på regulator

og ventil.

Max prøvetryk ved montering af

impulsledning

2

AFP cm

bar 25 25 16

I tilfælde af højere prøvetryk, skal impulsledning

demonteres ①.

Luk forbindelsen med en slutmuffe G ⁄ ISO 228.

Kontroller nominel tryk ② på ventilen.

Max prøvetryk er 1,5 × PN

80 250 630

Før genbrug ell er bortskaffelse

skal dette produ kt skilles ad, og

enkeltdelene skal sorteres i

forskellige materialegrupper.

Der henvises til de l okale

bestemmelser for bortskaffelse.

Definition af anlæg

Regulatoren anvendes til

differenstrykregulering af vand eller

glykolholdigt vand i varmeanlæg,

ernvarmeanlæg og i kølesystemer.

De tekniske data aflæses på typeskiltet.

Leveringsomfang ❶

Montering

Tilladte positionsmonteringer ❷

DN 15-80 ①

Medietemperatur op til 120 °C kan monteres i

alle positioner

DN 100-250 og DN 15-80 ②

Medietemperatur > 120 ºC

Må kun monteres på vandrette rør med

regulatordel hængende nedad.

Indbygning ❸

I frem- eller returledning

Ventilmontering ❹

1. Monter snavsfilter ① før regulator

2. Skyl anlægget igennem før montering af

ventil

3. Kontroller flowretning ① på ventilen

Flangerne ③ i rørsystemet skal være

parallelle og pakfladerne rene og uden

beskadigelser.

4. Monter ventilen

5. Spænd boltene krydsvis i 3 trin op til max.

moment

• Valgafimpulsledning

Impulsledning sæt AF (2×) ❻② kan

anvendes Best. nr. 003G1391.

Hvis der anvendes andre typer skal følgende

være opfyldt:

Rustfast Stål Ø 10 × 0,8

Stål Ø 10 × 1 DIN 2391

Kobber Ø 10 × 1 DIN 1754

• Forbindelse❼ af impuls-ledning ① i

rørsystemet

Montering i returledning ②

Montering i fremløbsledning ③

• Tilslutningtilrør❽①

Må ikke tilsluttes på underside af rør ❽②

p.g.a. snavs

• Impulsledning(Kobber)❾

1. Røret skæres vinkelret ① og afgrates

2. Monter støttebøsning ②

3. Monter konusring korrekt ③

4. Tryk impulsrøret ind i niplen til stop ④

5. Spænd omløber ⑤ Moment 40 Nm

DIN 17458,

DIN 2391

Isolering ❿

For medietemperaturer op til 100 °C skal

regulatoren isoleres ①.

Dimensioner, vægt ⓫

Flanger: Tilslutning efter DIN 2501, tætningsliste

Form C

Demontering ⓬

Advarsel

Fare for skoldning ved varmt vand.

Ventilen er åben ① uden regulator.

Pakningen ② er i reguleringsdelen.

Før demontering skal anlægget gøres trykløst.

Demontering sker i omvendt retning, som ved

montering

Påfyldning af system Opstart ⓮

Returtrykket ① må ik ke overstige

fremløbstrykket ②.

Overskridelse kan medføre skade på regulator

og ventil ③

1. Eventuelle afspærringsventiler ④ på

impulsledningerne åbnes

2. Ventilen i systemet åbnes langsomt

3. Afspærringsventil i fremløb ⑤ åbnes

langsomt

4. Afspærringsventil i returløb ⑥ åbnes

langsomt

Stop af anlæg

1. Ventil i fremløb ⑤ lukkes langsomt

2. Ventil i retur ⑥ lukkes langsomtdansk

Indstilling af differenstryk ⓯

Indstillingsområde se typeskilt ①

1. Opstart af anlæg se ⓮

2. Indstil ventil ③ til ca. 50% åben ②

3.

• Indregulereftermanometer④

• Veddrejningmeduret⑤ øges

indstillingen (eder spændes)

• Veddrejningmoduret⑥ reduceres

indstillingen (eder afspændes)

4. Indstillingen ⑦ kan plomberes

District Energy VI.CA.K2.1I DEN-SMT/SI

77

Page 8

Installation Guide AFP/VFG 2(21) DN 15-250

DEUTSCH

Sicherheitshinweise

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist

diese Anleitung vor der Montage

unbedingt zu beachten.

Montage, Inbetriebnahme und

Wartungsarbeitendürfennurvon

sachkundigen und autorisierten Personen

durchgeführt werden.

VorMontageundWartungsarbeitenamRegler

die Anlage:

- drucklos machen,

- abkühlen,

- entleeren und

- reinigen.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Anweisung zur Entsorgung

Dieses Produk t sollte vor dem

Recycling od er der Entsorgung

zerlegt und ggf. in unterschiedliche Materialgruppen

stets die örtlichen Entsorgungsbestimmungen.

Bestimmungsgemäße

Verwendung Der Regler dient der Diffe-

renzdruckregleungvonWasserundWasser-

Glykolgemischen für Hei zungs-, Fernheizungsund Kühlungsanlagen.

Die technischen Daten auf den Typenschildern

sind für den Einsatz maßgebend.

Lieferumfang ❶

*) Steuerleitung AF, Zubehör

Montage

Zulässige Einbaulagen ❷

DN 15-80 ①

Mediumstemperaturen bis 120 °C: Einbaulage

beliebig

DN 100-250 und bei DN 15-80 ②,

Mediumstemperatu ren größer 120 °C.

Einbau nur in waagrechte Rohrleitung mit nach

unten hängendem Antrieb zulässig

Einbauort, Einbauschema ❸

Vorlauf ① oder Rücklauf ②

Einbau Ventil ➍

1. Schmutzfänger ① vor dem Regler einbauen

2. Anlage vor dem Einbau des Ventils spülen

3. Durchflussrichtung ② auf dem

Ventilgehäuse beachten

4. Ventil einbauen

5. Schrauben über Kreuz in 3 Stufen bis zum

max. Drehmoment anziehendeutsch

8

DEN-SMT/SI VI.CA.K2.1I District Energy

sortiert werden. Beachten Sie

Flansche ③ in der Rohr-leitung müssen

parallel, Dichtflächen sauber und ohne

Beschädi gung sein.

Montage Ventil Antrieb

Ventile DN 150-250

Bei den Ventilen DN 150-250 muss die

Antriebstange in die Ventil-stange

einge schraubt werden.

Den Ventilen DN 150-250 beigefügte

Montageanleitung beachten.

Ventile DN 15-125 ❺

1. Antrieb am Ventil ansetzen

2. Antrieb wegen dem Steu erleitungsanschluss

① ausrichten

3. Überwurfmutter ② anziehen

Anzugsmoment 100 Nmdeutsch

Montage Steuerleitungen

Bei Einbau von Vorlagegefäßen ❻①,

bitte den Vorlagegefässen bei gefügte Montageanleitung beachten.

• WelcheSteuerleitungenverwenden?

Steuerleitungsset AF (2×) ❻② :

Bestellnummer: 003G1391

oder folgende Rohre verwenden:

Edelstahl Ø 10 × 0,8

Stahl Ø 10 × 1 DIN 2391

Kupfer Ø 10 × 1 DIN 1754

• Anschluss❼ der Steuerleitungen ① in der

Anlage

Einbau im Rücklauf ②

Einbau im Vorlauf ③

• Anschluss❽ an der Rohrleitung ①

Anschluss wegen Verschmutzung nicht nach

unten ②

• MontageSteuerleitung(Kupfer)❾

1. Rohr rechtwinklig ① ablängen und

entgraten

2. Einsteckhülsen ② beideseitig einfügen

3. Richtige Lage des Schneidrings ③

überprüfen

4. Steuerleitung ④ in die Verschraubung bis

zum Anschlag drücken

5. Überwurfmutter ⑤ anziehen,

Anzugsmoment 40 Nm

DIN 17458,

DIN 2391

Isolierung ❿

Bei Mediumstemperaturen bis 100 °C kann auch

der Druckantrieb ① isoliert werden.

Abmessungen, Gewichte ⓫

Flansche Anschlussmaße nach DIN 2501,

Dichtleiste Form C

Demontage ⓬

Gefahr

Verletzungsgefah r durch Heisswasser

Ventil ist ohne Antrieb offen ①, Abdichtung ②

befindet sich im Antrieb.

Vor Demontage Anlage unbedingt drucklos

machen.

Demontage in umgekehr-ter Reihenfolge wie

die Montage durchführen.

Dichtheits-, Druckprüfung ⓭

Druckerhöhung muss am +/- Anschluss

① gleichmäßig erfolgen. Keinesfall −

Druck über de n +Druck ansteigen

lassen.

Max. zulässige Drücke beachten, siehe unten.

Nichtbeachtung kann zu Undichtheit am

Antrieb führen.

Max. Prüfdruck [bar] mit

angeschlossenen Steuerleitungen

2

AFP cm

bar 25 25 16

Bei höheren Prüfdrücken müssen die

Steuerleitun-gen an den Rohrleitungen ①

entfernt werden.

Die Anschlüsse mit Stopfen G ⁄ ISO 228

schließen.

enndruck ② des Ventils beachten.

Max. Prüfdruck ist 1,5 × PN.

80 250 630

Füllung der Anlage,

Inbetriebnahme ⓮

Der Rücklaufdruck ① darf den

Vorlaufdruck ② nicht überschreiten.

Nichtbeachtung kann zu Schäden am Regler

③führen.

1. Eventuell in den Steuerleitungen

vorhandene Absperrventile ④ öffnen

2. Ventile in der Anlage öffnen

3. Absperrarmaturen ⑤ im Vorlauf langsam

öffnen

4. Absperrarmaturen ⑥ im Rücklauf langsam

öffnen

Außerbetriebnahme

1. Absperrarmaturen ⑤ im Vorlauf langsam

schließen

2. Absperrarmaturen ⑥ im Rücklauf langsam

schließendeutsch

Einstellung Differenzdruck ⓯

Sollwertbereich siehe Typenschild ①

1. Anlage in Betrieb nehmen, siehe ⓮

2. Volumenstrom an einer Armatur ③, über

welche der Differenzdruck gere-gelt wird,

auf ca. 50 % einstel len ②

3. Einstellung

• Druckanzeigen④ be-achten

• Rechtsdrehung⑤ erhöht den Sollwert

(Feder spannen)

• Linksdrehung⑥ reduziert den Sollwert

(Feder entspannen)

4. Der Sollwertsteller ⑦ kann plombiert

werden

Page 9

Installation Guide AFP/VFG 2(21) DN 15-250

SVENSKA

Säkerhetsmeddelande

För att undvika personskador och

skador på enheter är det absolut

nödvändigt att läsa och följa dessa

anvisningar noggrant före montering och

idrifttagande.

Erforderligt monterings-, igångkörningsoch underhållsarbete ska endast utföras av

kvalificerad, utbildad och auktoriserad personal.

Innan monterings- och underhållsarbete utförs

på motorn måste systemet vara:

- trycklöst

- nedsvalnat

- tömt

- rengjort

Följ anvisningarna från systemets tillverkare

eller systemets operatör.

Kasseringsanvisning

Denna produkt ska demonteras och

dess komponenter om möjligt

sorteras i olika gru pper före

återvinning eller kassering.

Följ alltid lokala föreskrifter om avfallshantering.

Definition av applikation

Regulatorn används för styrning av

differenstrycket i vatten och vatten glykol

blandningar för värme-, ärrvärme- och

kylsystem.

Tekniska data på typskylten avgör

användningen.

Leveransomfattning ❶

Montering

Monteringslägen ❷

DN 15-80 ①

Mediatemperatur upp till 120 °C

Lägesoberoende

DN 100-250

Och DN 15-80 ② Mediatemperatur > 120 °C

Får endast installeras i horisontella rörledningar

med reglerdelen hängande neråt.

Inbyggnads- och monteringsanvisningar

Tillopps- eller returledning

Montera ventil ➍

1. montera ett smutsfilter ① före regulatorn

2. spola systemet för montering av ventil

3. observera flödesriktning ② på ventilhuset

Rörledningens flänsar ③ måste vara

parallella och tätningsytorna måste vara

rena och oskadade.

4. Montera ventilen

5. Dra åt skruvarna korsvis i 3 steg upp till max

moment

Montering av reglerdel

Ventil DN 150-250

Ventiler DN 150-250 Reglerdelens

spindeln ska skruvas fast i

ventilspindeln.

Observera monteringsanvisningarna för ventiler

DN 150-250

Ventiler DN 15-125 ❺

1. placera reglerdelen på ventilen

2. räta upp reglerdelen, kontrollera läget för

impulsledningens anslutning ①

3. dra åt anslutnings-muttern ② med 100 Nm

Montera impulsledning

Följ installationsanvisningarna vid

montering av plomberingsbricka ❻①.

• Vilkenimpulsledningskaanvändas?

Impulsledningsset AF (2×) kan användas

Beställningsnummer : 003G1391

Om andra impulsledningar används,

kontrollera följande dimensioner

Rostfritt stål Ø 10 × 0,8

Stål Ø 10 × 1 DIN 2391

Koppar Ø 10 × 1 DIN 1754

• Anslutning❼ av impulsledning ① i

systemet

Montering i returledning ②

Montering i tilloppsledning ③

• Anslutning❽ till rörledningen ①

Ingen anslutning neråt ② smuts kan fastna

• Monteringavimpulsledning(Koppar)

1. Mät ut en rät vinkel ① och borra

2. Anslut de båda instickshylsorna ②

3. Kontrollera skärtätningens ③ läge

4. Tryck in impuls-ledningen ④ i den

gängade anslutningen tills det tar stopp

5. Dra åt anslutnings-mutter ⑤ med 40 Nm

DIN 17458,

Isolering

För mediatemperaturer upp till 100 °C kan

membranhuset ① isoleras

Mått och vikt ⓫

Flänsar: anslutningsdimensioner enligt DIN 2501,

plombering formulär C

Demontering ⓬

Varning

Risk för skållningsskador

Ventilen utan reglerdel är öppen ①, tätningen

② sitter i reglerdelen.

Före demontering ska systemet göras trycklöst.

Demontera i omvänd ordning till montering

DIN 2391

Läckage- och trycktest ⓬

Trycket måste öka konstant vid +/anslut − ningen ①. Trycket får inte

överstiga + trycket.

Observera max tillåtet tryck, se nedan.

Ovarsamhet kan orsaka skador på reglerdel

eller ventil.

Max test tryck (bar) med anslutna

impulsledningar

2

AFP cm

bar 25 25 16

Om testtrycket är högre demontera

impulsledningarna från rörledningen ①.

Proppa anslutningar med plugg G ¼ ISO 228.

Observera ventilens nominella tryck ②.

Max testtryck är 1,5 × PN

80 250 630

Uppfyllning av system

Igångsättning ⓮

Trycket i retur-ledning en ① får inte

överstiga trycket i tilloppsledn ingen ②.

Ovarsamhet kan orsaka skador på reglerdel ③

eller ventil.

1. Öppna eventuella avstängningsventiler ④

vid impulsledningarna

2. Öppna ventilerna i systemet m

3. Öppna avstängningen i tilloppsledningen ⑤

långsamt

4. Öppna avstängningen i returledningen ⑥

långsamt

Ta ur drift

1. Stäng avstängningen n ⑤ tilloppsledningen

långsamt

2. Stäng avstängningen ⑥ i returledningen

långsamt

Inställning av differenstryck ⓯

Inställningsområde se typskylt ①

1. Igångsättning av systemet se ⓮

2. Ställ in flödet för en anslutning ③ vid vilken

differenstrycket styrs till ca. 50% ②.

3. Justering

• Observeratryckindikatorerna④.

• Vridningtillhöger⑤ ökar

inställningsvärdet (ökar ädertrycket)

• Vridningtillvänster⑥ minskar

inställnings-värdet (minskar ädertrycket)

4. Justerskruven ⑦ kan plomberas

District Energy VI.CA.K2.1I DEN-SMT/SI

99

Page 10

Installation Guide AFP/VFG 2(21) DN 15-250

FRANCAIS

Consignes de sécurité

Pour éviter des dommages physiques

et matériels, il est absolument

nécessaire de lire attentivement et de

respecter ces instructions avant le montage et

la mise en service.

Le travail d’assemblage, de démarrage et de

maintenance nécessaire doit être effectué

uniquement par un personnel qualifié, formé et

autorisé.

Avant le travail d'assemblage et de maintenance

du contrôleur, le système doit être :

- dépressurisé

- refroidi

- vidé

- nettoyé

Suivre les instructions du fabricant du système

ou de son service.

Instructions d'élimination

Ce produit doit être d émonté et

ses composants doi vent être triés,

si possible, en diffé rents groupes

avant recyclage o u élimination.

Respectez tou jours les

réglementations locales en matière d'élimination

de déchets.

Conditions d’utilisation

Le régulateur est approprié pour la

régulation de la pression différentielle de

l’eau et de l’eau glycolée pour chauffage,

chauffage urbain et installations de

réfrigération.

Les données techniques sur les plaques

signalétiques sont déterminantes pour

l’utilisation.

Contenu de la livraison ❶

Montage

Orientations de montage autorisées ❷

DN 15-80 ①

Température du fluide jusqu’à 120 °C :

Orientation au choix

DN 100 -250et pour DN 15-80, si la température

du fluide est supérieure ② 120 °C :

Montage autorisé uniquement sur tuyauterie

horizontale, avec moteur vers le bas.

Lieu de montage,

schéma de montage ❸

Aller ① ou retourfrancais ②

Montage vanne ➍

1. Monter le filtre ① devant le régulateur

2. Rincer l’installation avant le montage

3. Respecter le sens d’écoulement ② indiqué

sur la vanne

Les brides ③ dans la tuyauterie doivent

être parallèles, les surfaces d’étanchéité

propres et sans dommages.

4. Monter la vanne

5. Serrer les vis en 3 étapes en croix, jusqu’au

couple de rotation max.

Montage vanne, moteur

Vannes DN 150-250

Pour les vannes DN 150-250, la tige du

moteur doit être vissé e dans la tige de la

vanne.

Respecter la notice de montage jointe, pour les

vannes DN 150-250.

Vannes DN 15-125 ❺

1. Positionner le moteur sur la vanne

2. Aligner le moteur avec le raccordement de

conduite de commande ①

3. Serrer l’écrou prisonnier ② , facteur de

serrage 100 Nm.

Montage conduites de commande

Avec montage de pots de condensation

❻①, respecter la notice de montage

jointe ces pièces.

• Quellesconduitesdecommande

choisir?

Le kit de conduite de commande

AF (2×) ❻② peut être utilisé:

Réf. de commande: 003G1391

Lors de l’utilisation d’autres conduites,

utiliser les dimensions suivantes:

Tuyauterie

Acier inox Ø 10 × 0,8

Acier Ø 10 × 1 DI N 2391

Cuivre Ø 10 × 1 D IN 175 4

• Raccordement❼ des conduites de

commande ① dans l’installation

Montage dans le retour ②

Montage dans l’aller ③

• Raccordement❽ la tuyauterie ①

Ne pas faire le raccordement vers le bas ②

cause de l’encrassement.

• Montageconduitedecommandecuivre❾

1. Couper le tuyau d’équerre ① et lisser les

arrêtes

2. Insérer les douilles de chaque côté ②

3. Vérifier la bonne position du raccord ③

olive

4. Pousser la conduite de commande ④ dans

le filetage jusqu’en butée

5. Serrer l’écrou prisonnier ⑤, facteur de

serrage 40 Nm

DIN 17458,

DIN 2391

Isolation ❿

Avec des températures de fluide jusqu’à 100 °C,

le moteur ① peut également être isolé.

Dimensions, poids ⓫

Dimensions raccordement ① brides selon DIN

2501, étanchéité forme C

Démontage ⓬

Danger

Risques de brûlures par l’eau chaude

La vanne n’est pas étanche sans moteur ①, le

cône d’étanchéité ② se trouve dans l’écrou de

fixation du moteur.

Impérativement mettre l’installation hors

pression avant tout démontage.

Pour le démontage suivre la procédure de

montage dans le sens inverse.

Contrôle d’étanchéité et

de pression ⓭

Une augmentation d e pression doit

s’effectuer d’une manière homogène

aux raccord ements +/- ①.

En aucun cas, il ne faut laisser croître la pressio n

- au-dessus de la pression +.

Respecter les pressions max. autorisées, voir

ci-dessous.

En cas de non-respect, une fuite peut survenir

sur le moteur.

Pression de contrôle max. (bar) avec

conduites de commande raccordées

2

AFP cm

bar 25 25 16

Avec des pressions de contrôle plus élevées, les

conduites de commande doivent être retirées

des tuyauteries ①.

Fermer les raccordements avec des bouchons G

¼ ISO 228 .

Respecter la pression nominale ② de la vanne.

La pression de contrôle max. est 1,5 × PN

80 250 630

Remplissage de l’installation, mise

en service ⓮

La pression retour ① ne doit pas

dépasser la pression aller ②.

1. Eventuellement, ouvrir les robinets

d’arrêt ④ présents dans les conduites de

commande

2. Ouvrir lentement les robinets d’arrêt ⑤ dans

l’aller

3. Ouvrir lentement les robinets d’arrêt ⑥ dans

le retour

Mise hors service

1. Fermer lentement les robinets d’arrêt ⑤

dans l’aller

2. Fermer lentement les robinets d’arrêt ⑥

dans le retourfrancais

Réglage de la pression

différentielle ⓯

Plage de réglage, voir plaque signalétique ①

1. Mettre l’installation en service, voir

paragraphe ⓮

2. Régler le débit ② environ 50% sur

une vanne ③, par laquelle la pression

différentielle est réglée.

3. Réglage

• Observerl’indicationdepression④

• Larotationdroite⑤ augmente la valeur

de consigne (tendre le ressort)

• Larotationgauche⑥ réduit la valeur de

consigne (détendre le ressort)

4. Le régleur de valeur de consigne peut être

plombé ⑦

10

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 11

Installation Guide AFP/VFG 2(21) DN 15-250

ČESKY

Bezpečnostní pokyny

Chcete-li se vyhnout zranění osob a

poškození zařízení, je bezpodmínečně

nutné si pečlivě pročíst tyto pokyny a

dodržovat je ještě před montáží a uvedení

zařízení do provozu.

Nezbytné montážní práce, kroky při uvádění

do provozu a opravy mohou provádět pouze

kvalifikovaní, proškolení pracovníci, kteří pro

tuto činnost byly určeni.

Před montáží nebo před případnou opravou

nebo servisem regulátoru je nutné, aby

regulovaný systém splňoval následující

podmínky:

- odtlakovaný

- ochlazený

- vyprázdněný

- vyčištěný

Potupujte podle návodu výrobce systému nebo

jeho provozovatele.

Pokyny pro likvidaci

Pokud to je možné, měl bý t by

tento výrobe k před recyklováním

nebo likvidací demontován a

jeho součásti roztříděny do

různých skupin.

Vždy postupujte podle místních předp isů pro

likvidaci.

Použití

Regulátor se používá k regulaci diferenčního

tlaku vody a směsi vody s glykolem v zařízení

pro vytápění, dálkové vytápění a chlazení.

Pro použití jsou rozhodující technické

parametry uvedené na typových štítcích.

Rozsah dodávky ❶

Montáž

Přípustné montážní polohy ❷

DN 15-80 ①

při teplotách prostředí do 120 °C může být

instalován v libovolné poloze

DN 100-250 a DN 15-18 ②

při teplotách prostředí vyšších než 120 °C je

montáž přípustná pouze do vodorovného

potrubí s pohonem svěšeným dolů

Umístění armatury ❸

Přívod ① nebo zpátečka ②

Montáž ventilu ➍

1. Před regulátor osaďte lapač nečistot ①

2. Zařízení před montáží ventilu propláchněte

3. Zkontrolujte směr proudění ② vyznačený na

tělese ventilu

Příruby ③ v potrubí musí být

rovnoběžné, těsnící plochy musí být

čisté a nepoškozené.

4. Namontujte ventil

5. Šrouby přitáhněte křížem na třikrát, až k

max. kroutícímu momentu.

Montáž pohonu ventilu

Ventil DN 150-250

U ventilů DN 150-250 musí být tyč

pohonu zašroubována do tyčk y ventilu.

U ventilů DN 150-250 postupujte podle

přiloženého návodu k montáži.

Ventily DN 15-125 ❺

1. Pohon nasaďte na ventil.

2. Pohon vyrovnejte vůči přípojce impulzniho

vedení ①

3. Přitáhněte přesuvnou matku ②. Utahovací

moment 100 Nm.

Montáž impulzního vedení

Při osazování předlohových nádobek

❻① postupujte podle příslušného

návodu k montáži.

• Jakéimpulznívedenípoužít?

Lze použít impulzní vedení AF (2×) ❻②:

obj.číslo: 003G1391

Při použití jiného vedení respektujte

následující rozměry :Trubka

Nerezová ocel Ø 10 × 0,8

Ocel Ø 10 × 1 DIN 2391

Měď Ø 10 × 1 D IN 175 4

• Přípojka❼ impulzního vedení ① v zařízení

Osazení armatury do zpátečky ②

Osazení armatury do přívodu ③

• Přípojka❽ impulzního vedení na potrubí ①

Přípojku z důvodů znečištění nesměrujte

dolů ②

• Montážimpulzníhovedení(měď)❾

1. Trubku zkraťte v pravém úhlu ① a

začistěte

2. Na obou stranách zasuňte zásuvná

pouzdra ②

3. Zkontrolujte správnou polohu závitového

kroužku ③

4. Impulzní vedení ④ vtlačte do šroubení až

na doraz.

5. Utáhněte přesuvnou matku ⑤, utahovací

moment 40 Nm

DIN 17458,

DIN 2391

Izolace ❿

Při teplotě media do 100 °C může být izolován i

tlakový pohon ①.

Rozměry, hmotnosti ⓫

Připojovací rozměry příruby podle DIN 2501,

izolační lišta tvaru C

Demontáž ⓬

Pozor

Nebezpečí popálení horkou vodou

Ventil je bez pohonu otevřený ①, těsnění ② je

na pohonu.

Před demontáží armatury zařízení

bezpodmínečně odtlakujte.

Demontáž provádějte v opačném sledu úkonů

jako montáž.

Zkouška těsnosti,

tlaková zkouška ⓭

Zvýšení tlaku musí probíhat současně

na přípojce + / - ①. V žádném případě

nenechte tlak stoupnout nad tlak +.

Uvědomte si max. přípustné tlaky - viz dole.

Nerespektování těchto pokynů může vést k

poškození pohonu nebo ventilu.

Max. zkušební tlak [bar] s napojeným

impulzním vedením

2

AFP cm

bar 25 25 16

Při vyšších zkušebních tlacích musí být

odpojeno impulzní vedení od potrubí ① .

Přípojky uzavřete ucpávkami G ⁄ ISO 228.

Zkontrolujte jmenovitý tlak ② ventilu.

Max. zkušební tlak je 1,5 × PN.

80 250 630

Napouštění zařízení, uvedení do

provozu ⓮

Tlak na zpátečce ① nesmí překročit tlak

na přívodu ②.

1. Otevřete uzavírací ventily ③, pokud jsou na

impulzním vedení instalovány.

2. Otevřete ventily ④ v zařízení.

3. Pomalu otevřete uzavírací armatury ⑤ na

přívodu.

4. Pomalu otevřete uzavírací armatury ⑥ na

zpátečce.

Odstavení z provozu

1. Pomalu uzavřete uzavírací armatury ⑤ na

přívodu.

2. Pomalu uzavřete uzavírací armatury ⑥ na

zpátečce.

Nastavení diferenčního tlaku ⓯

Požadovaný rozsah - viz typový štítek ①.

1. Uveďte zařízení do provozu -

viz odstavec ⓮.

2. Průtok na armatuře ③, pro kterou je

regulován diferenční tlak, nastavte asi na

50 % ②.

3. Nastavení

• Zkontrolujteúdajeotlaku④.

• Otáčenímmaticevpravo⑤ se

požadovaná hodnota zvyšuje (pružina se

napíná).

• Otáčenímmaticevlevo⑥ se požadovaná

hodnota snižuje (pružina se uvolňuje).

4. Nastavovací matice ⑦ může být

zaplombován.

District Energy VI.CA.K2.1I DEN-SMT/SI

1111

Page 12

Installation Guide AFP/VFG 2(21) DN 15-250

SPANISH

Nota de seguridad

A fin de evitar lesiones y daños a

personas y dispositivos, es

absolutamente imprescindible la lectura

y puesta en práctica de estas instrucciones antes

de las operaciones de montaje y puesta en

servicio.

Las operaciones necesarias de montaje, puesta

en marcha y mantenimiento deberán ser

realizadas únicamente por personal cualificado

y autorizado.

Antes de llevar a cabo las operaciones de

montaje y mantenimiento del controlador, el

sistema debe ser:

- despresurizado

- enfriado

- vaciado

- limpiado

Por favor, respete las instrucciones del fabricante

u operador del sistema.

Instrucciones de eliminación

Este producto debe ser

desmantelado, clasificando sus

componentes, siempre que sea

posible, en disti ntos grupos

destinados a operaciones de

Respete siempre las normas de eliminación

locales.

reciclado o eliminación.

Definición de la aplicación.

El regulador se utiliza para controlar la presión

diferencial del agua o agua glicolada para

sistemas de calefacción y aire acondicionado.

La utilización del regulador esta determinada

por las especificaciones técnicas del mismo.

Alcance del suministro ❶

*)

Accesorio, tubo de impulsión AF.

Montaje

Posición admisible de instalación ❷

DN 15-80 ①:

Temp. Máx. del fluido, 120 ºC.

Puede instalarse en cualquier posición.

DN 100-250 and DN 15-80 ②: > 120 °C

Puede instalarse solamente en tuberías

horizontales con el regulador hacia abajo..

Situación y esquema de instalación ❸

Montaje en impulsión ② o retorno ①.

Instalación de la válvula ➍

1. Instalar filtro ① antes que el regulador

2. Limpiar el sistema antes de instalar la válvula

3. Comprobar la dirección del fluido ② en la

válvula.

Las bridas ③ deben i nstalarse en

posición paralela y la superficie debe

estar limpia y sin daños.

4. Instalar la válvula

5. Apretar los tornillo en 3 etapas hasta el par

máximo.

Instalación de la válvula y el actuador

Válvulas DN 150 – 250

El eje del actua dor debe roscarse en el

eje de la válvula.

Vea las instrucciones de instalación de la válvula

DN 150 – 250.

Válvulas DN 15 – 125 ❺

1. Instalar el actuador en la válvula

2. Alinear el actuador, compruebe la posición

de la conexión del tubo de impulsión ①.

3. Apriete el casquillo de conexión ②. Par 100

Nm.

Instalación del tubo de impulsión

Cuando instale los dep ósitos de

sello ❻①, tenga en cuenta sus

instrucciones.

• Quetubodeimpulsiónutilizar?

Puede utilizarse el kit AF (2x) ❻②:

Código 003G1391

O utilizar las tuberías siguientes:

Ac. Inox. Ø 10 × 0,8

Acero Ø 10 × 1 DIN 2391

Cobre Ø 10 × 1 DI N 175 4

• Conexión❼ del tubo de impulsión ① en el

sistema.

Instalación en retorno ②

Instalación en impulsión ③

• Conexión❽ a la tuberia ①

No conectar hacia abajo ② para evitar

suciedad.

• Instalacióndeltubodeimpulsión(Cobre)❾

1. Cortar la tubería en secciones

rectangulares ① y limpiar las rebabas

2. Insertar los manguitos ② en ambos lados

3. Verificar la correcta posición del conector

③

4. Apretar el tubo de impulsión ④ en la junta

hasta que haga tope

5. Apretar la tuerca de unión ⑤.

Par 40 Nm

DIN 17458,

DIN 2391

Aislamiento ❿

El actuador ① debe aislarse para temperaturas

hasta 100 ºC.

Dimensiones, peso ⓫

Bridas: conexiones conforme a DIN 2501,

sello forma C

Weigth=Peso

Desmontaje ⓬

Peligro

Peligro de daños por agua calienter

La válvula sin actuador esta abierta ① ,El sello

② está en el actuador.

Despresurizar el sistema antes del desmontaje.

Efectuar el desmontaje en sentido inverso al

montaje.

Prueba de presión y fugas ⓭

La presión debe incrementarse

constantemente en ambas con exiones

+/- ①. No incre mentar la presión en –

antes que en +.

Recuerde la máxima presión permitida, ver

tabla, en caso contrario pueden producirse

daños en el actuador o la válvula.

Presión máx. de prueba (bar) con tubos

de impulsión conectados

2

AFP cm

bar 25 25 16

Desmonte los tubos de impulsión de la tubería

① antes de efectuar la prueba de presión máx.

Cierre las conexiones con tapones G ⁄ ISO 228.

Recuerde la presión nominal ② de la válvula

La pr. Máx. de prueba e s 1,5 × PN

80 250 630

Llenado del sistema.

Primera puesta en marcha ⓮

La presión de retorn o ① no puede

exceder la presió n de impulsión ②.

En caso contrario pueden producirse daños en

el regulador ③.

1. Abrir las unidades de cierre ④ disponibles

en los tubos de presión

2. Abrir lentamente las válvulas del sistema

3. Abrir lentamente los dispositivos de corte ⑤

en impulsión

4. Abrir lentamente los dispositivos de corte ⑥

en retorno.

Dejar fuera de servicio

1. Cerrar lentamente los dispositivos de corte

⑤ de corte en impulsión

2. Cerrar lentamente los dispositivos de corte

⑥ de corte en retorno.

Ajuste de la Presión Diferencial ⓯

Ver rango de ajuste en la etiqueta ①

1. Poner en marcha el sistema. Ver sección ⓮

2. Ajustar el caudal ③ al valor al que desea

controlar la presión diferencial, alrededor

del 50 %. ②

3. Ajuste

• Compruebelasindicacionesdepresión④.

• Girealaderecha⑤ para aumentar el

ajuste (comprime el muelle)

• Girealaizquierda⑥ para reducir el ajuste

(descomprime el muelle)

4. Fije el ajuste del punto de consigna ⑦.

12

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 13

Installation Guide AFP/VFG 2(21) DN 15-250

SUOMI

Turvallisuushuomautus!

Nämä ohjeet on ehdottomasti luettava

ja huomioitava ennen kokoonpanoa ja

käyttöönottoa henkilö- ja

omaisuusvahinkojen välttämiseksi.

Ainoastaan ammattitaitoiset ja valtuutetut

henkilöt saavat tehdä kokoonpano-, käynnistysja huoltotöitä.

Ennen säätimen kokoonpano- ja huoltotöitä

järjestelmälle on tehtävä seuraavat

toimenpiteet:

- Paineen poisto

- Jäähdytys

- Tyhjennys

- Puhdistus

Noudata järjestelmän valmistajan ohjeita.

Tuotteen hävittäminen jätteenä

Mikäli mahdollista tämä tuote

tulee purkaa ja lajitella puretut

osat ennen niide n kierrättämistä

tai hävit tämistä jätteenä.

Noudata aina paikallista

lainsäädäntöä ja jätehuoltomääräyksiä jätteiden

hävit tämisestä.

Käyttökohteet

Säädintä käytetään lämmitys-, kaukolämpöja jäähdytysjärjestelmissä olevan veden

sekä veden ja glykolin seoksen paine-eron

ohjaamiseen.

Käyttö määräytyy arvokilpien teknisten tietojen

mukaan.

Toimituslaajuus ❶

Kiinnitys

Sallitut asennusasennot ❷

DN 15-80 ①:

keskilämpötilat 120 °C:seen asti:

Voidaan asentaa kaikkiin asentoihin.

DN 100-250 ja DN 15-80 ②:

keskilämpötilat > 120 °C.

Asennus on sallittu vain vaakaputkistoihin siten,

että toimilaite on alaspäin.

Asennuspaikka ja asennuskaavio ❸

Meno- tai paluuvirtaus ①②

Venttiilin asennus ➍

1. Mudanerotin ① asennetaan linjaan ennen

säädintä.

2. Järjestelmä huuhdellaan ennen venttiilin

asennusta.

3. Huomioidaan virtauksen suunta ②

arvokilvestä.

Putkiston laip pojen ③ on oltava

yhdensuuntaiset j a tiivistepintojen on

oltava puhtaat ja vahingoittumattomat.

4. Asennetaan venttiili.

5. Ruuvit kiristetään ristikkäin kolmessa

vaiheessa maksimikireyteen saakka.

Venttiilin toimilaitteen asennus

Venttiilit DN 150-250

Venttiilit DN 150-250:

Toimilaitteen kara on kierrettävä

venttiilin karaan.

Noudatetaan venttiilien DN 150-250

asennusohjeita.

Venttiilit DN 15-125 ❺

1. Toimilaite asetetaan venttiiliin.

2. Toimilaite kohdistetaan impulssijohdon

liitoksen mukaan ①.

3. Liitosmutteri ② kiristetään.

Kiristysmomentti 100 Nm

Impulssijohdon asennus

Tasausastioita ❻① asennettaessa on

noudatettava niiden omia

asennusohjeita.

• Millaisiaimpulssijohtojapitääkäyttää?

Voidaan käyttää impulssijohtosarjaa

AF (2×) ❻②:

Tilausnro: 003G1391

Muita johtoja käytettäessä on huomioitava

seuraavat mitat:

Ruostumaton

teräs

Ter äs Ø 10 × 1 D IN 2391

Kupari Ø 10 × 1 D IN 17 54

• Impulssijohtojen❼① liittäminen

järjestelmään

Asennus paluuvirtaukseen ②

Asennus menovirtaukseen ③

• LiitäntäputkistoonÀ

• Eiliitäntää❽① alapuolelle likaantumisen

takia.

• Impulssijohdonasennus(kupari)❾

1. Putki katkaistaan 90 asteen kulmaan ① ja

jäysteet poistetaan.

2. Holkit ② laitetaan kumpaankin päähän.

3. Varmistetaan leikkuurenkaan ③ oikea

asento.

4. Impulssijohto ④ painetaan

kierreliitokseen vasteeseen saakka.

5. Kiristetään liitosmutteri ⑤.

Kiristysmomentti 40 Nm

Ø 10 × 0,8

DIN 17458,

DIN 2391

Eristys ❿

Myös painetoimilaite ① voidaan eristää

käytettäessä enintään 100°C:n keskilämpötiloja.

Mitat, painot ⓫

Laipat: liitoksen mitat DIN 2501:n mukaan,

C-t ii vis te

Purkaminen ⓬

Vaar a

Kuuman veden aiheuttama

tapatur mavaara.

Ilman toimilaitetta oleva venttiili on auki ①,

tiiviste ② on toimilaitteessa.

Ennen purkutöitä paine on ehdottomasti

poistettava järjestelmästä.

Purkaminen suoritetaan päinvastaisessa

järjestyksessä kokoonpanoon verrattuna.

Vuoto- ja painetestit ⓭

Painetta on tasaisesti lisättävä +/– liitännästä ①.

Painetta ei saa koskaan päästää +-paineen yli.

Noudatetaan suurimpia sallittuja painearvoja,

ks. alla.

Näiden ohjeiden laiminlyöminen saattaa

vahingoittaa toimilaitetta tai venttiiliä.

Suurin testipaine (bar) impulssijohdot

liitettyinä

2

AFP cm

bar 25 25 16

Mikäli käytetään korkeampia testipaineita,

impulssijohdot irrotetaan putkistoista ①.

Liitokset tulpataan G ⁄ ISO 228.

Venttiilin nimellispaine ②. otetaan huomioon.

Suurin testipaine on 1,5 × PN.

Järjestelmän täyttäminen,

käyttöönotto ⓮

Tämän ohjeen laiminlyöminen saattaa

vahingoittaa toimilaitetta tai venttiiliä ③.

1. Avataan impulssijohdoissa mahdollisesti

olevat sulkuventtiilit.

2. Avataan järjestelmän venttiilit ④ hitaasti.

3. Avataan menovirtauksen sulut ⑤ hitaasti.

4. Avataan paluuvirtauksen sulut ⑥ hitaasti.

80 250 630

Paluuvirtauksen paine ① ei saa ylittää

menovirtauksen painetta ②.

Käytöstä poistaminen

1. Suljetaan menovirtauksen sulut ⑤ hitaasti.

2. Suljetaan paluuvirtauksen sulut ⑥ hitaasti.

Paine-eroasetukset ⓯

Ks. asetusarvoalue arvokilvestä ①.

1. Järjestelmän käyttöönotto, ks. kohta ⓮.

2. Liittimestä ③, josta paine-eroa ohjataan,

asetetaan virtaamaksi n. 50 % ②.

3. Säätö

• Tarkkaillaanpainemittareita④.

• Asetusarvokasvaakierrettäessäoikealle

⑤ (jousi kiristyy).

• Asetusarvolaskeekierrettäessä

vasemmalle ⑥ (jousi löystyy).

4. Asetusarvosäädin ⑦ voidaan sinetöidä.

District Energy VI.CA.K2.1I DEN-SMT/SI

1313

Page 14

Installation Guide AFP/VFG 2(21) DN 15-250

POLSKI

Warunki bezpieczeństwa

Aby nie dopuścić do obrażeń ciała oraz

uszkodzenia urządzeń należy przed

montażem i uruchomieniem

urządzenia bezwzględnie zapoznać się z

niniejszymi instrukcjami i przestrzegać

zawartych w nich zaleceń.

Czynności związane z montażem,

uruchomieniem i konserwacją mogą

być wykonywane wyłącznie przez osoby

wykwalifikowane, przeszkolone i uprawnione.

Przed przystąpieniem do montażu i czynności

konserwacyjnych regulatora należy koniecznie:

- zlikwidować ciśnienie w układzie,

- ochłodzić układ,

- opróżnić układ,

- wyczyścić układ.

Należy stosować się do instrukcji producenta i/

lub operatora układu.

Instrukcja dotycząca utylizacji

Ten produkt przed przekazaniem

do ponownego przetworzenia

lub utylizacj i powinien zostać

rozmontowany, a jego

komponent y posortowane, o ile

to możliwe, na różne grupy.

Zawsze należ y przestrzegać lokalnych przep isów

dotycząc ych utylizacji odpadów.

Zakres zastosowań

Regulator stosowany jest do regulacji różnicy

ciśnień dla wody i roztworu woda-glikol

w układach grzewczych, instalacjach sieci

cieplnych i chłodzenia.

Dane techniczne na tabliczce znamionowej

określają zakres zastosowań.

Zakres dostawy ❶

Montaż

Dopuszczalne pozycje montażu ❷

DN 15-80 ①

Temperatura czynnika do 120 °C

Dowolna pozycja montażu

DN 100-250 i DN 15-80 ② gdy temperatura

czynnika jest wyższa niż 120 °C

Montaż dozwolony tylko na rurociągu

poziomym z napędem skierowanym do dołu.

Miejsce i schemat montażu ❸

Rurociąg zasilający lub powrotny ②①.

Montaż zaworu ➍

1. Zamontować filtr ① przed regulatorem.

2. Przed zamontowaniem zaworu przepłukać

instalację.

3. Zwrócić uwagę na wskaźnik kierunku

przepływu ② na korpusie zaworu.

Kołnie rze ③ na rurociągu muszą być

wzajemnie równoległe, a powierzchnie

pod uszczelk i czyste i bez uszkodzeń.

4. Zamontować zawór.

5. Dokręcać przeciwległe nakrętki w 3 krokach

do osiągnięcia maksymalnego momentu.

Montaż napędu

Zawory DN 150-250

W zaworach DN 150-250 trzpień

napędu musi zostać wkręcony w

trzpień zaworu.

Szczegóły znaleźć można w Instrukcji Montażu

zaworów DN 150-250.

Zawory DN 15-125 ❺

1. Umieścić napęd na zaworze.

2. Ustawić napęd pamiętając o pozycji

przyłącza przewodu impulsowego ①

3. Dokręcić nakrętkę łączącą ②.

Moment: 100 Nm

Podłączenie przewodów impulsowych

Jeśli instalowane są naczynia

kondensacyjne ❻①, szczegóły znaleźć

można w Instrukcji Montażu naczynia.

• Jakieprzewodyimpulsowenależy

zastosować?

Można zastosować zestaw rurek

impulsowych AF (2×) ❻②:

Nr zamówieniowy: 003G1391

• Jeśliwykorzystywanesąinnerurki,należy

zwrócić uwagę na następujące wymiary:

Stal nierdzewna Ø 10 × 0,8

Stal Ø 10 × 1 DIN 2391

Miedź Ø 10 × 1 DI N 1754

• Podłączenie❼ przewodów impulsowych ①

w układzie

Montaż na rurociągu powrotnym ②

Montaż na rurociągu zasilającym ③

• Podłączenie❽ do rurociągu ①

Zakazane jest podłączanie do dolnej

części rurociągu ② z uwagi na możliwość

zanieczyszczenia przewodu impulsowego.

• Podłączenierurekimpulsowych(miedź)❾

1. Obciąć rurkę prostopadle ① i oczyścić

krawędzie przekroju.

2. Włożyćtulejki② wspierające w oba

końce rurki.

3. Sprawdzić, czy położenie pierścieni

zaciskowych ③ jest prawidłowe.

4. Wcisnąćprzewódimpulsowy④ w łącznik

gwintowany najgłębiej jak można

5. Dokręcić nakrętkę łączącą ⑤.

Moment: 40 Nm

DIN 17458,

DIN 2391

Izolacja ❿

Dla temperatur czynnika do 100 °C napęd

ciśnieniowy ① może zostać zaizolowany.

Wymiary, wagi ⓫

Kołnierze – wymiary połączeń zgodne z DIN

2501, uszczelka typu C

Demontaż ⓬

Uwaga

Ryzyko poparzenia parą lub gorącą

wodą!

Zawór bez napędu jest otwarty ①,

uszczelnienie ② znajduje się w napędzie.

Przed demontażem należy bezwzględnie

zrzucić ciśnienie z układu.

Kolejność wykonywanych czynności przy

demontażu odwrotna w stosunku do kolejności

podczas montażu.

Próba ciśnieniowa i szczelności ⓭

Ciśnienie musi być systematycznie

podnoszone na podłączeniach + i -.

Zwrócić uwagę na max. dopuszczalne ciśnienie,

patrz poniżej.

Nieprzestrzeganie powyższego może

spowodować zniszczenie napędu lub zaworu.

Max. ciśnienia próbne [bar] przy

podłączonych rurkach impulsowych.

2

AFP cm

bar 25 25 16

Dla wyższych ciśnień próbnych należy odłączyć

rurki impulsowe ① od rurociągów.

Otwory zakorkowaă zaúlepkami z gwintem G ¼

wg ISO 228.

Sprawdzić wartość ciśnienia nominalnego ② na

korpusie zaworu.

Max ciśnienie próbne wynosi 1,5 × PN

80 250 630

Napełnianie układu. Pierwsze

uruchomienie. ⓮

Ciśnienie w rurociągu powrotnym ①

nie może być wyższe niż w rurociągu

zasilającym ②.

Nieprzestrzeganie powyższego może

spowodować zniszczenie napędu lub zaworu.

1. Otworzyć zaworki odcinające ③ na rurkach

impulsowych, jeśli są zainstalowane.

2. Powoli otworzyć zawory regulacyjne ④ w

układzie.

3. Powoli otworzyć zawór odcinający ⑤ na

zasilaniu.

4. Powoli otworzyć zawór odcinający ⑥ na

powrocie.

Zatrzymanie układu.

1. Powoli zamknąć zawór odcinający ⑤ na

zasilaniu.

2. Powoli zamknąć zawór odcinający ⑥ na

powrocie.

Nastawa regulowanej różnicy

ciśnień.

Zakres nastaw - patrz tabliczka znamionowa ①

1. Uruchomić układ - patrz rozdział ⓮.

2. Przy pomocy zaworu ③ zamontowanego na

odcinku na którym regulowana jest różnica

ciśnień, ustawić przepływ na poziomie ok.

50% przepływu max. ②.

3. Dokonać regulacji

• Obserwującwskazaniamanometrów④.

• Kręcićwprawo⑤ w celu zwiększenia

wartości nastawy (ściskanie sprężyny)

• Kręcićwlewo⑥ w celu zmniejszenia

wartości nastawy (luzowanie sprężyny)

4. Nakrętka nastawcza ⑦ może zostać

zaplombowana.

14

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 15

Installation Guide AFP/VFG 2(21) DN 15-250

ROMÂNĂ

Notă privind siguranţa în

funcţionare

Pentru a evita rănirea şi pagubele

provocate persoanelor şi

echipamentelor, este absolut necesară

citirea cu atenţie şi înţelegerea acestor

instrucţiuni înainte de montare şi de punere în

funcţiune.

Lucrările necesare de montaj, pornire şi

întreţinere trebuie efectuate numai de către

personal autorizat, instruit şi calificat.

Înainte de orice lucrări de montaj şi de

întreţinere la regulator, sistemul trebuie să fie:

- depresurizat

- răcit

- golit

- curăţat

Vă rugăm să respectaţi instrucţiunile

producătorului sistemului sau ale operatorului

sistemului.

Instrucţiuni de eliminare

Acest produs trebui e dezmembrat

şi, dacă este posibil,

componentele acestuia sortate în

diverse grupe, înainte de reciclare

sau scoatere din uz.

Respectaţi întotdeauna

reglementările p rivind scoaterea din uz valabile în

regiunea dumneavoastră.

Definirea aplicaţiei

Regulatorul este folosit pentru controlul

presiunii diferenţiale în circuite de încălzire şi

în reţele de încălzire sau de răcire cu apă sau

amestec apă-glycol.

Utilizarea este determinată de datele tehnice de

pe etichetele montate pe dispozitiv.

Scopul livrării ❶

Montaj

Poziţii admisibile de instalare ❷

DN 15-80 ①:

Temperatura mediului pînă la 120 °C:

Poate fi instalat în orice poziţie.

DN 100-250 şi DN 15-80 ②

Temperatura mediului >120 °C.

Instalarea este permisă numai pe conducte

orizontale, cu elementul de acţionare în partea

de jos.

Poziţia şi schema de instalare ❸

Pe tur sau pe retur ②①.

Instalarea vanei ➍

1. Instalaţi filtrul ① înaintea regulatorului.

2. Spălaţi sistemul înaintea instalării vanei.

3. Observaţi direcţia curgerii ② pe eticheta de

pe corpul vanei.

Flanşele ③ de pe conductele din

instalaţie trebuie să fie paralele şi cu

suprafeţele de etanşa re curate şi fără

lovituri.

4. Instalaţi vana.

5. Strângeţi şuruburile pe diagonală, în trei

etape, până la cuplul maxim de strângere.

Instalarea elementului de acţionare a

vanei

Vane DN150-250

Vane DN150-250:

Axul elem entului de acţionare trebuie

înşurubat în axul vanei.

Urmăriţi instrucţiunile de instalare pentru

vanele DN150-250.

Vane DN15-125 ❺

1. Montaţi acţionarea pe vană.

2. Aliniaţi elementul de acţionare şi verificaţi

poziţia conexiunii tubului de impuls ①.

3. Strângeţi piuliţa ② la un cuplu de 100Nm.

Instalarea tubului de impuls

La instalarea vasului de etanşa re ❻①

urmăriţi Instrucţiunile de instalare

pentru vasul de etanşare.

• Cetubdeimpulssăfolosim?

Puteţi folosi setul tubului de impuls ❻② tip

AF (2×):

Cod de comandă: 003G1391

• Dacăsefolosescaltetuburideimpuls,

respectaţi următoarele dimensiuni:

Oţel inox Ø 10 × 0,8

Oţel Ø 10 × 1 DIN 2391

Cupru Ø 10 × 1 DIN 175 4

• Montarea❼ tuburilor de impuls ① în sistem

Instalare pe conducta de retur ②

Instalare pe conducta de tur ③

• Montarea❽ pe ţeavă ①

Nu se va monta în partea de jos a ţevii ②,

pentru a nu colecta depuneri.

• Instalareatubuluideimpuls(Cupru)❾

1. Tăiaţi ţeava în două secţiuni

perpendiculare pe axul ei ① şi apoi

şlefuiţi-o.

2. Introduceţi manşoane ② la ambele

capete.

3. Verificaţi poziţionarea corectă a inelului de

tăiere ③.

4. Introduceţi tubul de impuls ④ în

conexiunea filetată până la limitator.

5. Strângeţi piuliţa ⑤ la un cuplu de 40 Nm.

Izolare ❿

Pentru temperaturi ale mediului până la 100 °C,

elementul de acţionare ① poate fi izolat.

Dimensiuni, mase ⓫

Flanşe: dimensiunile de conectare conform DIN

2501, forma etanşării C.

Demontare ⓬

Pericol de opărire!

Vana fără elementul de acţionare este

deschisă ②, etanşarea ① este în

elementul de acţionare.

Înainte de demontare scoateţi sistemul de

sub presiune!

Efectuaţi demontarea în ordine inversă

montării.

DIN 17458,

DIN 2391

Testele de presiune şi etanşeitate ⓭

Presiunea trebuie crescută constant la

conexiunile + / - À . Nu depăşiţi valoarea

presiunii de la conexiunea +.

Respectaţi presiunea maxim admisibilă,

conform tabelului de mai jos.

Neconformitatea cu datele din tabel poate

duce la distrugerea vanei sau a elementului de

acţionare.

Presiunea de test maximă la testele cu tuburi

de impuls conectate

2

AFP cm

bar 25 25 16

În cazul testării la o presiune mai mare

îndepărtaţi tuburile de impuls de pe conducte

①.

Închideţi conexiunile cu armături tip G ⁄ ISO

228.

Observaţi presiunea nominală ② a vanei.

80 250 630

Umplerea sistemului, punerea în

funcţiune

Presiunea de pe retur ① nu trebuie să

depăşească presiunea de pe tur ②.

Nerespectarea acestei condiţii poate avea ca

efect distrugerea vanei sau a elementului de

acţionare ③.

1. Deschideţi elementele de închidere ④

care pot fi prezente în circuitul tuburilor de

impuls.

2. Deschideţi încet vana

3. Deschideţi încet dispozitivul de închidere ⑤

din circuitul de tur.

4. Deschideţi încet dispozitivul de închidere ⑥

din circuitul de retur.

Scoaterea din funcţiune

1. Închideţi încet dispozitivul de închidere ⑤

din circuitul de tur.

2. Închideţi încet dispozitivul de închidere ⑥

din circuitul de retur.

Setarea presiunii diferenţiale ⓯

Domeniul de reglaj este notat pe eticheta cu

date tehnice ①

1. Porniţi sistemul conform instrucţiunilor din

secţiunea ⓮.

2. Reglaţi debitul prin dispozitivul ③ prin care

se controlează presiunea diferenţială, la cca.

50% ②

3. Reglaj

• Observaţiindicatoareledepresiune④

• Rotindspredreapta⑤, se ridică punctul

de reglaj, presând arcul.

• Rotindsprestânga⑥ , se coboară punctul

de reglaj, slăbind arcul.

4. Dispozitivul de setare a punctului de reglaj

⑦ se poate sigila.

District Energy VI.CA.K2.1I DEN-SMT/SI

1515

Page 16

Installation Guide AFP/VFG 2(21) DN 15-250

MAGYAR

Biztonsági megjegyzések:

A személyi sérülések és az eszközök

károsodásának elkerülése érdekében

elengedhetetlen ezeknek az

utasításoknak a figyelmes elolvasása az

összeszerelés előtt, és betartása az üzembe

helyezés során.

Az összeszerelést, üzembe helyezést és

karbantartást csak szakképzett, és arra

feljogosított személy végezheti.

A szerelési és karbantartási munkálatok előtt a

rendszert:

- nyomásmentesítse

- hűtse le,

- ürítse le

- tisztítsa meg

Kérjük, tartsa be a rendszer gyártójának és

üzemeltetőjének rendelkezéseit!

Hulladékelhelyezési utasítás

A hulladékban történő elhelyezés,

vagy újrahasznosítás előtt ezt a

terméket, ha van rá mód, szét kell

szerelni és alkatrészeit szét kell

válogatni és csoportosítani.

Mindig tartsa be a helyi hulladé kkezelési

szabályokat.

Üzemeltetési jellemzők

A szabályzó térfogatáramkorlátozásra és

nyomáskülönbség szabályozásra alkalmas fűtő,

távfűtő és hűtő rendszerekben. A folyadék íz ill.

víz-glikol elegy lehet.

A beállító lemezen feltüntetett adatok

meghatározzák a használat feltételeit.

Szállítási terjedelem ❶

*) Impulzus vezeték AF, tartozék

Szerelés

Lehetséges beépítési elrendezések ❷

DN 15 – 80 ①:

Közeghőmérséklet max. 120 °C:

Bármely helyzetben beépíthető.

DN 100 – 250 és DN 15-80 ②:

közeg hőmérséklet > 120 °C:

Csak vízszintes csőszakaszokba építhető be,

függőleges szelepmozgató helyzettel.

Beépítési hely és kapcsolási séma ❸

Előremenő vagy visszatérő ágba ①②.

Szelep beépítés ➍

1. Először építsen be szűrőt ①, aztán a

szabályzót.

2. A szelep beépítése előtt öblítse át a

rendszert!

3. A szeleptesten feltüntetett áramlási irányt ②

vegye figyelembe!

A csővezeték karimáinak ③

párhuzamosan kell állniuk, és a

tömítőfelületeknek szennyeződés

menteseknek és épeknek kell lenniük.

4. Szerelje be a szelepet!

5. 3 lépésben szorítsa meg az összekötő

csavarokat a maximális nyomatékig!

Szelep(mozgató) szerelése

Szelepek DN 150-250 méretig

A szelepmozgató szeleporsóját

csavarja bea szelep szeleporsójába!

Vegye figyelembe a DN 150-250 szelepek szerelési

útmutatóját!

Szelepek DN 15-125 méretig ❺

1. Illessze a mozgatót a szelephez!

2. Fordítsa be a szelepmozgatót, ügyelve az

impulzusvezeték csatlakozására ①!

3. Szorítsa meg a rögzítő ② anyát 100 Nm

nyomatékkal!

Impulzusvezeték bekötése

A forraszvégek ❻① beépítése előtt

tanulmányozza a forraszvégek

beépítési útmutatóját!

• Milyenimpulzusvezetékethasználjunk?

Az AF impulzusvezeték-szett (2×)❻②

használható:

Rendelési szám: 003G1391

vagy használja az alábbi vezetékeket:

Rozsdamentes

acél, átmérő

Acél, átmérő Ø 10 × 1 DIN 2391

Réz, átmérő Ø 10 × 1 DI N 175 4

• Azimpulzusvezeték❼ csatlakoztatása a

rendszerhez ①

Bekötés a visszatérő ágba ②

Bekötés az előremenő ágba ③

• Csatlakoztatás❽ a csővezetékhez ①

A leszálló ágba ② nem javasolt a

csatlakoztatás, a szennyeződés veszélye

miatt.

• Impulzusvezetékbekötése(réz)❾

1. Vágja el merőlegesen ① vezetéket, és

sorjázza le.

2. Helyezze el a hüvelyeket ② mindkét

oldalon!

3. Ellenőrizze, hogy a gyűrű ③ a megfelelő

helyen van-e!

4. Helyezze be ütközésig ④ az

impulzusvezetéket a menetes

csatlakozóba!

5. Húzza meg az egyesítő anyát ⑤

Nyomaték 40 Nm

Ø 10 × 0,8

DIN 17458,

Szigetelés ❿

100 °C közeghőmérsékletig a

nyomásszabályozó ① szigetelhető.

Méretek, súly ⓫

Karimák: csatlakozó méretek a DIN 2501 szerint,

C típ. tömítéssel

Szétszerelés ⓬

Vigyázat!

A forró víz személyi sérülést okozhat!

A szelepmozgató nélküli szelep nyitott ① , a

tömítés ② a szelepmozgatóban van.

Szétszerelés előtt nyomásmentesítse a

rendszert!

DIN 2391

A szétszererelést az összeszereléssel ellentétes

sorrendben végezze el!

Szivárgás- és nyomásteszt ⓭

A nyomást egyenletes sebességgel

kell növelni a +/- csatlakozáson ①!

Soha ne legyen magasabb a ’–’ oldali

nyomás a ’+’ oldali nyomásnál!

Vegye figyelembe a maximális megengedett

nyomást (lásd. alább)!

A nemmegfelelés a szelepmozgató ill. a szelep

károsodását eredményezheti!

Max. próbanyomás [bar] csatlakoztatott

impulzusvezetékekkel

2

AFP cm

bar 25 25 16

Nagyobb próbanyomás esetén távolítsa el az

impulzusvezetékeket a csővezetékekről ①!

Zárja le az impulzusvezetékek csatlakozásait G

¼ ISO 228 dugaszokkal!

Vegye figyelembe a szelep(ek) névleges

nyomását ②!

A max. próbanyomás értéke: 1,5 × PN

80 250 630

A rendszer feltöltése, üzembe

helyezés ⓮

A visszatérő nyomás ① nem lehet

nagyobb, mint az előremenő ②!

A nemmegfelelés a szabályzó ③ károsodását

eredményezheti.

1. Nyissa ki az elzáróegységeket ④, melyek

feltehetően az impulzusvezetékeken

találhatóak!

2. Lassan nyissa ki a szelepeket a rendszerben!

3. Lassan nyissa ki az elzáró szerelvényeket ⑤ az

előremenő ágban!

4. Lassan nyissa ki az elzáró szerelvényeket ⑥ a

visszatérő ágban!

Üzemen kívül helyezés

1. Lassan zárja az elzáró szerelvényeket ⑤ az

előremenő ágban!

2. Lassan zárja az elzáró szerelvényeket ⑥ a

visszatérő ágban!

A nyomáskülönbség beállítása ⓯

Az alapérték-tartomány a géptörzslapon ①

található.

1. Lapozzon az üzembehelyezésről szóló

fejezethez ⓮!

2. Állítson be ~50%-os térfogatáramot ② azon

az elemen ③, amely a nyomáskülönbséget

szabályozza!

3. Beállítás

• Vegyegyelembeanyomásjelzőket④!

• Jobbraforgatva⑤ növeli a beállított

értéket (összenyomja a rugót)

• Balraforgatva⑥ csökkenti a beállított

értéket (lazítja a rugót)

4. Az alapérték-beállító ⑦ leplombálható.

16

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 17

Installation Guide AFP/VFG 2(21) DN 15-250

ЛОРУССКИ

Примечания по технике

безопасности

Во избежание получения травм или

повреждений устройства, перед

началом работ по его монтажу и

прочитайте настоящую инструкцию и

тщательно ее соблюдайте. Монтаж, наладку и

техническое обслуживание оборудования

может выполнять только

квалифицированный персонал, имеющий

допуск к таким работам.

Перед началом работ по монтажу или

обслуживанию электропривода необходимо

произвести следующие действия с

трубопроводной системой:

Следуйте указаниям производителя системы

или оператора системы.

вводу в эксплуатацию, обязательно

- сбросить давление;

- охладить;

- опорожнить;

- прочистить.

Инструкция по утилизации

Перед переработкой или

утилизацией следует

это устройство

возможно, рассортировать его

элементы по группам

материалов

Всегда соблюдайте местные инструкция по

утилизации.

разобрать

и, если это

Область применения

Этот регулятор предназначен для

регулирования перепада давления воды и

водных смесей гликоля в трубопроводных

системах централизованного

теплоснабжения и охлаждения.

Границы применения определяют

технические характеристики на фирменной

табличке регулятора.

Комплектация ❶

Монтаж

Допустимые положения регулятора

при монтаже ❷

ДУ 15-80 ①

Температура перемещаемой среды до 120 °С.

Монтаж в любом положении

ДУ 100 – 250 и ДУ 15 – 80 ②, температура

перемещаемой среды выше 120 °С.

Монтаж разрешается только на

горизонтальном трубопроводе

регулирующим элементом вниз

Размещение регулятора ❸

(схема установки)

На подающем ① или обратном ②

трубопроводе

Монтаж клапана ➍

1. Перед регулятором установить сетчатый

фильтр ①.

2. Перед установкой клапана промыть

систему.

3. Сверить направление потока и стрелки ②

на корпусе клапана.

Фланцы ③ на трубопровод е должны

быть установлены пара ллельно, а

уплотняемые поверхности должны

быть чистыми и без повреждений.

4. Установить клапан

5. Крестообразно затянуть болты втри этапа

до достижения максимального крутящего

момента.

Монтаж регулирующего элемента

Клапаны ДУ 150 – 250

Для клапанов ДУ 150-250 шток

регулирующего элемента должен

быть завинчен в шток клапана.

Одновременно обратите внимание на

инструкцию по монтажу, прилагаемую к

партии клапанов ДУ 150-250

Клапаны ДУ 15 – 125 ❺

1. Поместить регулирующий элемент на

клапане.

2. Повернуть элемент до требуемого

положения штуцера ① для импульсной

трубки

3. Затянуть соединительную гайку ②

крутящим моментом 100 Нм

Монтаж импульсных трубок

При установке уплотнительных

элементов соблюдайте инструкции

по их монтажу. ❻①

• Какуюимпульснуютрубкуследует

выбрать?

Можно использовать комплект

импульсных трубок AF (2×) ❻②:

Кодовый номер: 003G1391

Если используются другие импульсные

трубки, то их размеры следует выбирать в

соответствии с приведенной таблицей:

Материал трубки Размер

Нержавеющая

сталь

Сталь ø 10 × 1 DIN 2 391

Медь ø 10 × 1 DIN 1754

• Подключение❼ импульсных трубок ① к

системе

Монтаж на обратном трубопроводе ②

Монтаж на подающем трубопроводе ③

ло-русски

• Подключение❽ к трубопроводу ①

Подключение импульсных трубок снизу

② запрещено, так как это может привести

к их засорению

• Монтажмеднойимпульснойтрубки❾

1. Отрезать трубку под прямым углом ① и

снять заусенцы.

2. Вставить втулку ② в оба конца трубки.

3. Проверьте правильность положения

разрезного кольца ③.

ø 10 × 0,8

DIN 17458,

DIN 2391

4. До упора вдвинуть импульсную трубку

④ в резьбовое соединение

5. Затянуть соединительную гайку ⑤

крутящим моментом 40 Нм.

Теплоизоляция

При температурах перемещаемой среды до

100 °С регулирующий элемент ① может быть

также изолирован.

Габаритные и

присоединительные размеры ⓫

Фланцы: присоединительные размеры в

соответствии с DIN 2501, форма уплотнения

Демонтаж ⓬

Опасно!

При демонтаже существует

опасность ожога горячей вод ой

Клапан без регулирующего элемента открыт

для выхода воды ①. Уплотнение находится в

регулирующем элементе ②.

Перед монтажом следует сбросить давление

в системе!

Демонтаж выполняется в обратном порядке

по отношению к монтажу.

Испытание на прочность и

герметичность ⓭

Давление в точках присоединения

импульсных трубок +/- ① должно

повышаться постепенно.

Не увеличивать давление односторонне на

штуцере + регулятора.

Соблюдать макс. допустимое давление, см.

ниже.

Несоблюдение этих требований может

привести к поломке клапана или

регулирующего элемента.

Макс. испытательное давление [бар] с

подключенными импульсными трубками

2

AFP см

бар 25 25 16

В случае испытательного давления выше,

указанного в таблице, необходимо снять

импульсные трубки на трубопроводах ①.

Закрыть соединения заглушками G ¼ ISO 228.

Прочтите значение условного давления на

корпусе клапана ②.

Макс. испытательное давление

составляет 1,5 × PУ.

80 250 630

District Energy VI.CA.K2.1I DEN-SMT/SI

1717

Page 18

Installation Guide AFP/VFG 2(21) DN 15-250

Заполнение системы. Первый

запуск ⓮

Давление в трубопроводе после

клапана ① не должно превышать

Несоблюдение этого требования может

привести к поломке клапана или

регулирующего элемента.

1. Открыть запорные краны ③ на мпульсных

2. Медленно открыть клапан ④ в системе.

3. Медленно открыть запорное устройство

4. Медленно открыть запорное устройство ⑥

Отключение системы

1. Медленно закрыть запорное устройство

2. Медленно закрыть запорное устройство

давления до к лапана ②

трубках, если таковые имеются.

⑤ на подающем трубопроводе.

на обратном трубопроводе.

⑤ на подающем трубопроводе.

⑥ на обратном трубопроводе.

Настройка перепада давления ⓯

Диапазон настройки указан на фирменной

табличке регулятора. ①

1. Запустить систему (см. в разделе ⓮).

2. Установить расход воды с помощью

клапана ③, которым регулируется

перепад давления, приблизительно на

50% от расчетного ②.

3. Настройка

• Следитьзапоказаниямиманометра④.

• Поворотнаправо⑤ увеличивает

уставку давления (сжимает пружину)

• Поворотналево⑥ снижает уставку

давления (отпускает пружину)

4. Шпиндель настройки ⑦ может быть

опломбирован

18

DEN-SMT/SI VI.CA.K2.1I District Energy

Page 19

Installation Guide AFP/VFG 2(21) DN 15-250

District Energy VI.CA.K2.1I DEN-SMT/SI

1919

Page 20

Installation Guide AFP/VFG 2(21) DN 15-250

73696440/VI.CA.K2.1I

Produced by Danfoss A/S © 06/2013

Loading...

Loading...